Patents

Literature

47 results about "Aluminum oxide hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infobox references. Aluminium hydroxide oxide or aluminium oxyhydroxide, AlO(OH) is found as one of two well defined crystalline phases, which are also known as the minerals boehmite and diaspore. The minerals are important constituents of the aluminium ore, bauxite.

Releasable corrosion inhibitor compositions

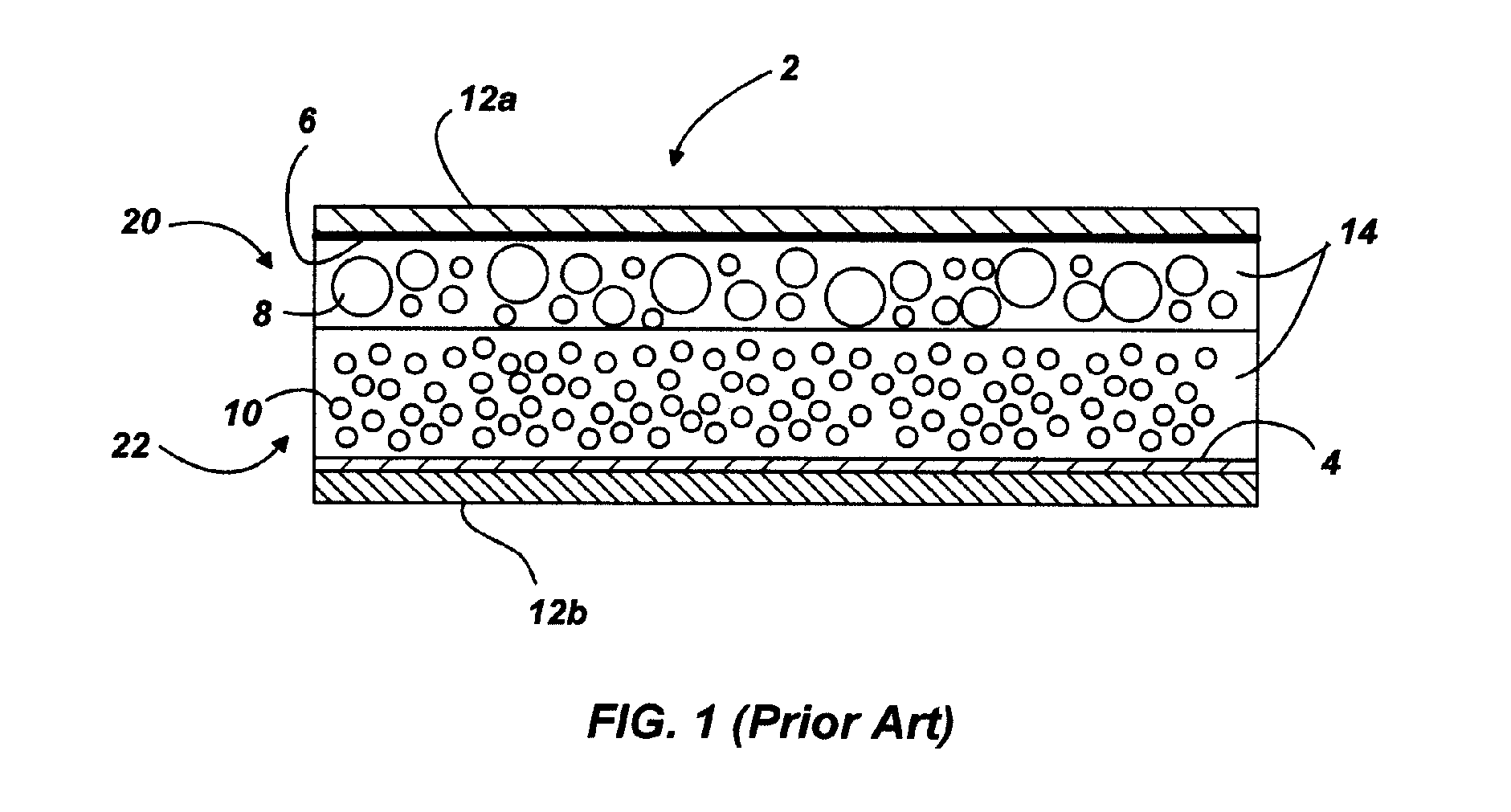

InactiveUS6933046B1Without degrading physical property and performance of coatingReduce impactMaterial nanotechnologyPigmenting treatmentCarboxylic acidMetal

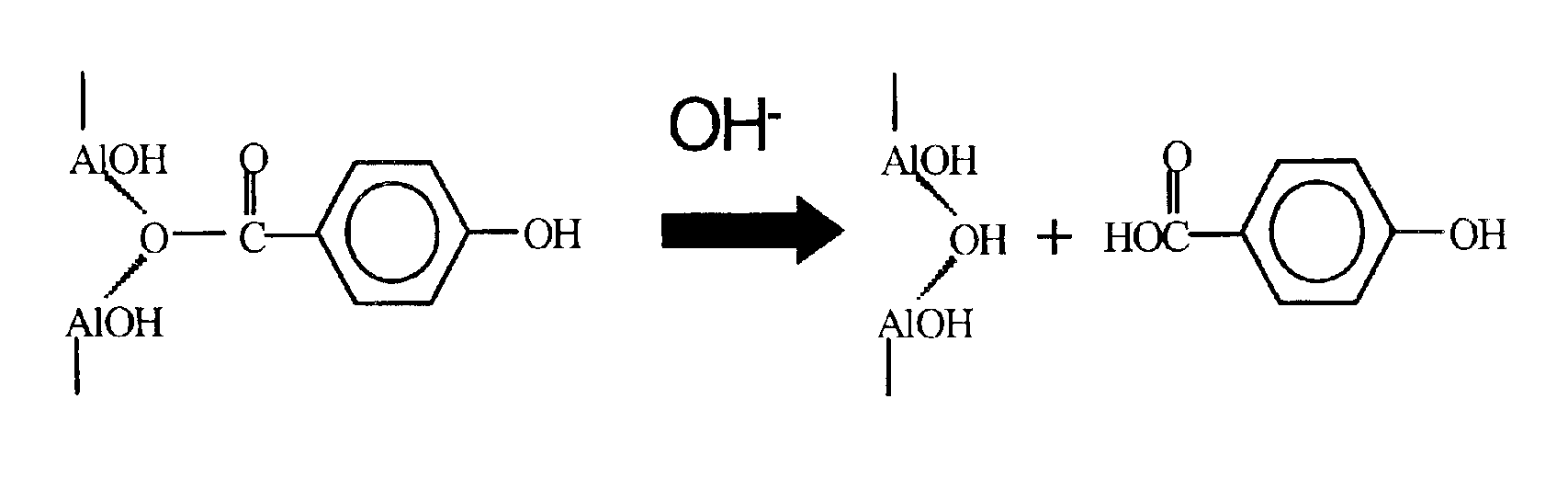

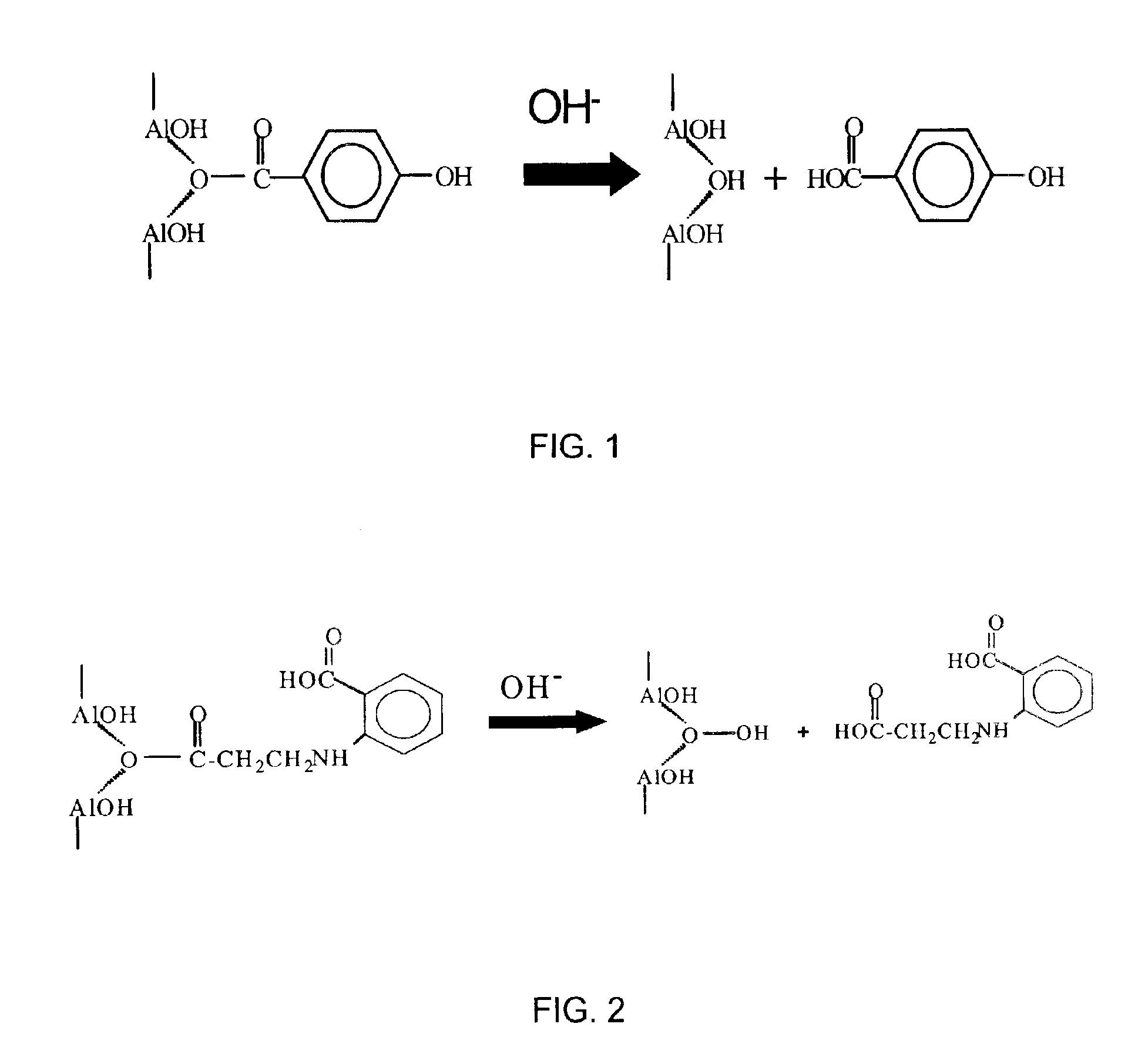

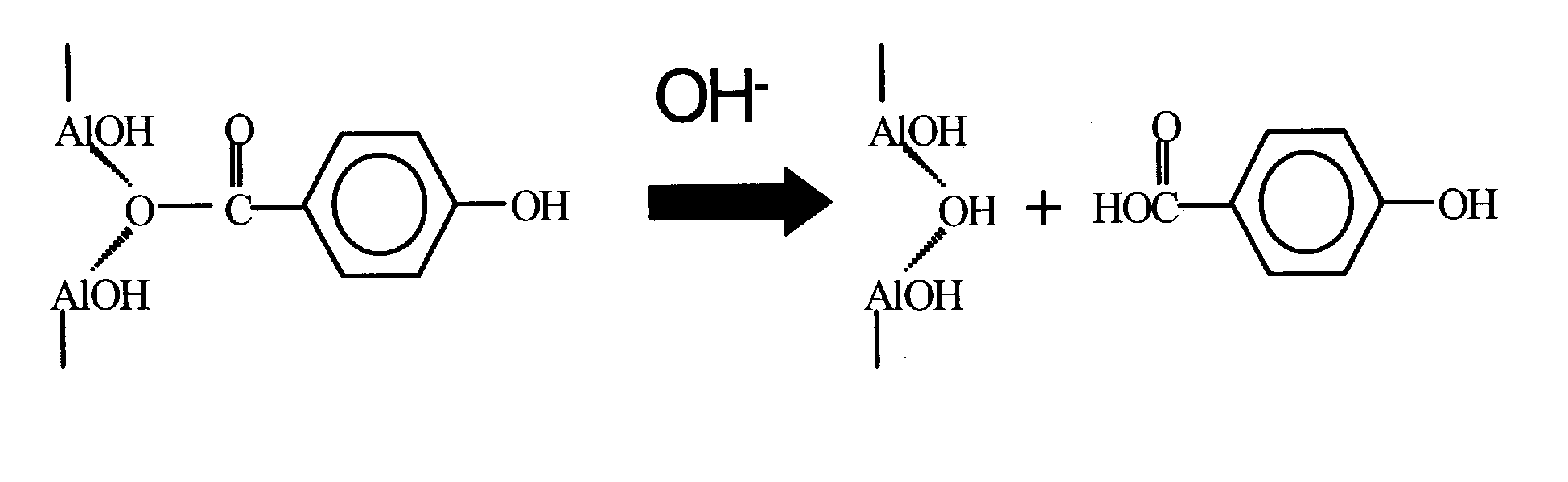

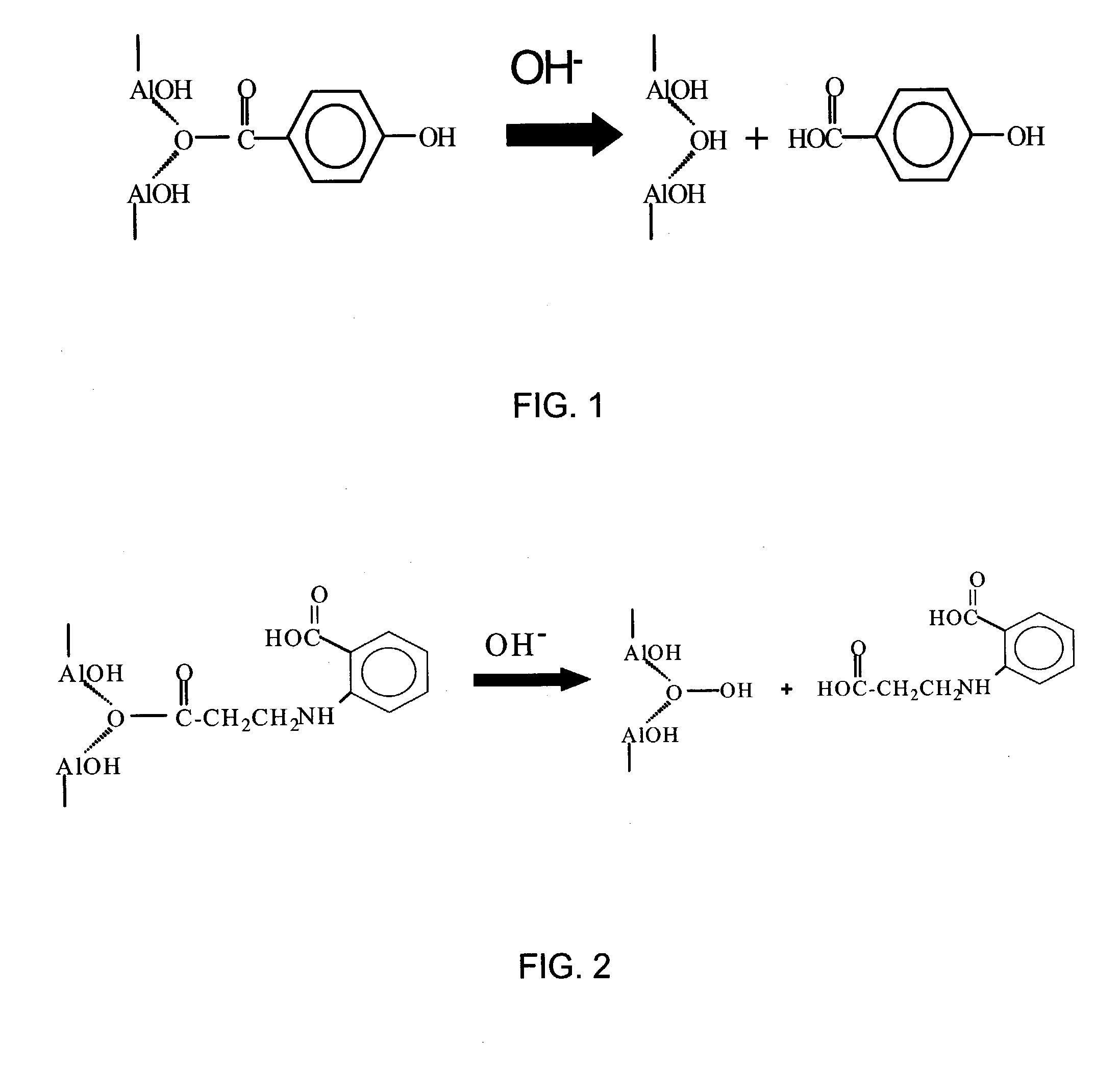

A new class of releasable corrosion inhibiting materials for protective coatings, methods of making the same, methods of using the same, and coatings containing the same are provided. The materials comprise one or more corrosion inhibitors that are chemically anchored to the surface of a particle having an aluminum oxyhydroxide surface through a carboxylate bond. The carboxylate / aluminum-oxyhydroxide-surface bond breaks under corrosion-causing conditions (for example the presence of high levels of hydroxide ions generated by the cathodic oxygen reduction reaction on metals such as iron and aluminum) thereby allowing the corrosion inhibitors to detach from the particle surface when corrosion is present.

