Graphene elastic polymer phase-change composite material and preparation method thereof

A phase change composite material, elastic polymer technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of affecting the repeated use characteristics of materials, unstable composite materials, and decreased modification effect, and achieve the preparation cost. Low cost, obvious thermal conductivity, improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Dissolve graphite oxide in water, stir for 15 minutes, ultrasonicate for 1 hour, and configure graphene oxide solutions with different concentrations: the concentration is 5mg / ml, 3mg / ml;

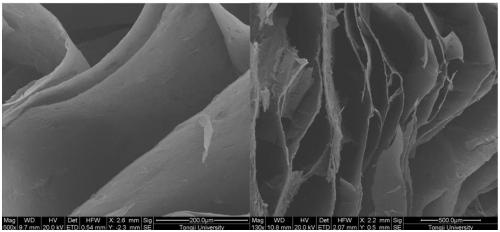

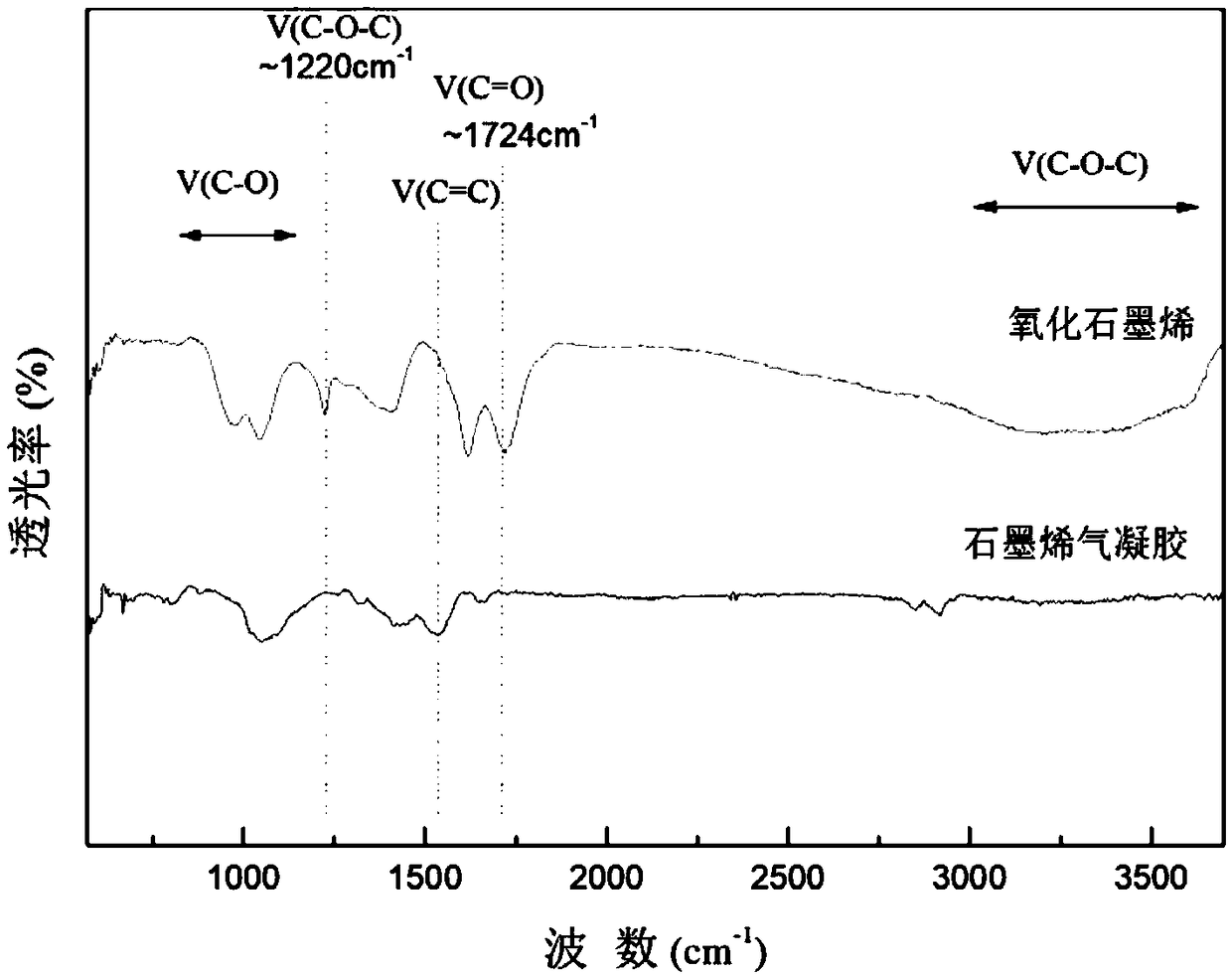

[0037] (2) Take 60ml of 5mg / ml graphene oxide solution, put it in a 100ml reactor for hydrothermal reaction for 15h, and the hydrothermal temperature is 180°C to obtain graphene hydrogel, freeze-dry in a vacuum dryer for 24h, Less than 2Pa, the freezing temperature is -60°C, and graphene airgel is obtained.

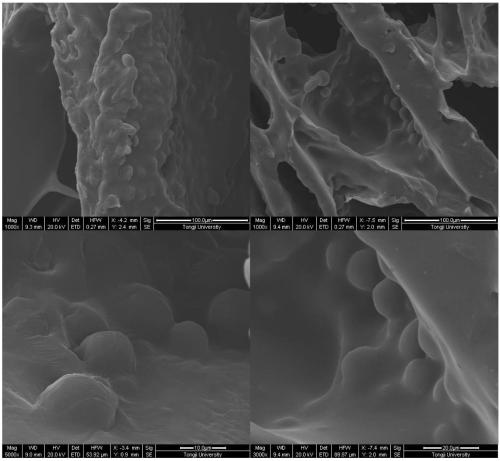

[0038] (3) Take 100ml of a 3mg / ml graphene oxide solution, mix it with 20g of molten paraffin, stir at 80°C for 45min at a stirring rate of 10000r / min, wash it with deionized water after cooling, and dry it on filter paper at room temperature to obtain a phase transition microsphere. capsule.

[0039] (3) Use a styrene-acrylic emulsion with a solid content of 50%. The phase change microcapsules and the elastic polymer are mixed and stirred evenly at a mass ratio of 1:1, and ...

Embodiment 2

[0042] (1) Dissolve graphite oxide in water, stir for 15 minutes, ultrasonicate for 1 hour, and configure graphene oxide solutions with different concentrations: the concentrations are 7mg / ml and 2mg / ml;

