Patents

Literature

186results about How to "Improve interface structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

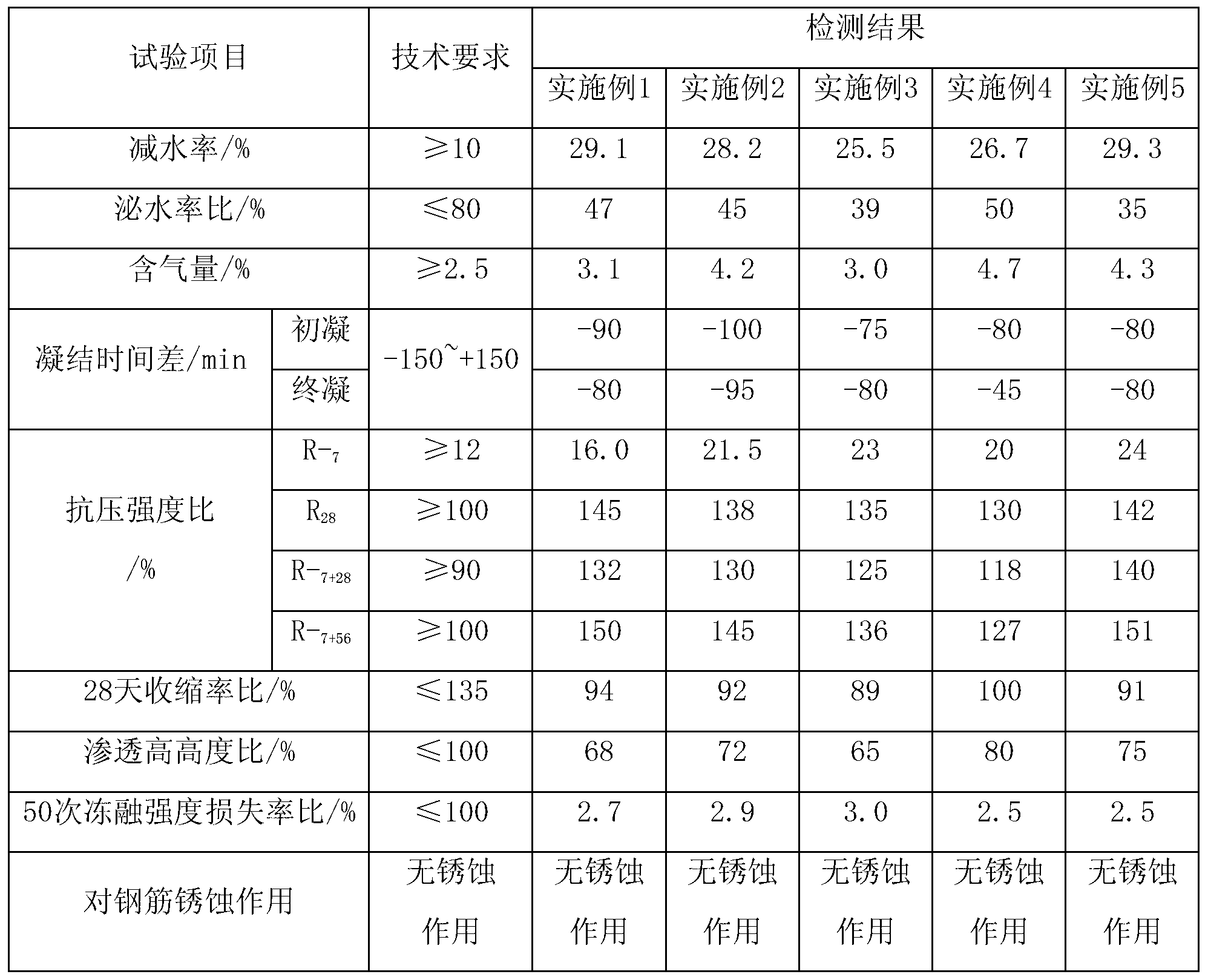

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

High-strength and high-conductivity dispersion-strengthened alloy and preparation method thereof

InactiveCN101956094AImprove conductivityImprove interface structureElectro conductivityHigh conductivity

The invention relates to a high-strength and high-conductivity dispersion-strengthened alloy, which comprises a copper base, a ceramic dispersion-strengthening phase and a doping element, wherein the ceramic dispersion-strengthening phase may be one or several of ZrO2, Y2O3, MgO, Al2O3 and TiB2 which accounts for 0.1 to 2 mass percent of the copper alloy; and the doping element may be one or several of Ni, Y, Ag, Ti, Zr and Hf which accounts for 0.1 to 1 percent of the copper alloy. In the invention, the problems of ceramic particle agglomeration caused by low bonding performance of the copper and ceramic interface, the roughening of the ceramic particles in sintering and material conductivity reduction caused by the scattering of electrons at the copper and ceramic interface are solved, and the dispersion-strengthened alloy with higher hardness and higher conductivity is obtained. The invention also relates to a preparation method of the high-strength and high-conductivity dispersion-strengthened alloy.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

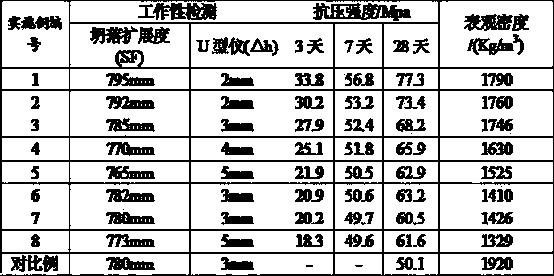

Self-compacting light aggregate concrete and preparation method thereof

InactiveCN103803904ALow densityLow apparent densitySolid waste managementStructural engineeringWater reducer

The invention provides self-compacting light aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete preparation. The self-compacting light aggregate concrete consists of such raw materials as cement, fly ash, silica fume, floating beads, light fine aggregate, light coarse aggregate, a water reducing agent and water. The self-compacting light aggregate concrete provided by the invention has the advantages of being low in appearance density, high in slump expansion degree and capable of avoiding floating of the floating beads; self-compacting light aggregate concrete differing in grade, especially self-compacting light aggregate concrete with strength grade above C60 and appearance density at 1400-1800kg / m<3>, can be prepared through the raw materials.

Owner:北京中联新航建材有限公司

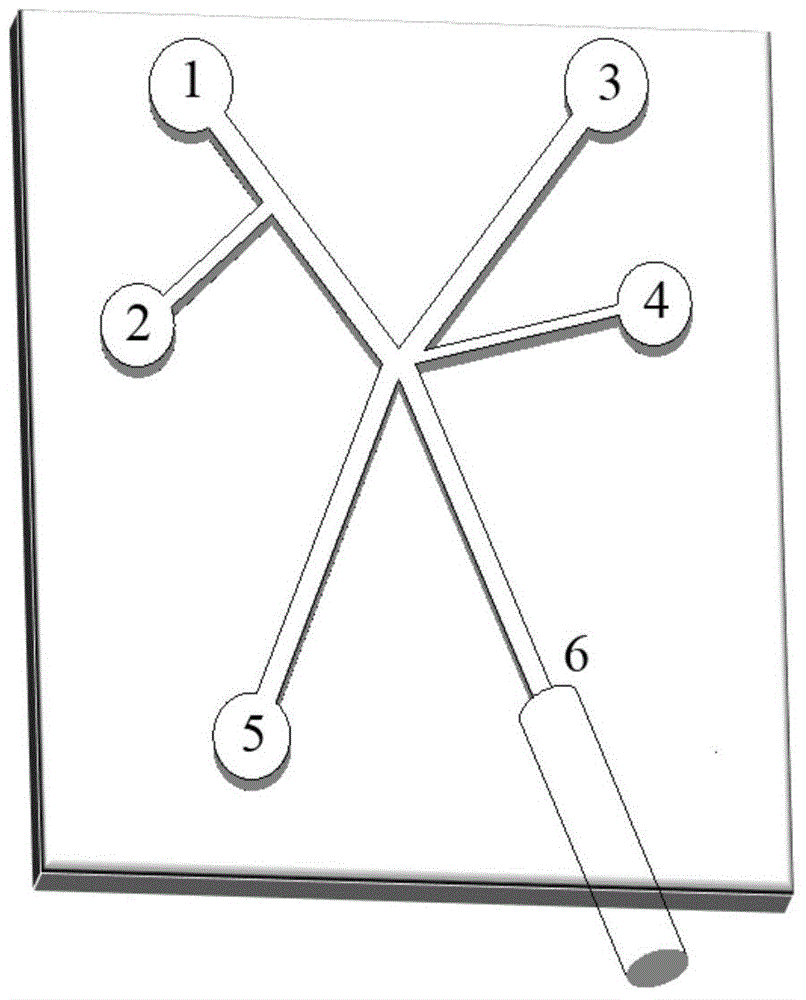

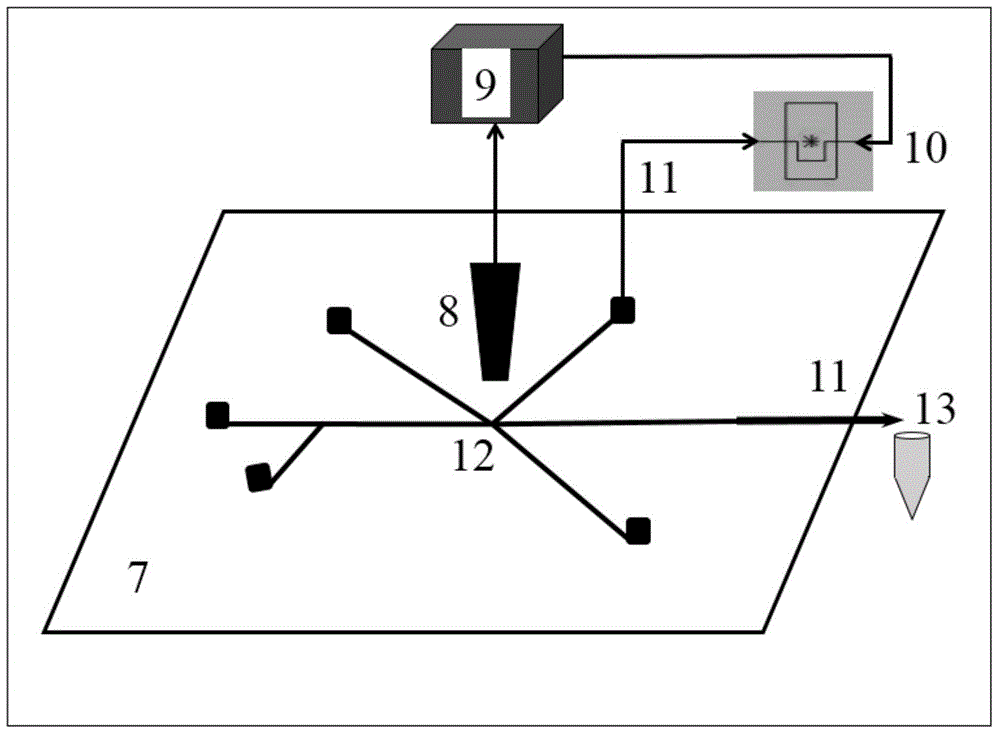

System and method for low-cost and efficient separation and obtaining of single cell

ActiveCN104877898AImprove degree and precisionIncrease the scope of applicationBioreactor/fermenter combinationsFungiMicrofluidic chipDroplet microfluidics

According to the present invention, based on a liquid droplet microfluidic chip technology, a system and a method for low-cost and efficient separation and obtaining of single cell is designed and constructed. The system comprises a microfluidic chip, a liquid droplet signal detector, a signal analysis and sorting control unit, an electromagnetic valve, a conduct pipe, and a liquid droplet collection micro-pipe. The single cell separation process comprises that: liquid droplets wrapping cells are subjected to online continuous generation and directional flow, signal acquisition and analysis and sorting control are performed when passing through a signal acquisition zone, and when the sorting condition (for example: the liquid droplet only warps single cell) is met, the work of the electromagnetic valve is controlled to make the force applying state and the flow direction of the liquid droplet be changed so as to separate and collect the single liquid droplet, such that the obtaining of the single cell can be achieved through the de-emulsification, the extraction and other operations. According to the technical method of the present invention, a set of the simple and feasible system and the simple and feasible method suitable for the liquid droplet sorting, cell separation and single cell obtaining of different detection methods are provided, and the method has advantages of high efficiency, short time consumption, low cost, no pollution, wide application range, strong extensibility and the like compared with the traditional single cell obtaining method.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

