Patents

Literature

36results about How to "Guaranteed not to overheat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

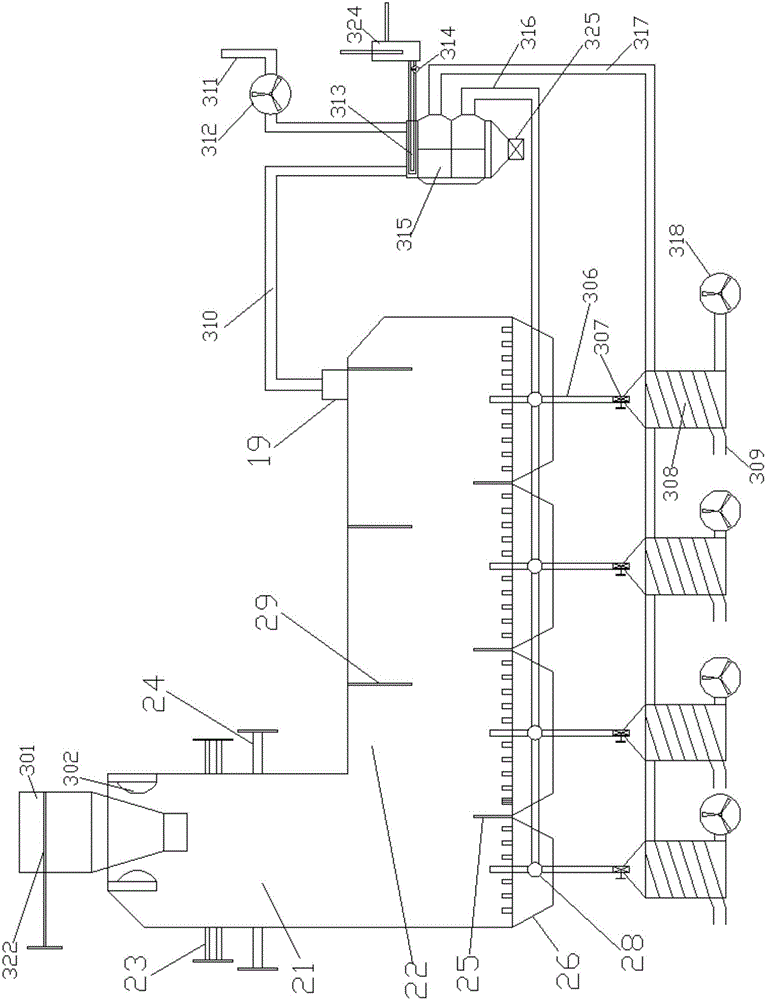

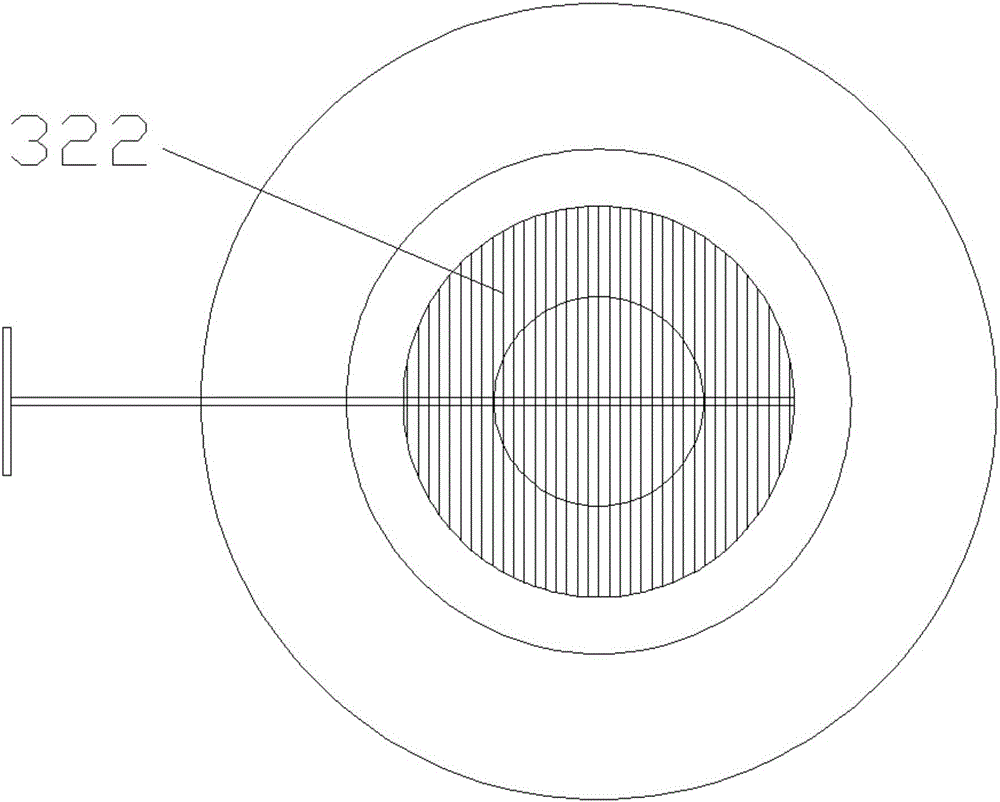

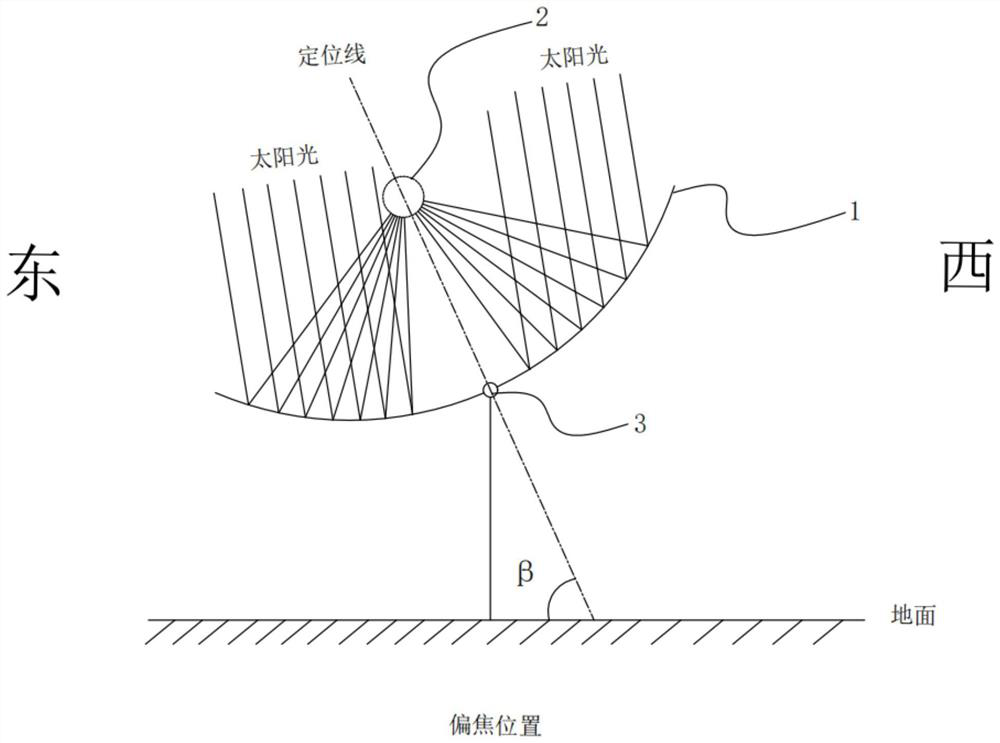

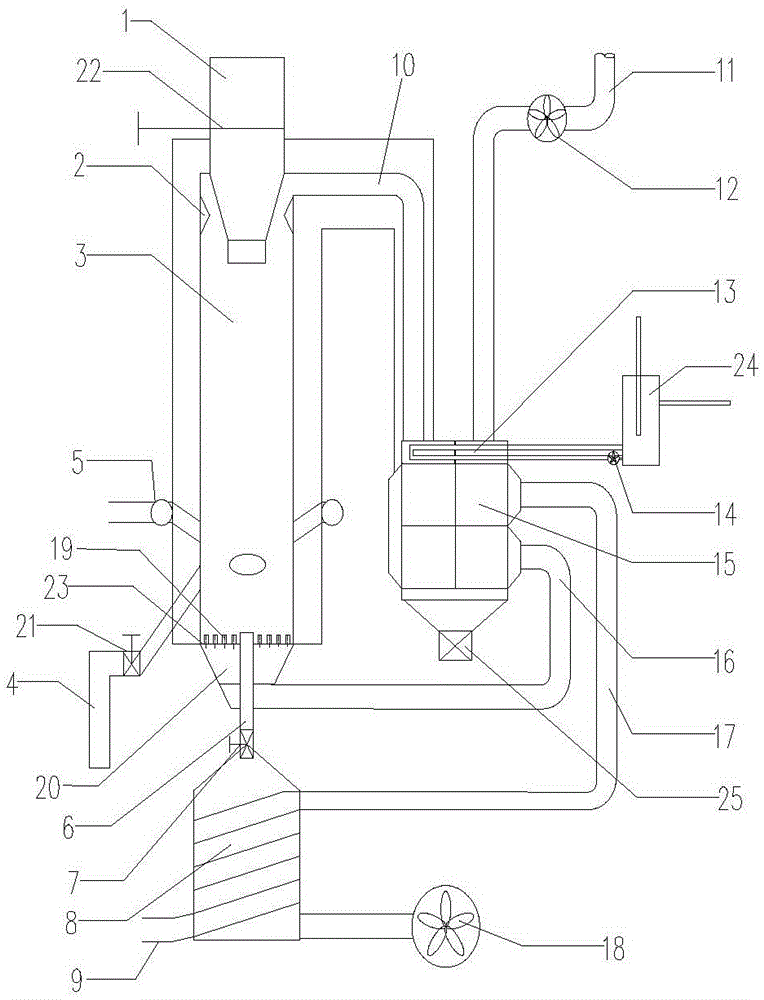

Precoated sand recycling system

InactiveCN105750489ASpread evenlyAvoid scourCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterCombustion

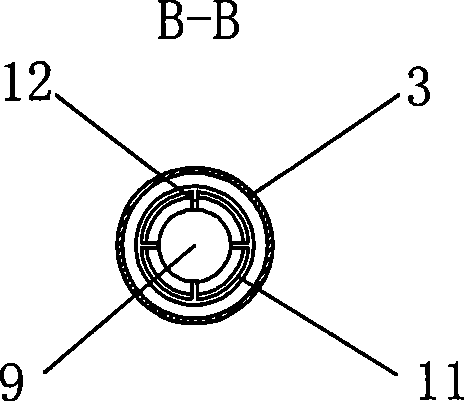

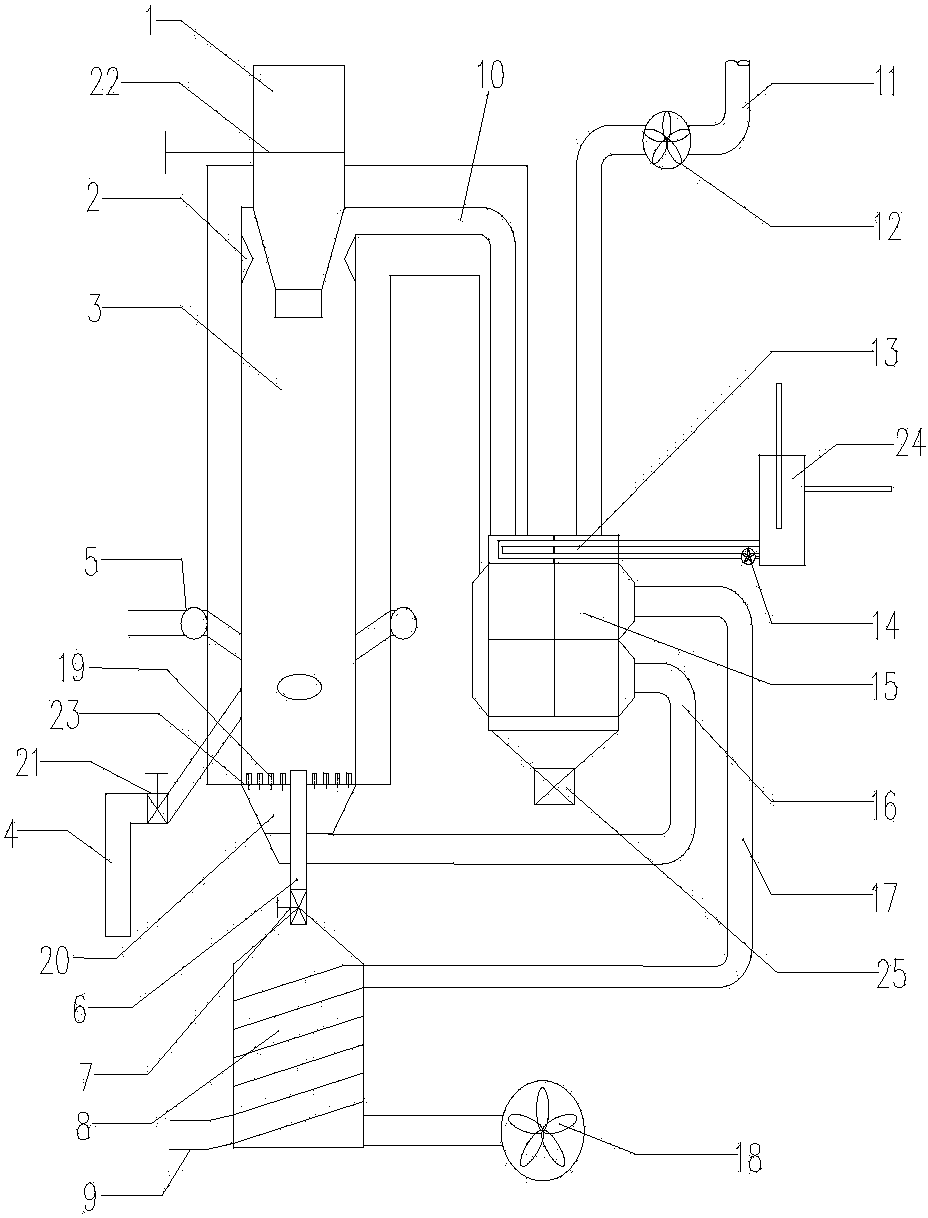

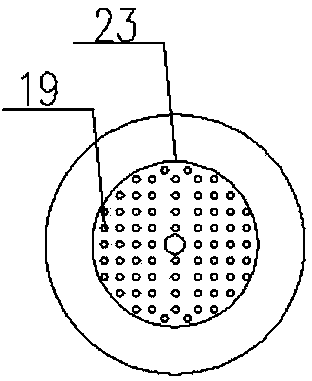

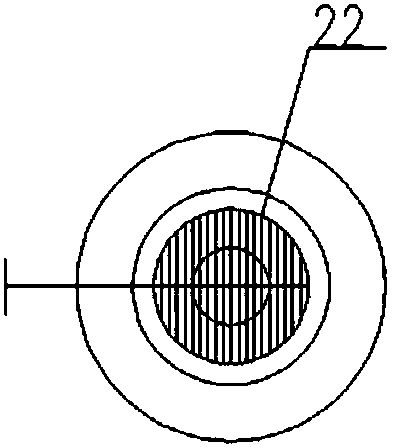

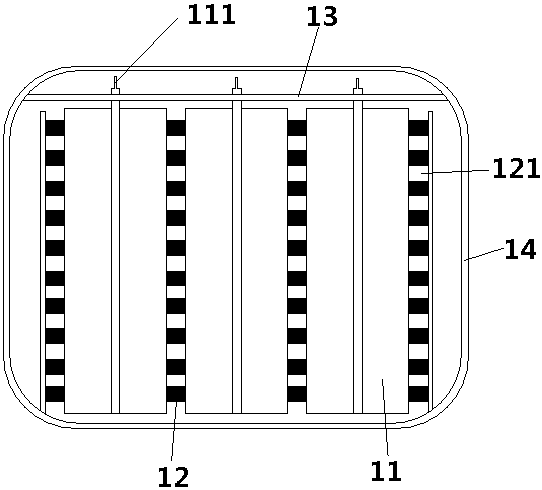

The invention discloses a precoated sand recycling system which comprises an upright suspension combustion hearth and a horizontal type boiling bed, wherein the bottom of the horizontal type boiling bed is partitioned by lower partitioning plates so as to form a plurality of uniform bottom air distribution cabins; a hot air hole is formed in each bottom air distribution cabin; a fume exhaust hole for exhausting fume is formed in the horizontal type boiling bed; the fume exhaust hole in the horizontal type boiling bed is communicated with a fume exhaust pipeline through a flue; a draft fan is arranged at an end part of the fume exhaust pipeline; a dividing wall cooler is arranged below the air distribution cabins of the horizontal type boiling bed; the top end of the dividing wall cooler is connected with the horizontal type boiling bed through a sand falling tube; an air outlet is formed in the upper part of the dividing wall cooler; a sand outlet and an air inlet are formed in the bottom of the dividing wall cooler; the air outlet is connected with an air preheater through a first hot air tube; the inlet of the air preheater is communicated with the first hot air tube; the outlet of a gas conveying pipeline is communicated with hot air holes of the air distribution cabins through a second hot air tube.

