Patents

Literature

72results about How to "Realize impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material flowing deformation disturbed effect testing system and testing method thereof

InactiveCN1948945ASimple structureEvenly loadedFlow propertiesMaterial strength using single impulsive forceMaterials testingAxial pressure

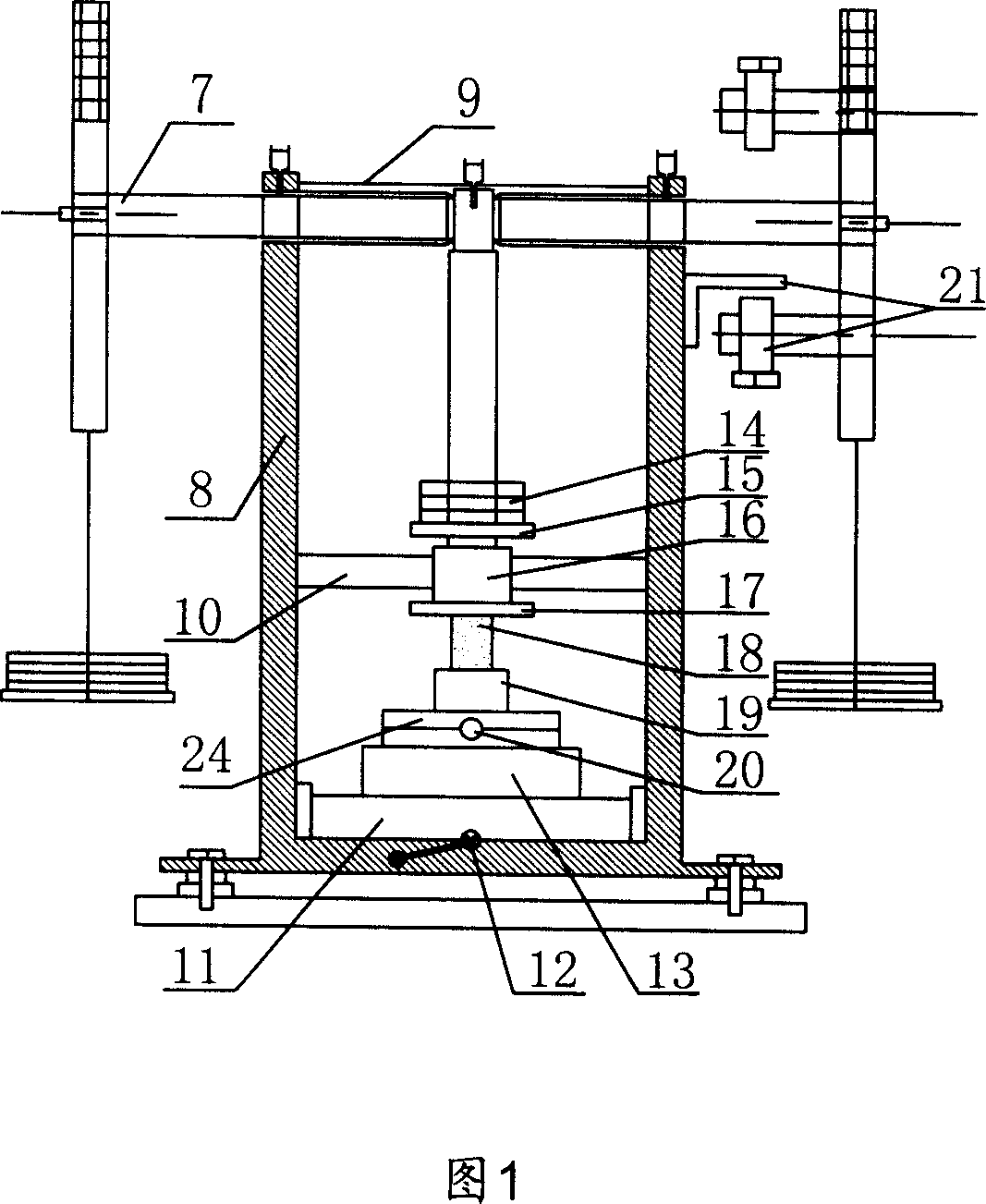

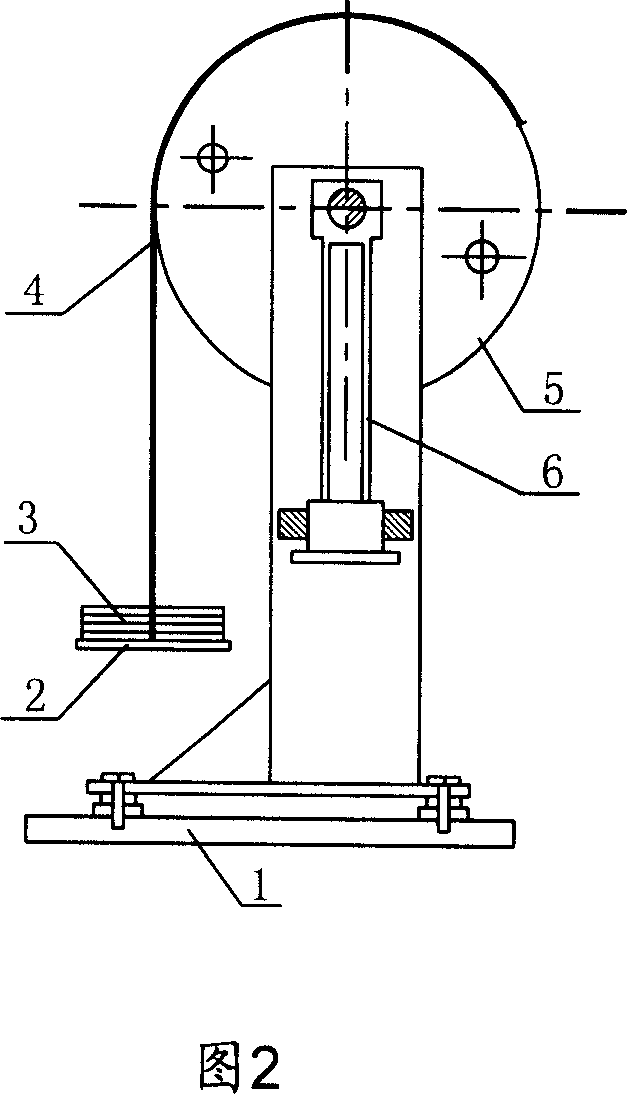

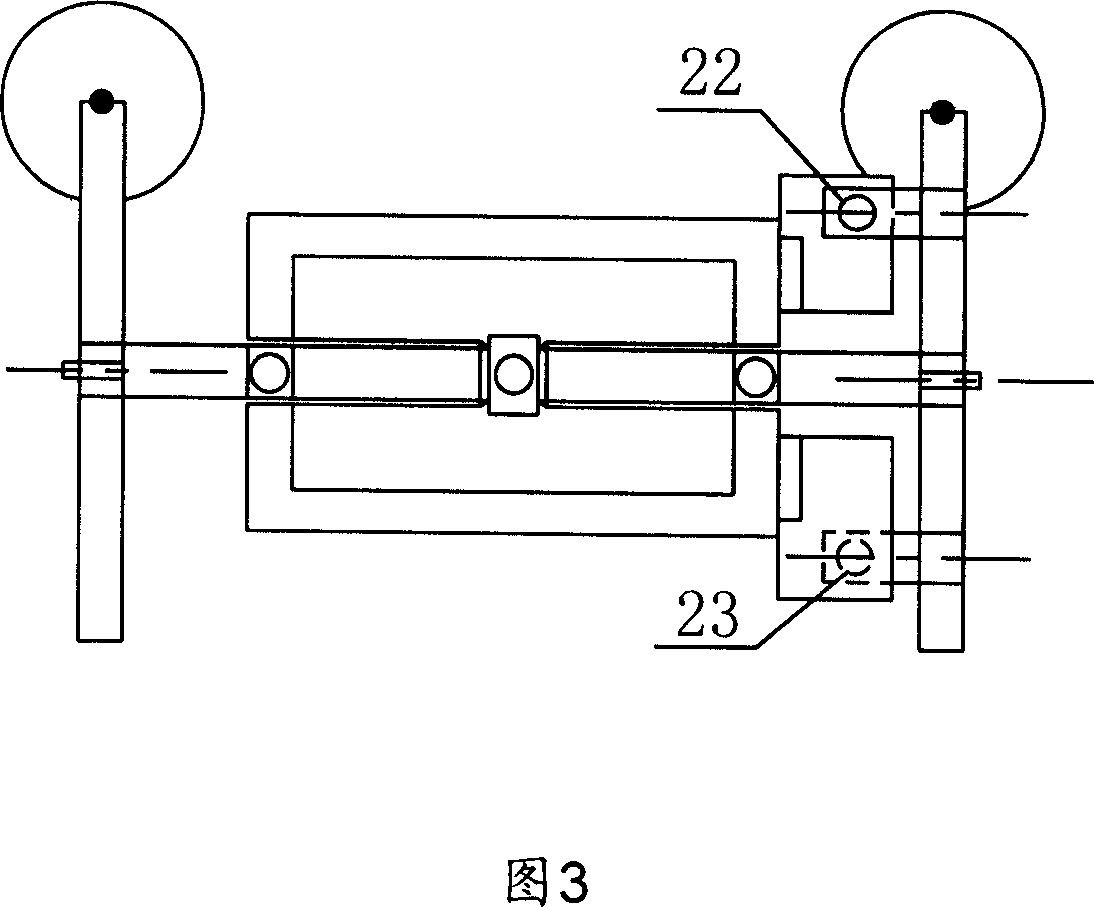

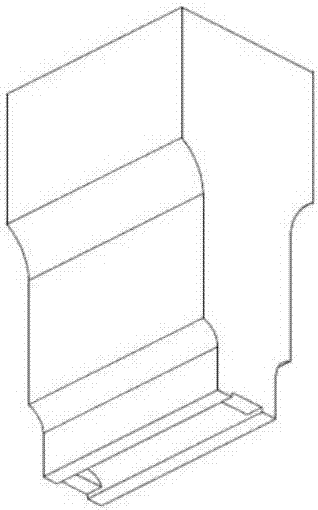

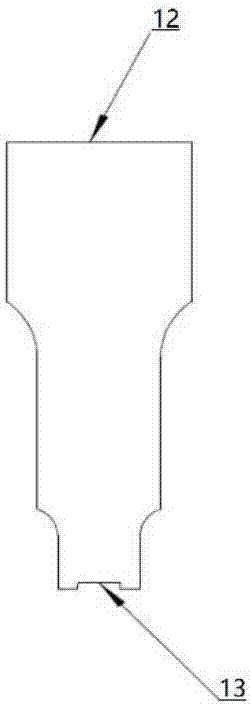

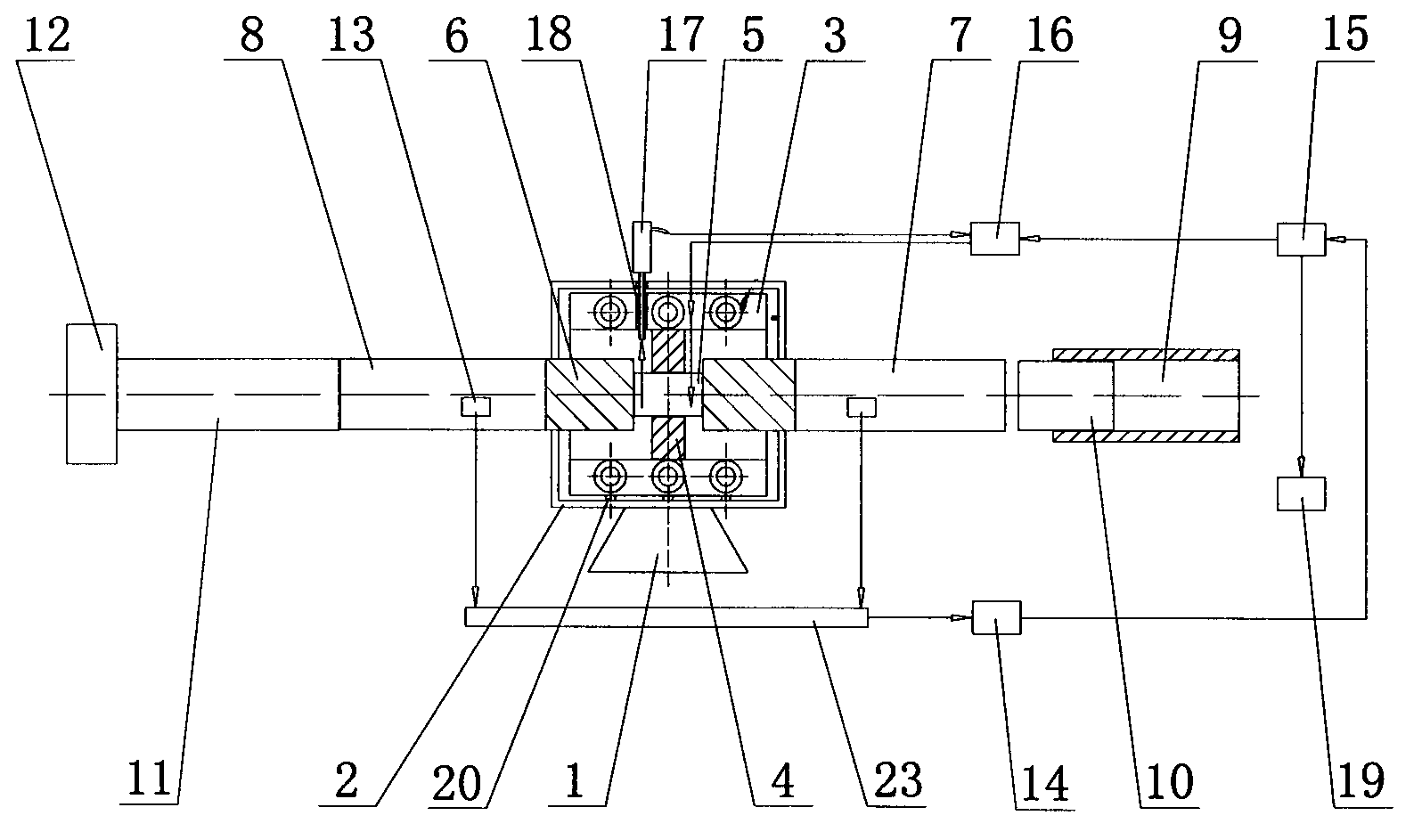

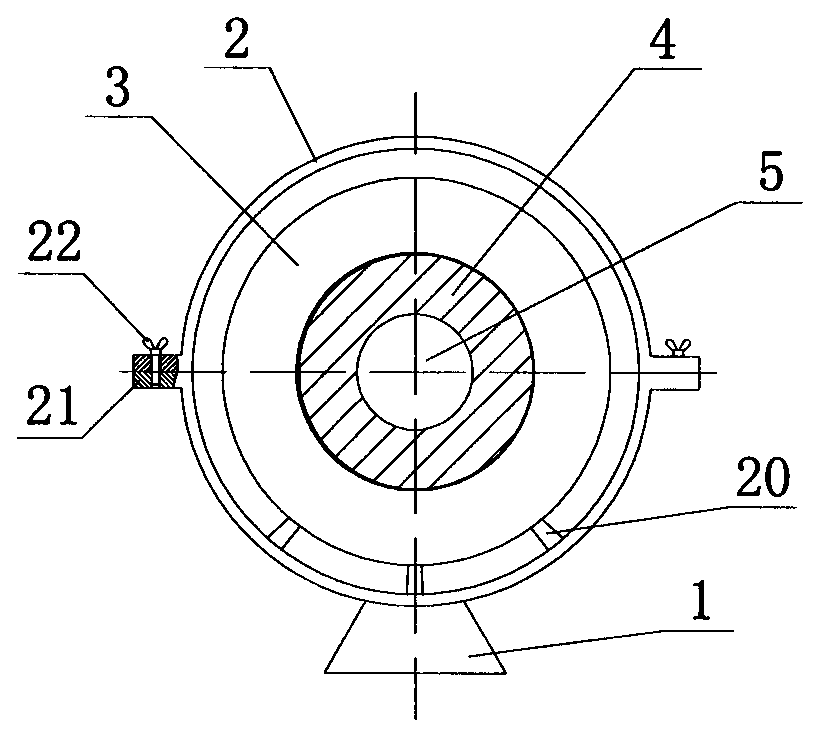

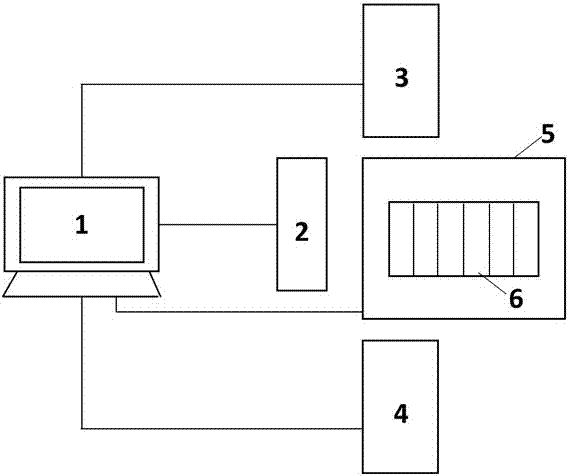

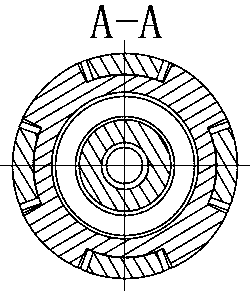

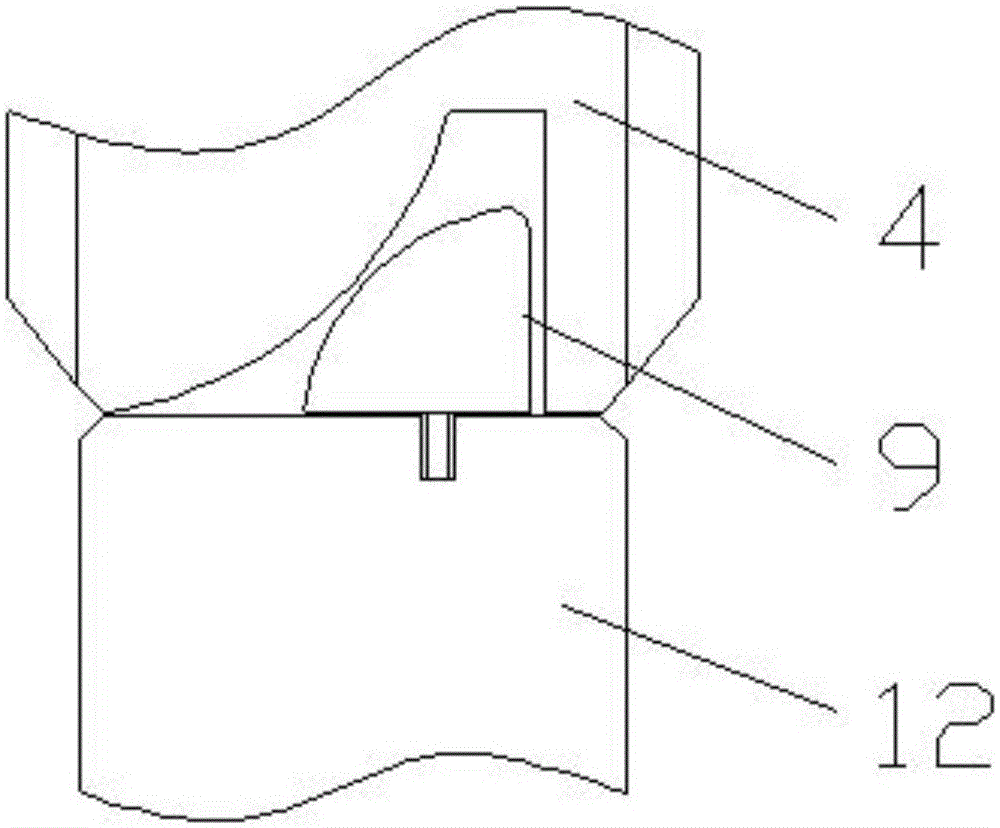

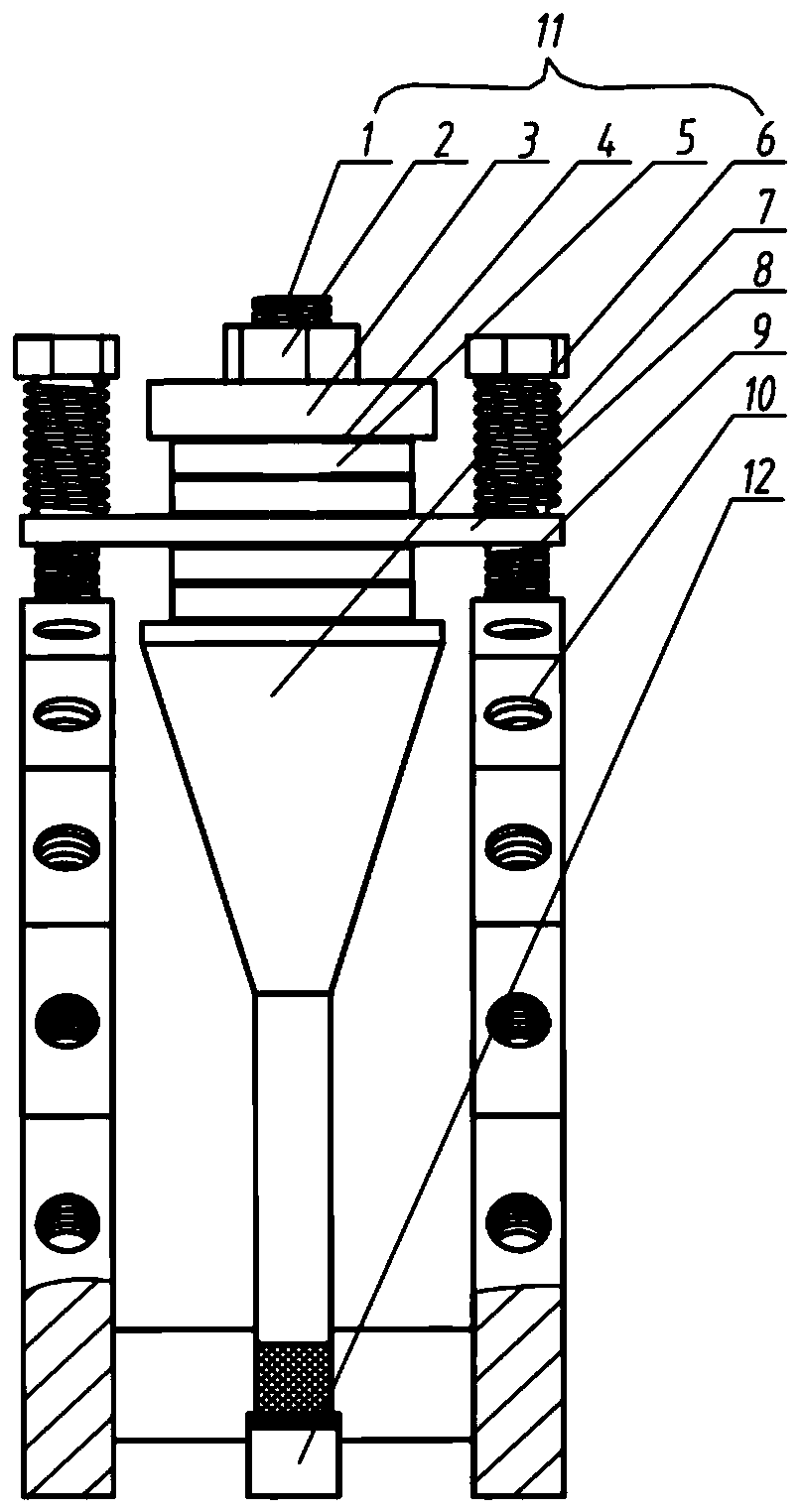

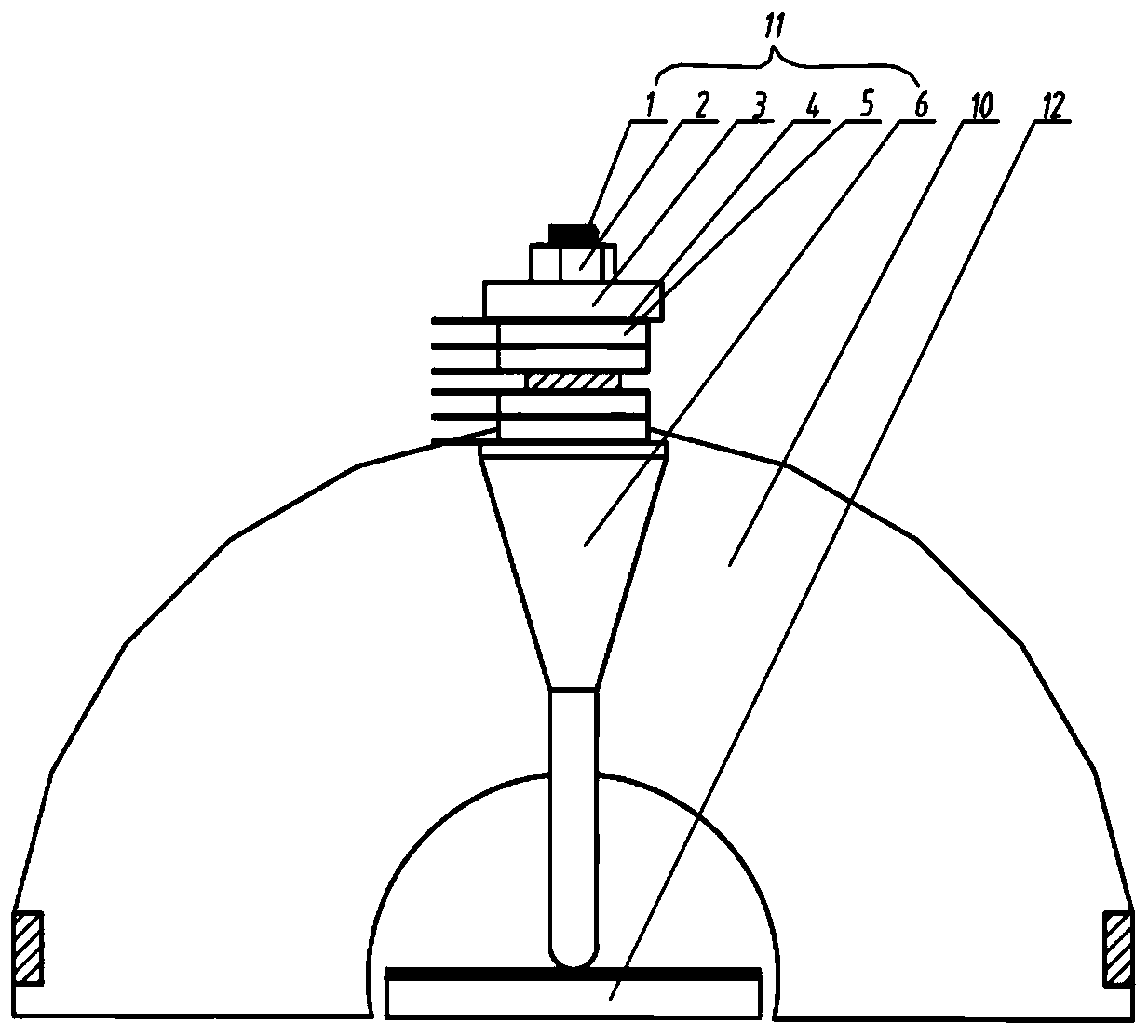

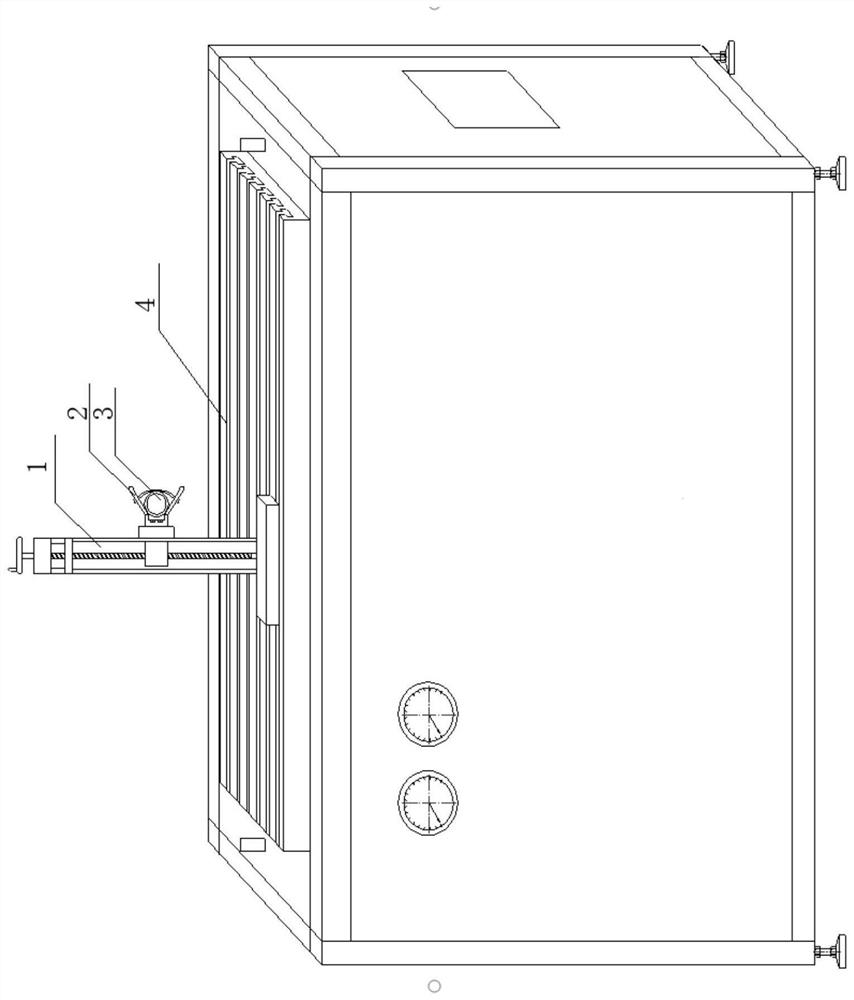

The invention discloses material fluid deformation disturbance effect experimental system and method. It includes dead load loading system realized by loading system, crankshaft force enlarging device, and force transmission connecting rod, disturbance loading system realized by impact and blasting disturbance loading devices, confining pressure loading system realized by tri-axial pressure tank includes closed box set ring capsule. The material fluid deformation disturbance effect experimental system can realize uniaxial and tri-axial fluid deformation experiences, uniaxial and tri-axial fluid deformation disturbance experiments for the testing specimen. It has the advantages of simple structure, low cost, precise testing, suiting for various materials testing specimen to do fluid deformation disturbance experiment, especially for rock testing specimen.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