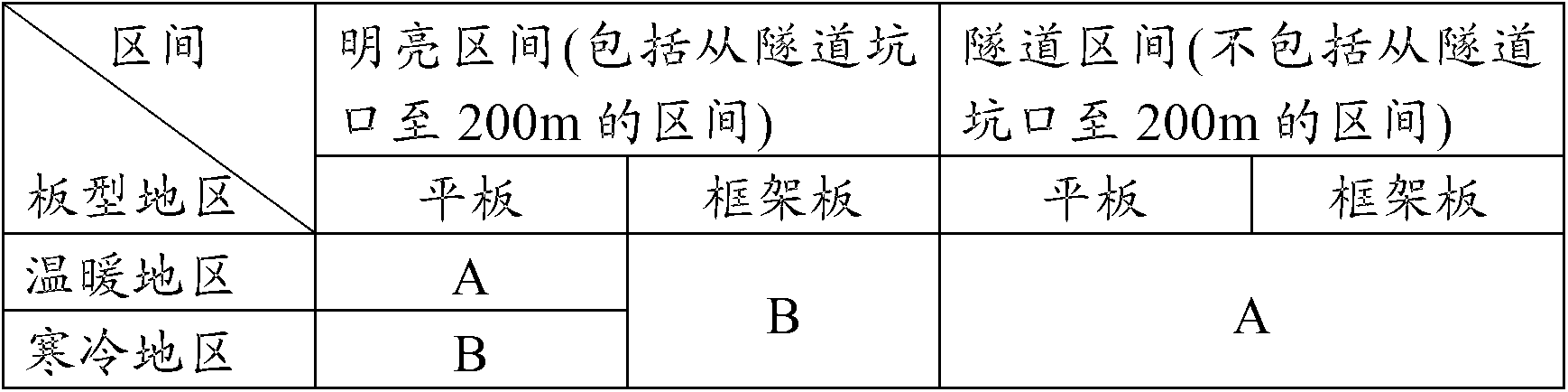

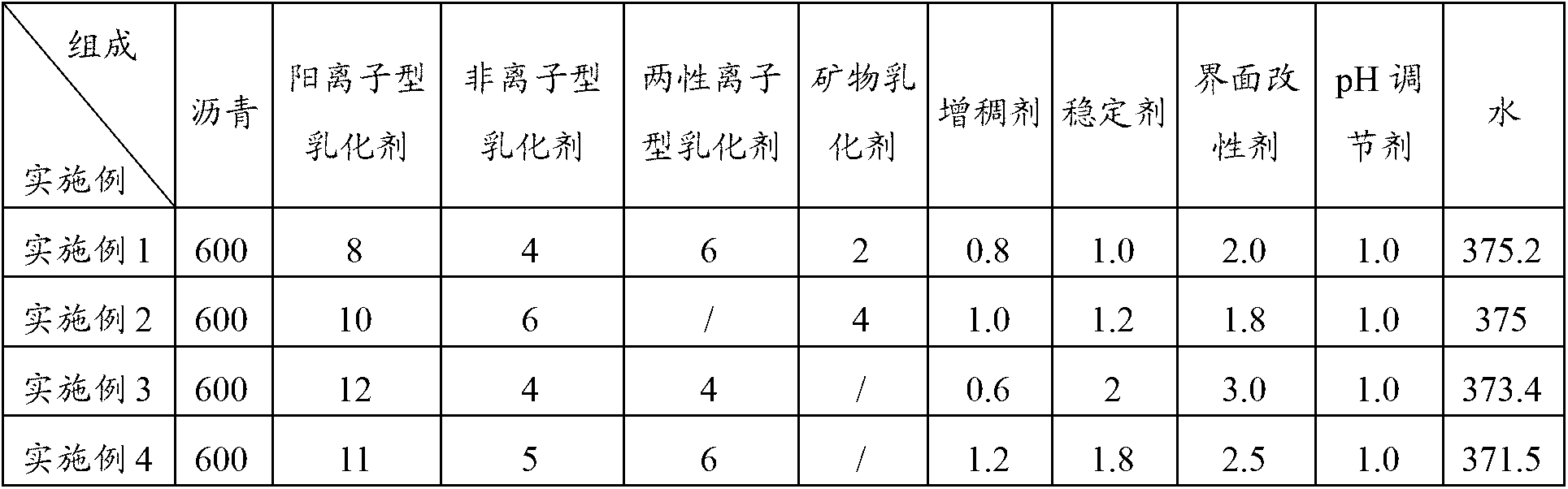

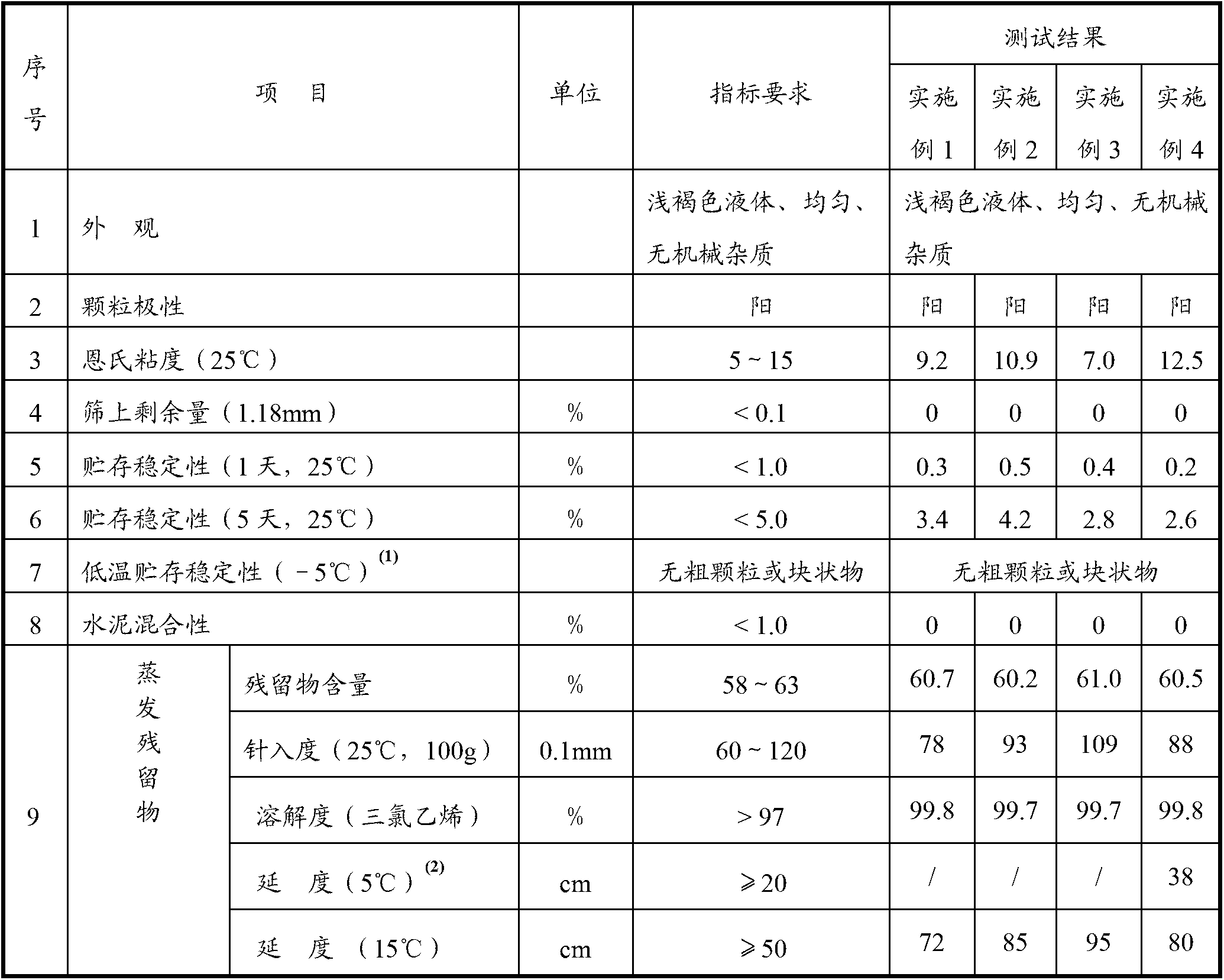

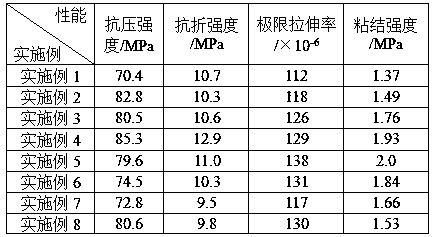

Cement-emulsified asphalt mortar for slab tracks in severe cold areas

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

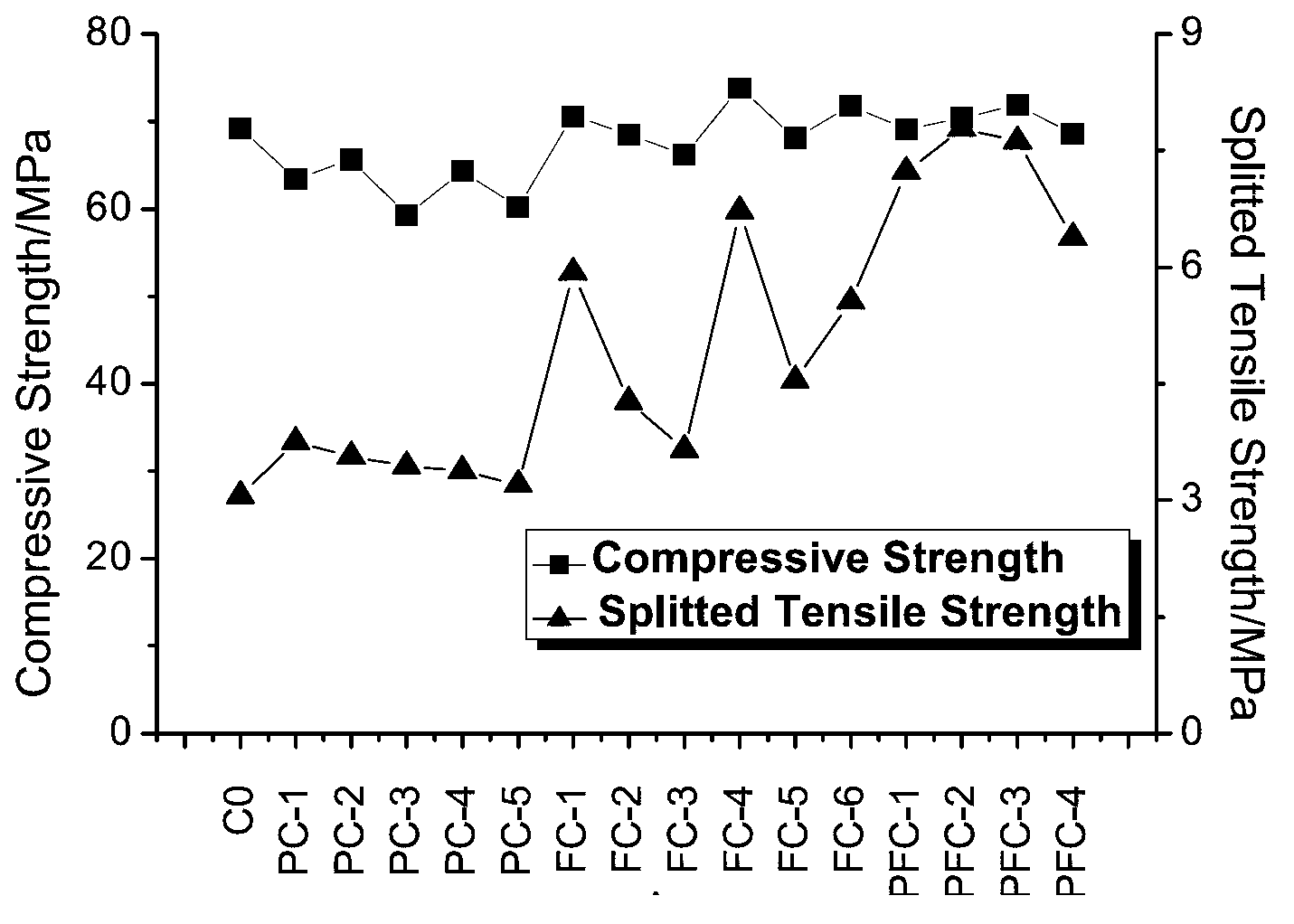

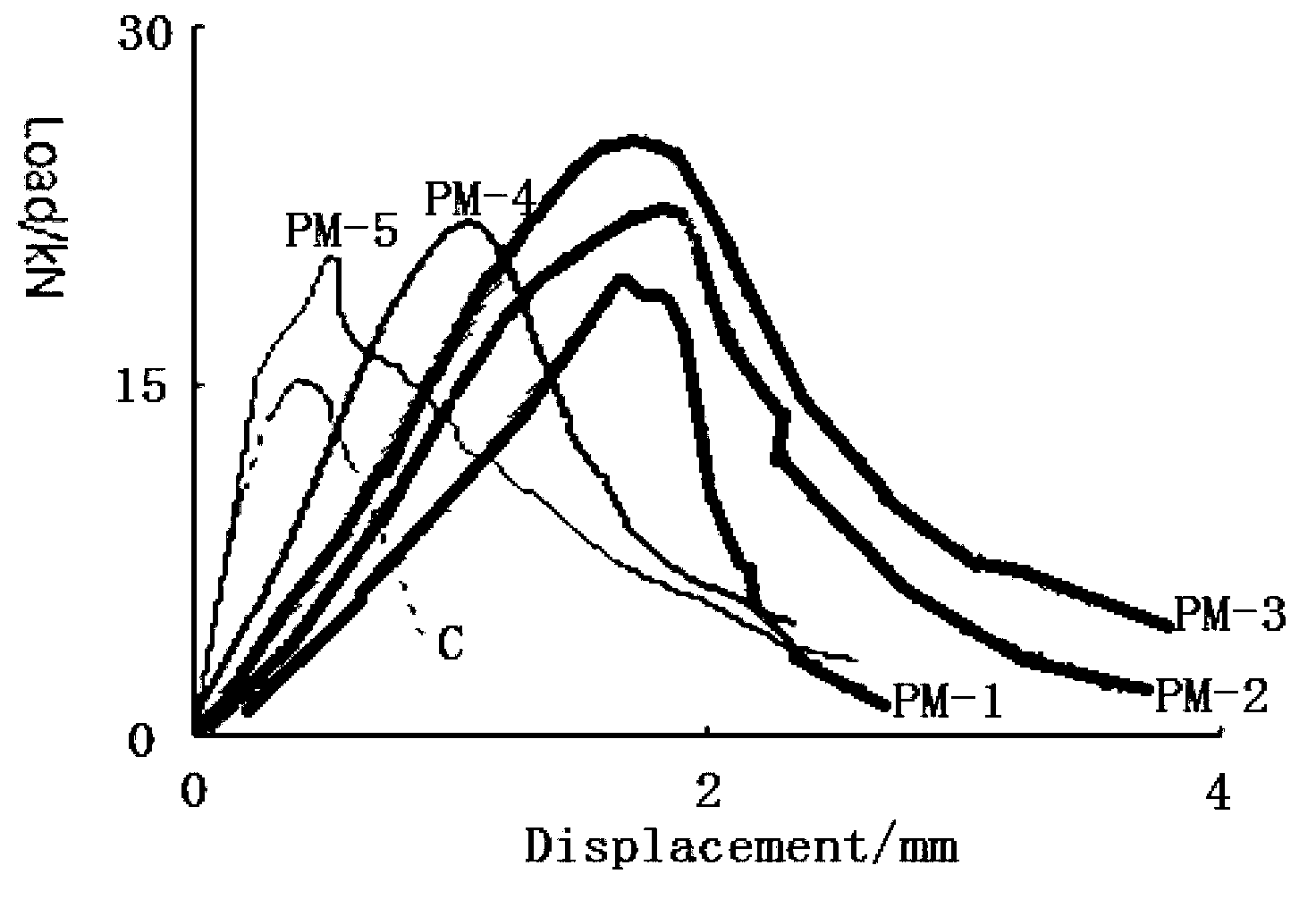

Fibre-polymer compound toughened concrete and preparation method for same

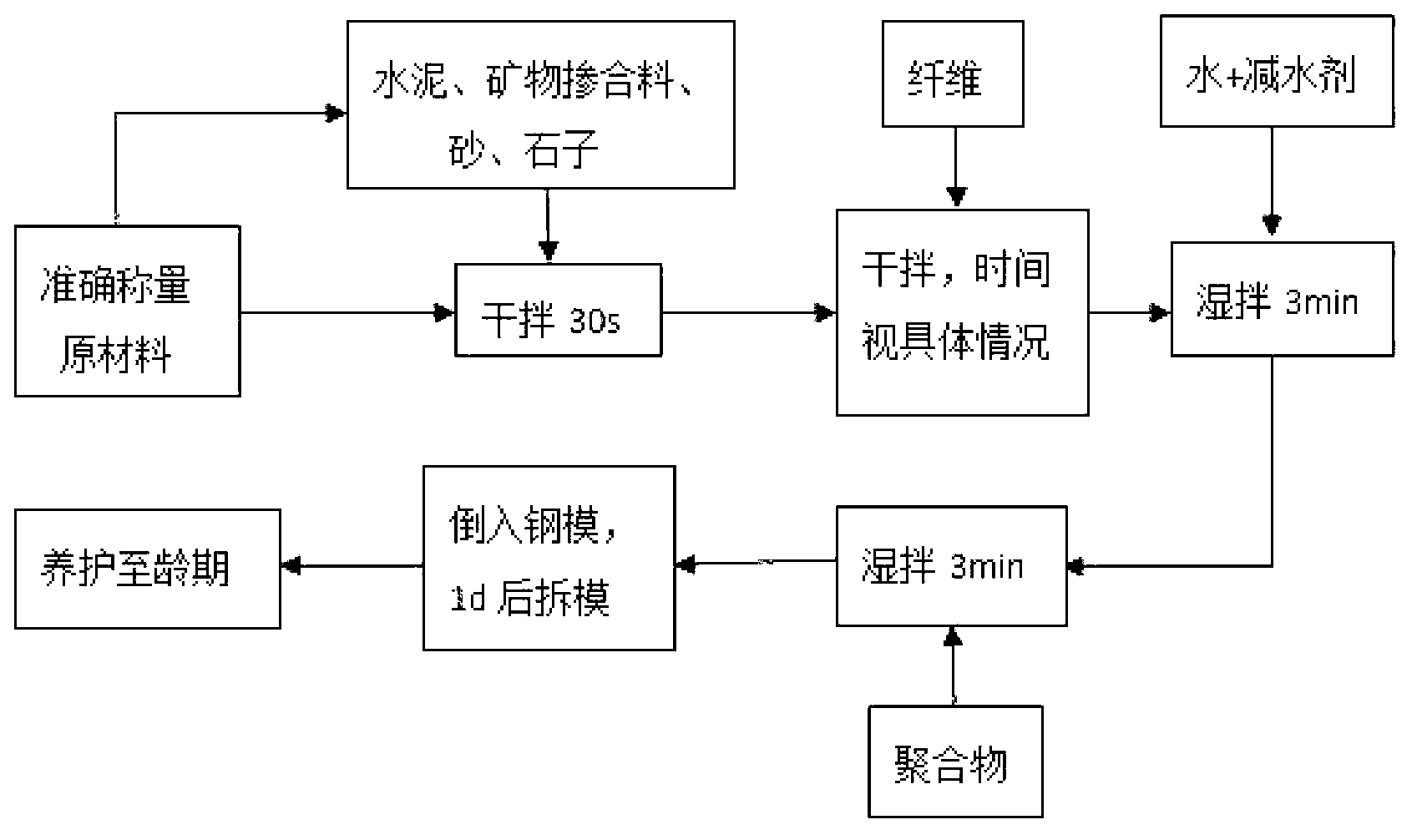

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

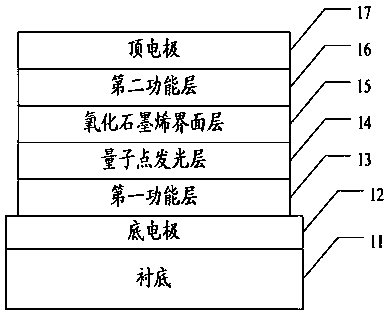

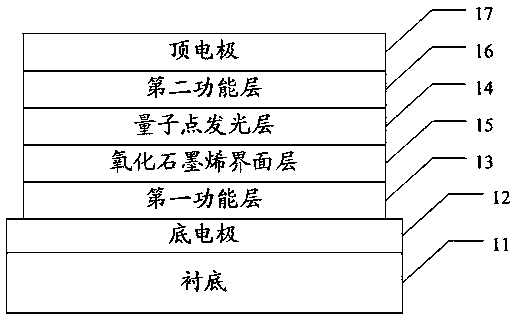

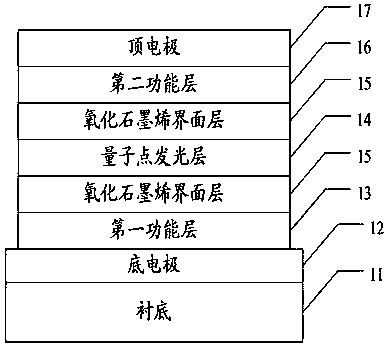

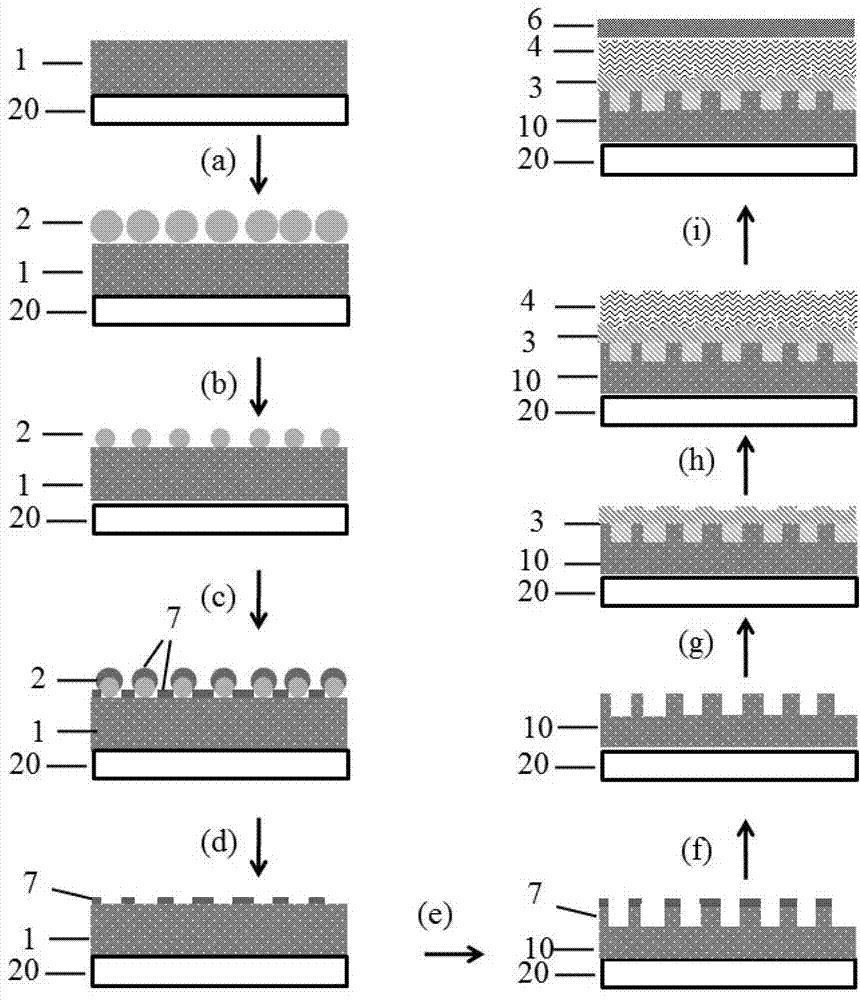

QLED device with graphene oxide interfacial layer and preparation method thereof

ActiveCN109390476AImprove performanceImprove interface structureSolid-state devicesSemiconductor/solid-state device manufacturingNanoparticleQuantum dot

The present invention discloses a QLED device with graphene oxide interfacial layer and a preparation method thereof. The QLED device with the graphene oxide interfacial layer includes a substrate, abottom electrode, a first functional layer, a quantum dot luminescent layer, a second functional layer, and a top electrode, wherein the substrate, the bottom electrode, the first functional layer, the quantum dot luminescent layer, the second functional layer, and the top electrode are sequentially stacked. Graphene oxide interfacial layers with functionalized functional groups are included between the first functional group and the quantum dot luminescent layer, and / or between the quantum dot luminescent layer and the second functional layer. By adding the oxide interfacial layers with functionalized functional groups between the quantum dot luminescent layer and the functional layers, the quantum dots and the nanoparticles in the functional layers can be closely anchored by electrostatic interaction or bonding, thereby effectively improving the interface structure between the luminescent layer and the functional layers, passivating interface defects, and effectively improving the performance of the QLED device.

