Patents

Literature

724results about How to "Realize the heating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotary lifting-type gear sleeve automatic high frequency quenching device

InactiveCN102382953ARealize the heating effectReduce labor intensityIncreasing energy efficiencyFurnace typesGear wheelElectric machinery

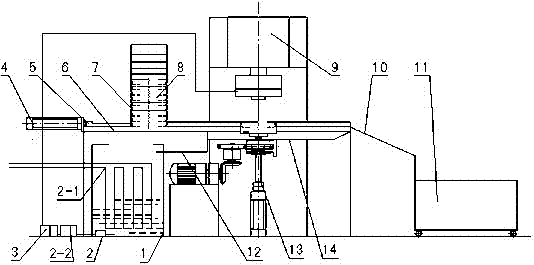

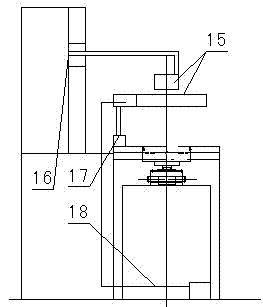

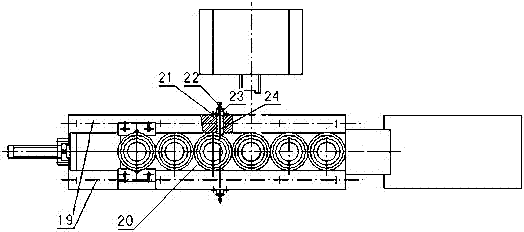

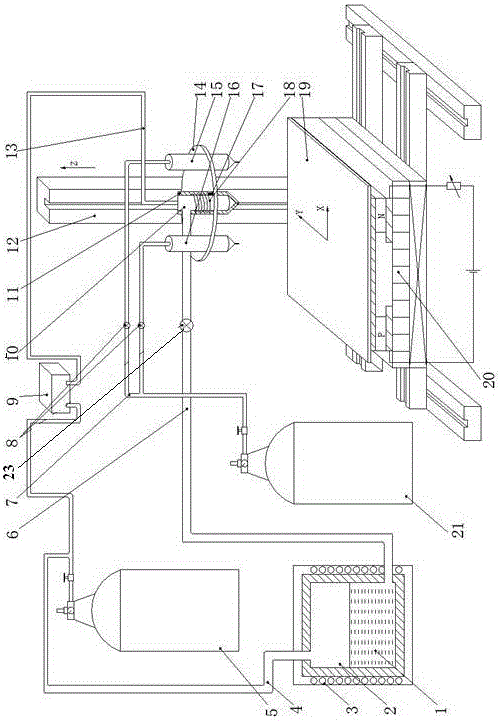

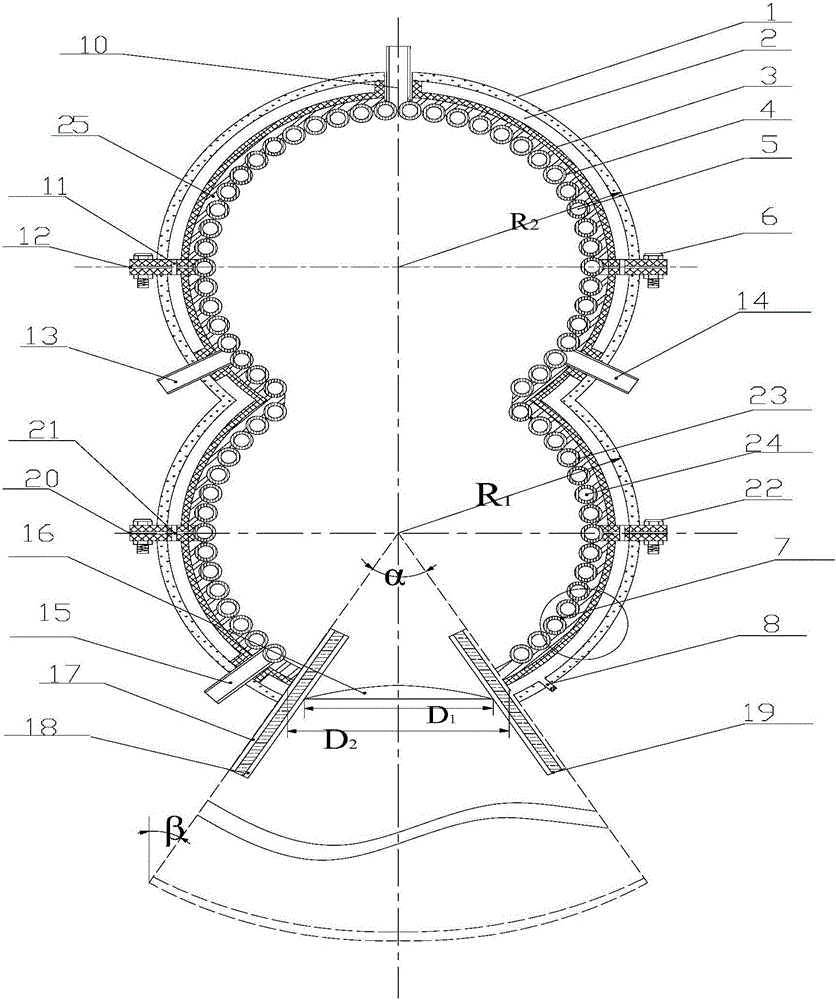

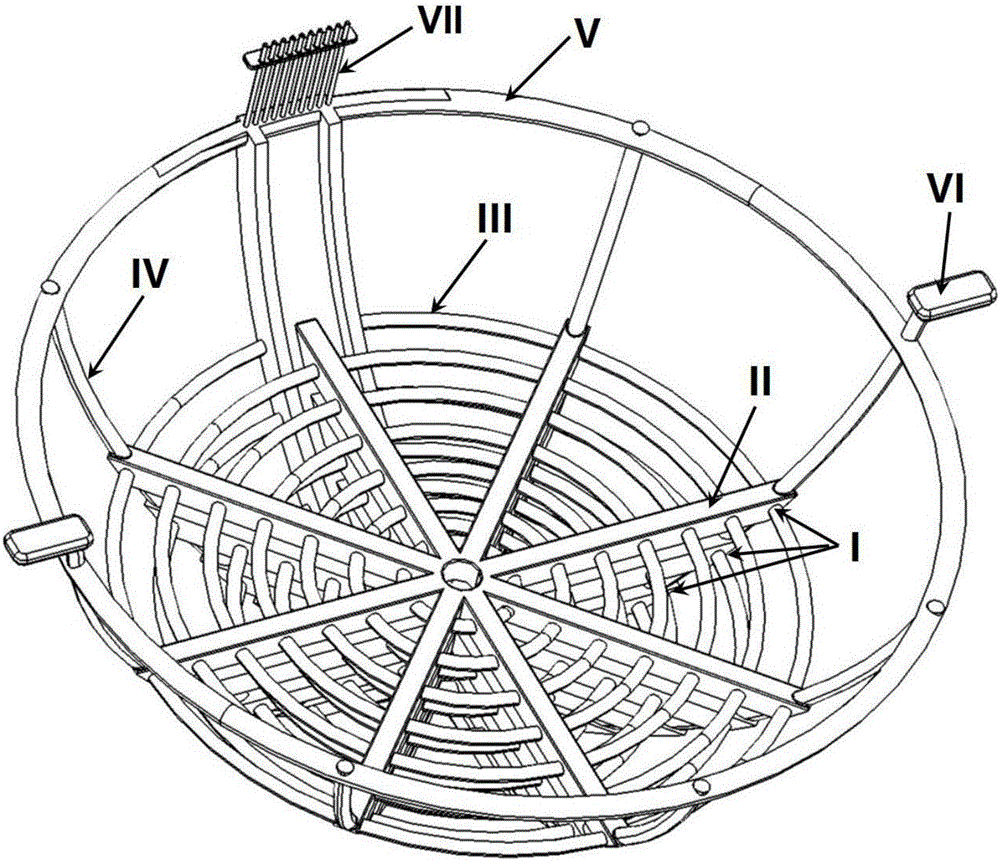

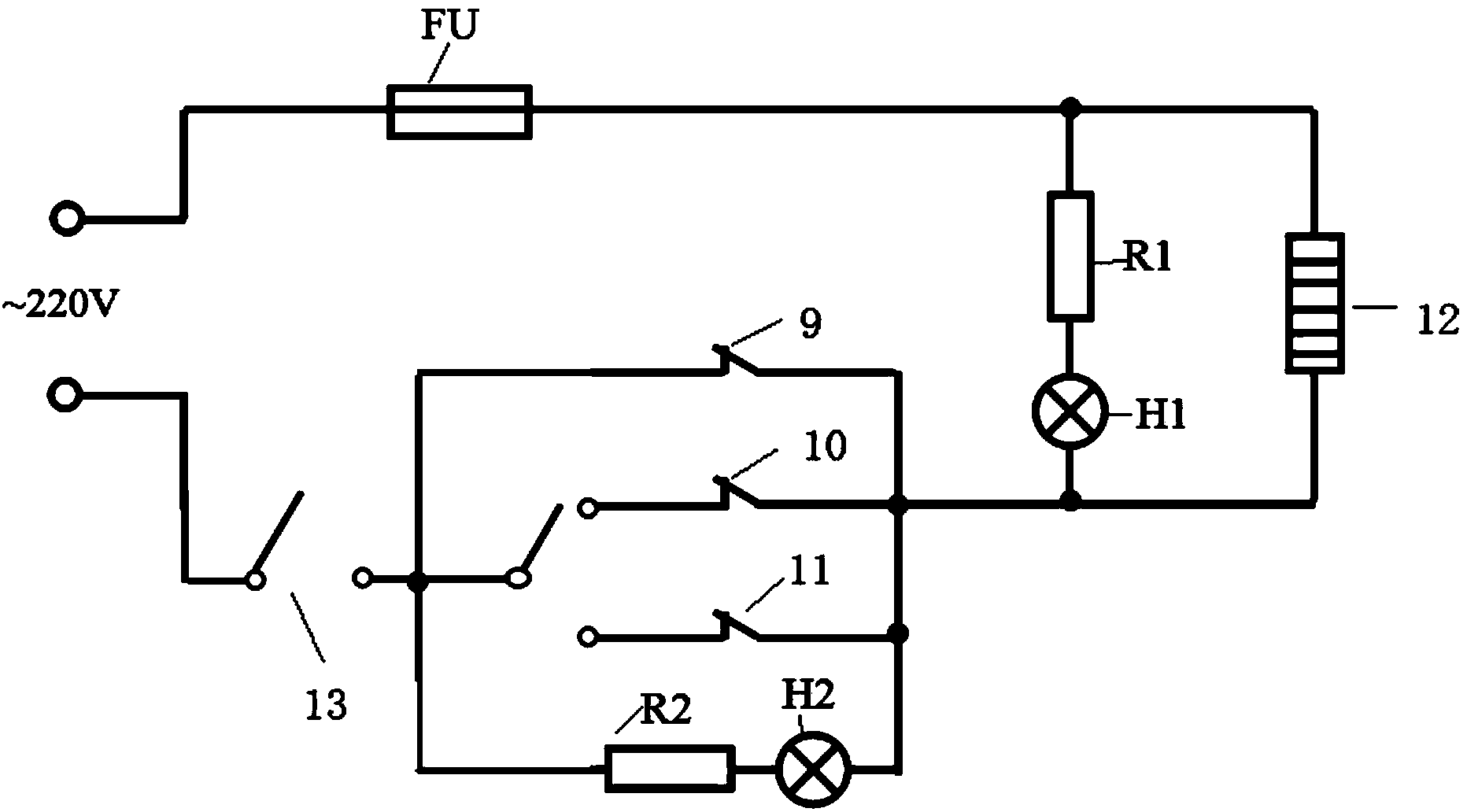

The invention discloses a rotary lifting-type gear sleeve automatic high frequency quenching device, which is composed of a bed, a pushing mechanism, a left and right guide rails component, an automatic rotating and elevating component, high frequency induction quenching, a liquid cooling device, a discharging mechanism and PLC; a piston rod end of a pushing cylinder (4) arranged on an end-face at one side of the bed (6) is connected to a pushing plate (5), and the pushing plate (5) is supported against a workpiece circumcircle in a storing rack (7) arranged in the left and right guide rails component; elastic fixed mounts (21) are symmetrically arranged at the outboard of the left and right guide rails at a third material groove station formed between the left and right guide rails (19),a spring pin (24) passes through an adjusting bolt (22), a spring of the spring pin (23) and the left and right guide rails to form inner apertures which are supported against the workpiece circumcircle in the material groove station; a spline shaft controlled by a motor through a gear and a cylinder is provided at the lower part of a fourth material groove station, the end of the spline shaft isconnected with a workpiece positioning seat; a high frequency induction coil and a spray liquid loop supported by a coil pedestal and a cooling rack supporter are provided over the fourth material groove station. The rotary lifting-type gear sleeve automatic high frequency quenching device realizes the purposes of automatic quenching and cooling workpiece.

Owner:ANHUI MINGYAN GEAR

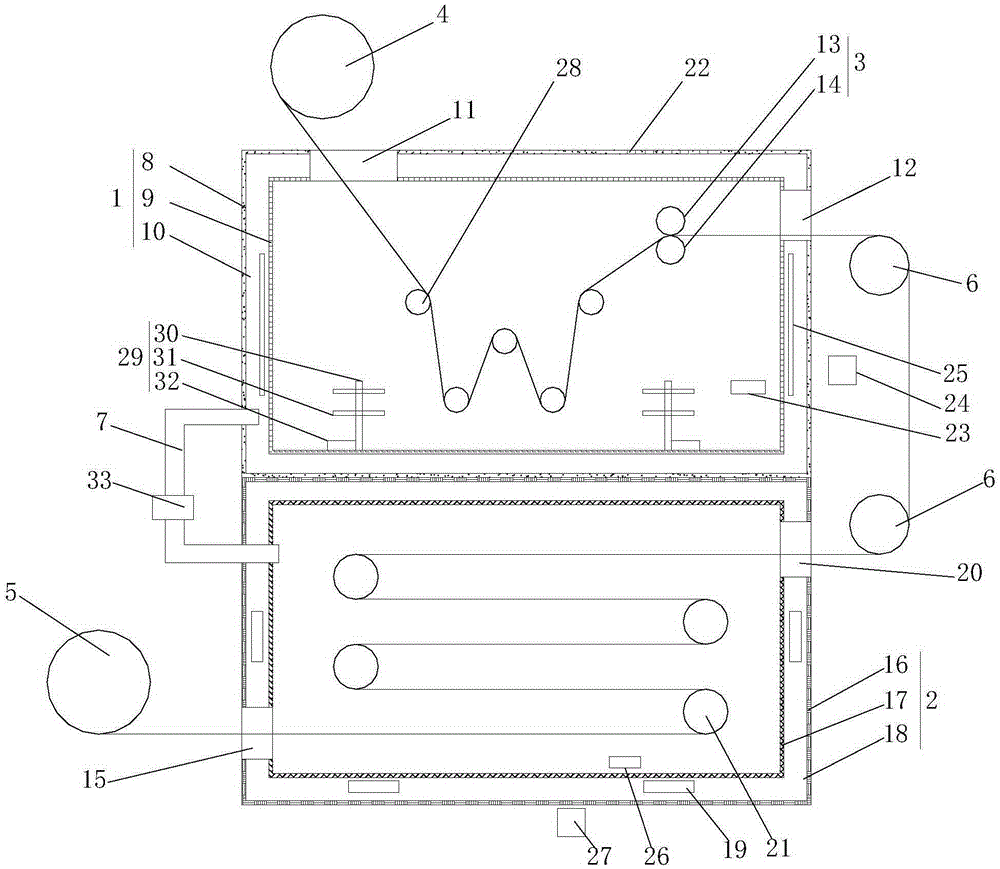

Cloth printing and dyeing device

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

Preparation and forming integrated three-dimensional printing method and preparation and forming integrated three-dimensional printing device for amorphous alloy materials

ActiveCN105728728AGuaranteed amorphous propertiesAchieve preparationAdditive manufacturing apparatusSelective laser meltingManufacturing technology

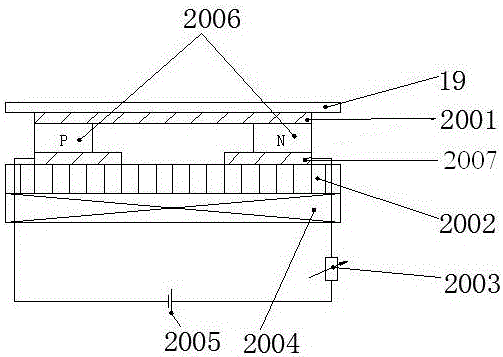

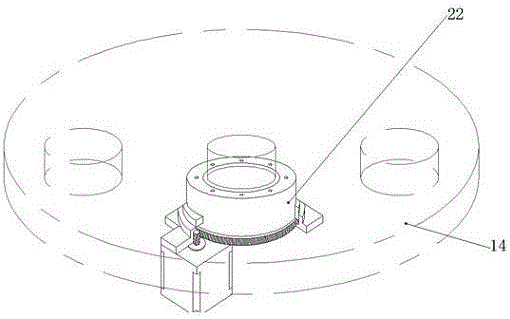

The invention relates to a preparation and forming integrated three-dimensional printing method and a preparation and forming integrated three-dimensional printing device for amorphous alloy materials, belonging to the technical field of micro-droplet jetting material increase manufacturing and amorphous alloy preparation. Crystalline molten metal is directly jetted by using a metal droplet jetting material increase manufacturing technology; environmental cooling of a substrate before metal droplet jetting and deposition droplet cooling after the metal droplet jetting are realized by adopting a method of combining a rotatable double-jetting liquid nitrogen cooling device with a cold substrate; and by using a point-to-point cooling method for two times, the molten metal can be quenched and amorphized, and further the integration of preparation of the amorphous alloy materials and three-dimensional forming of a large-size complex structure are realized. According to the preparation and forming integrated three-dimensional printing method and the preparation and forming integrated three-dimensional printing device disclosed by the invention, the limit of a traditional preparation method of an amorphous alloy in a forming critical dimension of a bulk amorphous alloy is overcome; the defects of crystallization behavior and buckling deformation generated in the selective laser melting three-dimensional printing process of amorphous alloy powder are avoided; and the problem that the amorphous alloy materials are difficult to machine is solved, and the preparation and structure forming integrated three-dimensional printing of the amorphous alloy materials is realized.