Owner:TDA RES

Nanoparticles modified with multiple organic acids

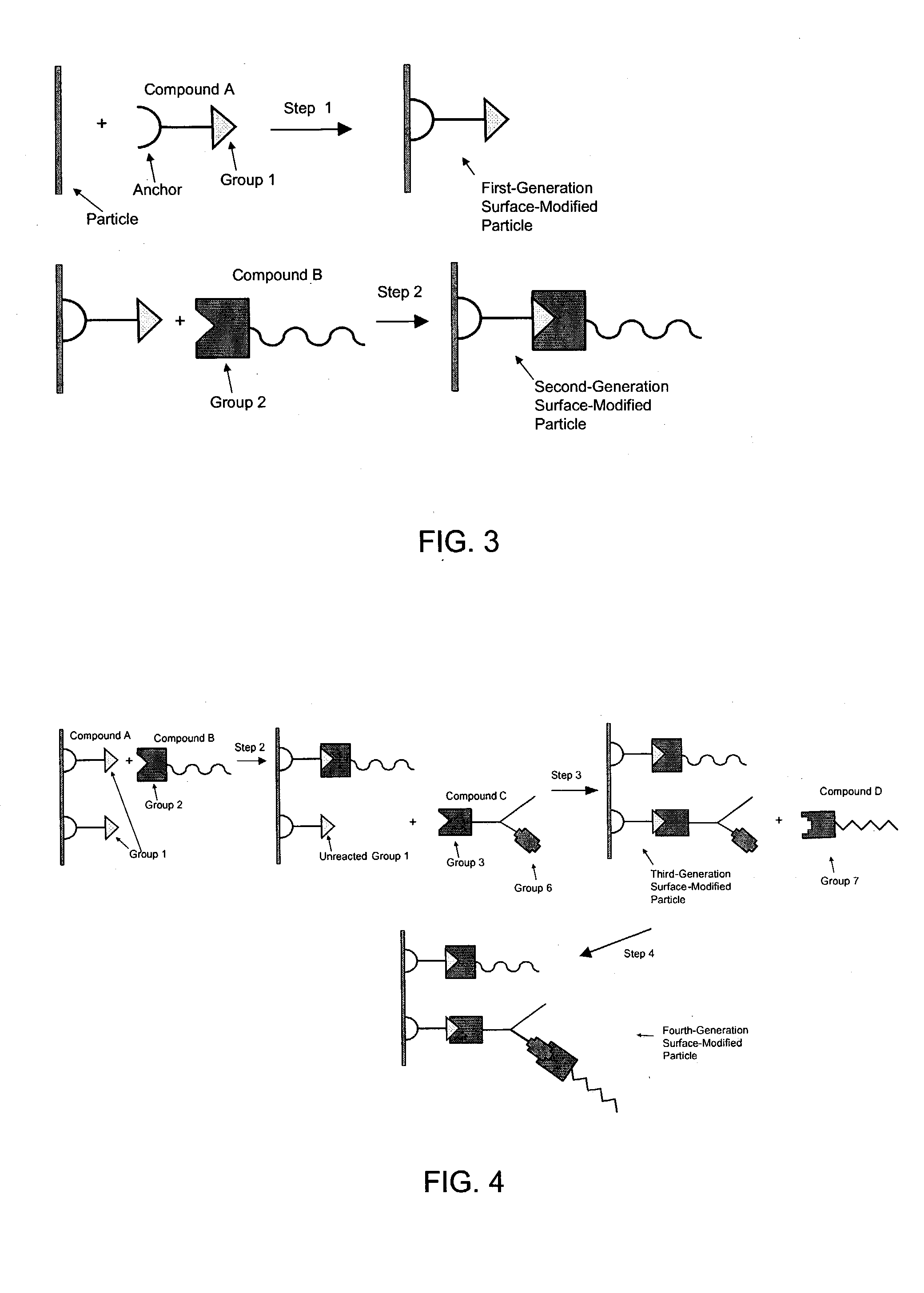

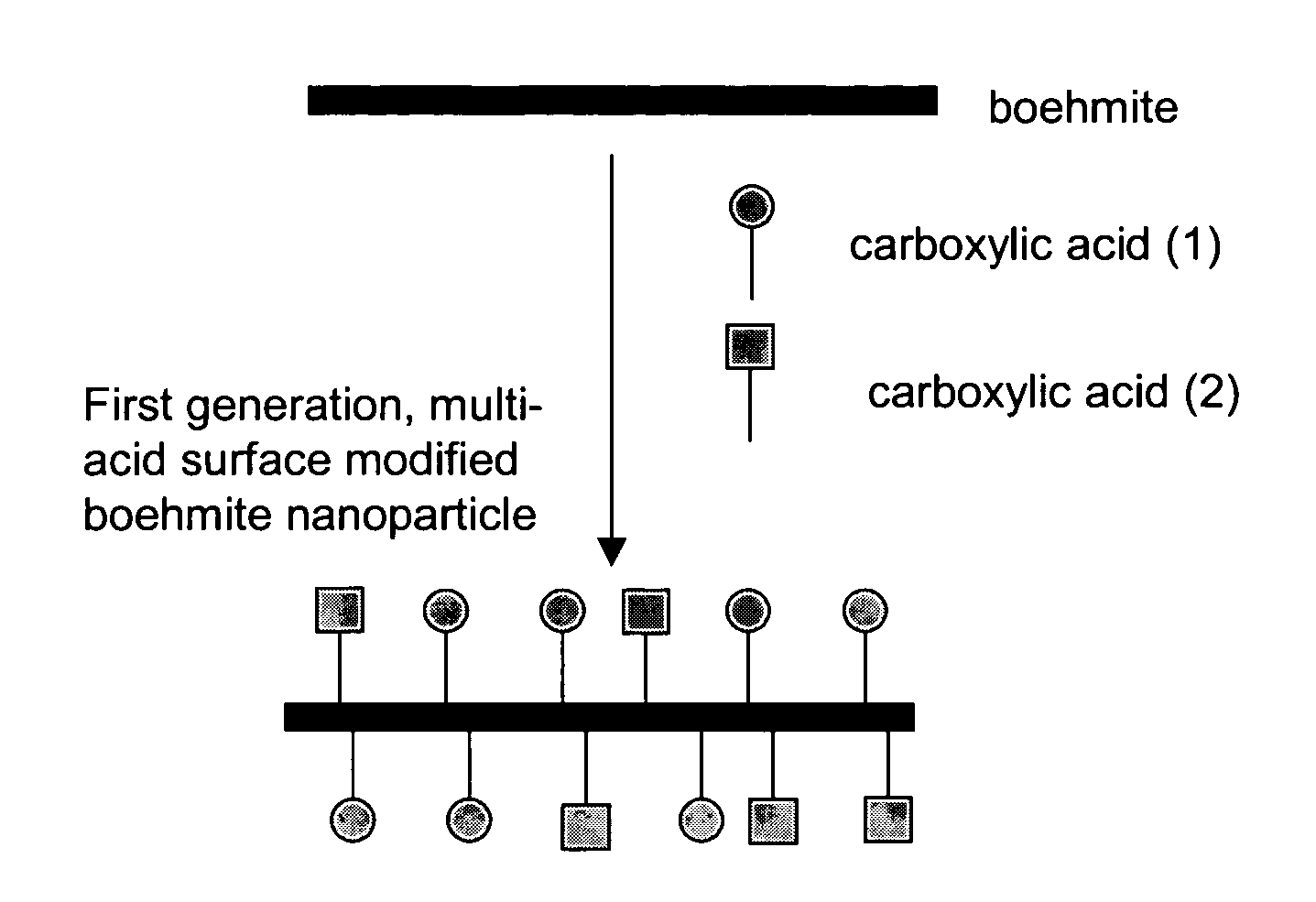

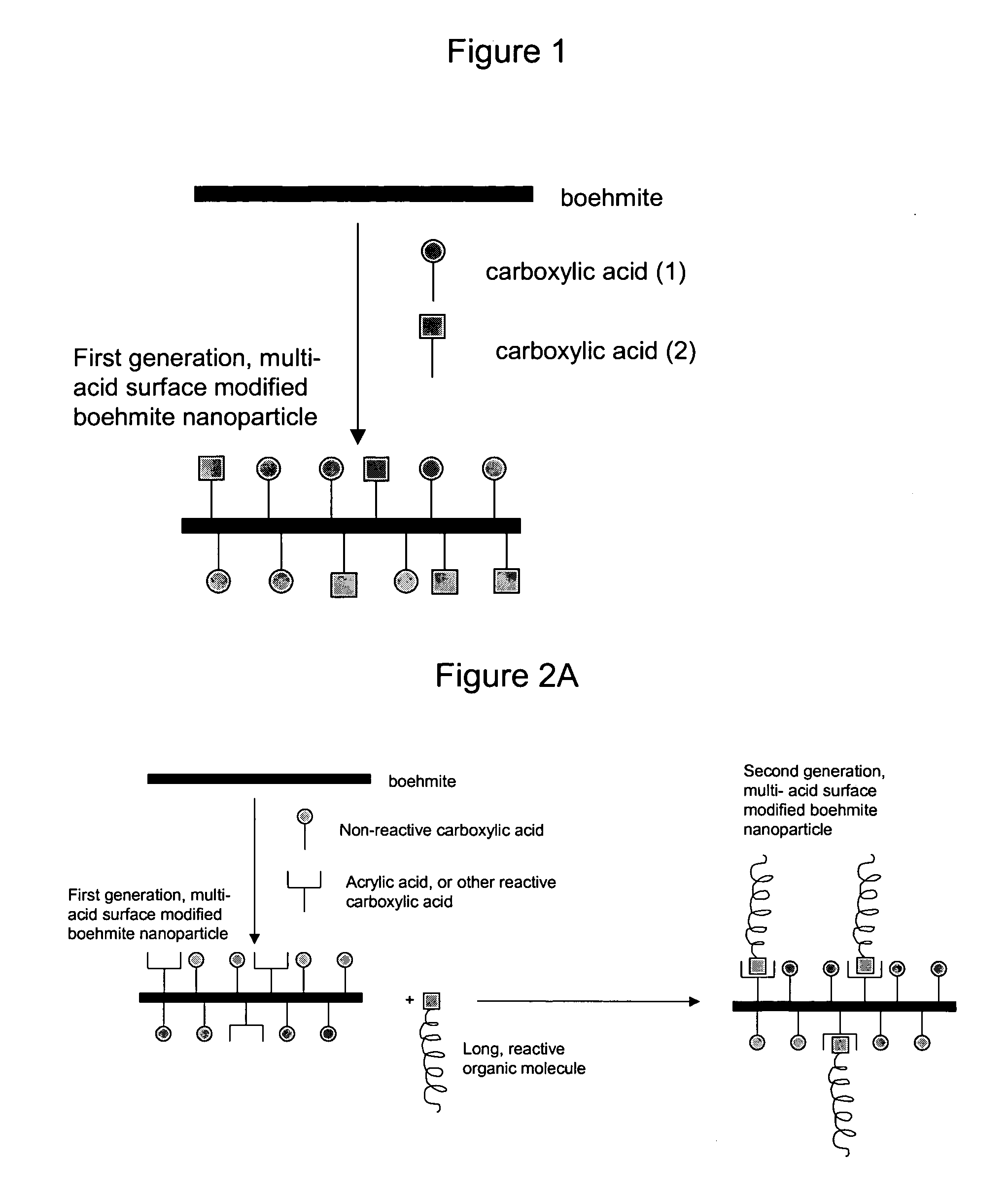

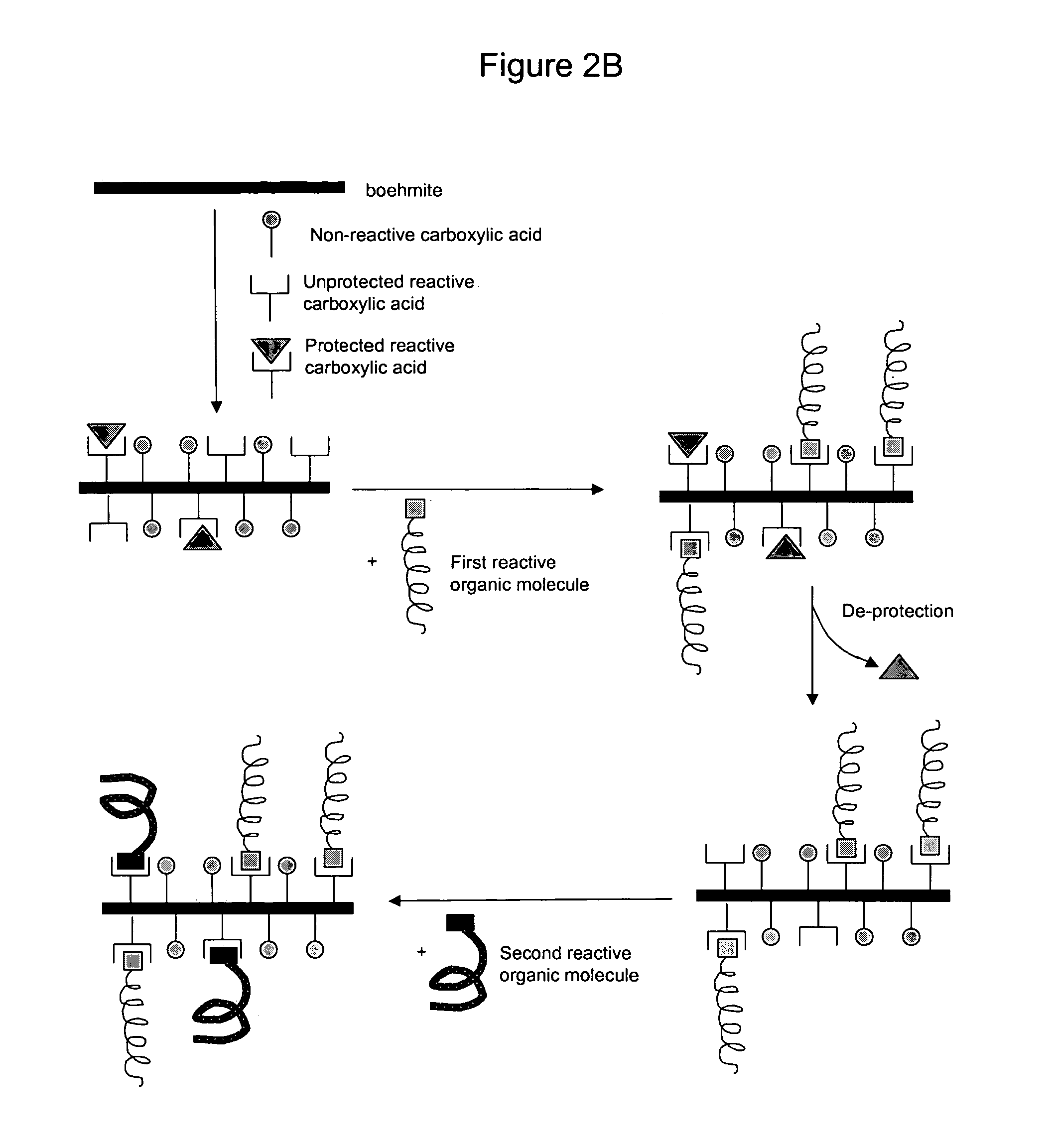

InactiveUS20070098990A1Reduce the amount requiredPigmenting treatmentMaterial nanotechnologySolubilityOrganic acid