Owner:TCL CORPORATION

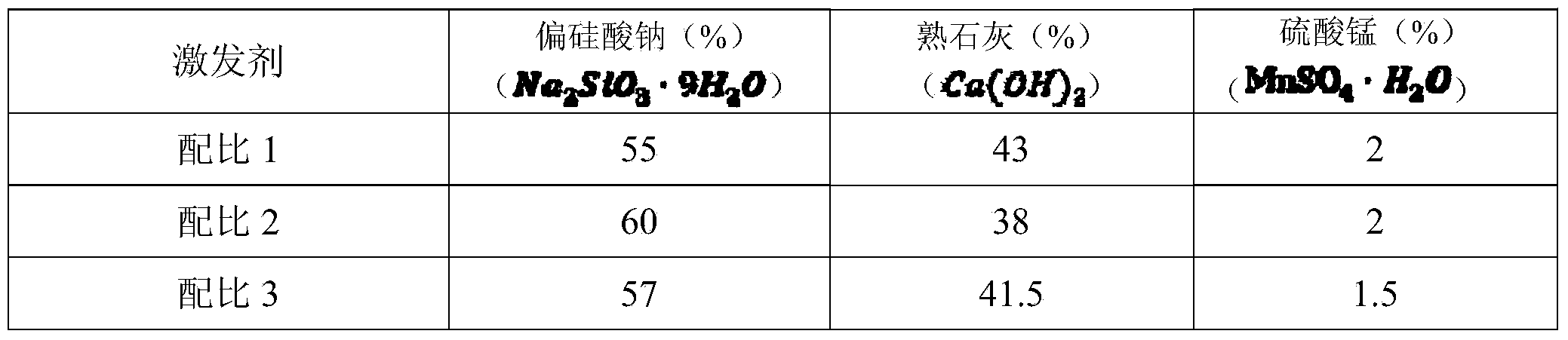

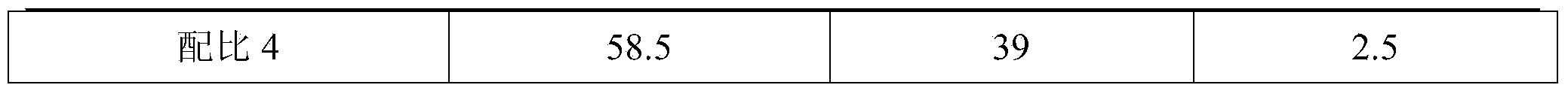

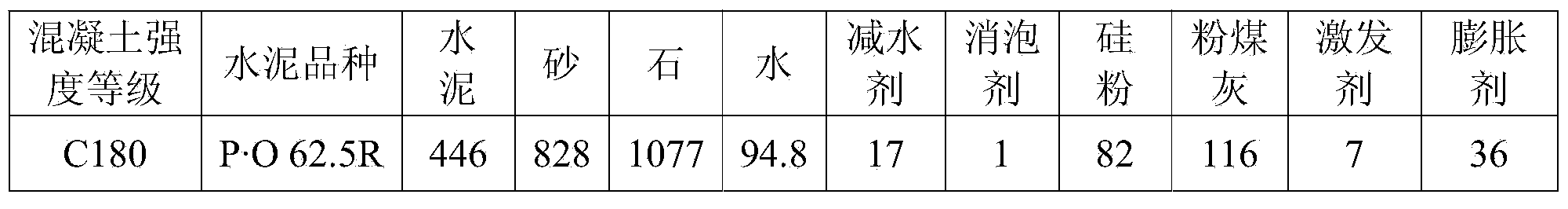

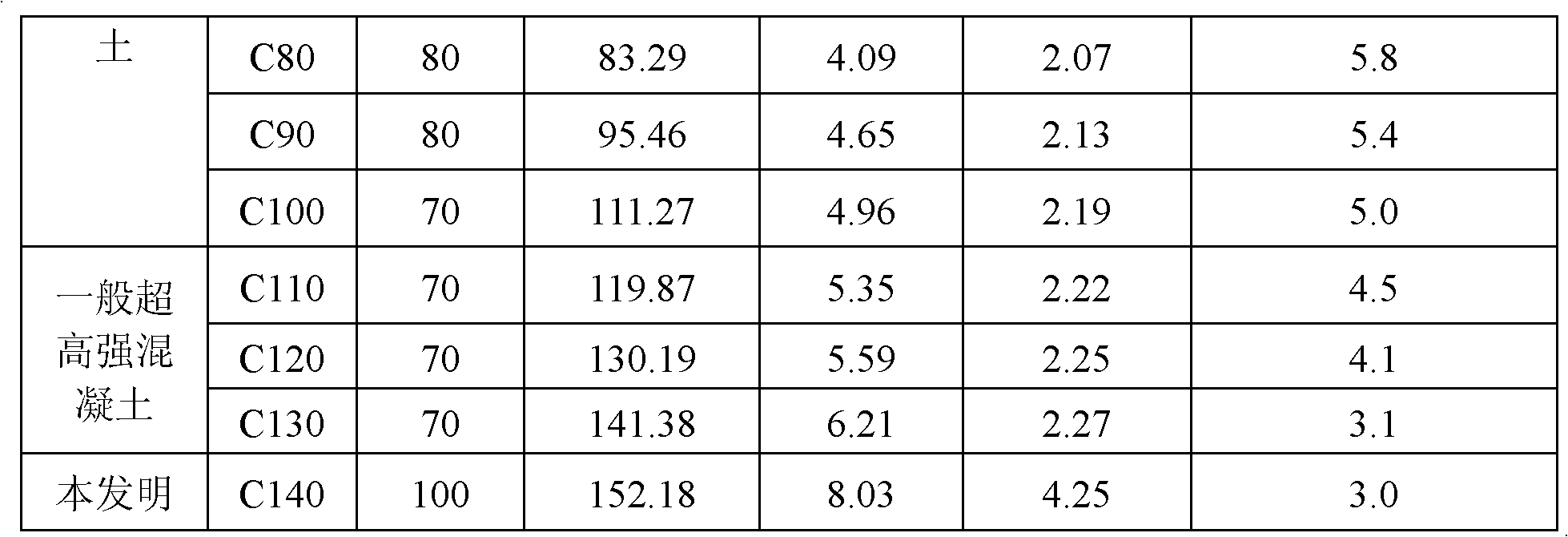

C180 strength-grade concrete for formed steel concrete composite structure

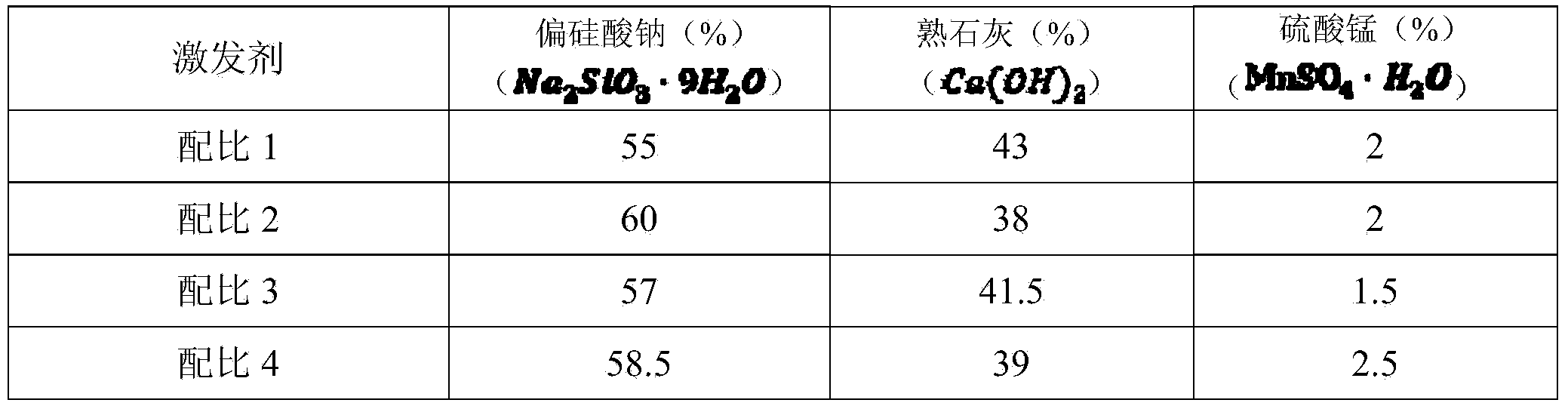

The invention discloses a C180 strength-grade concrete for a formed steel concrete composite structure, which is composed of 446 parts of cement, 828 parts of fine aggregate, 1077 parts of coarse aggregate, 94.8 parts of water, 17 parts of concrete superplasticizer, 1 part of defoaming agent, 82 parts of silicon powder, 116 parts of expanding agent, 7 parts of activator and 36 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

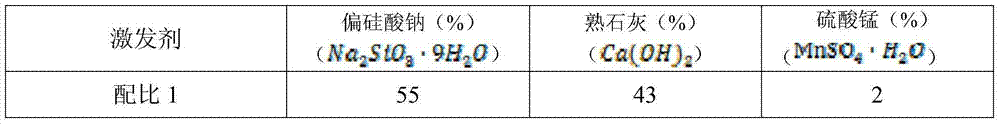

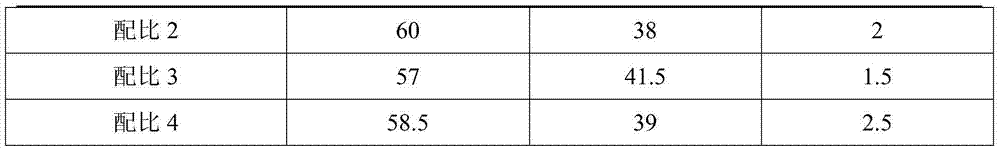

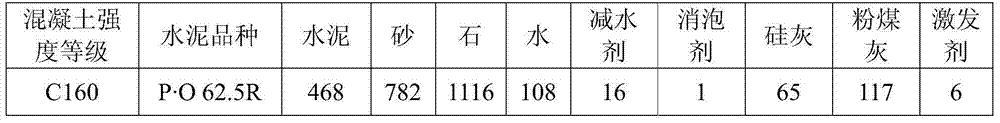

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

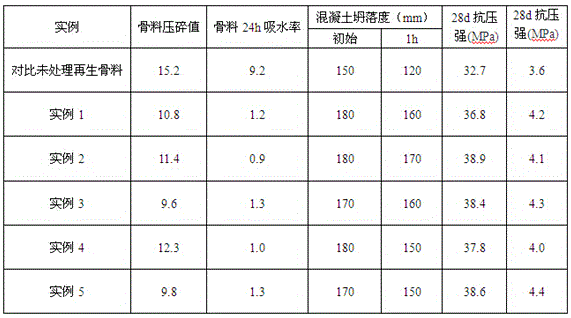

Durable and permeable concrete based on multistage recycled aggregate and preparation method of concrete

InactiveCN106478003AGood water permeabilityHigh mechanical strengthSolid waste managementFiberPolyethylene oxide

The invention provides a preparation method of durable and permeable concrete based on multistage recycled aggregate. The method comprises steps as follows: construction waste bricks and waste concrete are manually crushed, sieved in three ranges of 5-10 mm, 10-20 mm and 20-30 mm, washed and aired to form recycled aggregate; industrial waste slag and steel slag are washed clean, aired and mixed with silica fume, polyethylene oxide and water to form an adhesive after stirring, recycled aggregate is added, and the mixture is stirred and left to stand to form modified recycled aggregate; natural aggregate is added to the modified recycled aggregate and turned over uniformly, cement, polyethylene fibers, a water reducer and water are added, the mixture is stirred and subjected to layering mold charging, stirring formation, compaction and curing, and the durable and pervious concrete based on the multistage recycled aggregate is obtained. The permeable concrete prepared with the method contains multistage pores and has good water permeability, mechanical strength and excellent durability.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Recycled aggregate surface treating agent and use method thereof

The invention discloses a recycled aggregate surface treating agent and a use method thereof. The recycled aggregate surface treating agent is characterized by comprising the following components in percentage by weight: 4%-6% of acrylate, 0.2%-0.9% of peroxysulphate, 0.1%-0.5% of triethanolamine, 3%-5% of a cross-linking agent, 1%-3% of a silane coupling agent, 0.5%-1% of lignosulphonate calcium and 83.6%-91.2% of water. According to the recycled aggregate surface treating agent, the water absorption rate of recycled aggregates can be obviously decreased, and the property of an interfacial transition zone between the recycled aggregates and cement stone is improved, so that the concrete strength is improved.

Owner:HUAIAN TESTING CENT FOR CONSTR ENG

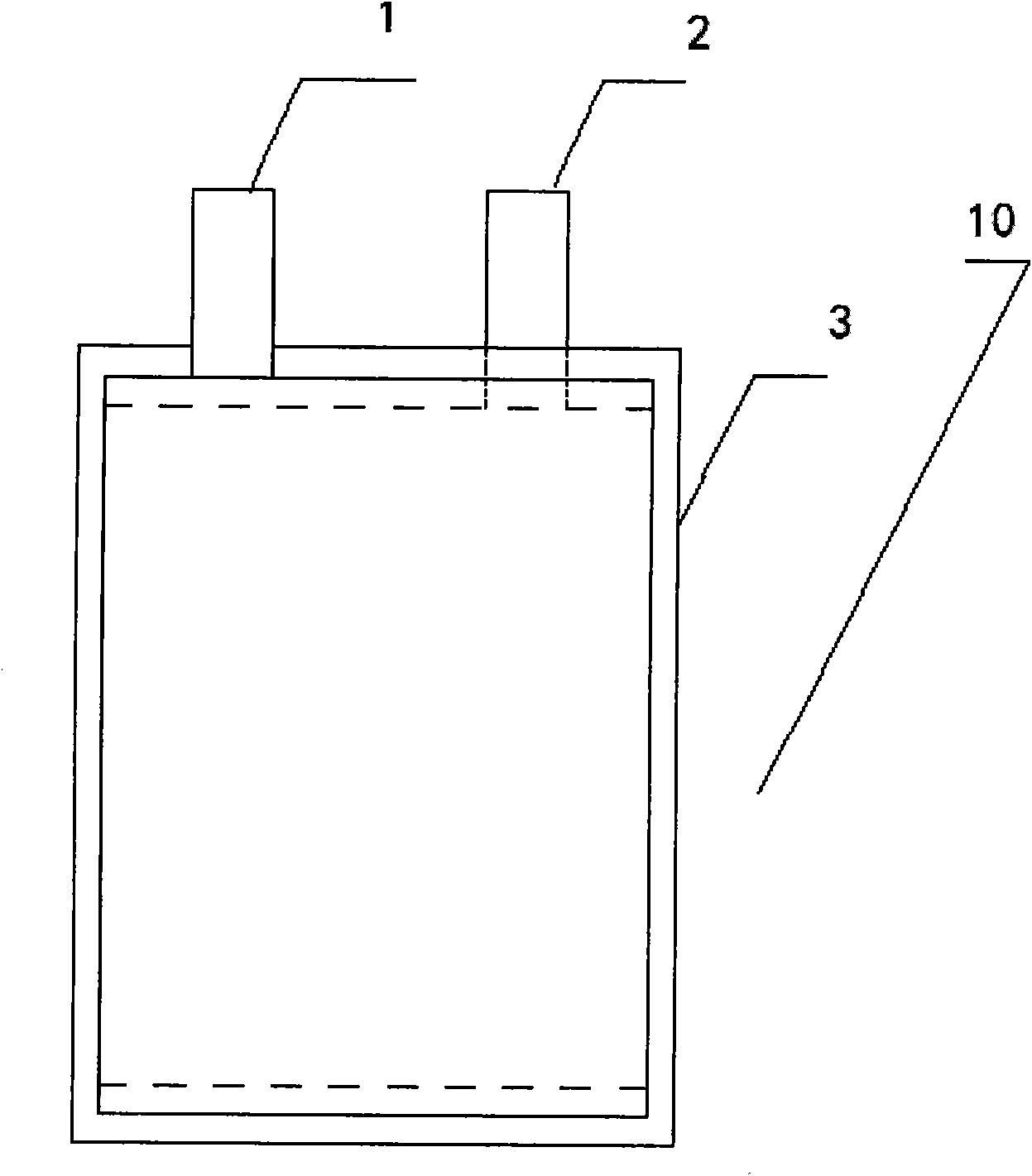

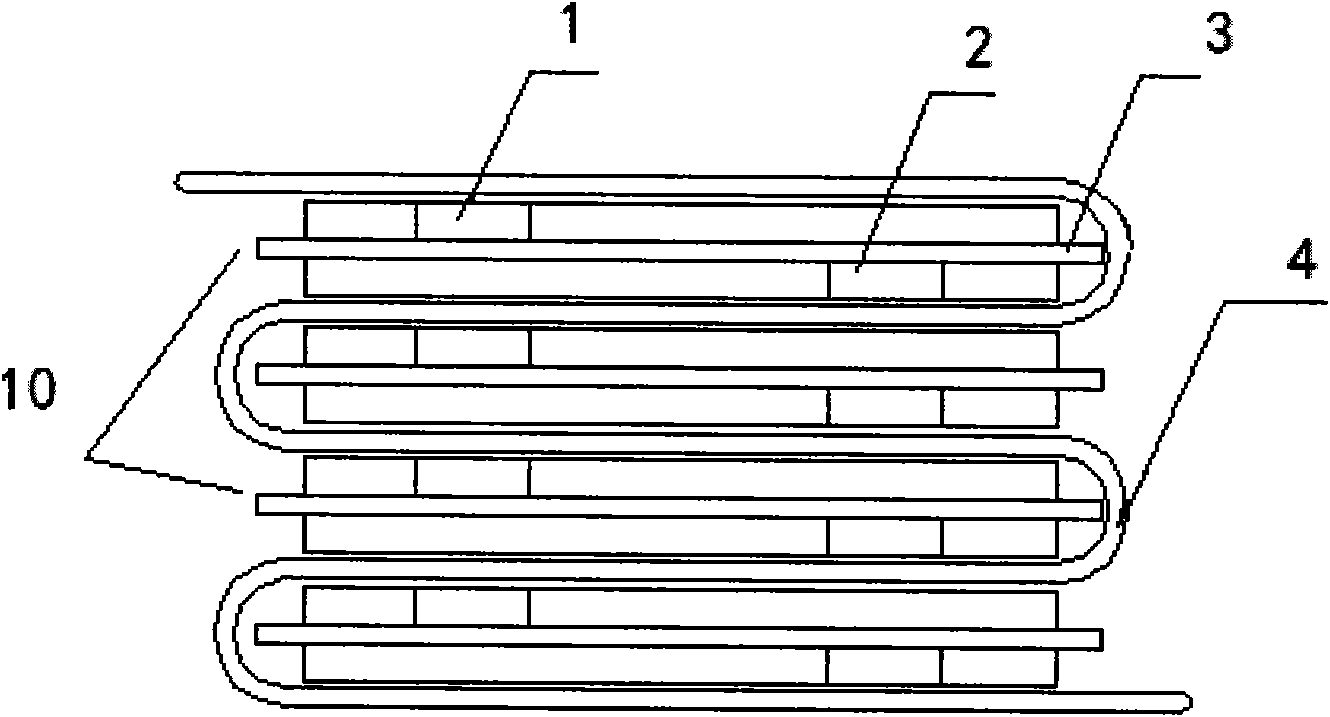

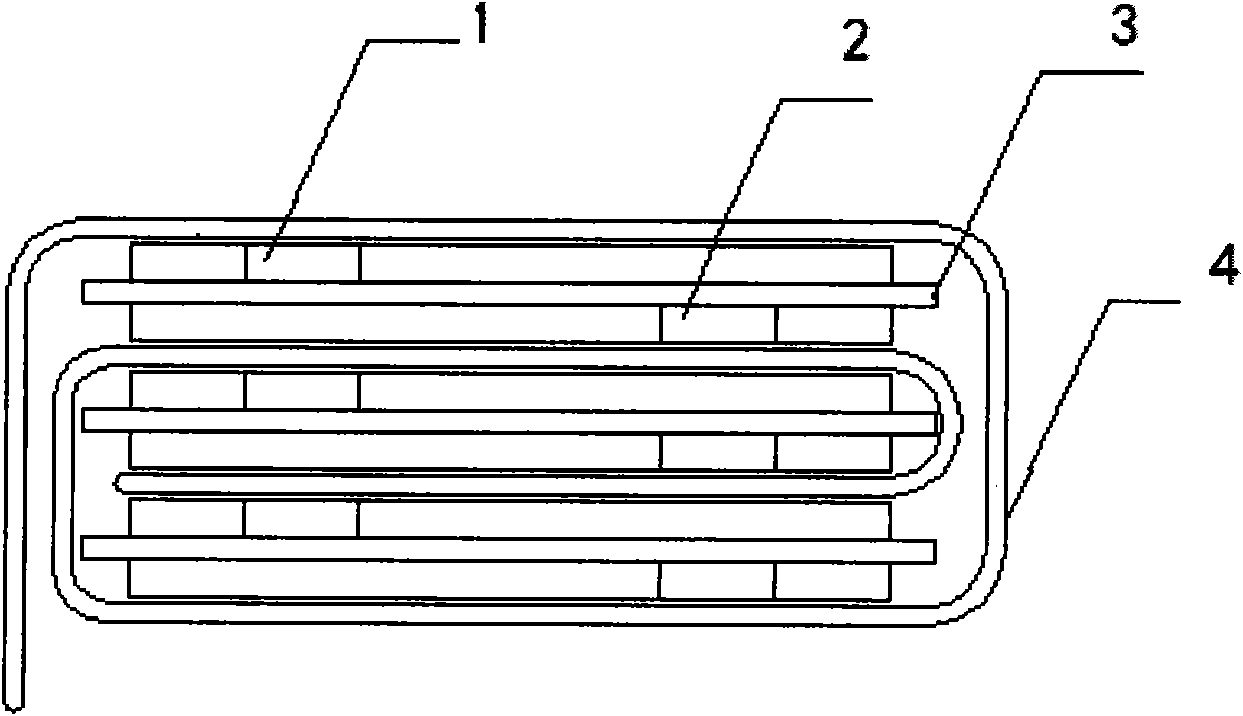

Core structure of lithium ion battery

InactiveCN101630757ALower internal resistanceImprove interface structureFinal product manufactureSecondary cellsInternal resistanceLithium-ion battery

The invention relates to a core structure of a lithium ion battery. In the core structure of the lithium ion battery, a core is formed by laminating and winding core monomers by means of a core septum; the core monomer is pressed by correspondingly laminating an anode sheet and a cathode sheet on two sides of the septum; and an anode ear of the anode sheet and a cathode ear of the cathode sheet are separated and positioned on two sides of the same side of the core monomer. The core septum wound with a plurality of the laminated core monomers can wind along the same direction and can also have a Z-shaped winding structure. The core is formed by laminating and winding the core monomers with the anode ears and the cathode ears by means of the core septum; the lithium battery with the core structure can effectively improve an interface structure between the core inner sheet formed by the laminated sheets and the septum, reduce the internal resistance of the core, improve the circulation performance and the rate discharge performance and can also prevent potential safety hazard triggered by misplacement of the anode sheet and the cathode sheet in the assembling process.