Owner:JILIN UNIV

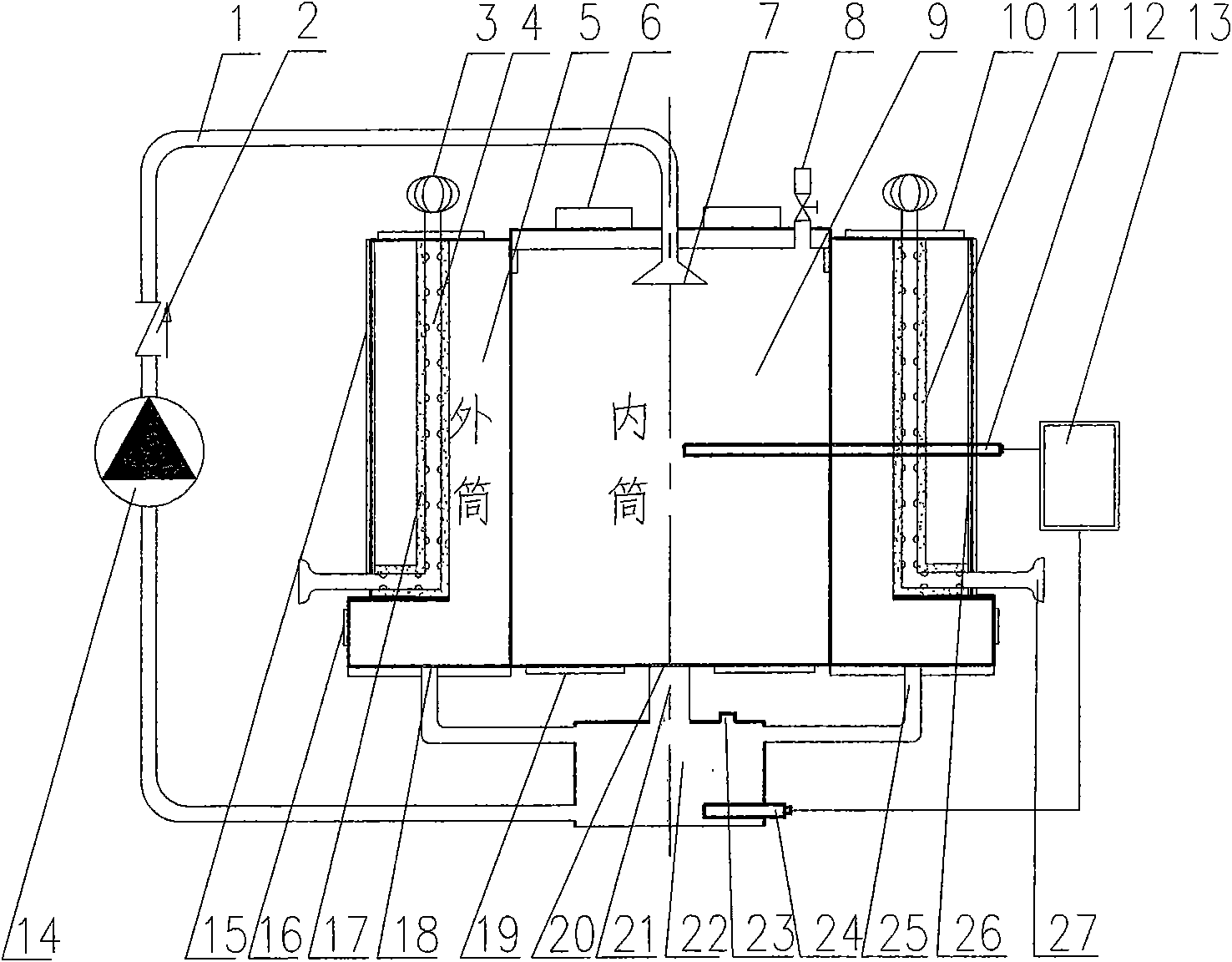

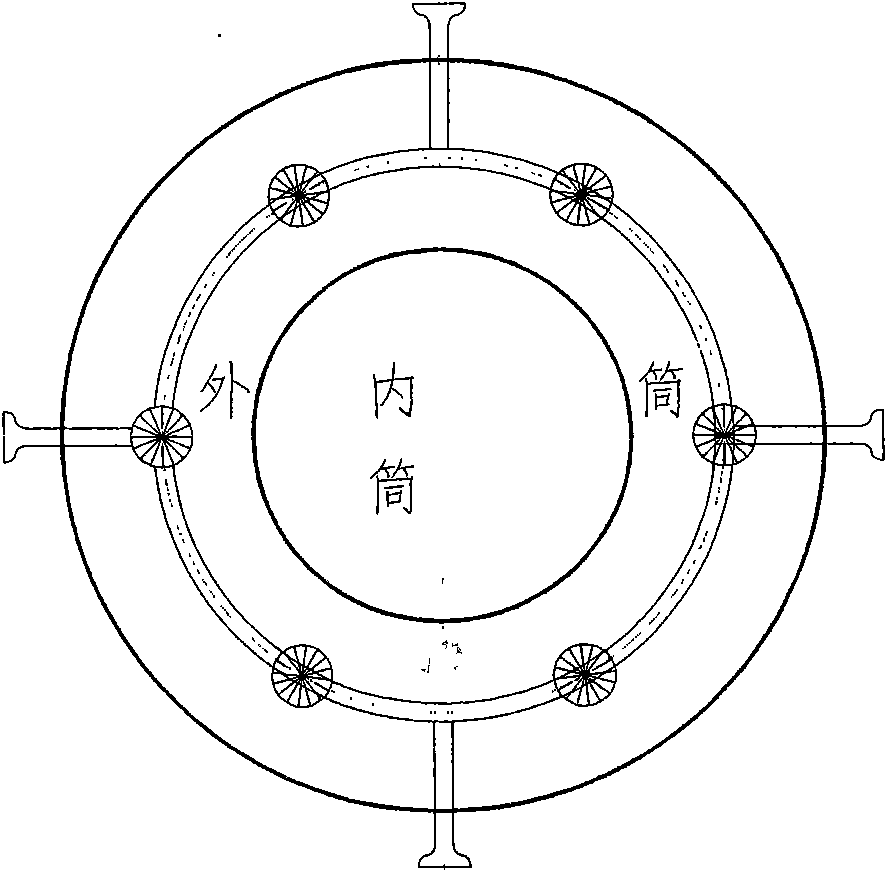

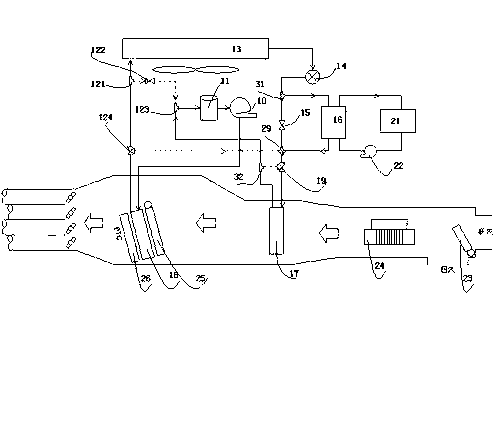

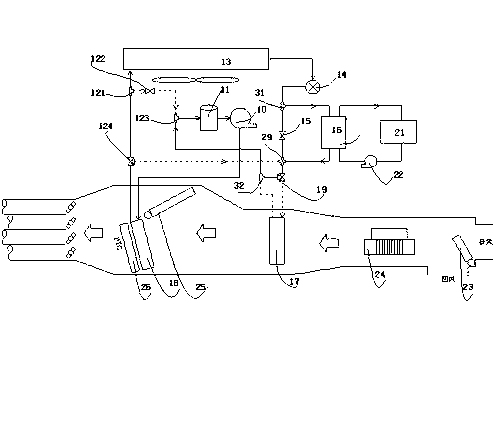

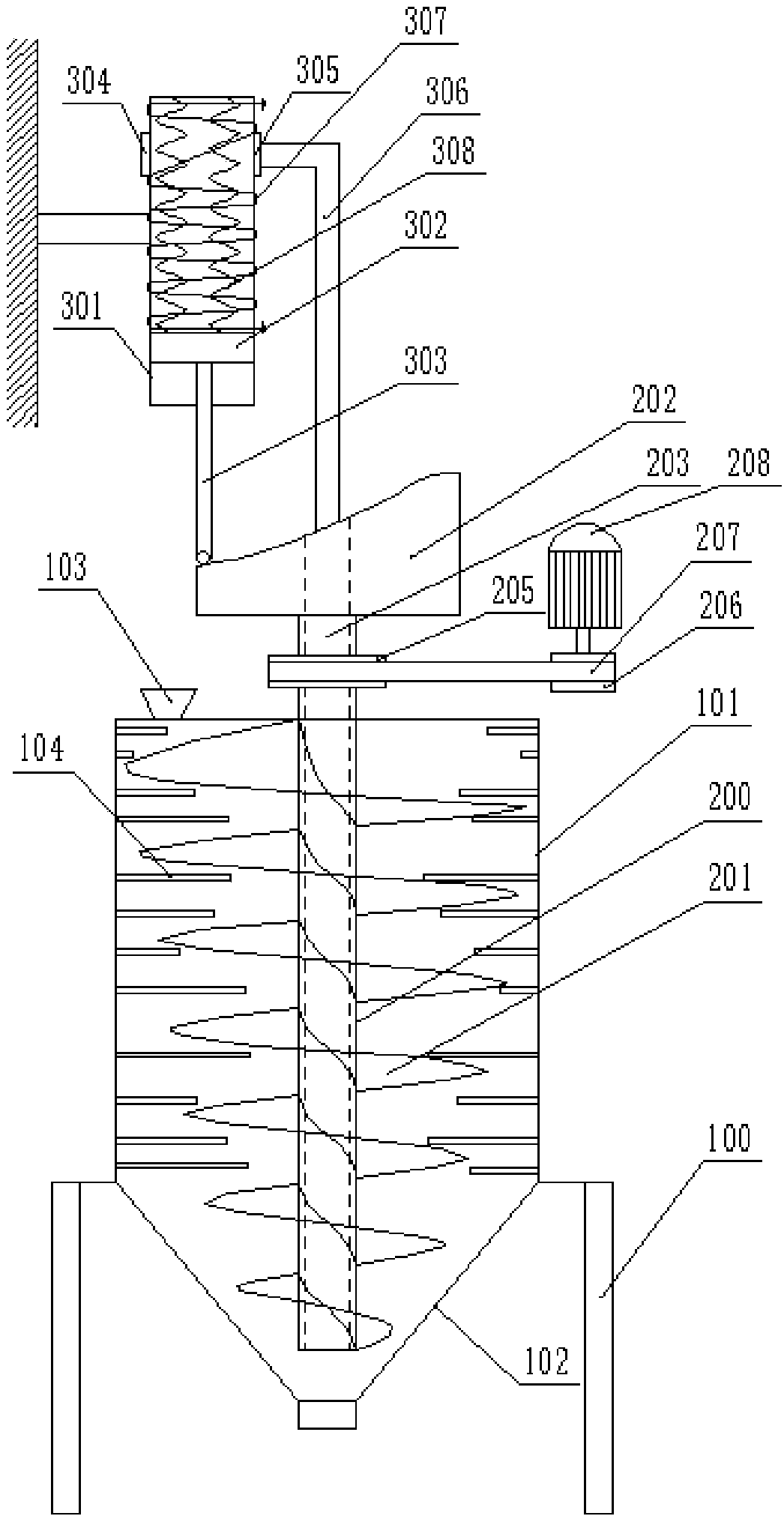

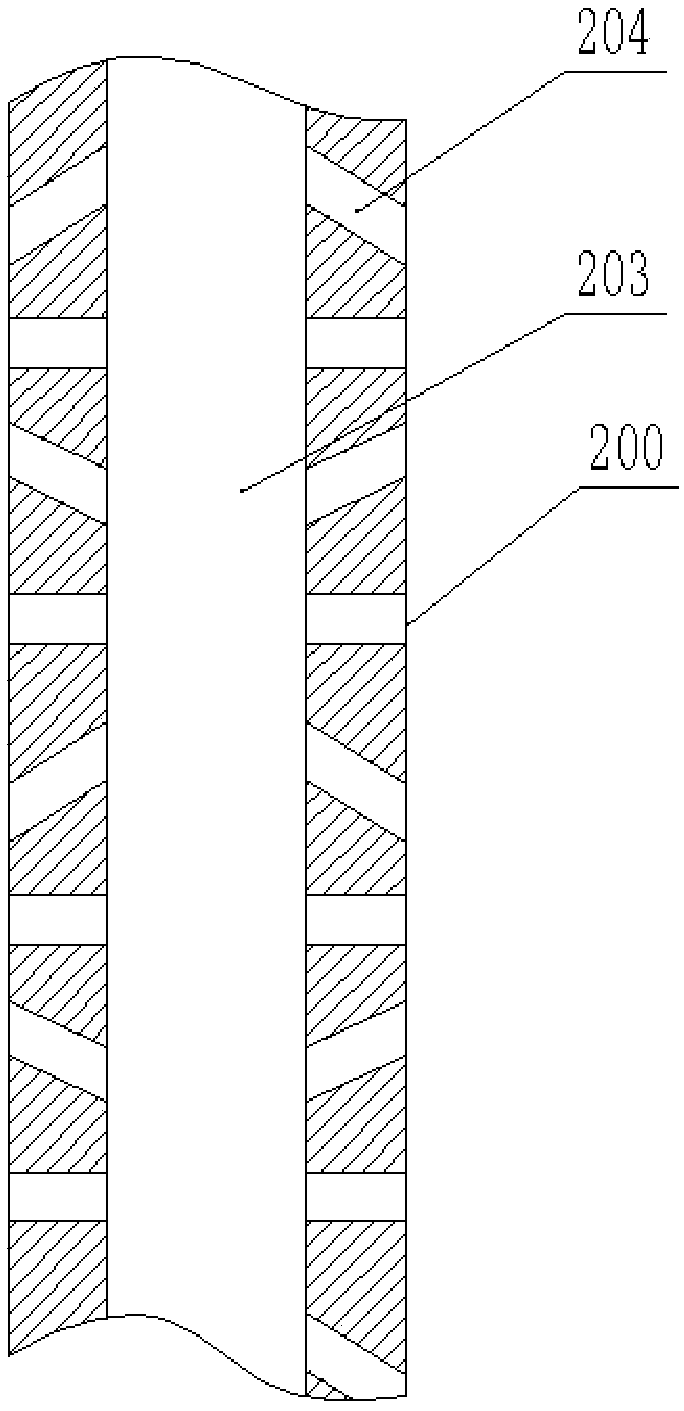

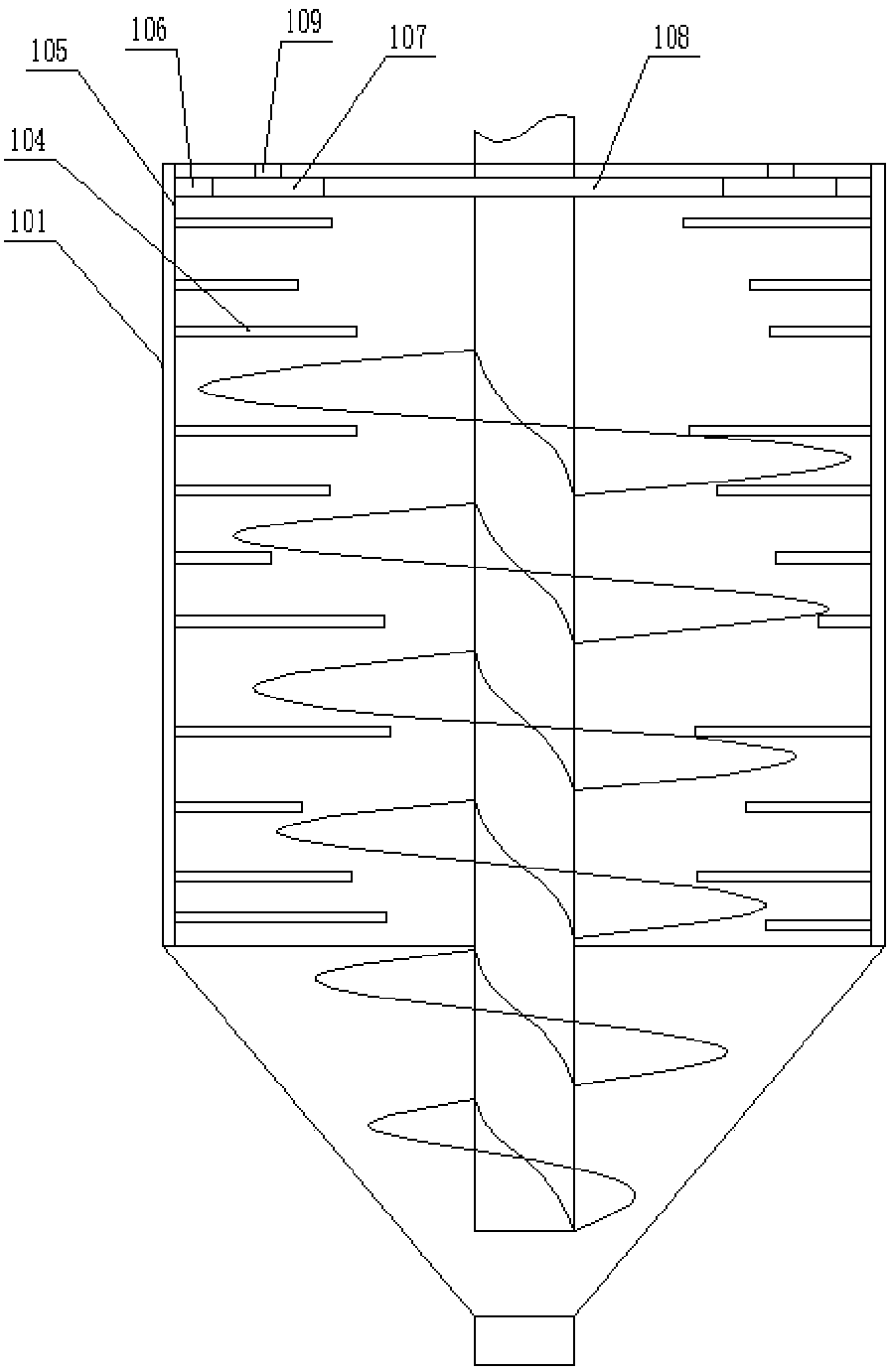

Integrated methane dry fermentation device

InactiveCN101560466AMeet aerobic needsImprove bioprocessabilityBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityTemperature control

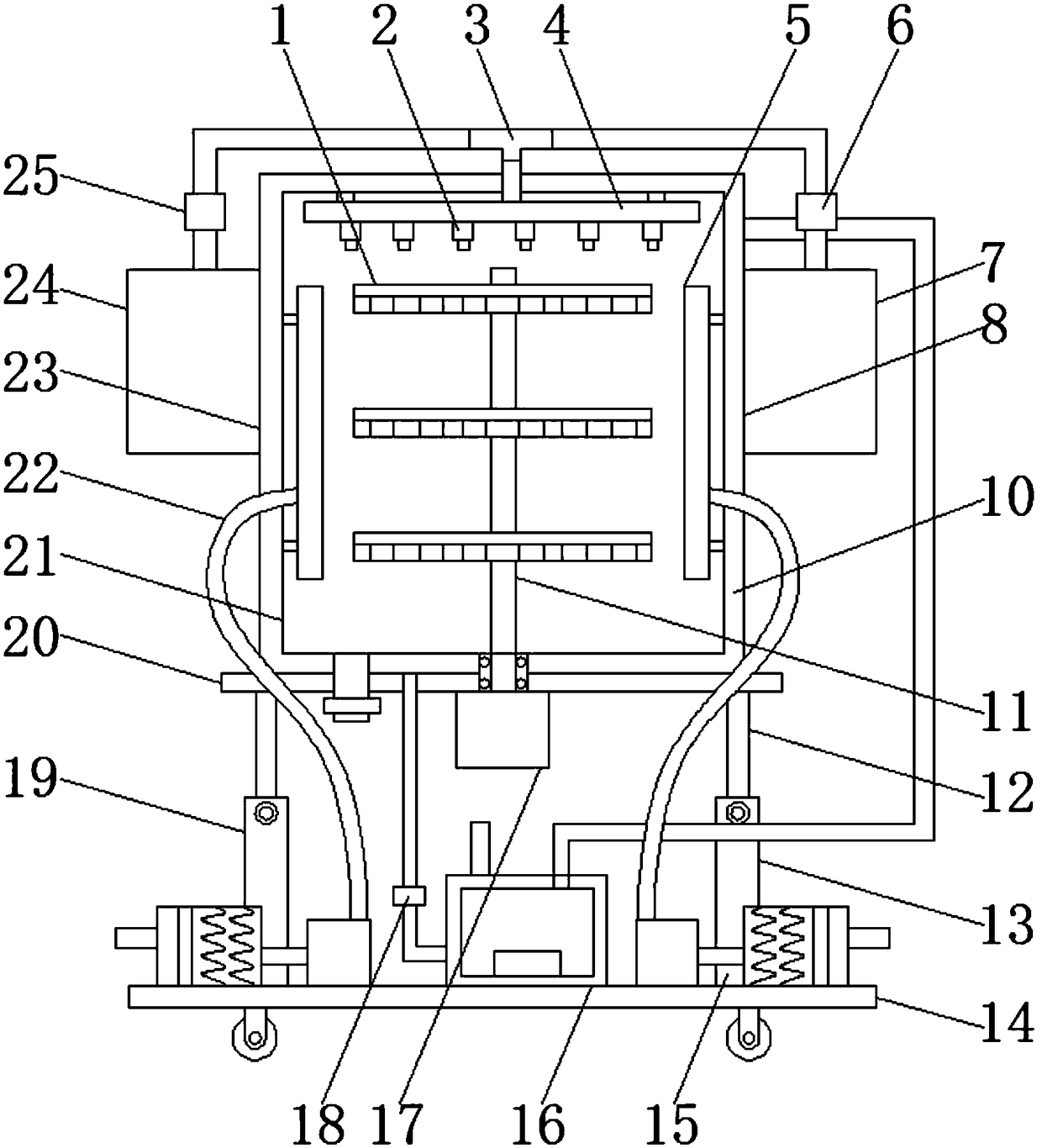

The invention relates to an integrated methane dry fermentation device and belongs to the field of energy conservation. The device consists of two parts, namely an anaerobic fermentation tank 9 of an inner cylinder and a stack retting tank 5 of an outer cylinder; and the anaerobic fermentation tank 9 of the inner cylinder is wrapped by the stack retting tank 5 of the outer cylinder, wherein the stack retting tank 5 of the outer cylinder consists of an outer cylinder feed port 10, an outer cylinder discharge port 16, a heat insulating layer 15, a thermal reflecting film 26, an outer cylinder filter screen 18, an outer cylinder fermenting liquid outlet 25, a liquid storage box 22, an air draft cover 27, an air cap 3, an air guide pipeline 4, a gravel stratum 17 and a net 11; and the anaerobic fermentation tank 9 of the inner cylinder consists of an inner cylinder feed port 6, an inner cylinder discharge port 19, an air outlet 8, a temperature sensor 12, an inner cylinder filter screen 20, an inner cylinder fermenting liquid outlet 21, a temperature controller 13, a liquid storage box 22, an electric heater 24, a circulating water pump 14, a liquid storage pipeline 1, a one way valve 2 and a nozzle 7. The device strengthens a ventilation control system, a liquid stream stirring system and a temperature controlling system of the methane dry fermentation device, has the advantages of reasonable structure, high processing efficiency, energy conservation, convenient subsequent processing, no environmental pollution and the like and is in particular suitable for the methane fermentation of a low-temperature region.

Owner:UNIV OF SCI & TECH BEIJING

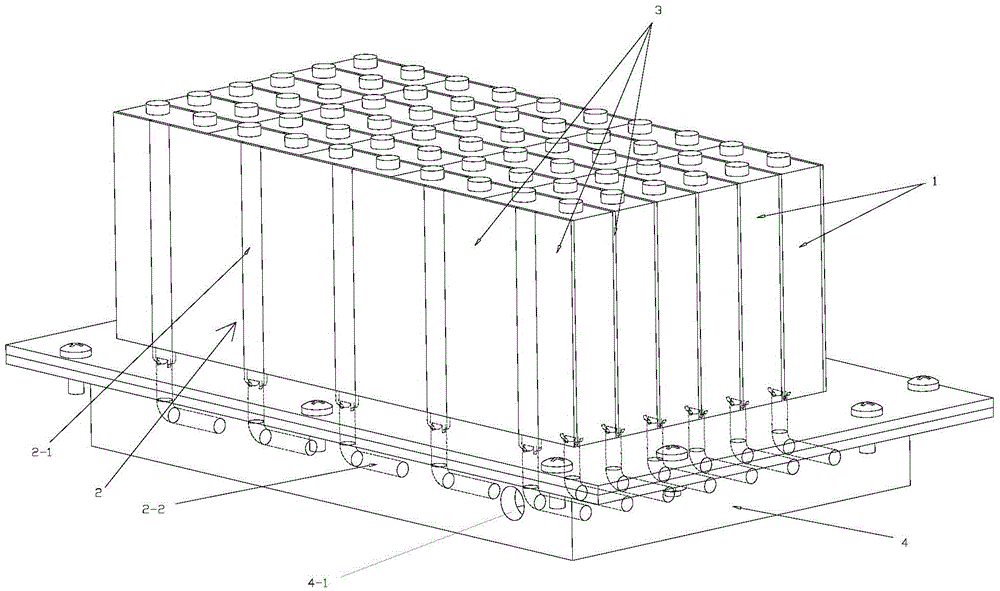

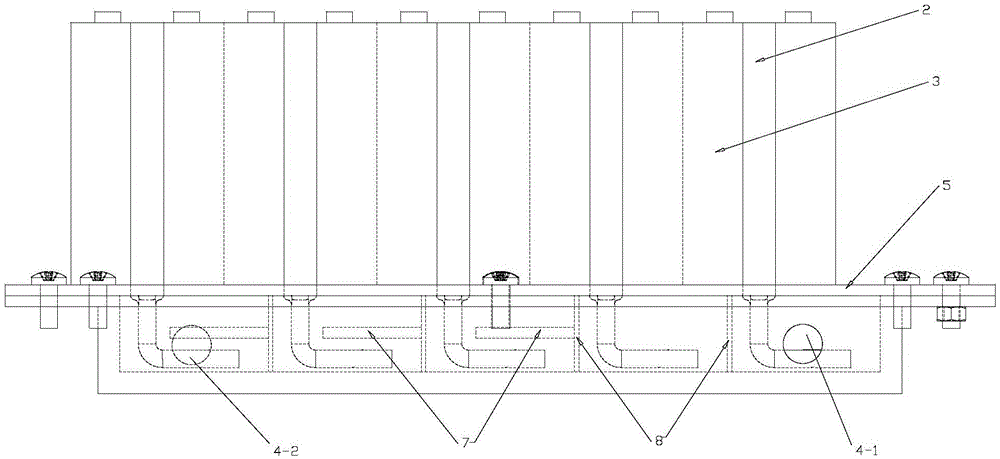

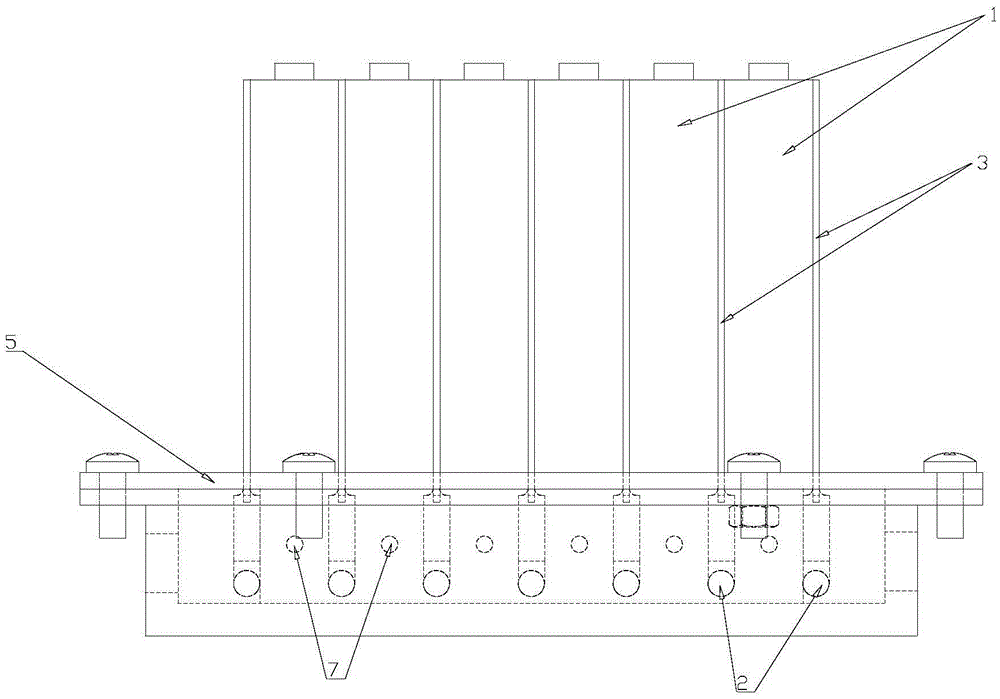

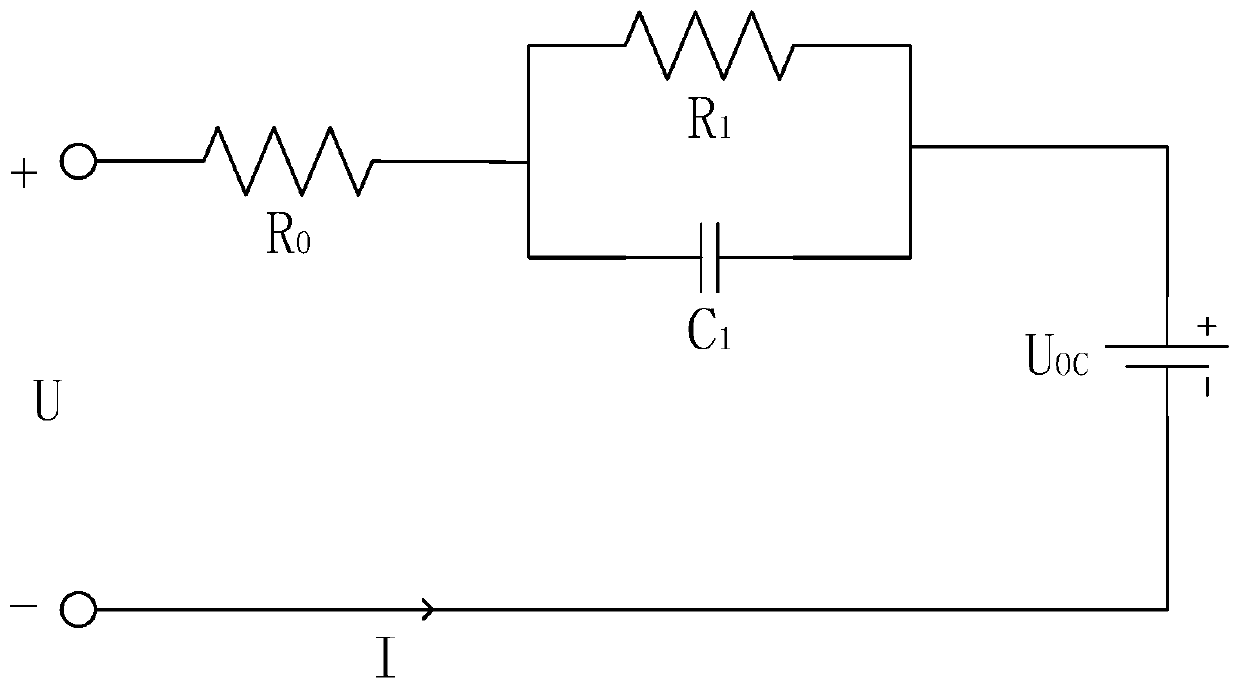

Power battery composite heat management system and method thereof

ActiveCN105633509AImprove thermal conductivityReduce weightSecondary cellsPower batteryHeat management