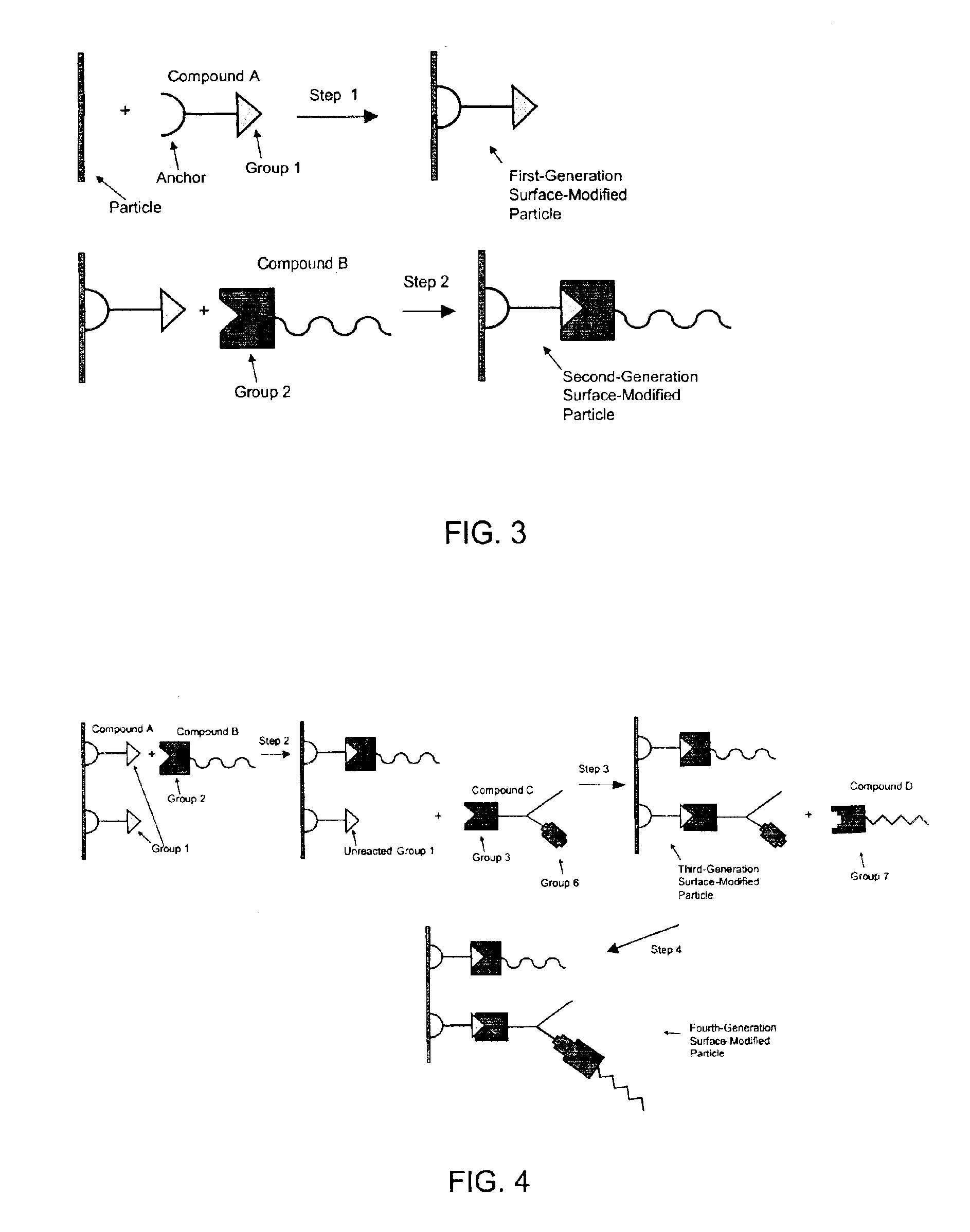

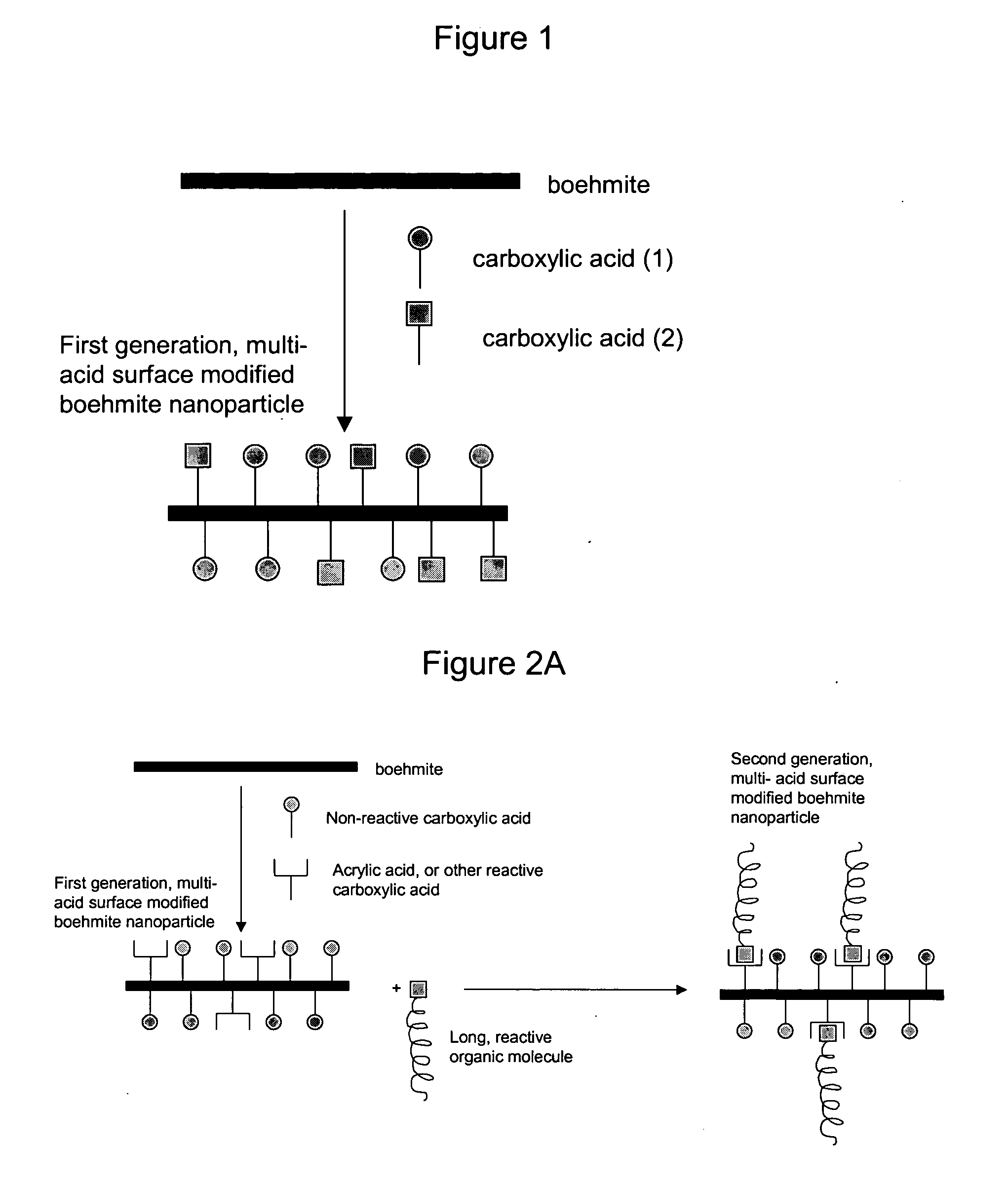

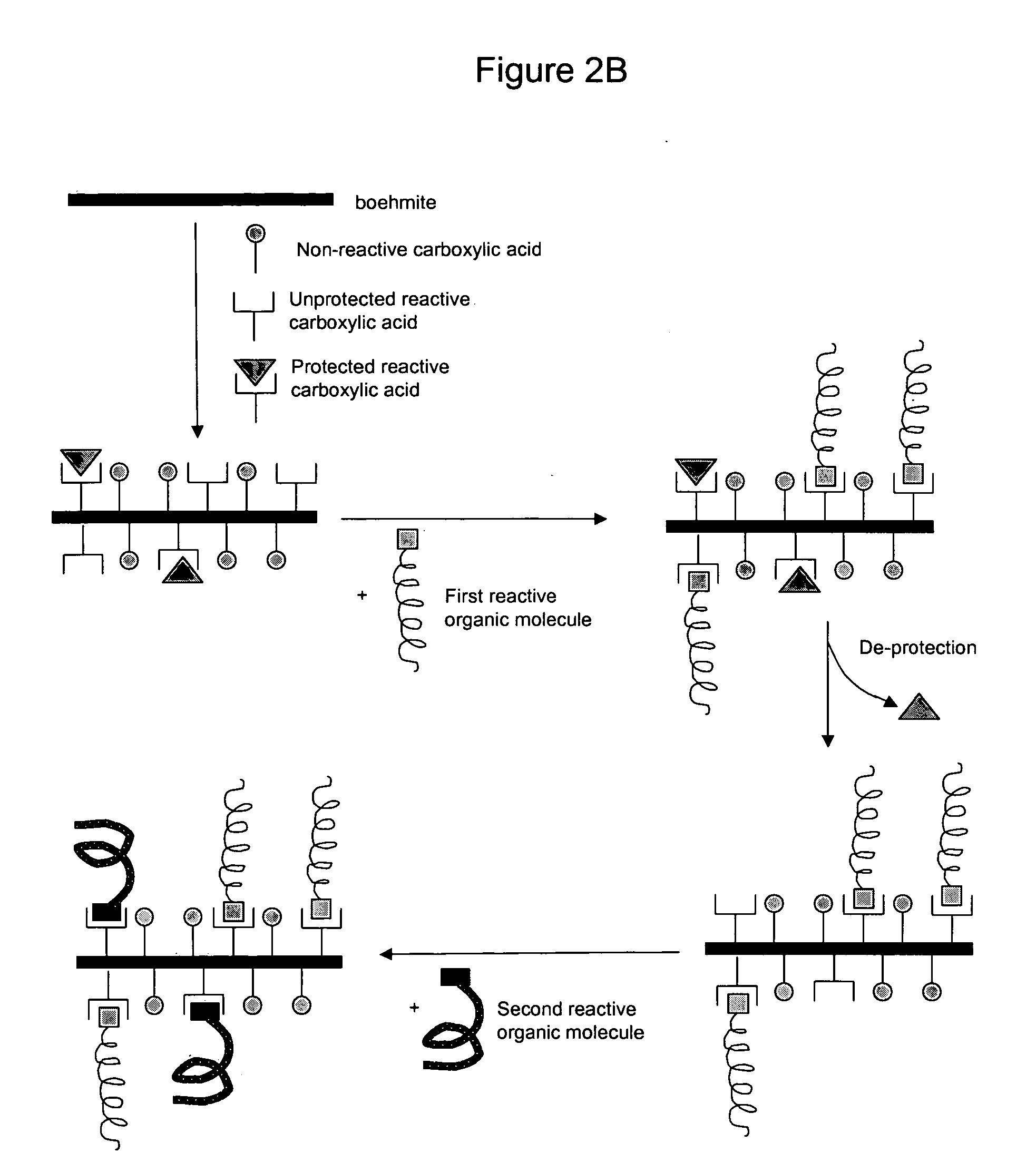

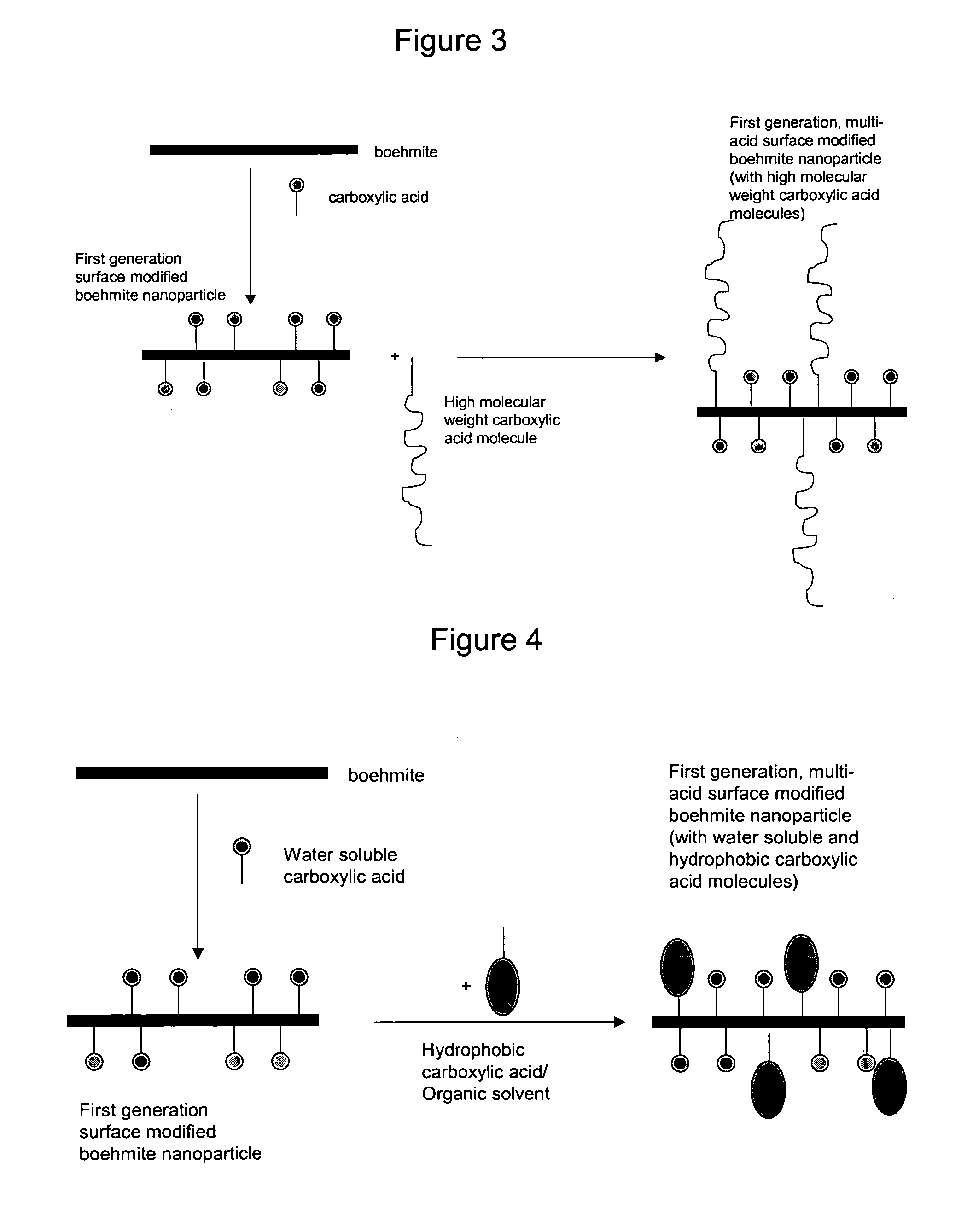

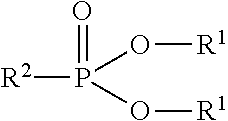

Surface-modified nanoparticles of boehmite, and methods for preparing the same. Aluminum oxyhydroxide nanoparticles are surface modified by reaction with selected amounts of organic acids. In particular, the nanoparticle surface is modified by reactions with two or more different carboxylic acids, at least one of which is an organic carboxylic acid. The product is a surface modified boehmite nanoparticle that has an inorganic aluminum oxyhydroxide core, or part aluminum oxyhydroxide core and a surface-bonded organic shell. Organic carboxylic acids of this invention contain at least one carboxylic acid group and one carbon-hydrogen bond. One embodiment of this invention provides boehmite nanoparticles that have been surface modified with two or more acids one of which additional carries at least one reactive functional group. Another embodiment of this invention provides boehmite nanoparticles that have been surface modified with multiple acids one of which has molecular weight or average molecular weight greater than or equal to 500 Daltons. Yet, another embodiment of this invention provides boehmite nanoparticles that are surface modified with two or more acids one of which is hydrophobic in nature and has solubility in water of less than 15 by weight. The products of the methods of this invention have specific useful properties when used in mixture with liquids, as filler in solids, or as stand-alone entities.

Owner:TDA RES

Releasable corrosion inhibitor compositions

InactiveUS20050176851A1Reduce the impactWithout degrading physical property and performance of coatingPigmenting treatmentMaterial nanotechnologyMaterials scienceMetal

A new class of releasable corrosion inhibiting materials for protective coatings, methods of making the same, methods of using the same, and coatings containing the same are provided. The materials comprise one or more corrosion inhibitors that are chemically anchored to the surface of a particle having an aluminum oxyhydroxide surface through a carboxylate bond. The carboxylate / aluminum-oxyhydroxide-surface bond breaks under corrosion-causing conditions (for example the presence of high levels of hydroxide ions generated by the cathodic oxygen reduction reaction on metals such as iron and aluminum) thereby allowing the corrosion inhibitors to detach from the particle surface when corrosion is present.

Owner:TDA RES

Nanoparticles modified with multiple organic acids

InactiveUS7244498B2Reduce the amount requiredPigmenting treatmentMaterial nanotechnologyOrganic acidSolubility

Surface-modified nanoparticles of boehmite, and methods for preparing the same. Aluminum oxyhydroxide nanoparticles are surface modified by reaction with selected amounts of organic acids. In particular, the nanoparticle surface is modified by reactions with two or more different carboxylic acids, at least one of which is an organic carboxylic acid. The product is a surface modified boehmite nanoparticle that has an inorganic aluminum oxyhydroxide core, or part aluminum oxyhydroxide core and a surface-bonded organic shell. Organic carboxylic acids of this invention contain at least one carboxylic acid group and one carbon-hydrogen bond. One embodiment of this invention provides boehmite nanoparticles that have been surface modified with two or more acids one of which additional carries at least one reactive functional group. Another embodiment of this invention provides boehmite nanoparticles that have been surface modified with multiple acids one of which has molecular weight or average molecular weight greater than or equal to 500 Daltons. Yet, another embodiment of this invention provides boehmite nanoparticles that are surface modified with two or more acids one of which is hydrophobic in nature and has solubility in water of less than 15 by weight. The products of the methods of this invention have specific useful properties when used in mixture with liquids, as filler in solids, or as stand-alone entities.

Owner:TDA RES

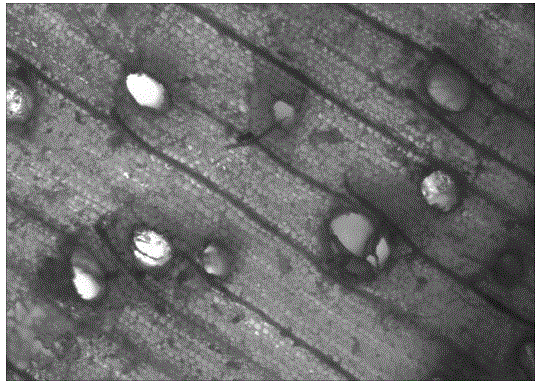

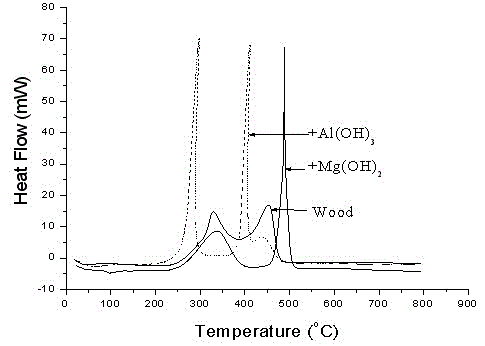

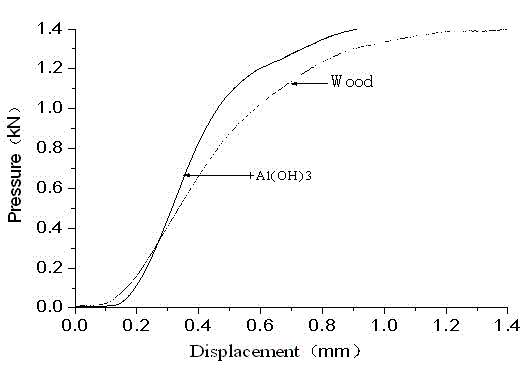

Nanometer hydroxide wood composite material and preparation method thereof

InactiveCN102873724AStrong mechanical propertiesImprove flame retardant performanceMaterial nanotechnologyWood impregnation detailsAluminum oxide hydroxideAluminium hydroxide

The invention discloses a nanometer hydroxide wood composite material. The nanometer hydroxide wood composite material is a high-quality composite wood material which consists of fast-growing wood serving as a base body and inorganic nanometer hydroxide serving as a reinforcing body. The inorganic nanometer hydroxide is uniformly filled in nanometer cavities among microfibers of the fast-growing wood, and is nanometer aluminum hydroxide, nanometer aluminum oxyhydroxide, nanometer magnesium hydroxide or nanometer magaldrate. The nanometer wood composite material is prepared from the fast-growing wood serving as the base body for the first time by a (microwave) hydrothermal method, surface activity and dispersion conditions of nanometer particles in a matrix and influence of a boundary structure on the mechanical property and the flame retardant property of the composite material are researched, so that filled wood is strengthened and has multiple functions of flame retardance, smoke suppression and the like, and the novel material with the excellent mechanical property and the good flame retardant property is obtained.

Owner:ANHUI AGRICULTURAL UNIVERSITY

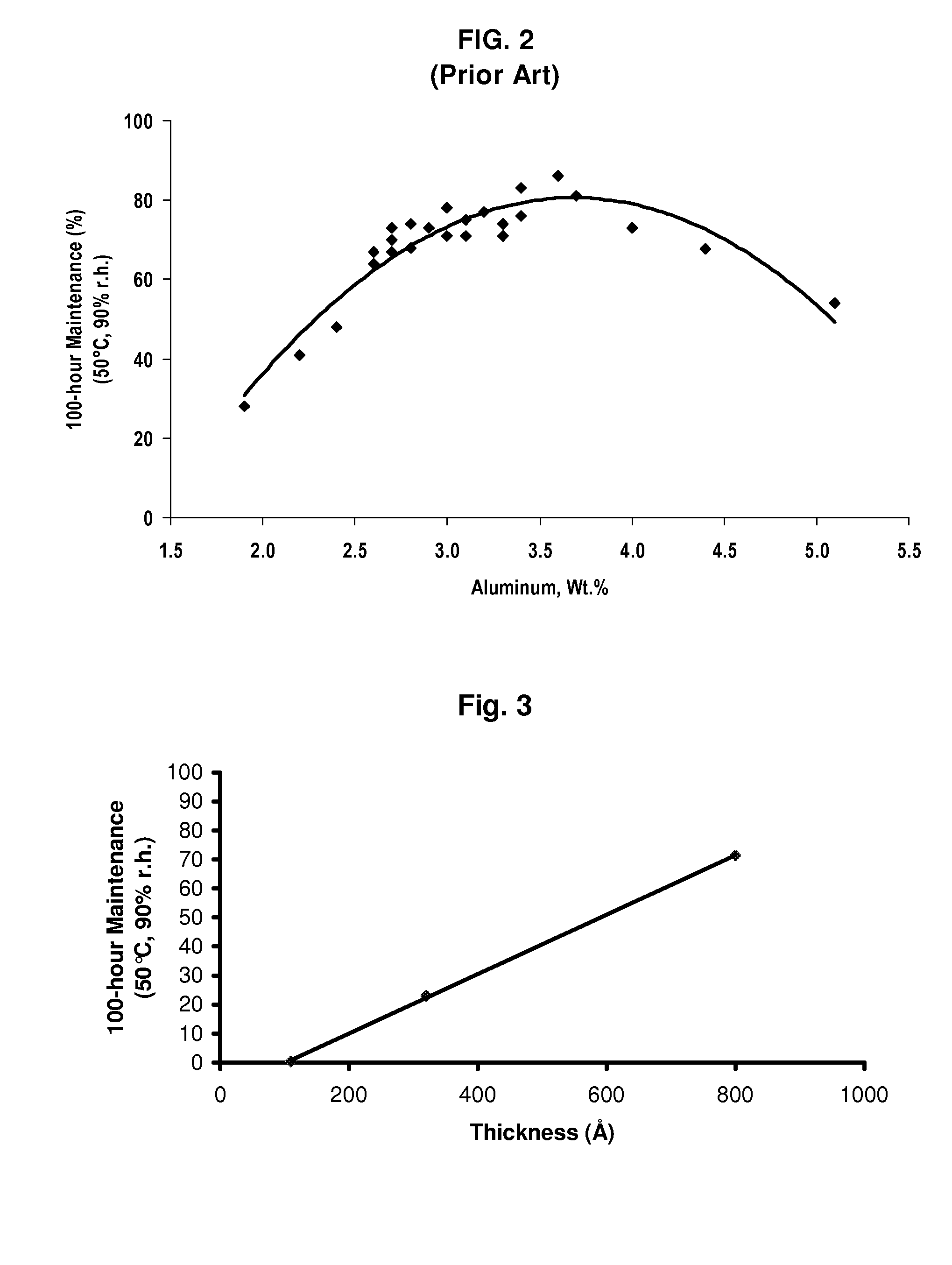

Moisture-resistant electroluminescent phosphor with high initial brightness and method of making

Owner:GLOBAL TUNGSTEN & POWDERS CORP

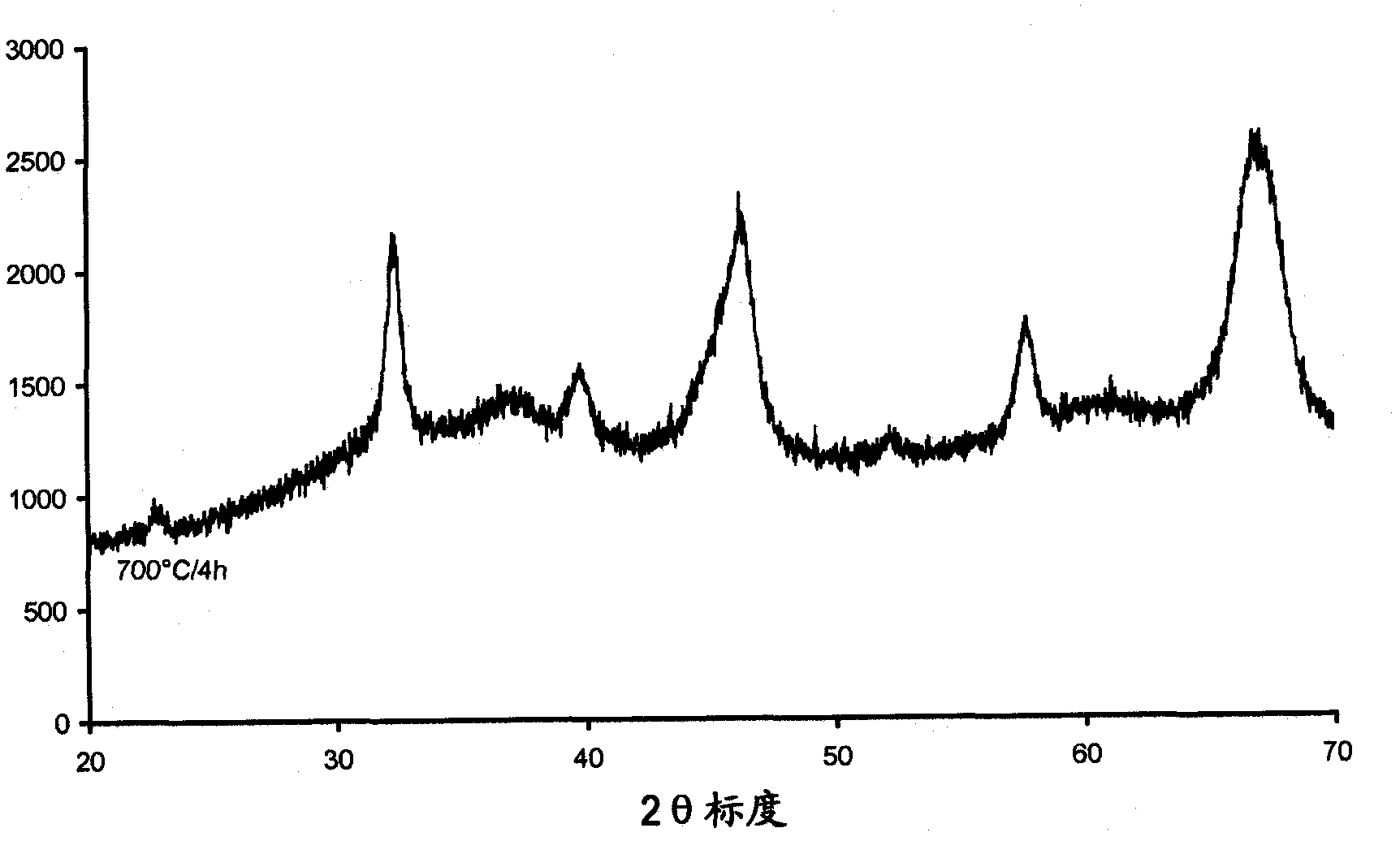

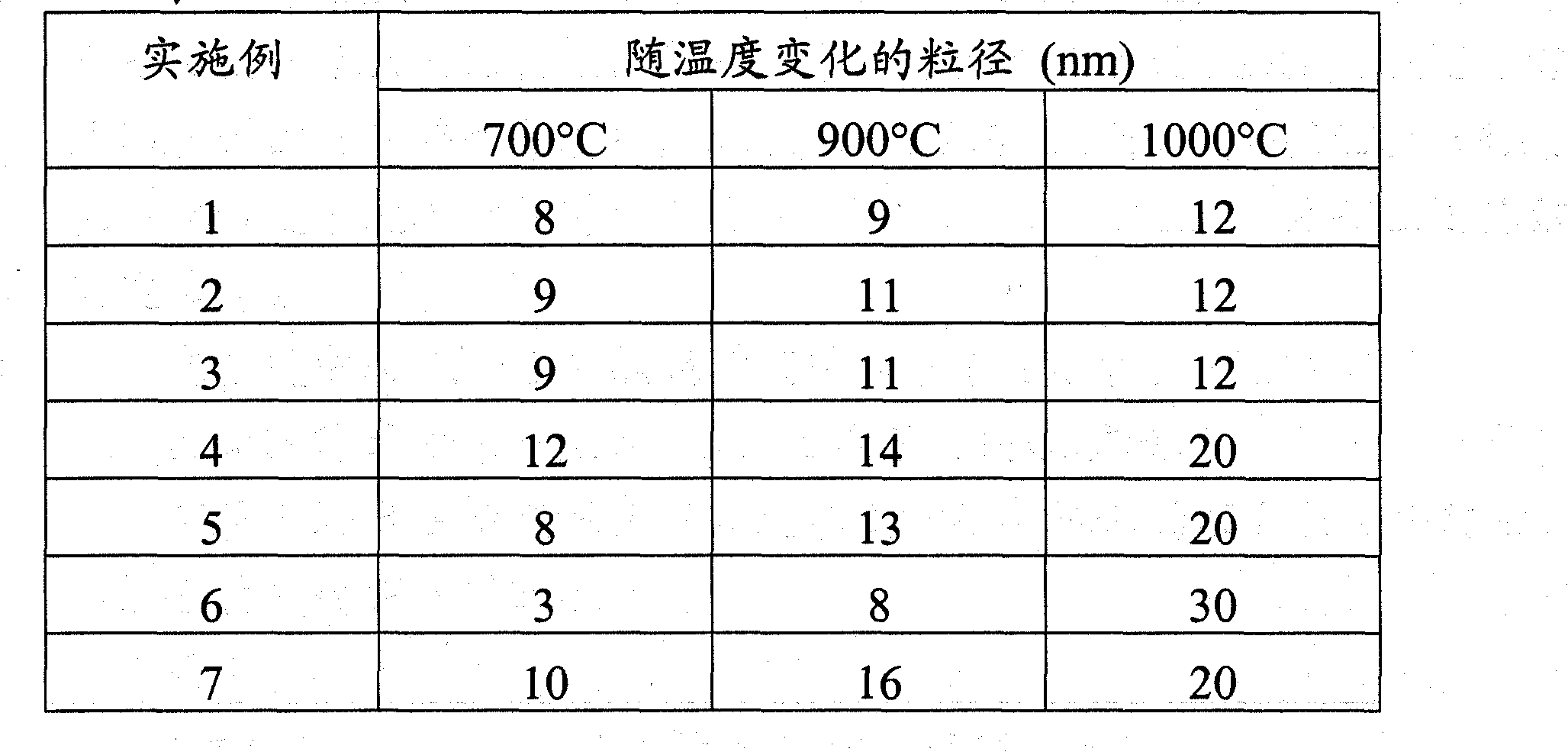

Composition including a lanthanum perovskite on an alumina or aluminium oxyhydroxide substrate, preparation method and use in catalysis

InactiveCN102341170APromote reductionNitrous oxide captureMaterial nanotechnologyAluminium hydroxideAluminum oxide hydroxide

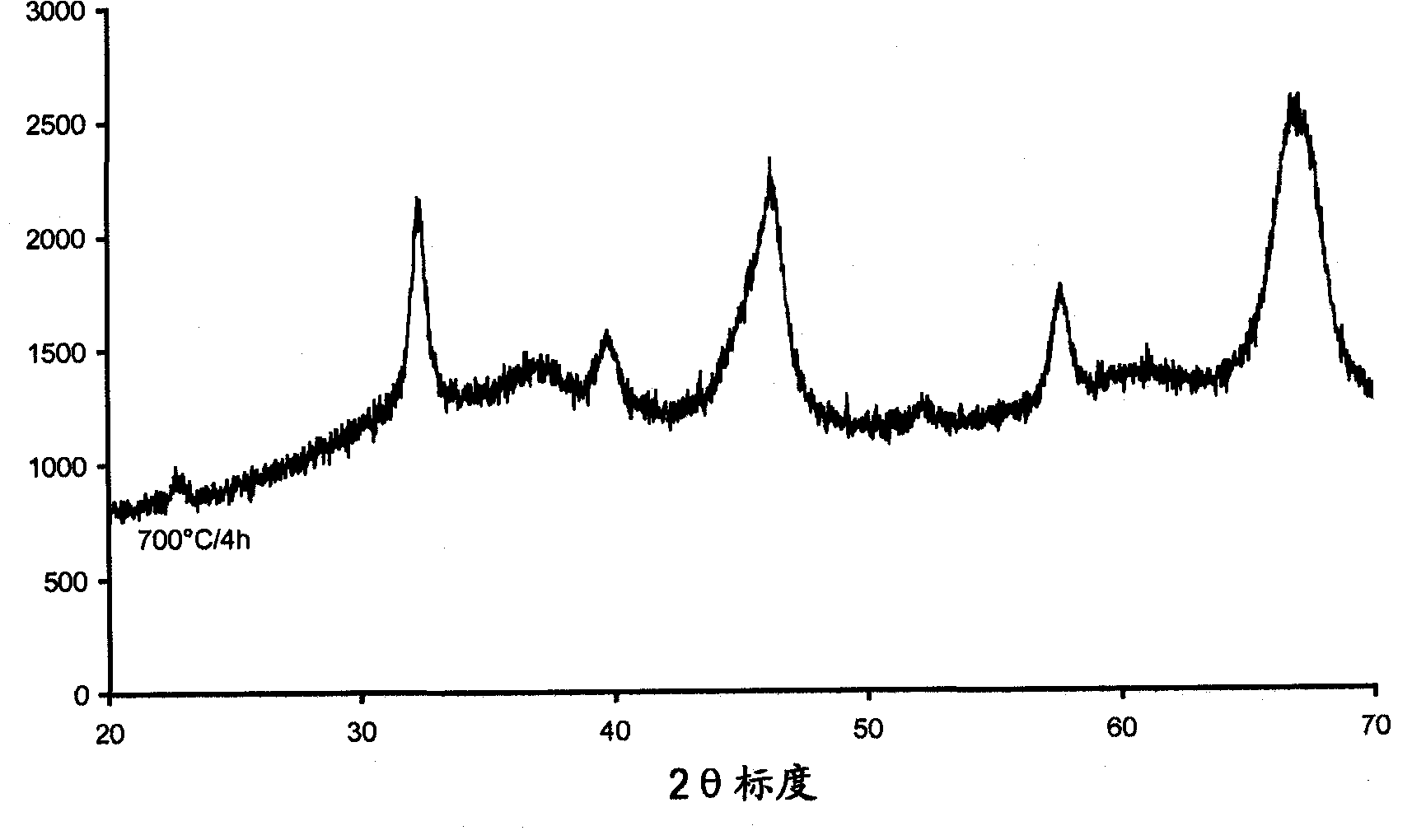

The composition according to the invention includes a perovskite of the formula LaMO3, where M is at least one element selected from among iron, aluminium or manganese, in the form of particles dispersed on an alumina or aluminium oxyhydroxide substrate, characterised in that after calcination at 700 C for 4 hours, the perovskite is in the form of a pure crystallographic phase, and in that the size of the perovskite particles does not exceed 15 nm. The composition according to the invention can be used in the field of catalysis.

