Patents

Literature

86 results about "Boundary structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical viewing system and method for detecting boundary structures

ActiveUS20060058643A1Increase awarenessFor accurate visualizationImage enhancementImage analysisDisplay processingBoundary structure

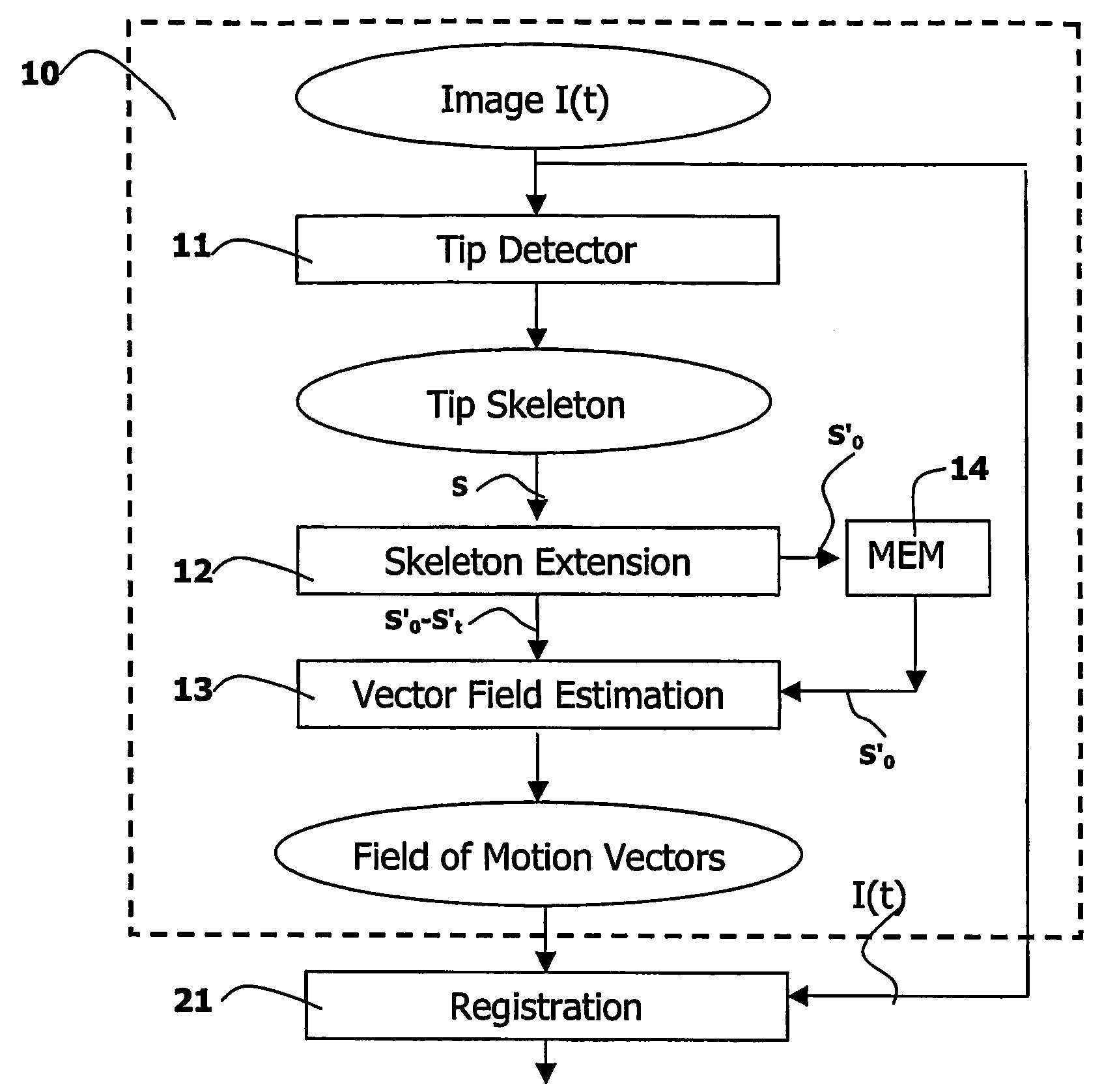

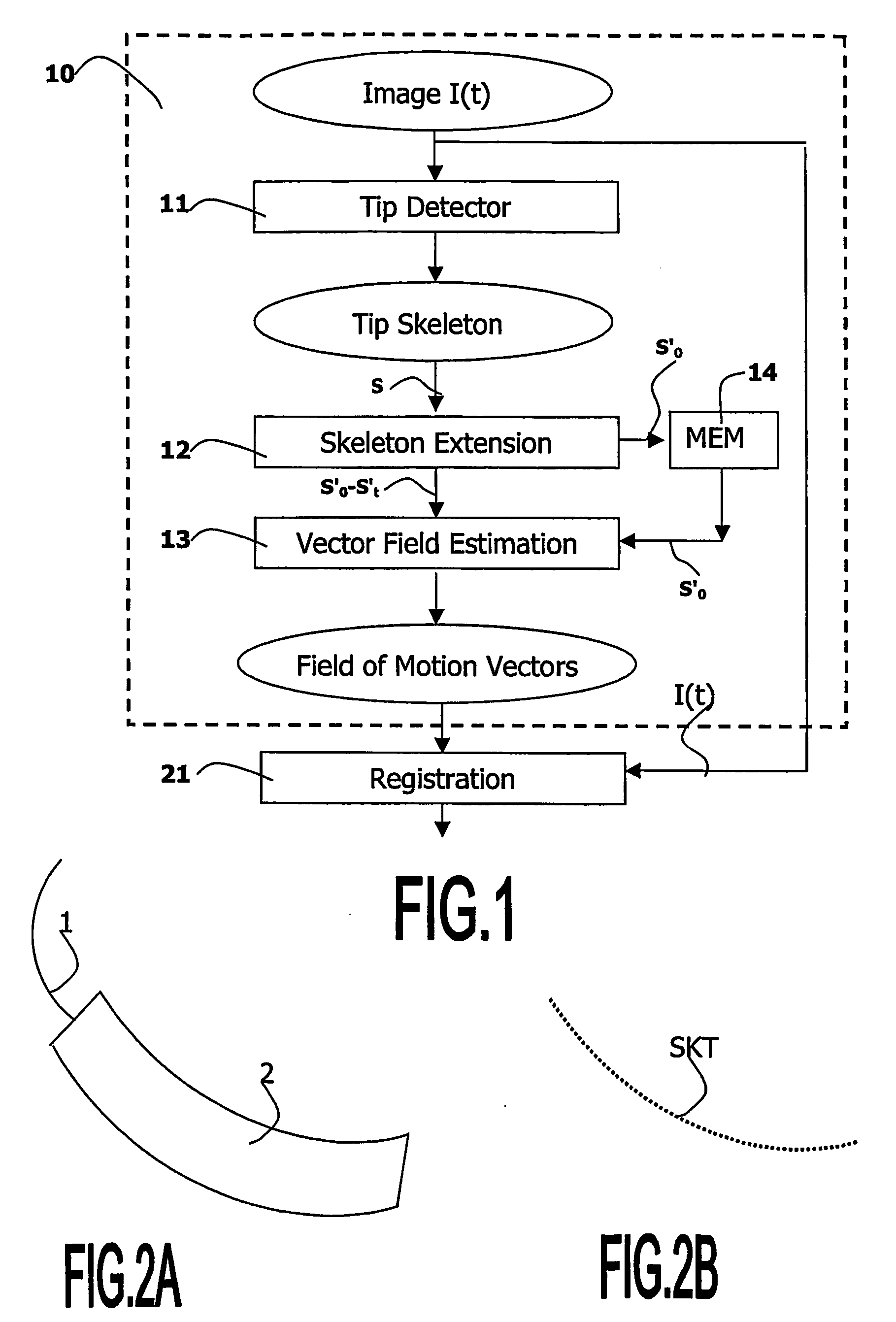

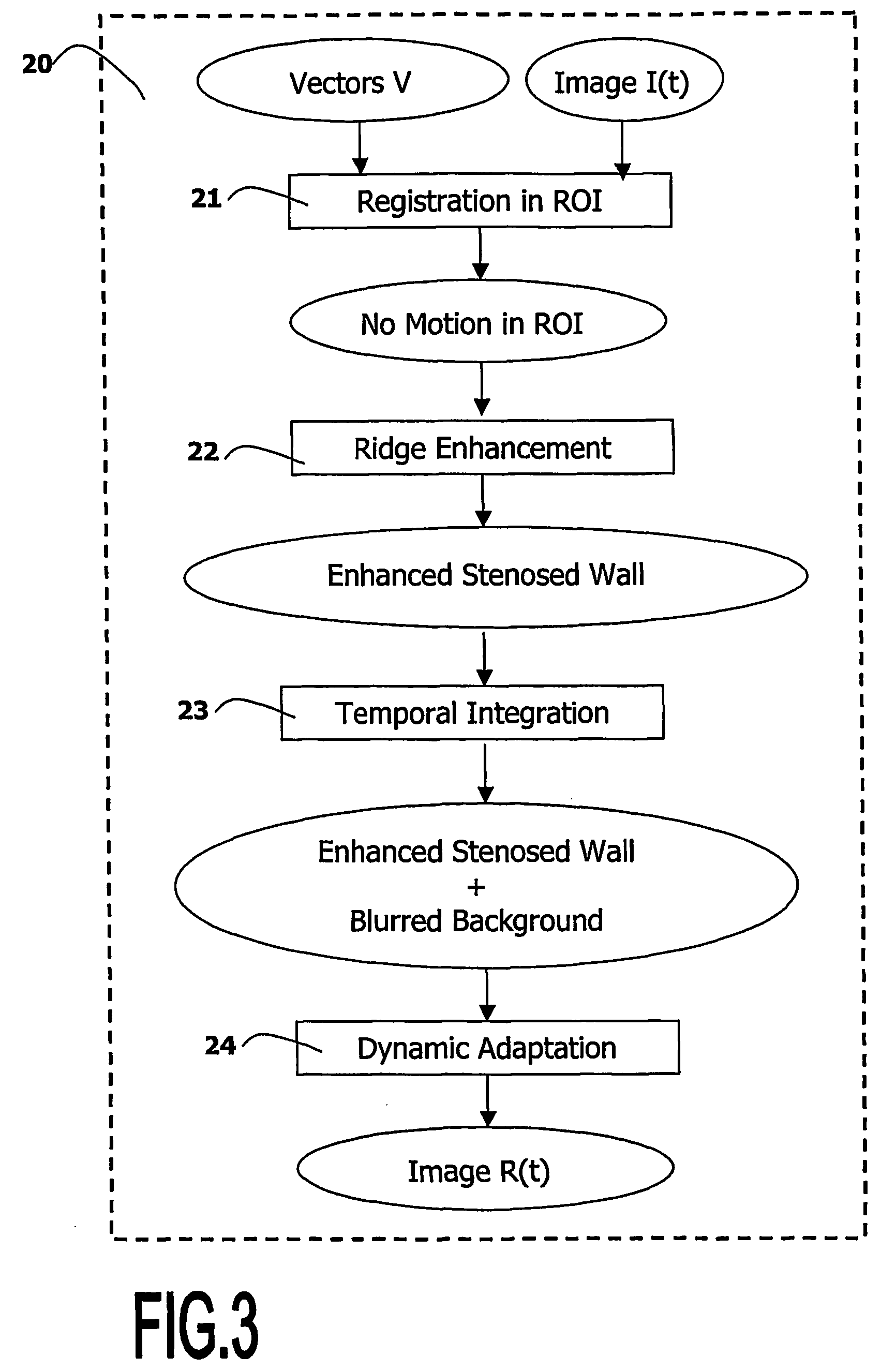

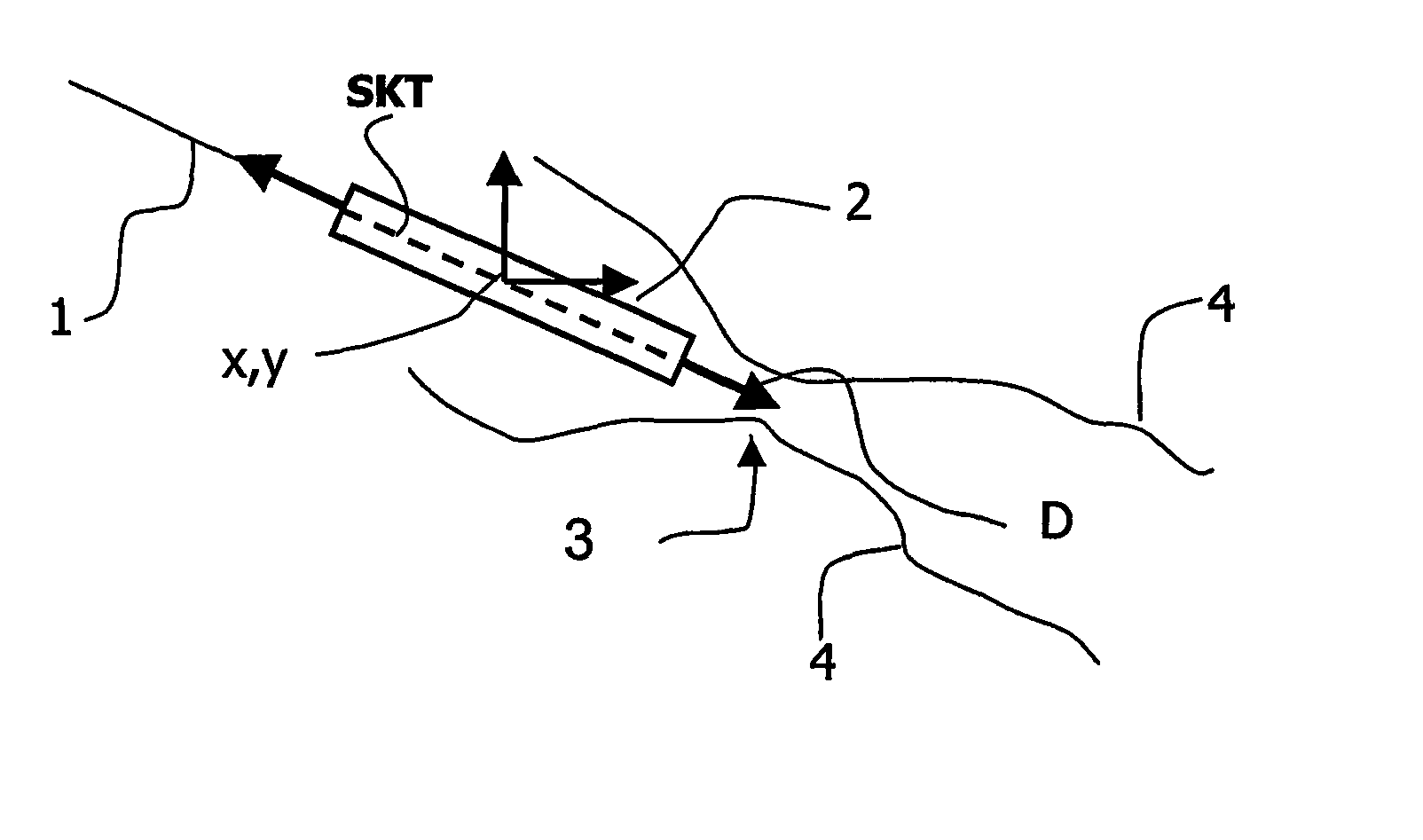

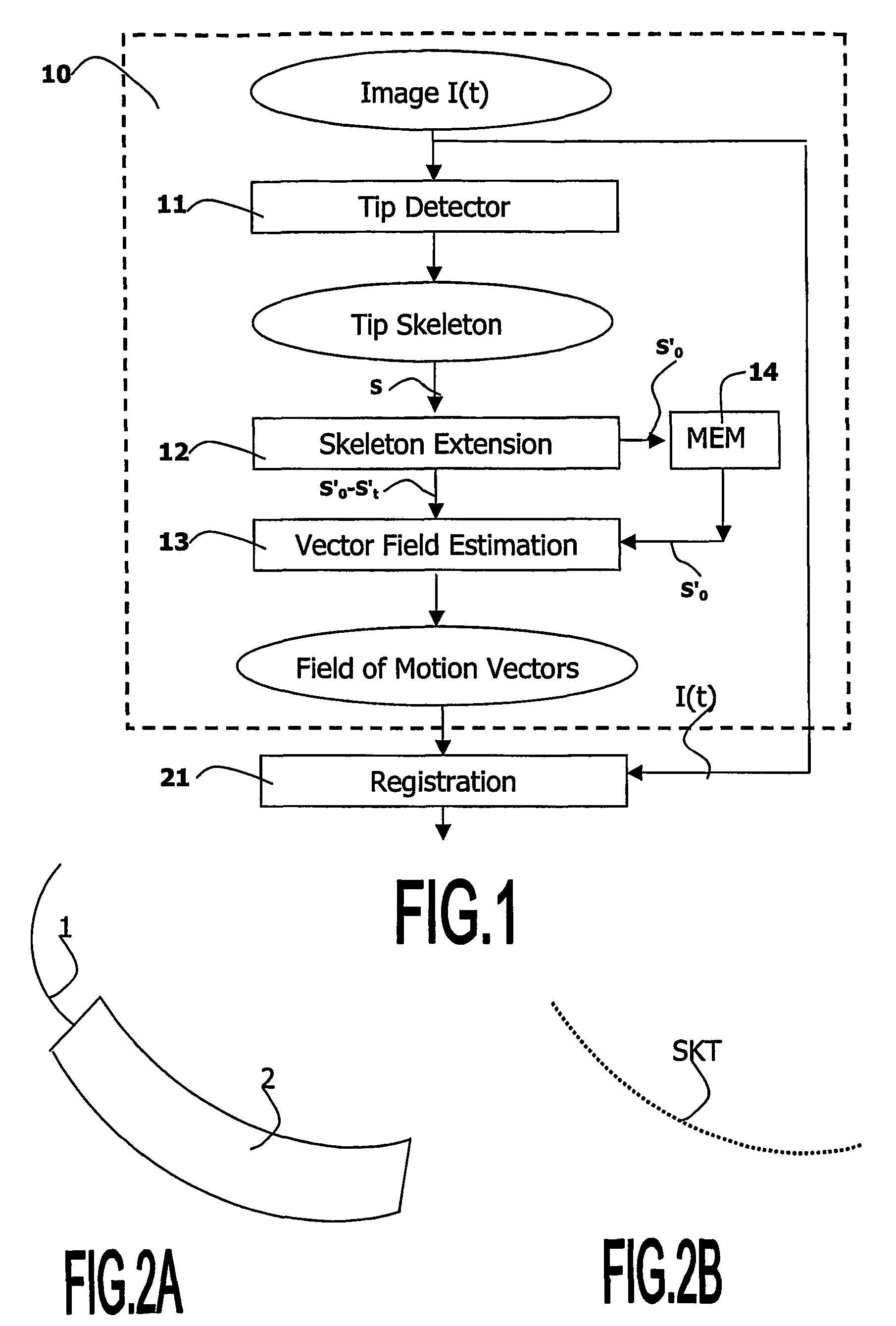

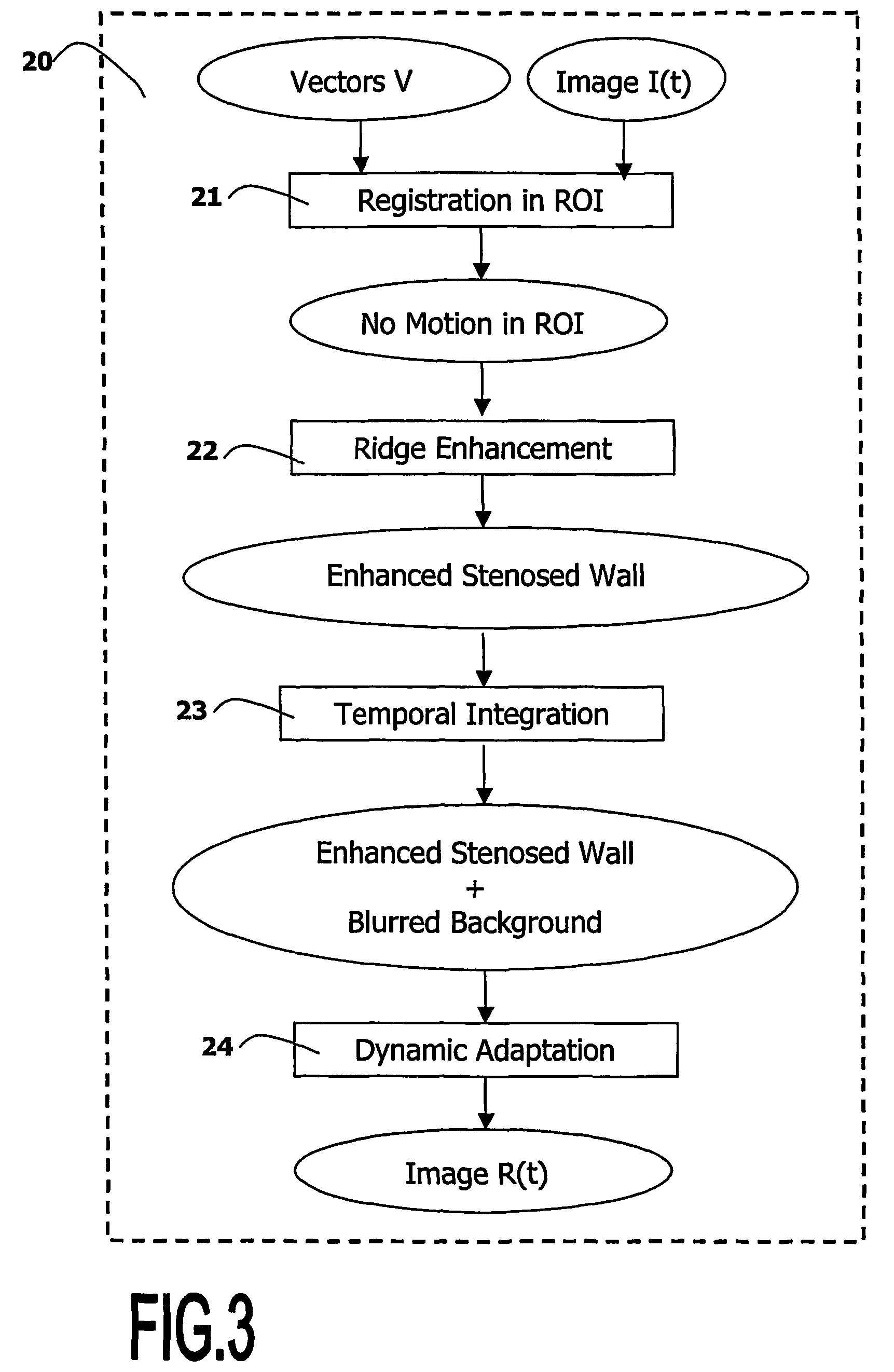

A medical viewing system for displaying a sequence of medical images that represents moving and / or positioning a guide-wire, in a blood vessel, which guide-wire has a guide-wire tip that is contrasted with respect to the guide wire, this system comprising acquisition means that acquires an original sequence of noisy images called live sequence and processing means for processing said live sequence of images in real time, the processing means comprising: first means (10) for automatically detecting the guide-wire tip, yielding skeleton information of the guide-wire tip and a field of motion vectors based on said skeleton information; second means (20) for automatically registering the guide-wire tip with respect to a reference based on the field of motion vectors and for enhancing the guide-wire and the vessel walls while blurring the background in the registered images; and comprising: Display means for displaying a live sequence of processed images.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

