Improvement method for stacked package of three-dimensional chip of microsystem

A three-dimensional chip, stacked packaging technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of heat, stress, low integration density, etc., to reduce stress problems, reduce thermal stress problems, The effect of interconnecting high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

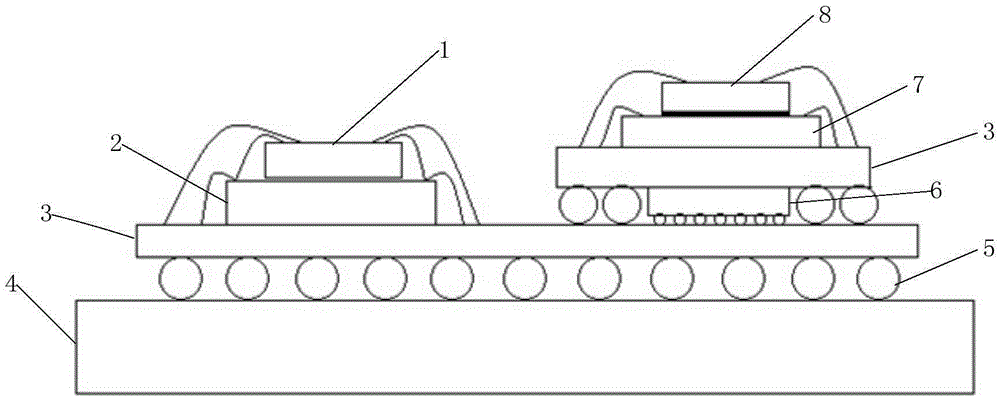

[0021] Such as figure 1 As shown, an improved method for microsystem three-dimensional chip stack packaging, the specific steps are as follows:

[0022] 1) First, according to the needs of microsystem packaging applications, design the redistribution layer and TSV layout on the silicon interposer A to realize the interconnection between devices;

[0023] 2) Mount the ASIC device and execution / sensor device on the adapter base with a placement machine, and use a wire bonding machine to complete the interconnection between ASIC and execution / sensor, and ASIC / execution / sensor and adapter board;

[0024] 3) According to the requirements of data and signal processing, design the redistribution layer and TSV layout of the silicon-based interposer B;

[0025] 4) Mount the memory device on the adapter board with a mounter, and complete the interconnection bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com