Owner:RHODIA OPERATIONS SAS

Textile surface coatings of iron oxide and aluminum oxide

A textile substrate is provided which is coated with a film comprising iron (III) oxide hydroxide and aluminum oxide hydroxide. This film or coating is formed by contacting the textile substrate with an aqueous solution comprising ferrous or ferric salts and aluminum salts. The iron (II), iron (III), and aluminum ions are hydrolyzed and the iron (II) ions are also oxidized under controlled conditions. These hydrolyzed species then, it is believed, coprecipitate or copolymerized to on the textile surface to form a smooth, coherent, substantially amorphous iron (III) oxide / aluminum oxide hydroxide film or coating on the surface of the substrate without forming an insoluble iron (III) or aluminum hydroxide precipitate in the solution. This is accomplished by controlling the reaction conditions such that the rates of adsorption onto the substrate surface of both iron (III) and aluminum oxide hydroxides are greater than the rates of formation of said same oxide hydroxide particles. The resultant coating is substantially amorphous with extremely limited crystalline formation. The obtained substrate has very good color fastness, bacteriostatic, and virus removing properties and can be utilized as an inexpensive and effective water filtration article.

Owner:MILLIKEN & CO

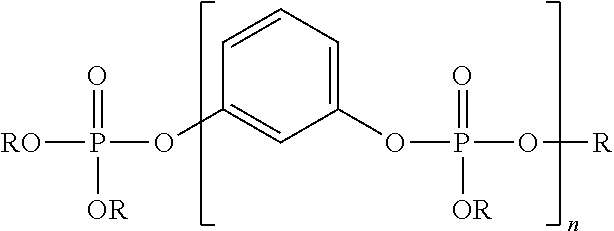

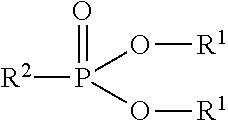

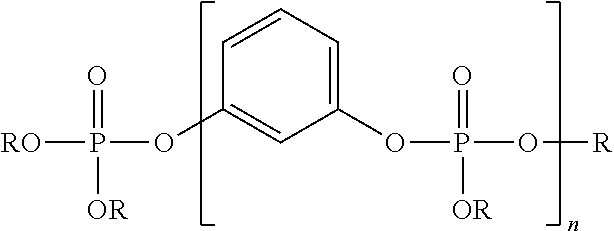

Hydrolysis stabilizer for thermoplastic molding compositions

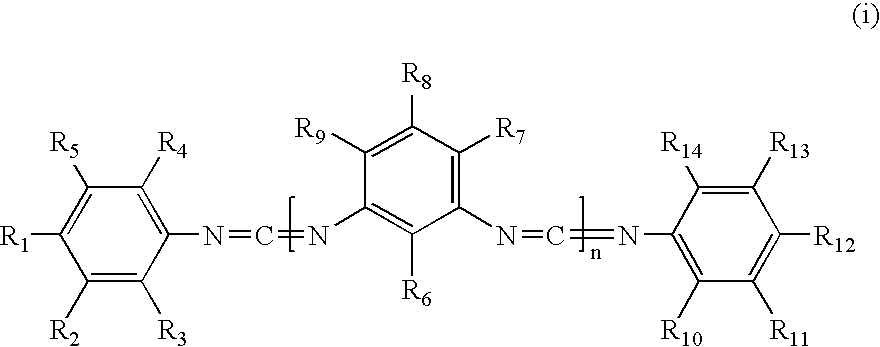

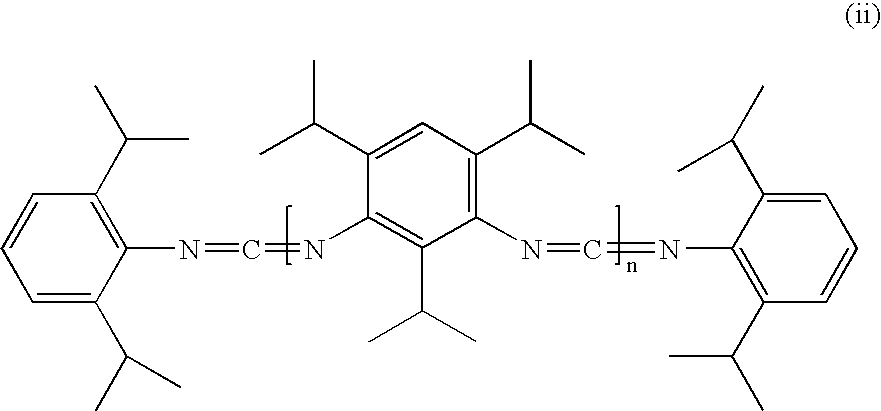

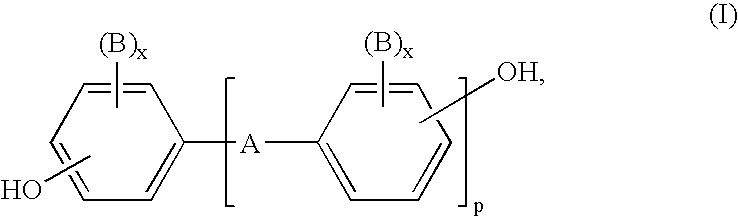

A hydrolytic stabilizer mixture is disclosed. The mixture comprise i) at least one carbodiimide and ii) co-stabilizer selected from the group consisting of aluminum oxide and aluminum oxyhydroxide. The mixture is useful in imparting to polymeric systems improved resistance to hydrolysis.

Owner:COVESTRO LLC

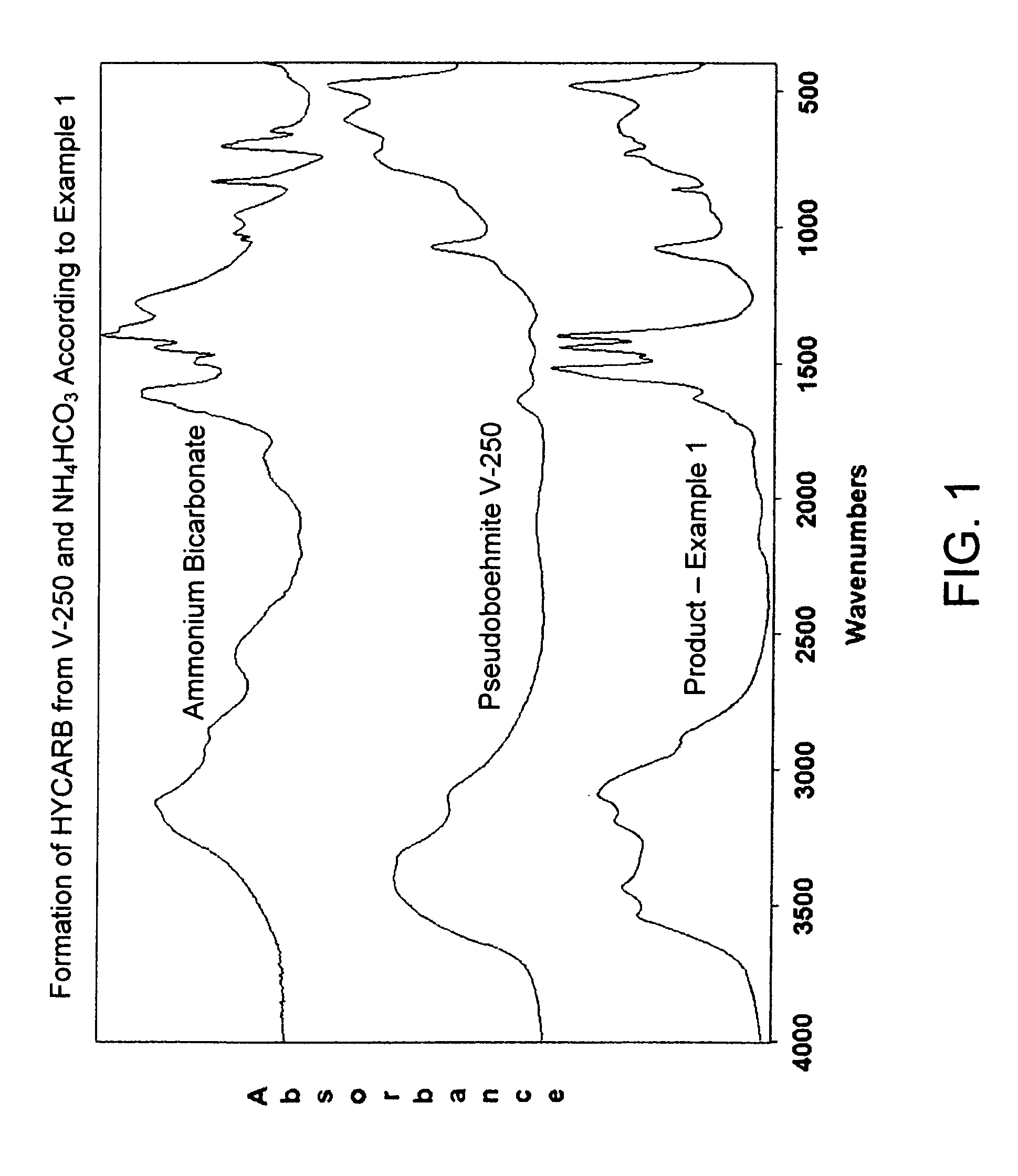

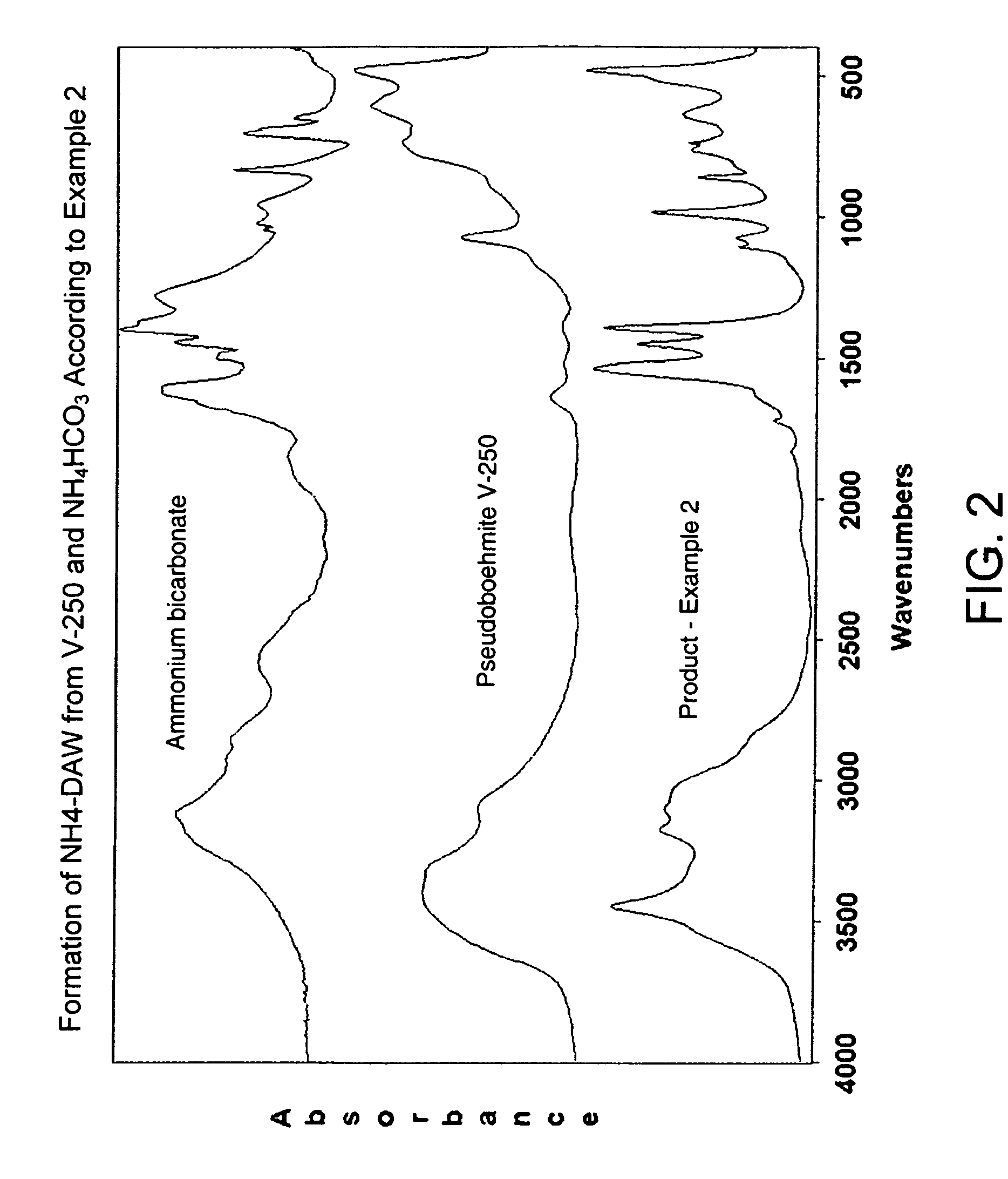

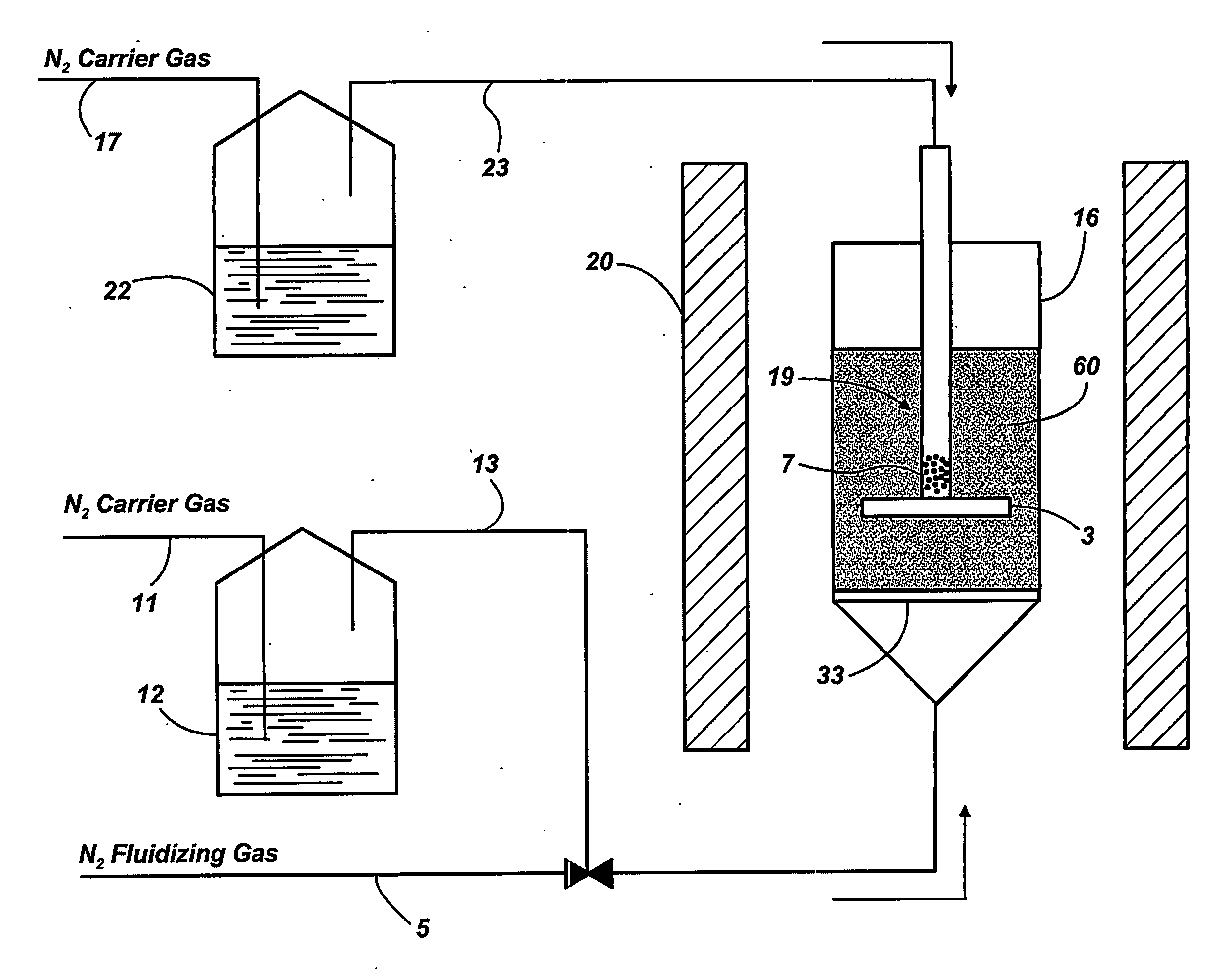

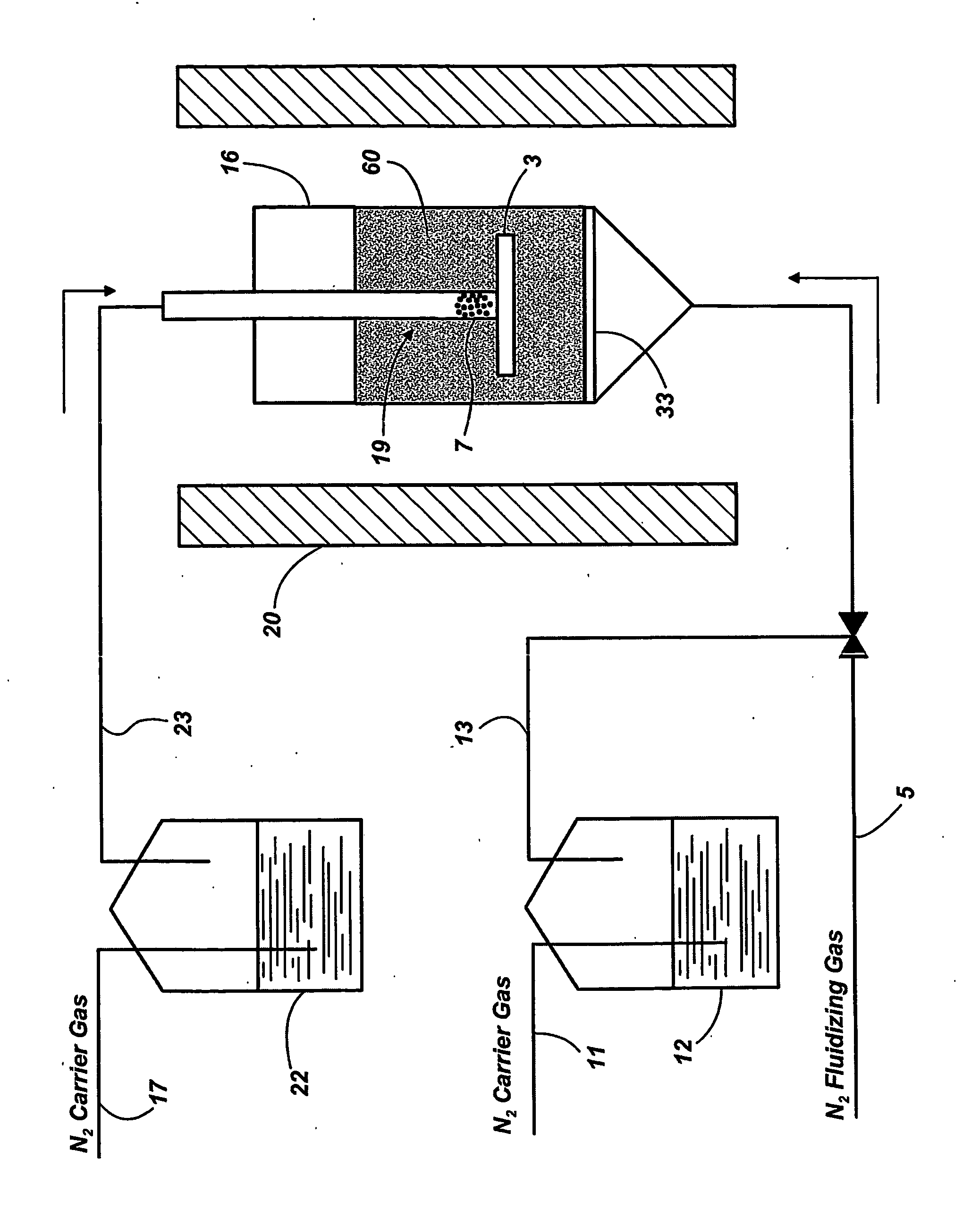

Process for Conversion of Aluminum Oxide Hydroxide

ActiveUS20100148116A1Other chemical processesAmmonium carbonates/bicarbonatesAluminium hydroxideAluminum oxide hydroxide