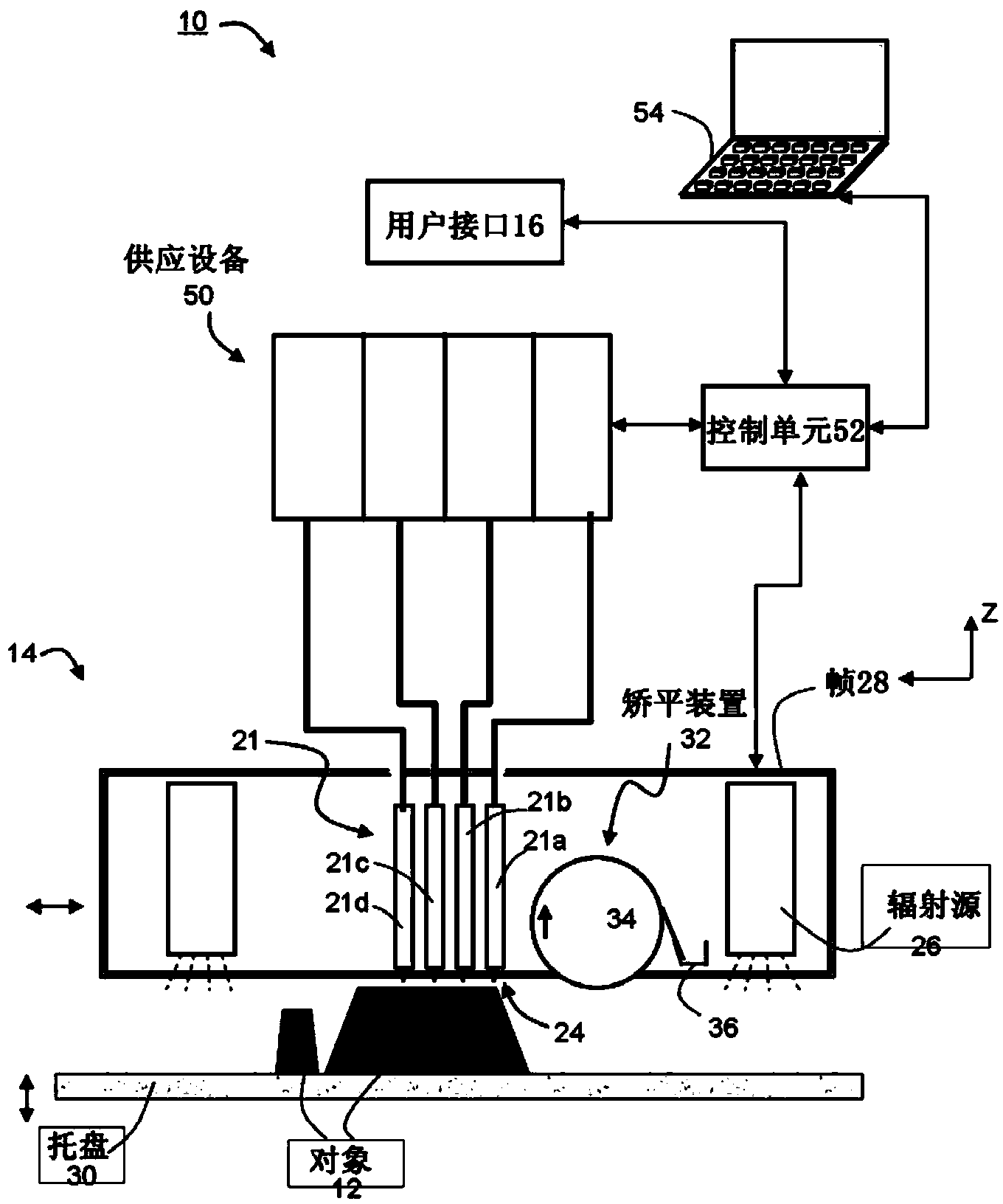

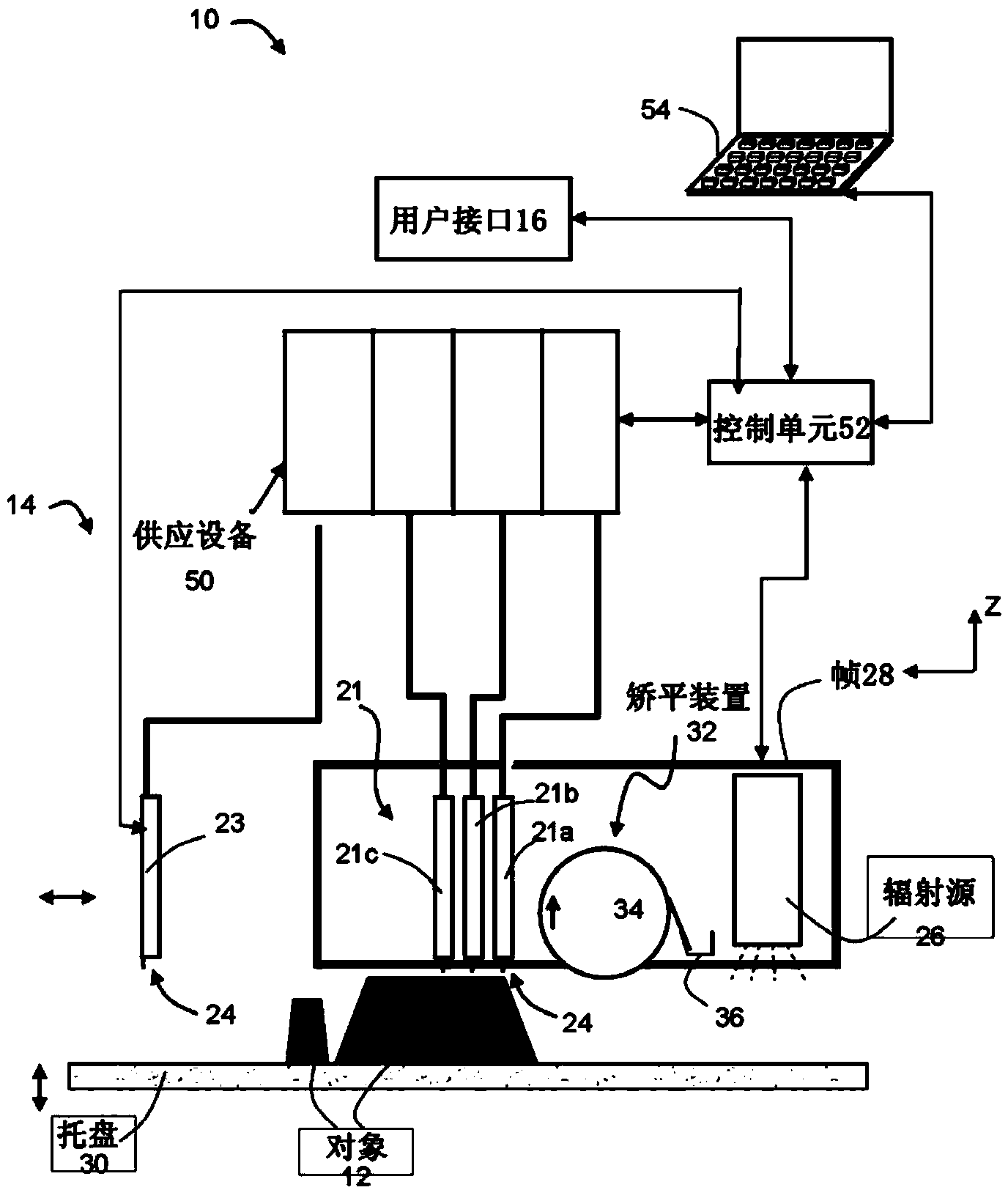

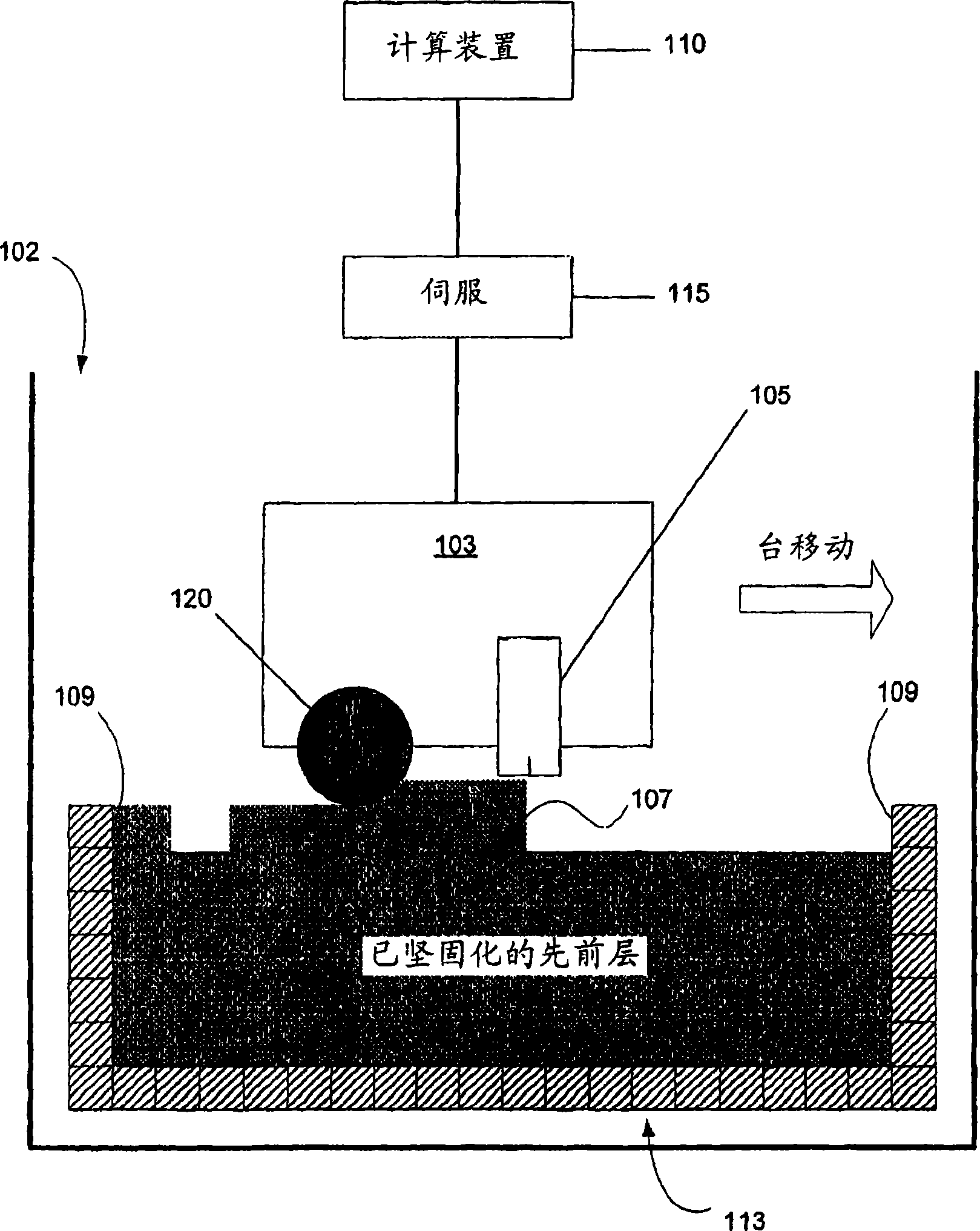

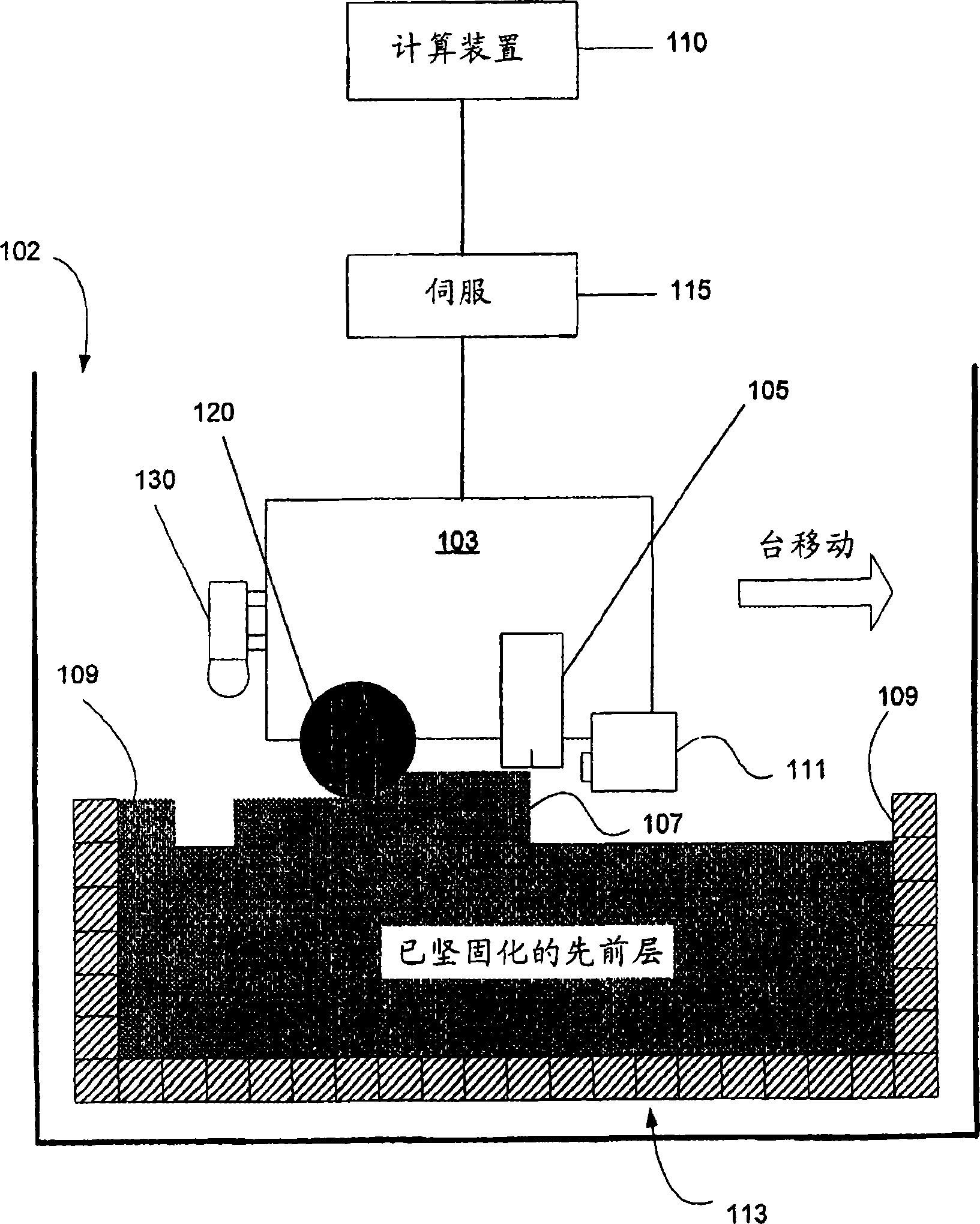

System and method for additive manufacturing of an object

ActiveCN103747943AAdditive manufacturing apparatusPrinted electric component incorporationGratingInter layer

A method of additive manufacturing of a three-dimensional object is disclosed. The method comprises sequentially forming a plurality of layers each patterned according to the shape of a cross section of the object. In some embodiments, the formation of at least one of the layers comprises performing a raster scan to dispense at least a first building material composition, and a vector scan to dispense at least a second building material composition. The vector scan is optionally along a path selected to form at least one structure selected from the group consisting of (i) an elongated structure, (ii) a boundary structure at least partially surrounding an area filled with the first building material, and (iii) an inter-layer connecting structure.

Owner:STRATASYS LTD

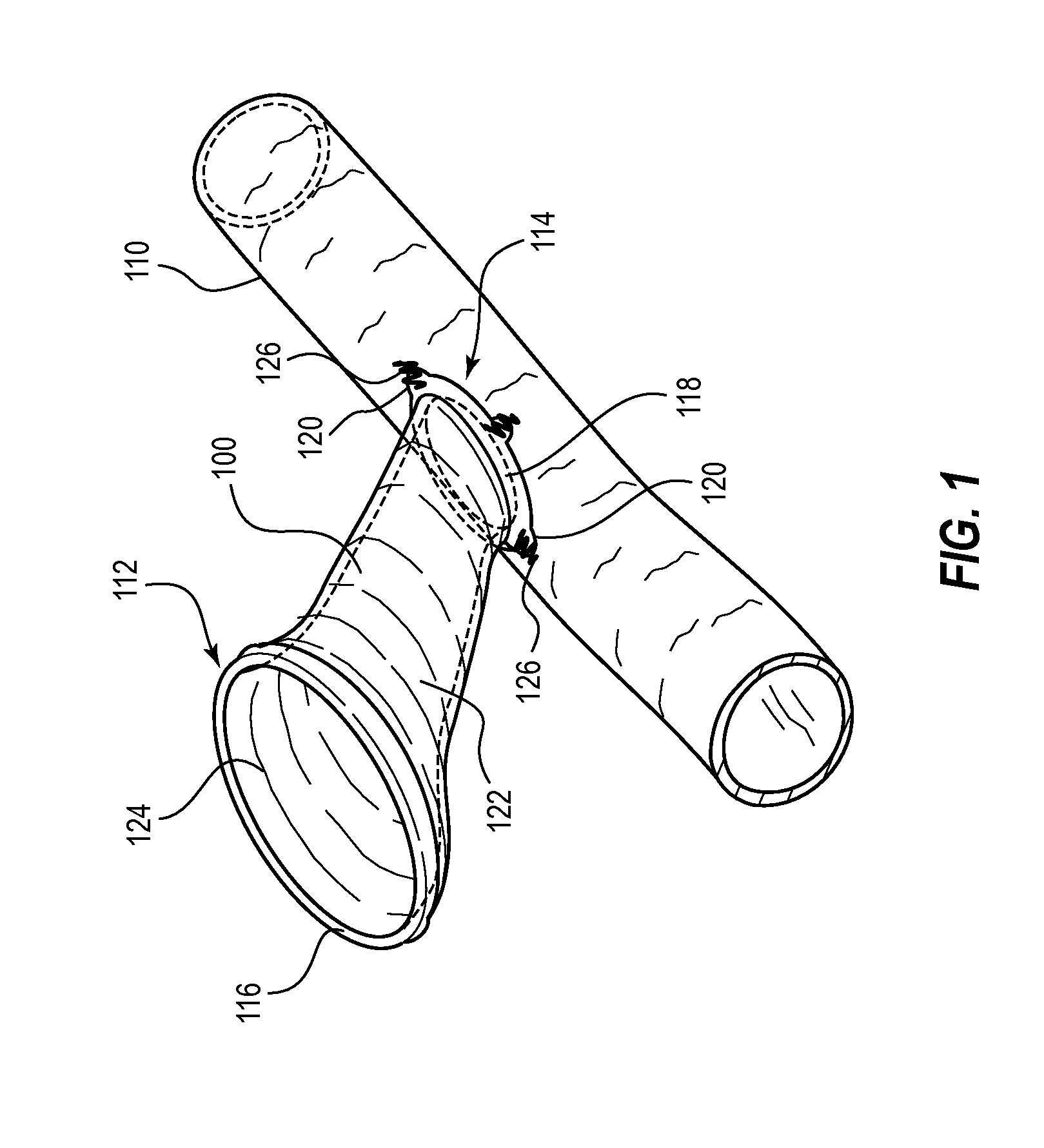

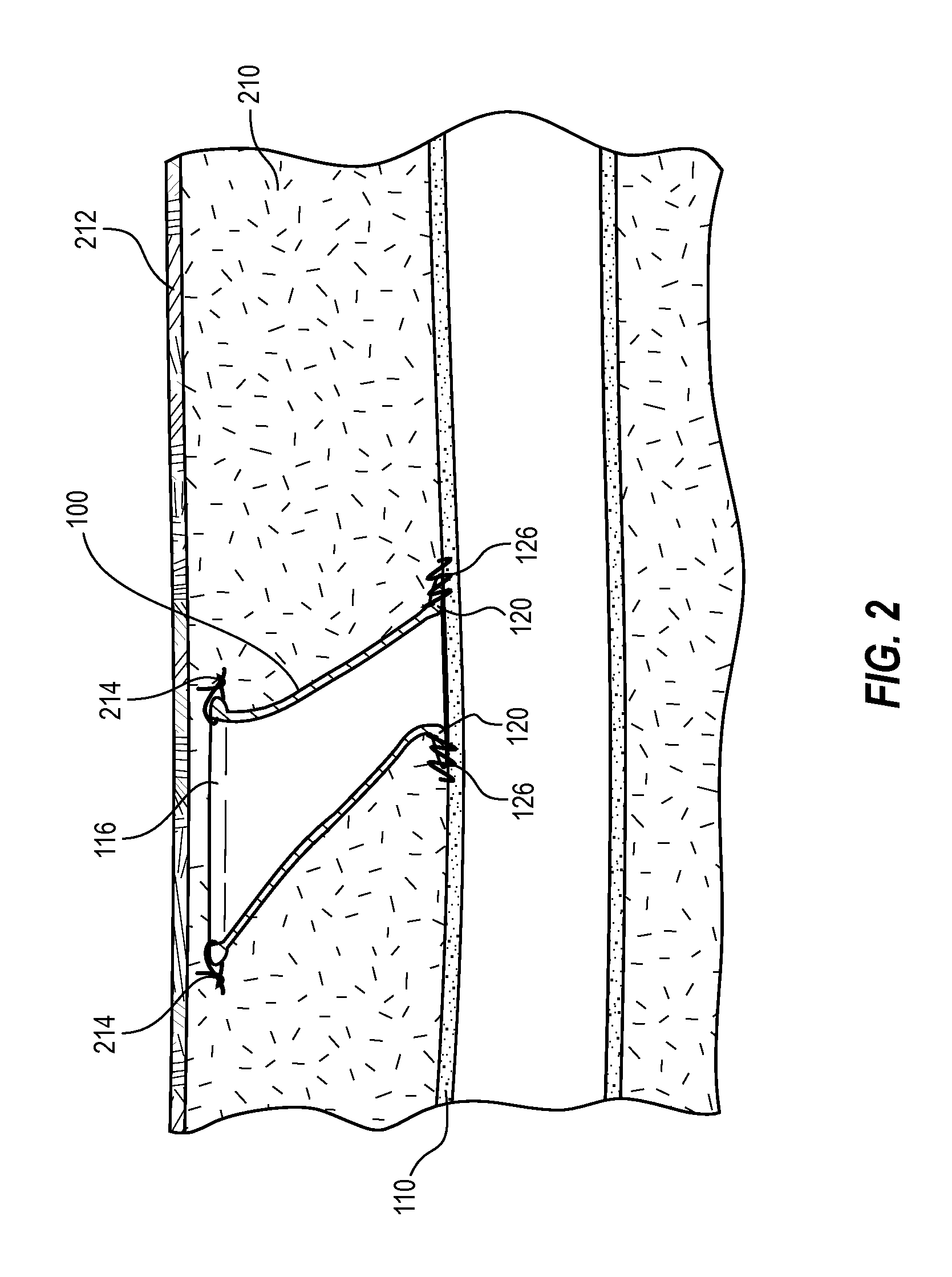

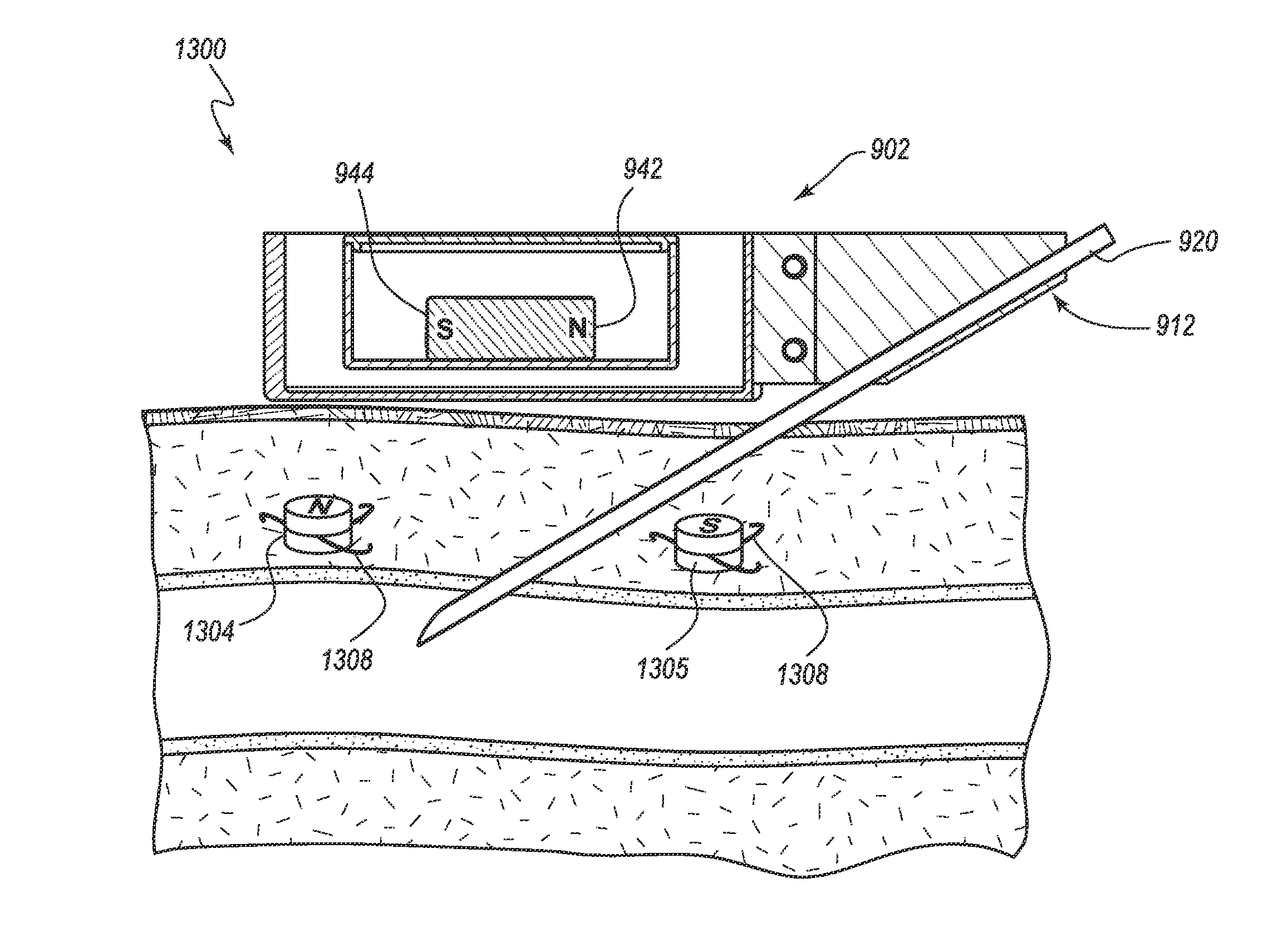

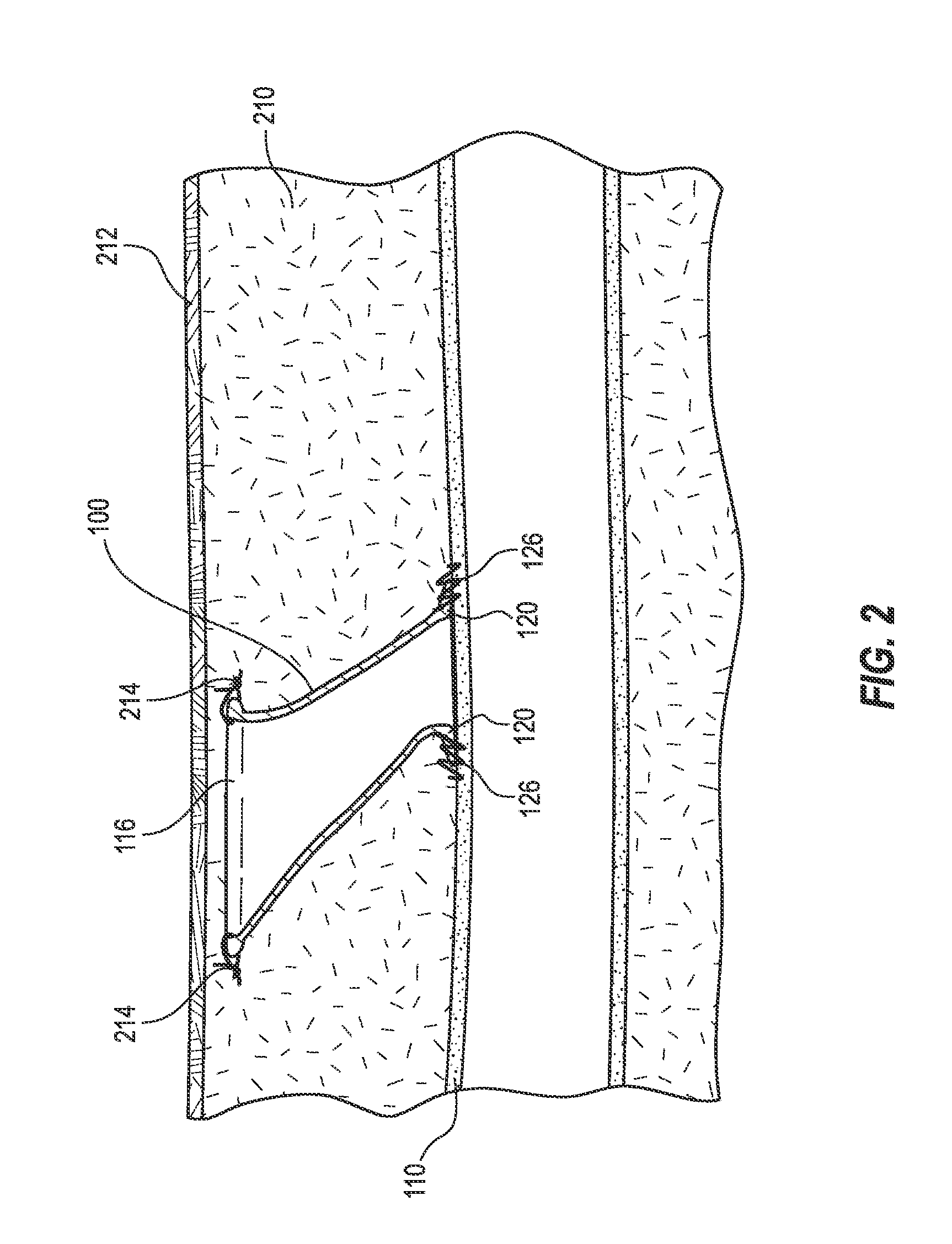

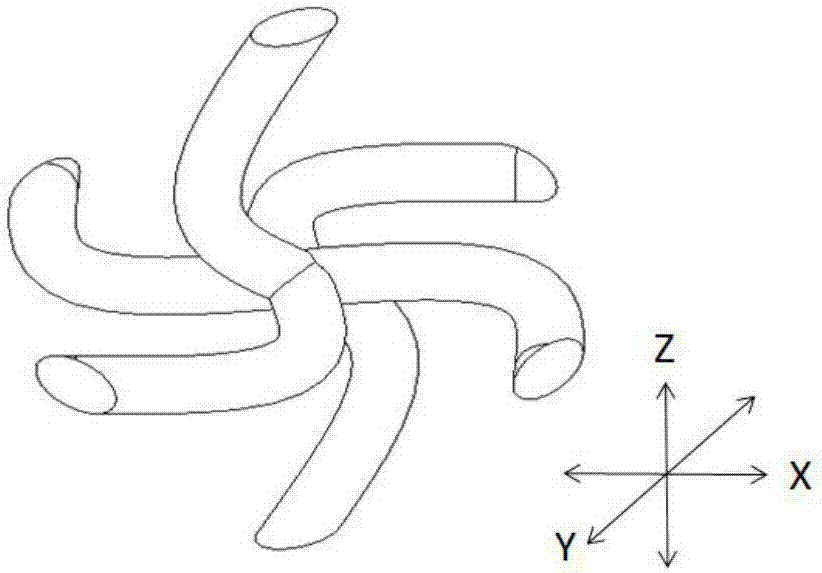

Repetitive entry conduit for blood vessels

A subcutaneous needle conduit attaches directly to a blood vessel or other biological boundary structure. The subcutaneous needle conduit is tapered such that a proximal end is wider than a distal end. A body of the subcutaneous needle conduit guides the tip of a needle or other canula from the proximal end to the distal end. The subcutaneous needle conduit may be funnel-shaped. An elongated funnel shape may be used to selectively provide access to a plurality of desired access sites along an axis of a blood vessel. Other shapes, such as sluice-shaped, may also be used. The subcutaneous needle conduit may be located beneath the skin surface using, for example, tactile sensation, magnetism, metal detection, detection of a signal emitted from a minute transponder, detection of light emission, or through other detection methods.