Owner:西安合力汽车配件有限公司

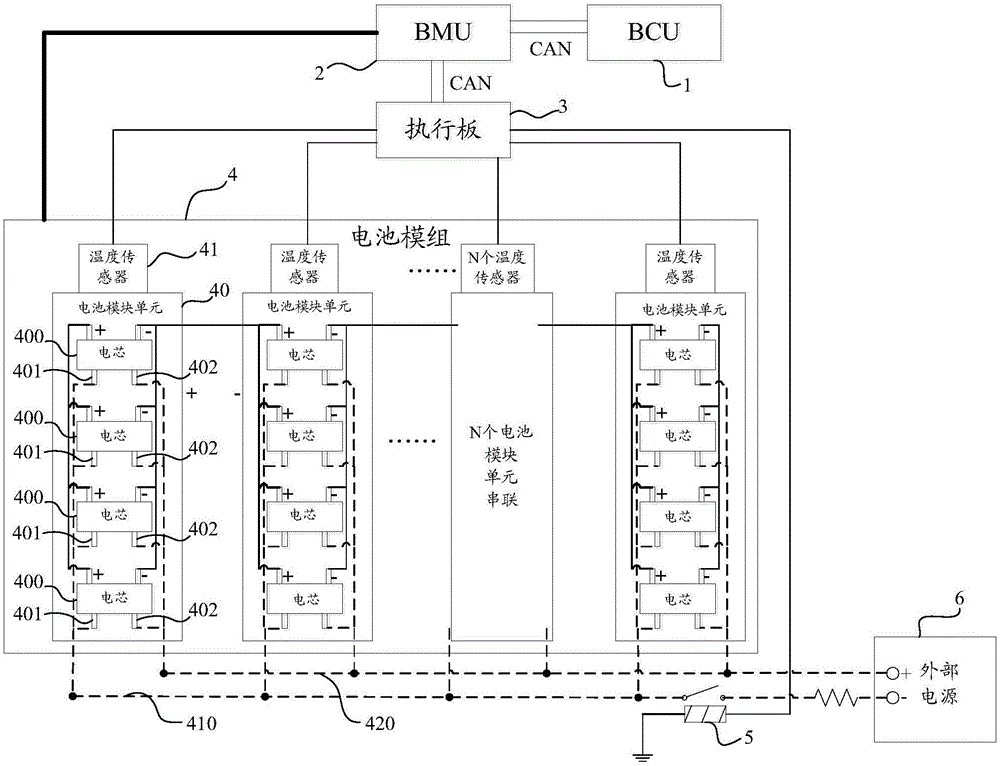

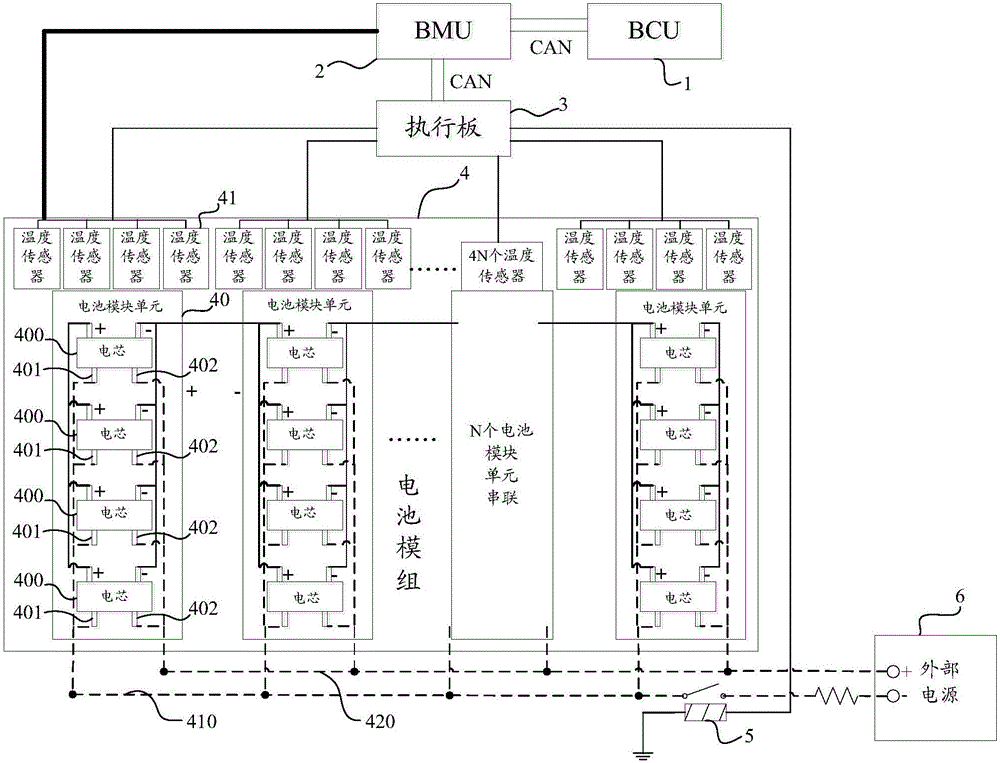

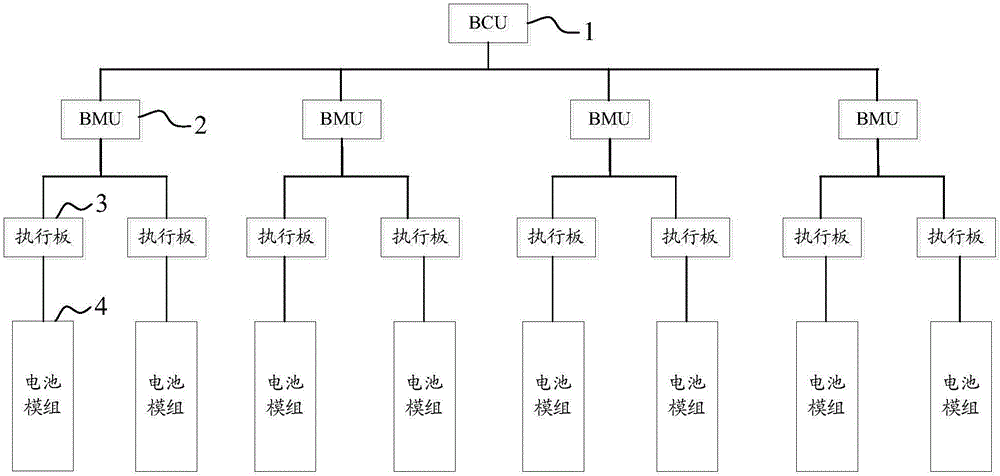

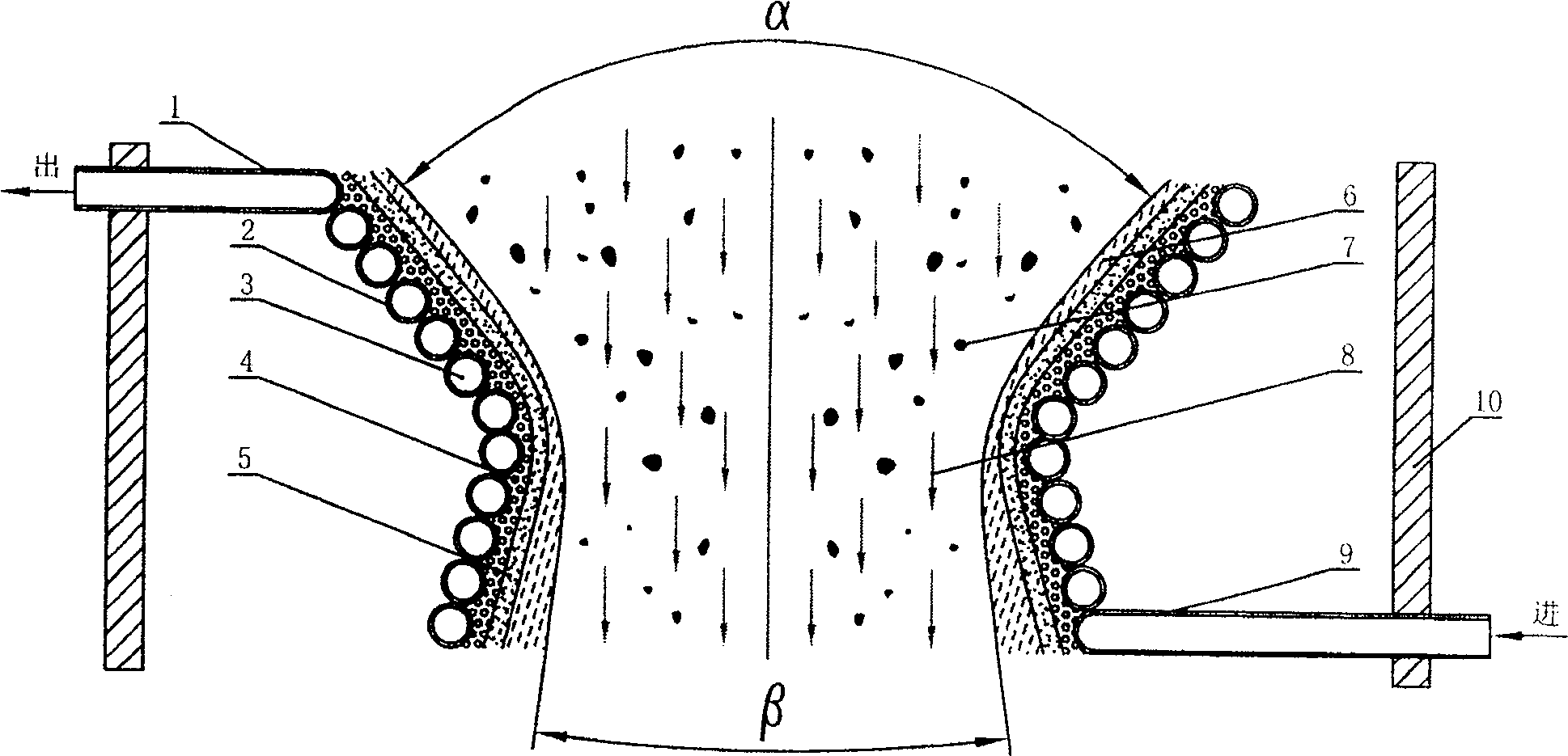

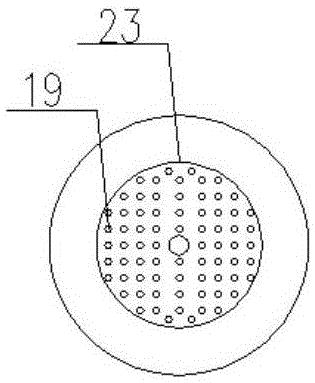

Battery system and electric automobile

ActiveCN106099254AImprove heating efficiencyMeet high power demandsCharging stationsCell temperature controlElectrical batteryCharge and discharge

The invention provides a battery system and an electric automobile. The battery system comprises battery modules, wherein each of the battery modules comprises a plurality of battery module units; each of the battery module units comprises a plurality of batteries; a first heating pole and a second heating pole connected with the first heating pole are arranged on each of the batteries; each first heating pole is serially connected to a first branch; the second heating pole is serially connected to a second branch; the first branch is connected with a cathode of an external power supply; the second branch is connected with an anode of the external power supply; a temperature sensor is arranged in each of the battery module units and is used for detecting the temperature of the battery; an executing plate is used for collecting a temperature signal acquired by the temperature sensor. According to the battery system provided by the invention, the heating pole arranged on the battery can realize the heating of the battery. Such a heating manner increases the heating efficiency and guarantees the battery to be free from being overheated, and meanwhile, the increasing of the battery temperature can be completed within a short period of time, the battery temperature can reach the temperature for high-power charging and discharging, and the high power requirement of the whole vehicle is met.

Owner:BEIJING ELECTRIC VEHICLE

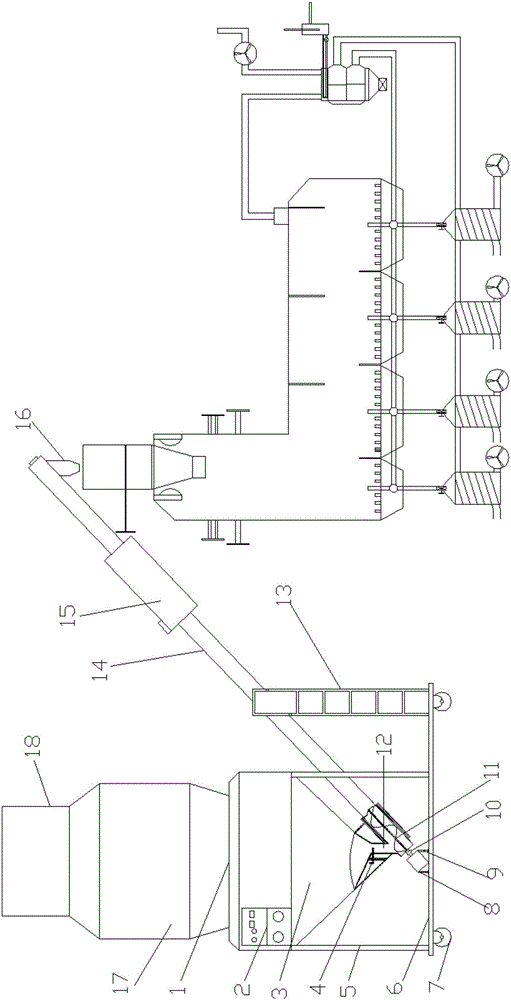

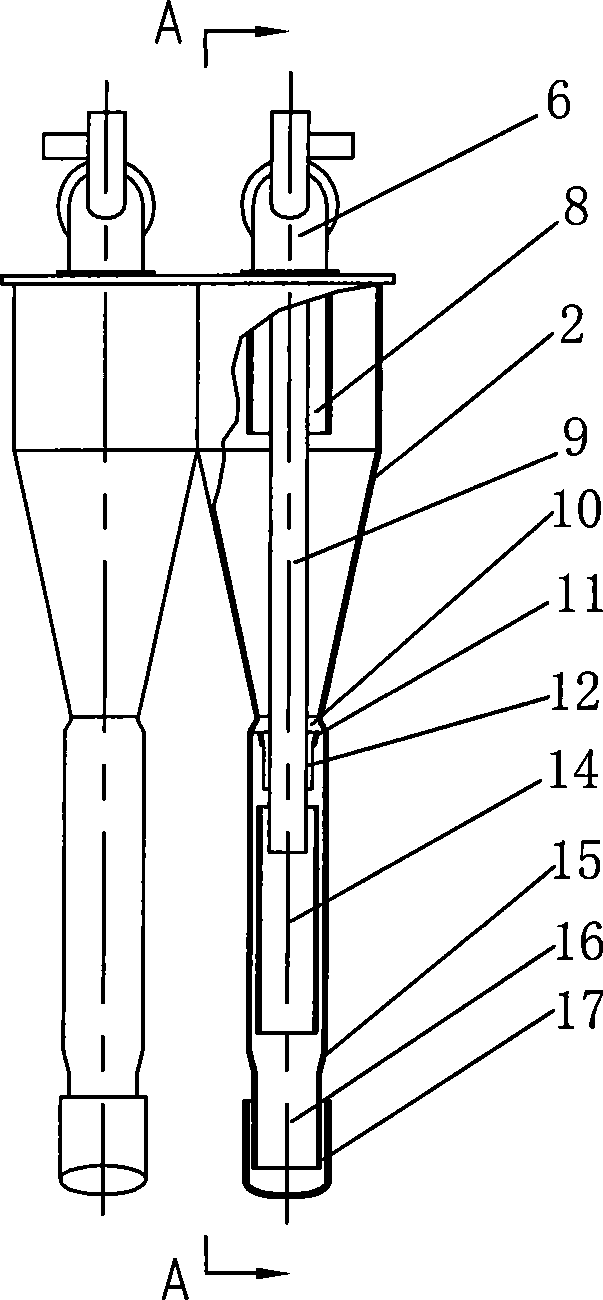

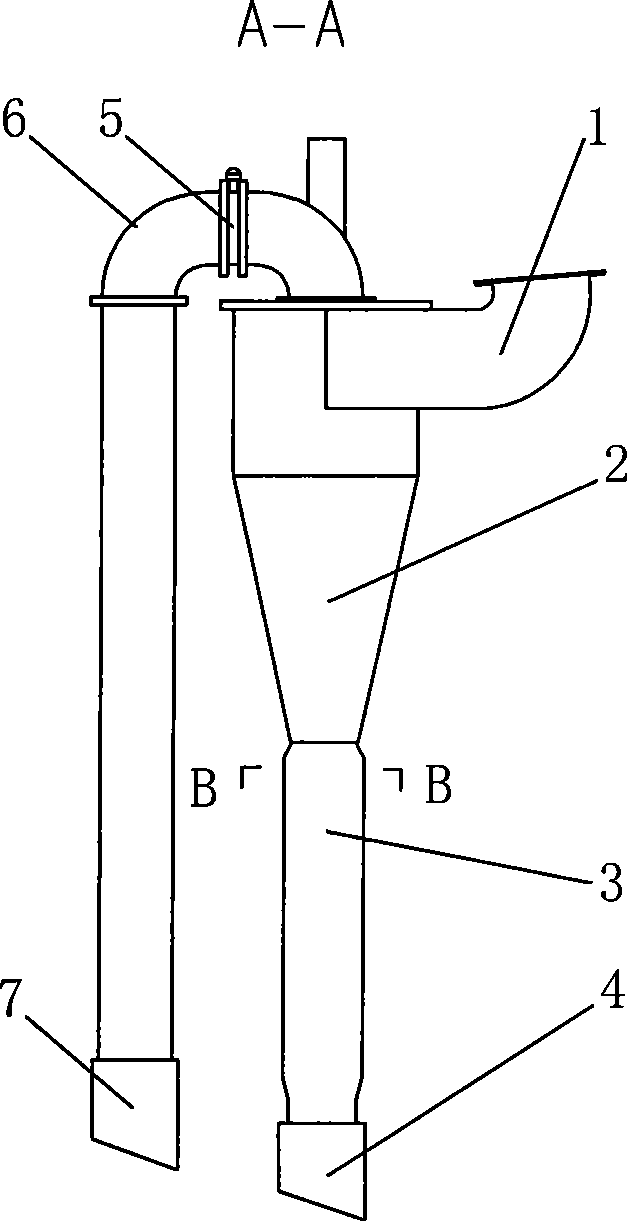

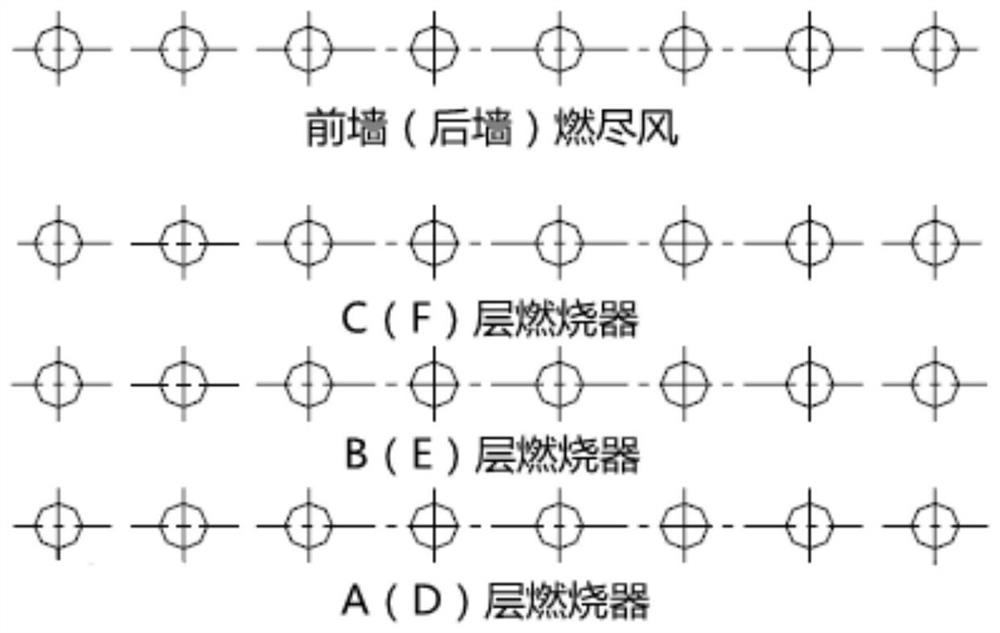

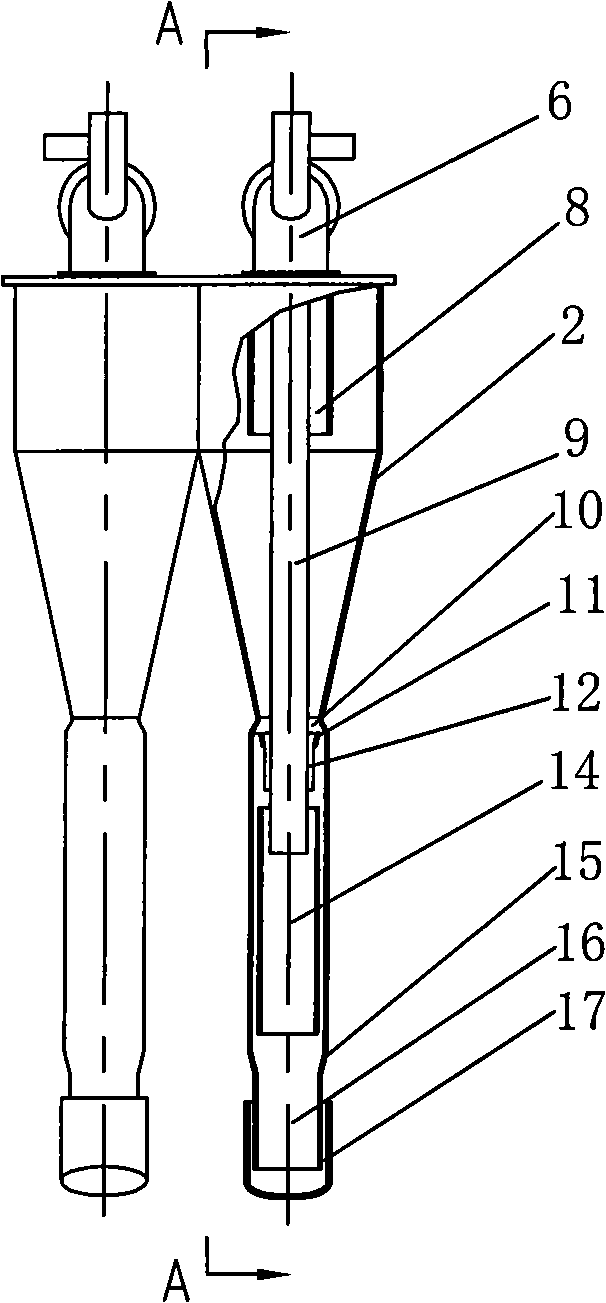

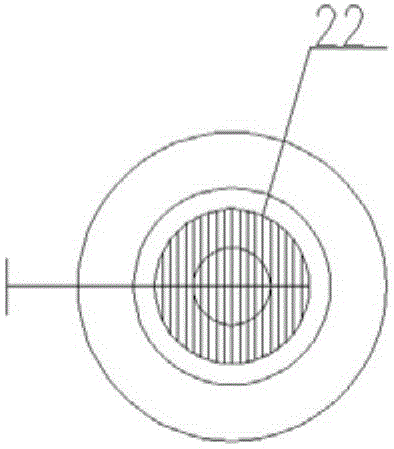

Pulverized coal burner

ActiveCN101446412AAchieve igniteEffective firePulverulent fuel combustion burnersCycloneCombustion chamber

A pulverized coal burner comprises at least one cyclone with a primary air powder tangential inlet line and a middle tapered shrinkage segment; an exhaust gas pipe having an exhaust gas adjusting air door and inserted on the top of the cyclone; a primary pulverized coal burning chamber and a secondary pulverized coal burning chamber arranged on the straight outlet segment of the cyclone; a micro-oil oil gun arranged on the top of the cyclone and inserted and penetrating the inlet of the exhaust gas pipe to the inlet of the primary pulverized coal burning chamber; a concentration ring and a rotation-eliminating blade arranged outside the throat at the interface of the shrinkage segment and the straight outlet segment of the cyclone; and a secondary air nozzle arranged at the outlet of the secondary pulverized coal burning chamber. The pulverized coal burner can achieve burn a great amount of pulverized coal by strengthened combustion and gradual amplification of trace oil by adopting the technical measures, such as ignition using micro-oil gasification oil gun, secondary pulverized coal burning, adjustable exhaust gas flow rate and pulverized coal concentration ratio, further pulverized coal concentration and rotation elimination, thereby achieving ignition of anthracite and lean coal, and achieving high oil saving rate. The coal burner is particularly suitable for W-shaped flame boiler.