Owner:TCL CORPORATION

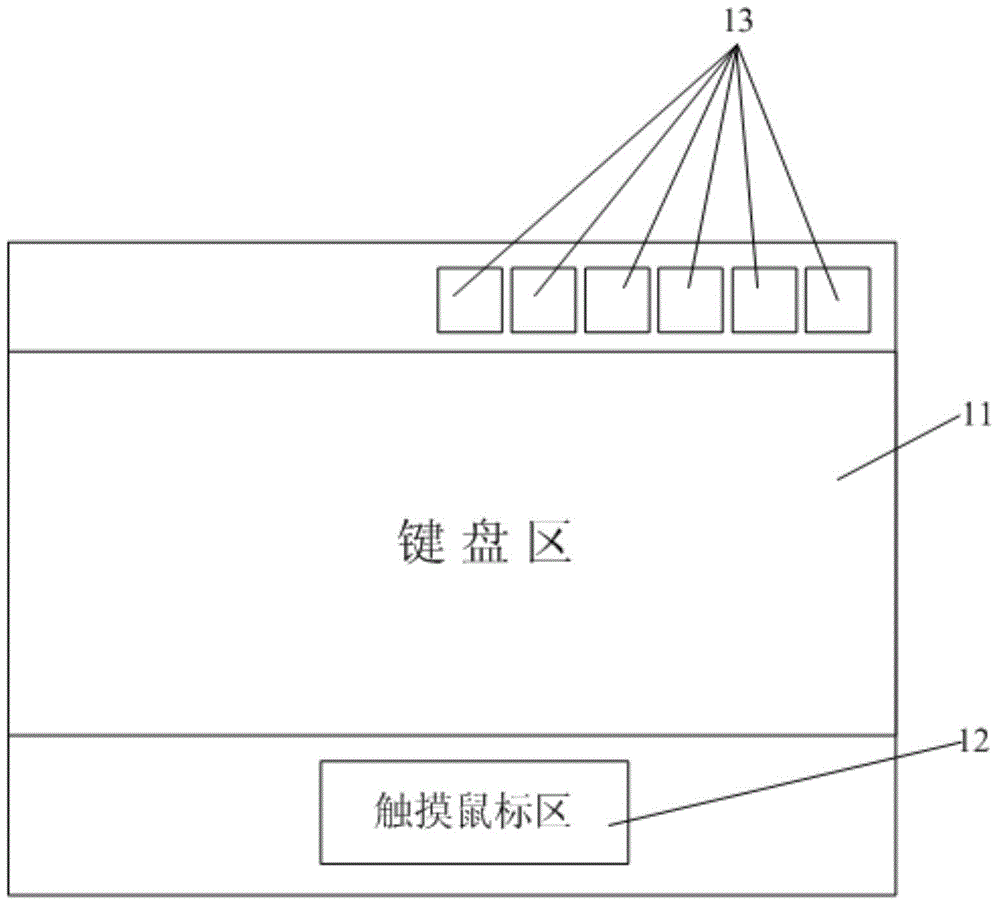

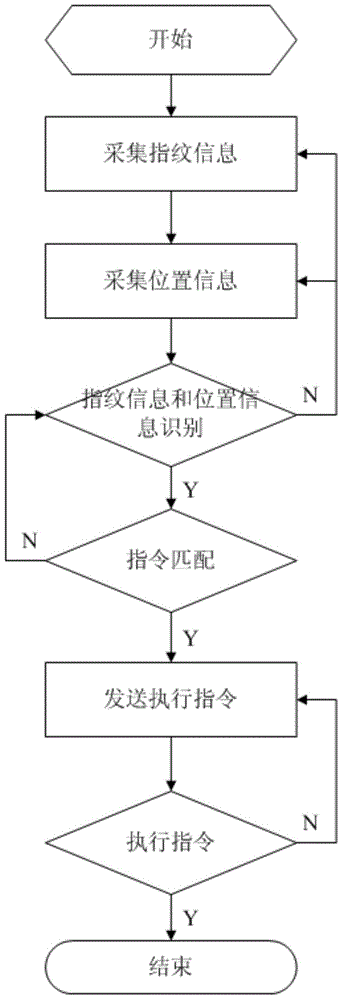

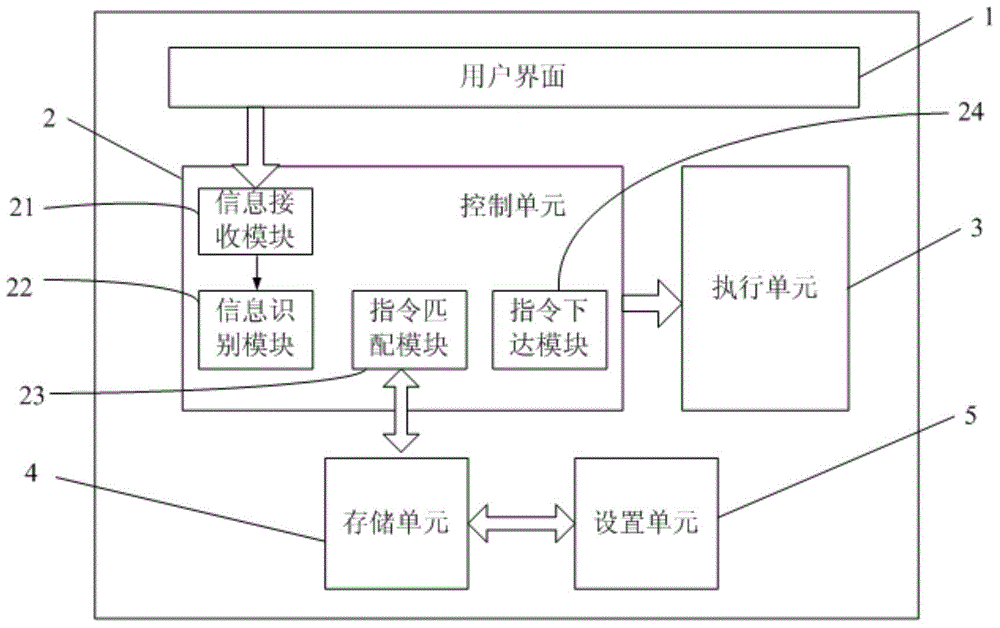

Electronic device control method and electronic device

ActiveCN104536766AImprove interface structureImprove ease of usePrint image acquisitionSpecific program execution arrangementsHuman–computer interactionElectric equipment

The invention relates to an electronic device control method and an electronic device. The electronic device control method comprises the steps of collecting fingerprint information and position information in one touch action of a user, recognizing executing commands corresponding to the collected fingerprint information and position information, and executing the corresponding executing commands. According to the electronic device control method and the electronic device, while use convenience is improved, a user interface structure is further optimized.

Owner:BOE TECH GRP CO LTD

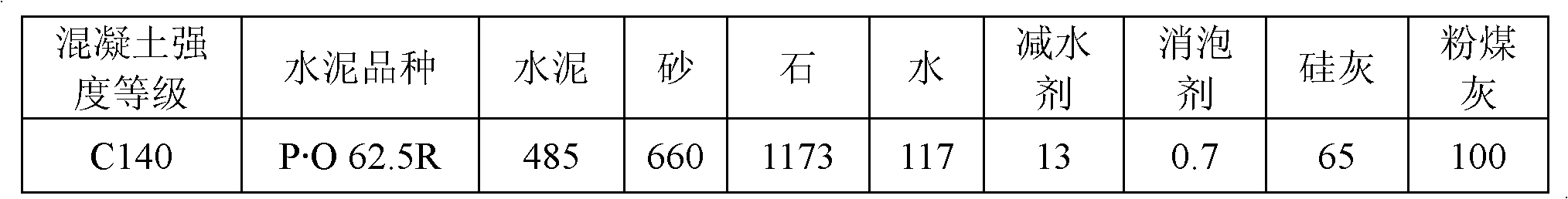

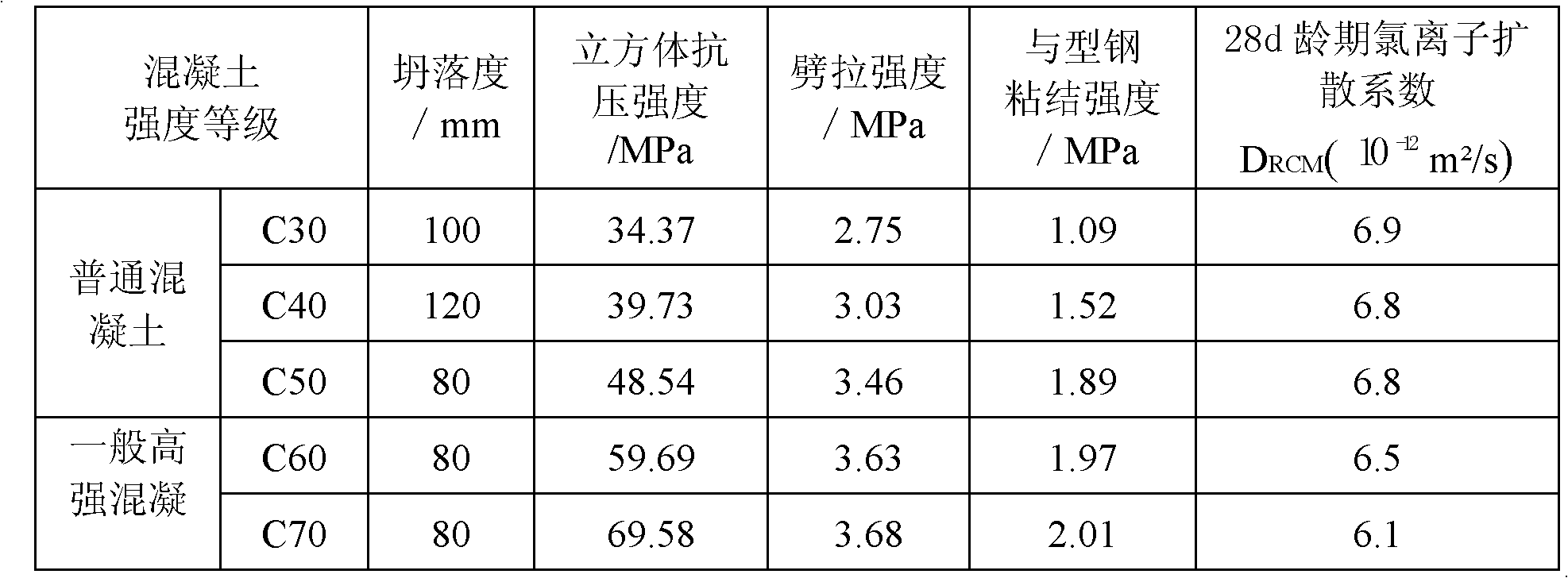

Concrete with strength grade of C140 used for profile steel-concrete composite structure

InactiveCN101913815AIncreased durabilityHigh Strength and DurabilitySolid waste managementCarrying capacityNatural state

The invention discloses concrete with strength grade of C140 used for a profile steel-concrete composite structure. The concrete is characterized by being prepared from cement, fine aggregate, coarse aggregate, water, a water reducing agent, an antifoaming agent, siliceous dust, coal ash(kg / m<3>) in a mixing proportion of 485:660:1,173:117:13:0.7:65:100. A preparation method of the concrete comprises the following steps of: adding the fine aggregate and the water in an amount of which is a half based on the total weight of the used water into a forced mixer according to the weight proportion in turn; uniformly stirring for 1 to 2 minutes; adding the coarse aggregate into the mixer; uniformly stirring for 2 to 4 minutes; adding the cement, the siliceous dust and the coal ash into the mixer; uniformly stirring for 2 to 3 minutes; adding the water reducing agent, the antifoaming agent and the rest water into the mixer; uniformly stirring for 2 to 5 minutes; and discharging to obtain a concrete mixture. The concrete can obviously improve the adhesive property between profile steel and the concrete in a natural state, effectively exert respective capacity and cooperative work performance of both materials, greatly improve the carrying capacity and performance of members, and improve the durability, high volume stability and economy of the members.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

In situ self-generation aluminum nitride enhanced magnesium-base composite material and preparation method thereof

InactiveCN101148723AEvenly distributedImprove mechanical propertiesMagnesium matrix compositeGraphite

The Mg-base composite material with in-situ autogeneous reinforcing AlN phase contains Mg alloy base in 80-95 wt% and reinforcing AlN ceramic grain in 5-20 wt%. Its Mg alloy base contains Al in 0-9 wt%. The Mg-base composite material is prepared through the following steps: 1. melting Mg-Al alloy material under the protection of mixed gas comprising SF6 in 10 vol% and CO2 in 90 vol%; 2. pressing aluminum foil coated Mg3N2 powder into the Mg-Al melt; 3. maintaining the temperature for the Mg3N2 powder and the Al in the melt to react completely; and 4. stirring the melt and skimming the scum with a graphite disc, casting into metal mold and solidifying to obtain the composite material. The composite material has the features of light weight, high strength, high modulus, high heat resistance, etc. and may be applied widely.