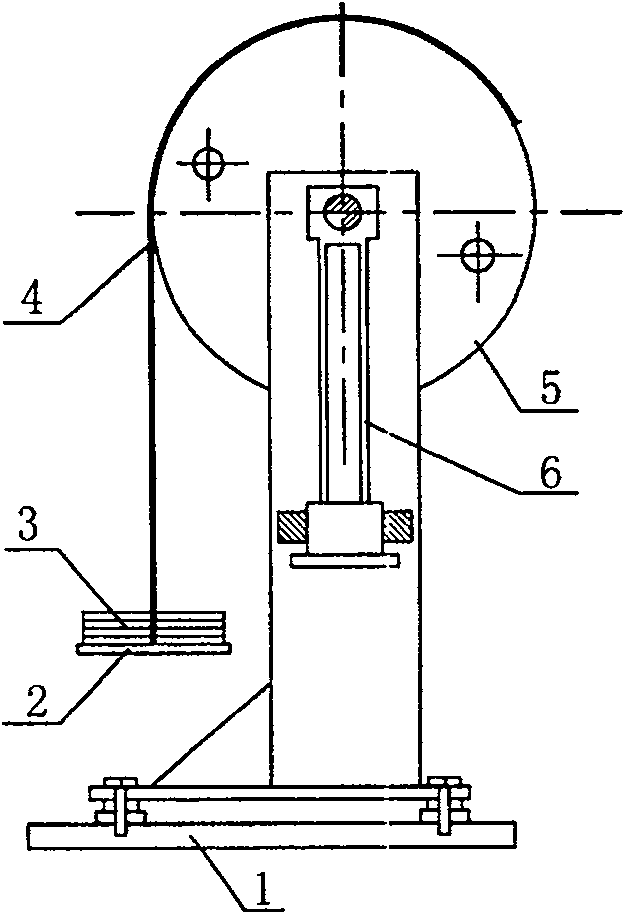

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

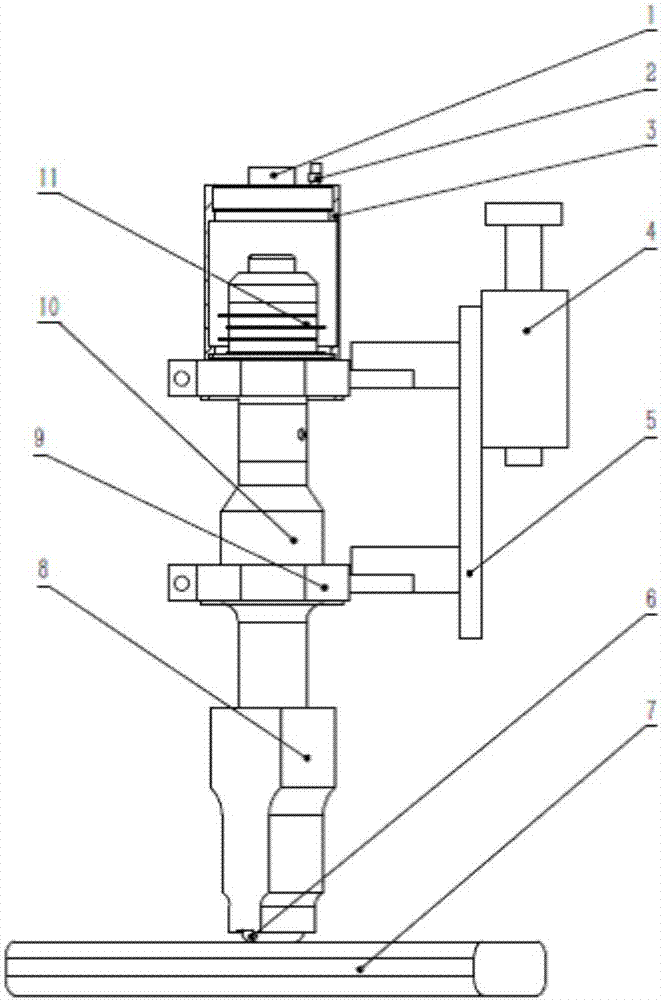

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

Device for rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment

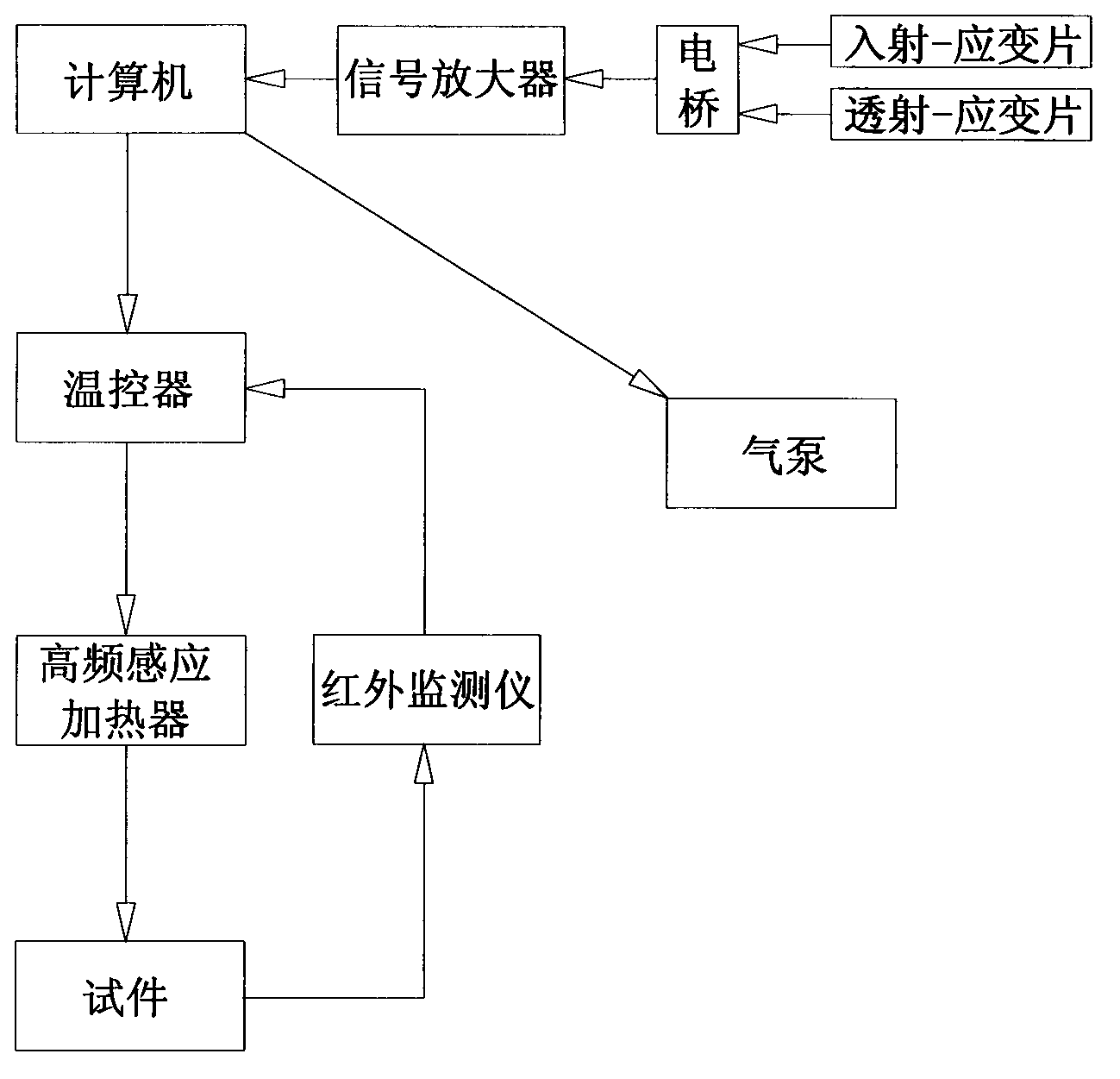

InactiveCN103018094AEliminate performance impactFast heatingPreparing sample for investigationStrength propertiesAudio power amplifierInduction heater

The invention discloses a device for a rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment. The device adopts the technical scheme that a sample is mounted in the middle of a ceramic sleeve at the center of a high-frequency induction heater in a shielding cover; the both ends of the sample are connected with the inner ends of two short ceramic bars; the outer ends of the two short ceramic bars are connected with one end of an incidence bar and one end of a transmission bar respectively; stress wave signals of strain gages are measured from the incidence bar and the transmission bar respectively, and sent to a computer for data processing through an electric bridge and an amplifier; the computer controls the warming of the high-frequency induction heater and the sample through a temperature controller; and the sample temperature is fed back to the temperature controller by another infrared monitor. The device overcomes the defects that the available device for the split Hopkinson pressure bar experiment is complicated in structure, complicated to operate, low in working efficiency and difficult in data processing; and the quality of the experiment is influenced seriously. The device is suitable for the Hopkinson pressure bar experiments in different laboratories, in particular to the heating of the sample and the immediate processing of the information of the strain gages.

Owner:HUNAN UNIV OF SCI & TECH

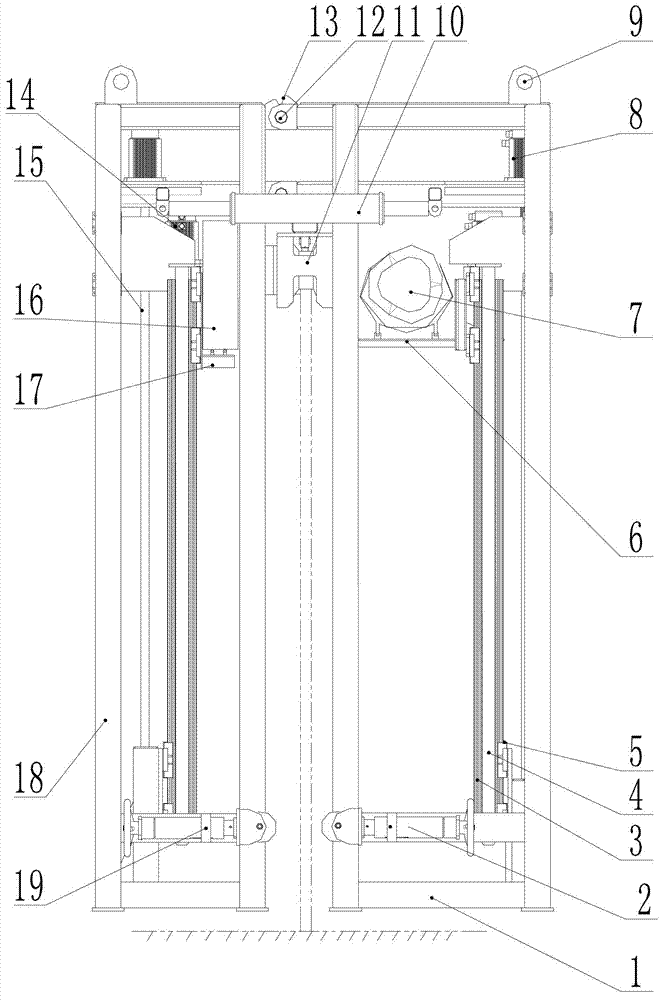

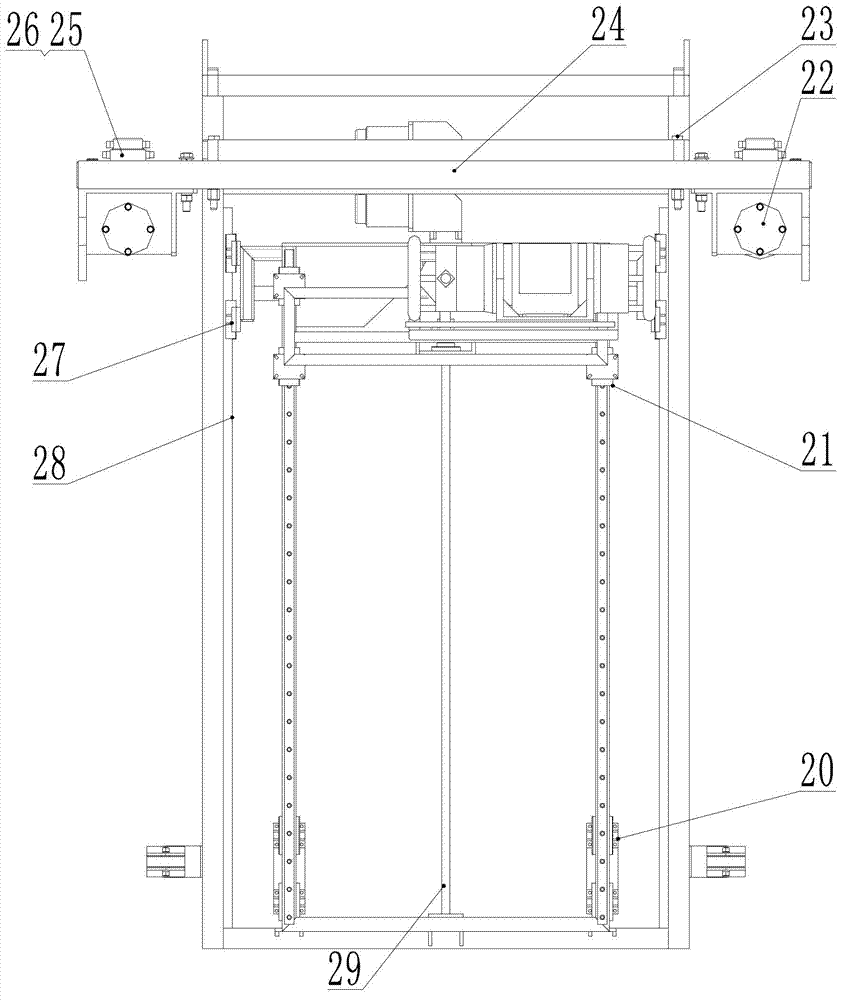

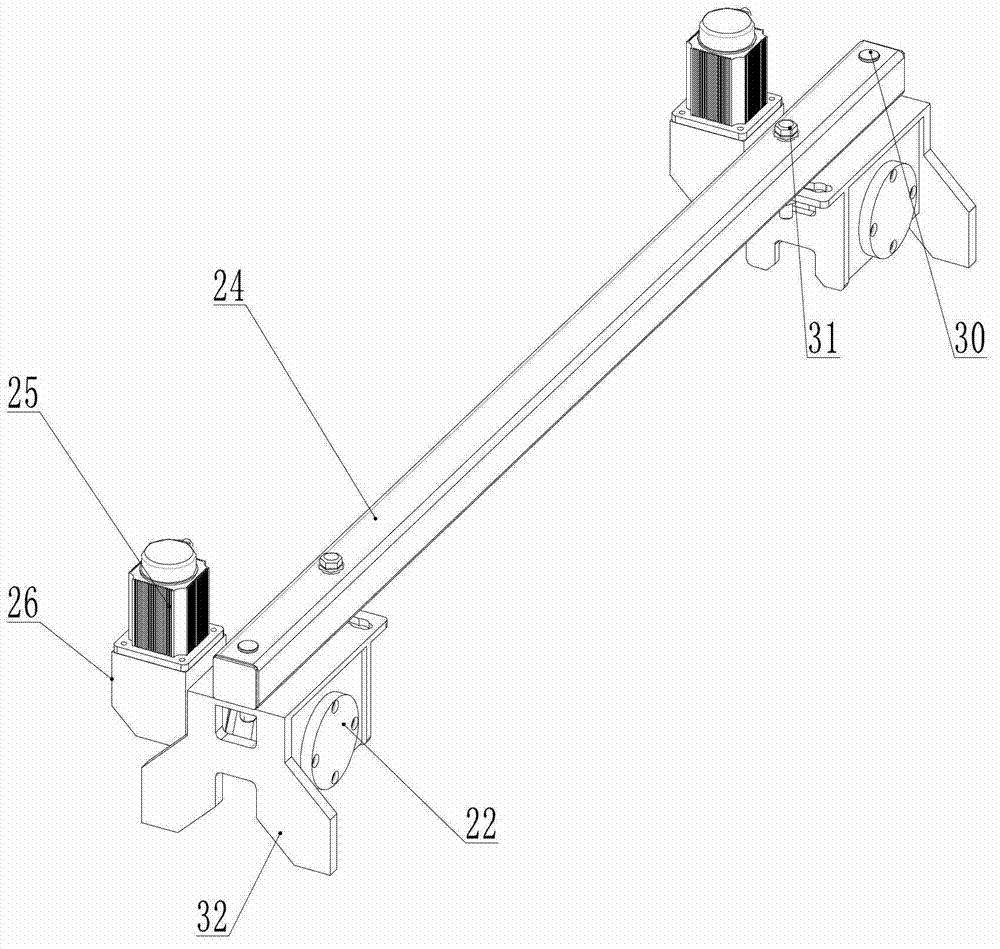

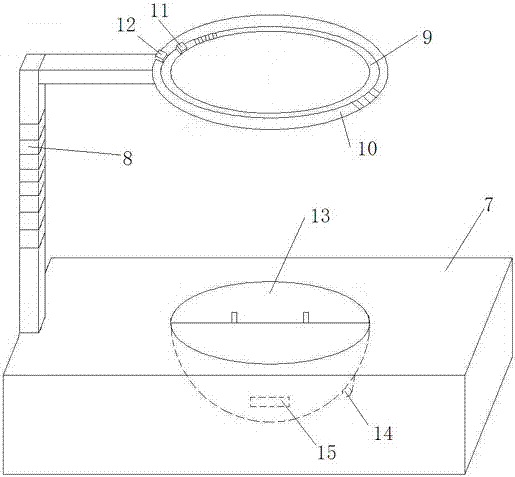

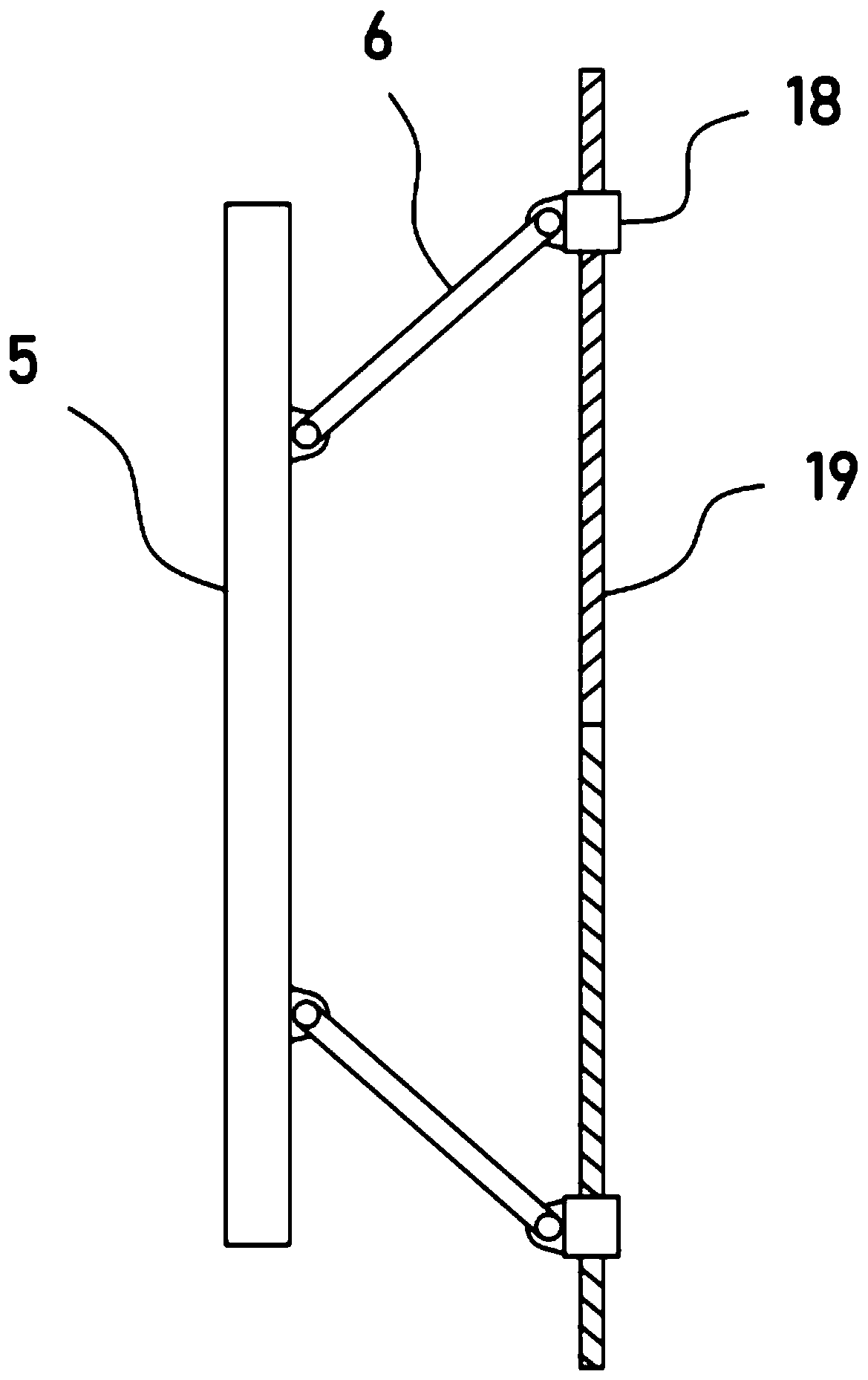

X-ray digital nondestructive detection device and method of welding seam of storage tank

ActiveCN103196928AReliable completionObjective completionMaterial analysis by transmitting radiationDigital imagingStructural engineering

The invention relates to an X-ray digital nondestructive detection device of a welding seam of a storage tank, and a detection method using the same, and mainly solves the problems of high flaw detection cost and influence on detection quality in the conventional X-ray film method. The device comprises a riding seat type gantry rack, movement guide mechanisms, a transverse movement mechanism, longitudinal movement mechanisms and a digital imaging system, wherein the riding seat type gantry rack consists of an outer rack and an inner rack; a mechanical buffer is arranged between the inner rack and the outer rack; the transverse movement mechanism is arranged at the upper end of the outer rack; two movement guide mechanisms are respectively arranged on the lower parts of the outer rack and the inner rack; and a longitudinal movement mechanism is respectively arranged on the opposite inner sides of the inner rack and the outer rack. The digital nondestructive detection on the welding seam of 0 to 3m through a digital imaging device and an X-ray flaw detector is realized by using each mechanism in the device and using a synchronization telescoping driving control method. The method is high in degree of automation, high in positioning accuracy and high in imaging speed; and the x-ray digital nondestructive detection on the welding seam of the storage tank can be reliably, objectively and accurately accomplished.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Laser real-time dynamic cladding repair and stress control system and method of damaged gears

ActiveCN107150175ACladding achievedTo achieve reinforcementMetal working apparatusLaser beam welding apparatusImpact systemControl system

The invention discloses a laser real-time dynamic cladding repair and stress control system of damaged gears. The system comprises an optical-infrared coupled dynamic monitoring and measuring system, a laser cladding system, a laser impact system and a clamping table respectively connected with a center control system; the cladding of cladding materials is realized through the heat effect of cladding laser; and impact waves generated by impacting on laser radiated materials are acted on the material surface of a laser cladding layer to realize reinforcement of the laser cladding layer and to eliminate such defects as air holes and loose structures generated in the cladding layer in the laser cladding process. The repair method is suitable for such failure forms as gear fatigue cracks, pitting, gear breakage and gear surface wear, and quickly realizes the shape recovery of gears through laser cladding repair without wasting classing materials; and through laser impact stress control, the defects generated in the laser cladding process are eliminated, the mechanical performances of the repaired gears are guaranteed, subsequent complicated machining is not needed, the repair efficiency is improved, and the gear repair cost is reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Big-diameter water supply and drainage pipeline inner wall desilting device

The invention discloses a big-diameter water supply and drainage pipeline inner wall desilting device, and relates to the technical field of water supply and drainage. The big-diameter water supply and drainage pipeline inner wall desilting device comprises a support frame, wherein a drainage hole corresponding to a pipeline is formed in the support frame; a horizontal plate is in driving connection on the support frame through a vertical reciprocating mechanism; a rotating mechanism extending to the inside of the pipeline is arranged on the horizontal plate; the rotating mechanism is connected with a scraping plate in abut joint with the inner wall of the pipeline through a regulating structure; a spray head facing the inner wall of the pipeline is arranged at the bottom of the rotating mechanism; and a spray head is connected with an external pressure water source. The scraping plate is driven to rotate through the installed rotating mechanism; the rotating scraping removal on sludgeon the inner wall of the pipeline is realized; meanwhile, through the installed vertical reciprocating mechanism, the scraping plate can be driven to do vertical reciprocating movement, so that the cleaning effect of the pipeline is more sufficient; the impact effect on the sludge on the inner wall of the pipeline is realized through the pressure water flow sprayed out from the installed spray head; the sludge cleaning speed is effectively accelerated; and the pipeline sludge cleaning operation is simple and efficient.