Owner:TEITELBAUM GEORGE P +2

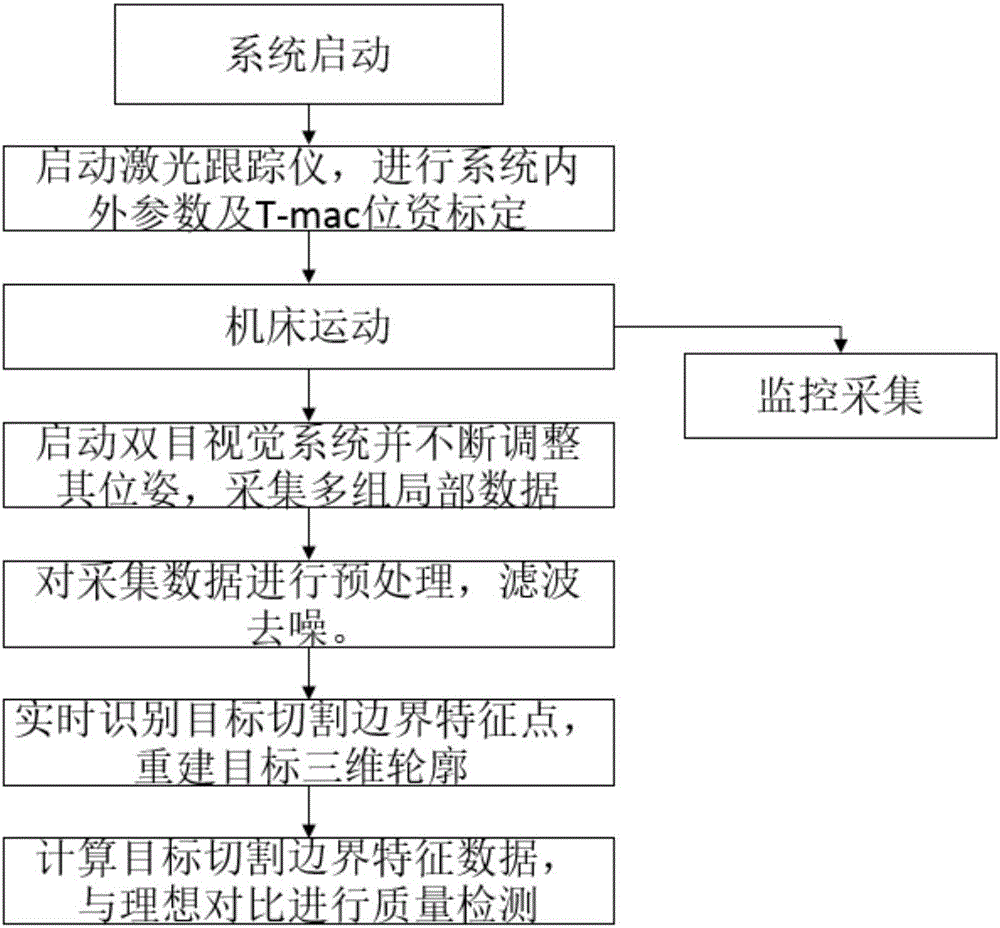

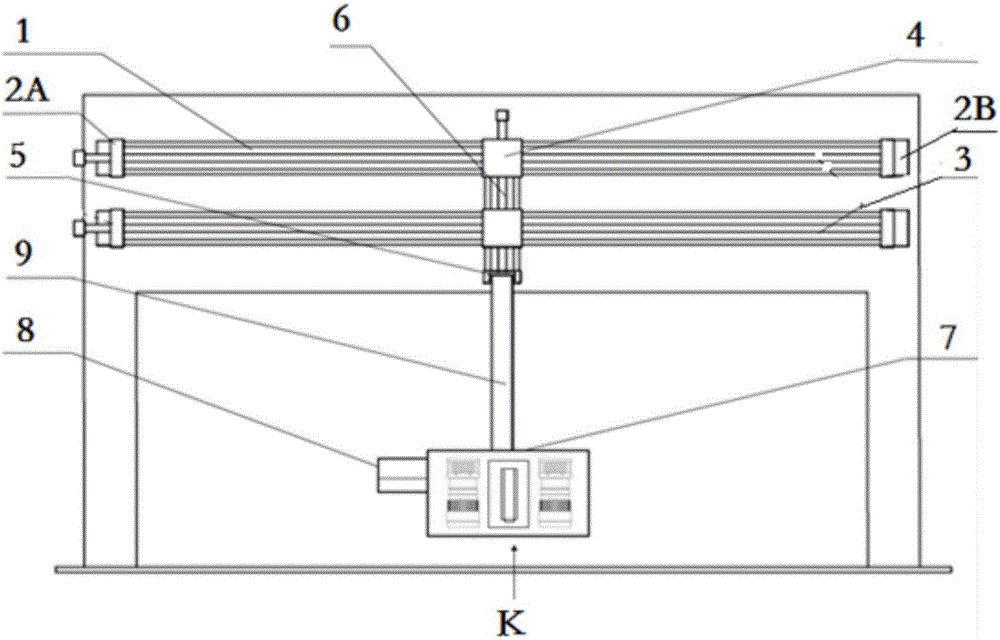

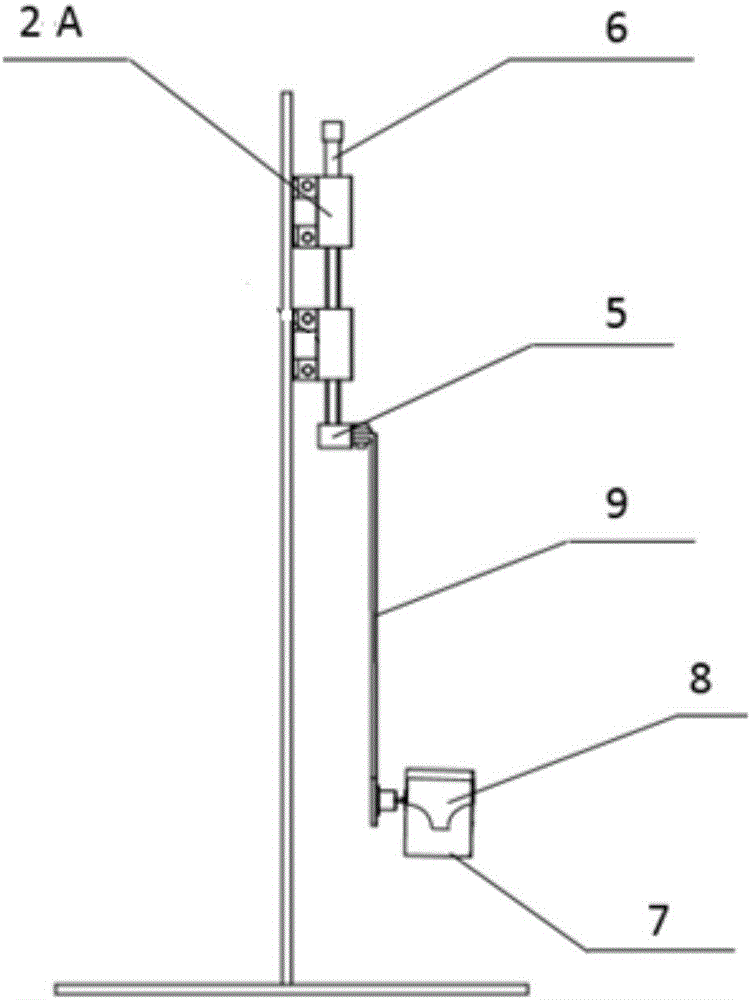

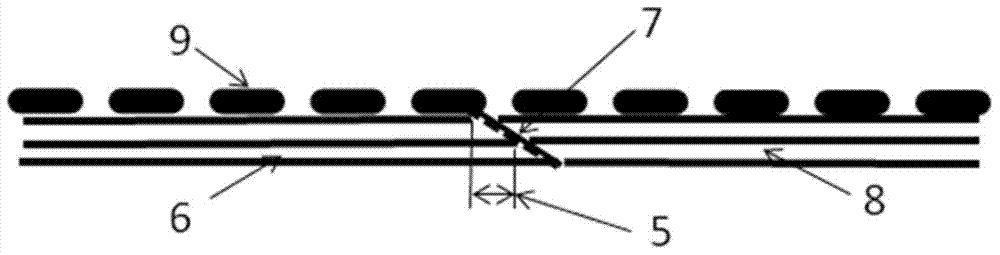

Non-contact online detection method for chemical milling cutting of large parts

InactiveCN106841206AMeet the requirements of chemical milling cutting quality inspectionMeet the requirements of cutting quality inspectionOptically investigating flaws/contaminationUsing optical meansVisual perceptionMachine tool

The invention discloses a non-contact online detection method for chemical milling cutting of large parts, belongs to the technical field of laser measurement, and relates to a non-contact online detection method for measuring the milling cutting quality of large parts. The detection method comprises the steps: integrating a binocular vision system onto a beam of a machine tool, and measuring local data of a boundary of a large part by adjusting the pose of the binocular vision system; calibrating internal and external parameters of a binocular camera and a T-Mac pose, acquiring measurement data, performing part boundary structure feature point extraction on the data and thus obtaining local three-dimensional information of the part boundary. The local measurement data is unified to a global coordinate system so as to achieve the overall three-dimensional information measurement and reconstruction. The detection method is high in measurement efficiency and convenient in pose adjustment, an original structure of the machine tool is not destroyed during installation, no contact with parts occurs, and the precision is high. The non-contact online detection method has the advantages of real-time measurement, thereby meeting the requirements of milling cutting quality inspection of large parts.

Owner:DALIAN UNIV OF TECH

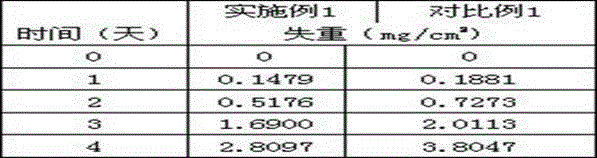

Method for preparing high-coercivity neodymium-iron-boron magnet through grain boundary diffusion

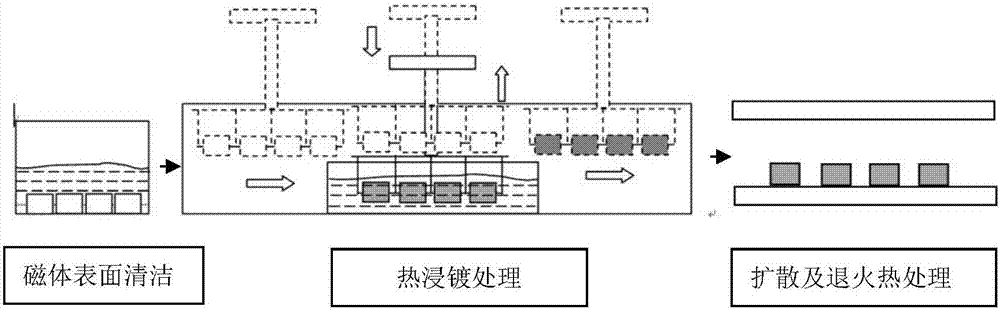

InactiveCN106887323AUniform thicknessHigh bonding strengthInductances/transformers/magnets manufactureMagnetic materialsAlloyDip-coating

The invention discloses a method for preparing a high-coercivity neodymium-iron-boron magnet through grain boundary diffusion, and belongs to the field of magnetic materials. Low-melting-point metal is one of Ga, Zn and Sn, low-melting-point alloy is prepared from R-M, R is one or more of La, Ce, Pr, Nd, Gd, Tb, Dy, Ho and Y, and M is one or more of Cu, Al, Ga, Sn and Ag. The method comprises the process steps that the surface of a neodymium-iron-boron magnet is cleaned firstly, then the magnet is subjected to vacuum preheating, and the magnet is placed in a vacuum melting metal or alloy solution for hot dip coating to achieve surface coating; finally, the neodymium-iron-boron magnet obtained after hot dip coating is subjected to diffusing heat treatment and subsequent annealing treatment, the boundary structure and grain boundary phase distribution of the magnet are improved, and the needed high-coercivity neodymium-iron-boron magnet is obtained. The magnet surface coating is even and high in binding strength, and uniformity of the grain boundary diffusion process and the structure and performance of the magnet are promoted; meanwhile, the thickness of an attached layer on the surface of the magnet can be flexibly controlled by controlling dip coating time and taking-out speed, and waste of diffusion source metal or alloy is avoided; the heat dip coating process is continuous, fast and suitable for volume continuous production.

Owner:UNIV OF SCI & TECH BEIJING

Recipe and preparation method of high-voltage gradient zinc oxide resistance card

The invention discloses a recipe and a preparation method of a high-voltage gradient zinc oxide resistance card. The recipe of the zinc oxide resistance card of the invention reasonably and preferably adopts the ingredients and the contents of the zinc oxide resistance card, the zinc oxide resistance card prepared by the recipe has the high-voltage gradient as high as 350 to 600v / mm, and at the same time, under the high-voltage gradient, the zinc oxide resistance card can maintain good nonlinear characteristic, electrical property and ageing-resistant characteristic to meet the miniaturization requirement of electronic components such as lightning protectors in practical application. In the preparation method of the zinc oxide resistance card of the invention, the accessory ingredients and trace ingredients in the zinc oxide resistance card have fine granularity, are matched, and are uniformly mixed, the impurity mixing quantity is reduced, at the same time, because the low-temperature heat-insulation process is added in the sintering process, the zinc oxide resistance card forms a stable crystal boundary structure which is favorable for improving the stability of the zinc oxide resistance card and the phase change of the bismuth oxide in the secondary heat treatment process, so the electrical property of the zinc oxide bismuth oxide can be improved.

Owner:NINGBO ZHENHAI GUOCHUANG HIGH VOLTAGE ELECTRIC APP

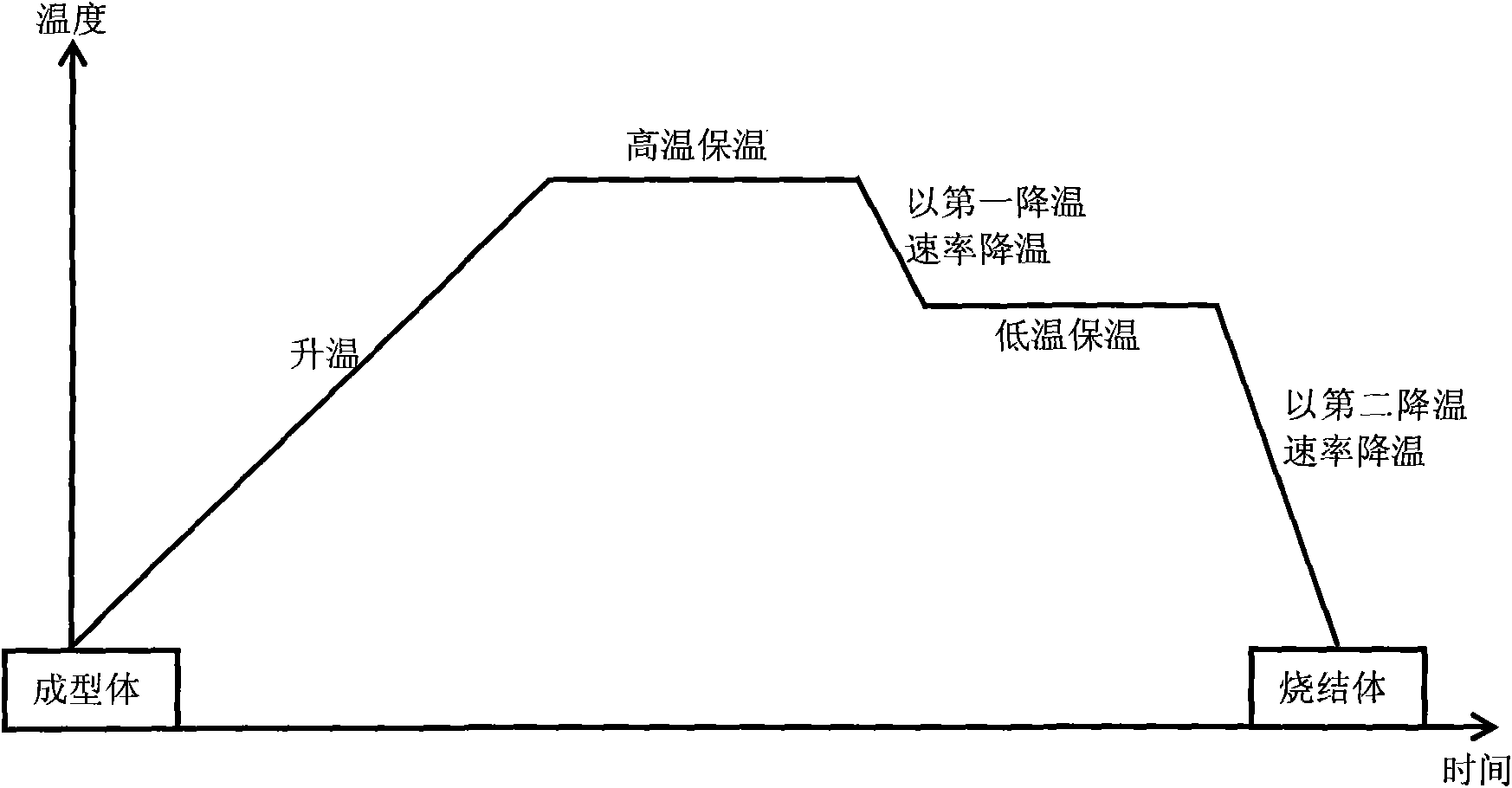

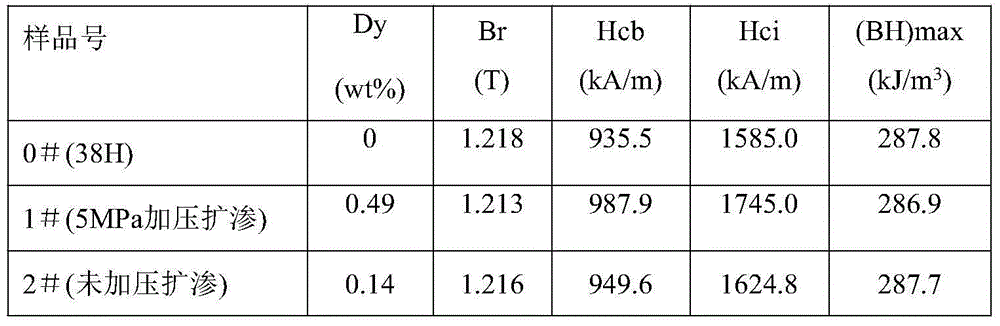

Method for preparing high-performance sintered Nd-Fe-B magnet by using two-step grain boundary diffusion technique

InactiveCN107256795AIncrease profitAvoid abnormal growthSolid state diffusion coatingInductances/transformers/magnets manufactureRare earthAlloy

The invention discloses a method for preparing a high-performance sintered Nd-Fe-B magnet by using the two-step grain boundary diffusion technique, and belongs to the field of rare earth permanent magnetic materials. The method includes: laying a low-melting-point alloy diffusion source R1-R2-TM thin band on a surface of a clean commercial sintered Nd-Fe-B magnet, wherein the R1 is randomly selected from La, Ce, Pr, and Nd, the R2 is selected from at least one of Dy and Tb, and the TM is selected from at least one of Cu, Al, Ti, Zn, Co, Ni, and Fe; performing heat treatment at the temperature of 650-800 DEG C for 6-24 hours, and allowing Tb / Dy to diffuse toward the inner part of the magnet along a grain boundary; performing heat treatment at the temperature of 850-950 DEG C for 1-4 hours, allowing the Tb / Dy enriched in a grain boundary phase to diffuse toward a surface layer of grains, and forming a Tb / Dy-rich shell structure; performing annealing at the temperature of 450-550 DEG C for 1.5-2.5 hours, and further adjusting a boundary structure; and finally acquiring the high-performance sintered Nd-Fe-B magnet. The advantages of the method are that the Tb / Dy is fully used to reinforce a grain surface transition layer so as to improve the coercivity; the time of the high temperature heat treatment is shortened, and energy can be saved; abnormal growth of grains can be avoided; and the method is suitable for thick magnets.

Owner:UNIV OF SCI & TECH BEIJING

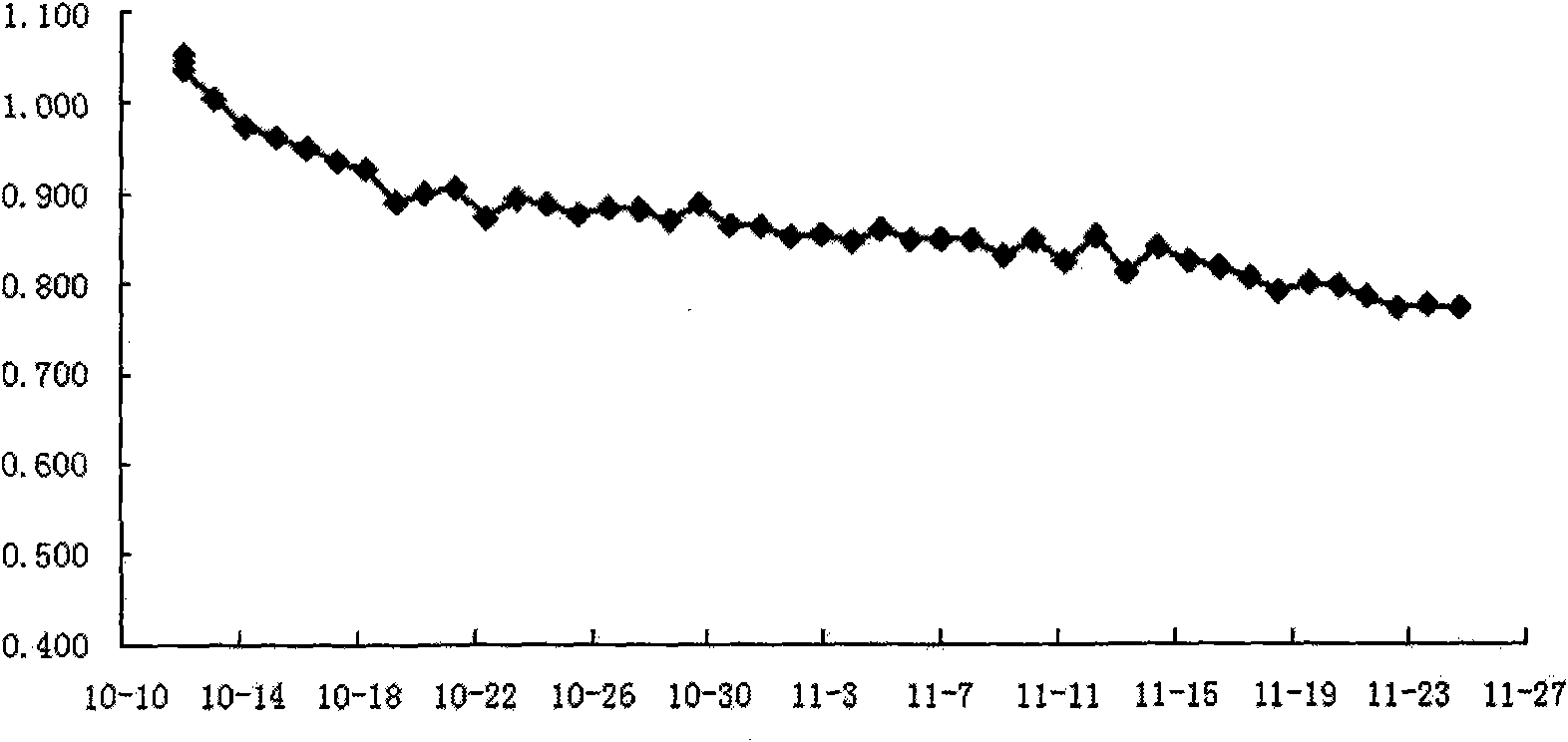

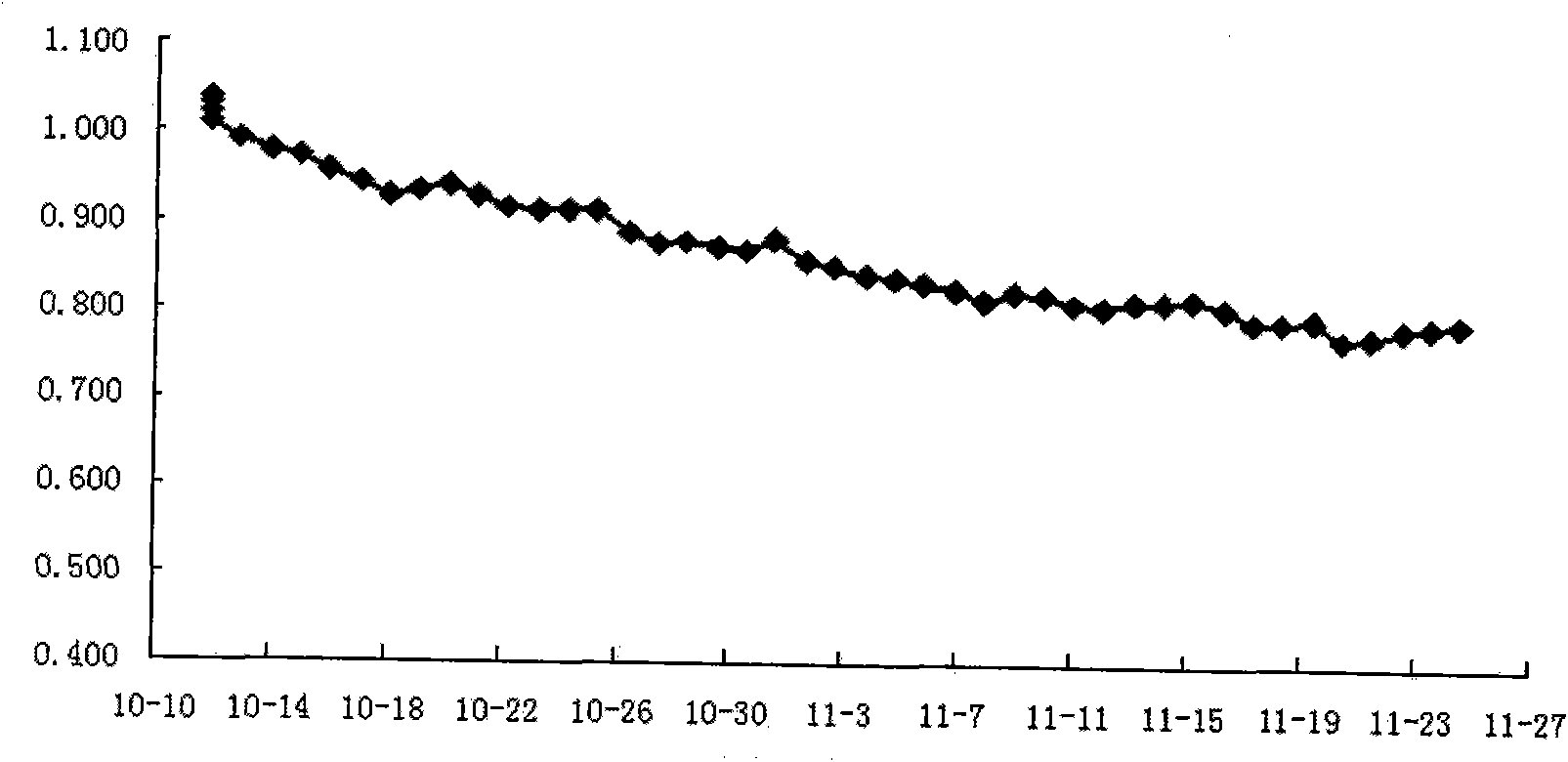

Method for accelerating permeation of Dy/Tb adhesive layer on surface of sintered neodymium-iron-boron magnet

