Preparation method of aluminum hydroxide adjuvant

A technology of aluminum hydroxide and adjuvant, applied in the field of preparation of aluminum hydroxide adjuvant, can solve the problems of affecting immune effect, weakening antigen presentation, and unfavorable batch-to-batch consistency control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

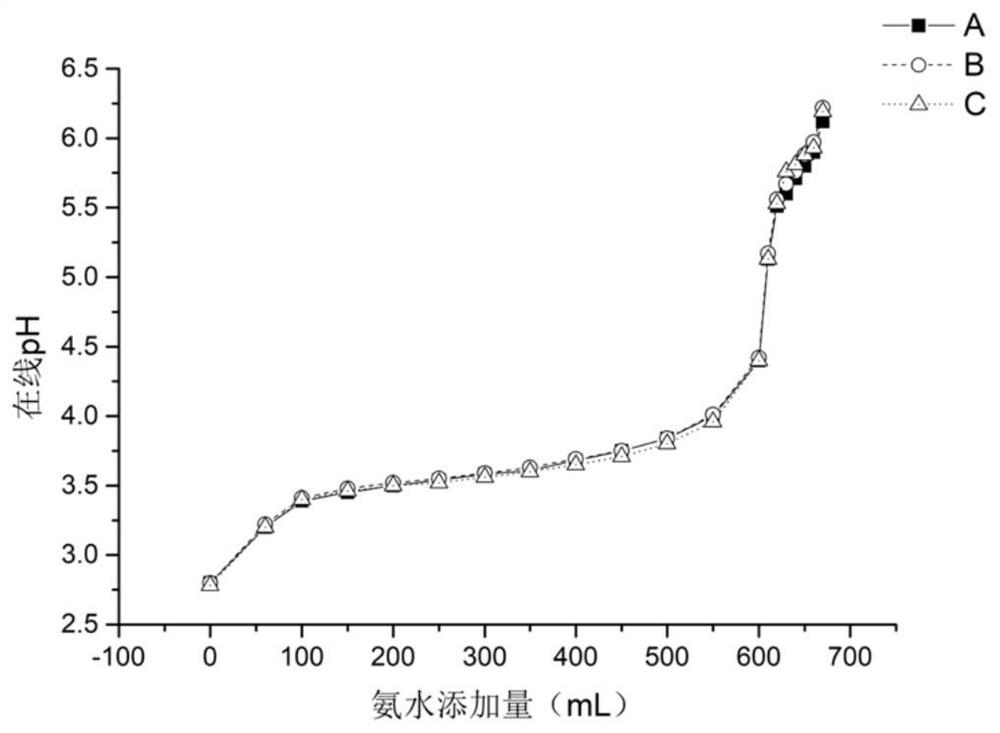

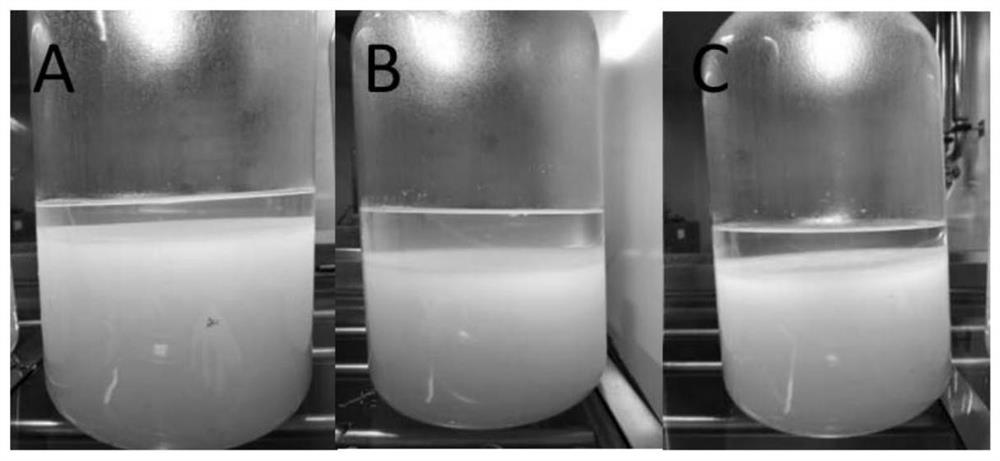

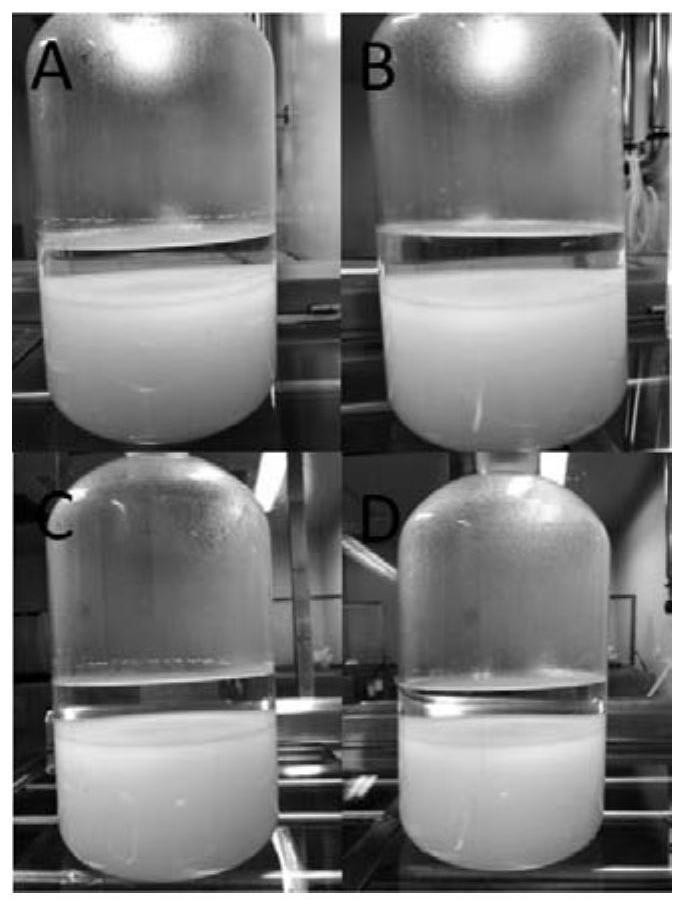

[0027] Embodiment 1, the preparation of aluminum trichloride adjuvant of the present invention

[0028] 1) Preparation of aluminum chloride solution: take AlCl 3 ·6H 2 O was dissolved in water for injection to make a concentration of 0.04g / ml aluminum chloride solution, which was poured into the preparation container through a filter.

[0029] 2) Preparation of ammonia solution: take ammonia solution with a concentration of 25-28%, add 3 times the volume of water for injection to dilute, and mix well;

[0030] 3) Take the aluminum chloride solution prepared in step 1), heat it to 60° C., stir at a speed of 200 rpm, and simultaneously add the ammonia solution in step 2) in the form of a spray, wherein the speed of the pump in the spray equipment is 20 rpm, when three When the pH value of the aluminum chloride solution exceeds 4.4, adjust the rotating speed of the pump in the spray equipment to be 9rpm until the pH value of the aluminum chloride solution is 6.50, leave it for ...

Embodiment 2

[0031] Embodiment 2, the preparation of aluminum trichloride adjuvant of the present invention

[0032] 1) Preparation of aluminum chloride solution: take AlCl 3 ·6H 2 O is dissolved in water for injection, and making concentration is the aluminum trichloride solution of 0.04g / ml, squeezes in the preparation container by filter;