Owner:张超

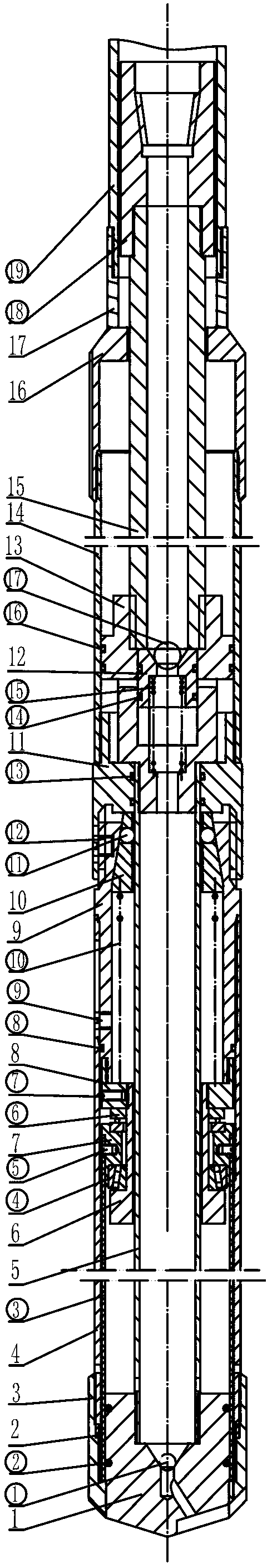

Novel hydraulic piston sampling machine tool

InactiveCN103226070AReduce drill wall thicknessFast sampling speedWithdrawing sample devicesHollow coreDrill bit

The invention discloses a novel hydraulic piston sampling machine tool. A piston drill bit is in screwed connection with the lower end of a hollow core rod. The upper end of the hollow core rod is in screwed connection with the lower end of an upper piston. The upper end of the upper piston is in screwed connection with the lower end of a main shaft. The main shaft is of a driving drill pipe structure which is in a hexagonal prism shape or flat. A torque transmission connector is arranged on the main shaft in a sleeved mode and can move in the axial direction of the main shaft relative to the main shaft. The torque transmission connector and the main shaft rotate synchronously together. The lower end of the torque transmission connector is in screwed connection with the upper end of a hydraulic cylinder body. The inner diameter of the torque transmission connector is larger than that of the hydraulic cylinder body. An inner cavity of the cylinder body is matched with the upper piston in a sliding and sealing mode. The lower end of the cylinder body is in screwed connection with the upper end of a movable piston. The lower end of the movable piston is in spline fit with the upper end of a taper sleeve, connected and limited through screws. The lower end of the taper sleeve is in spline fit with the upper end of an outer tube and connected and limited through screws. The lower end of the outer tube is in screwed connection with an outer drill bit. Static pressure sampling, static pressure + rotation sampling and impact sampling are achieved. The pumping effect of the bottom of a hole when a drill tool is lifted is eliminated. Hidden danger of dropping of samples when the drill tool is lifted is eliminated, and the novel hydraulic piston sampling machine tool has the advantages of being high in reliability of sampling and high in adaptability to formation conditions.

Owner:李国民 +4

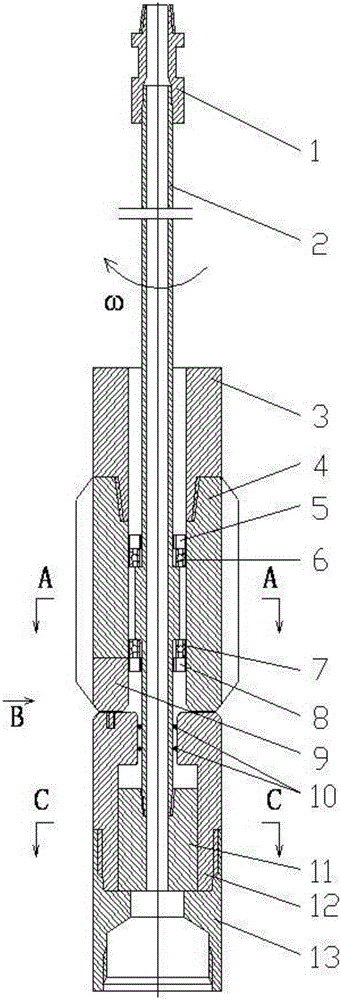

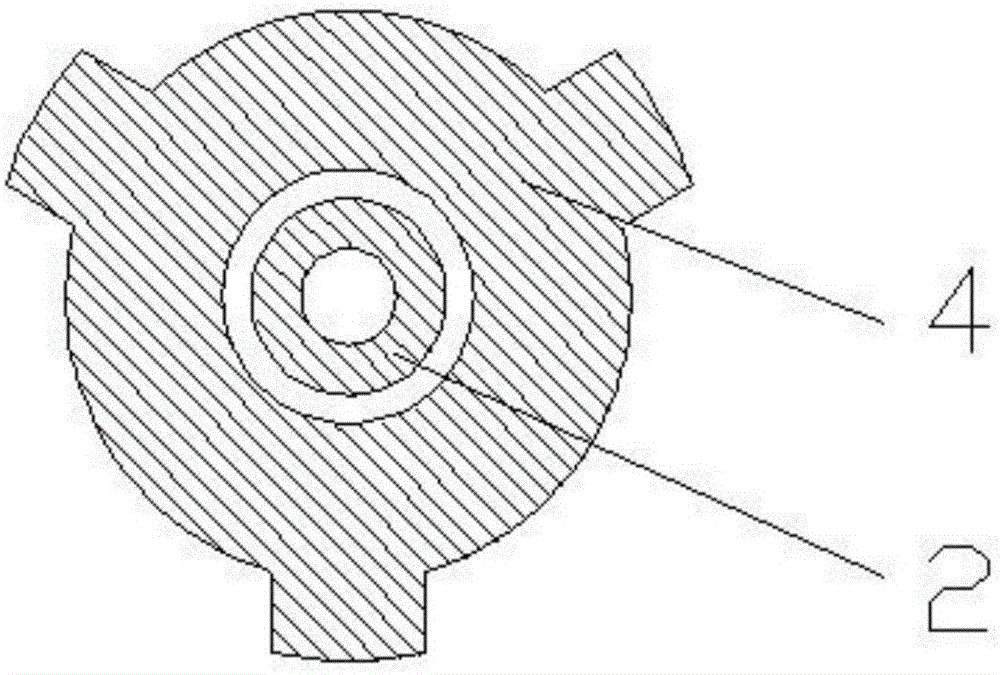

Ultrasonic vibration device for coaxial ultrasonic-assisted laser shot peening

ActiveCN110804692APromotes dynamic recrystallization behaviorImprove efficiencyMechanical vibrations separationVibration amplitudeUltrasonic vibration

The invention provides an ultrasonic vibration device for coaxial ultrasonic-assisted laser shot peening. The ultrasonic vibration device mainly comprises a vibration rod, an amplitude-change pole, piezoelectric ceramic, first optical glass and second optical glass, wherein through holes are formed in the centers of the vibration rod and the amplitude-change pole in the axial direction; the lowerend of the vibration rod is fixedly connected with the upper end of the amplitude-change pole; the first optical glass is positioned at the top of the vibration rod; the second optical glass is positioned at the bottom of the amplitude-change pole; the upper end of the vibration rod extends out of the upper surface of an upper shell and is fixedly connected with the upper surface of the upper shell; the piezoelectric ceramic is arranged on the vibration rod. According to the ultrasonic vibration device, after the piezoelectric ceramic is electrified, electric energy is converted into mechanical energy to generate ultrasonic waves, and amplification of mechanical vibration amplitude is achieved through the amplitude-change pole. The through holes formed in the centers of the vibration rod and the amplitude-change pole in the axial direction provide a propagation channel for laser, and coaxial propagation of ultrasonic vibration waves and laser shock waves is achieved. Coupling of the ultrasonic vibration waves and the laser shock waves in the propagation process is ensured, the dynamic recrystallization behavior of a material is promoted, and a metal part with an ultrafine grain surface is prepared.

Owner:JIANGSU UNIV

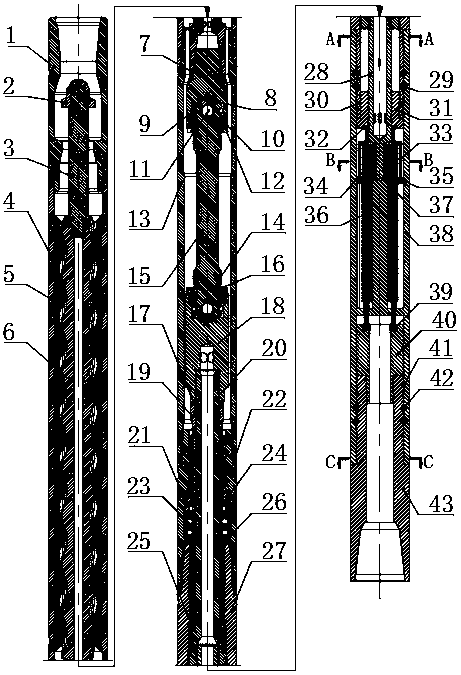

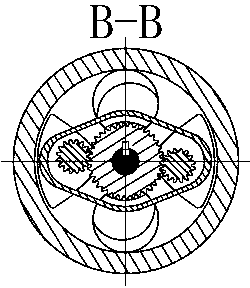

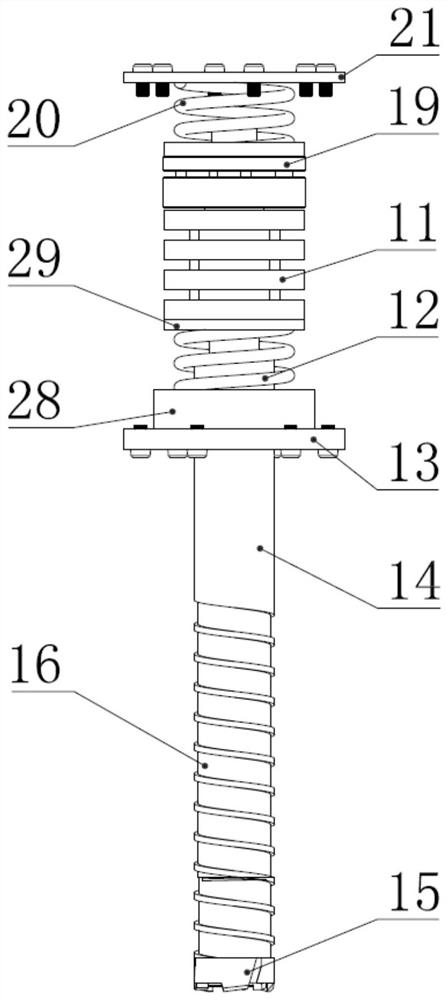

Screw rod type circumferential direction percussion drilling tool

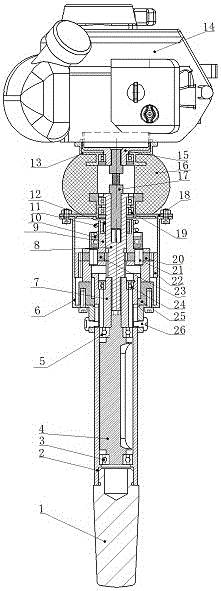

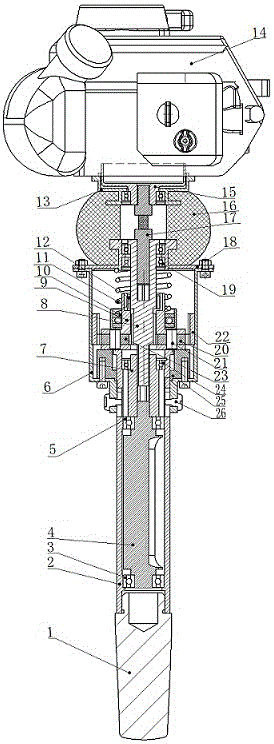

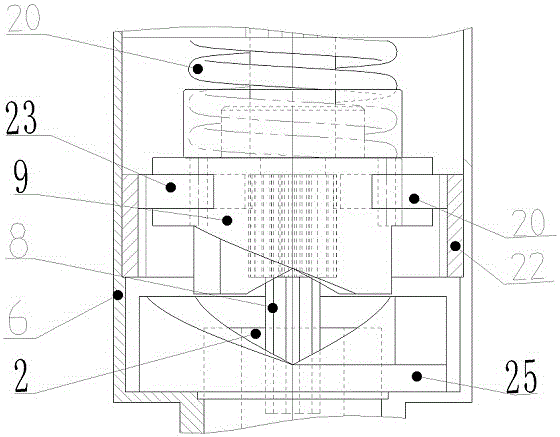

PendingCN108798503AReliable performanceRealize high-frequency impactDrilling drivesHydro energy generationDrill bitRock breaking

The invention provides a screw rod type circumferential direction percussion drilling tool. The stick-slip vibration phenomenon generated by a drill bit in the process of drilling is reduced. According to the technical scheme, the screw rod type circumferential direction percussion drilling tool is composed of a power assembly, a cardan shaft assembly, a drive assembly and an impact assembly, theupper portion of the power assembly is connected with a drilling rod, the lower portion of the power assembly is connected with the cardan shaft assembly, the drive assembly and the impact assembly insequence, and the lower portion of the power assembly is connected with the drill bit. When working, drilling fluid enters from the upper joint to a drive screw rod to rotate, contiguous screw rod transmission shafts and gear driving shafts are driven to rotate in sequence, and thus gears are driven to rotate. Through gear meshing, a percussion hammer is driven to rotate by a driven gear to crashand impact a shell body to generate an impact effect, and torsional vibration generated by the collision is transferred to the lower joint, finally is transferred to the drill bit to break up rocks.The screw rod type circumferential direction percussion drilling tool can generates torsional impact vibration continuously, the rock breaking efficiency of the drill bit is improved, the phenomenonsof sticking of tool and stick slipping generated are effectively reduced or even avoided, torque is balanced, the drill bit is protected, the service life of the drill bit is prolonged, and the drilling speed is increased.

Owner:SOUTHWEST PETROLEUM UNIV

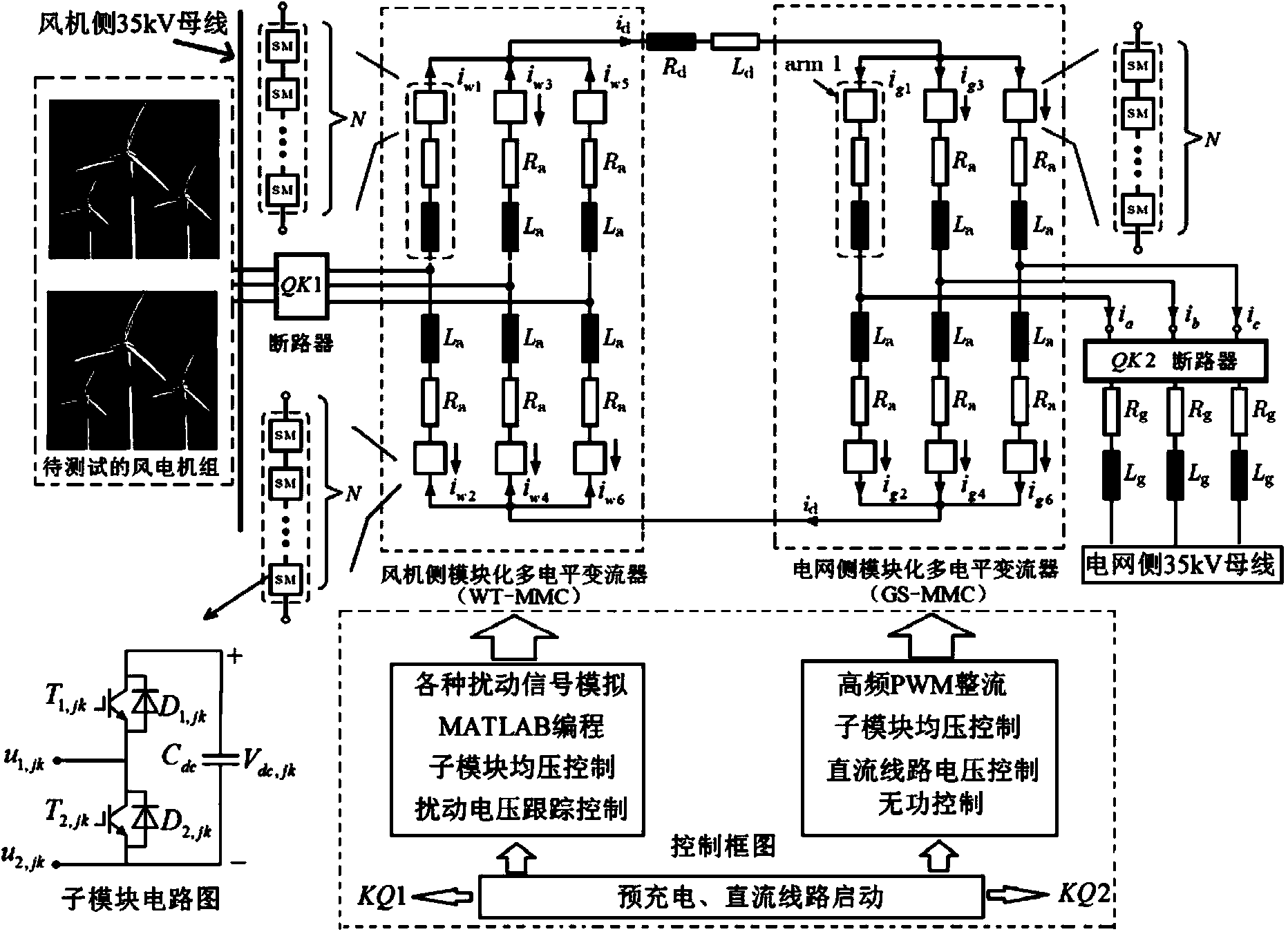

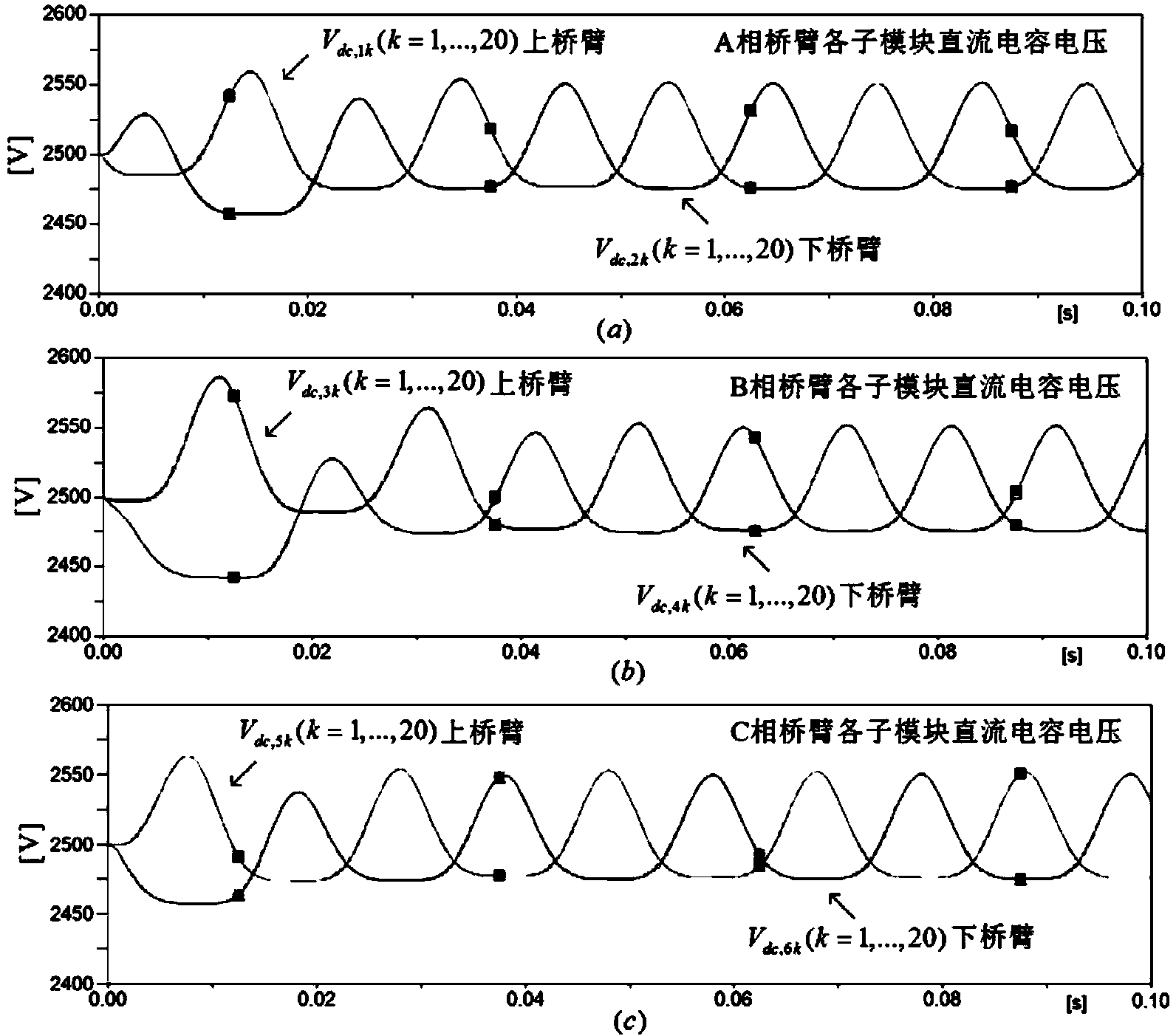

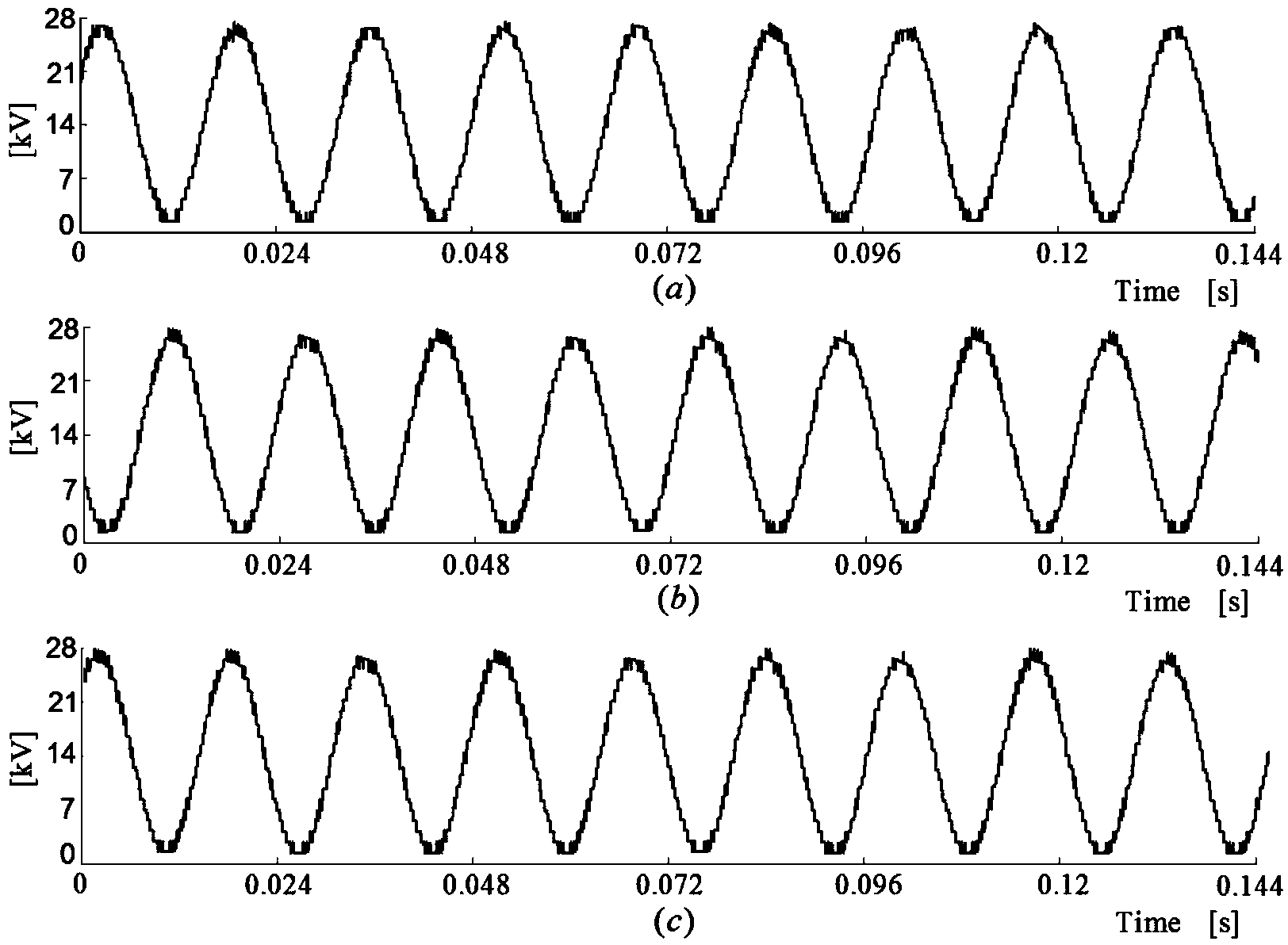

Device and method for testing power grid adaptability of wind power generating unit

InactiveCN103969578AMeet the requirements of dynamic characteristic testMeet diversityDynamo-electric machine testingTest powerTransformer

A device for testing power grid adaptability of a wind power generating unit comprises two modularized multi-level current converters in back connection, a disturbance generating module and a direct-current-charging starting module. The disturbance generating module comprises a software signal generating unit used for generating disturbance control signals and a control unit used for executing the control signals to generate disturbance signals, and the disturbance generating module is connected with the modularized multi-level current converter connected with a 35KV bus of the wind power generating unit. The device has the advantages that flexible simulation of various disturbances like voltage fluctuation, frequency hopping, voltage harmonic or three-phase unbalance and flickering of the wind power generating unit under a grid-connected voltage level; the modularized multi-level current converters are adopted, a transformer is not needed, and the device can be directly connected in a power grid, at a 35KV grid-connected voltage level, of a current wind power generating unit.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

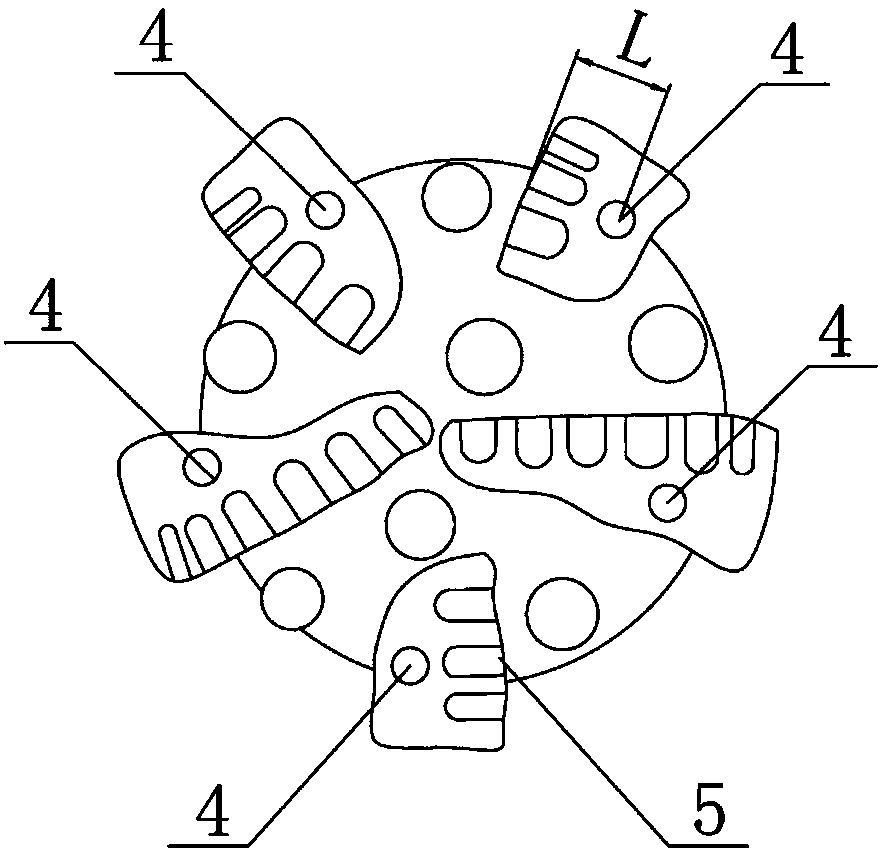

Impeller type differential torque impactor

ActiveCN108049803AResolve easily-caused obstaclesSolve the problem of encountering cardsBorehole drivesUpper jointEngineering

