Halogen-free flame-retardant PBT resin with high CTI and preparation method of halogen-free flame-retardant PBT resin

A PBT resin and flame retardant technology, applied in the field of high CTI halogen-free flame retardant PBT resin and its preparation, can solve the problems of low char formation rate and low flame retardant efficiency, achieve high flame retardant level, increase CTI value, Improve the effect of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

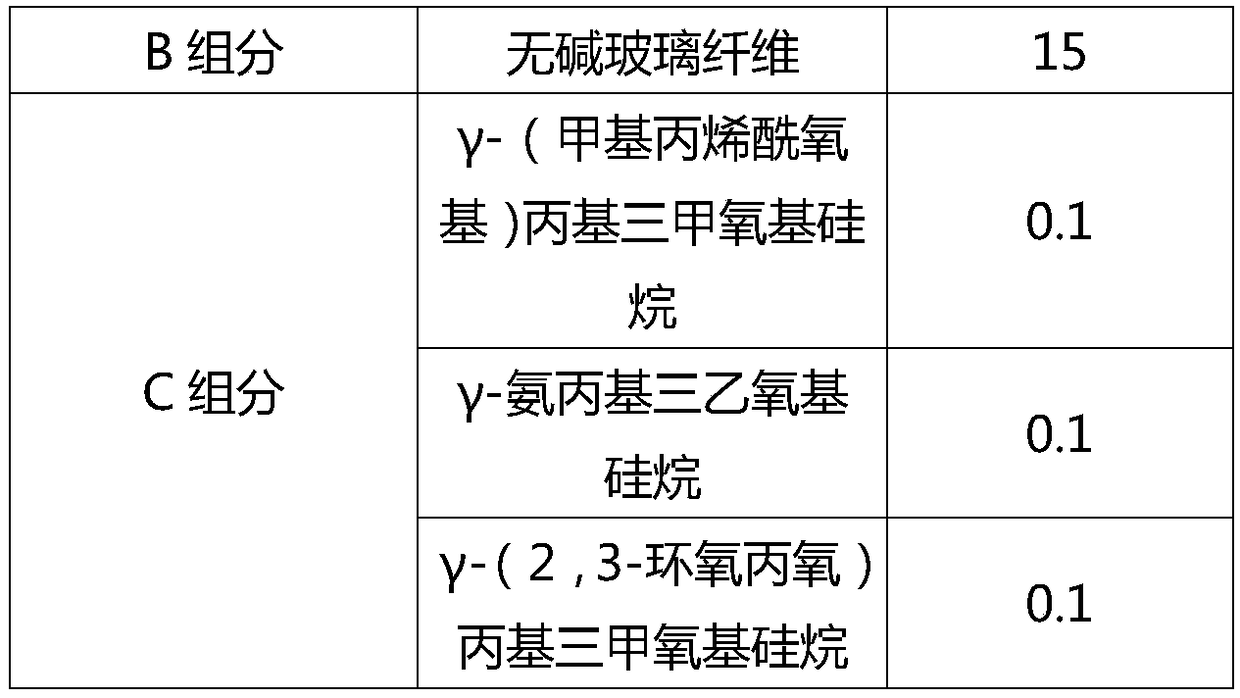

[0027] Each raw material ratio of table 1 embodiment 1

[0028]

[0029]

[0030] Mix components B and C, then place them in a high-speed mixer, and pre-mix for 20 minutes; then add component A to components B and C in a high-mix state, and mix for 7 minutes; then put the high-mix mixture Add it into the co-rotating parallel twin-screw extruder at a temperature of 190-230°C (the first zone is 190°C, the second zone is 200°C, the third zone is 210°C, the fourth zone is 210°C, the fifth zone is 230°C, the sixth zone is 230°C, and the seventh zone is 230°C. Zone 220°C, Zone 8 210°C, Zone 9 210°C, Head 200°C), melt extrusion and granulation.

Embodiment 2

[0032] Each raw material ratio of table 2 embodiment 2

[0033]

[0034] The steps used in the preparation method are the same as in Example 1

Embodiment 3

[0036] Table 3 Embodiment 3 each raw material proportioning

[0037]

[0038] The steps used in the preparation method are the same as in Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com