ActiveCN104388952ARapid penetrationInhibit growthInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyRare earth

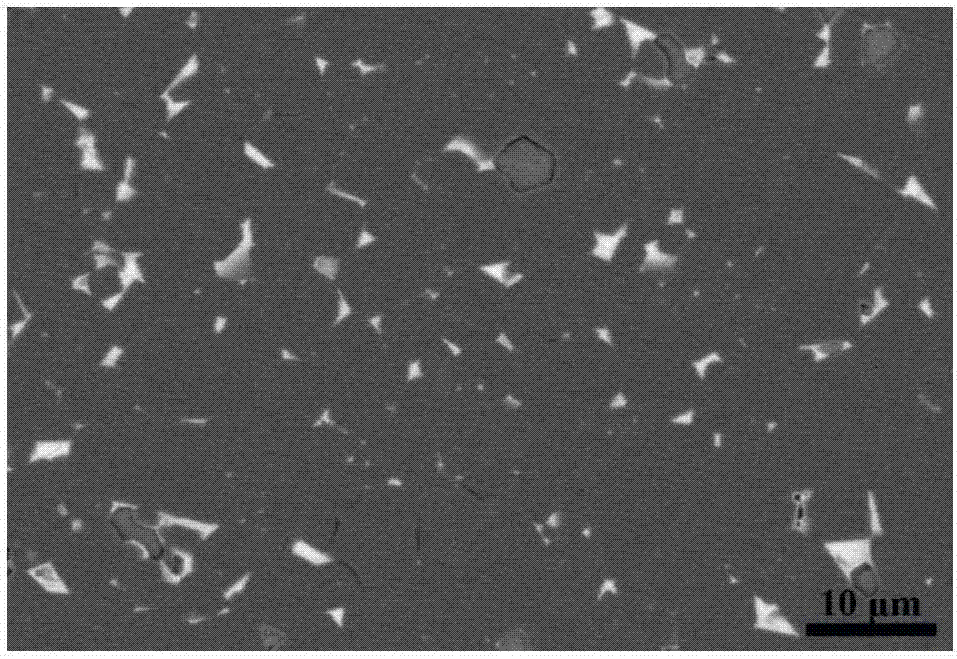

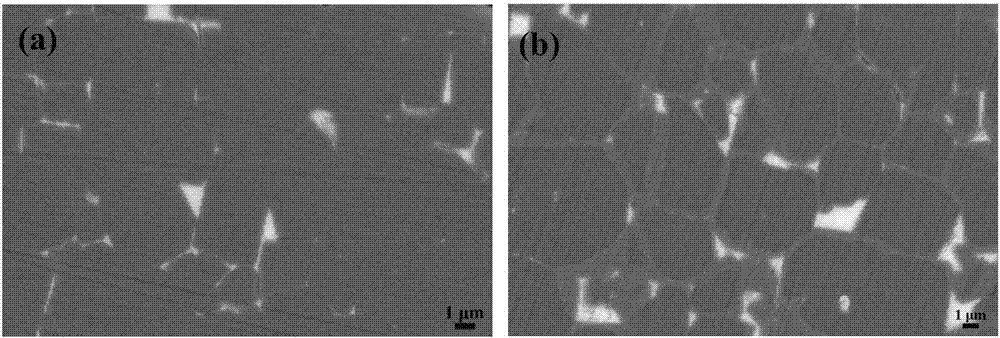

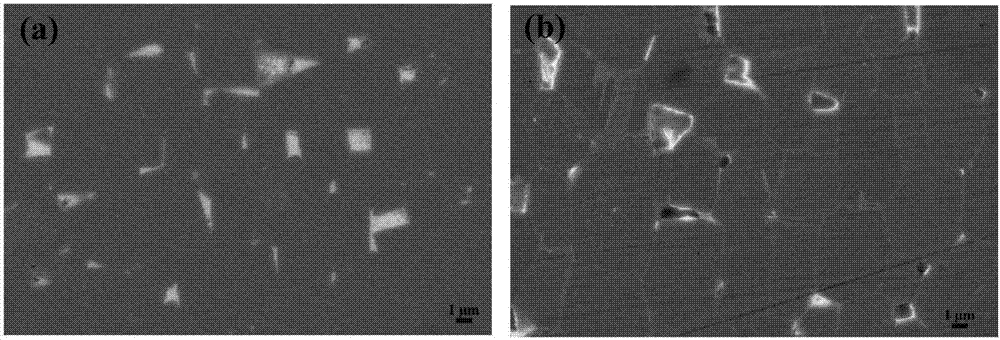

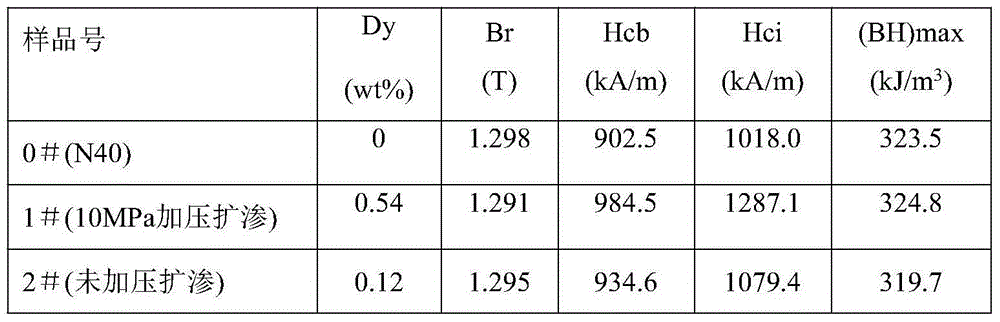

The invention belongs to the field of rare earth permanent magnetic materials, and particularly relates to a method for accelerating permeation of a Dy / Tb adhesive layer on the surface of a sintered neodymium-iron-boron magnet. The method is characterized in that a Dy / Tb element is subjected to high-pressure thermal treatment of 1-100MPa after being adhered to the surface of a sintered neodymium-iron-boron magnet, so as to accelerate permeation of the Dy / Tb element on a grain boundary of the sintered neodymium-iron-boron magnet, thus a high-coercivity magnet is obtained. The method specifically comprises the following processing steps: firstly, carrying out cleaning treatment on the surface of the neodymium-iron-boron magnet; attaching the Dy / Tb element to the clean surface of the neodymium-iron-boron magnet, and then carrying out high-pressure thermal treatment on the Dy / Tb element, so as to rapidly permeate the Dy / Tb element on the grain boundary of the magnet; further improving the magnet boundary structure through medium-temperature thermal treatment, and finally obtaining the high-coercivity neodymium-iron-boron magnet. The method has the outstanding advantages that the permeation of the Dy / Tb element on the grain boundary can be accelerated through high-pressure thermal treatment; a relatively thick sample can be processed; the thermal treatment temperature is greatly reduced; the thermal treatment time is shortened; and the efficiency is significantly improved.

Owner:UNIV OF SCI & TECH BEIJING

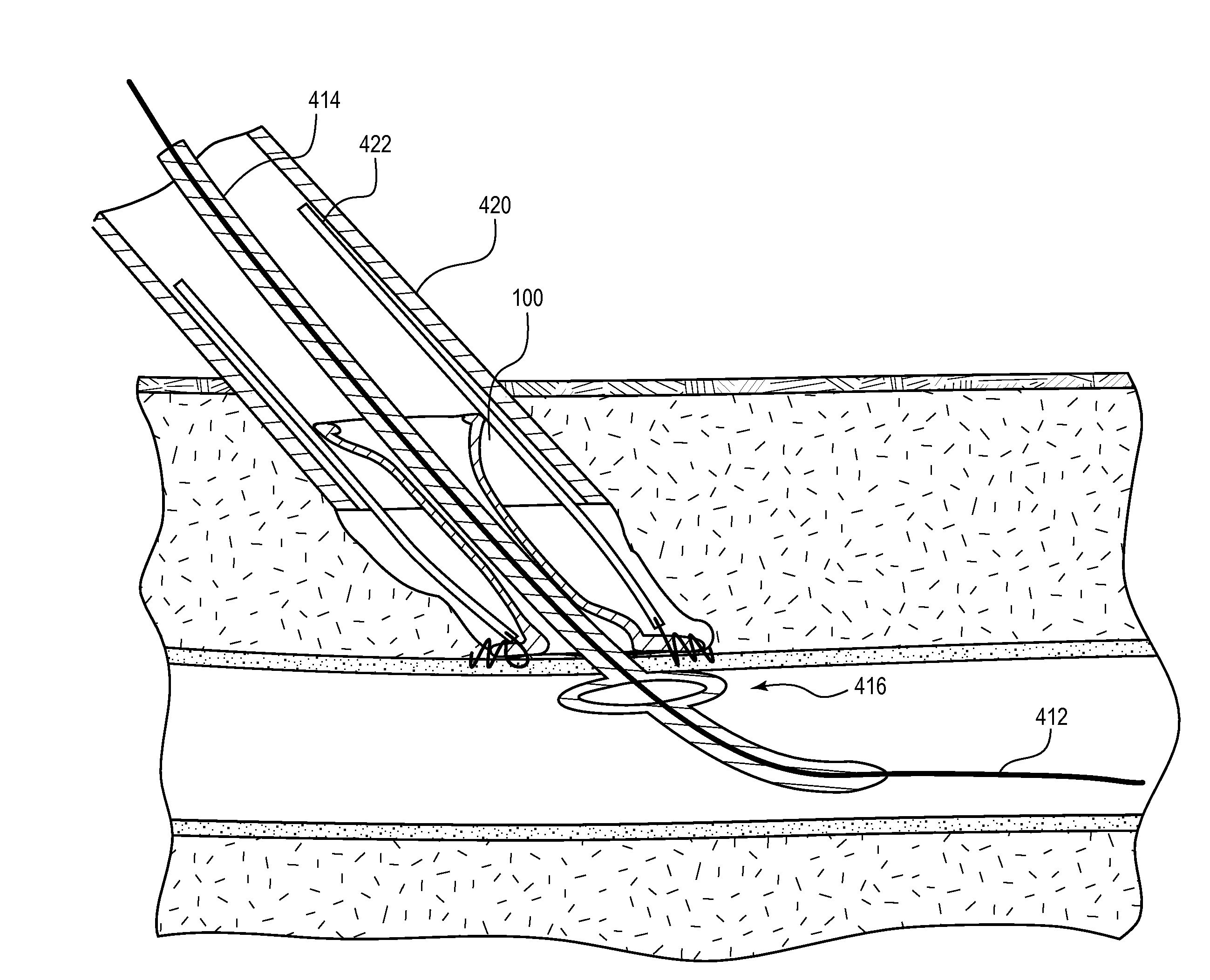

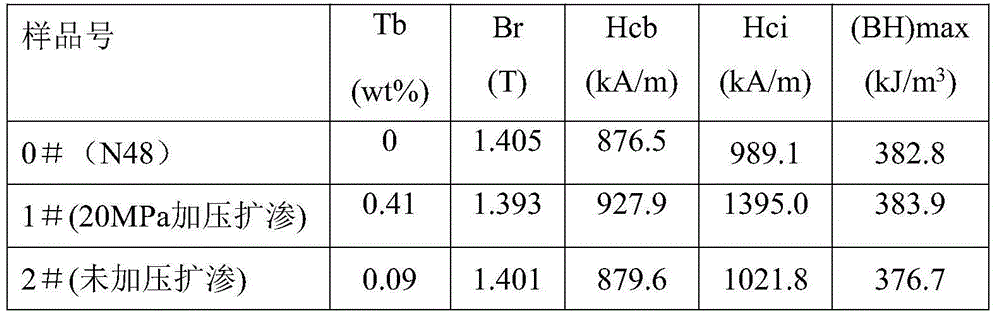

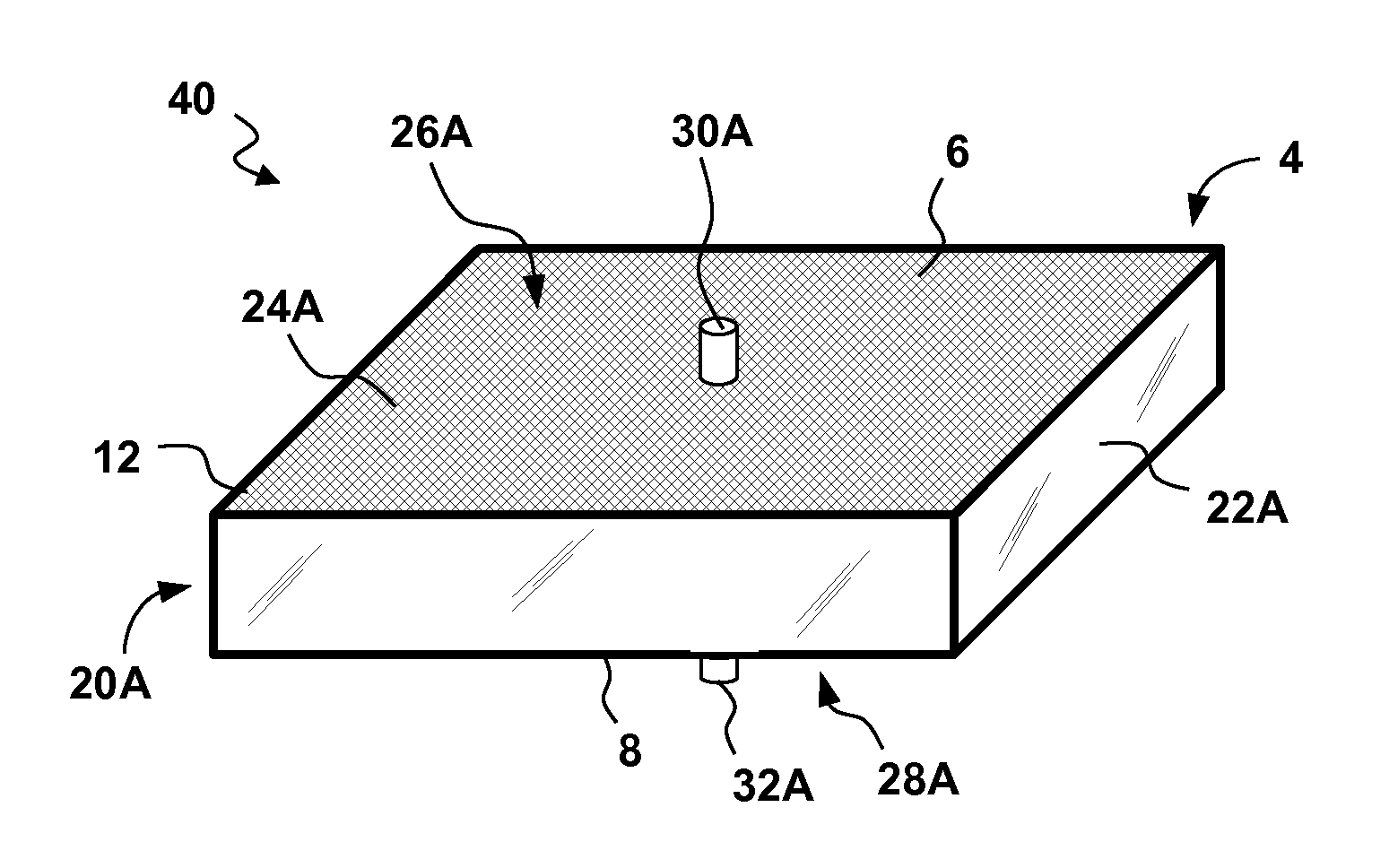

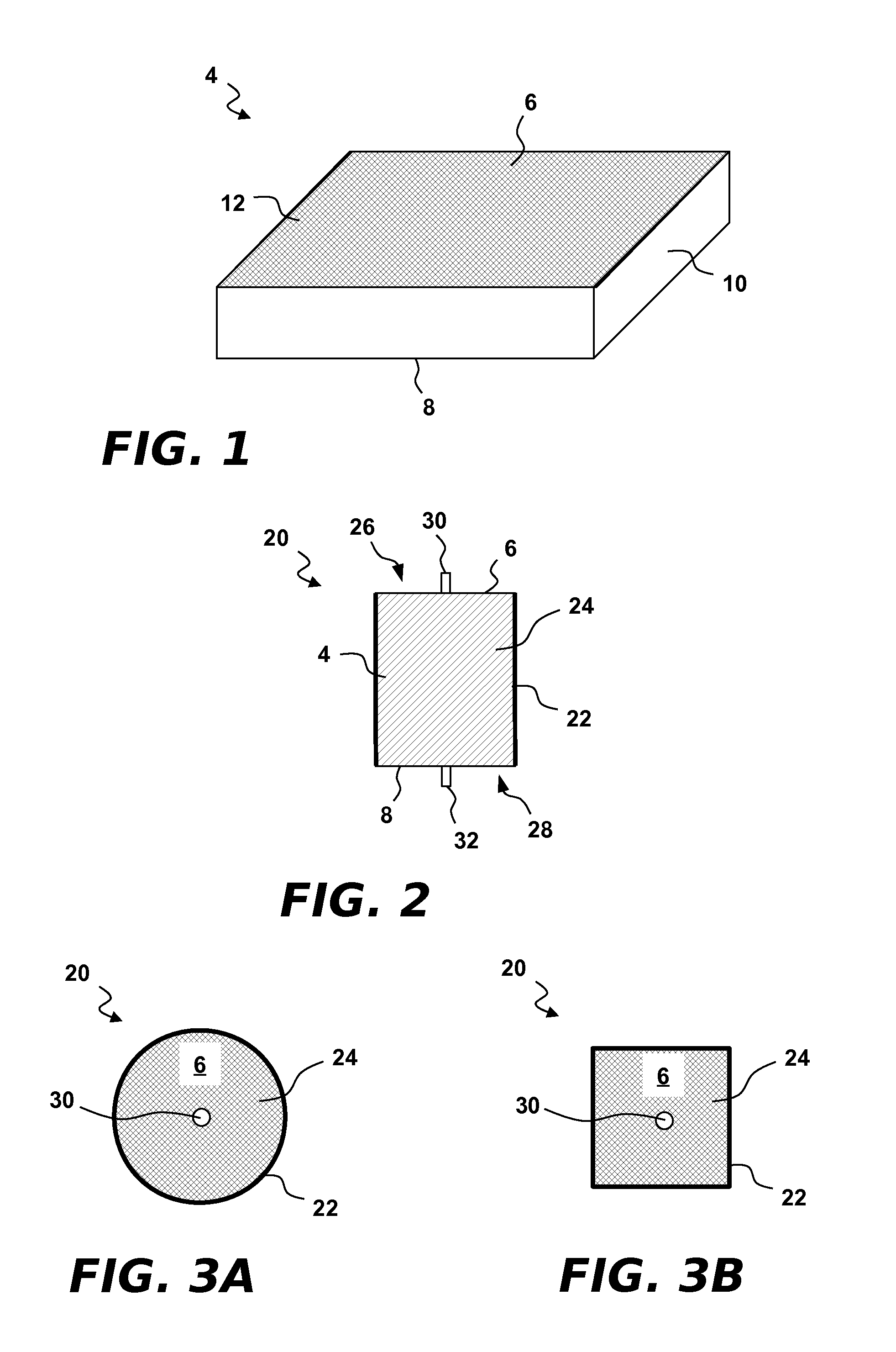

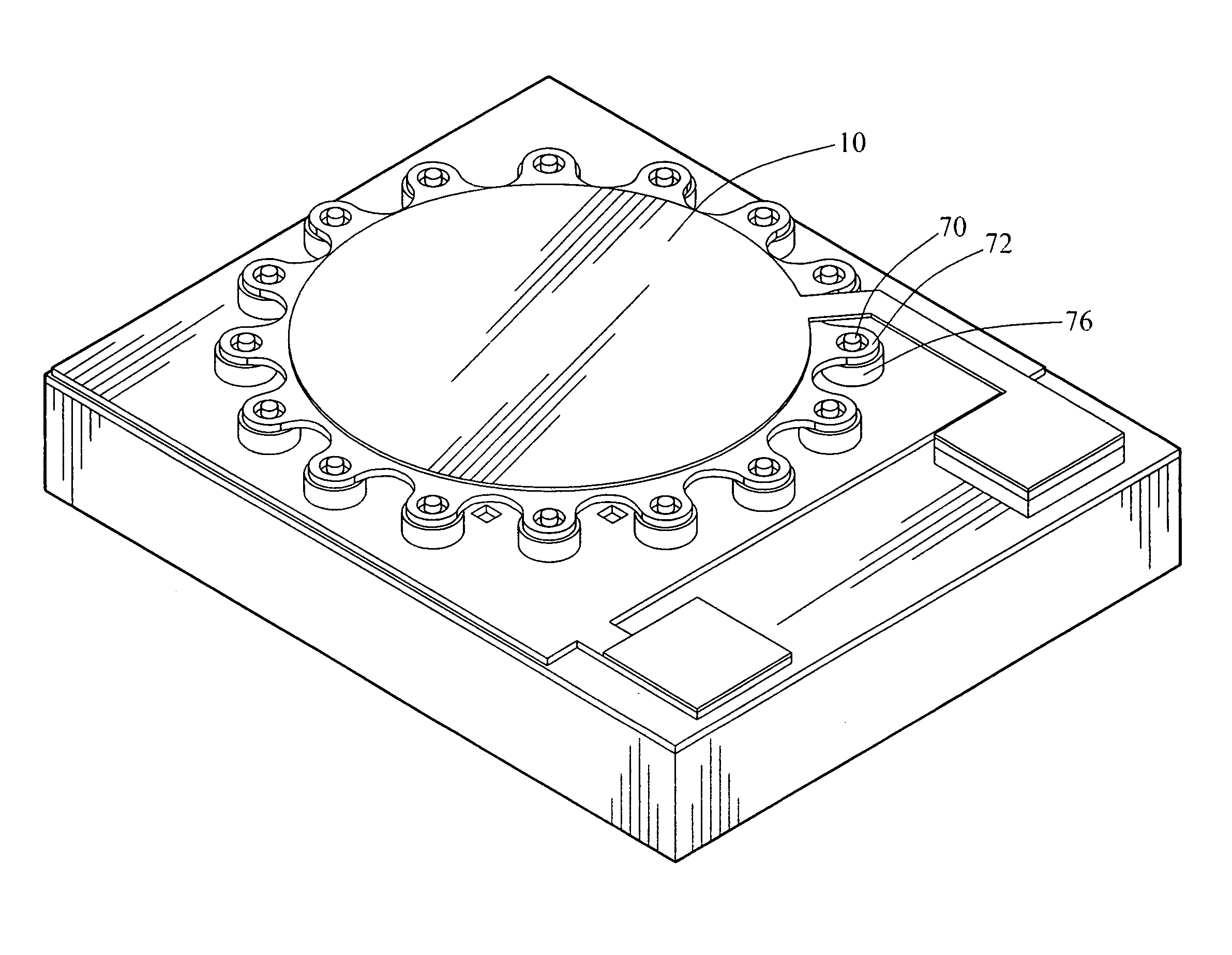

Detection and guide systems and methods for accessing blood vessels

A detection and guide system provides access to desired blood vessel locations. An implant formed of a biocompatible material is implanted within a mammalian body proximate an outer surface of a blood vessel. The detection and guide system may be configured to be positioned outside the mammalian body to detect the implant and to guide a needle to the desired entry site of the biological boundary structure. A needle guide may be coupled to a housing of the detection and guide system and directed at an angle such that positioning the implant detector over the implant aligns an opening through the needle guide with the desired entry site. The detection and guide system may, for example, provide metal detection of a metallic implant or magnetic detection of a magnetic implant.