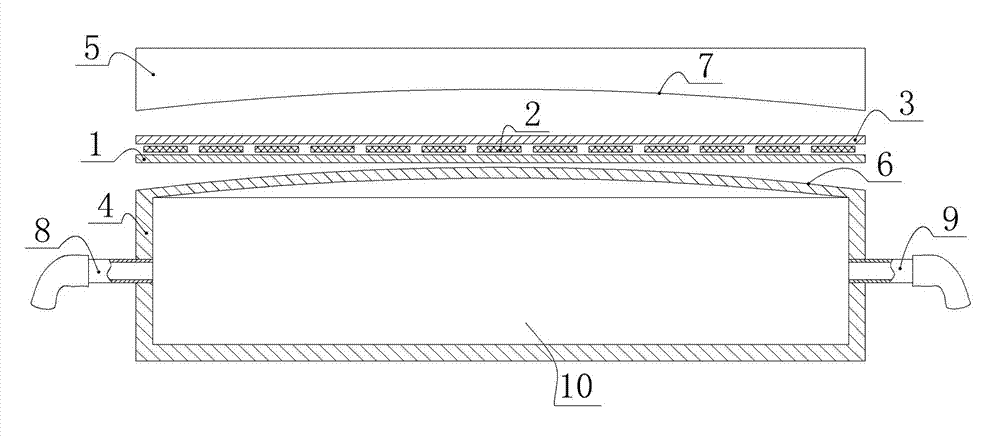

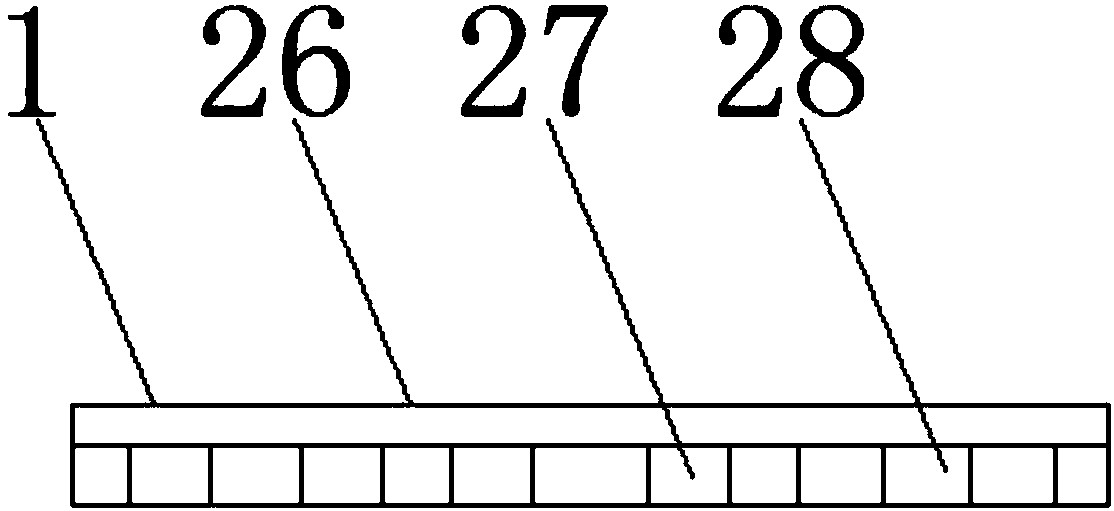

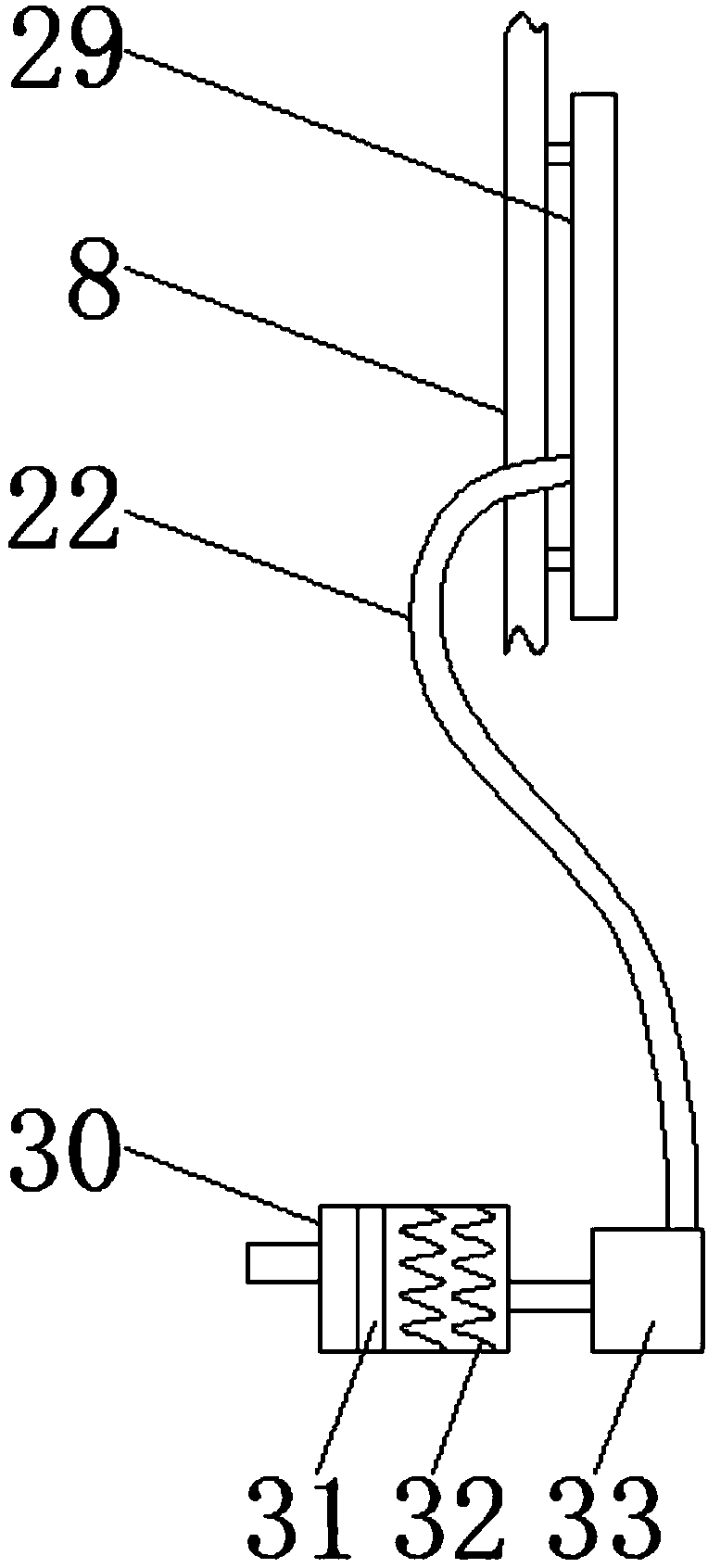

The invention discloses a power battery composite heat management system and a method thereof. The power battery composite heat management system comprises a water tank filled with a circulating fluid, a circulating pump, a sealing cover plate of the water tank, and a battery pack array which is fixedly mounted above the sealing cover plate and is composed of a plurality of battery cells, wherein a temperature equalizing plate and a heat pipe are adhered onto the surface of each battery cell respectively, and cooing sections of the heat pipes pass through the sealing cover plate to be arranged in the circulating fluid in the water tank; a circulating fluid inlet is formed in one side end of the water tank, a circulating fluid outlet is formed in the other side end of the water tank, and a circulating fluid turbulent flow structure is arranged inside the water tank, so that the circulating fluid flows into the circulating fluid outlet from the circulating fluid inlet of the water tank in a curve flowing manner. The system and the method thereof can solve the technical problems such as heat dissipation, battery pack temperature difference reduction, battery preheating and heat cyclic utilization under different working conditions of batteries; and meanwhile, the system is compact and simple in structure and convenient in installation and maintenance, accords with the development tendency of battery heat management systems and electric automobiles, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Loop-type multi-phase flow erosion test device

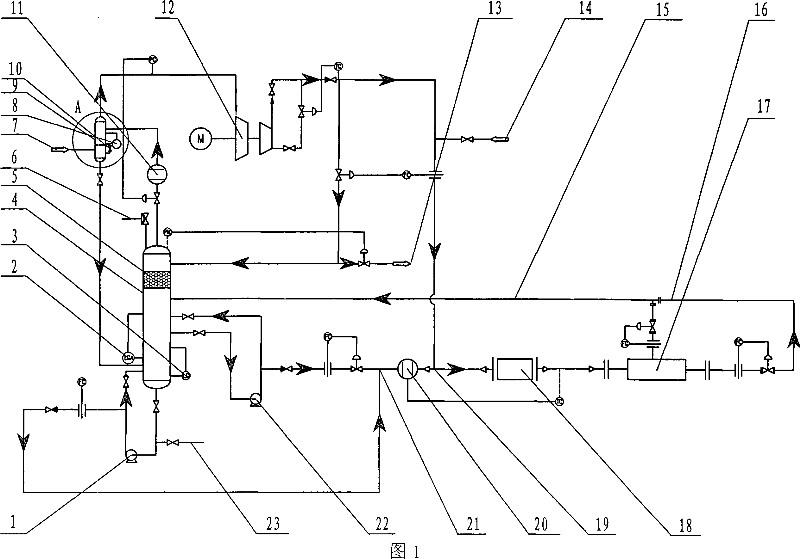

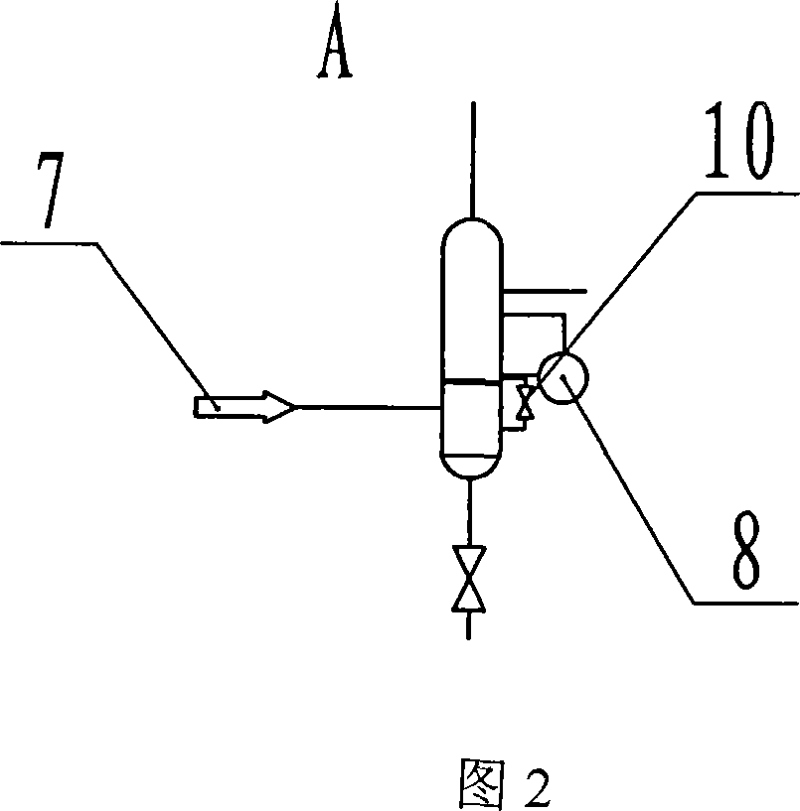

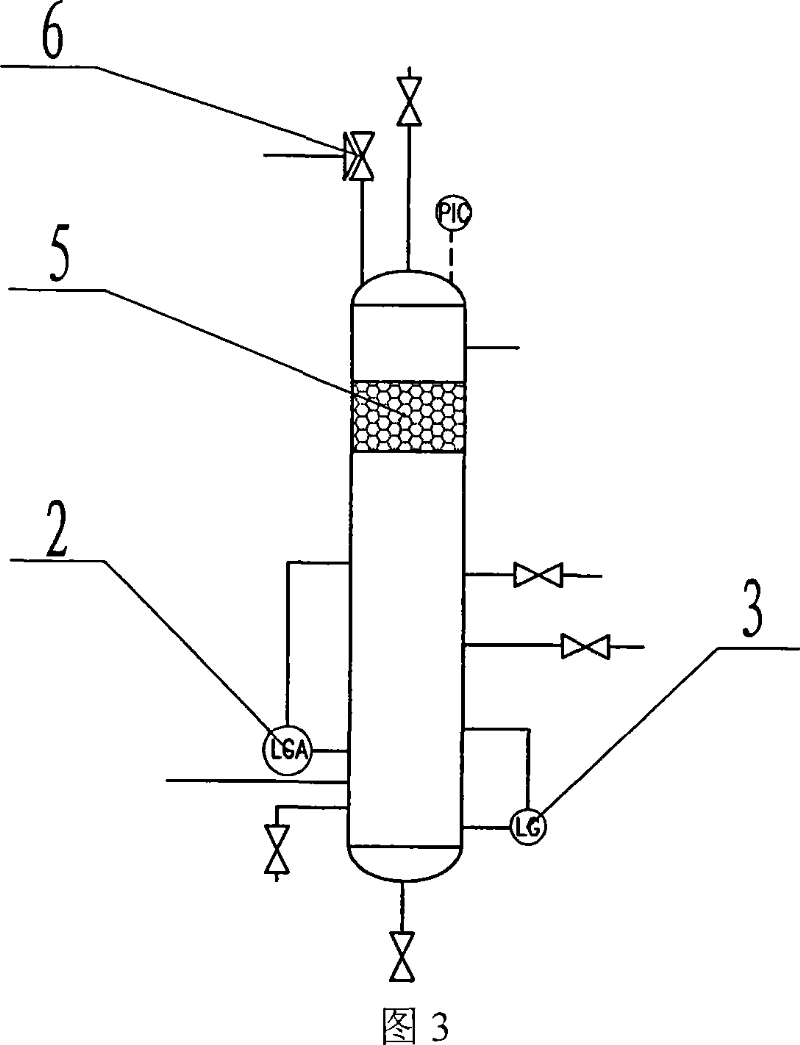

InactiveCN101038250AUniform atomizationEnsure balanceWeather/light/corrosion resistancePipeline systemsPipe fittingGas phase

The present invention discloses a ring-road type multi-phase flow erosion tester comprising a gas, oil and water three-phase separation tank and pipe circulating systems of said three phases including, in detail, a gassy system ranging from an export at the top part of the three-phase separation tank, a cooler and a cyclone separator, a circulating gas screw compressor to the pipe filter; an oil phase system ranging from an export at the middle part of the three-phase separation tank, a diesel magnetic drive pump, a heater to the pipe filter; and a water phase system ranging from an export at the bottom part of the three-phase separation tank, a wastewater metering pump, a heater to the pipe filter. After mixing, the three phases are connected to the three-phase separation tank through the pipe filter and a testing platform for pieced to be tested. The present invention is capable of simulating erosion study cases in practical pipe fittings such as tee joints, bend pipes, transition pipes and liner pipes to perform a transient characteristics prediction study of gas, oil and water multi-phase flow erosion destruction.

Owner:ZHEJIANG SCI-TECH UNIV

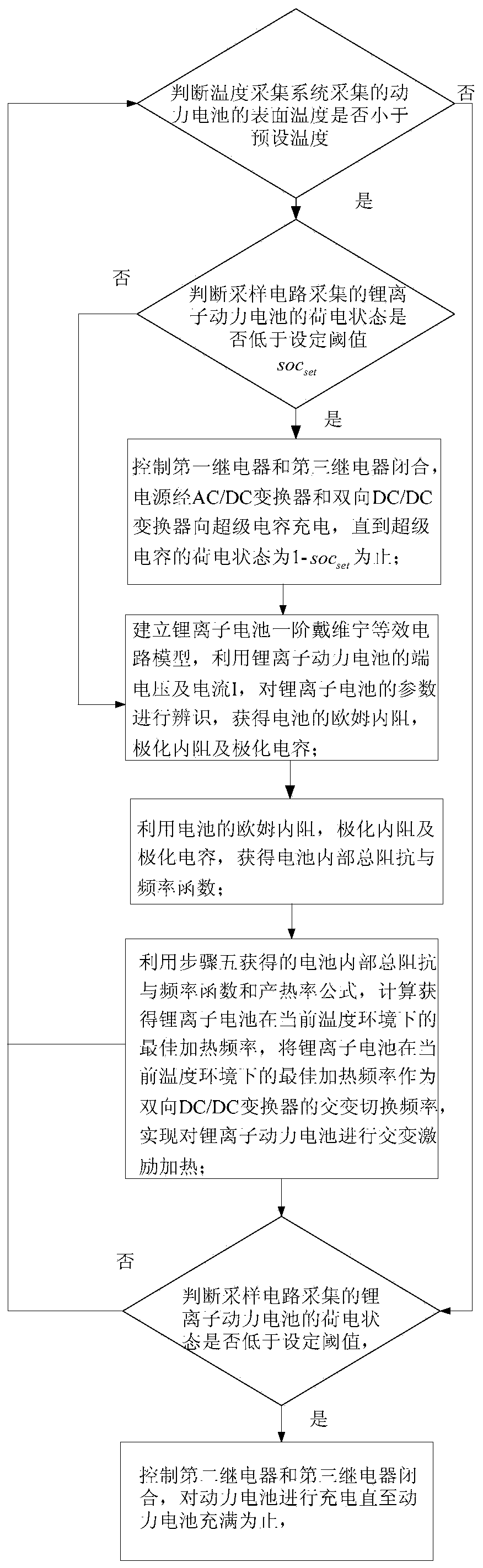

Charging/ heating control method for electric car power battery

ActiveCN109786878AReduce energy consumptionPrevent overchargingSecondary cells charging/dischargingVehicular energy storageCapacitanceElectric cars

The invention relates to a charging / heating control method for an electric car power battery, relates to the technical field of lithium-ion power battery heating and charging, and solves the problemsthat preheating needs to be carried out when the lithium-ion power battery is used under a low temperature environment but an existing external heating device is uneven in temperature distribution soas to be likely to damage the battery. By use of the method, when the surface temperature of the lithium-ion power battery is lower than a set temperature and the SOC (State Of Charge) of the batteryis lower than a preset value, a power supply charges a super capacitor, and the super capacitor carries out alternating frequency charging and discharging on the lithium-ion power battery through bidirectional DC (Direct Current) / DC. Otherwise, the lithium-ion power battery provides self-heating energy, the alternating frequency charging and discharging is carried out on the super capacitor through the bidirectional DC / DC, and the alternating frequency excitation heating of the lithium-ion power battery is realized. When the temperature of the lithium-ion power battery is greater than a set temperature and the lithium-ion power battery is not fully charged, the lithium-ion power battery is charged until the electric quantity of the lithium-ion power battery is full. The method is suitablefor heating and charging the power battery.

Owner:HARBIN UNIV OF SCI & TECH

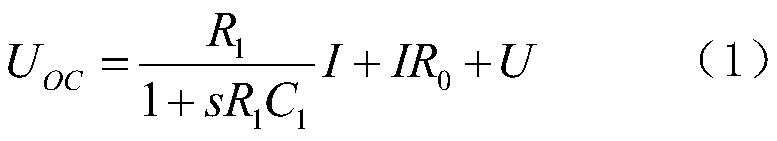

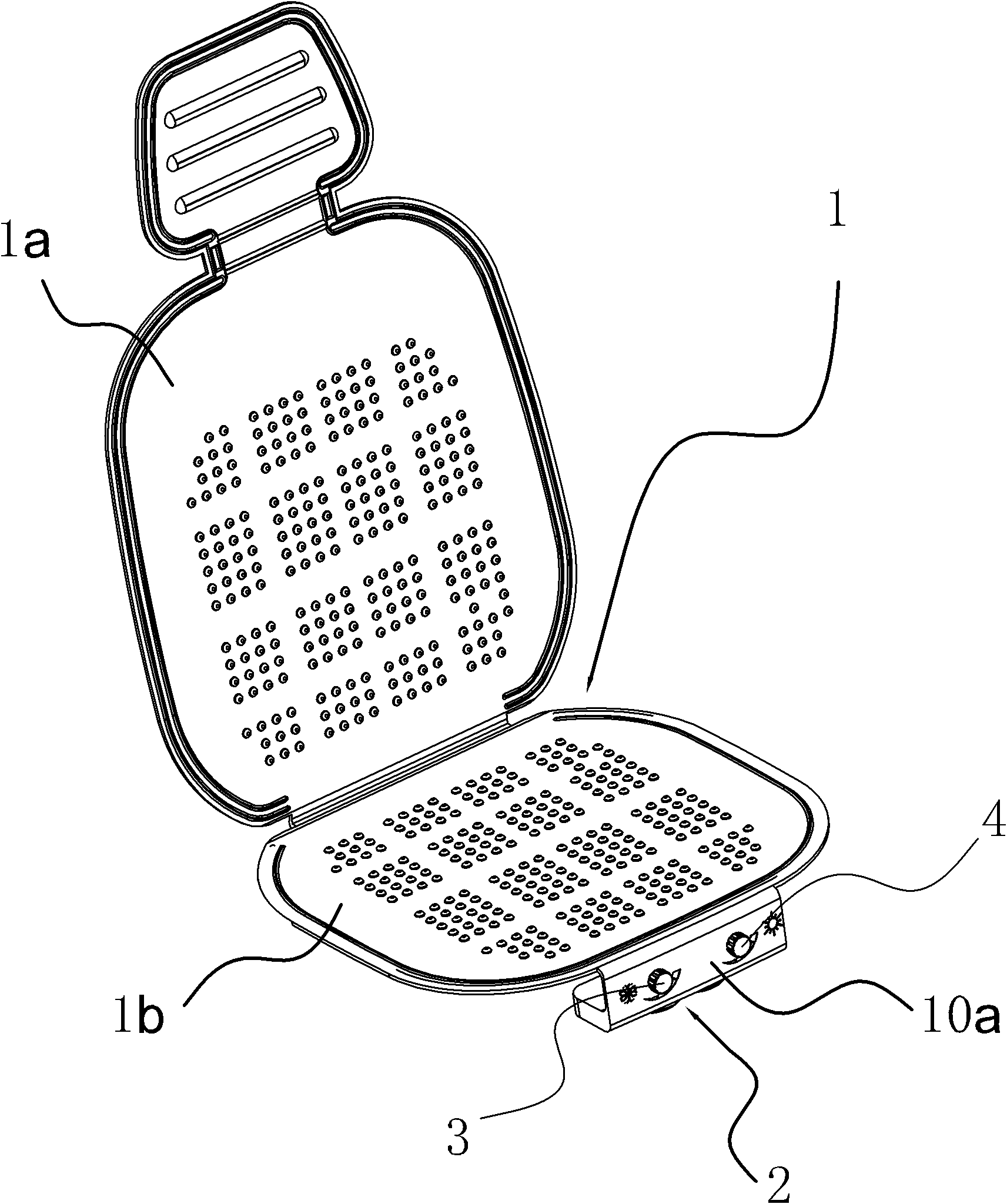

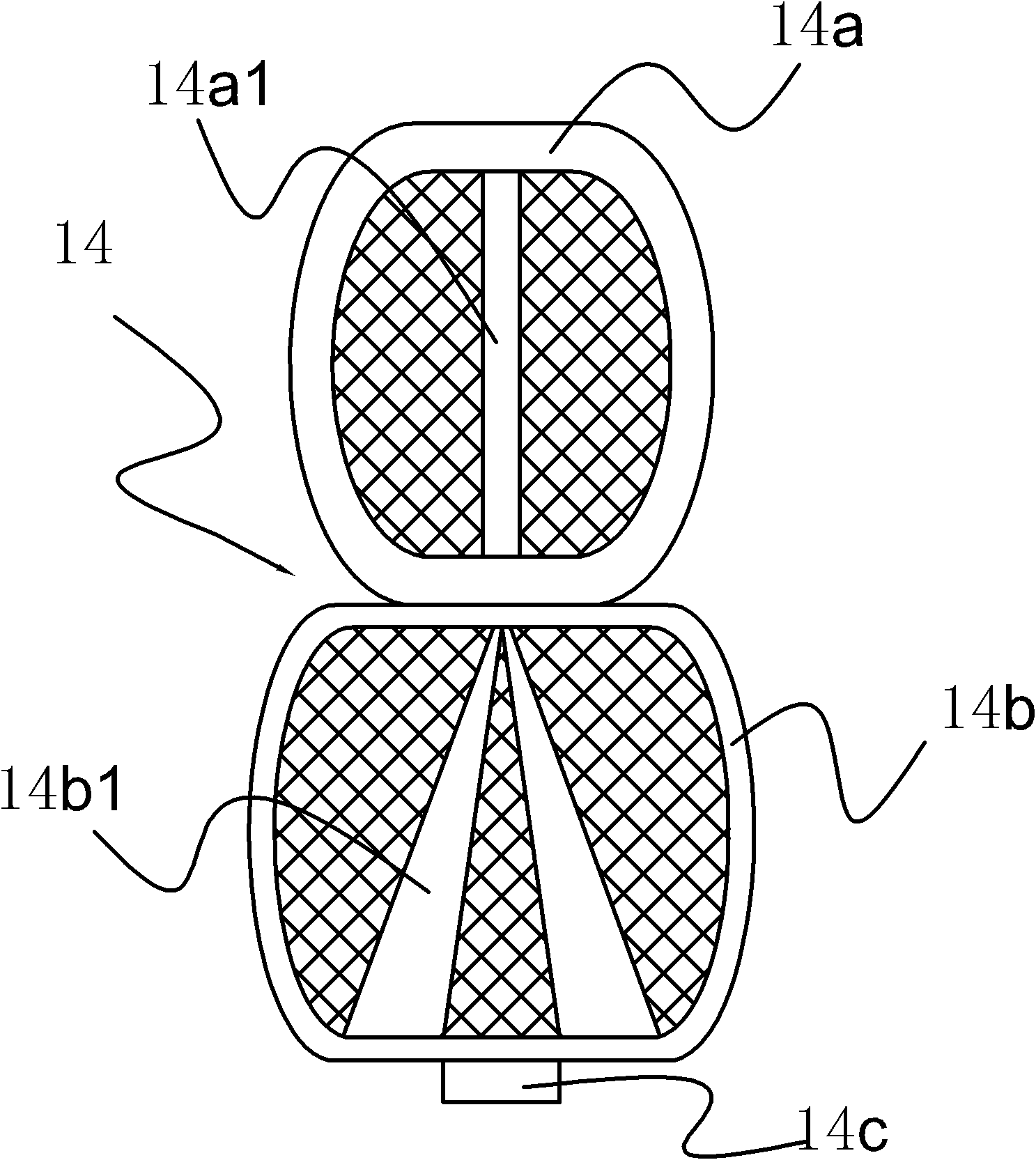

Cold-heat type automobile seat cushion

InactiveCN102310793AIncrease temperatureEffective temperature regulationSeat heating/ventillating devicesTemperature controlEngineering

The invention provides a cold-heat type automobile seat cushion, belonging to the technical field of automobiles and solving the problems that the traditional automobile seat cushion cannot provide refrigerating and heating functions simultaneously. The cold-heat type automobile seat cushion comprises a cushion body which is internally provided with a temperature control member and a temperature-controlled adjusting device for adjusting the cold and heat temperatures of the cushion body. The cold-heat type automobile seat cushion is characterized in that the temperature-controlled member is ametal plate clamped inside the cushion body; the temperature-controlled adjusting device is arranged at the side part of the cushion body and comprises a casing and a conducting strip, a refrigerating strip, a heat radiator and a fan which are sequentially arranged inside the casing; the conducting strip and the metal plate are connected to form a whole; one end face of the refrigerating strip istightly attached and fixed with one side end face of the conducting strip; the other end face of the refrigerating strip is tightly attached and fixed with the heat radiator; and ventilating ports are arranged on the corresponding wall bodies of the casing. The temperature control over the conducting strip is realized by using a semiconductor refrigerating strip, thereby the adjustment on the cold and heat temperature of the cushion body is realized. The cold-heat type automobile seat cushion has a simple structure and convenience for use.

