Patents

Literature

189 results about "Impact time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

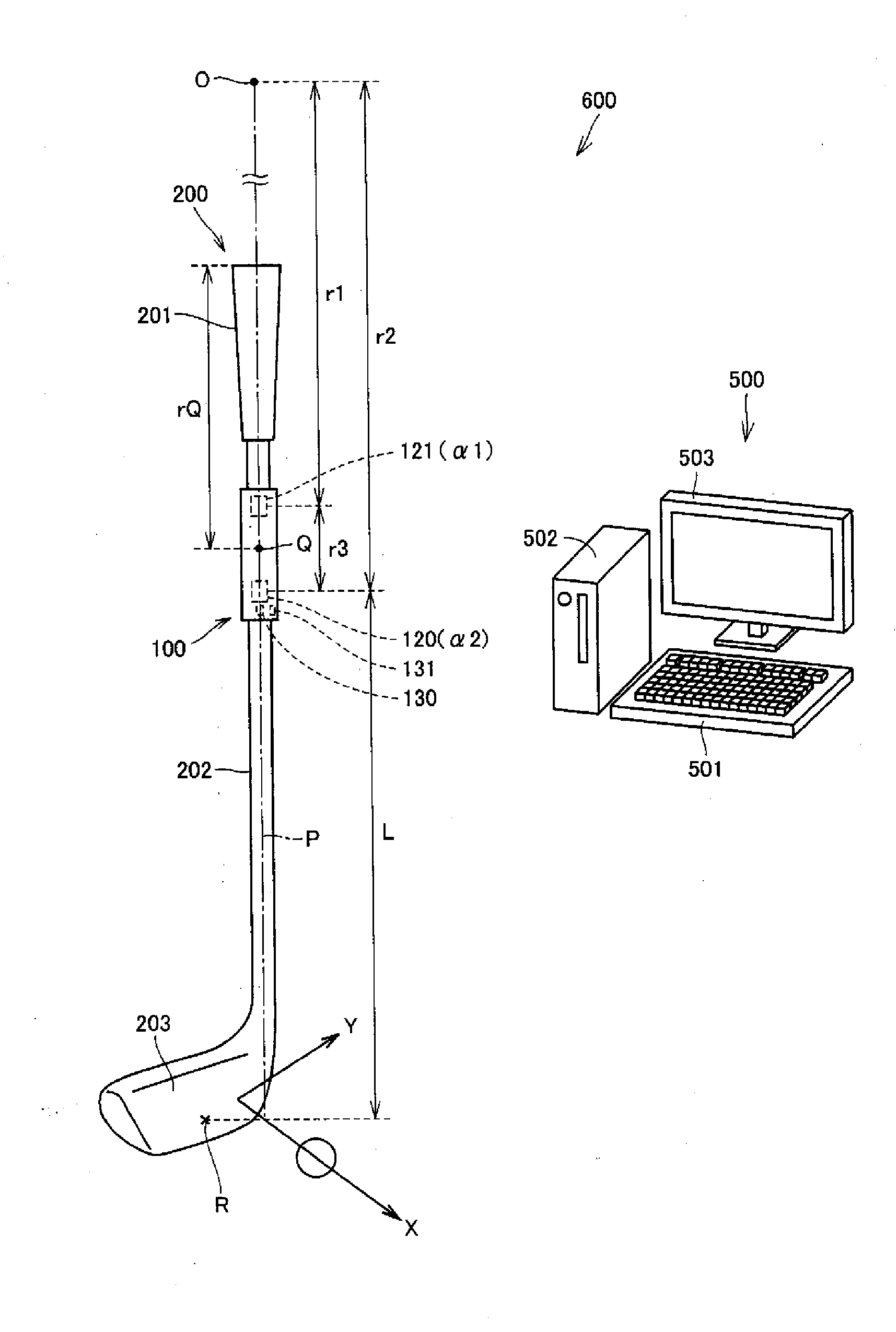

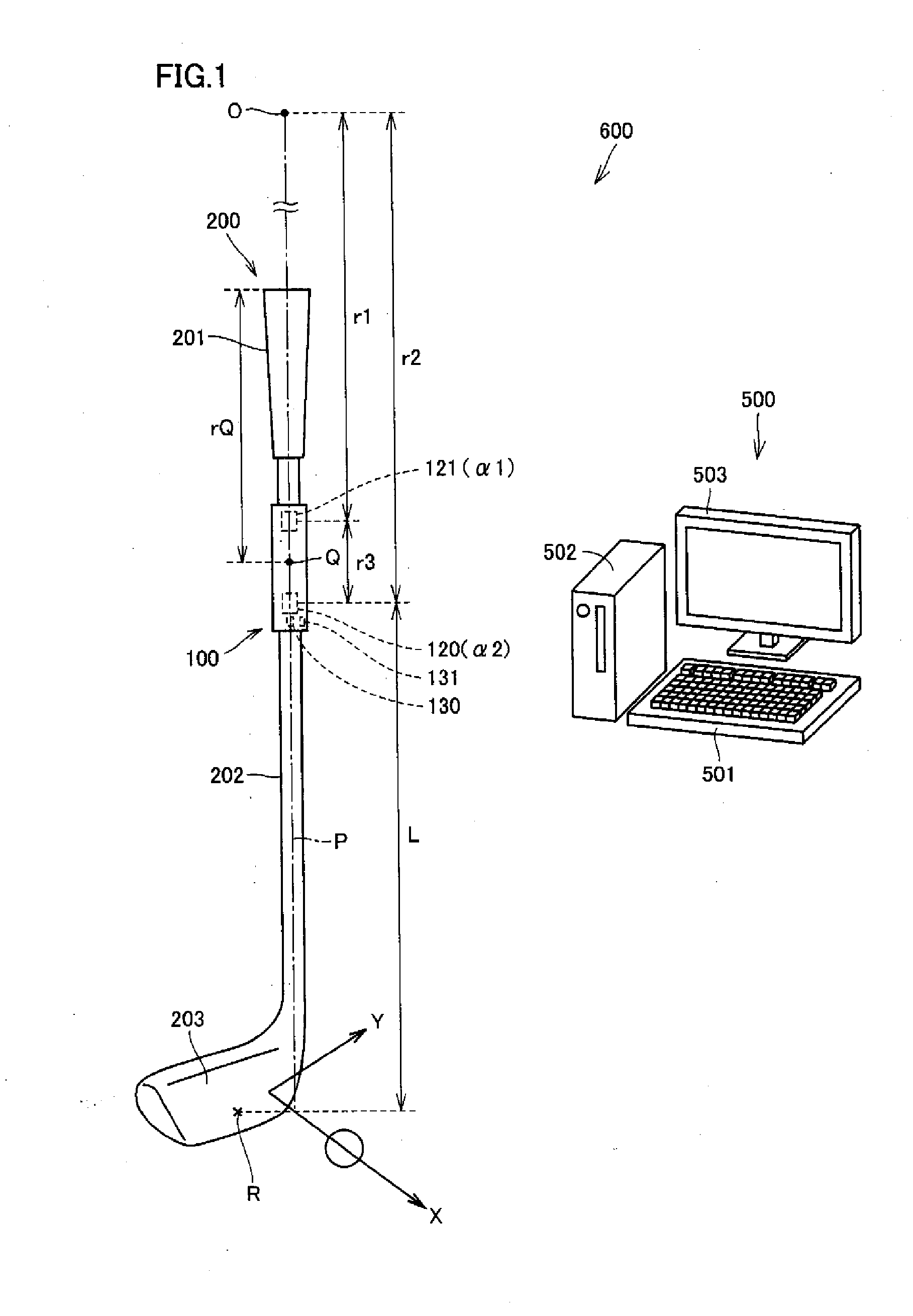

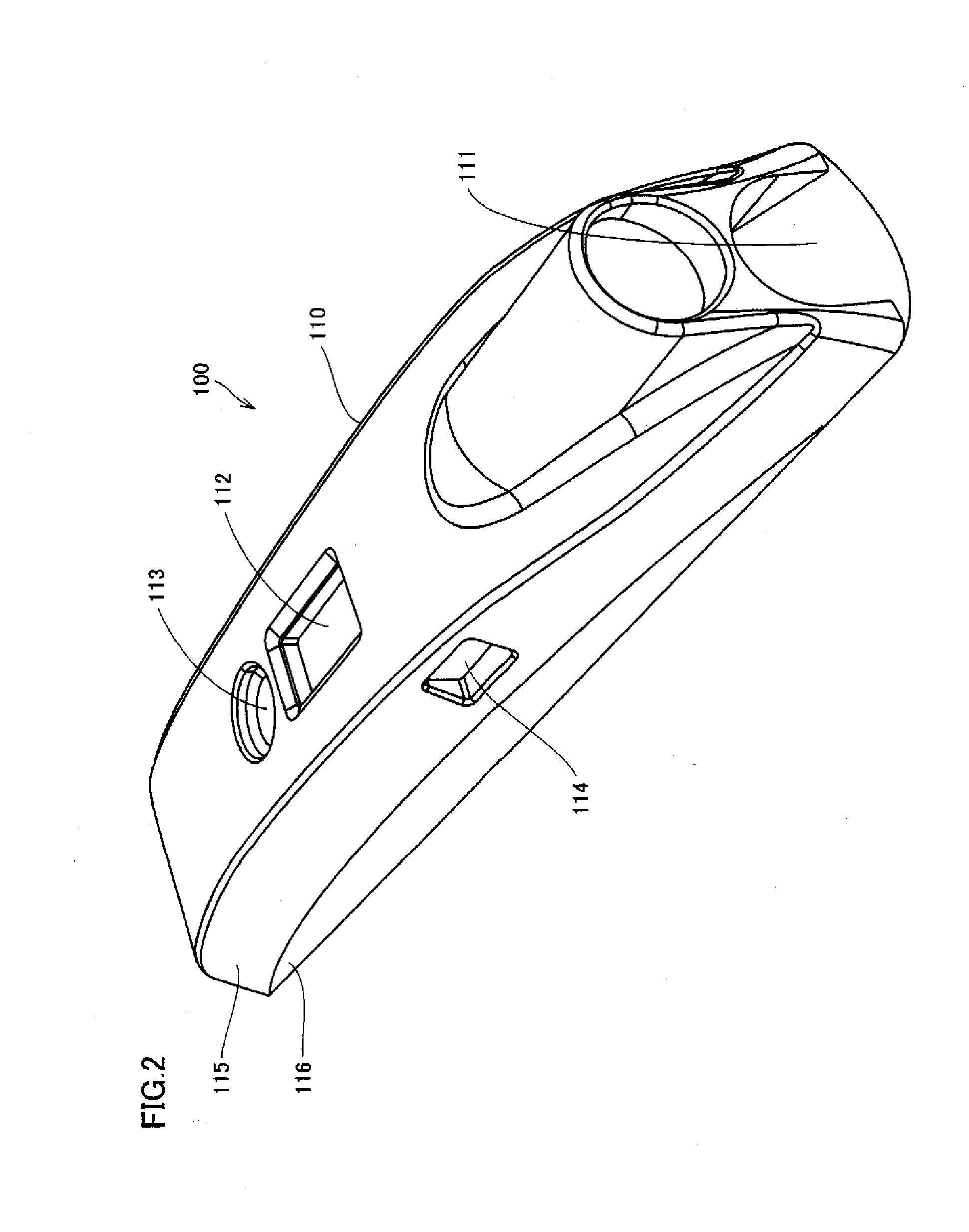

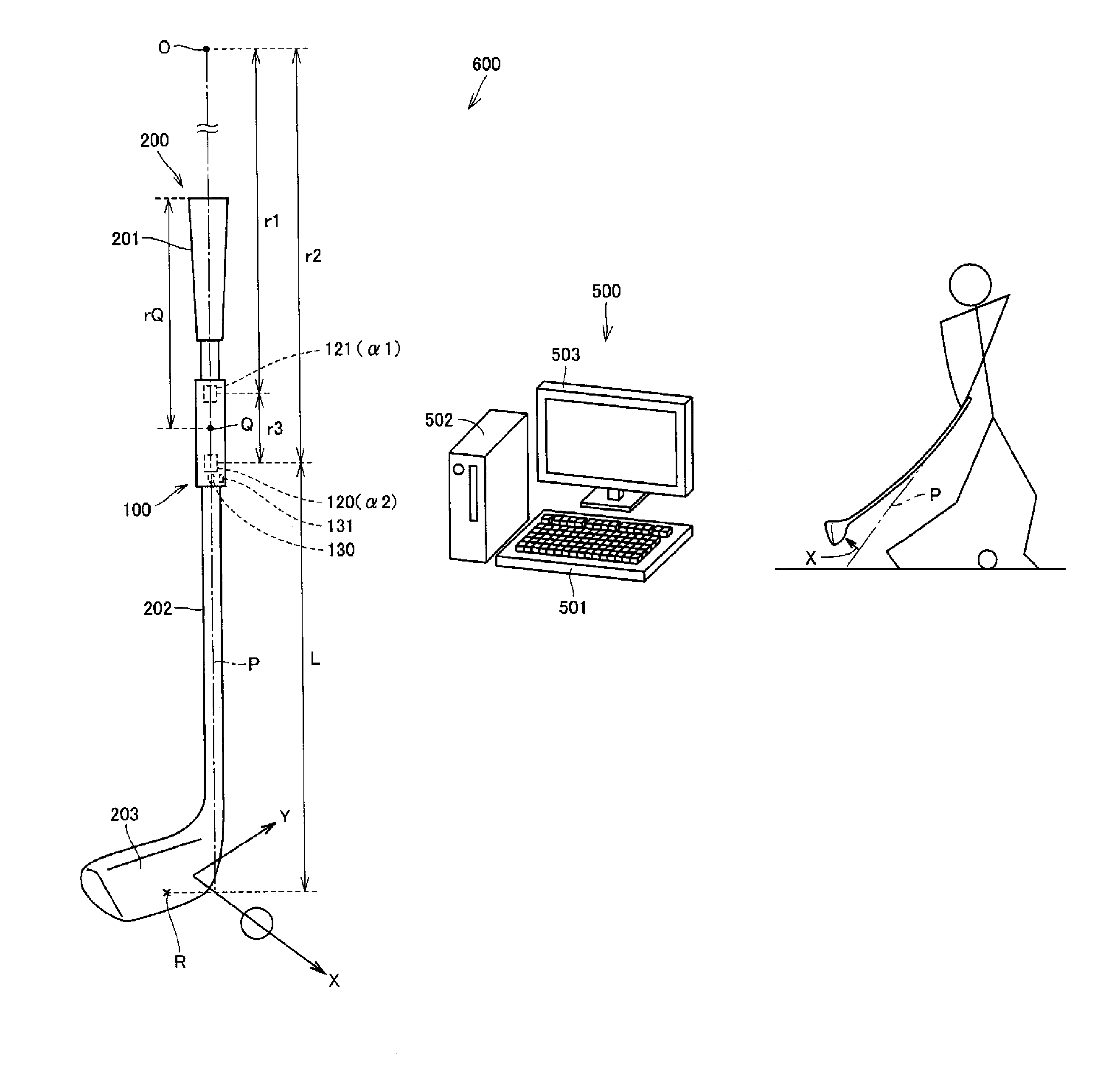

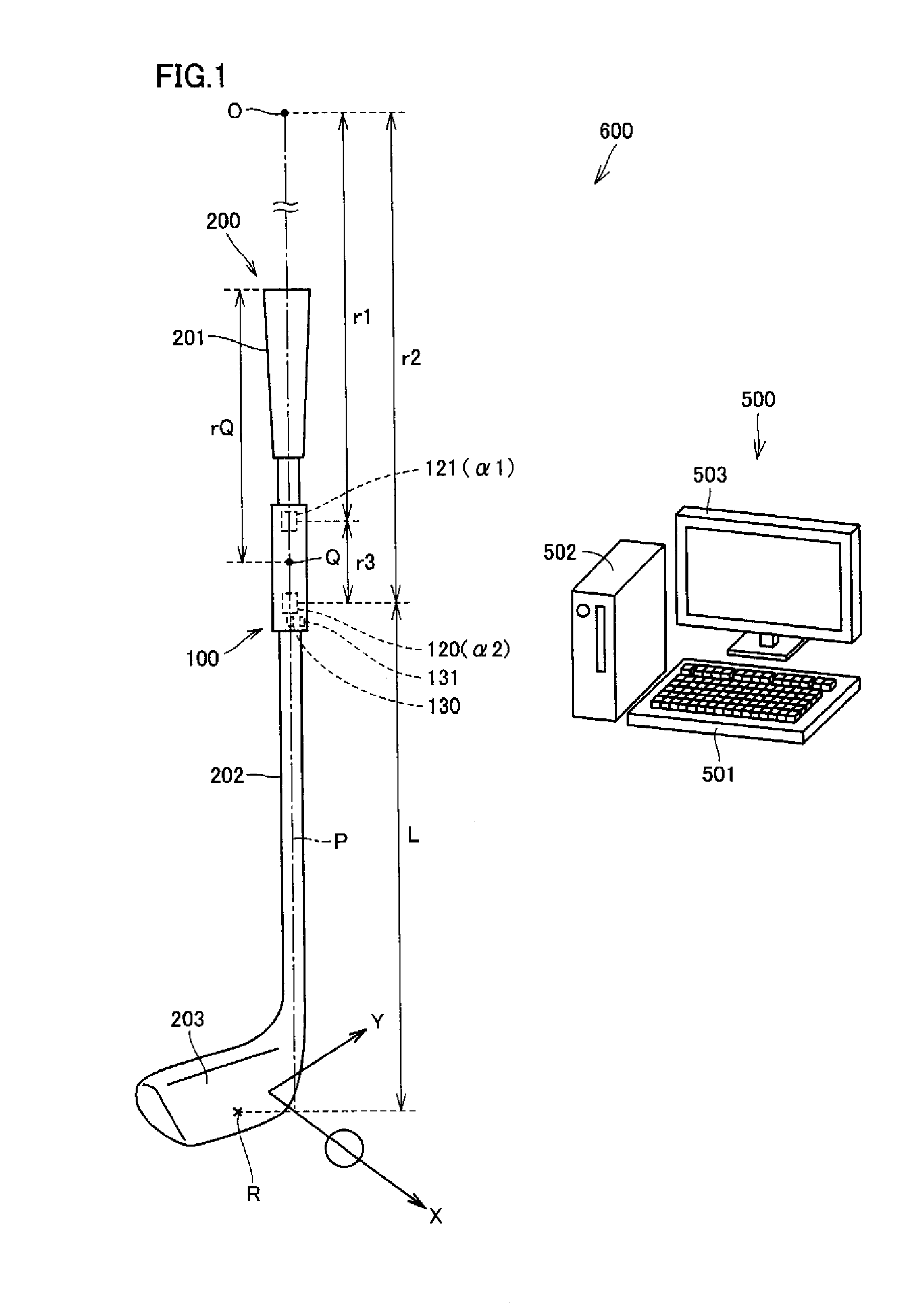

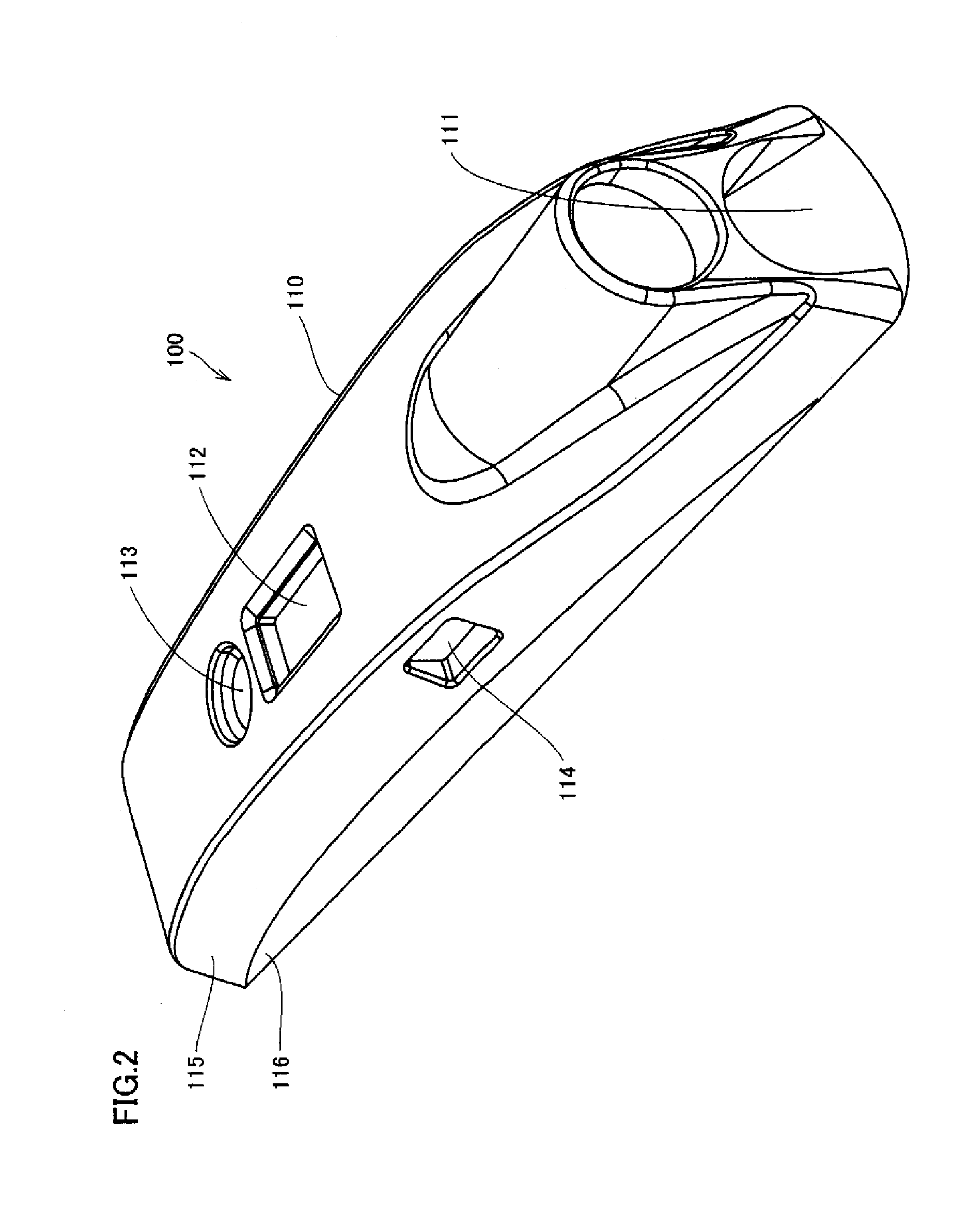

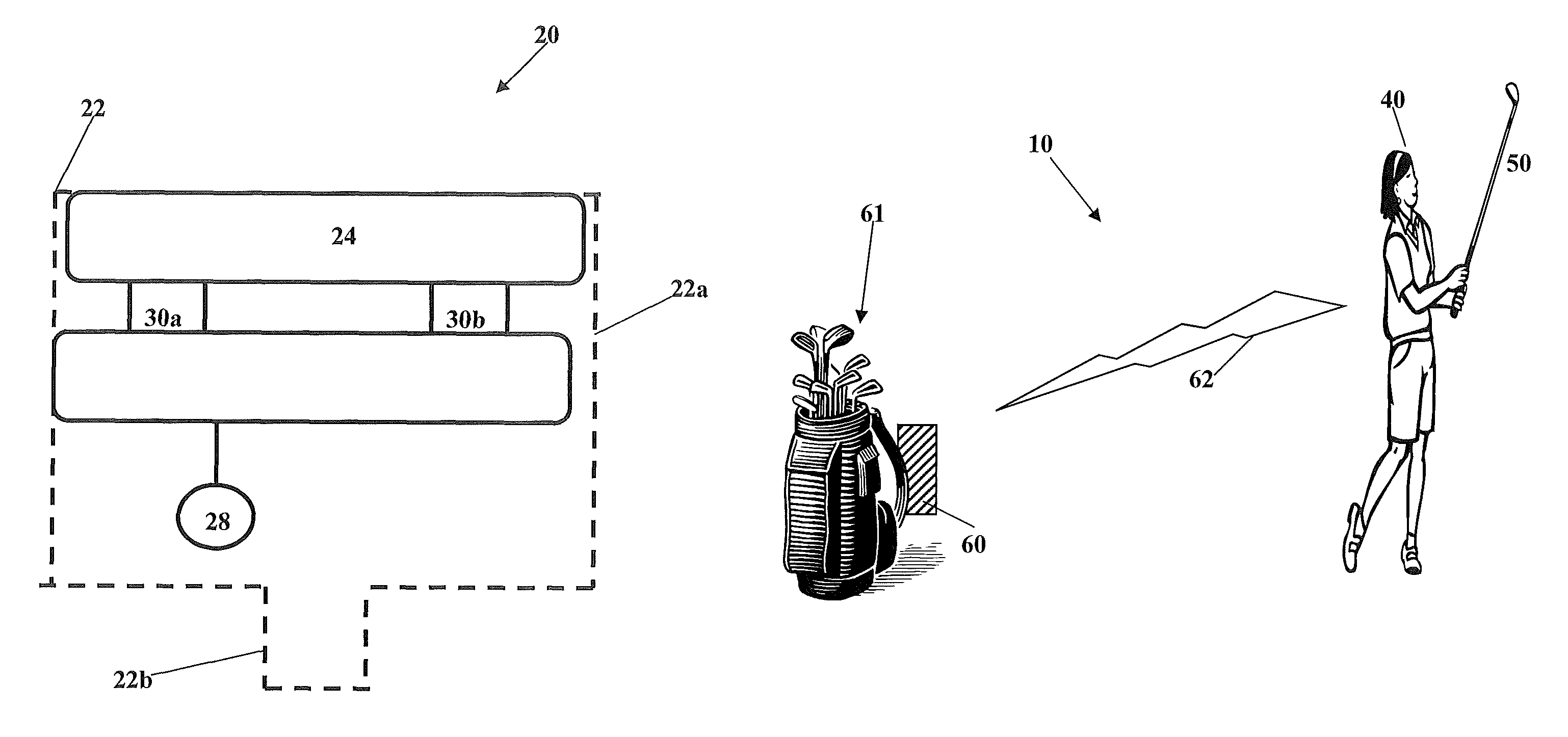

Swing analyzer and golf club shaft selecting system

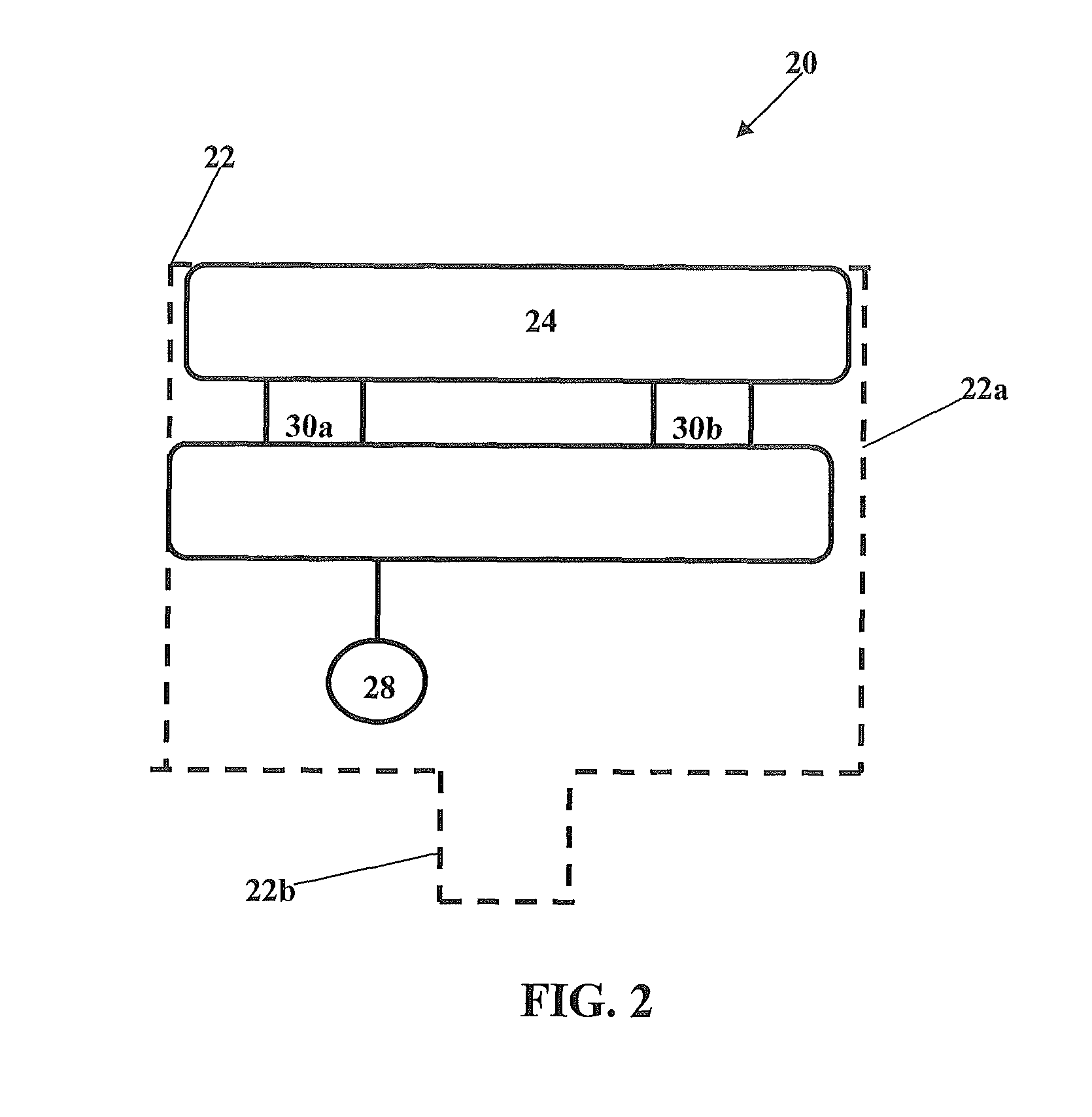

ActiveUS20100210371A1Simple structureGymnastic exercisingGolfing accessoriesMeasurement deviceEngineering

A measuring device includes a strain gauge, a processing unit calculating an expected bending point value corresponding to a bending point position, and a display unit capable of displaying an output value from the processing unit. The processing unit calculates the expected bending point value based on a measured value of strain gauge at a first time point during a swing of the user and a measured value of strain gauge at a second time point closer to an impact time point than the first time point. The processing unit stores in advance conversion data for converting the expected bending point value to recommended kick point output value indicating kick point, and the processing unit outputs the recommended kick point output value corresponding to the calculated expected bending point value to the display unit.

Owner:MIZUNO CORPORATION

Swing analyzer and golf club shaft selecting system

ActiveUS8888603B2Simple structureGymnastic exercisingGolfing accessoriesMeasurement deviceEngineering

A measuring device includes a strain gauge, a processing unit calculating an expected bending point value corresponding to a bending point position, and a display unit capable of displaying an output value from the processing unit. The processing unit calculates the expected bending point value based on a measured value of strain gauge at a first time point during a swing of the user and a measured value of strain gauge at a second time point closer to an impact time point than the first time point. The processing unit stores in advance conversion data for converting the expected bending point value to recommended kick point output value indicating kick point, and the processing unit outputs the recommended kick point output value corresponding to the calculated expected bending point value to the display unit.

Owner:MIZUNO CORPORATION

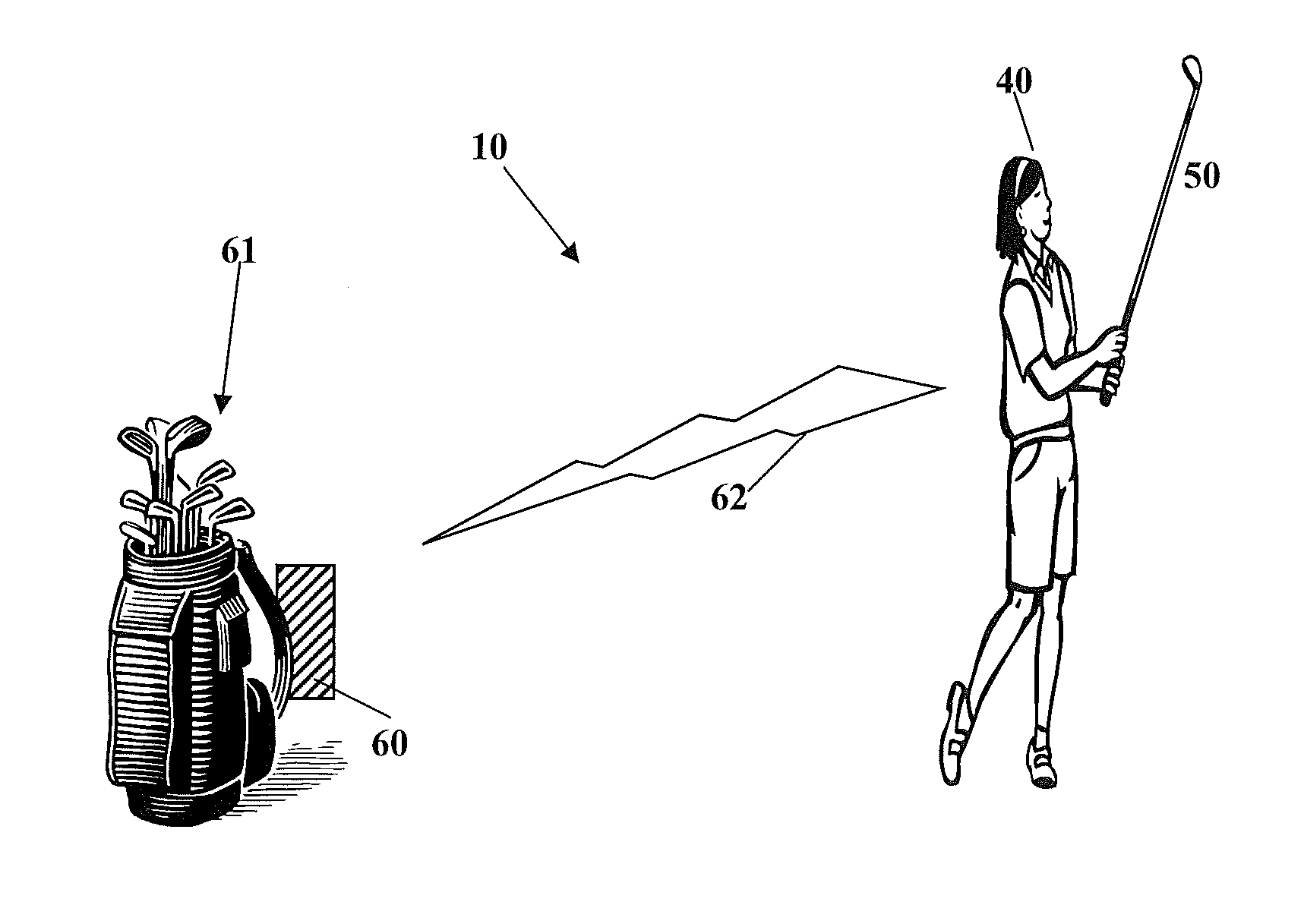

Method and system for shot tracking

A method for predicting a golfer's swing speed, wherein the method comprises determining that the golfer is addressing a golf ball to swing a golf club, monitoring a backswing, determining a transition time, monitoring a downswing, determining an impact time, transmitting data for the golfer's swing to a receiver for analysis and generating a golfer's swing speed using a length of a shaft of the golf club.

