Patents

Literature

53results about How to "High strength and durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

C190 strength-grade concrete for formed steel concrete composite structure

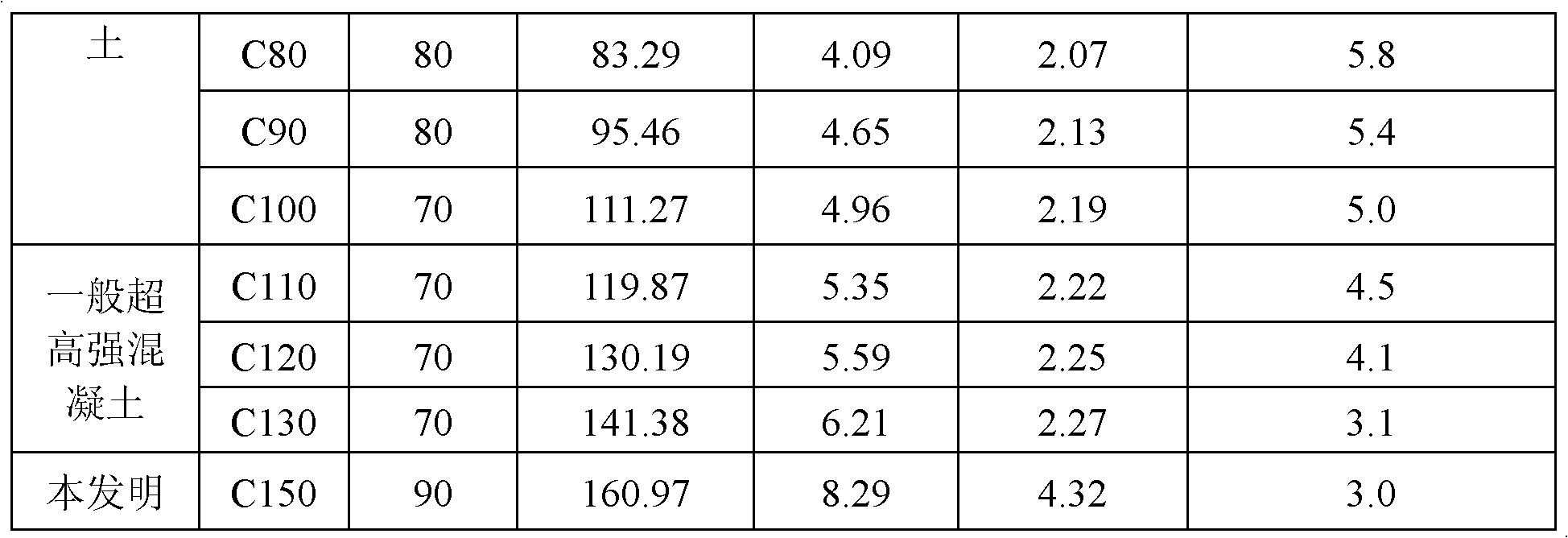

InactiveCN103553459AImprove workabilityImprove volume stabilitySolid waste managementDefoaming AgentsBond properties