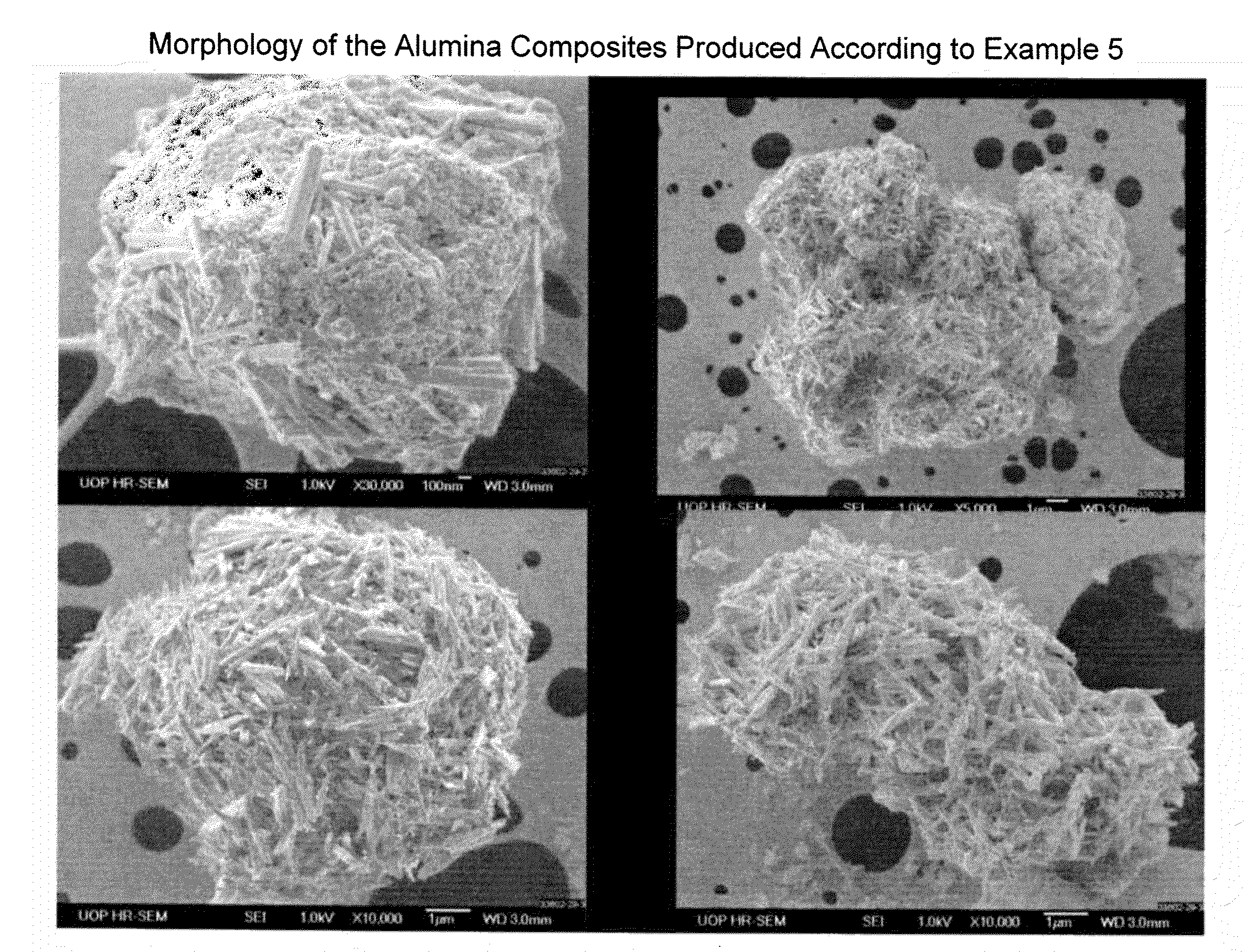

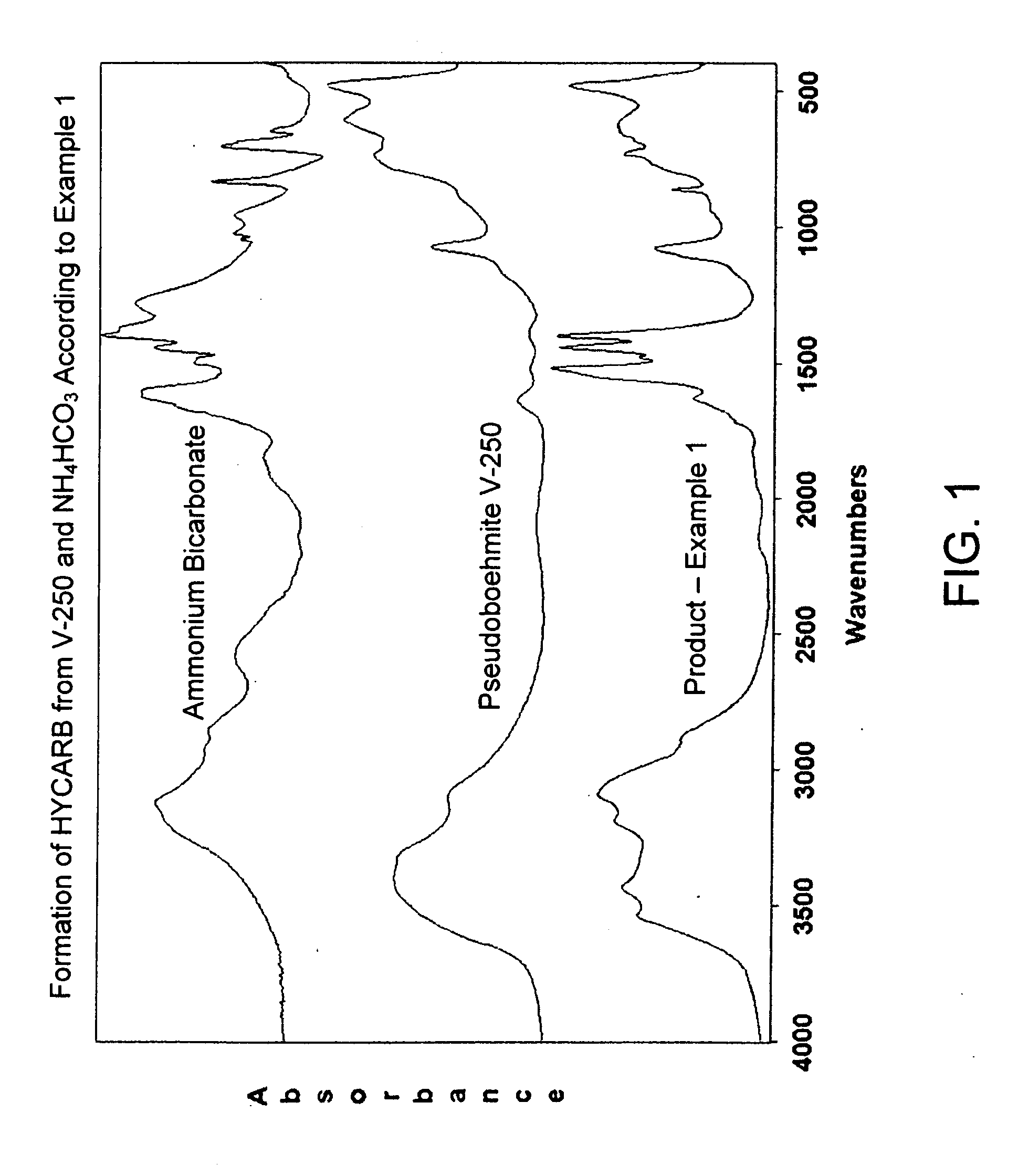

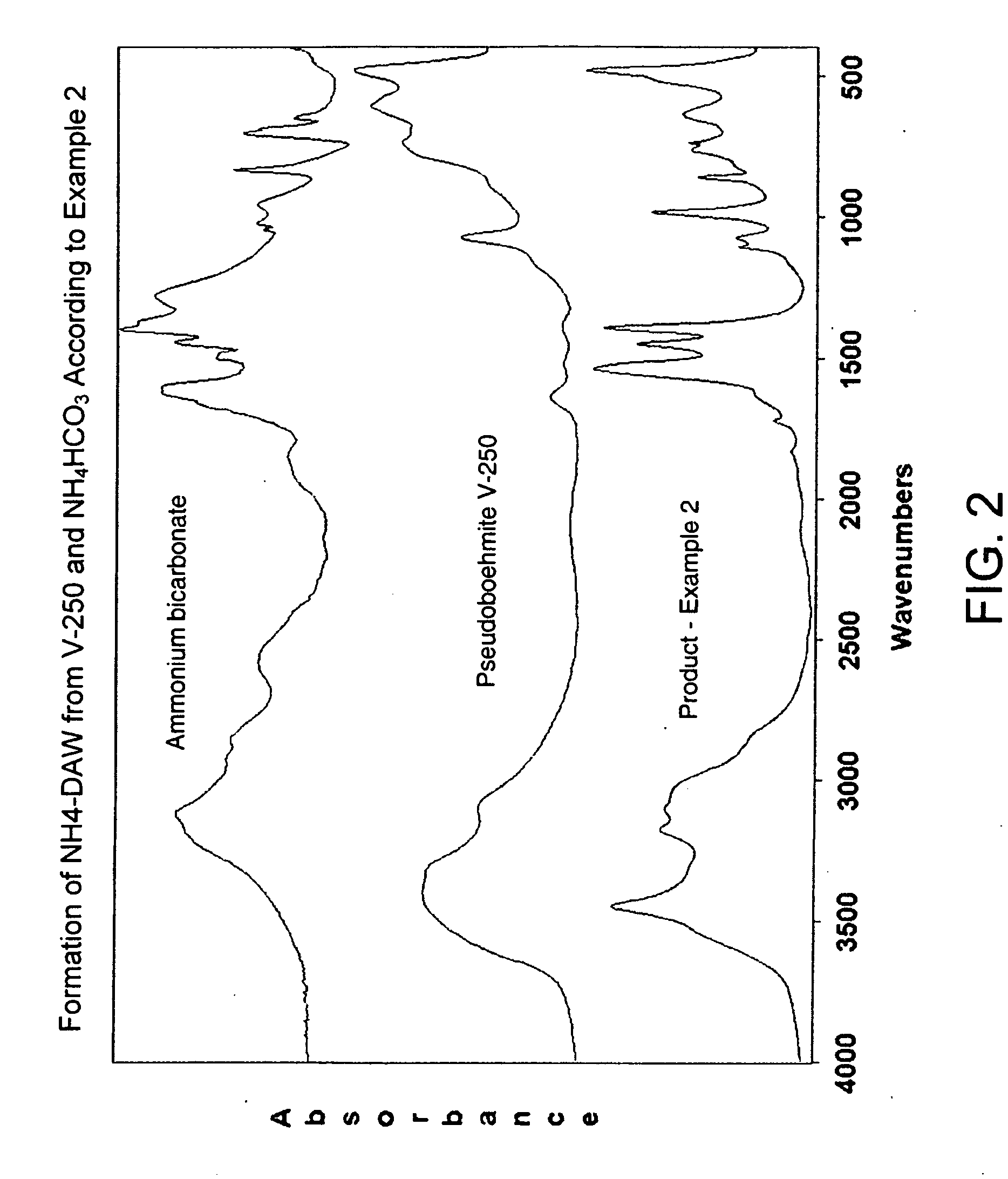

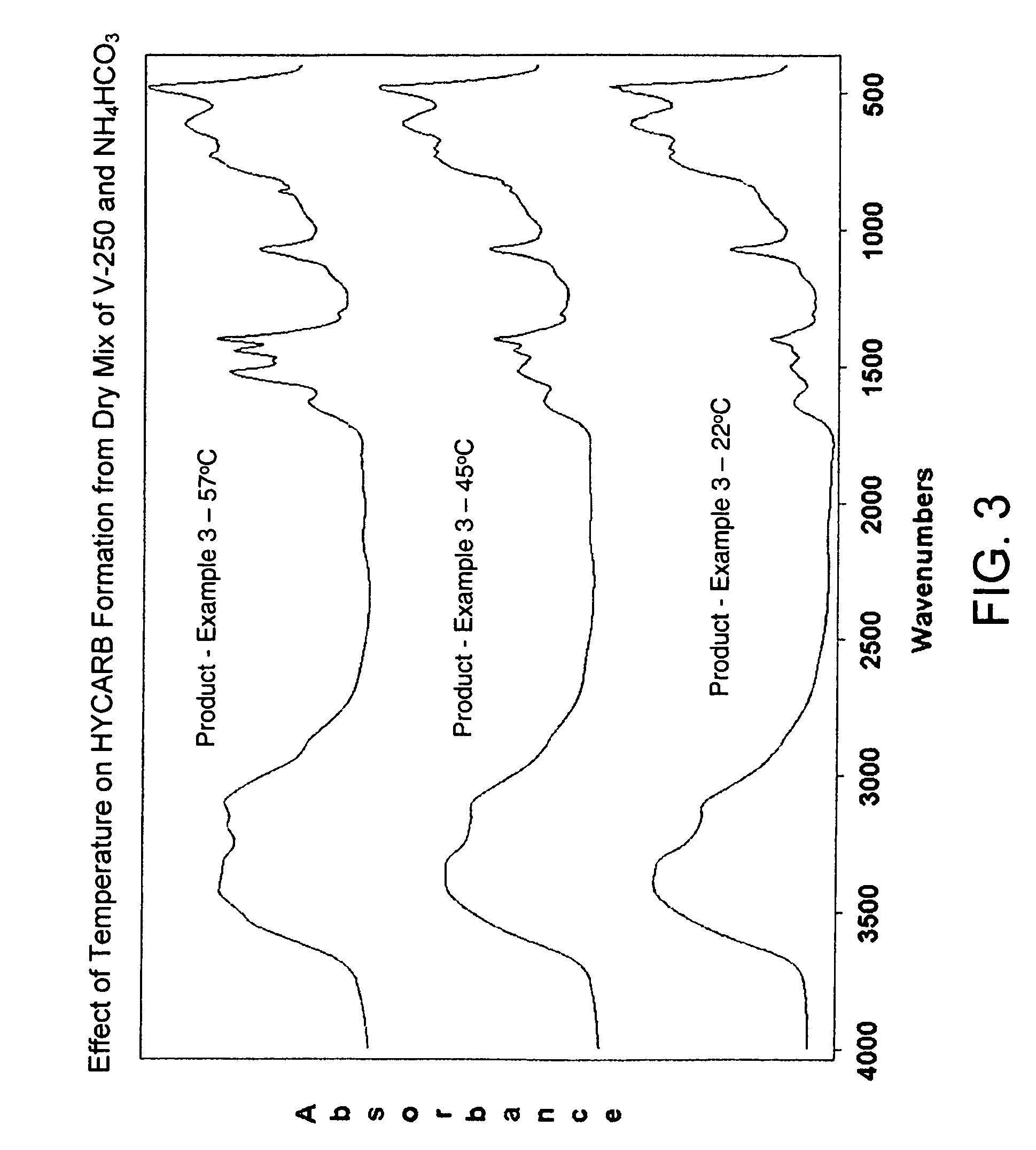

The present invention is a process for the conversion of aluminum oxide hydroxide (AlOOH) to aluminum oxide. About 30 to 70 wt-% of AlOOH, about 30 to 70 wt-% ammonium hydrogencarbonate NH4HCO3 and 0 to 20 wt-% water are combined to produce a mixture. This mixture is then cured at a temperature from about 30° to about 90° C. to convert at least 5% of the AlOOH to a ammonium hydroxycarbonate (dawsonite-type) intermediate and then the dawsonite-type intermediate is decomposed at a temperature from about 130° to 320° C. to produce aluminum oxide. The aluminum oxide can be further calcined at 500° to 800° C. to produce a gamma-theta phase alumina.

Owner:UOP LLC

Additives for preparing rheology-modified aqueous fluids

InactiveUS6906010B2Sure easyImprove responseFlushingDrilling compositionAluminum oxide hydroxidePotassium carbonate

A rheology modified aqueous fluid composition comprising clay, water, magnesium oxide, aluminum oxide hydroxide, sodium carbonate or potassium carbonate, and calcium oxide or calcium hydroxide. The magnesium oxide and aluminum oxide hydroxide are prepared by a specific thermal treatment protocol involving heating of appropriate precursors within a specified temperature range. The pH of the composition is at least about 10. The composition is prepared by admixing the components and, optionally, sodium oxide or sodium hydroxide for pH adjustment as necessary. A substantially dry rheology modification agent comprising the enumerated components, not including the water, is also included. The resulting composition preferably exhibits shear-thinning capability including very rapid thinning upon application of shear forces and also rapid viscosification upon removal of such forces.

Owner:PRINCE ENERGY

Flame-retardant thermoplastic polyurethane comprising coated metal hydroxides based on aluminum

The invention relates to a flame-retardant thermoplastic polyurethane based on at least one diisocyanate and on at least one substance reactive toward isocyanate, and preferably on at least one chain extender, and also optionally on at least one catalyst, and comprising at least one flame retardant, and also optionally additives and / or auxiliaries, where one flame retardant is a metal hydroxide at least to some extent surrounded by a coating, and the metal hydroxide is aluminum hydroxide, aluminum oxide hydroxide, or a mixture of said hydroxides, and also to an associated production process and use.

Owner:BASF AG

Flame-retardant thermoplastic polyurethane comprising coated metal hydroxides based on aluminum

The invention relates to a flame-retardant thermoplastic polyurethane based on at least one diisocyanate and on at least one substance reactive toward isocyanate, and preferably on at least one chain extender, and also optionally on at least one catalyst, and comprising at least one flame retardant, and also optionally additives and / or auxiliaries, where one flame retardant is a metal hydroxide at least to some extent surrounded by a coating, and the metal hydroxide is aluminum hydroxide, aluminum oxide hydroxide, or a mixture of said hydroxides, and also to an associated production process and use.

Owner:BASF SE

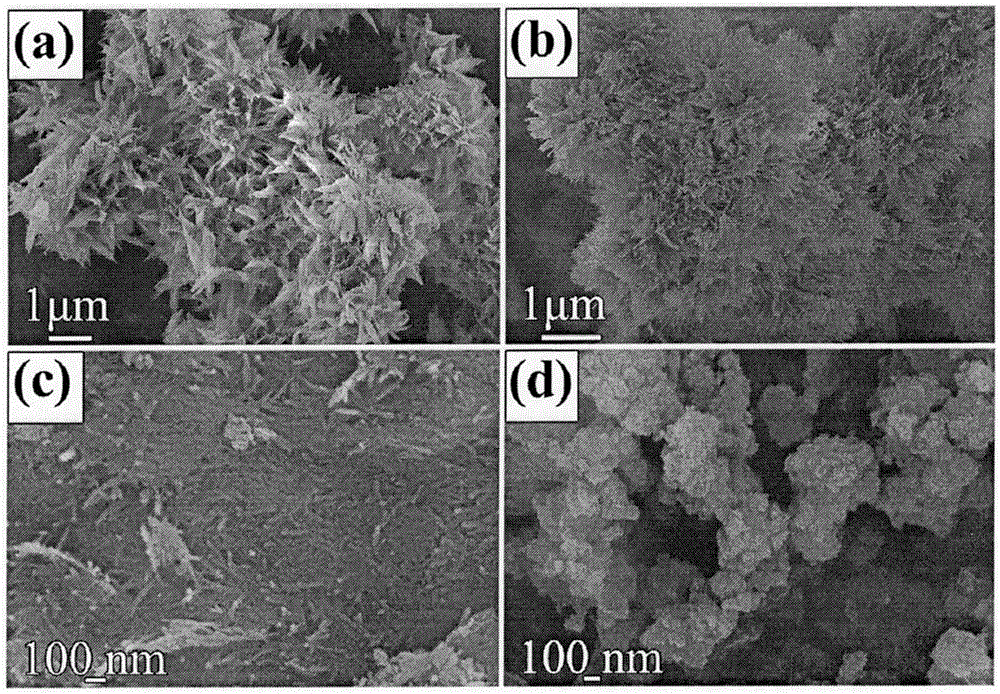

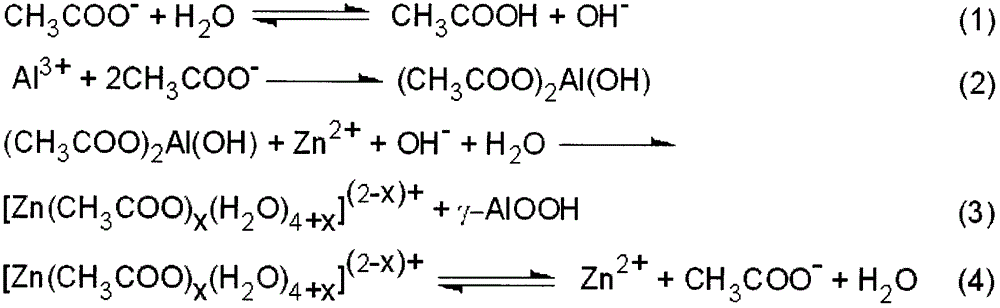

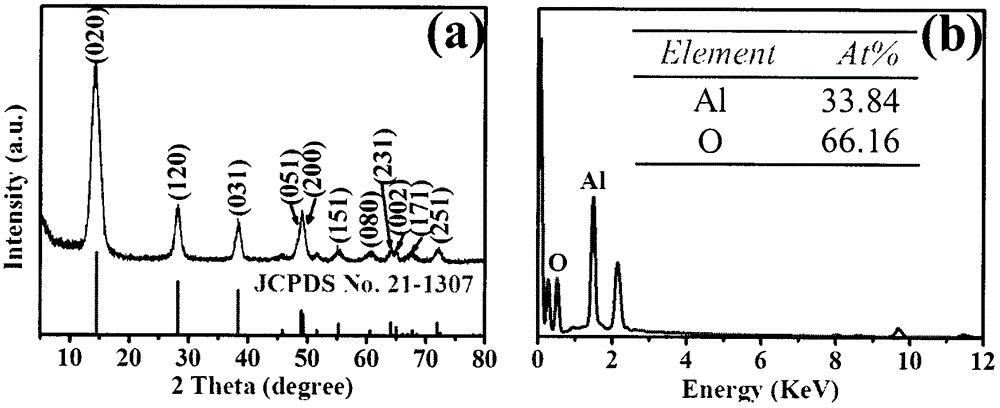

Preparation method of gamma-AlOOH and gamma-Al2O3 nanotube and nanostructure

InactiveCN105948087ALower the build temperatureReduce pressure requirementsMaterial nanotechnologyAluminium oxide/hydroxide preparationMuffle furnaceAluminium salts

