Surface Modification Method of Spherical Alumina for High Strength Epoxy Molding Compound

A technology of spherical alumina and epoxy molding compound, which is applied in the field of surface modification of spherical alumina for high-strength epoxy molding compound, can solve the problem of long production process and production cycle, inactivation of phosphorus-containing curing agent, and unsuitable for batch production. Production and other problems, to achieve the effect of good molding, improved compatibility, good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

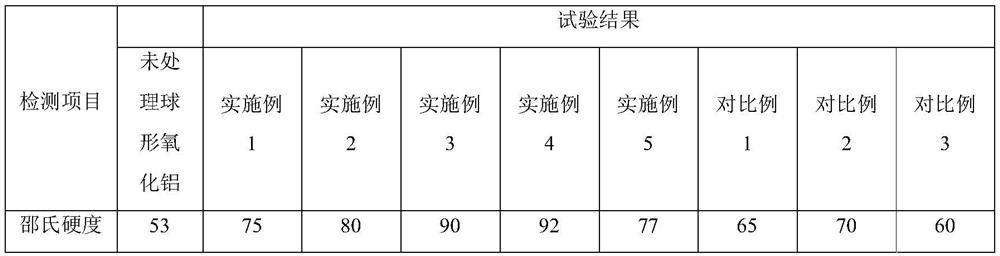

Examples

Embodiment 1

[0028] (1) Hydroxylation of spherical alumina: put 1 kg of spherical alumina of 9-11 μm into a stirrer, and add a mixed solution of 100 g of hydrogen peroxide and 100 g of pure water, stir for 4 hours at a temperature of 60 ° C, and filter and crush Dry to obtain 1 kg of aluminum oxide hydroxide.

[0029] (2) Surface modification: put 1 kg of hydroxylated alumina into the powder surface modification machine, and spray a mixture of 7 g of KBM573, 0.1 g of acetic acid, 14 g of pure water, and 7 g of isopropanol. Mix down for 1 hour.

[0030] (3) Heat treatment: 1 kg of surface-modified alumina was put into a muffle furnace, and heat-treated at 300° C. for 6 hours to obtain 1 kg of surface-heat-treated alumina.

Embodiment 2

[0032] (1) Hydroxylation of spherical alumina: Put 1 kg of spherical alumina of 9-11 μm into a stirred tank, add a mixed solution of 100 g of hydrogen peroxide and 100 g of pure water, stir for 4 hours at 60°C, and filter with suction Dry and crush to obtain 1 kg of aluminum oxide hydroxide.

[0033] (1) Surface modification: Put 1 kg of hydroxylated aluminum oxide in step (2) into the stirred tank, and spray the mixed solution of A18717 g, 0.1 g of acetic acid, 14 g of pure water, and 7 g of isopropanol, and mix at 110 ° C for 1 Hour.

[0034] (1) Heat treatment: 1 kg of surface-modified alumina was put into a muffle furnace, and heat-treated in a heat flow field of 300° C. for 6 hours to obtain 1 kg of surface heat-treated alumina.

Embodiment 3

[0036] (1) Hydroxylation of spherical alumina: put 1 kg of spherical alumina of 9-11 μm into a stirred tank, add a mixed solution of 100 g of hydrogen peroxide and 100 g of pure water, stir for 4 hours at 80 ° C, and filter with suction Dry and crush to obtain 1 kg of aluminum oxide hydroxide.

[0037] (2) Surface modification: put step (2) 1 kg of hydroxylated aluminum oxide into a stirred tank, and add 7 g of bisamino A178, 0.1 g of acetic acid, 14 g of pure water, and a mixed solution of 7 g of isopropanol in a spray mode. Mix at 110°C for 1 hour.

[0038] (3) Heat treatment: 1 kg of surface-modified alumina was put into a muffle furnace, and heat-treated in a heat flow field of 300° C. for 6 hours to obtain 1 kg of surface heat-treated alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com