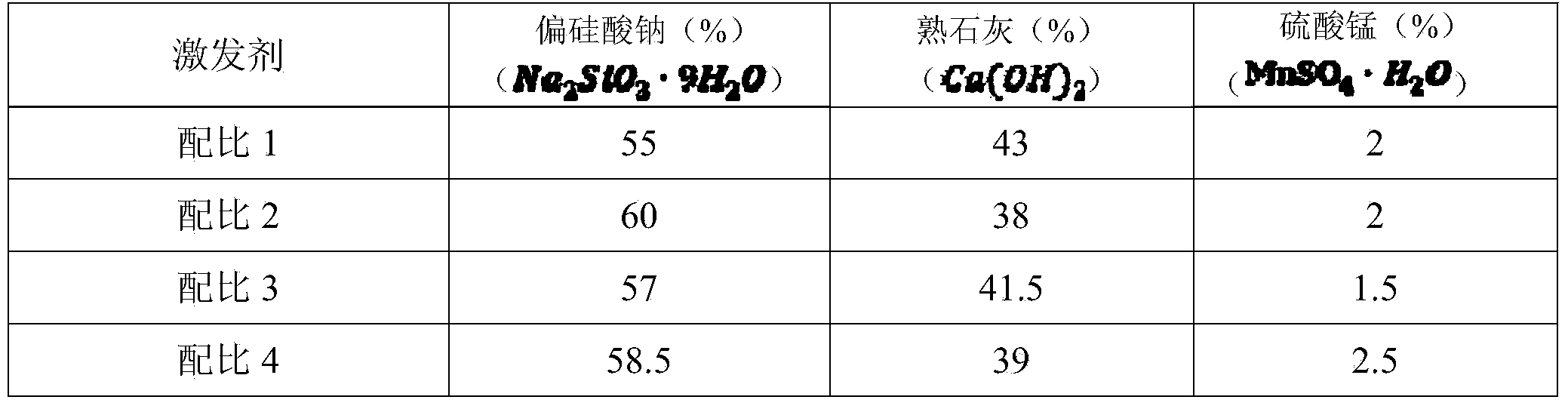

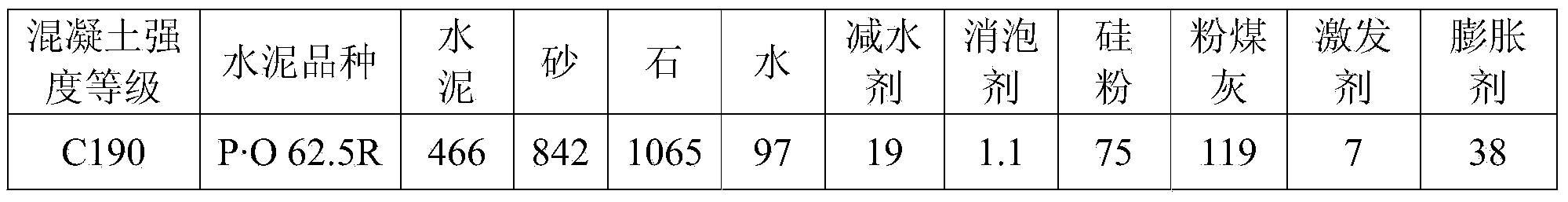

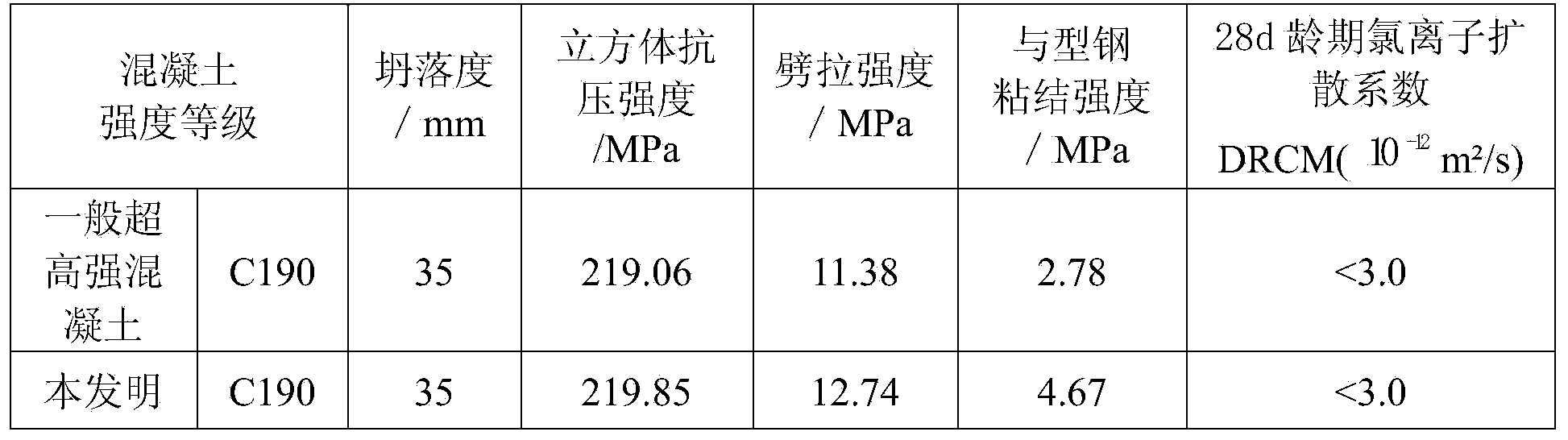

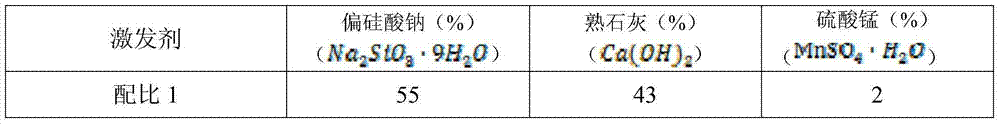

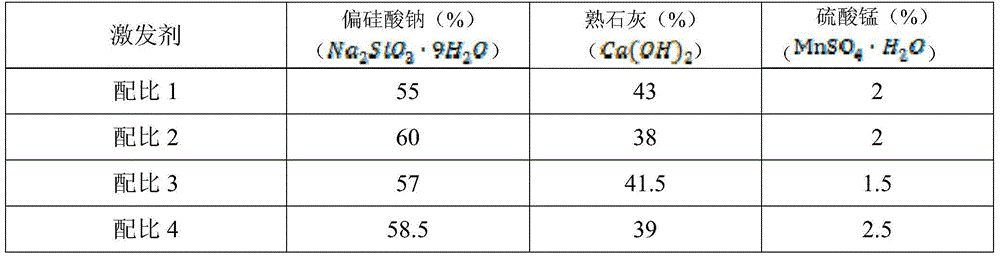

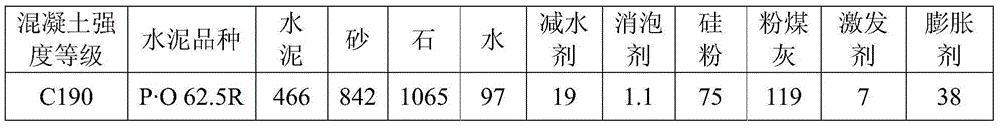

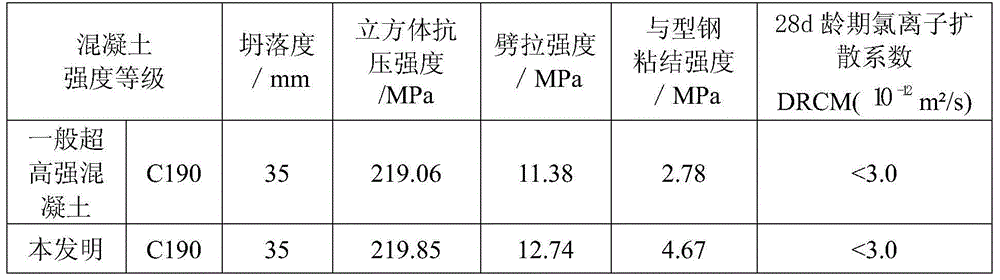

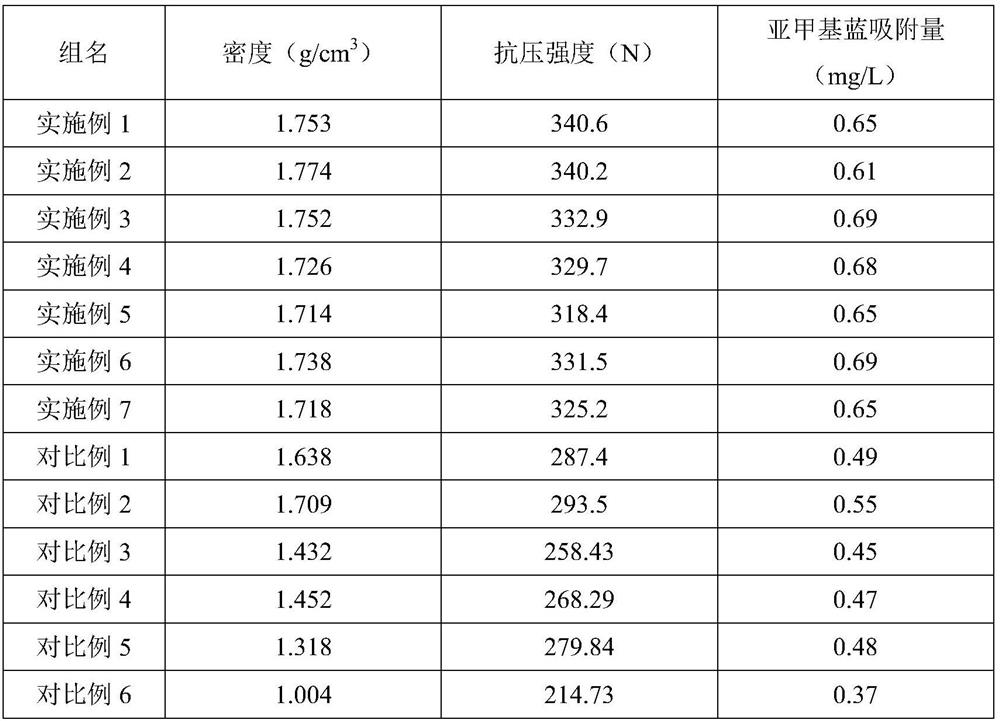

The invention discloses a C190 strength-grade concrete for a formed steel concrete composite structure, which is composed of 466 parts of cement, 842 parts of fine aggregate, 1065 parts of coarse aggregate, 97 parts of water, 19 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 75 parts of silicon powder, 119 parts of expanding agent, 7 parts of activator and 38 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

