Flame-retardant glass fiber reinforced polyamide 610/polyamide 612 (PA610/PA612) alloy composite and preparation method thereof

A PA612, PA610 technology, applied in the field of flame retardant glass fiber reinforced PA610/PA612 alloy composition and its preparation field, can solve the problems of limited use of flame retardants, reduce the mechanical properties of materials, electrical insulation properties, hysteresis, etc., and achieve residence time Short, improve antioxidant properties, prevent decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

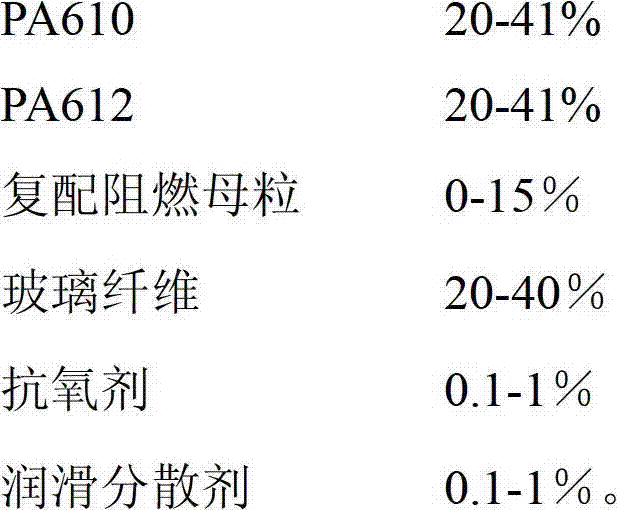

[0027] Flame-retardant glass fiber reinforced PA610 / PA612 alloy composition, including each component of weight percent content shown in Table 1; Its preparation method is as follows:

[0028] (1) Weigh the raw materials according to the weight percentage content shown in Table 1, put them into a high-mixer and mix them for 2 to 5 minutes, and then discharge; the compound flame retardant masterbatch in Table 1 includes the following components in mass percentage content : Iron-removing red phosphorus masterbatch: 50%; anti-migration agent: 25%; high CTI additive: 25%;

[0029] (2) Add the above-mentioned mixed raw materials into a twin-screw extruder, extrude and granulate, and obtain the flame-retardant glass fiber reinforced PA610 / PA612 alloy composition; the extrusion temperature, screw rotation speed of the twin-screw extruder The number and other parameters are shown in Table 2.

[0030] The raw material formula of table 1 comparative example 1~3 and embodiment 1~8

[0...

Embodiment 9

[0035] Embodiment 9, performance test

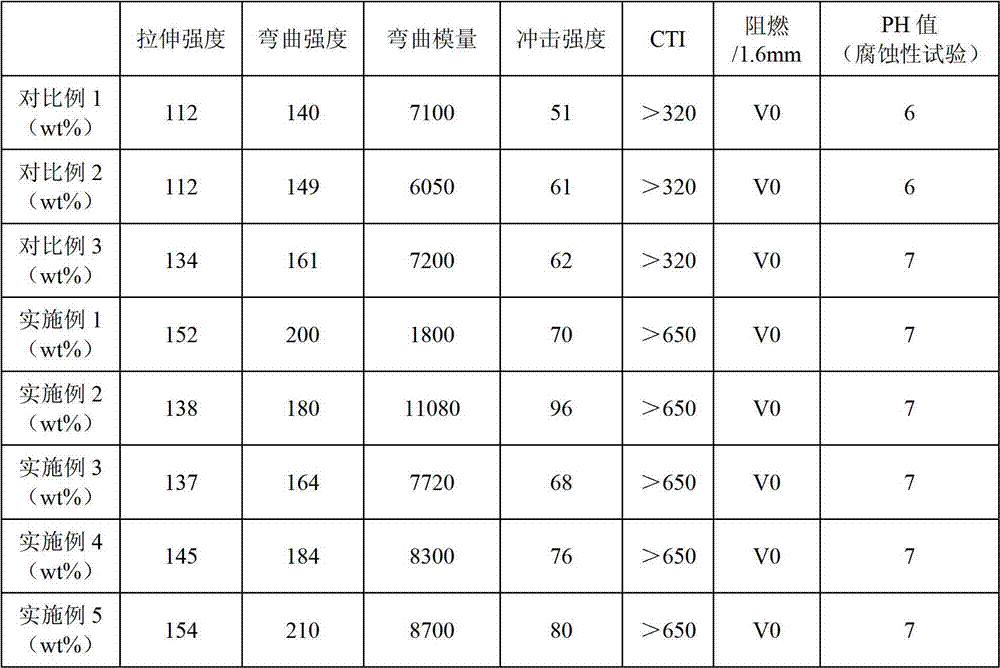

[0036] Using ASTM standards, performance tests and comparisons were performed on the PA610 / PA612 alloy composition samples prepared in Examples 1-8 and Comparative Examples 1-3. The test performance comparison is shown in Table 3:

[0037] table 3

[0038]

[0039]

[0040] As can be seen from Table 3, compared with Comparative Examples 1, 2, and 3, Example 1 shows that the high CTI and low-separation flame-retardant PA6 / PA12 alloy composition prepared by the compound flame-retardant masterbatch system of the present invention has The following advantages:

[0041] (1) Higher comprehensive mechanical properties: greater improvements have been made in mechanical properties such as tensile strength, flexural strength, flexural modulus, and impact strength;

[0042] (2) Higher CTI value: increase CTI from 320V to 660V;

[0043] (3) The PH value obtained from the corrosion test changed from acidic to neutral, indicating that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com