Owner:TEITELBAUM GEORGE P +2

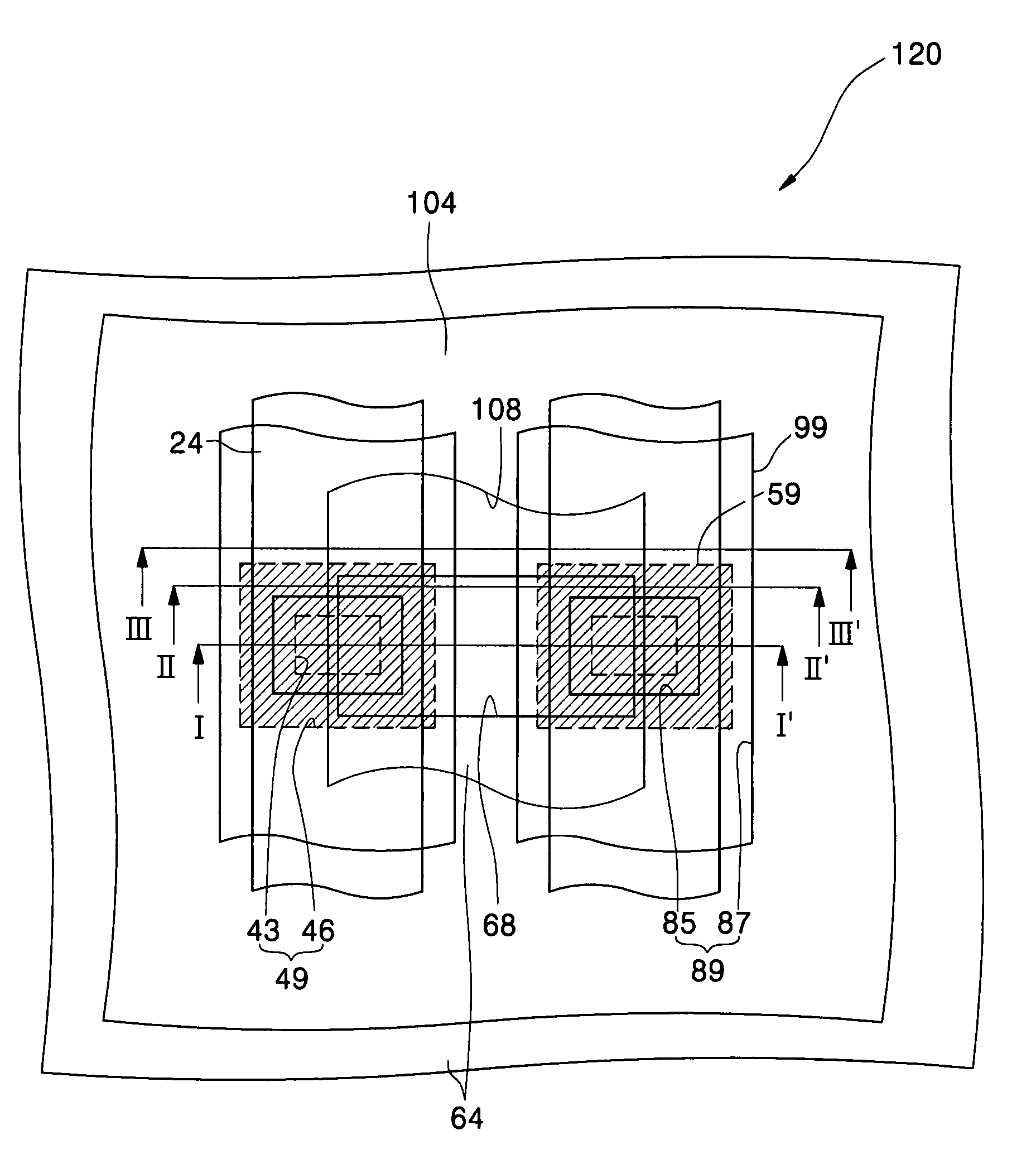

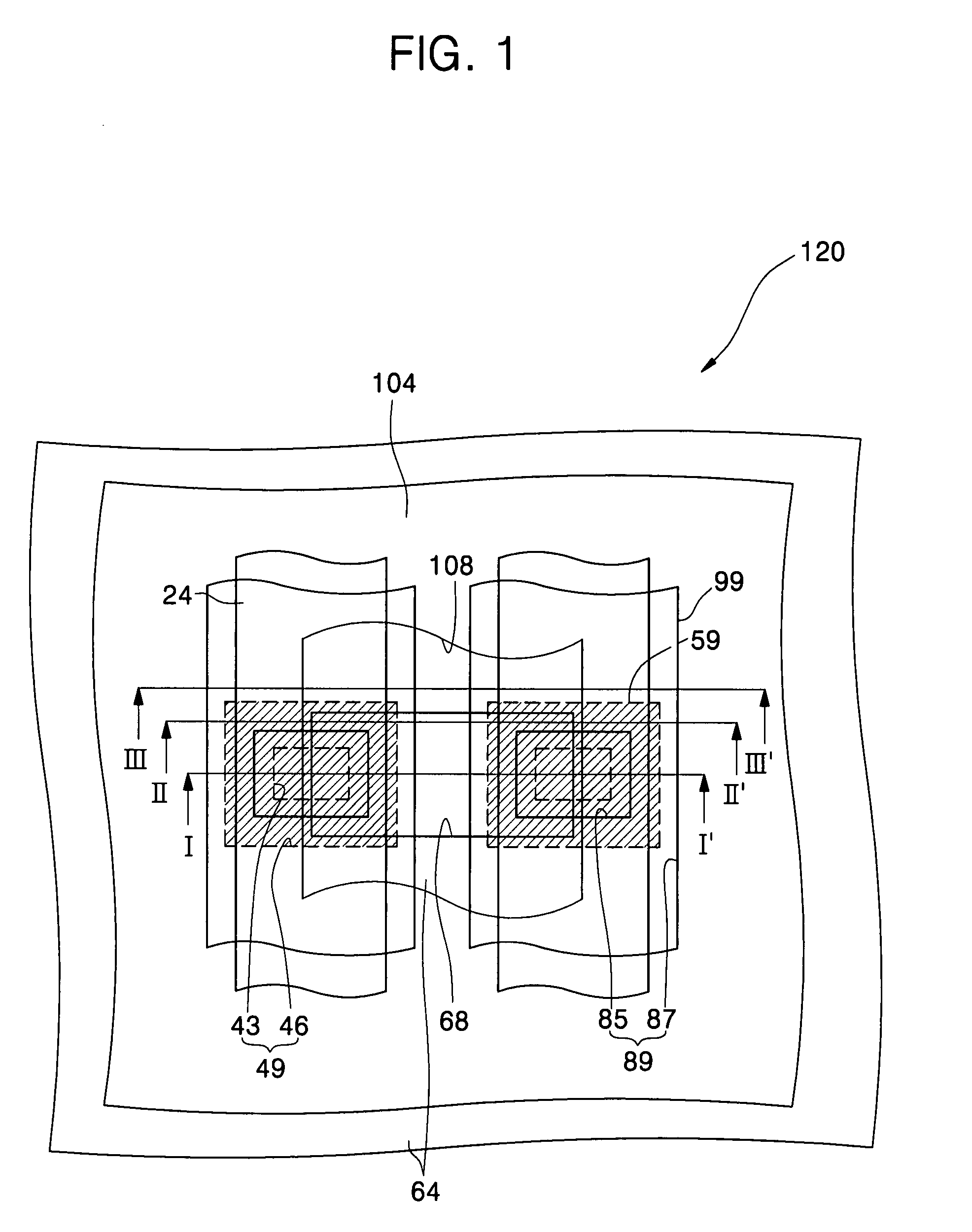

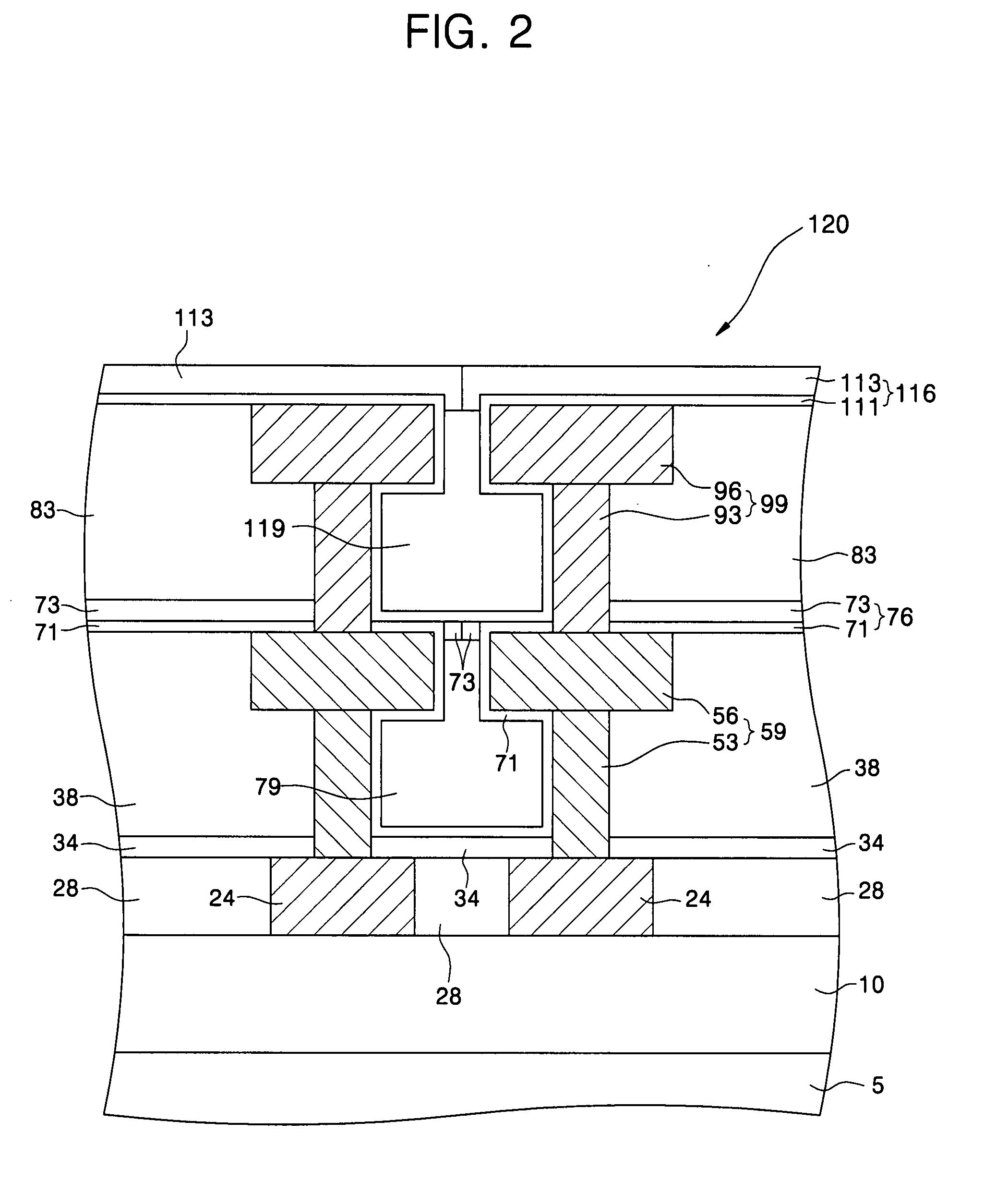

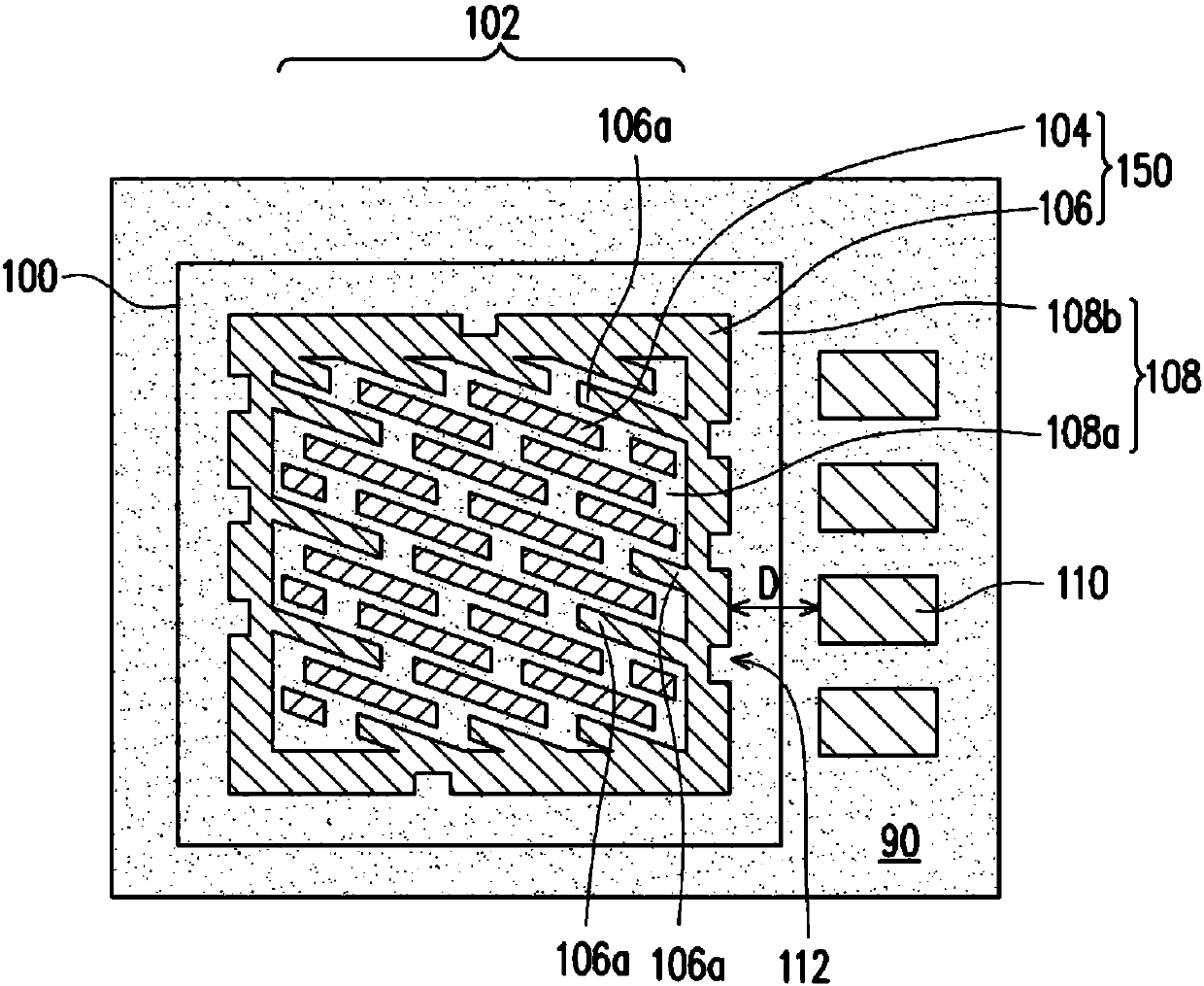

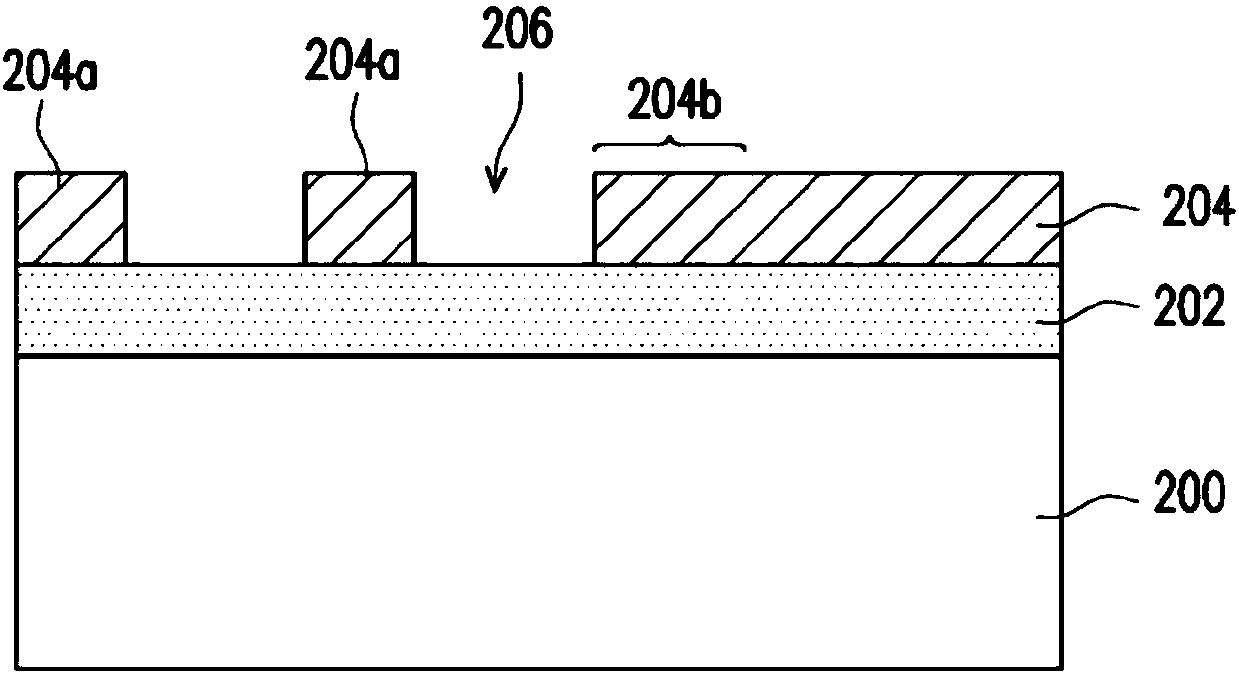

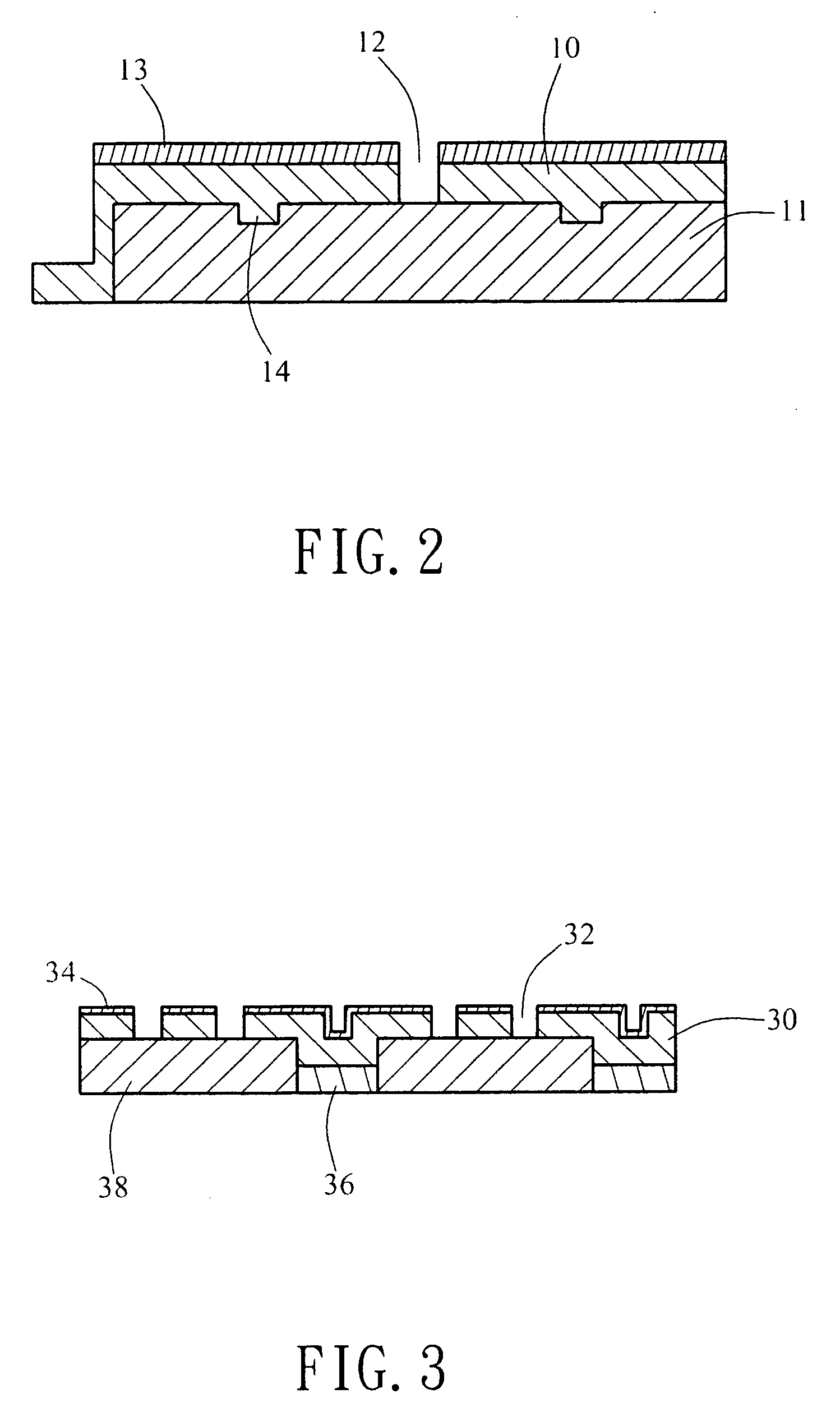

Void boundary structures, semiconductor devices having the void boundary structures and methods of forming the same

InactiveUS20080042268A1Simple definitionReduce parasitic capacitanceSemiconductor/solid-state device detailsSolid-state devicesBoundary structureSemiconductor

Void boundary structures, semiconductor devices having the void boundary structures, and methods of forming the same are provided. The structures, semiconductor devices and methods present a way for reducing parasitic capacitance between interconnections by forming a void between the interconnections. The interconnections may be formed on a semiconductor substrate. An upper width of each of the interconnections may be wider than a lower width thereof. A molding layer encompassing the interconnections may be formed. A void boundary layer covering the molding layer may be formed to define the void between the interconnections.

Owner:SAMSUNG ELECTRONICS CO LTD

A method and a system for producing an object using solid freeform fabrication

InactiveCN1852803APower drive mechanisms3D object support structuresEngineeringSolid freeform fabrication

A method of producing an object through solid freeform fabrication includes selectively depositing a boundary structure that defines a surface of the object, and depositing a flowable build material (107) within the boundary structure, wherein the flowable build material (107) forms a portion of the object by flowing to the boundary structure.

Owner:HEWLETT PACKARD DEV CO LP

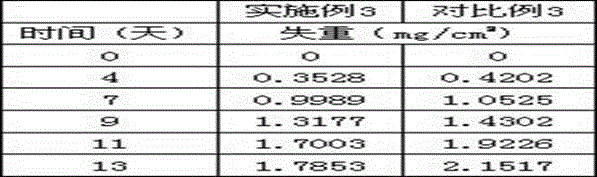

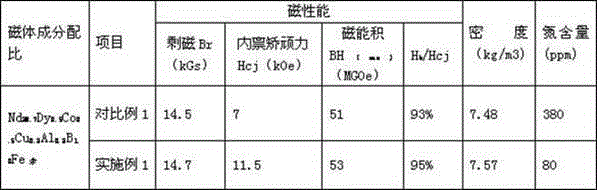

Manufacturing method for improving magnetic performance of sintered neodymium-iron-boron magnet

InactiveCN104143403ANitrogen content decreasedThe total amount is stableInorganic material magnetismInductances/transformers/magnets manufactureHafniumNitrogen gas

A high-magnetism sintered neodymium-iron-boron magnet is characterized by comprising, by weight, 27-31% of rare earth elements, 0.9-1.2% of boron, 0-3.0% of cobalt, 0-2% of adding elements and the balance iron, the rare earth elements comprise two or more of neodymium, praseodymium, dysprosium, terbium and holmium, and the adding elements comprise two or more of aluminum, copper, gallium, niobium, zirconium, titanium and hafnium. A manufacturing method includes the working procedures of batching, smelting, hydrogen breaking, pulverizing, forming and sintering, and argon protection is selected for replacing nitrogen protection in the working procedures from smelting to sintering, so that the content of nitrogen in the sintered neodymium-iron-boron magnet is reduced substantially, the total quantity of the rare earth elements in the magnet is relatively stable, the coercivity of the magnet is improved, and the magnetic performance is kept well. A magnet crystal boundary structure change caused by the nitrogen does not exist in the production process, and the corrosion-resistant capacity of the sintered magnet is improved.