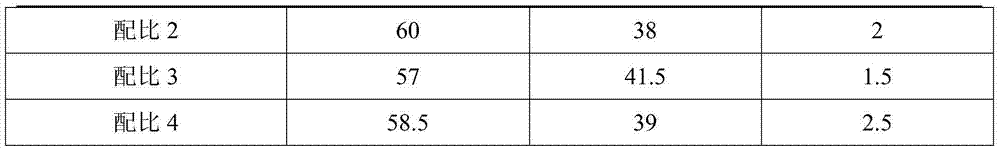

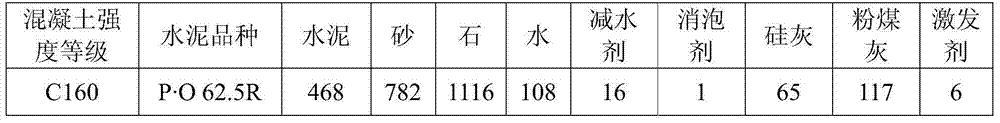

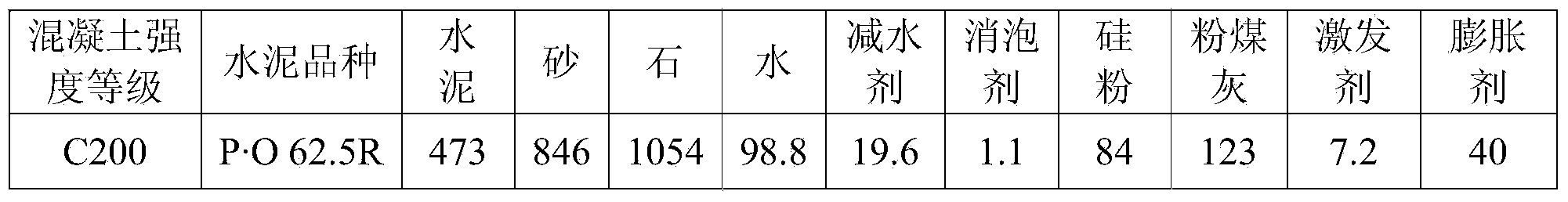

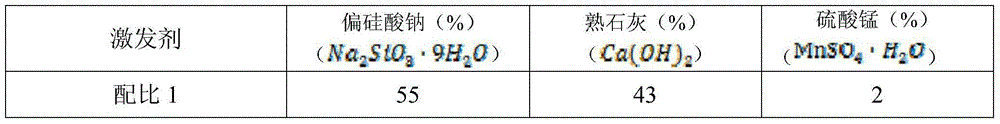

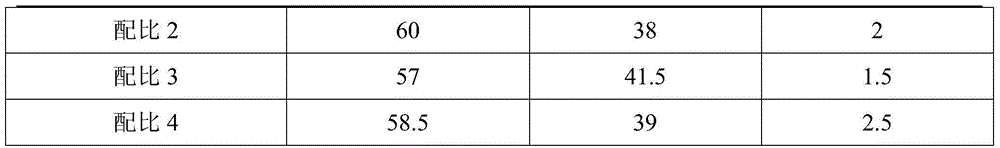

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

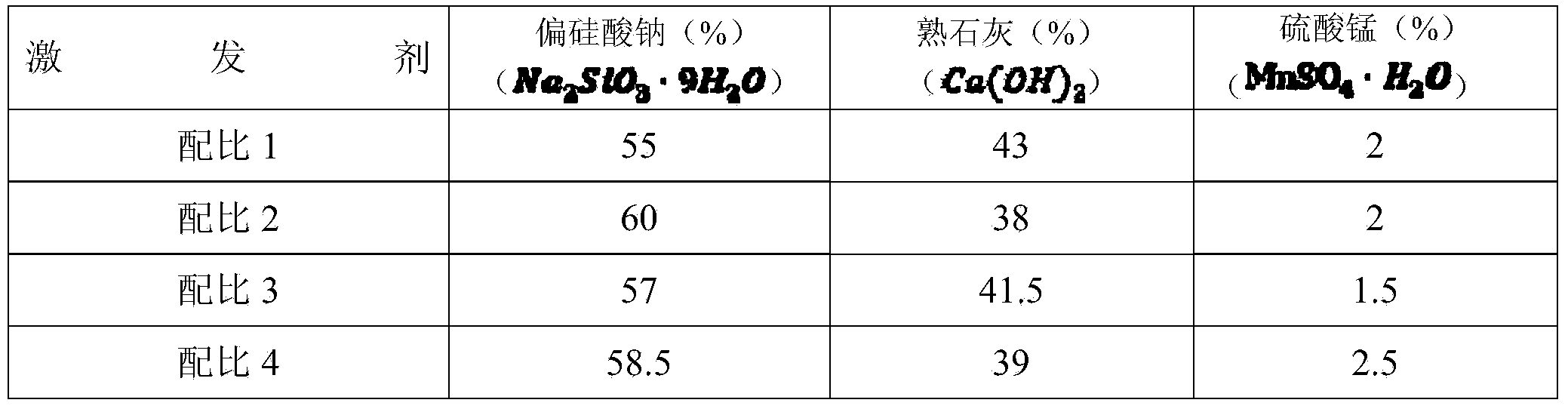

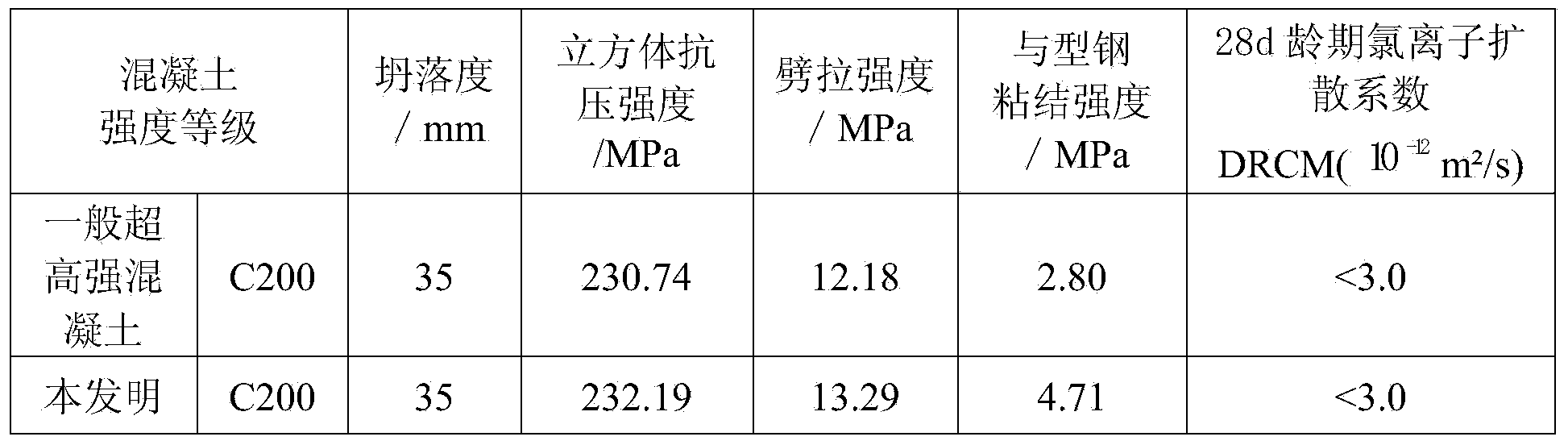

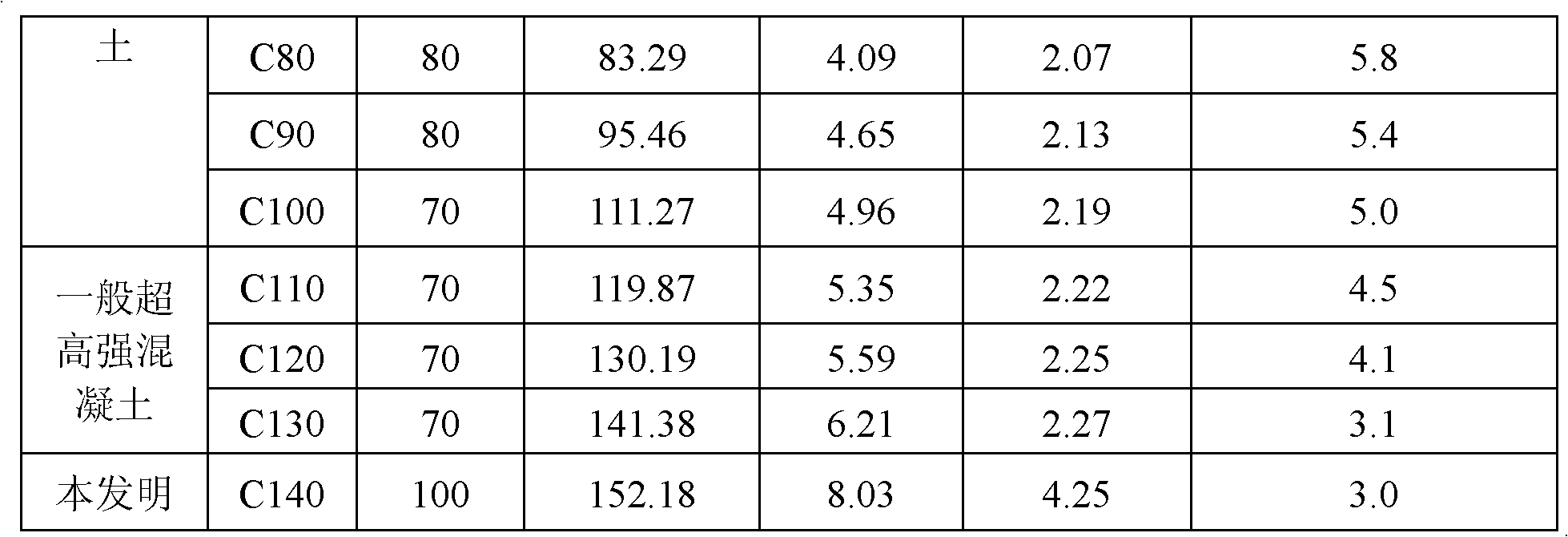

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460AIncreased durabilityHigh Strength and DurabilitySolid waste managementNatural stateSuperplasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

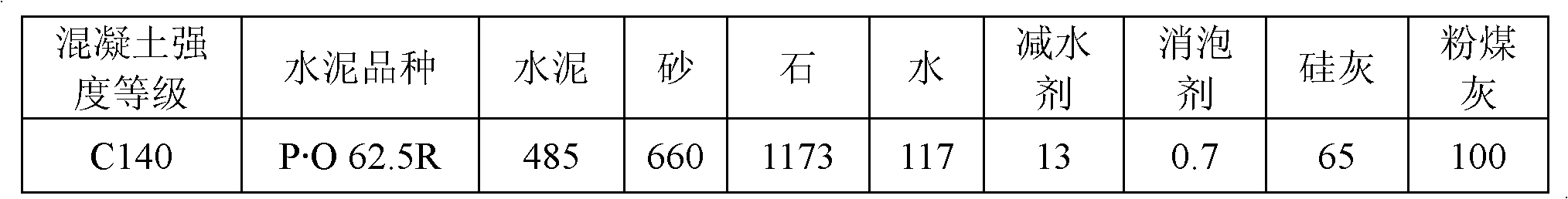

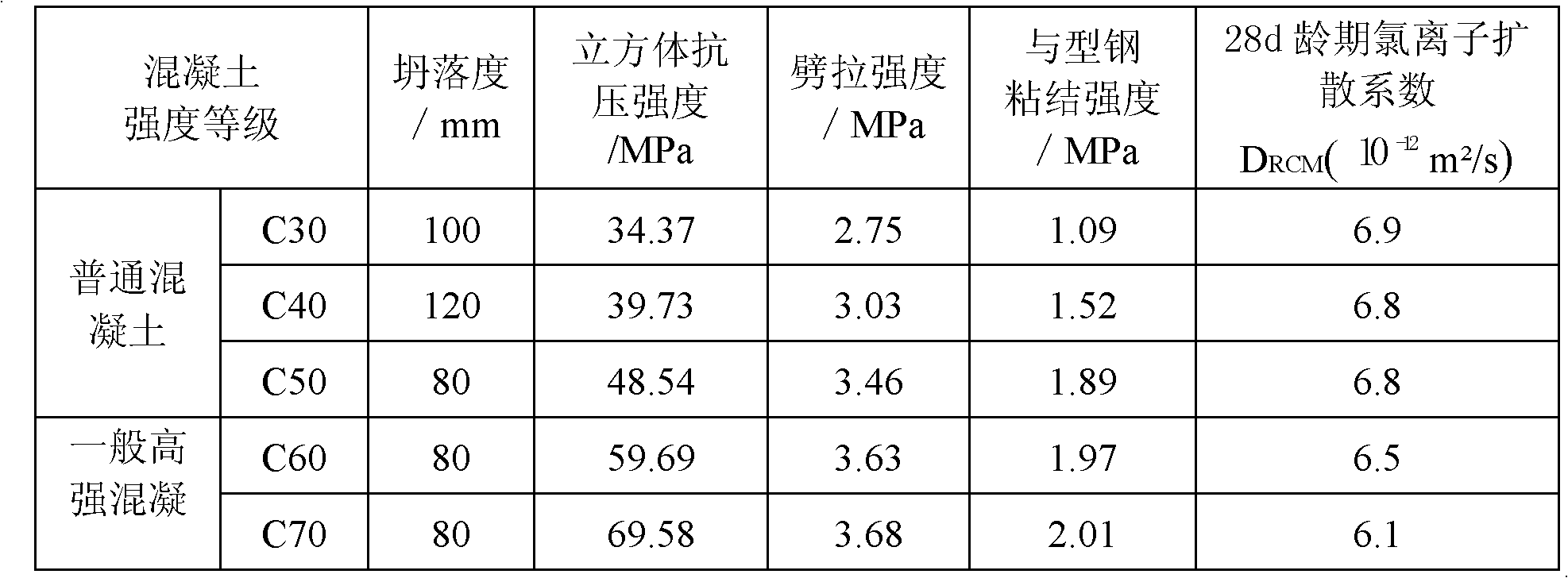

Concrete with strength grade of C140 used for profile steel-concrete composite structure