Owner:TOPGOLF CALLAWAY BRANDS CORP

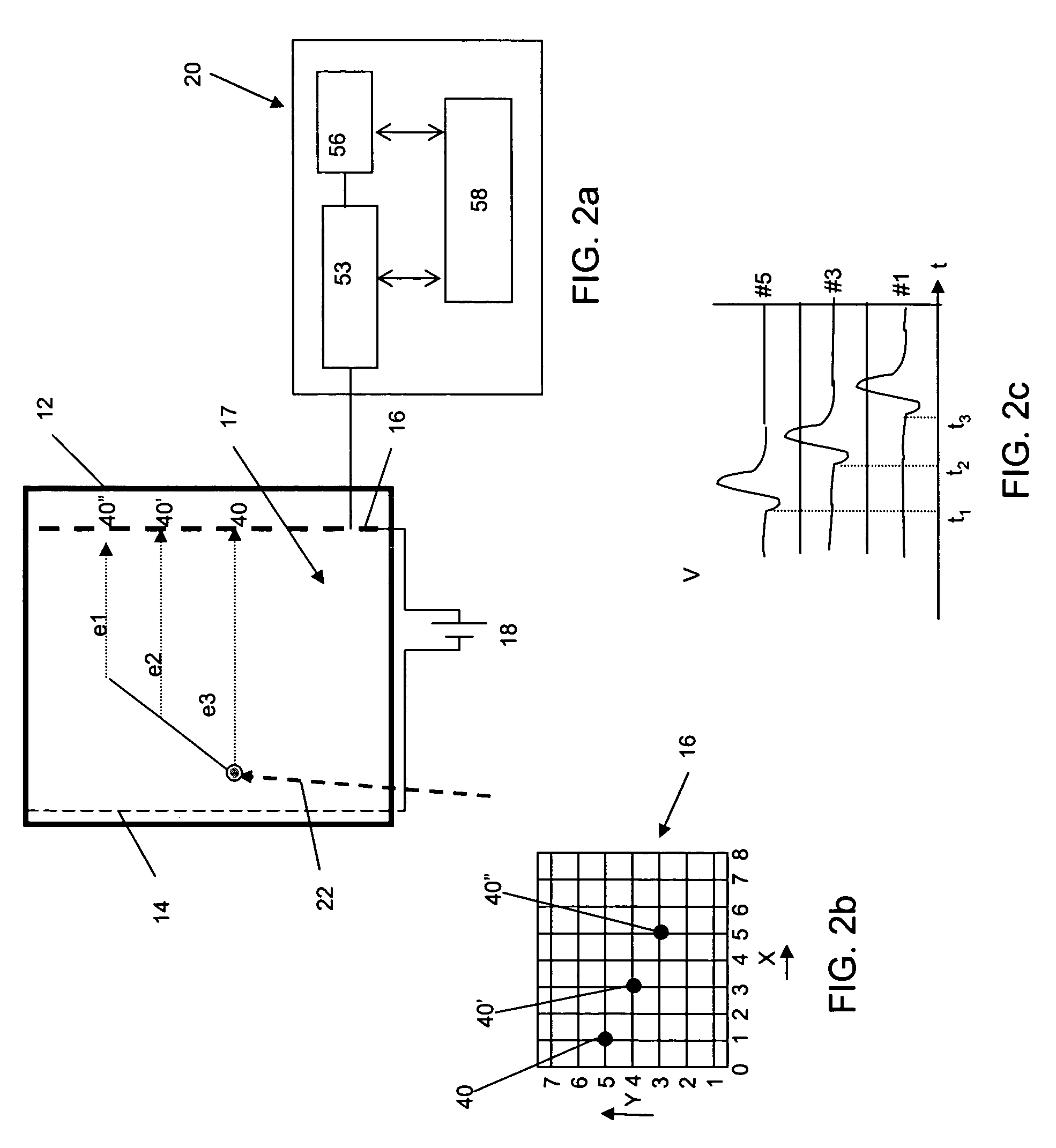

Neutron source detection camera

InactiveUS20060017000A1Measurement with semiconductor devicesMaterial analysis by optical meansNeutron emissionImaging equipment

A neutron imaging apparatus for obtaining an image of the general shape of a neutron emitting source and a bearing of the source relative to the apparatus, the apparatus comprising a chamber comprising a gas with a high probability of interacting with low energy neutrons, releasing collision products that maintain the neutron momentum, and generating ionization particles. The chamber comprises an electrode for providing an electronic signal indicative of the impact location of ionization particles on the electrode and a field to drift the ionization particles to the electrode. A readout indicates the location and time of impact of each ionization particle on the electrode; a memory stores a plurality of the electronic signals; and a computer receives and analyzes the signals and impact times and indicates the location of the source of neutrons by using back projection algorithms to calculate three-dimensional vectors indicative of the neutron path directions.

Owner:TEMPLE UNIVERSITY

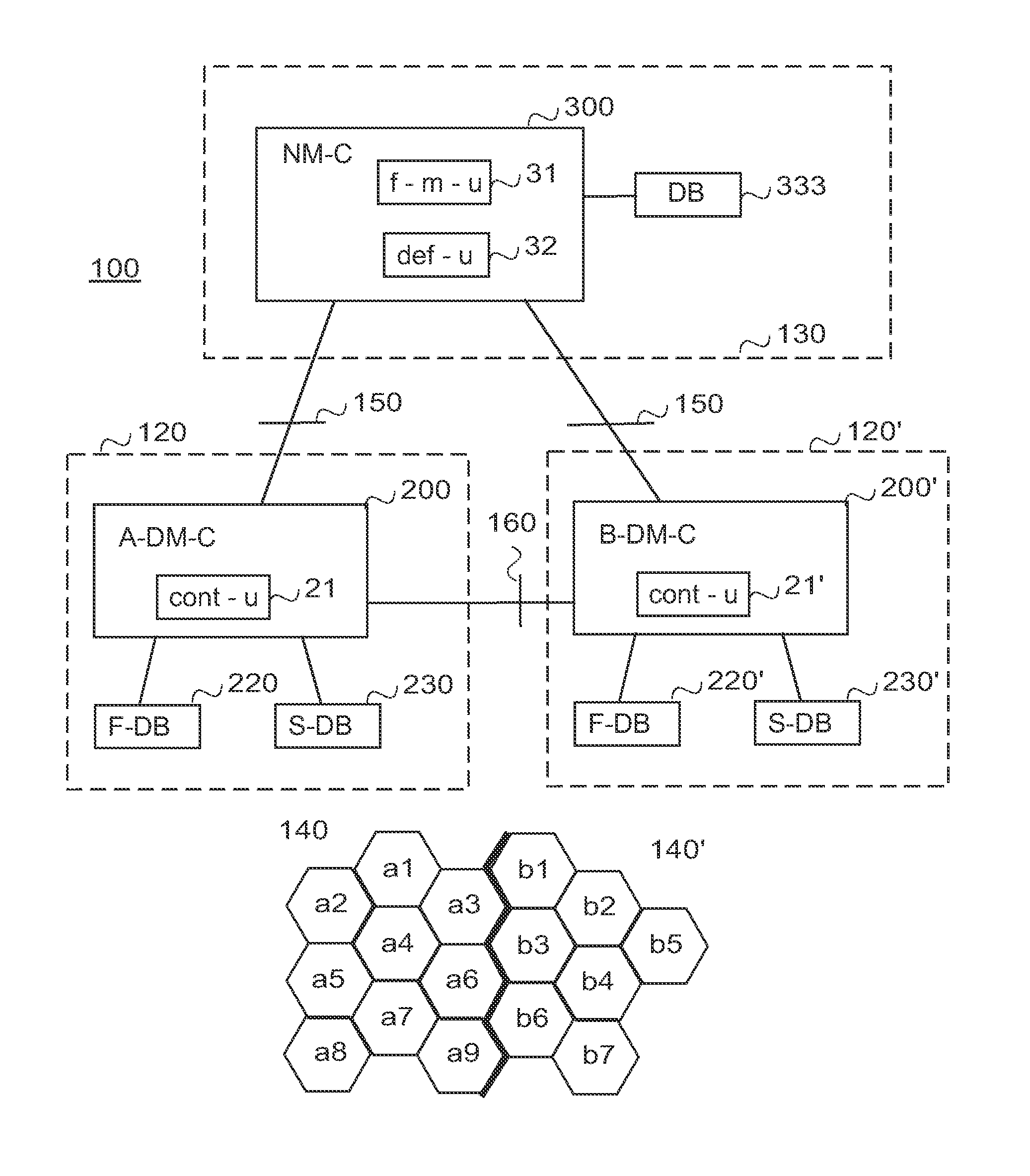

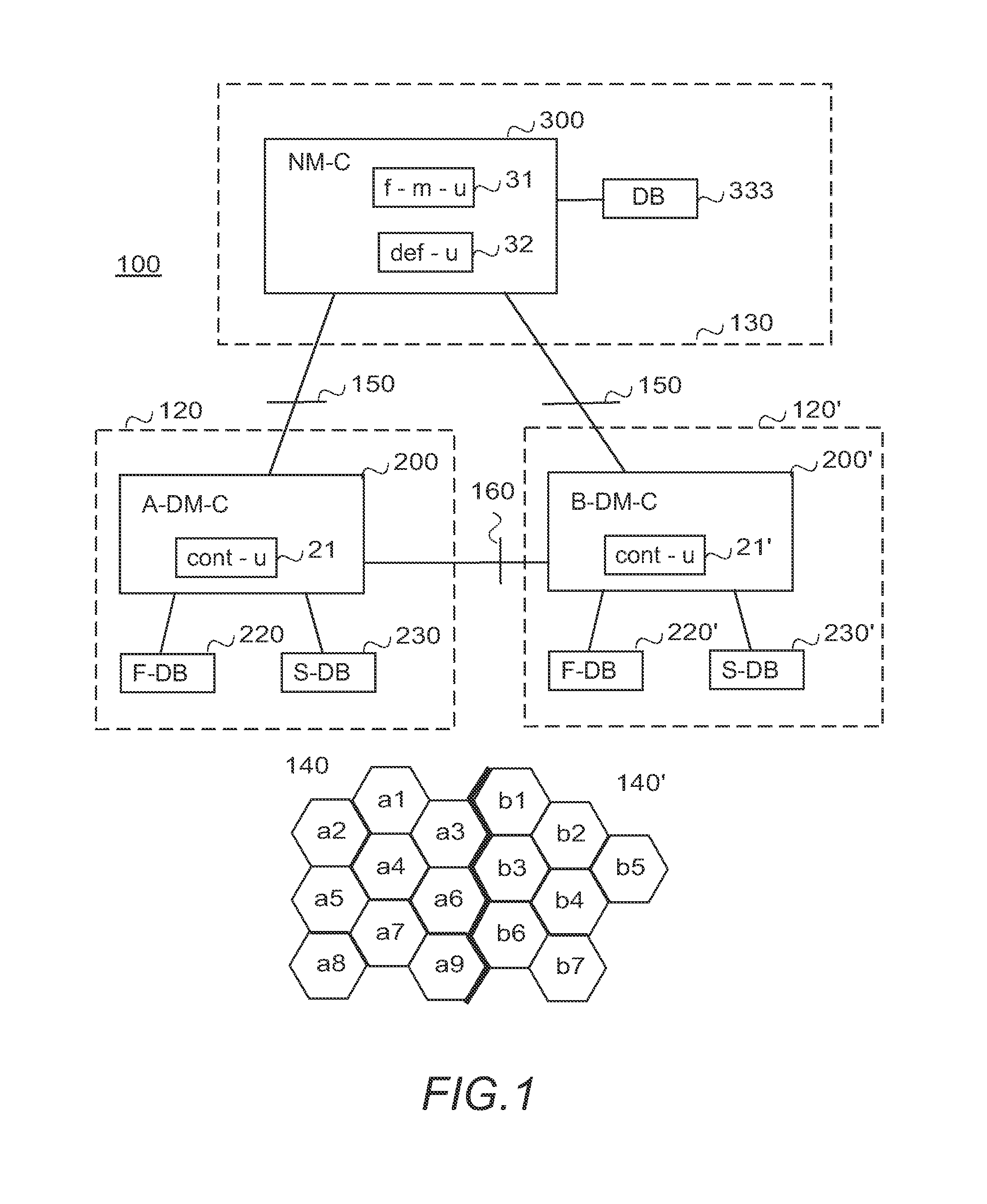

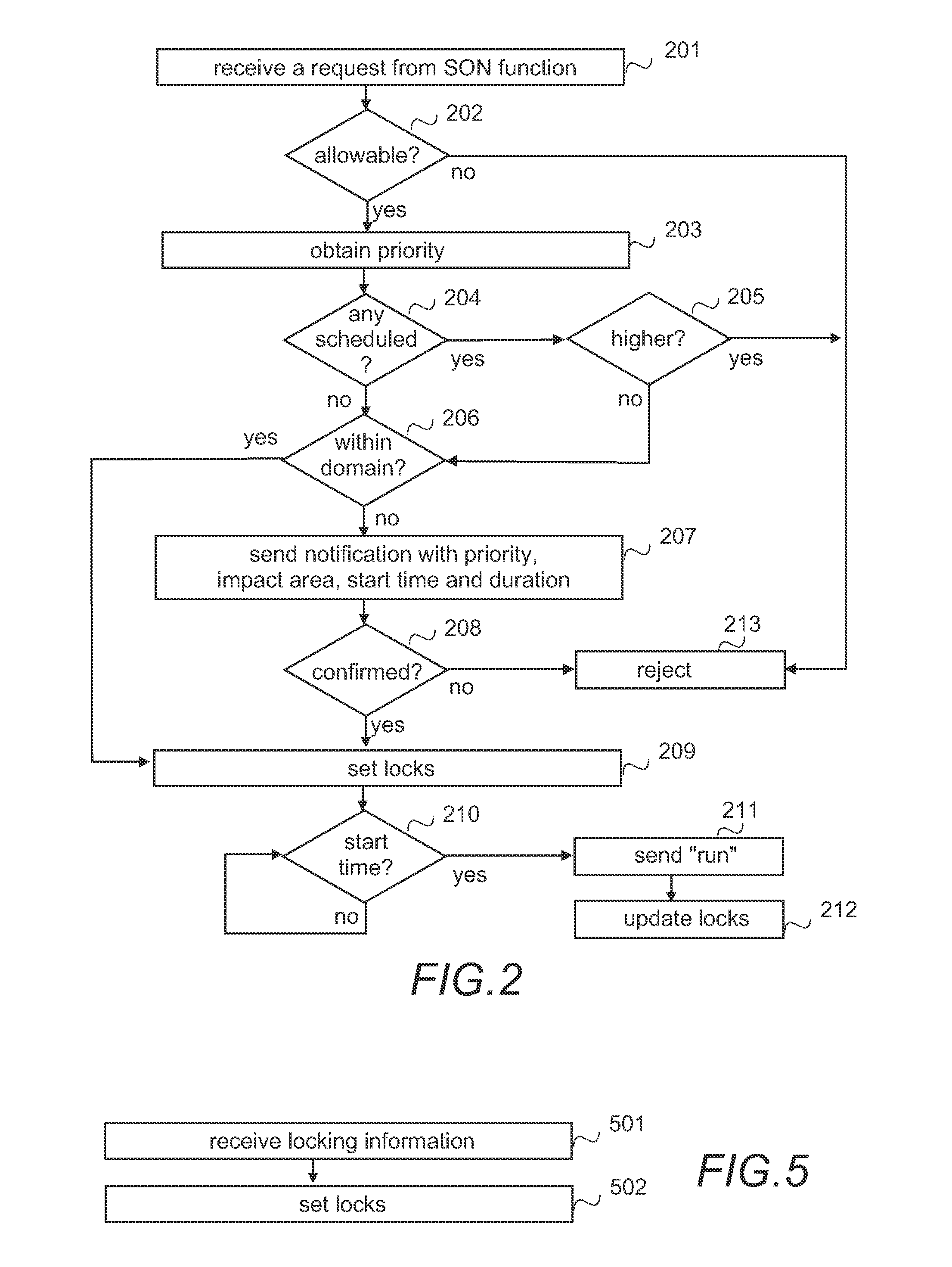

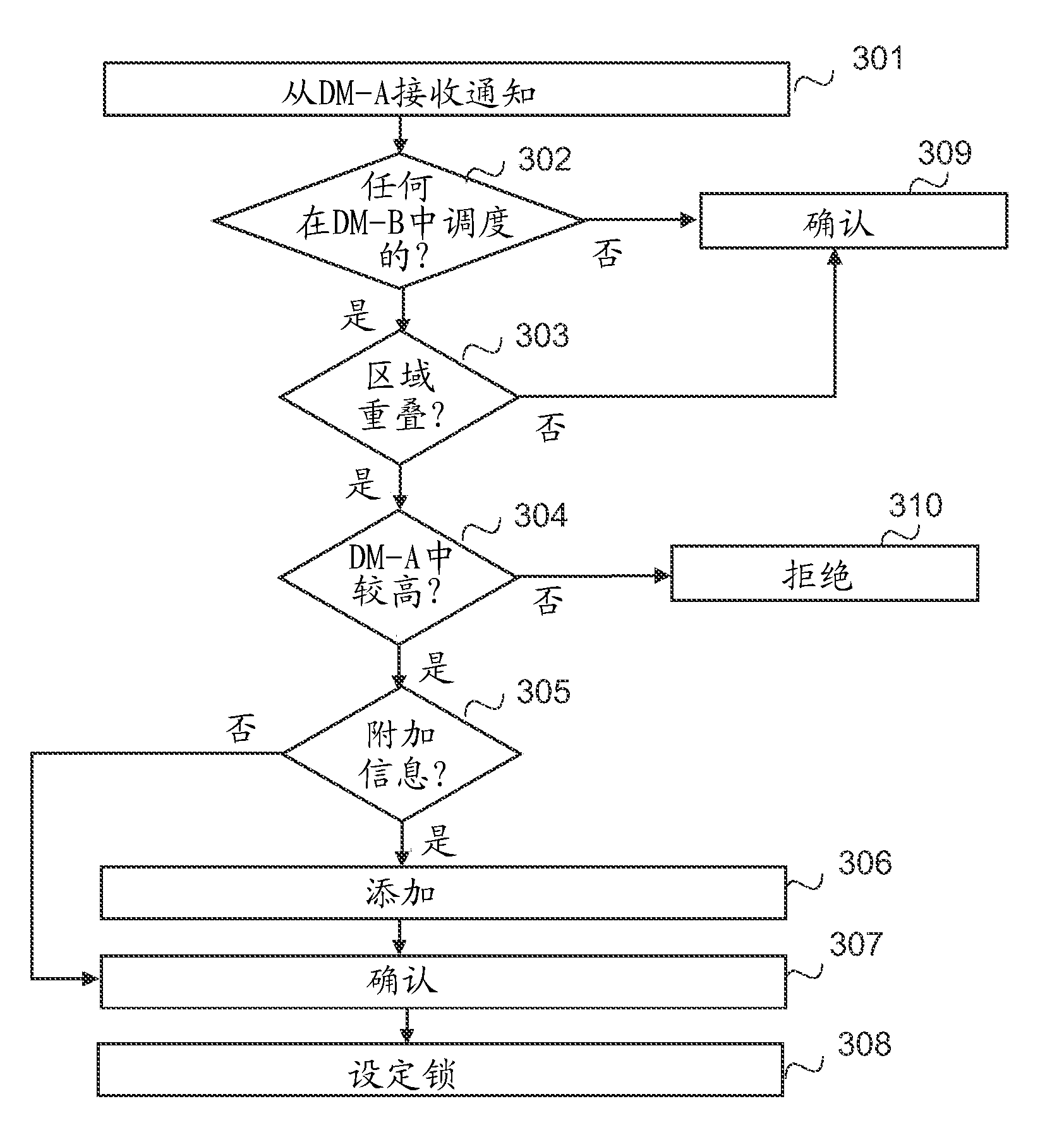

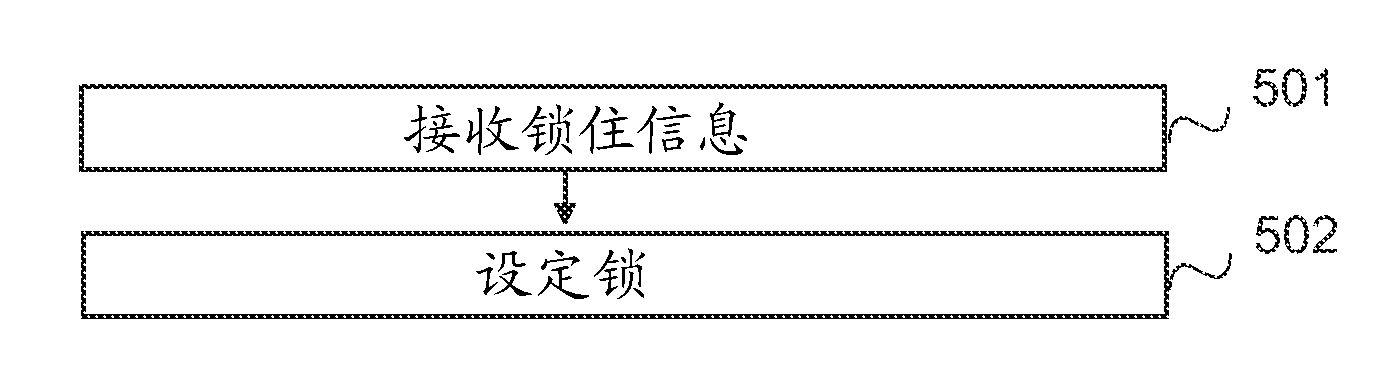

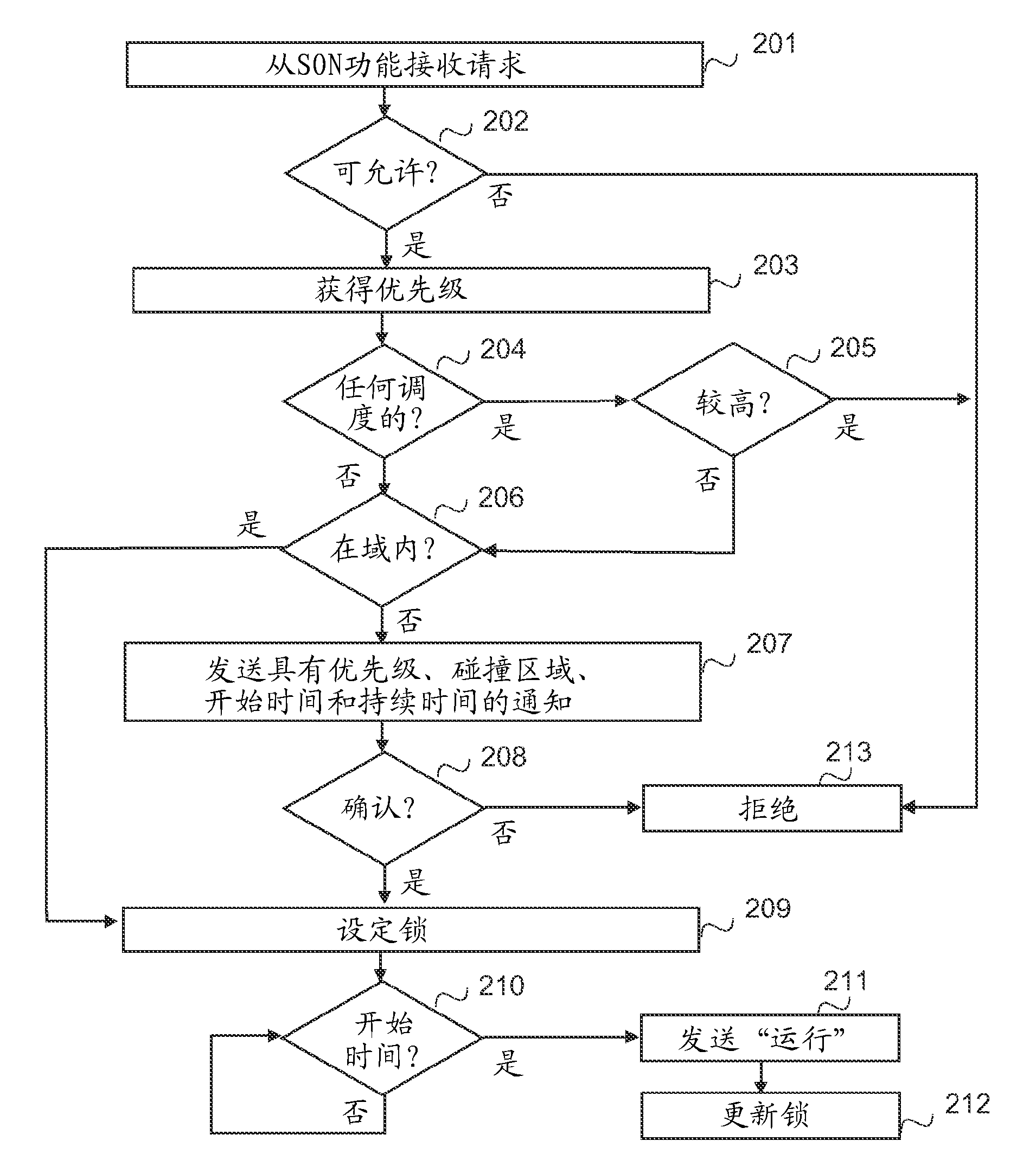

Coordination in self-organizing networks

ActiveUS20140040450A1Less processing capacityLess exchangingNetwork topologiesDigital computer detailsImpact areaSelf-organizing network

To decide, whether or not a SON function instance is allowed to execute, a priority, an impact time and an impact area for the SON function instance is determined, and priorities of other SON function instances scheduled to be run during the impact time of the requesting SON function instance and having an overlapping impact area are compared to the priority of the requesting SON function instance.

Owner:NOKIA SOLUTIONS & NETWORKS OY

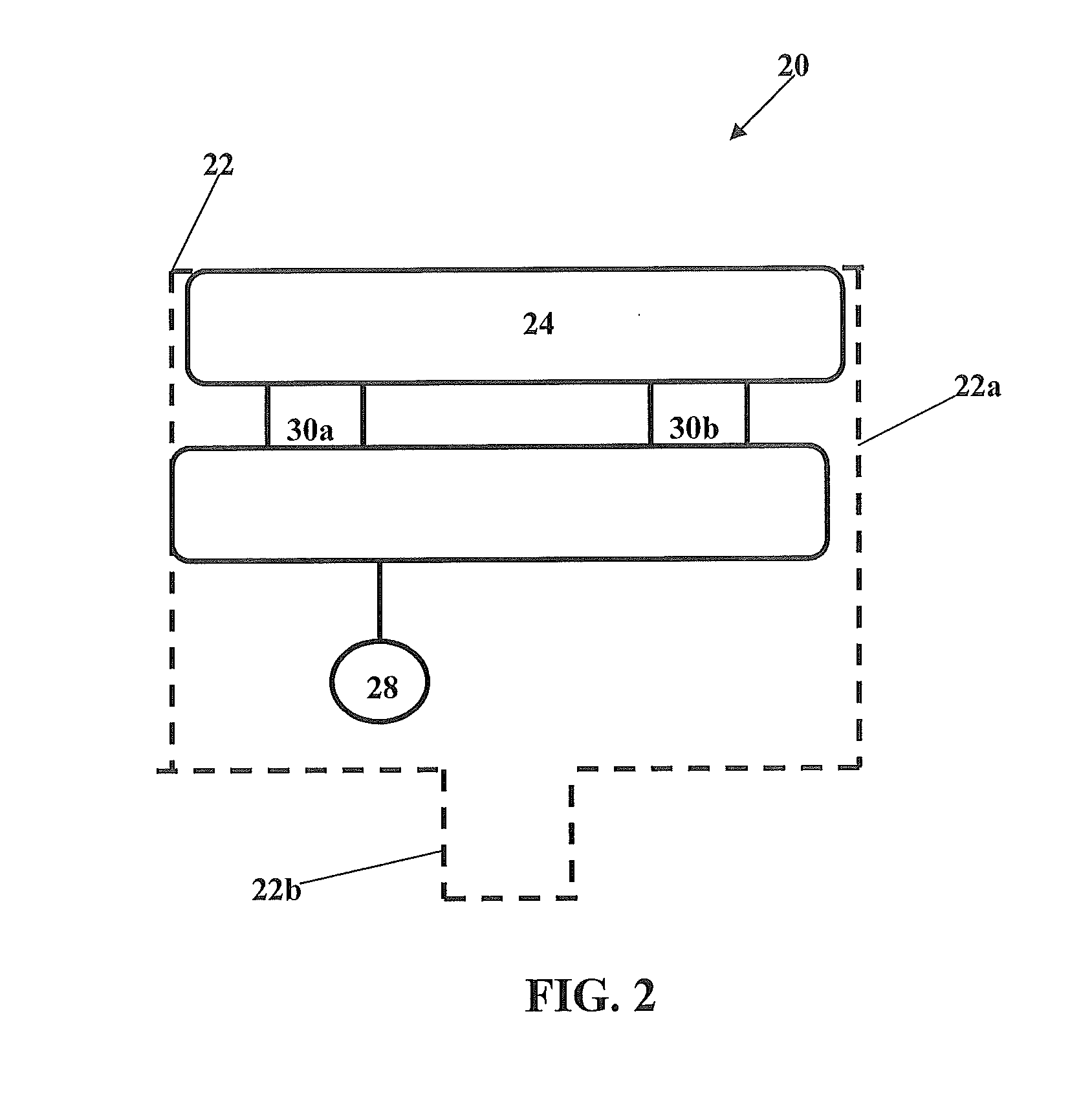

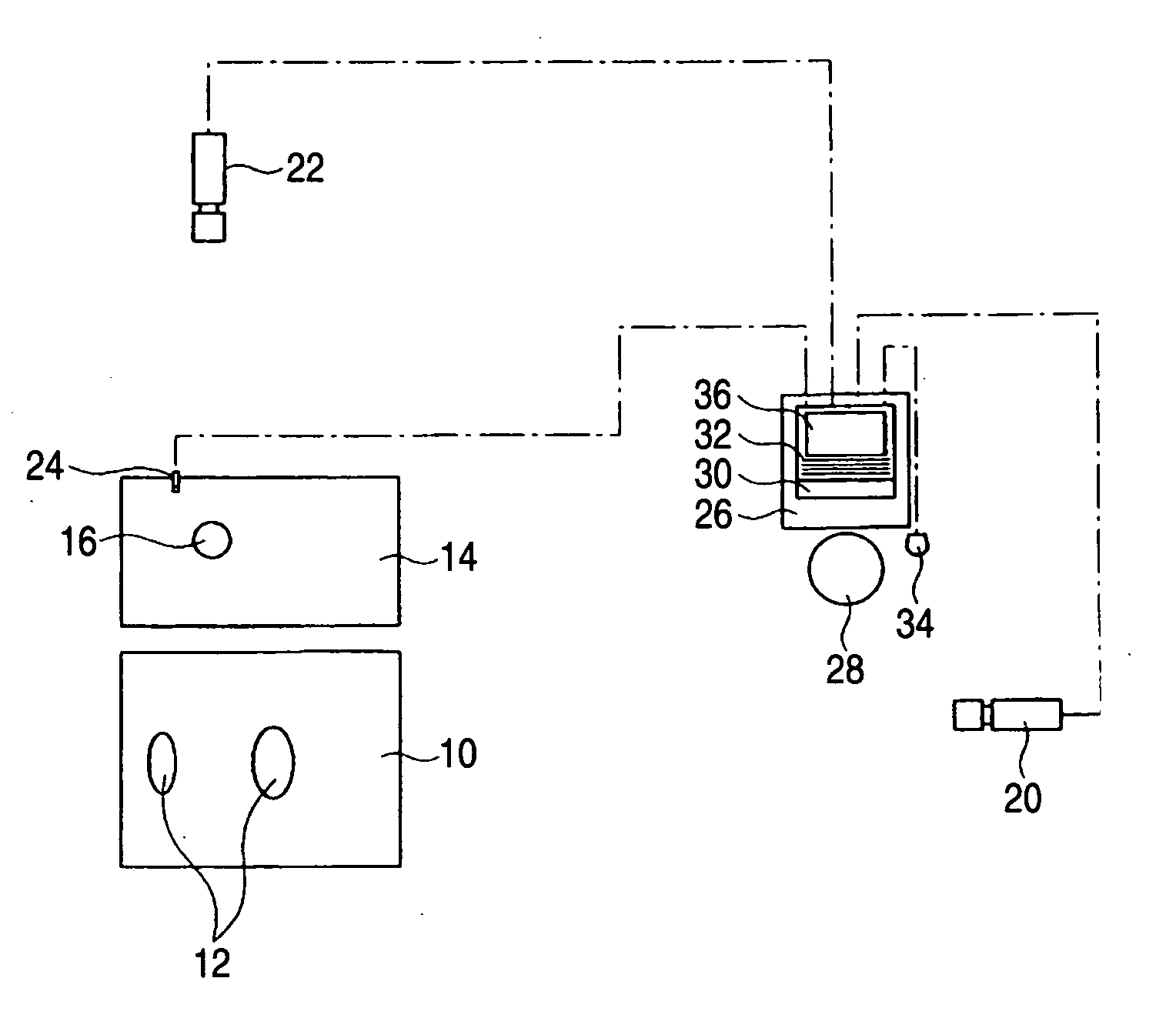

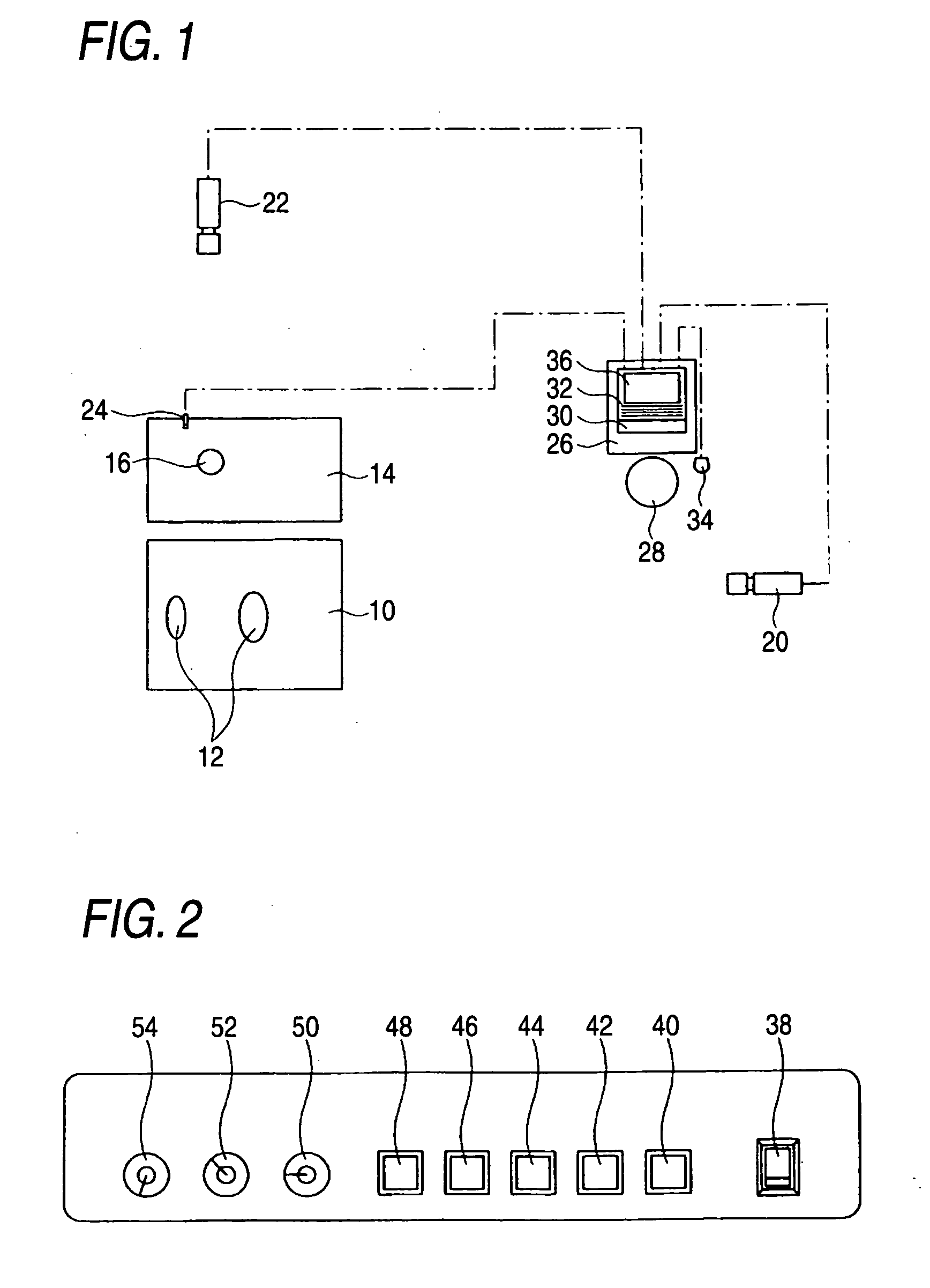

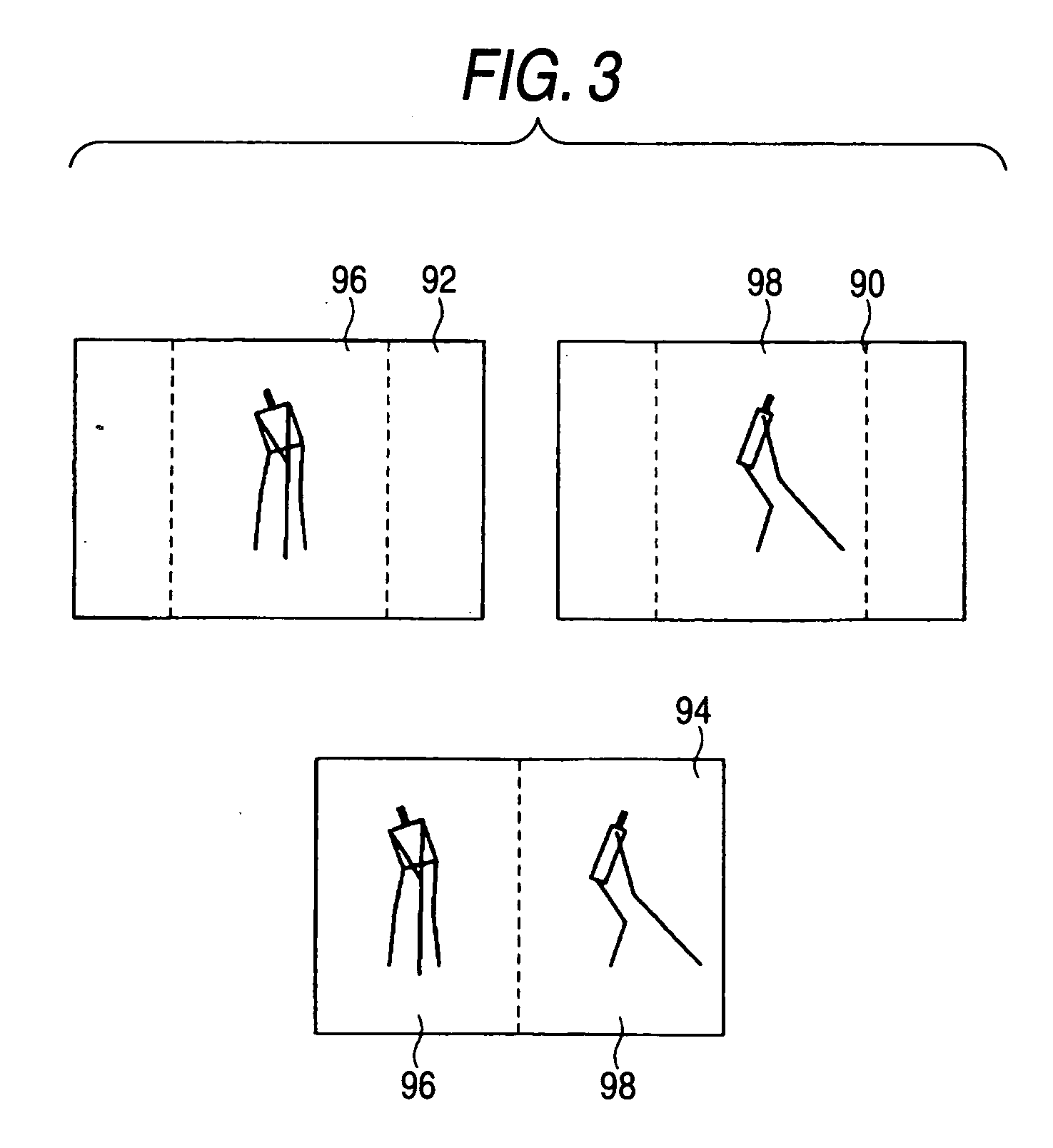

Video analysis system of swing motion

InactiveUS20060281060A1Easy to determineEasy to displayCosmonautic condition simulationsGymnastic exercisingComputer visionImpact time

A video analysis system of swing motion includes an imaging unit that images video of swing motion, an impact detection unit that detects impact, a control unit and a video display unit. The control unit has (a) a function of receiving the video of the swing motion from the imaging unit; (b) a function of receiving an impact detection signal from the impact detection unit; (c) a function of recording the video of swing motion received from the imaging unit into the control unit; and (d) a function of, when the control unit records into the control unit the video of the swing motion received from the imaging unit, determining an impact time based on the impact detection signal received from the impact detection unit, to record images of the swing motion for a predetermined time period containing the impact time.