Owner:NINGBO KETIAN MAGNET +1

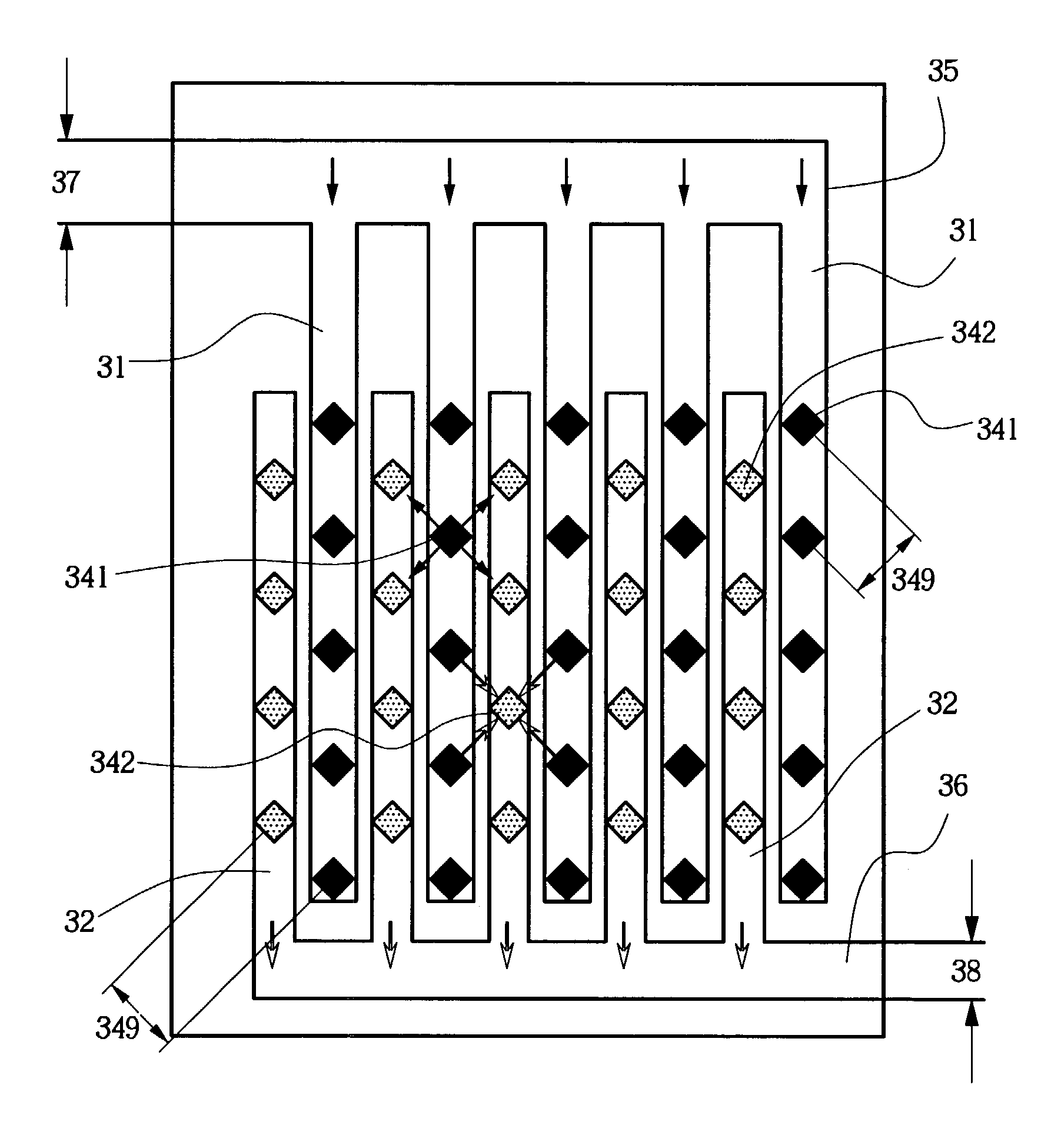

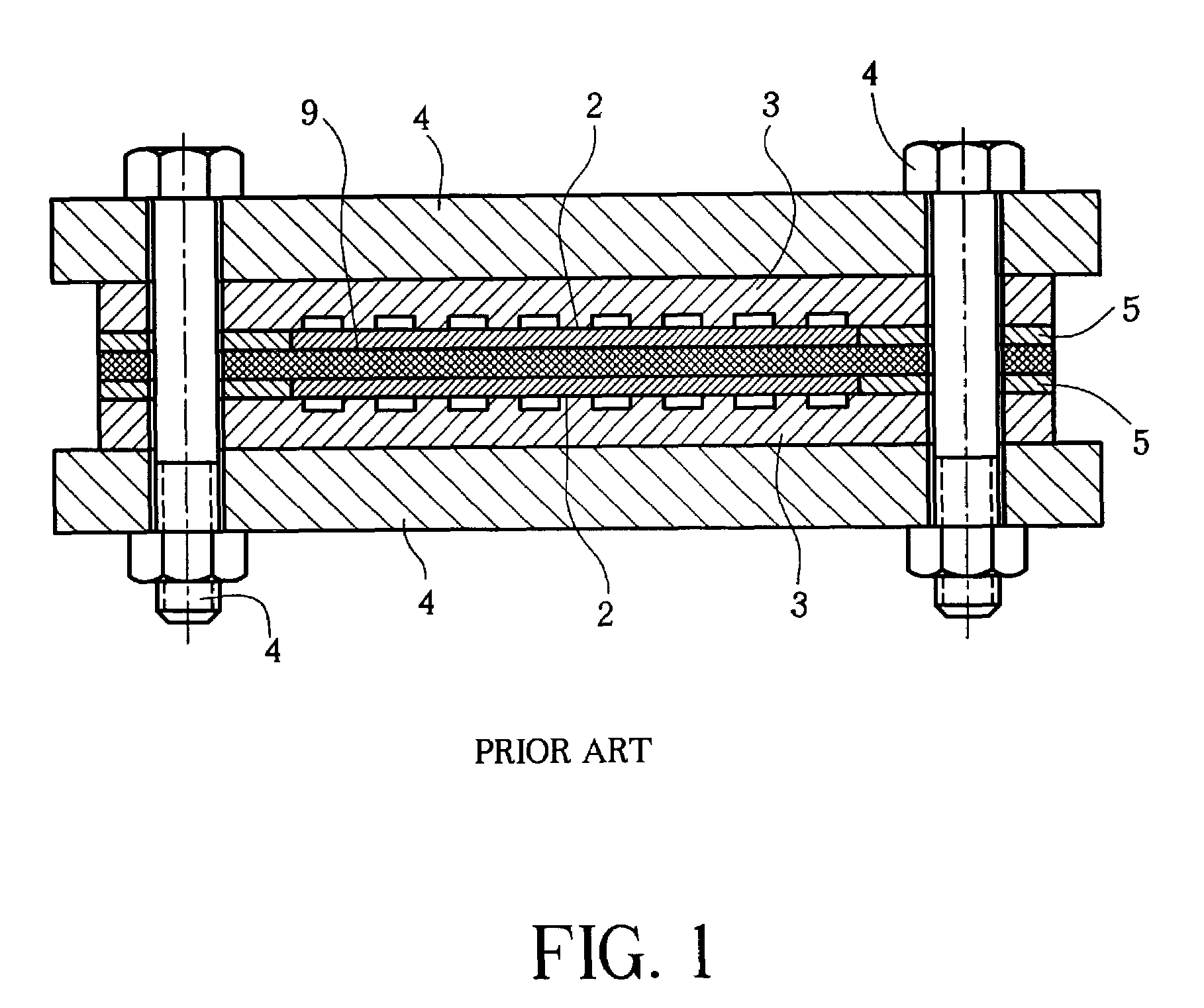

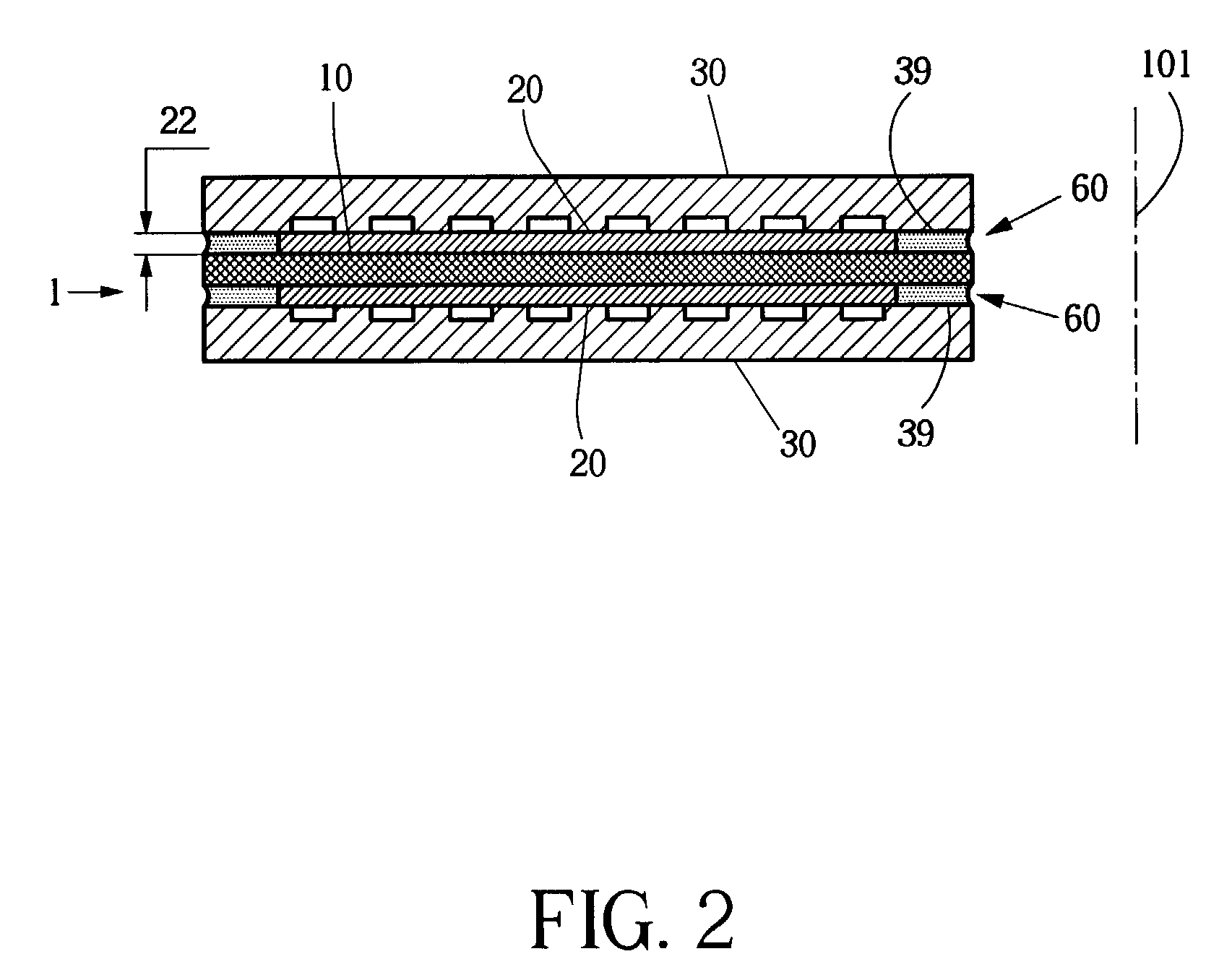

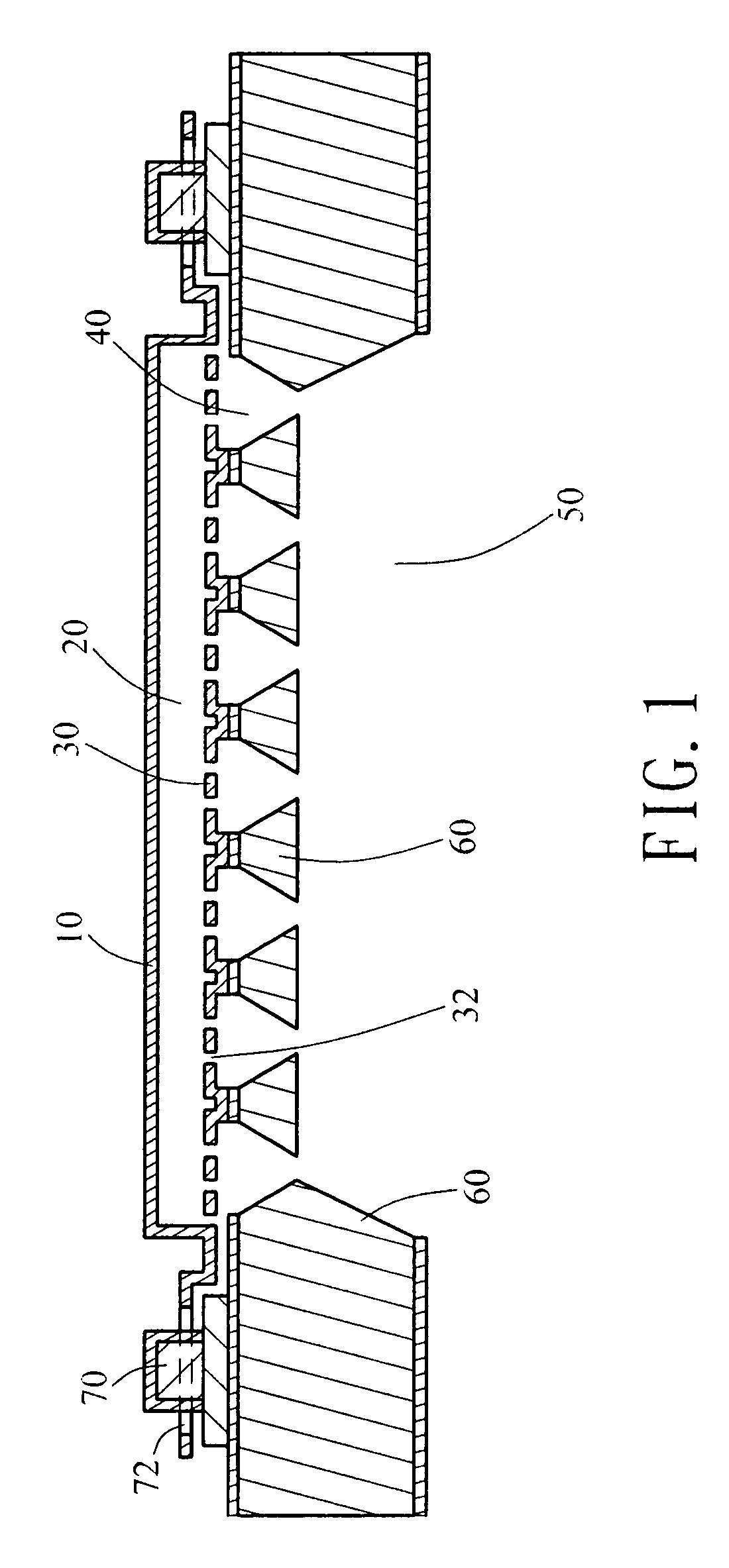

Fuel cell

InactiveUS7341800B2Bonded firmlyIncreased durabilityFuel cells groupingCell electrodesIn planeFlow resistivity

A simple, inexpensive and highly efficient fuel cell has boundary structures made of a photo-sensitive material in combination with selective patterning. Printed circuit board (PCB) fabrication techniques combine boundary structures with two and three dimensional electrical flow path. Photo-sensitive material and PCB fabrication techniques are alternately or combined utilized for making micro-channel structures or micro stitch structures for substantially reducing dead zones of the diffusion layer while keeping fluid flow resistance to a minimum. The fuel cell assembly is free of mechanical clamping elements. Adhesives that may be conductively contaminated and / or fiber-reinforced provide mechanical and eventual electrical connections, and sealing within the assembly. Mechanically supporting backing layers are pre-fabricated with a natural bend defined in combination with the backing layers' elasticity to eliminate massive support plates and assist the adhesive bonding. Proton insulation between adjacent and electrically linked in-plane cell elements is provided by structural insulation within the central membrane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

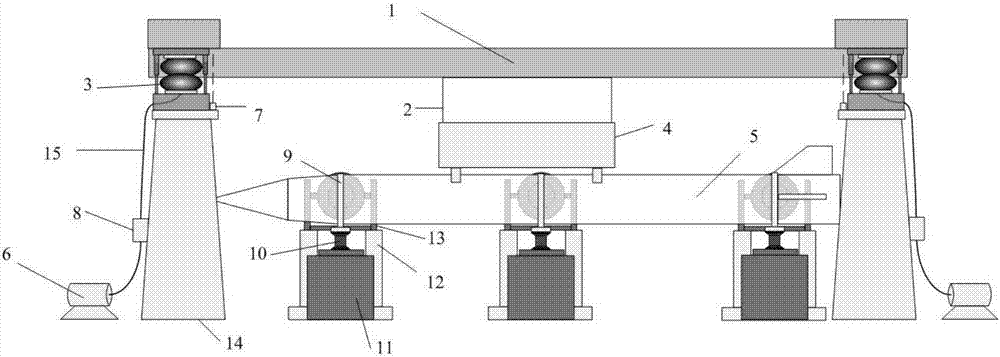

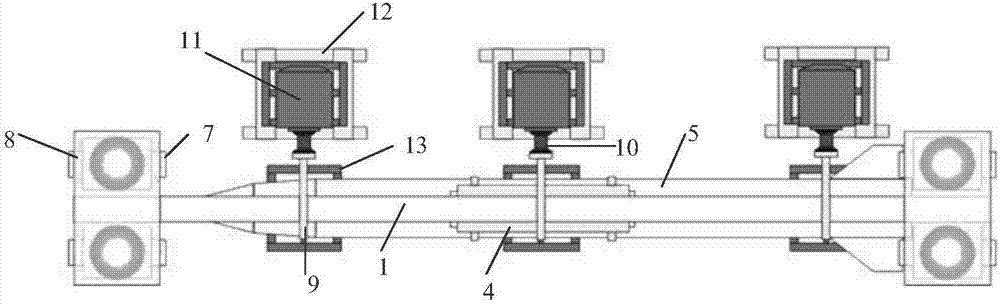

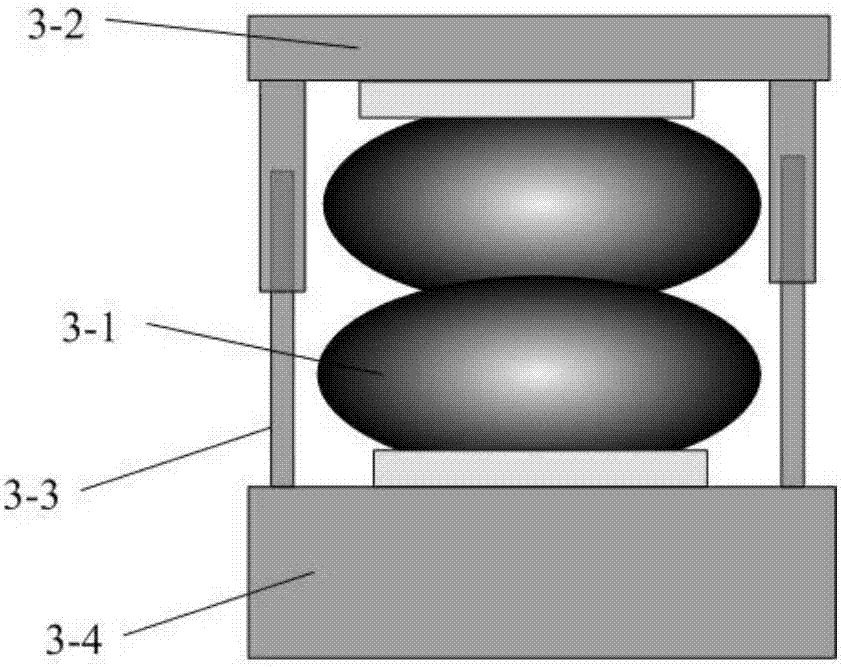

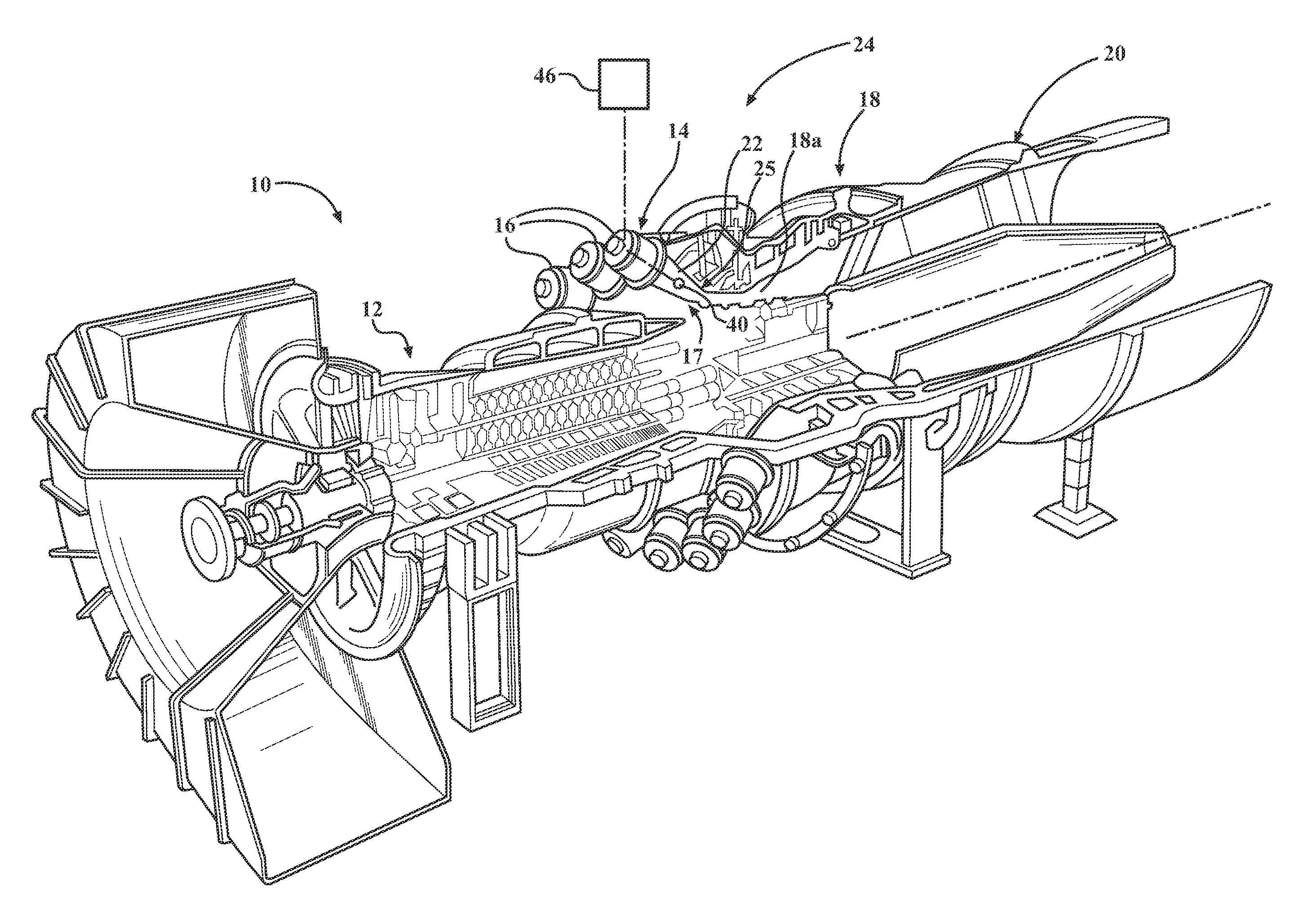

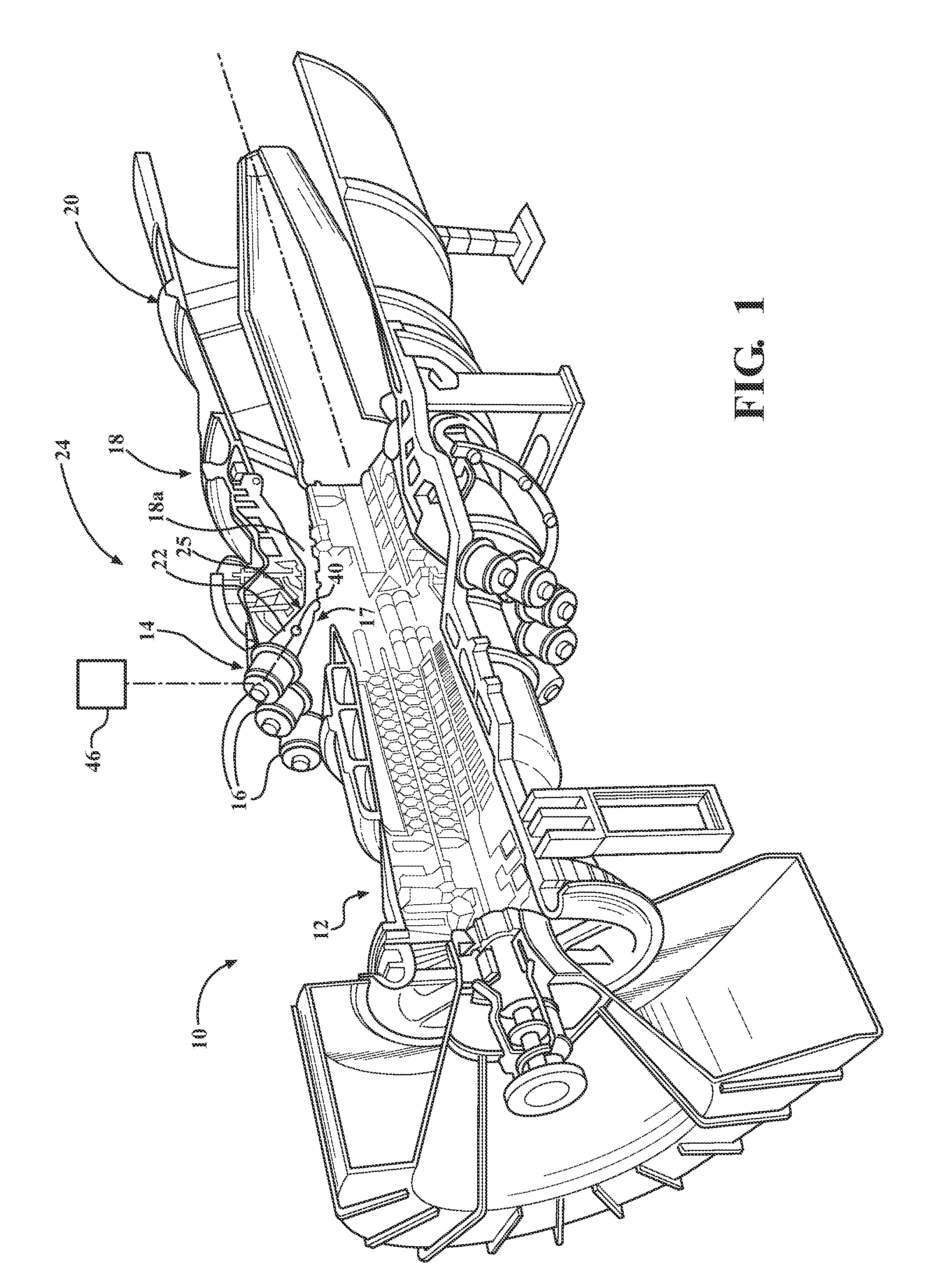

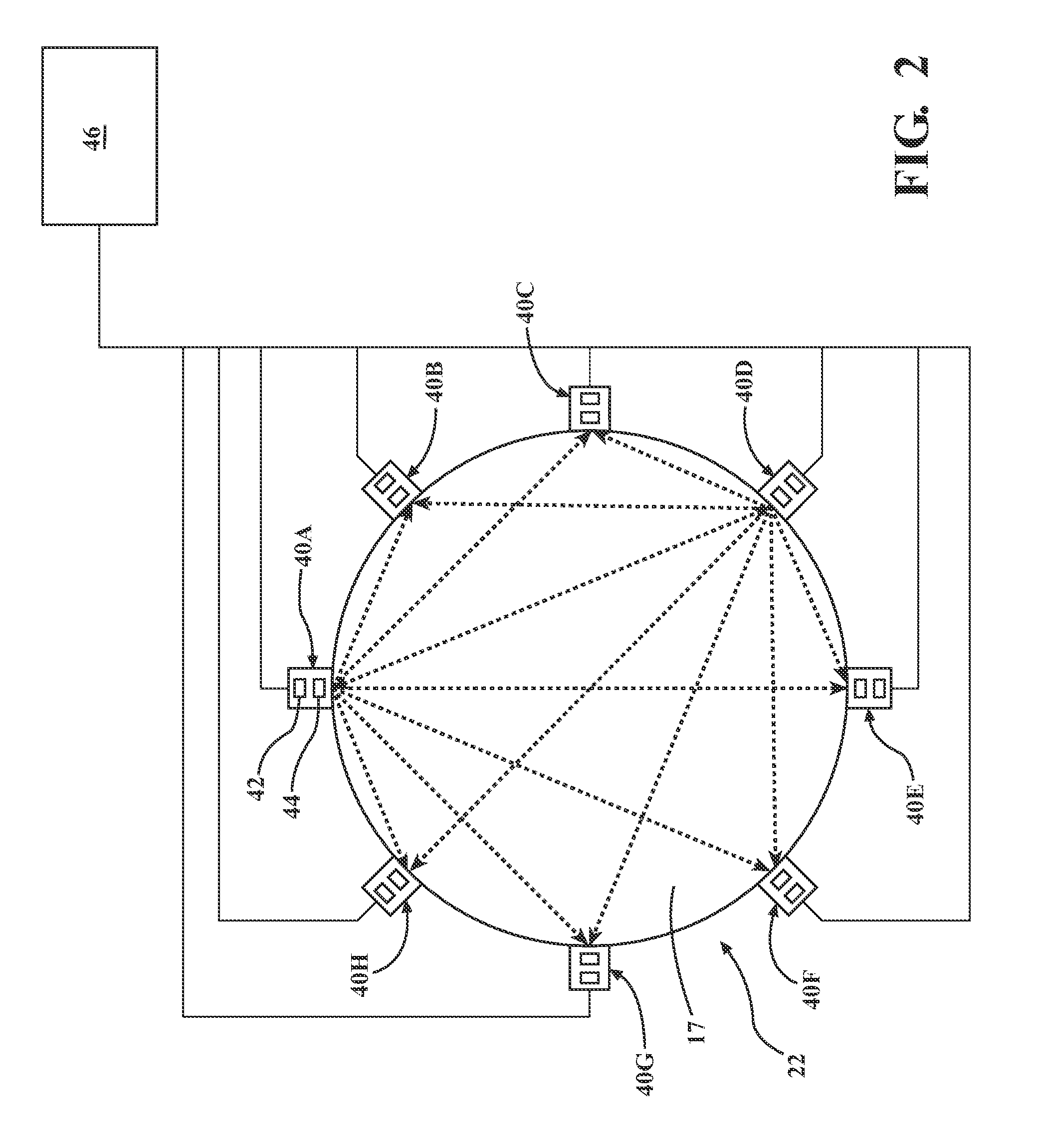

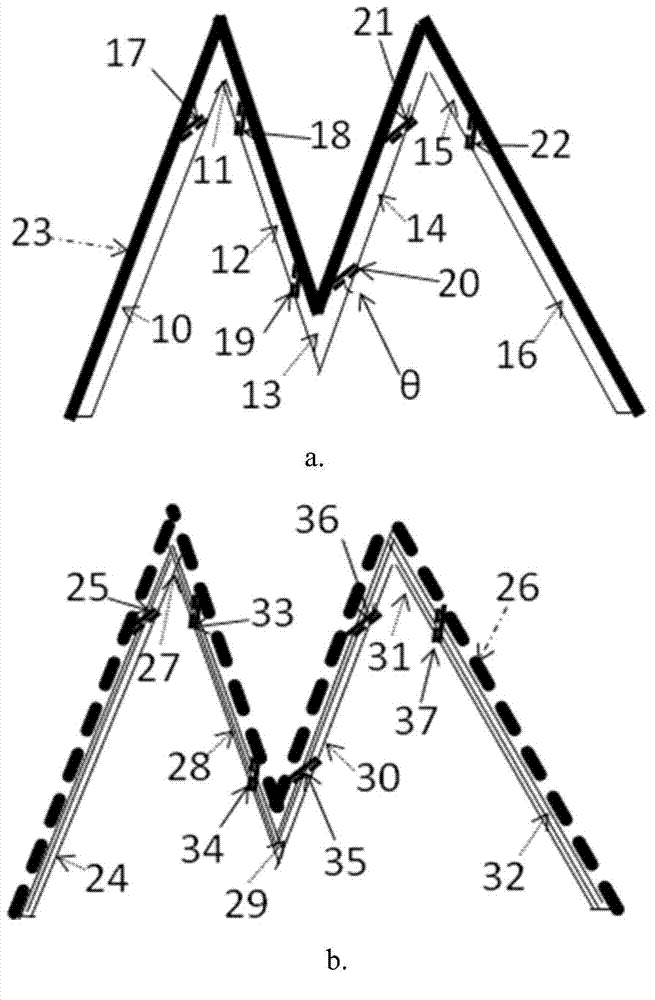

A large-scale missile hanging-on-the-plane vibration test device and method

ActiveCN107121254ARealize the vibration test requirements of the full elastic hanging machineEffectively assess the dynamic strength of missilesVibration testingSupporting systemAir spring

A large-scale missile hanging-on-the-plane vibration test device is composed of a hanging-on-the-plane simulated boundary structure support member, a hanger switch-over device, air spring support systems, a hanger, a hanging-on-the-plane missile, air compressors, laser displacement meters, pressure controllers, vibration tools, bulbs, vertical vibrating tables, horizontal vibrating table mounting bases, horizontal vibrating tables and test bearing bases. The large-scale missile hanging-on-the-plane vibration test device is characterized in that the hanging-on-the-plane missile is mounted on the hanger; the hanger is mounted on the hanging-on-the-plane simulated boundary structure support member through the hanger switch-over device; the hanging-on-the-plane simulated boundary structure support member is mounted on the air spring support systems and the air spring support systems are installed on the test bearing bases; the vertical vibrating tables and the horizontal vibrating tables are connected to the vibration tools through the bulbs; and the vibration tools are used for fixing the hanging-on-the-plane missile.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Low dielectric-epoxy resin/mesoporous molecular sieve hybrid material and preparation method thereof

InactiveCN101638505AEvenly dispersedLow dielectric constantPlastic/resin/waxes insulatorsDielectricMolecular sieve

The invention belongs to the field of organic / inorganic hybrid materials and discloses a low dielectric-epoxy resin / mesoporous molecular sieve hybrid material and a preparation method thereof. The hybrid material comprises the following components in portion by weight: epoxy resin prepolymer 70-91.2, mesoporous molecular sieves 0.1-12 and curing agent 8.8-25. The epoxy resin hybrid material containing mesoporous molecular sieves of the invention has a dielectric constant which is reduced by 0.1 to 0.9 at 100kHz compared with that of pure epoxy resin at 100kHz and retains the original excellentperformance of epoxy matrix resin at the same time. According to the preparation method of the invention, the mesoporous molecular sieves uniformly disperse in the resin and form an excellent boundary structure, and the obtained hybrid material has a low dielectric constant and an excellent thermal mechanical property and can be used in the fields of printed circuit boards, electronic package andthe like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Medical viewing system and method for detecting boundary structures

InactiveUS7991453B2Increase awarenessFor accurate visualizationImage enhancementImage analysisMotion vectorGuide wires

