Digital fatigue impact test instrument and test method

A shock test and fatigue technology, applied in the field of vibration and shock, can solve the problems of roughly obtaining a single shock process, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

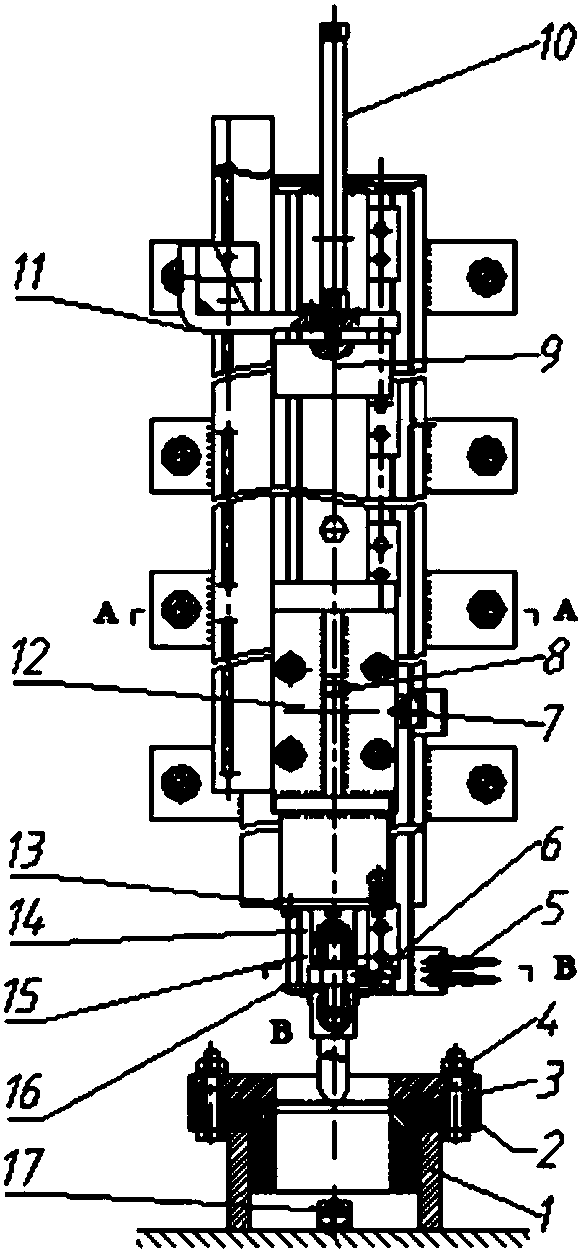

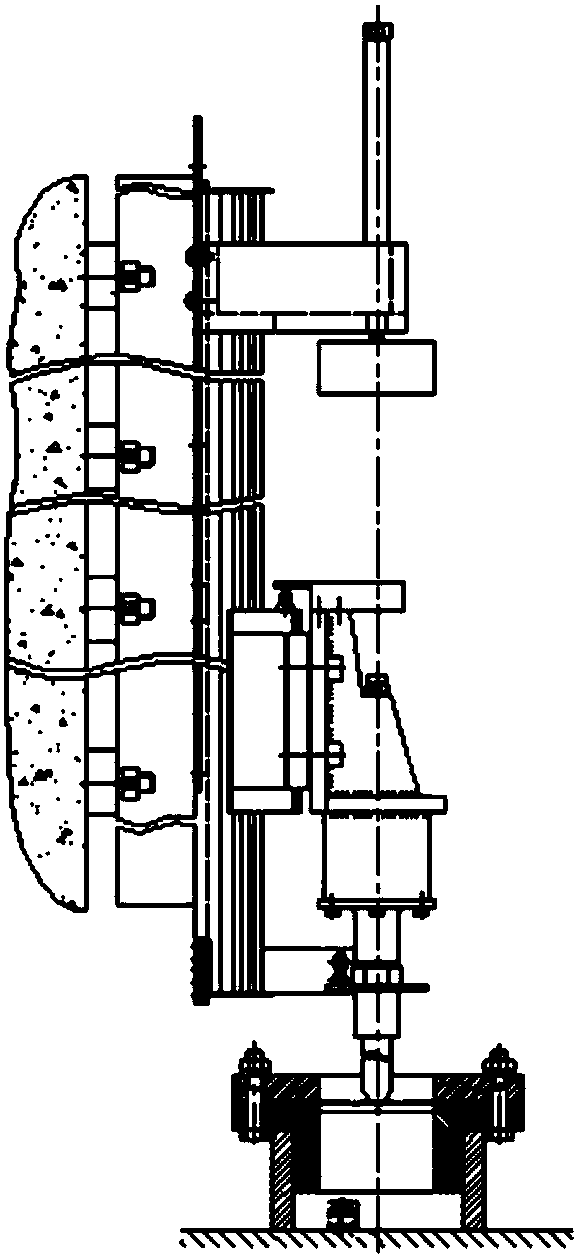

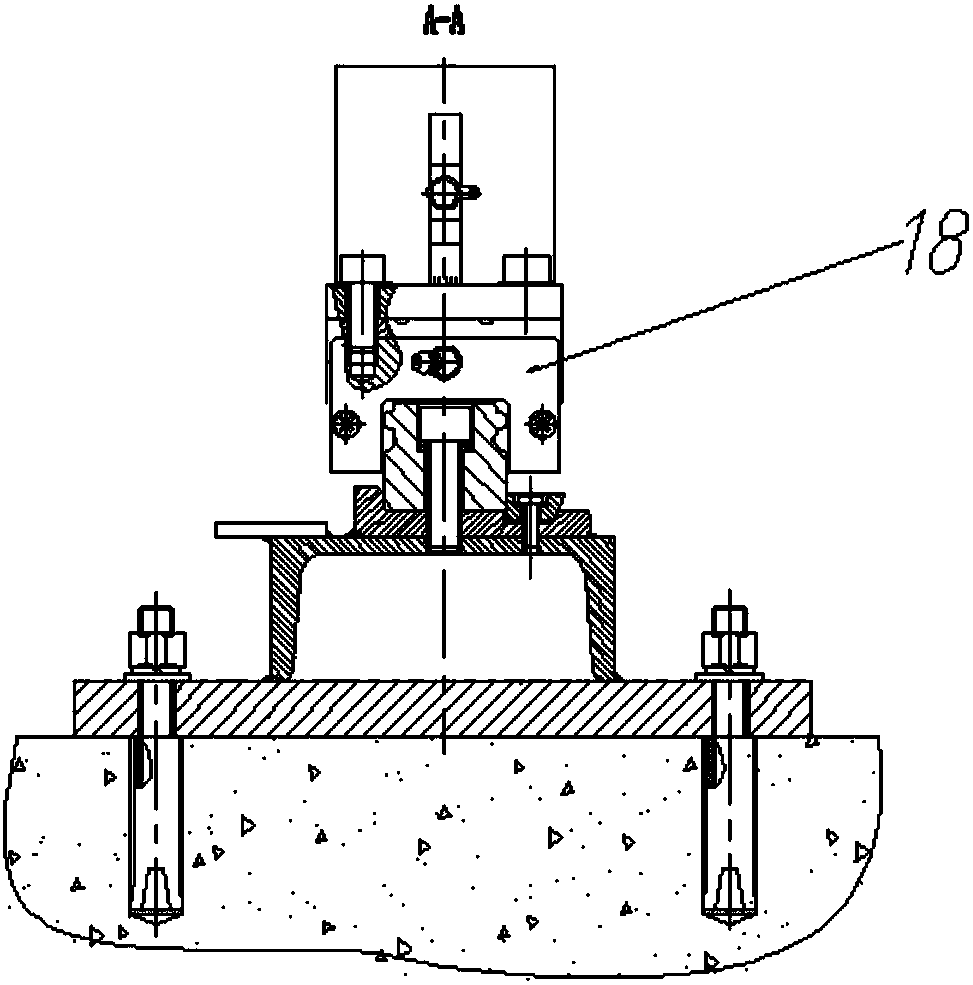

[0043] The specific implementation of this experimental instrument is composed of six parts: mechanical part, electrical part, data acquisition part, data processing part, the working principle of the whole instrument and the test effect after the implementation of the experimental instrument. Through the coordination and cooperation of various parts, the fatigue impact process is fully automated, Multiple shocks are continuous, and the description of the shock process is fully digital. The following combines the specific design principles of the instrument and the structure of each part and the attached Figure 1 to Figure 8 This application is further described.

[0044] This application designs a digital fatigue impact tester, collects the experimental data of the impact process through acceleration sensors, force sensors and photoelectric sensors, and uses the gravitational potential energy of the impact hammer head itself to convert it into kinetic energy to achieve impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com