Owner:SHANGHAI JIAO TONG UNIV

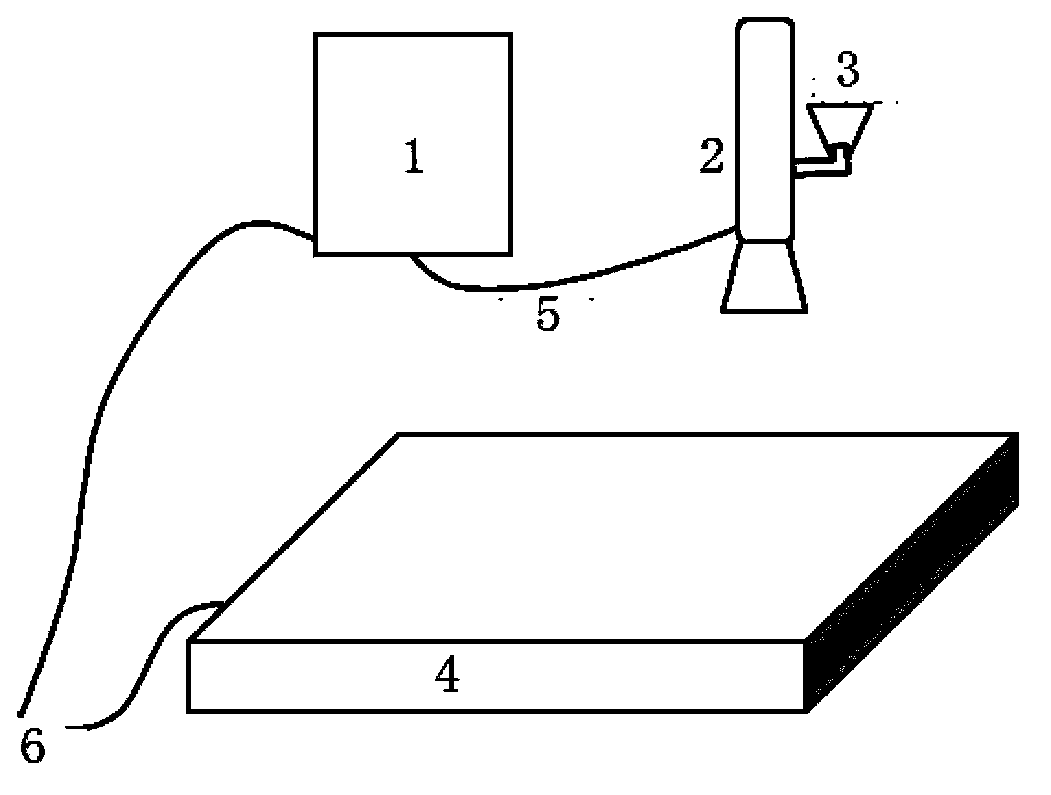

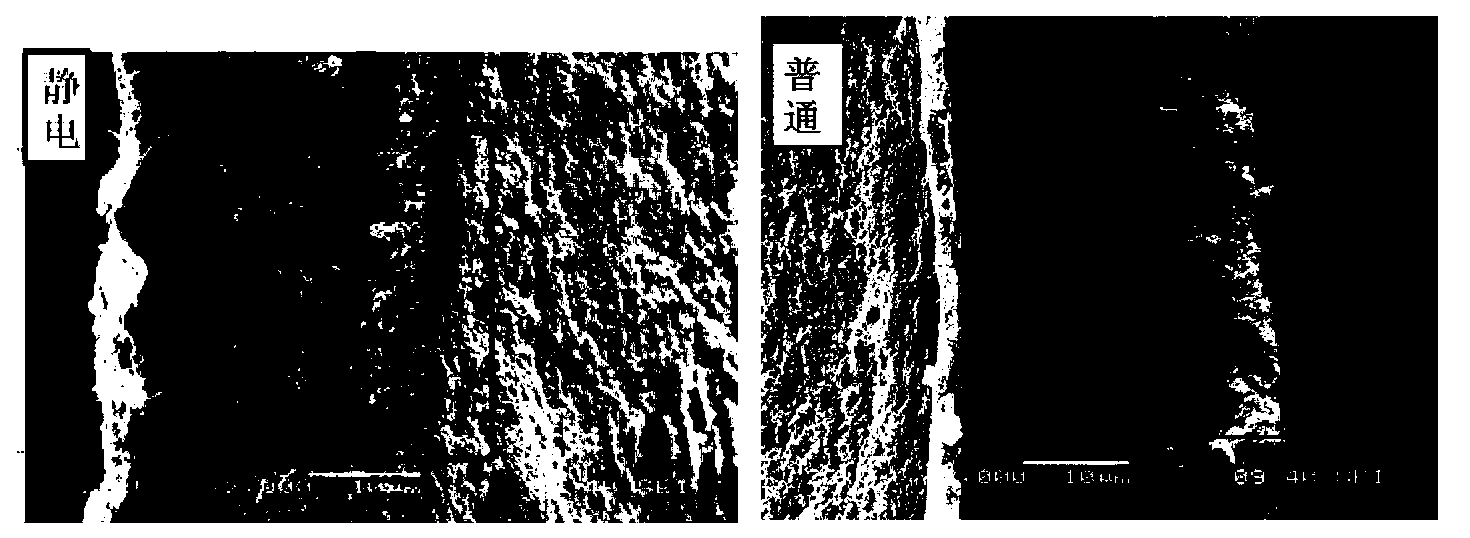

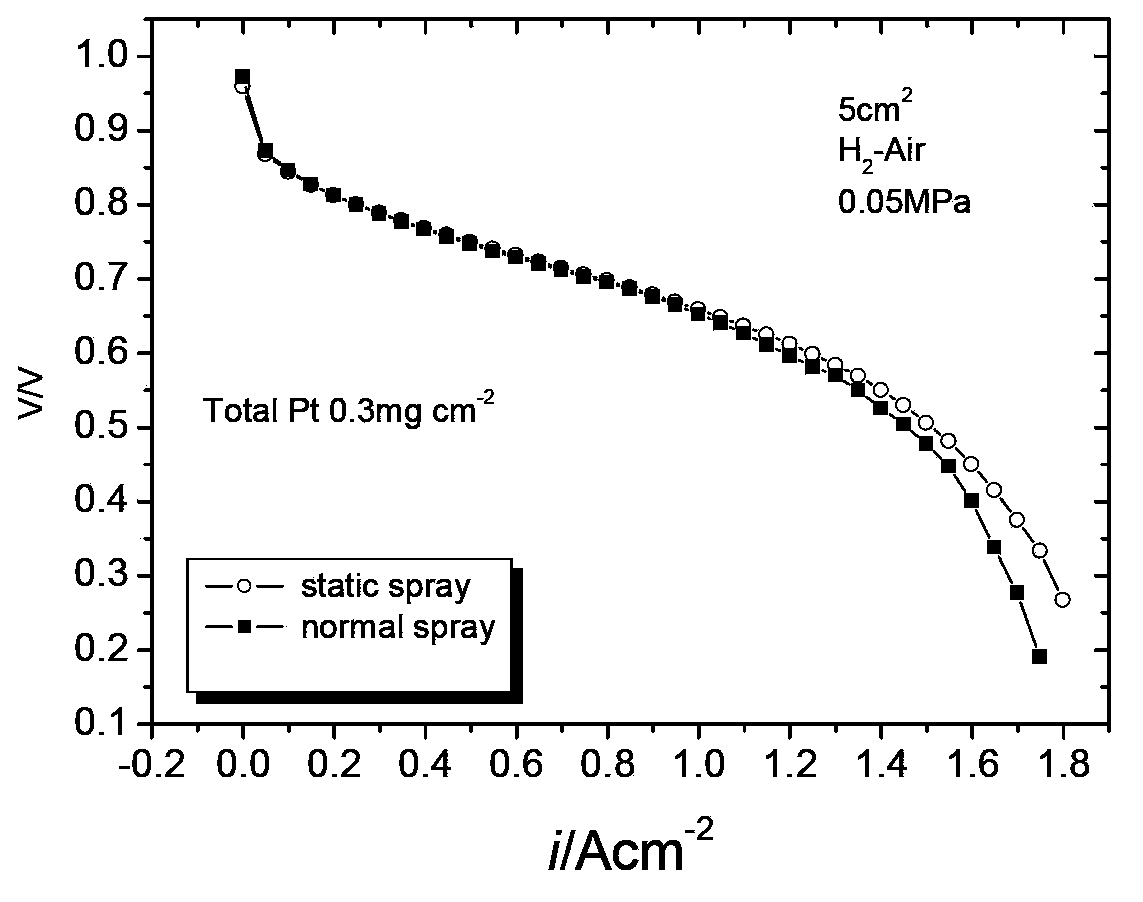

Preparation method for membrane electrode of fuel cell

InactiveCN104056741AIncrease profitImprove interface structureLiquid spraying plantsCell electrodesFuel cellsEngineering

The invention provides a preparation method for a membrane electrode of a fuel cell. In the process of spraying slurry, the slurry is loaded with electrostatic charges through an electrostatic generator, so as to increase the adsorbability between the slurry and the membrane, improve the Pt utilization rate of a catalytic layer, improve the performance of the membrane electrode and reduce the Pt loading amount.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

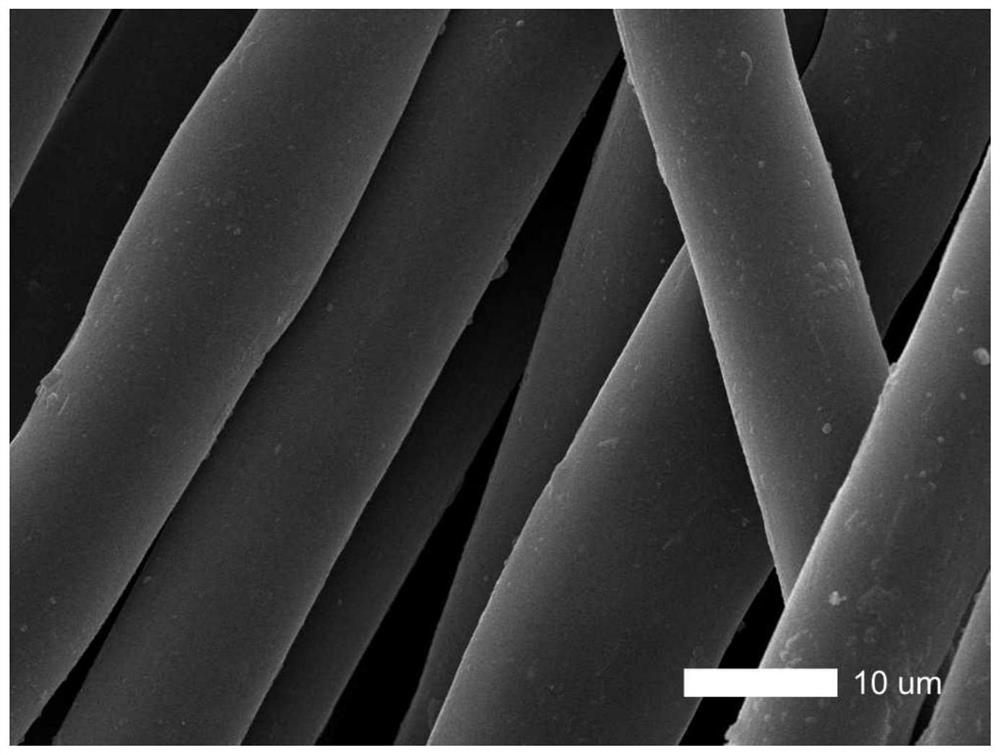

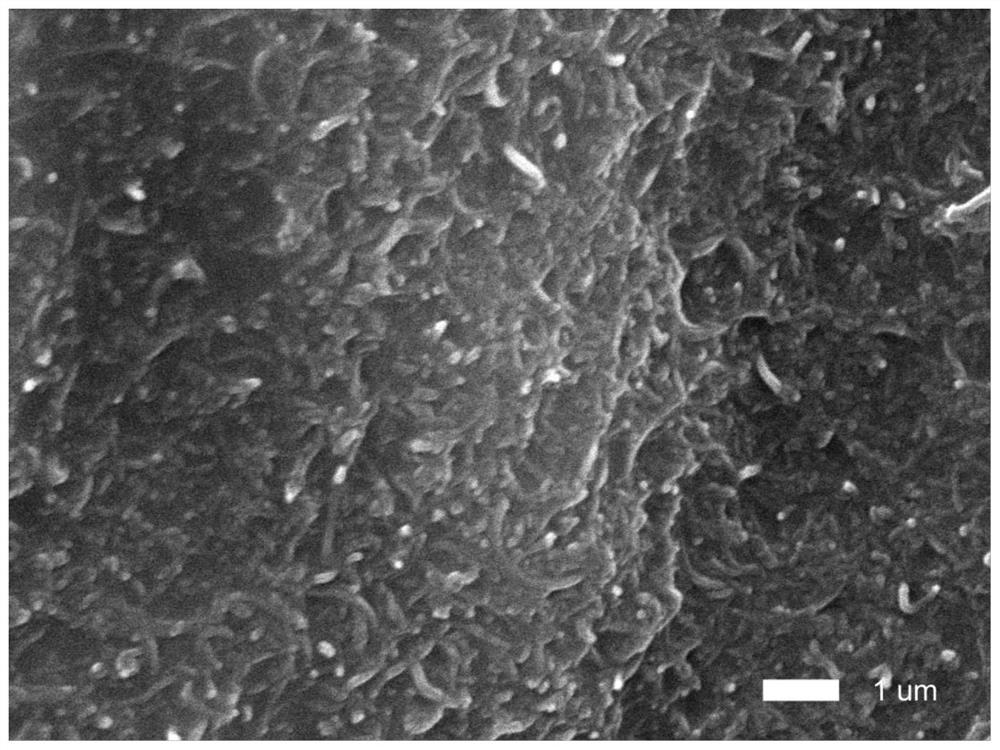

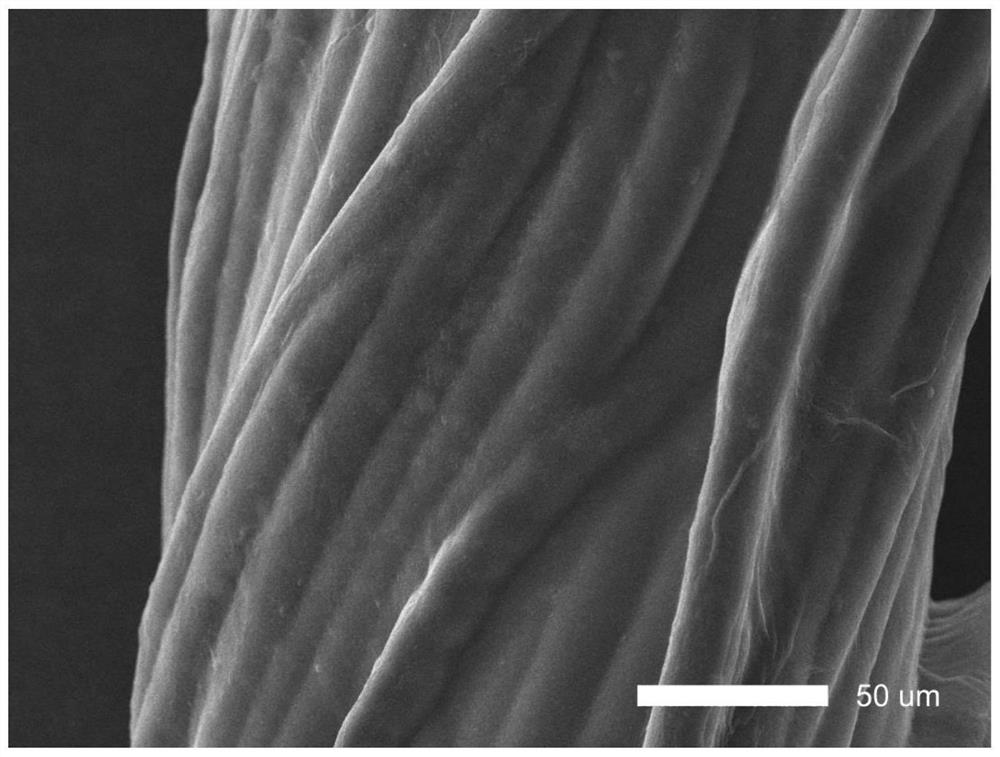

Layer-by-layer self-assembly composite conductive fiber bundle and preparation method thereof

ActiveCN111636195AImprove conductivityHigh specific surface areaPhysical treatmentFiber bundleConductive coating

The invention provides a layer-by-layer self-assembly composite conductive fiber bundle and a preparation method thereof. The method comprises the following steps that firstly, a fiber bundle is subjected to oxygen plasma pretreatment to finish physical modification of fibers, so that the surface of the fiber bundle has a certain active group; and then, through a layer-by-layer self-assembly method, electropositive substances and electronegative substances are alternately deposited on the surface of the fiber bundle through the combination of electrostatic forces of positive charges and negative charges to form a composite conductive coating, in this way, the layer-by-layer self-assembly composite conductive fiber bundle formed by compositing a fiber bundle body and the composite conductive coating deposited on the fiber bundle body is prepared. The preparation method is simple and controllable, and the conductivity of the composite conductive fiber bundle can be regulated and controlled by controlling the self-assembly time, the number of self-assembly layers and the type and concentration of electropositive / electronegative substances; and the conductive coating of the prepared composite conductive fiber bundle is uniform and compact in structure and excellent in conductivity, and can be widely applied to the fields of wearable electronic devices, energy storage, sensing and the like.

Owner:WUHAN TEXTILE UNIV

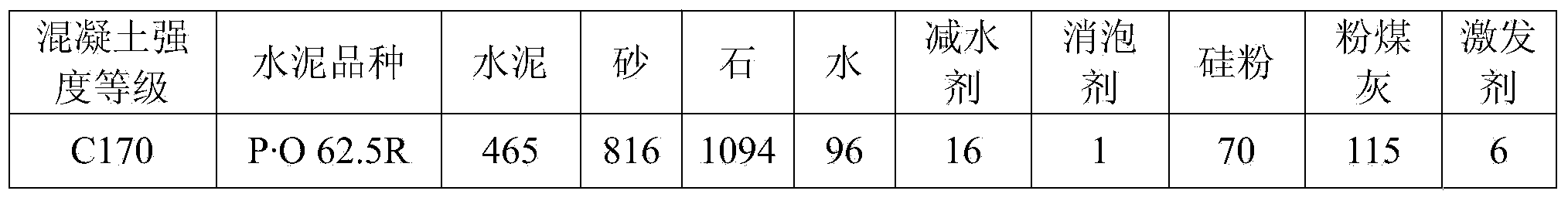

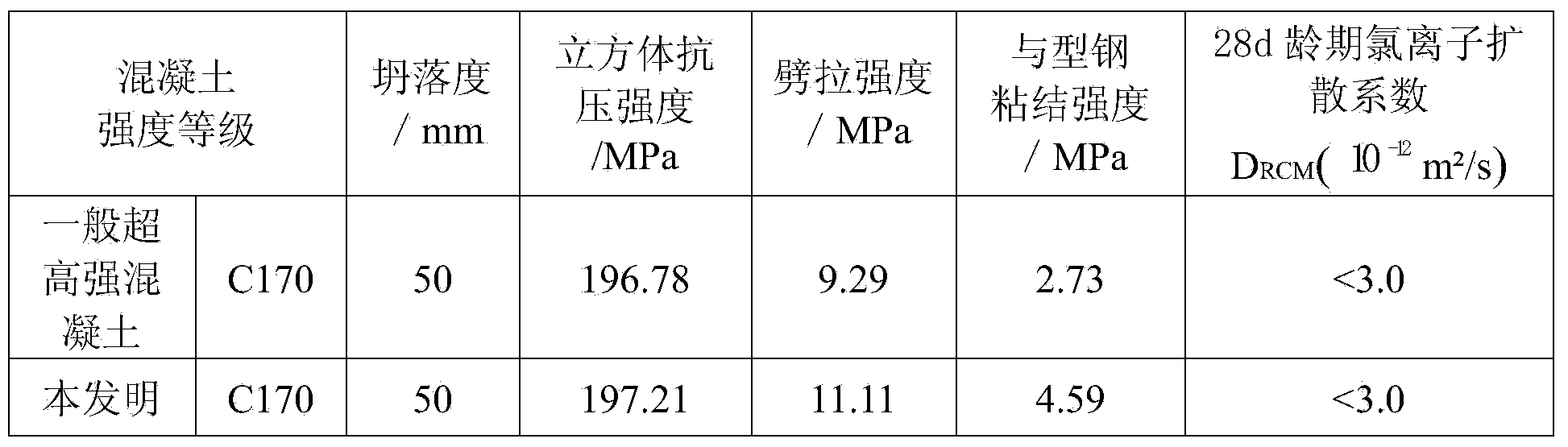

C170 strength-grade concrete for formed steel concrete composite structure

The invention discloses a C170 strength-grade concrete for a formed steel concrete composite structure, which is composed of 465 parts of cement, 816 parts of fine aggregate, 1094 parts of coarse aggregate, 96 parts of water, 16 parts of concrete superplasticizer, 1 part of defoaming agent, 70 parts of silicon powder, 115 parts of fly ash and 6 parts of activator. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has favorable working performance and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

