Site heat treatment device for air cylinder groove

A technology of heat treatment devices and grooves, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of poor time control, difficult temperature control, and unsatisfactory heat treatment effects, etc., and achieve good heat treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

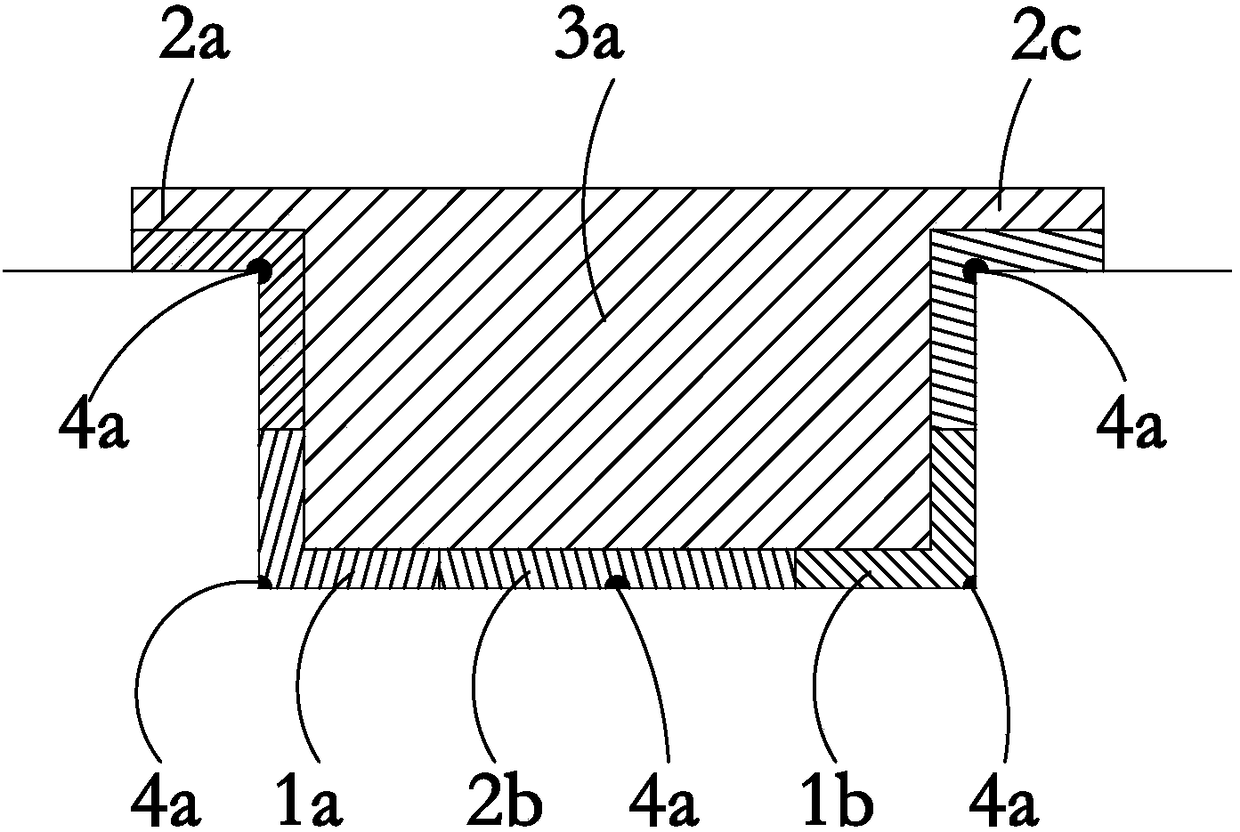

[0036] Such as figure 1 The heat treatment device shown is for heat treatment of the crack repair at the two corners of the cylinder groove bottom, the device body includes: the first main heating zone 1a, the second main heating zone 1b, the first auxiliary heating zone 2a, the second auxiliary The hot zone 2b, the third auxiliary heating zone 2c and the heat preservation zone 3a, the first auxiliary heating zone 2a, the first main heating zone 1a, the second auxiliary heating zone 2b, the second main heating zone 1b, and the third auxiliary heating zone 2c in sequence Connect and cover all the inner walls of the cylinder groove, and the first auxiliary heating zone 2a, the first main heating zone 1a, the second main heating zone 1b, and the third auxiliary heating zone 2c respectively cover the corner of a cylinder groove, and the second auxiliary heating zone The hot area 2b covers most of the bottom surface of the cylinder groove to provide auxiliary heat between the first...

