Releasable corrosion inhibitor compositions

a corrosion inhibitor and composition technology, applied in the direction of group 3/13 element organic compounds, synthetic resin layered products, natural mineral layered products, etc., can solve the problems of bridge collapse, fatal airplane and train crash, leakage and subsequent explosion of natural gas pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

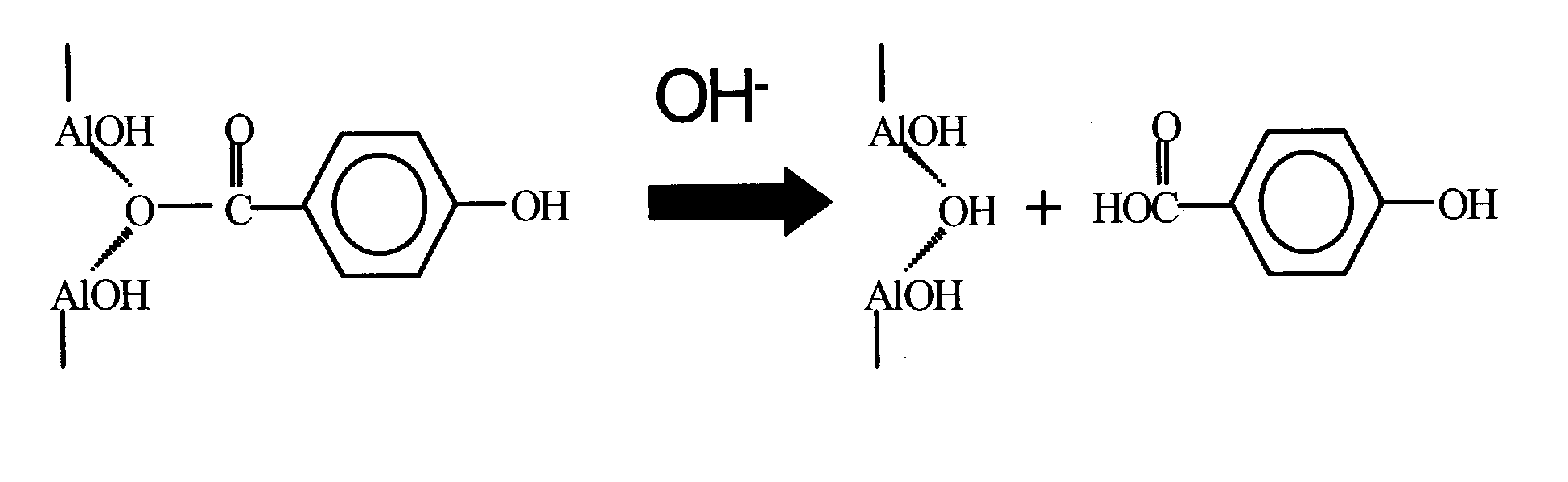

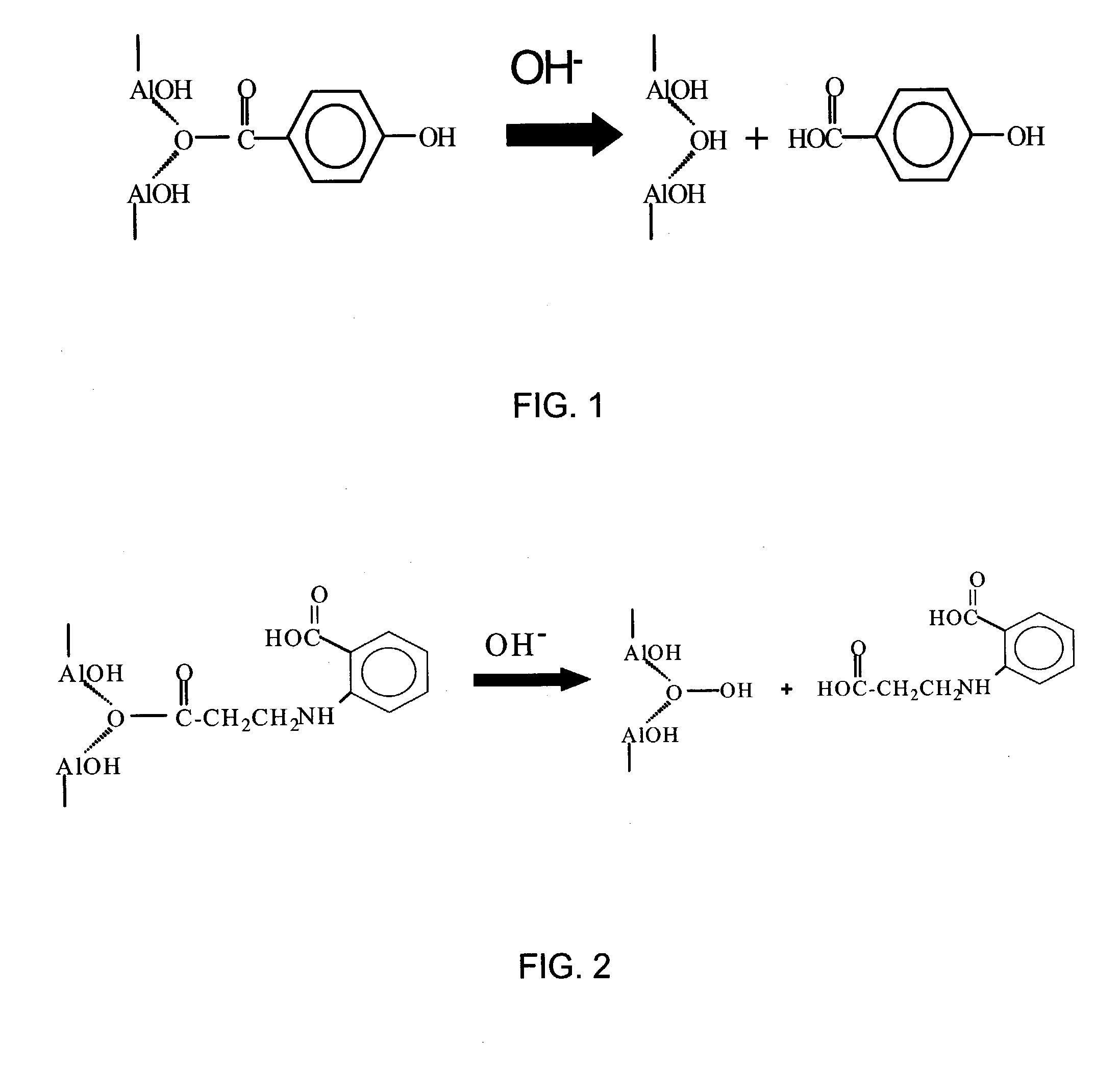

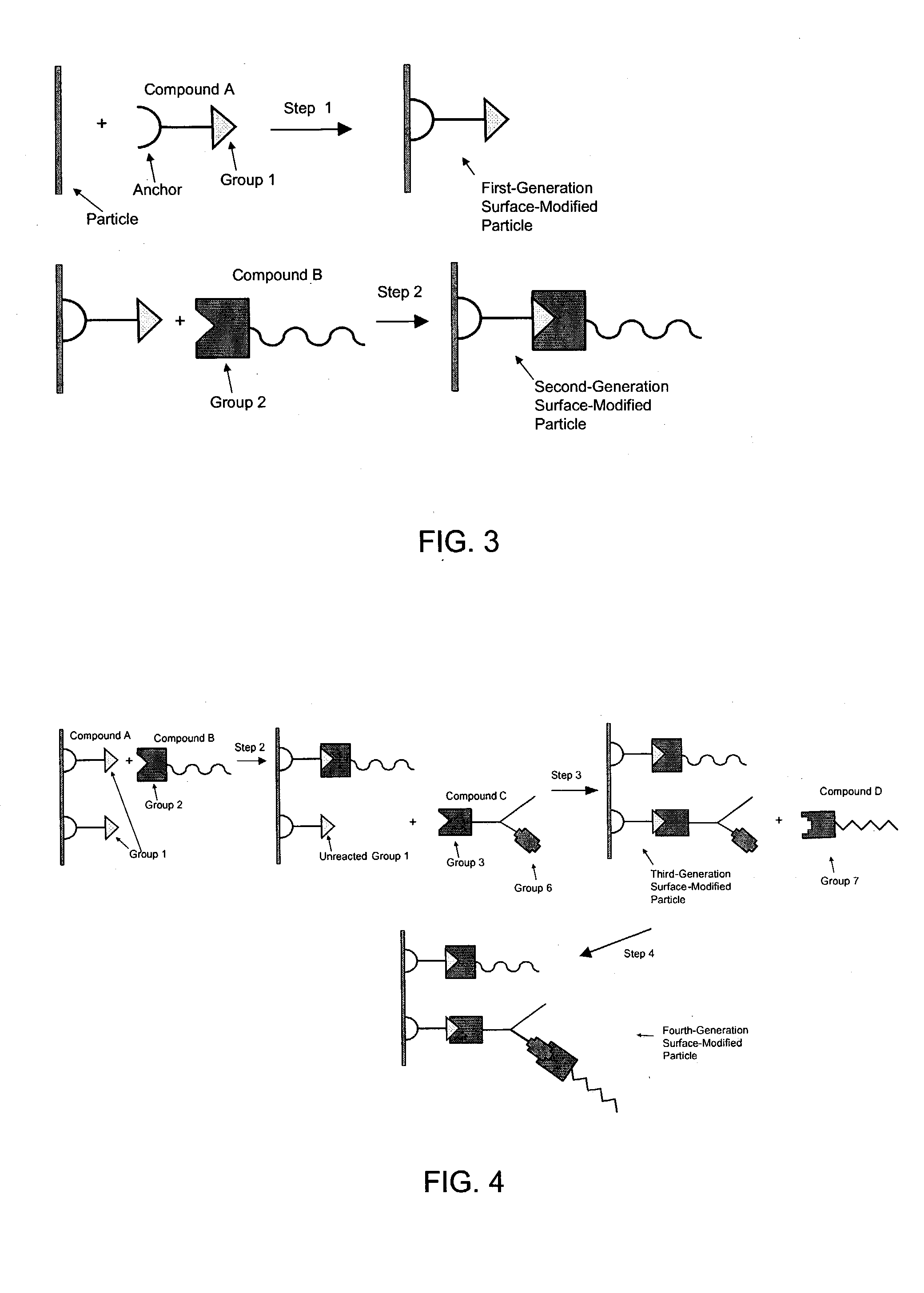

Method used

Image

Examples

example

[0068] The following examples are non-limiting examples of the compositions of corrosion inhibiting particle materials. In the following examples “dried” means spray-dried. Dispersion or redispersion of the dried materials was achieved by stirring with a Cowles blade or mixing with mini-media in a ball mill. The initial syntheses (e.g. chemically anchoring the carboxylic acid to the particle surface) uses a 15-wt % dispersion of boehmite in water. In the following examples this refers to using 150 grams of boehmite or pseudoboehmite in 1000 grams of water. Both boehmite and pseudoboehmite were used as the aluminum oxyhydroxide materials from which the corrosion inhibiting particles were prepared. The aluminum oxyhydroxides that were used were Catapal A (pseudoboehmite) and Catapal D (boehmite), both produced by Sasol, North America. The use of these materials is illustrative and is not to be construed as limiting.

[0069] A typical aqueous preparation of the carboxylate-anchored alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ratio | aaaaa | aaaaa |

| Corrosion properties | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com