A medical viewing system for displaying a sequence of medical images that represents moving and / or positioning a guide-wire in a blood vessel, which guide-wire has a guide-wire tip that is contrasted with respect to the guide wire, this system comprising acquisition means that acquires an original sequence of noisy images called live sequence and processing means for processing said live sequence of images in real time, the processing means comprising: first means (10) for automatically detecting the guide-wire tip, yielding skeleton information of the guide-wire tip and a field of motion vectors based on said skeleton information; second means (20) for automatically registering the guide-wire tip with respect to a reference based on the field of motion vectors and for enhancing the guide-wire and the vessel walls while blurring the background in the registered images; and comprising: Display means for displaying a live sequence of processed images.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Grain boundary corrosion method of high niobium beta titanium alloy

InactiveCN103512791AImprove production efficiencyEasy to operatePreparing sample for investigationNiobiumSilk cloth

The invention discloses a grain boundary corrosion method of a high niobium beta titanium alloy. The grain boundary corrosion method comprises the steps of cutting a metallographic specimen from the high niobium beta titanium alloy, firstly coarse grinding the metallographic specimen, and then fine grinding. The method further comprises the following steps: 1. covering a layer of real silk cloth on a side of a piece of polishing cloth for polishing, adopting the polishing cloth covered with the real silk cloth to carry out mechanical polishing to the fine ground metallographic specimen until the surface of the metallographic specimen is bright and free from scratch; 2. preparing a corrosive agent; 3. placing the mechanically polished metallographic specimen in the corrosive to soak and corrode until the corroded side of the metallographic specimen becomes silver gray; 4. taking out the soaked and corroded metallographic specimen, using water to wash away the residual corrosive agent, and then using ethyl alcohol to rinse the metallographic specimen and drying. The method is simple to operate, easy to control conditions and high in specimen preparing efficiency, can quickly, easily and effectively obtain the clear and complete crystal boundary structure, and solves the problems that the high niobium beta titanium alloy is not easy to polish and does not have a proper corrosion method.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

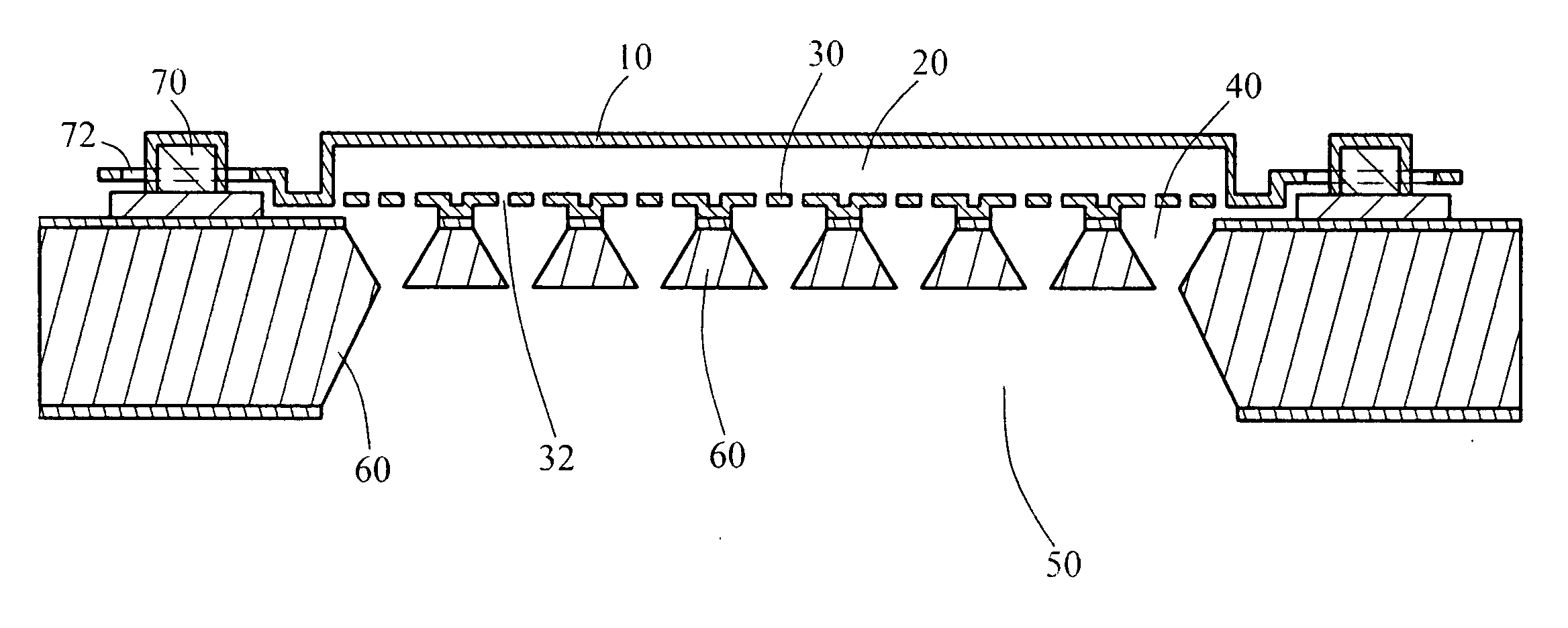

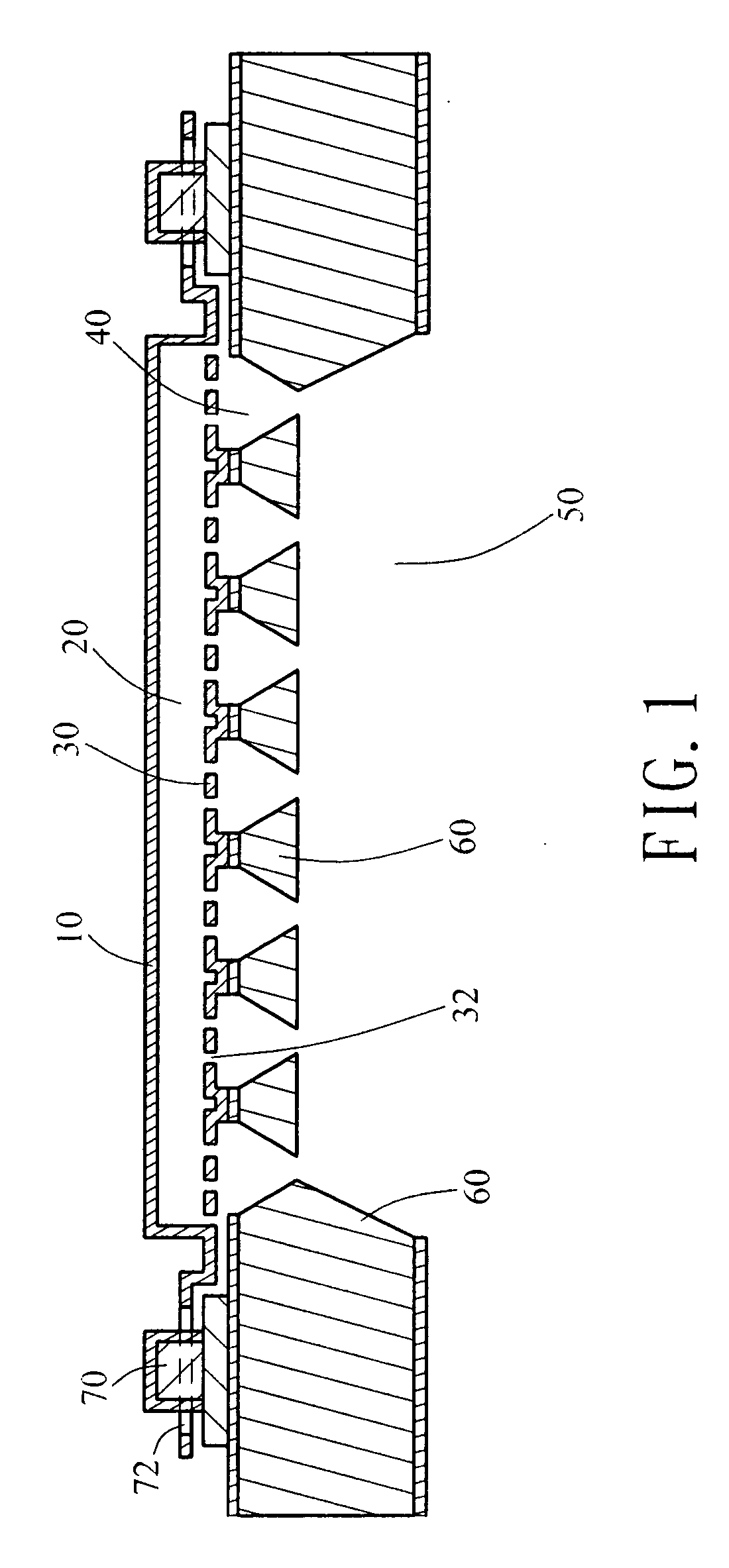

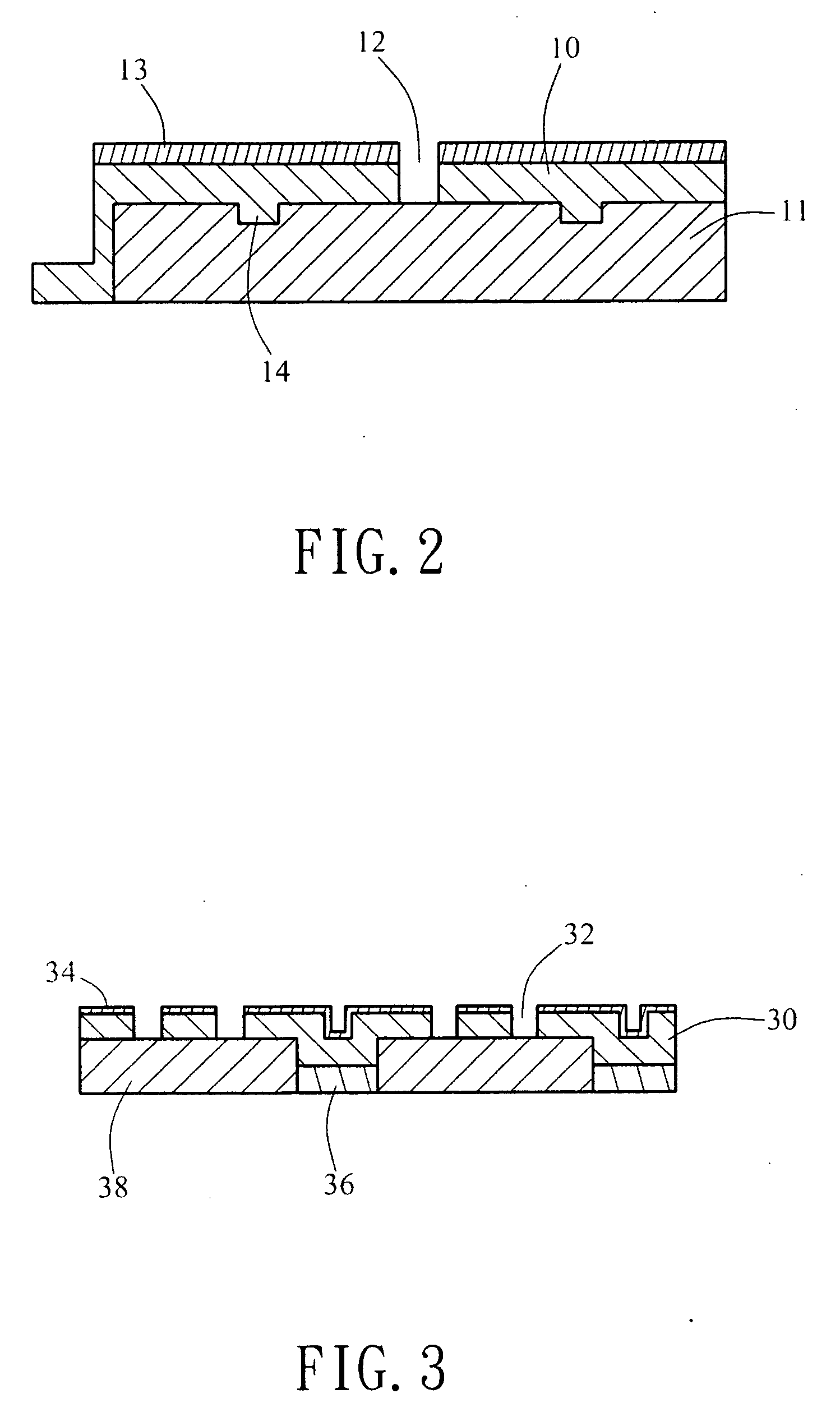

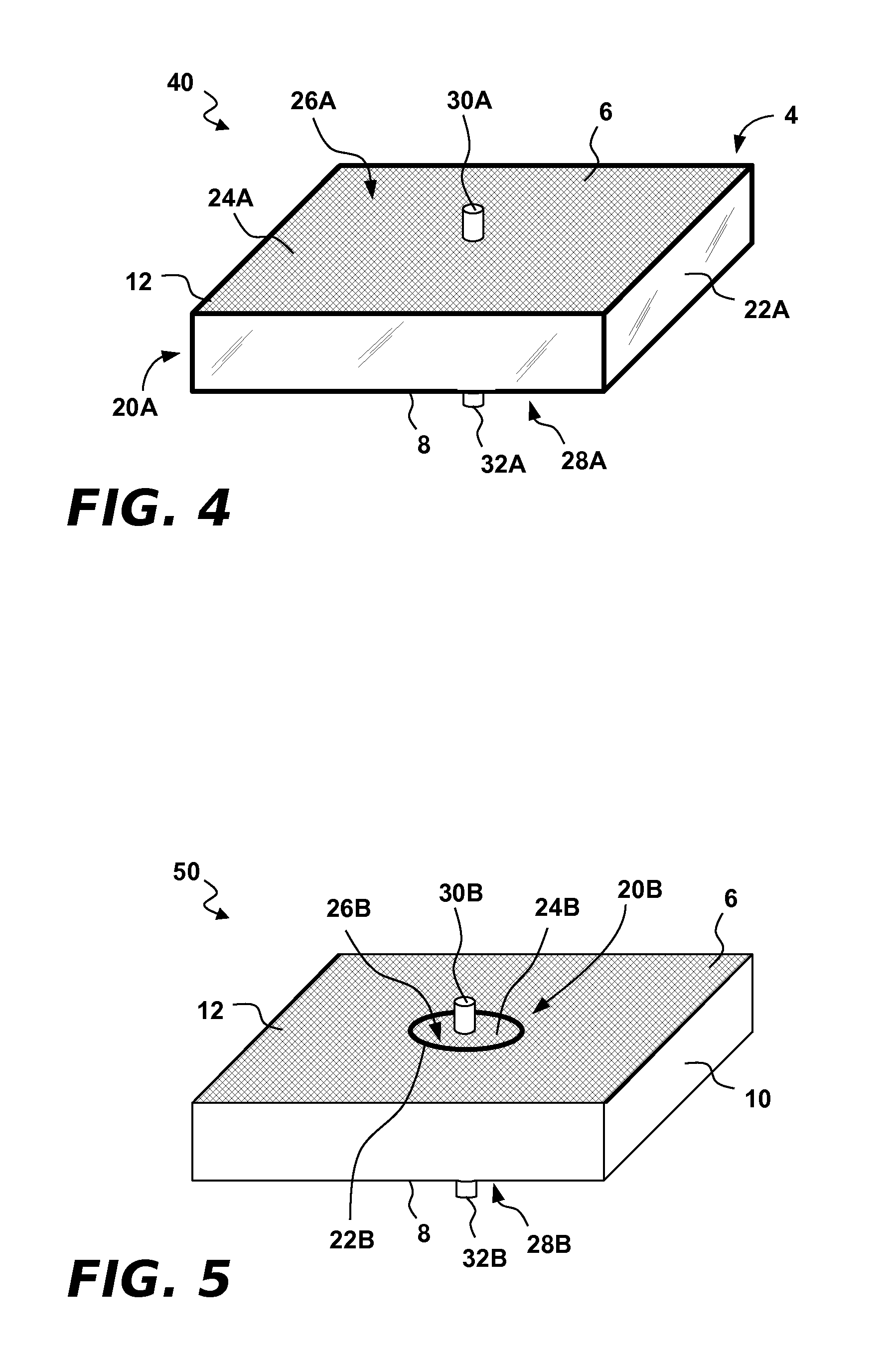

Micro acoustic transducer and manufacturing method therefor

ActiveUS20070160248A1Increased mechanical sensitivityImprove firmnessPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesTransducerEngineering

A micro acoustic transducer and manufacturing method are provided. Firstly, a substrate having one first and second cavities is provided. Then, a backplate with a plurality of acoustic holes is formed on the substrate, and a diaphragm is formed on the backplate. An air gap is formed between the backplate and the diaphragm. The air gap, second cavity, and first cavity are communicated with each other through the acoustic holes. A plurality of rings is formed around the diaphragm. These rings are used to hitch pillars formed on the substrate or fasteners can be formed on the substrate for fastening the diaphragm on fastener holes. Through the arrangement of the rings or fasteners used as the boundary structure of the diaphragm, the mechanical sensitivity of the diaphragm is improved. Moreover, the backplate is supported by a single crystal structure formed by etching the substrate such that the stability is promoted.

Owner:IND TECH RES INST

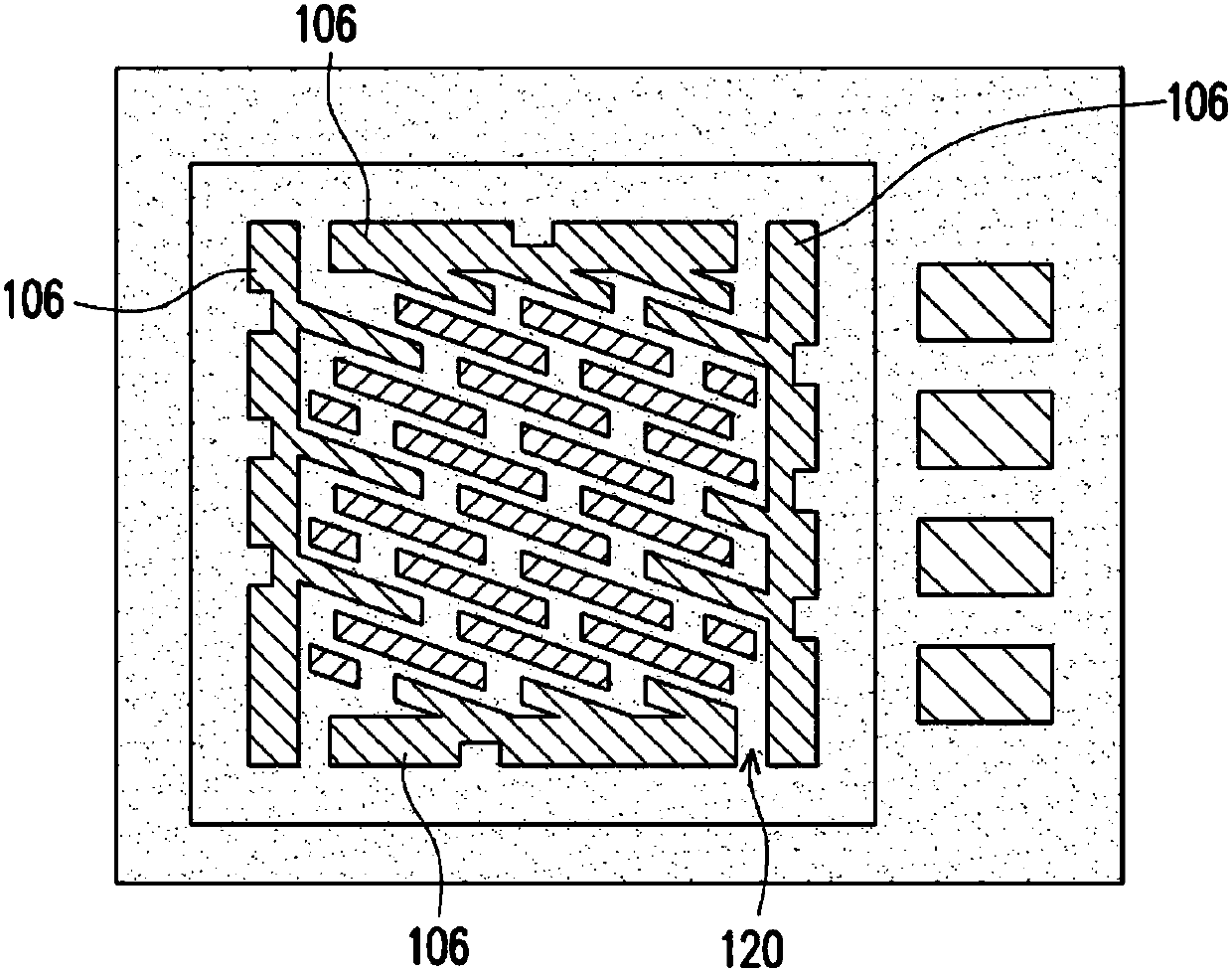

Active area structure and formation method therefor

ActiveCN107818980ABlocking stressAvoid damageTransistorSemiconductor/solid-state device manufacturingActive layerElectrical and Electronics engineering

The invention discloses an active area structure and a formation method therefor. The active area structure comprises an element area, an active layer and a shallow trench insulating layer. The element area is defined on a substrate. The active layer is formed by a top part of the substrate, and the active layer comprises a plurality of element units arranged in the element area and a boundary structure surrounding the element area, wherein the boundary structure comprises at least one branch extending inward into the element area, and the branch is positioned among part of the plurality of element units. The shallow trench insulating layer comprises a first part and a second part, the first part is formed in the boundary structure so as to enable the plurality of element units to be insulated from each other, and the second part surrounds an outer periphery of the boundary structure. The second part of the shallow trench insulating layer is used for isolating the plurality of elementunits from a surrounding active area.

Owner:UNITED MICROELECTRONICS CORP +1

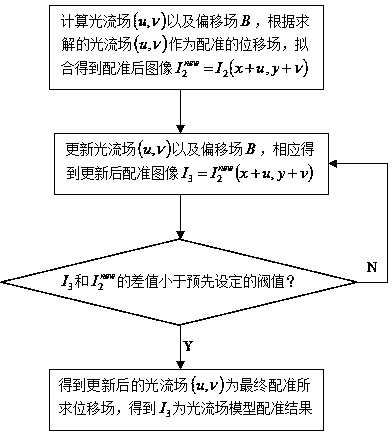

Anisotropic optical flow field and deskew field-based brain MR (magnetic resonance) image registration method

InactiveCN103871056AReduce blurrinessHigh precisionImage analysisDiagnostic recording/measuringUniform fieldResonance

The invention provides an anisotropic optical flow field and deskew field-based brain MR (magnetic resonance) image registration method, and discloses an optical flow field model-based image registration and biased field recovery coupling model. Aiming at the defect that a biased field can easily cause low registration accuracy of the traditional registration model, the anisotropic optical flow field and the deskew field are combined, and are brought into a unified variational framework, thus the two can supplement each other, and in view of the fact that global regular terms of a Horn model are incapable of guiding the optical flow precisely due to the lack of image information and the movement is insufficient, the image structure information is introduced to regulate the optical flow field, so as to get smooth and accurate optical flow information. According to the anisotropic optical flow field and deskew field-based brain MR image registration method, the image gradation non-uniform field can be restored while registration is performed, and the influence of the biased field is reduced; the image structure information is introduced to reduce the registration results fuzzy degree and retain the image structure information, the integrity of boundary structure information is guaranteed, and further recovery of real images is facilitated. The registration precision is greatly improved, and the robustness is good.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Conductive substrate and touch screen having same

ActiveUS20140016047A1Improve conductivityDiffraction reductionCircuit optical detailsLayered productsEngineeringTouchscreen

Owner:LG ELECTRONICS INC +1

High-strength magnesium alloy tube

InactiveCN101805865AImprove mechanical properties at room temperatureHigh strengthBand shapeRare earth

The invention relates to a high-strength magnesium alloy tube containing the following components in percent by weight: 7.8%-9.2% of aluminum Al, 0.2%-0.8% of zinc Zn and 0.2%-0.5% of manganese Mn. The high-strength magnesium alloy tube is characterized by also containing 0.5%-2.0% of rare earth RE in percent by weight. Because the rare earth RE can react with the aluminum Al to generate an Al-RE compound, the dispersion-strengthening function of the Al-RE compound can improve the strength of alloy and refine crystal particles so that the amount of a Mg17Al12 phase in the alloy is reduced, the original continuous and semi-continuous net-shaped crystal boundary structure is gradually changed into an interrupted and dispersion-distribution belt-shaped structure so that the fine crystal strengthening and the crystal boundary strengthening are more obvious, and meanwhile, the rare earth RE has the function of strong solid-dissolving strengthening, and the comprehensive mechanical properties of the alloy at room temperature are improved.

Owner:嘉兴中科亚美合金技术有限责任公司

Acoustic transducer in system for gas temperature measurement in gas turbine engine

InactiveUS20150185089A1Vibration measurement in solidsGas-turbine engine testingTransducerEngineering

An apparatus for controlling operation of a gas turbine engine including at least one acoustic transmitter / receiver device located on a flow path boundary structure. The acoustic transmitter / receiver device includes an elongated sound passage defined by a surface of revolution having opposing first and second ends and a central axis extending between the first and second ends, an acoustic sound source located at the first end, and an acoustic receiver located within the sound passage between the first and second ends. The boundary structure includes an opening extending from outside the boundary structure to the flow path, and the second end of the surface of revolution is affixed to the boundary structure at the opening for passage of acoustic signals between the sound passage and the flow path.

Owner:SIEMENS ENERGY INC

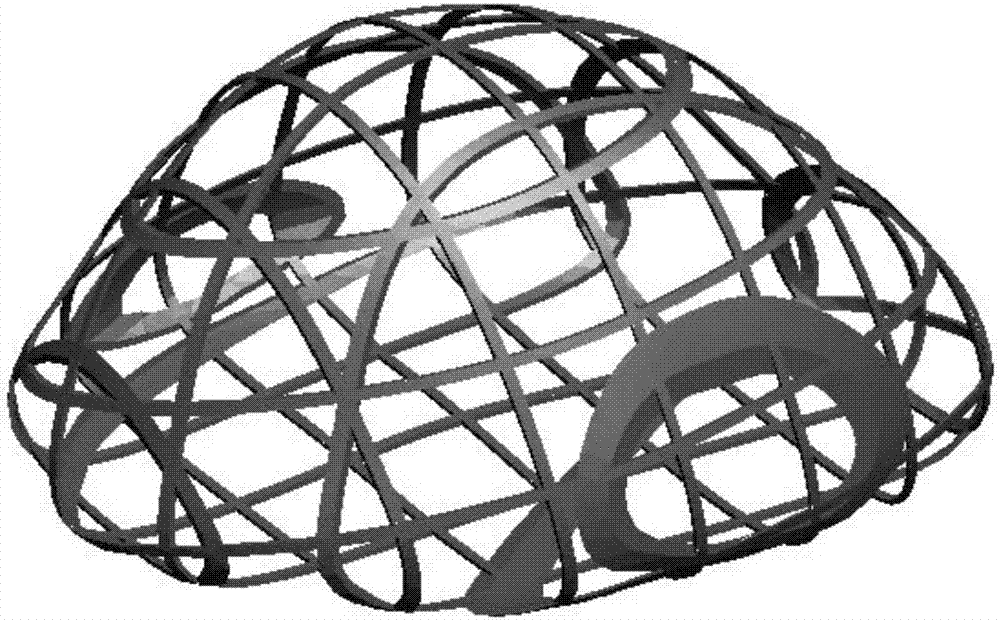

Degradable mammary scaffold

A degradable mammary scaffold comprises a three-dimensional boundary structure and an inner filling structure; the outline of the three-dimensional boundary structure matches with actual tumor outline of an implant taking patient, the outline of the three-dimensional structure is extended by 1-5 mm along a normal direction based on the actual tumor outline, and the inner filling structure includes a three-dimensional elastic unit array that may intersect with the three-dimensional boundary structure to form the degradable mammary scaffold; after the degradable mammary scaffold is implanted in a human body, mammary form can be repaired, and good overall elasticity and good deforming characteristic to simulate natural mammary tissues are imparted; the unique porous structure of the degradable mammary scaffold helps ingrowth of tissue cells, and mammary implant separation, displacement and other risks are solved; with degrading of the scaffold, autogenous tissues replace the scaffold structure gradually, and finally self-repair is achieved.

