Silane coupling agent modified diabase permeable concrete

A technology of silane coupling agent and permeable concrete, which is applied in the field of influence of silane coupling agent modified diabase aggregate on the performance of permeable concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1 Raw materials and test methods

[0040] 1.1 Test raw materials

[0041] (1) Cement: P.O 42.5 grade ordinary Portland cement, produced by Guangxi China Resources Cement Co., Ltd. The physical and mechanical properties of cement are shown in Table 1.

[0042] Table 1 Cement physical and mechanical performance indicators

[0043]

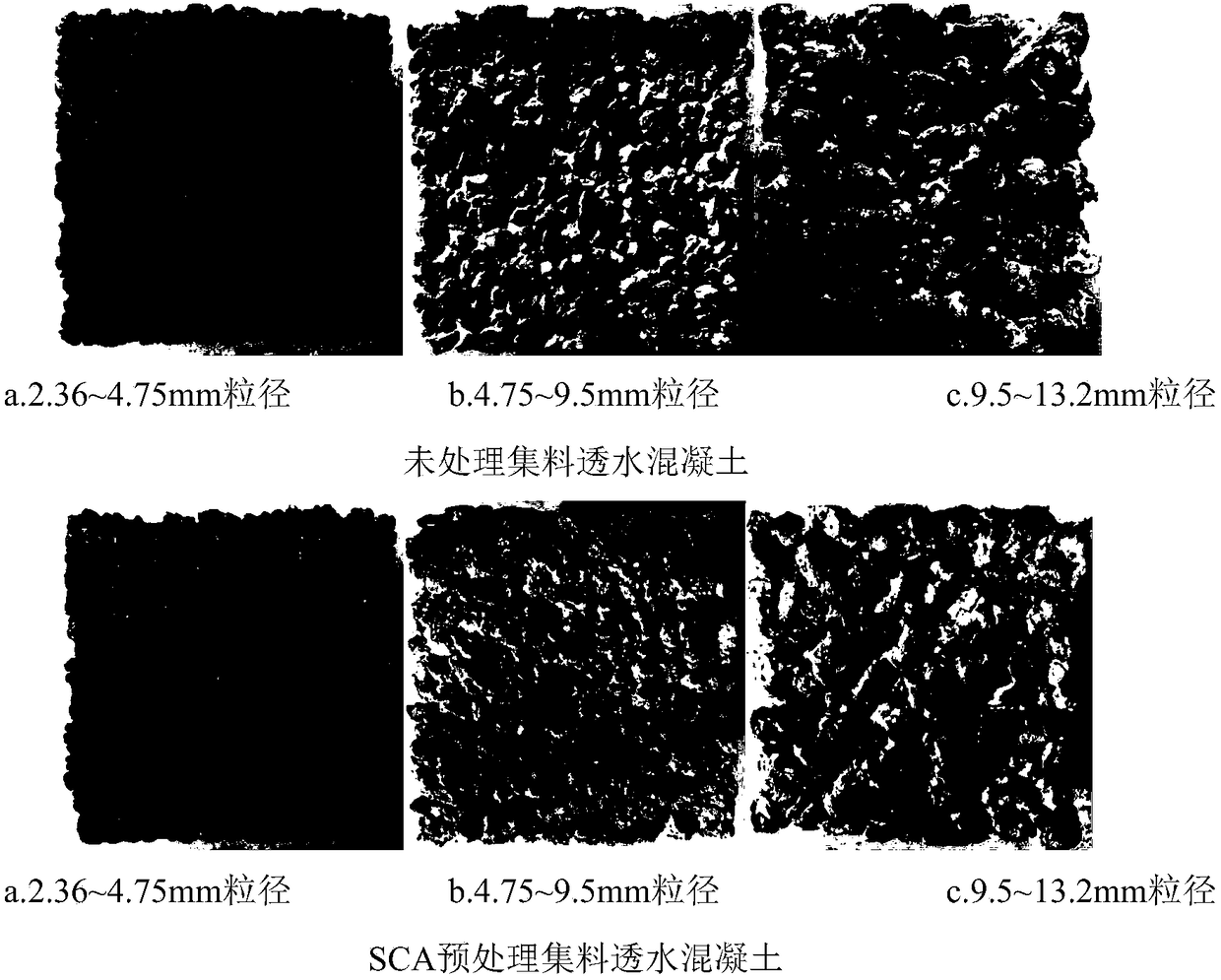

[0044] (2) Aggregate: Diabase gravel, particle size 2.36-4.75mm, 4.75-9.5mm, 9.5-13.2mm, produced by Guangxi Tiandong County Diabase Mining Co., Ltd. The chemical element analysis results of the aggregate are shown in the table 2. See Table 3 for physical performance indicators.