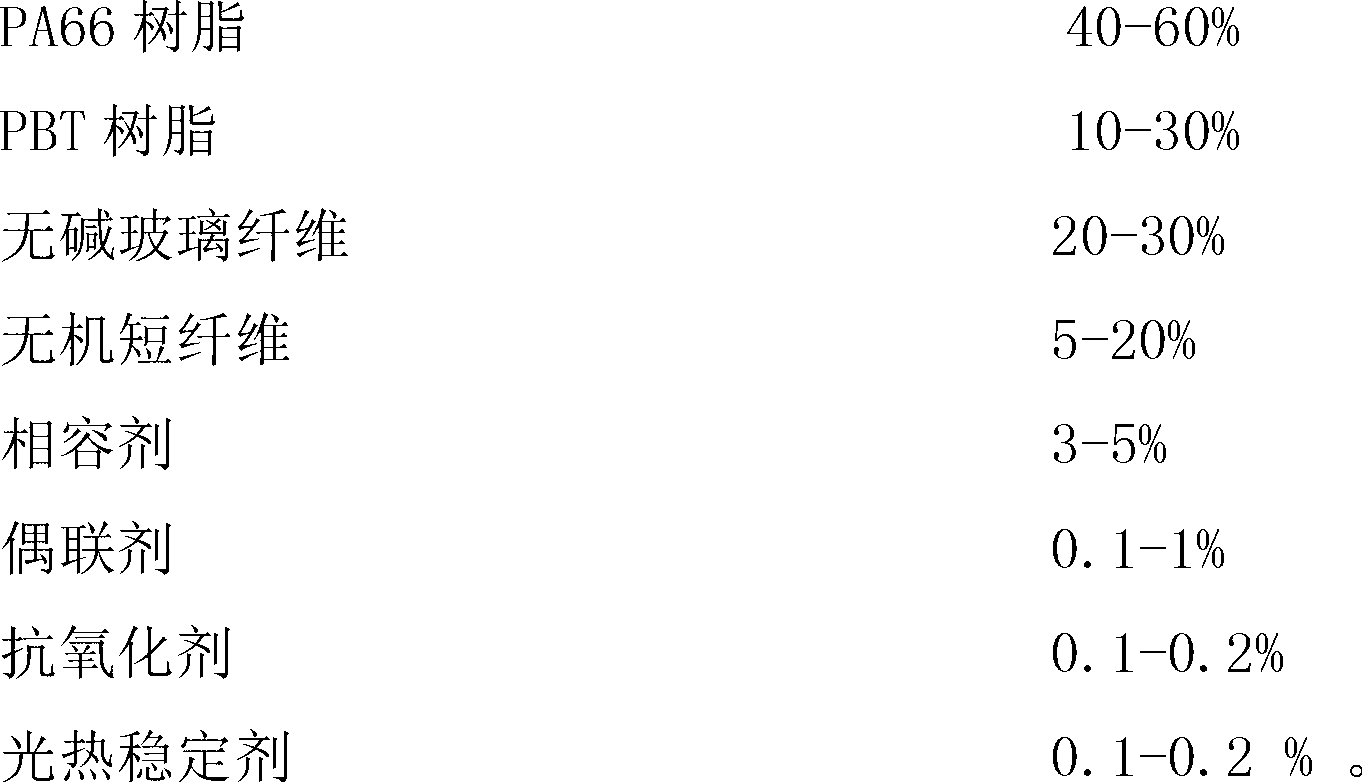

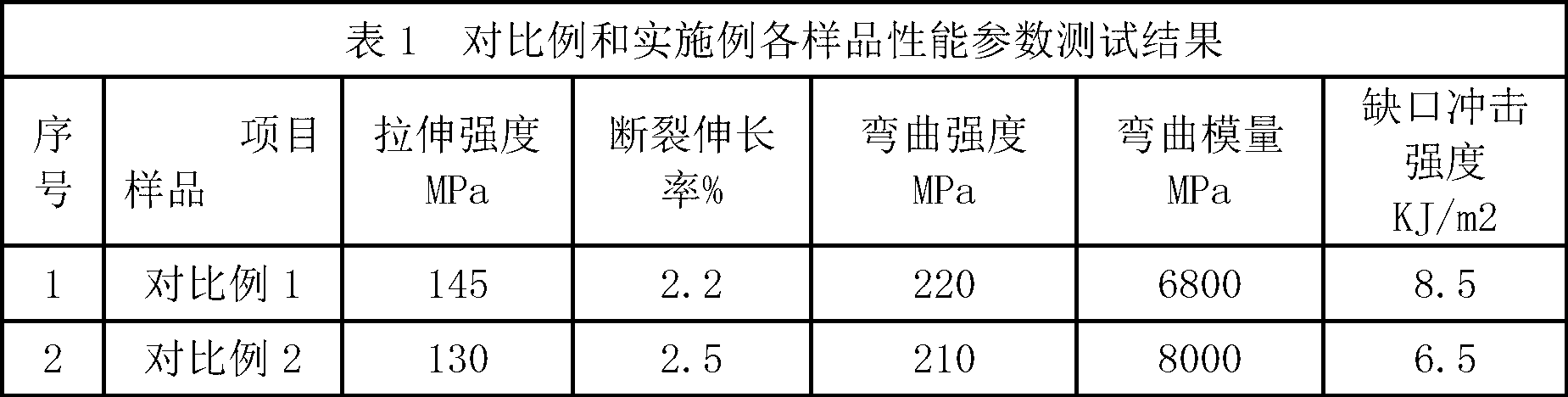

Glass-fiber-reinforced PA66/PBT (polyamide 66/polybutylene terephthalate) resin alloy material and preparation method thereof

InactiveCN103013109AEvenly dispersedThe distribution of microscopic crystal phase structure is fineMutual solubilityPolyamide

The invention discloses a glass-fiber-reinforced PA66 / PBT (polyamide 66 / polybutylene terephthalate) resin alloy material and a preparation method thereof. The glass-fiber-reinforced PA66 / PBT resin alloy material comprises the following main raw materials: PA66 resin, PBT resin, alkali-free glass fiber, inorganic chopped fiber, coupling agent, compatilizer, antioxidant, photo-thermal stabilizer and the like. In the modified material, the alkali-free glass fiber and inorganic chopped fiber not only have the function of reinforcement, but also have the function of promoting uniform dispersion and mutual solubility among the PA66, PBT and compatilizer; the coupling agent and compatilizer in the material have the functions of performing surface treatment on the glass fiber and inorganic chopped fiber and enhancing the compatibility with PA66 / PBT alloy; thus, the aggregative state structure of the material is fundamentally changed, the compatibility and crystallinity are greatly changed, and various properties of the PA66 / PBT alloy are sufficiently displayed in deed; and meanwhile, the cost can be lowered, and the application range of PA66 can be widened.

Owner:CHENGDU SOLVER TECH

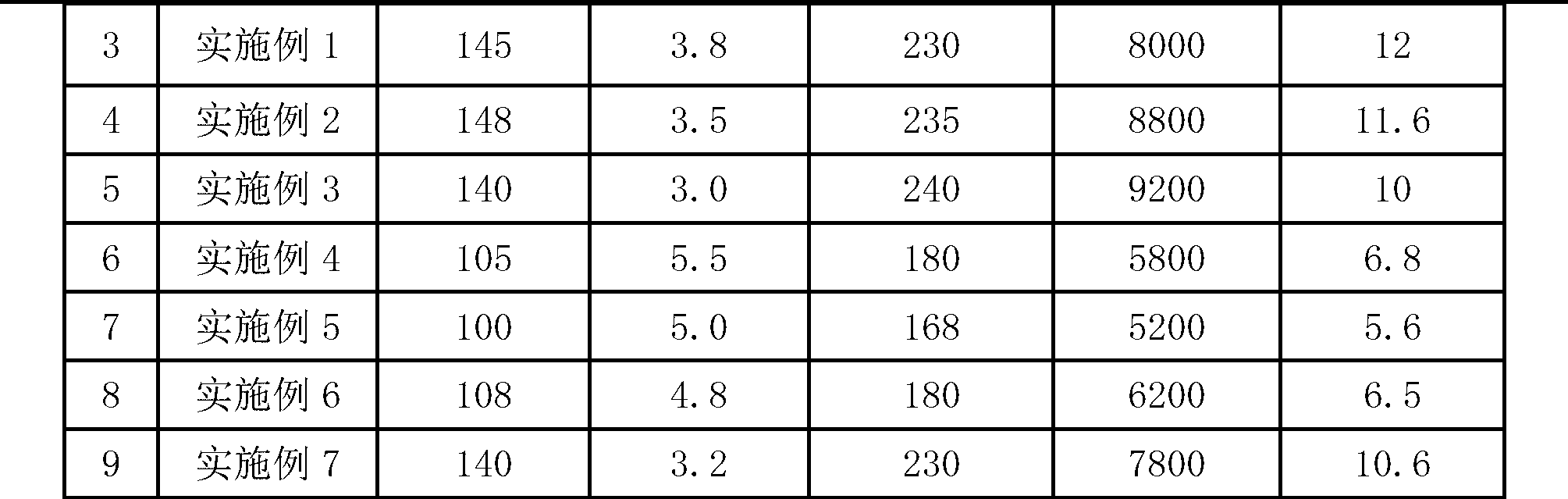

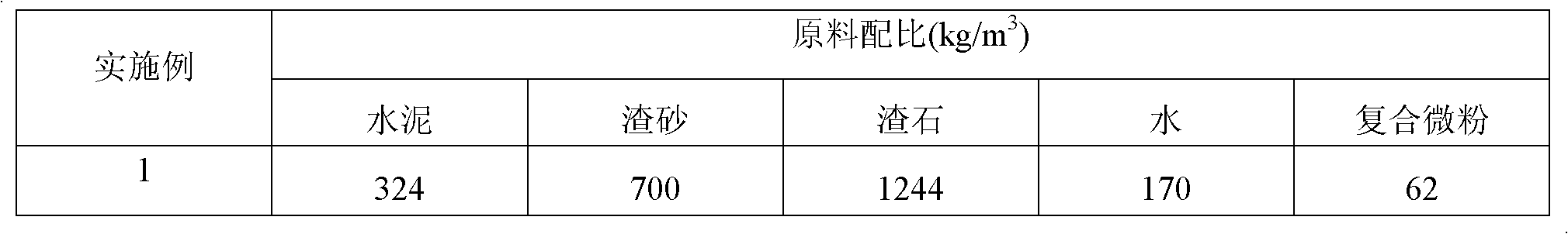

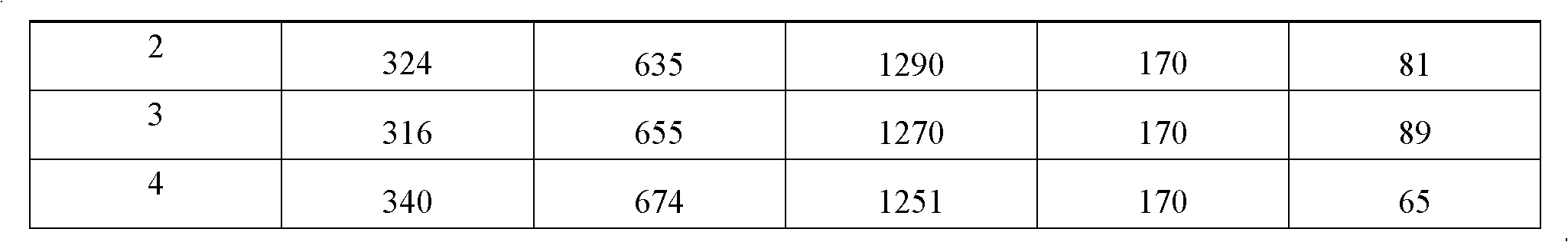

Composite high titanium and dry slag pavement concrete and preparation method thereof

InactiveCN102329113ALose weightImprove bending and tensile strengthSolid waste managementBreaking strengthSlag

The invention discloses composite high titanium and dry slag pavement concrete and a preparation method thereof, belonging to the field of concrete. The composite high titanium and dry slag pavement concrete with high breaking strength, which is prepared from high titanium and dry slag aggregate, comprises the following raw materials calculated according to each cubic meter of concrete: 300-340kgof cement, 630-710kg of high titanium and dry slag sand, 1200-1300kg of high titanium and dry slag stone, 160-175kg of water and 55-95kg of high titanium and dry slag composite powder. The invention also provides the preparation method of the pavement concrete. The raw materials are mixed according to the weight portion and feeding sequences of the high titanium and dry slag stone, the cement andthe high titanium and dry slag composite micropowder, the high titanium and dry slag sand and the water. The breaking strengths of the composite high titanium and dry slag pavement concrete obtained by the invention are 7d-6.16-6.38MPa and 28d-7.5-7.68Mpa respectively.

Owner:PANZHIHUA UNIV

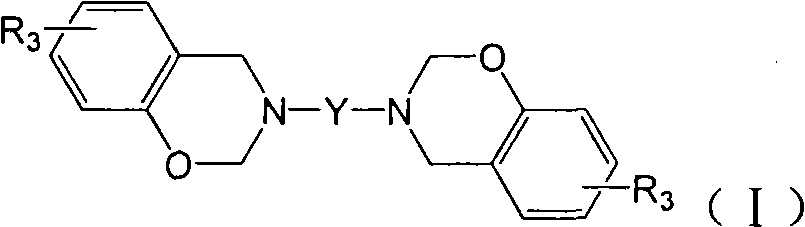

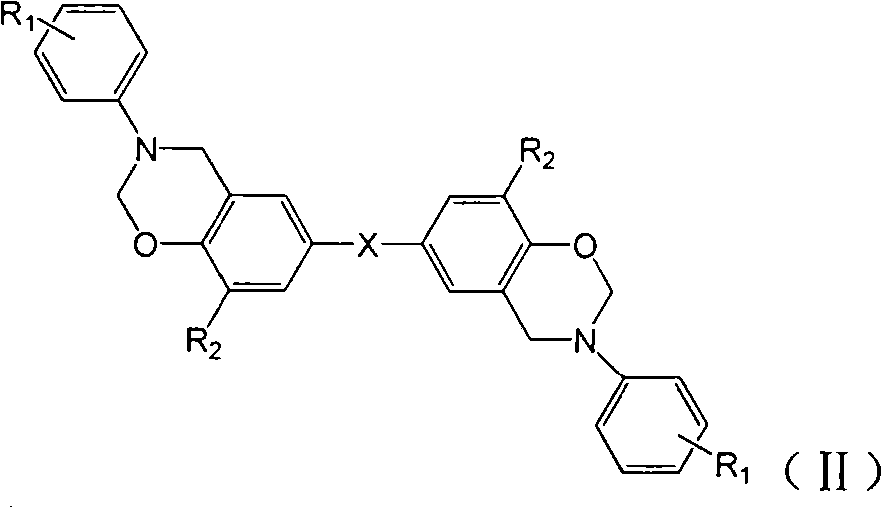

Thermoset polybenzoxazine-polyimide resin composite/mesoporous molecular sieve hybrid material and preparation method thereof

The invention belongs to the field of organic / inorganic hybrid materials, and discloses a thermoset polybenzoxazine-polyimide resin composite / mesoporous molecular sieve hybrid material, which consists of a thermoset polybenzoxazine-polyimide resin composite and a mesoporous molecular sieve, wherein the mesoporous molecular sieve mass content of the hybrid material is 0.5 to 15 percent. Through a preparation method of the invention, the polybenzoxazine-polyimide resin composite / mesoporous molecular sieve hybrid material with a good interface structure and high comprehensive performance can be obtained. Compared with resin composites, the hybrid material not only maintains the heat resistance of substrate resin materials, but also has higher room-temperature storage modulus and lower dielectric constant so as to broaden the application prospect of the polybenzoxazine-polyimide resin composite in the fields of electrical engineering, electronics, information, military, aviation, aerospace and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

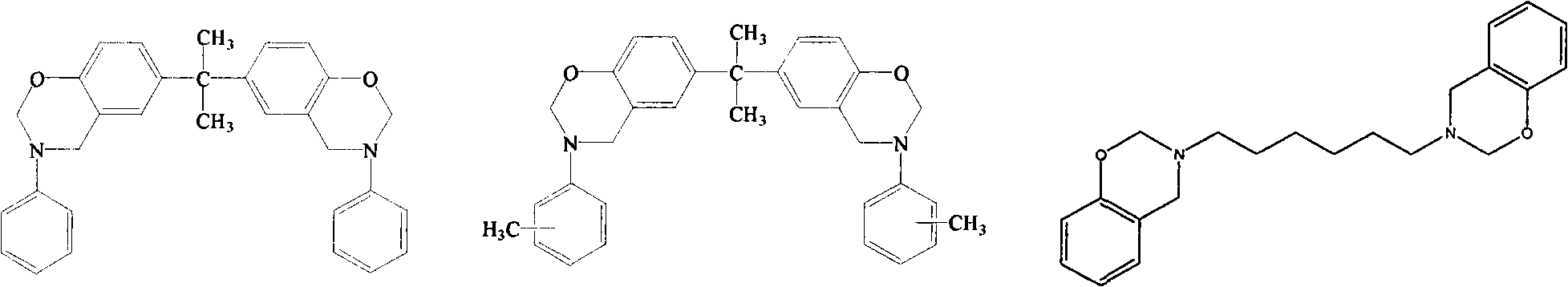

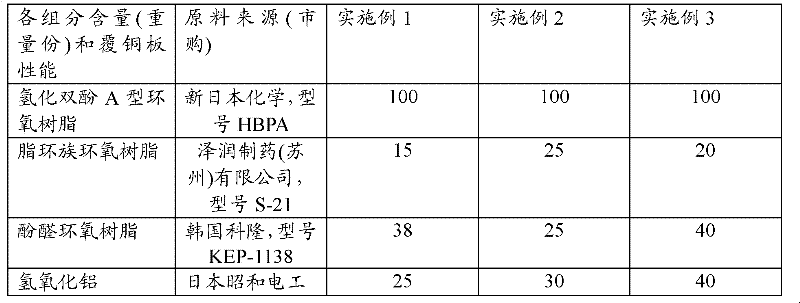

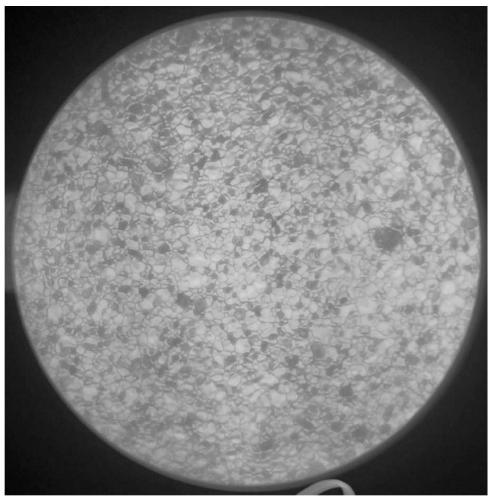

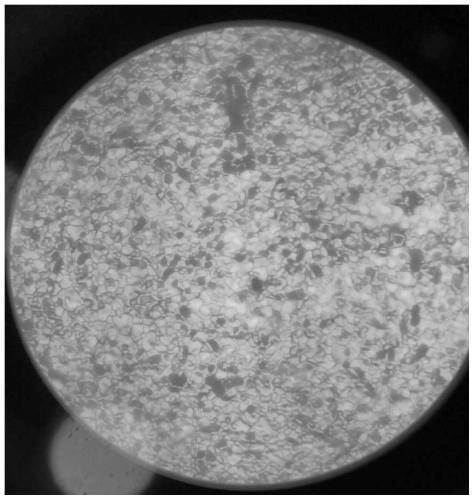

Halogen-free resin composition and copper clad plate prepared from composition

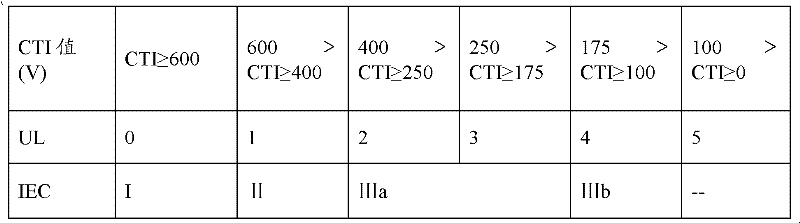

ActiveCN102286190AHigh CTI valueReduce dosageCircuit susbtrate materialsMetal layered productsOrganic solventComparative Tracking Index

The invention discloses a halogen-free resin composition. The composition is prepared by fully mixing hydrogenated bisphenol A type epoxy resin, alicyclic epoxy resin, novolac epoxy resin curing agent, aluminum hydroxide serving as an inorganic filler and organic solvent uniformly. The invention also discloses a copper clad plate prepared from the halogen-free resin composition. The copper clad plate has good thermal stability and creepage tracing property. The halogen-free resin with high comparative tracking index (CTI) resin is adopted, and the consumption of the aluminum hydroxide servingas the inorganic filler is reduced, so that the composition has high CTI value, avoids series problems caused by using excessive aluminum hydroxide and simultaneously realizes halogen-free and environment-friendly properties.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

Electrode silver paste for functional ceramics and preparation method of electrode silver paste

ActiveCN111292873AAvoid damageImprove dispersion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention discloses electrode silver paste for functional ceramics and a preparation method of the electrode silver paste. The electrode silver paste is prepared from the following components in percentage by mass: 55 to 85 weight percent of a silver mixture, 0.8 to 1.8 weight percent of lead-free glass powder, 0.1 to 1 weight percent of a phase-forming compound and 13 to 44 weight percent ofan organic carrier. The preparation method is characterized by comprising the steps of premixing part of an organic carrier with lead-free glass powder sheets and the phase-making compound to form slurry, grinding and dispersing the slurry by a grinder, adding all silver mixture, grinding until the fineness of the slurry is less than 5 microns, mixing the residual organic carrier, and carrying outdouble-planet stirring defoaming to obtain the electrode silver paste for the functional ceramics. By solving the problems of sintering compactness of the metallized layer and regulation and controlof a glass phase interface structure, high carrier mobility, strong adhesive force, thermal expansion matching property, assembly reliability, environmental stability and cost economy of the functional ceramic metallized layer are finally realized, and the production process requirements of printing, dipping, spraying and hole dropping can be met.