Owner:BRIDGESTONE SPORTS

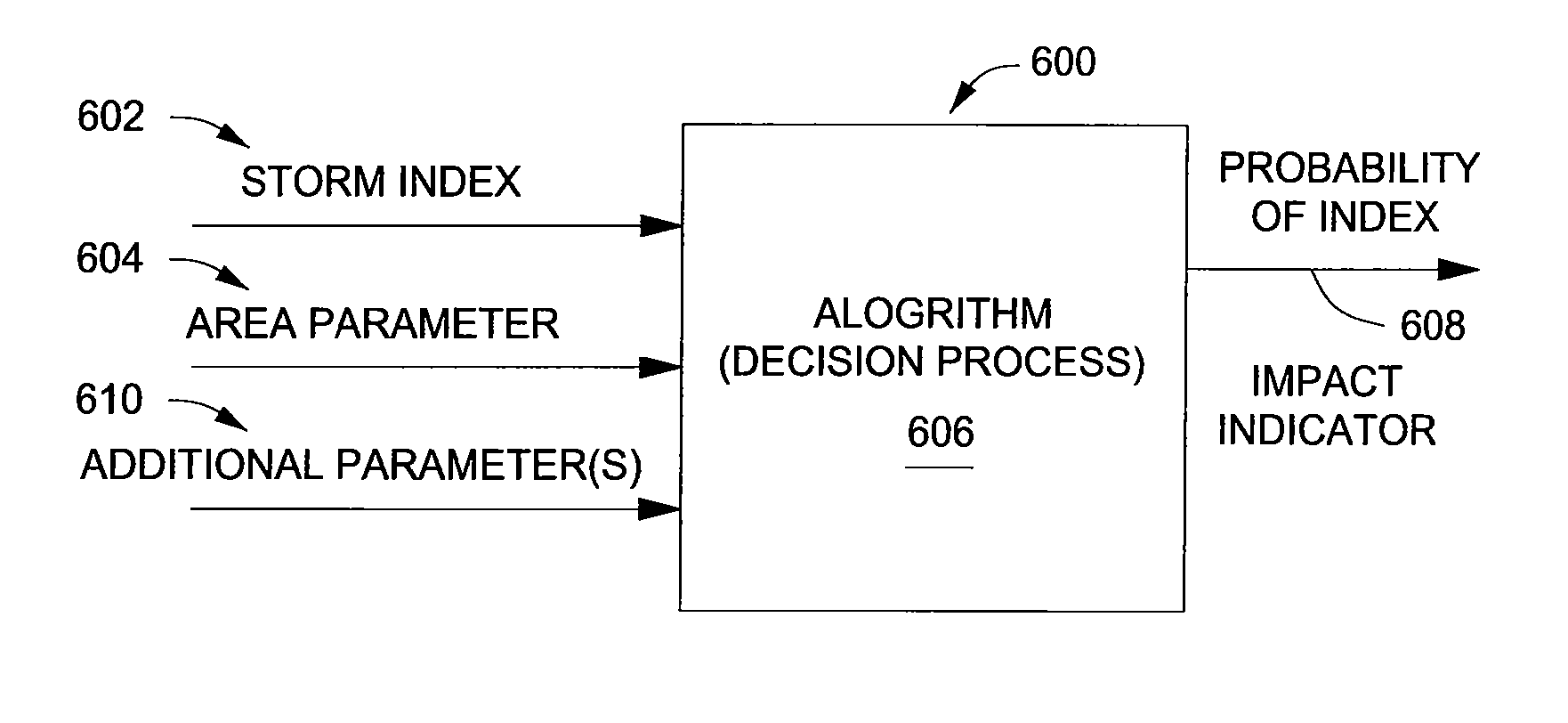

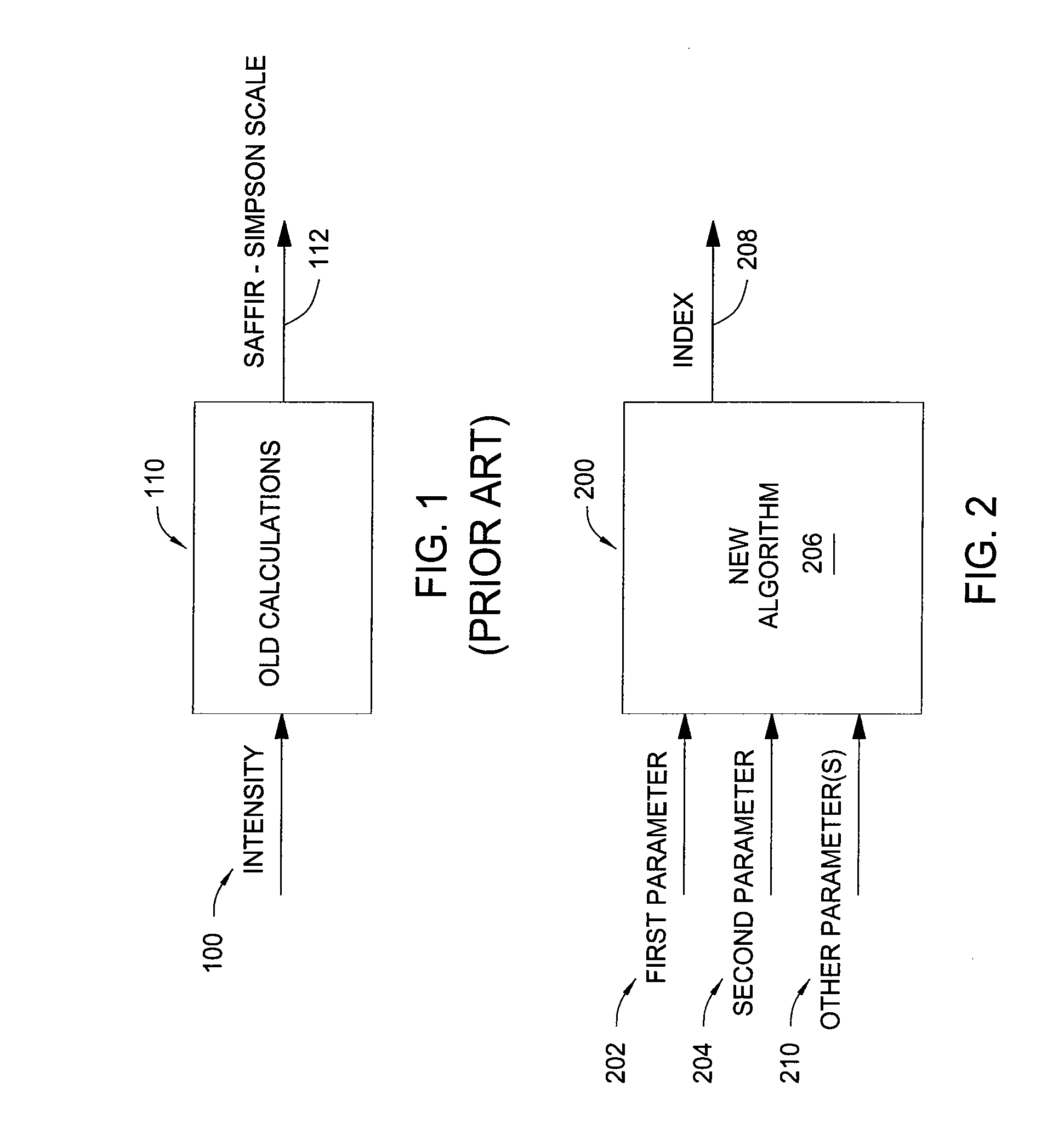

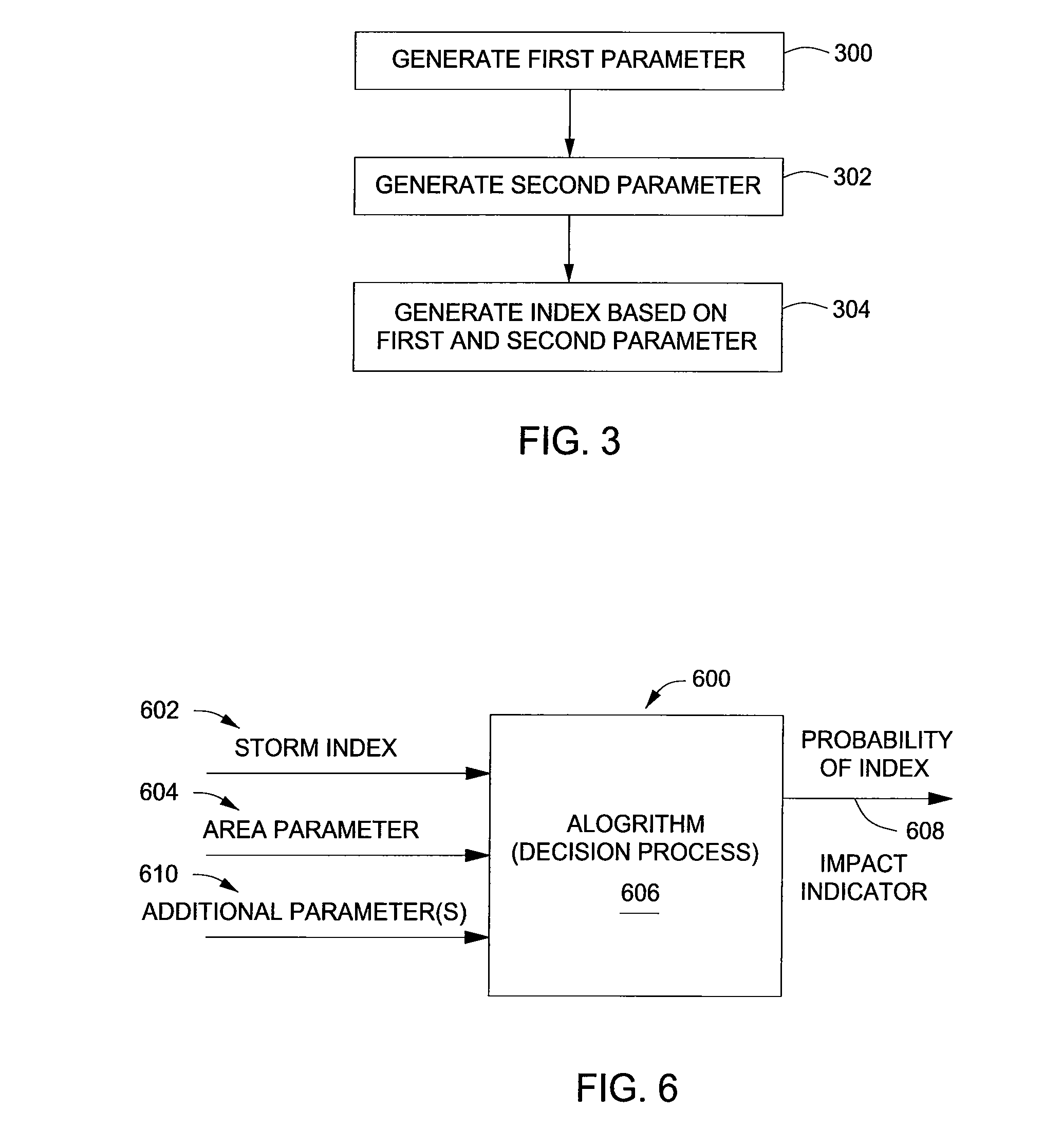

Methods of calculating impact time for storms

InactiveUS20070221743A1Precise definitionClearer ideaWeather condition predictionFog dispersionAtmospheric sciencesImpact time

At least one method for indicating a weather condition includes indexing a storm based on two or more parameters. One of the parameters is a travel speed of the storm and a second parameter is a location of the storm. The method further includes providing a time before the storm impacts a recipient based on the travel speed of the storm and a track distance to the recipient location. The method further includes delivering the time before the storm impacts the location to the recipient.

Owner:UNIVERSAL WEATHER & AVIATION

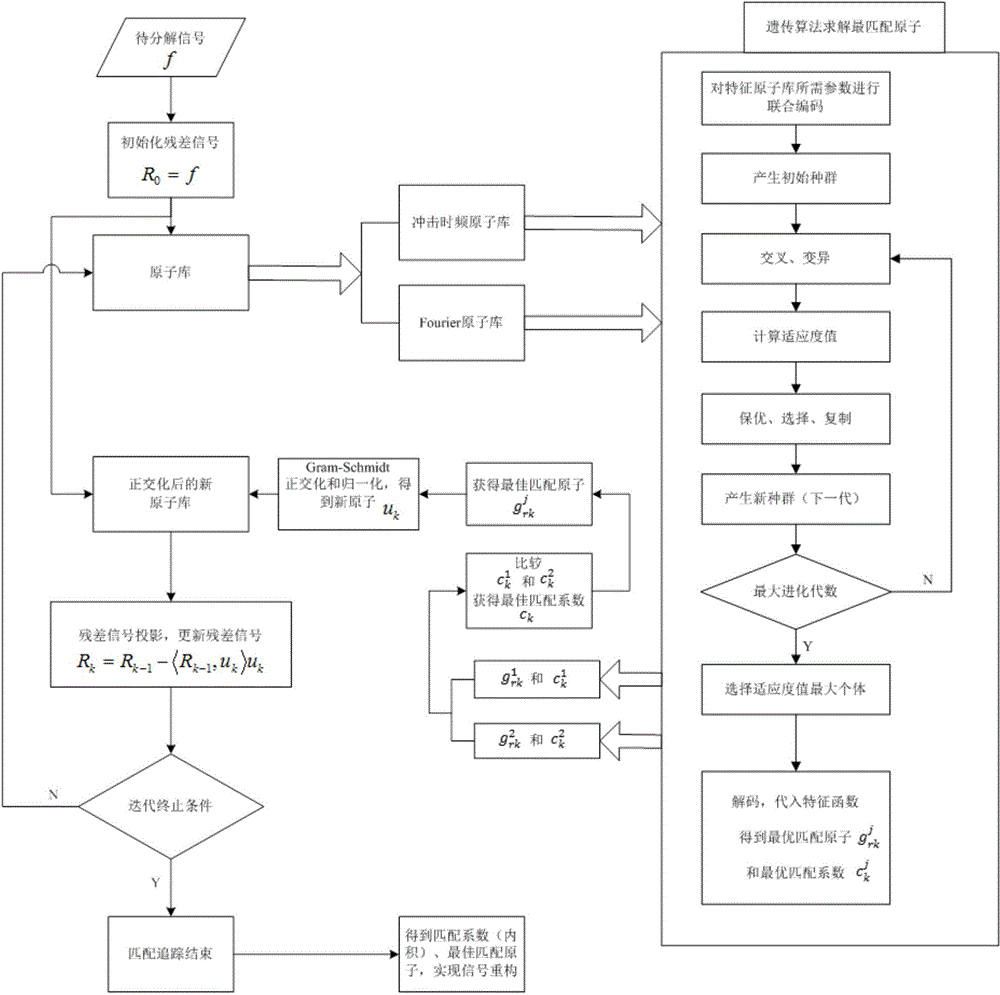

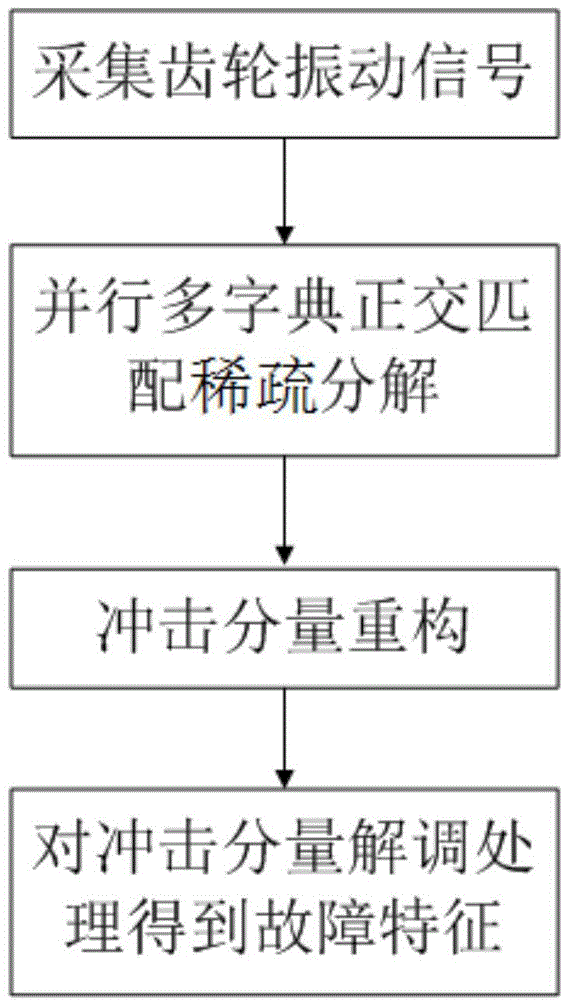

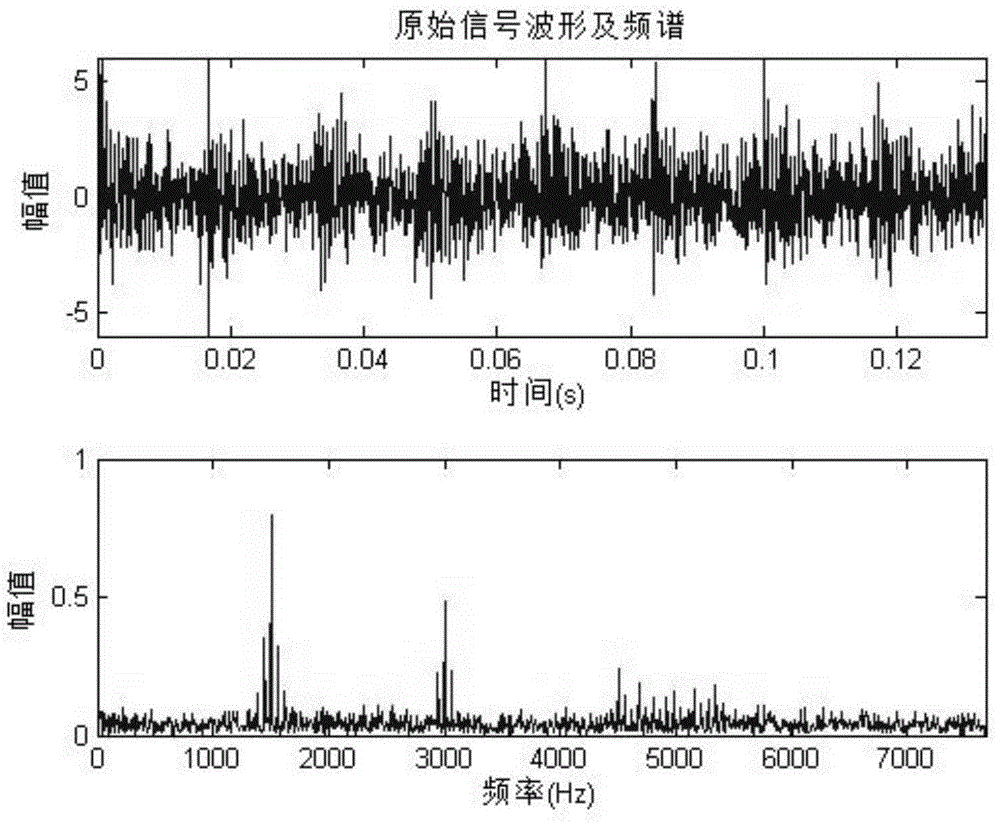

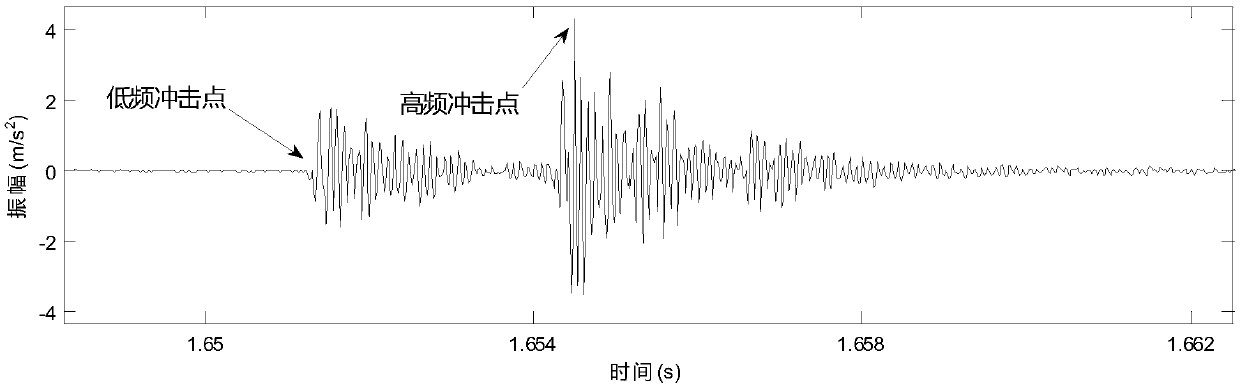

Gear fault diagnosis method based on orthogonal match between multiple parallel dictionaries

The invention relates to a gear fault diagnosis method based on the orthogonal match between multiple parallel dictionaries. According to the method, gear vibration signals are expressed in the mode of linear superposition of simple and sparse atoms of the multiple parallel dictionaries. As for the multiple parallel dictionaries, Fourier dictionaries and impact time frequency dictionaries are selected to form the multiple dictionaries according to the characteristics of the gear vibration signals, matched atoms are selected in parallel in all sub-dictionaries with a genetic algorithm, coefficients of all orders are compared to obtain a most matched atom, Gram-Schmidt orthogonalization is performed on the atom, and then a new atom library is formed. Analysis signals are projected to the atom library, and the projections are subtracted from the signals to form residual signals to be decomposed the next time. The decomposition process is completed after the iteration end conditions are met, the matched atoms and the matching coefficient are extracted, the matched atoms based on the impact time frequency dictionaries are reconstructed, corresponding impact components can be obtained, and then fault information of the gear vibration signals is demodulated and extracted for fault diagnosis.

Owner:BEIJING UNIV OF TECH

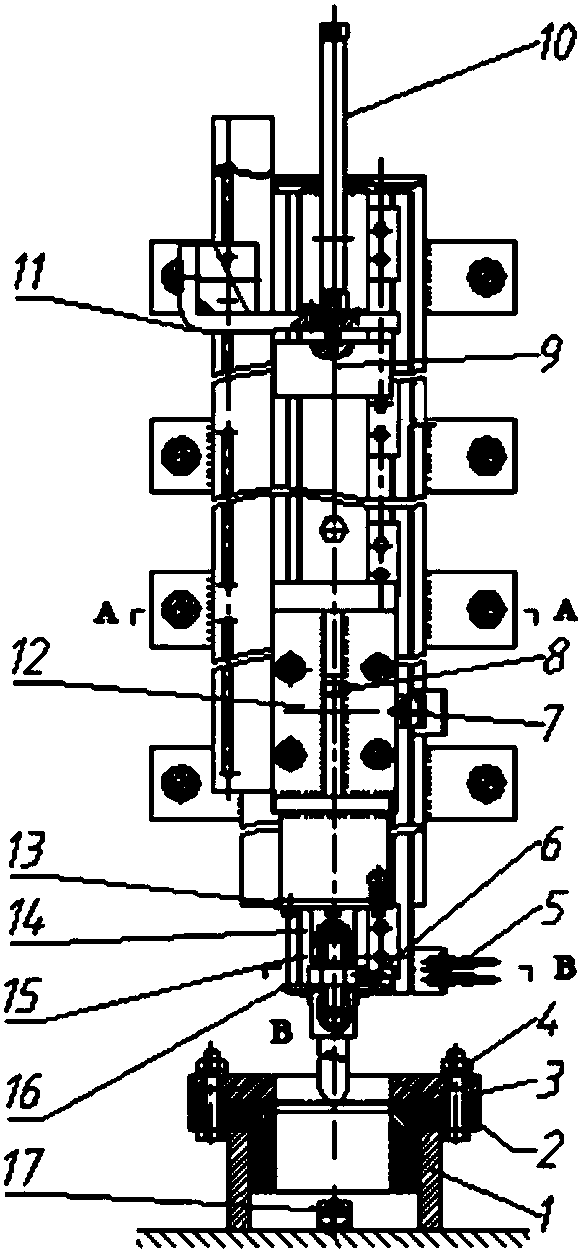

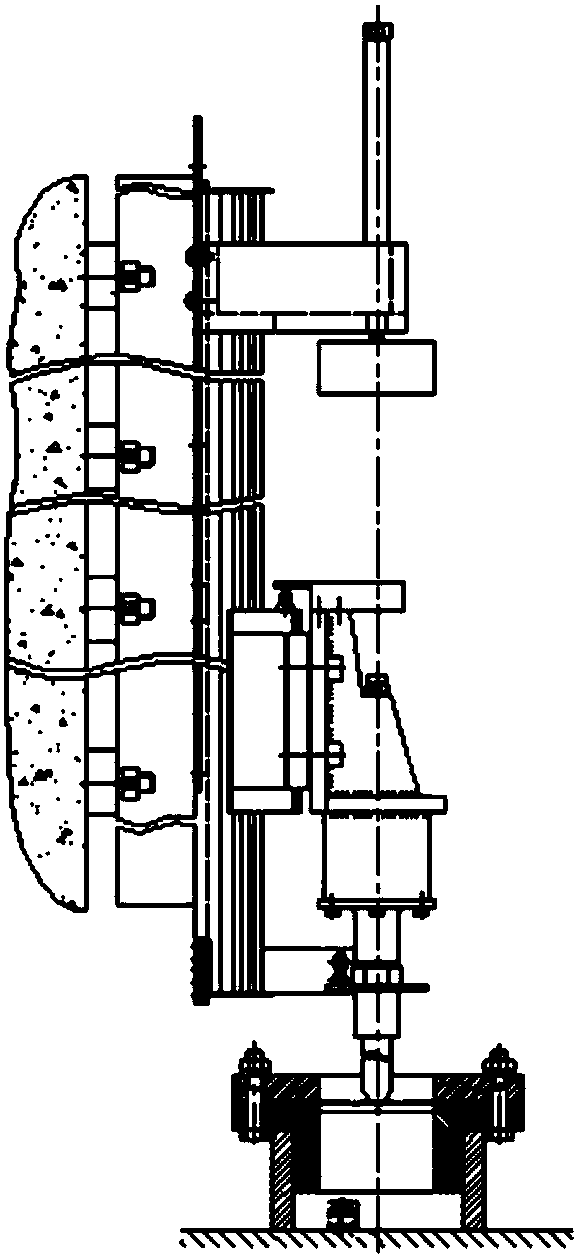

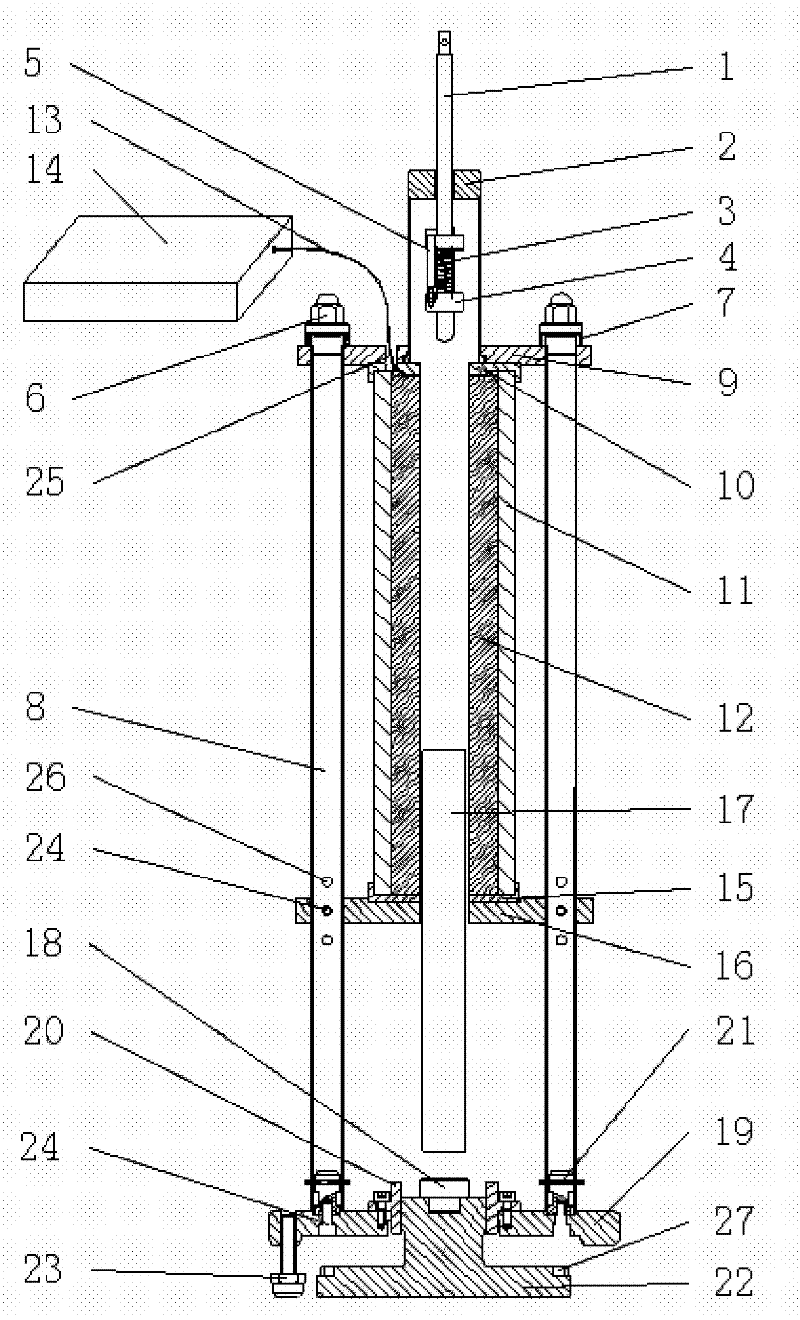

Digital fatigue impact test instrument and test method

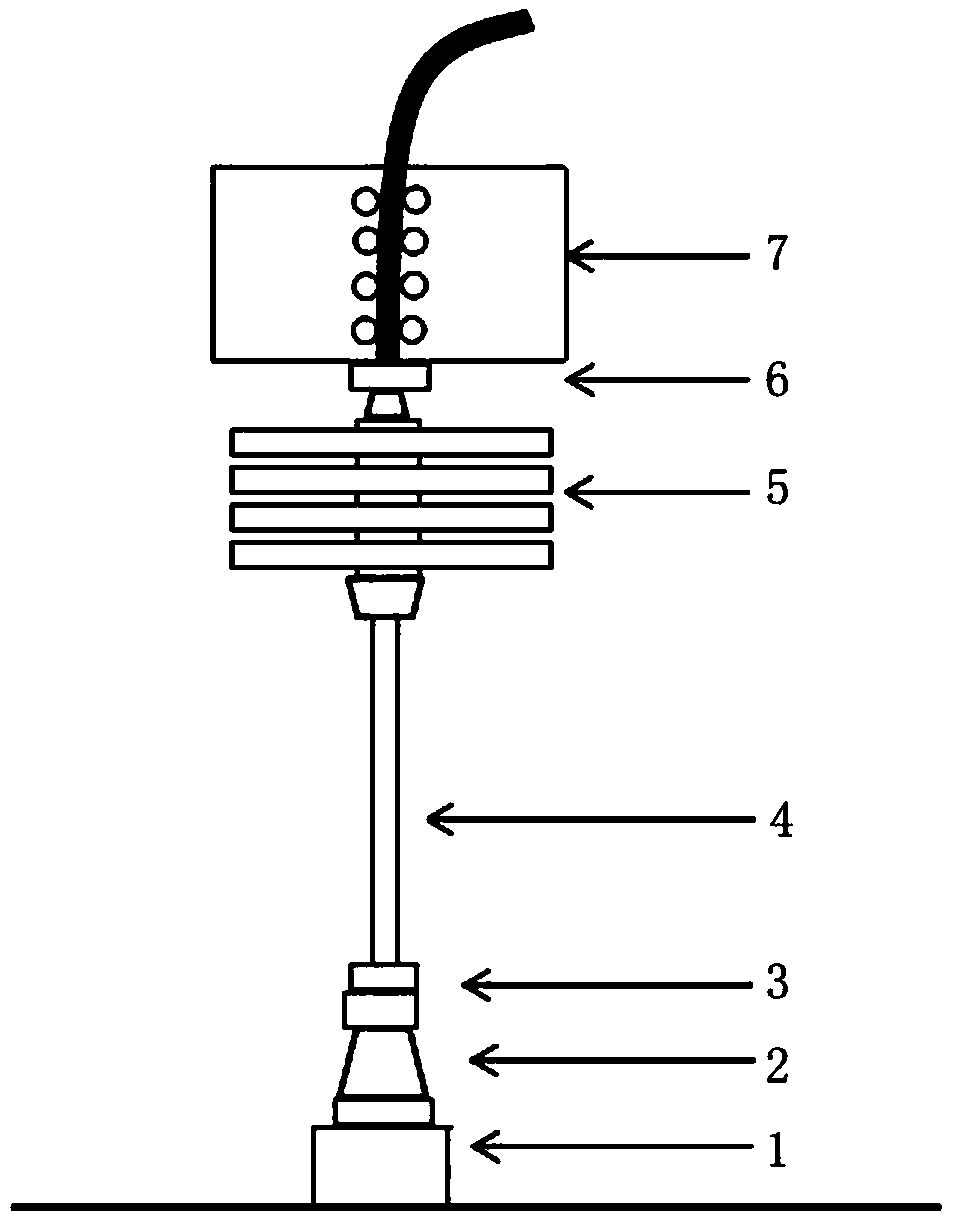

InactiveCN107941447APower-off position controllableAchieve fatigue shockMaterial strength using repeated/pulsating forcesShock testingData acquisitionContact force

The invention discloses a digital fatigue impact test instrument and a test method, comprising a guide rail, a guide rail support frame, a specimen fixture, an impact hammer head, a light shield, an acceleration sensor, a force sensor, a photoelectric sensor, a cylinder control valve, a cylinder, and an electromagnet , travel switch and computer. When the impact hammer head descends from a height along the linear guide rail to impact the test specimen, the data acquisition card records the experimental data of the impact process, and under the action of the cylinder and the electromagnet, the impact hammer head can rise to the set position to prepare for the next impact. The instrument can not only control the number of impacts and collect sensor data during the impact process, but also obtain the impact contact force, impact energy, impact time, acceleration, displacement, and velocity in each impact process. The relationship between the changes in the physical quantities involved , to realize the automation, continuous and full digitalization of the fatigue impact process, which is of great significance to the accurate simulation, design and failure mechanism exploration of the material impact resistance process.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