[0033] 2) Preparation of ammonia solution: take ammonia solution with a concentration of 25-28%, add 3 times the volume of water for injection to dilute, and mix well;

[0034] 3) Take the aluminum chloride solution prepared in step 1), heat it to 60° C., stir at a speed of 200 rpm, and simultaneously add the ammonia solution in step 2) in the form of a spray, wherein the speed of the pump in the spray equipment is 20 rpm, when three When the pH value of the aluminum chloride solution exceeds 4.4, adjust the rotating speed of the pump in the spray equipment to be 9rpm until the pH value of the aluminum chloride solution is 6.60, leave it for 21 hou...

Embodiment 3

[0035] Embodiment 3, the preparation of aluminum trichloride adjuvant of the present invention

[0036] 1) Preparation of aluminum chloride solution: take AlCl 3 ·6H 2 O is dissolved in water for injection, and making concentration is the aluminum trichloride solution of 0.04g / ml, squeezes in the preparation container by filter;

[0037] 2) Preparation of ammonia solution: take ammonia solution with a concentration of 25-28%, add 3 times the volume of water for injection to dilute, and mix well;

[0038] 3) Take the aluminum chloride solution prepared in step 1), heat it to 60° C., stir at a rotating speed of 200 rpm, and simultaneously add the aqueous ammonia solution in step 2) in a spray form, wherein the rotating speed of the pump in the spraying device is 20 rpm, when three When the pH value of the aluminum chloride solution exceeds 4.4, adjust the rotating speed of the pump in the spray equipment to be 9rpm until the pH value of the aluminum chloride solution is 6.78, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com