[0045] Table 2 Aggregate chemical element analysis results table (unit: %)

[0046]

[0047] Table 3 Aggregate Physical Performance Index

[0048]

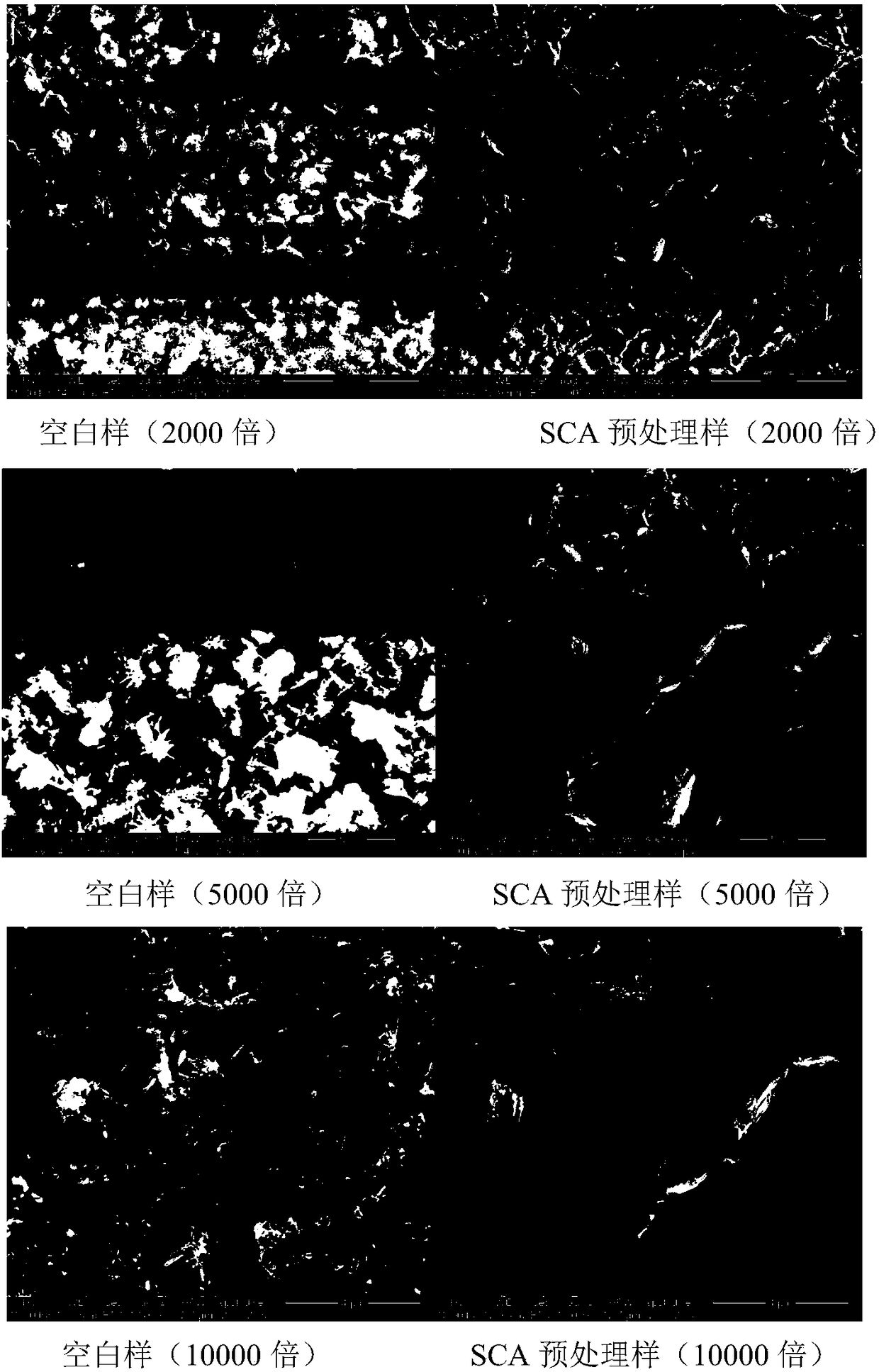

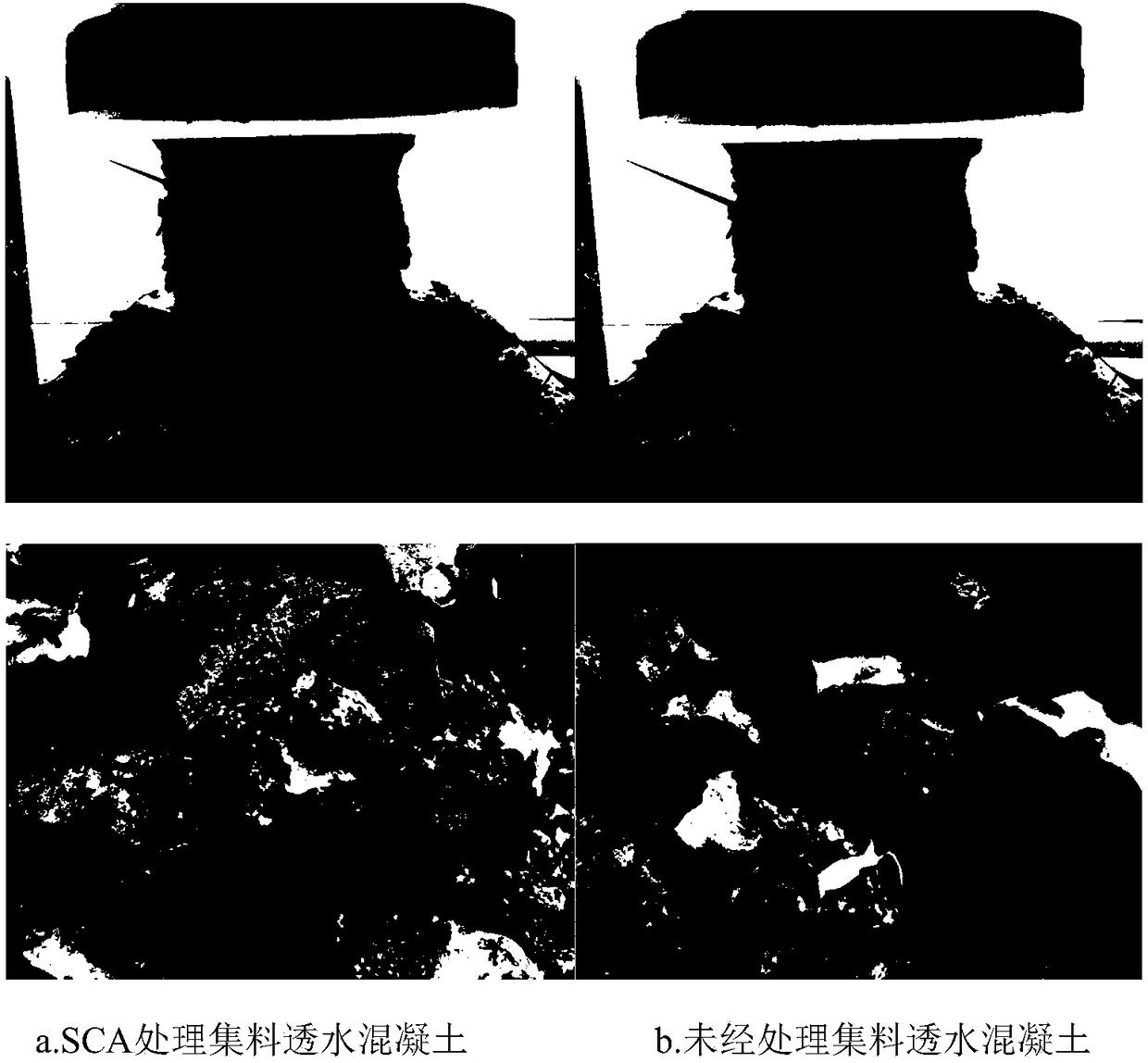

[0049] (3) Silane coupling agent: model KH-570 (γ-methacryloxypropyltrimethoxysilane), light yellow colorless transparent liquid, melting point -48°C, boiling point 190°C, density 201.05g / cm 3 , produced by...

Embodiment 2

[0084] 1 Raw materials and test methods

[0085] 1.1 Test raw materials

[0086] (1) Cement: P.O 42.5 grade ordinary Portland cement, produced by Guangxi China Resources Cement Co., Ltd. The physical and mechanical properties of cement are shown in Table 7.

[0087] Table 7 cement physical and mechanical performance indicators

[0088]

[0089] (2) Aggregate: Diabase gravel, particle size 2.36-4.75mm, produced by Guangxi Tiandong County Diabase Mining Co., Ltd. The chemical element analysis results of the aggregate are shown in Table 8, and the physical performance indicators are shown in Table 9.

[0090] Table 8 Aggregate chemical element analysis results table (unit: %)

[0091]

[0092] Table 9 Aggregate Physical Performance Index

[0093]

[0094]

[0095] (3) Silane coupling agent: model KH550 (γ-aminopropyltriethoxysilane), produced by Dinghai Plastic Chemical Co., Ltd., Dongguan, Guangdong; water reducing agent: polycarboxylic acid powder water reducing ...

Embodiment 3

[0106] The preparation method of permeable concrete is the same as in Example 2, except that the silane coupling agent is KH560 (γ-(2,3-glycidyloxy)propyltrimethoxysilane)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com