The invention provides an impeller type differential torque impactor, and solves the phenomenon of sticky slip and vibration produced by a drilling bit in a drilling process. The technical scheme of the impeller type differential torque impactor is that the impeller type differential torque impactor consists of an upper joint, a power assembly, an impact assembly and a lower joint, wherein the upper part of the upper joint is connected with a drilling rod while the lower part of the upper joint is connected with the power assembly; the power assembly produces high-speed rotation motion under an impact effect of drilling fluid so as to drive a flange transmission shaft to be rotated; the flange transmission shaft drives an eccentric impact hammer to be rotated at high speed through a transmission shaft and a transmission pin and also drives an outer gear to be rotated, the outer gear is meshed with an inner gear shell, and lower rotation speed is transmitted to the inner gear shell, sothat an impact transmission shaft is driven to be rotated at lower rotation speed, a rotation speed difference between the impact transmission shaft and an eccentric impact block is formed, and an impact effect is produced to transmit torsional vibration produced by collision to the lower joint through the impact transmission shaft. According to the impeller type differential torque impacter disclosed by the invention, torsional impact and vibration can be continuously produced, so that the rock breaking efficiency of the drilling bit is improved, and the phenomenon of drilling sticking and sticky slip can be effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV +2

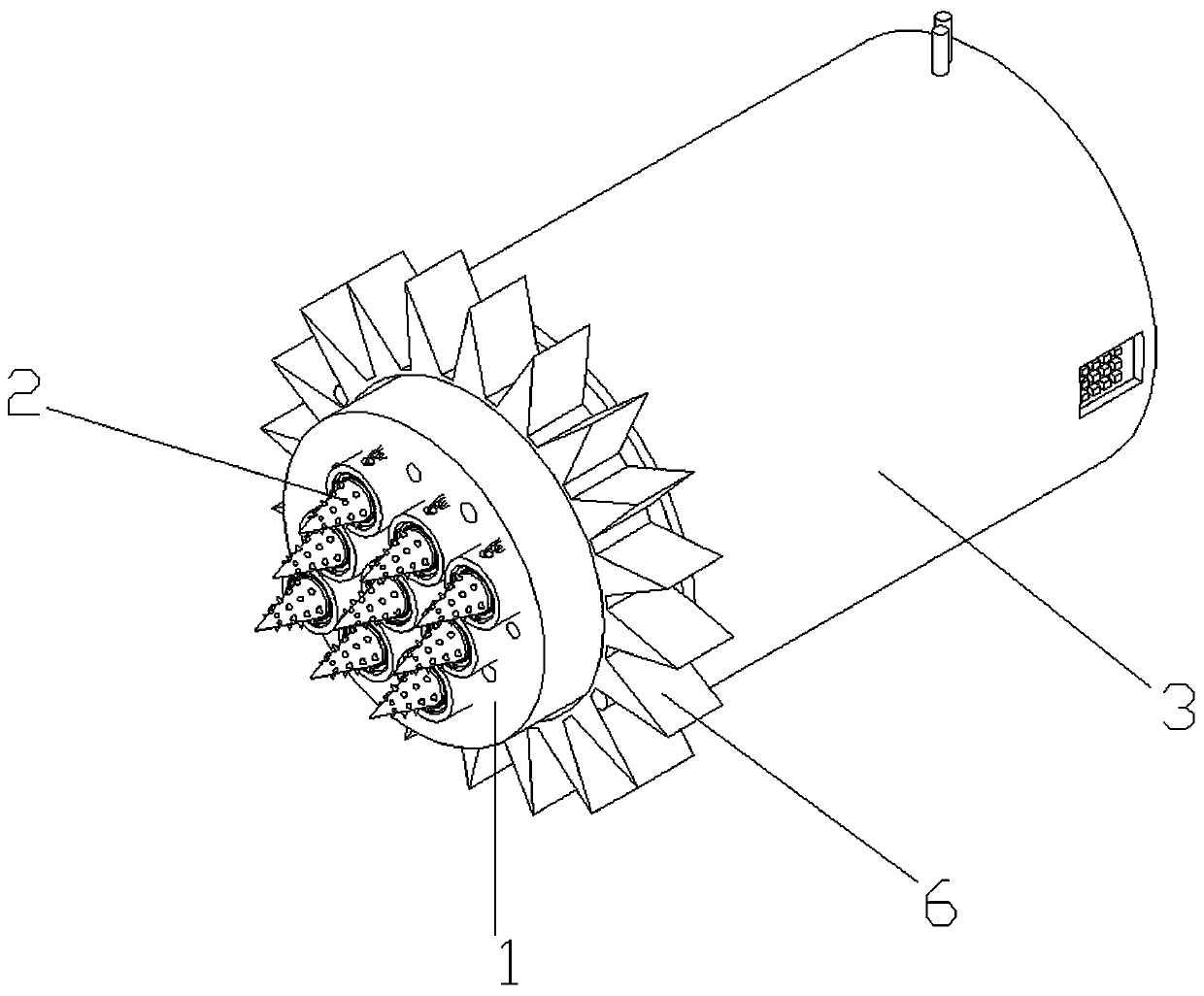

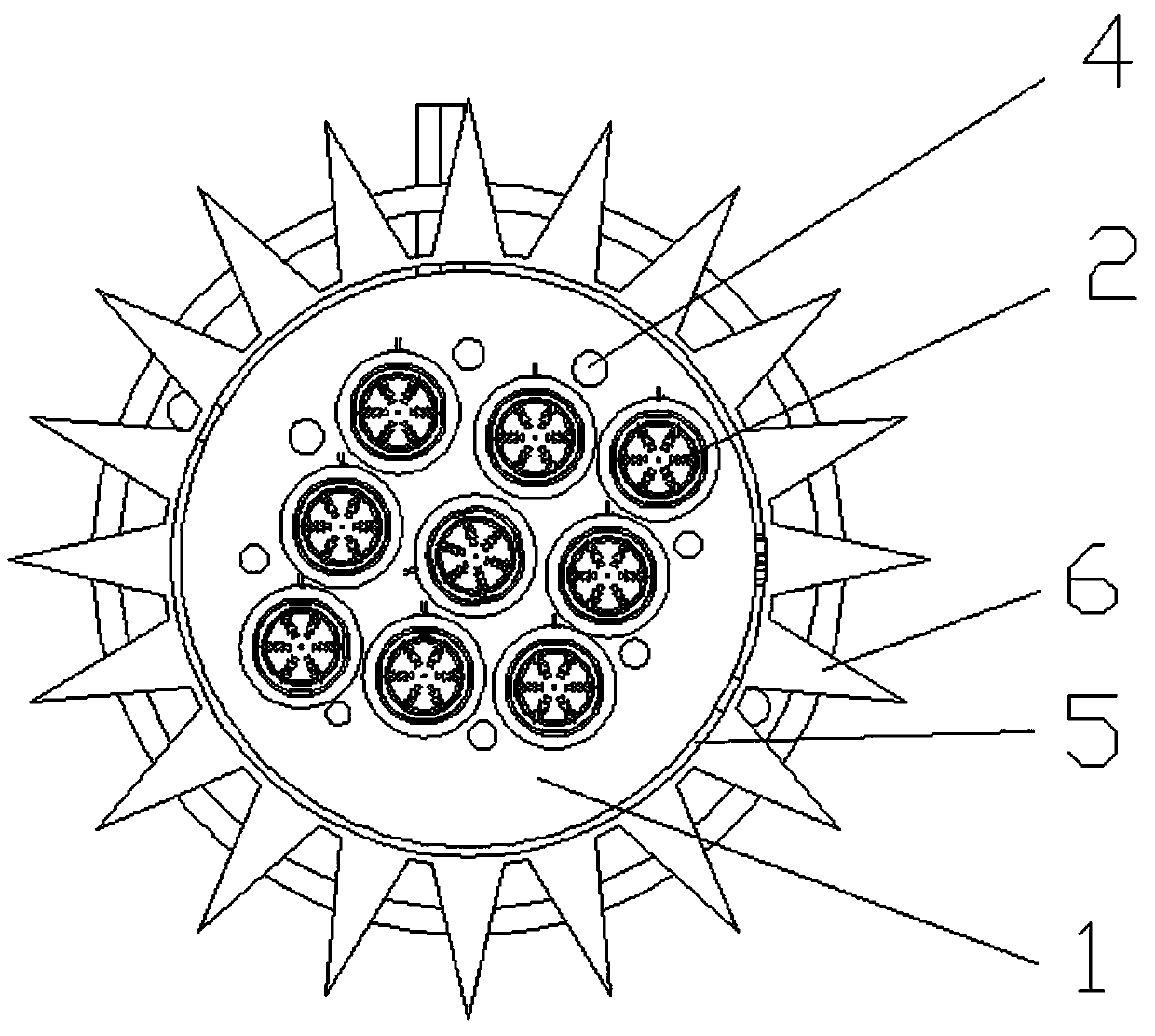

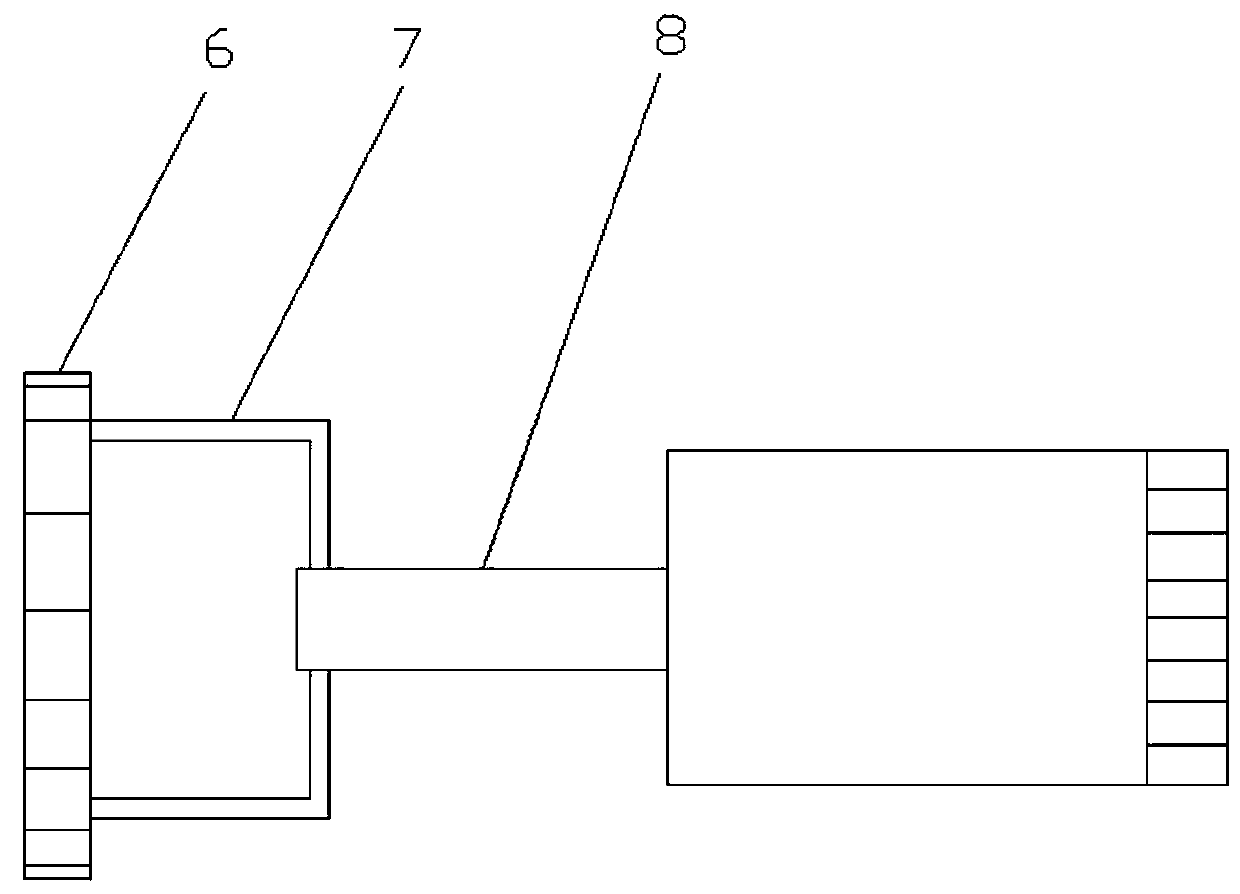

Electromagnetic impulsive rock breaking and drilling device and application method

The invention discloses an electromagnetic impulsive rock breaking and drilling device and an application method. The device comprises a mounting disc. A plurality of drill bit mechanisms are arrangedon one side of the mounting disc, the other side of the mounting disc is fixedly connected to the end part of a shield, and each drill bit mechanism comprises a mounting barrel fixedly arranged in the mounting disc, and a self-rotating drill bit capable of moving front and back is arranged in the mounting barrel. In addition, the invention discloses the application method corresponding to the device. The device solves the problem that an existing rock breaking technique is insufficient in safety, pollutes the environment and is low in efficiency, and meanwhile, achieves impulsive rock breaking and rotary drilling functions.

Owner:CHINA THREE GORGES UNIV

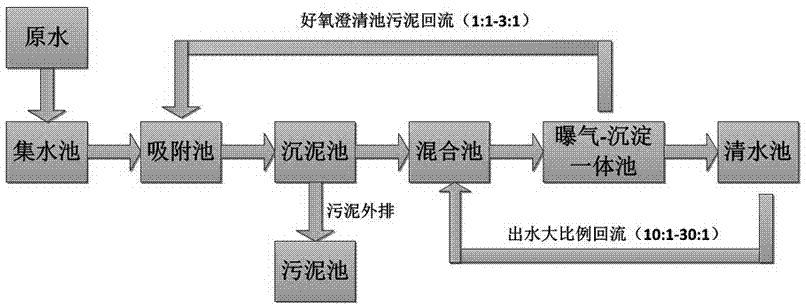

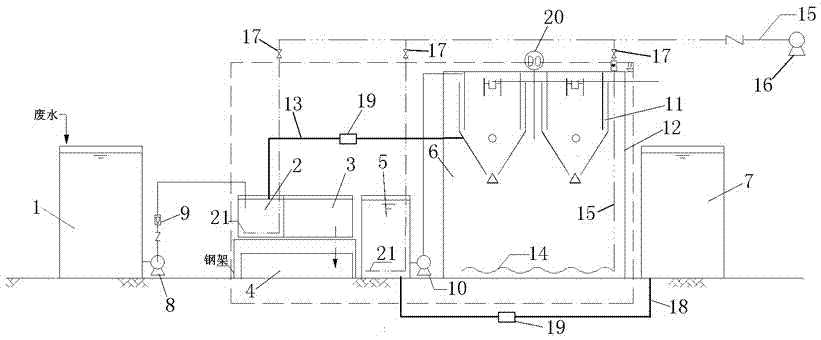

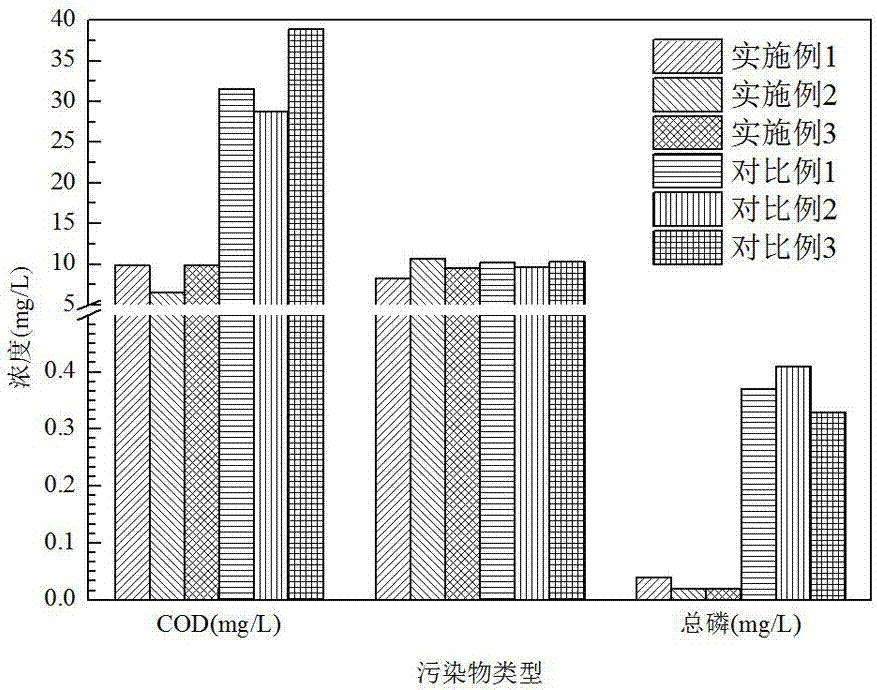

Efficient short-range internal-recycle integrated bioreactor with synchronous denitrifying function

PendingCN107311410ASmall footprintLess investmentOther chemical processesWater contaminantsSludgeWastewater

The invention discloses an efficient short-range internal-recycle integrated bioreactor with a synchronous denitrifying function. The efficient short-range internal-recycle integrated bioreactor with the synchronous denitrifying function comprises a water collecting tank, and a water inlet of the water collecting tank is communicated with a wastewater outlet. The efficient short-range internal-recycle integrated bioreactor is provided with the water accumulation tank, an adsorption tank, a settling tank, a mixing tank, an aerating-aerobiotic clarifying system and a clean water tank along a wastewater purifying direction, a first wastewater lifting pump is arranged between the water collecting tank and the adsorption tank, a second wastewater lifting pump is arranged between the mixing tank and the aerating-aerobiotic clarifying system, the settling tank is communicated with a sludge tank, the aerating-aerobiotic clarifying system comprises an aerobiotic three-phase separator and an aerating clarifying tank, the aerobiotic three-phase separator is arranged inside the aerating clarifying tank and communicated with the adsorption tank through a sledge backflow pipe, an aerating hose is arranged at the bottom of the aerating clarifying tank and connected with a fan through an air pipe, and a first electrically-controlled flow valve is arranged on the air pipe. The efficient short-range internal-recycle integrated bioreactor with the synchronous denitrifying function has the advantages that technological processes are simplified greatly, about 1 / 3 of floor space of a sewage treatment facility is saved, investment on pipelines is reduced, and convenience in operation and management and simplicity in controlling are realized.

Owner:江西夏氏春秋环境研究院有限公司

Mechanical drilling impactor

InactiveCN105019824APrevent suctionRealize purely mechanical impactBorehole drivesPush upsHigh pressure

The invention provides a mechanical drilling impactor comprising at least a drilling rod and a drilling rod joint. An upper part of the drilling rod is sleeved with an impact unit. A lower part of the drilling rod is provided with a transmission unit. The transmission unit comprises an external hexagonal joint, an inner hexagonal joint, a conversion joint and an O-type sealing ring. The impact unit comprises an impact hammer, a bearing and a shifting block. When the shifting block rotates to a notch of an inclined surface of the impact hammer, the impact hammer falls under the effect of gravity and then impacts the inner hexagonal joint and the conversion joint. Then the shifting block continues rotating. When the shifting block rotates out of the notch of the inclined surface, the shifting block pushes up the impact hammer. The provided drilling impactor powered by rotation of the drilling rod has following advantages: simple structure and easy operation. The operation of the impactor is not impacted by factors such as flushing fluid flow or sand content. The impactor is not provided with easily damaged parts such as springs and impact energy of the impactor is adjustable. The impactor can be widely applied in environment such as deep hole, high temperature or high pressure. By use of the impactor, drilling efficiency and drilling quality are increased; drilling cost and construction period are reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

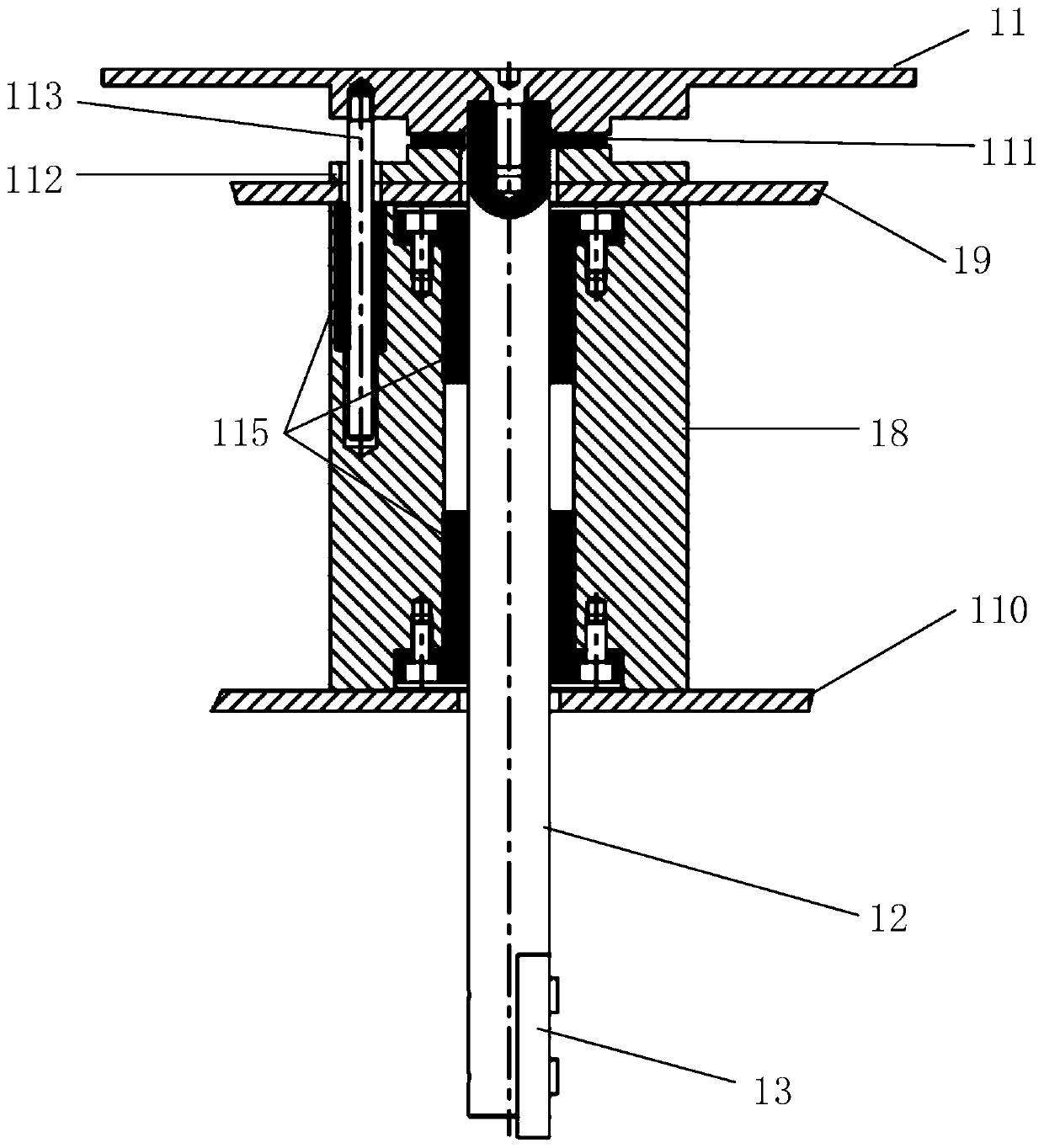

Automatic tap density measuring device

PendingCN109883883AAffects the ranging scan processAccurate settingSpecific gravity measurementVertical vibrationAuto regulation

The invention discloses an automatic tap density measuring device. The automatic tap density measuring device comprises a vibration mechanism, a ranging scanning device and a control system, wherein acapacitor is arranged on the vibration mechanism; the vibration mechanism is used for applying vertical vibration action on powder particles in the container; the ranging scanning device is arrangedabove the vibration mechanism; the ranging scanning device is used for ranging and scanning the powder surface in the container; and the control system is used for performing automatic control and data acquisition on the vibration mechanism and the ranging scanning device. The automatic tap density measuring device can automatically adjust the vibration amplitude, frequency and vibration times andmonitor the changing process of powder piling density, thereby improving the measuring accuracy of the tap density and the automatic level of the operation process.