Owner:TAIZHOU TAI CHENG ELECTRONICS TECH

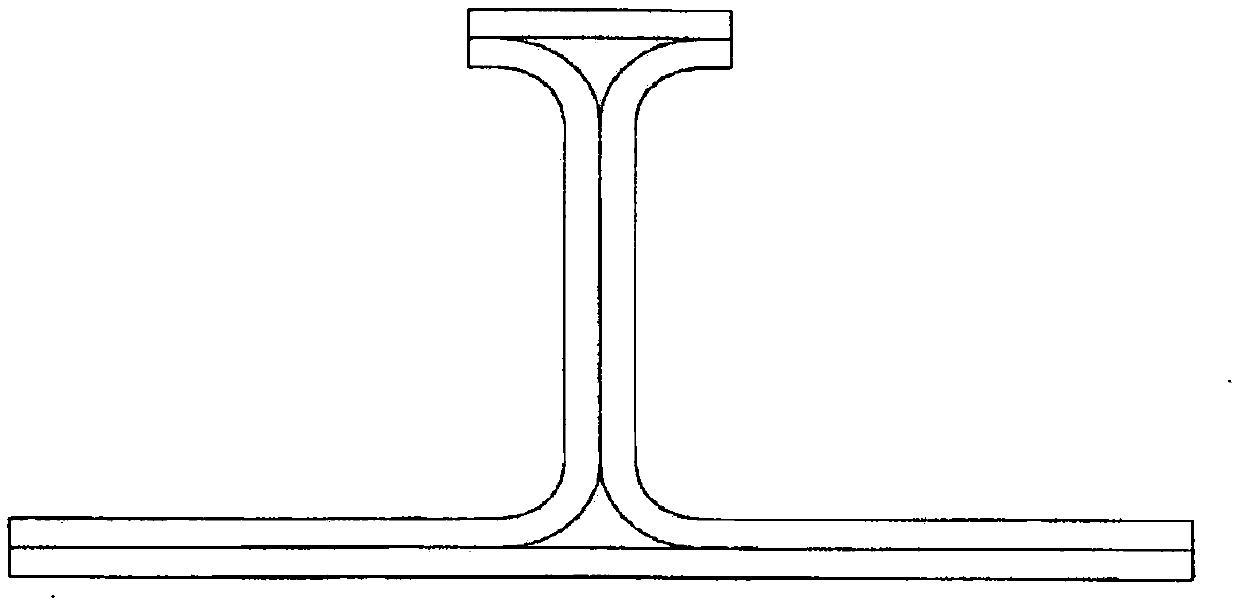

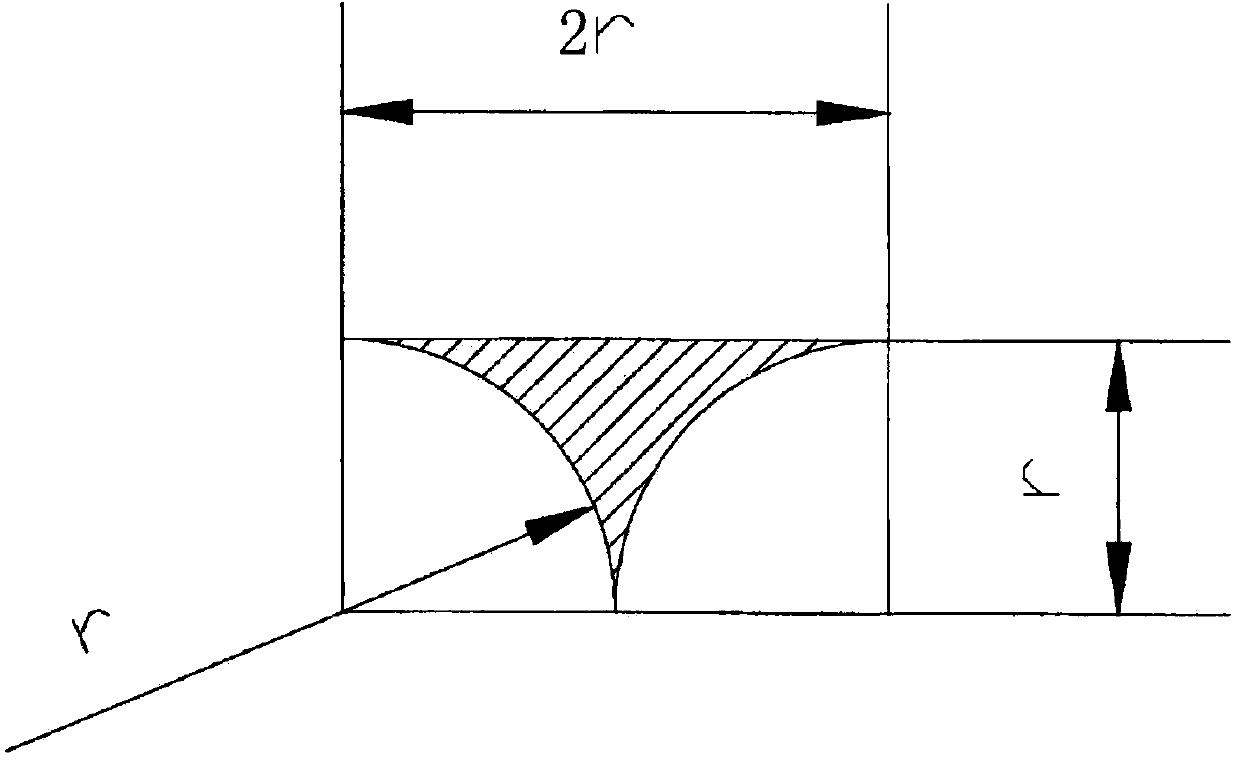

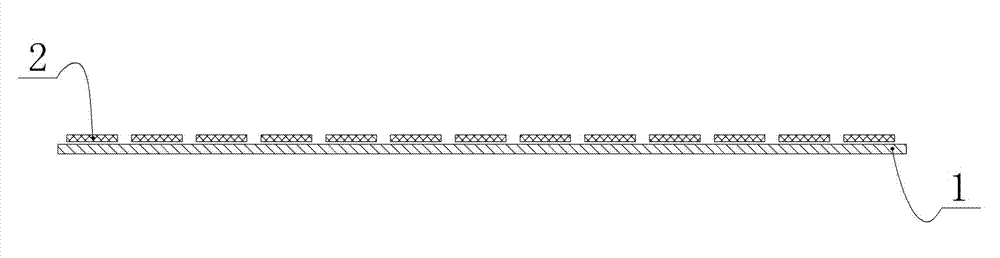

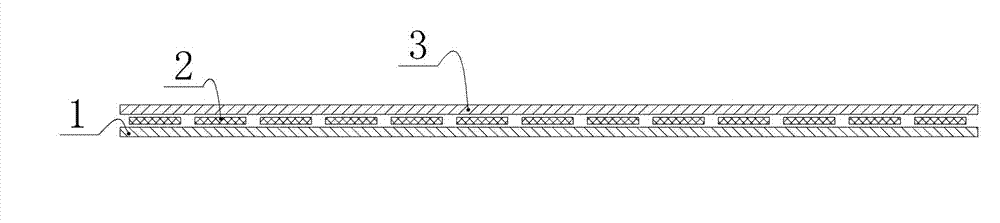

Filled 0-degree carbon fiber prepreg preforming tooling and preforming process

The invention discloses a filled 0-degree carbon fiber prepreg preforming tooling and a preforming process. The tooling comprises a forming pressure plate, forming mandrels, a base plate and limit stops, wherein multiple forming mandrels are closely and parallelly arranged on the base plate, the chamfers of the forming mandrels are consistent with an R angle of a long joist, filled 0-degree carbon fiber prepregs are located at the chamfers of the forming mandrels, the pressure plate is arranged above the mandrels, and the outer sides of the mandrels at the two ends are respectively provided with a limit stop. The preforming process comprises the following steps: (1) manufacturing a preforming tooling; (2) calculating the theoretic application amount of filled 0-degree carbon fiber prepregs; and (3) filling the 0-degree carbon fiber prepregs: weighting the 0-degree carbon fiber prepregs, cutting the 0-degree carbon fiber prepregs into fiber bundles with a size of 3-4mm, feeding the cut 0-degree carbon fiber prepregs into the preforming tooling, slightly compacting the prepregs by using a scraping plate, and after the prepregs are subjected to vacuum compaction on a heating platform at temperature of 70-80 DEG C for 15 min, transferring the prepregs to a normal-temperature workbench for cooling, and then taking out the obtained products. According to the invention, the forming quality of long joists is improved, and a situation that the shape of long joists after being manufactured is irregular is greatly improved.

Owner:SHENYANG AIRCRAFT CORP

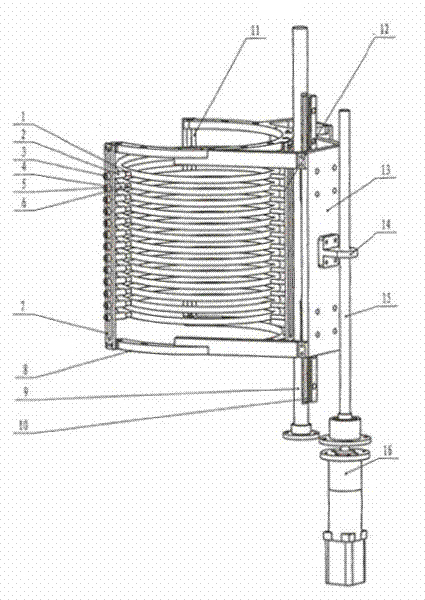

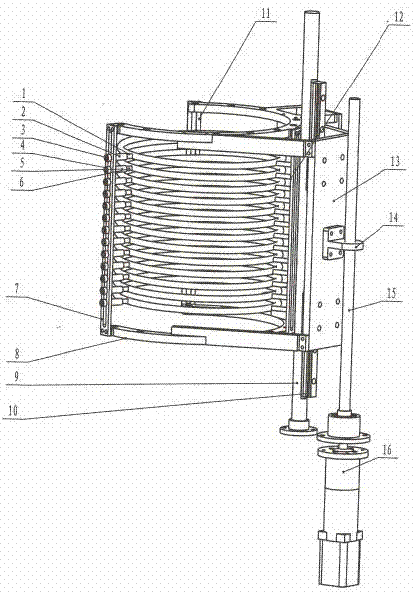

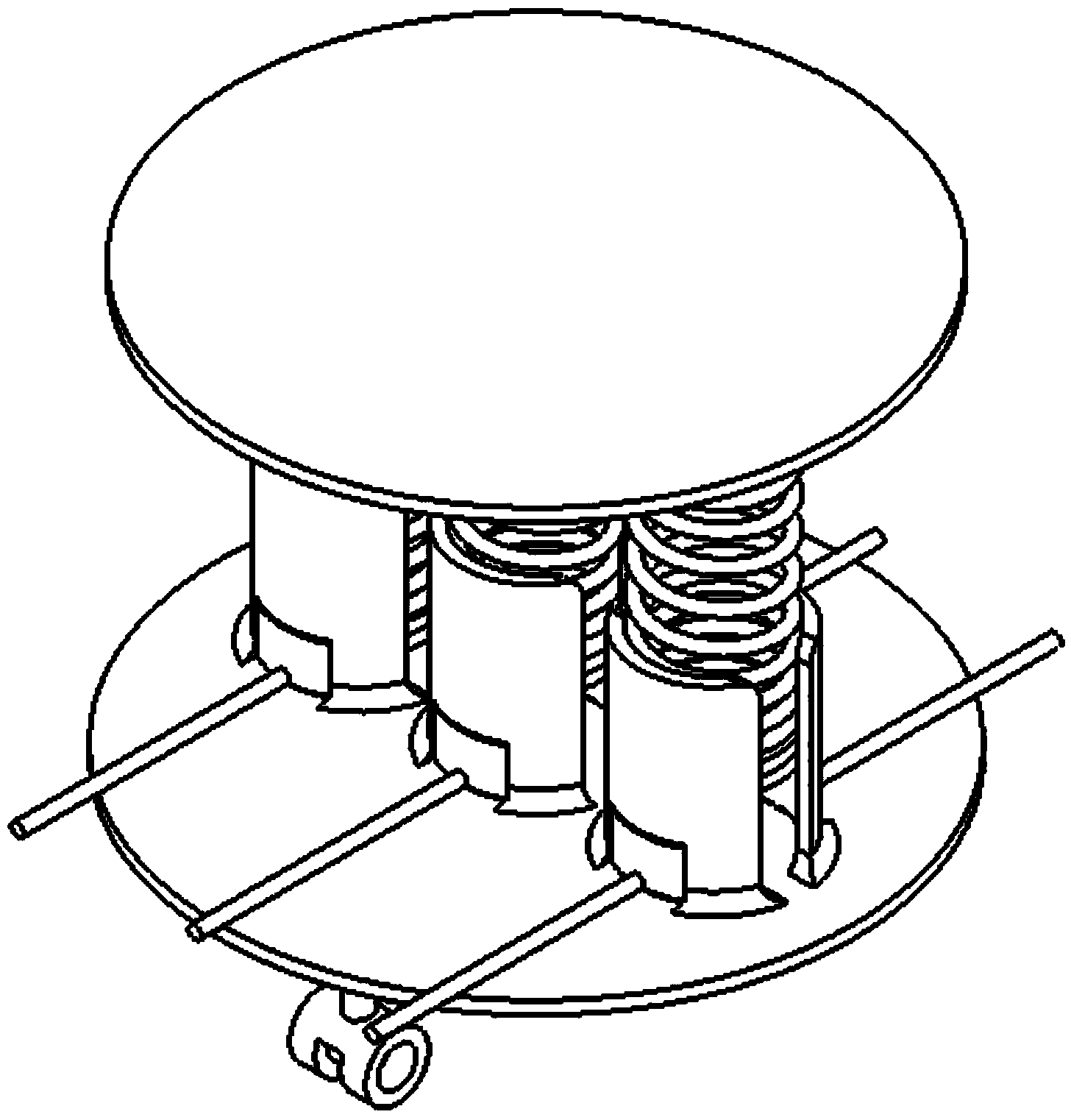

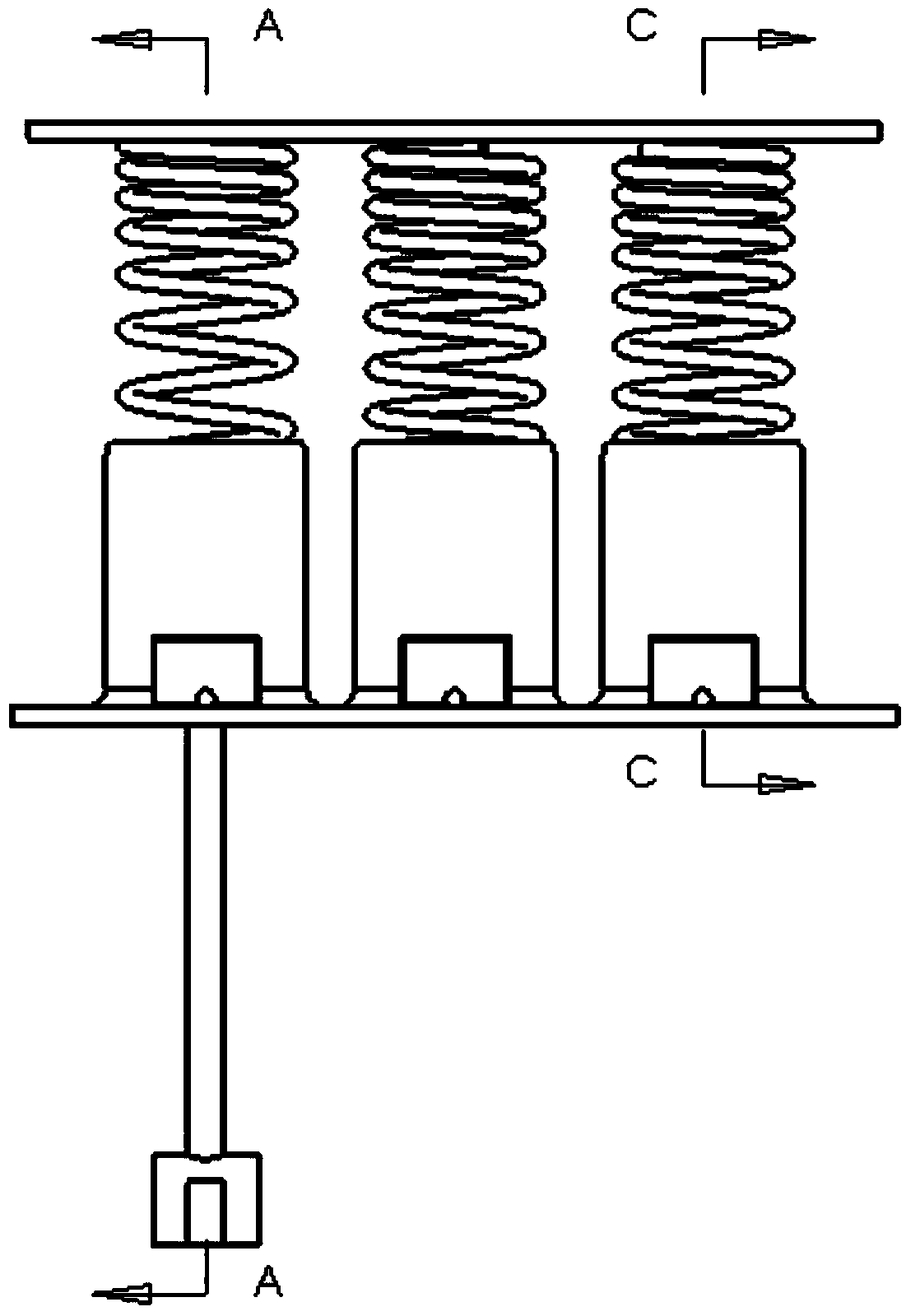

A movable and adjustable induction heating coil mechanism

The invention discloses a movable and adjustable induction heating coil mechanism, which solves the problem that a heating coil in a conventional induction heating mechanism cannot move and the degree of closeness of the heating coil cannot be adjusted. The movable and adjustable induction heating coil mechanism comprises a rack, a V-shaped movable base and a semi-cylindrical coil bracket (8). A vertical guide rail (10) is arranged on a guide rail support (9). The inside surface of a bottom plate guide rail sliding plate (13) on the V-shaped movable base is in sliding fit with the guide rail (10). The V-shaped bracket, extended towards lateral surfaces, on the V-shaped movable base is fixedly connected with the semi-cylindrical coil bracket (8). Vertical adjustment grooves are formed on each fixed vertical bar. A plurality of adjustment bolts are arranged in the vertical adjustment grooves. A lead screw nut (14) is arranged on the outside surface of the bottom plate guide rail slidingplate (13) on the V-shaped movable base. A lead screw (15) is fixedly connected with an output shaft of a lifting adjustment motor (16) arranged on the rack. The movable and adjustable induction heating coil mechanism has a simple structure and low cost.

Owner:SHANXI SEMICORE CRYSTAL CO LTD

Car air-conditioning system

ActiveCN103158486AAvoid the impact of high and low temperatureExtended service lifeAir-treating devicesVehicle heating/cooling devicesRefrigerantChiller

A car air-conditioning system comprises a heating component temperature control circuit and a heat pump system with a refrigerant circulation loop. The heating component temperature control circuit and the heat pump system with the refrigerant circulation loop exchange heat through a double passageway heat exchanger. The car air-conditioning system comprises a refrigerating mode, a heating mode and a demist mode. The heat pump system with the refrigerant circulation loop comprises a compressor, a gas-liquid separator, a heater and a cooler, a compartment outer heat exchanger and a throttling component. The heater and the cooler conduct heating, cooling or demisting on the compartment according to working condition requirements in the compartment. The refrigerant passes through the heater after coming out from the compressor, the heater can choose whether to conduct heat exchange, and then the refrigerant flows into the compartment outer heat exchanger. The heater of the heat pump system just passes hot refrigerant, and the cooler just passes the cold refrigerant so as to avoid heat and cold shock and improve service life.

Owner:SANHUA HLDG GRP

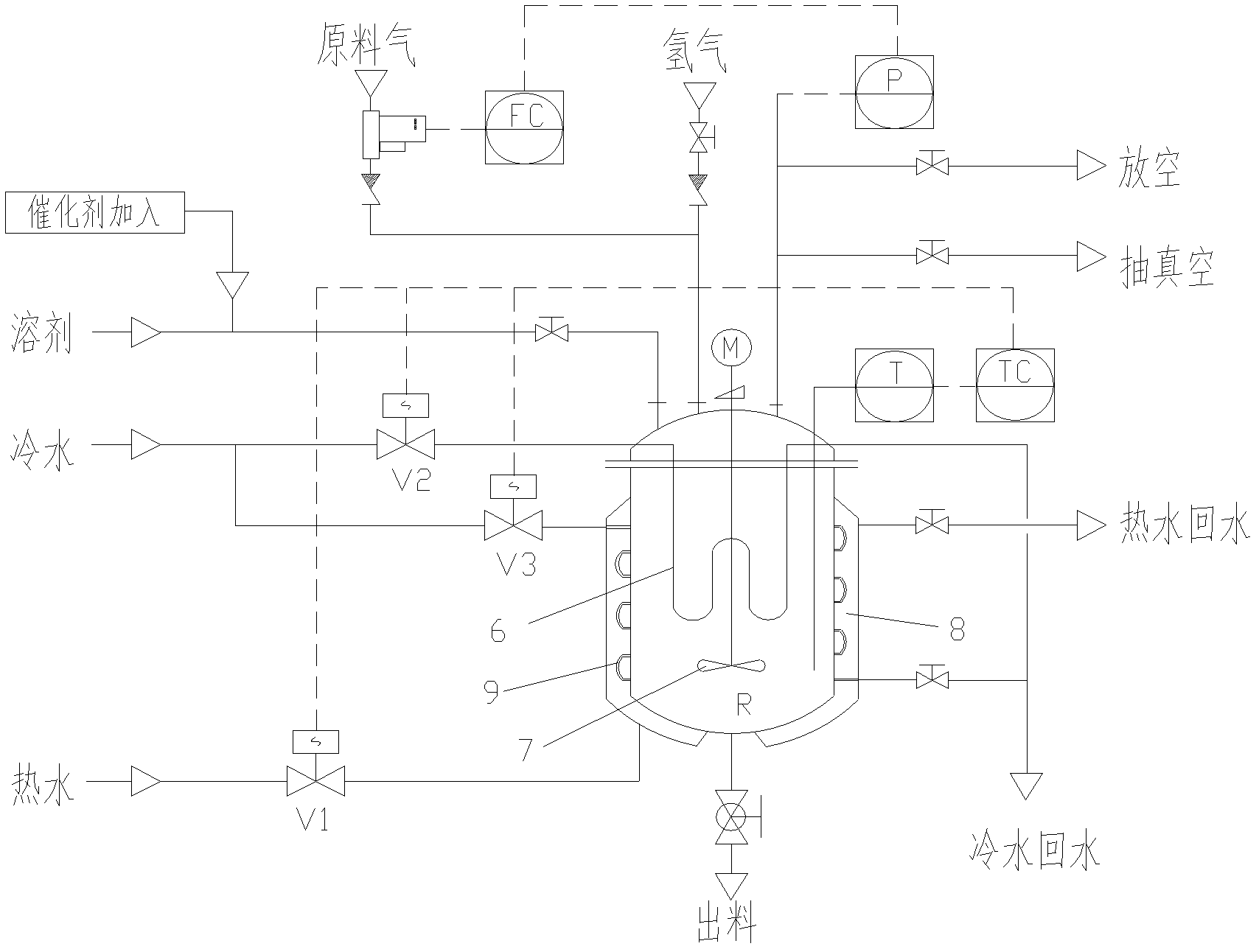

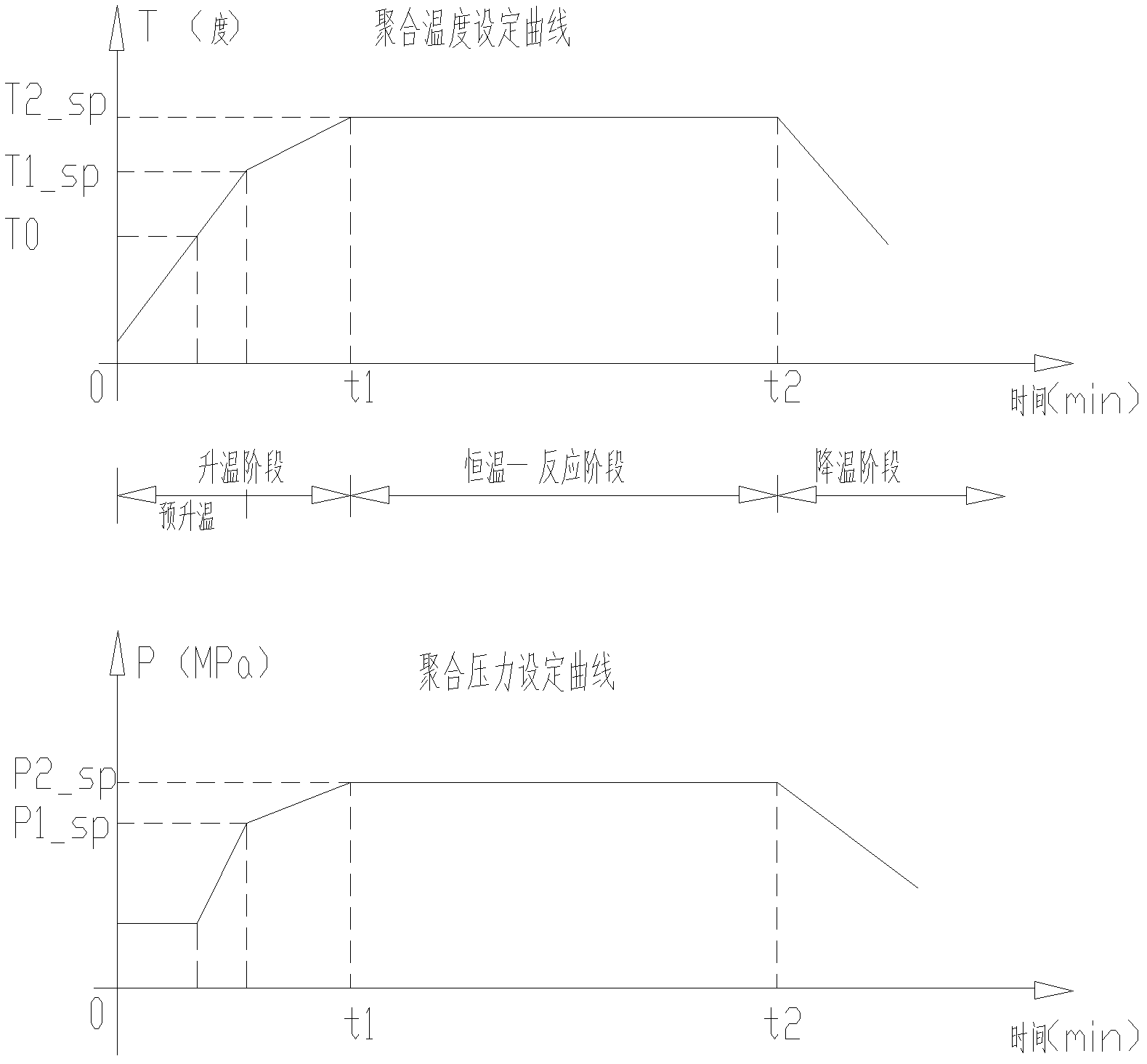

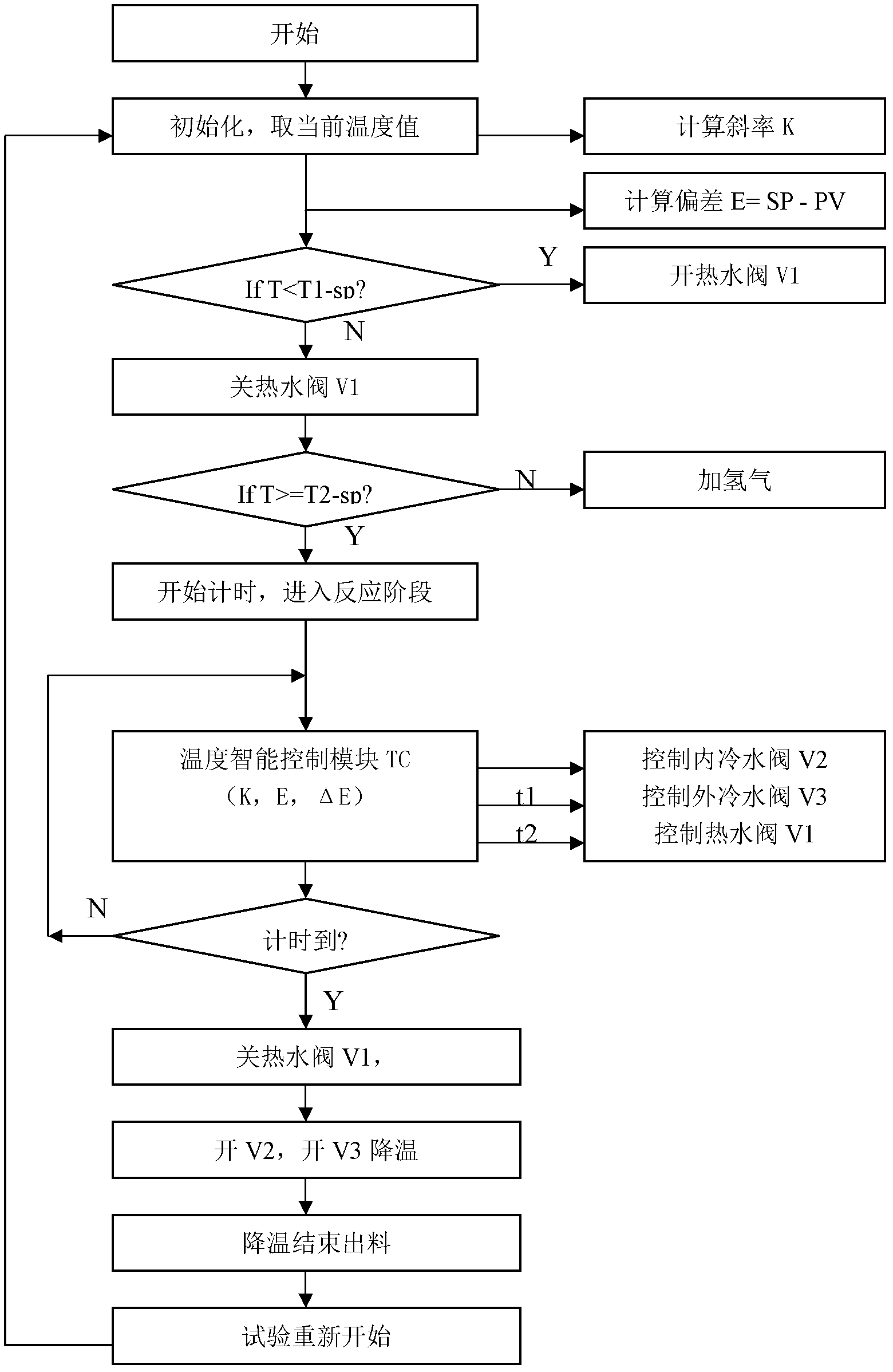

Method and system for olefin polymerization temperature control

ActiveCN103130927AImprove performanceImprove quality stabilityTemperature control using electric meansTemperature controlAutomatic control