InactiveCN101913815AIncreased durabilityHigh Strength and DurabilitySolid waste managementCarrying capacityNatural state

The invention discloses concrete with strength grade of C140 used for a profile steel-concrete composite structure. The concrete is characterized by being prepared from cement, fine aggregate, coarse aggregate, water, a water reducing agent, an antifoaming agent, siliceous dust, coal ash(kg / m<3>) in a mixing proportion of 485:660:1,173:117:13:0.7:65:100. A preparation method of the concrete comprises the following steps of: adding the fine aggregate and the water in an amount of which is a half based on the total weight of the used water into a forced mixer according to the weight proportion in turn; uniformly stirring for 1 to 2 minutes; adding the coarse aggregate into the mixer; uniformly stirring for 2 to 4 minutes; adding the cement, the siliceous dust and the coal ash into the mixer; uniformly stirring for 2 to 3 minutes; adding the water reducing agent, the antifoaming agent and the rest water into the mixer; uniformly stirring for 2 to 5 minutes; and discharging to obtain a concrete mixture. The concrete can obviously improve the adhesive property between profile steel and the concrete in a natural state, effectively exert respective capacity and cooperative work performance of both materials, greatly improve the carrying capacity and performance of members, and improve the durability, high volume stability and economy of the members.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Floating body material and manufacturing technique thereof

The invention relates to a floating body material, in particular to a floating body material and a manufacturing technique thereof for an observation platform at the bottom of the sea. The floating body material comprises bisphenol A type epoxy resin, modified acrylonitrile-butadiene rubber latex, hollow glass microsphere, polyether amine, gamma-glycidoxypropyltrimethoxysilane, a silane coupling agent and polyvinyl alcohol fiber; and the floating body material comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 0-10 parts of modified acrylonitrile-butadiene rubber latex, 12-18 parts of hollow glass microsphere, 15-20 parts of polyether amine, 2-3 parts of gamma-glycidoxypropyltrimethoxysilane, 1-2 parts of silane coupling agent and 2 parts of polyvinyl alcohol fiber. The invention provides the floating body material and the manufacturing technique thereof for the observation platform at the bottom of the sea; and the observation platform adopting the floating body material can be soaked in the seawater for use in a long term.

Owner:SECOND INST OF OCEANOGRAPHY MNR

C170 strength-grade concrete for formed steel concrete composite structure

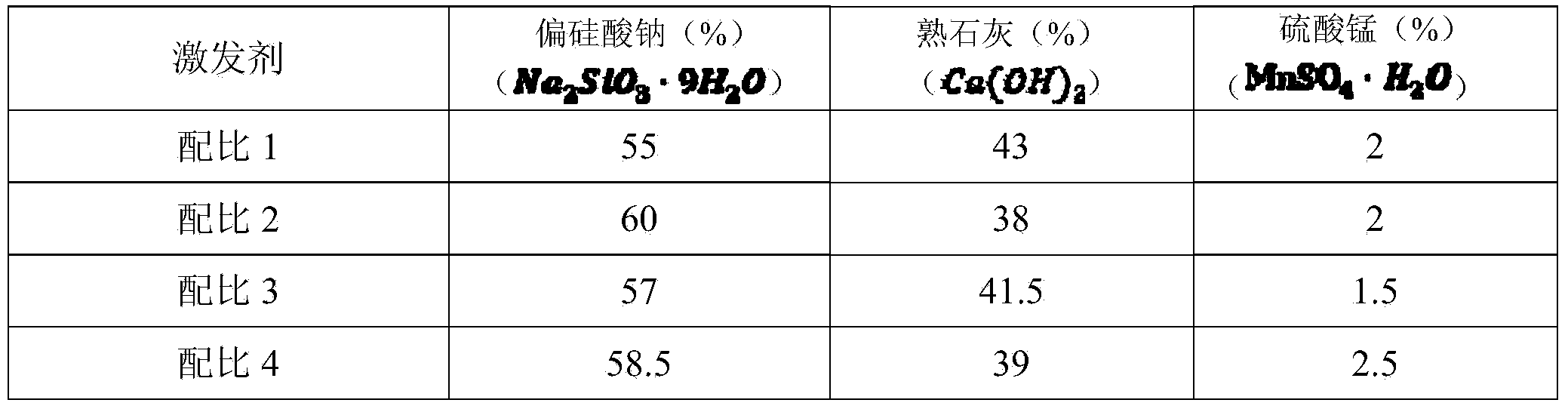

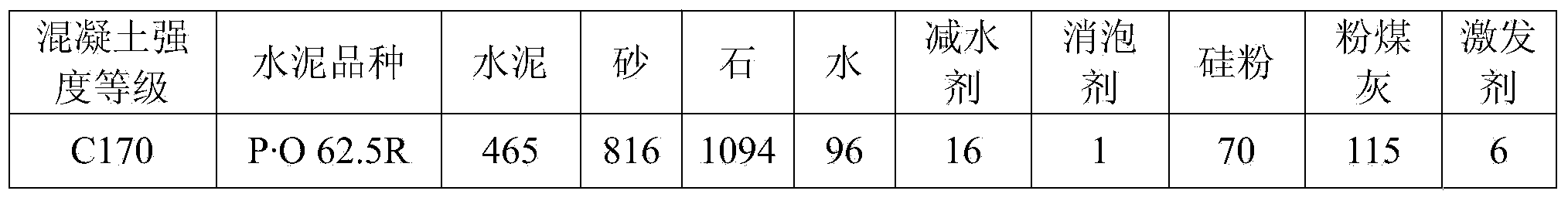

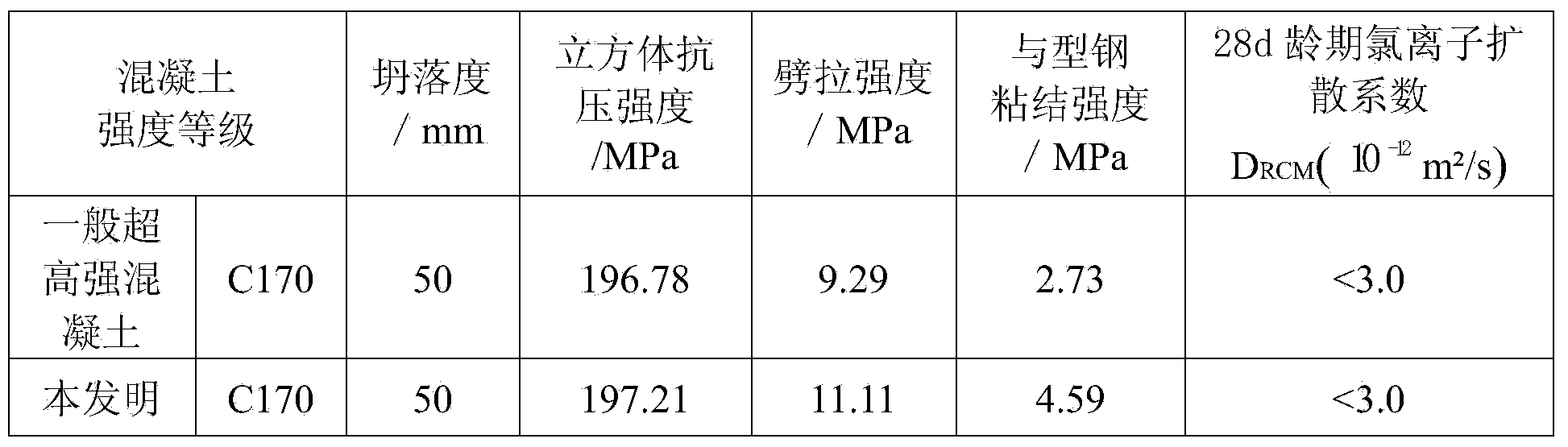

The invention discloses a C170 strength-grade concrete for a formed steel concrete composite structure, which is composed of 465 parts of cement, 816 parts of fine aggregate, 1094 parts of coarse aggregate, 96 parts of water, 16 parts of concrete superplasticizer, 1 part of defoaming agent, 70 parts of silicon powder, 115 parts of fly ash and 6 parts of activator. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has favorable working performance and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

