Bridge pier anti-collision component based on FRP and polyurethane foam filled honeycomb-shaped rubber concrete

A technology of rubber concrete and polyurethane foam, which is applied to bridge parts, bridges, bridge materials, etc., can solve the problems of increasing construction costs and increasing the protection area of bridge piers, achieve the integrity of the overall structure, and solve the problem of poor impact resistance and energy dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

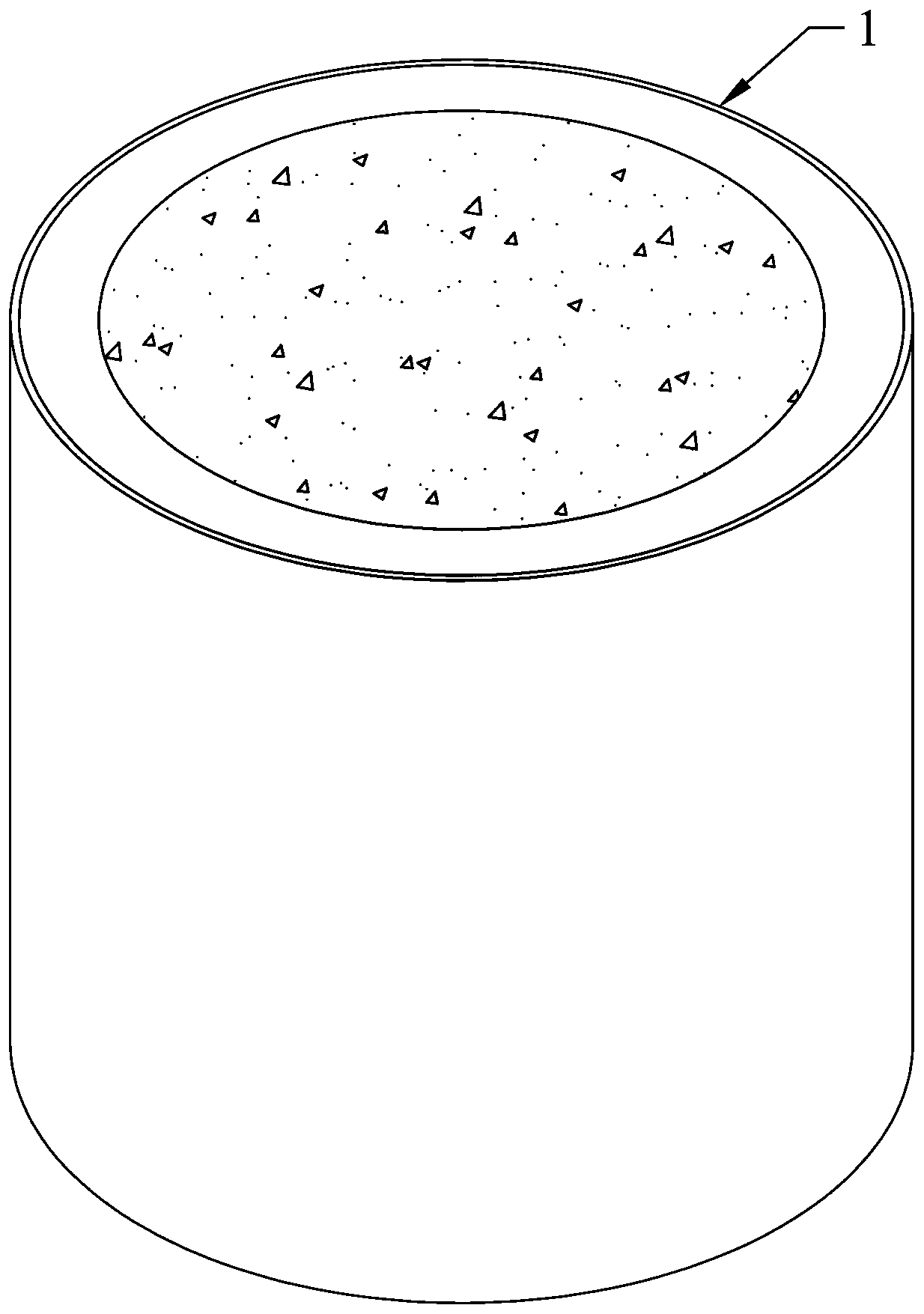

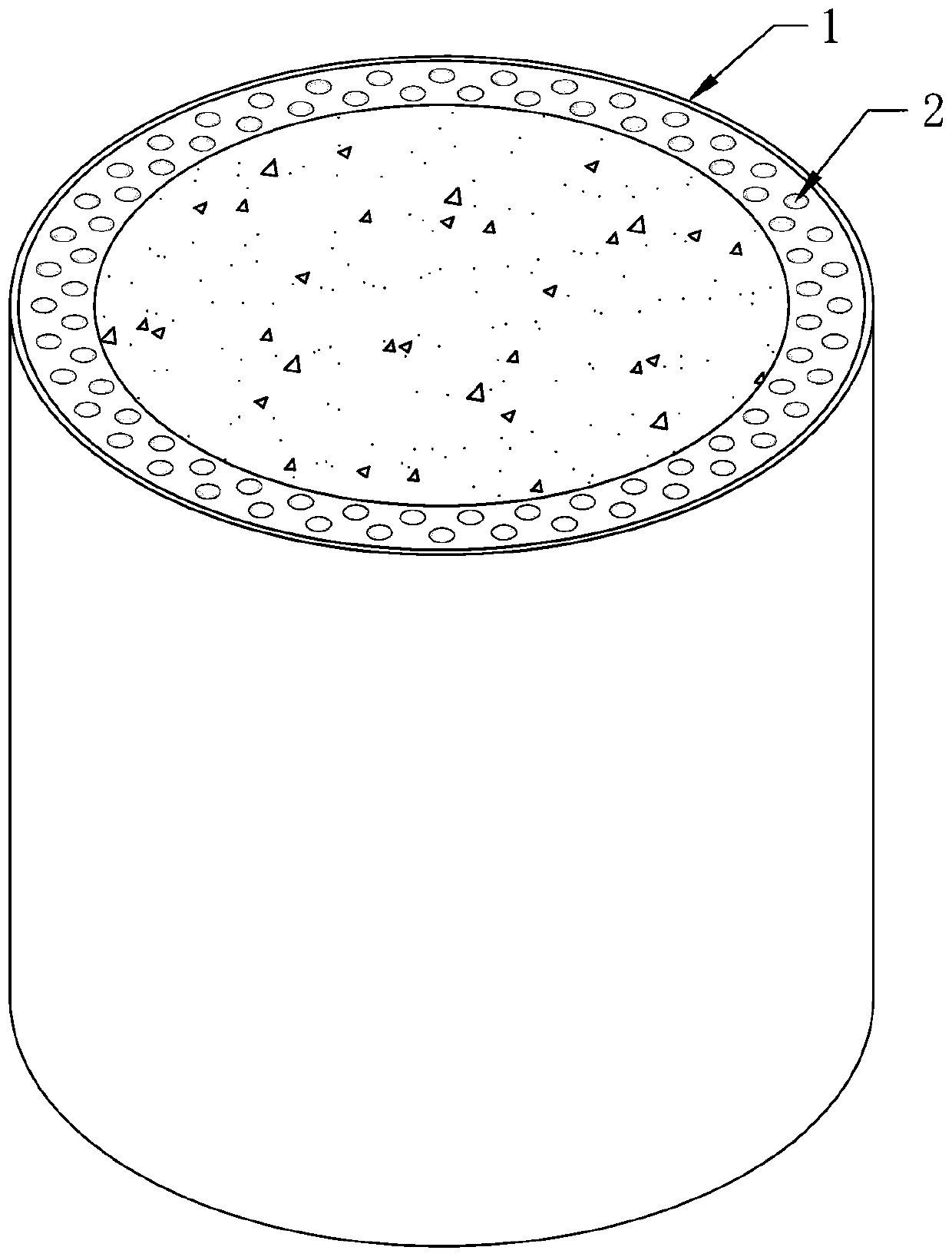

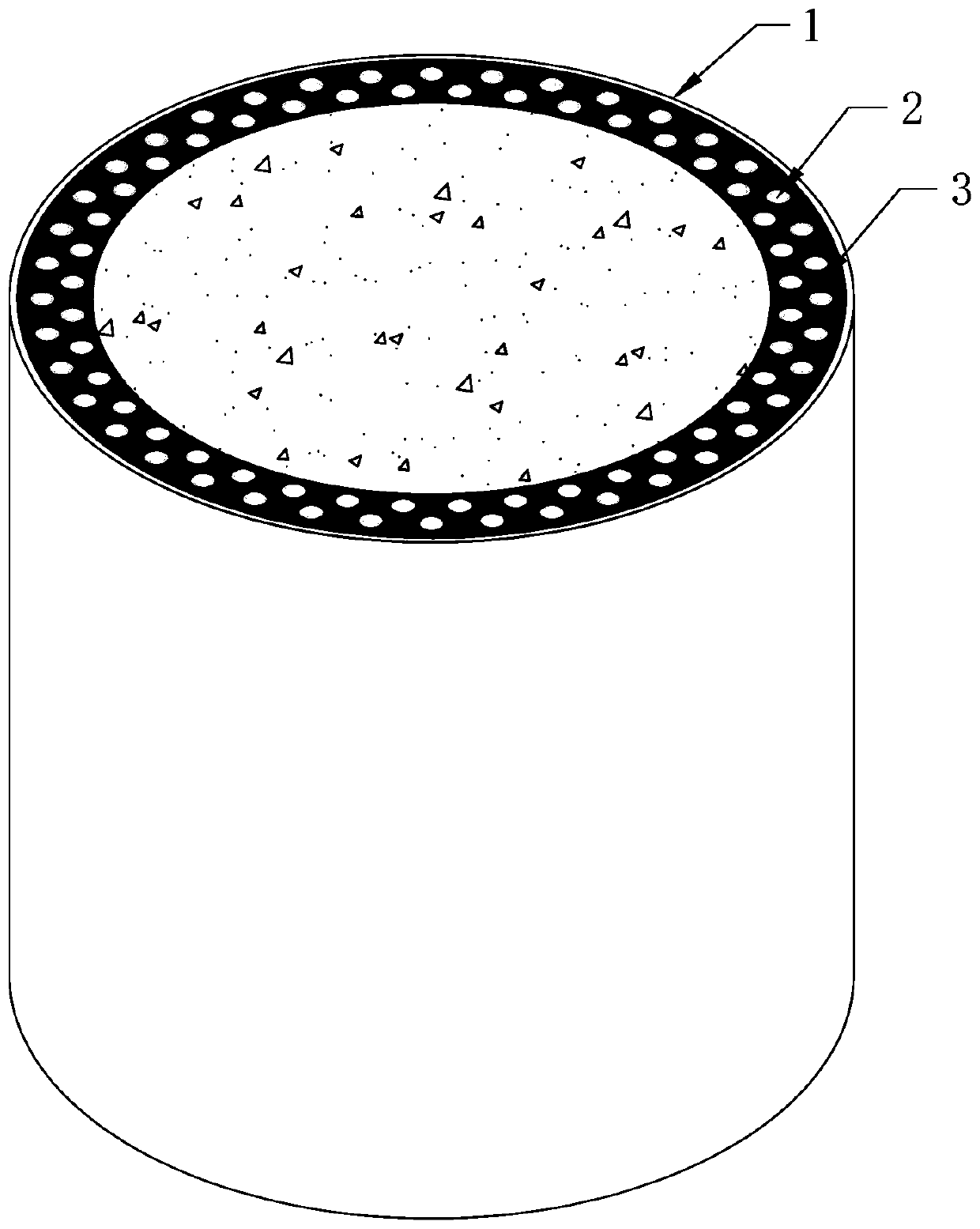

[0025] A bridge pier anti-collision component based on FRP and polyurethane foam filled honeycomb rubber concrete. The bridge pier anti-collision component is arranged on the outside of the pier substructure, and the bridge pier substructure is a connection structure between the pier and the road surface; the pier anti-collision component includes FRP sleeves, polyurethane foam Layer and rubber concrete layer; FRP sleeve, polyurethane foam layer and rubber concrete layer are an integrated structure; the FRP sleeve is enclosed on the outside of the rubber concrete layer; the rubber concrete layer is provided with multiple layers of discretely distributed filling The hole is filled with a polyurethane foam layer composed of polyurethane foam.

[0026] Further, the cross section of the rubber concrete layer is circular, rectangular or rounded rectangular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com