Owner:SOUTH CHINA AGRI UNIV

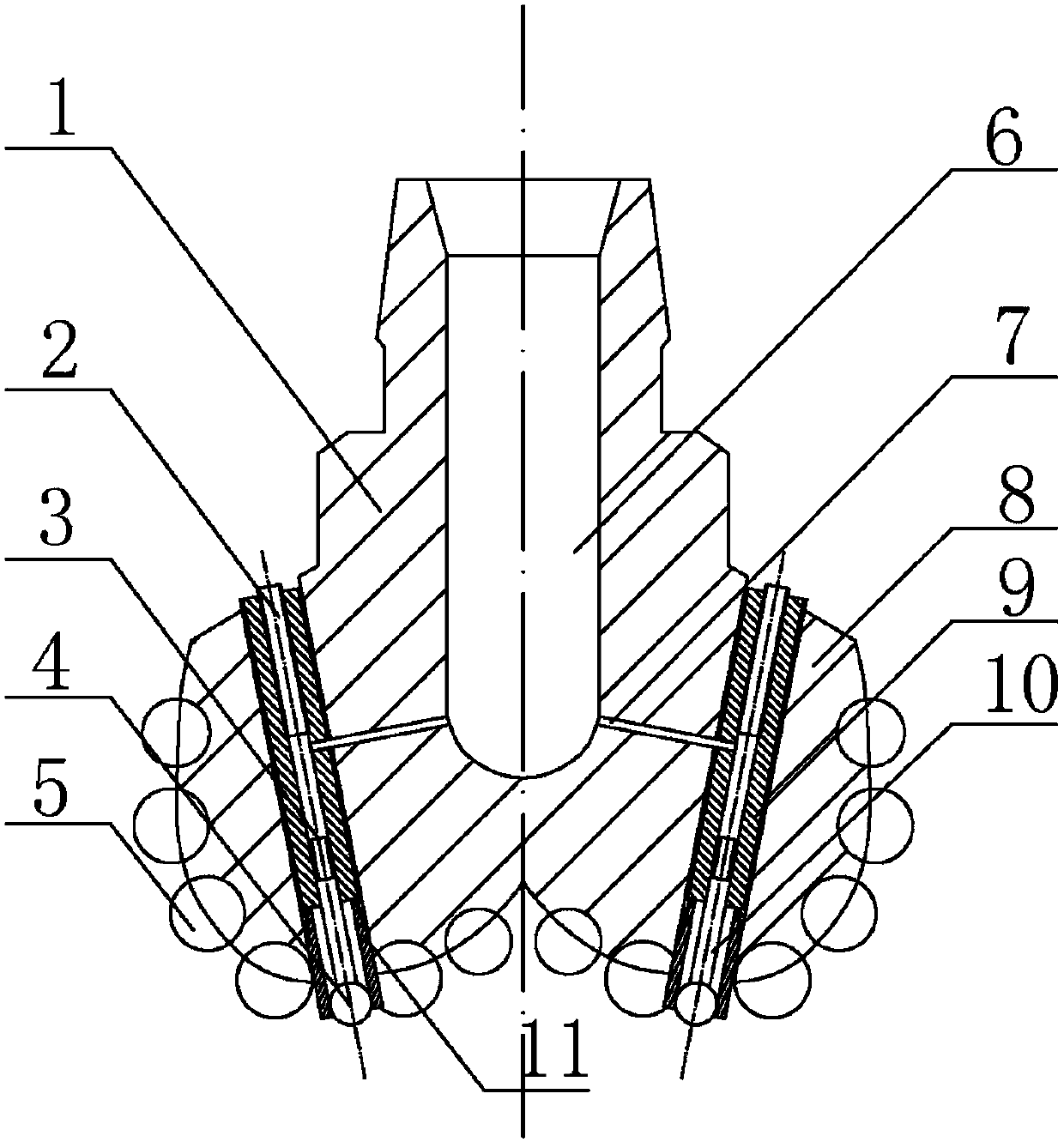

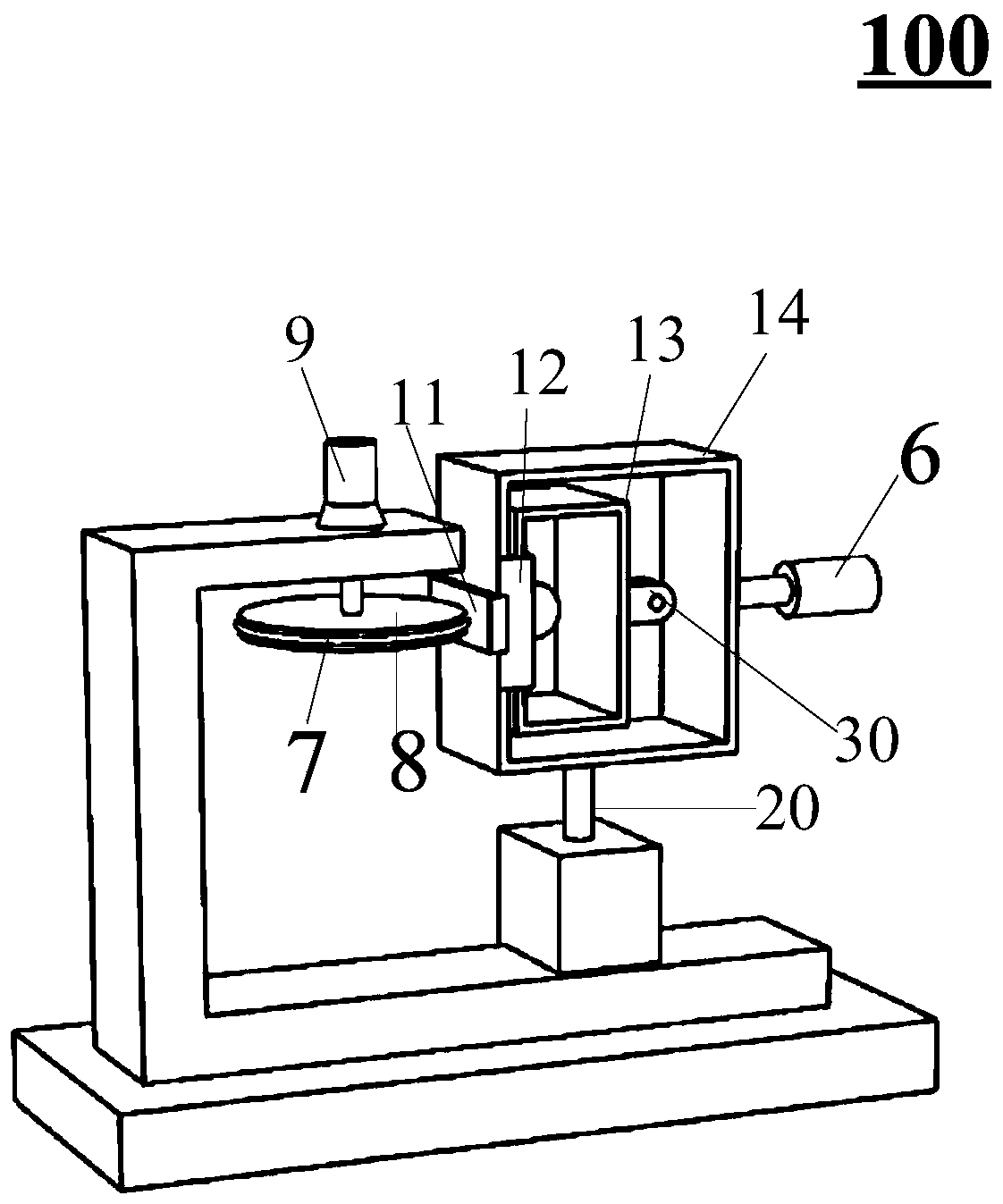

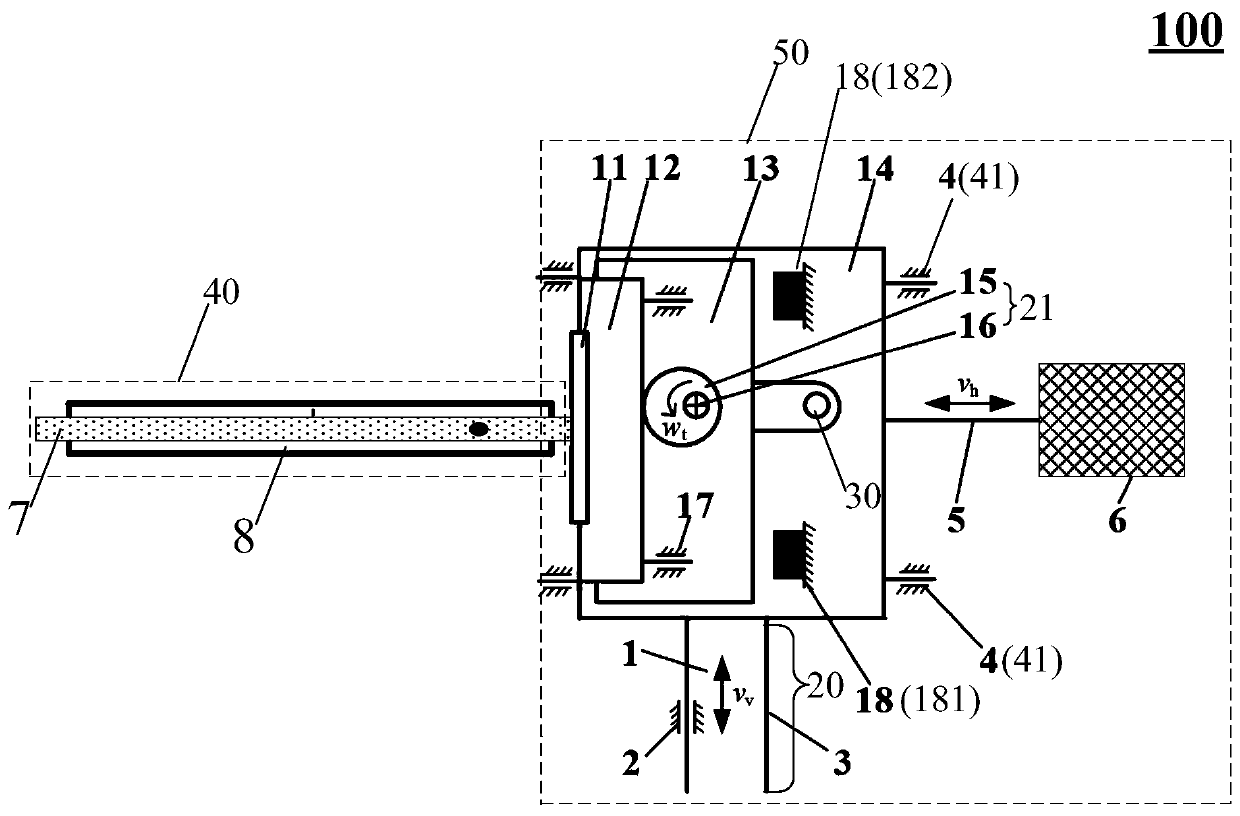

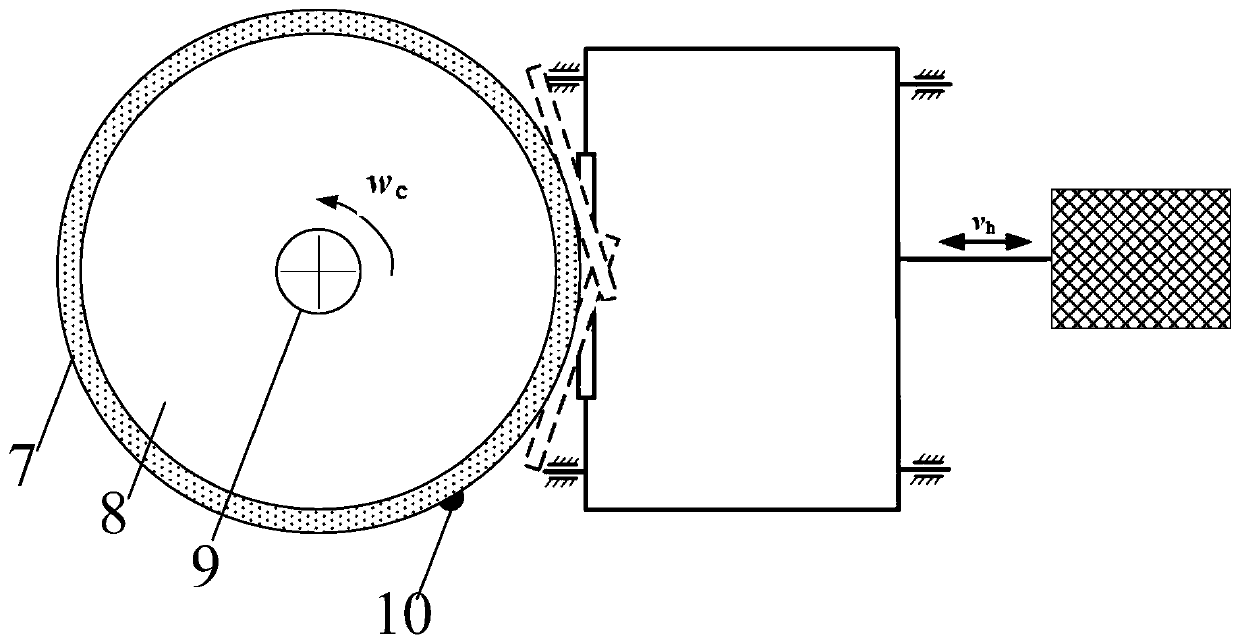

Variable-angle ultrasonic impact test device and method

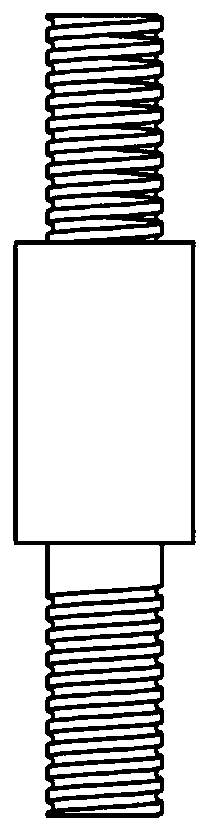

ActiveCN111537174ARealize impactImplement wear testMaterial strength using single impulsive forceShock testingEngineeringAcoustics

The invention provides a variable-angle ultrasonic impact test device and a variable-angle ultrasonic impact test method. The device comprises a supporting table, a pre-pressing plate, a Langevin vibrator and an impact carrying table. A threaded hole is formed in the middle of each surface of the upper end of the supporting table; the pre-pressing plate is incompletely fixed in the threaded hole through a bolt; the pre-pressing plate is used for supporting the Langevin vibrator, the Langevin vibrator achieves adjustment of multiple impact attack angles within the range of 0-180 degrees on thesupporting table, different friction materials are pasted to the impact area at the lower end of an amplitude-change pole and the upper surface of the impact carrying table respectively or simultaneously, and ultrasonic impact fatigue or abrasion tests of different types of friction materials are achieved.

Owner:JIANGSU UNIV

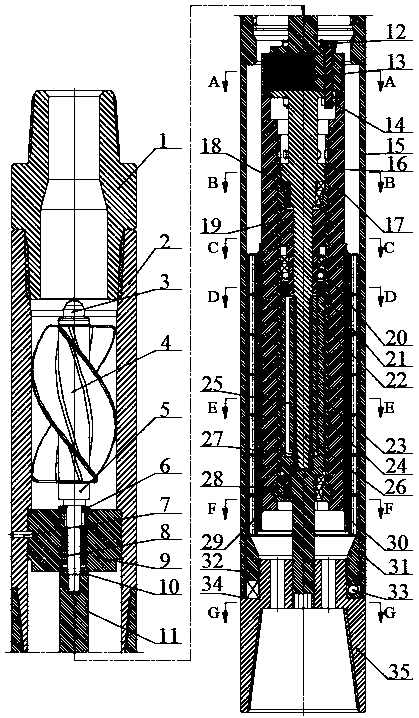

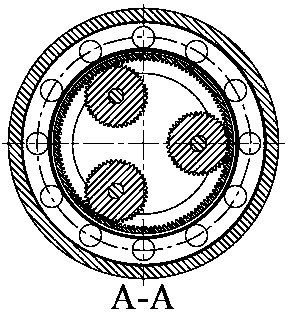

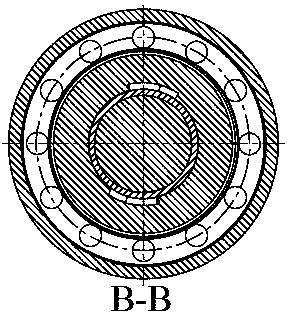

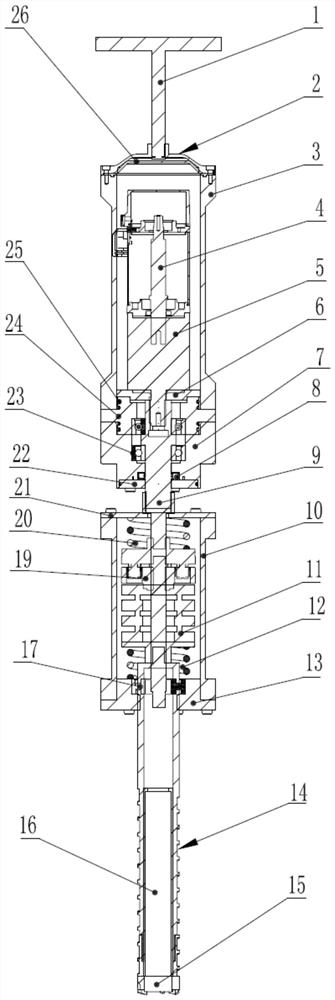

Percussion drill for deep sea vehicle rock core sampling

ActiveCN112780205ARealize impactImprove energy consumption ratioUnderwater drillingCore removalDC - Direct currentRock core

The invention relates to deep sea geology rock core sampling, in particular to a percussion drill for deep sea vehicle rock core sampling. The percussion drill comprises a power rotation unit and an impact unit, and further comprises a vibration generation unit located between the power rotation unit and the impact unit; and the power rotation unit comprises a rear sealing cover, a pressure-resistant shell, a brushless direct current motor, a speed reducer, a front sealing cover, a transmission shaft and a deep sea oil filling compensation diaphragm, the front sealing cover and the rear sealing cover are fixed to the front end and the rear end of the pressure-resistant shell correspondingly, the rear sealing cover, the pressure-resistant shell and the front sealing cover form a closed cavity, the brushless direct current motor, the speed reducer and the transmission shaft are all arranged in the cavity, an output shaft of the brushless direct current motor is connected with the speed reducer, and the transmission shaft is connected with an output shaft of the speed reducer. Rock can be broken by means of high-frequency impact movement under low drilling pressure and low drilling power consumption, and the drilling efficiency of the drill is greatly improved.

Owner:NAT DEEP SEA CENT +1

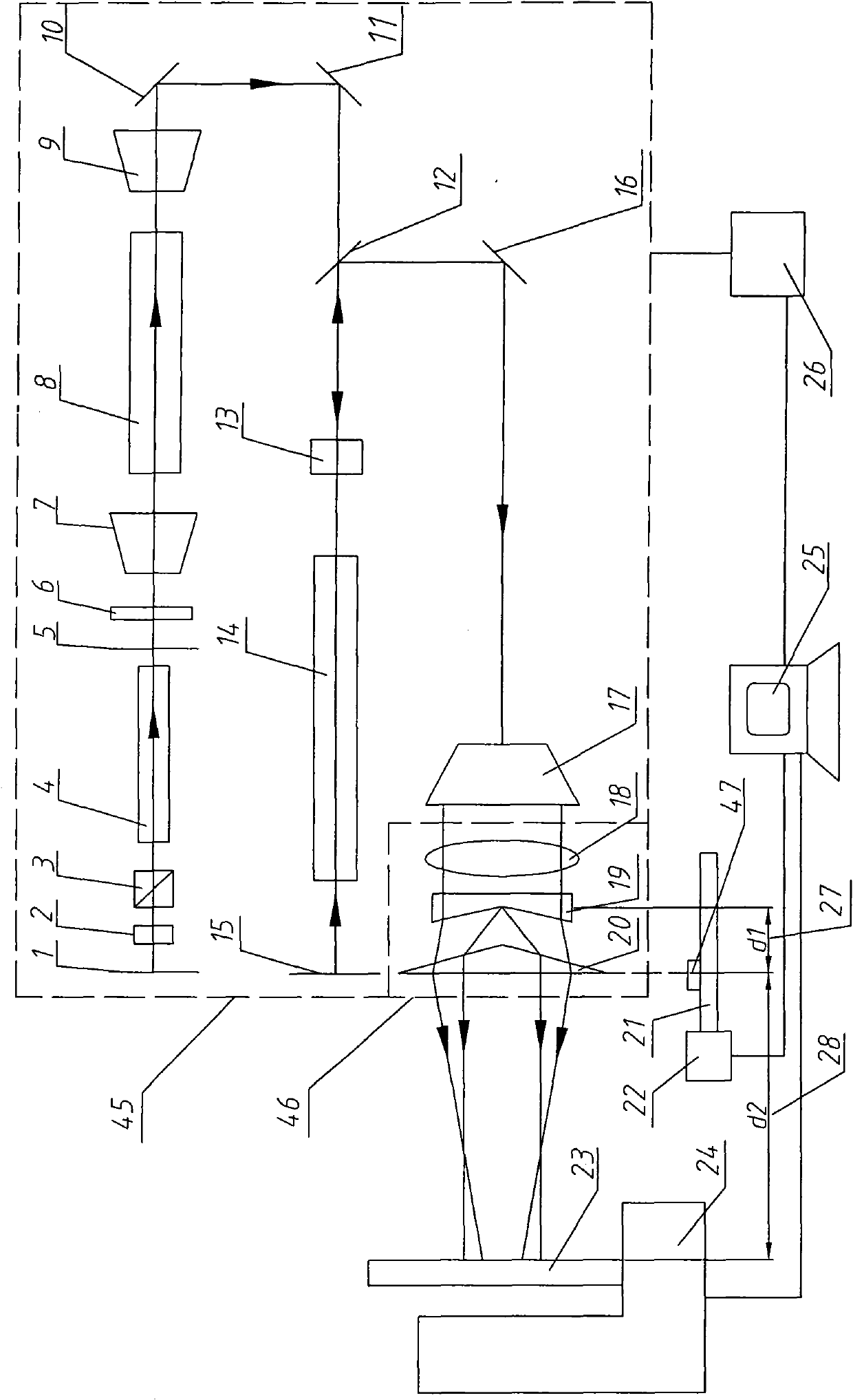

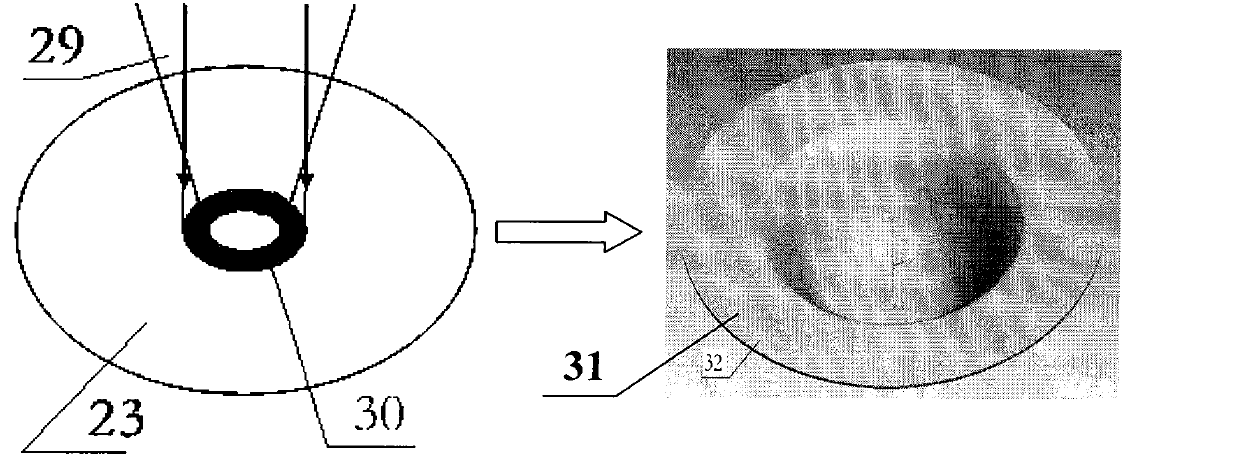

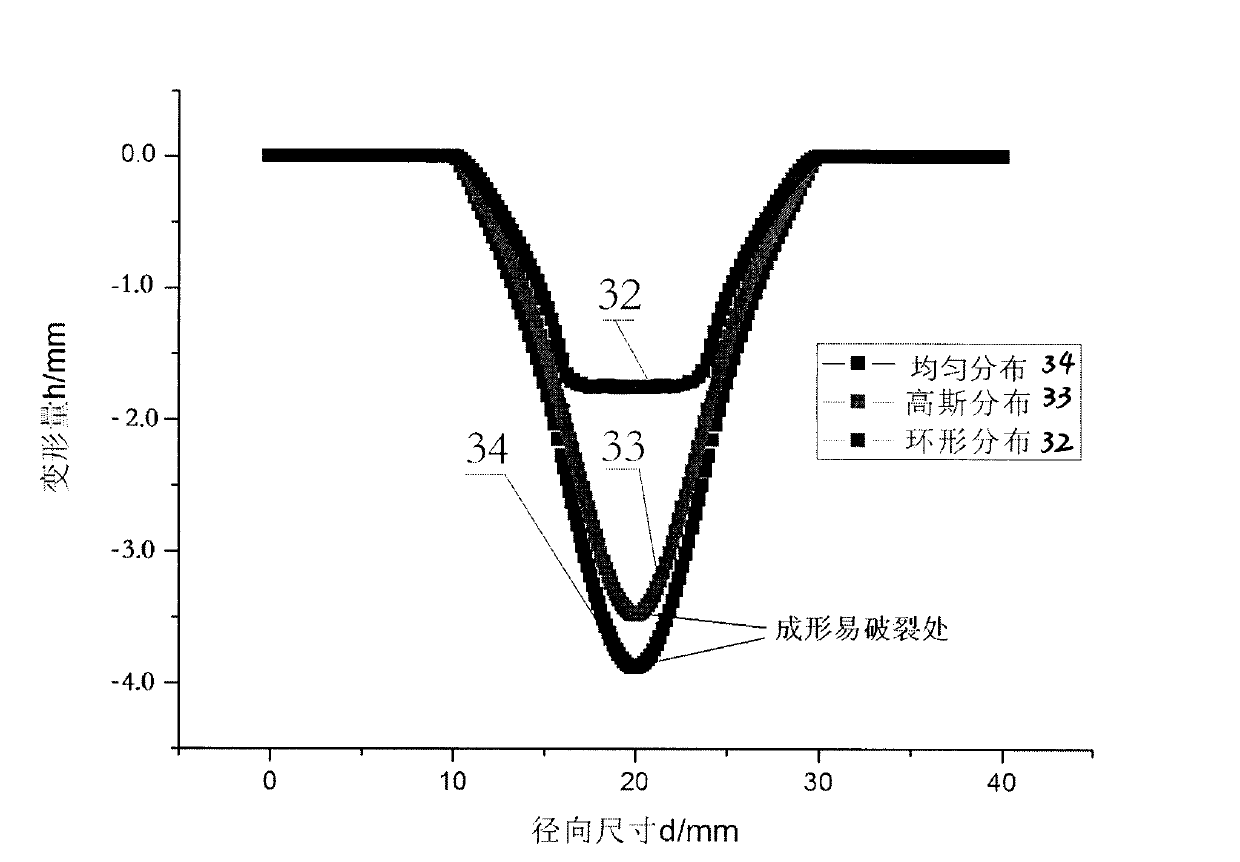

Metal plate material ring-shaped light spot laser impact forming method and device