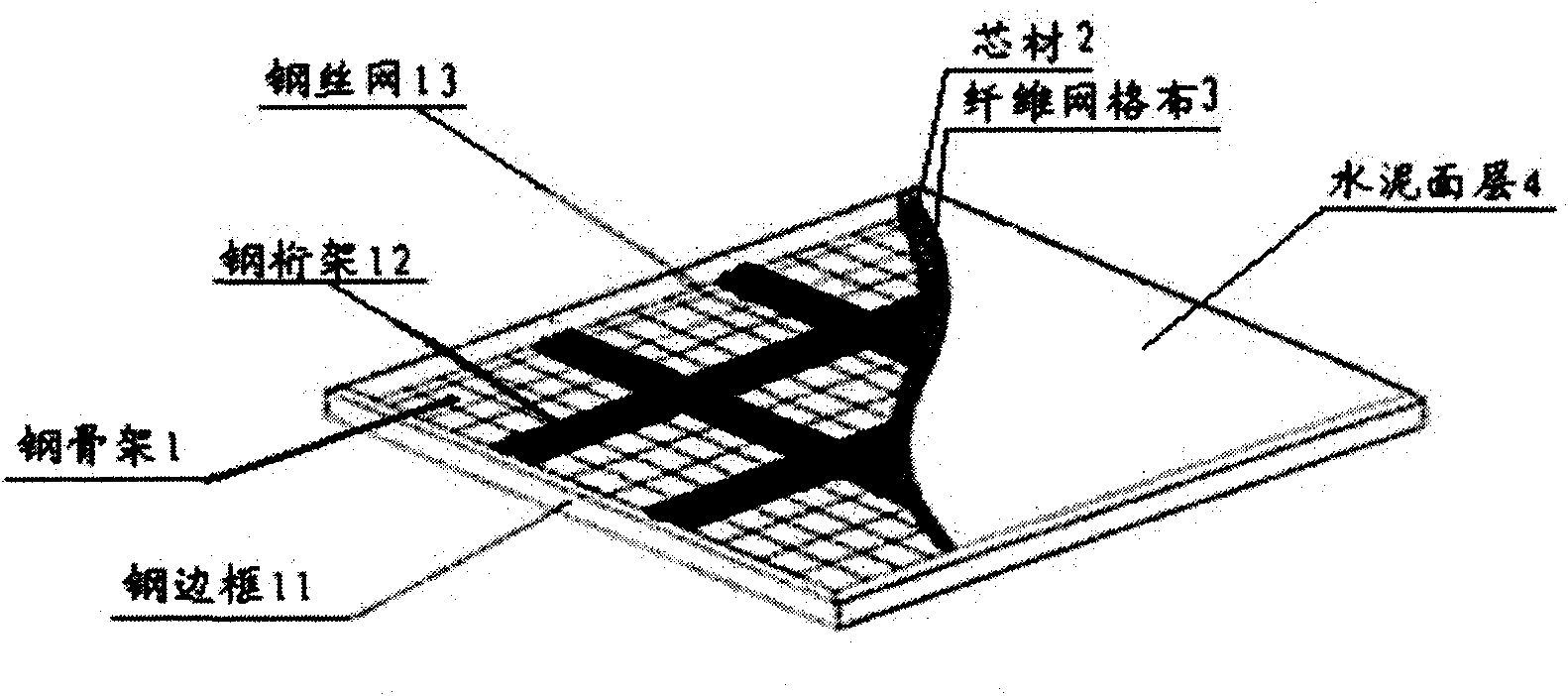

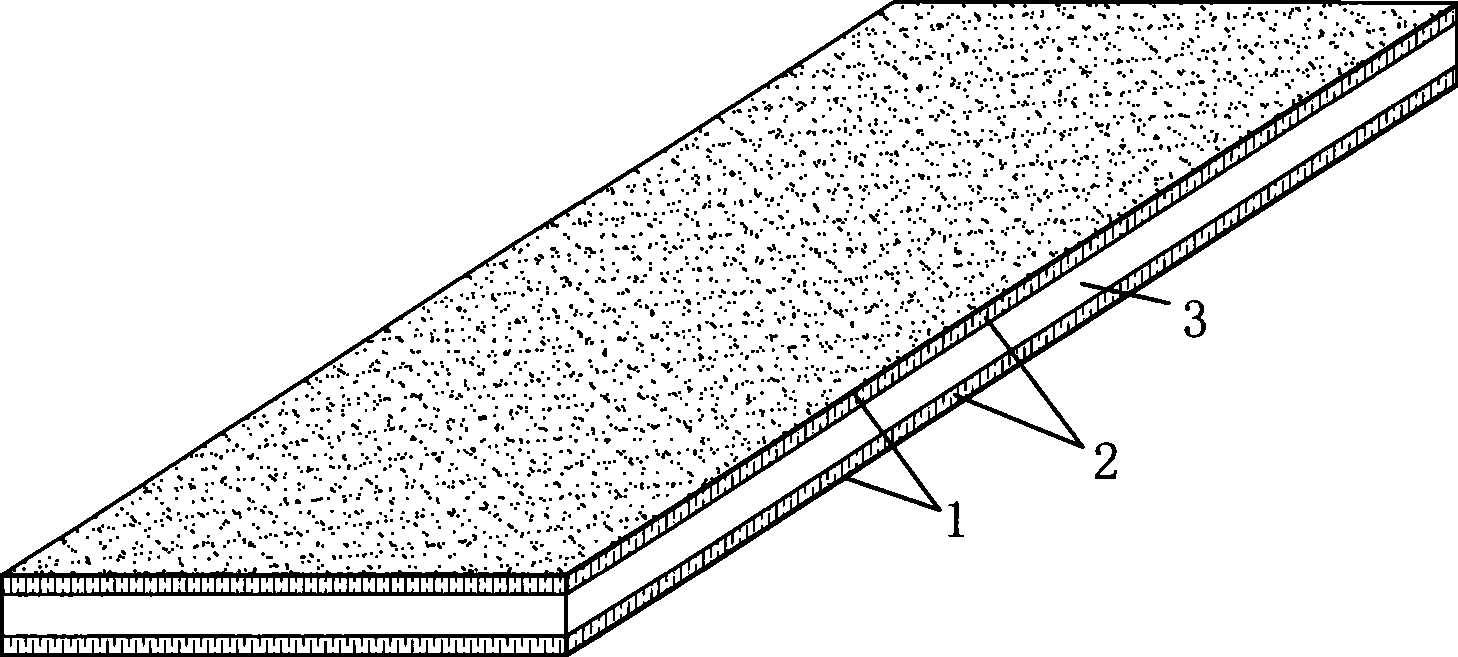

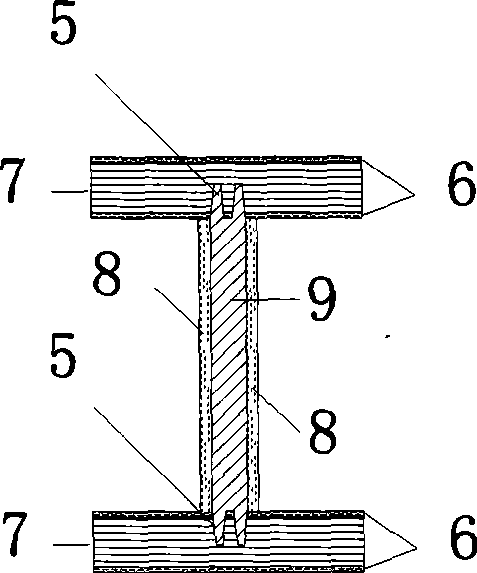

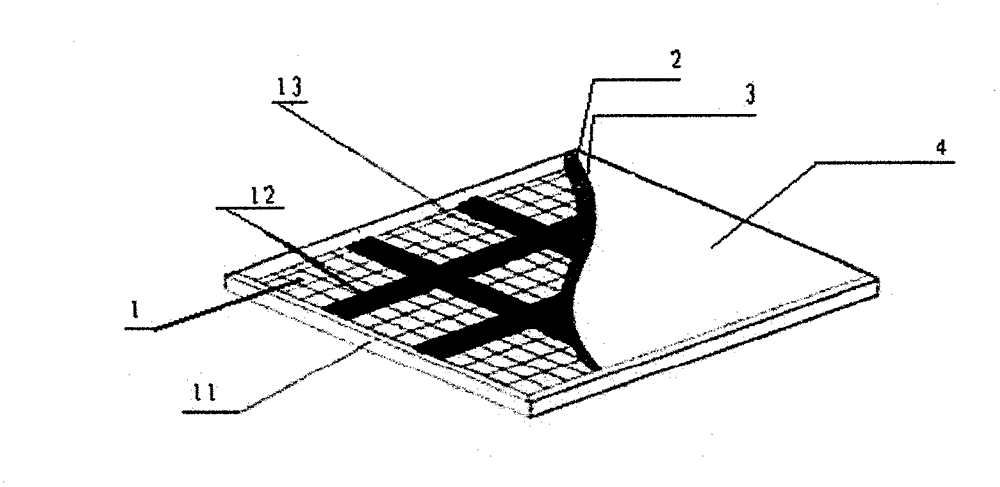

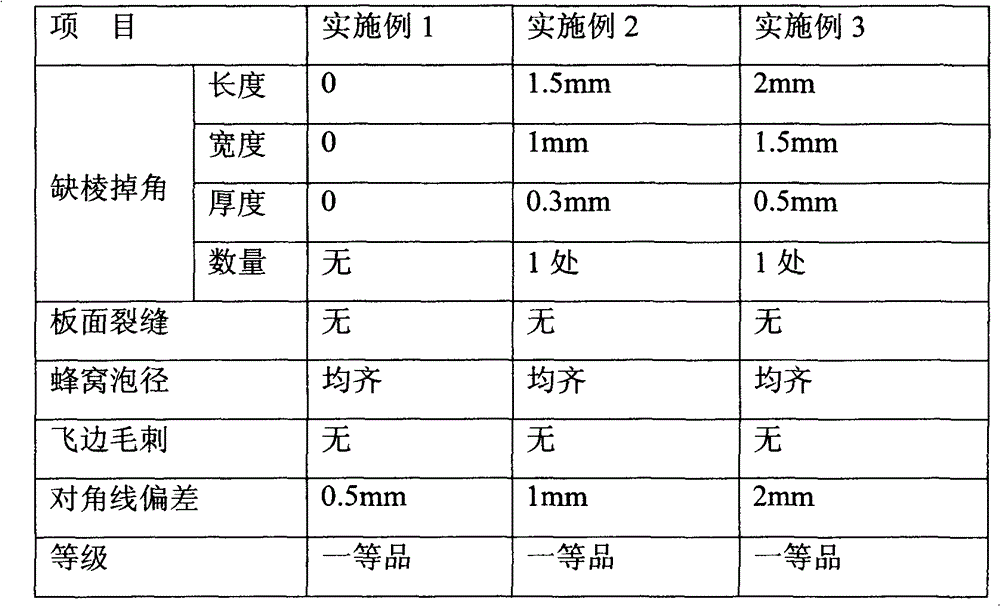

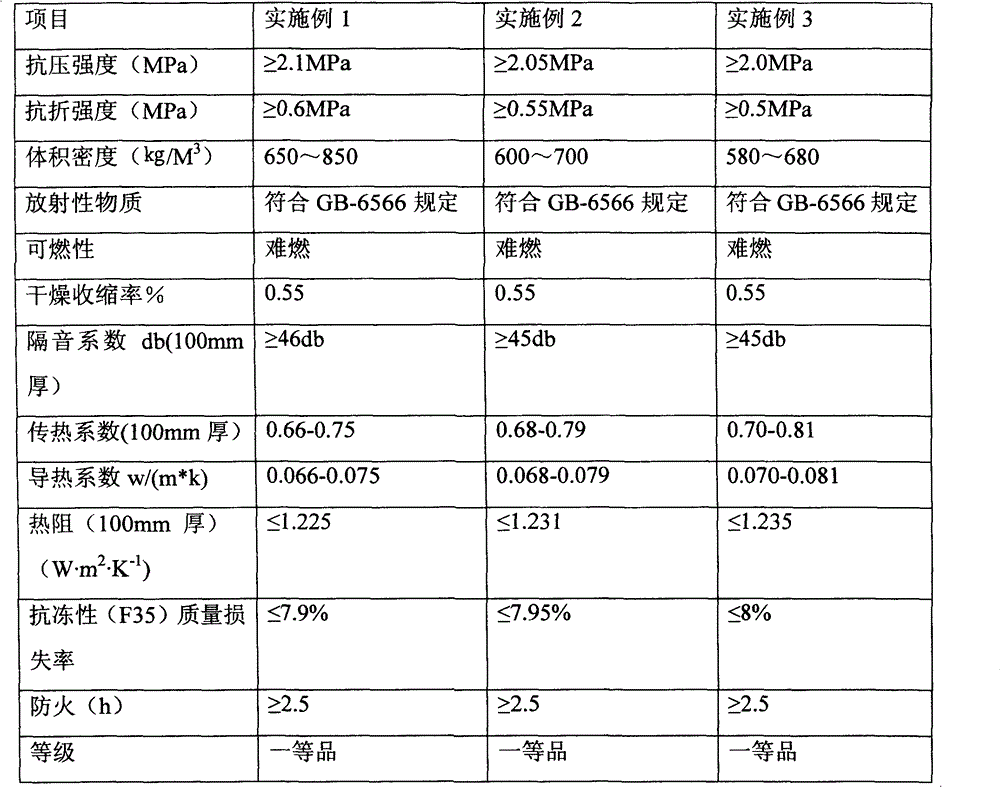

Heat-preserving and fire-proof composite plate with light weight and producing method thereof

InactiveCN102155070ALow costNo pollution in the processRoof covering using slabs/sheetsRoof toolsFiberSurface layer

The invention relates to a heat-preserving and fire-proof composite plate with light weight and a producing method thereof; specifically, the method comprises the following steps: integrally welding a steel side frame, a steel truss and two layers of steel wire nets into a steel framework, and placing the formed steel framework in a mould; blending and mixing quick-hardened sulfate aluminum cement and coal ash, adding water and a foaming agent, and adding admixture and continuously mixing uniformly if necessary; pouring the obtained mixture into the mould with the steel framework to form a core plate in an injection molding manner; after the core plate is solidified, paving a layer of fiber net cloth on the surface of the core plate, and forming a cement surface layer on the fiber net cloth to obtain the composite plate of the invention. The composite plate has the excellent performances of light weight, heat preservation, fire resistance, shock resistance, weight bearing and the like, and can be widely used as a roof plate, a net frame plate, a floor plate, and the like.

