Environment-friendly flame-retardant reinforced polypropylene resin and preparation method thereof

A polypropylene resin and flame retardant technology, applied in the field of polypropylene resin, can solve the problems of insignificant improvement in thermodynamic properties, poor dimensional stability, and low thermal deformation temperature of ABS flame retardant modified resin, so as to reduce personal and Environmental safety hazards, improving mechanical properties, and the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

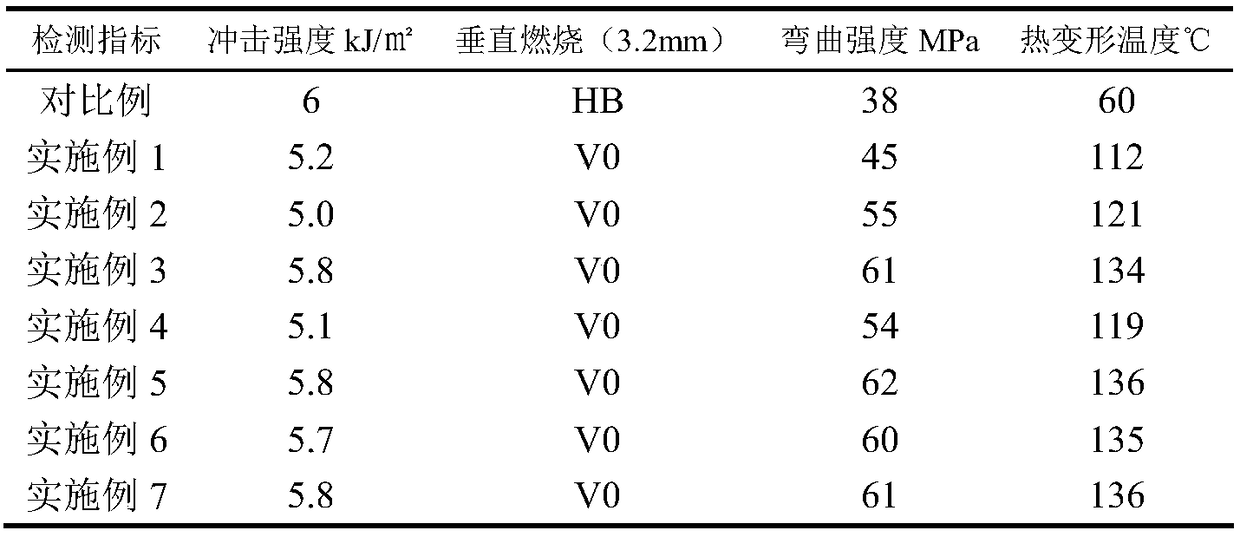

Examples

Embodiment 1

[0023] The raw materials are divided into three groups of A, B and C, and the raw materials of each group are weighed according to the following proportions by weight:

[0024] Component A: 100 parts of ABS resin, 20 parts of decabromodiphenylethane, 6 parts of antimony trioxide, 1 part of pentaerythritol stearate, 0.4 part of antioxidant;

[0025] Component B: 15 pieces of glass fiber cut yarn, the length is 30-50mm;

[0026] Component C: 0.2 parts of γ-mercaptopropyltriethoxysilane and 0.1 part of γ-aminopropyltriethoxysilane.

[0027] The process of using the above raw materials to prepare modified polypropylene resin: first put components B and C in a high-speed mixer for 20 minutes of premixing. The gamma-mercaptopropyl group and gamma-aminopropyl group in the silane coupling agent in the embodiment can be well compatible with ABS resin, and can also increase resin and resin, resin and glass fiber cut yarn, resin and other components The cross-linking effect between the...

Embodiment 2

[0029] The raw materials are divided into three groups of A, B and C, and the raw materials of each group are weighed according to the following proportions by weight:

[0030] Component A: 100 parts of ABS resin, 18 parts of 1,2-bis(tetrabromophthalimide)ethane, 7 parts of antimony trioxide, 1.5 parts of pentaerythritol stearate, 0.5 parts of antioxidant ;

[0031] Component B: 20 pieces of glass fiber cut yarn, the length is 30-50mm;

[0032] Component C: 0.2 parts of γ-(methacryloyloxy)propyltrimethoxysilane, 0.3 parts of γ-glycidyl ether propyltrimethoxysilane; γ- (Methacryloyloxy) propyl and γ-glycidyl ether propyl can be well compatible with ABS resin, and at the same time can increase the relationship between resin and resin, resin and glass fiber cut yarn, resin and other components The cross-linking effect improves the stability of the three-dimensional network structure of the modified resin, which is conducive to maintaining or improving the mechanical propertie...

Embodiment 3

[0035] The raw materials are divided into three groups of A, B and C, and the raw materials of each group are weighed according to the following proportions by weight:

[0036] Component A: 100 parts of ABS resin, 18 parts of decabromodiphenylethane, 8 parts of antimony trioxide, 1 part of pentaerythritol stearate, 0.5 part of antioxidant;

[0037] Component B: 25 pieces of glass fiber cut yarn, the length is 30-50mm;

[0038] Component C: 0.3 parts of γ-(3,2 glycidoxy)methyltrimethoxysilane, 0.3 parts of γ-glycidyl ether propyltrimethoxysilane; γ-(3,2 glycidoxy) methyl group and γ-glycidyl ether propyl group can be well compatible with ABS resin, and can increase resin and resin, resin and glass fiber cut yarn, resin and other The cross-linking effect between the components improves the stability of the three-dimensional network structure of the modified resin, thereby helping to maintain or improve the mechanical properties of the resin product.

[0039] The preparation pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com