Owner:JIANGSU UNIV

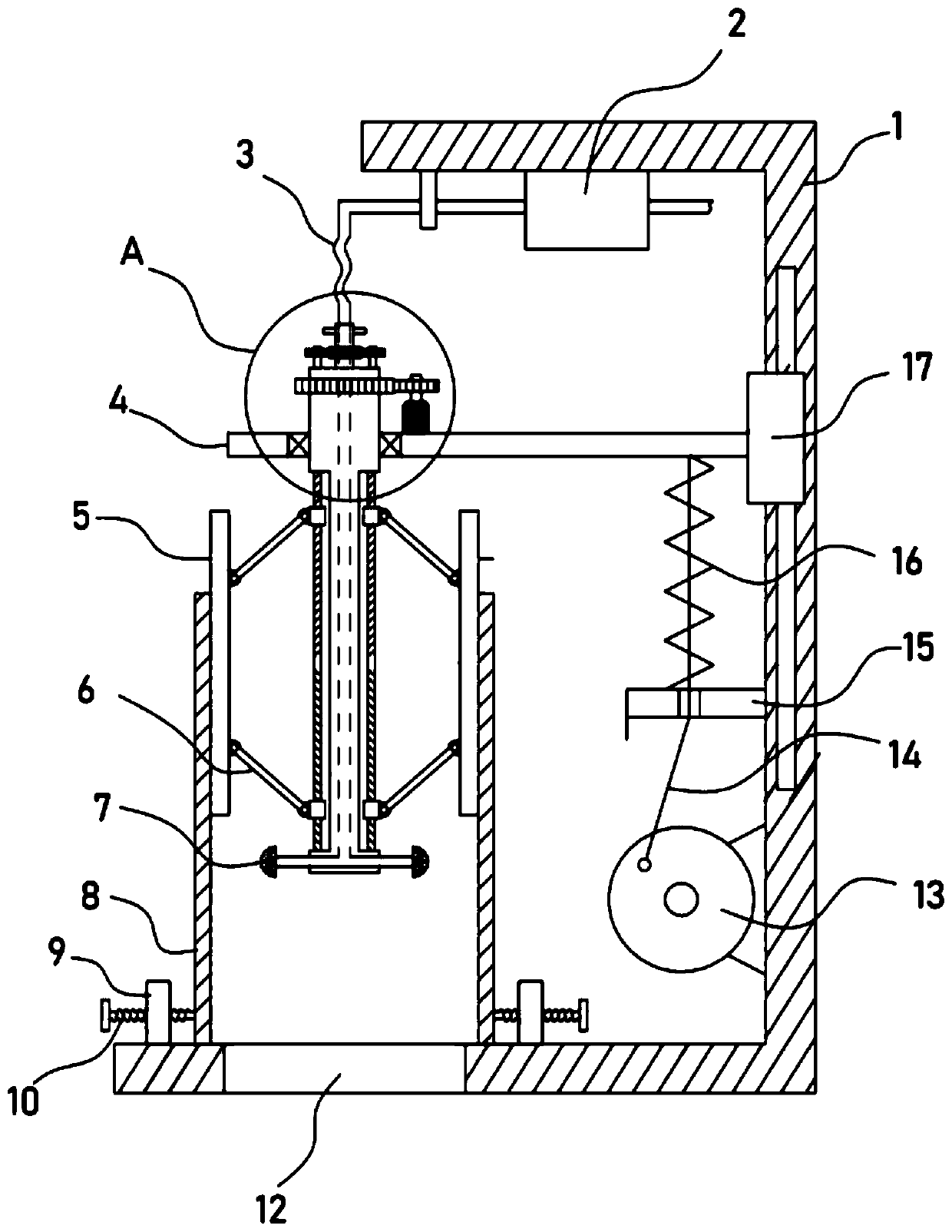

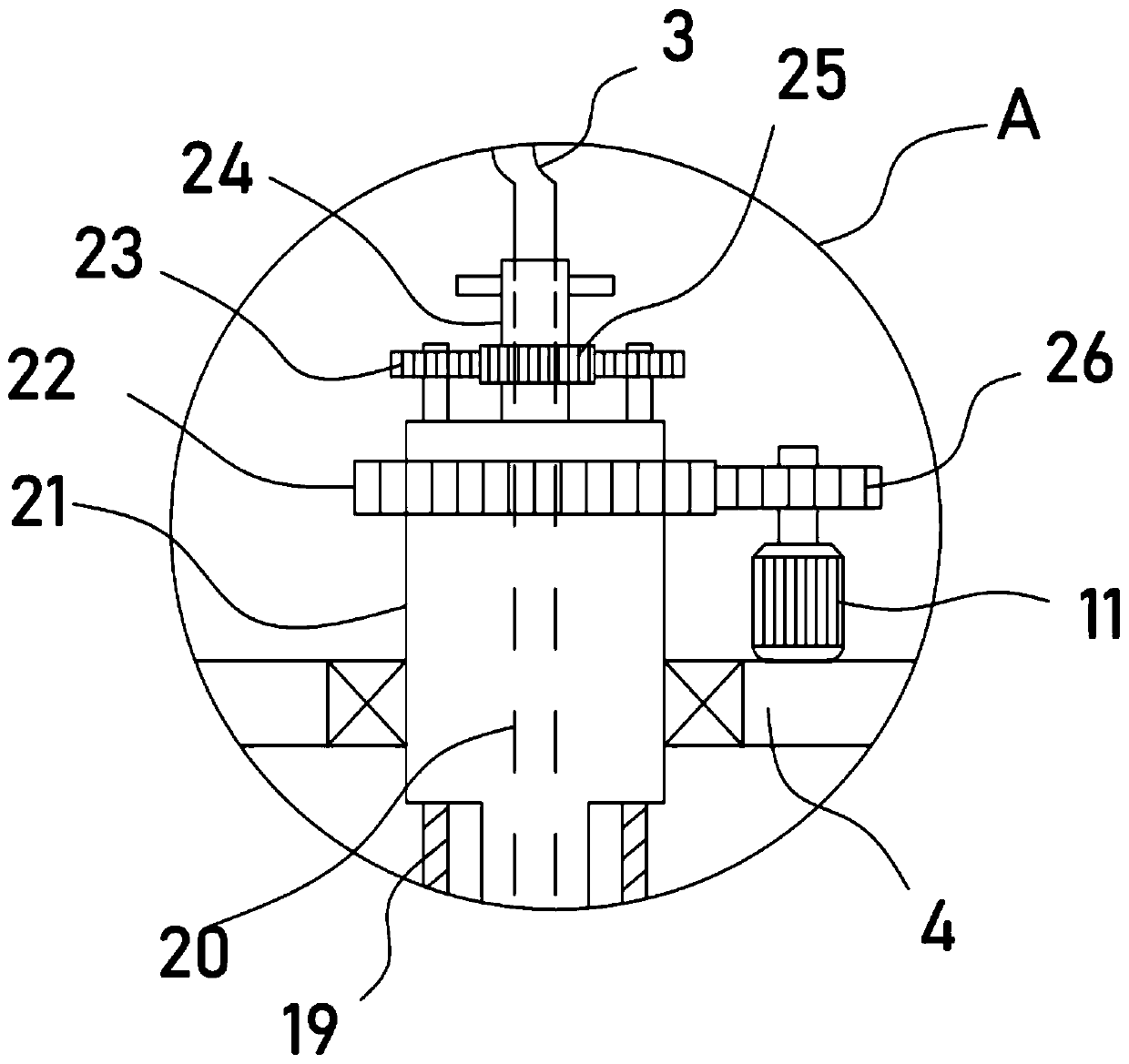

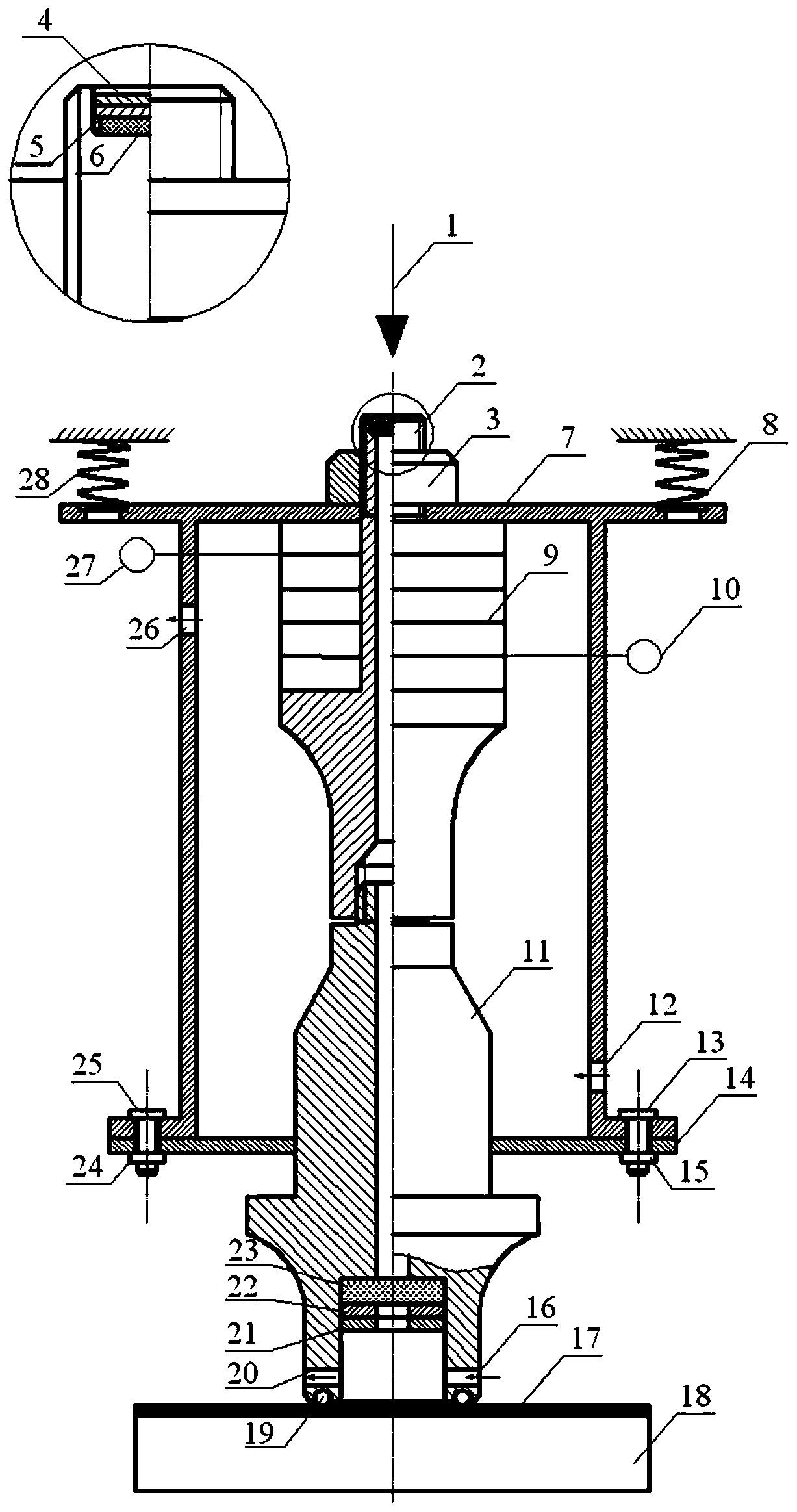

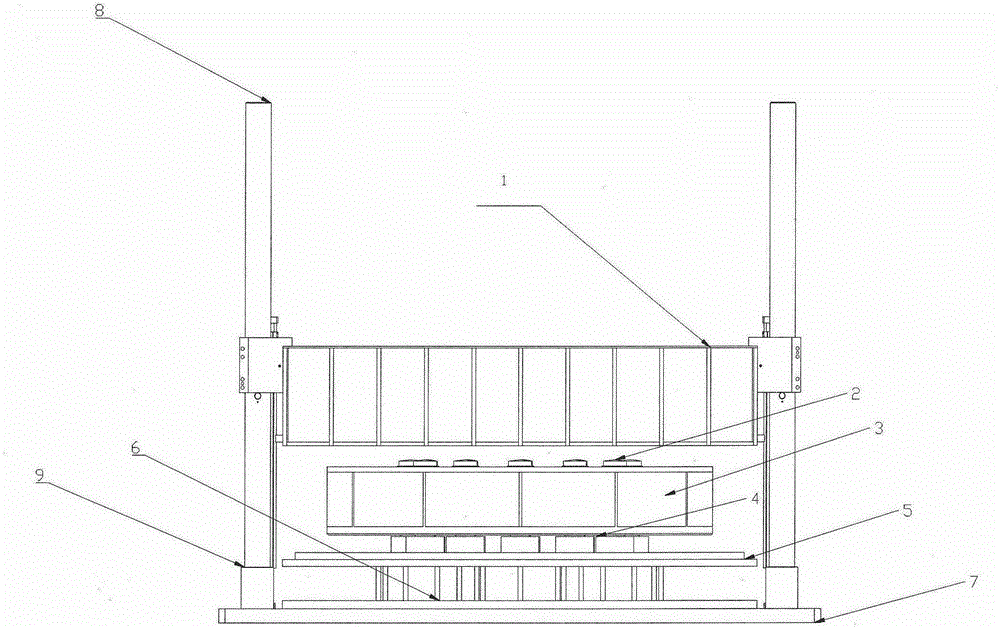

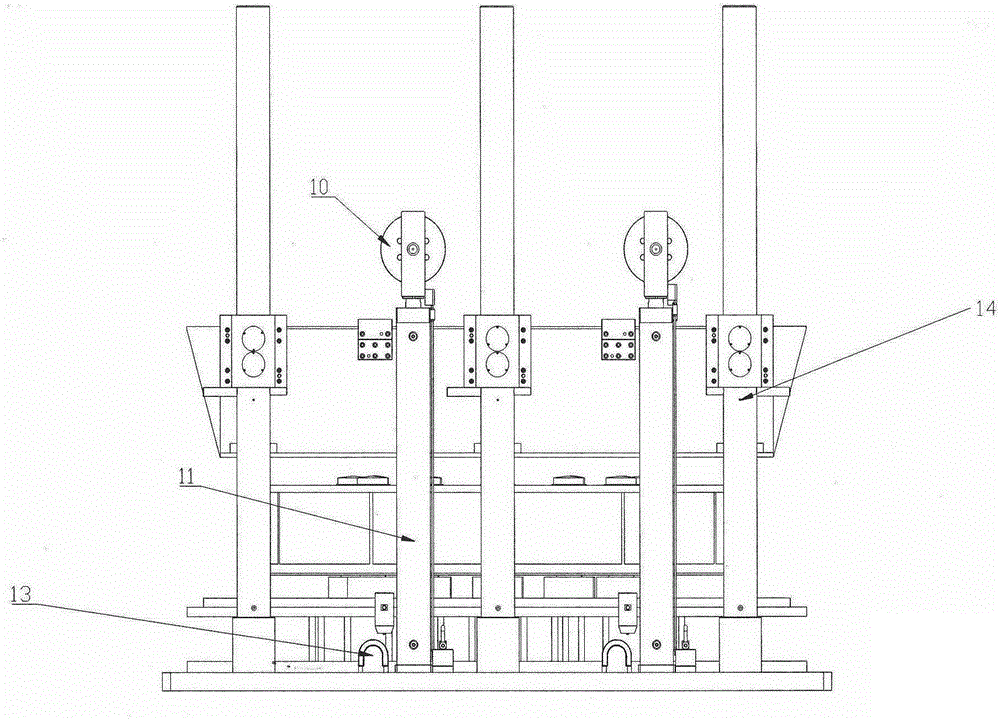

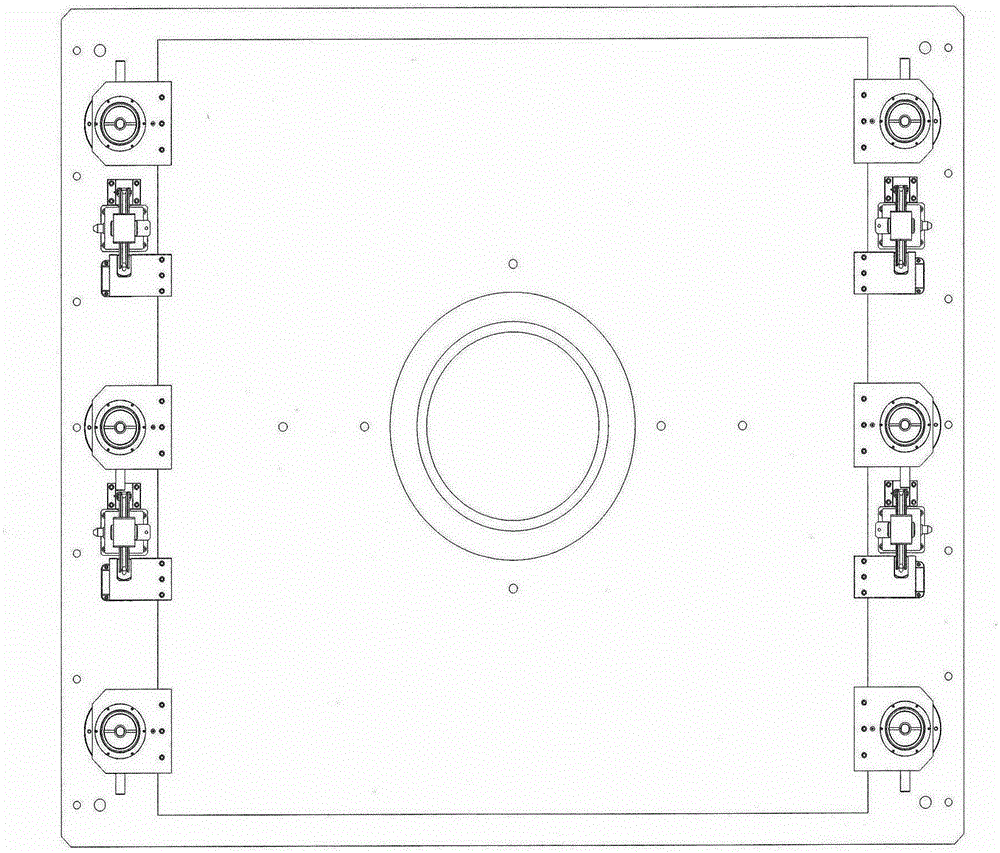

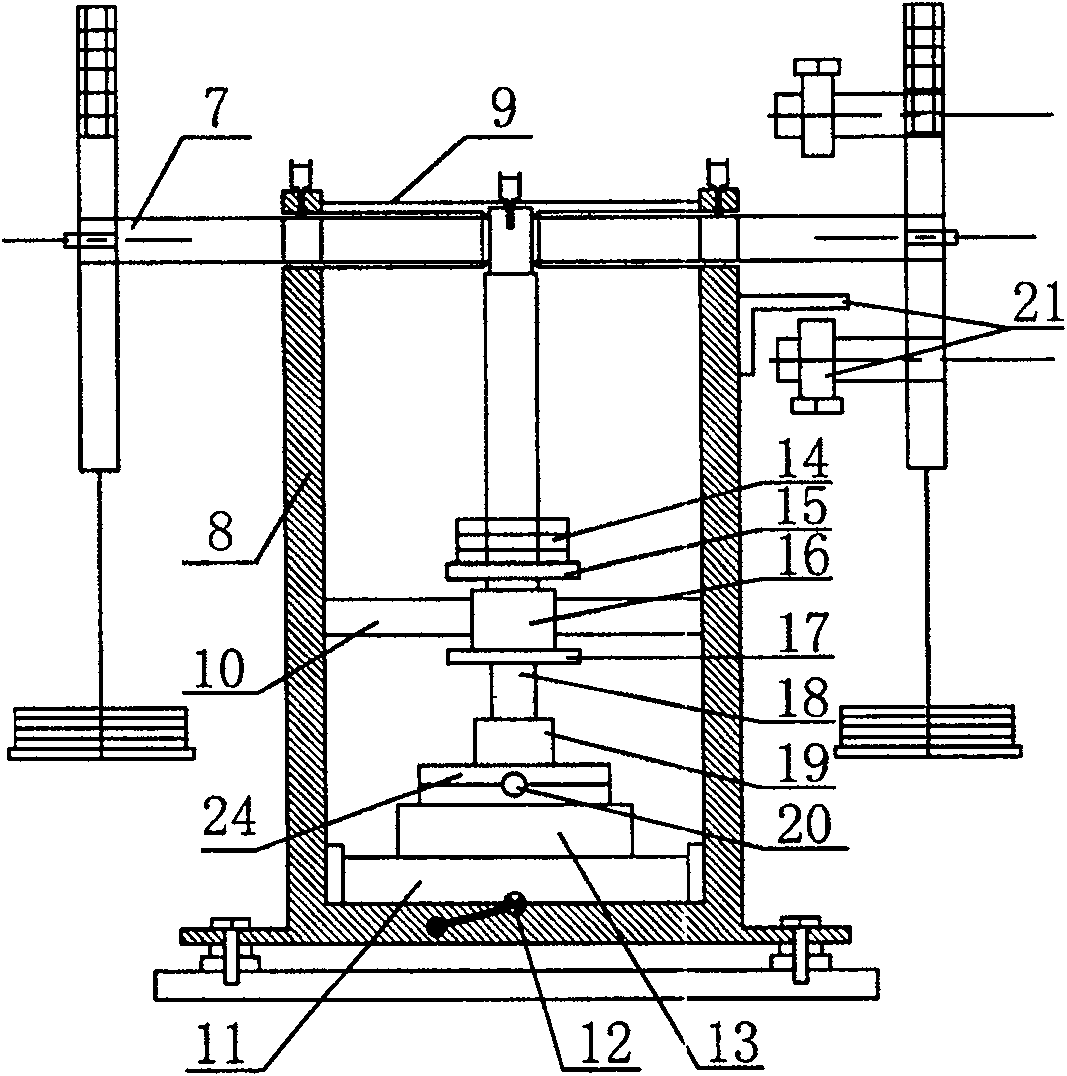

Detection apparatus used for simulating impact of coil on platen in short circuit of transformer

ActiveCN105158088AImprove vertical accuracyHigh positioning accuracyStrength propertiesControl systemEngineering

The invention provides a detection apparatus used for simulating the impact of a coil on a platen in a short circuit of a transformer. The apparatus comprises a horizontally arranged hammerhead, a base, a bracing frame composed of guiding assemblies vertically arranged at two sides of the base, a hydraulic system and a measurement control system, wherein a clamp, a sensor and a force transmission rack are coaxially piled up on the base in sequence, and the upper surface of the force transmission rack is uniformly provided with waveform generators. The apparatus can simulate coil impact effects under the working conditions of individual operation of high-tension or low-tension coils or combined operation of high-tension and low-tension coils, avoids the limitation of simulation of only combined operation of coils, and can simulate actual impact conditions and magnitude and meet requirements of detection of multiple types of platens; the apparatus is simple in structure and manufacturing, low in cost and easy in installation and dismounting; the apparatus is provided with a through hole extending from top to bottom, which facilitates observation of the states of a detected sample in the process of detection; and the apparatus is provided with multiple safety protection measures, so in multiple aspects, the hammerhead is prevented from harming workers and the apparatus due to accidental falling during working of the apparatus.

Owner:CHINA ELECTRIC POWER RES INST +1

Composite shocking rolling self-adjusted PDC drill

PendingCN107654195ARealize impactControl the depth of cut into the formationDrill bitsConstructionsPiston rodDrill bit

The invention belongs to the field of oil well drilling, and particularly relates to a composite shocking rolling self-adjusted PDC drill. The drill comprises a drill body, sealing tightening nuts, hydraulic pushing devices, shocking rolling balls, piston rods, shocking rolling ball limit sleeves and the like; a shocking rolling device cover is arranged in each drill blade wing, the sealing tightening nuts are installed in the shocking rolling device covers, the hydraulic pushing devices are arranged at the lower portions of the sealing tightening nuts, and the piston rods are connected with the hydraulic pushing devices and the shocking rolling balls respectively; the shocking rolling balls are arranged in the shocking rolling ball limit sleeves and installed on the bottoms of the drill blade wings. A shocking effect of the drill can be achieved, the cutting depth of the drill in a stratum is controlled, the friction resistance between the drill and the stratum is reduced, and the adaptability and drilling efficiency of the PDC drill to the stratum can be improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