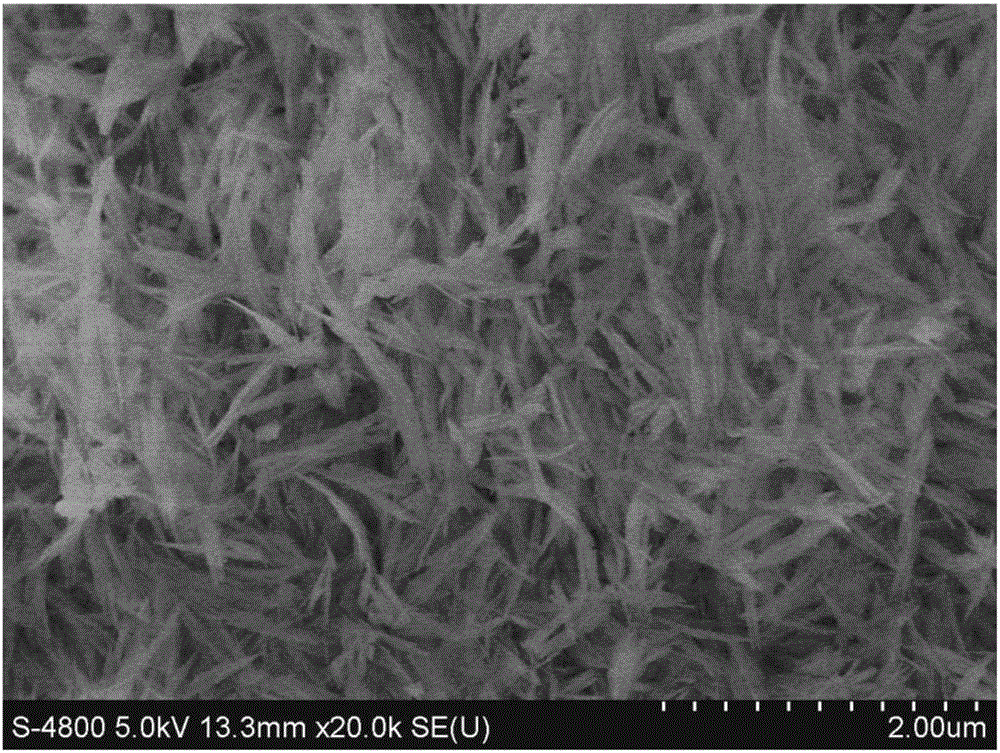

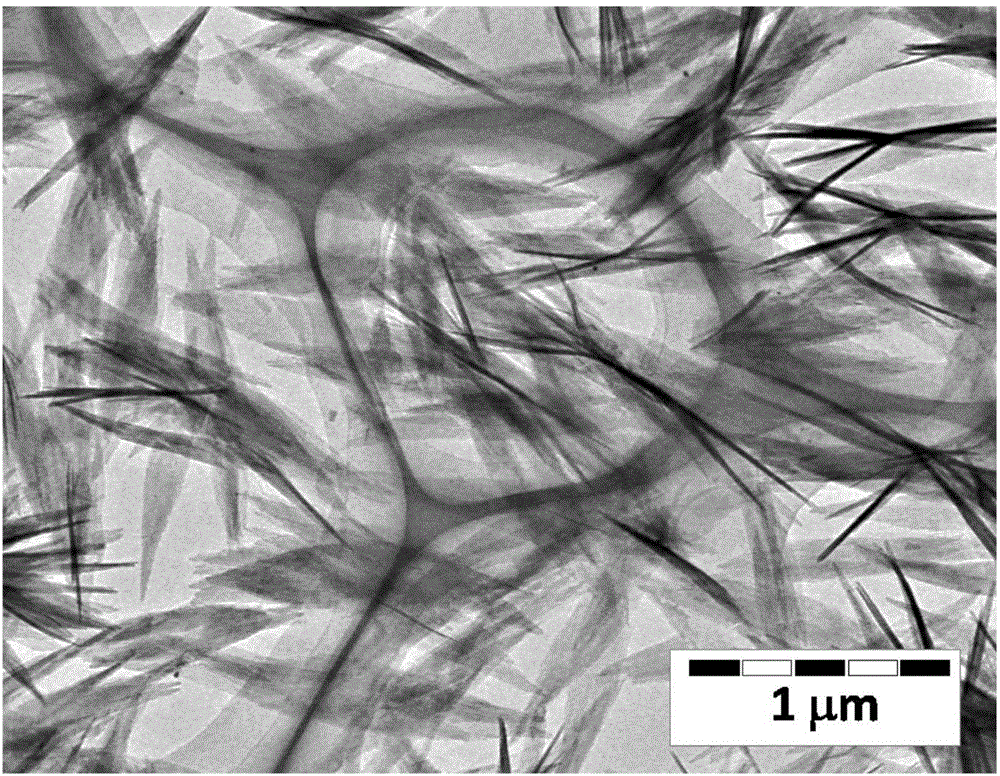

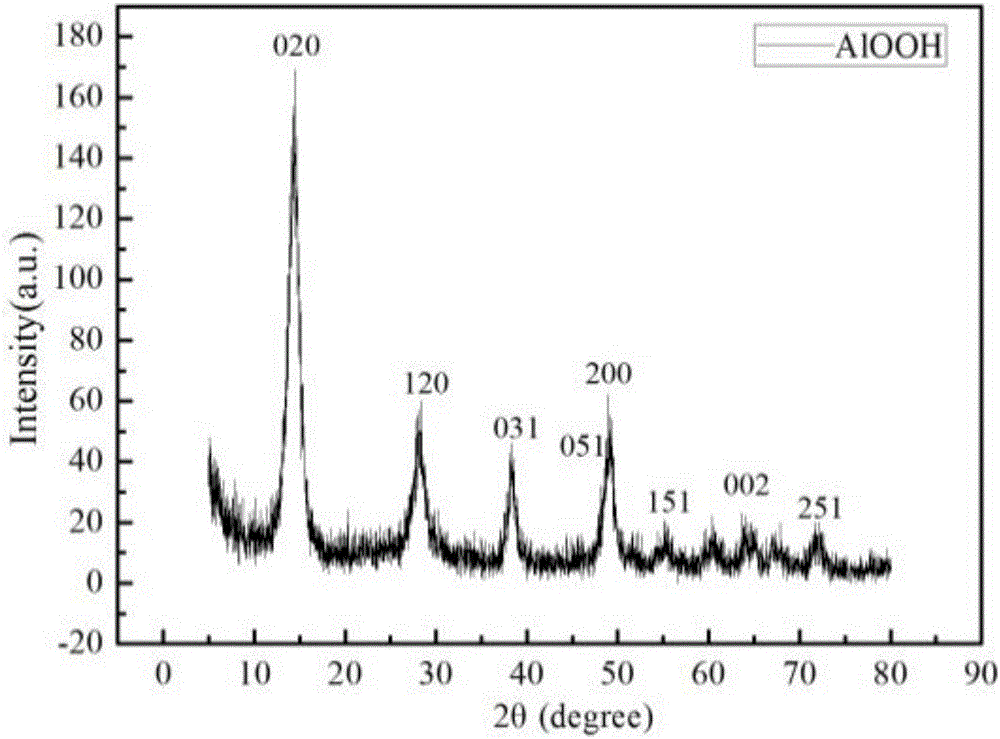

Disclosed is a method for preparing gamma-AlOOH and gamma-Al2O3 through ionic-liquid-assisted hydrothermal synthesis. The method is characterized in that divalent metal ions are utilized to drive a decomposition reaction of a precursor so as to generate gamma-AlOOH in a mild condition. The method comprises main steps: 1) dissolving aluminium salt, an ionic liquid and divalent metal ions in deionized water according to different ratios, and performing uniform stirring; 2) transferring the obtained solution to a reactor and performing a reaction at different reaction temperatures for a while; 3) after the reaction is over, performing cooling to the room temperature, performing centrifugalization, performing alternate washing with deionized water and absolute ethanol, and performing drying to obtain a precursor of gamma-AlOOH; and 4) putting the precursor of gamma-AlOOH in a muffle furnace, and carrying out calcination to obtain a gamma-Al2O3 nanometer material with the identical shape. According to the method, gamma-AlOOH in the shape of a needle-shaped crystal whisker, a nanotube, and a bamboo-leaf-shaped nanometer flower and gamma-Al2O3 converted from gamma-AlOOH are synthesized. The obtained gamma-Al2O3 is relatively high in degree of crystallinity and specific surface area and has comparatively high potential of large-scale production.

Owner:NANKAI UNIV

Calcium carbonate hydroxodialuminates comprising a hexagonal platelet-shaped crystal habit

InactiveUS7919066B2Improve water absorptionPigmenting treatmentOther chemical processesAluminum oxide hydroxideAluminium hydroxide

A process is provided for preparing calcium carbonate hydroxodialuminates which have a hexagonal platelet-shaped crystal habit and are of the formula (A):CamAl2(OH)6+2(m−1)An*nH2O (A)where m=3.5 to 4.5 and An=carbonate which may be partly replaced by perchlorate and / or trifluoromethanesulfonate (triflate) and n=0 to 6, comprising the steps of reacting calcium oxide or calcium hydroxide with optionally activated aluminum oxohydroxide or aluminum hydroxide and simultaneously or subsequently with a carbonate source consisting of carbon dioxide or alkali metal (bi)carbonate and optionally further reacting the product obtained in step (a) with perchloric acid and / or trifluoromethanesulfonic acid or optionally calcining the product obtained in step (a) at 200° C. to 900° C. and subsequently exchanging ions in the presence of a perchlorate and / or triflate salt, optionally in the presence of alkali metal (bi)carbonate, in water. The present invention further relates to the aluminates thus obtained in compositions and stabilizer systems and to the use thereof.

Owner:NABALTEC AG

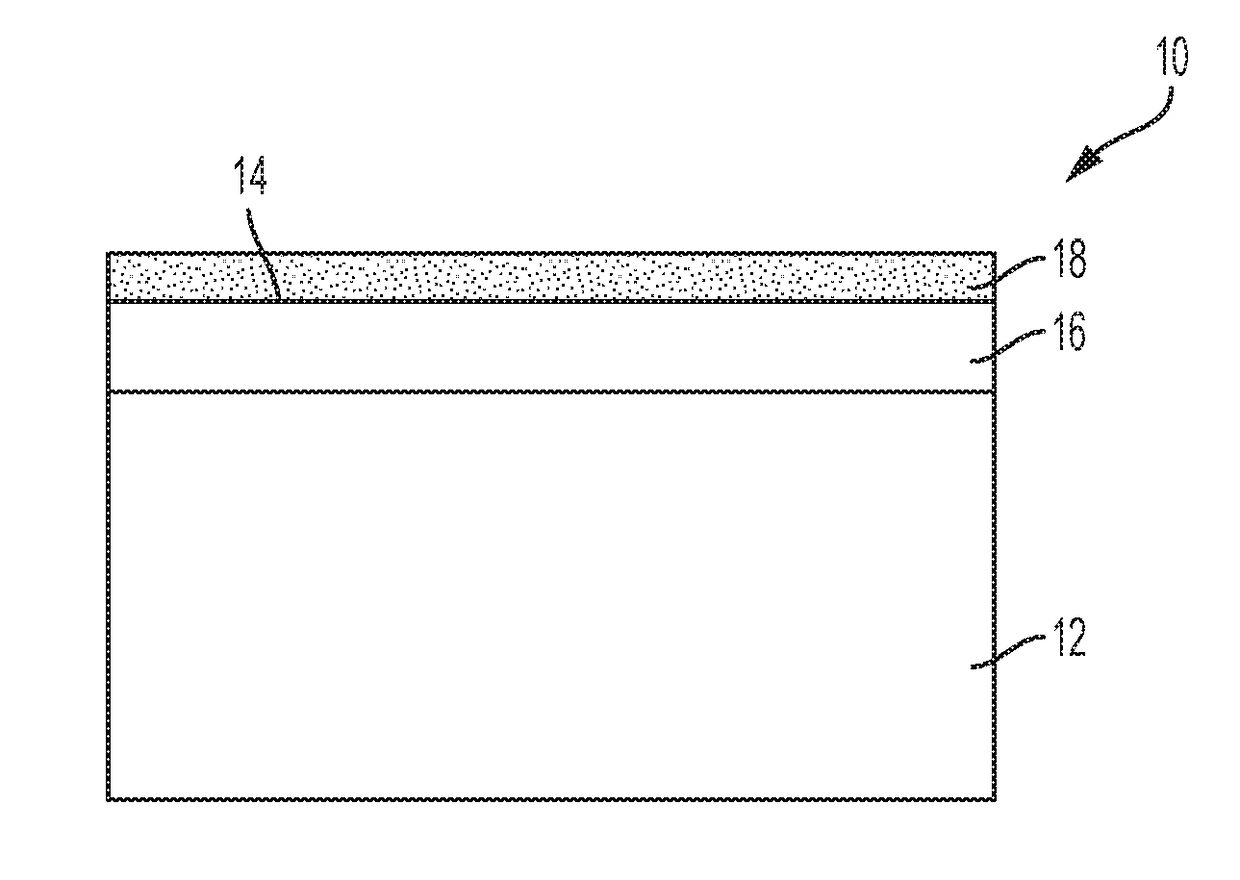

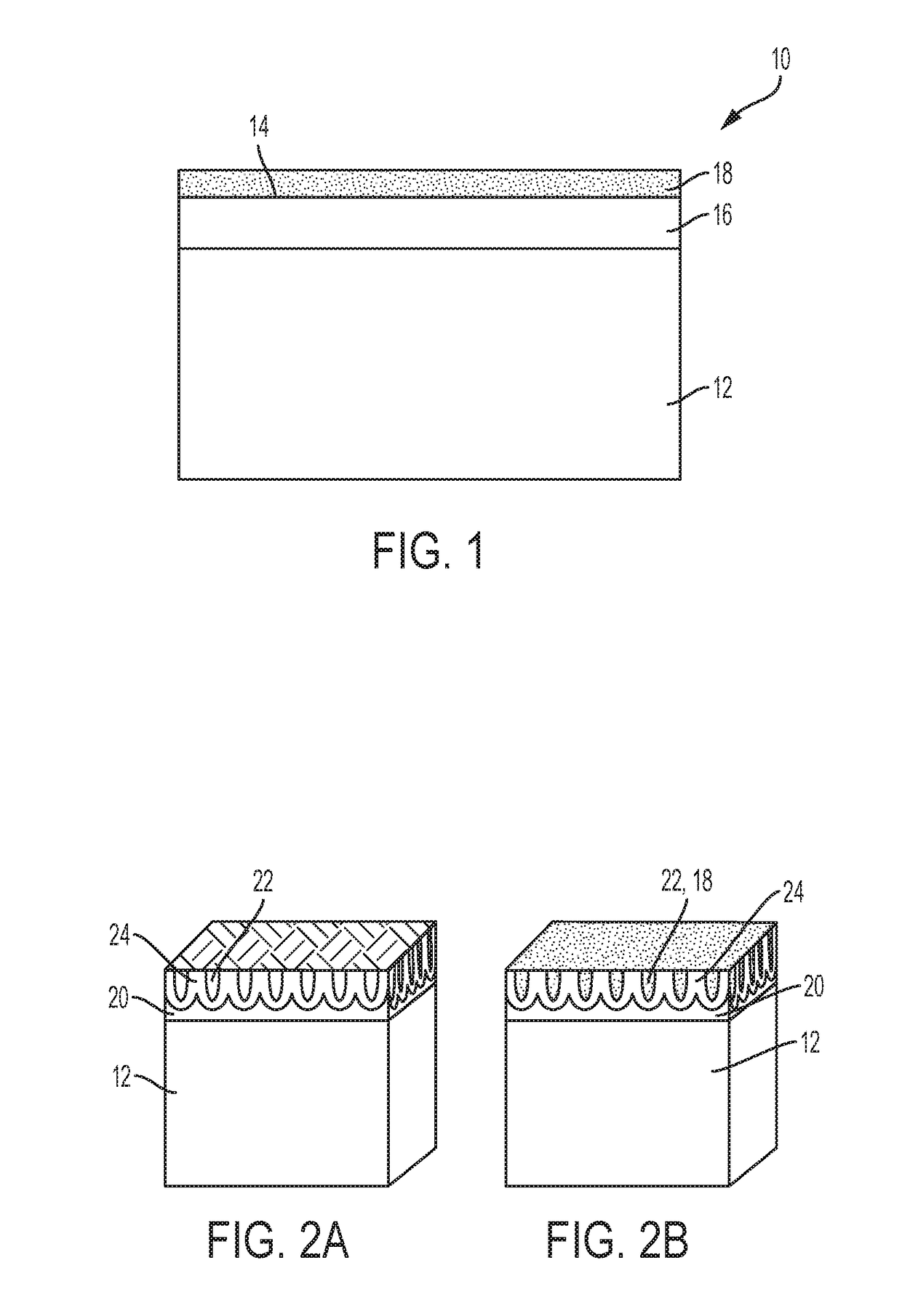

Treated anodized metal article and method of making

A method is disclosed for treating an anodized metal surface. According to the method, polynuclear clusters comprising aluminum oxide hydroxide are applied to the anodized metal surface.

Owner:HAMILTON SUNDSTRAND CORP

Process for conversion of aluminum oxide hydroxide

ActiveUS7947250B2Aluminium oxide/hydroxide preparationAluminium-carbonate compoundsAluminium hydroxideAluminum oxide hydroxide

The present invention is a process for the conversion of aluminum oxide hydroxide (AlOOH) to aluminum oxide. About 30 to 70 wt-% of AlOOH, about 30 to 70 wt-% ammonium hydrogencarbonate NH4HCO3 and 0 to 20 wt-% water are combined to produce a mixture. This mixture is then cured at a temperature from about 30° to about 90° C. to convert at least 5% of the AlOOH to a ammonium hydroxycarbonate (dawsonite-type) intermediate and then the dawsonite-type intermediate is decomposed at a temperature from about 130° to 320° C. to produce aluminum oxide. The aluminum oxide can be further calcined at 500° to 800° C. to produce a gamma-theta phase alumina.

Owner:UOP LLC

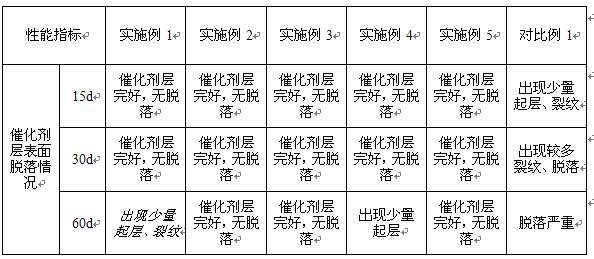

Method for preparing fuel cell membrane electrode through inorganic in-situ bonding

ActiveCN112271301AGood effectHigh bonding strengthCell electrodesFuel cellsPtru catalystCarbon fibers

The invention provides a method for preparing a fuel cell membrane electrode through inorganic in-situ bonding. Carbon fiber paper is coated with carbon powder slurry prepared from carbon powder, urea, silicon dioxide aerogel and an adhesive, a gas diffusion layer is prepared, then a carbon-carrying interface of the gas diffusion layer is coated with catalyst slurry prepared from a catalyst, sodium hydroxide, a thickening agent, water and a Nafion solution, and the carbon-carrying interface of the gas diffusion layer is coated with carbon powder slurry prepared from carbon powder, urea, silicon dioxide aerogel and an adhesive. And then laminating and hot-pressing are performed on the upper surface and the lower surface of the proton exchange membrane which is mixed and coated with aluminumoxyhydroxide and a Nafion solution to obtain the fuel cell membrane electrode. According to the method, the silicon dioxide aerogel and the silicon dioxide in-situ firm bonding catalyst are added into the carbon loading layer to prevent falling off, meanwhile, aluminum hydroxide bonding is formed in situ on the surface of the proton exchange membrane and the catalyst layer, the bonding strength of the catalyst layer and the proton exchange membrane is high, the prepared membrane electrode adopts inorganic in-situ bonding, micropores are well reserved, Adhesion is firm, and degradation causedby the influence of the wet environment is avoided.

Owner:山东汉德自动化控制设备有限公司

Calcium carbonate hydroxodialuminates comprising a hexagonal platelet-shaped crystal habit

InactiveUS20090292052A1Improve water absorptionPigmenting treatmentOther chemical processesAluminateAluminium hydroxide

A process is provided for preparing calcium carbonate hydroxodialuminates which have a hexagonal platelet-shaped crystal habit and are of the formula (A):CamAl2(OH)6+2(m−1)An*nH2O (A)where m=3.5 to 4.5 and An=carbonate which may be partly replaced by perchlorate and / or trifluoromethanesulfonate (triflate) and n=0 to 6, comprising the steps of reacting calcium oxide or calcium hydroxide with optionally activated aluminum oxohydroxide or aluminum hydroxide and simultaneously or subsequently with a carbonate source consisting of carbon dioxide or alkali metal (bi)carbonate and optionally further reacting the product obtained in step (a) with perchloric acid and / or trifluoromethanesulfonic acid or optionally calcining the product obtained in step (a) at 200° C. to 900° C. and subsequently exchanging ions in the presence of a perchlorate and / or triflate salt, optionally in the presence of alkali metal (bi)carbonate, in water. The present invention further relates to the aluminates thus obtained in compositions and stabilizer systems and to the use thereof.

