Halogen-free resin composition and copper clad plate prepared from composition

A technology of resin composition and epoxy resin, applied in the field of copper clad laminate and halogen-free resin composition, can solve the problems of reducing hydroxyl concentration, easy to wear drill bit, poor adhesion between copper foil and base material, etc. Dimensional stability, thermal expansion coefficient reduction, heat resistance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

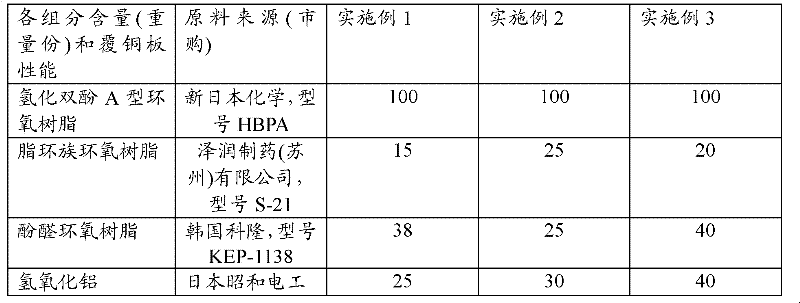

Embodiment 1

[0036] According to the amount of each component in the following table 2 (according to parts by weight), each component is fully mixed evenly, and stirred in a high-speed disperser for 4 hours; then use 7628 glass fiber cloth for gluing, and dry in a vertical gluing machine to obtain For the prepreg, the speed of the gluing machine is 15m / min, and the parameters of the prepared prepreg are: the gelation time is 75S; the resin content is 40%; the kinematic viscosity of the resin powder is 470P; Laminated with copper foil, pressed and formed in a vacuum press to obtain a copper-clad laminate. The pressing parameters are: vacuum degree 0.01MPa; pressure 400PSI; hot plate temperature 120-220°C; pressing time 145min. The Td, T260, T288 and CTI values of the copper clad laminates are tested, and the test results are listed in Table 2; the thermal expansion properties of the copper clad laminates are tested, and the test results are listed in Table 4.

Embodiment 2

[0038] Repeat Example 1 according to the amount of each component specified in Table 2 below (by weight), and the test results are listed in Table 2.

Embodiment 3

[0040] Repeat Example 1 according to the amount of each component specified in Table 2 below (by weight), and the test results are listed in Table 2.

[0041] Table 2

[0042]

[0043]

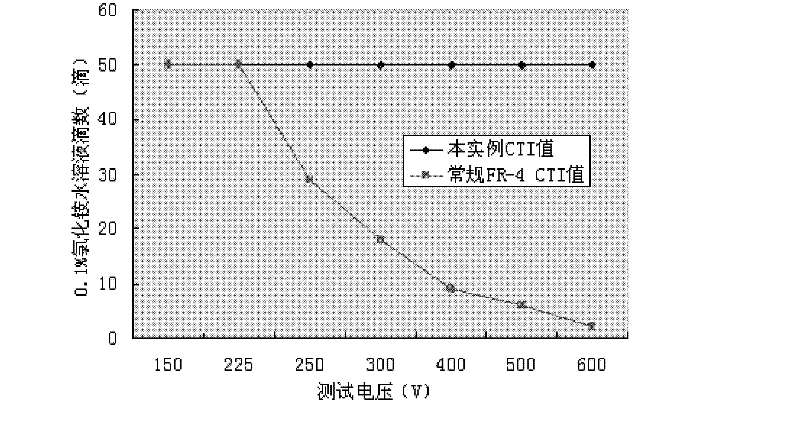

[0044] figure 1 It is a comparison chart of the CTI value of the copper clad laminate of the embodiment and the conventional FR-4. It can be seen from the figure that the CTI of the conventional FR-4 is about 225V, while the CTI value of the present embodiment can withstand 600V.

[0045] Table 3 is a comparison of the performance of the copper clad laminates prepared in the examples and conventional FR-4.

[0046] Table 3 shows the performance comparison between the copper clad laminate of the example and the conventional FR-4.

[0047] project

Conventional FR-4

The copper clad laminate of this embodiment

T260

30min

>60min

T288

3min

>10min

CTI

<225V

≥600V

Td

305℃

≥340℃

[0048] The above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com