Owner:EASTERN BOILER CONTROL CO LTD +1

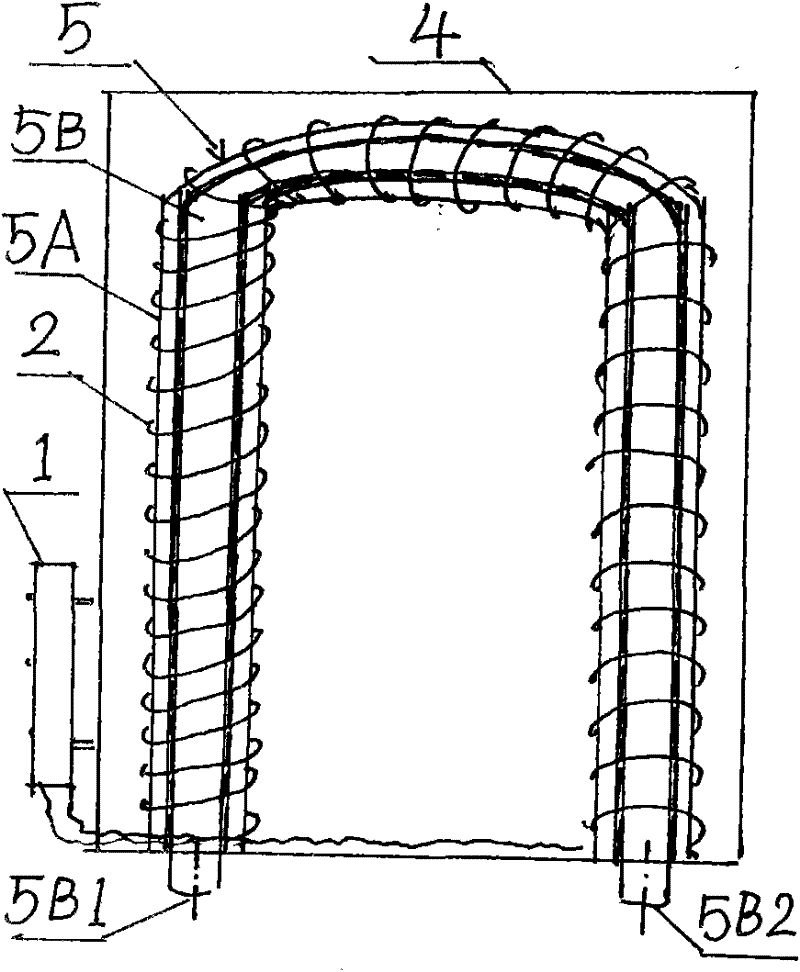

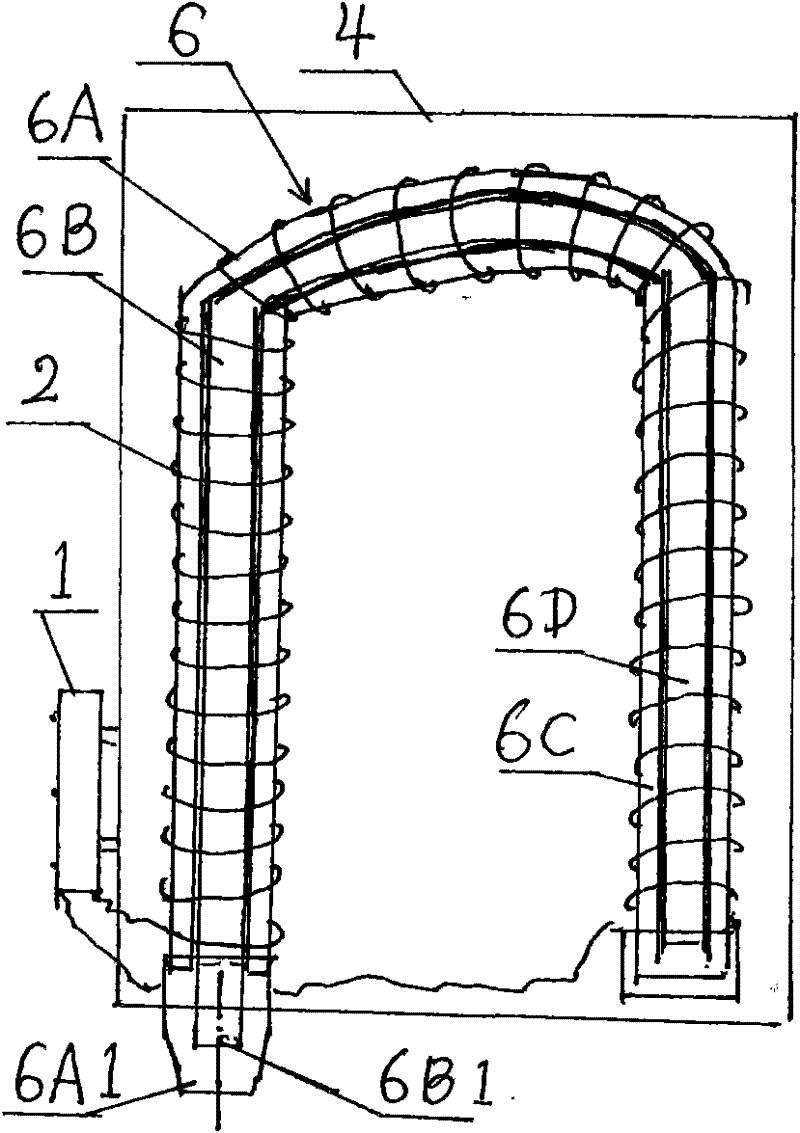

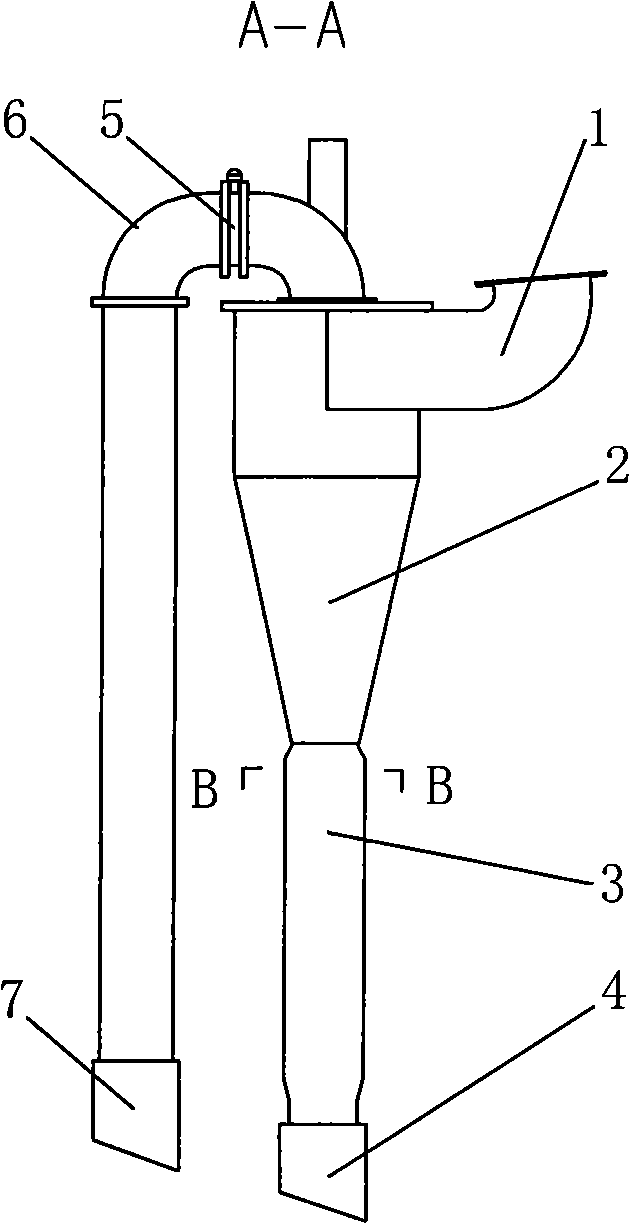

Precoated sand hot-process regeneration equipment and regeneration method

InactiveCN103894538AIncrease the number of landingsExtended stayMould handling/dressing devicesAir preheaterFluidized bed

The invention belongs to the technical field of energy engineering, and relates to precoated sand hot-process regeneration equipment mainly utilizing a vertical fluidized bed furnace and a precoated sand hot-process regeneration method. The precoated sand hot-process regeneration equipment comprises a vertical fluidized bed furnace, a charging hopper, a nozzle for oppositely spraying coal gas, a flue, a smoke discharging pipeline, a dividing wall cooler and an air preheater, wherein the dividing wall cooler is arranged below the vertical fluidized bed furnace, the top end of the dividing wall cooler is connected with the vertical fluidized bed furnace through a sand falling pipe, the air inlet of the dividing wall cooler is connected with an air blower, the air outlet of the dividing wall cooler is connected with the air preheater through a hot air pipe I, the inlet of an air conveying pipe of the air preheater is communicated with the hot air pipe I, the outlet of the air conveying pipe is communicated with an air chamber through a hot air pipe II, and the flue is connected with the smoke discharging pipeline through a cavity of the air preheater. The precoated sand hot-process regeneration method comprises the steps: starting, feeding, and stabilizing. The precoated sand hot-process regeneration equipment is high in energy utilization rate, perfect in regeneration, simple in operation, and energy-saving and environment-friendly.