Owner:XI AN JIAOTONG UNIV

High-coercivity neodymium iron boron magnet surface coating slurry and neodymium iron boron magnet preparation method

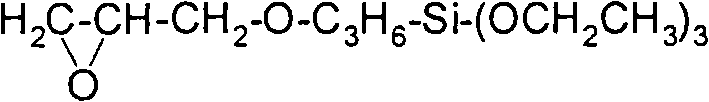

ActiveCN108630368AImprove bindingFacilitated DiffusionInductances/transformers/magnets manufactureMagnetic materialsCross-linkRare earth

The invention provides high-coercivity neodymium iron boron magnet surface coating slurry and a neodymium iron boron magnet preparation method. The high-coercivity neodymium iron boron magnet surfacecoating slurry is prepared from, in weight percent, 35-60% of low-melting-point metal powder or rare earth alloy powder, 20-40% of poly-hydrocarbon resin, 5-12 % of cross-linking agents and the rest organic solvents. The preparation method of a neodymium iron boron magnet includes the steps: coating the surface of a sintered magnet with the slurry; performing heating, curing, diffusion heat treatment and homogenizing annealing to obtain a needed high-coercivity neodymium iron boron magnet. The slurry solves the problem that coated powder easily falls off, a boundary structure and grain boundary phase distribution are improved, and the coercivity of the magnet is improved without reducing residual magnetism.

Owner:大地熊(包头)永磁科技有限公司

Semiconductor Through-Wafer Electrical Signal-Carrying Waveguide

A through-wafer electrical signal communication apparatus and method utilize a semiconductor substrate having first and surfaces and a continuous peripheral edge. The first surface supports active integrated circuit components. An electromagnetic waveguide supports data communication through the semiconductor substrate. The waveguide has an electrically conductive waveguide boundary structure surrounding a waveguide interior region formed by a portion of the semiconductor substrate. The waveguide is sized and configured to propagate electromagnetic waves of selected wavelength and propagation mode from a first waveguide end to a second waveguide end. A signal launching structure radiates electromagnetic waves into the first waveguide end. A signal pickup structure receives electromagnetic waves from the second waveguide end. The apparatus and method may utilize one or more of the waveguides. The waveguides may include a real waveguide, one or more virtual waveguide formed using light energy, and / or a hybrid waveguide comprising real and virtual waveguide structures.

Owner:IBM CORP

Micro acoustic transducer and manufacturing method therefor

ActiveUS8094844B2Increased mechanical sensitivityImprove firmnessElectrostatic transducersDeaf-aid setsTransducerSingle crystal

A micro acoustic transducer and manufacturing method are provided. Firstly, a substrate having one first and second cavities is provided. Then, a backplate with a plurality of acoustic holes is formed on the substrate, and a diaphragm is formed on the backplate. An air gap is formed between the backplate and the diaphragm. The air gap, second cavity, and first cavity are communicated with each other through the acoustic holes. A plurality of rings is formed around the diaphragm. These rings are used to hitch pillars formed on the substrate or fasteners can be formed on the substrate for fastening the diaphragm on fastener holes. Through the arrangement of the rings or fasteners used as the boundary structure of the diaphragm, the mechanical sensitivity of the diaphragm is improved. Moreover, the backplate is supported by a single crystal structure formed by etching the substrate such that the stability is promoted.

Owner:IND TECH RES INST

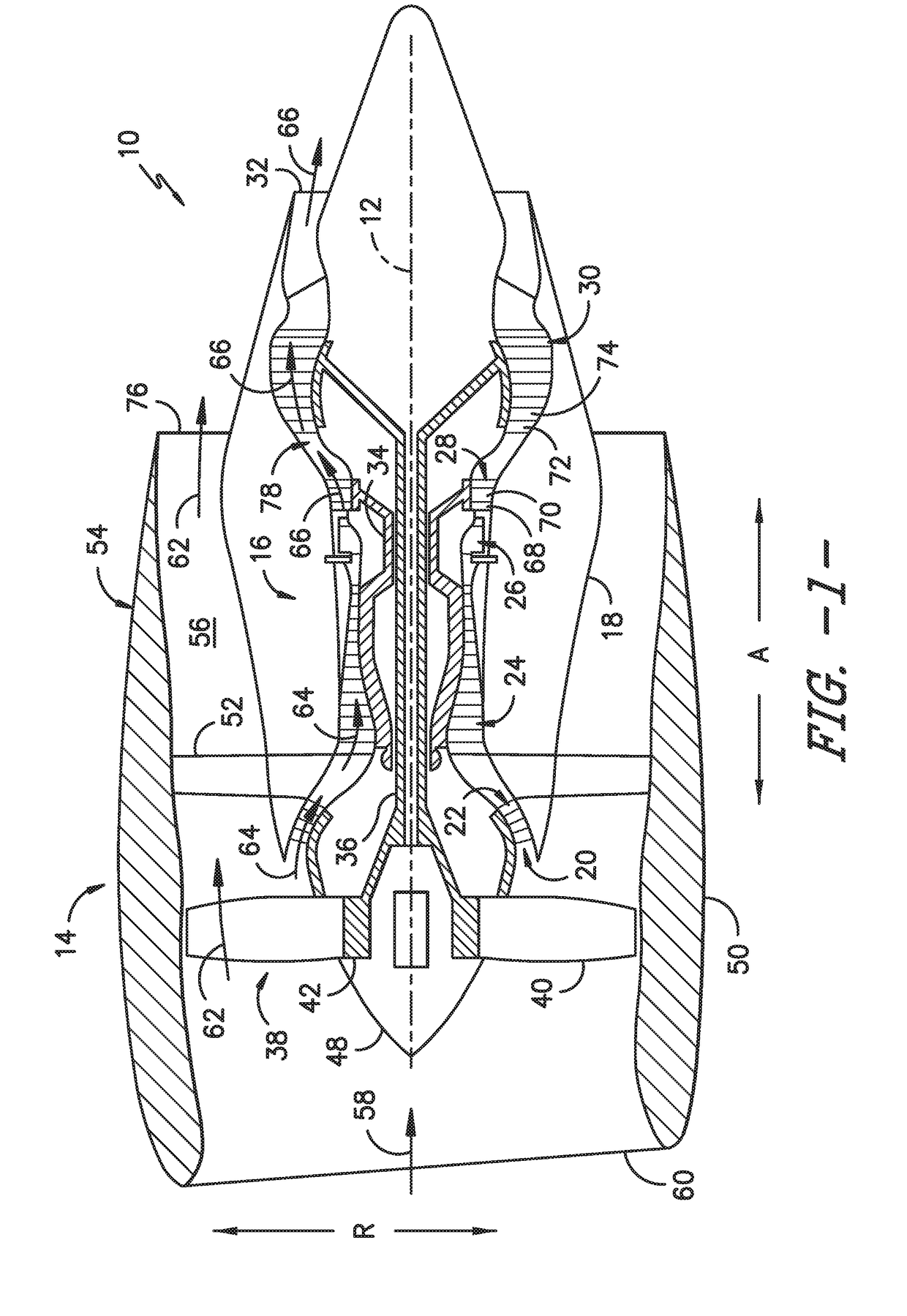

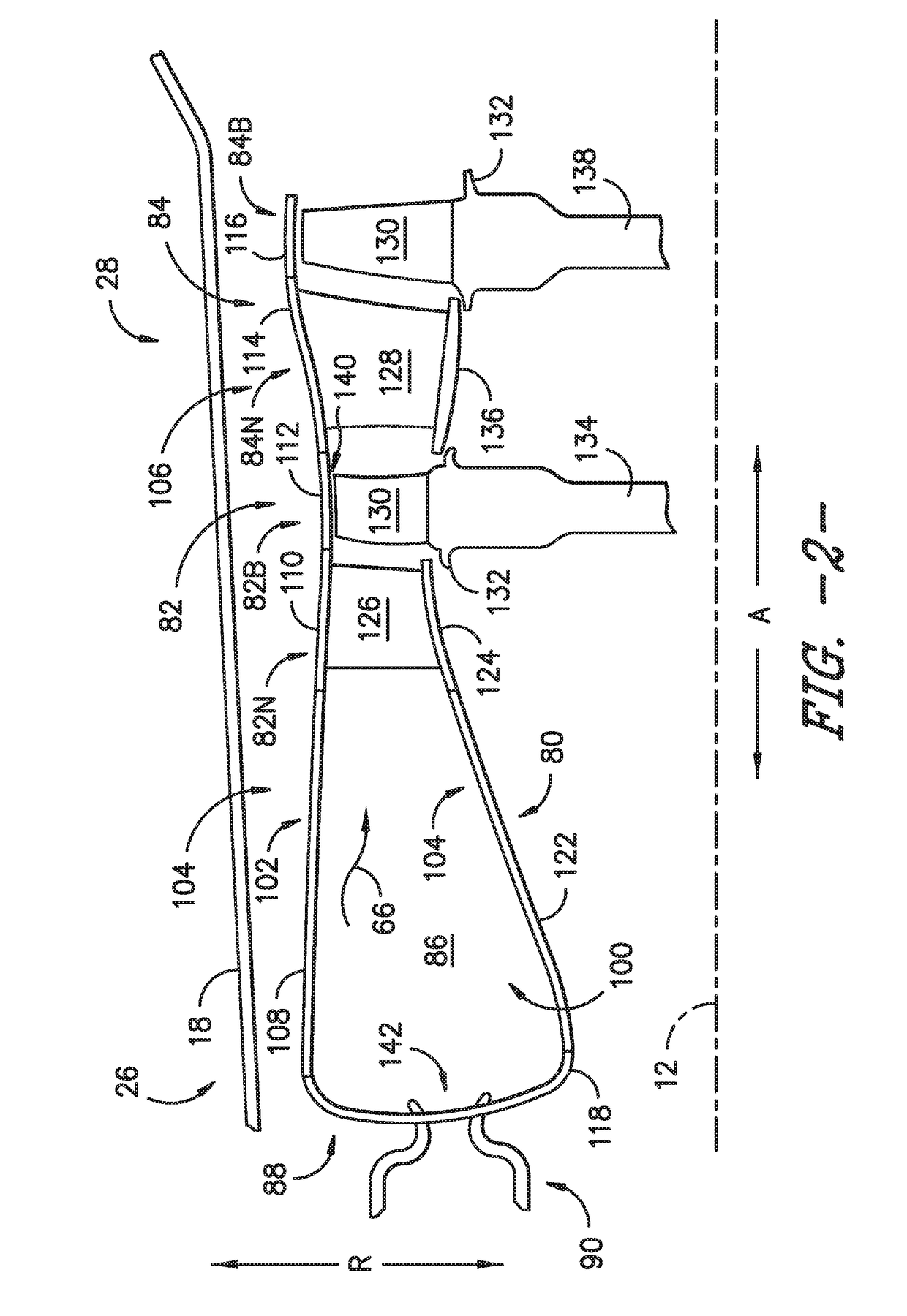

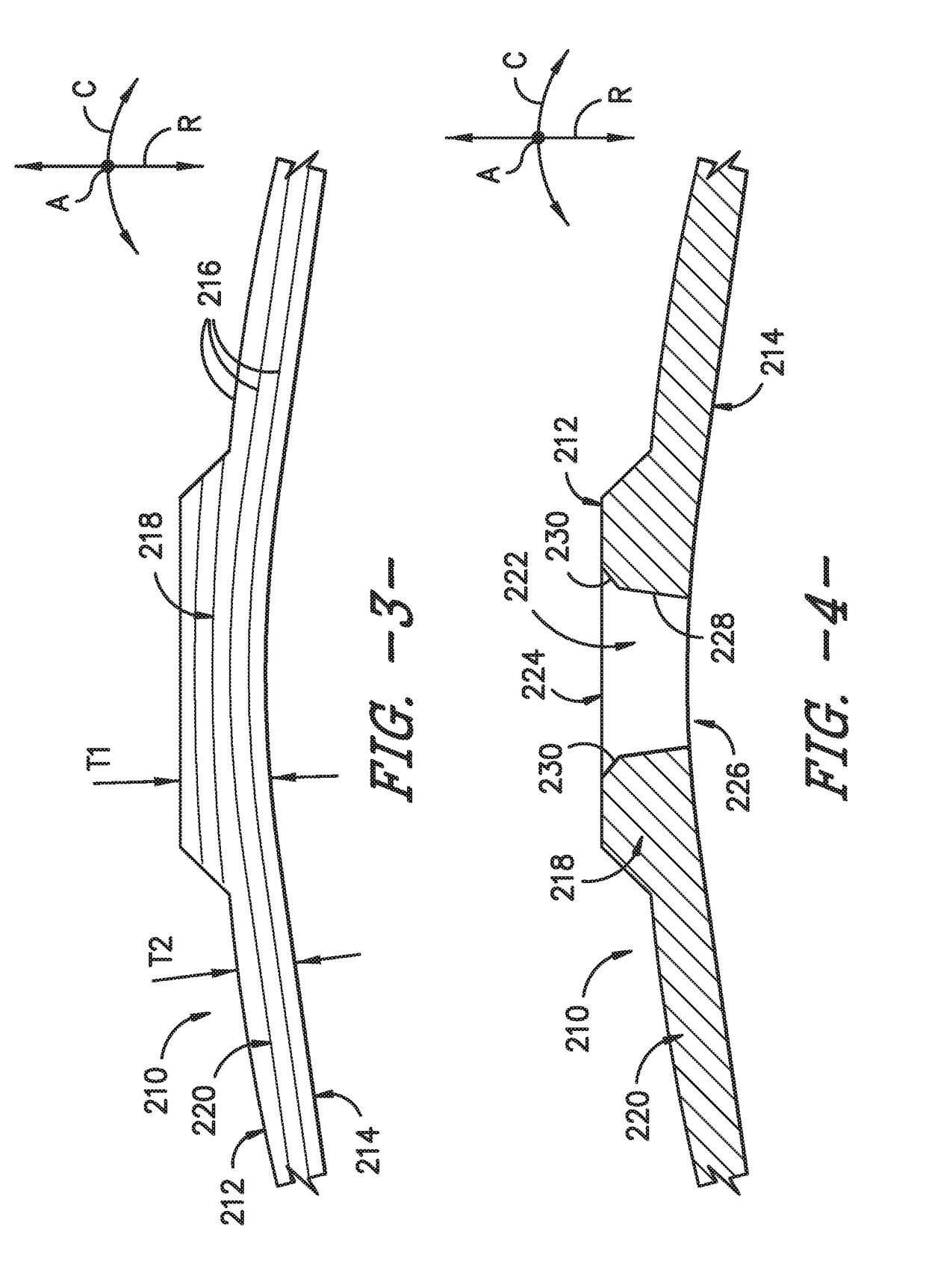

Flow path assemblies for gas turbine engines and assembly methods therefore

Flow path assemblies and methods for forming such flow path assemblies for gas turbine engines are provided. For example, a method for assembling an airfoil with a boundary structure to form a flow path assembly is provided. The method includes machining an opening into the boundary structure. The opening is sized to receive an airfoil or other component. The method also includes machining a cutout into the boundary structure proximate the opening. A locking feature is inserted into the cutout. When the airfoil is inserted into the opening, the locking feature interlocks the airfoil with the boundary structure. To seal the airfoil with the boundary structure, the airfoil is pressed against or into the boundary structure. When the airfoil is pressed, the locking feature is compressed such that a seal is formed between the airfoil and the boundary structure to seal the flow path assembly.

Owner:GENERAL ELECTRIC CO

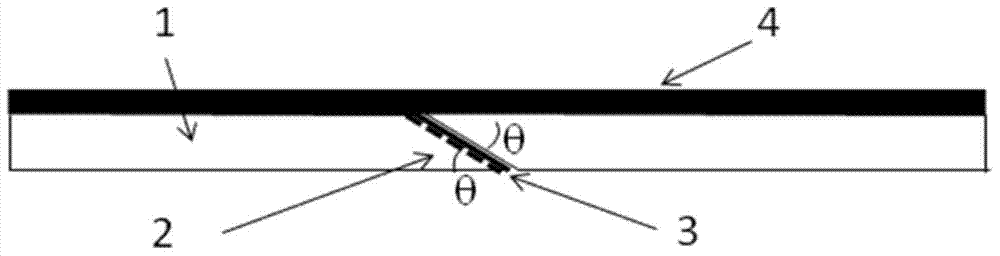

Technological cover plate of combined structure and production method therefor

ActiveCN104842606AQuality improvementHigh activity coordinationSynthetic resin layered productsFastening meansRubber materialForming face

The present invention belongs to the technical field of composite materials manufacturing and particularly relates to a technological cover plate of a combined structure and a production method therefor . The technological cover plate of the combined structure is compsoed of a split forming face plate, a separation area and a connection body. The split forming face plate is of a composite material structure and is formed by sub forming face plates, wherein the sub forming face plates are provided with wedge-shaped boundary structures and are overlapped through the separation area. The separation areas are formed by film structure materials with the single layer having demolding / pasting two functions. The connection body is made of rubber materials. During production, the wedge-shaped boundary structures of the sub forming face plates are produced by a prepreg gradient pasting method, the sub forming face plates are connected to form the split forming face plate through the separation area, the connection body is integrally arranged on the split forming face plate, and the split forming face plate, the seperation area and the conenction body are formed through one-step curing. The technological cover plate of the combined structure is provided with an interior structure having a high motion coordination performance, has a high-quality surface forming effect, and has an important engineering value for production of skins of irregular profile structures made of composite materials.

Owner:AVIC COMPOSITES

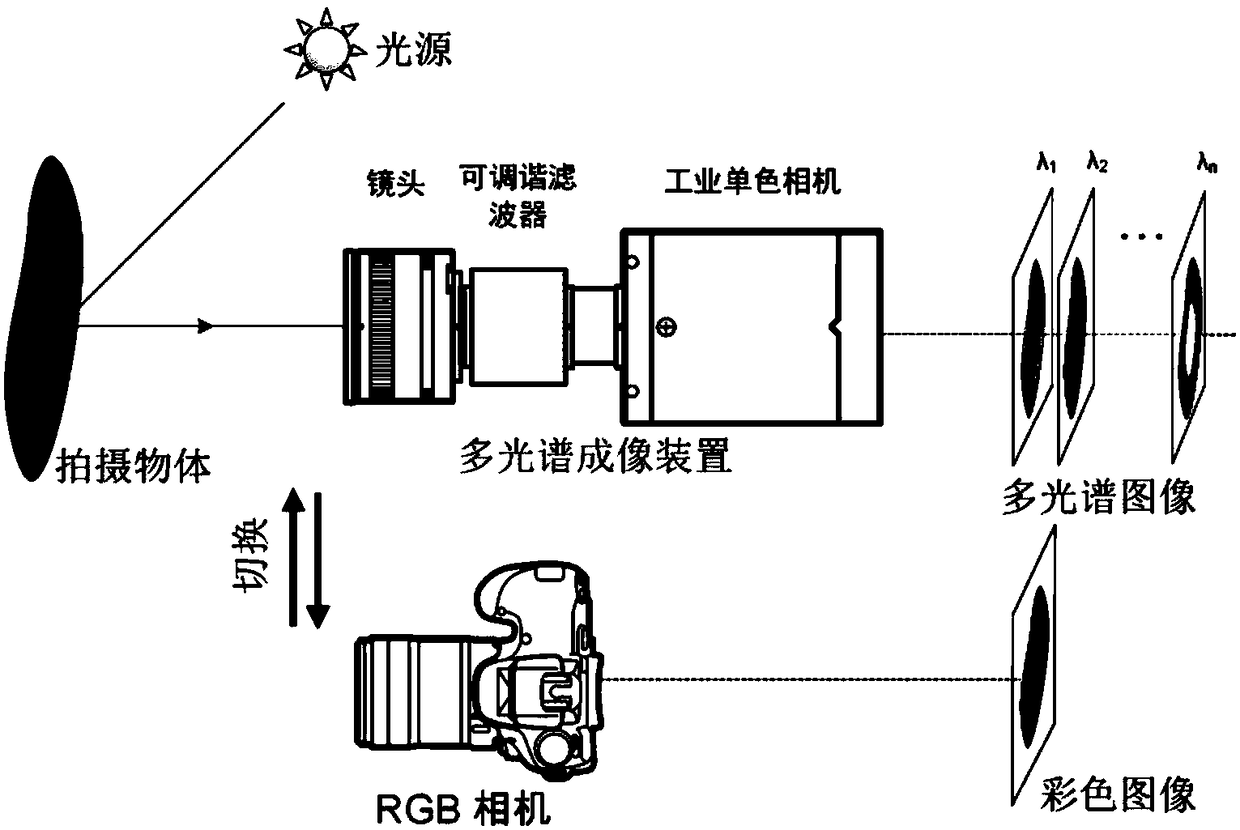

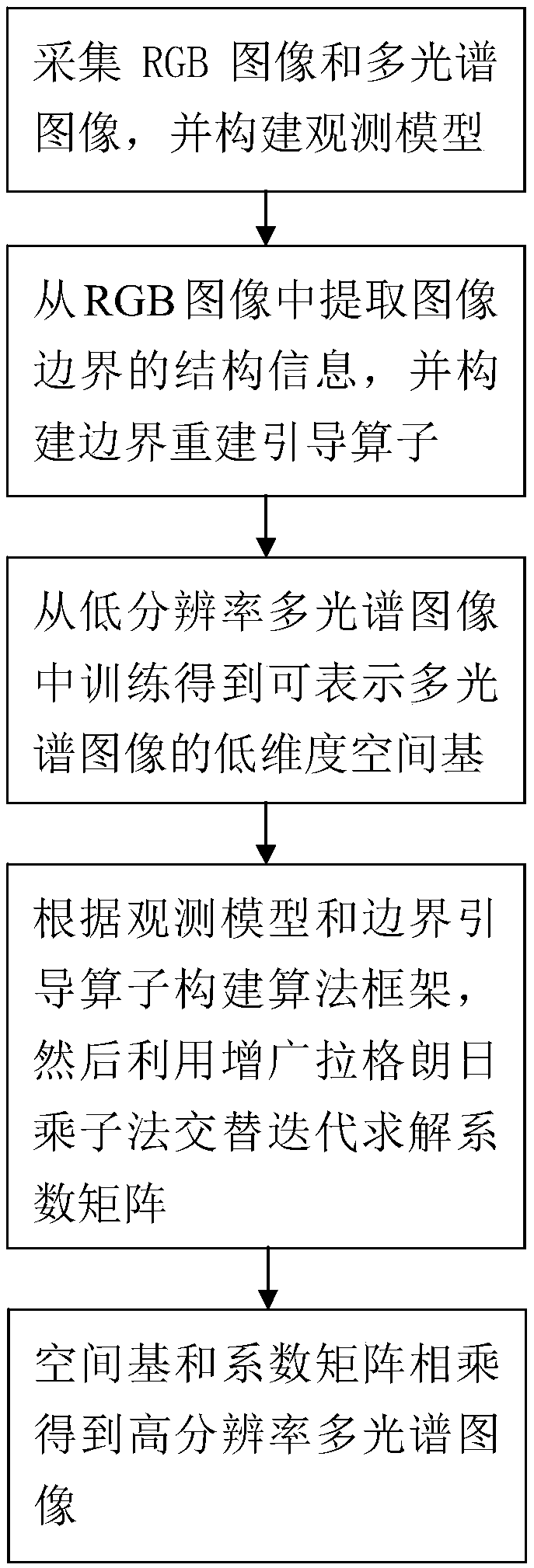

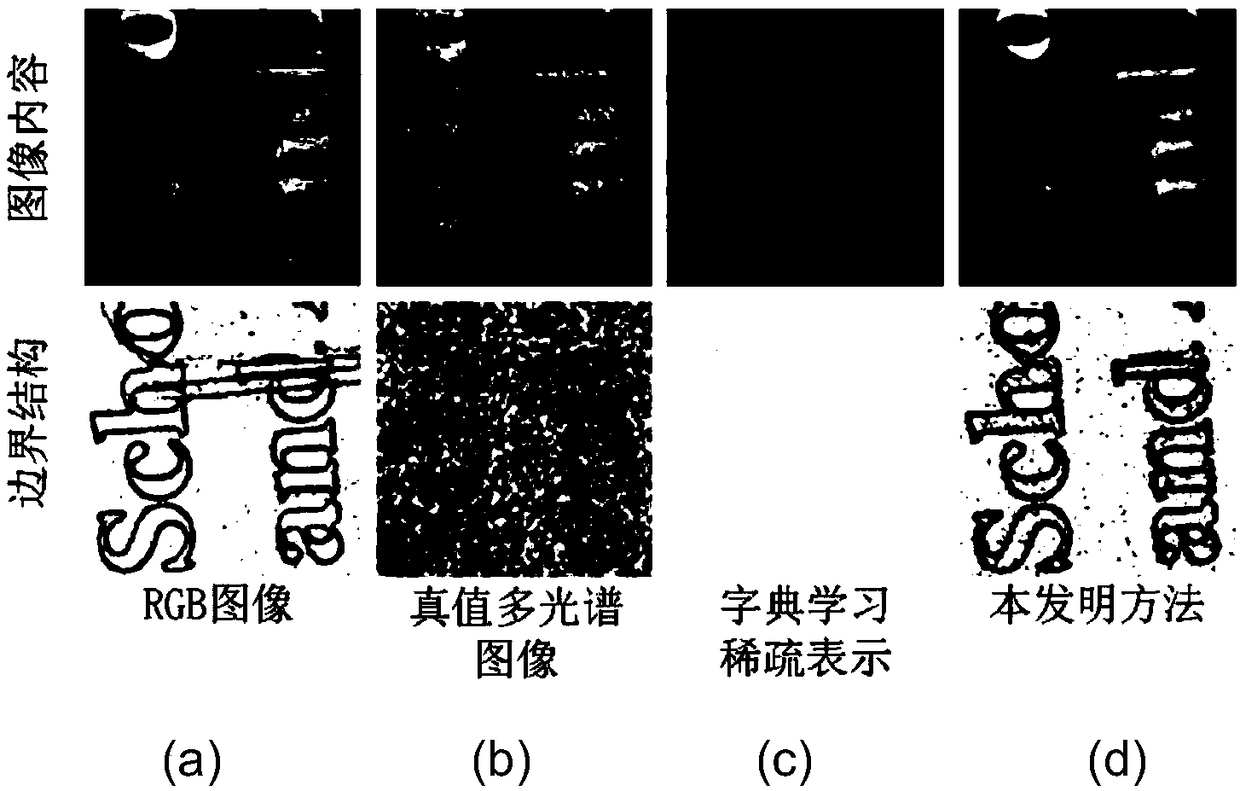

Multi-spectral image super-resolution reconstruction method based on color image fusion

ActiveCN109360147ALighten the computational burdenHigh-precision spectral domain resolutionGeometric image transformationColor imageRgb image

The invention discloses a multi-spectral image super-resolution reconstruction method based on color image fusion. Firstly, the high-resolution color image and low-resolution multi-spectral image areacquired and registered, then the inverse camera response function and spectral sensitivity function coupled in the color image are acquired, and the observation model based on the content of the acquired image is constructed. High-resolution multispectral images are solved by this model, Firstly, the boundary structure information is extracted from the captured RGB image, In order to guide the reconstruction of high-resolution multispectral images, the basis of the solution space is trained from the acquired multispectral images, and an iterative algorithm framework based on image fusion is constructed to solve the coefficients of the multispectral images on the spatial basis. Finally, the coefficients are combined with the spatial basis to obtain the high-resolution multispectral images.The invention reduces the error of the traditional multi-spectral image super-resolution method due to the information loss and improves the reconstruction precision of the multi-spectral image by utilizing the boundary guidance and the content fusion of the RGB image.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com