Low dielectric-epoxy resin/mesoporous molecular sieve hybrid material and preparation method thereof

A technology of mesoporous molecular sieve and epoxy resin, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of lower dielectric constant, lack of environmental protection in preparation process, and poor comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

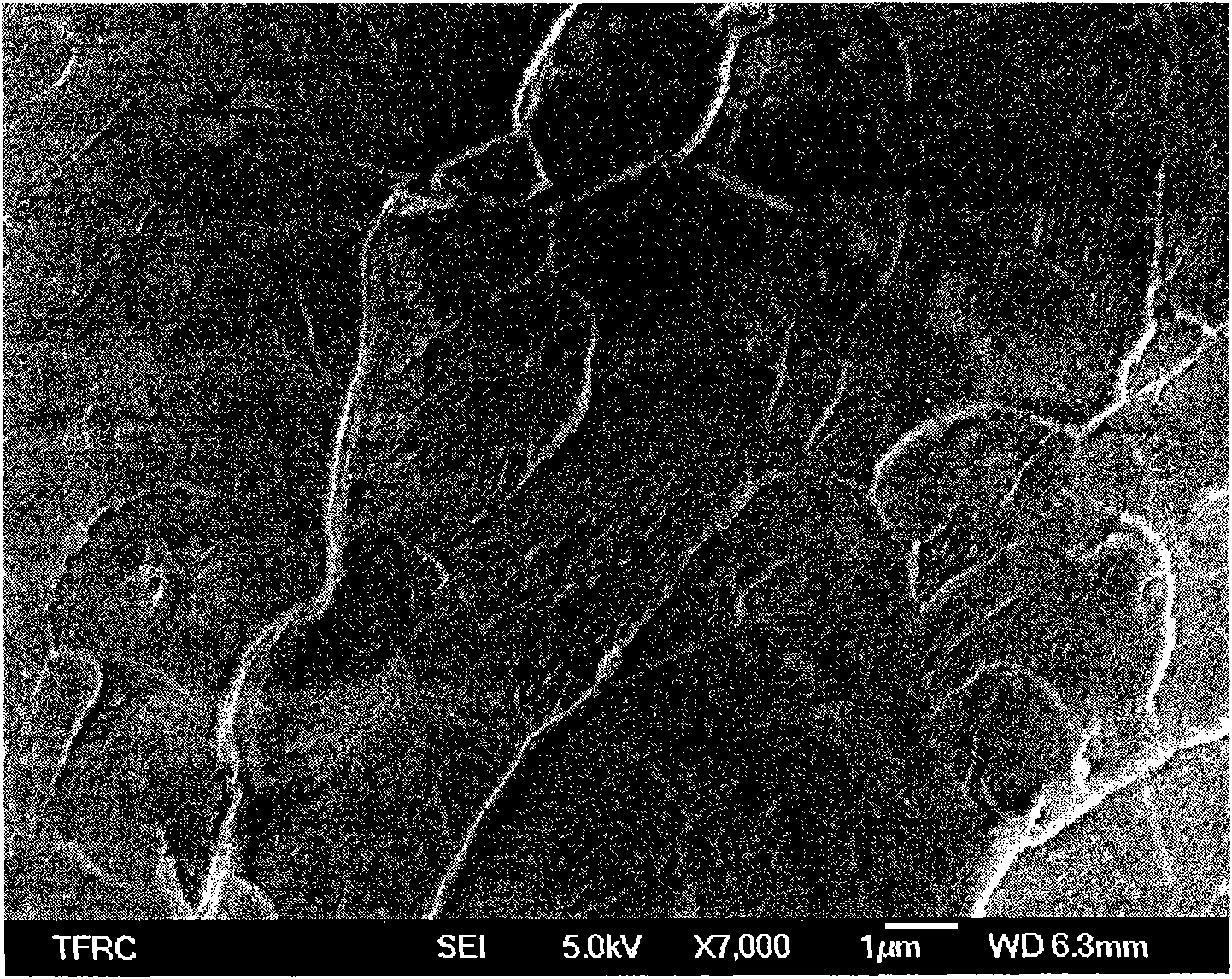

[0063] 1. Composite of mesoporous molecular sieve and epoxy resin

[0064] a) Drying of mesoporous molecular sieves: at 250°C, dry 0.50g of MCM-41 for 2 hours under the condition of an absolute vacuum higher than 0.1MPa to exclude moisture and small air molecules in the pores of the molecular sieve;

[0065] b) Pretreatment of epoxy resin prepolymer: put 8.34g of EP-828 in a vacuum oven, heat at 80°C to reduce its viscosity, and then remove air bubbles under the condition that the absolute vacuum degree is higher than 0.1MPa.

[0066] c) Mixing of mesoporous molecular sieve and epoxy resin prepolymer: Mix 8.34g of EP-828 obtained in b) with 0.5g of fully dried MCM-41, and disperse with magnetic stirring at 80°C for 8h, so that the mesoporous molecular sieve Disperse evenly in epoxy resin to obtain EP-828 prepolymer containing MCM-41.

[0067] 2. Curing molding

[0068] Heat and melt 1.16g m-phenylenediamine at 80°C, mix evenly with the EP-828 prepolymer containing MCM-41, an...

Embodiment 2

[0079] According to the same process as in Example 1, 0.3g MCM-41 was vacuum-dried at 250°C for 2 hours; 8.52g of pretreated EP-828 was mixed with 0.3g of dried MCM-41, and then ultrasonicated at 80°C Disperse for 8 hours, then mix evenly with 1.18g of molten m-phenylenediamine, heat cure and form, and obtain 828 type epoxy resin hybrid material containing 3% MCM-41.

[0080] Adopt the method identical with embodiment 1, record glass transition temperature and be: 202.1 ℃; Test frequency range: 100Hz~10MHz, record the dielectric constant of the 828 type epoxy resin hybrid material containing 3%MCM-41 at 100kHz The lower is 4.20, which is 0.13 lower than the dielectric constant of pure 828 epoxy resin.

Embodiment 3

[0082] According to the same process as in Example 1, 0.30g of SBA-15 was vacuum-dried at 250°C for 2 hours; 8.05g of pretreated E-51 was mixed with 0.30g of dried SBA-15, and then dispersed by magnetic stirring at 80°C 8h, and then mixed with molten 1.65g of anhydrous piperazine, heat-cured and molded to obtain a type 51 epoxy resin hybrid material containing 3% SBA-15.

[0083] Using the same method as in Example 1, the recorded glass transition temperature is: 129.7°C; the test frequency range: 100Hz to 10MHz, and the dielectric constant of the 51 type epoxy resin hybrid material containing 3% SBA-15 is recorded at 100kHz The lower is 4.21, which is 0.30 lower than the dielectric constant of pure 51 type epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com