Owner:QINGDAO UNIV

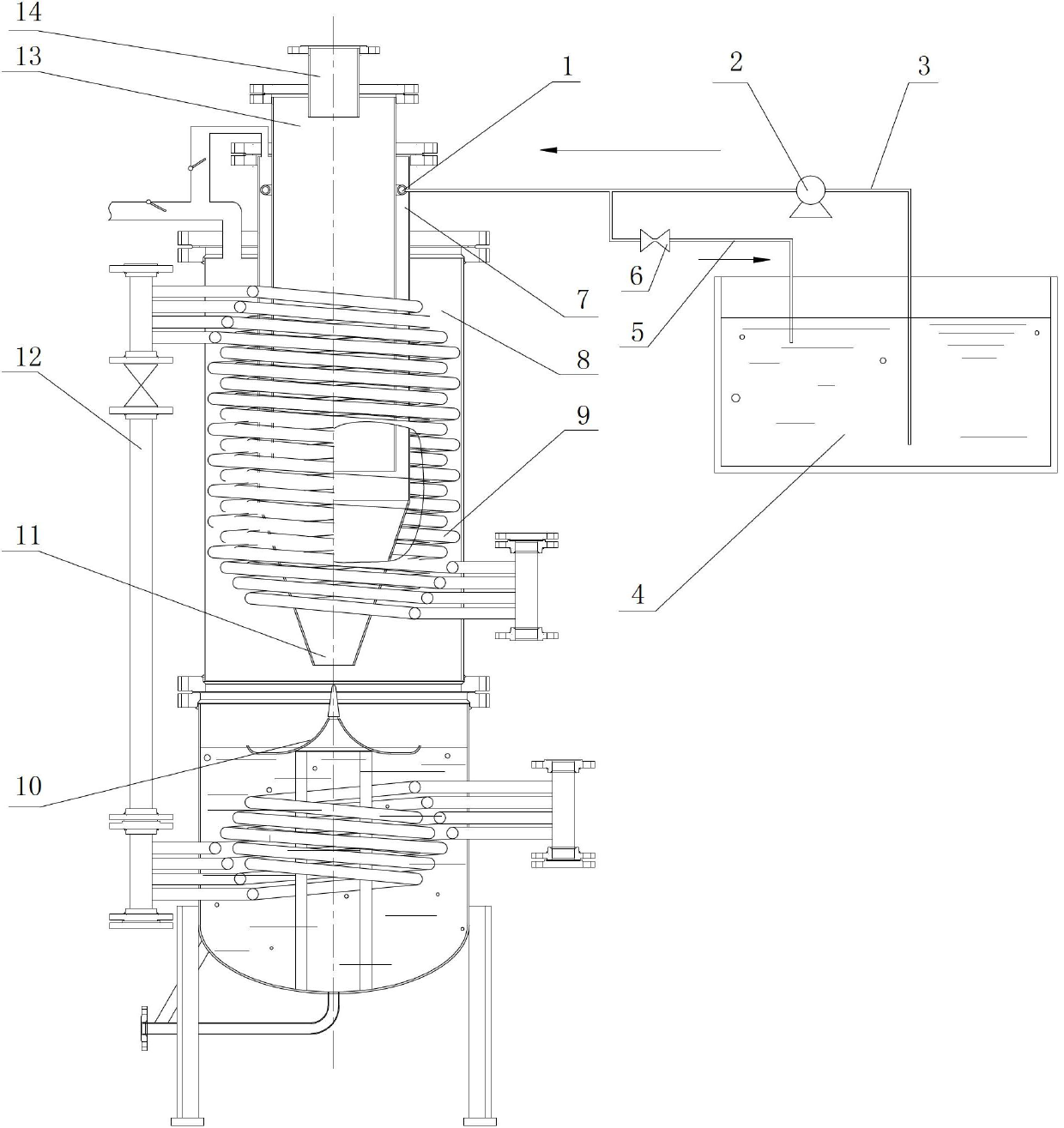

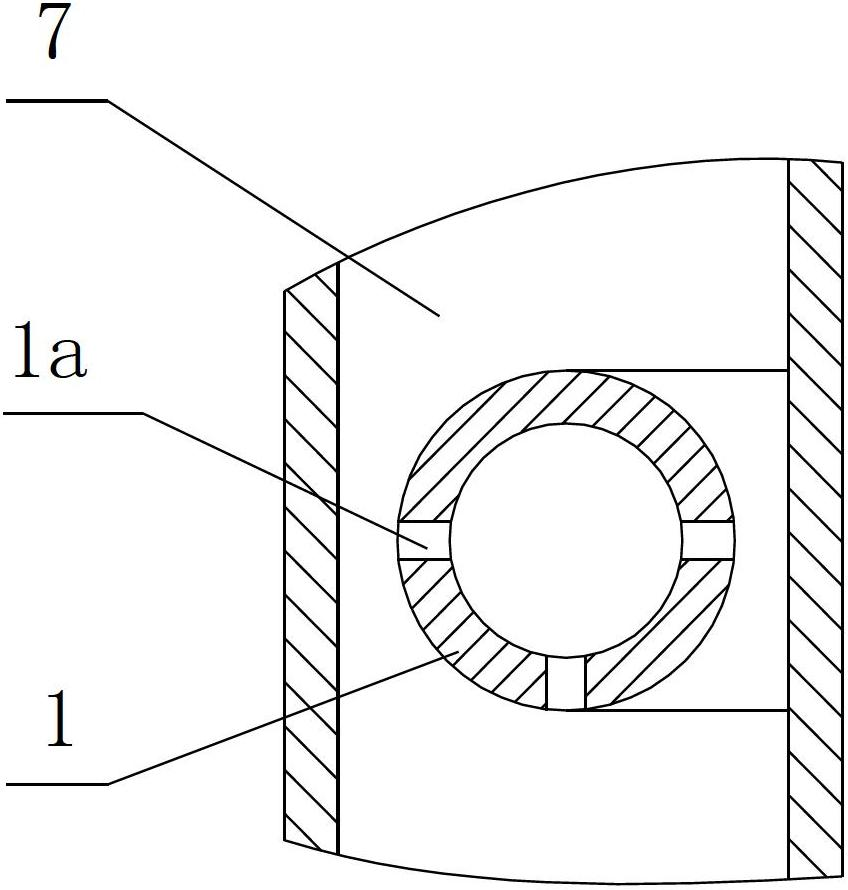

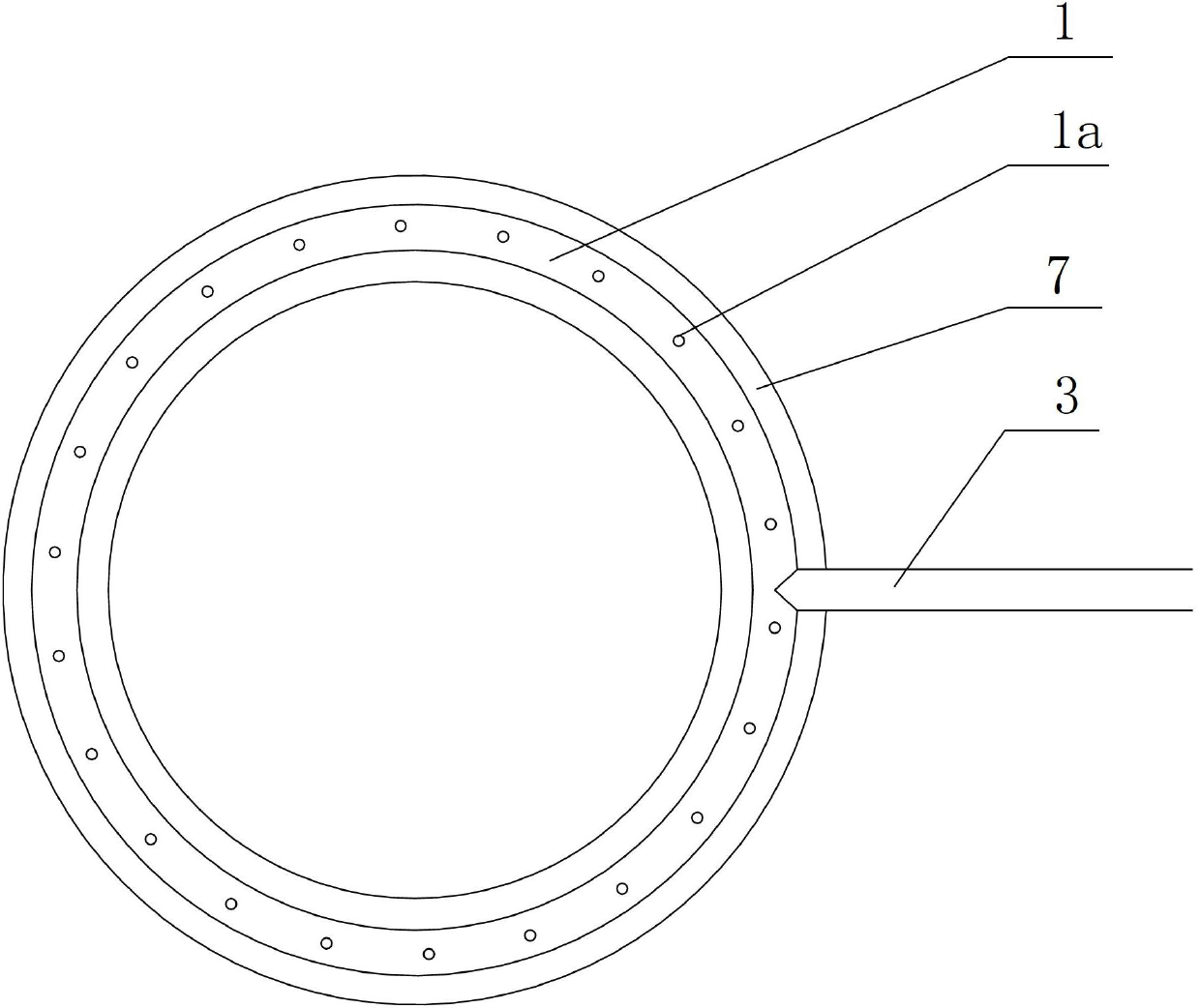

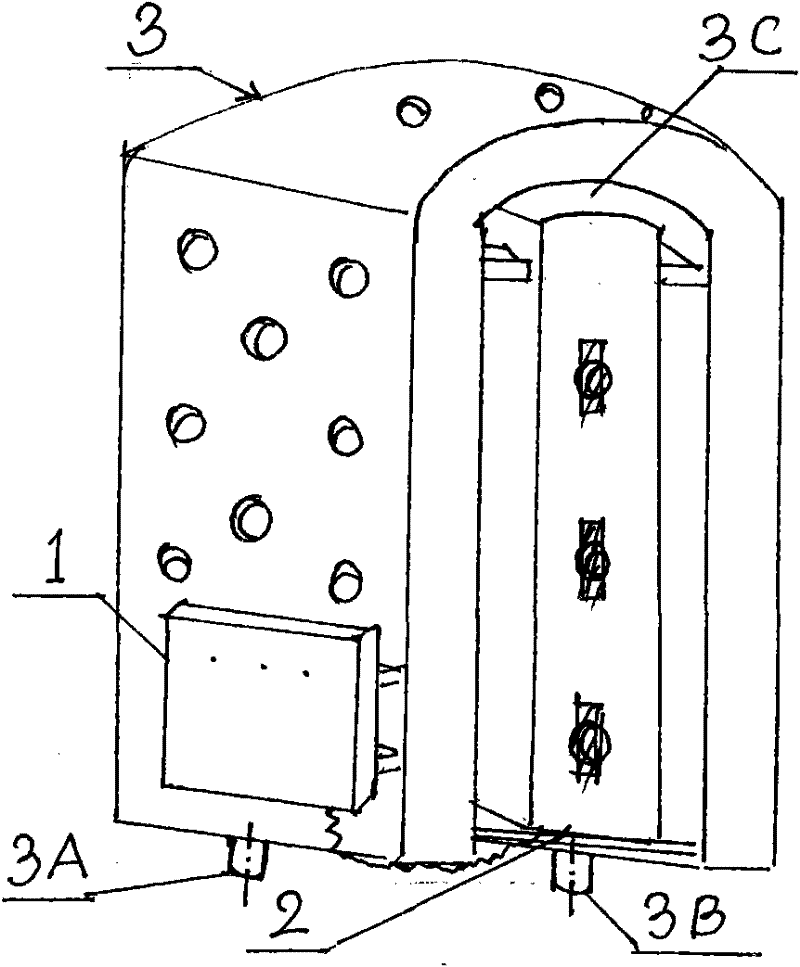

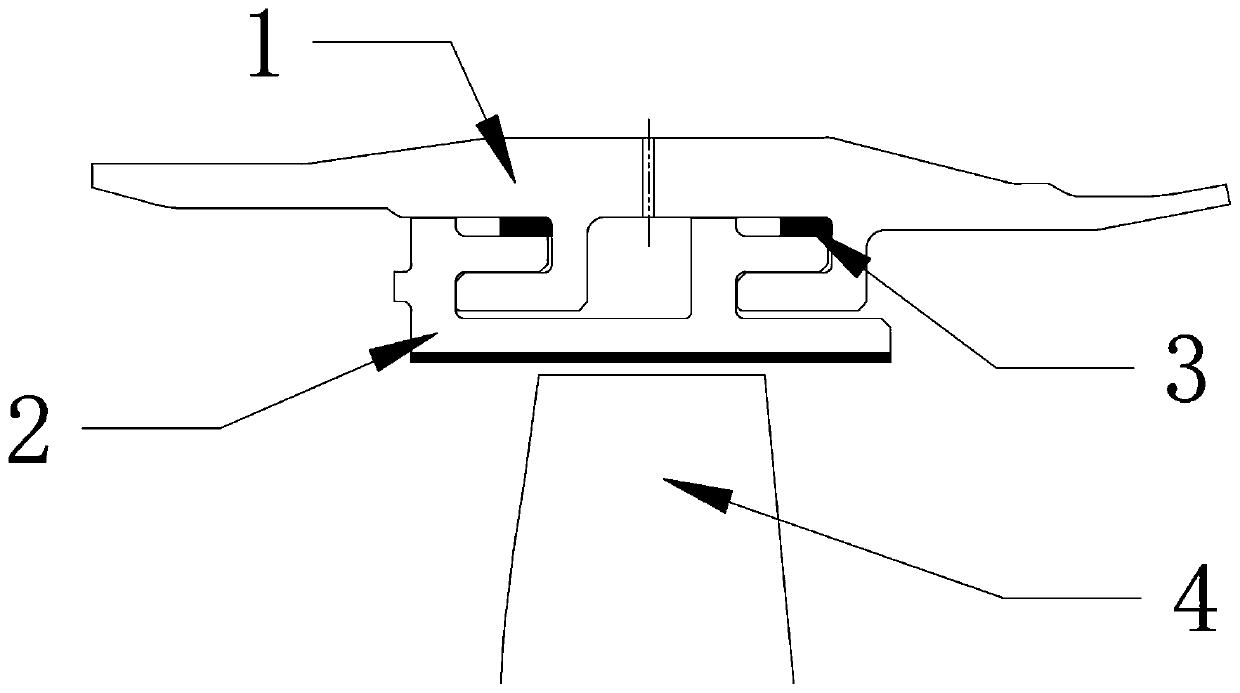

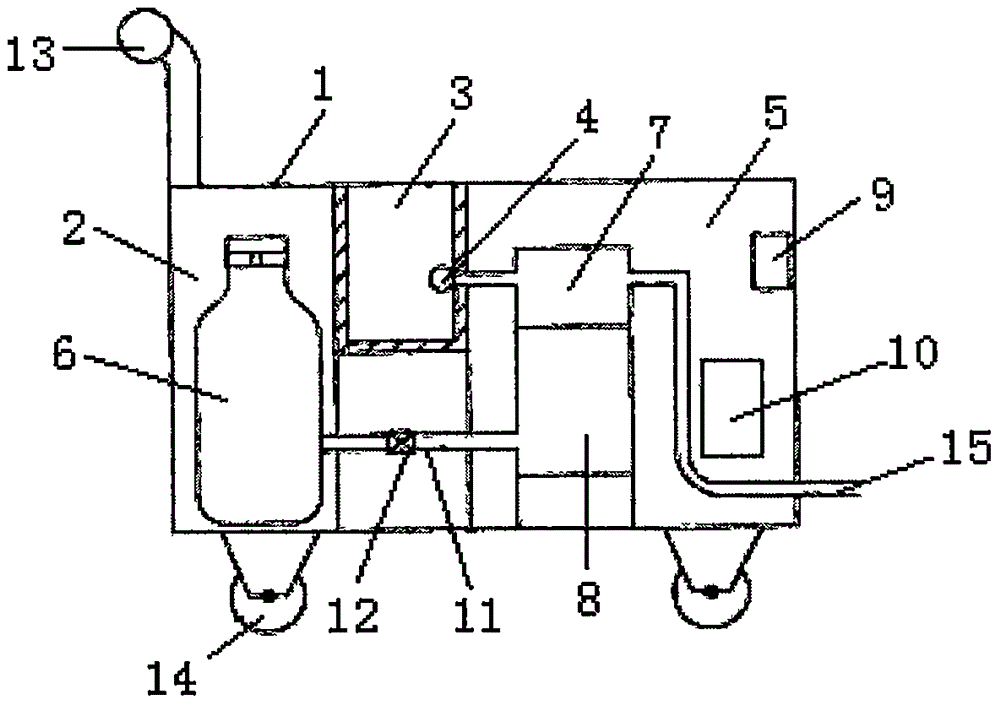

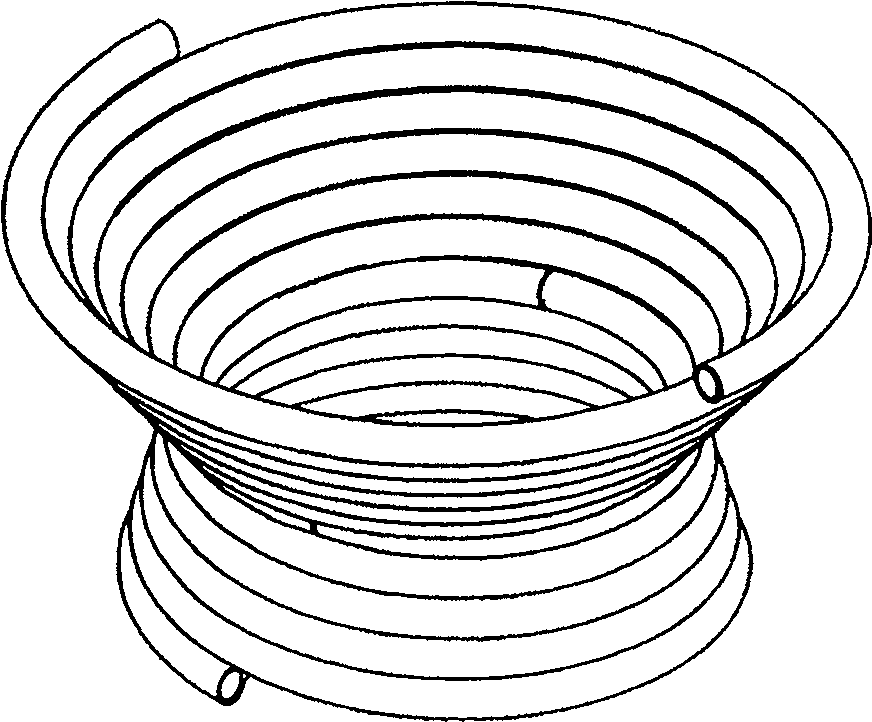

Device for maintaining water level of smoke-impact water spinning type LNG (Liquefied Natural Gas) heating gasification furnace

InactiveCN102679146AGuaranteed uptimeImprove cooling effectNon-pressured vesselsPressure vesselsCombustion chamberFully developed

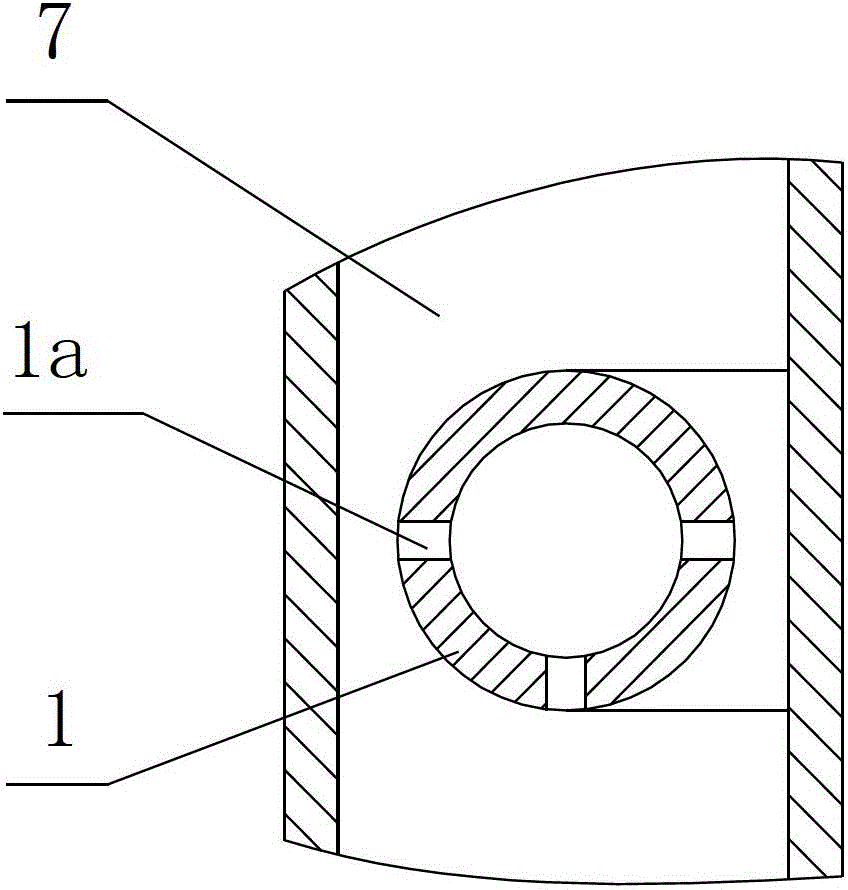

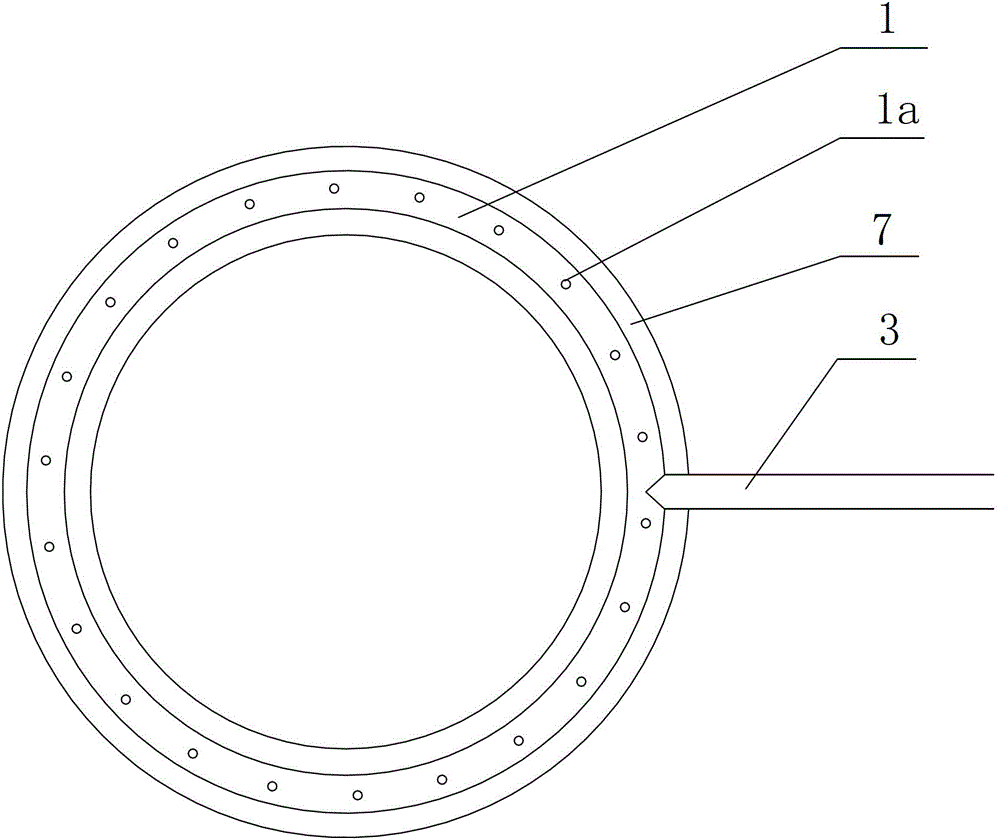

The invention relates to an improved device of a smoke-impact water spinning type LNG (Liquefied Natural Gas) heating gasification furnace and particularly relates to a device for maintaining a water level of the smoke-impact water spinning type LNG heating gasification furnace. An annular pipe ring (1) is horizontally arranged on the top of a vertical combustor jacket (7) which consists of an inner barrel and an outer barrel, and a plurality of water replenishing holes (1a) are formed in the peripheral wall of the annular pipe ring (1); and the annular pipe ring (1) is connected to a water tank (4) through a water inlet pipe (3), and a water supply power pump is arranged on the path of the water inlet pipe (3). The device disclosed by the invention has the advantages of ensuring to continuously replenish water into the heating gasification furnace, keeping the water level of a water pool in the heating gasification furnace to be stabilized in an optimal position, most fully developing the effects of smoke impact, splashing and entraining of water drops, water mist and water vapor, and ensuring the normal operation of the heating gasification furnace. The device disclosed by the invention is capable of effectively cooling the wall of a combustor to ensure that the wall of the combustor is not overheated, obtaining novel available functions except for ensuring and maintaining the working water level of the heating gasification furnace, ensuring the normal and safe operation of the smoke-impact water spinning type LNG heating gasification furnace, and improving the operation efficiency of the furnace.

Owner:SHANGHAI UNIV OF ENG SCI

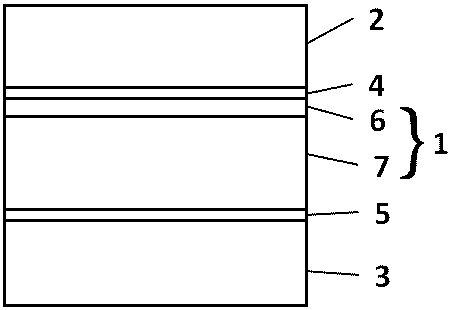

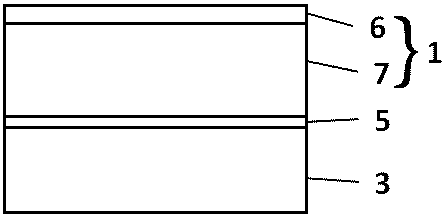

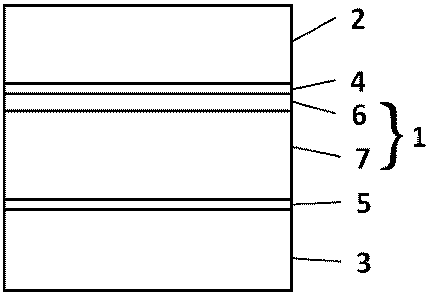

Battery packaging material, flexibly packaged battery and battery heat control device

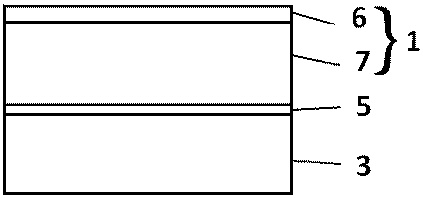

PendingCN107154468ALong-term resistance to coolant corrosionImprove corrosion resistanceSecondary cellsJackets/cases materialsComposite filmHeat control

The invention relates to a battery packaging material for packaging a battery. The solving scheme for aluminum plastic composite films for packaging the battery includes that the battery packaging material comprises an aluminum foil layer and plastic layers; the plastic layers are arranged on the surfaces of the aluminum foil layer by means of composition; the aluminum foil layer is made of anticorrosion aluminum alloy. The battery packaging material has the advantage that the shortcoming of insufficient anticorrosion properties of battery packaging materials for packaging batteries in the prior art can be overcome by the aid of the battery packaging material.

Owner:谢彦君

Coal gasification method

ActiveCN104498102AGuaranteed not to overheatReduce escapeGasification processes detailsGranular/pulverulent flues gasificationBrown coalThermodynamics

The invention provides a coal gasification method. The coal gasification method comprises the following steps: grinding the coal, drying, pressurizing and transporting the pulverized coal, and gasifying the pulverized coal in a gasification furnace. On the model selection of a coal grinder, primary air entering the coal grinder from a hot blast heater is annularly distributed, the temperature of the hot air entering the coal grinder is ensured to be higher than the conversion temperature of brown coal, the local surface of the brown coal is ensured not to be overheated, and the escape of volatile components in the brown coal can be reduced; the high-volatility brown coal is adopted as a raw material, the coal grinding system is controlled, the maximum concentration of oxygen is 4 percent, a new flow of low-pressure nitrogen is supplemented to a coal grinder sealing system, an nitrogen inlet in the system is also increased, the impact on a grinding roll is reduced, and the vibration of the coal grinder is reduced; the combustion temperature in the gasification furnace is 150 to 200 DEG C higher than the flowing temperature of lime-ash. Under the temperature and pressure, not only can the conversion rate of carbon in the gasification furnace be ensured to reach 99 percent, but also the lime-ash is good in flow characteristic.

