Device for rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment

A Hopkinson compression rod and rapid heating technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complex experimental system, complex data processing system, inevitable local rod heating, etc., to eliminate the influence of material properties , The effect of increasing the heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

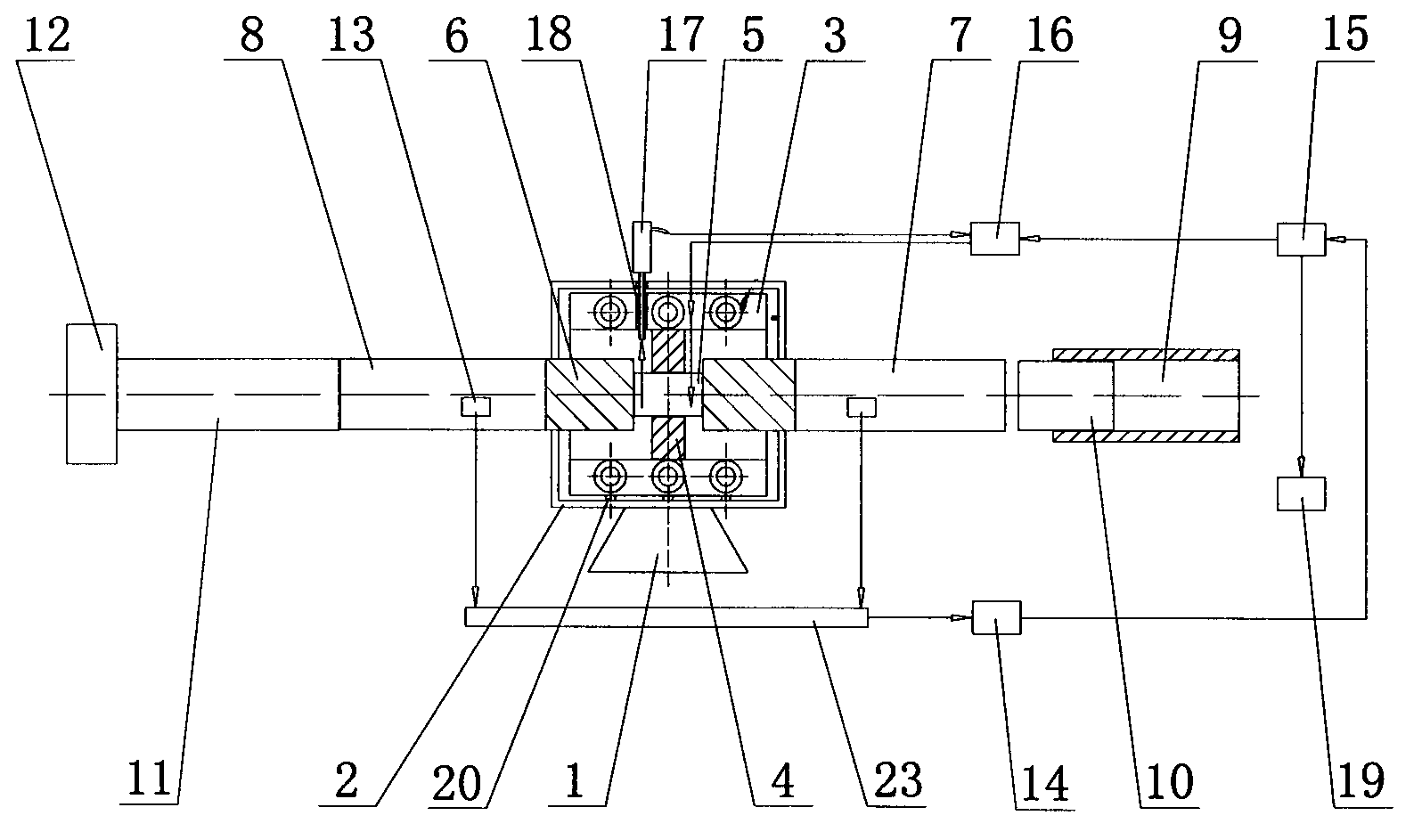

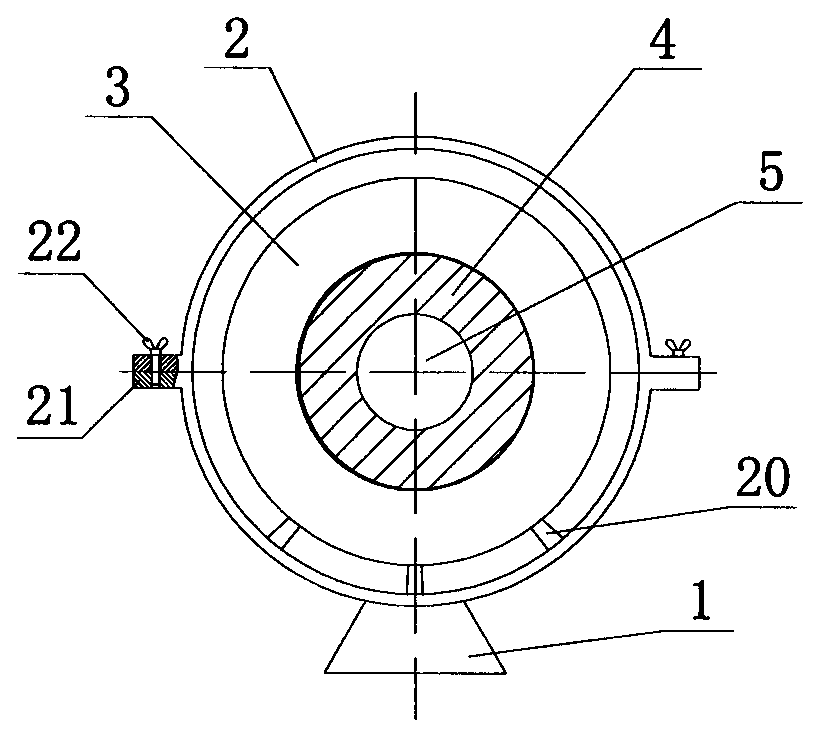

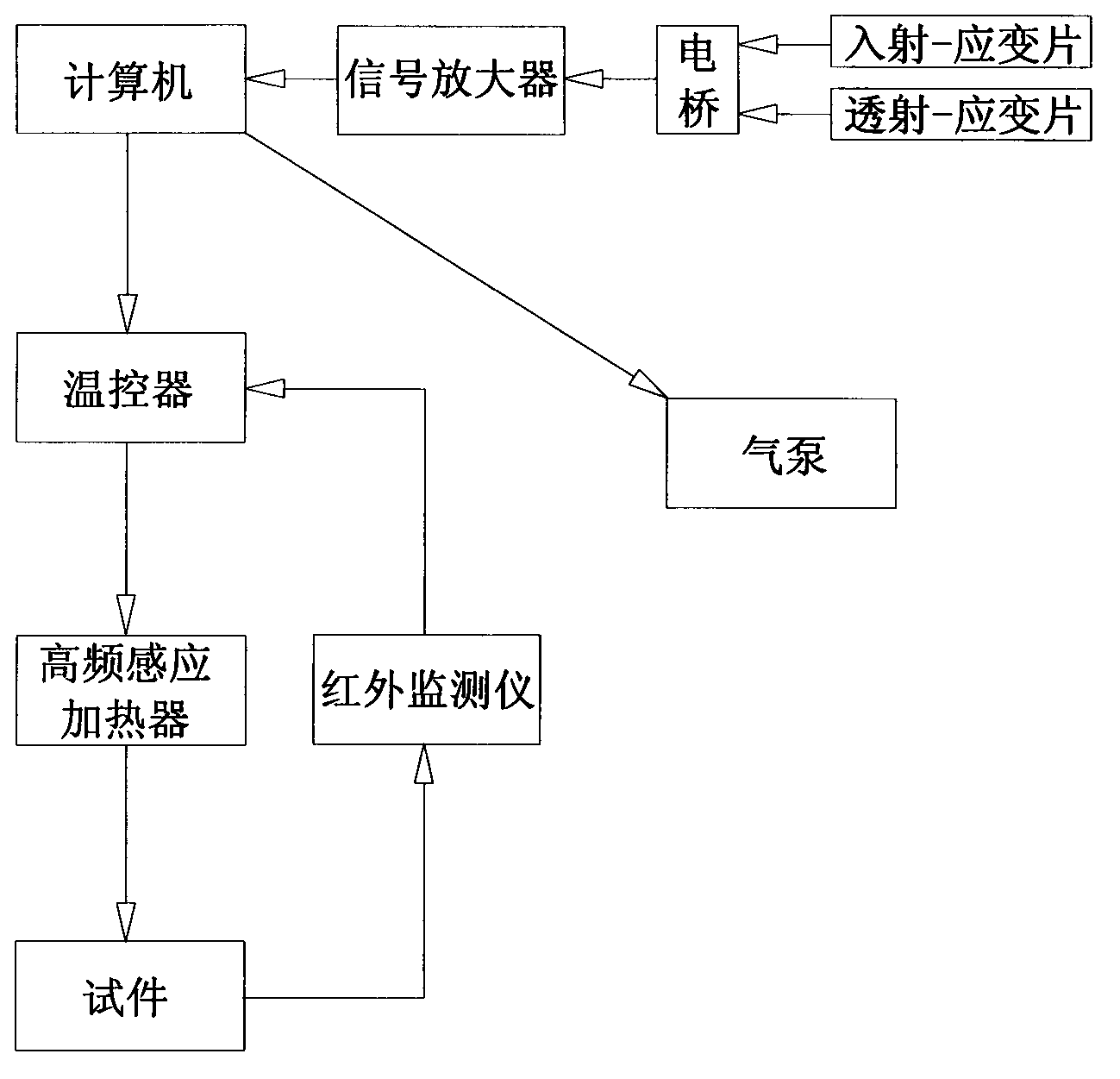

[0031] In conjunction with the accompanying drawings, a fast-heating type quasi-static high-temperature Hopkinson pressure rod experimental device, which includes a supporting base 1 outside the shielding cover 2, and a high-frequency induction heater 3 inside the shielding cover 2, for the convenience of use and operation, The shielding cover 2 is cylindrical and is opened and closed at 21 places of the upper and lower opening and closing ears, and is fixed with a butterfly-shaped manual tightening nut 22; in order to ensure the safety and heating effect of the high-frequency induction heater 3, the high-frequency induction heater 3 and Three rows and three rows of at least 9 isolation pillars 20 made of ceramic materials are arranged between the shielding covers 2; the center of the high-frequency induction heater 3 is provided with a ceramic sleeve 4, and the central device of the ceramic sleeve 4 is a sample 5, and the sample 5 is two The ends are connected with the inner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com