Embodiment 2

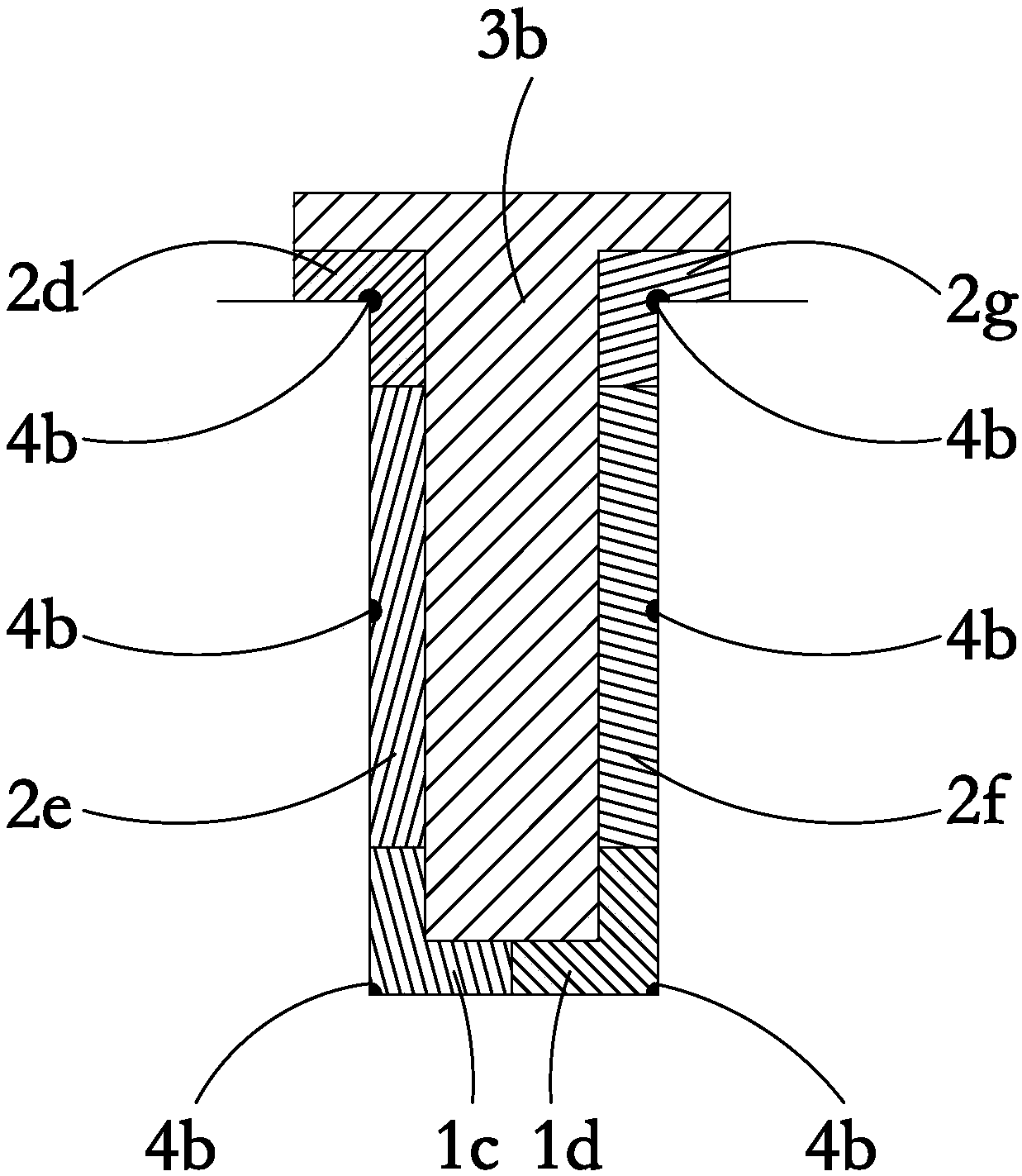

[0041] Such as figure 2 The heat treatment device shown is for heat treatment for crack repair at the two corners of the bottom of the cylinder groove. The device includes a first main heating zone 1c, a second main heating zone 1d, a first auxiliary heating zone 2d, and a second auxiliary heating zone 2e, the third auxiliary heating zone 2f, the fourth auxiliary heating zone 2g and the heat preservation zone 3b, the first auxiliary heating zone 2d, the second auxiliary heating zone 2e, the first main heating zone 1c, the second main heating zone 1d, the third The auxiliary heating area 2f and the fourth auxiliary heating area 2g are sequentially connected and cover the entire inner wall of the cylinder groove, and the first auxiliary heating area 2d, the first main heating area 1c, the second main heating area 1d, and the third auxiliary heating area 2e Covering the corners of one cylinder groove respectively, the heat preservation zone 3b covers the first auxiliary heating ...