Owner:铜陵市世纪朝阳数码科技有限责任公司

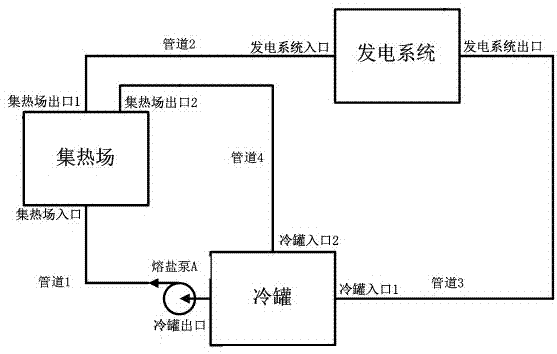

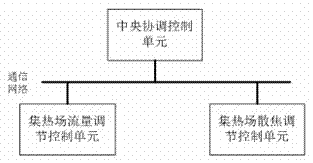

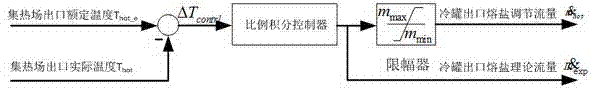

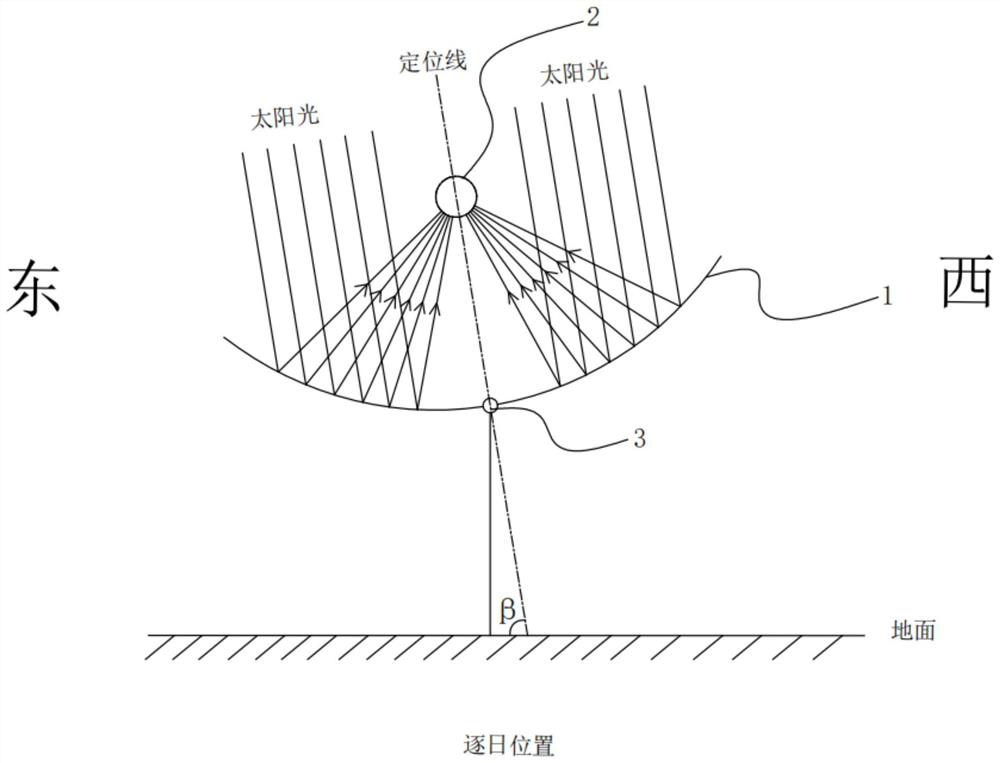

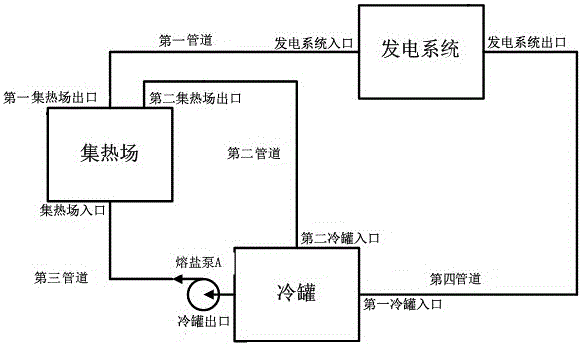

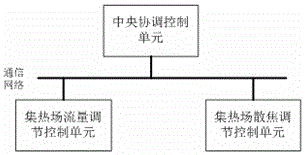

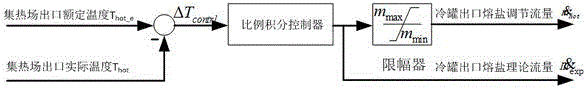

Coordinated control device for light field fused salt flow adjustment and defocusing adjustment of groove type photo-thermal power station

ActiveCN105444437AGuaranteed uptimeGuaranteed not to overheatSolar heating energySolar heat collector controllersEngineeringStreamflow

The invention relates to the technical field of solar groove type photo-thermal power generation, in particular to a coordinated control device for light field fused salt flow adjustment and defocusing adjustment of a groove type photo-thermal power station. The coordinated control device comprises a heat collecting field flow adjustment control unit, a heat collecting field defocusing adjustment control unit and a central coordinated control unit, wherein the heat collecting field flow adjustment control unit and the heat collecting field defocusing adjustment control unit are connected through a communication network and are connected with the central coordinated control unit. The heat collecting field flow adjustment control unit is used for controlling the flow of a cold tank outlet according to commands of the central coordinated control unit. By means of the coordinated control device, a photo-thermal power generation system is made to guarantee that fused salt stably flows without condensation when solar illumination intensity is poor according to solar illumination intensity differences in time, meanwhile, the temperature of the fused salt is controlled not to exceed the standard when the solar illumination intensity is too high, and therefore the photo-thermal power generation system can stably operate with high efficiency for a long time under complex and diversified weather conditions.

Owner:中国东方电气集团有限公司

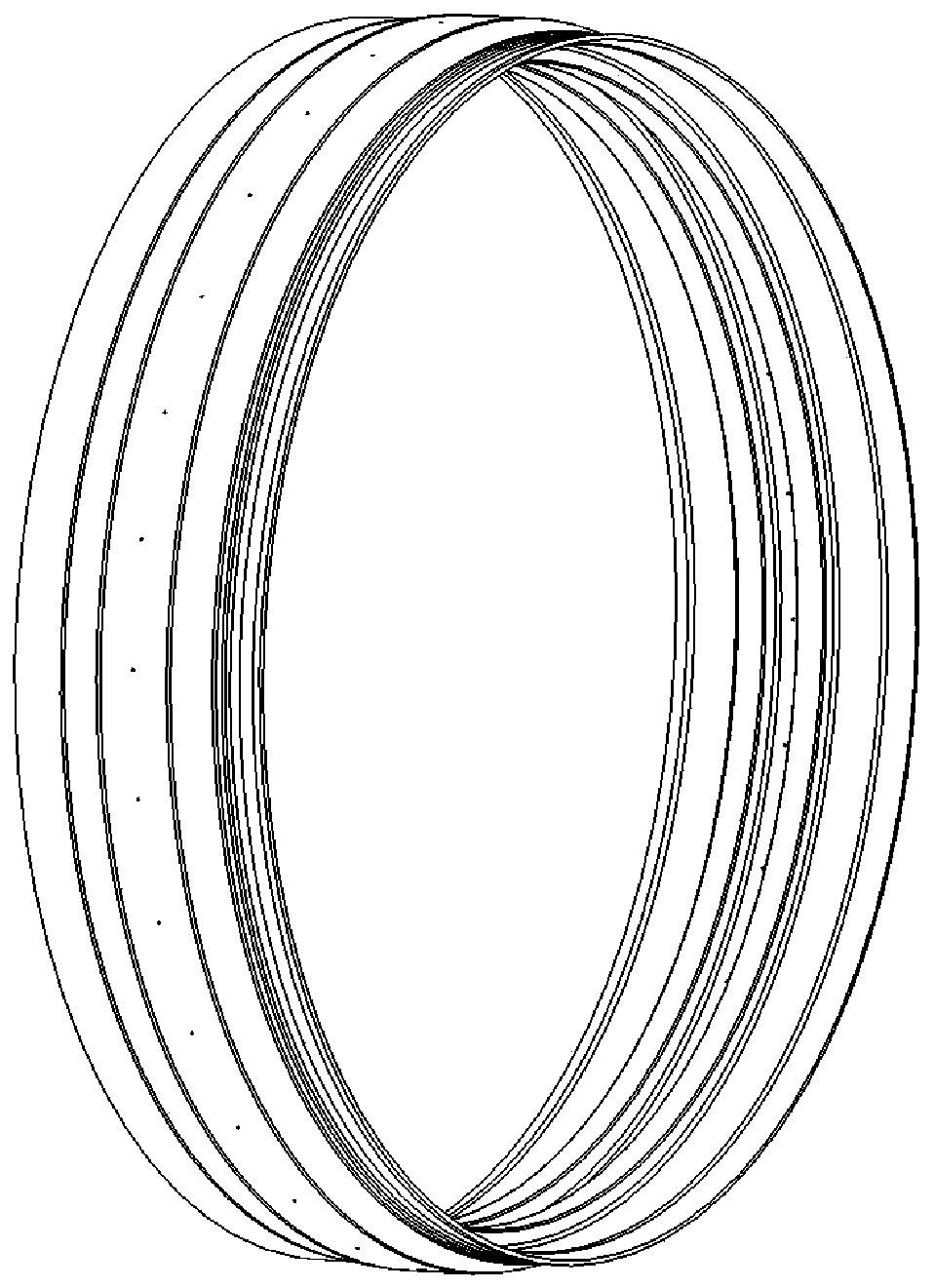

Electromagnetic type water heater and electromagnetic resistance dual-core water heater

InactiveCN102235739ALarge heating areaIncrease profitWater heatersThermal waterElectromagnetic shielding

The invention discloses an electromagnetic type water heater and an electromagnetic resistance dual-core water heater, wherein the electromagnetic type water heater is formed by connecting a double-wall or sleeve or box-shaped magnetism-conductive water discharge body, a resonance coil and an integrated controller by virtue of power lines; and the electromagnetic resistance dual-core water heater is formed by connecting the water inlet of a resistance water heater and the water outlet of the electromagnetic type water heater, or placing the resistance water heater in the electromagnetic type water heater to be connected with and the integrated controller by virtue of power lines. For the electromagnetic type water heater and the electromagnetic resistance dual-core water heater, the magnetic energy in various directions of an electromagnetic field are scientifically utilized so that the energy efficiency is improved, and heat insulation is carried out on the resonance coil and the integrated controller by utilizing a heat insulation material and temperature difference of cold and hot water, and a dual-core simple and reliable technical structure in which a low-middle temperature zone is heated by electromagnetic energy and a mid-high temperature zone is subjected to resistance heating is adopted, thereby efficiently solving the problems that the resonance coil and the integrated controller are low in energy efficiency, low in hot water temperature, high in cost and the like, and can be easily damaged due to overheat. The electromagnetic type water heater and the electromagnetic resistance dual-core water heater have the obvious beneficial effects that the energy consumption is low, the cost is low, energy is saved, the hot water temperature is high, and more applications can be met.

Owner:陈土和

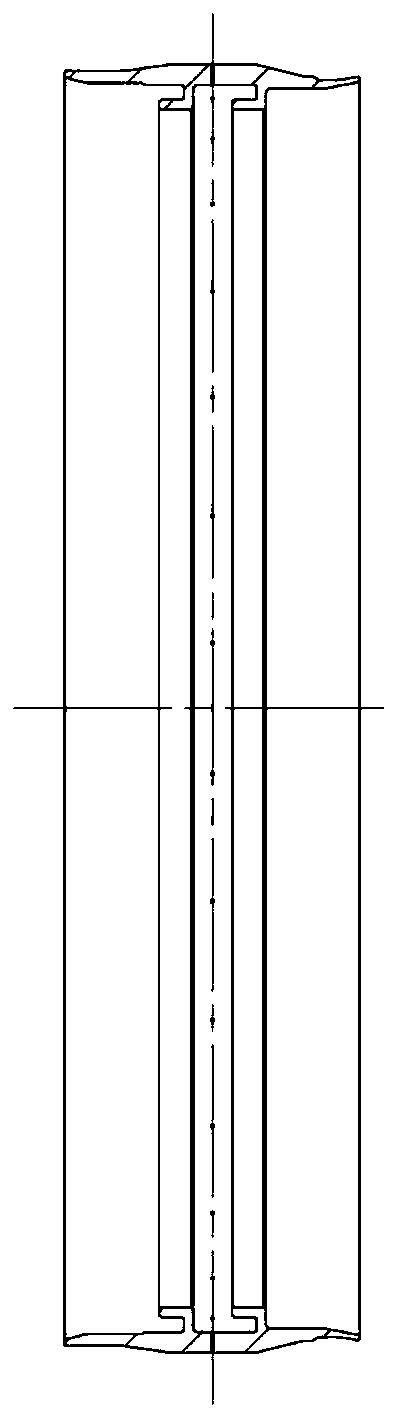

Combined-type cooling seal structure for high-pressure turbine rotor exterior ring

ActiveCN110847982APrecise control of thermal deformationAvoid direct contactBlade accessoriesLeakage preventionCombustion chamberJet flow

The invention discloses a combined-type cooling seal structure for a high-pressure turbine rotor exterior ring. The structure comprises a combustion chamber outer casing, the high-pressure turbine rotor exterior ring and auxiliary seal structures. Segmentation design is used for the high-pressure turbine rotor exterior ring; an opposite face of an upper blade of the high-pressure turbine rotor exterior ring is coated with a high-temperature resistant abrasive coating; impact cooling holes are formed along circumferences of the combustion chamber outer casing; and a connecting structure betweenthe combustion chamber outer casing and the high-pressure turbine rotor exterior ring is improved, so a cool air chamber is formed between the combustion chamber outer casing and the high-pressure turbine rotor exterior ring. In this way, the high-pressure turbine rotor exterior ring can be cooled efficiently through cool air jet-flow impacting. Through configuration of the auxiliary seal structures such as a seal ring and a seal baffle, cool air can be sealed, so a thermal load of a high-temperature component, namely the high-pressure turbine rotor exterior ring can be reduced; thermal deformation of the hot-end component can be controlled; a usage amount of the cool air is reduced; cooling effects are maximized; and the structure is more stable and reliable.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

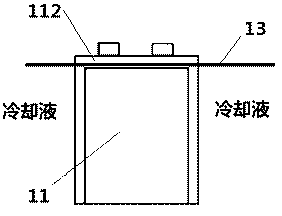

Long-life soft-pack battery thermal control device

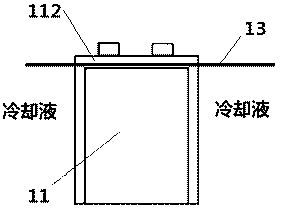

PendingCN107346807AReduce intermediate linksNo contact resistanceSynthetic resin layered productsSecondary cellsEngineeringAluminum foil

The invention relates to a soft-pack battery thermal control device, in particular to a soft-pack battery thermal control device which can be soaked into cooling water. Furthermore, in view of the defect that the anticorrosion performance of packaging materials for batteries is not inadequate in the prior art, the invention provides a corresponding packaging material; the packaging material is made from an aluminum foil layer resistant to cooling water corrosion and a plastic layer arranged on the surface of the aluminum foil layer.

Owner:谢彦君

Battery packaging material, flexibly packaged battery and battery heat control device

PendingCN107154471AImprove heat transfer efficiencyReduce cooling requirements to the outside worldSecondary cellsElectrical equipmentComposite filmEngineering

The invention relates to battery packaging materials for packaging batteries, in particular to a battery packaging material applied to packaging a flexibly packaged battery for vehicles and the flexibly packaged battery. The solving scheme for aluminum plastic composite films for packaging the battery includes that the battery packaging material comprises an aluminum foil layer and plastic layers; the plastic layers are arranged on the surfaces of the aluminum foil layer by means of composition; the aluminum foil layer is made of anticorrosion aluminum alloy. The battery packaging material and the flexibly packaged battery have the advantage that the shortcoming of insufficient anticorrosion properties of battery packaging materials for packaging batteries in the prior art can be overcome by the aid of the battery packaging material and the flexibly packaged battery.

Owner:谢彦君

Movable type steam car washer

InactiveCN106269629AGuaranteed not to overpressureEnsure safetyCleaning apparatus for vehicle exteriorsCleaning using liquidsSteam pressureCombustor

Owner:SHANTOU JIENENG ELECTRICAL APPLIANCE TECH

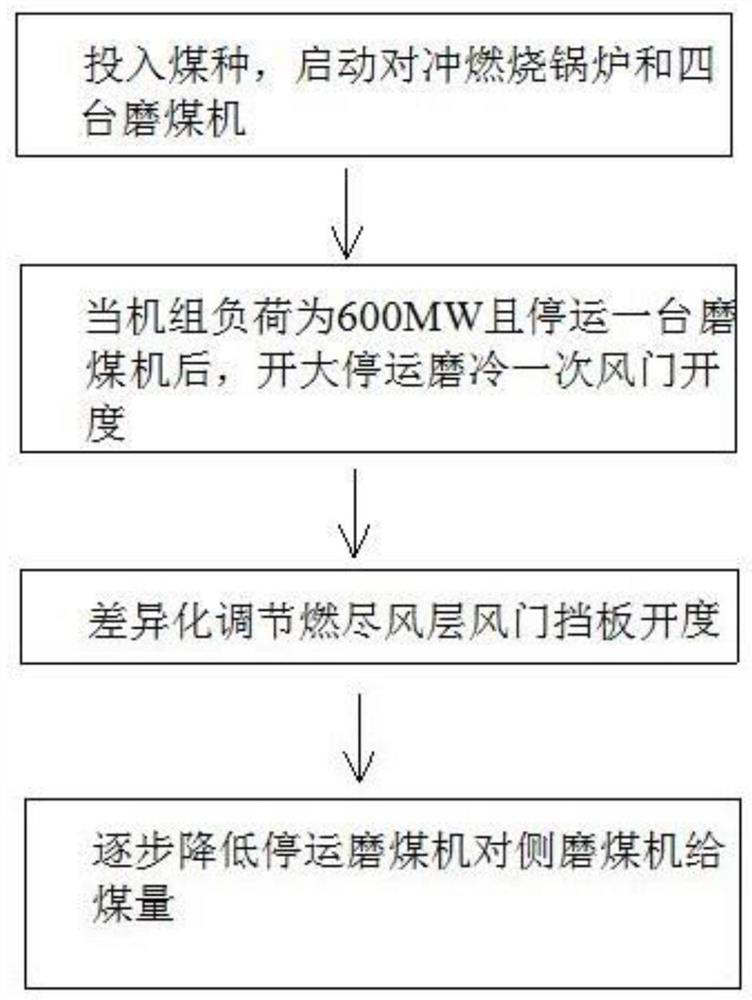

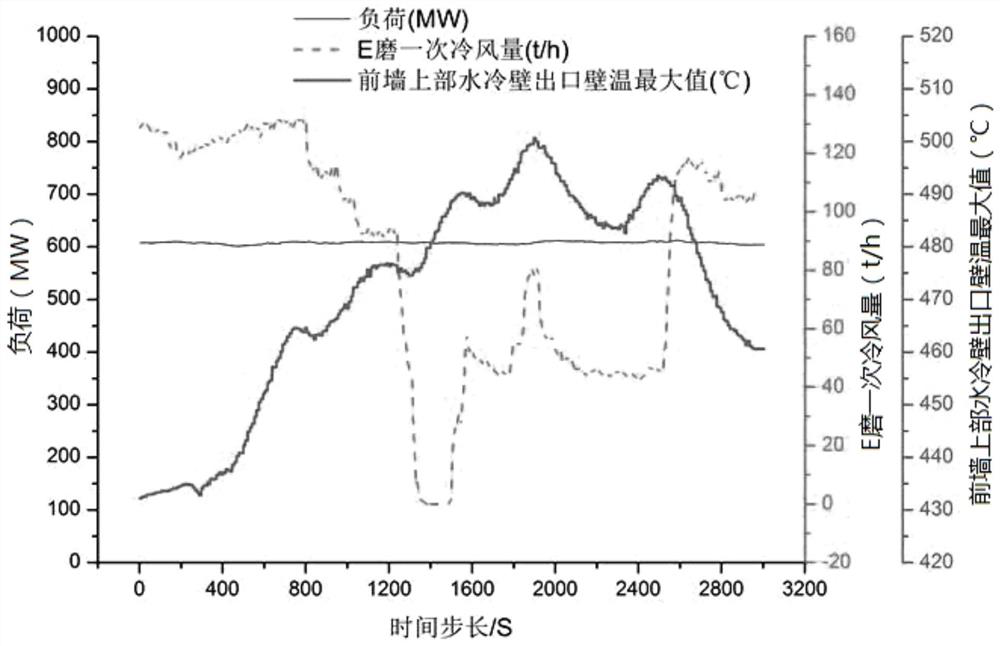

Method for adjusting wall temperature of opposed firing boiler after low-load milling stop