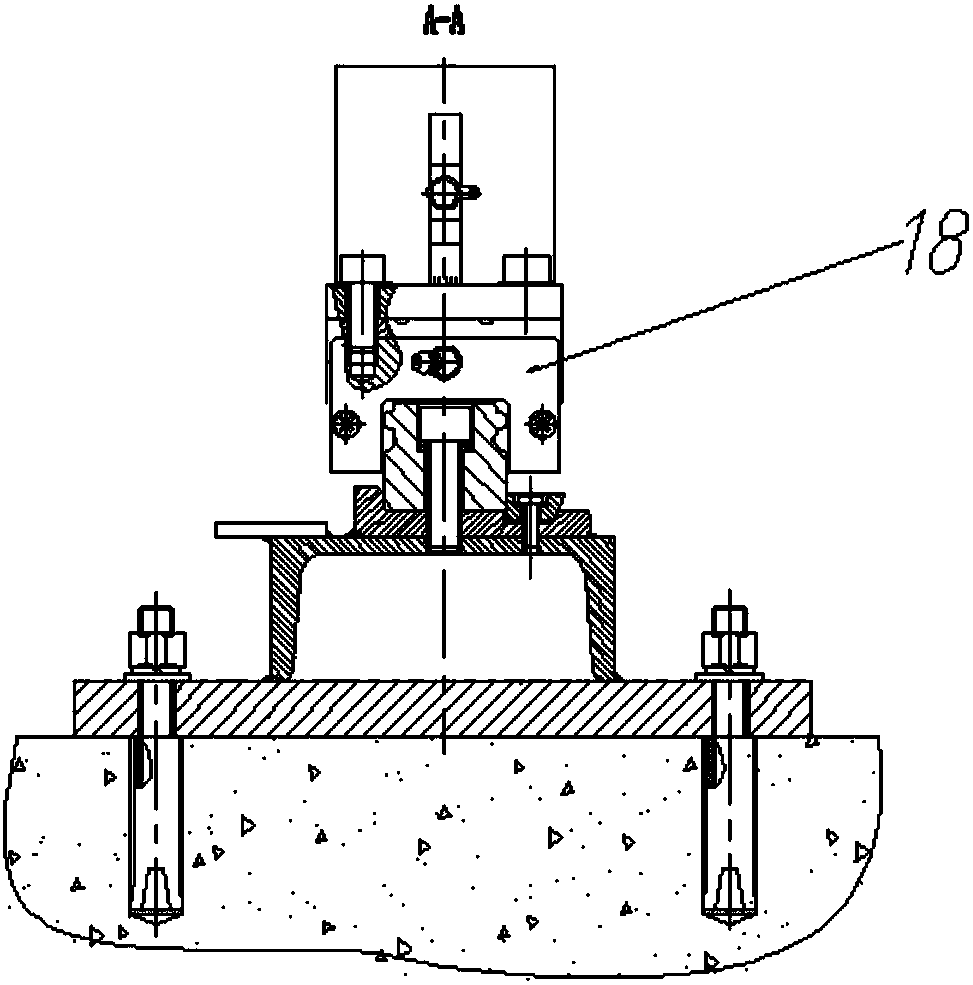

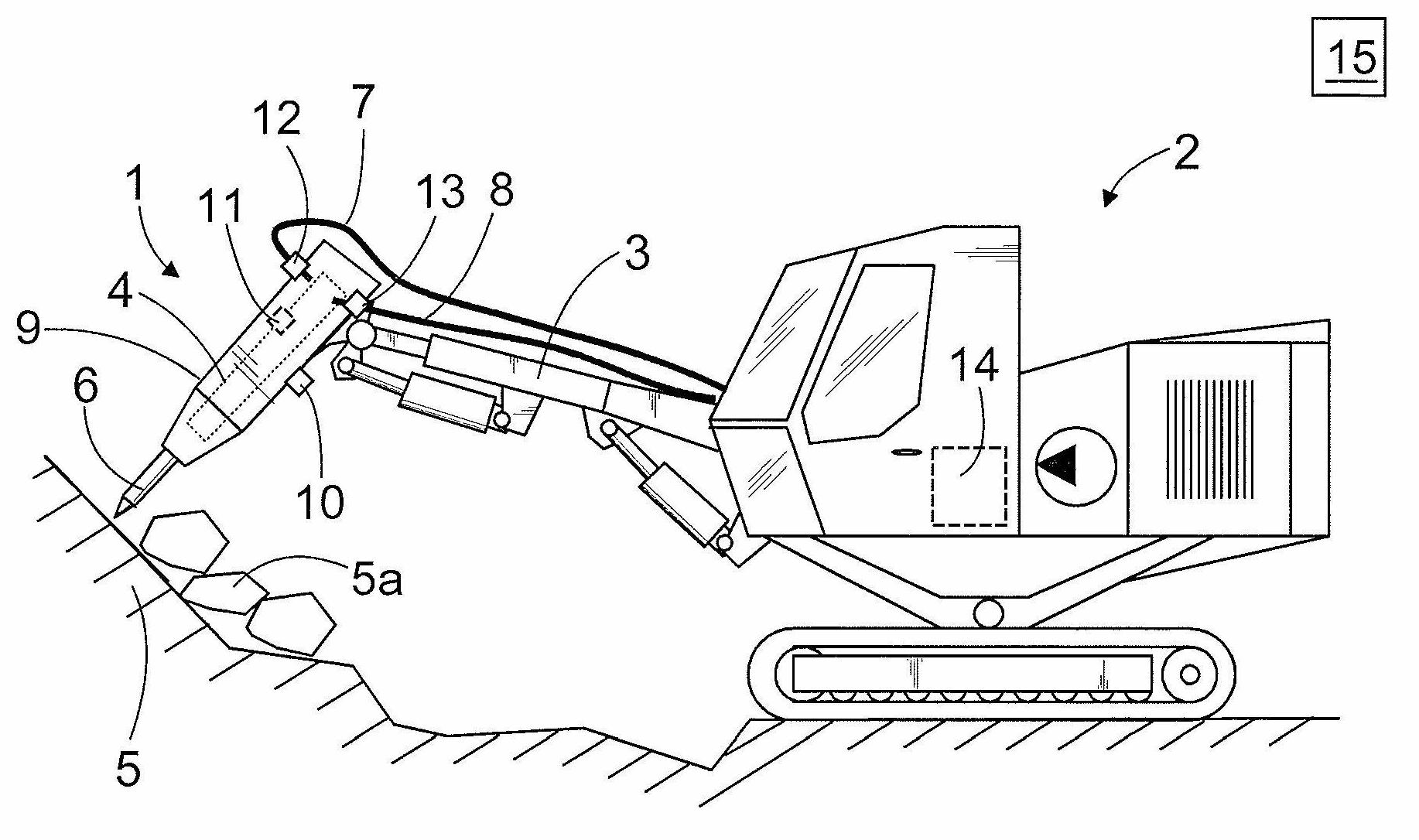

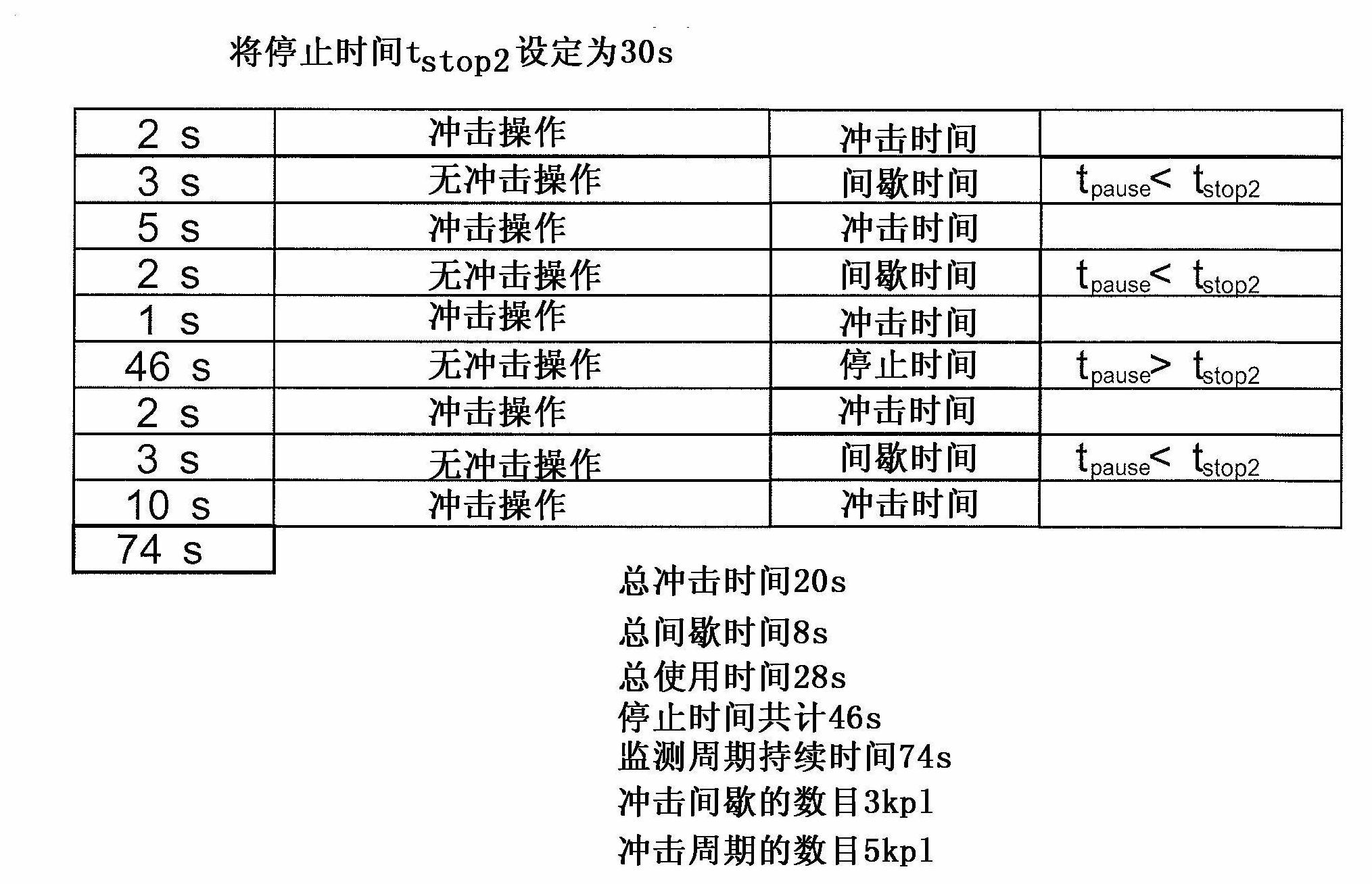

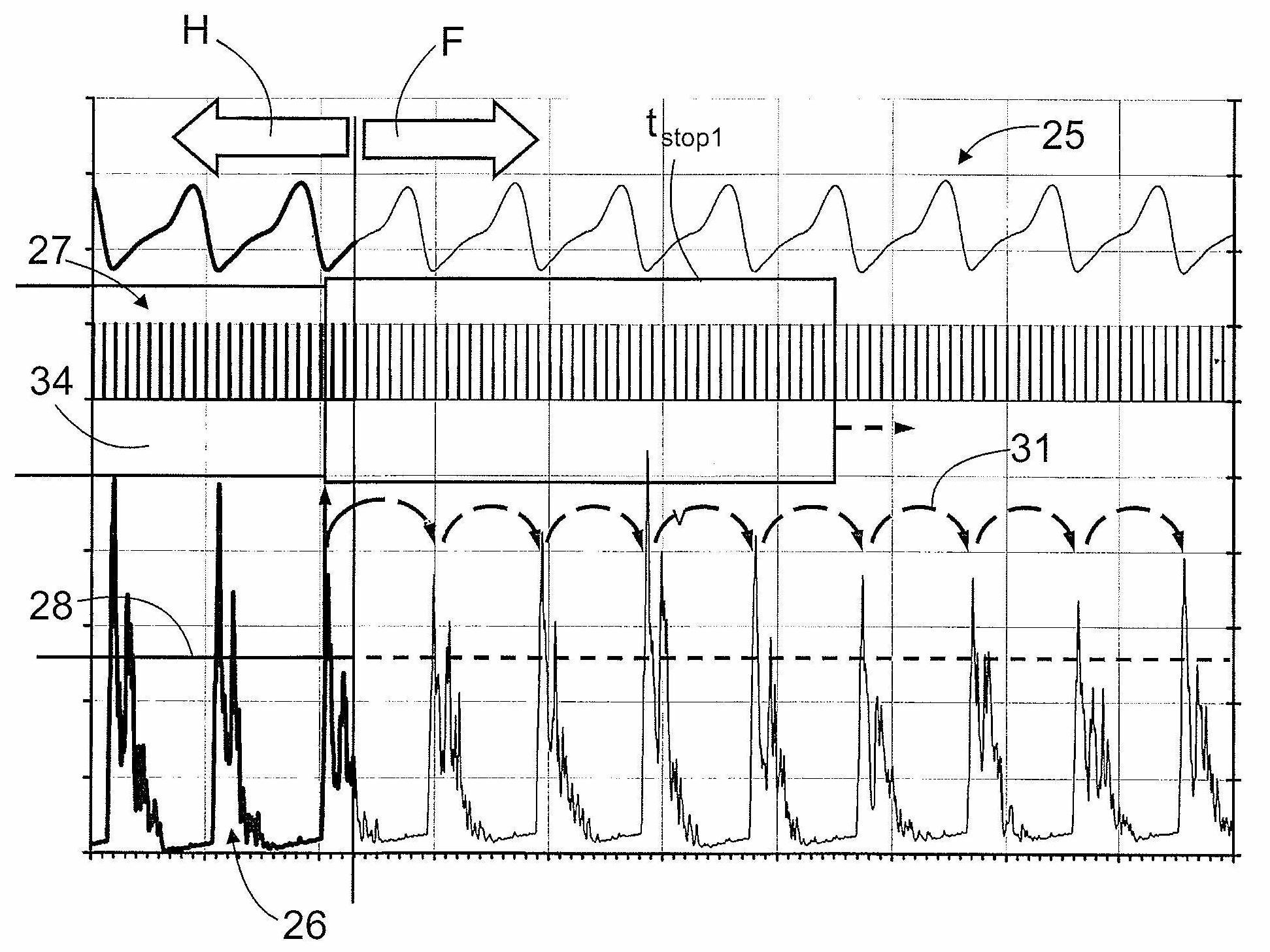

Method for determining usage rate of breaking hammer, breaking hammer, and measuring device

InactiveCN102667008AKnow operating lifeLoad revealMachine part testingRegistering/indicating working of vehiclesMeasurement deviceTime limit

The invention relates to a method and measuring device for determining the usage rate of a breaking hammer, and to a rock breaking device. The measuring device (10) comprises a sensor (11) for measuring a physical phenomenon caused by the operation of the percussion device (4).The measuring results are processed, and they are used to determine the start and end times of the operation of the percussion device. By means of a timing device (61), it is possible to determine the duration of an impact cycle (IC) which is added to a time counter (62).The durations of impact cycles added cumulatively to the time counter indicate the total percussion time of the breaking hammer. Impact pauses (IP) between impact cycles are also monitored, and pauses shorter than a predefined time limit (tstop2) are taken into account as part of the usage rate.

Owner:SANDVIK MINING & CONSTR OY

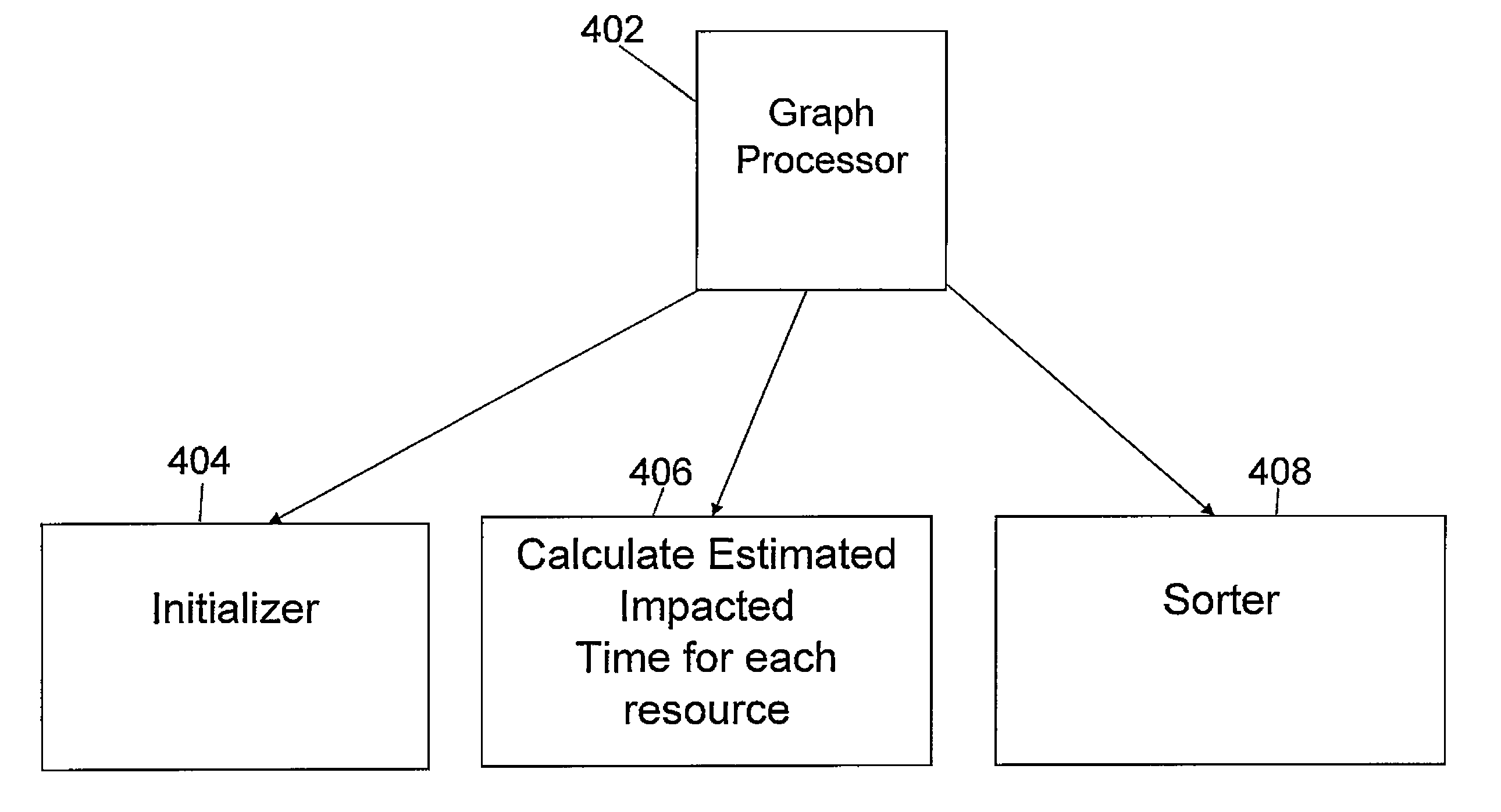

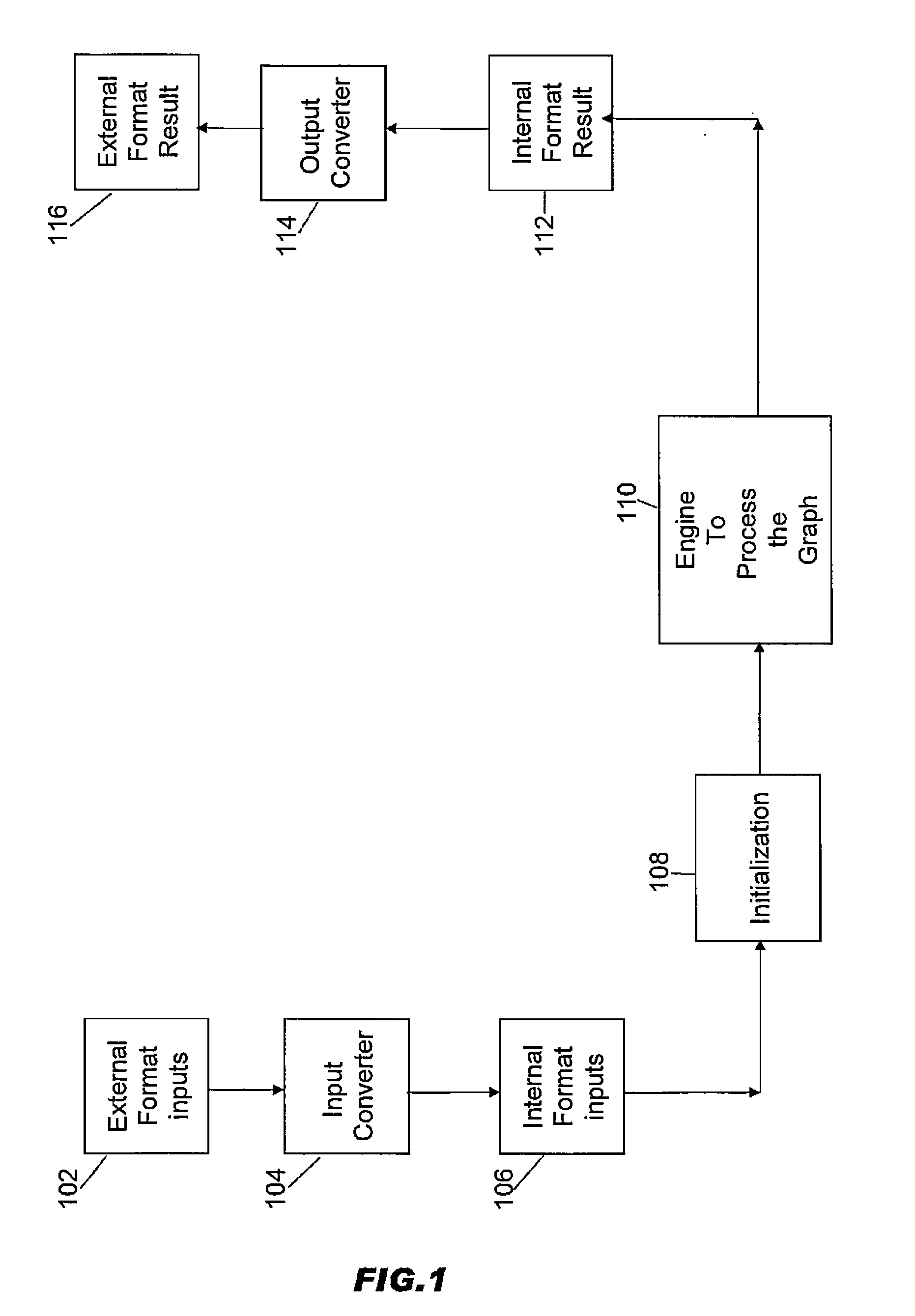

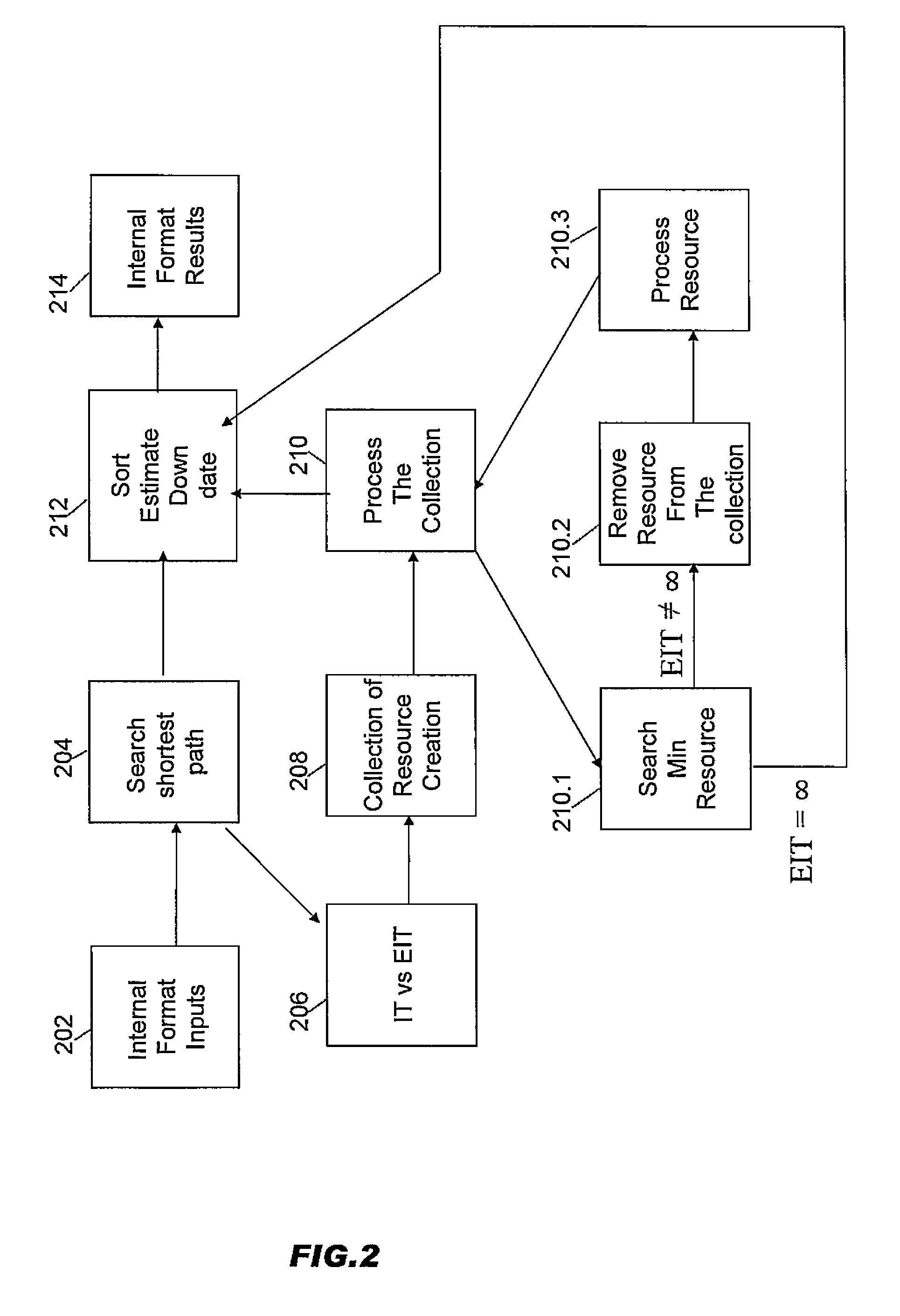

Event impact analysis

InactiveUS20130041924A1Avoid influenceDigital data information retrievalDigital data processing detailsDirected graphPropagation time

A method and system for analyzing impact of an event on resources of a network. A directed graph is generated and includes nodes and edges. Each node represents a resource. Each edge connects, and is directed from, a predecessor node to a successor node. The event impacts the resource at an event node. A propagation time (PT) is determined for each edge. The PT is a time interval for an impact of the event to travel along each edge from the predecessor node to the successor node. An initial estimated impact time (EIT) is set for each node. The EIT for each node is an estimated time at which the event impacts each node. The EIT of each node that is directly or indirectly connected to the event node by one or more edges is updated. A list of the updated nodes is sent to an output device.

Owner:IBM CORP

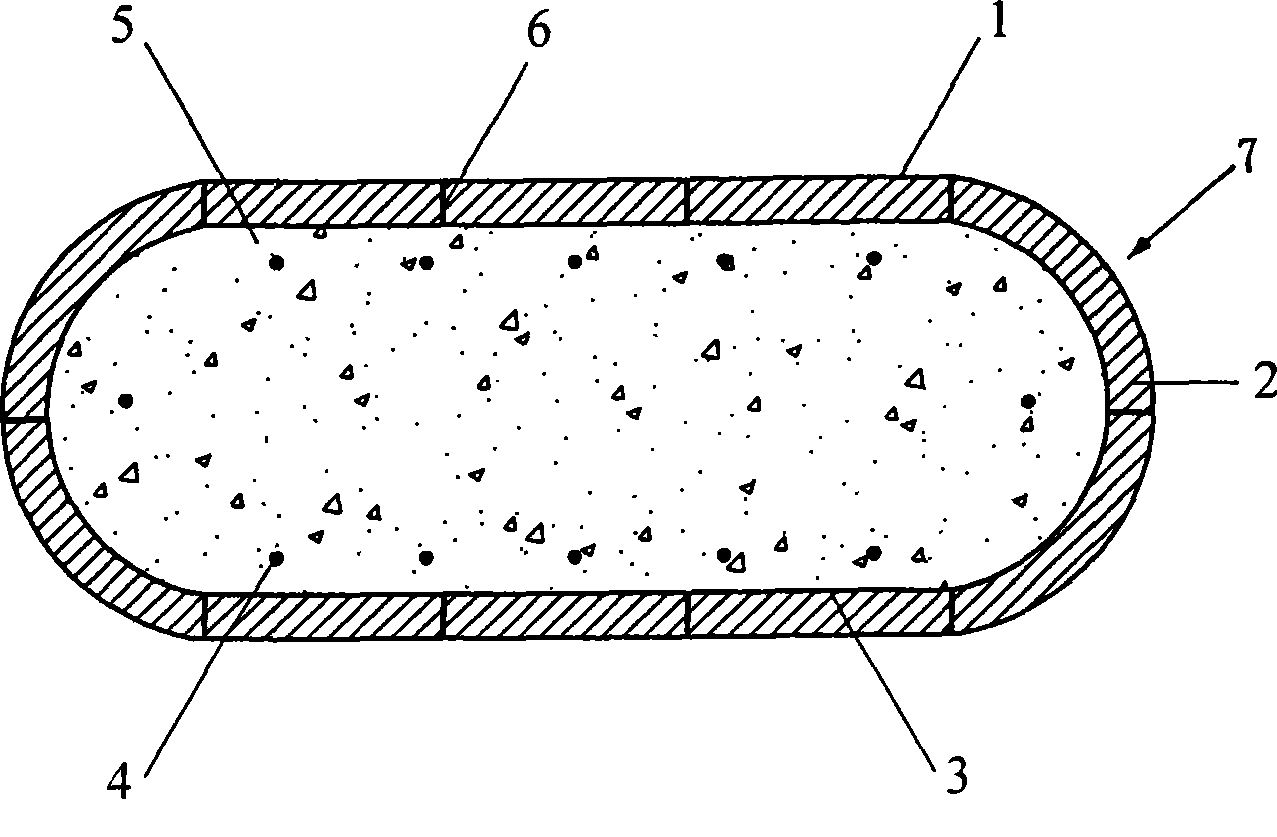

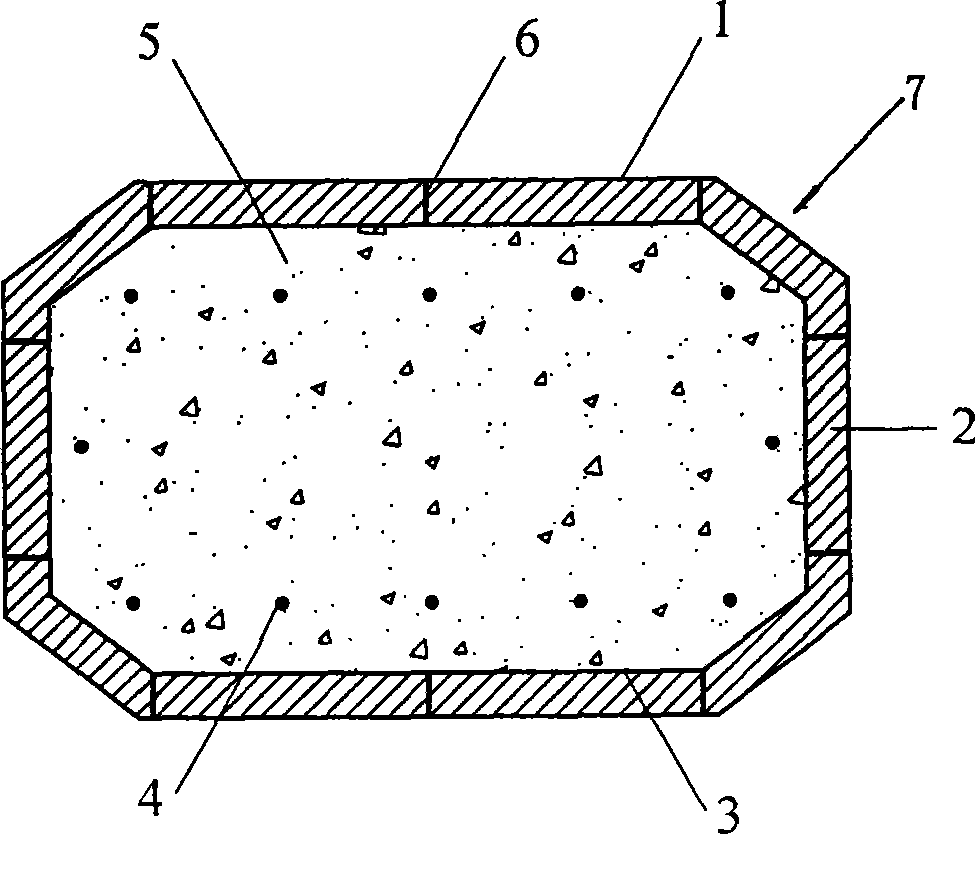

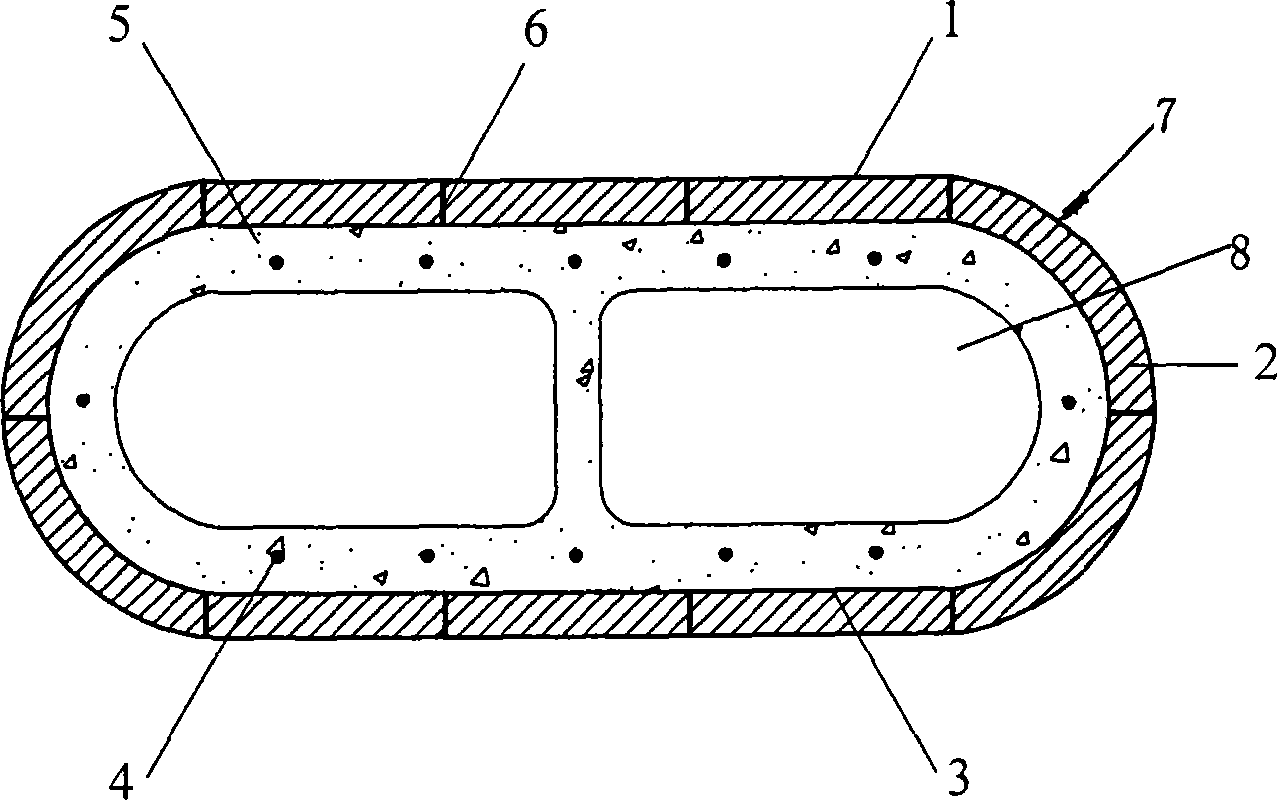

Composite material lattice sandwich tube restriction concrete foot stall with buffering energy-absorbing function

InactiveCN101509226AExtended impact timeReduce impact forceStrutsBridge structural detailsEnergy absorptionRebar

The invention relates to a concrete pier stud confined by a composite structure sandwich pipe which has the buffer energy-absorption effect. The concrete pier stud is characterized by consisting of a pier stud jacket (7) and an internal concrete core (5) which is casted in the pier stud jacket (7); a reinforcing steel bar (4) which is arranged along the axial direction of the pier stud jacket (7) and takes effect of increasing tensile strength is pre-embedded in the internal concrete core (5); and the pier stud jacket (7) consists of an external composite pipe (1), an internal composite pipe (3), a lattice (6) connecting the external composite pipe (1) and the internal composite pipe (3) and buffer material (2) which is filled in a space surrounded by the external composite pipe (1), the internal composite pipe (3) and the lattice (6). The invention uses a composite lattice sandwich layer to enwrap the outside of the concrete pier stud, the buffer material in the sandwich layer transforms and releases impact energy by the energy for the structure or the material to recover the elastic deformation by self and can prolong the impact time, thereby reducing the impact force and achieving the effect of protecting the vehicle, the ship and the bridge, and at the same time, the concrete pier stud can increase the strength and the corrosion resistance and reduce the construction cost.