Owner:河北中体建筑工程有限公司

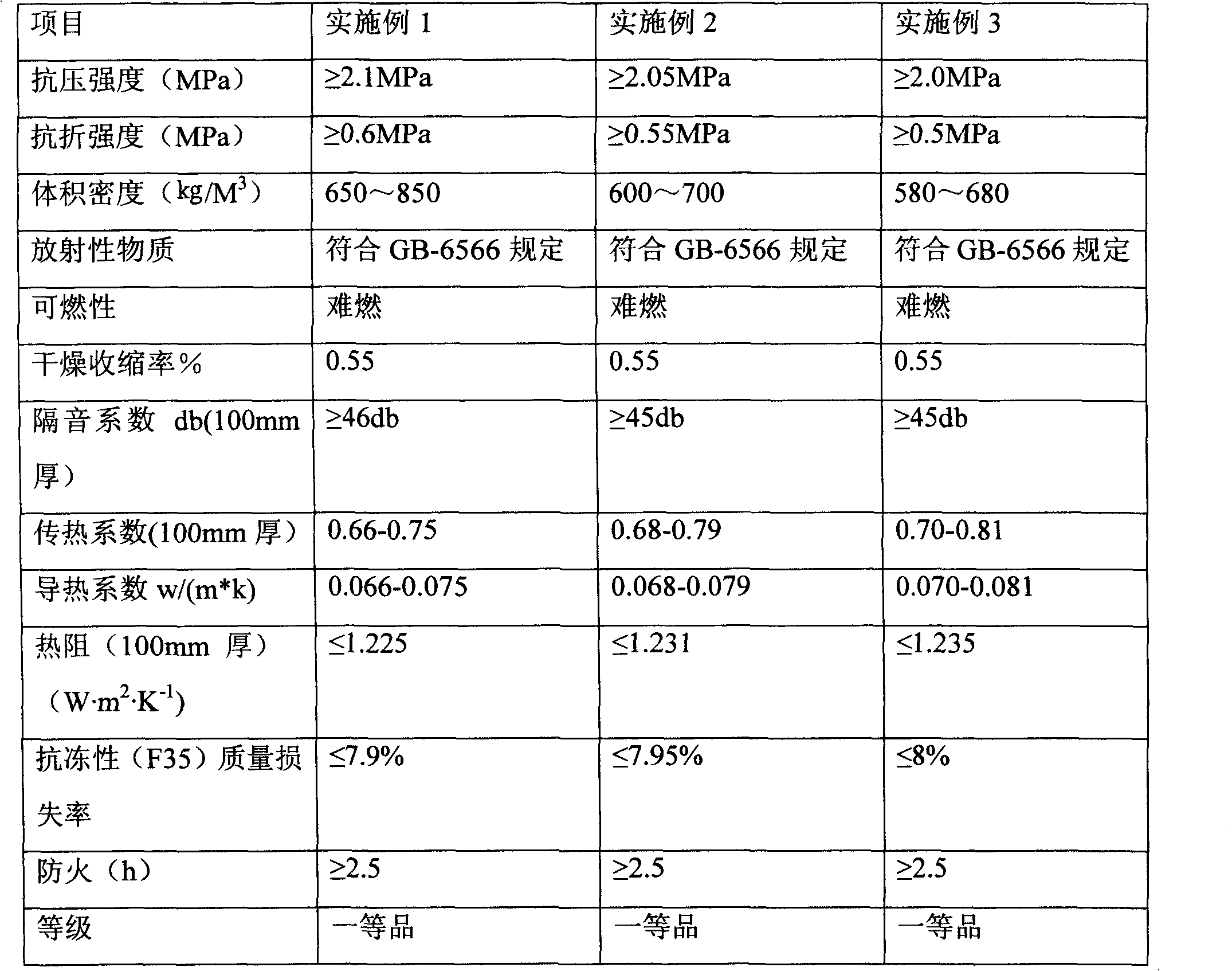

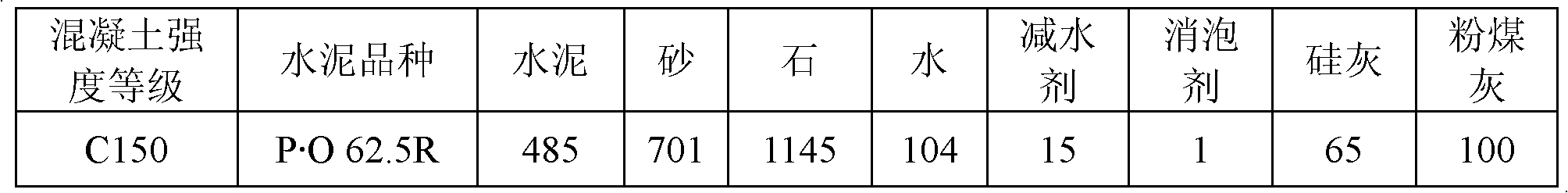

C150 (strength grade) concrete for section steel-concrete combined structure

InactiveCN101913822AIncreased durabilityHigh Strength and DurabilitySolid waste managementCement mixing apparatusDefoaming AgentsPulverised fuel ash

The invention discloses C150 (strength grade) concrete for a section steel-concrete combined structure, which is characterized by being prepared by mixing cement, fine aggregate, coarse aggregate, water, water reducer, defoaming agent, siliceous dust and flash ash in a mass / volume ratio of 485:701:1,145:104:15:1:65:100. The preparation method of the concrete comprises: adding the fine aggregate and half of the total amount of water into a forceful stirrer in turn according to a weight mixing ratio, uniformly stirring for 1 to 2 minutes, adding the coarse aggregate, uniformly stirring for 2 to 4 minutes, adding the cement, the siliceous dust and the flash ash, uniformly stirring for 2 to 3 minutes, adding the water reducer, the defoaming agent and the rest of water, uniformly stirring for 2 to 5 minutes, and discharging to obtain a concrete mixture. The concrete has obviously improved section steel binding performance in a natural state and can effectively play respective capability and coordinate operation performance with the section steel, thereby improving the bearing capacity and performance of a member considerably and improving the durability, high-volume stability and economy of the member.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for manufacturing plastic mould of automobile door plate loudspeaker mask

The invention discloses a method for manufacturing a plastic mould of an automobile door plate loudspeaker mask. The method comprises the following steps: (A) selecting a plastic component structure:a left decoration component and a right decoration component of the automobile door plate loudspeaker mask; (B) selecting a mould structure: (a) designing a die cavity of the mould; (b) designing a die core: adopting the following methods: adding a belting pile in a hook shape on the die core; polishing the face of the die cavity before processing the texture; and increasing the thickness of an installation clamping position; (c) designing a parting face and a template; (d) designing a sprue; (e) designing an ejection system; and (f) cooling: cooling and solidifying the plastic components quickly; injecting PP into the die cavity by an injection molding machine, recovering an ejector bar to a position where the mould is closed under the action of a recovery bar and a return spring and completing the mould. The invention has easy method, simple and convenient operation, high strength, high temperature resistance, high accuracy, strong degree of durability, stable performance and good insulation property, reduces a large number of time and expenses consumed by repairing the mould and saves various costs by more than 50% in the design and processing of the mould.

Owner:WUHAN JIAMENG PLASTIC PROD

Concrete with strength grade of C100 used for steel reinforced concrete combined structure

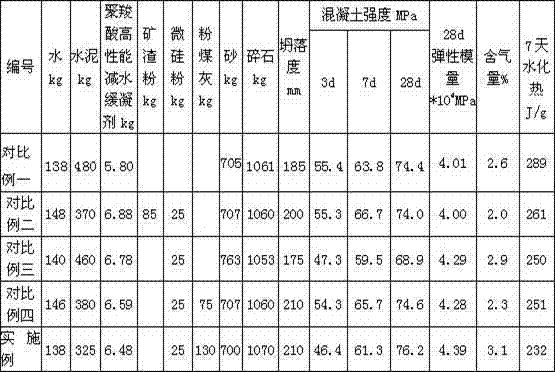

InactiveCN101250040AIncreased durabilityHigh Strength and DurabilitySolid waste managementSuperplasticizerWater reducer

The invention discloses a concrete with strength grade of C100 for composite structure of section steel reinforced concrete, wherein the mix proportion of the concrete is 450 : 510 :1190 :144 : 12 : 60 : 90 of cement : coarse aggregate : fine aggregate : water : high efficiency water reducing agent : silica fume : fly ash, and the unit is Kg / m3. The concrete has the advantages of good mechanical property (comprises strength property, plasticity property and bonding capacity among the section steels), sound working property, good durability and relatively low cost and is adapted for composite structure of section steel reinforced concrete, further using the concrete can reduce construction procedure, save steels, increase construction efficiency and obtain significant economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

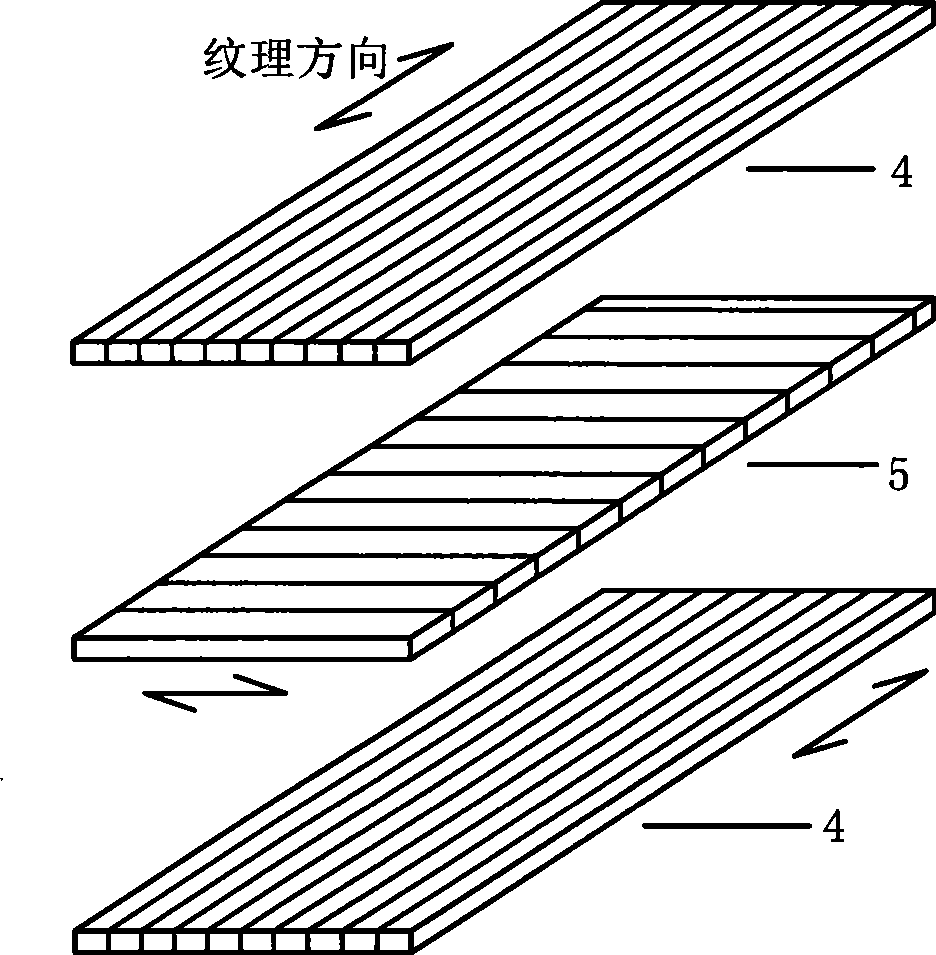

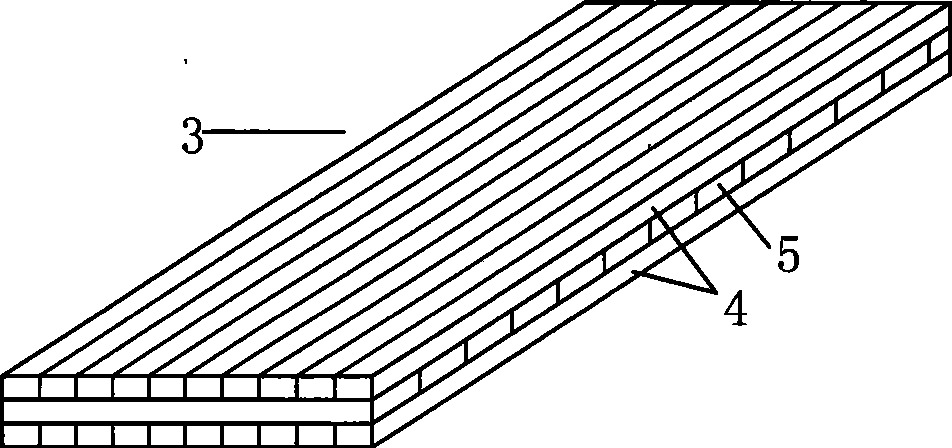

High-strength plywood for building shutter panel

InactiveCN101498171AEasy to assemble and disassembleHigh turnoverSynthetic resin layered productsWood layered productsHigh turnoverWeather resistance

The invention provides a veneer which is used for fair-faced concrete building template and has the advantages of lightness, high strength, convenient disassembly and assembly, easy cutting, high cost performance, weather resistance, corrosion prevention, strong durability, easy demoulding, high turnover frequency and being suitable for industrial production. The veneer consists of a covering film, a panel and a core plate; the covering film is prepared from a resin pressed film; the panel is prepared by gluing a gum dipping fiber reinforced composite material; and the core plate is a three-layer structural plate. The invention is mainly used for panels in building template systems, particularly for panels of fair-faced concrete templates.