ActiveCN113108308APrevent overheating problemsSolve the problem of rapid and large rise in wall temperatureFuel supply regulationCasings/liningsThermodynamicsEngineering

The invention discloses a method for adjusting the wall temperature of an opposed firing boiler after low-load milling stop. The adjusting method is used for adjusting the wall temperature of the opposed firing boiler under the low load when the number of coal mills is changed from four to three. The adjusting method comprises the steps that the opening degree of cold primary air of the shutdown mill, the opening degree of over fire air and the coal feeding amount of the coal mill on the opposite side of the shutdown coal mill are adjusted; and the adjusting process specifically comprises the steps of increasing the opening degree of the cold primary air of the shutdown mill and adjusting the opening degree of the over fire air differentially. The coal feeding amount of the coal mill on the opposite side of the shutdown coal mill is gradually reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

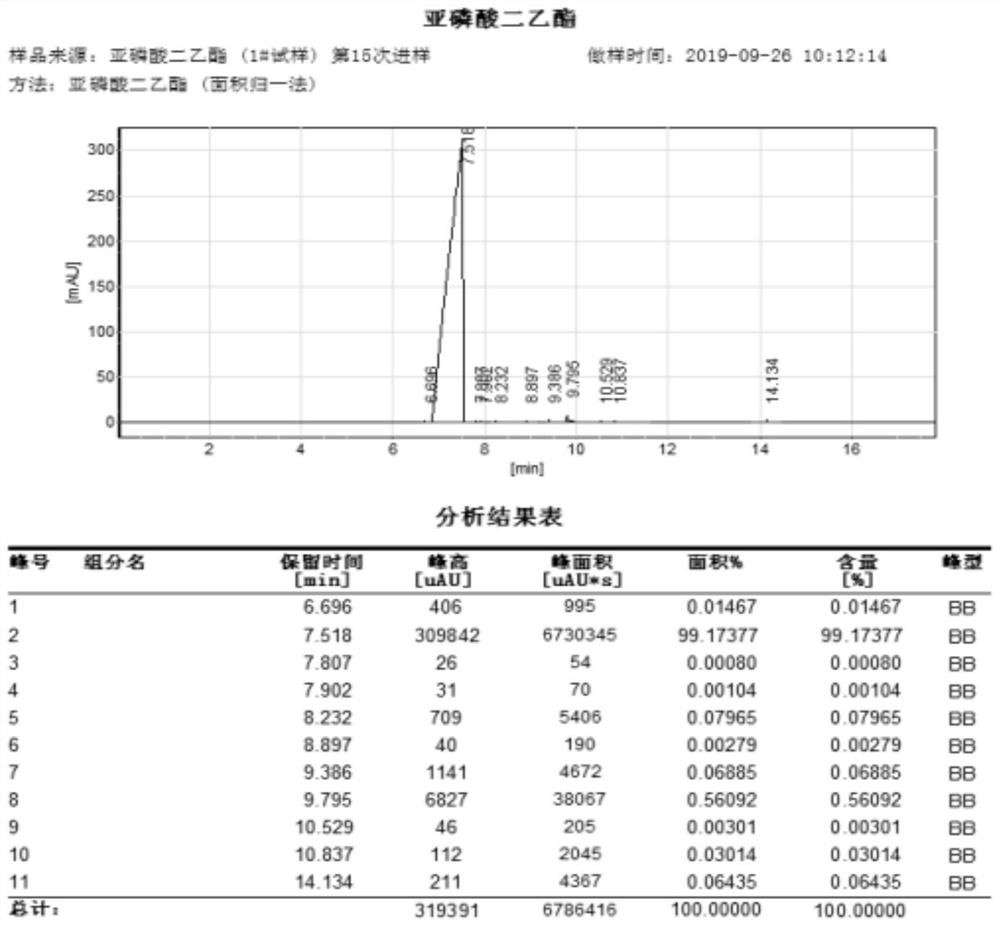

Synthesis method of diethyl phosphite

PendingCN111995639AMild responseHigh yieldGroup 5/15 element organic compoundsPhosphorous acidDiethyl phosphate

The invention relates to a synthesis method of diethyl phosphite. The method comprises the following steps: putting triethyl phosphite into a stirring reactor; adding phosphorous acid into the stirring reactor in batches under a stirring condition; wherein the batch adding frequency is 4-5 times, the temperature is controlled to be less than or equal to 35 DEG C in the phosphorous acid batch adding process, the temperature is kept at 50-60 DEG C for 30 minutes after phosphorous acid is added, then the temperature is increased at 2.5-5 DEG C / h, the temperature is gradually increased at 60-90 DEG C, and the reaction is carried out for 3-5 hours to obtain diethyl phosphite. The method is prepared by directly reacting triethyl phosphite with phosphorous acid, does not need a solvent or a catalyst in comparison with the traditional process, and is mild in reaction and higher in yield, and the yield can reach 97-99%; no side reaction occurs in the reaction process, the product purity is goodand can reach 99% or above, and the method is low in cost, safe, environmentally friendly and suitable for industrial production.

Owner:LIAONING DOPP WEINONG CHEM & INDAL

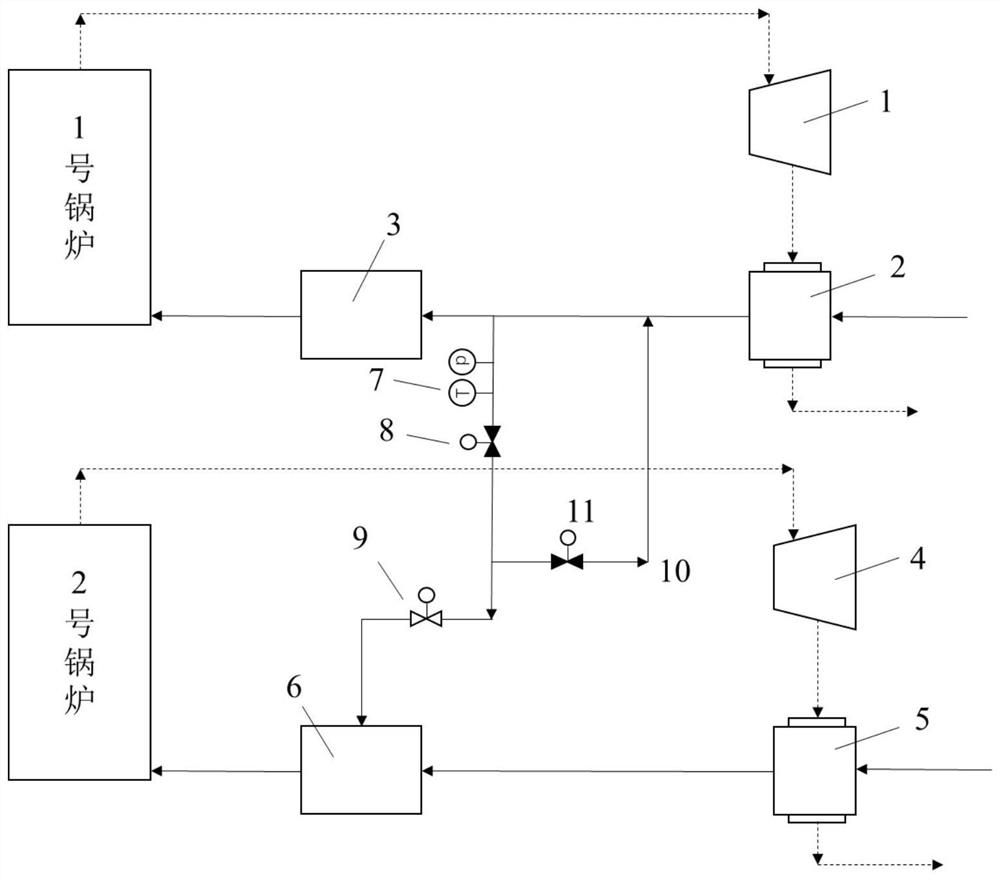

Boiler start-stop adjusting system and method for main-pipeline unit

ActiveCN113483316AIncrease feed water temperatureGuaranteed exhaust gas temperatureSteam generation plantsSteam engine plantsThermodynamicsProcess engineering

The invention discloses a boiler start-stop adjusting system and method for a main-pipeline unit. The boiler start-stop adjusting system comprises a high-pressure cylinder of a first boiler, a first high-pressure heater of the first boiler, a first boiler economizer, a high-pressure cylinder of a second boiler, a first high-pressure heater of the second boiler, and a second boiler economizer, which are arranged in a high-pressure cylinder water outlet system, wherein the first-stage steam extraction of the high-pressure cylinder of the first boiler is connected to the first high-pressure heater of the first boiler; outlet water of the high-pressure heater is divided into two paths, the first path is connected into a water supply system of the first boiler economizer, and the second path is connected into a water supply system of the second boiler economizer through a water outlet pipeline; the first-stage steam extraction of the high-pressure cylinder of the second boiler is connected to the first high-pressure heater of the second boiler; and outlet water of the high-pressure heater is connected into the second boiler economizer. The system and the method can effectively solve the problem of uneven heating when the second boiler of the main-pipeline unit is started and stopped, coal consumption is reduced, and the flexibility of a thermal power generating unit participating in peak regulation is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

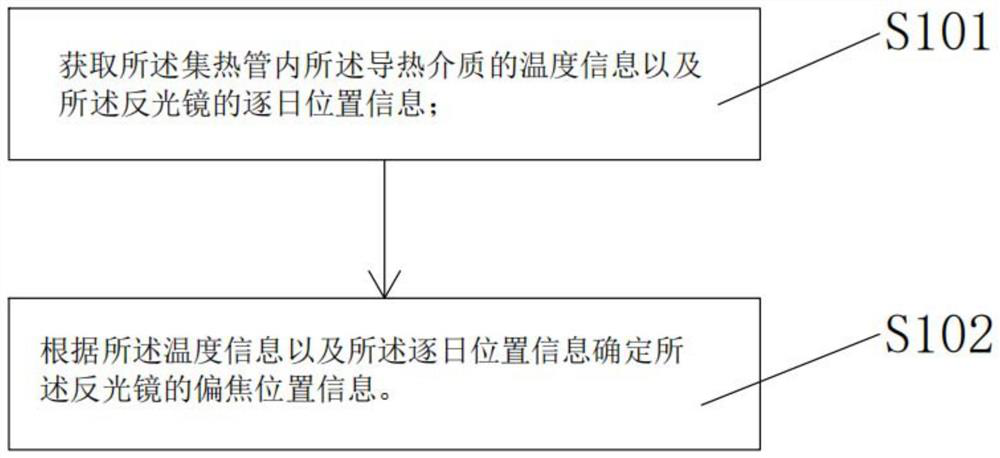

Trough type heat collector control method and device

PendingCN114739022ASmall temperature fluctuationsGuaranteed not to overheatSolar heating energySolar heat collector controllersCollector deviceEngineering

The invention discloses a groove type heat collector control method and device, and belongs to the field of light energy heat utilization device control, and the method comprises the steps that temperature information of a heat-conducting medium in a heat collecting pipe and day-by-day position information of a reflective mirror are obtained; and determining offset focus position information of the reflector according to the temperature information and the day-by-day position information. And based on the temperature information of the heat-conducting medium and the day-by-day position information, the offset focus position information of the reflective mirror is confirmed to adjust the position of the reflective mirror and change the heat collection rate of the reflective mirror, so that the temperature of the heat-conducting medium in the heat collection pipe is adjusted, the temperature fluctuation of the heat-conducting medium is reduced, and the heat-conducting temperature is kept within a reasonable range. Therefore, the service life of the heat-conducting medium and the service life of the heat collector can be prolonged.

Owner:CHINA SHIPBUILDING NEW POWER CO LTD +1

A preparation method for forming a wear-resistant coating on the inner wall of an aluminum alloy cylinder

ActiveCN110284039BImprove compactnessHigh bonding strengthAlkali metal silicate coatingsTransportation and packagingAl powderSpray Granulation

The invention relates to a preparation method for forming a wear-resistant coating on the inner wall surface of an aluminum alloy cylinder, comprising the following steps: first uniformly mixing graphene powder, Al powder, etc. to obtain a mixed powder; mixing the above mixed powder with polyvinyl alcohol liquid Mix evenly and heat, and then spray granulate to obtain low-temperature self-propagating composite material; stir and mix low-temperature self-propagating composite material and water glass to obtain slurry; inject the slurry into the cylindrical inner cavity of the aluminum alloy workpiece, And the aluminum alloy workpiece is installed on the horizontal turntable to rotate, and the aluminum alloy workpiece is heated during the rotation process, so that the slurry is uniformly solidified on the inner wall surface of the cylindrical inner cavity; after the slurry is uniformly solidified, keep the rotating At the same time, the cured slurry is melted with an oxyacetylene flame, so that the cured slurry reacts to form a coating. The reaction process temperature of the invention is lower, and the compactness and bonding strength of the coating are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

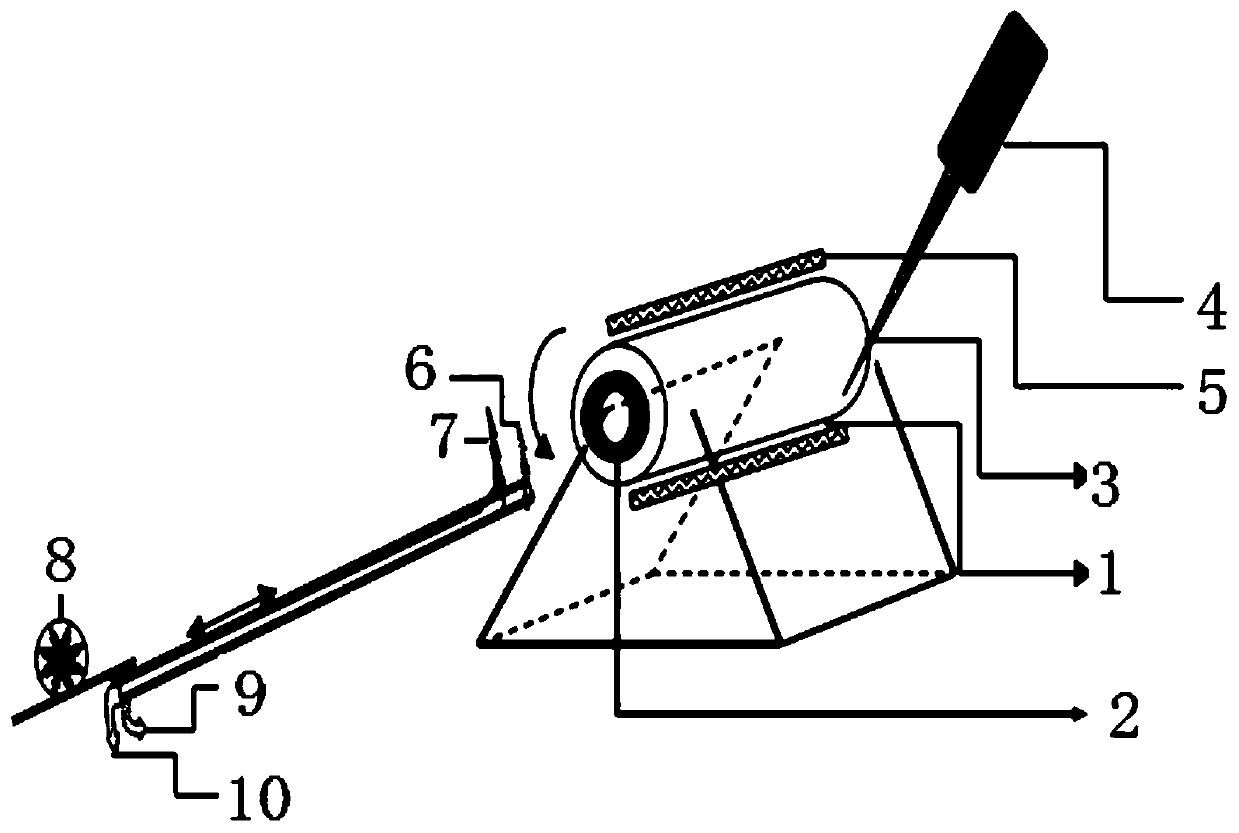

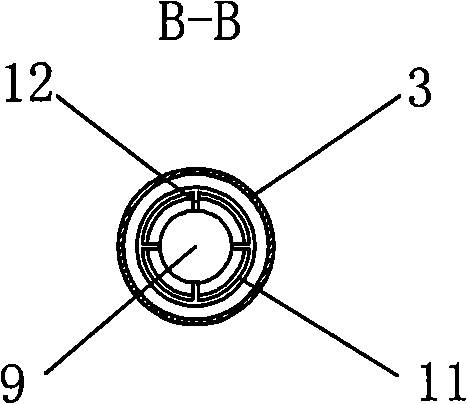

Outlet of admixture of hot gas and grains of liquid dregs

ActiveCN100523145CCorrosion resistanceGuaranteed not to overheatGranular/pulverulent flues gasificationPipe waterHeat resistance

This invention discloses an exit of a mixture of hot gas and liquid slag granules. The exit has a serpentine-pipe water-cooling wall. The cooling medium in the serpentine pipe enters from the bottom and exits from the top. The inner surface of the water-cooling wall is coated with a layer of refractory casting material. During the working process, part of liquid slag granules form a solid slag layer and a liquid slag layer at the inner side of the refractory casting material, while hot gas and the rest slag exit through the center. The cross section of the exit tunnel is circular. The longitude section of the exit is X-shape, the furl angle alpha is 80-120 deg., and the expanding angle beta is 30-60 deg. The exit has such advantages as good heat resistance, long service life, low blockage probability, simple and tight structure, and wide applications.

Owner:CHANGZHENG ENG

Method for preparing methyl tertiary butyl ether (MTBE)

ActiveCN102351661BImprove balance conversionGuaranteed purityChemical industryEther preparation by compound additionFixed bedCatalytic distillation

The invention discloses a method for preparing methyl tertiary butyl ether (MTBE). The method is characterized in that: an external circular heat-removing fixed bed reactor is connected in series in front of an original mixed-phase fixed bed reactor. The method comprises the following steps of: (1) inputting mixed C4 serving as a raw material into the external circular heat-removing fixed bed reactor for reacting till the content of isobutene in the mixed C4 serving as the raw material is lowered below 30 percent by weight; (2) introducing the reacted material into the mixed-phase fixed bed reactor for reacting; and (3) introducing the reacted material discharged out of the mixed-phase fixed bed reactor into a catalytic distilling tower for performing deep etherification and separating. The method can adapt to the raw material change of an upstream device, so that the equilibrium conversion rate of the MTBE is increased, the temperature of the catalytic distilling tower is prevented from surpassing a temperature limit, the raw material purity of a downstream device is ensured, and an MTBE device does not to halt during replacement of a catalyst.

Owner:HUIZHOU YUSSEN CHEM CO LTD

Pulverized coal burner

ActiveCN101446412BConcentration ratio is adjustableAchieve ignitePulverulent fuel combustion burnersCycloneCombustion chamber

A pulverized coal burner comprises at least one cyclone with a primary air powder tangential inlet line and a middle tapered shrinkage segment; an exhaust gas pipe having an exhaust gas adjusting air door and inserted on the top of the cyclone; a primary pulverized coal burning chamber and a secondary pulverized coal burning chamber arranged on the straight outlet segment of the cyclone; a micro-oil oil gun arranged on the top of the cyclone and inserted and penetrating the inlet of the exhaust gas pipe to the inlet of the primary pulverized coal burning chamber; a concentration ring and a rotation-eliminating blade arranged outside the throat at the interface of the shrinkage segment and the straight outlet segment of the cyclone; and a secondary air nozzle arranged at the outlet of the secondary pulverized coal burning chamber. The pulverized coal burner can achieve burn a great amount of pulverized coal by strengthened combustion and gradual amplification of trace oil by adopting the technical measures, such as ignition using micro-oil gasification oil gun, secondary pulverized coal burning, adjustable exhaust gas flow rate and pulverized coal concentration ratio, further pulverized coal concentration and rotation elimination, thereby achieving ignition of anthracite and lean coal, and achieving high oil saving rate. The coal burner is particularly suitable for W-shaped flame boiler.