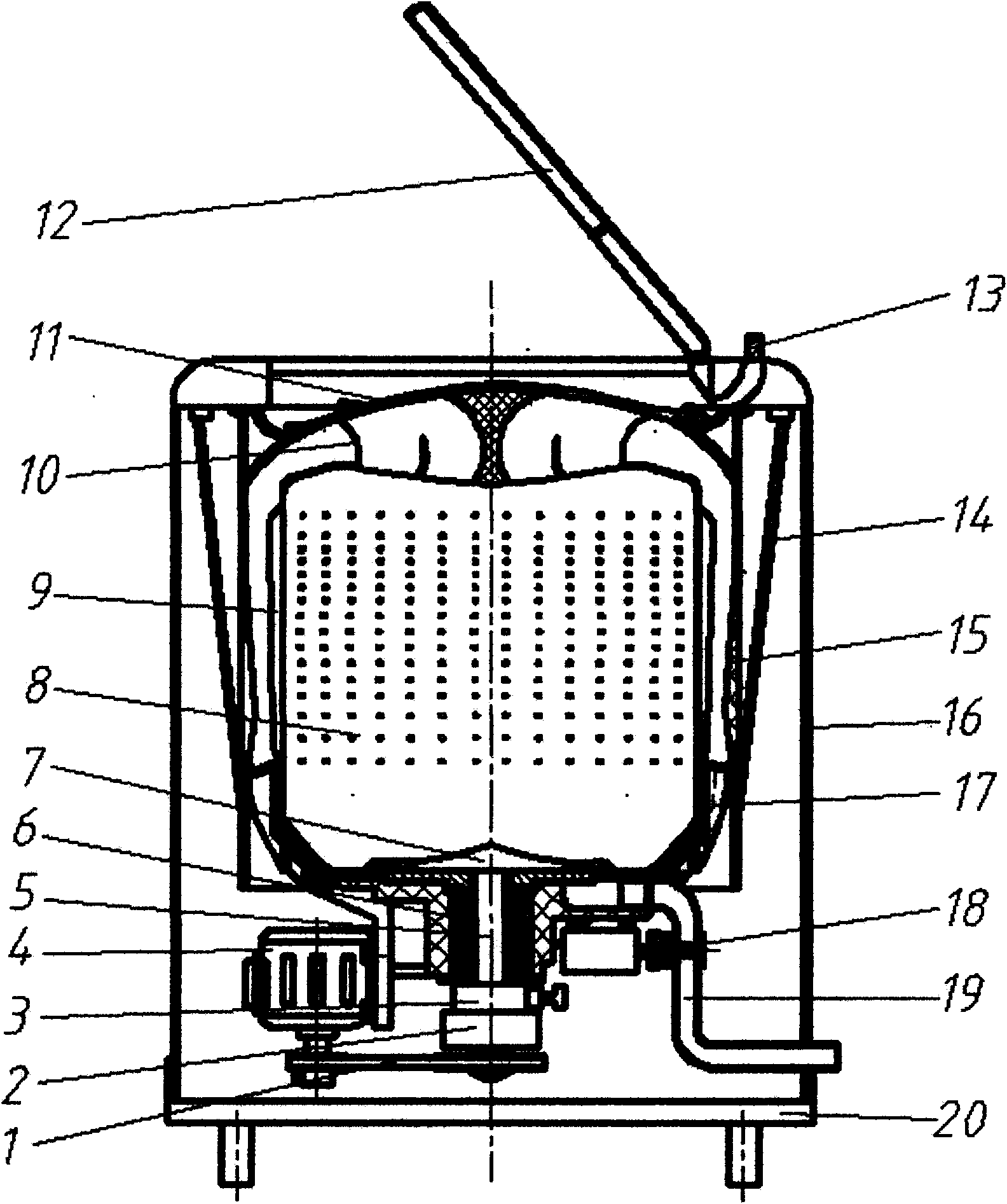

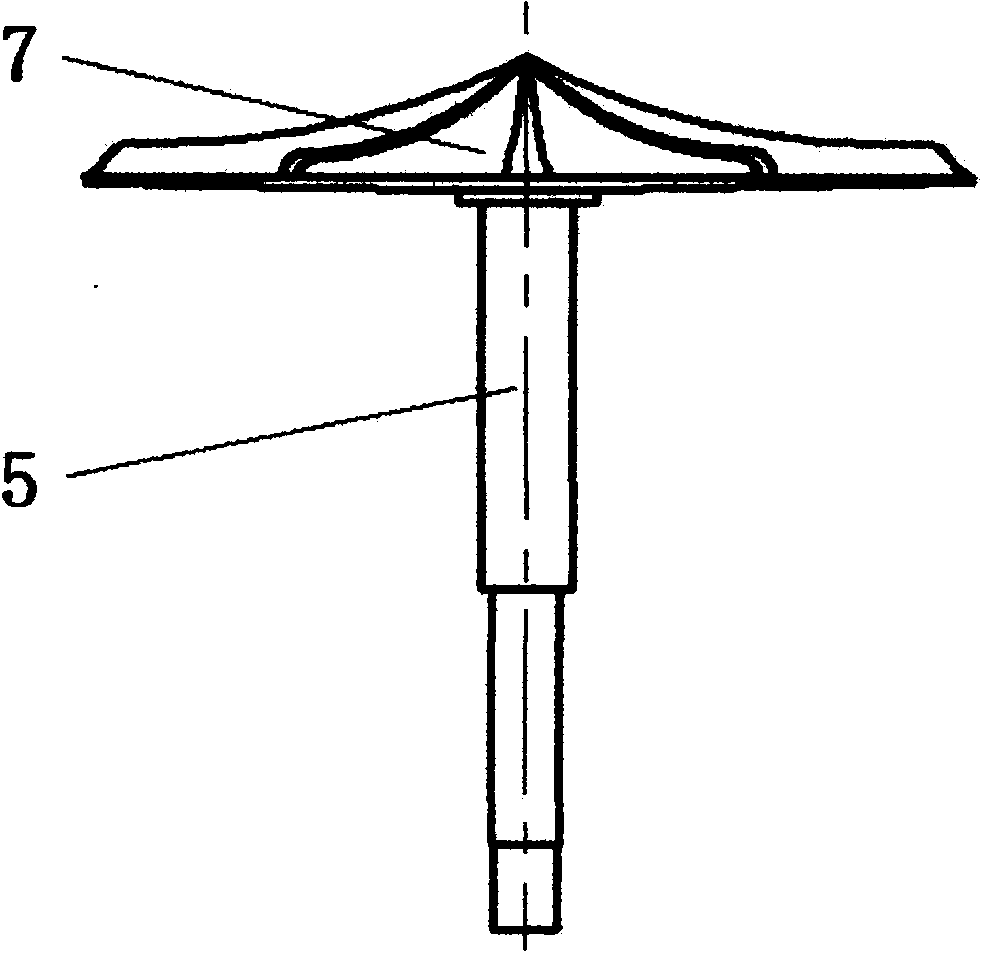

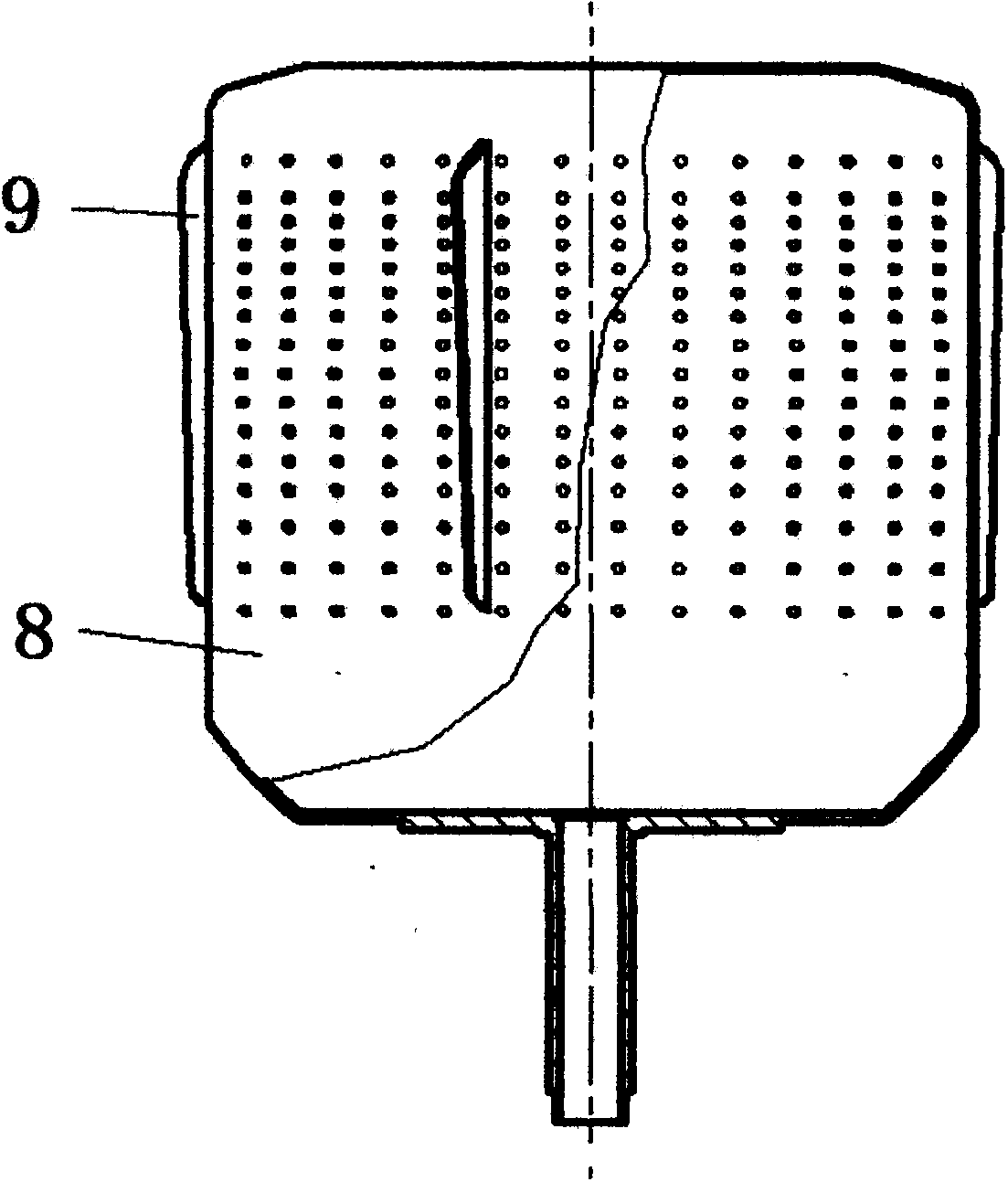

Centrifugal washing machine with revolving drum externally provided with vanes

InactiveCN103526502AFully soakedReach flipOther washing machinesWashing machine with receptaclesImpellerElectricity

A centrifugal washing machine with a revolving drum externally provided with vanes comprises an outer shell, a motor, a transmission box, a synchronous holding mechanism, a water containing shell structure and the revolving drum. The water containing shell structure is located inside the outer shell. The revolving drum is arranged inside the water containing shell structure. The motor is arranged at the bottom of the outer shell. An impeller is arranged at the bottom of the revolving drum. A center shaft is arranged below the impeller. A sleeve shaft is arranged outside the center shaft. The center shaft and the sleeve shaft are respectively located through a bearing bush. The impeller and the center shaft are connected into a whole. The revolving drum is connected to a revolving speed box through the sleeve shaft. The sleeve shaft and the revolving drum are connected into a whole. A sealing structure is arranged on the upper portion of a rotary shaft. The vanes are arranged outside the revolving drum. A planet wheel mechanism is arranged inside the transmission box and the synchronous holding mechanism is arranged outside the transmission box. The motor is connected with the impeller through the transmission box, so that positive rotation and negative rotation of the impeller are achieved. According to the centrifugal washing machine with the revolving drum externally provided with the vanes, the centrifugal washing method is adopted, so that the washing efficiency is improved, time, electricity and water are saved, abrasion is low, and the twining degree is low.

Owner:QINGDAO UNIV OF SCI & TECH

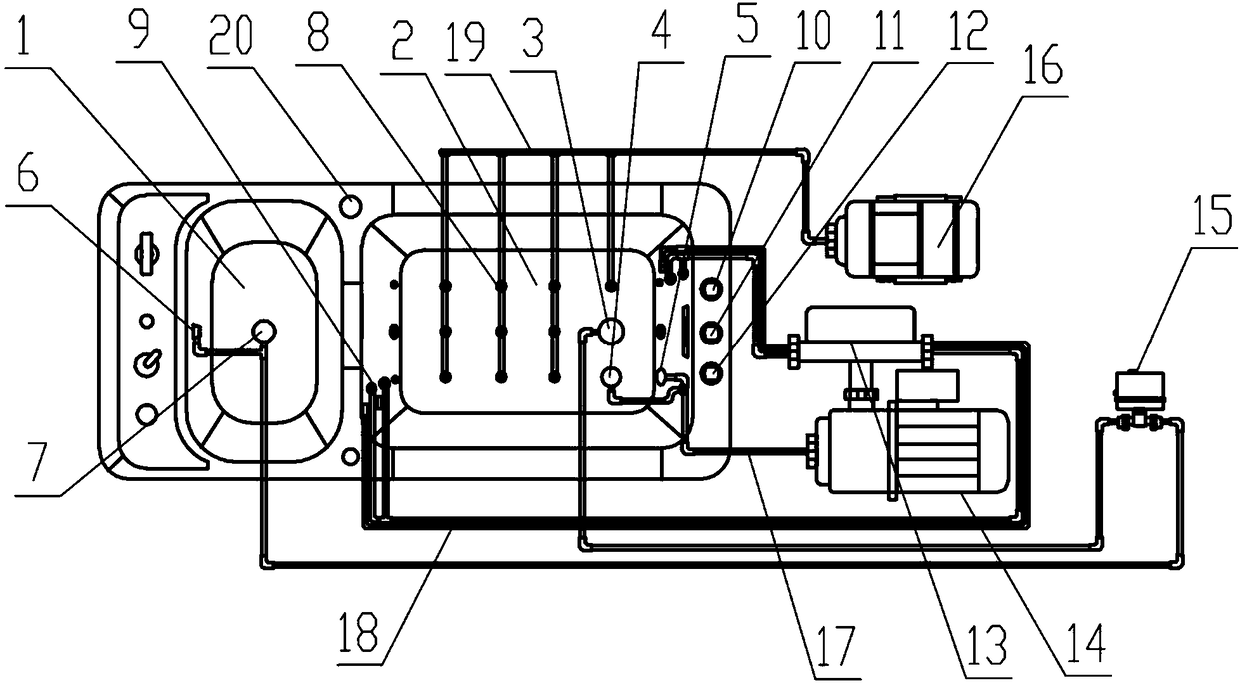

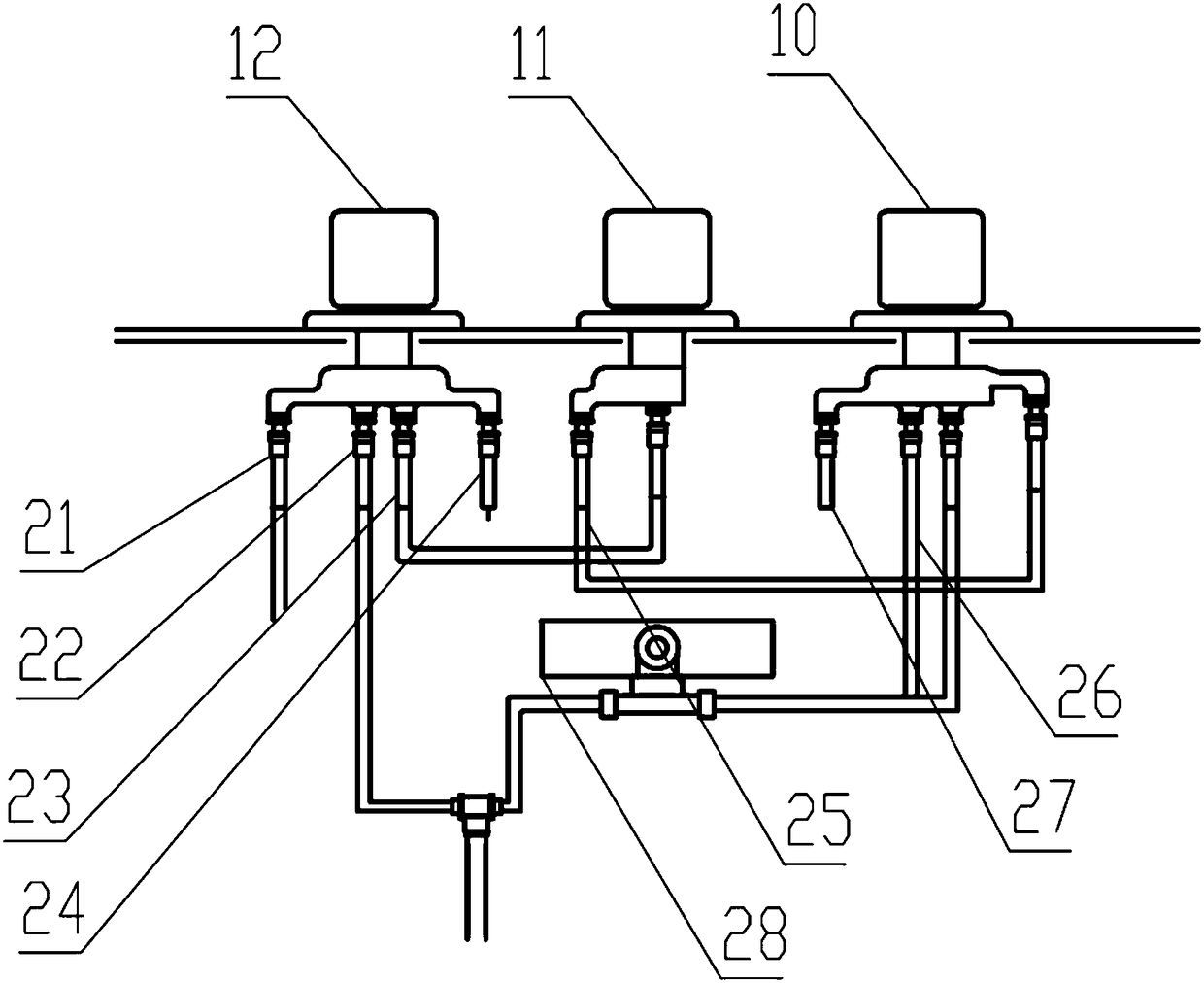

Bathing hydrotherapy machine for babies

PendingCN108478066APrevent drowningImprove cardiopulmonary functionBathsDouchesMuscle strengthMassage

The invention provides a bathing hydrotherapy machine for babies. The machine comprises a bathing tank, a hydrotherapy tank, a thermostat, a water pump, an electric ball valve and a wind pump; the bathing tank is internally provided with a water overflowing port and a water discharging port, the hydrotherapy tank is internally provided with an electric water discharging port, a manual water discharging port, a water return port, bubble nozzles, vortex nozzles, a functional faucet, a switch faucet and a thermostatic faucet. The bathing hydrotherapy machine has the following advantages that through the arrangement of the thermostat and the thermostatic faucet, it can be effectively ensured that the temperature is always in a comfortable and safe state when the babies have a bath and hydrotherapy; by forming the water overflowing port and the water discharging port in the bathing tank, the situation can be avoided that the babies are drowned during bathing due to the excessively-high water level; by arranging the bubble nozzles and the vortex nozzles in the hydrotherapy tank, the functions of vortex impact and bubble massage can be achieved, the cardio-pulmonary functions of the babies are effectively improved, the blood circulation is improved, the myospasm is relieved, the joint mobility is improved, the muscle strength is enhanced, the coordination is improved, the balance ability of the babies is improved, the gaits are corrected, and the growth and development of the babies are promoted.

Owner:北京仁和益科技发展有限公司

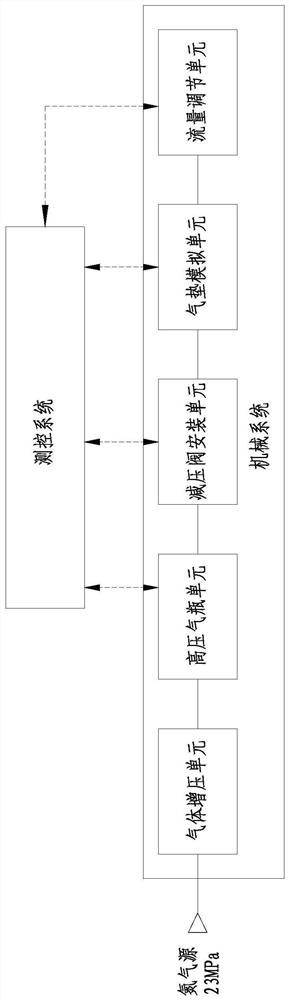

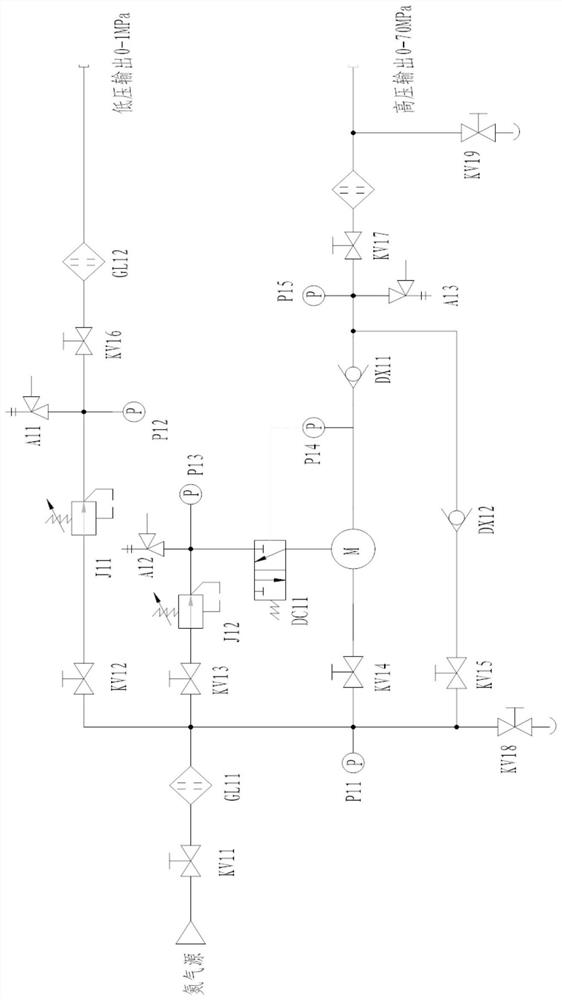

Valve impact performance test pipeline and system

PendingCN112903280ASimple structureReal-time dynamic measurementMachine valve testingThermodynamicsGas cylinder

The invention belongs to the technical field of valve tests, and discloses a valve impact performance test pipeline and system. The system comprises a mechanical system and a measurement and control system, the mechanical system is used for providing a gas medium and working conditions for a tested piece, and the measurement and control system is used for controlling the gas medium and the working conditions and automatically collecting and storing test parameters. The mechanical system comprises a gas pressurizing unit, a high-pressure gas cylinder unit, a pressure reducing valve mounting unit, a gas cushion simulation unit and a flow adjusting unit; the gas pressurizing unit is used for pressurizing a gas medium; the high-pressure gas cylinder unit is used for storing and releasing a gas medium; the pressure reducing valve mounting unit is used for clamping and fixing a tested valve; the air cushion simulation unit is used for simulating the volume change of a pipeline behind the tested valve; the flow simulation unit is used for simulating working conditions when the valve flows are different.

Owner:XIAN AEROSPACE PROPULSION INST

Hand-held shock impact internal combustion tamping pickaxe

The invention provides a hand-held vibration impact internal combustion tamping pickaxe comprising an internal combustion engine, shock absorbers, an impact mechanism and a shock mechanism. The hand-held shock impact internal combustion tamping pickaxe is characterized in that the internal combustion engine is connected with the shock absorbers through pressure plates, the lower ends of the shock absorbers are connected with a box body of the impact mechanism, and the impact mechanism is arranged in the box body; the impact mechanism comprises energy storage springs, driving shafts, an upper cam impact block, a lower cam impact block, planet gears, a gear ring and the like, a sun gear is designed and machined on the driving shafts, and the shock mechanism is connected with the impact mechanism in a matched mode through connecting sleeves; and the shock mechanism comprises shock shafts, outer sleeves and a shock head, the shock shafts are eccentric shafts, and high-frequency shock can be achieved at a high speed. Shock and impact dual functions of the tamping pickaxe are achieved by means of the method that spring energy is utilized by the upper cam impact block of a deceleration strip of a planetary mechanism to continuously impact the shock shaft outer sleeves.

Owner:蓬莱奥斯勃机械有限公司

Current-carrying friction and wear testing machine for pantograph slide plate and its application method

ActiveCN110186799BCompact structureSimple structureInvestigating abrasion/wear resistanceCircular discContact pressure

The invention discloses a current-carrying friction wear testing machine for a pantograph slide plate and a using method, and relates to the technical field of mechanical devices, wherein a contact line mounting structure comprises a rotating disc, a first driving motor, a contact line and a convex point; the contact line and the convex point rotate along with the rotating disc under the driving of the first driving motor; a pantograph slide plate mounting structure comprises a slide plate, a mounting frame, a swing frame, a main frame, a first movement control device, a swing control device,a second movement control device and a pressure control device; the mounting frame applies pressure to the sliding plate to change the contact pressure between the sliding plate and the contact line or the convex point; the slide plate swings under the driving of the swing control device, horizontally moves relative to the r rotating disc under the driving of the first movement control device, andvertically moves relative to the rotating disc under the driving of the second movement control device. Therefore, a service environment close to a bow net system is created, and a sliding plate damage mechanism under the coupling action of mechanical impact and thermal shock can be simulated.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

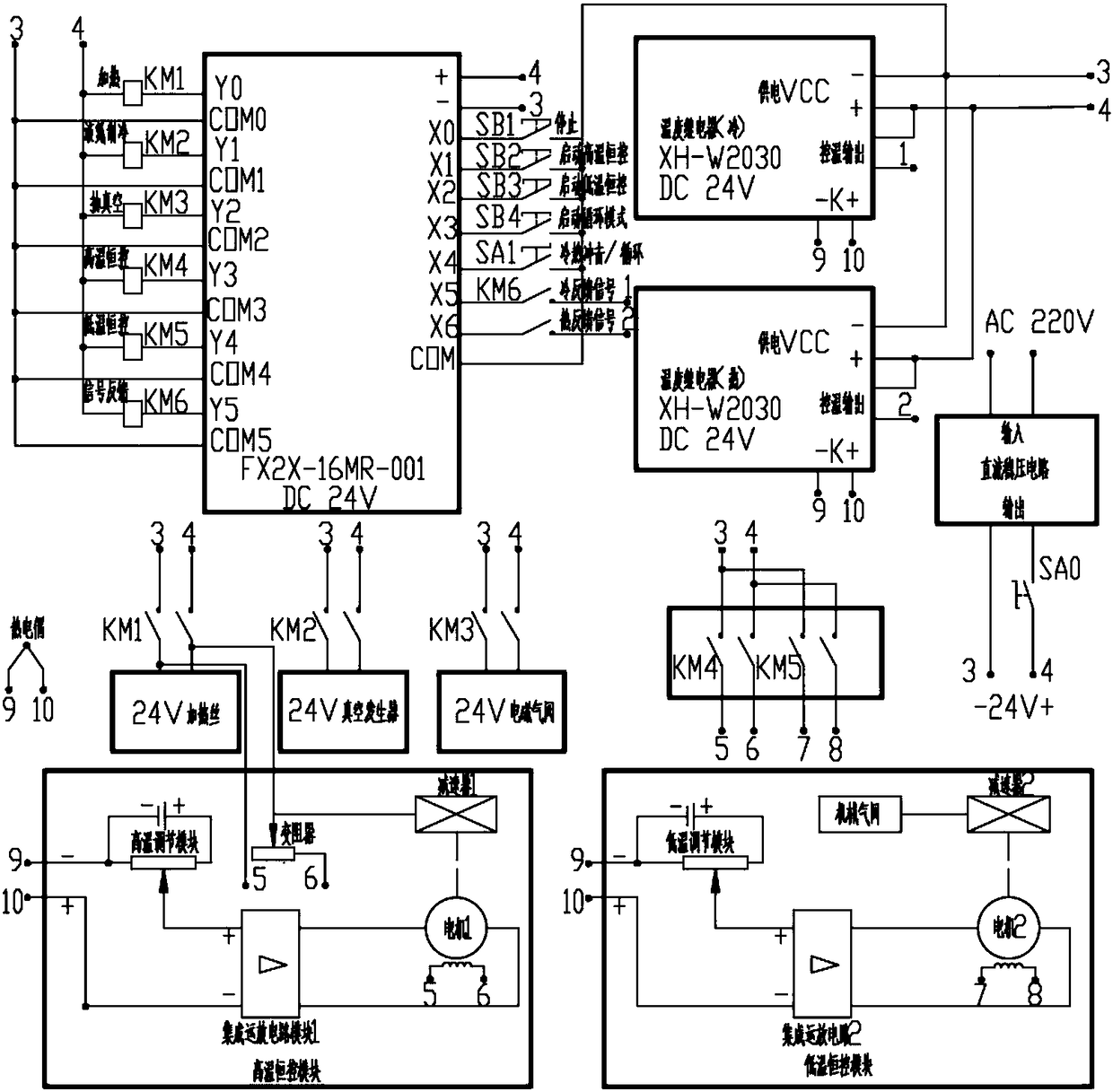

Temperature control system of temperature change reliability testing device

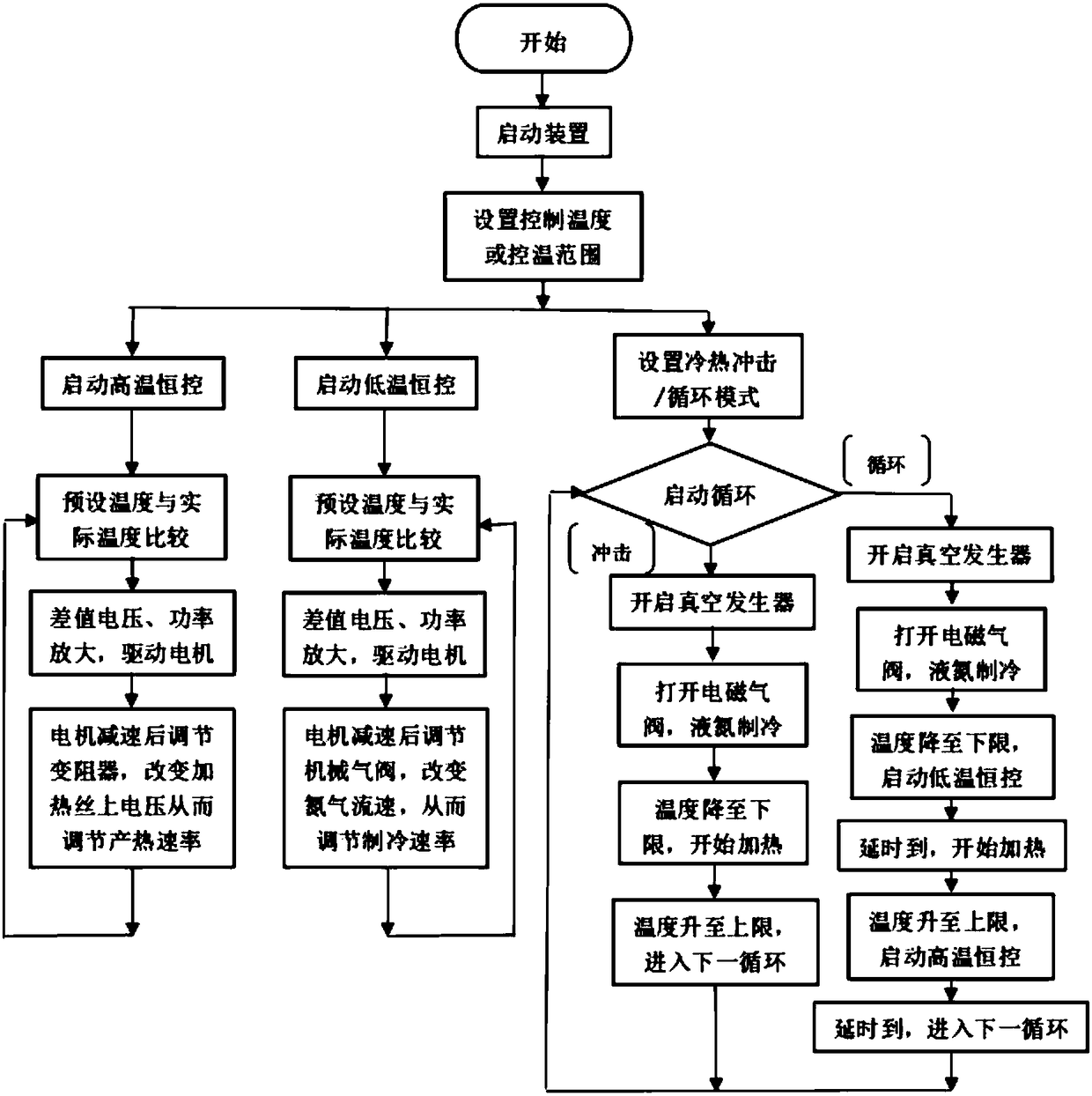

ActiveCN108445932ASave the waste of transferring back and forthReduce wasteTemperatue controlTemperature controlControl system

The invention discloses a temperature control system of a temperature change reliability testing device. The system comprises a PLC, a high temperature constant control module, a low temperature constant control module, a cold temperature relay, a hot temperature relay, a DC voltage stabilizing circuit, a thermocouple, heating wires, a power supply, a vacuum generator, an electromagnetic air valve, a plurality of contactors and a plurality of buttons. The temperature control system of a temperature change reliability testing device can realize constant temperature steady state control and coldand hot shock of a cold and hot cycle testing device, the anti-interference ability and sensitivity of the system are improved, and the system is optimized to a certain extent in space occupation.