Owner:SHANGHAI BOHONG ENERGY-SAVING TECH CO LTD

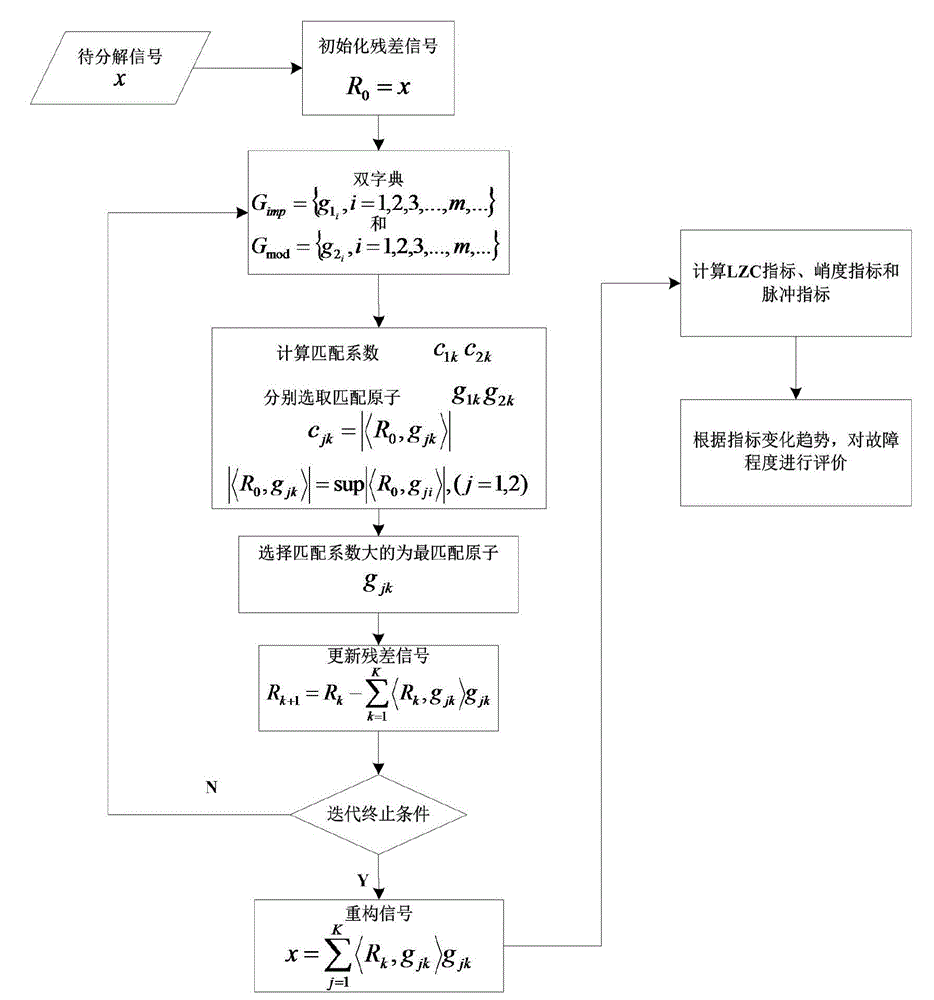

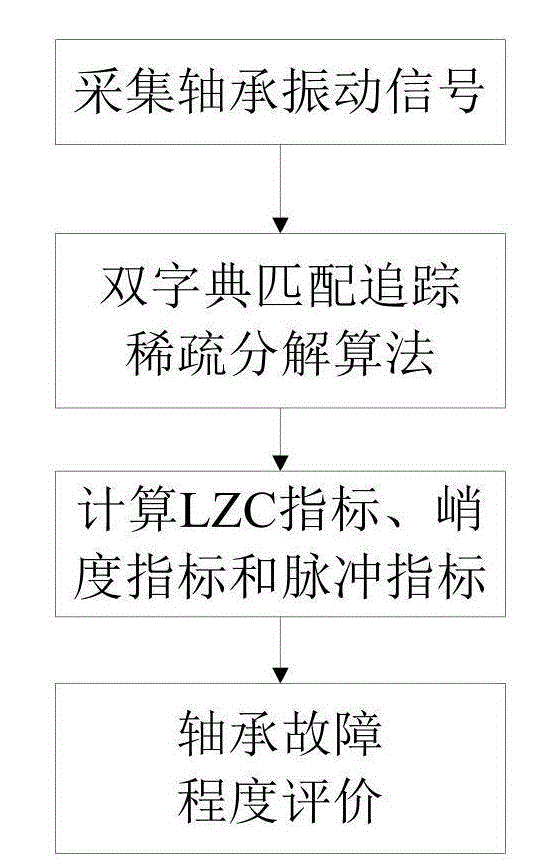

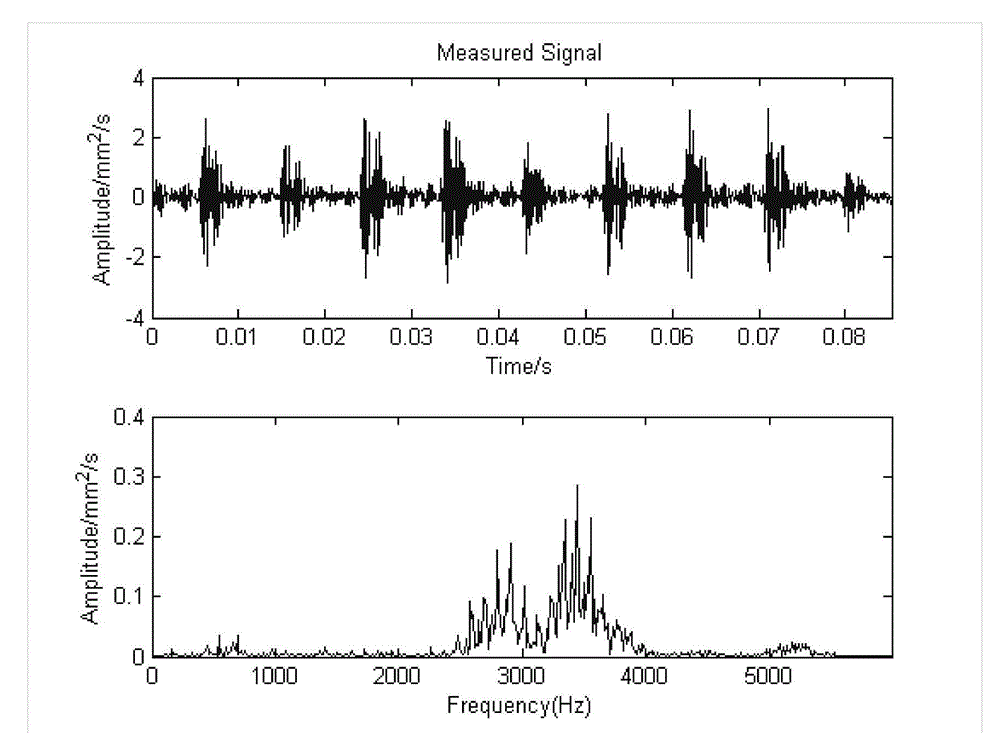

Double-dictionary matching pursuit bearing fault degree evaluation method based on multiple index properties

Provided is a double-dictionary matching pursuit bearing fault degree evaluation method based on multiple index properties, and belongs to the technical field of bearing fault diagnosis. The index properties include an LZC index, a kurtosis index and a pulse index. According to bearing vibration signal features, a modulation dictionary and an impact time frequency dictionary are selected to form a double dictionary, matched atoms are selected in each sub-dictionary of the double dictionary in each iteration, and coefficients of various orders are compared to obtain the most matched atom. An analysis signal is projected on an iteration atom of each time, and the signal is subtracted by the projection to form a residual signal for next decomposition. The decomposition process is finished after iteration ending conditions are met, the matched atoms and the matching coefficients are extracted, signals are reconstructed, an LZC index, a kurtosis index and a pulse index of the reconstructed signal are calculated, and fault degree evaluation is achieved through the change tendency of the three indexes.

Owner:BEIJING UNIV OF TECH

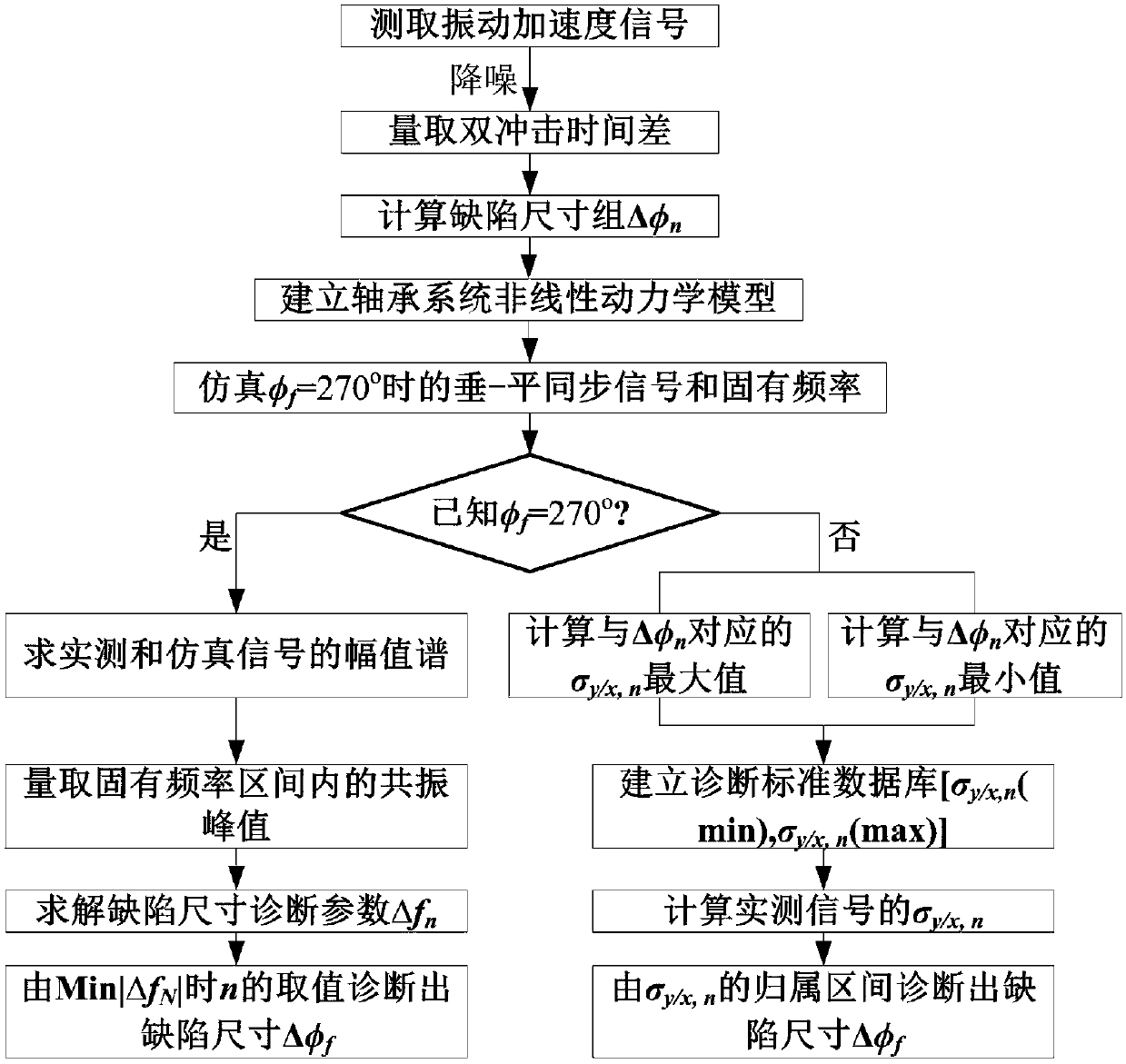

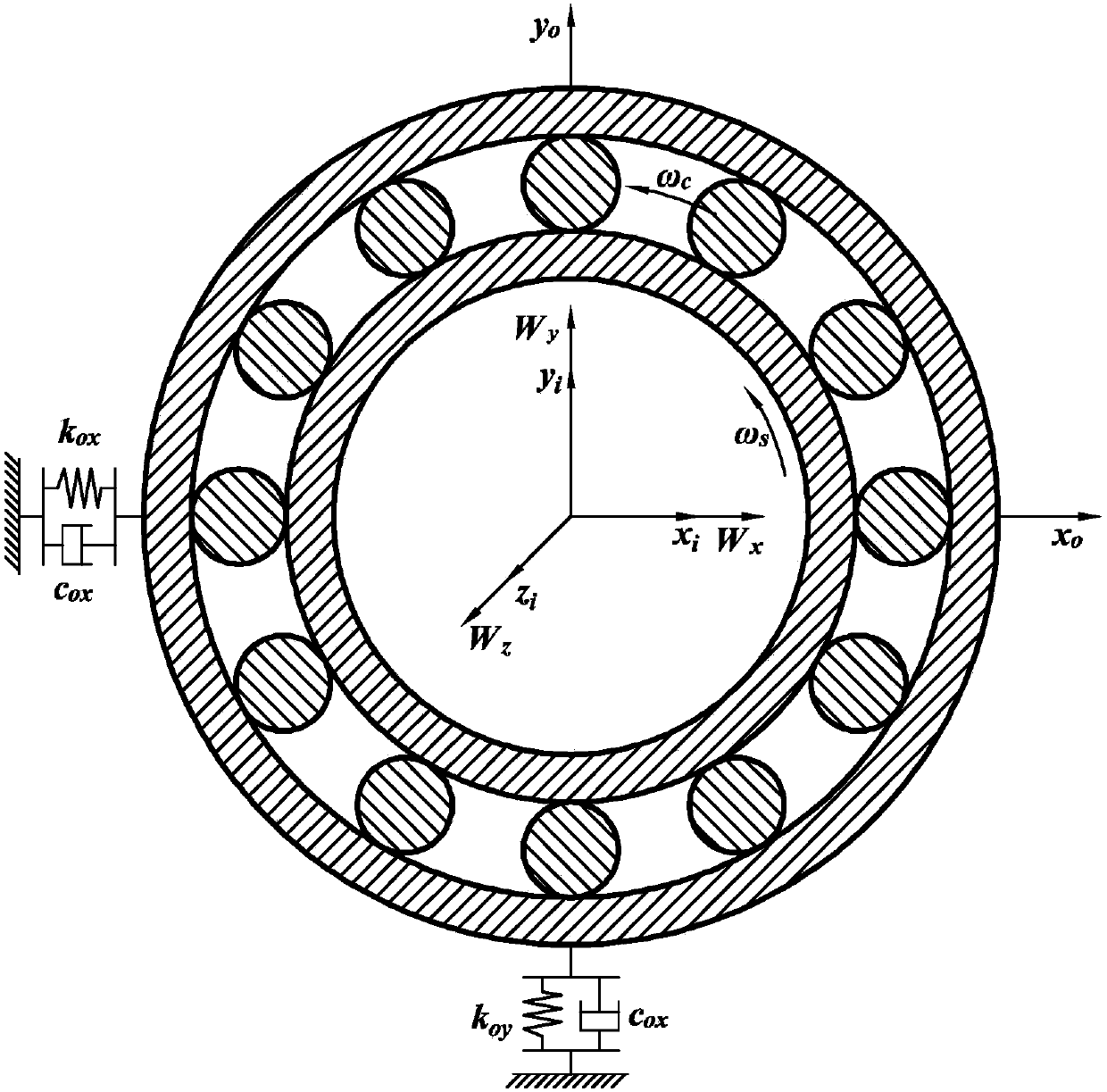

Rolling bearing outer ring defect full-size quantitative diagnosis method

ActiveCN107704695AAvoid misdiagnosisMeet the urgent needs of economic developmentGeometric CADMachine bearings testingDiagnosis standardsDefect size

The invention discloses a rolling bearing outer ring defect full-size quantitative diagnosis method. Firstly primary diagnosis is performed on an actual measurement signal based on an impact time difference to obtain a basic size and selectable sizes of an outer ring defect. Secondly a nonlinear dynamics model of a bearing system is built, and through numerical solving, a vertical-horizontal synchronous simulation vibration signal corresponding to each defect size is obtained. For the situation that a defect angle is 270 degrees, Fourier transform is performed on the actual measurement signaland a simulation signal of each selectable defect size to obtain corresponding amplitude spectrums, a minimum diagnosis parameter Min / delta fN / of the actual measurement signal is solved, and an outerring defect size is diagnosed out. For the situation that the defect angle is 250-290 degrees, an outer ring defect full-size quantitative diagnosis standard database is established based on a vertical-horizontal synchronous standard deviation, and by determining an attribution interval of the vertical-horizontal synchronous standard deviation of the actual measurement signal, the outer ring defect size is diagnosed out.

Owner:BEIJING UNIV OF TECH

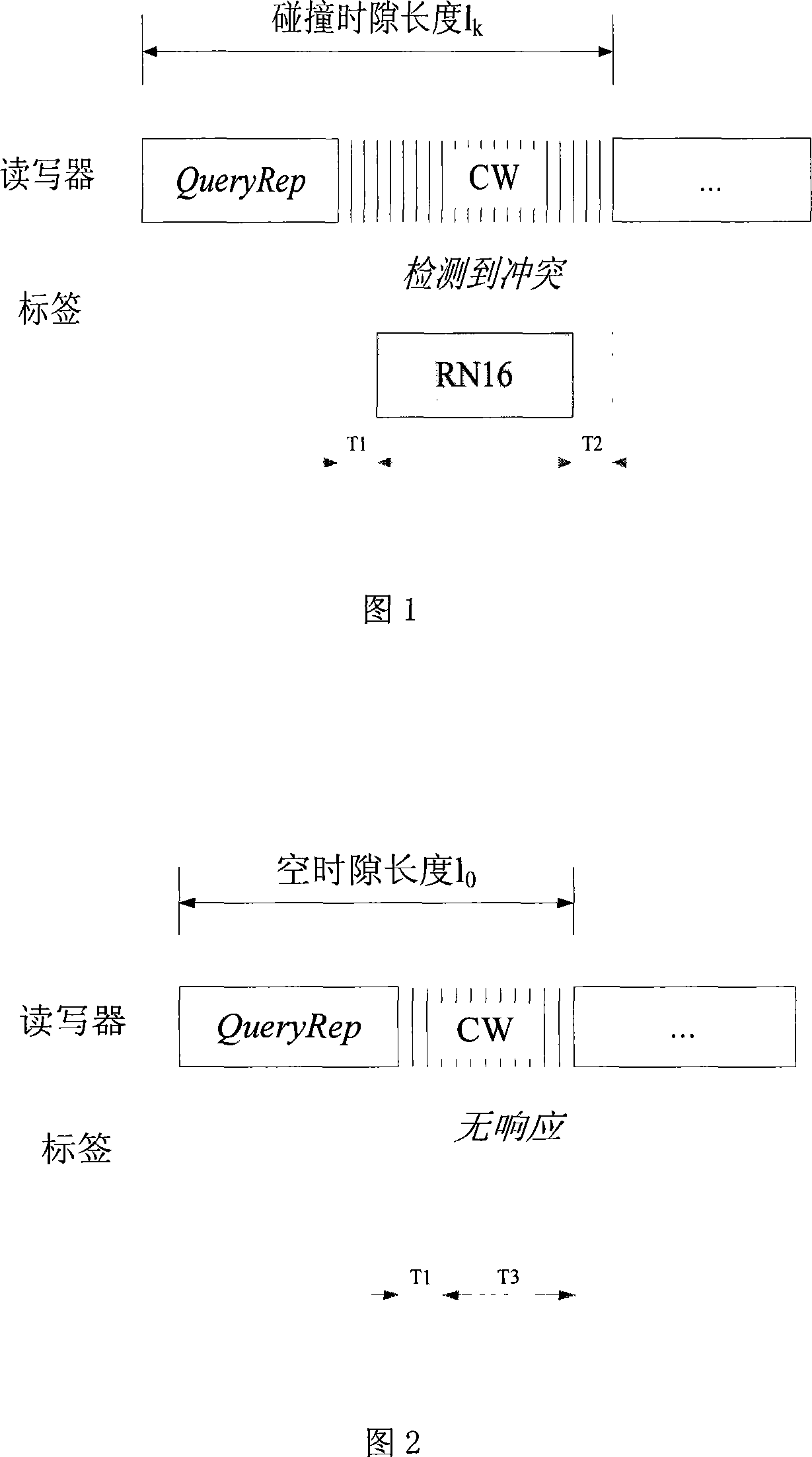

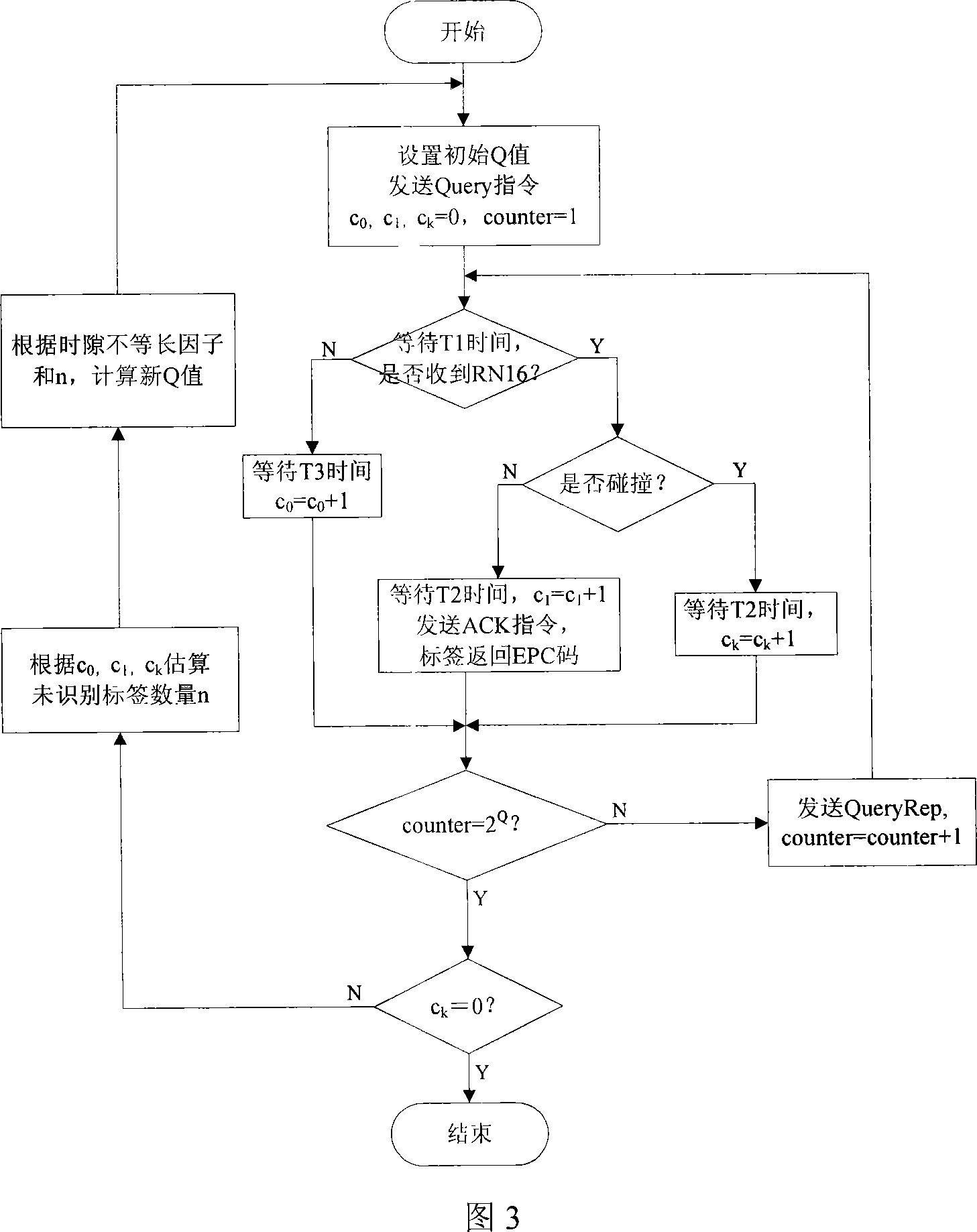

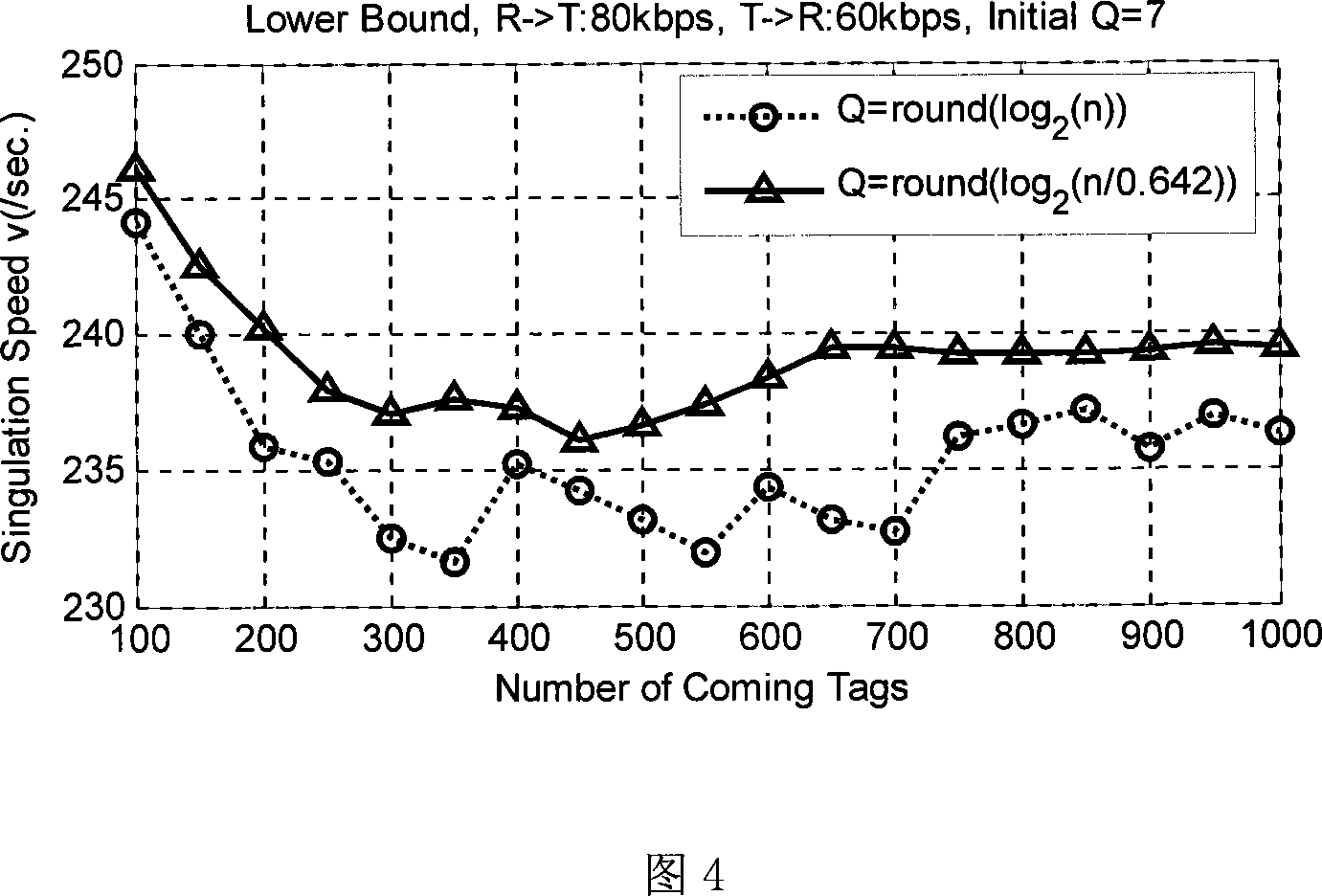

Radio frequency identification process frame length selection method based on slotted random

InactiveCN101169818AFast recognitionReasonable frame lengthSensing record carriersComputer scienceImpact time

The invention belongs to the technical field of radiofrequency identification, and particularly relates to a method for selection frame length during time slot-based random frequency identification procedure. The method includes initiating a reader / writer; allowing the reader / writer to receive data returned from a tag, adding 1 to space time slot number c0 if the data is not received; and if the data is received, judging generation of collision; adding 1 to impact time slot number ck if having collision; and if no collision generation, running a successful identification process and adding 1 to the successful time slot number c1; the reader / writher judges whether a counter is equal to 2Q once completing one data identification process; and repeating the processes until all data in the frame is identified. Number n of an unidentified tag is estimated according to c0, c1 and ck, a new Q value is calculated according to the n and a time slot difference factor a, then a new identification process is performed until all tags are identified. By reasonably setting time slot difference factor, the invention enables the reader / writer to select reasonable frame length for the next frame to reduce tag collision generation and improve identification speed of the tag.

Owner:FUDAN UNIV

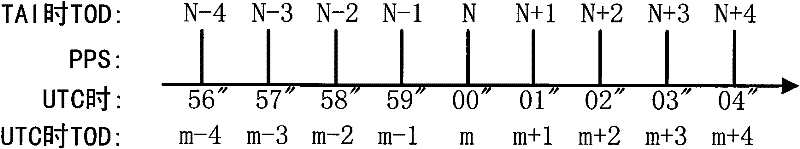

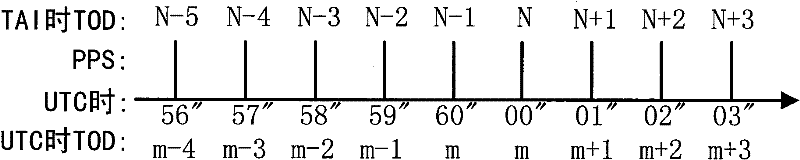

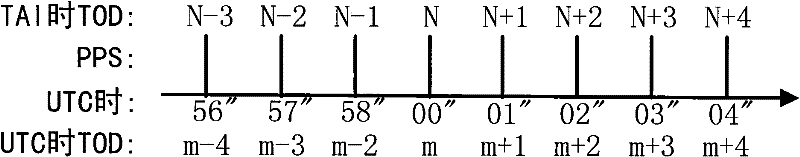

Timing time leap second processing method

ActiveCN102281114AGuaranteed to workTo avoid the impact of time synchronizationTime-division multiplexSystem timeComputer science

The invention discloses a time service time leap second processing method, which includes two processes: the input is atomic time and leap second forecast, the output is coordinated universal time, and the input is coordinated universal time and leap second forecast, and the output is atomic time. The present invention adopting the above-mentioned technical scheme provides the conversion from UTC to atomic time, and the conversion from atomic time to UTC. The two time system conversion methods ensure that the systems using UTC and atomic time can be synchronized and unified at the time when the leap second occurs. Avoid the impact of leap seconds on time synchronization and ensure the normal operation of the time synchronization system.