Owner:EASTERN BOILER CONTROL CO LTD +1

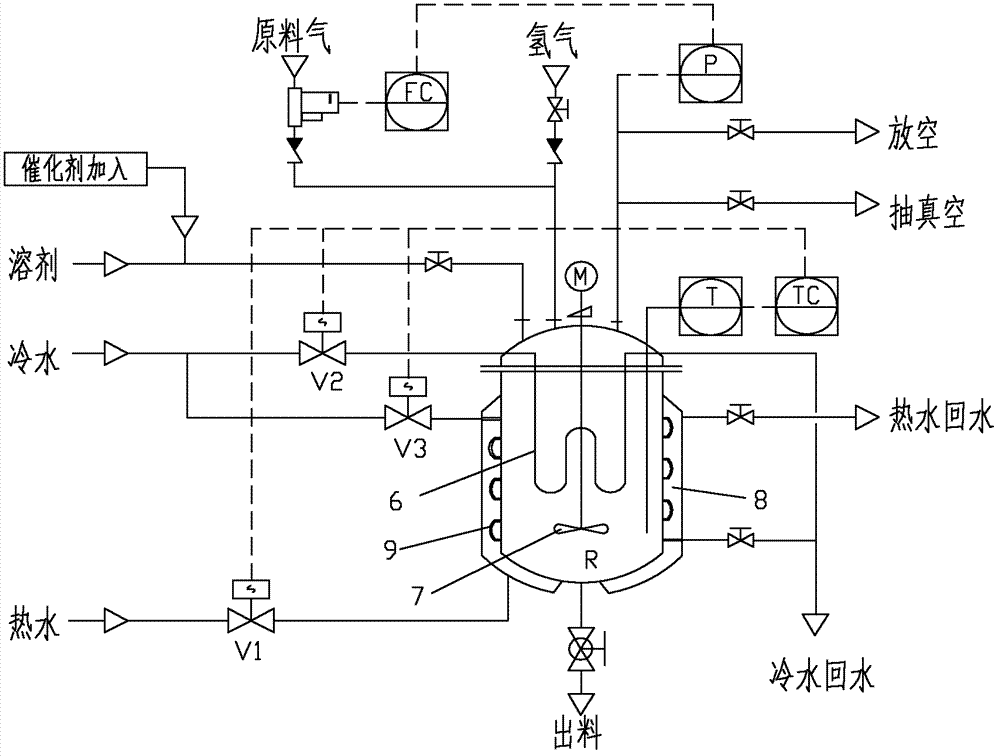

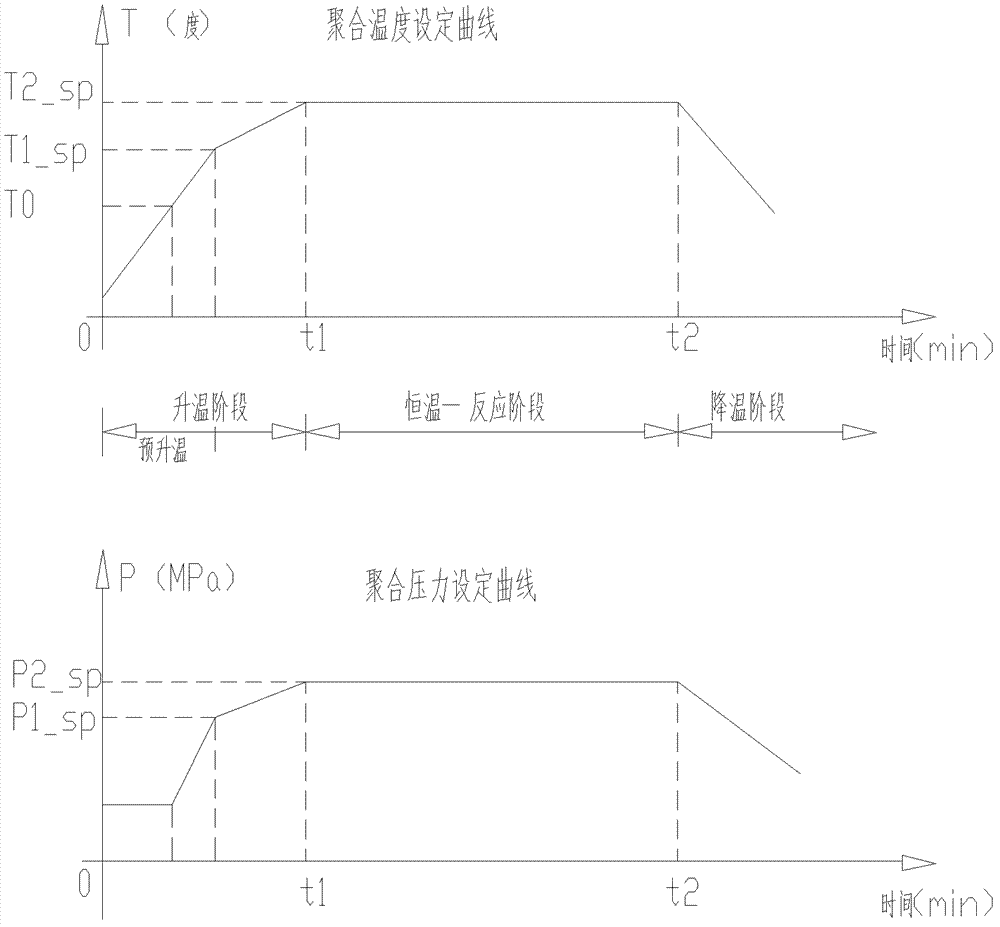

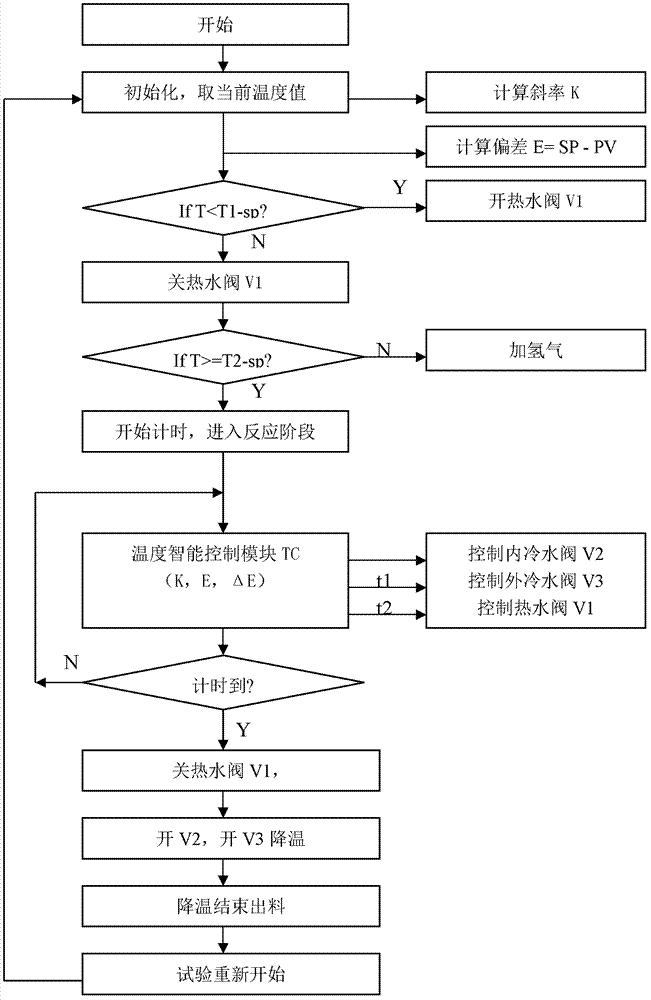

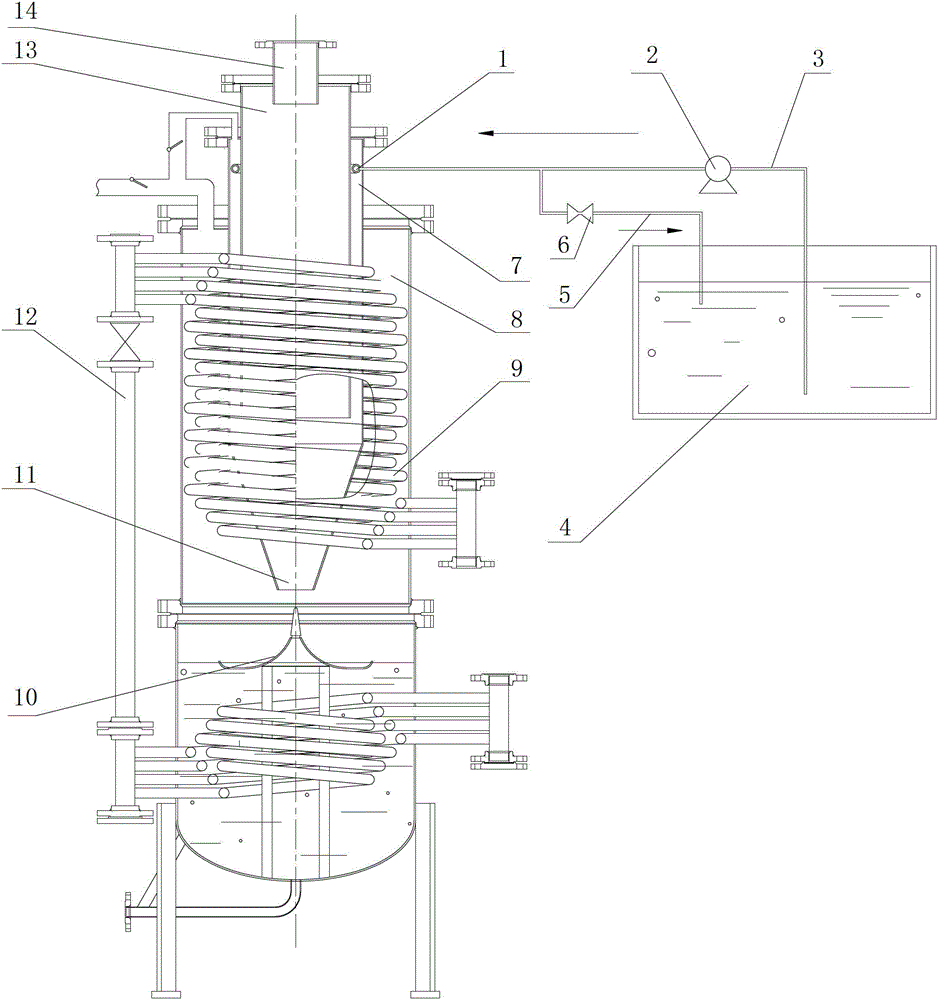

Method and system for olefin polymerization temperature control

ActiveCN103130927BRealize the heating effectSmooth and precise temperature controlTemperature control using electric meansTemperature controlAutomatic control

The invention relates to a method and a system for olefin polymerization temperature control. The method and the system for the olefin polymerization temperature control aims at solving the problems that a polymerization reaction in the prior art is severe, temperature fluctuation is large in the process of heating and heat dissipation and bad influences on performance and quality of a polyolefin product are caused due to lag of the temperature. An artificial intelligent method is adopted. A manipulated variable of the method is the temperature. According to a designed intelligent controller, in the process of the polymerization reaction, opening time of a hot water valve, an inner cold water valve and an outer cold water valve is controlled according to deviation and slope rate of the temperature fluctuation so that accurate control of the polymerization temperature and continuously automatic control of three steps of temperature rising, temperature maintaining and temperature dropping are achieved in the process of an intermittent polymerization reaction. The invention further provides a control device for the olefin polymerization reaction. According to application, control requirements for a temperature parameter of the olefin polymerization device can be completely satisfied according to the intelligent control method, dynamic property of the system is improved and the performance and the quality of the olefin product are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for maintaining water level of smoke-impact water spinning type LNG (Liquefied Natural Gas) heating gasification furnace

InactiveCN102679146BGuaranteed uptimeImprove cooling effectNon-pressured vesselsPressure vesselsCombustion chamberFully developed

The invention relates to an improved device of a smoke-impact water spinning type LNG (Liquefied Natural Gas) heating gasification furnace and particularly relates to a device for maintaining a water level of the smoke-impact water spinning type LNG heating gasification furnace. An annular pipe ring (1) is horizontally arranged on the top of a vertical combustor jacket (7) which consists of an inner barrel and an outer barrel, and a plurality of water replenishing holes (1a) are formed in the peripheral wall of the annular pipe ring (1); and the annular pipe ring (1) is connected to a water tank (4) through a water inlet pipe (3), and a water supply power pump is arranged on the path of the water inlet pipe (3). The device disclosed by the invention has the advantages of ensuring to continuously replenish water into the heating gasification furnace, keeping the water level of a water pool in the heating gasification furnace to be stabilized in an optimal position, most fully developing the effects of smoke impact, splashing and entraining of water drops, water mist and water vapor, and ensuring the normal operation of the heating gasification furnace. The device disclosed by the invention is capable of effectively cooling the wall of a combustor to ensure that the wall of the combustor is not overheated, obtaining novel available functions except for ensuring and maintaining the working water level of the heating gasification furnace, ensuring the normal and safe operation of the smoke-impact water spinning type LNG heating gasification furnace, and improving the operation efficiency of the furnace.

Owner:SHANGHAI UNIV OF ENG SCI

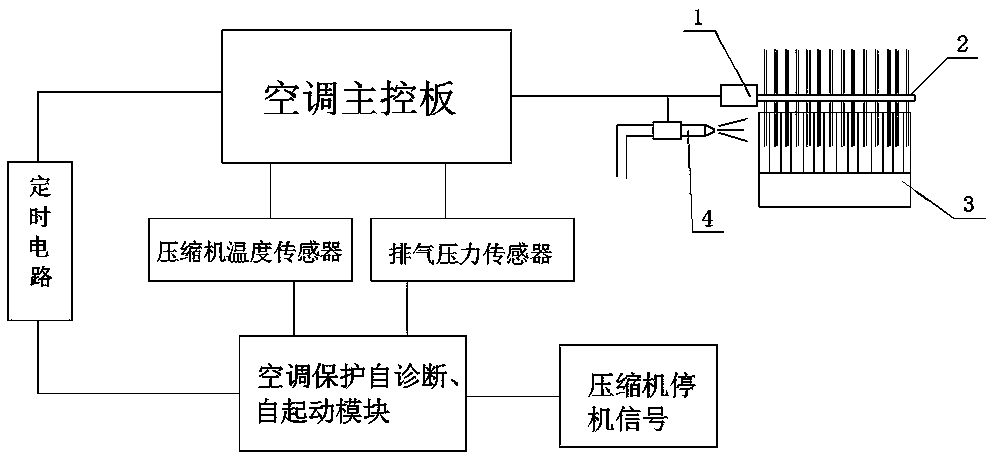

Computer room air conditioner protection protection shutdown self-diagnosis self-starting device

InactiveCN103697564BSo as not to damageSafe and stable operationMechanical apparatusSpace heating and ventilation safety systemsComputer moduleEngineering

The invention discloses a self-diagnosis and self-starting device for the protection and protection of an air-conditioner in a machine room, which is characterized in that it has an air-conditioning protection self-diagnosis and self-starting module connected to the main control board of the air conditioner, and the air-conditioning protection self-diagnosis and self-starting module described in the timing circuit Detect the compressor temperature sensor, discharge pressure sensor signal and compressor stop signal respectively. When the above signals appear at the same time, it means that the air conditioner is shut down due to high pressure protection, thereby triggering the timing circuit. When the time is up, the air conditioner protection self-diagnosis and self-starting module will restart. Detect the signals of the compressor temperature sensor and the exhaust pressure sensor, and if the signals return to normal, power off and reset the main control board, and start the air conditioner. It can automatically detect the shutdown status, and can automatically reset and start the machine. Resetting the air conditioner in time can ensure that the electronic components in the computer room do not overheat, and ensure the safe and stable operation of communication equipment.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

