Method and system for olefin polymerization temperature control

A technology of olefin polymerization and automatic control system, which is applied in the direction of temperature control by electric means, can solve the problems of severe polymerization reaction, excessive temperature fluctuation, and adverse effects on the performance and quality of polyolefin products, and achieves performance and quality stability. Improve, stable and accurate temperature control, solve the effect of unbalanced heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

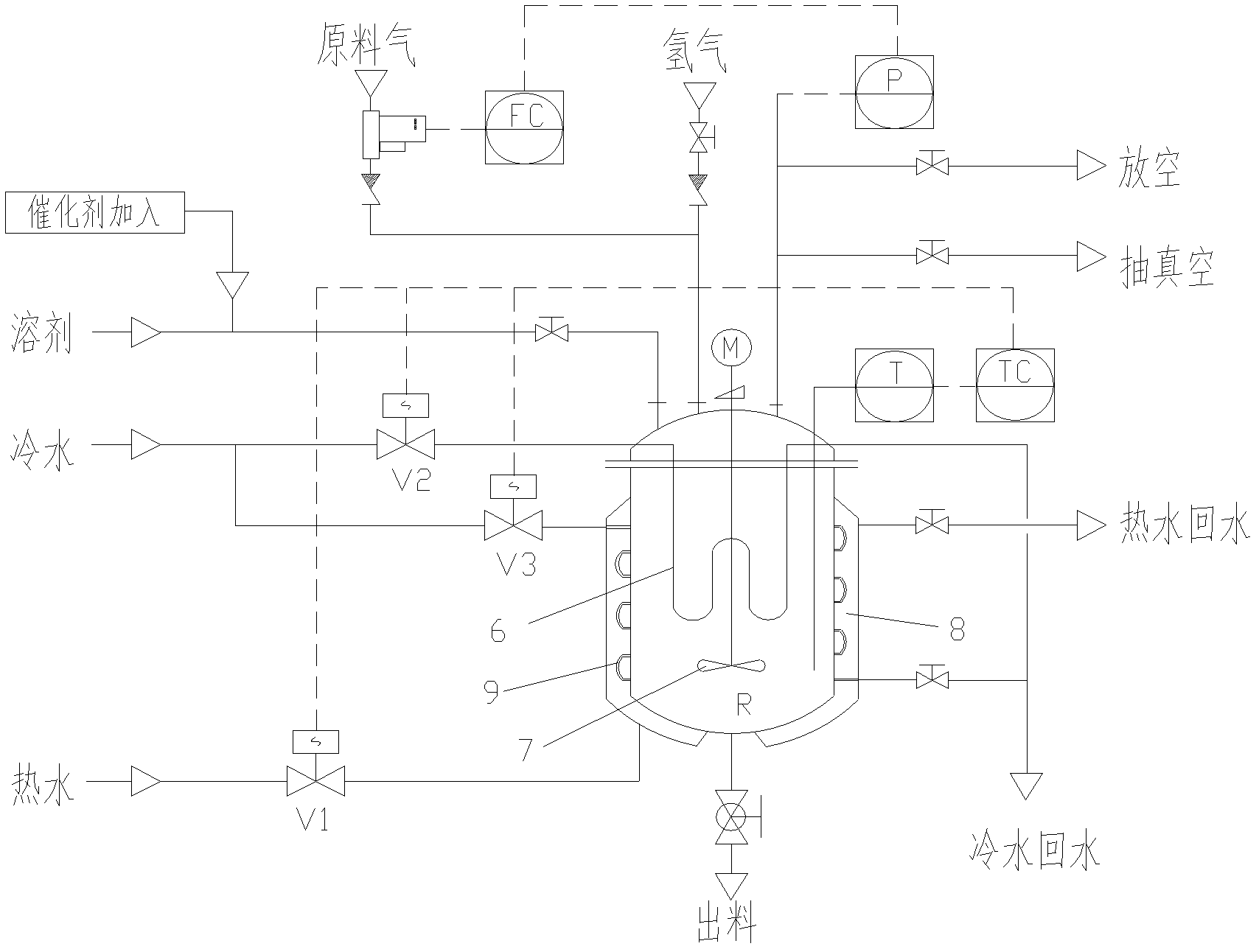

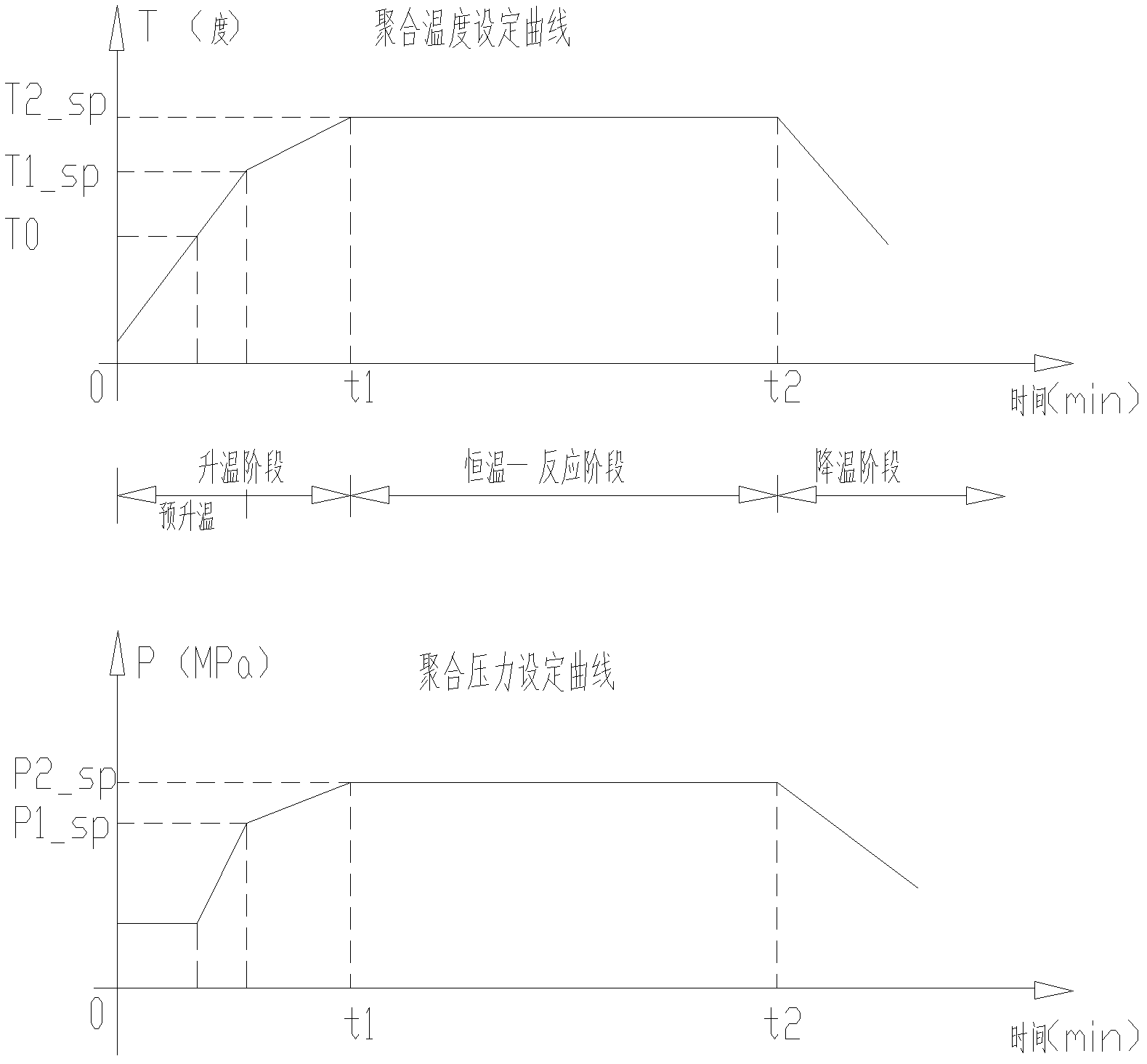

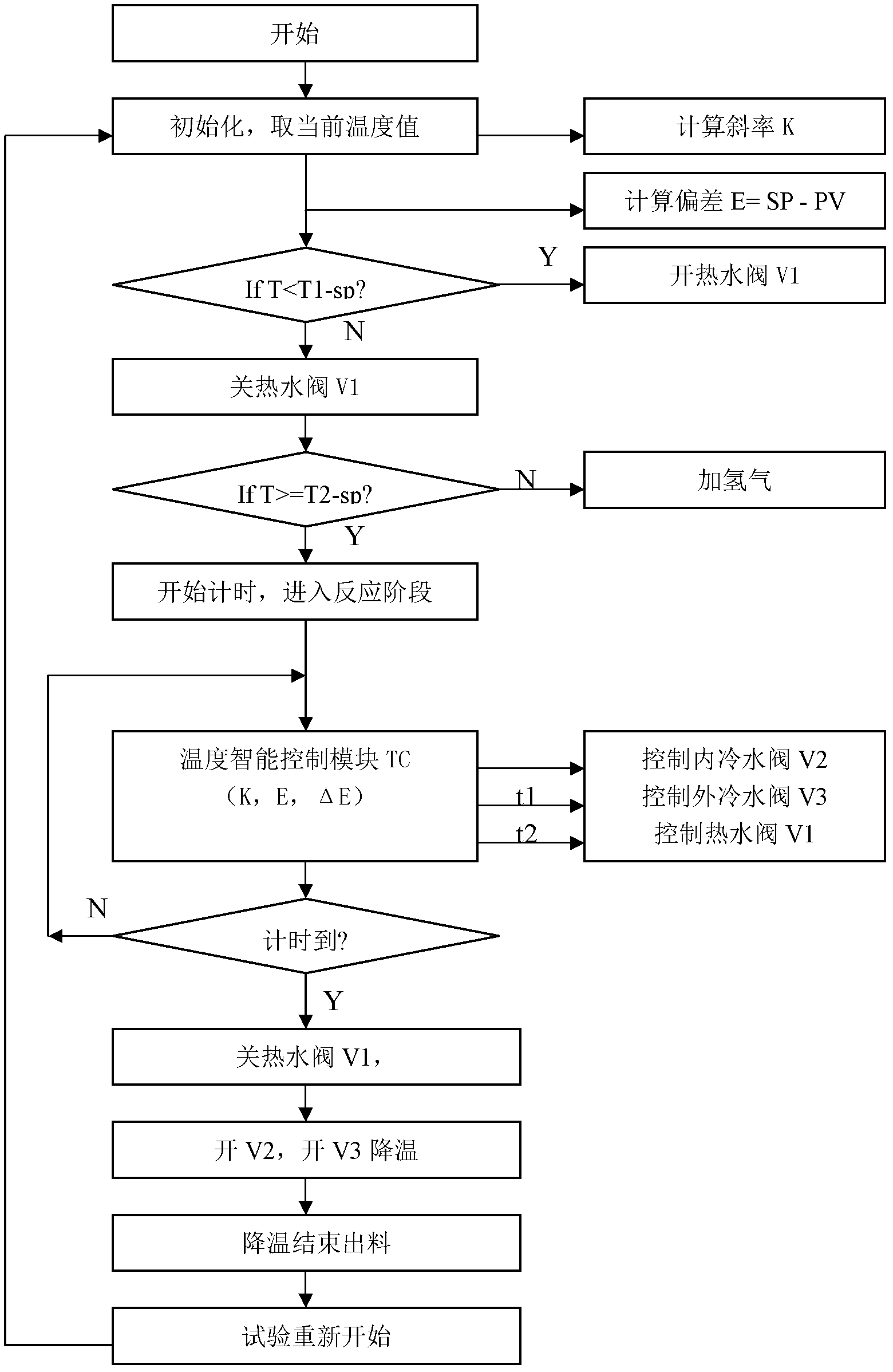

[0042] Temperature Control of Small Ethylene Polymerization Unit

[0043] At the beginning of the test, pre-set the preheating temperature T1_SP: 75°C, the reaction temperature T2_SP: 85°C, and the reaction time t: 2 hours according to the type and amount of the olefin catalyst; Wait for the raw materials; then open the hot water valve V1, and the jacket of the kettle is fed with hot water to raise the temperature. When the temperature reaches T0, the pressure in the