Composition including a lanthanum perovskite on an alumina or aluminium oxyhydroxide substrate, preparation method and use in catalysis

A technology of aluminum hydroxide and composition, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, manganese compound, etc., can solve the problem of reduced catalytic activity of perovskite and achieve favorable reducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

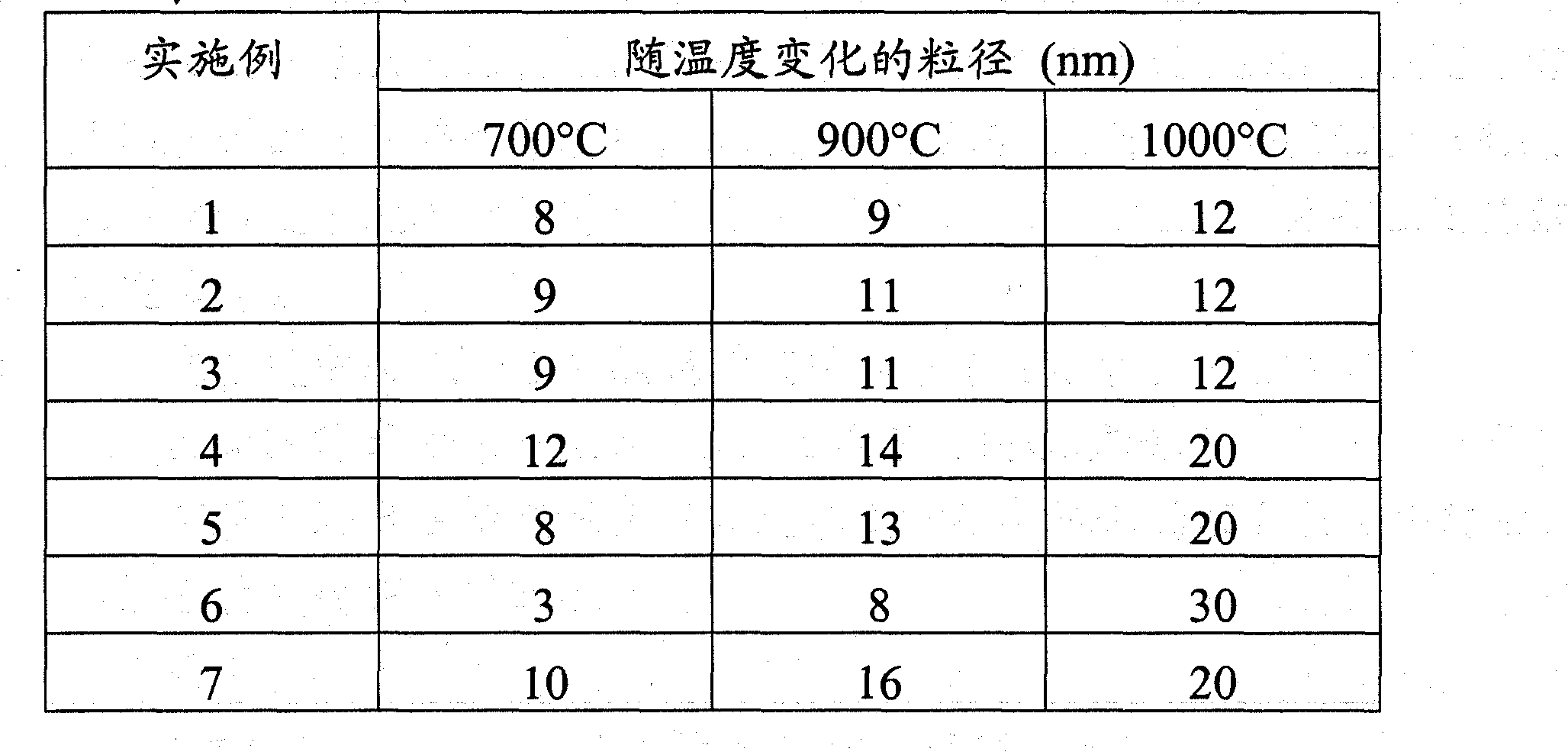

[0079] This example relates to the preparation of lanthanum-iron-based perovskite (LaFeO 3 ), the carrier contains 6% lanthanum, and the respective ratios (expressed by oxide weight) of perovskite and carrier are 10% and 90%.

[0080] Solutions containing lanthanum-doped alumina and ferrous acetate and lanthanum acetate salts were prepared in advance. For this, 2.26 g of ferrous acetate were diluted in 75 ml of water and 4.46 g of lanthanum acetate were diluted in 75 ml of water. These solutions were mixed and the pH of the mixture thus obtained was 5.4. In addition, the specific surface area will be 180m 2 A dispersion was prepared by dispersing 27 g of doped alumina per gram in 150 ml of water. The ferrous acetate and lanthanum acetate solutions were added to the alumina dispersion to obtain a liquid mixture containing lanthanum-doped alumina and ferrous and lanthanum acetate salts. 11.3 g of 28% NH 4 OH solution was added to the mixture to bring the final pH to 10; pre...

Embodiment 2

[0084] This example relates to the preparation of lanthanum iron perovskite based compositions according to the method of the invention, wherein lanthanum is substoichiometric (La 0.9 FeO 3 ), which is dispersed on the same alumina support as in Example 1, and the respective ratios (expressed by oxide weight) of perovskite and support are 10% and 90%.

[0085]Dilute 2.4g of ferrous acetate in 75ml of water, and 4.25g of lanthanum acetate in 75ml of water. These solutions were mixed and the pH of the mixture thus obtained was 5.5. In addition, a dispersion containing the same amount of alumina as in Example 1 was prepared. The ferrous acetate solution and the lanthanum acetate solution were added to the alumina dispersion. 10 g of sodium hydroxide were then added to the mixture thus obtained to bring the final pH to 10 and the formation of a precipitate was observed. The obtained precipitate was stirred for 1 h30. The precipitate was filtered on a Büchner funnel.

[0086]...

Embodiment 3

[0089] This example relates to the preparation of compositions based on lanthanum iron perovskites doped with cerium and calcium (La 0.9 Ce 0.05 Ca 0.05 FeO 3 ), which is dispersed on the same alumina support as in Example 1, and the respective ratios (expressed by oxide weight) of perovskite and support are 10% and 90%.

[0090] On the one hand, 4.09g of lanthanum acetate, 0.22g of cerium acetate and 0.11g of calcium acetate were diluted in 75ml of water; on the other hand, 2.31g of ferrous acetate was diluted in 75ml of water. These solutions were mixed to obtain an acetate mixture with a pH of 5.5. In addition, a dispersion containing the same amount of alumina as in Example 1 was prepared. A solution of ferrous acetate, cerium acetate, calcium acetate and lanthanum acetate was added to the alumina dispersion. 14 g of sodium hydroxide were then added to the mixture thus obtained to bring the final pH to 10 and the formation of a precipitate was observed. The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com