Owner:SINO PLATINUM METALS CO LTD +1

Interface treating agent of unsaturated polyester mortar as concrete repairing material

InactiveCN1390885AGood deformabilityHigh bonding strengthBuilding insulationsRepair materialMaterials science

An interface treating agent of unsaturated polyester mortar (UPM) for repairing concrete is prepared from EP as primary cemonting agent, organic silica rubber as modifier, plastisizer, coupling agent, epoxy solidifying agent and filler. It can greatly increase the adhesion between concrete and repairing material.

Owner:TONGJI UNIV

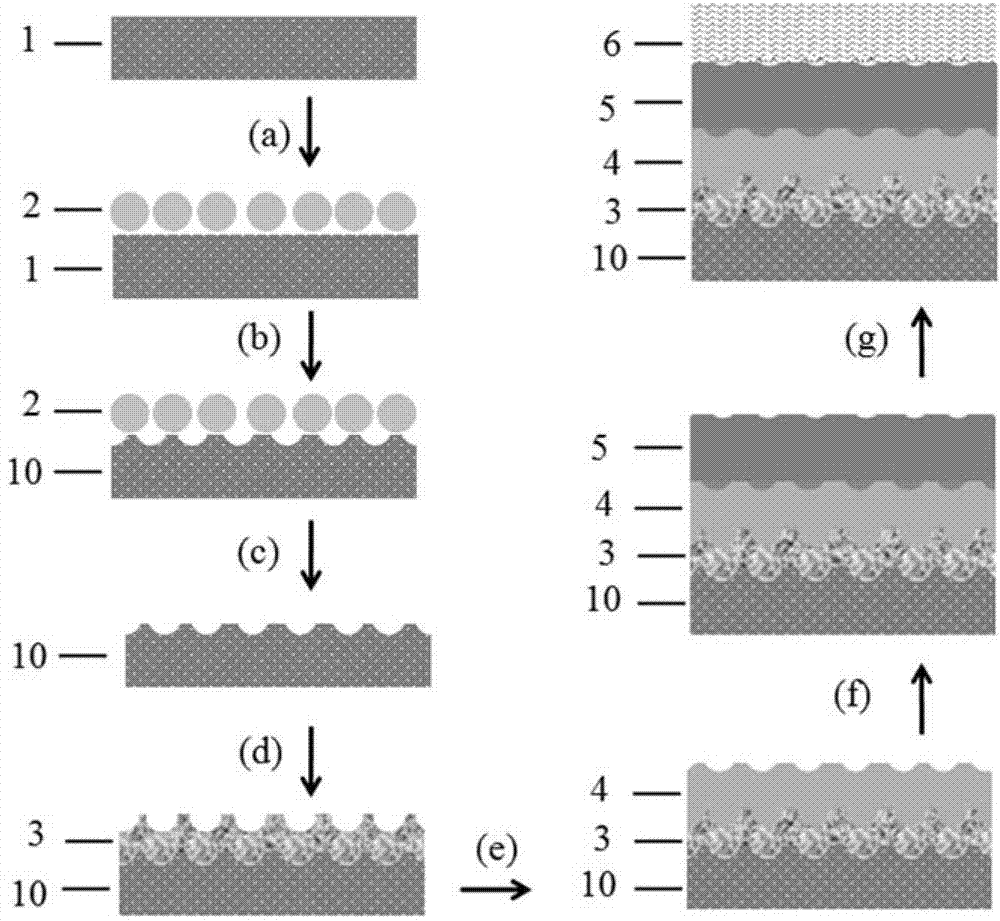

Patterned electrode, preparation method and organic solar cell

ActiveCN102832348AImprove PCEPromote absorptionFinal product manufactureSolid-state devicesOrganic solar cellNano structuring

The invention discloses a preparation method for a patterned electrode. The preparation method comprises the following steps of: (1) covering the surface of the electrode by using a nano-structured layer, wherein the coverage rate of the nano-structured layer on the surface of the electrode is 15 to 100 percent; (2) corroding the electrode by using the nano-structured layer as a template; and (3) removing the nano-structured layer to obtain the patterned electrode. The preparation method is simple, and nicks on the surface of the patterned electrode are easy to control. The invention discloses the patterned electrode obtained by the preparation method. By the patterned electrode, the optimization of the morphological structure of an organic light active layer can be induced in the preparation process of an organic solar cell, so that the performance of the organic solar cell can be improved, and the photoelectric energy conversion efficiency of the solar cell can be improved. The invention also discloses the organic solar cell. The organic solar cell can be efficiently manufactured, and the cost is low.

Owner:ZHEJIANG UNIV

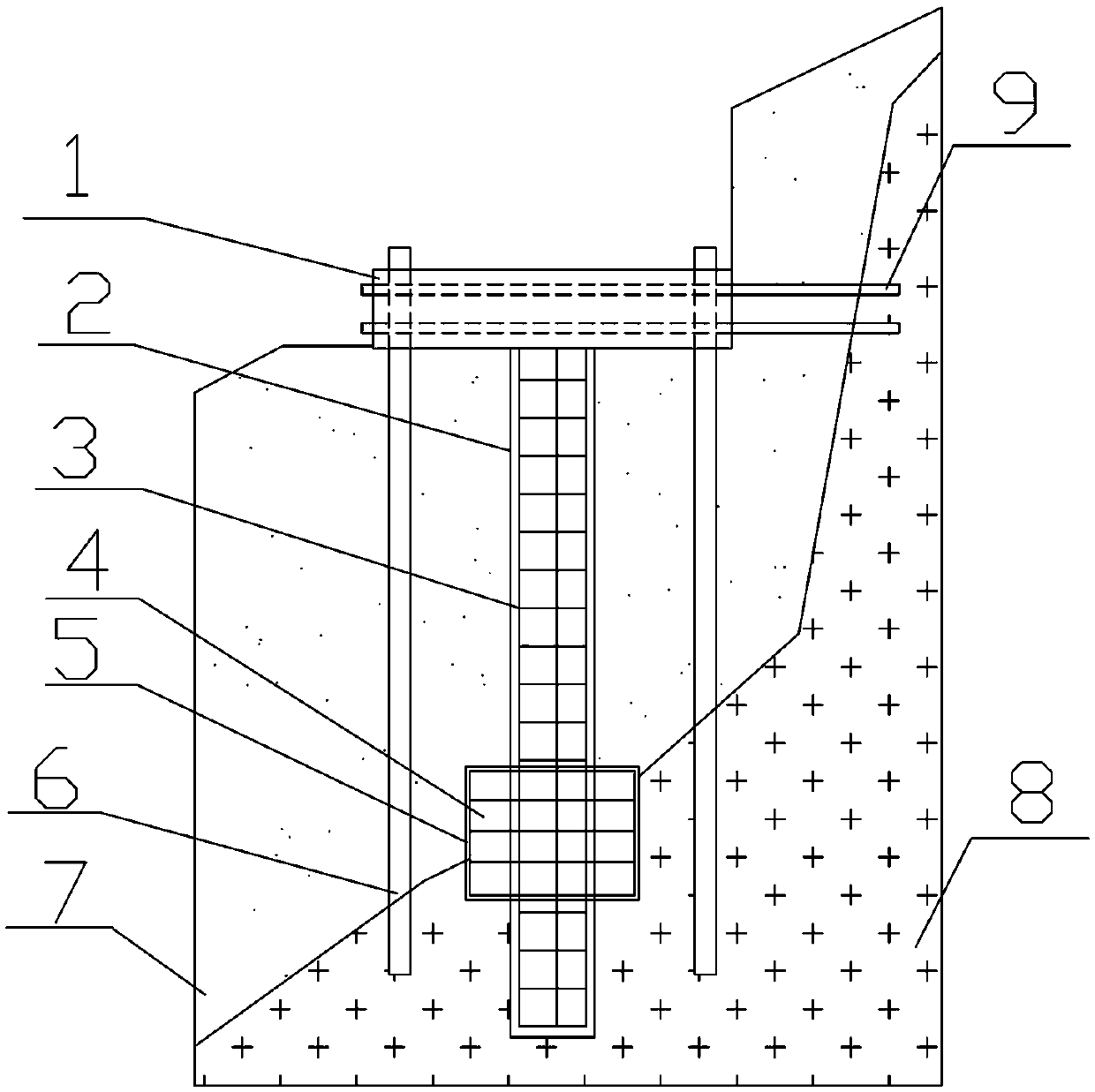

Construction method of bridge pile foundation in mountainous area

ActiveCN105507340AHigh strengthReduce the problem of crack growthFoundation engineeringSoil horizonGrout

The invention discloses a construction method of a bridge pile foundation in a mountainous area. The construction method comprises the following steps: (1) staking out in survey, namely locating position of the pile foundation; (2) digging a hole, namely enlarging hole on the bottom rock of a pile hole after digging the pile hole to form an enlarge hole cavity; (3) placing a steel reinforcement cage and an enlarged steel reinforcement cage, namely placing a main steel reinforcement cage in the pile hole and placing the enlarged steel reinforcement cage in the enlarged hole cavity; (4) pouring concrete, namely pouring concrete into the pile hole by adopting a guide pipe method and manufacturing a bearing platform; and (5) arranging anchor cables, namely drilling around the pile foundation, mounting a vertical anchor cable and a horizontal anchor cable, grouting by adopting a hole bottom grout returning method, and punching the vertical anchor cable and the horizontal anchor cable into the rock by passing through the soil layer. The construction method is simple; the pile foundation bearing capability is strong.

Owner:NANYANG INST OF TECH

High-performance nanofiber modified polymer cement-based repairing mortar and preparation method thereof

The invention relates to a high-performance nanofiber modified polymer cement-based repairing mortar. The repairing mortar comprises, by mass, 25.0-29.5% of cement, 52.2-52.7% of quartz sands, 1.4-2.0% of dispersible latex powder, 0.4-1.0% of nano-SiO2, 3.5-5.2% of fly ash, 1.8-3.5% of metakaolin, 0.07-0.14% of fibers, 0.18-0.24% of a water reducer, 0.03-0.04% of a silicone antifoaming agent, 0.01-0.02% of cellulose ether, and the balance of water. The invention discloses a preparation method of the repairing mortar. The method of the invention is simple and is easy to implement, and the obtained repairing mortar has excellent performances, and is suitable for repairing the reinforced concrete structure.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

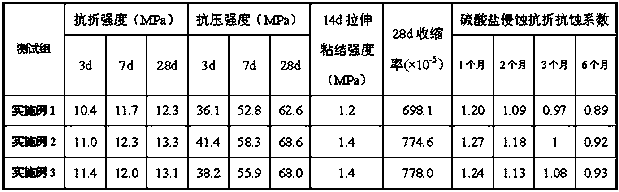

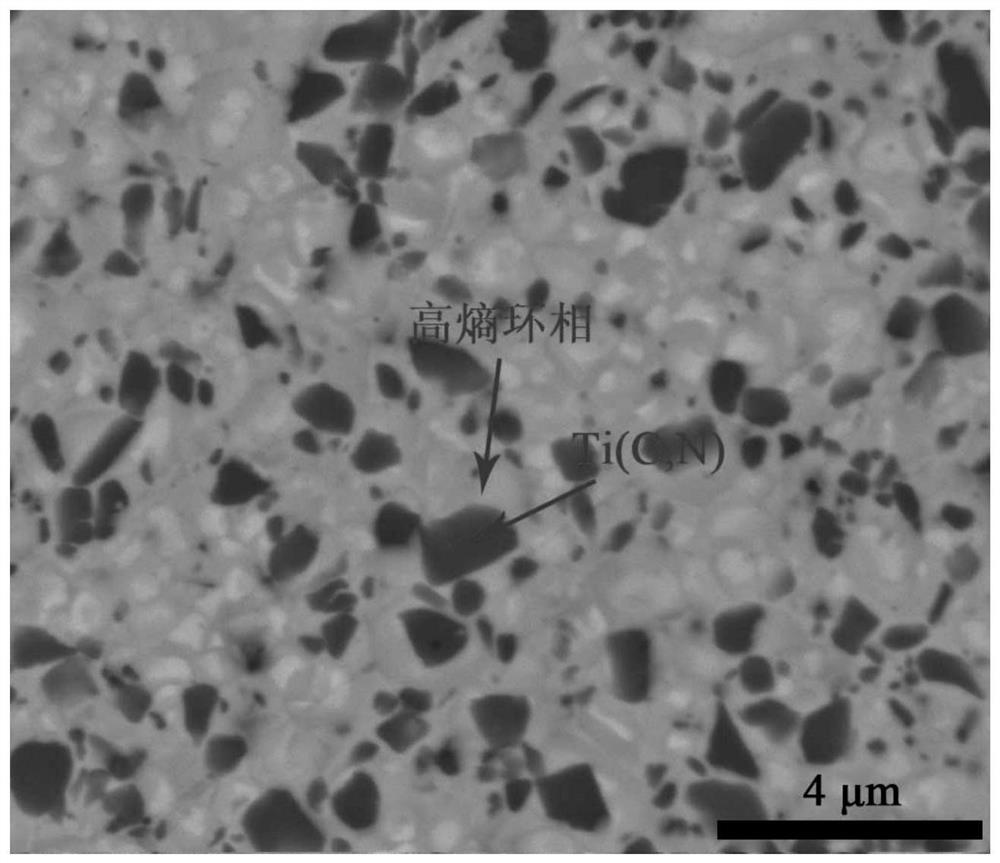

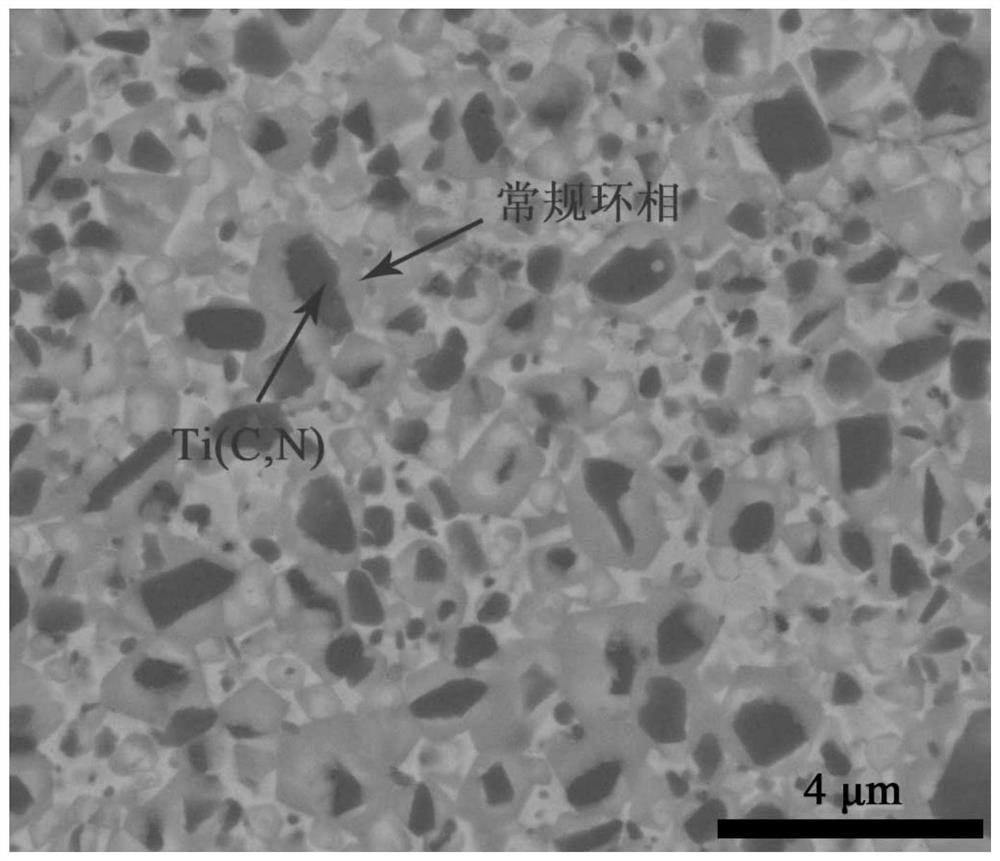

Ti (C, N)-based metal ceramic with high entropy ring phase structure and preparation method thereof

ActiveCN111850373AHigh hardnessImprove surface machining accuracySolid state diffusion coatingCarbideMaterials science

The invention discloses a Ti (C, N)-based metal ceramic with a high entropy ring phase structure and a preparation method thereof. The ring phase structure of the Ti (C, N)-based metal ceramic is a high-entropy carbide ceramic, and the composition of the Ti (C, N)-based metal ceramic is a (Ti, M)(C, N) solid solution, wherein M is selected from three or more of metal elements in a group IVB, a group VB and a group VIB, and the content molar ratio of any two metal elements in the (Ti, M)(C, N) solid solution is between 0.8 and 1.2. In the preparation process of the Ti (C, N)-based metal ceramic, nano carbide-binding phase composite powder is prepared through a low-temperature carbothermic reduction method, traditional multi-element addition carbide is replaced, and meanwhile the carbide issufficiently dissolved and precipitated through higher sintering temperature so as to obtain the high-entropy carbide ring phase structure. The obtained metal ceramic has higher hardness and high-temperature oxidation resistance than conventional metal ceramic, can improve the surface machining precision and service life of a cutter, and is widely applied to the fields of bearing materials, cutting tools, die materials and the like.

