Nanometer hydroxide wood composite material and preparation method thereof

A nano-magnesium hydroxide, hydroxide technology, applied in nanotechnology, impregnated wood, nanotechnology and other directions, to achieve good flame retardant performance, improve the level of rational utilization and utilization, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

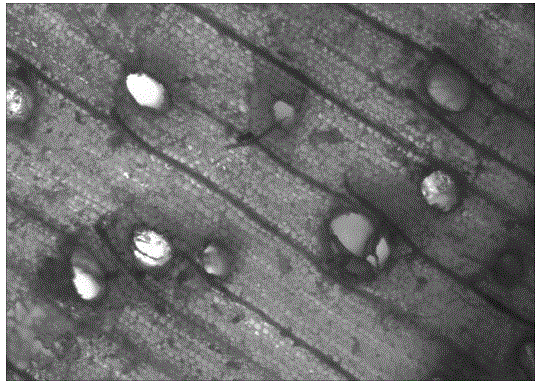

Image

Examples

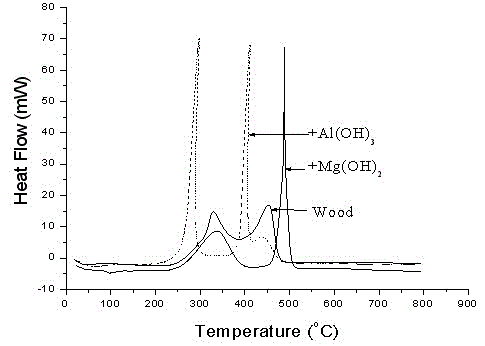

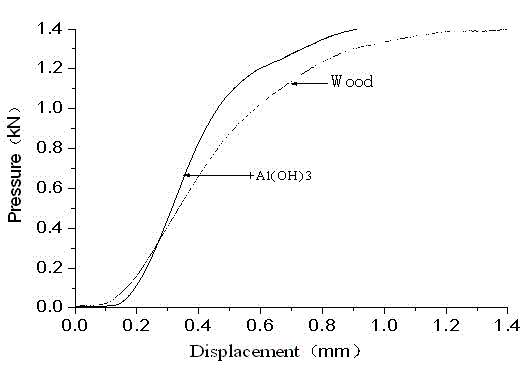

Embodiment 1

[0030] Populus 69 (poplar), a fast-growing forest widely planted in northern Anhui Populus deltoids cv. I-69 / 55 ). The logs are peeled and sawn into boards with a thickness of about 5cm. After air-drying in a ventilated place, the boards are processed into 20 mm (radial direction)×20 mm (chord direction)×30 mm (longitudinal direction), with a volume of 12cm 3 With a mass of 3.0 g, the wood was pretreated for 1 hr using ultrasound to increase the reactive groups of the wood. Prepare 100 mL 1.0 mol L -1 Al(NO3 )·9H 2 O and 3.0 mol L -1 CO(NH 2 ) 2 Add concentrated ammonia water to adjust pH = 6. Use a vacuum decompression system (vacuum degree of 0.1 MPa) to vacuum impregnate the precursor liquid for 24 hours, then inject about 6-8 mL of the precursor liquid into the wood matrix. Pour the impregnated wood block into a hydrothermal reaction kettle, heat at 120 °C for 12 hr, take out the test piece after cooling to room temperature, wash it with deionized water, and then dr...

Embodiment 2

[0033] Populus 69 (poplar), a fast-growing forest widely planted in northern Anhui Populus deltoids cv. I-69 / 55 ). The logs are peeled and sawed into boards with a thickness of about 5 cm. After air-drying in a ventilated place, the boards are processed into 20 mm (radial direction)×20 mm (chord direction)×30 mm (longitudinal direction), and the wood is pretreated by microwave for 3 hours. To increase the active groups of wood. Prepare 100 mL 1.0 mol L -1 NaAlO 2 solution, using a vacuum decompression system to vacuum impregnate the precursor liquid for 24 hours, inject about 6-8 mL of the precursor liquid into a volume of 12 cm 3 In a wood matrix with a mass of 3.0 g. Pour the impregnated wood block into a hydrothermal reaction kettle, heat at 60 °C for 12 hr, or directly heat the wood block at 60-100 °C in an oven for 6-12 hr, cool to room temperature, take out the test piece and wash it with deionized water Afterwards, vacuum degree is 0.1 atm at 70 °C, and vacuum dry...

Embodiment 3

[0036] Populus 69 (poplar), a fast-growing forest widely planted in northern Anhui Populus deltoids cv. I-69 / 55 ). The logs are peeled and sawed into boards with a thickness of about 5 cm. After being placed in a ventilated place to dry, the boards are processed into 20 mm (radial) × 20 mm (chord) × 30 mm (longitudinal), and the wood is pretreated by microwave for 3 hours. Increase the reactive groups of wood. Prepare 100 mL 0.2mol·L -1 Mg(NO 3 ) 2 9H 2 O and 0.2 mol L -1 CO(NH 2 ) 2 The mixed solution was mixed and concentrated ammonia water was added to adjust the pH=5, and the precursor liquid was vacuum impregnated for 24 hours and injected into the wood matrix using a vacuum decompression system. Pour the impregnated wood block into a hydrothermal reaction kettle, heat at 160 °C for 10 hr, take out the test piece after cooling to room temperature, wash with deionized water, and then dry it in vacuum at 0.1 atm at 70 °C for 48 hr to obtain inorganic Flame retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com