Owner:NABALTEC AG

Preparation method of aluminum hydroxide adjuvant

PendingCN113559255AGood lookingUniform responseAluminium hydroxide preparationAntibody medical ingredientsAluminium chlorideParticulate (substance)

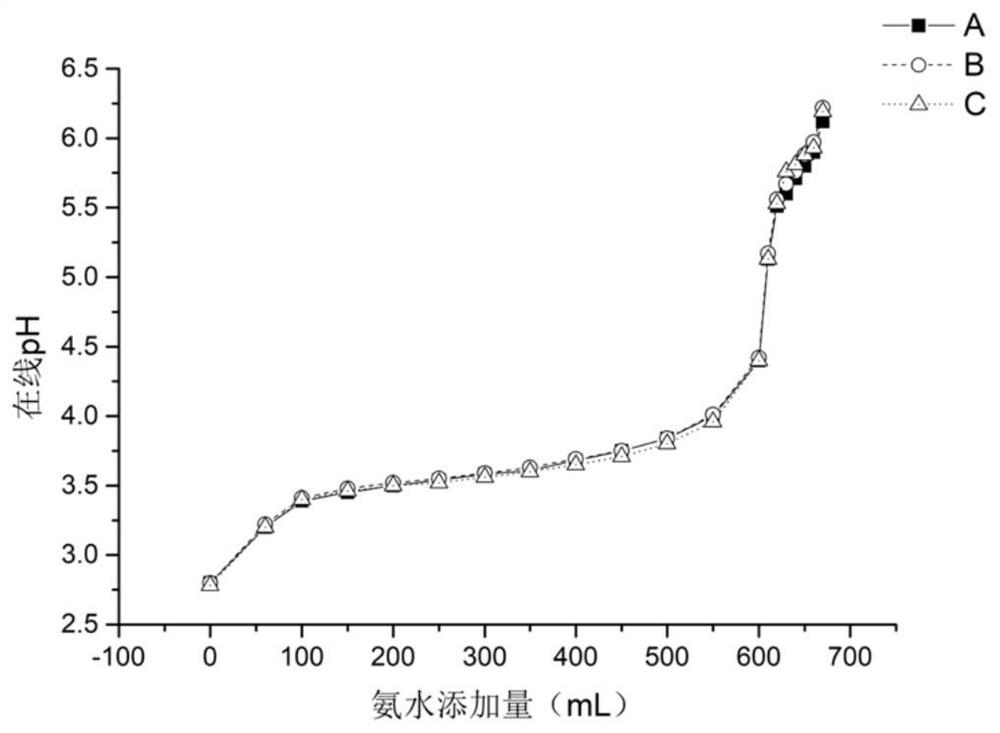

The invention discloses a preparation method of an aluminum hydroxide adjuvant. The preparation method comprises the step of: adding ammonia water into an aluminum trichloride solution in a spray form until the pH value of the solution is 6.4-6.8. According to the method for preparing the aluminum hydroxide adjuvant, which is disclosed by the invention, the ammonia water is added into the aluminum trichloride solution in a spray form, so that the reaction of the ammonia water and the aluminum trichloride is more uniform, and the formed non-hydroxyl aluminum oxide large-particle substances are obviously reduced; meanwhile, the ammonia water and the aluminum trichloride solution fully react with each other by controlling the terminal point online pH of the adjuvant to be 6.4-6.8; and the consistency of important quality indexes such as appearance, pH, particle size and the like of the aluminum hydroxide adjuvant prepared after the dialysis high pressure operation is better than that of an adjuvant in the prior art.

Owner:CHENGDU INST OF BIOLOGICAL PROD

Preparation method of resin matrix composite material toughened by nano-scale aluminum oxide hydroxide sheet material

ActiveCN106366575AAchieve tougheningImprove interlaminar fracture toughnessCarbon fibersAluminum oxide hydroxide

The invention discloses a preparation method of a resin matrix composite material toughened by a nano-scale aluminum oxide hydroxide sheet material, and belongs to the technical field of high performance of composite materials. The method comprises the steps that aluminum nitrate powder, carbamide powder and deionized water are mixed, stirred and transferred into an oil bath, and a mixing solution is obtained; sealing is performed under the temperature of 160 DEG C for 24 h, and a paste is obtained; the paste is washed and filtered in a decompression mode till a filtrate is neutral, and a filter cake is obtained; ethyl alcohol is used for washing, and finally the obtained filter cake is dispersed into ethyl alcohol again for use; dried nano-scale aluminum oxide hydroxide sheet powder m-phenylenediamine crystals are placed into an acetone solvent, and a mixed solvent is obtained; the mixed solvent is added into epoxy resin, and uniform stirring is performed to obtain a glue solution containing the nano-scale aluminum oxide hydroxide sheet material. The nano-scale aluminum oxide hydroxide sheet material is prepared through the simple and low-cost method, the nanometer material is added into the carbon fiber / epoxy composite material, the composite material is toughened, and the interlaminar fracture toughness of the composite material is greatly improved.

Owner:DALIAN UNIV OF TECH

Morphology-controllable hollow aluminum oxide microspheres as well as preparation method and application thereof

InactiveCN111484056AShape is easy to controlLarge specific surface areaWater/sewage treatmentAluminium hydroxide preparationMicrosphereFreeze-drying

The invention discloses morphology-controllable hollow aluminum oxide microspheres as well as a preparation method and application thereof, and belongs to the technical field of inorganic synthetic materials. The preparation comprises the following steps: adding soluble aluminum salt, urea and a dispersing agent into a medium, wherein the used soluble aluminum salt is Al2(SO4)3, Al(NO3)3, AlCl3 and the like; and carrying out hydrothermal treatment to obtain a hydroxyl alumina precursor, and washing, freeze-drying and calcining the precursor to obtain the hollow Al2O3 microspheres. By adoptingthe scheme, the morphology-controllable hollow aluminum oxide microspheres can be obtained, and the obtained product can be applied to the fields of soil remediation, sewage treatment, cosmetics, coatings and the like.

Owner:HENAN UNIVERSITY +1

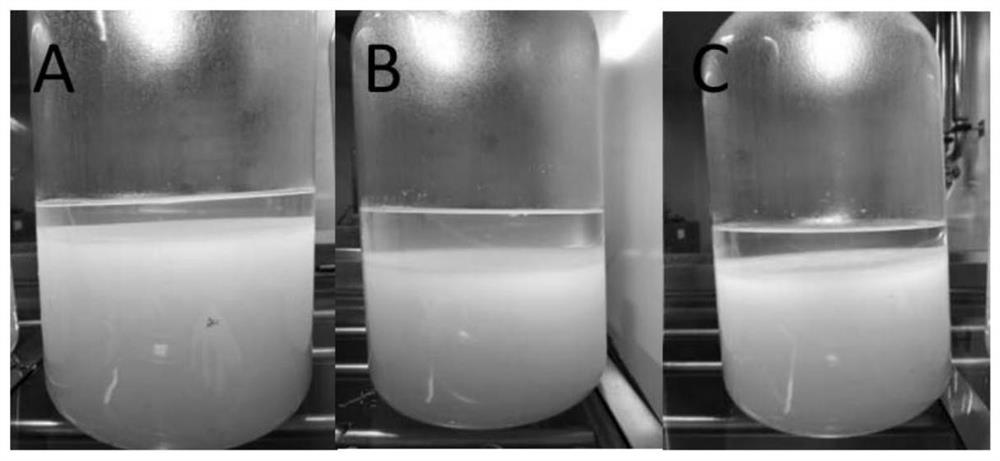

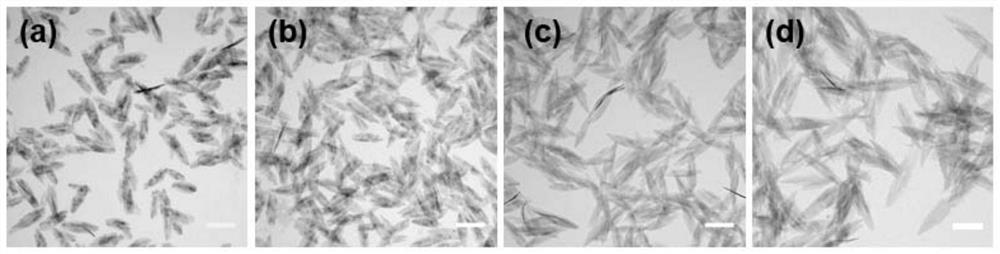

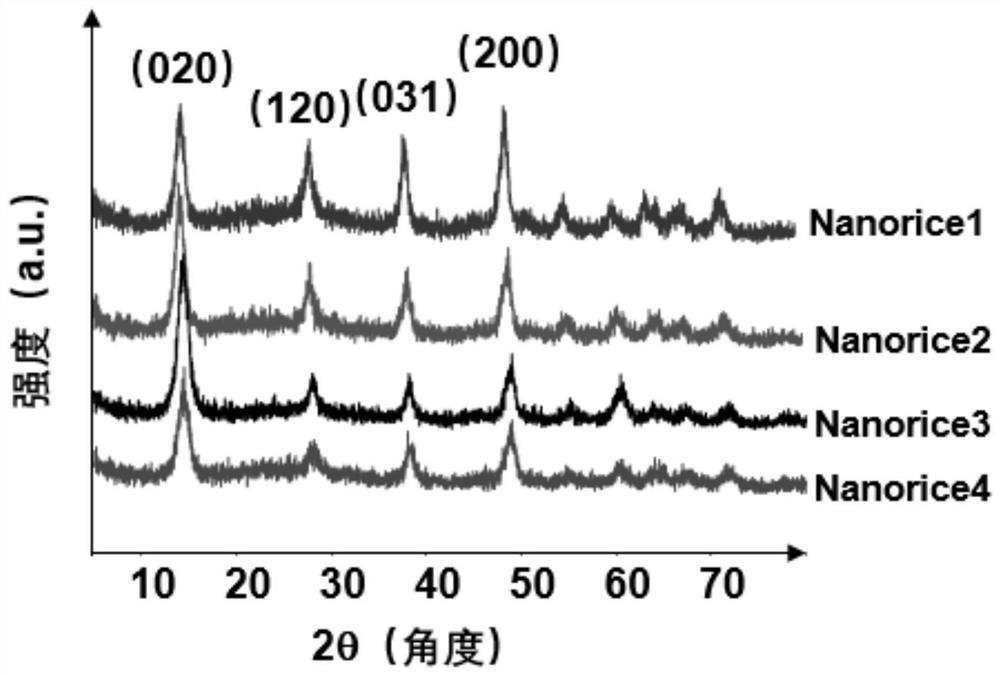

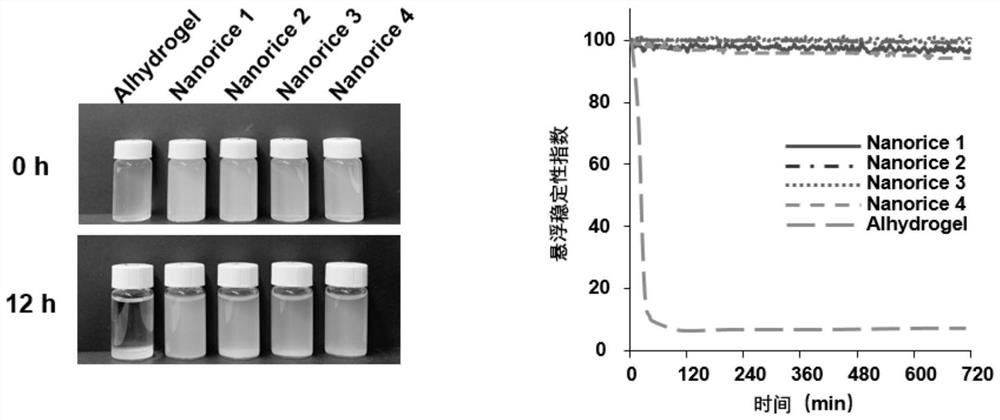

Preparation method of rice-grain-shaped hydroxyl alumina nano adjuvant with good suspension stability

PendingCN113648408AImprove homogeneityImproving immunogenicityNanomedicineAluminium hydroxide preparationAdjuvantAluminum oxide hydroxide

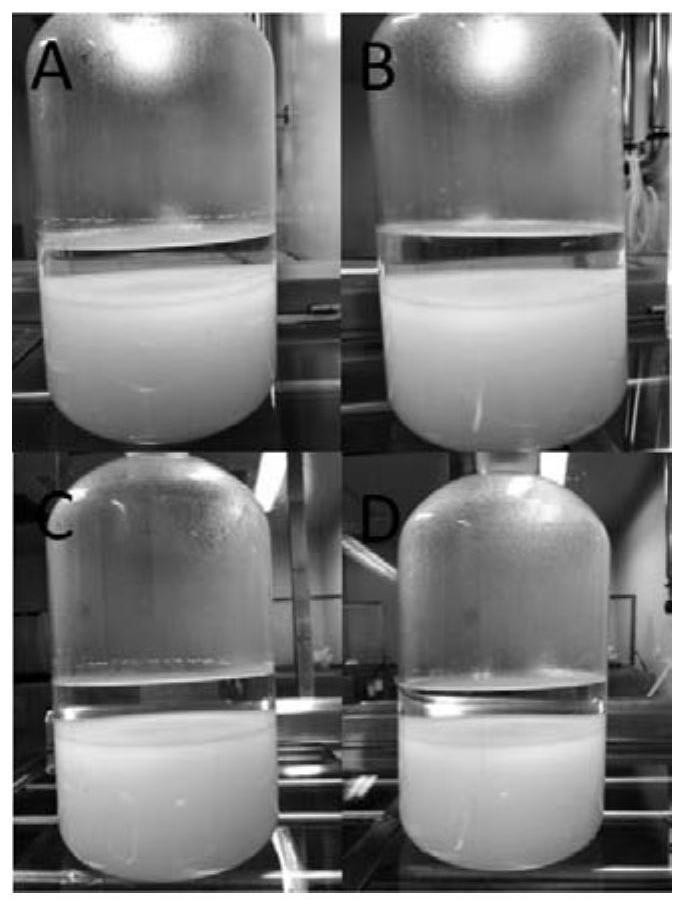

The invention discloses a preparation method of a rice-grain-shaped hydroxyl alumina nano-material with good suspension stability, the method uses a mixed solution of inorganic aluminum salt and urea as a reactant, a nano-sized hydroxyl alumina adjuvant is prepared through a hydrothermal method, and the prepared hydroxyl alumina adjuvant nano-material has the advantages of uniform morphology, uniform dispersion, and good homogeneity and immunogenicity. Compared with the existing commercial hydroxyl aluminum oxide adjuvant, the rice-grain-shaped hydroxyl aluminum oxide adjuvant has outstanding and excellent suspension stability, and has a good prospect in vaccine preparation, production and application.

Owner:DALIAN UNIV OF TECH

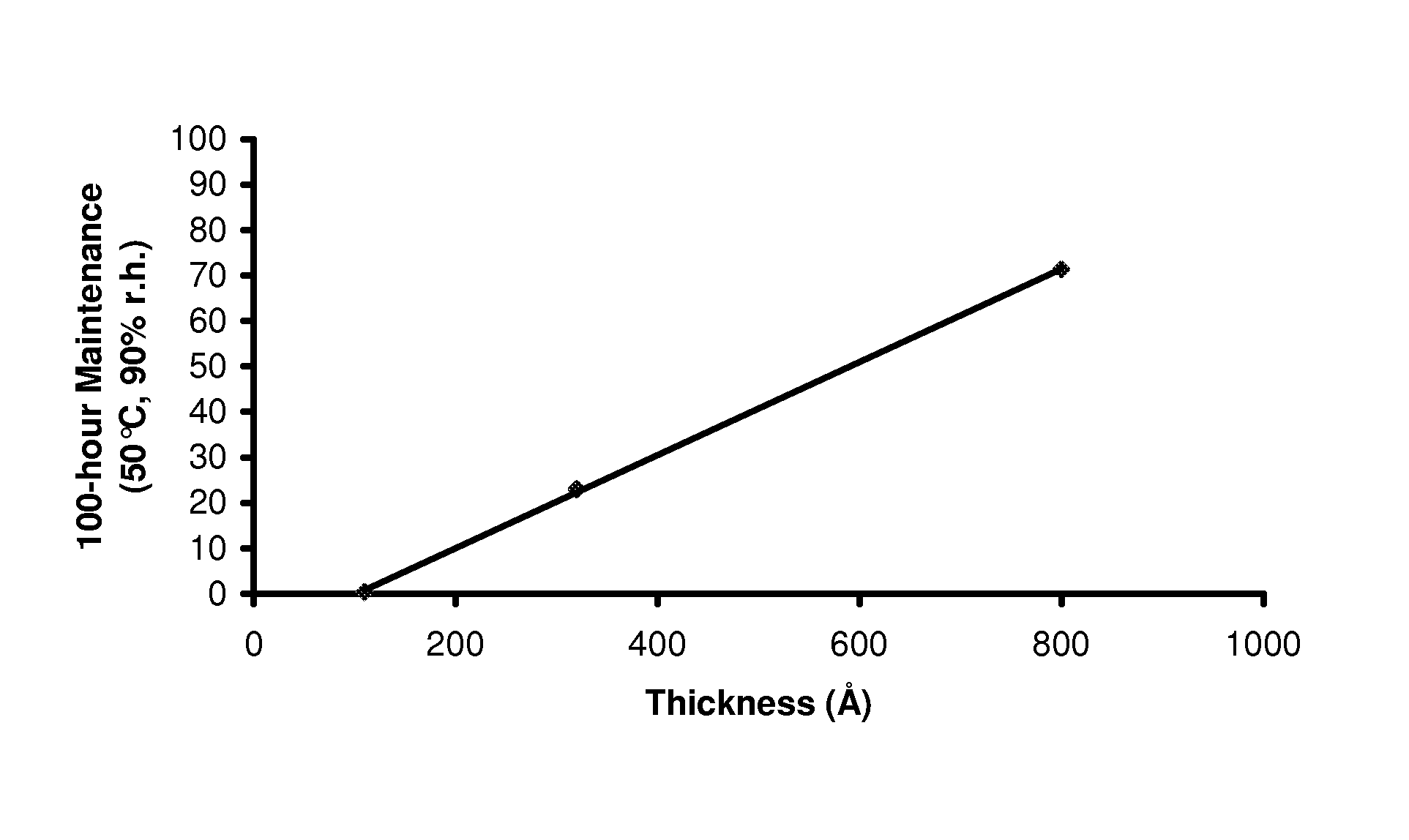

Method to encapsulate phosphor via chemical vapor deposition

InactiveUS20070160753A1Liquid surface applicatorsDischarge tube luminescnet screensAluminateGas phase

The maintenance characteristics of the phosphors used in VUV-excited devices such as plasma display panels can be improved by applying a coating of an aluminum oxyhydroxide compound by reacting vaporized trimethylaluminum with water vapor at a temperature of about 430° C. or above. In particular, the maintenance of an europium-activated, calcium-substituted barium hexa-aluminate phosphor is significantly improved following exposure to a high intensity VUV flux.

Owner:OSRAM SYLVANIA INC

Preparation method of surface-energy-controllable aluminum hydroxide nano adjuvant

PendingCN114028556AWell mixedStable pHSsRNA viruses positive-senseViral antigen ingredientsImmune effectsAdjuvant

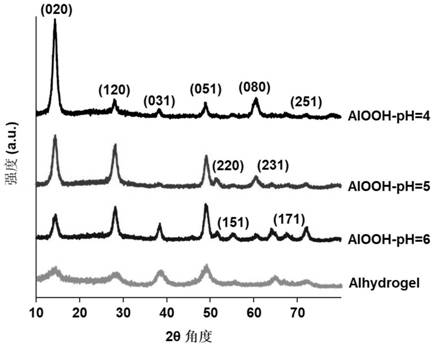

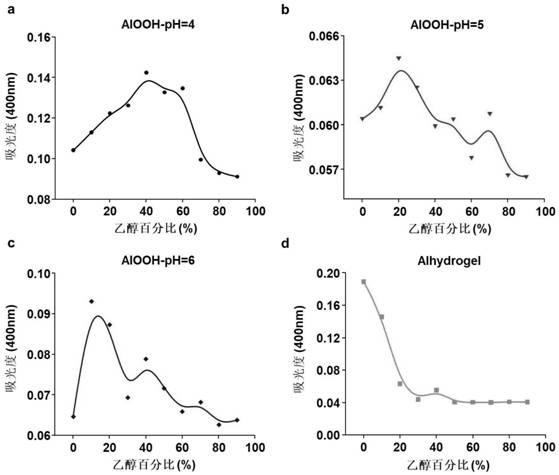

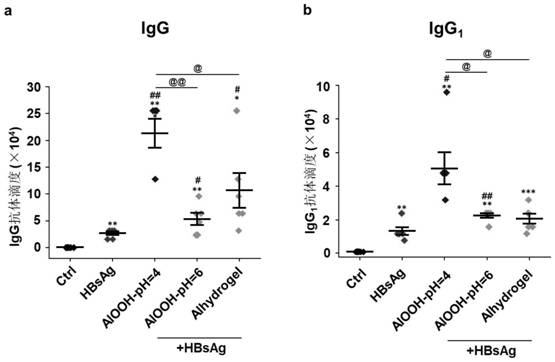

The invention relates to the field of biological medicine, and particularly discloses a preparation method of a surface-energy-controllable aluminum hydroxide nano adjuvant. The method is based on a hydrothermal synthesis method, the specific orientation of crystal growth is controlled by changing the pH value of a precipitation system, and finally the purpose of controlling the surface free energy of the AlOOH nano material is achieved. The method is simple to operate, raw materials are low in price, and reaction products are good in stability and repeatability. The prepared hydroxyl alumina nano material is uniform in morphology and dispersion, and has a good prospect in vaccine preparation and production. Besides, the vaccine preparation formula based on the AlOOH adjuvant and the immune effect verification method provided by the invention are simple and high in operability, and a good strategy is provided for engineering development and further clinical transformation of the vaccine preparation.