Owner:CENT SOUTH UNIV

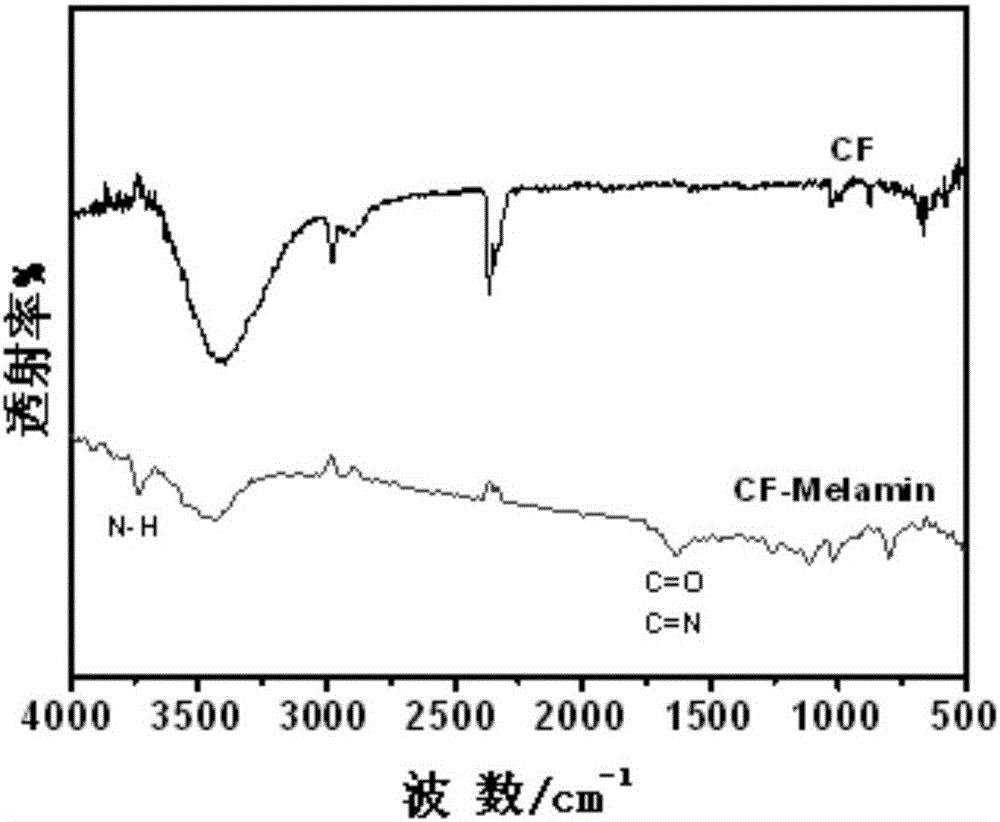

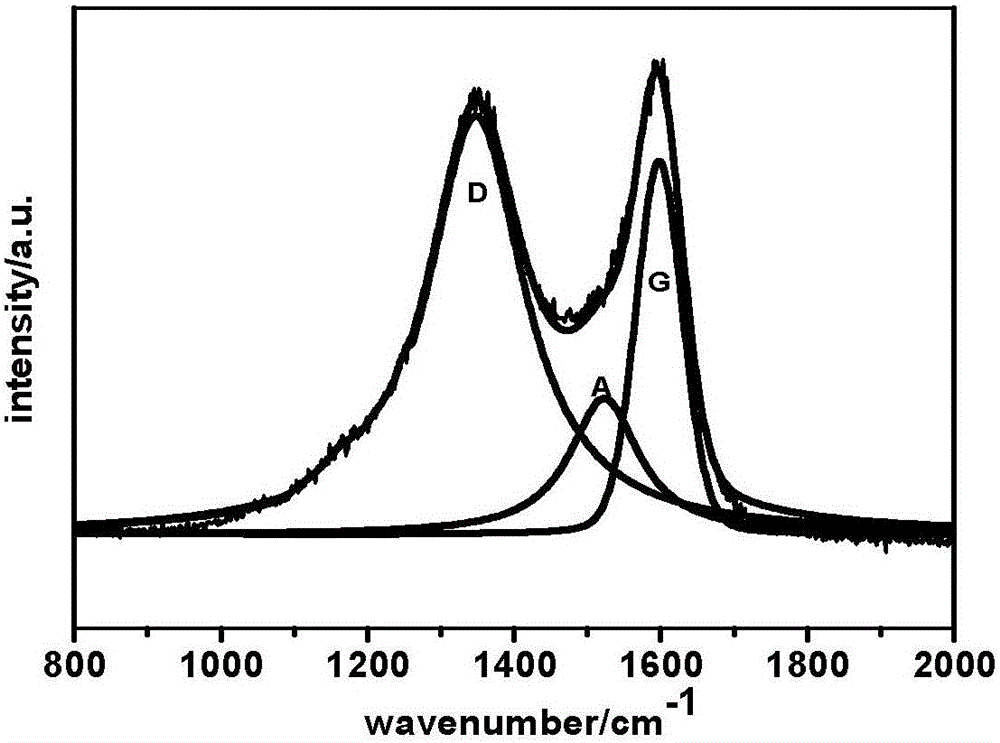

Supercritical fluid technology-based carbon fiber surface grafting method

ActiveCN104987532AEffective wettingImprove the interface binding forceBulk chemical productionCross-linkFiber

The invention discloses a supercritical fluid technology-based carbon fiber surface grafting method, and relates to a carbon fiber surface modifying method. The purpose of the invention is to solve the problems of few reaction sites of grafted micro-molecular substances, easy cross-linking of graft copolymers, and low bonding strength between modified carbon fibers and resin of present carbon fiber surface modifying methods. The method disclosed in the invention comprises the following steps: removing an epoxy coating layer on the surface of the carbon fibers; 2, oxidizing the carbon fibers; 3, carrying out acylchlorination on the carbon fibers; and 4, grafting the surface of the carbon fibers with melamine. The surface of the carbon fibers is grafted with melamine, and the quantity of reaction sites is large, so convenience is provided for a next step grafting reaction. The molecular weight of melamine is small, and melamine and polymers are difficult to cross-link, so melamine has very good dispersion, and undergoes a grafting reaction with good homogeneity on the surface of the carbon fibers in order to facilitate improvement of the interface performances of a composite material. The method is used for surface modification of the carbon fibers.

Owner:HARBIN INST OF TECH

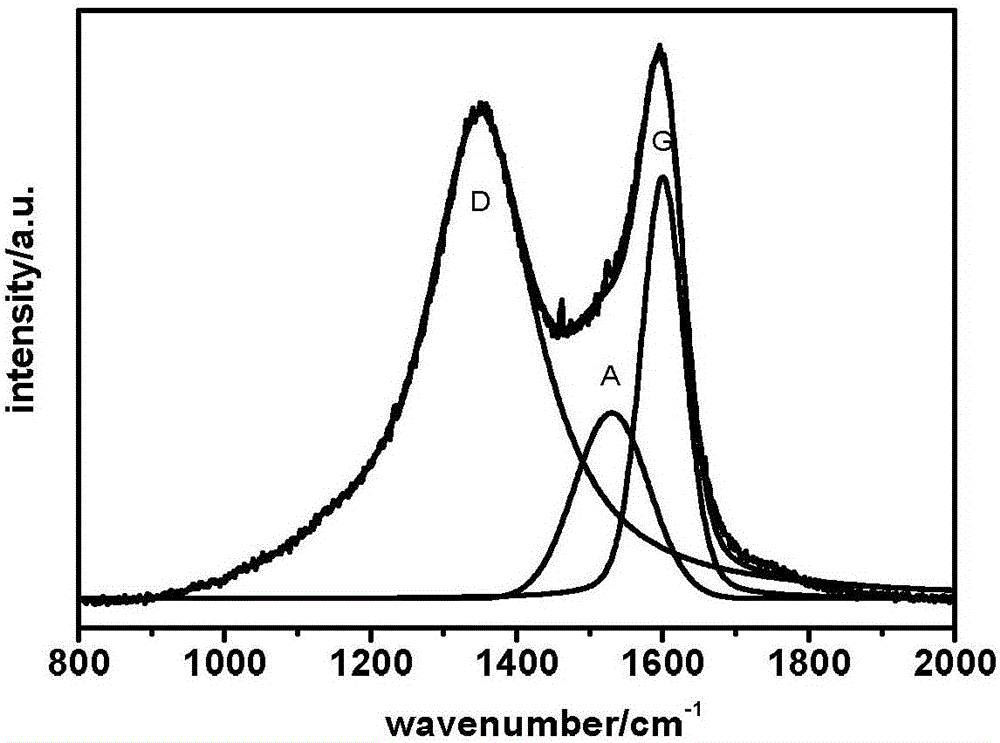

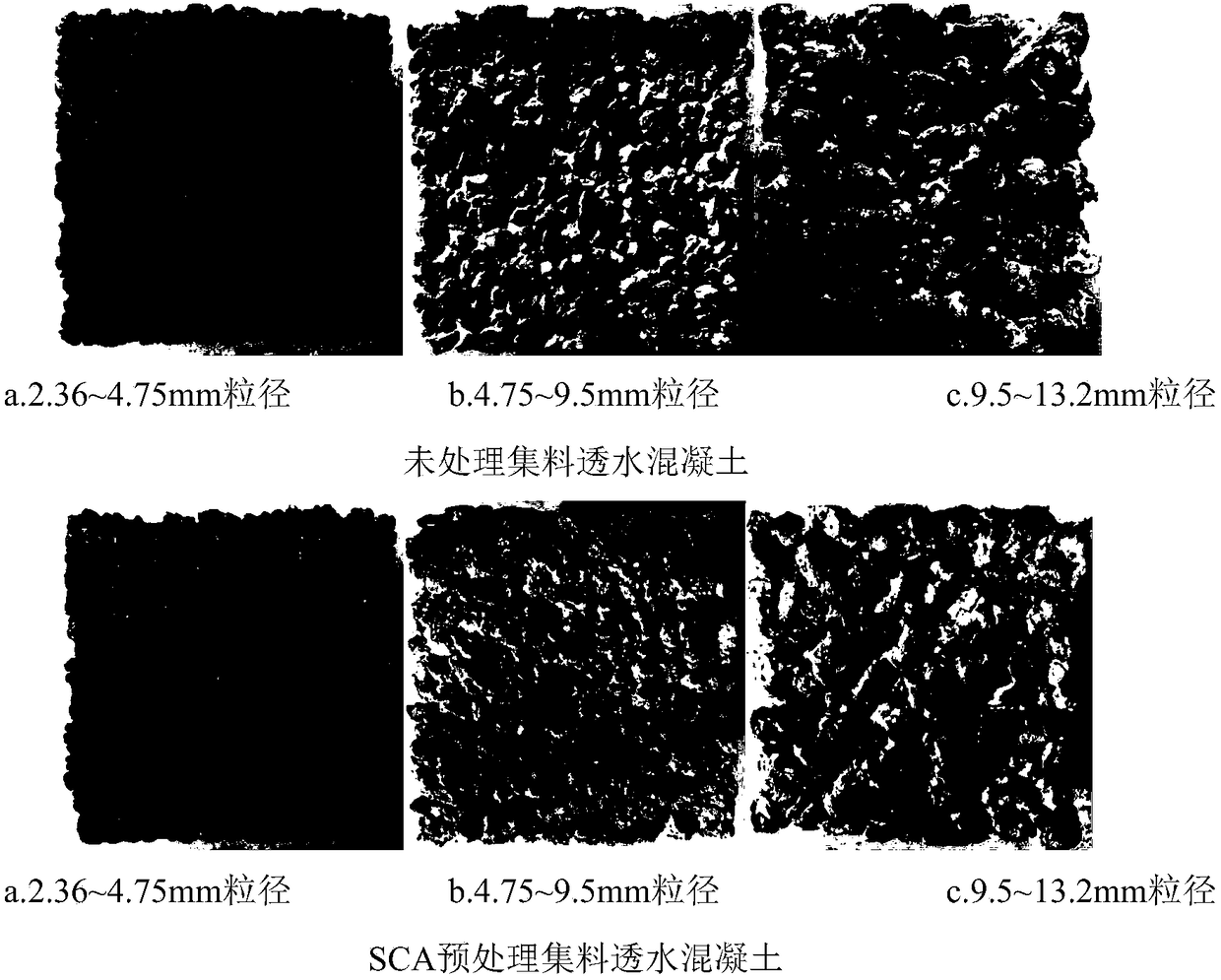

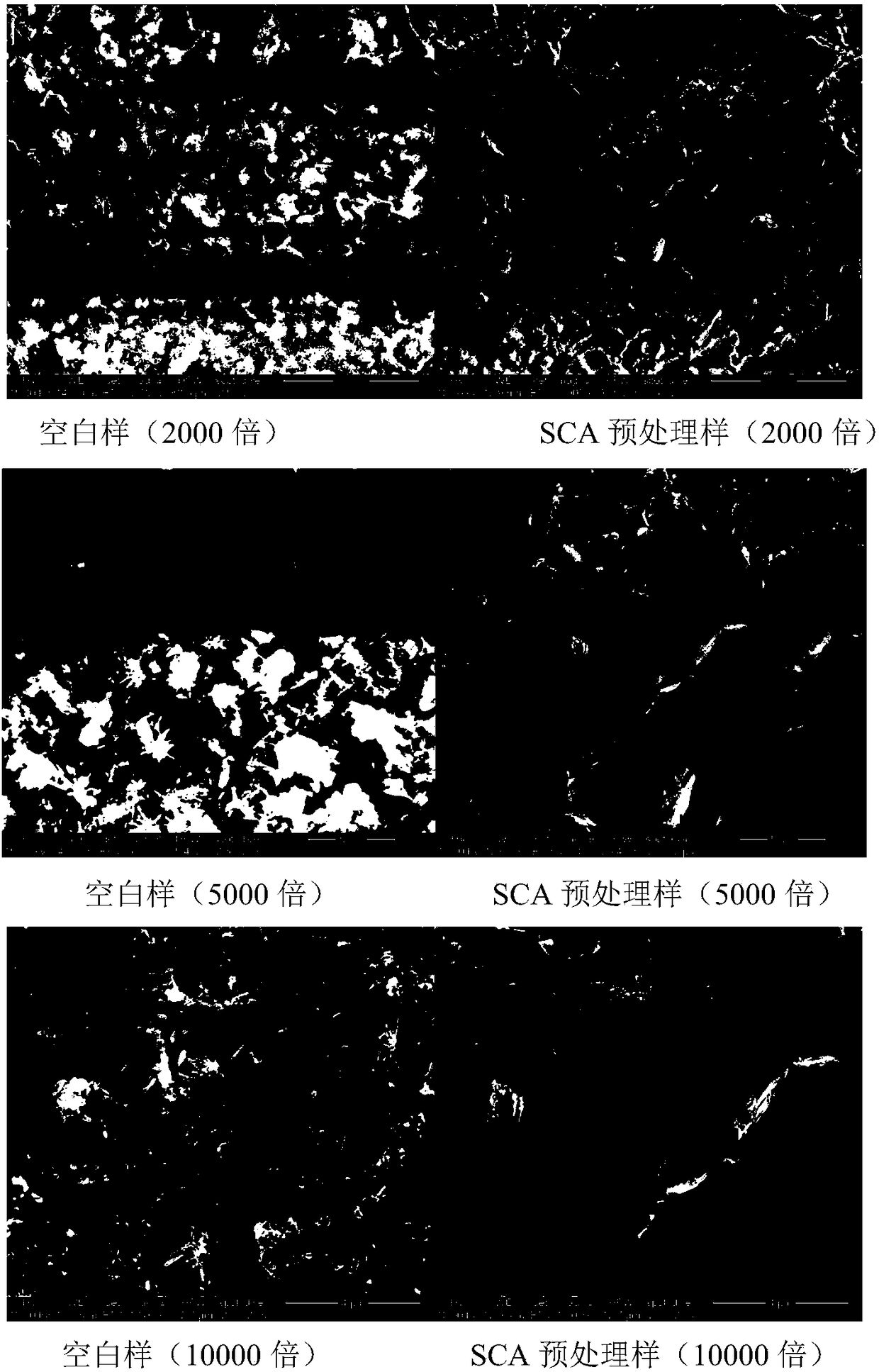

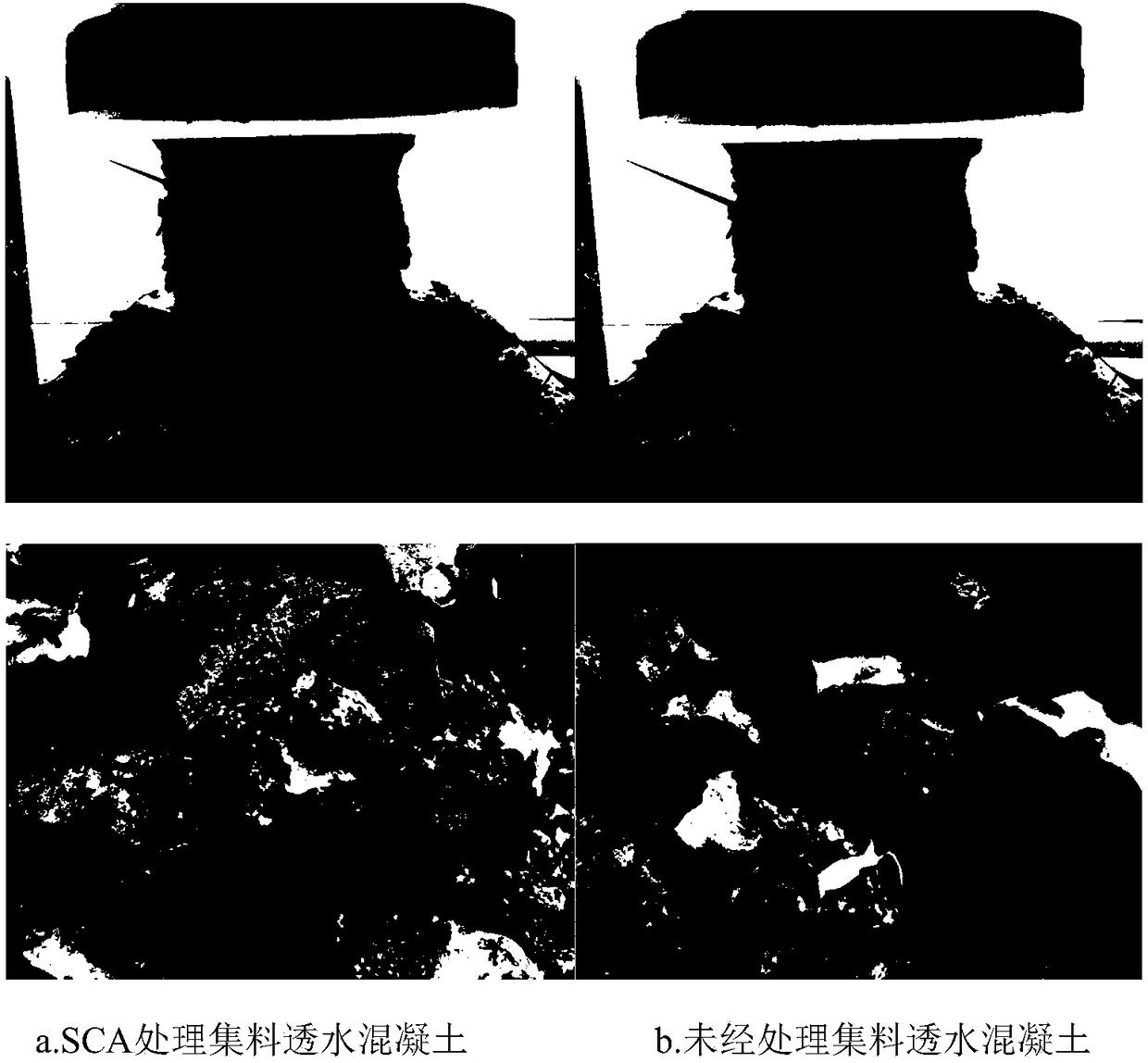

Silane coupling agent modified diabase permeable concrete

ActiveCN108358547AImprove mechanical propertiesGood modification effectCeramicwarePorosityPermeability coefficient

The invention provides a preparation method of silane coupling agent modified diabase permeable concrete. The method comprises the following steps: silane coupling agent modified diabase as aggregateis uniformly mixed with cement and a water reducing agent, molding and demolding are performed, and the silane coupling agent modified diabase permeable concrete is obtained. Mechanical properties ofpermeable concrete are obviously improved by SCA modified diabase aggregate, and permeability is decreased to a certain extent. The smaller the particle size of aggregate is, the higher the increase amplitude of strength of the SCA modified aggregate permeable concrete specimen is, and the better the modification effect is; the larger the particle size is, the higher the porosity of the SCA modified aggregate specimen is and the higher the permeability coefficient is. According to comprehensive consideration of requirements of maximum practical economy and ecological benefit of engineering, anSCA solution with concentration of 1% is more appropriate for pretreatment.

Owner:广西建设职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com