The invention relates to a method and a system for olefin polymerization temperature control. The method and the system for the olefin polymerization temperature control aims at solving the problems that a polymerization reaction in the prior art is severe, temperature fluctuation is large in the process of heating and heat dissipation and bad influences on performance and quality of a polyolefin product are caused due to lag of the temperature. An artificial intelligent method is adopted. A manipulated variable of the method is the temperature. According to a designed intelligent controller, in the process of the polymerization reaction, opening time of a hot water valve, an inner cold water valve and an outer cold water valve is controlled according to deviation and slope rate of the temperature fluctuation so that accurate control of the polymerization temperature and continuously automatic control of three steps of temperature rising, temperature maintaining and temperature dropping are achieved in the process of an intermittent polymerization reaction. The invention further provides a control device for the olefin polymerization reaction. According to application, control requirements for a temperature parameter of the olefin polymerization device can be completely satisfied according to the intelligent control method, dynamic property of the system is improved and the performance and the quality of the olefin product are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

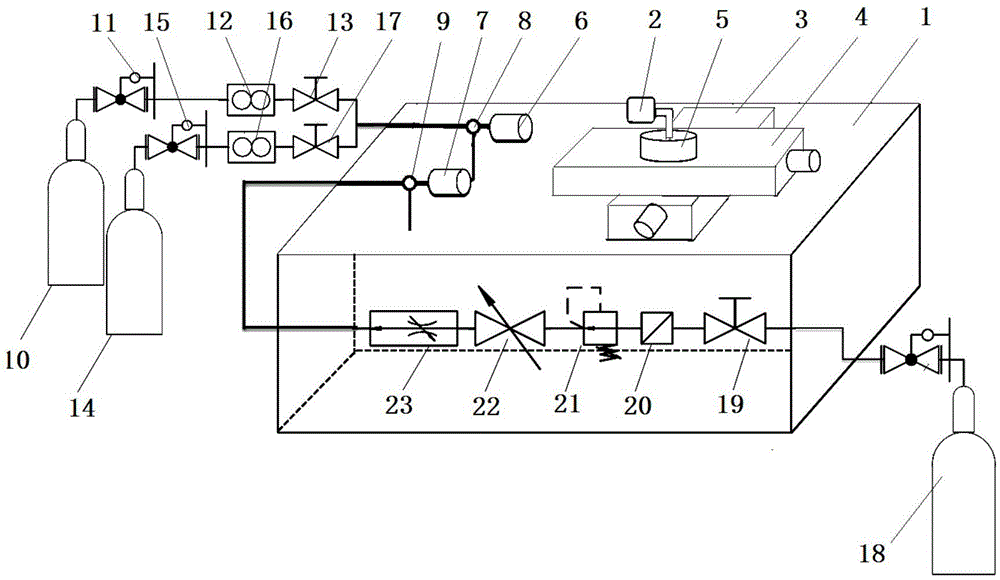

Combined loading test device

InactiveCN105571968AReal working environmentRealize the heating effectInvestigating abrasion/wear resistanceEngineeringTest platform

The invention relates to the field of thermal performance test and cooling efficiency test of thermal protection systems of aircraft, in particular to a combined loading test device. The combined loading test device comprises a test platform, a gas heating component which is used for heating a test piece, an air flow cooling component which is used for cooling the test piece, a temperature monitoring device which is used for acquiring the temperature information of the test piece in real time, and a control device which is used for controlling the gas heating component and the air flow cooling component according to the temperature information. According to the combined loading test device, the test piece is heated by the gas heating component, so that the disadvantages in the conventional heating mode are overcome; the shear effect caused by high-temperature air flow convection heating environment and air flow scouring, and the oxidation corrosion effect of a combustion product on the surface coating of a component when the test piece is used are truly simulated, and the working environment of the test piece can be truly simulated.

Owner:CHINA AIRPLANT STRENGTH RES INST

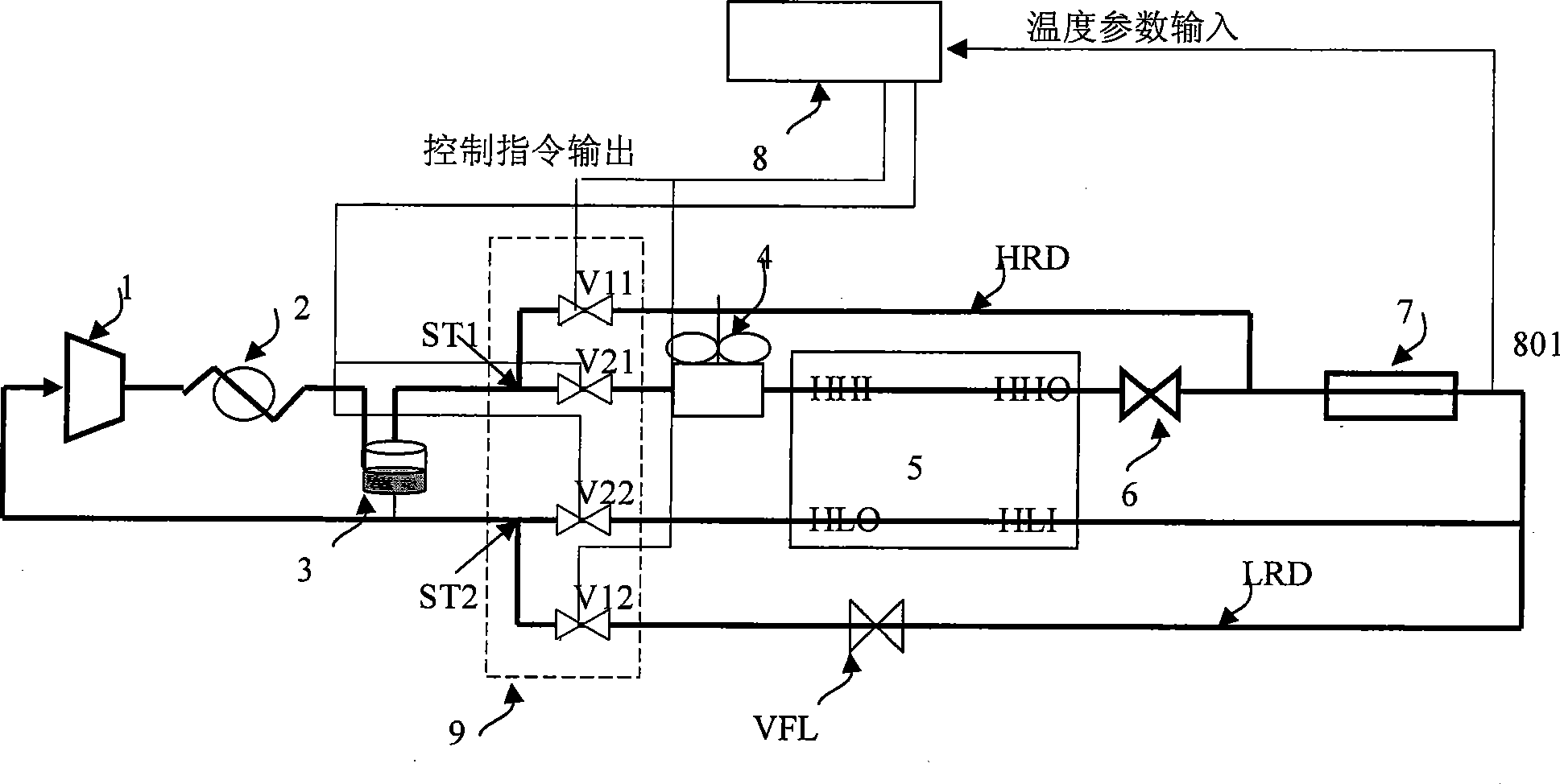

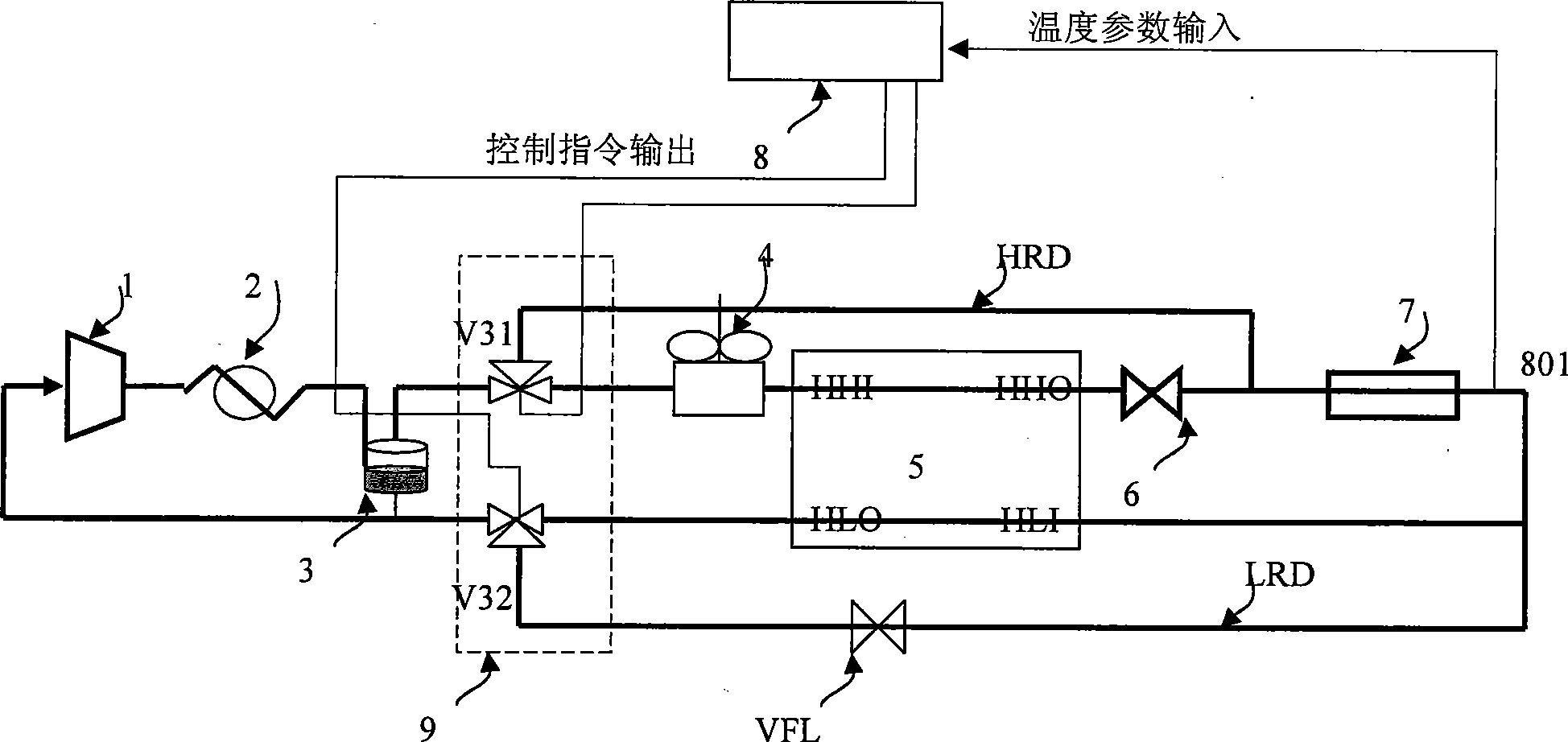

Thermal storage defrosting or temperature controlling mixed working substance copious cooling throttle refrigeration system

InactiveCN101398242AAchieve defrostingRealize the heating effectCorrosion preventionRefrigeration safety arrangementChillerEngineering

The invention relates to a mixed-work substance deep-cooling throttle refrigeration system which utilizes restored compression heat for realizing evaporator defrosting and temperature change controlling, comprising a compressor, a heat accumulator, a lubricant separator, an aftercooler, an regenerated heat exchanger unit, throttle refrigeration elements, an evaporator unit, a control unit and a control execution unit set. The control execution unit set comprises a controllable heating valve set and a controllable refrigerating valve set and can realize controllable operation of heating and refrigerating; as to the different working conditions of the mixed-work substance deep-cooling throttle refrigeration system, the controlling method can realize the refrigerating and heating of the evaporator so as to meet controlling demands in different working conditions according to the comparison between a pre-set value and an input parameter and by controlling the opening and closing of the controllable valves and the change of the flowing direction. The system can utilize the restored compressed heat to realize evaporator defrosting and temperature change controlling without extra heating sources, thus reducing the energy consumption of the system.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

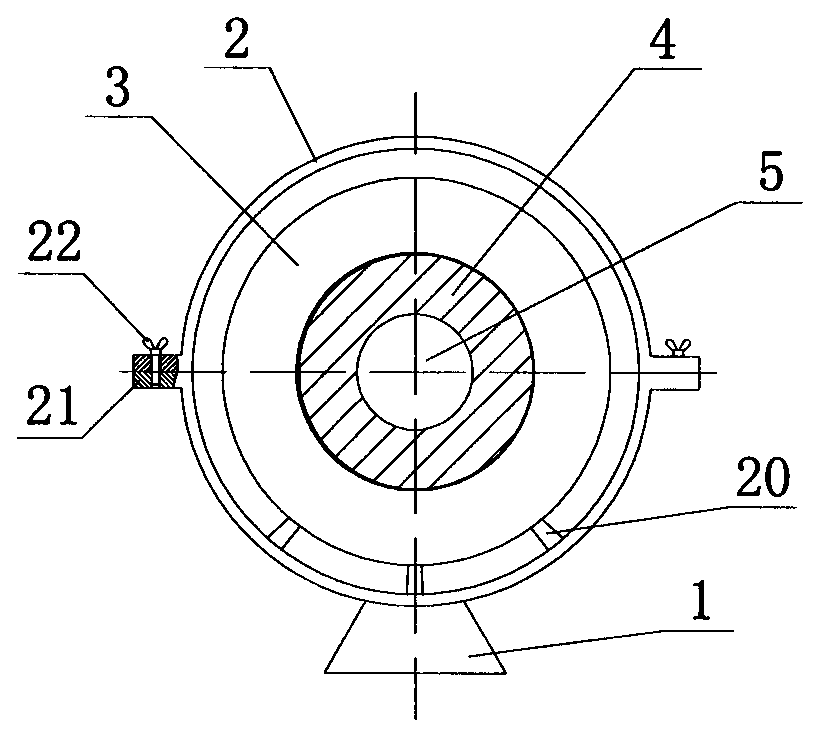

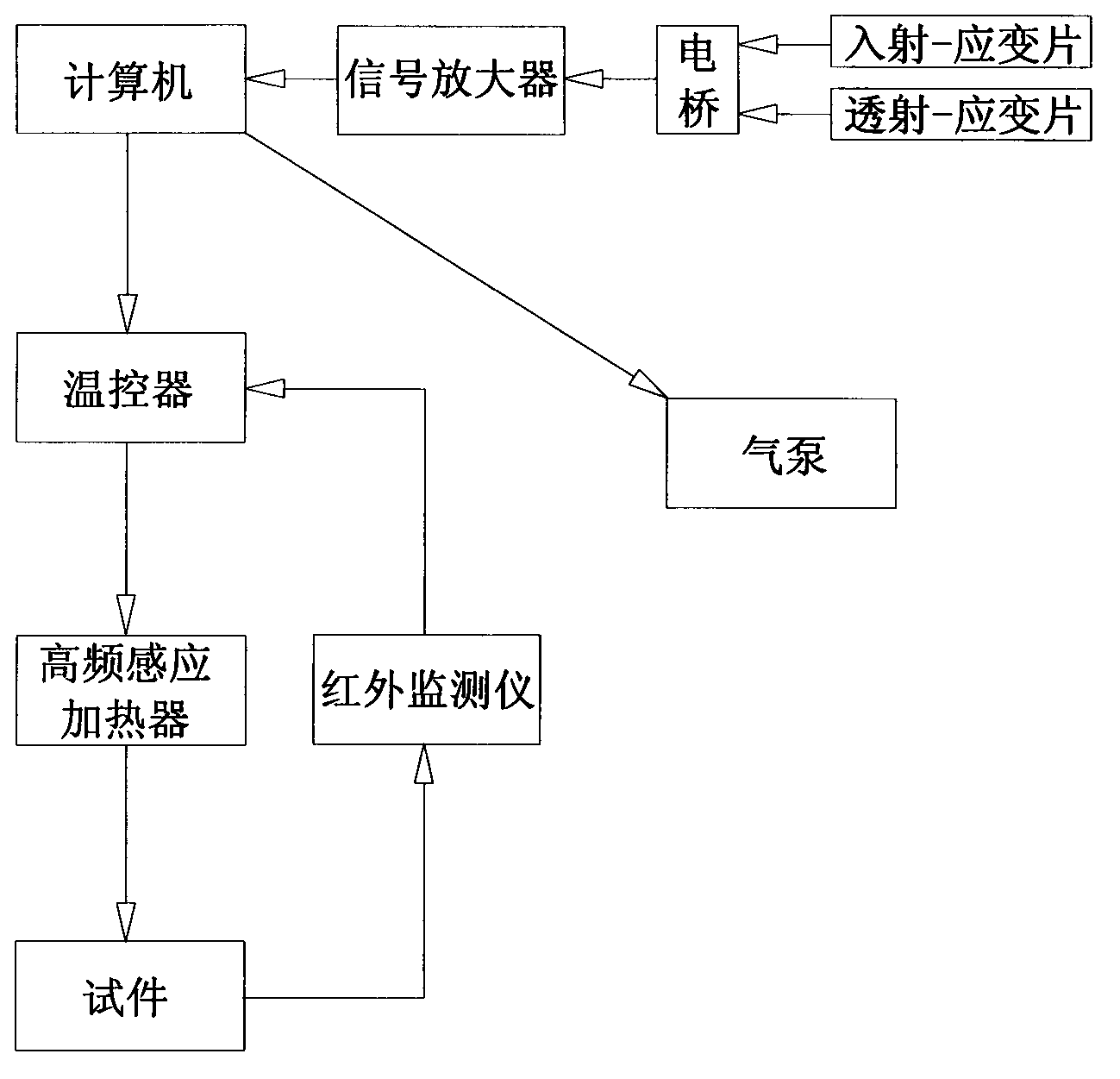

Device for rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment

InactiveCN103018094AEliminate performance impactFast heatingPreparing sample for investigationStrength propertiesAudio power amplifierInduction heater

The invention discloses a device for a rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment. The device adopts the technical scheme that a sample is mounted in the middle of a ceramic sleeve at the center of a high-frequency induction heater in a shielding cover; the both ends of the sample are connected with the inner ends of two short ceramic bars; the outer ends of the two short ceramic bars are connected with one end of an incidence bar and one end of a transmission bar respectively; stress wave signals of strain gages are measured from the incidence bar and the transmission bar respectively, and sent to a computer for data processing through an electric bridge and an amplifier; the computer controls the warming of the high-frequency induction heater and the sample through a temperature controller; and the sample temperature is fed back to the temperature controller by another infrared monitor. The device overcomes the defects that the available device for the split Hopkinson pressure bar experiment is complicated in structure, complicated to operate, low in working efficiency and difficult in data processing; and the quality of the experiment is influenced seriously. The device is suitable for the Hopkinson pressure bar experiments in different laboratories, in particular to the heating of the sample and the immediate processing of the information of the strain gages.

Owner:HUNAN UNIV OF SCI & TECH

Arc solar panel and processing technology

InactiveCN102856410AExtended service lifeStable in natureFinal product manufacturePhotovoltaic energy generationTransmittancePolyester resin

The invention relates to an arc solar panel which comprises a plastic substrate and a plurality of solar silicon crystal boards regularly arranged on the plastic substrate. The solar silicon crystal boards are used for photovoltaic power generation. The arc solar panel is characterized in that polyester resin layers with light transmittance performance are attached to the upper surfaces of the solar silicon crystal boards; and the lower surface of the plastic substrate is of the same curved surface shape with the outer surface of an automobile top plate. A processing technology of the arc solar panel, which is disclosed by the invention, comprises the following steps of: c, adhering the solar silicon crystal boards; d, arranging the polyester resin layers; 3, loading a die; f, filling a heating medium; g, carrying out hot embossing; and h, carrying out cooling sizing. According to the arc solar panel disclosed by the invention, the firmness of the integral arc solar panel is effectively ensured and the capacity of receiving the sunlight is ensured. The technology for manufacturing the arc solar panel, which is disclosed by the invention, has simple and reasonable steps and can be used for effectively ensuring the quality of the manufactured arc solar panel.

Owner:张正泉

Disinfecting device with drying function for medical instrument

InactiveCN108524975APrevent slippingAchieve disinfectionDrying gas arrangementsLavatory sanitoryWater storageElectrical resistance and conductance

The invention discloses a disinfecting device with a drying function for a medical instrument. The disinfecting device comprises a third water pump, a motor, heating resistance wires, exhaust fans, adisinfecting cabinet and a top plate. A disinfectant solution in a solution storage tank is enabled to enter a water storage box through a solution guiding pipe by utilizing the third water pump and then is further sprayed through spray nozzles so as to disinfect the medical instrument on the top part of a placement plate, and the placement plate is driven to rotate by utilizing rotation of the motor, so that the purpose of comprehensively disinfecting the medical instrument is realized, the disinfecting efficiency and a disinfecting effect of the medical instrument are increased, and the environment friendliness of equipment is increased; the heating resistance wires are utilized for heating air in a heating tank, and the exhaust fans are utilized for enabling the heated air in the heating tank to be further blown out through air outlets of an air outlet box after entering the air outlet box through an air guiding pipe, so that the purpose of heating the air in the disinfecting cabinet is realized, and the purpose of drying the disinfected and washed medical instrument is further realized.