Owner:HOHAI UNIV CHANGZHOU

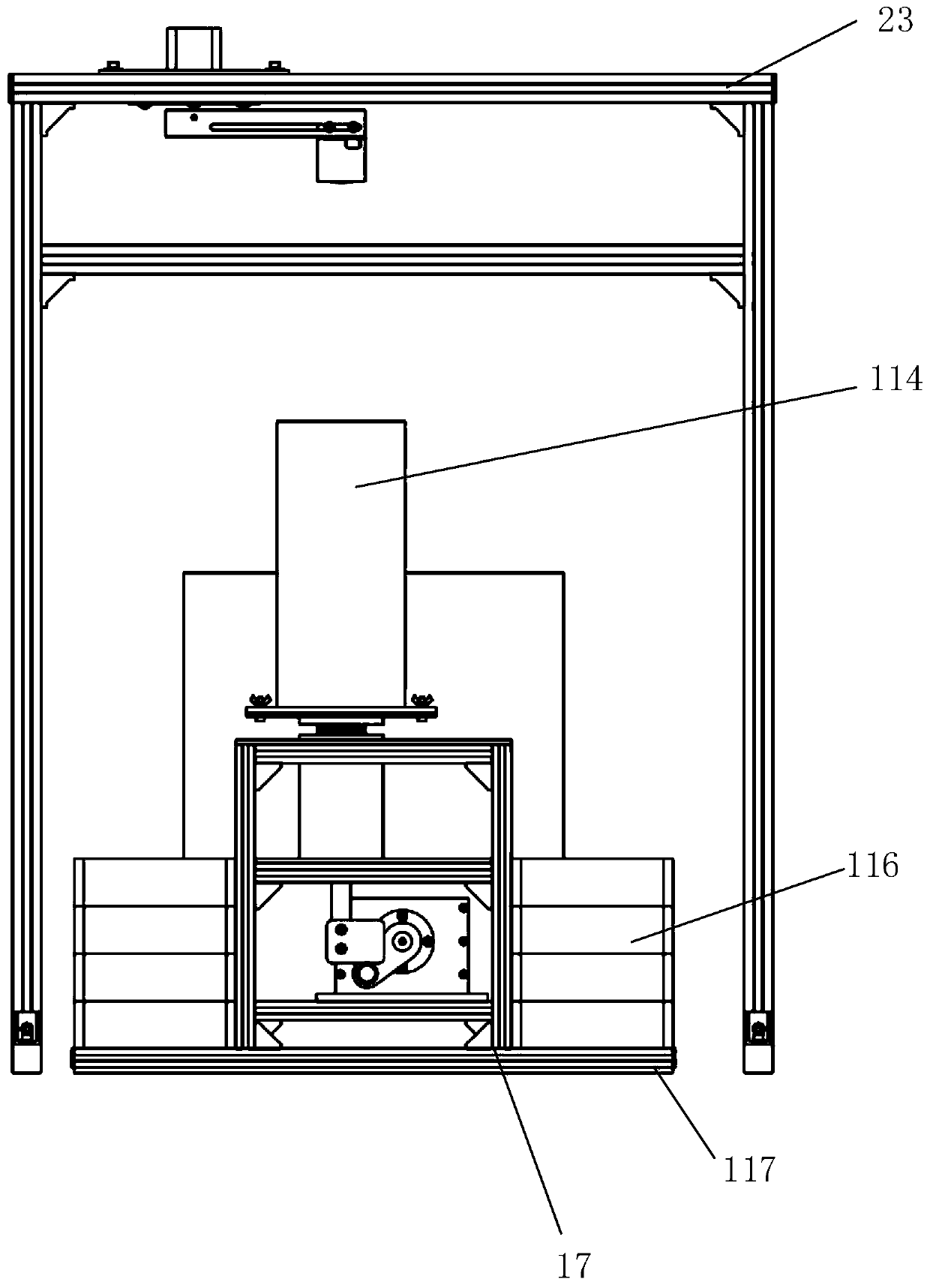

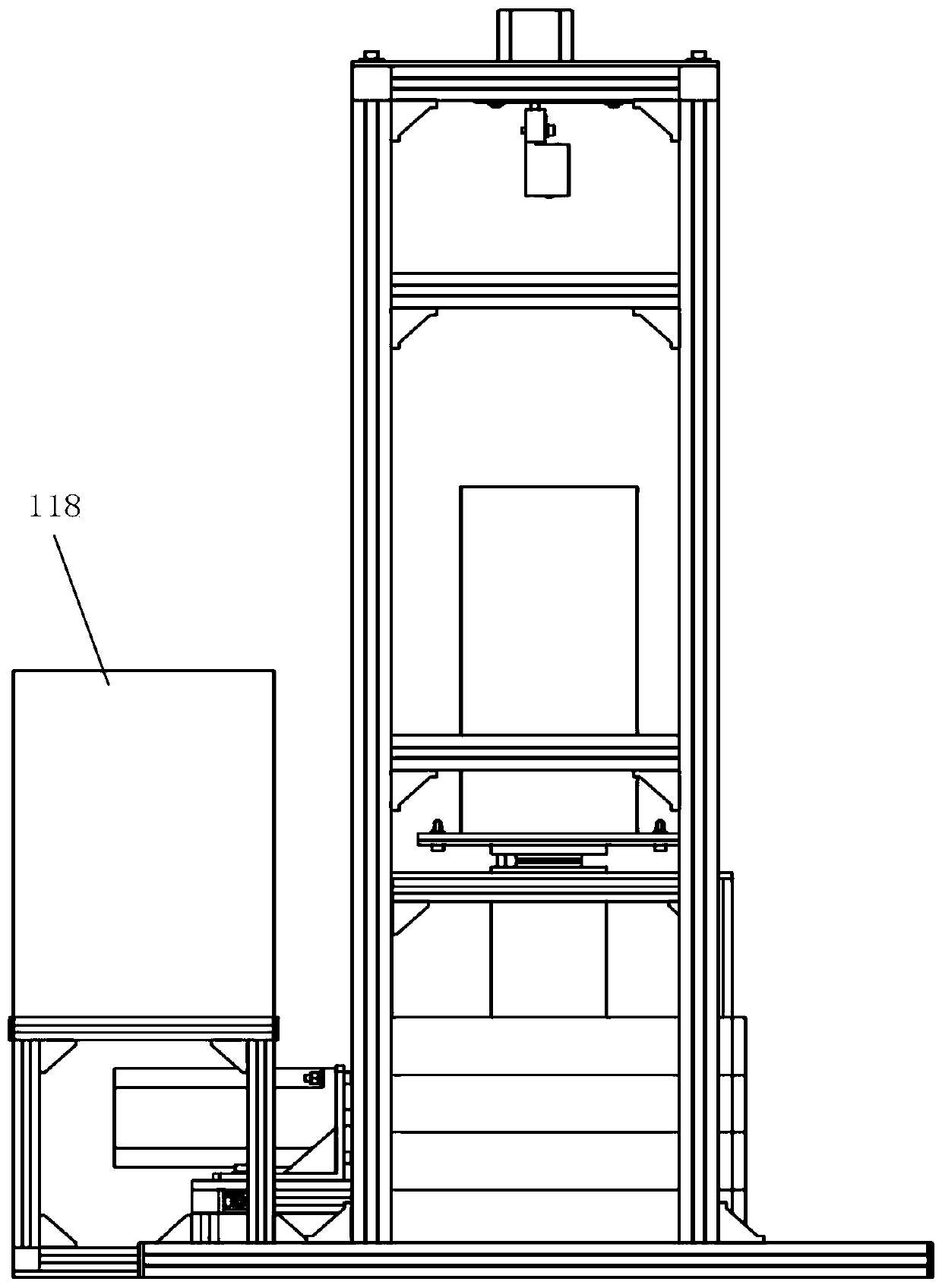

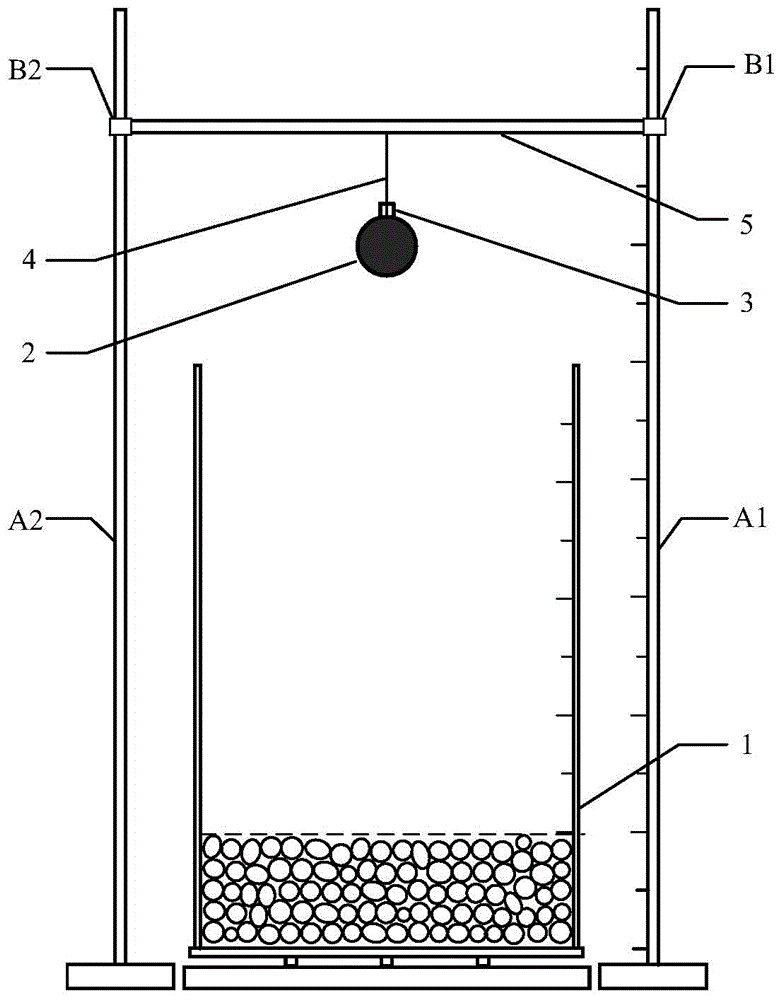

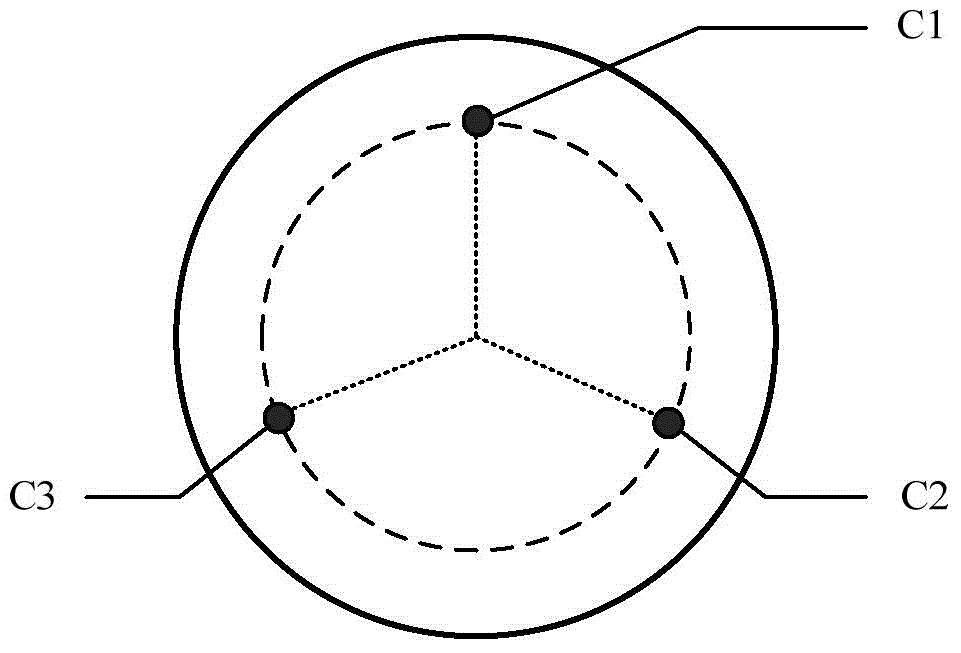

Granular material buffer performance measuring system

InactiveCN104964901ARealize impactAccurate measurementMaterial analysisImpact systemInelastic collision

The invention provides a granular material buffer performance measuring system. A granular substance is a rapid energy dissipating system, and energy is consumed mainly through intergranular non-elastic collision and sliding friction, and an intergranular force chain structure can increase the action area and the action time of external load, so impact load is certainly buffered, and destroys brought by the impact are reduced. The measuring system is composed of a fixed support, a granule impact system, a mechanical response measuring system and an image acquisition system, so vertical impact to the granular substance is realized, the acceleration of an impact substance and the impact force born by a baseboard can be accurately measured, the change of the surface form of the granule and the movement of the impact substance in the impact process is recorded, and a reliable device is provided for accurately measuring the buffer performance of the granular substance. The device can realize control and adjustment of the thickness of a granule layer and the impact height, and the influences of the thickness of the granule layer and the impact height on the buffer characteristic of the granule layer are researched.

Owner:DALIAN UNIV OF TECH

Material flowing deformation disturbed effect testing system and testing method thereof

InactiveCN100567944CSimple structureEvenly loadedFlow propertiesMaterial strength using single impulsive forceConstant loadExperimental methods

The invention discloses an experimental system and an experimental method for the rheological disturbance effect of materials, including a constant load loading system, which implements a constant load on a test piece through a loading device, a crankshaft expansion device and a force transmission connecting rod; and also includes a disturbance loading system, The impact disturbance load and the blast disturbance load are applied to the specimen through the impact disturbance loading device and the blast disturbance loading device; it also includes a confining pressure loading system, which applies confining pressure load to the specimen through a triaxial pressure box. The triaxial pressure box includes a closed box body, and an annular capsule is arranged in the closed box body, which can realize confining pressure load on the test piece. Through the above-mentioned material rheological disturbance effect experiment system, it is possible to carry out uniaxial rheological experiment, uniaxial rheological disturbance experiment, triaxial rheological test and triaxial rheological disturbance experiment on the test piece. The structure is simple, the cost is low, and the test is accurate. It is suitable for performing rheological disturbance tests on various material test pieces, and is especially suitable for performing long-term rheological disturbance experiments on rock test pieces.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

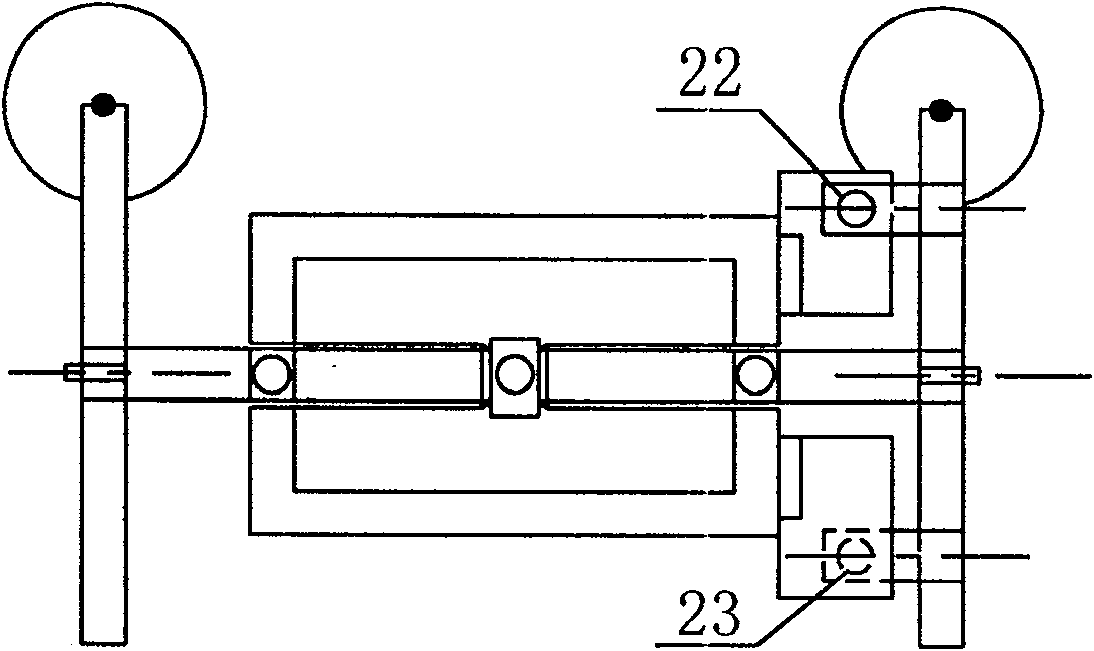

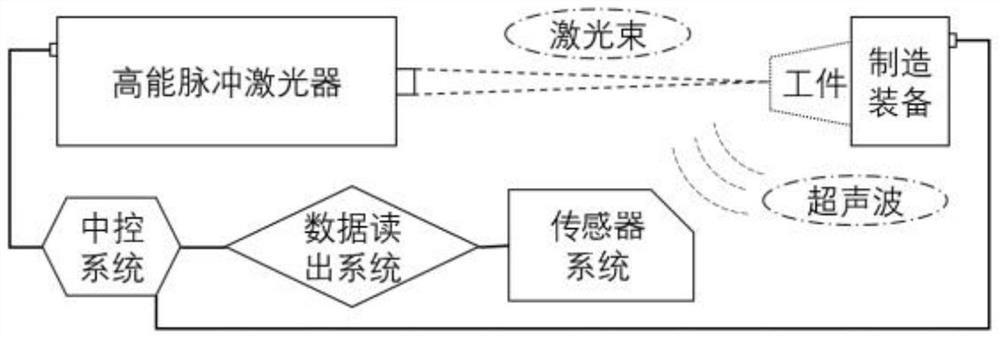

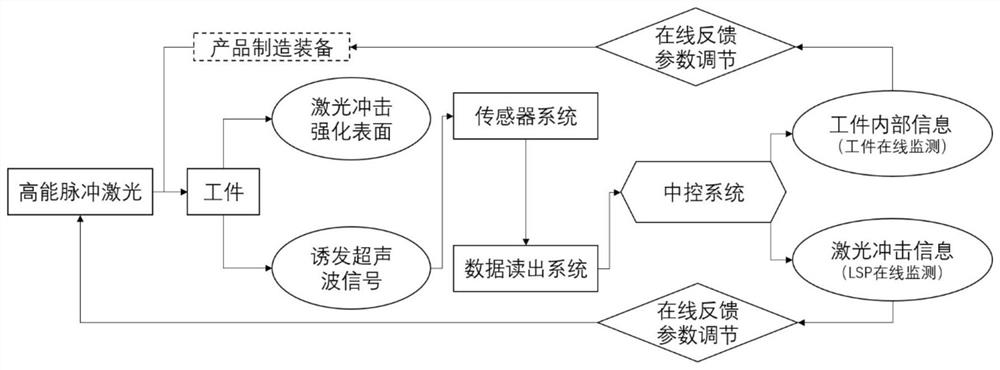

High-energy pulse laser processing and measuring integrated system and method

ActiveCN112280968ARealize two-way online monitoringRealize online monitoringAdditive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesLaser processingControl system

The invention discloses a high-energy pulse laser processing and measuring integrated system and a method. The high-energy pulse laser processing and measuring integrated system comprises a set of high-energy pulse laser system which can be used for laser shock peening and ultrasonic wave generation at the same time, a set of sensor system which is used for receiving ultrasonic waves, a set of data reading system which is used for converting sensor data, and a set of central control system is used for coordinately controlling all equipment; high-energy pulse laser generated by the high-energypulse laser system induces and generates shock wave laser shock peening on the surface of a workpiece according to a path, the ultrasonic waves are generated in the interior of the workpiece; the sensor system receives an ultrasonic signal and inputs the ultrasonic signal to the central control system through the data reading system; the central control system carries out calculation on the ultrasonic data to obtain internal information of the workpiece and laser shock information; and real-time parameter adjustment are carried out on the high-energy pulse laser and workpiece product manufacturing equipment according to the laser shock information and the internal information of the workpiece. According to the high-energy pulse laser processing and measuring integrated system and the method, shock peening and ultrasonic detection are achieved at the same time, and the detection accuracy is improved.

Owner:XI AN JIAOTONG UNIV

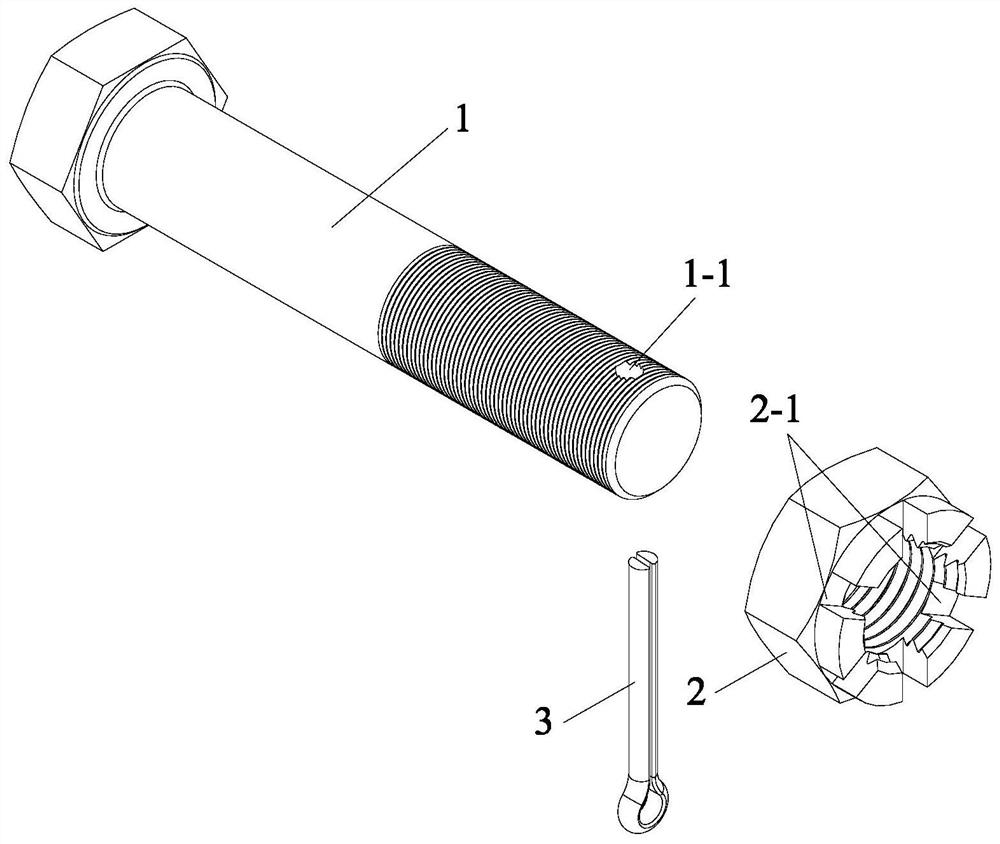

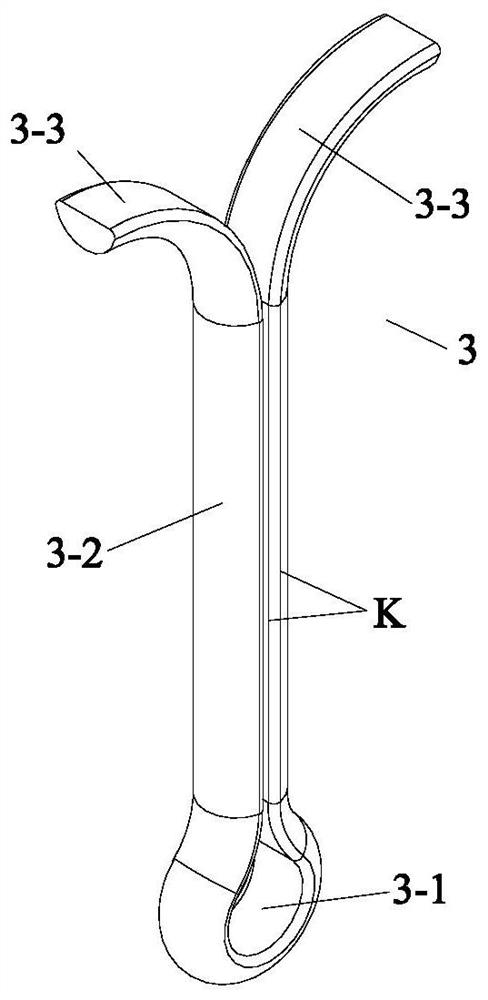

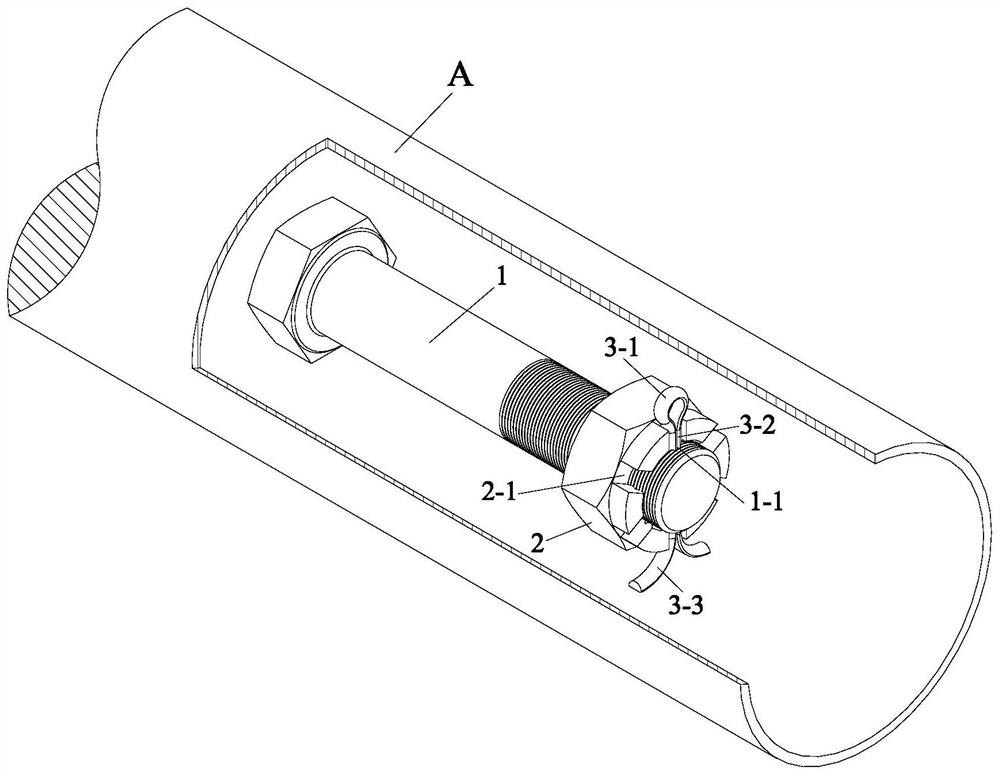

Pin splitter applied to narrow space and using method thereof

PendingCN112828825AAvoid being scratchedAvoid smashingMetal-working hand toolsHand heldField of view

The invention discloses a pin splitter applied to narrow space and a using method thereof, and belongs to the technical field of handheld special fastening tools. The pin splitter comprises a coaxial positioning sleeve, a pin splitting firing pin mechanism, a handheld probe and a bolt lantern ring positioning rod, and the handheld probe comprises a handle, a sliding groove base, an opening clamping ring, a positioning rod inserting hole, a firing pin guiding sliding groove, a firing pin pull rod through hole and a sleeve inserting hole. The pin splitter applied to the narrow space is suitable for the special situations that due to the fact that the diameter of a round pipe component A is too small, conventional tools and visual fields are limited, and pin splitting operation lacks necessary operation space, the operation process can be greatly simplified, the pin splitting quality and the acceptance efficiency can be enhanced, meanwhile, the operation difficulty is effectively reduced, and the risks that an operator is scratched, injured by a crashing object or sprained and the like are avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com