Owner:DALIAN UNIV OF TECH

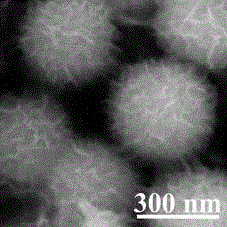

Sea urchin-shaped aluminum oxyhydroxide ball and preparation method thereof

InactiveCN104445318BNoveltyImprove adsorption capacityMaterial nanotechnologyAluminium oxides/hydroxidesPtru catalystAluminum oxide hydroxide

The invention discloses a sea urchin-shaped aluminum oxyhydroxide ball and a preparation method thereof. The surface of the aluminum oxyhydroxide ball has a fluffy structure and the appearance is a sea urchin. The preparation includes the following steps: taking a mixed solution of water and alcohol, and dropping Mercapto carboxylic acid inducer, stir to obtain a uniform solution, add aluminum salt to the uniform solution, stir evenly to obtain an emulsion; heat the emulsion to react to prepare aluminum oxyhydroxide; after the reaction, centrifuge and wash the reaction solution, Sea urchin-shaped alumina oxyhydroxide balls were obtained. The invention adopts a simple one-step solvothermal method to prepare sea urchin-shaped aluminum oxyhydroxide balls with a particle size of less than 1 micron. The preparation process is simple, and the prepared product has a novel appearance and a high surface area, because a high specific surface corresponds to a high reactivity , so it is beneficial to adsorb heavy metal ions in pollutants or be used to catalyze the degradation of organic matter, so it has broad application prospects in the fields of adsorbents and catalysts.

Owner:UNIV OF JINAN

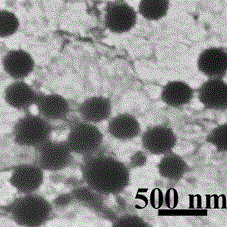

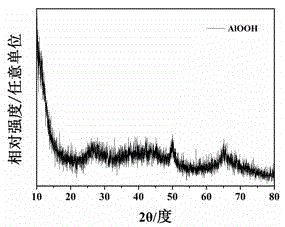

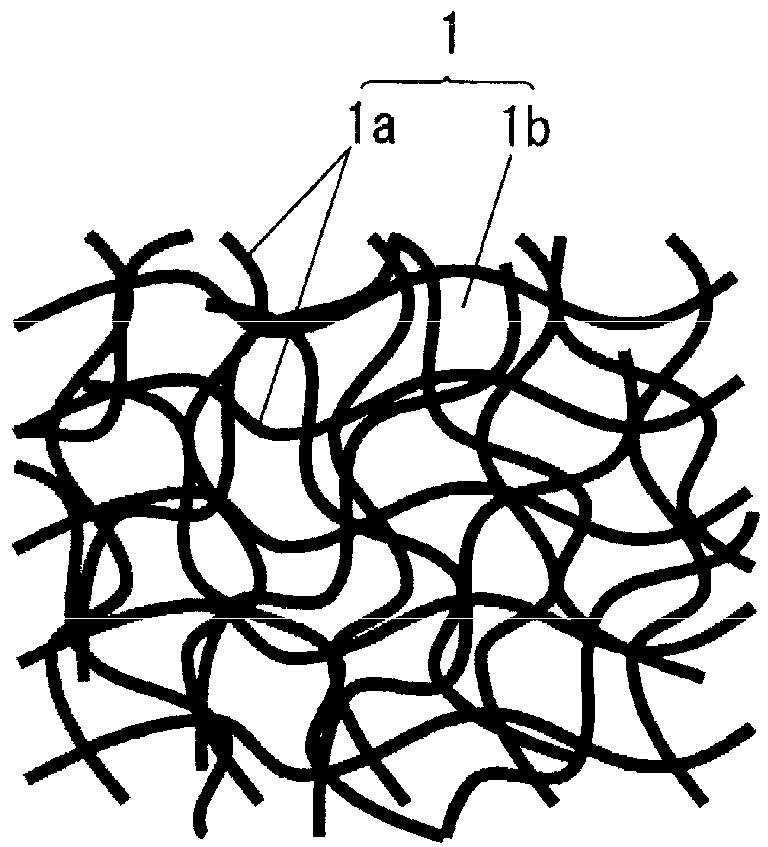

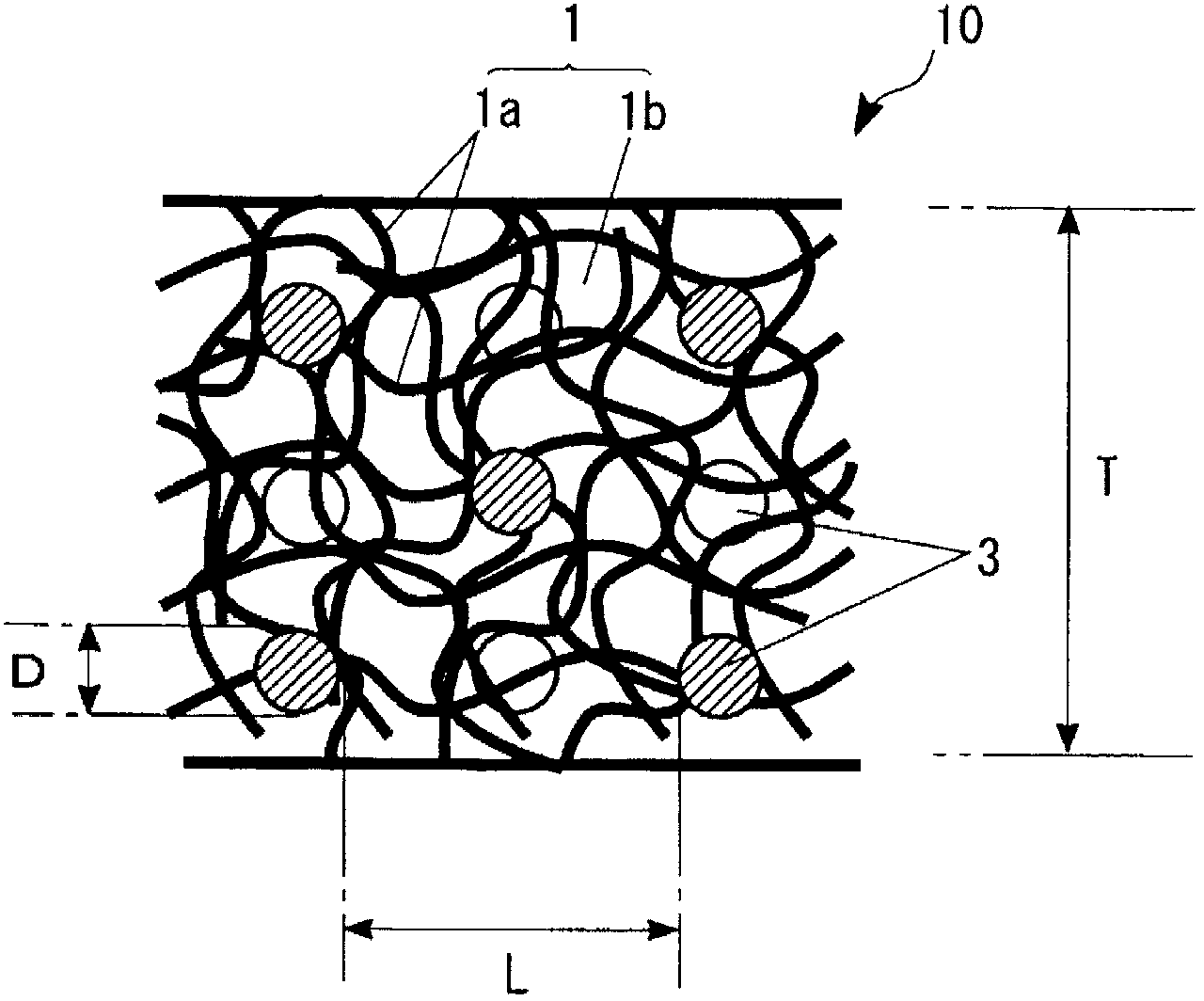

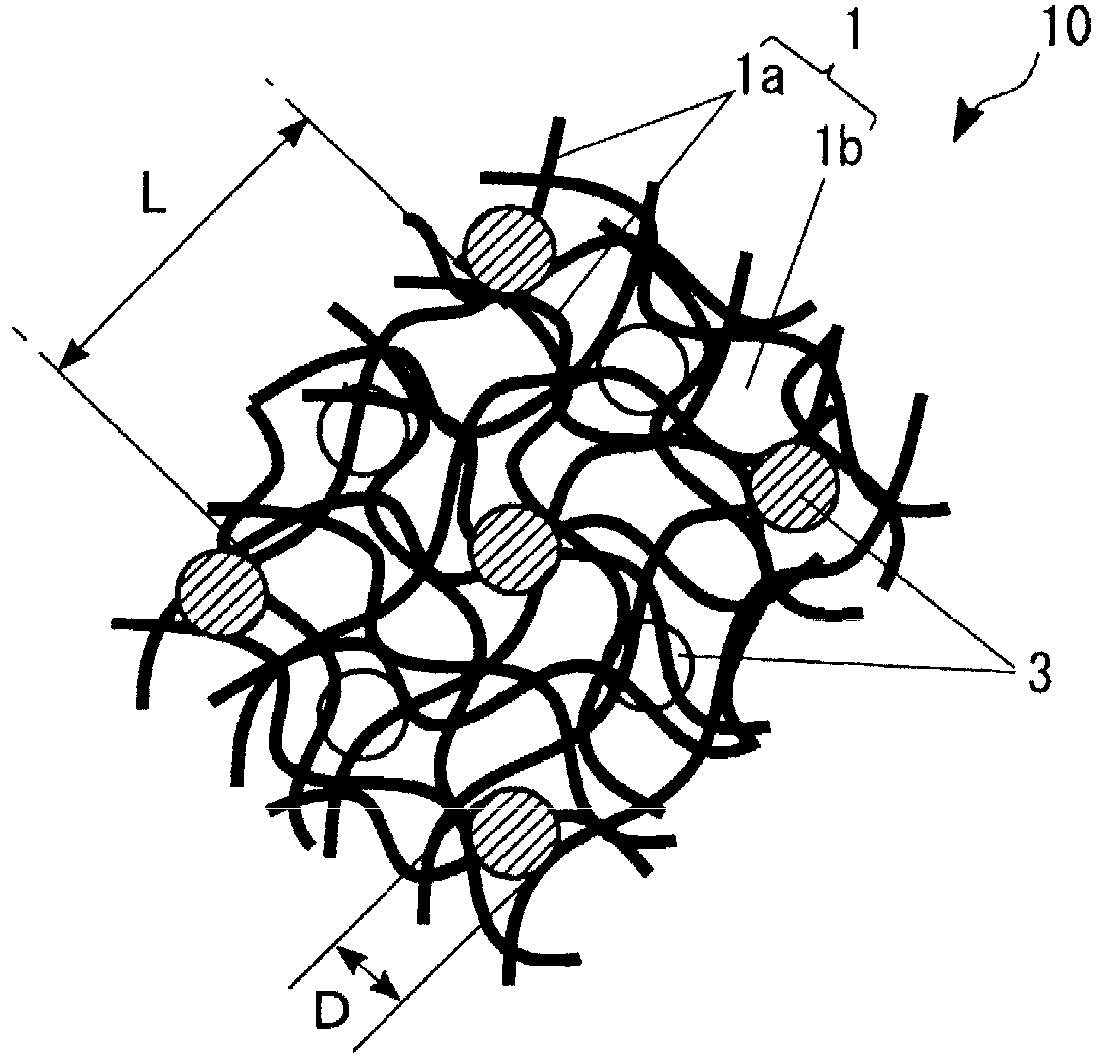

Composite having metal microparticles dispersed therein and process for production thereof, and substrate capable of generating localized surface plasmon resonance

InactiveCN103348234AIncrease the intensity of the absorption spectrumEvenly dispersedMaterial nanotechnologyColor/spectral properties measurementsAlumina hydrateAluminum oxide hydroxide

A nanocomposite (10) comprises: a matrix layer (1) which comprises solid backbone parts (1a) and voids (1b) formed by the solid backbone parts (1a); and metal microparticles (3) which are fixed on the solid backbone parts (1a) of the matrix layer (1). The solid backbone parts (1a) comprise an aluminum oxyhydroxide or an alumina hydrate and form a three-dimensional network structure. In the metal microparticles (3), metal microparticles having an average particle diameter falling within the range of 3-100 nm and particle diameters falling within the range of 1-100 nm make up 60% or more of the metal microparticles (3). The metal microparticles (3) exist in such a manner that the metal microparticles (3) are not in contact with one another and any two adjacent metal microparticles (3) are apart from each other by a distance that is equal to or greater than the particle diameter (D L ) of one of the two adjacent metal microparticles (3) which has a larger particle diameter (D) than that of the other one. Each of the metal microparticles (3) has a part that is exposed to the voids (1b) of the matrix layer (1), and the metal microparticles (3) exist in a state dispersed three-dimensionally in the matrix layer (1).

Owner:NIPPON STEEL CHEMICAL CO LTD

Diatomite-based hierarchical porous composite humidity-controlling material and preparation method thereof

PendingCN112774622AImproved humidity controlReduce manufacturing costOther chemical processesSilicon compoundsAluminium chlorideOXALIC ACID DIHYDRATE

The invention relates to a diatomite-based hierarchical porous composite humidity-controlling material and a preparation method thereof, diatomite is used as a silicon source and a carrier, a partial alkali dissolution-hydrothermal forming method is adopted, the diatomite and sodium hydroxide are subjected to alkali dissolution for 10-40 min at the temperature of 50-80 DEG C according to the mass ratio of 1.5-3.5, and mixed ore pulp of sodium silicate and diatomite is prepared; and an oxalic acid solution with the mass fraction of 30%-60% and low corrosivity is added into the mixed ore pulp, acidification is carried out to generate white carbon black, crystalline aluminum chloride and sodium hydroxide are added according to the molar ratio of 1: 3-1: 1, aging is carried out for 30-150 minutes, uniformly stirring is carried out, a mixture is transferred into a reaction kettle, hydrothermal reaction is carried out for 6-12 hours at the temperature of 100-150 DEG C, and then filtering, washing and drying are carried out. The main components of the material are amorphous silicon dioxide and hydroxyl aluminum oxide; the nitrogen adsorption specific surface area is 110 m < 2 > / g, the pore volume is 0.15 cm < 3 > / g, and the average pore size is 10-40 nm; under the environment temperature of 10-30 DEG C and the relative humidity of 95% and 85%, the maximum moisture absorption capacities respectively reach 25% and 20% or above; and under the environment temperature of 10-30 DEG C and the relative humidity of 45% and 35%, the maximum moisture liberation amount reachesmore than 15% and 10%, which are improved by more than 3 times compared with the diatomite, so that the material has a good application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

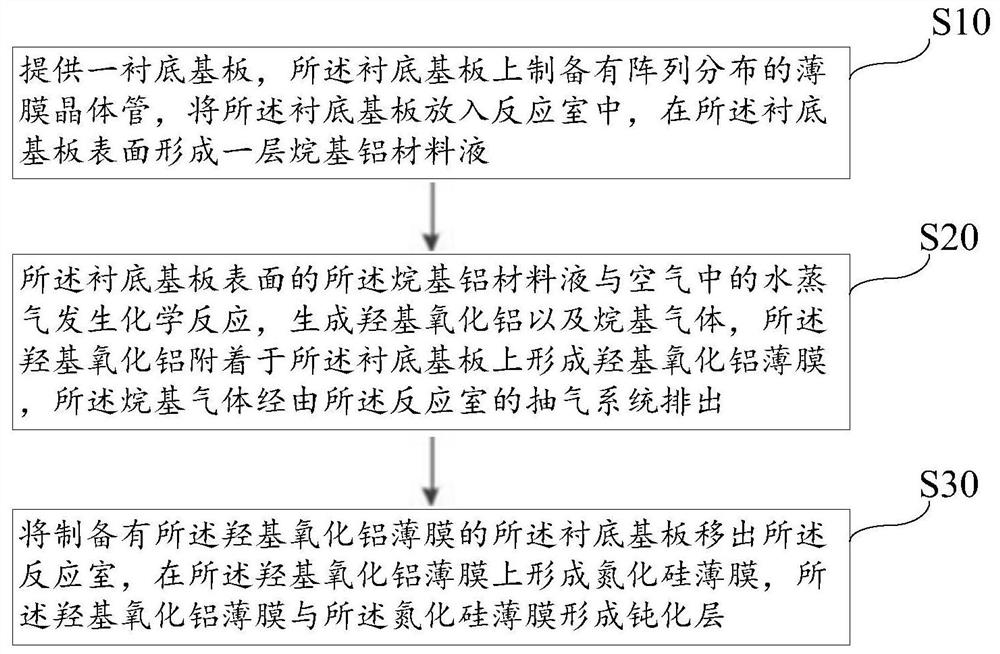

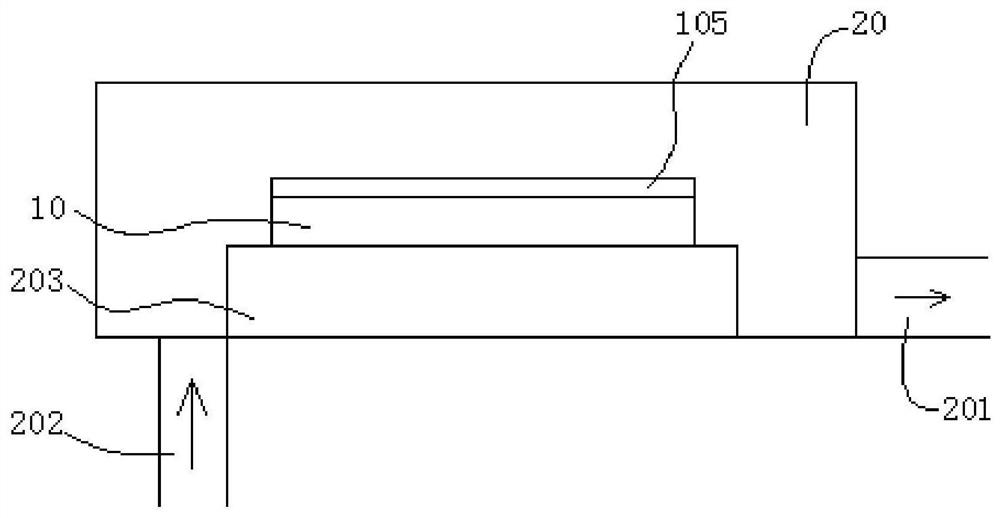

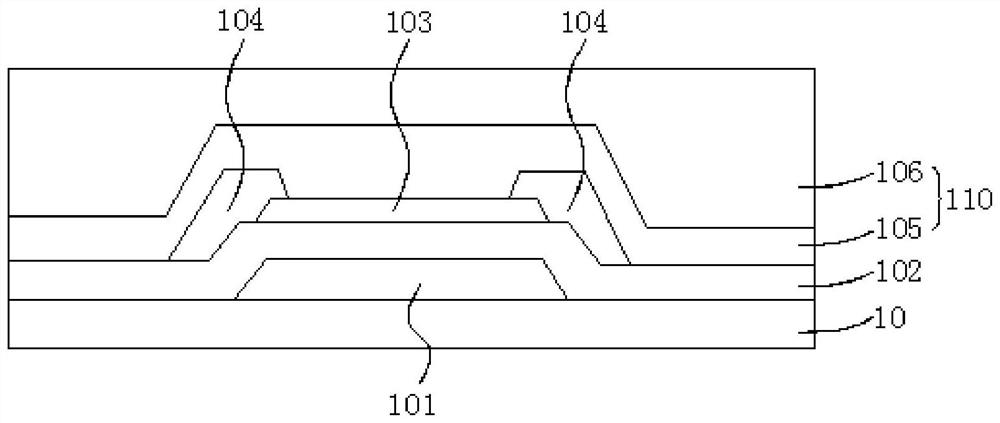

A kind of array substrate and preparation method thereof

ActiveCN110211883BImprove performanceThe chemical reaction process is fast and efficientSemiconductor/solid-state device detailsSolid-state devicesIndiumChemical reaction

The invention provides an array substrate and a preparation method thereof. According to the method, a layer of alkyl aluminum material solution is formed on the surface of a substrate with a thin film transistor; the alkyl aluminum material solution is subjected to a chemical reaction with water vapor to generate hydroxyl aluminum oxide and alkyl gas; the hydroxyl aluminum oxide is attached to the substrate to form a hydroxyl aluminum oxide film; the alkyl gas is discharged through a gas extraction system of a reaction chamber; and then a silicon nitride film is formed on the hydroxyl aluminum oxide film, so that a passivation layer of a composite structure of the hydroxyl aluminum oxide film and the silicon nitride film is formed. The hydroxyl aluminum oxide film is adopted to replace asilicon dioxide film in a conventional passivation layer, so that the energy consumption and the cost are relatively low, and the problem that the performance of a device is influenced due to the factthat an H element enters an indium gallium zinc oxide semiconductor layer can be solved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Landscape water treatment purification material and preparation method thereof

PendingCN112573610AImprove toughnessPromote degradationOther chemical processesAlkali metal oxides/hydroxidesPorous carbonAluminum oxide hydroxide

The invention discloses a preparation method of a landscape water treatment purification material. The method comprises the following steps: (1) dispersing aluminum oxyhydroxide into an ethanol watersolution, uniformly stirring to obtain a AlOOH solution, heating a carbon material precursor to 1000-1200 DEG C at a heating rate of 1-3 DEG C / min under the protection of inert gas, calcining for 1-3hours, keeping the temperature for 30 minutes, cooling to room temperature to obtain carbon nanosheets, and adding the carbon nanosheets into an oxidizing acid solution for oxidation reaction to obtain porous carbon nanosheets; (2) soaking the porous carbon nanosheet into the AlOOH solution, carrying out ultrasonic treatment for 20-30 minutes, then sequentially adding a polyurethane solution and apoly L-lactic acid solution, and continuously carrying out ultrasonic treatment for 30-60 minutes to obtain a blended solution; and (3) placing the blended solution in an environment with the vacuumdegree of 0.05-0.1 MPa for 3-5 hours, casting the blended solution on a stainless steel mold, drying to obtain a film, washing the obtained film with deionized water 2-3 times, and drying in a vacuumdrying oven with the temperature of 20-30 DEG C for 18-24 hours to obtain the product. The landscape water treatment purification material disclosed by the invention is good in toughness and has a good treatment effect on landscape water.

Owner:神美科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com