Owner:芜湖博创新能源科技有限公司

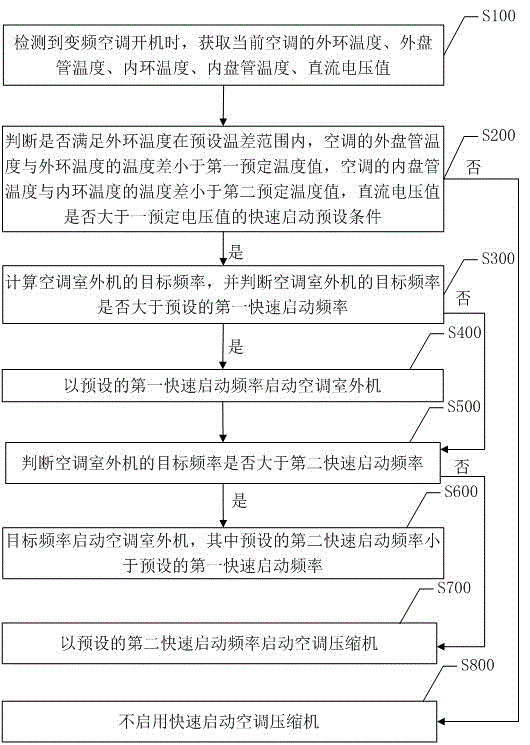

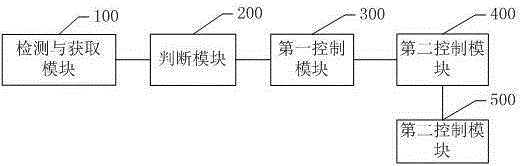

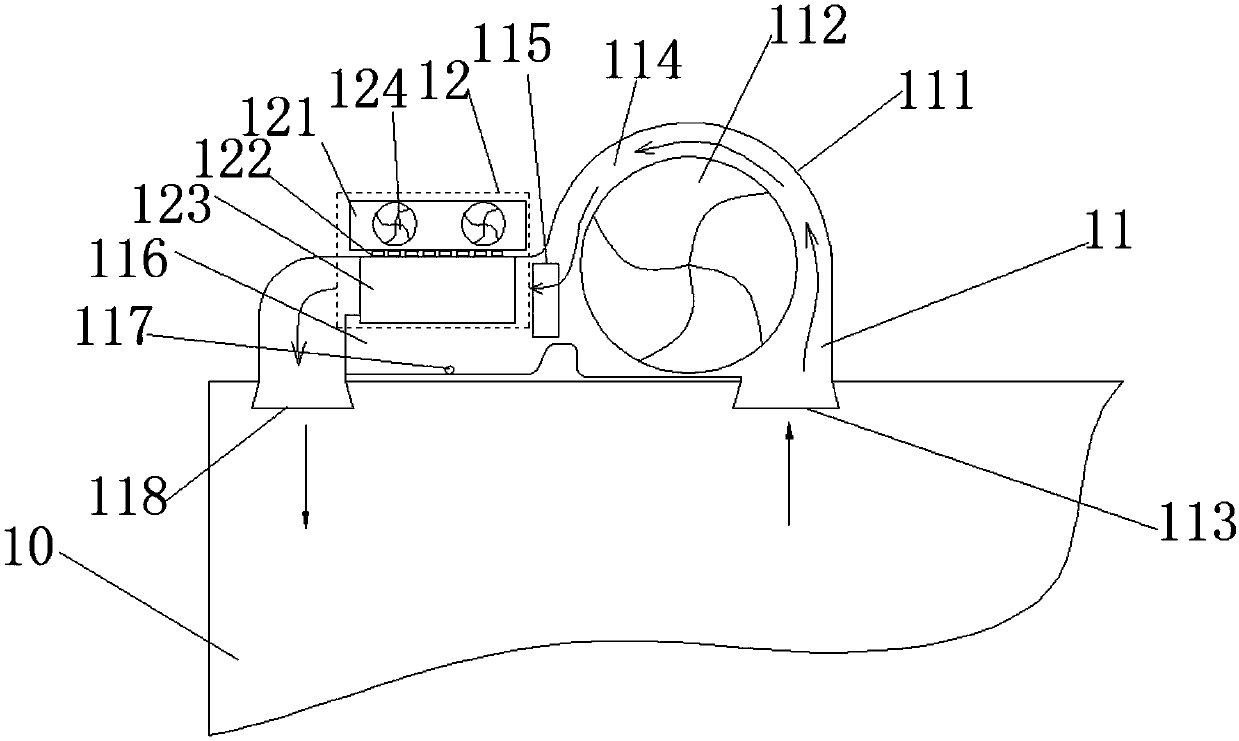

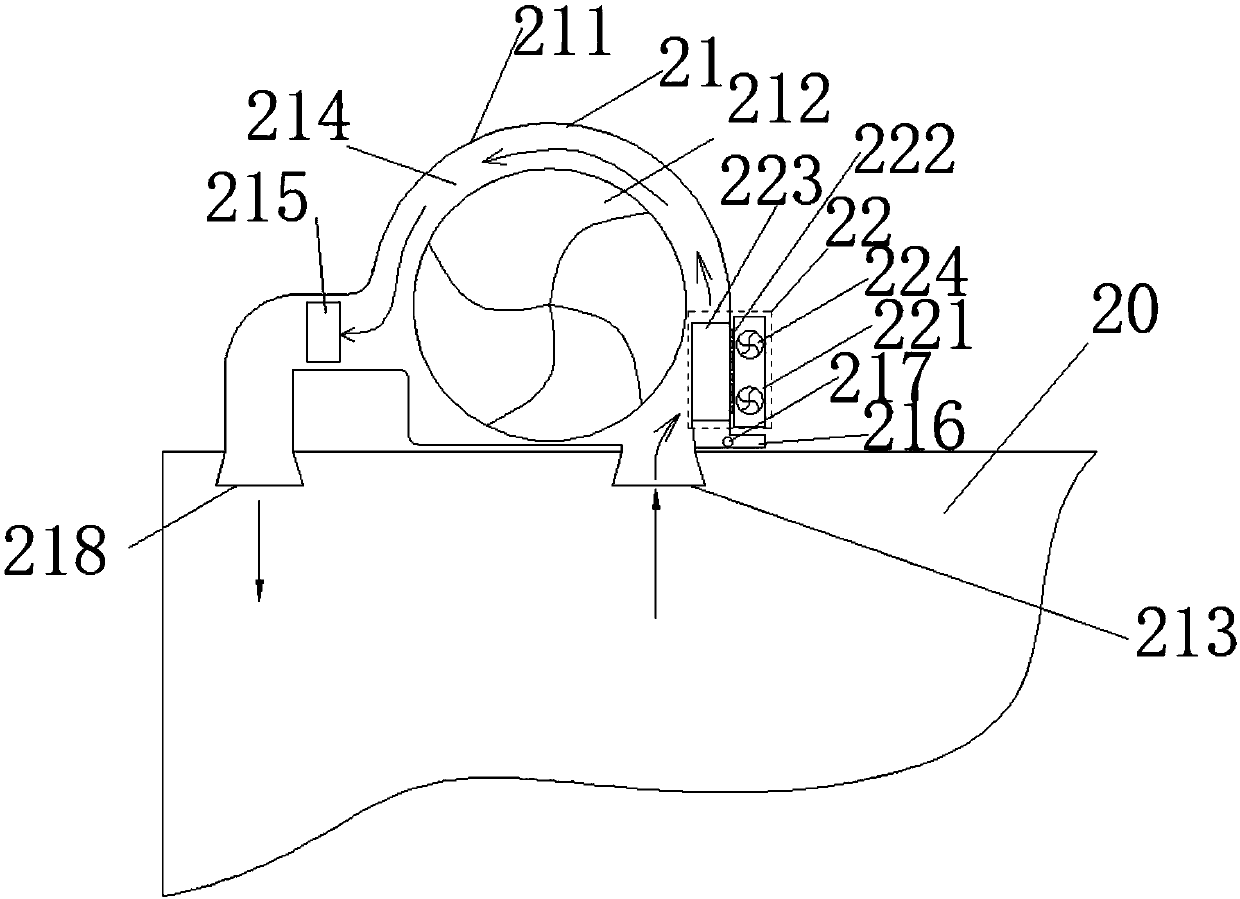

Control method and system for quick starting of compressor of outdoor unit of variable-frequency air conditioner

ActiveCN105222277AReduce startup timeRealize the cooling effectMechanical apparatusSpace heating and ventilation safety systemsStart timeHeating effect

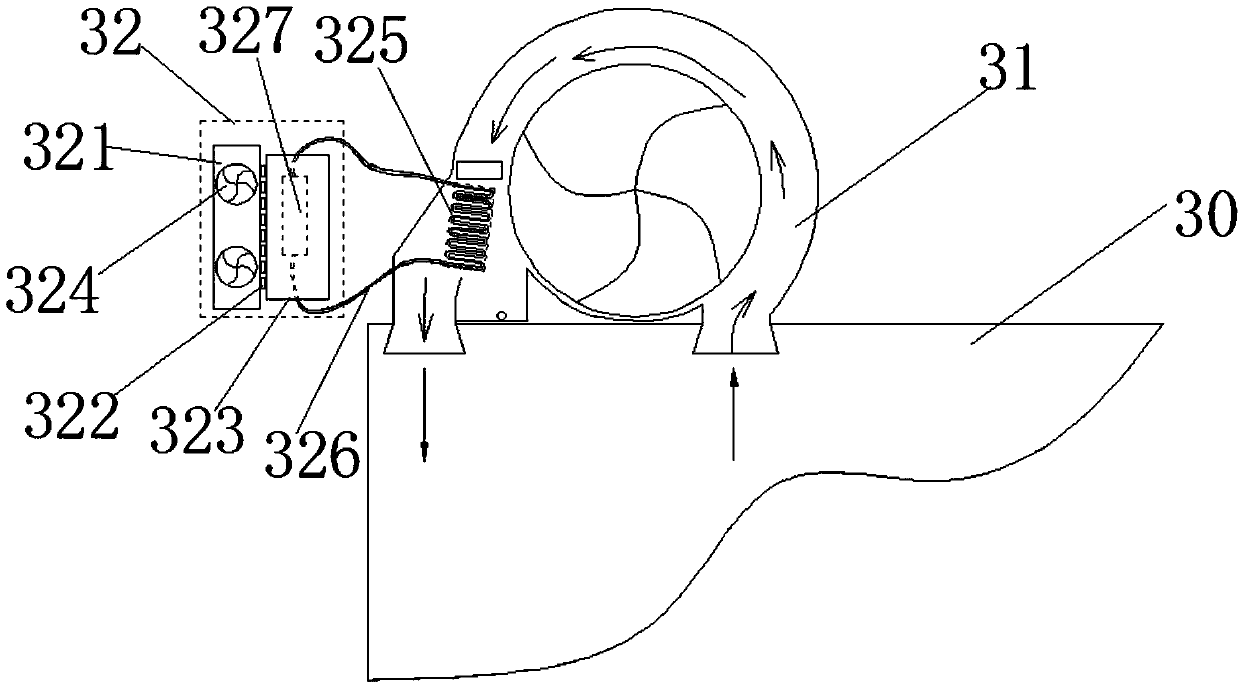

The invention discloses a control method and system for quick starting of a compressor of an outdoor unit of a variable-frequency air conditioner. The method comprises the steps that when the variable-frequency air conditioner is turned on, whether the variable-frequency air conditioner meets preset conditions at present is judged; if yes, a quick starting mode is triggered; and after the quick starting mode is triggered, a calculated outdoor target frequency is compared with a preset quick starting frequency, and a quick starting frequency is selected to start the compressor of the air conditioner according to a comparison result. According to the control method and system, the starting time of the compressor of the air conditioner can be shortened, and the refrigerating or heating effect of the air conditioner can be achieved more quickly; meanwhile, the requirement that the compressor is started without frequency hopping is met in the aspect of control, the requirement for the quick refrigerating and heating capacity is met in the aspect of performance, and the requirement for stable operation of the compressor is met in the aspect of reliability.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Method for achieving temperature control in elevator car and elevator system

InactiveCN107720498ARealize the cooling effectRealize the heating effectLighting and heating apparatusBuilding liftsTemperature controlElevator system

The invention discloses a method for achieving temperature control in an elevator car and an elevator system. The method comprises the steps that based on an elevator car controller, a user command isreceived and comprises a temperature control command; based on a temperature sensor, the current temperature in the elevator car is obtained; the magnitude and plus-minus relations between the current temperature and the temperature value in the temperature control command are judged, and based on the magnitude relation and the plus-minus relation, a semiconductor cooler work command and / or an air capacity control command are / or generated; the air capacity control command is sent to a motor driving a cross flow fan to work, so that the motor drives the cross flow fan to work; and the semiconductor cooler work command is sent to a semiconductor cooler, so that the semiconductor cooler works according to the semiconductor cooler work command. According to the method for achieving temperature control in the elevator car and the elevator system, the semiconductor refrigeration and heating effects can be controlled for the elevator car.

Owner:GUANGDONG HUANYU ELECTRONICS TECH CO LTD

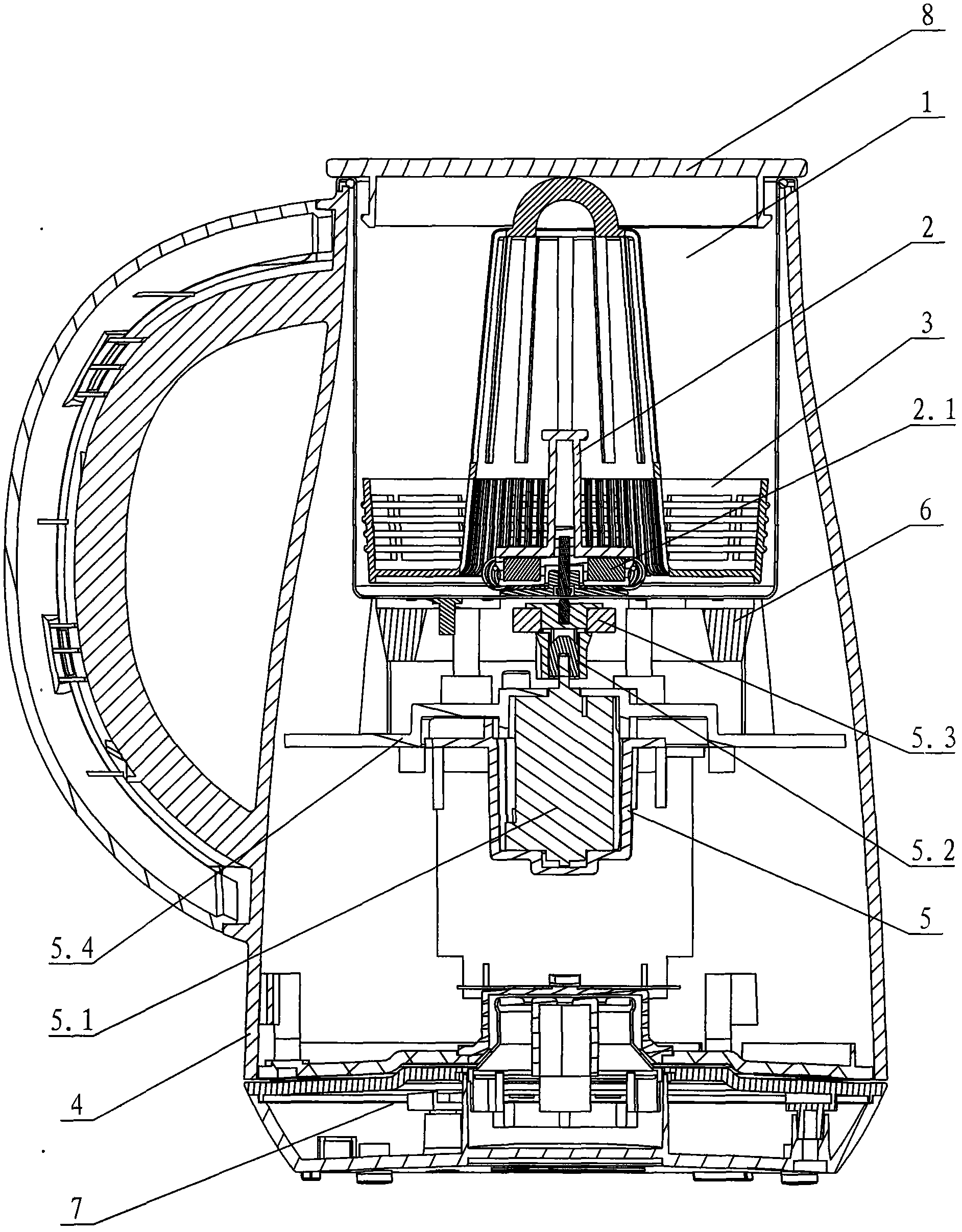

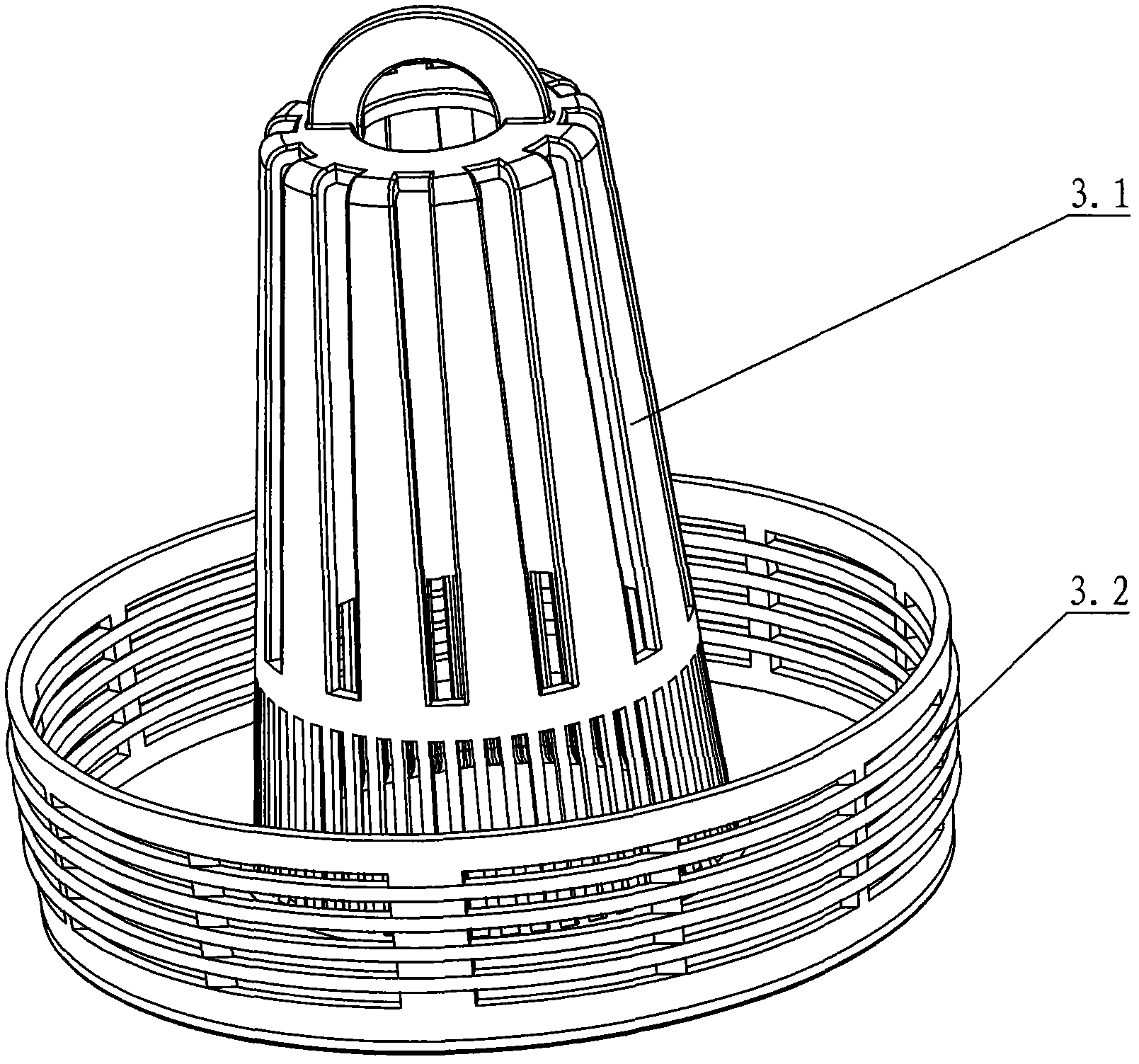

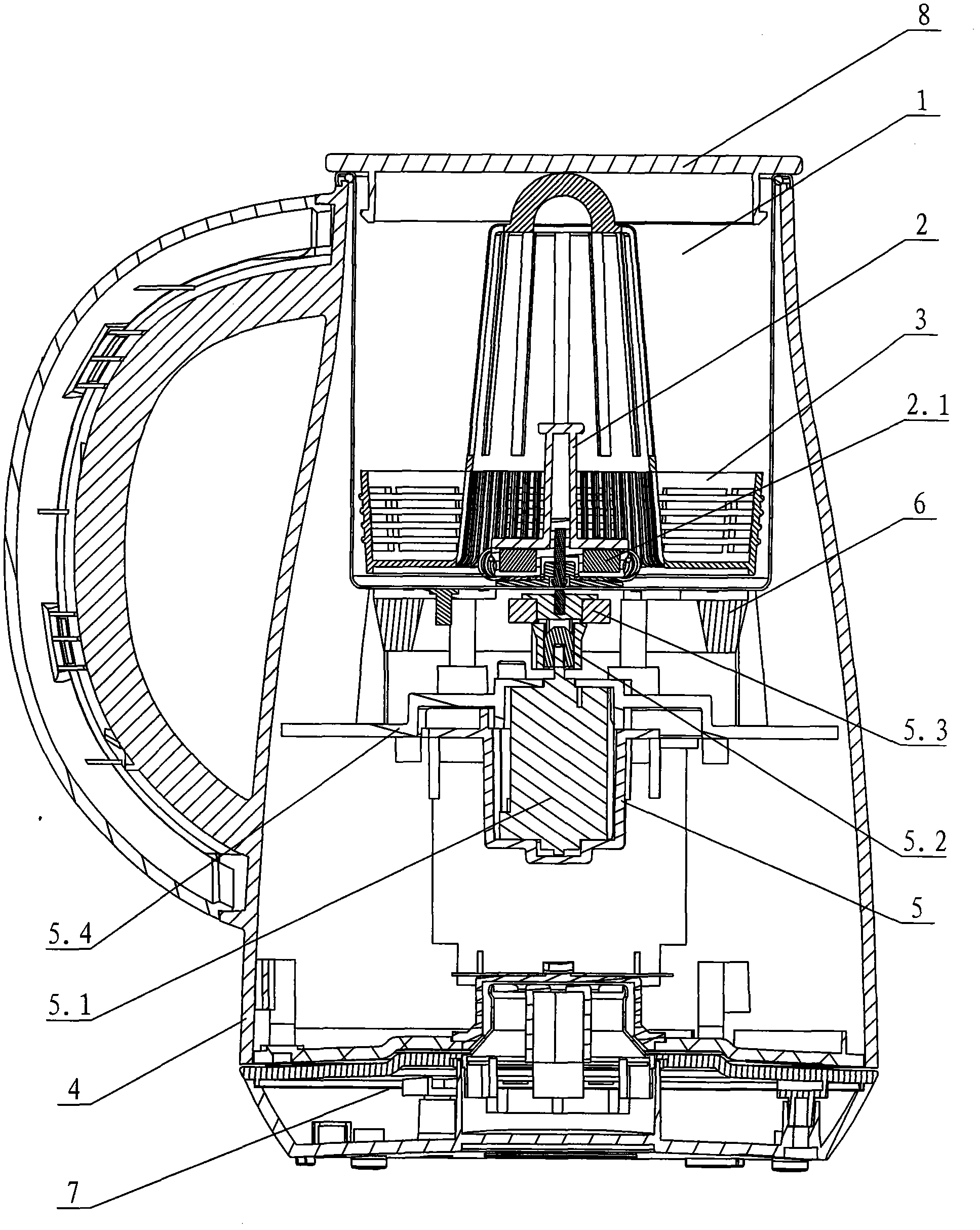

Multifunctional combined appliance

InactiveCN102058327AEnough room to exerciseAffect normal workVessels with intergral heatingEngineeringMotion space

The invention discloses a multifunctional combined appliance comprising a power supply control device, a driving part and a heating part, wherein the driving part and the heating part are arranged in a body on which a detachable vessel is arranged, and the vessel is a sealing body provided with an opening; a stirring and foaming assembly is arranged at a driver position of the driving part corresponding to the vessel; and the stirring and foaming assembly comprises a mesh bracket and a stirring head with a magnetic element which is arranged at the lower part of the stirring head. The invention has the characteristics of simple and reasonable structure, easiness for cleaning, convenience and safety for operation and low manufacture cost. By additionally arranging the mesh bracket and the stirring head which are freely detached on the vessel, one machine with multiple functions is realized; the driving part drives the stirring head in a magnetic force way to rotate at high speed so as to drive liquid in the vessel to flow and dissolve massive beverage additives in the mesh bracket. A convex column on the mesh bracket ensures that the stirring head has enough motion space and also prevents added massive beverage additives from influencing the normal work of the stirring head, thereby achieving the functions of heating, foaming and stirring a beverage.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

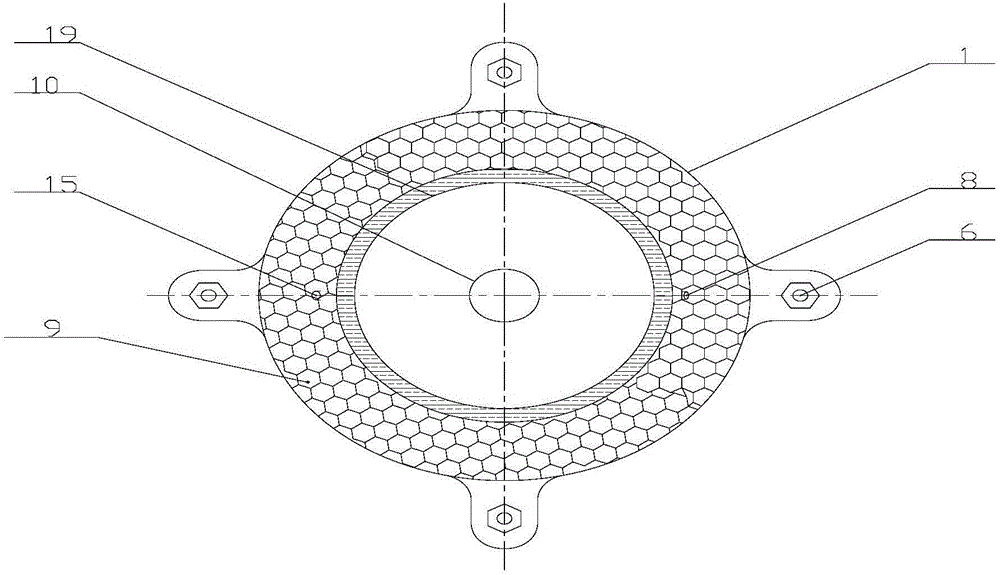

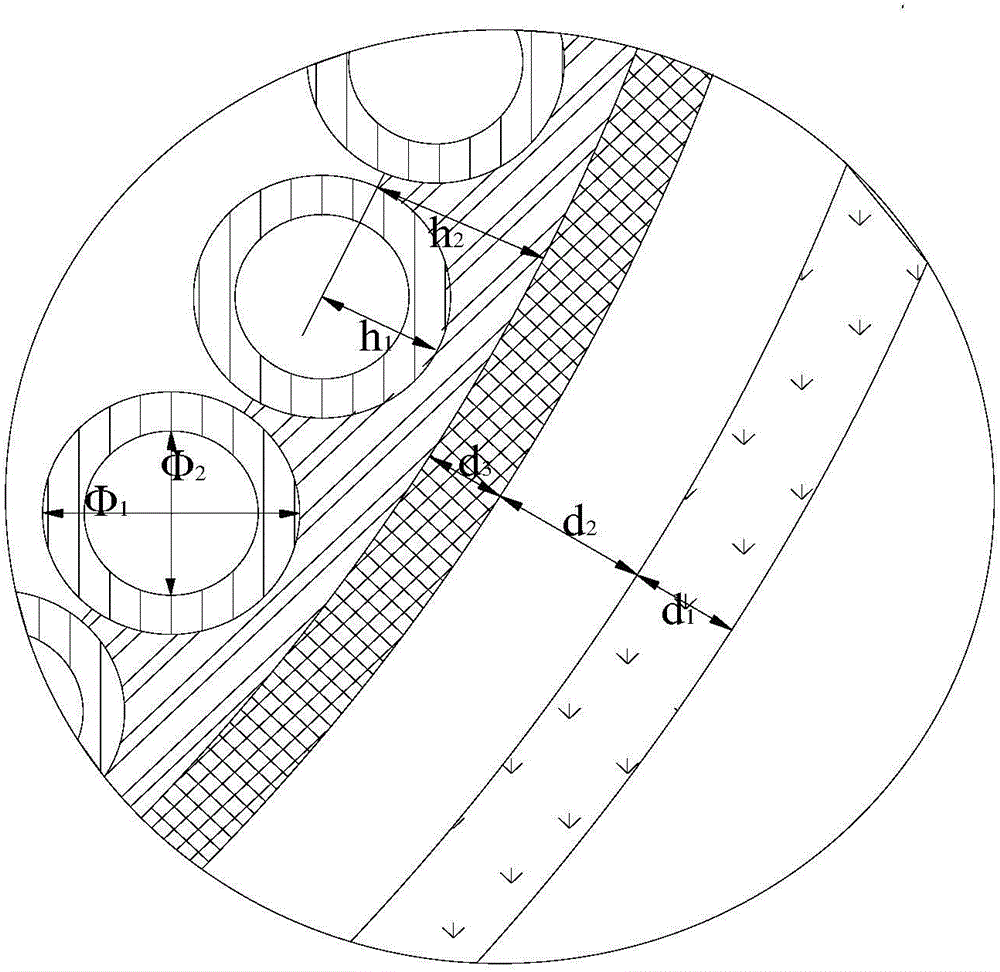

Semi-embedding type eight-shaped cavity type solar receiver and working method thereof

InactiveCN105841363AReduce convective heat lossEfficient heat absorptionSolar heating energySolar heat collector controllersLight reflectionHeat losses

The invention discloses a semi-embedding type eight-shaped cavity type solar receiver and a working method thereof. The solar receiver comprises a regular hexagonal convex mirror, a glass housing, a heat insulation vacuum layer, a steel inner shell, a soft heat transfer layer, a helical heat exchange coil tube, a heat conductive fluid, light reflection type wind shields and a cavity mouth convex mirror, wherein different from the traditional heat absorber, the solar receiver is in an eight shape, and independent feeding and discharge holes are formed in a low-temperature heating part and a high-temperature heating part and can be used for heating working media with different temperature requirements in a middle-high temperature solar heat utilization system and transporting the media with different temperatures respectively; the media can be secondarily heated by utilizing the focusing action of the regular hexagonal convex mirror; semi-embedding type connection between the soft heat transfer layer and the helical heat exchange coil tube makes the coil tube more uniformly heated, and thus heat spots are prevented from occurring; and through the focusing and closing actions of the cavity mouth convex mirror, the effects of efficiently absorbing heat and reducing convective heat loss can be reached.