kettle starts to increase. When the temperature reaches T1_SP, the hot water valve V1 is disconnected. After adding a certain amount of hydrogen, add the raw material gas ethylene, and increase the pressure to P2_sp: 1.03Ma, and then increase with the consumption of the polymerization reaction. Supplement raw material gas ethylene to maintain stable pressure. When the temperature reaches the reaction set temperature T2_SP, start the intelligent controller, start timing, and enter the reaction stage.

[0044] Dur...

Embodiment 2

[0048] Temperature Control of Small Propylene Polymerization Unit

[0049] At the beginning of the test, pre-set the preheating temperature T1_SP: 65°C, the reaction temperature T2_SP: 70°C, and the reaction time t: 2 hours according to the type of catalyst and the amount of feed; add a certain amount of silane, catalyst, etc. to the kettle under nitrogen protection Raw materials; a certain amount of hydrogen is introduced; and a certain amount of liquid-phase propylene is added. Then the hot water valve V1 is opened, and hot water is fed into the kettle jacket to raise the temperature. When the temperature reaches T1_SP, the hot water valve V1 is disconnected, and when the kettle temperature reaches the reaction set temperature T2_SP, start the intelligent controller, start timing, and enter the reaction stage.

[0050] The temperature control in the reaction stage is the same as that of the ethylene polymerization unit. When the constant temperature reaction timer expires, ...

Embodiment 3

[0052] Temperature Control of Ethylene Propylene Copolymerization Test

[0053] Carry out liquid-phase bulk homopolymerization of propylene first, and the method is the same as in Example 2: Application of a propylene polymerization device. After the completion, the mixed gas of ethylene and propylene in different proportions in the gas distribution tank is introduced into the polymerization kettle. During the copolymerization, the pressure, temperature, time, and stirring speed in the kettle are determined according to the specific test. The temperature control process of the ethylene propylene copolymerization test can also be completed by the intelligent control method and the olefin polymerization control device provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com