Embodiment 3

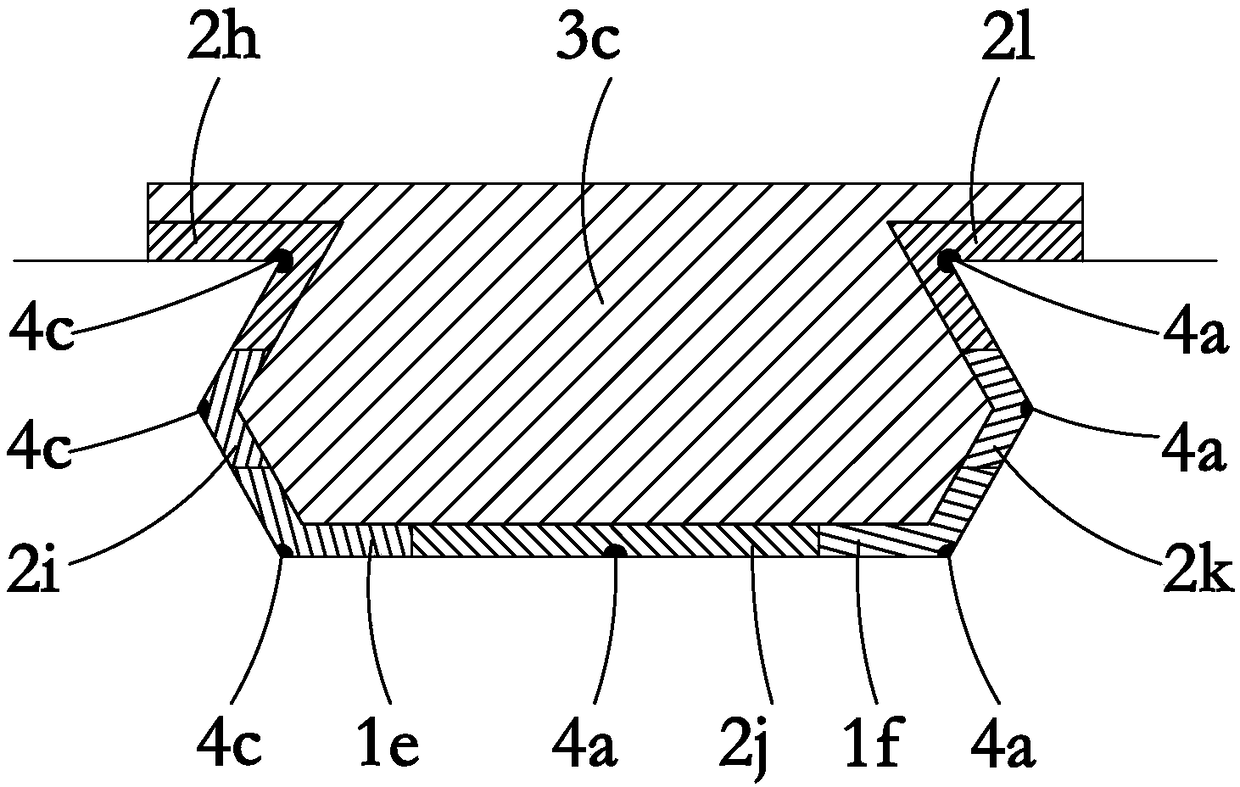

[0044] Such as image 3The heat treatment device shown is for heat treatment for crack repair at the two corners of the bottom of the cylinder groove. The device includes a first main heating zone 1e, a second main heating zone 1f, a first auxiliary heating zone 2h, and a second auxiliary heating zone 2i, the third auxiliary heating zone 2j, the fourth auxiliary heating zone 2k, the fifth auxiliary heating zone 2l and the heat preservation zone 3c, the first auxiliary heating zone 2h, the second auxiliary heating zone 2i, the first main heating zone 1e, the third The auxiliary heating area 2j, the second main heating area 1f, the fourth auxiliary heating area 2k, and the fifth auxiliary heating area 2l are sequentially connected and cover the entire inner wall of the cylinder groove, and the first auxiliary heating area 2h, the second auxiliary heating area 2i , the first main heating zone 1e, the second main heating zone 1f, the fourth auxiliary heating zone 2k, and the fifth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com