Owner:SOUTH CHINA UNIV OF TECH

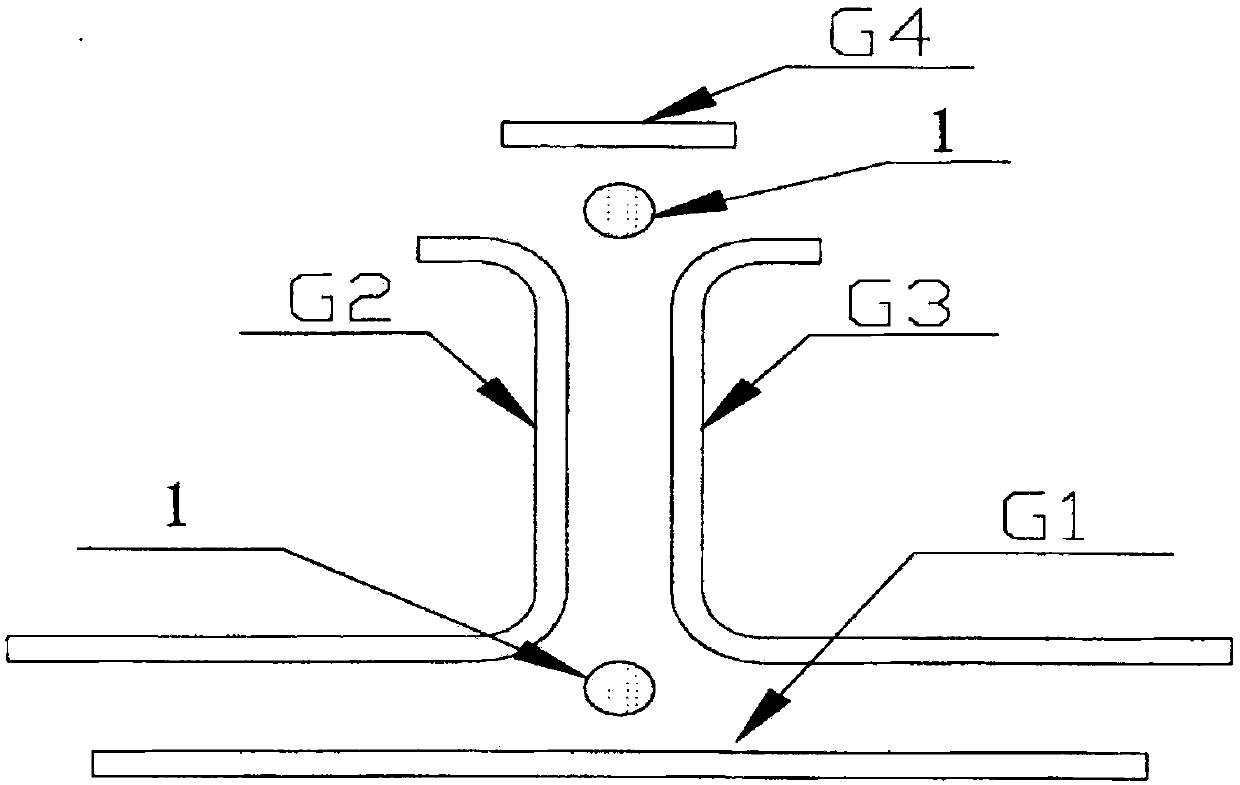

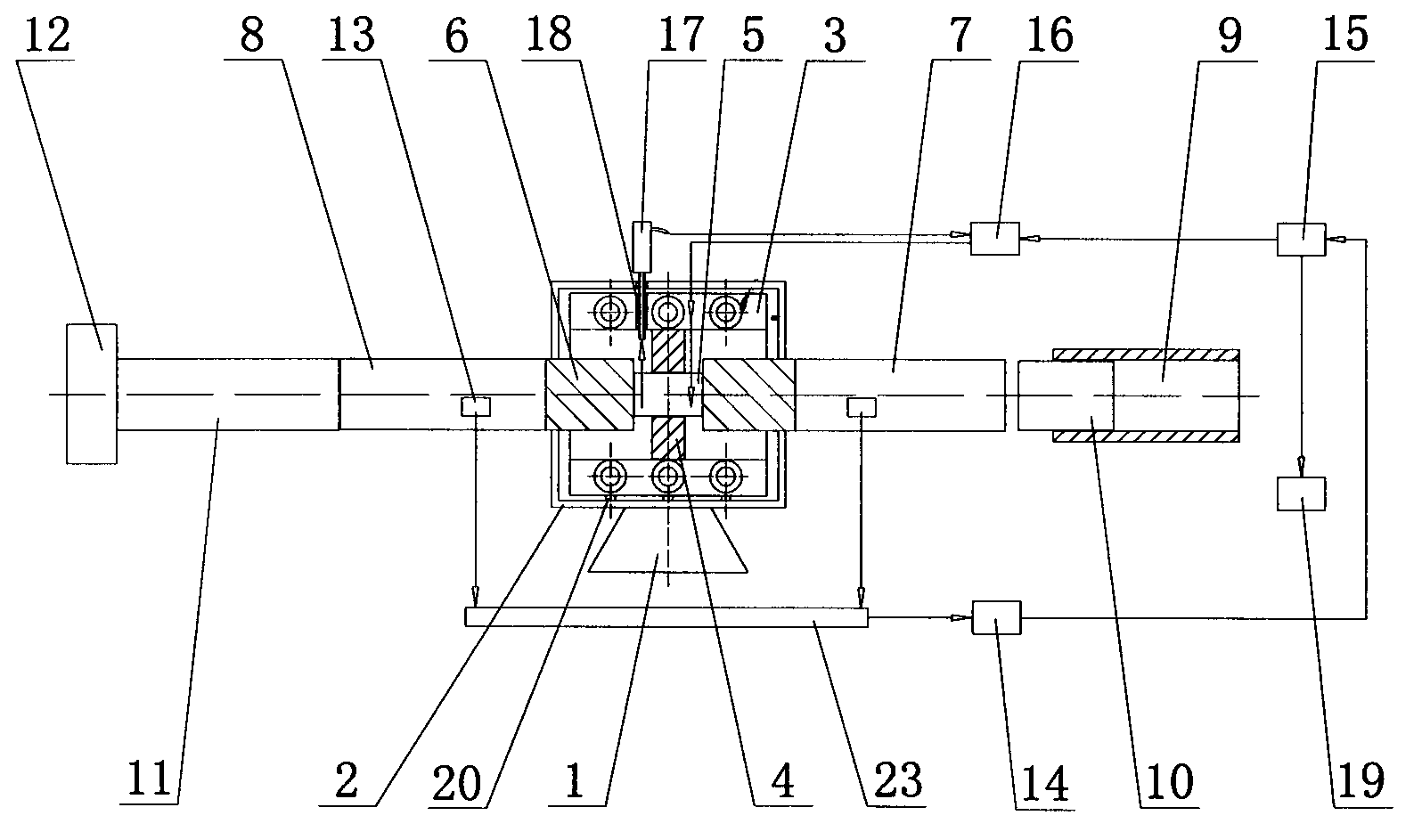

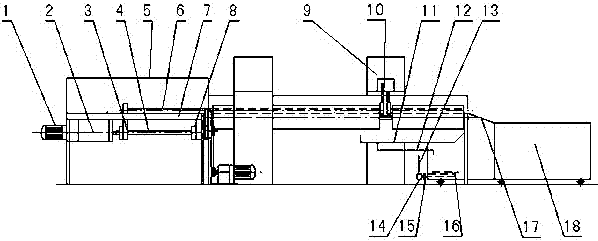

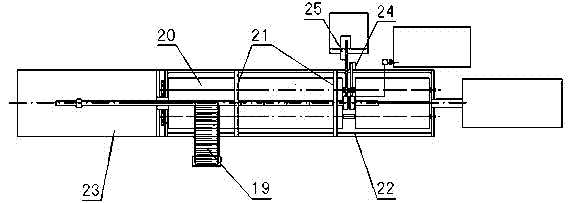

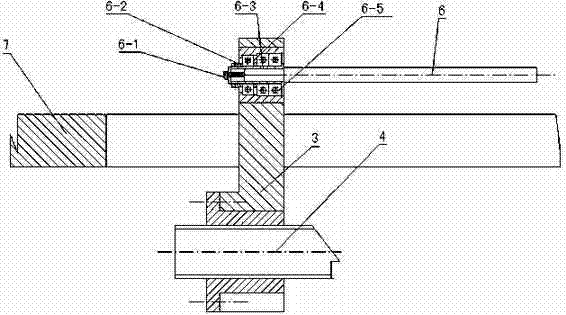

High-frequency automatic quenching machine for reverse gear shafts of transmission cases

InactiveCN102337383ARealize the heating effectTo achieve the purpose of quenchingFurnace typesIncreasing energy efficiencyProgrammable logic controllerElectric machinery

The invention discloses a high-frequency automatic quenching machine for reverse gear shafts of transmission cases, which comprises a material pushing mechanism, a supporting roller mechanism, an automatic feeding mechanism, a material pressing rack mechanism, a heating power supply, a quenching liquid cooling device, an unloading mechanism and a PLC (programmable logic controller), wherein a through groove formed on a nut seat (3) on a transmission lead screw (4) of a material pushing motor (1) in the material pushing mechanism along a bed body of the material pushing rack can drive a material pushing rod (6) in a rotating sleeve (6-3) to push workpieces which are converted onto the supporting roller mechanism from the automatic feeding mechanism out of a working position between the roller surfaces of a left supporting roller (20-6) and a right supporting roller (20-7) one by one and mutually push the workpieces into an outer circular induction coil (10-1) in a heating power supply (9) for heating, then the workpieces enter a liquid spraying ring in the quenching liquid cooling device for performing liquid spraying and quenching, and the workpieces further enter a material barrel (18) through an unloading plate (17) after the workpieces are cooled. The high-frequency automatic quenching machine realizes the purpose of performing automatic heating and quenching on the workpieces, greatly reduces the labor intensity, improves the production efficiency, and is suitable for large-batch and large-scale production and processing of the reverse gear shafts of the transmission cases.

Owner:ANHUI MINGYAN GEAR

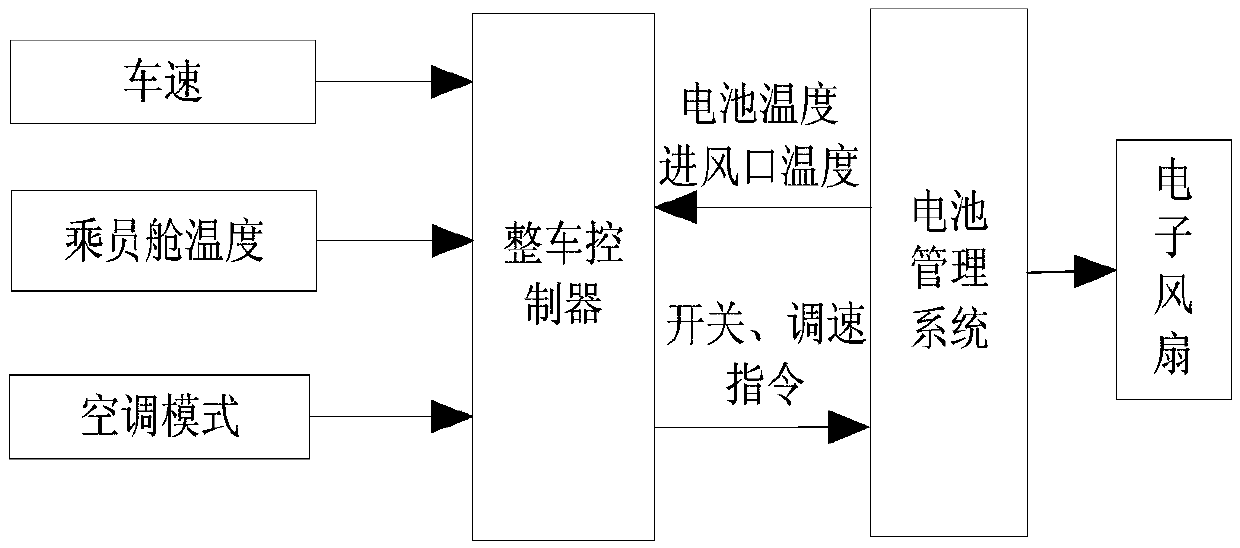

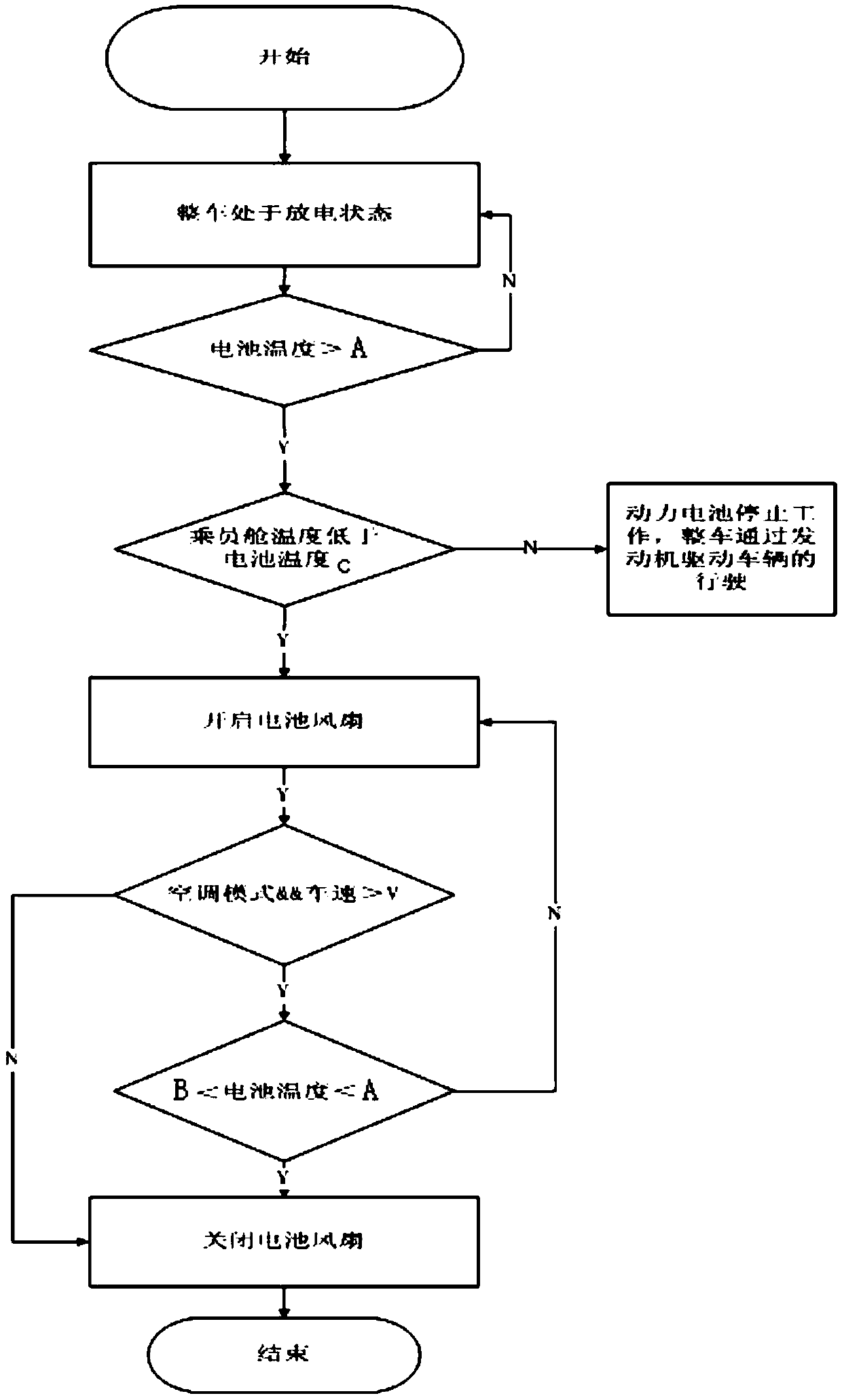

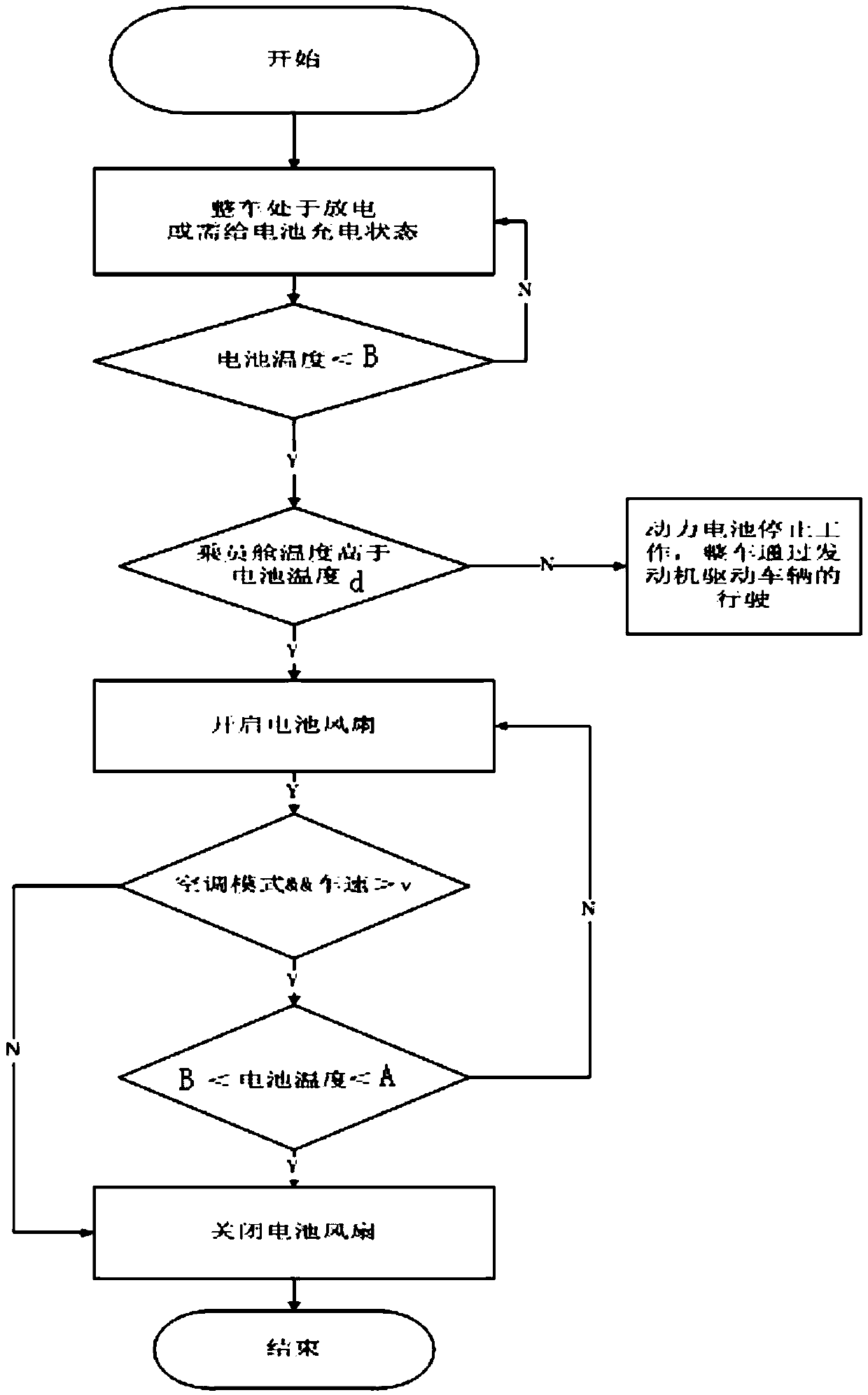

Temperature control device and control method for batteries of hybrid electric vehicles

ActiveCN105514525ACompact structureExtended service lifeSecondary cellsBatteriesTemperature controlAir volume

The invention relates to a temperature control device and a control method for batteries of hybrid electric vehicles. The temperature control device and the control method have the advantages that requirements on maximizing the capacity of the batteries and space utilization and minimizing modification on vehicle bodies can be met, the integrated temperature control device for the batteries is in a matching computational design, gaps between the single batteries in battery shells are sufficiently utilized, the cooling air volumes are controlled, the single batteries can be cooled or heated by the aid of air in passenger compartments via inner flow guide plates, air channel pipes, air outlet pipes, electronic fans and upper covers, and pressures of the air in the passenger compartments, noise reduction strategies, heat instability faults of the batteries and the like are taken into consideration by the aid of the control method; the temperature control device for the batteries is compact in structure, the batteries can be maintained to the greatest extent and can assuredly work within appropriate temperature ranges, the safety of the batteries can be guaranteed, the service lives of the batteries can be prolonged, the energy utilization rate can be increased, and the comfort of the integral vehicles can be improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