Owner:郑州威科姆科技股份有限公司

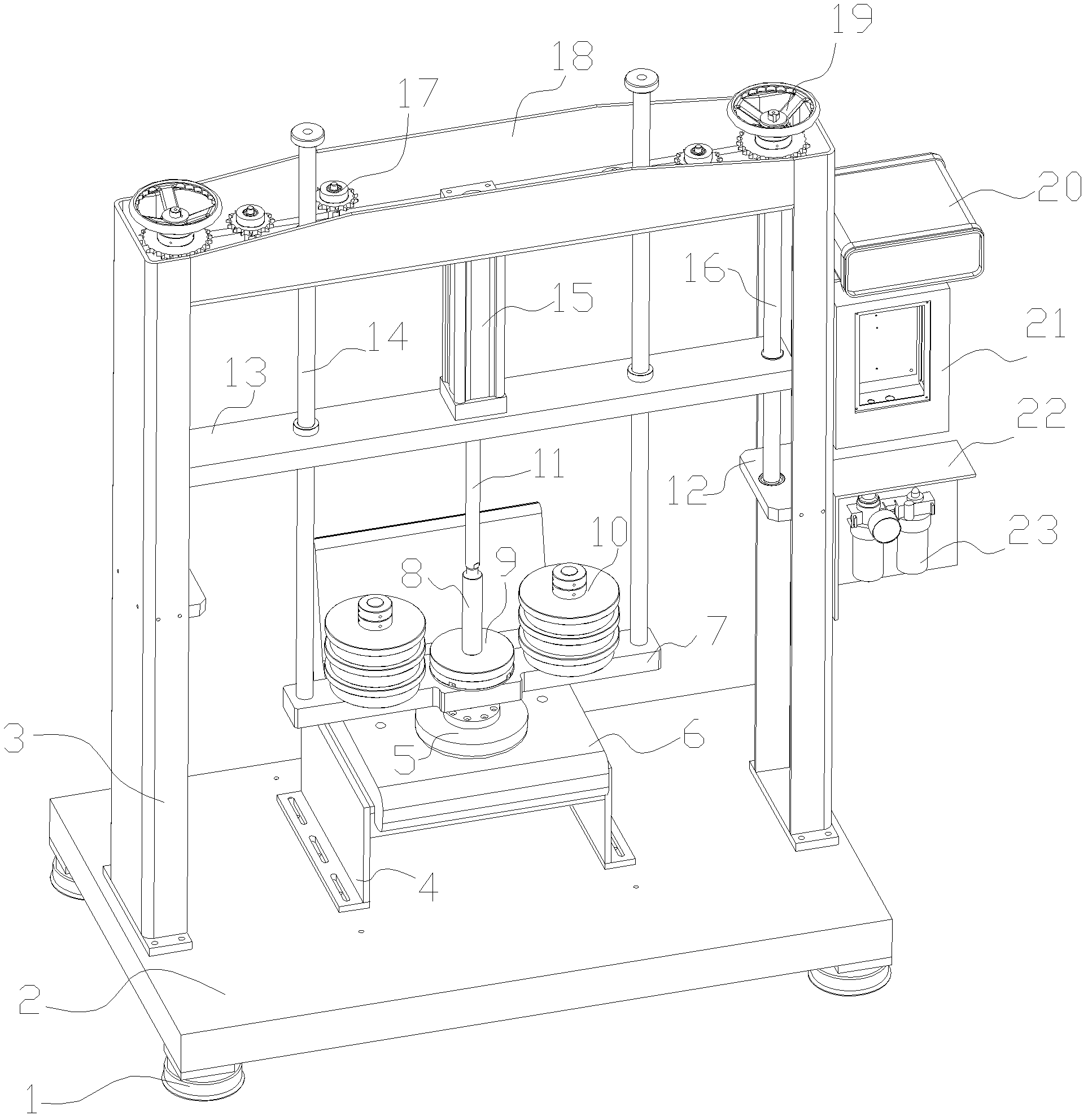

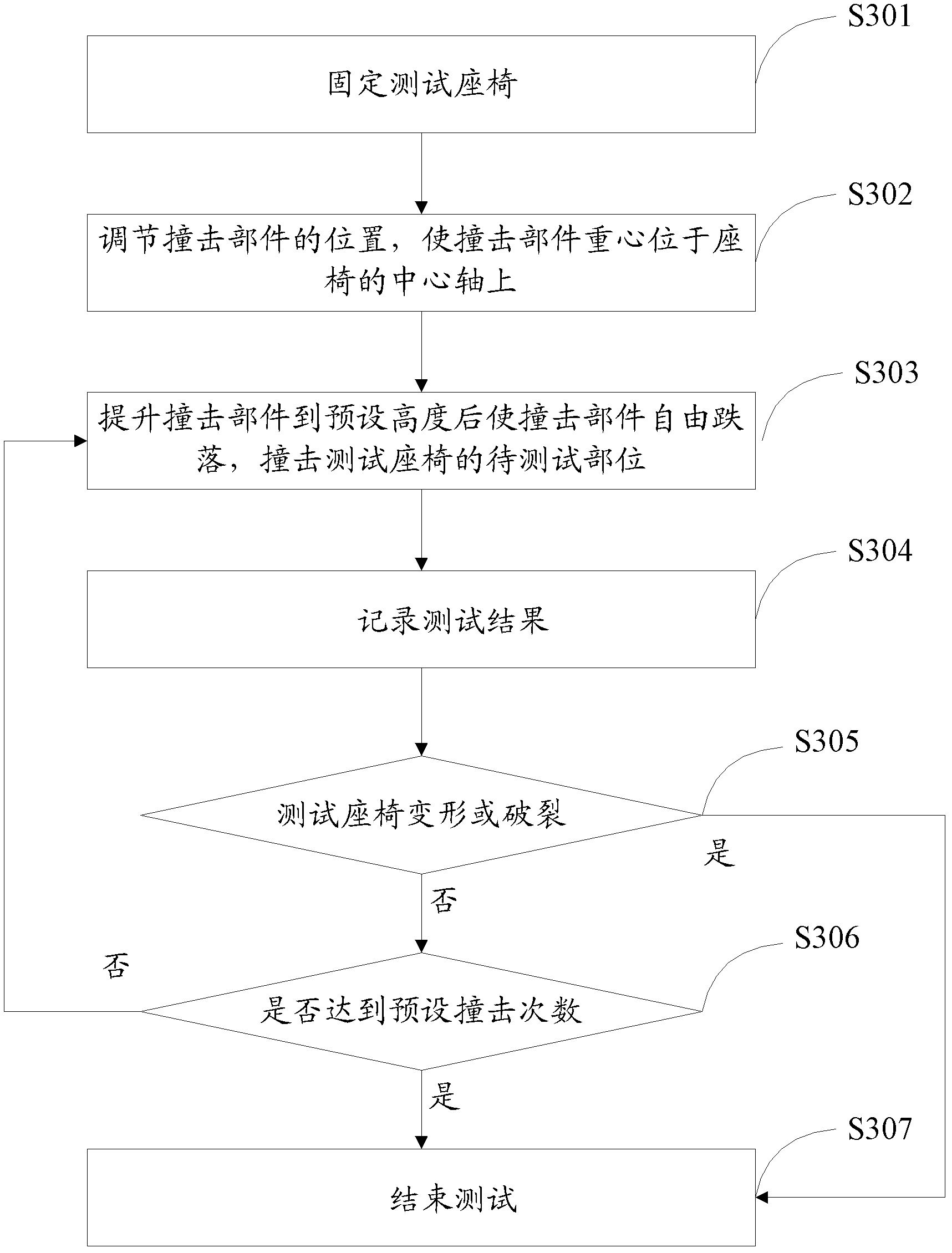

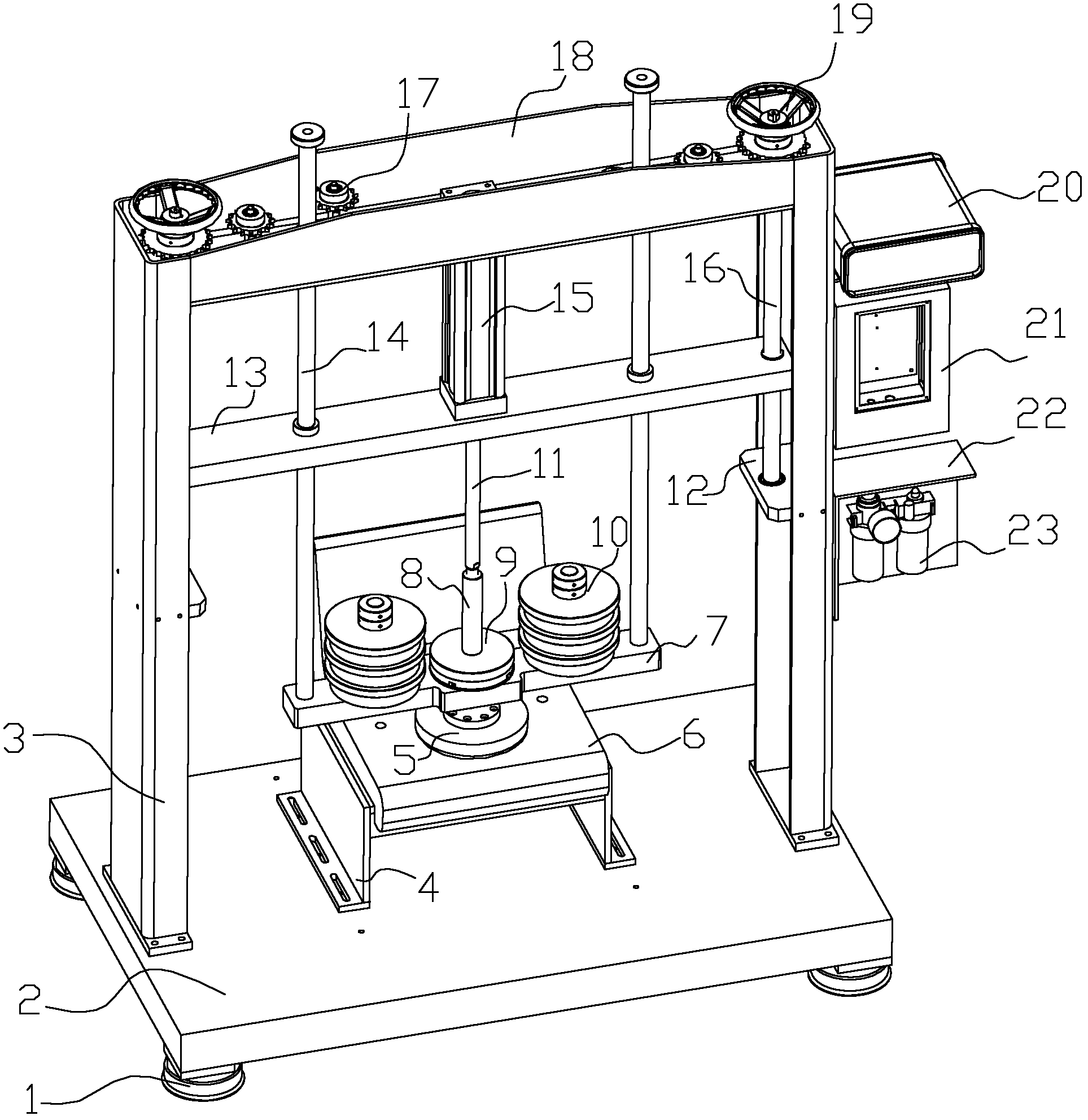

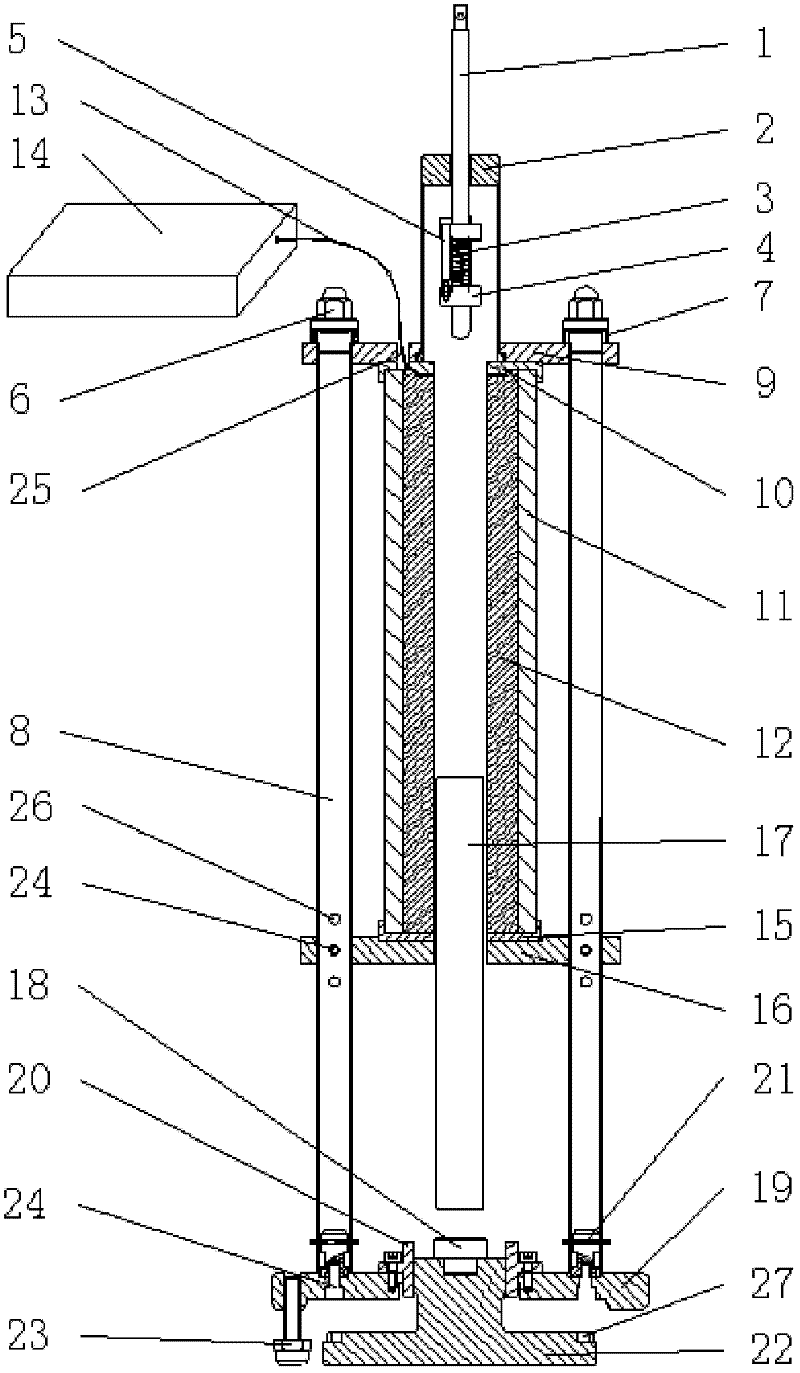

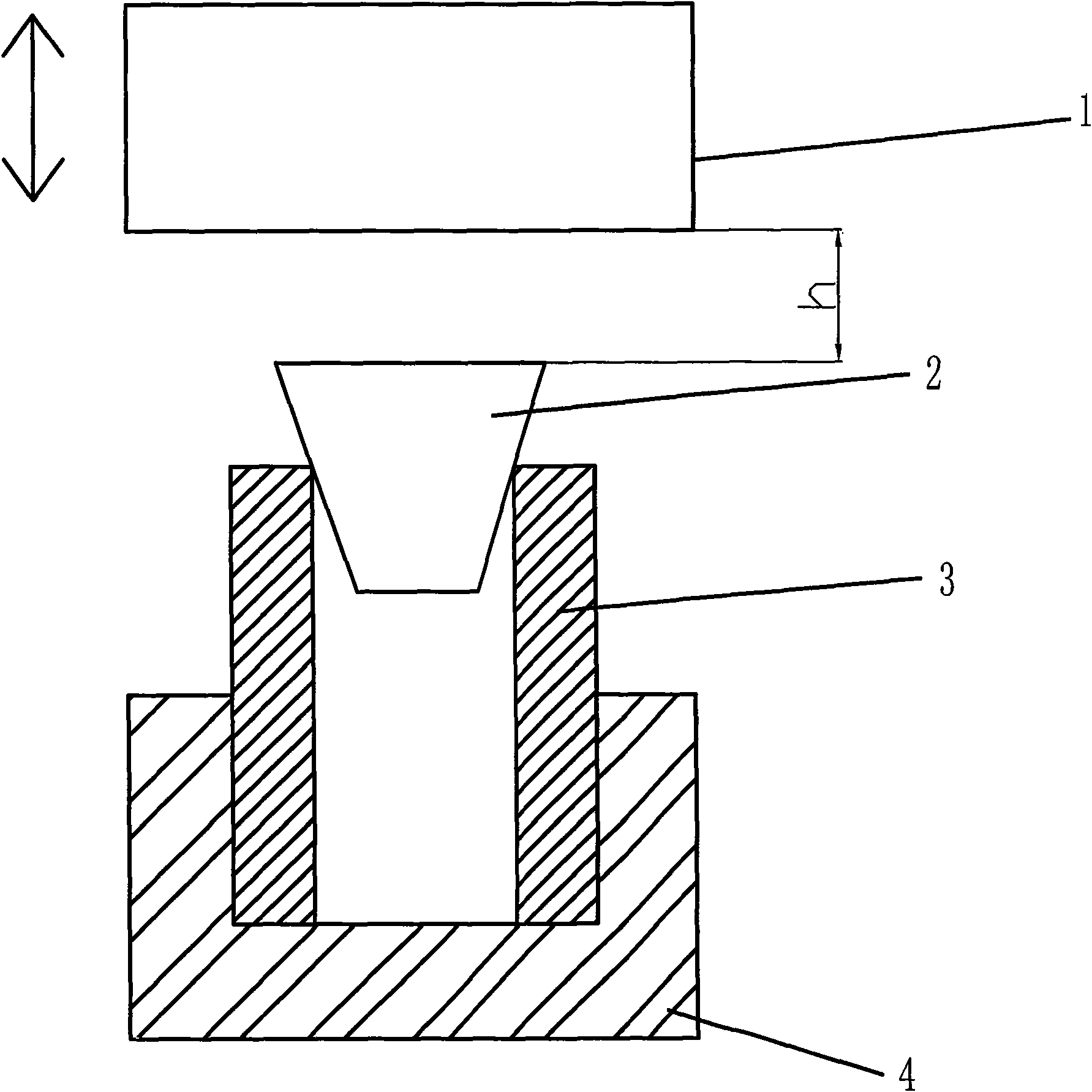

Chair vertical impact test device and test method

InactiveCN102564876AImprove securityThe test method is simple and fastMaterial strength using repeated/pulsating forcesCrash testEngineering

The invention discloses a chair vertical impact test device and a test method. The test device comprises a test board, a mounting support, an impact part and a lifting mechanism, wherein the test board includes a base and a supporting seat fixed on the base, and the supporting seat bears a test seat. The mounting support comprises a left vertical column, a right vertical column and a beam which is arranged at the top end of the left and the right vertical columns. The left and the right vertical columns are fixed on the base. The impact part is lifted to the prearranged suspension height of the beam by the lifting mechanism in a first condition and is freely released to impact the part to be tested of the test chair in a second condition. By means of the test method, the impact part is repeatedly lifted to the prearranged height to drop freely and impact the part to be tested of the test chair. If the test chair deforms or is fractured within the prearranged impact times, the chair is determined to pass the test; otherwise, the chair fails the test. According to the test device and the test method, the impact part drops freely from the suspension state, accordingly an impact load vertical to the part to be tested of the test chair is imposed, and the strength of the test chair in a vertical direction can be tested after repeating a plurality of tests.

Owner:GUANGZHOU ACT INDAL

Controlled source of pulse codes

InactiveCN102508289AIdeal Pseudorandom PropertiesHigh resolutionSeismologySignal-to-noise ratio (imaging)Image resolution

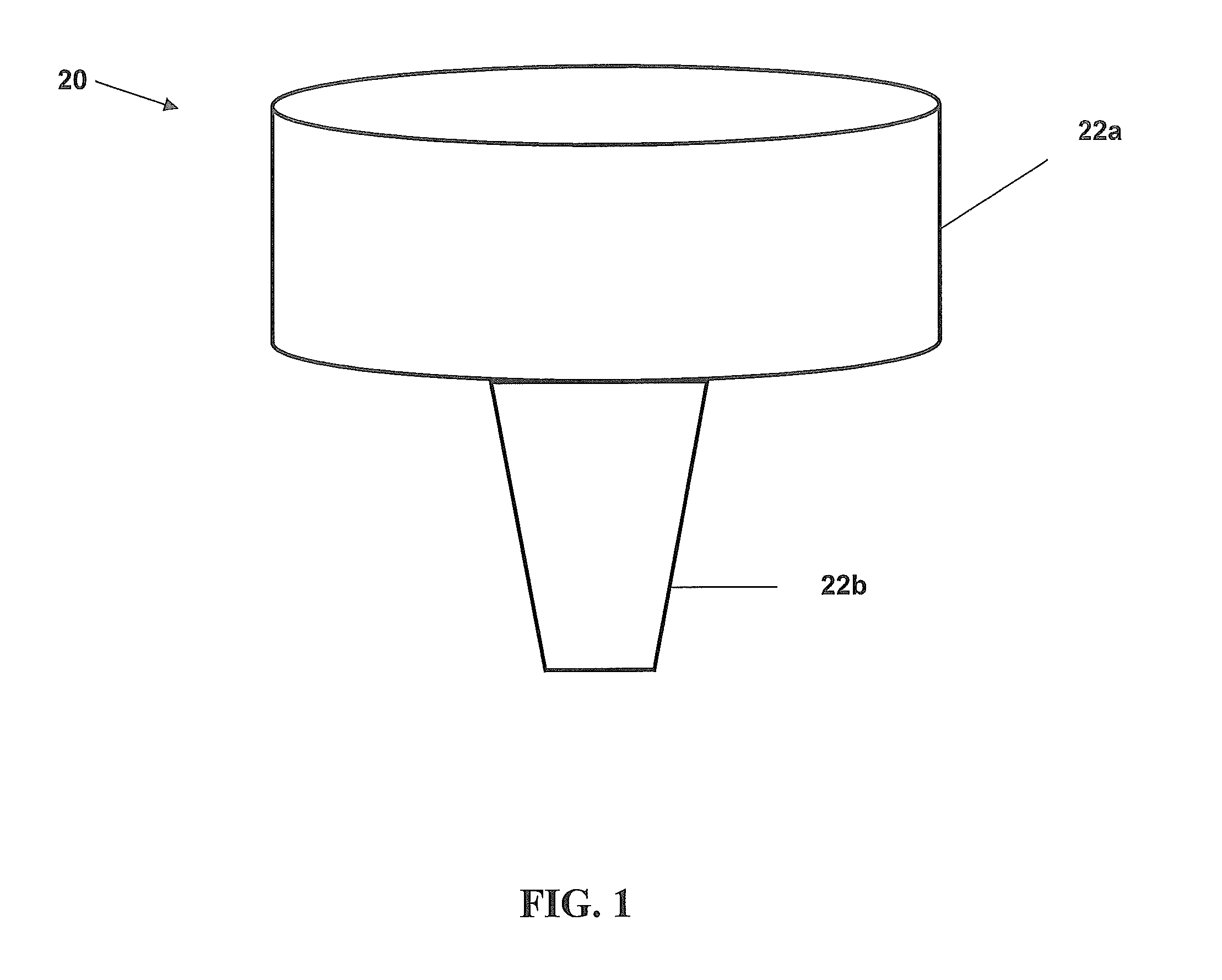

The invention relates to a controlled source of pulse codes. The bottom end of a base connection carriage is connected with a lower pressing plate at the lower one-third position of the carriage, a coil cylinder and a coil are arranged between an upper pressing plate and the lower pressing plate, a fastening screw penetrates through a locating sleeve to be connected with the upper pressing plate and the carriage, a code controller is connected with the coil, an adjustable screw support cylinder is installed in the middle of the upper pressing plate, and an adjustable screw is connected with the adjustable screw support cylinder to form the controlled source. Coding impact orders generated by the controlled source of the pulse codes has ideal paseudo-random characteristics, can notably reduce impact times, improves construction efficiency, and has high seismic prospecting resolution ratio and signal to noise ratio due to the fact that codes stimulate obtained original seismographic records which can be equivalent to macro-energy single-pulse source signals after relevant decoding operation. Mechanical parts of the controlled source can be rapidly disassembled and assembled, and is convenient to carry and construct, applicable to earthquake exploration in cities and mountainous regions and superficial layer projects, simple in structure, convenient to carry and high in stability.

Owner:JILIN UNIV

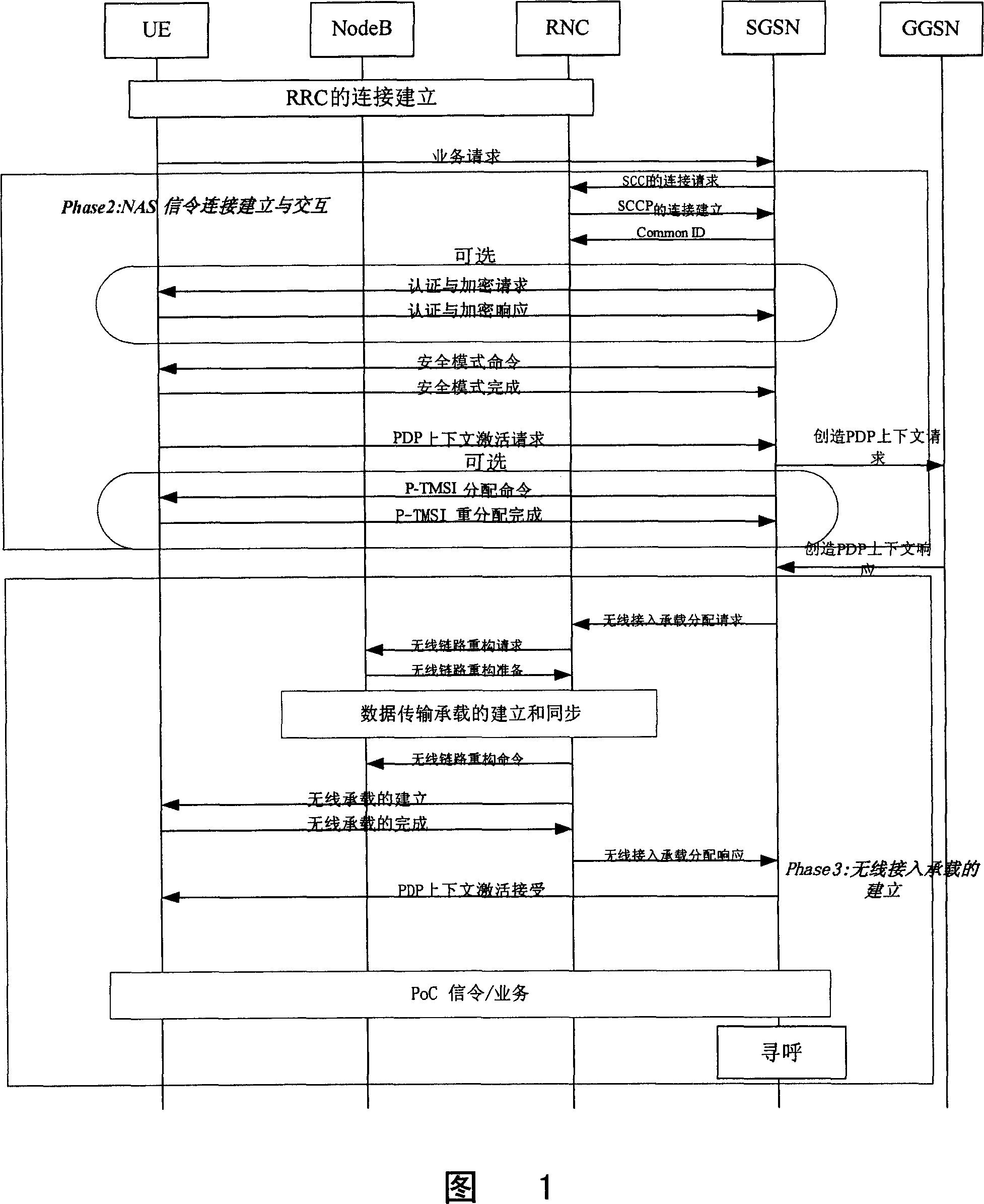

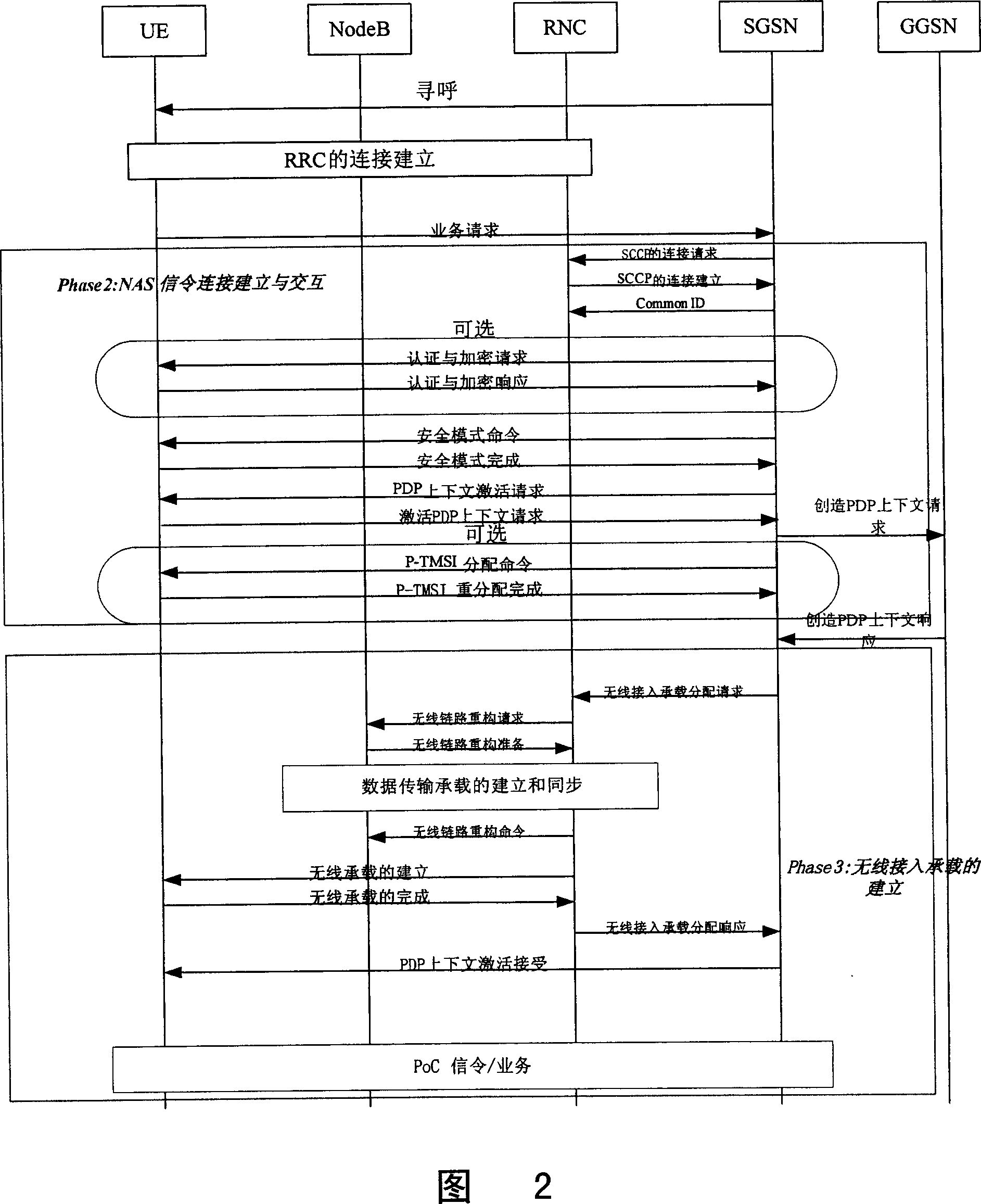

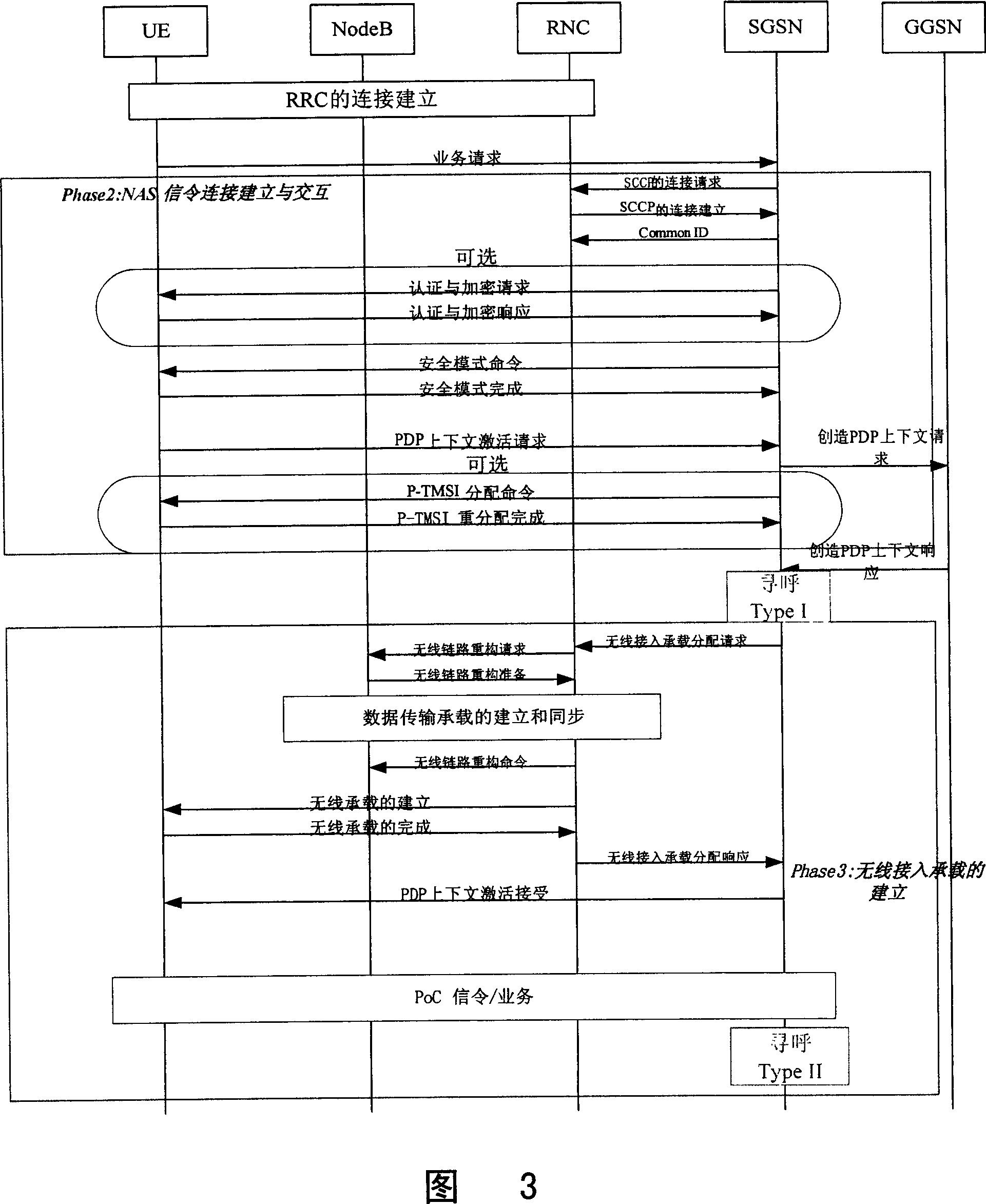

Method for reducing time delay established by calling in mobile communication system

ActiveCN1972501AShorten the timeReduce latencyConnection managementRadio/inductive link selection arrangementsRelevant informationTime delays

This invention relates to mobile communication system method to reduce call establishing time lag, which establishes time lag for lint and to impact time lag sensitive business quality to result one long time cause to fulfill all process to send out call ends. This invention can preprocess call business information in non-interface layer in interacting process to process index and process calls information according to spare situation of called end.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

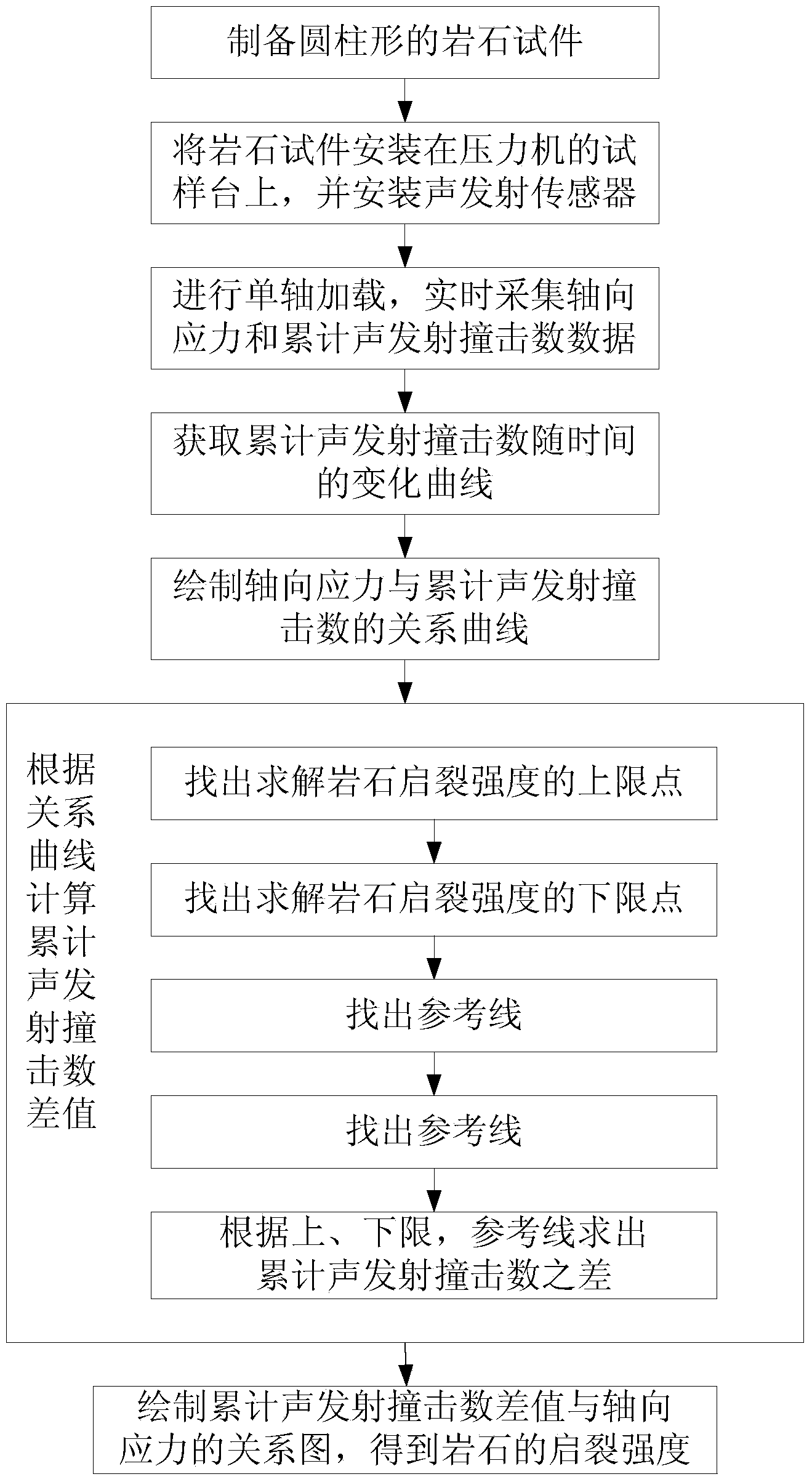

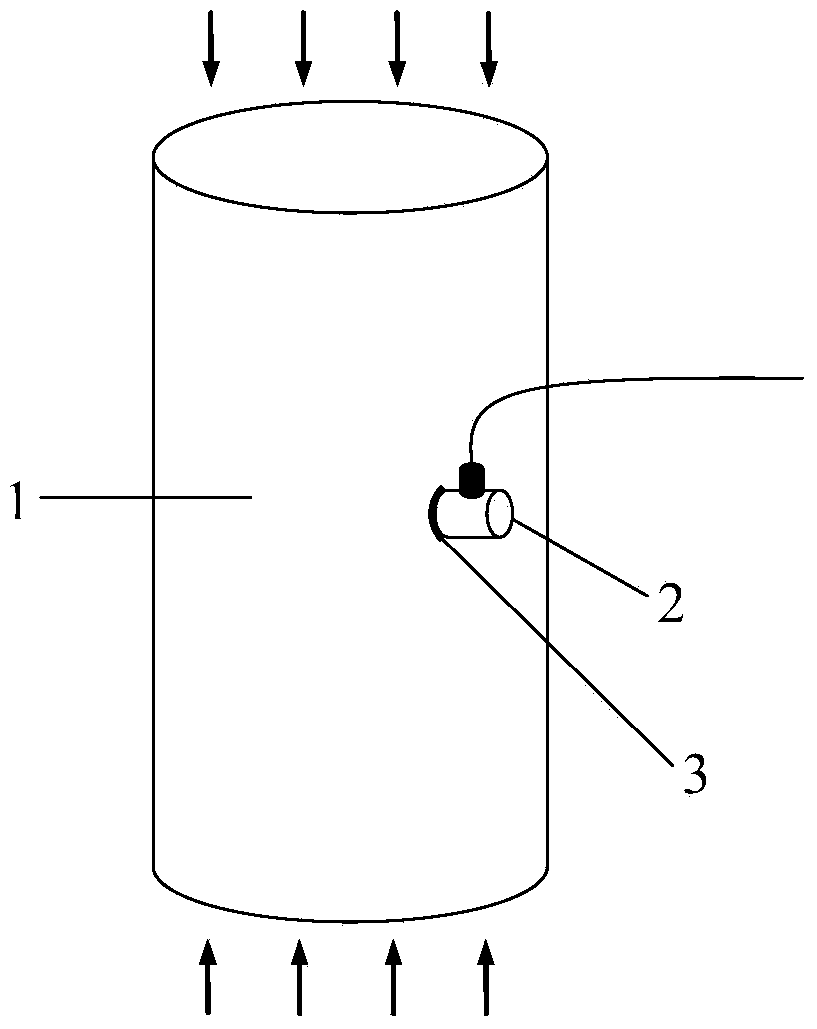

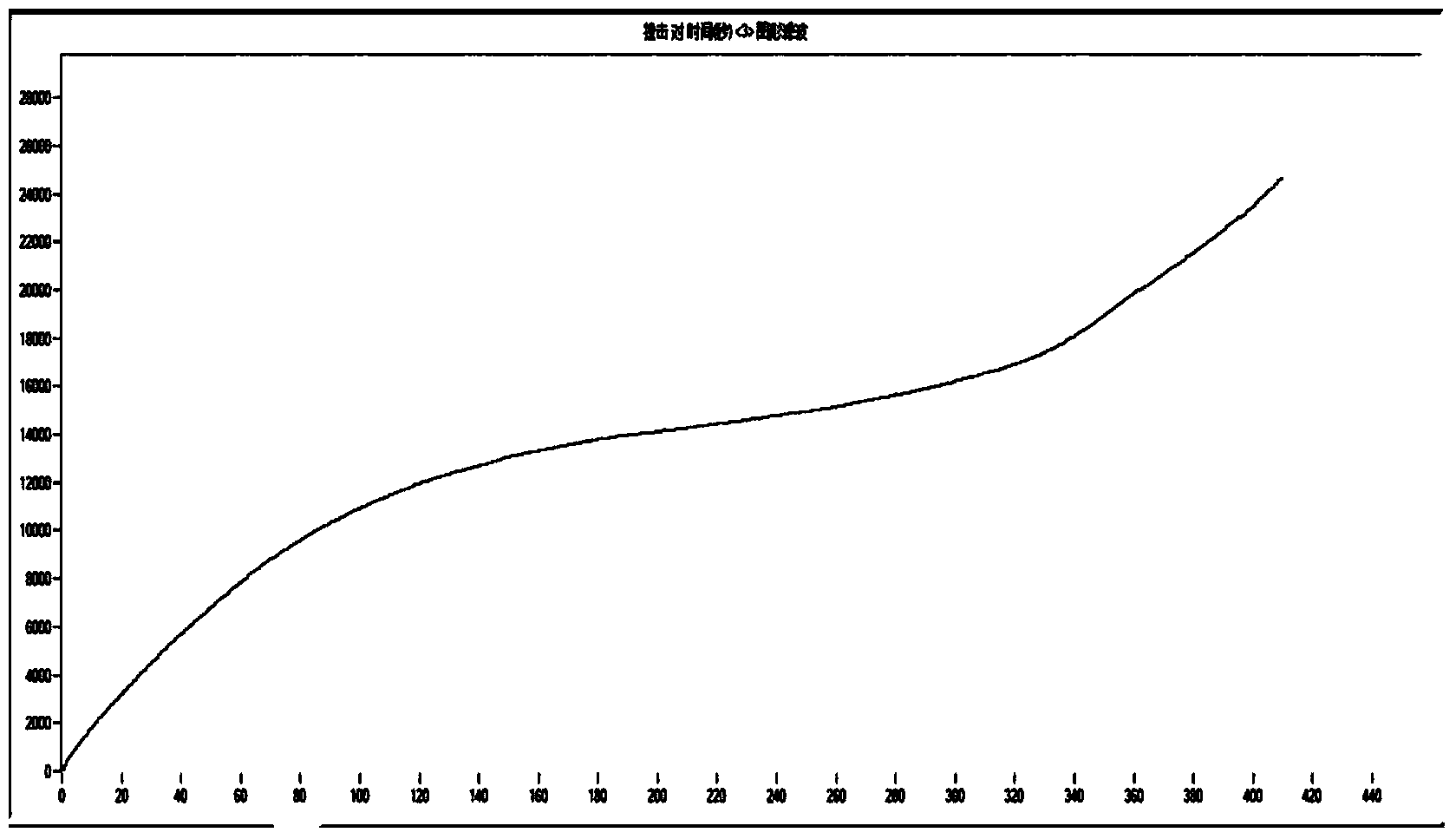

Method for objectively determining crack initiation strength of rock on basis of accumulated sound emission impact times