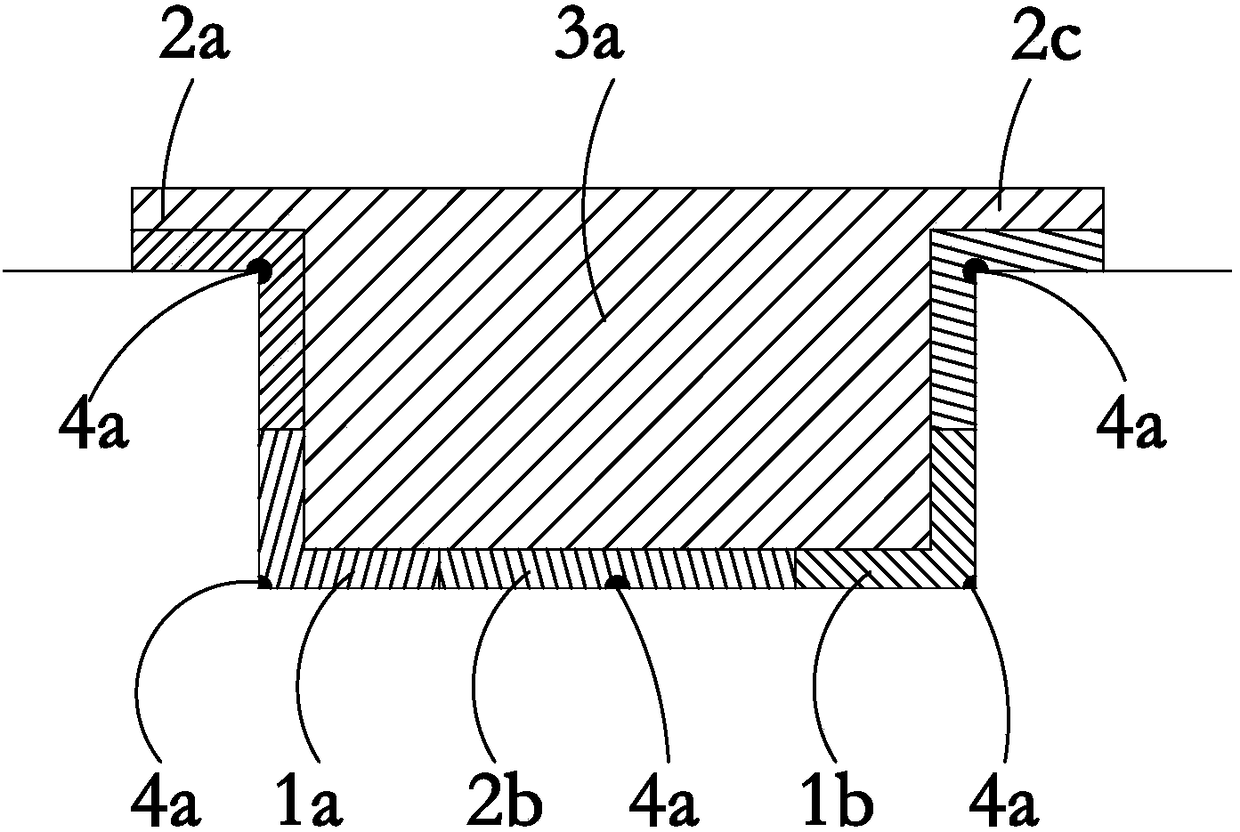

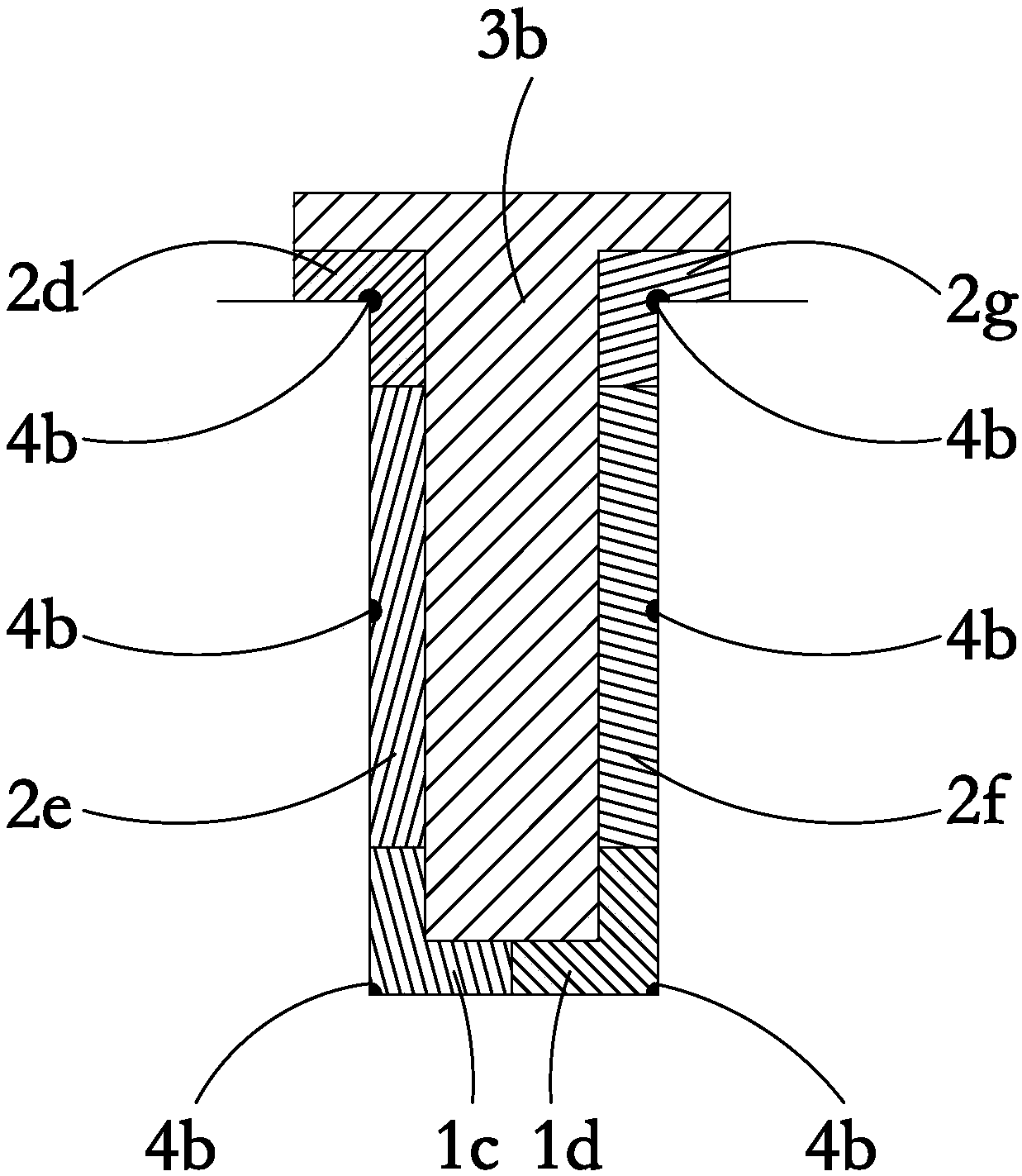

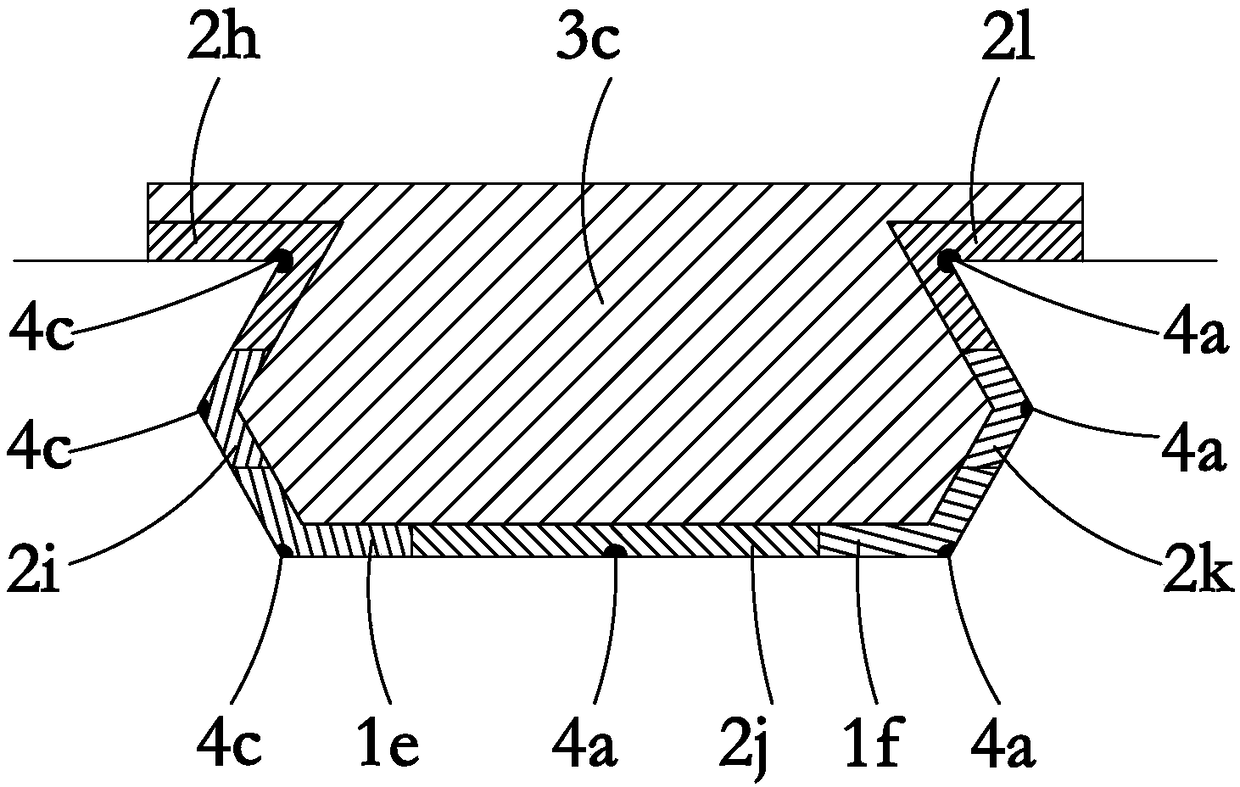

Site heat treatment device for air cylinder groove

InactiveCN108085473AControl heat treatment temperatureControl timeFurnace typesHeat treatment furnacesControl systemTherapeutic effect

The invention relates to a site heat treatment device for an air cylinder groove, which comprises a device main body and a control system; the device main body is provided with a main heating zone andan assistant heating zone; the main heating zone covers a to-be-repaired position of the air cylinder groove, and the assistant heating zone is located in at least one side of the main heating zone;heating components are arranged in the main heating zone and the assistant heating zone; the control system is connected with the heating component for controlling the work of the heating component and the heating temperature. Through the main heating zone, the to-be-repaired zone is heated; the main heating zone is performed with assistant heating and heat insulation through the assistant heatingzone, so as to realize heat treatment of every part of the groove; the heat treatment temperature and time are effectively controlled, thus no partial overheat is guaranteed; the main heating zone and the assistant heating zone can be set and switched according to the repair zone; the heat treatment effect is good.

Owner:四川中电福溪电力开发有限公司 +1

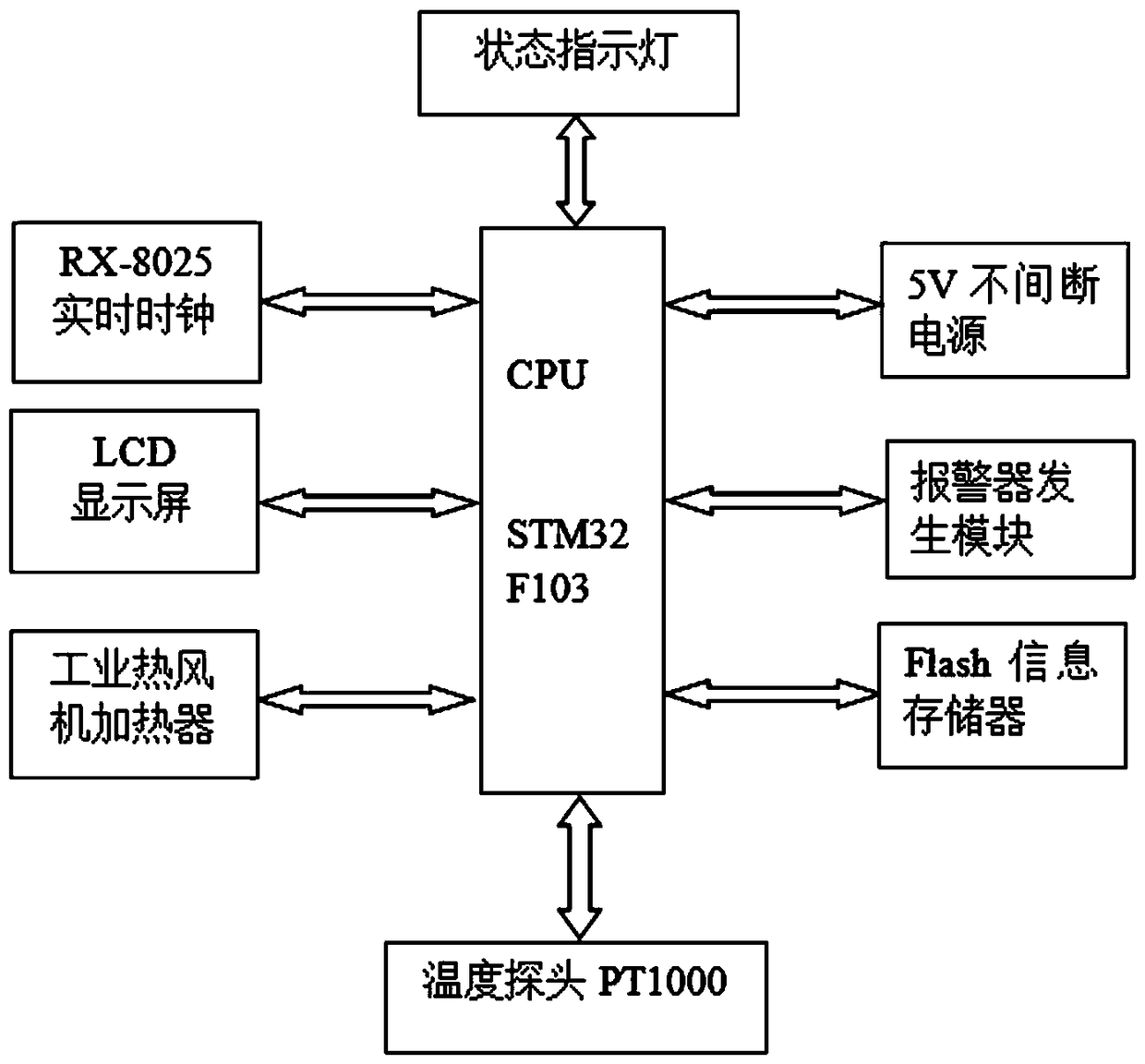

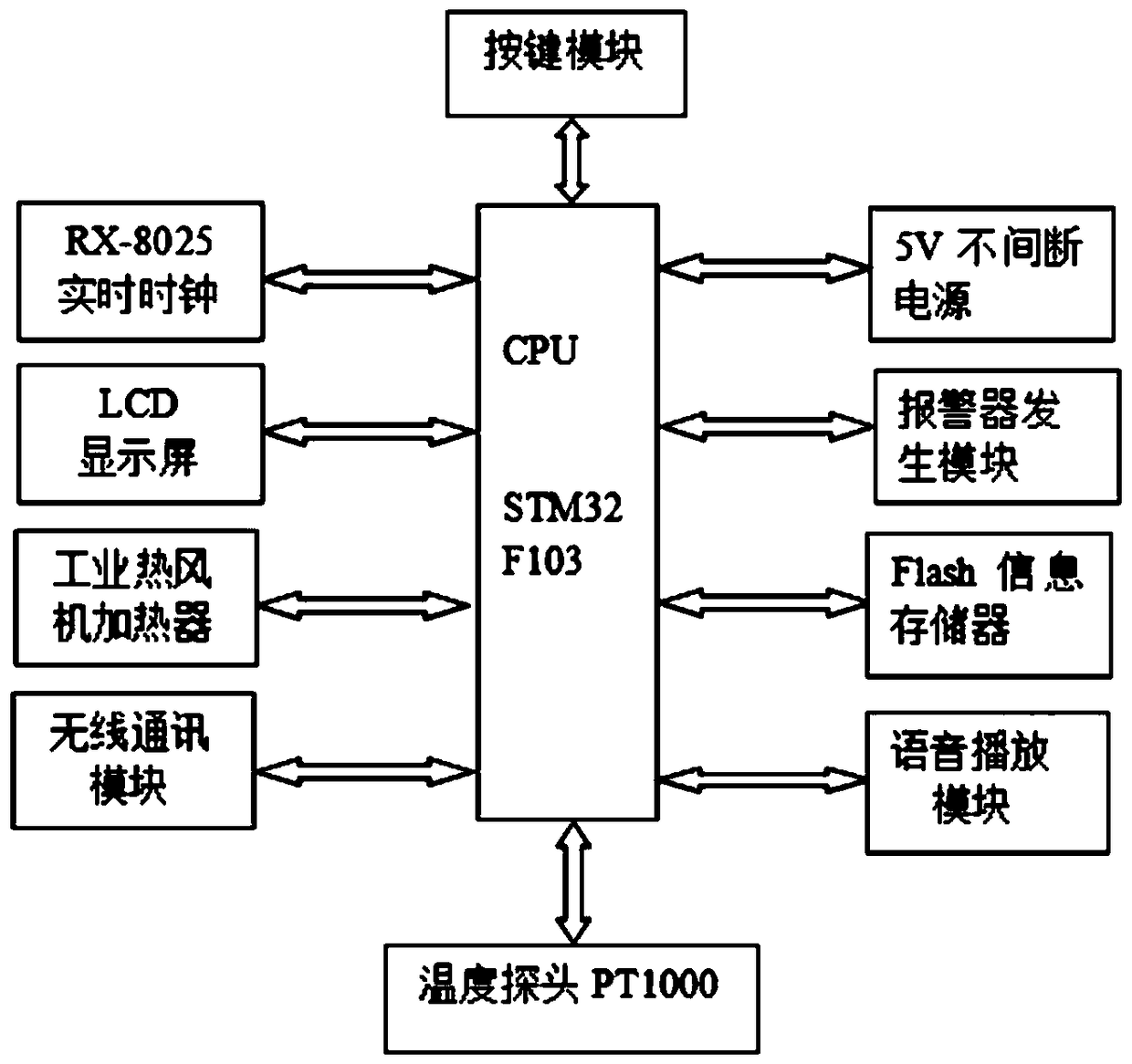

Portable sf6 cylinder heating system

ActiveCN105927853BEasy to carryEasy to controlVessel geometry/arrangement/sizeContainer filling methodsGas cylinderEngineering

The invention discloses a portable type SF6 gas cylinder heating system. A control module, a display module, an alarm generating module, a Flash information storage and a temperature sensor are arranged in a housing, wherein a state indicator lamp is arranged on the housing; an interface module is arranged on the control module; the heating module adopts an industrial hot-air blower; the control module is connected with the industrial hot-air blower through a serial interface; when the temperature is detected to be a normal temperature, a power supply of the industrial hot-air blower is opened by the control module to control the hot air blower to work, and the state indicator lamp gives green light; when the temperature is detected to exceed a line-crossing value, the alarm generating module alarms, the state indicator lamp gives red light, the red light is displayed on the display module, and the power supply of the industrial hot-air blower is switched off by the control module. According to the portable type SF6 gas cylinder heating system, constant control on temperature is realized by virtue of the control module, the industrial hot-air blower and the like, so that the gas charging efficiency is improved, the gas residual rate is reduced, and potential safety hazards can be avoided.

Owner:STATE GRID CORP OF CHINA +1

A coal gasification method

ActiveCN104498096BGuaranteed not to overheatReduce escapeGasifier feeding meansGasification processes detailsBrown coalThermodynamics

The invention provides an efficient coal gasification method, and the specific preparation steps include: coal grinding and drying, pulverized coal pressurization and transportation, and gasification furnace gasification. In the type selection of the coal mill, the present invention distributes the primary air from the hot blast stove into the coal mill in a ring shape, and at the same time ensures that the temperature of the hot air entering the coal mill is not greater than the conversion temperature of the lignite, and ensures that the local surface of the lignite does not exceed temperature, reducing the escape of volatile components in lignite; the present invention uses high-volatile lignite as raw material, controls the coal grinding system, and the maximum oxygen concentration is 4%, and a new low-pressure nitrogen gas is added to the coal grinding machine sealing system in the system, and at the same time Increase the nitrogen inlet in the system, reduce the impact on the grinding rod, and reduce the vibration of the coal mill; the program in the present invention will start the lock hopper unloading cycle, and the total unloading cycle time is 3 minutes. It can be seen that the whole process has a high degree of automation and high efficiency. High and short.

Owner:海鑫电力设备制造(南通)有限公司

Optical field molten salt flow and defocus adjustment coordination control device for trough photothermal power station

ActiveCN105444437BGuaranteed uptimeGuaranteed not to overheatSolar heat devicesSolar thermal energy generationEngineeringControl unit

The invention relates to the technical field of solar groove type photo-thermal power generation, in particular to a coordinated control device for light field fused salt flow adjustment and defocusing adjustment of a groove type photo-thermal power station. The coordinated control device comprises a heat collecting field flow adjustment control unit, a heat collecting field defocusing adjustment control unit and a central coordinated control unit, wherein the heat collecting field flow adjustment control unit and the heat collecting field defocusing adjustment control unit are connected through a communication network and are connected with the central coordinated control unit. The heat collecting field flow adjustment control unit is used for controlling the flow of a cold tank outlet according to commands of the central coordinated control unit. By means of the coordinated control device, a photo-thermal power generation system is made to guarantee that fused salt stably flows without condensation when solar illumination intensity is poor according to solar illumination intensity differences in time, meanwhile, the temperature of the fused salt is controlled not to exceed the standard when the solar illumination intensity is too high, and therefore the photo-thermal power generation system can stably operate with high efficiency for a long time under complex and diversified weather conditions.

Owner:中国东方电气集团有限公司

Film-coated sand thermal regeneration equipment and its regeneration method

InactiveCN103894538BIncrease the number of landingsExtended stayMould handling/dressing devicesAir preheaterFluidized bed

The invention belongs to the technical field of energy engineering, and relates to precoated sand hot-process regeneration equipment mainly utilizing a vertical fluidized bed furnace and a precoated sand hot-process regeneration method. The precoated sand hot-process regeneration equipment comprises a vertical fluidized bed furnace, a charging hopper, a nozzle for oppositely spraying coal gas, a flue, a smoke discharging pipeline, a dividing wall cooler and an air preheater, wherein the dividing wall cooler is arranged below the vertical fluidized bed furnace, the top end of the dividing wall cooler is connected with the vertical fluidized bed furnace through a sand falling pipe, the air inlet of the dividing wall cooler is connected with an air blower, the air outlet of the dividing wall cooler is connected with the air preheater through a hot air pipe I, the inlet of an air conveying pipe of the air preheater is communicated with the hot air pipe I, the outlet of the air conveying pipe is communicated with an air chamber through a hot air pipe II, and the flue is connected with the smoke discharging pipeline through a cavity of the air preheater. The precoated sand hot-process regeneration method comprises the steps: starting, feeding, and stabilizing. The precoated sand hot-process regeneration equipment is high in energy utilization rate, perfect in regeneration, simple in operation, and energy-saving and environment-friendly.

Owner:QINGDAO UNIV

A coal gasification method

ActiveCN104498102BGuaranteed not to overheatReduce escapeGasification processes detailsGranular/pulverulent flues gasificationSlagNitrogen gas

The present invention provides an gasification method. The specific preparation steps include: coal grinding and drying, grouped coal pressing and transportation, and gasification stove gas.In the selection of the coal mill, the present invention puts out the hot air furnace into the wind distribution of the coal mill, and at the same time ensure that the hot air temperature of the coal milling machine is not greater than the conversion temperature of lignite, and the local surface of the lignite is not overTemperature, reduce the emergence of waves in lignite; the present invention uses high volatile lignite as the raw material to control the coal mill system, and the oxygen concentration is maximum of 4%.Increase the import of nitrogen in the system, reduce the impact on the stick of the stick, and reduce the vibration of the coal mill; the combustion temperature in the gasification furnace of the present invention is 150 to 200 ° C than the ash flowing temperature.Under this temperature and pressure, not only can the conversion rate in the furnace reaches 99%, but the ash slag has a good flow characteristics.

Owner:铜陵市世纪朝阳数码科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com