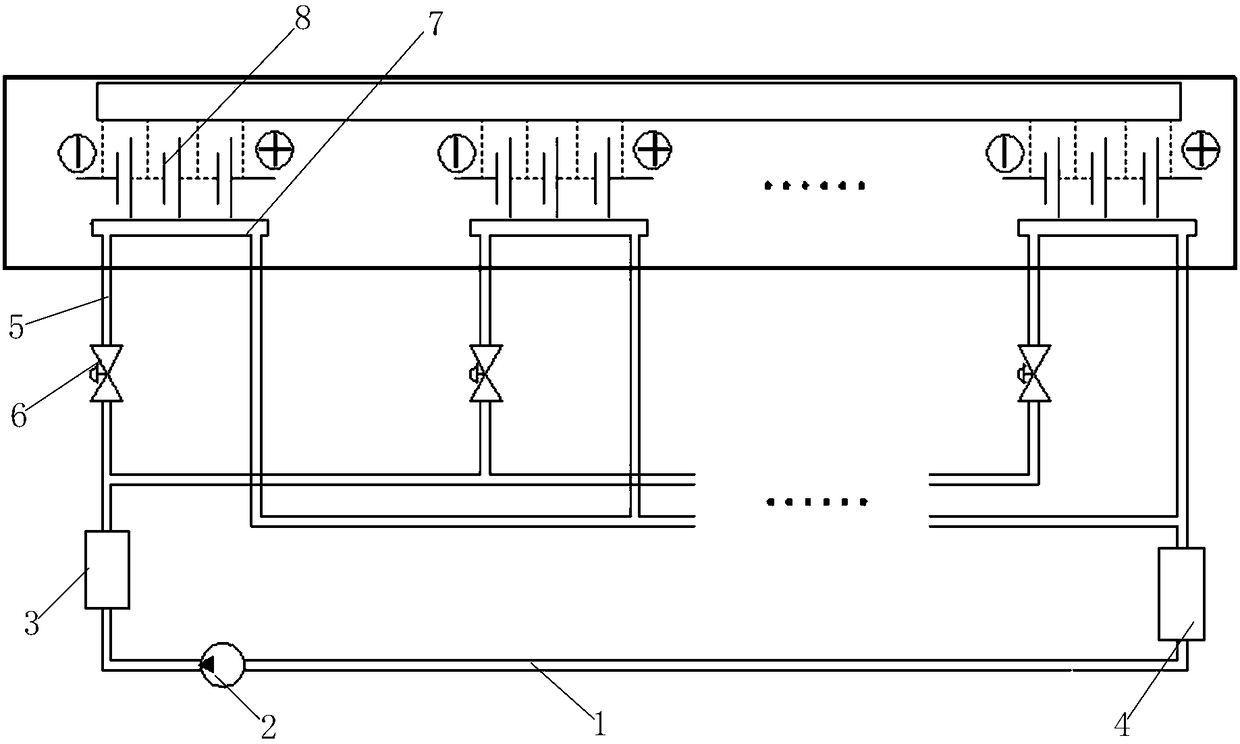

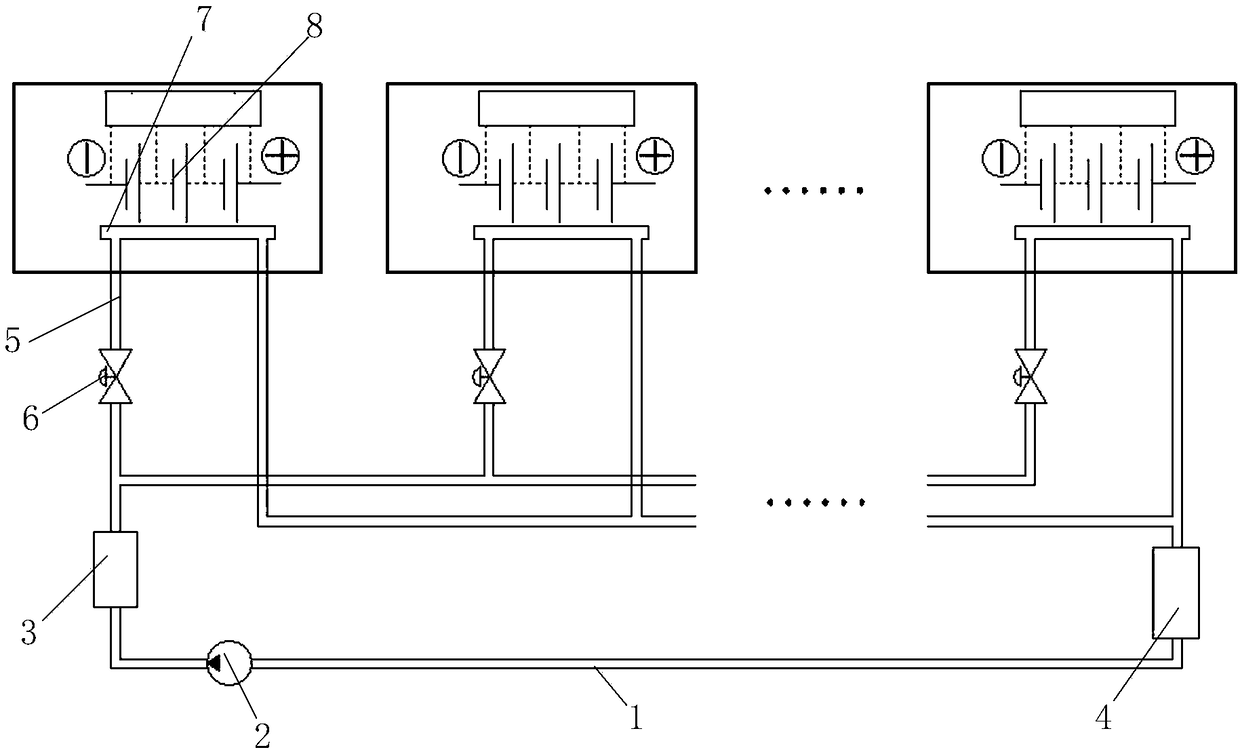

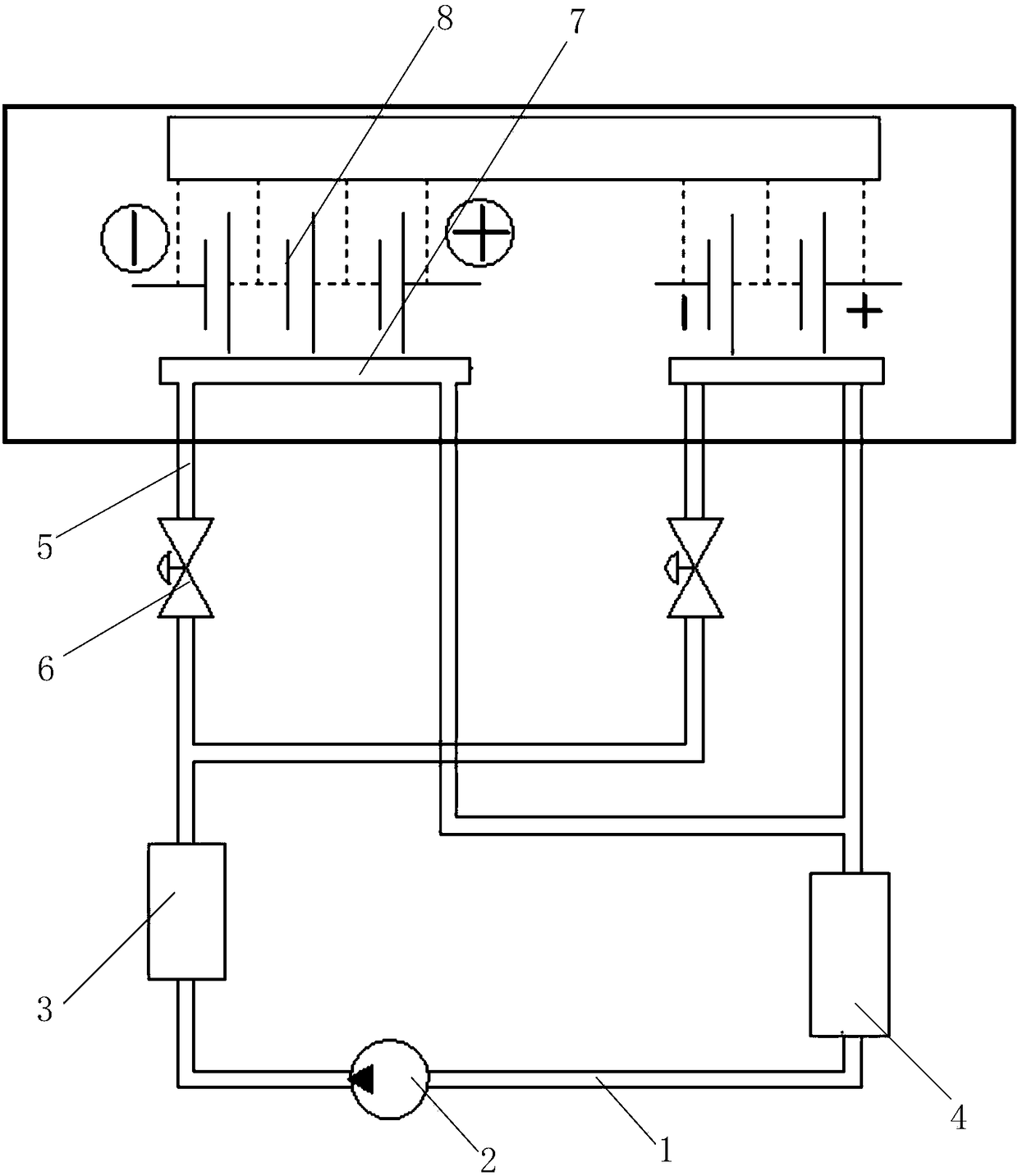

Thermal management system for battery pack, and battery pack

InactiveCN108336445AExtended service lifeImprove cooling effectCell temperature controlBatteriesElectrical batteryEngineering

The invention relates to a thermal management system for a battery pack, and the battery pack, belonging to the technical field of thermal management of batteries. The objective of the invention is torealize separate temperature adjustment of a plurality of battery modules via the thermal management system. According to a main technical scheme in the invention, the thermal management system for the battery pack comprises a main liquid circulation pipeline, which is internally provided with a circulation water pump, a heater and a radiator; a plurality of branch liquid circulation pipelines, which are successively arranged between the outlet and the inlet of the main liquid circulation pipeline and are connected with each other in parallel; a plurality of flow control valves, which are separately arranged in the plurality of branch liquid circulation pipelines; and a plurality of heat exchangers, which are respectively connected with the plurality of branch liquid circulation pipelinesand are respectively connected with a plurality of battery modules for thermal adjustment of the battery modules. The thermal management system for the battery pack can be used for separate temperature adjustment of a plurality of battery modules at the same time.

Owner:CH AUTO TECH CORP CO LTD

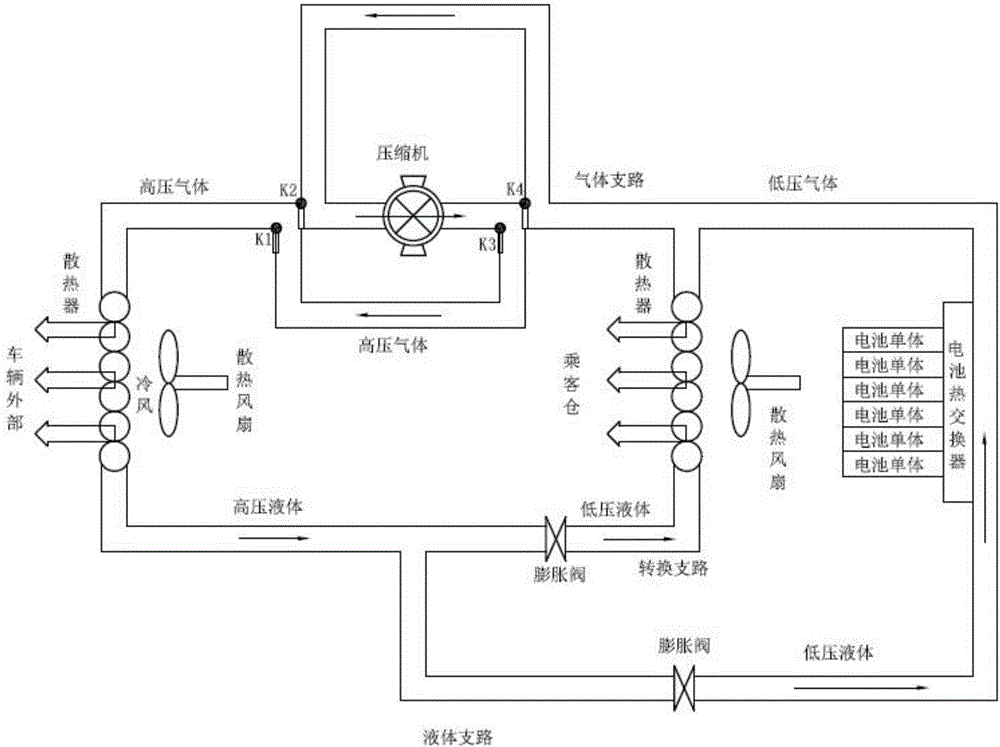

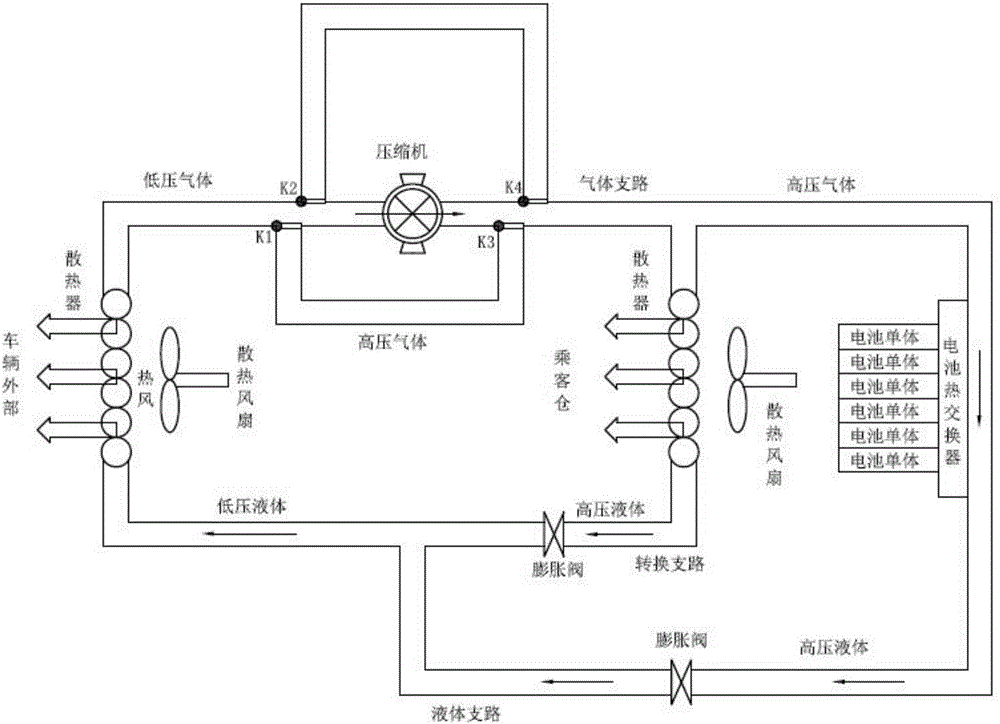

Battery heat management system realized by using heat pump technology

InactiveCN106374157AAchieve coolingRealize the heating effectSecondary cellsVehicular energy storagePower batteryHeat management

The invention relates to the technical field of electric automobile power batteries, and provides a battery heat management system realized by using a heat pump technology. The battery heat management system comprises a heat exchanger in contact with a battery core surface, and a compressor, a radiator, a radiating fan, an expansion valve, a controller, a closed-loop pipeline and a multi-channel valve, wherein the controller is used for judging whether a battery needs cooling or heating; the multi-channel valve is arranged on the closed-loop pipeline, and the valve is controlled by the controller; the heat exchanger is in physical contact with the battery core surface and a cooling pipeline; throttling and pressure reduction are realized through the expansion valve, and meanwhile the temperature of liquid is reduced; the radiator and the radiating fan are used for radiating gas of pipelines and converting the gas into low-pressure liquid together. According to the principle of phase change heat dissipation, the battery is cooled and heated efficiently through the conversion between the liquid and the gas so as to realize the transfer of heat, so that the temperature of the battery is effectively controlled in an ideal temperature range, quick cooling and quick cooling of the battery are realized, and the temperature uniformity of the battery is guaranteed.

Owner:臻昊(北京)新能源科技有限公司

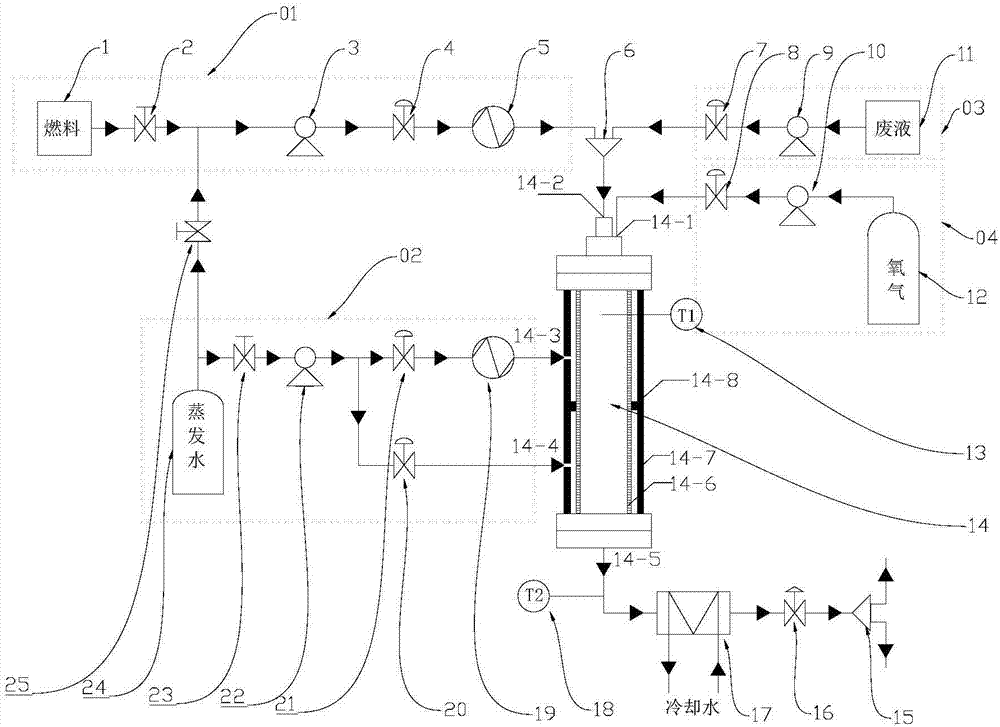

Supercritical water oxidation system and starting method thereof

ActiveCN107500462AAvoid problems such as fouling and cloggingRealize the heating effectMultistage water/sewage treatmentWater/sewage treatment by oxidationEnvironmental engineeringOxygen

The invention relates to the technical field of resource and environment, in particular to a supercritical water oxidation system and a starting method thereof. The system comprises a fuel branch, evaporable water branches, a waste liquid branch, an oxygen branch, a water membrane reactor and a mixer; the fuel branch and the waste liquid branch are respectively connected to the mixer, and the mixer is connected with a raw material inlet of the water membrane reactor; the evaporable water branches are respectively connected to a raw material inlet and a side wall surface of the water membrane reactor, and the oxygen branch is connected with an oxygen inlet of the water membrane reactor. The supercritical water oxidation system adopts the fuel as a starting simulation material to start the supercritical water oxidation reaction of the simulation material, thereby achieving an effect for warming a furnace; then the real waste liquid is gradually used to substitute the fuel, so that the waste liquid can be directly injected into the reactor without being preheated.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

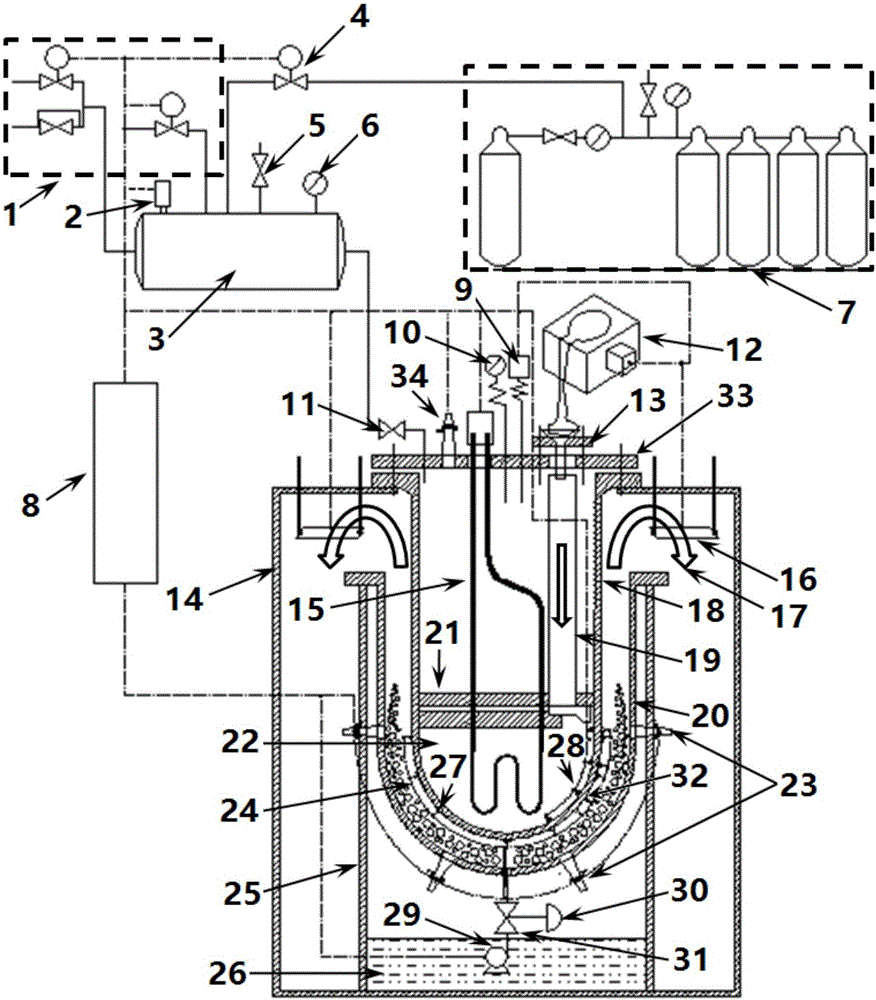

Safety testing system used for reactor pressure vessel under serious accident condition

ActiveCN106251919ADifferent cooling effectsHeating evenlyNuclear energy generationNuclear monitoringReactor pressure vesselEngineering

The invention provides a safety testing system used for a reactor pressure vessel under a serious accident condition. The safety testing system comprises a heater and a containment vessel, wherein a lower end enclosure of the containment vessel is at a suspension state, an overflow tower is arranged below the containment vessel, a spherical end enclosure of the overflow tower is at a suspension state, a reservoir for storing cooling water is arranged below the overflow tower, the lower end enclosure of the whole containment vessel is soaked in the cooling water, the heater is arranged in the containment vessel and is used for evenly heating a melt in the containment vessel at the constant temperature or at the varied temperature, the melt is poured into the containment vessel through a pouring channel at the top part of the containment vessel, the cooling water in the overflow tower is heated and boiled under the action of high temperature of the melt, a boiling tank and a steam flow are formed in the overflow tower, the containment vessel and a pressure device are connected through a pipeline and a valve, a pair of gas supply devices are connected on the pressure device, and the pressures of the gas supply devices are adjusted by the pressure device. According to the safety testing system used for the reactor pressure vessel under the serious accident condition, the failure process of the containment vessel at the high temperature gradient under the serious accident condition is simulated, and the maximum pressure value allowed in the containment vessel is acquired.

Owner:ZHEJIANG UNIV OF TECH

Temperature control unit based on shape memory alloy

ActiveCN104078276ARealize on-offRealize the heating effectThermal switch detailsTemperature controlShape-memory alloy

The invention discloses a temperature control unit based on shape memory alloy. One end of the temperature limiter shape memory alloy of a temperature control switch of the temperature control unit is bonded to a heat conduction top cover, and the other end of the temperature limiter shape memory alloy is connected with an insulating sheet. A first conducting strip is bonded below the insulating sheet, and a base of the temperature control switch is formed by integrally connecting a cylindrical hollow structure and a bottom disc. The insulating sheet, the first conducting strip and the temperature limiter shape memory alloy are arranged in the cylindrical hollow structure. The cylindrical surface of the base is provided with an opening, and a conducting strip of the temperature control switch is embedded into the opening. The base of the temperature control switch is an insulator, the bottom of the first conducting strip in a temperature limiter is provided with a round piece, the bottom of the first conducting strip is connected with a lever, and the lever is connected with a button of a temperature control unit application device. The temperature limiter shape memory alloy is one-way shape memory alloy. By means of the shape memory alloy, the temperature control unit has the advantages of being high in stability, simple, safe, high in control precision, high in response speed and the like.

Owner:SOUTH CHINA UNIV OF TECH

Plastic particle mixing dryer

InactiveCN108204732AStir wellAchieving stirringGranular material dryingDrying gas arrangementsHelical bladeReciprocating motion

The invention belongs to the technical field of plastic manufacturing, and specifically discloses a plastic particle mixing dryer comprising a material barrel and a discharging hopper. The inner wallof the material barrel is provided with a plurality of columnar bulges, and a rotating shaft is provided with helical blades; the top of the rotating shaft is provided with an end cam, and the rotating shaft and the end cam are internally provided with through holes which communicate with each other; the side wall of the rotating shaft in the material barrel is provided with air outlets which communicate with the through holes; a support frame is provided with a cylinder, and the lower end face of an ejector rod in the cylinder abuts against the concave side of the end cam; a coil is wound onthe outer wall of the cylinder, and connected to an AC motor; and the outer wall of the cylinder is provided with a one-way air inlet valve and a one-way air outlet valve, and a hot air pipe communicating with the through holes is installed between the one-way air outlet valve and the end cam. According to the technical scheme, hot air is intermittently discharged into a drying oven through the quick reciprocating motion of a cylinder piston, so that plastic particles are switched between two motion states, namely irregular movement and falling-down, and the plastic particles are mixed thoroughly.

Owner:重庆市中塑新材料有限公司

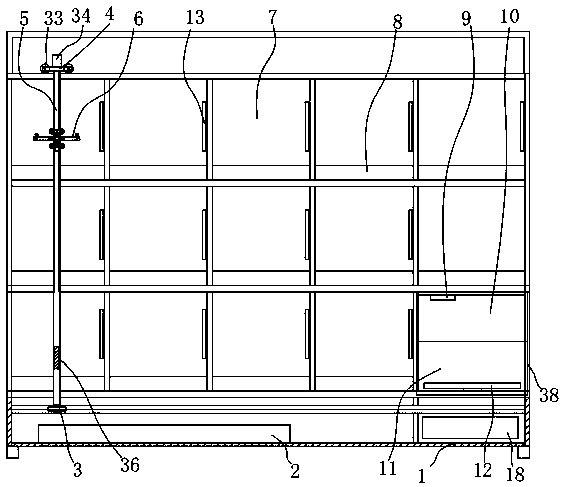

Automatic catering vending system

PendingCN107798784AAchieve heatingCarrying outApparatus for meter-controlled dispensingControl theoryRefrigeration

The invention relates to an automatic catering vending system. The automatic catering vending system comprises a cabinet body, a computer, input equipment, a refrigerating bin and a heating bin, wherein a carrying bin is arranged on the rear side of the refrigerating bin; a transverse sliding track is arranged on the top of the carrying bin; a carrying trolley is arranged on the transverse slidingtrack and is provided with a longitudinal sliding track; the longitudinal sliding track is provided with a lifting trolley; a rear sealing door is arranged on the rear side of the heating bin; a microwave heater is arranged in the heating bin; and refrigeration equipment is arranged at the bottom of the cabinet body. Different kinds of fast food are refrigerated by the separated refrigerating bin, workers can supplement goods in idle time favorably, supply of fast food of a vending place can be ensured for a long time, owing to an integrated structure, use and mounting of equipment are facilitated, the heating bin is integrated in the cabinet body, heat of the fast food is realized, left-right movement of the lifting trolley is realized by the carrying trolley in the carrying bin, liftingcontrol over a clamping seat is realized by lifting of the lifting trolley, and fast movement of the clamping seat is realized favorably to carry the fast food.

Owner:苏州卓膳餐饮管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com