ActiveCN103760024AUniqueness guaranteedShorten test timeMaterial strength using tensile/compressive forcesTest samplePeak value

The invention belongs to the field of rock performance tests and specifically relates to a method for objectively determining crack initiation strength of a rock based on accumulated sound emission impact times. The purpose is to accurately identify the crack initiation strength value. The method comprises the followings: preparing a cylindrical rock test piece, installing the rock test piece on a test sample table of a press machine, installing a sound emission sensor in the middle part of a rock sample, uniaxially loading the rock test piece, synchronizing the sound emission monitoring and the loading process, acquiring the data of axial stress and accumulated sound emission impact times in real time, acquiring a curve of the accumulated sound emission impact times changing along with the time, drawing a curve of the relation between the axial stress and the accumulated sound emission impact times, calculating the difference of the accumulated sound emission impact times according to the relation curve, and drawing a relation schema of the difference of the accumulated sound emission impact times and the axial stress, wherein the stress corresponding to the peak of the difference of the accumulated sound emission impact times is the crack initiation strength of the rock. The method eliminates the subjective judgment of a user, and guarantees the uniqueness of the solution.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

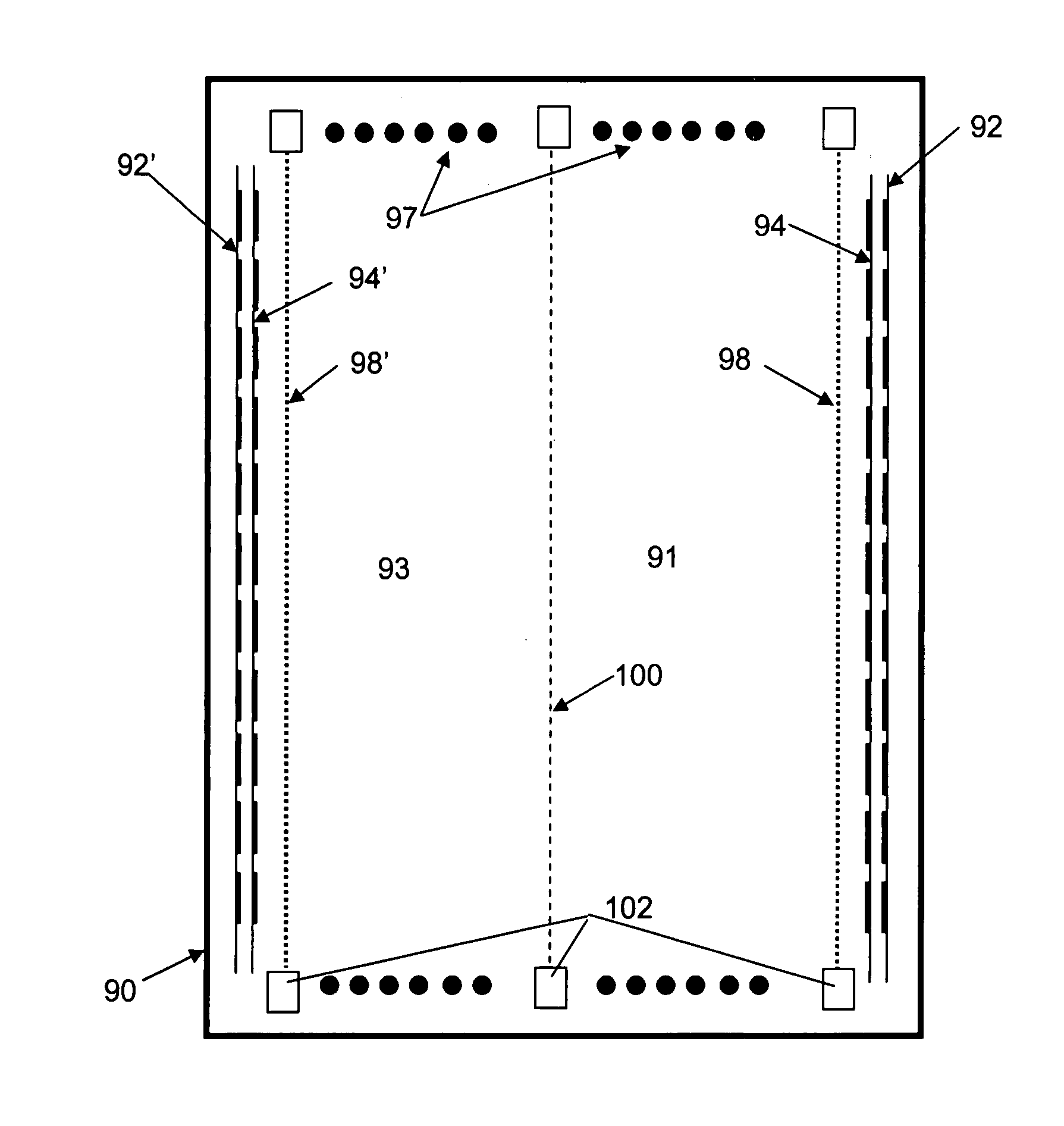

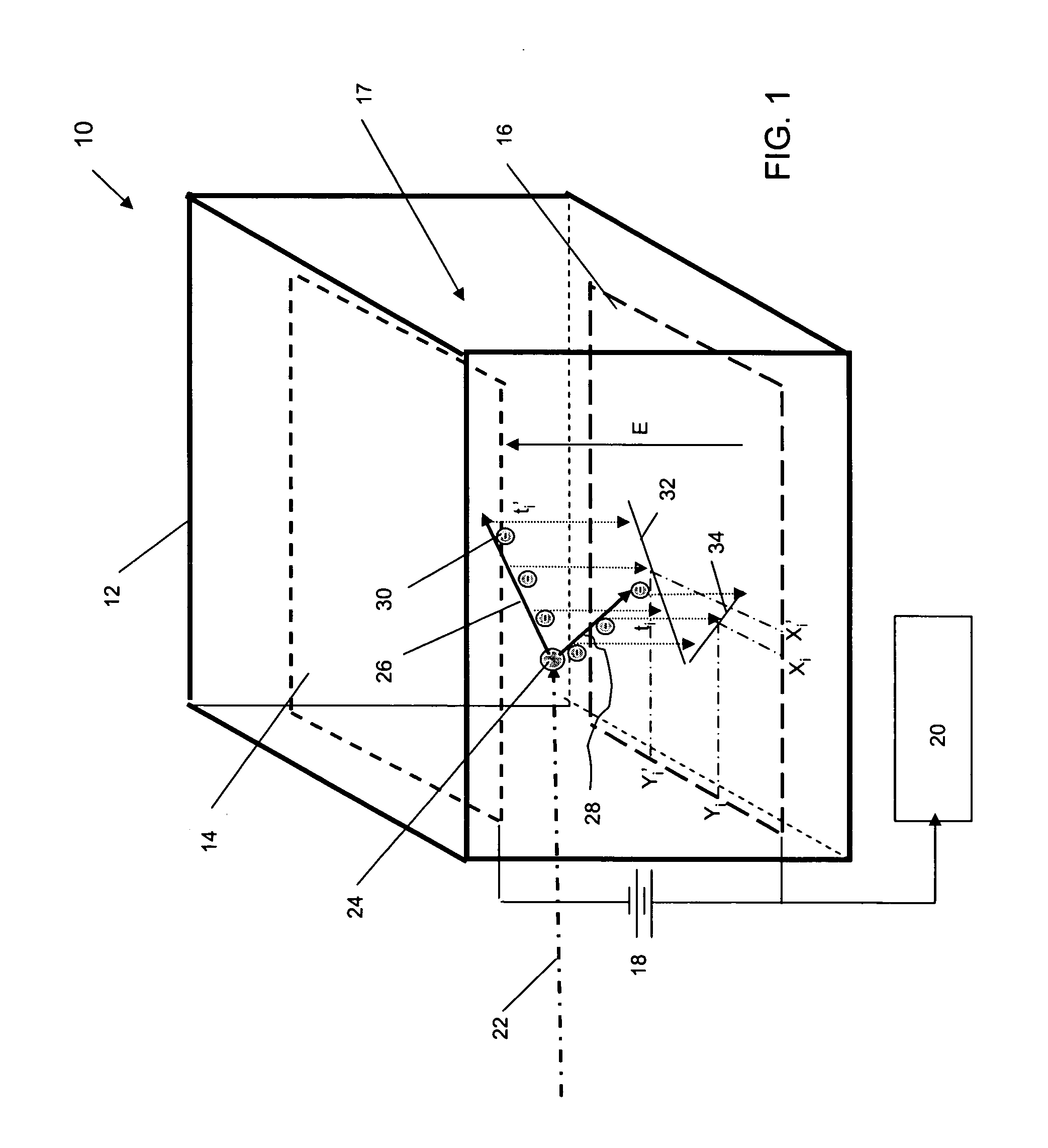

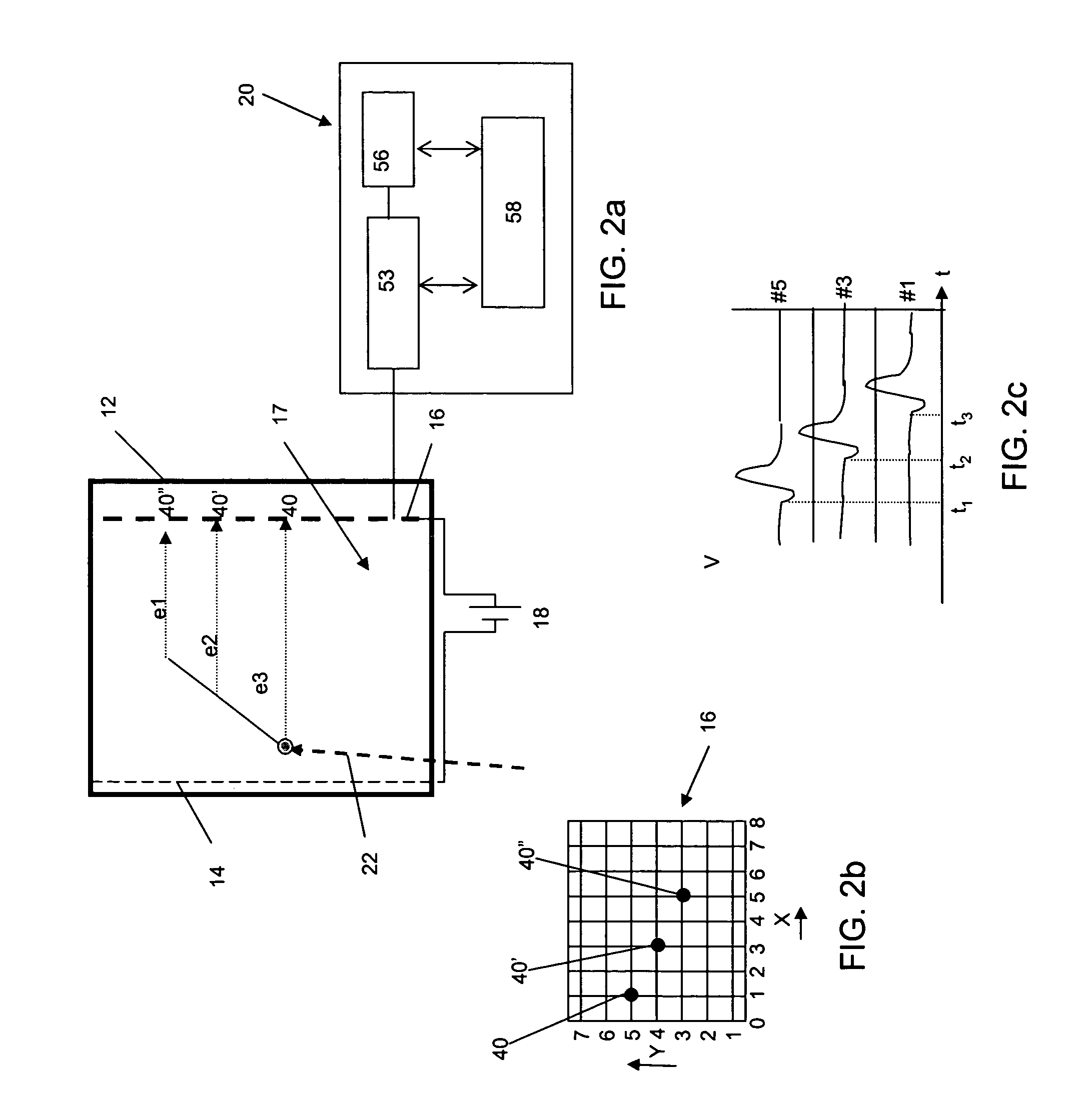

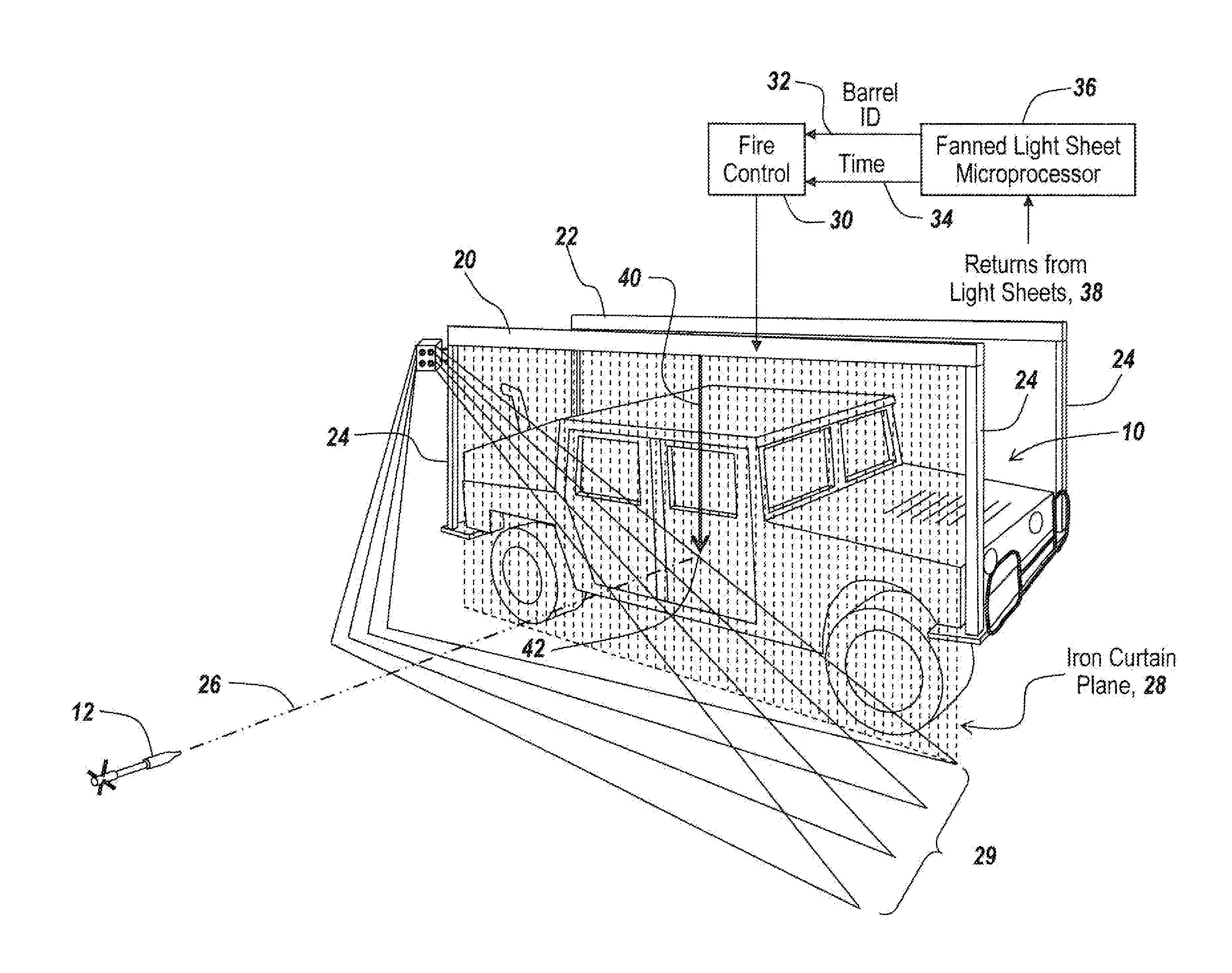

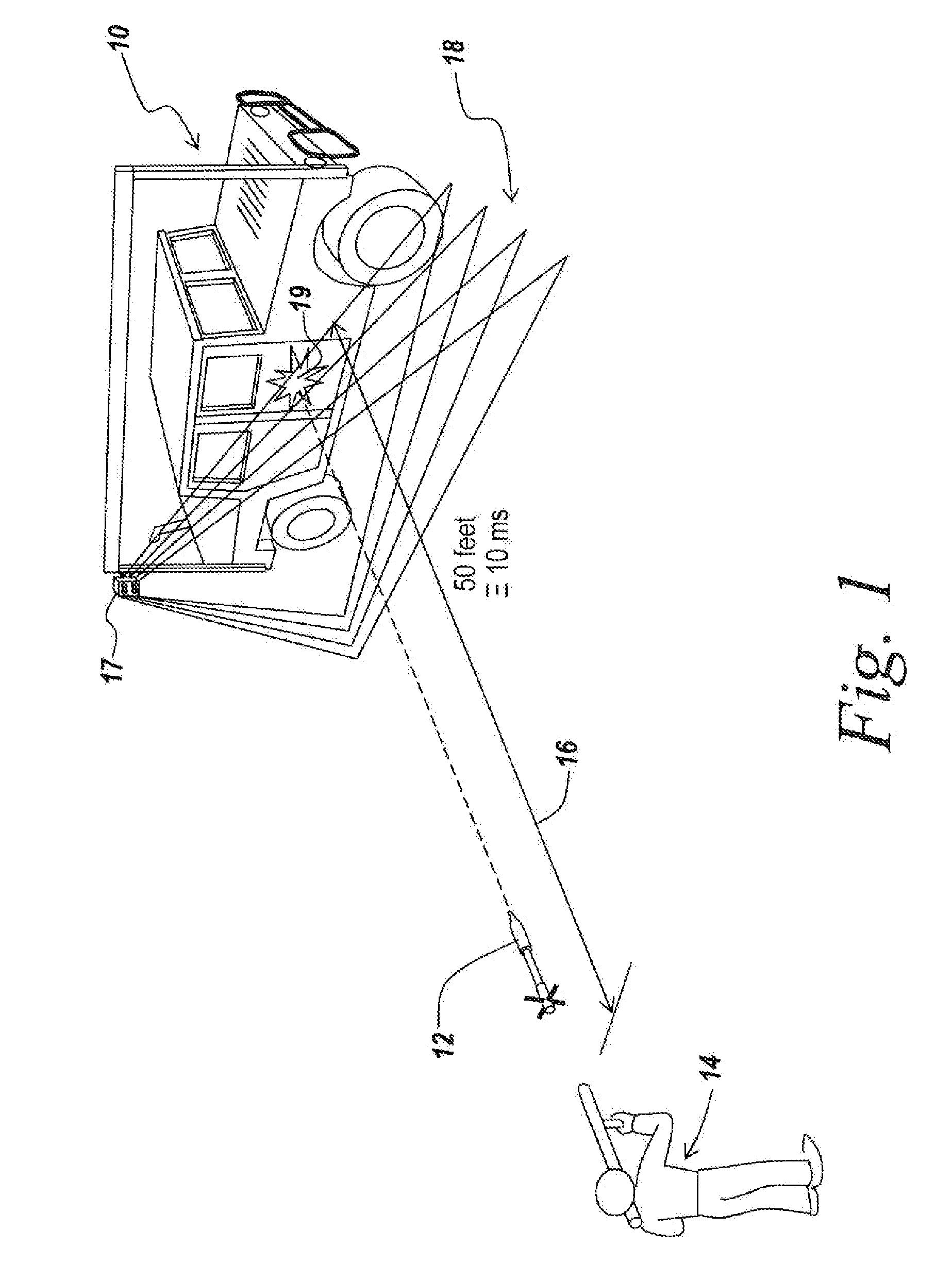

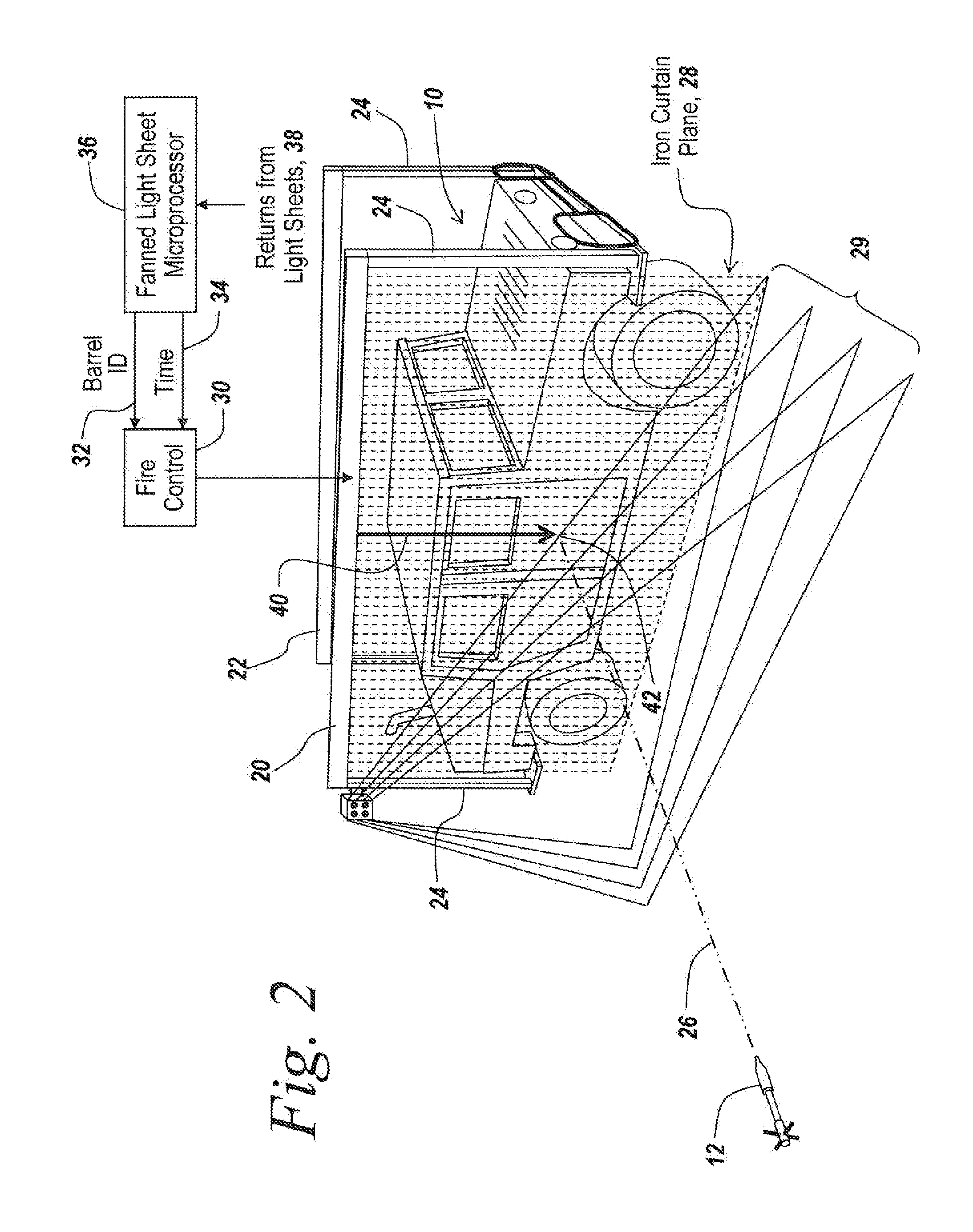

Method And Apparatus For Protecting Vehicles And Personnel Against Incoming Projectiles

InactiveUS20110204145A1Sufficient dataLow accuracyDefence devicesOptical rangefindersFire controlEngineering

A projector of multiple skewed light planes or sheets is located adjacent a vehicle to be protected and detectors are arranged to defect the penetration of the light sheets by an incoming object, with the time intervals between the piercing of the planes defining the path of the incoming object and its expected impact time. An array of bullet-firing barrels is arranged to project bullets in ah iron curtain under control of a fire control module that fires a round in a barrel above the projected flight path such that the round impacts the nose of the object and disables it. It is thus the piercing of the skewed light sheets mat provides information as to the impact point of the object as well as its time of arrival so that a round can be fired to intercept the object as it arrives at the iron curtain.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

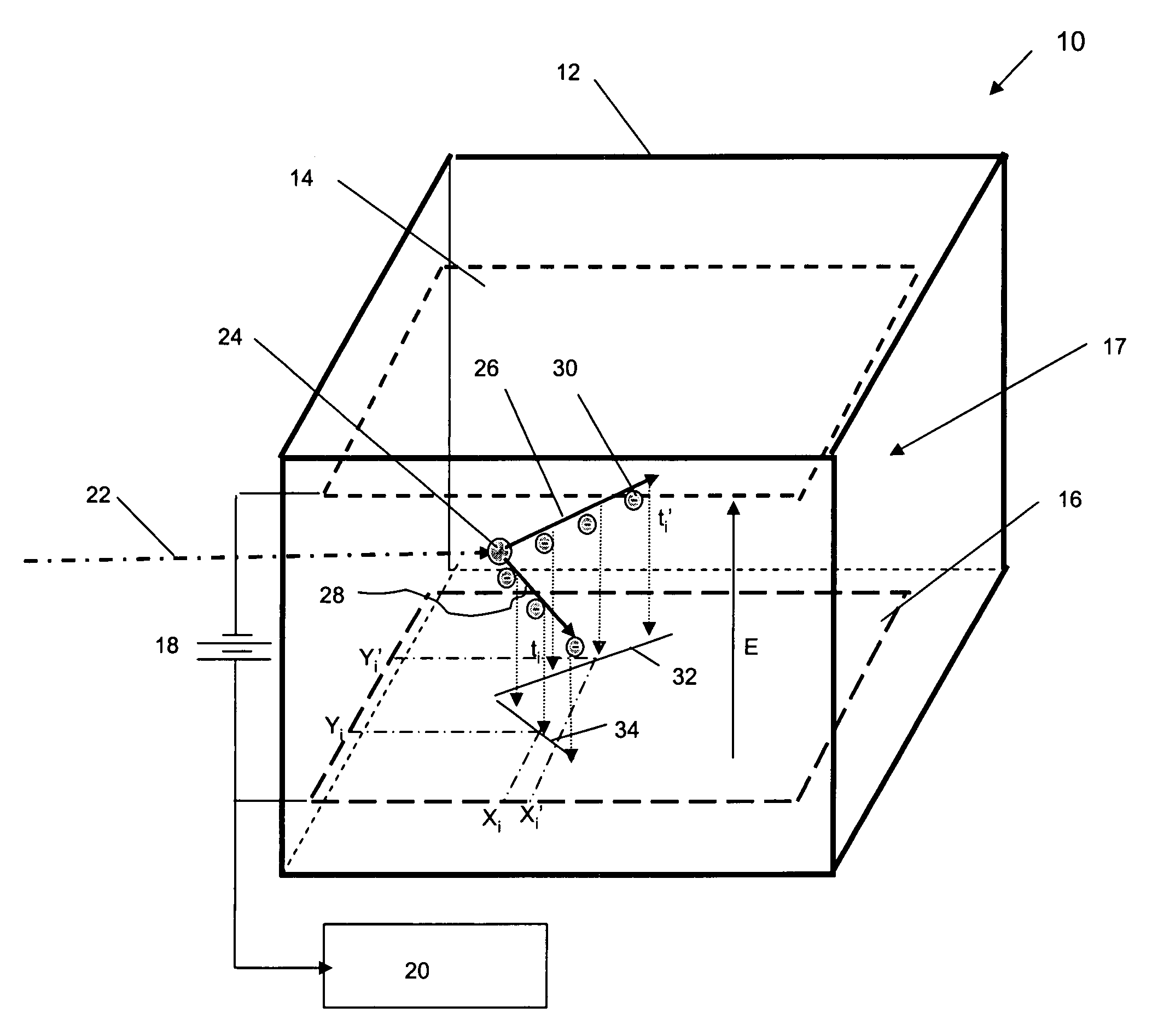

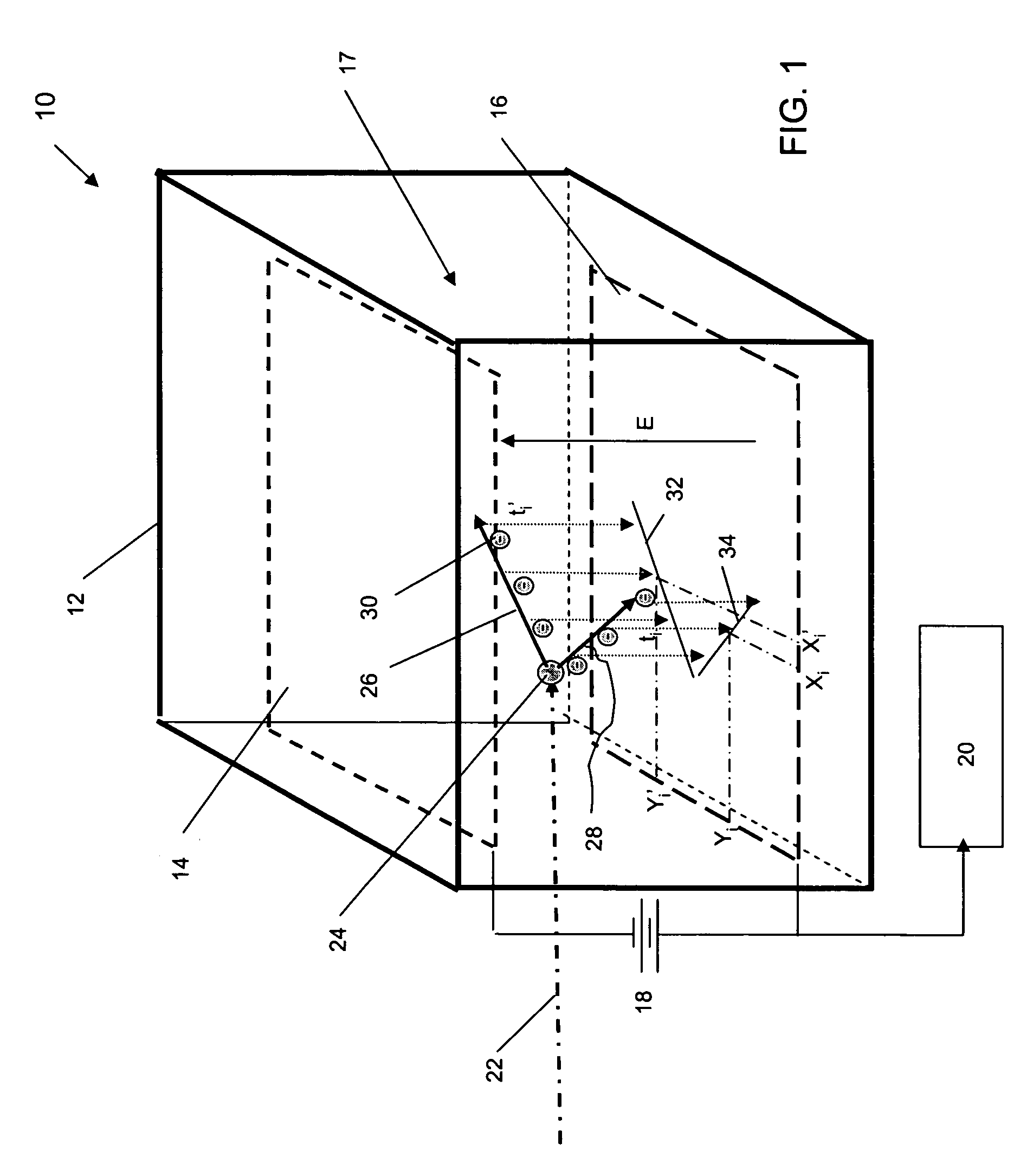

Neutron source detection camera

InactiveUS7049603B2Material analysis by optical meansX/gamma/cosmic radiation measurmentNeutron emissionMomentum

A neutron imaging method for obtaining an image of the general shape of a neutron emitting source and a bearing of the source relative to an apparatus comprising a chamber comprising a gas with a high probability of interacting with low energy neutrons, releasing collision products that maintain the neutron momentum, and generating ionization particles. The chamber comprises an electrode for providing an electronic signal indicative of the impact location of ionization particles on the electrode and a field to drift the ionization particles to the electrode. A readout indicates the location and time of impact of each ionization particle on the electrode; a memory stores a plurality of the electronic signals; and a computer receives and analyzes the signals and impact times and indicates the location of the source of neutrons by using back projection algorithms to calculate three-dimensional vectors indicative of the neutron path directions.