[0043] (2) Take 60ml of 7mg / ml graphene oxide solution, put it in a 100ml reactor for hydrothermal reaction for 15h, and the hydrothermal temperature is 180°C to obtain graphene hydrogel, freeze-dry in a vacuum dryer for 24h, Less than 2Pa, the freezing temperature is -60°C, and graphene airgel is obtained.

[0044] (3) Take 100ml of 2mg / ml graphene oxide solution, mix it with 20g of molten paraffin, stir at 80°C for 45min at a stirring rate of 10000r / min, wash it with deionized water after cooling, and dry it on filter paper at room temperature to obtain a phase transition microstructure. capsule.

[0045] (4) Use a styrene-acrylic emulsion with a solid content of 50%. The phase change microcapsules and the elastic polymer are mixed and stirred evenly at a mass ratio of 1...

Embodiment 3

[0048] (1) Dissolve graphite oxide in water, stir for 15 minutes, ultrasonicate for 1 hour, and prepare graphene oxide solutions with different concentrations: the concentrations are 4mg / ml and 2mg / ml;

[0049] (2) Take 60ml of 4mg / ml graphene oxide solution, put it in a 100ml reactor for hydrothermal reaction for 15h, and the hydrothermal temperature is 180°C to obtain graphene hydrogel, freeze-dry in a vacuum dryer for 24h, Less than 2Pa, the freezing temperature is -60°C, and graphene airgel is obtained.

[0050] (3) Take 100ml of 2mg / ml graphene oxide solution, mix it with 20g of molten paraffin, stir at 80°C for 45min at a stirring rate of 10000r / min, wash it with deionized water after cooling, and dry it on filter paper at room temperature to obtain a phase transition microstructure. capsule.

[0051] (4) Use a styrene-acrylic emulsion with a solid content of 50%. The phase change microcapsules and the elastic polymer are mixed and stirred evenly at a mass ratio of 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com