Owner:TEMPLE UNIVERSITY

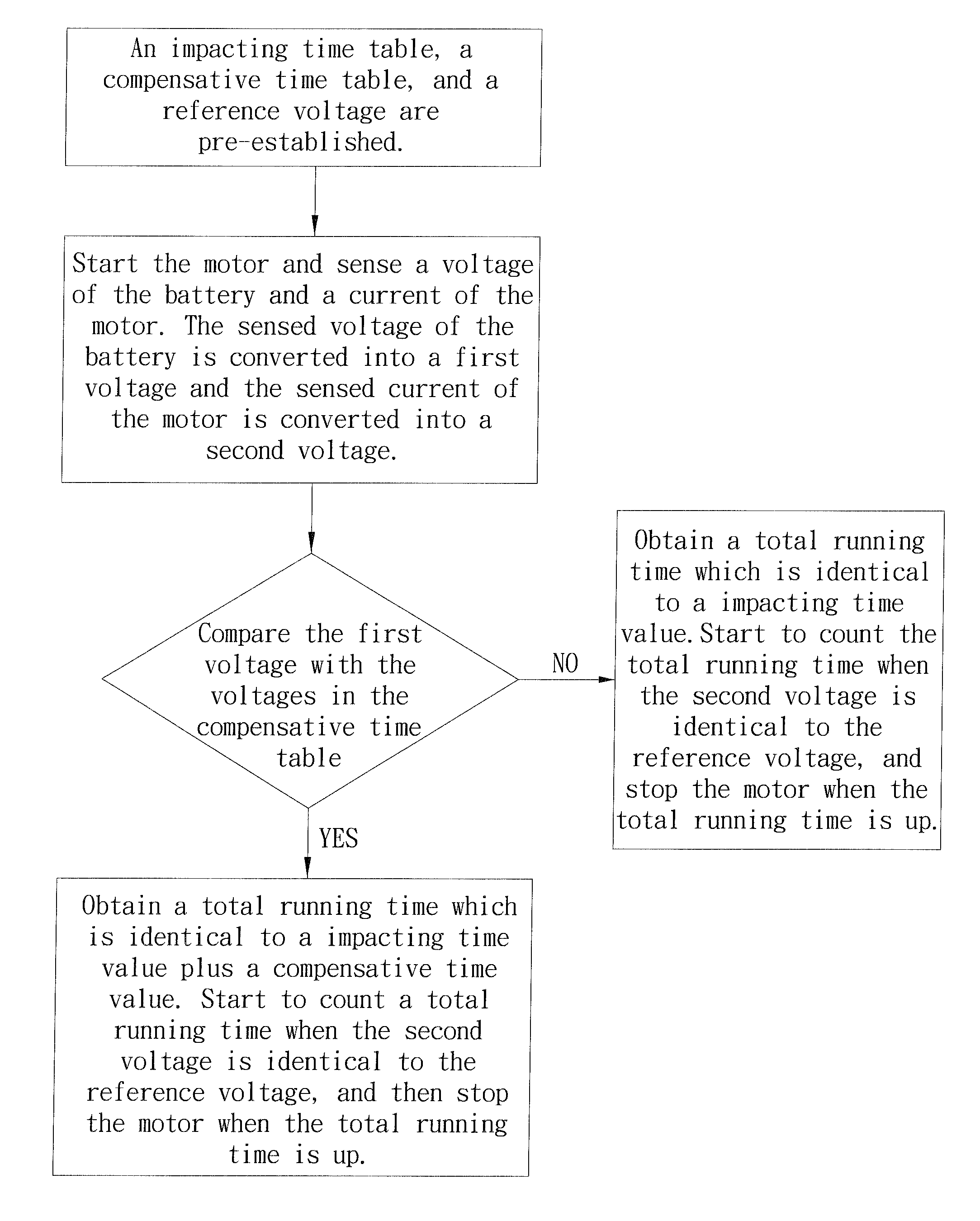

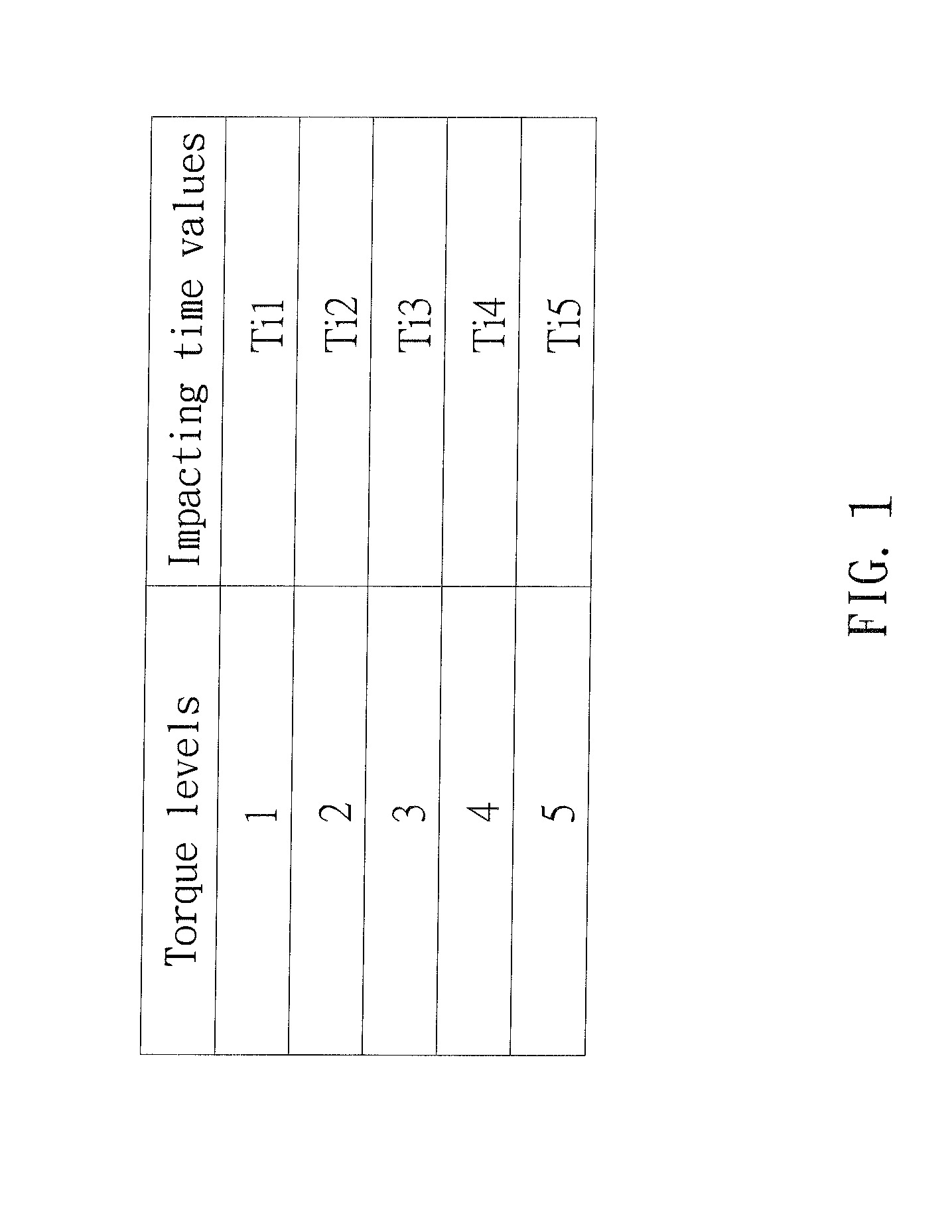

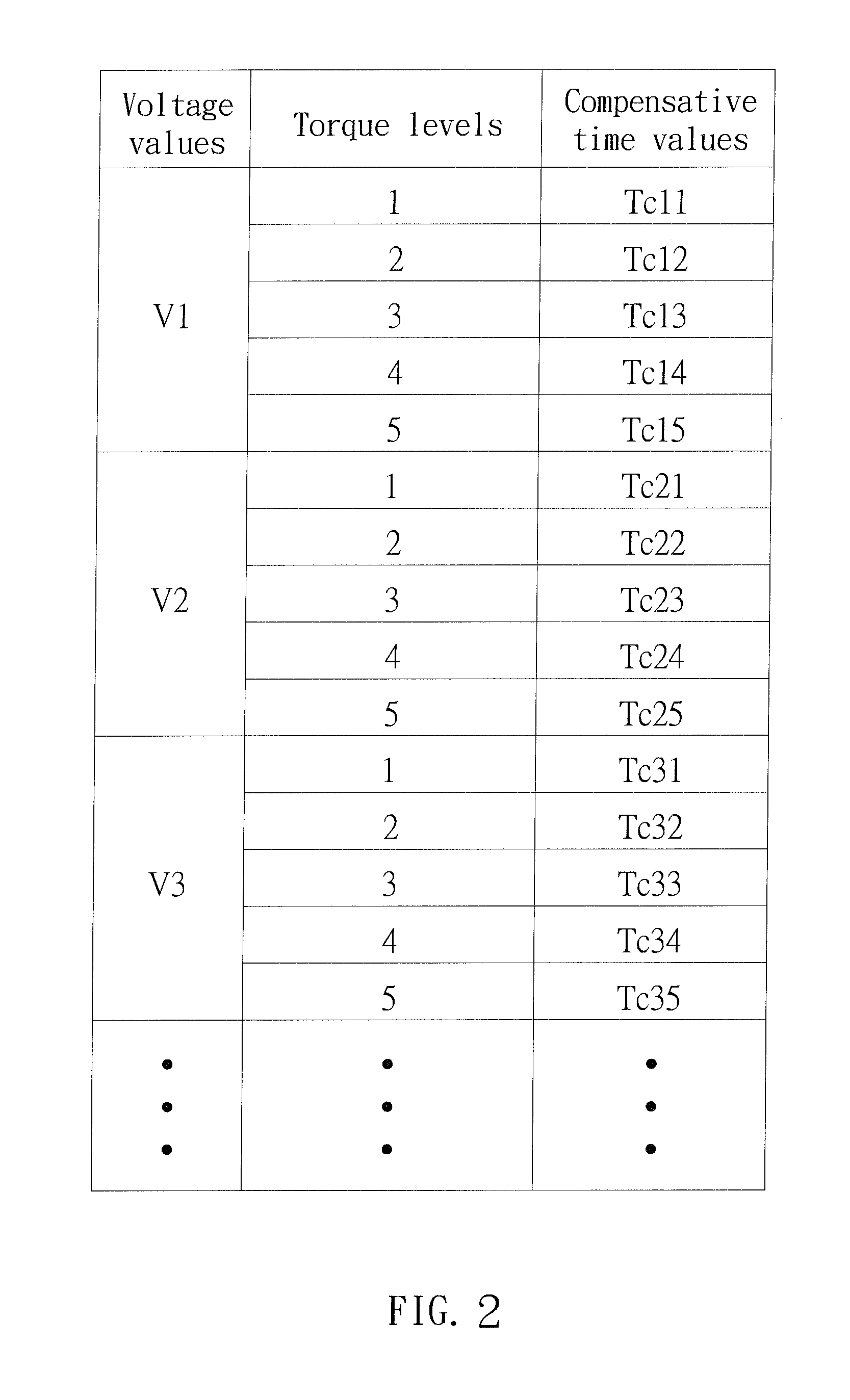

Method of controlling torque output of impact power tool and the control apparatus

InactiveUS20140042951A1Reduce turning timeLow torque levelBatteries circuit arrangementsElectric motor controlPower toolControl theory

An impact power tool includes a motor, a battery, a hammer mechanism and a control apparatus. The motor runs in the same speed no matter what torque level is selected. The motor runs for a total running time which is identical to an impacting time plus a compensative time. The impacting time is decided according to the selected torque level, and the compensative time is decided according to the power of the battery. An impacting time table and a compensative time table are pre-established to decide the impacting time value and the compensative time value. Therefore, the impact power tool always provides the theory torque output of the selected torque even if the battery is low.

Owner:MOBILETRON ELECTRONICS +1

Coordination in self-organizing networks

ActiveCN103477673AReduce exchangeLess processing capacityNetwork topologiesData switching networksImpact areaSelf-organizing network

To decide, whether or not a SON function instance is allowed to execute, a priority, an impact time and an impact area for the SON function instance is determined, and priorities of other SON function instances scheduled to be run during the impact time of the requesting SON function instance and having an overlapping impact area are compared to the priority of the requesting SON function instance.

Owner:NOKIA NETWORKS OY

Method and system for shot tracking

A method for predicting a golfer's swing speed, wherein the method comprises determining that the golfer is addressing a golf ball to swing a golf club, monitoring a backswing, determining a transition time, monitoring a downswing, determining an impact time, transmitting data for the golfer's swing to a receiver for analysis and generating a golfer's swing speed using a length of a shaft of the golf club.

Owner:TOPGOLF CALLAWAY BRANDS CORP

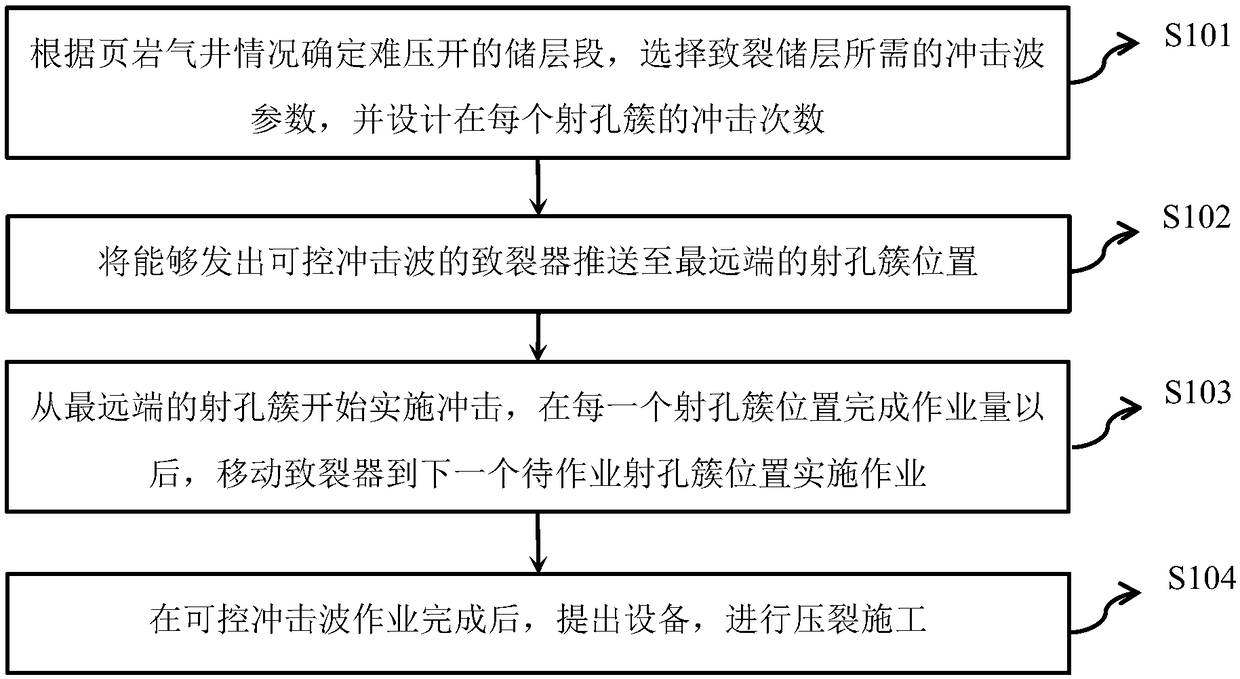

Controllable impact-wave shale reservoir pre-fracturing method

The invention discloses a controllable impact-wave shale reservoir pre-fracturing method. The controllable impact-wave shale reservoir pre-fracturing method comprises the following steps that 1, a reservoir section difficult to split is determined according to shale gas data, impact-wave parameters required by fracturing a reservoir are selected, and the impact times of each perforation cluster are designed; 2, a fracturing device capable of producing controllable impact waves is pushed to the perforation cluster position at the farthest end; 3, impact is carried out beginning from the perforation cluster at the farthest end, and after operation amount is completed at each perforation cluster position, the fracturing device is moved to a next perforation cluster position to be operated foroperation; 4, after controllable impact-wave operation is completed, a device is lifted out, and fracturing construction is performed. By adopting the controllable impact-wave shale reservoir pre-fracturing method, cracks can further extend under multiple times of impact effect, a crack net is formed around a well shaft, and fracturing pressure of a reservoir can be reduced or a reservoir difficult to fracture can be fractured open.

Owner:西安闪光能源科技有限公司

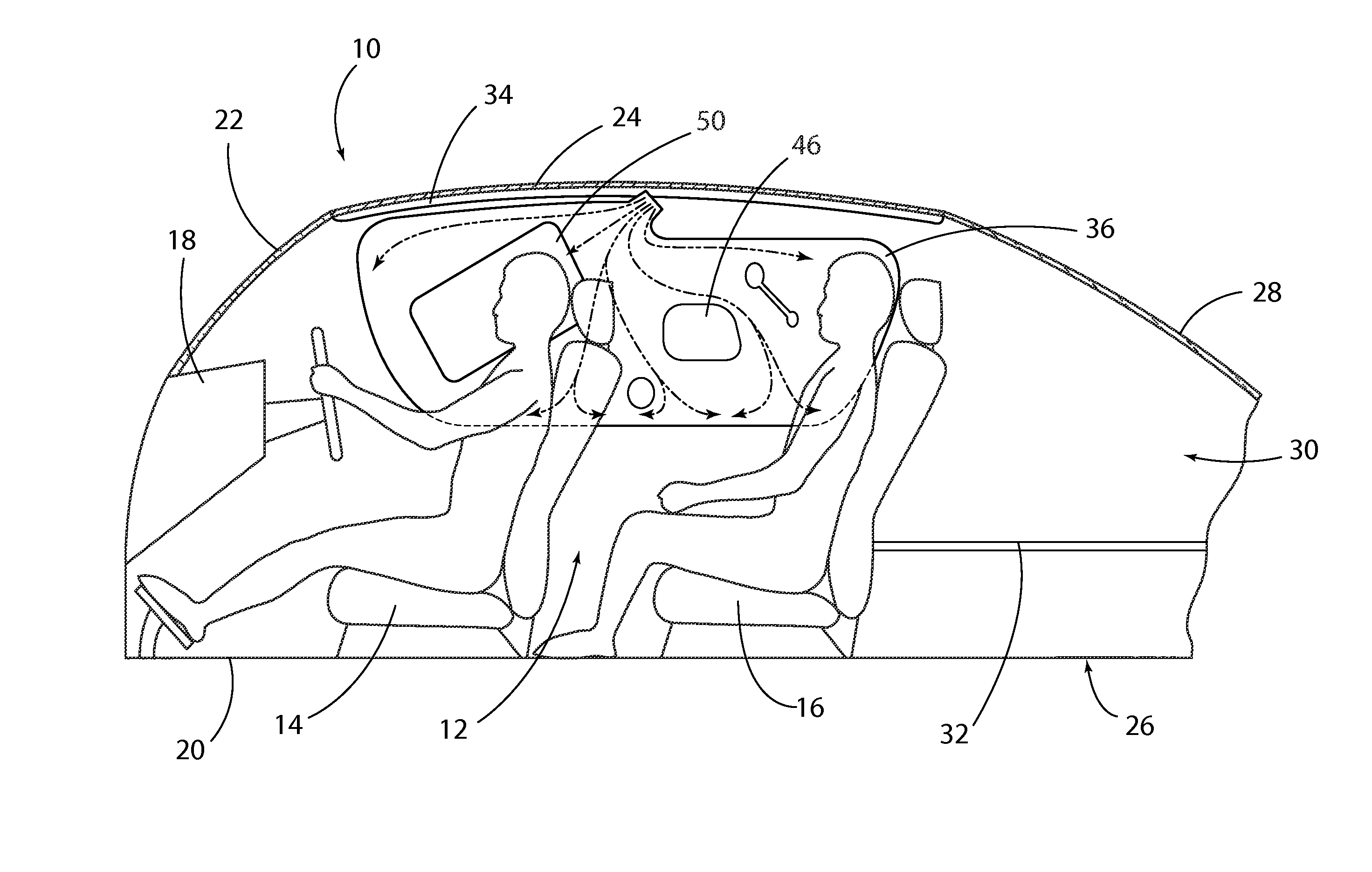

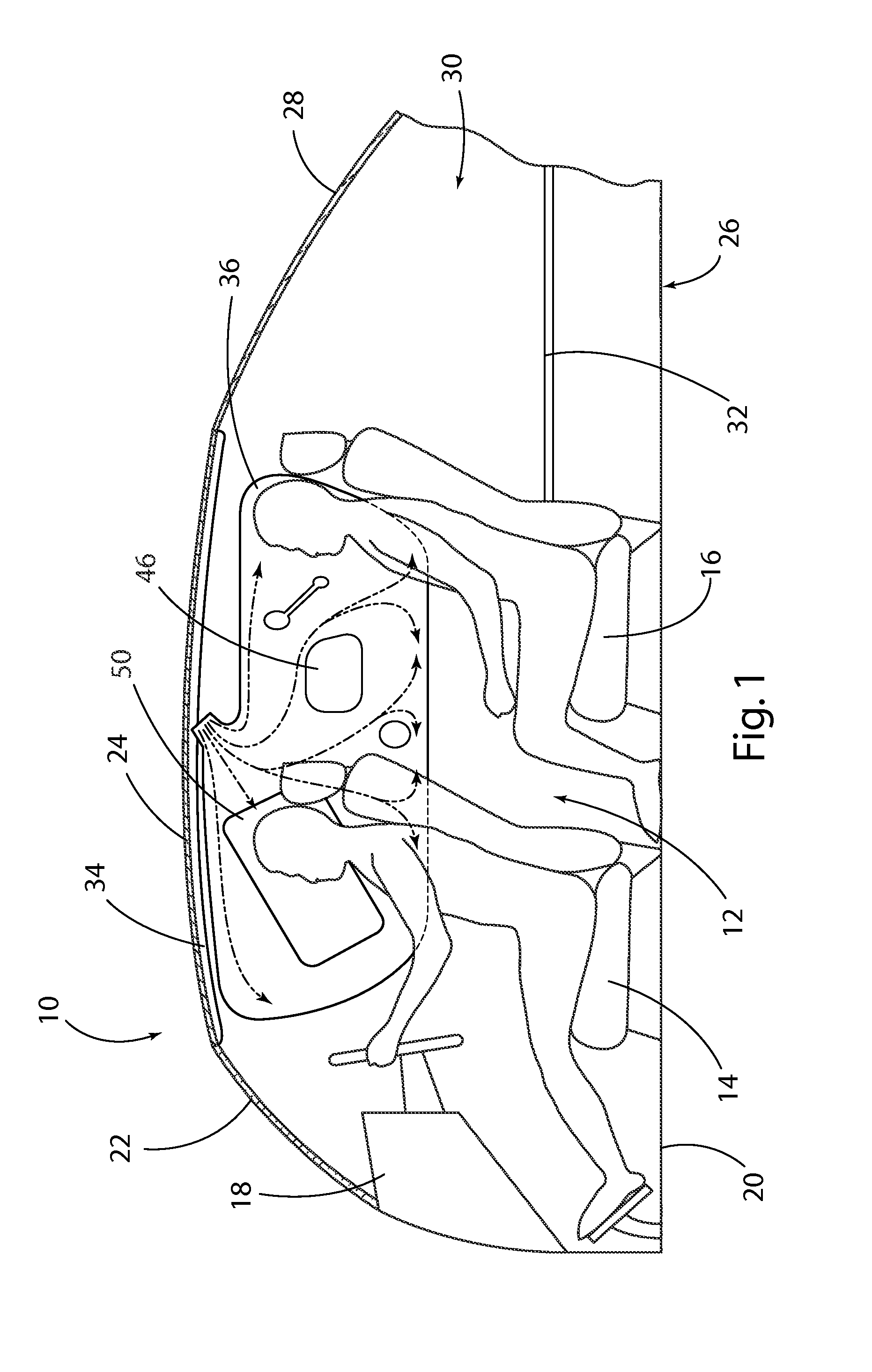

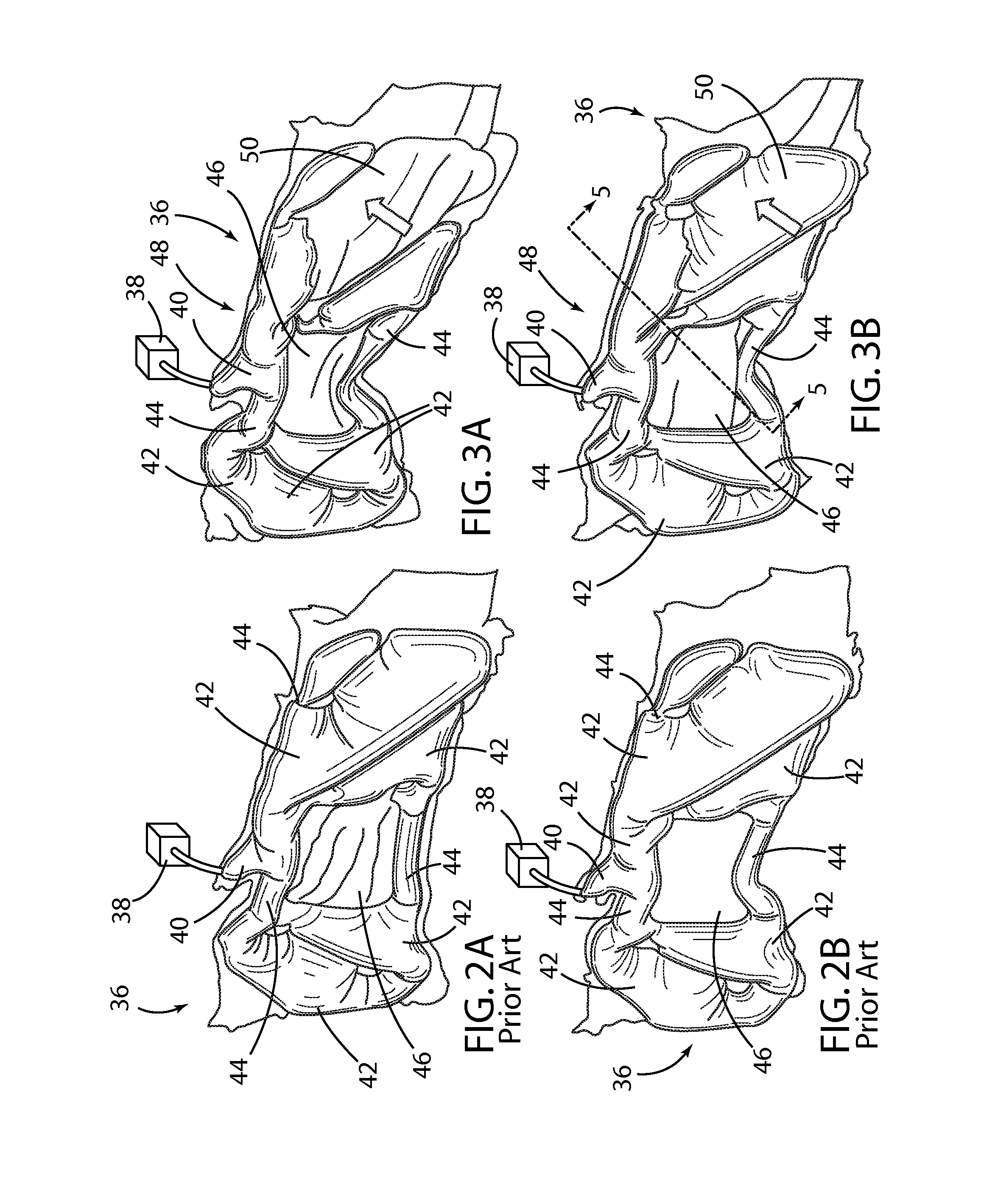

Vehicle side air curtain with controlled pressure chamber

InactiveUS20150054265A1Extended durationHigh pressurePedestrian/occupant safety arrangementEngineeringUpper thoracic region

A vehicle side air curtain has an inflator, a main inflatable chamber, and an integral separate, self-contained controlled pressure chamber in limited fluid communication with the main inflatable chamber of the side air curtain and disposed for impact by the head and upper thoracic region of a vehicle occupant. The main inflatable chamber is inflated to an initial pressure within an initial impact time period immediately following actuation of the inflator and a second lower stabilized pressure thereafter to extend the duration of the pressurization of the main inflatable chamber of the side air curtain beyond the initial impact time period. The controlled pressure chamber of the side air curtain is inflated to an initial pressure substantially lower than the first pressure of the main inflatable chamber and favorable to side impact occupant protection immediately following actuation of the inflator pressure.

Owner:FORD GLOBAL TECH LLC

Method for evaluating dynamic damage of material under repeated impacts

InactiveCN101852705AImprove accuracyImprove reliabilityMaterial strength using repeated/pulsating forcesDamage factorEngineering

The invention discloses a method for evaluating the dynamic damage of a material under repeated impacts, which comprises the following steps of: 1. measuring and calculating the original average wave speed v0 of a test specimen prior to an impact test by using the ultrasonic method; 2. carrying out a repeated impact test on the test specimen; 3. Measuring by adopting an ultrasonic wave method and calculating the average wave speed vn of the test specimen after the nth impact; 4. calculating the damage factor of the test specimen after the nth impact: Dn=1-vn2 / v02; and 5. calculating the arithmetic average of the damage factors of at least three test specimens made of the same material after the nth impact, and evaluating the dynamic damage degree of the material with factors under different impact times. The invention has simple measuring method, is suitable for measuring various materials of different characters, can be used for quantitative evaluation on the damage degree of materials and structures under dynamic load effects such as explosion, impact, penetration and the like, improves the accuracy and the reliability of the evaluation method, and can carry out quantitative comparison and evaluation on the repeated impact resistance of different materials.

Owner:NANJING UNIV OF SCI & TECH

Hard alloy impact fatigue testing method

ActiveCN101608990AShorten development timeReduce R&D costsMaterial strength using repeated/pulsating forcesFree fallingPunching

The invention provides a hard alloy impact fatigue testing method sequentially comprising the following steps: (1) preparing a hard alloy standard sample with a thin wall and in a cylinder shape, and a platform or a conical squeeze head, wherein the diameter of the bottom surface of the squeeze head is larger than the diameter of a bore of the standard sample; (3) adjusting the strength of impact energy; (4) starting up an impact fatigue machine and a cam rotary knob, driving a punching head to do vertical, reciprocating and free-falling movement to enable the punching head to impact the bottom surface of the squeeze head, transferring the impact energy to the standard sample till the standard sample breaks, and taking the impact time and the impact energy of the breaking at the moment as the impact fatigue value of the hard alloy. The invention can fast test the impact fatigue performance of the hard alloy, thereby effectively shortening the research and develop time of hard alloy products and saving research and develop costs.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

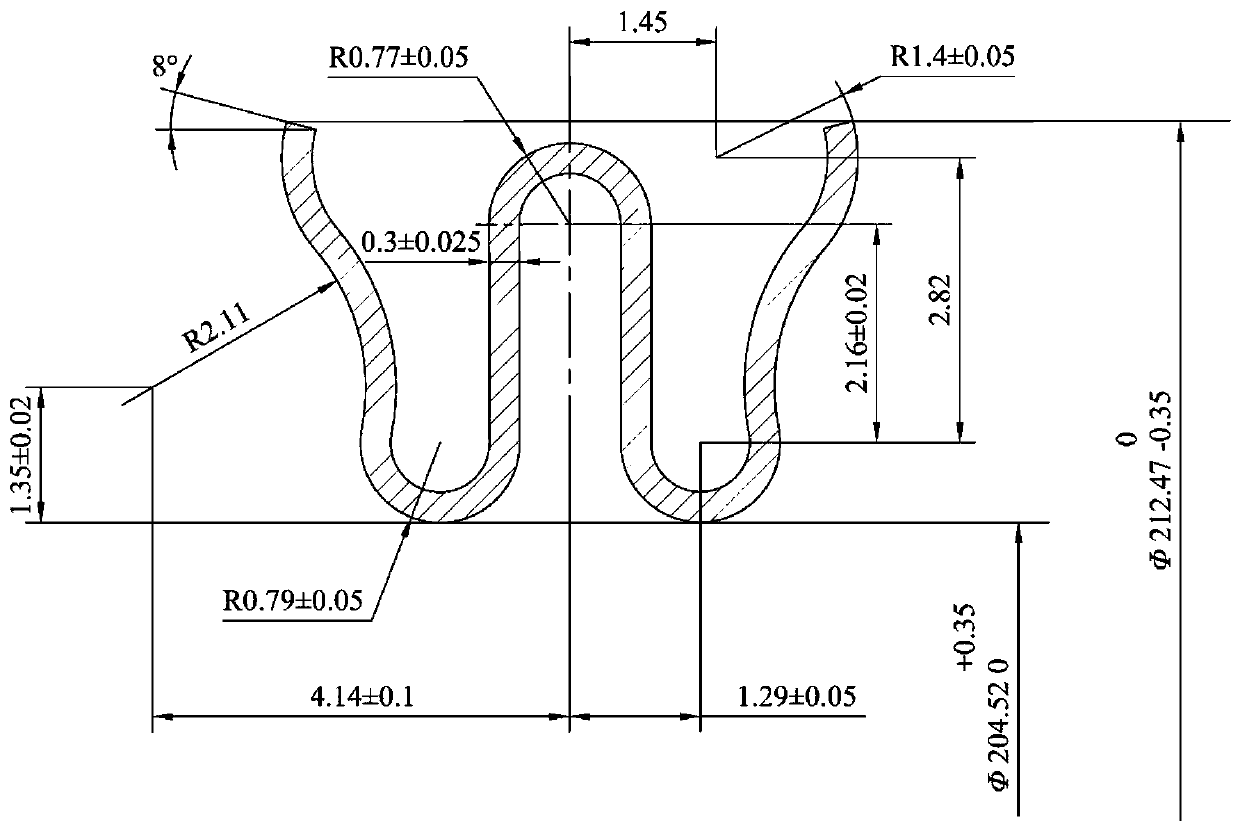

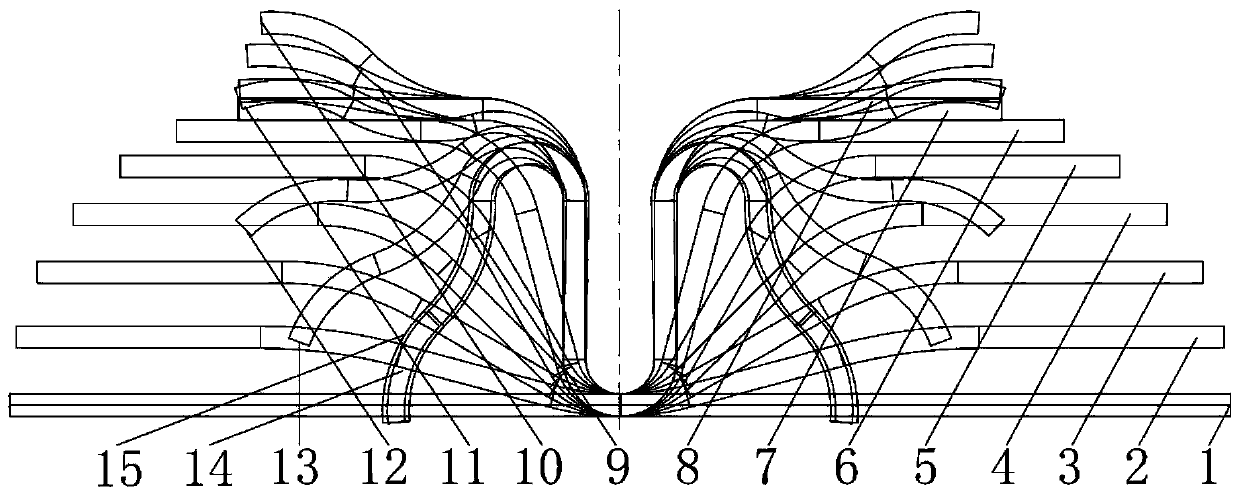

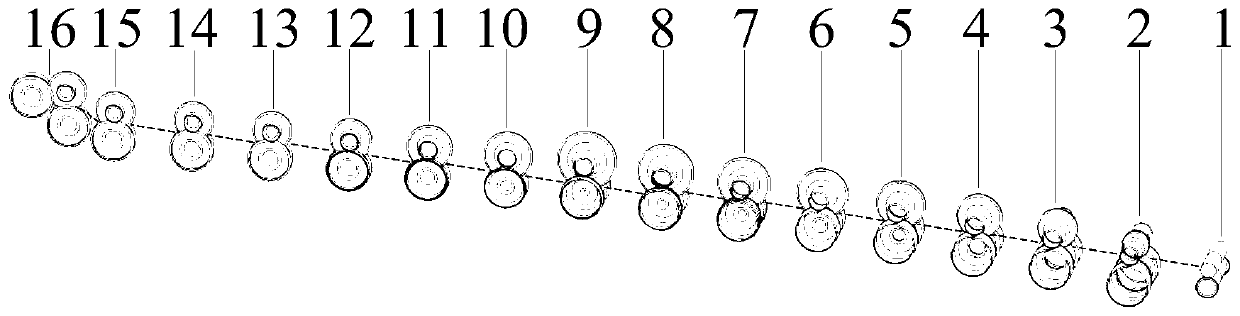

Aero-engine W-shaped sealing ring manufacturing method

InactiveCN110125214AReduce manufacturing costReduce technical riskShaping toolsMetal sheetImpact time

The invention discloses an aero-engine W-shaped sealing ring manufacturing method. The aero-engine W-shaped sealing ring manufacturing method includes the steps that step 1, the number of required rolling passes for forming is calculated according to a structural form of a W-shaped sealing ring required to be formed; step 2, rollers for each rolling pass are designed, and all roller pairs are machined and produced; and step 3, technological machining of the W-shaped sealing ring is carried out. According to the aero-engine W-shaped sealing ring manufacturing method, by roll bending and circlebending forming, the continuous technological manufacturing method within a tolerance range can be guaranteed, the production cost can be reduced, the degree of technology automation is high, the technical risk is low, and the improvement of forming quality is facilitated; and by using rubbers or rubber bags filled with liquids as moulds, and sheet metal can be wrapped and pasted on the corresponding rigid moulds for forming under the action of pressure, so that the rubbers are in contact with the surfaces of materials when parts are formed, the surface quality of workpieces can be protected without mechanical damages, energy can be absorbed, impact time is prolonged, and metal sheets produce more plastic deformation, so that parts which meet production requirements are formed, the energyis saved, and the efficiency is high.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com