Owner:NANJING UNIV OF TECH

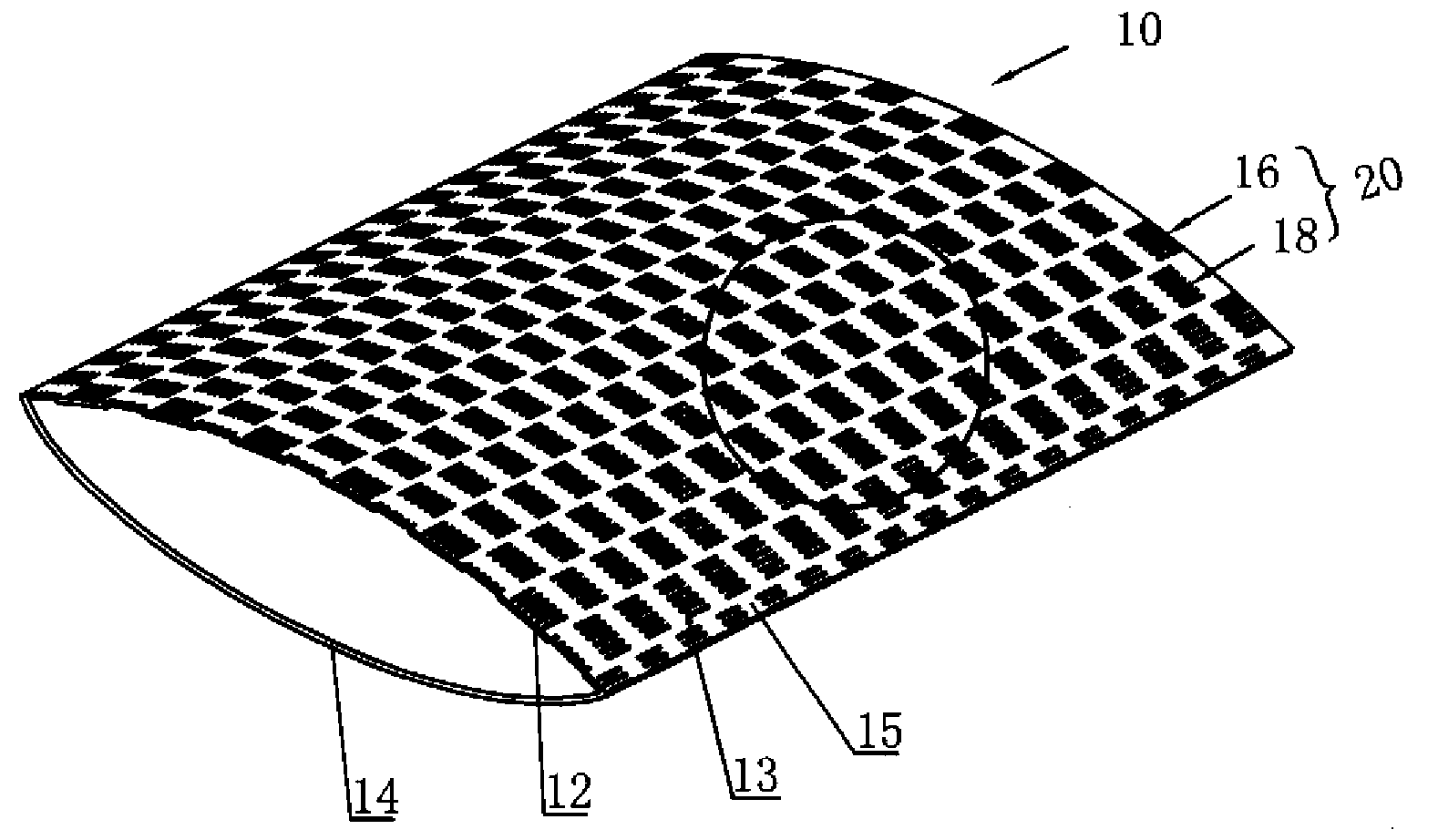

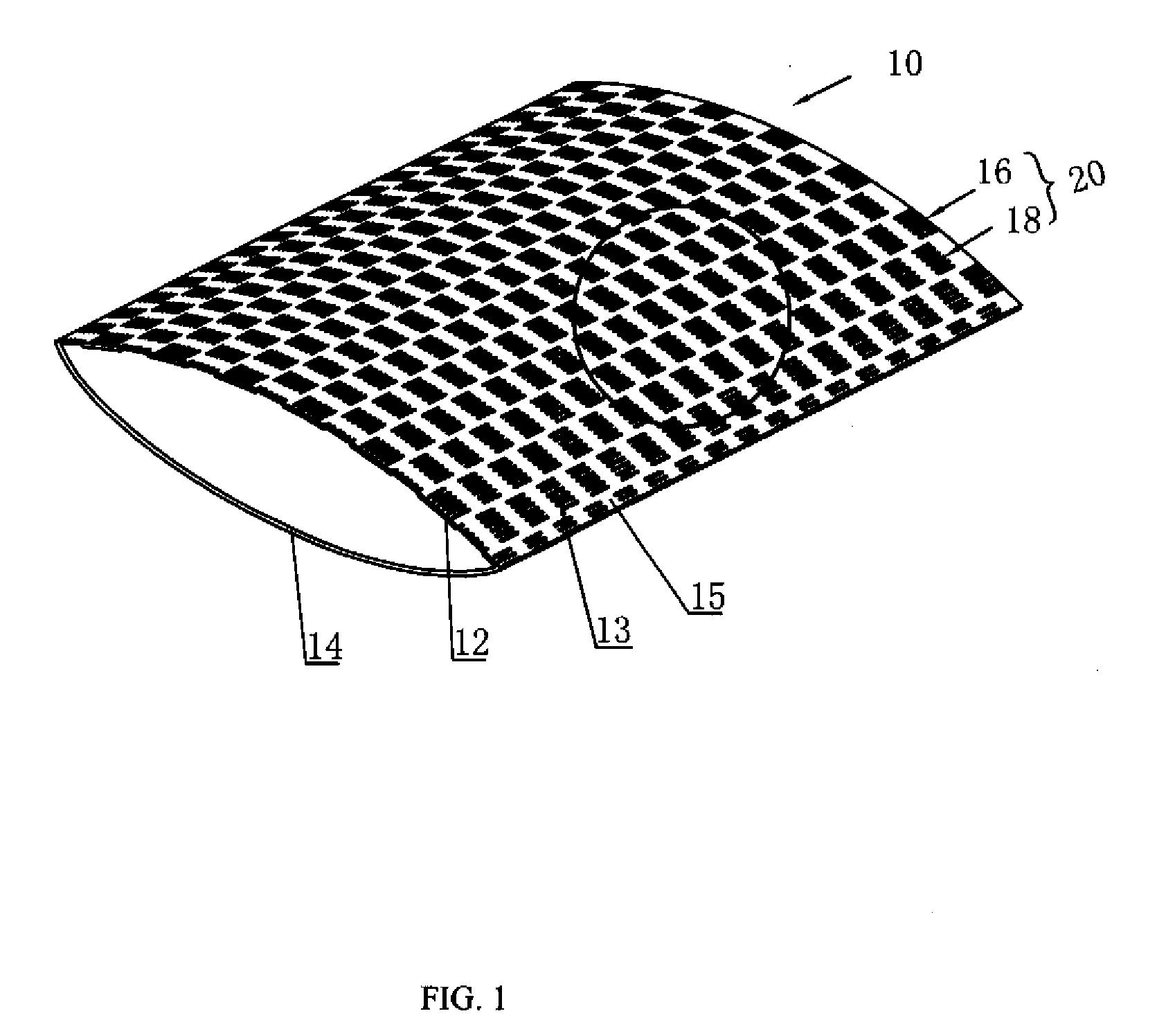

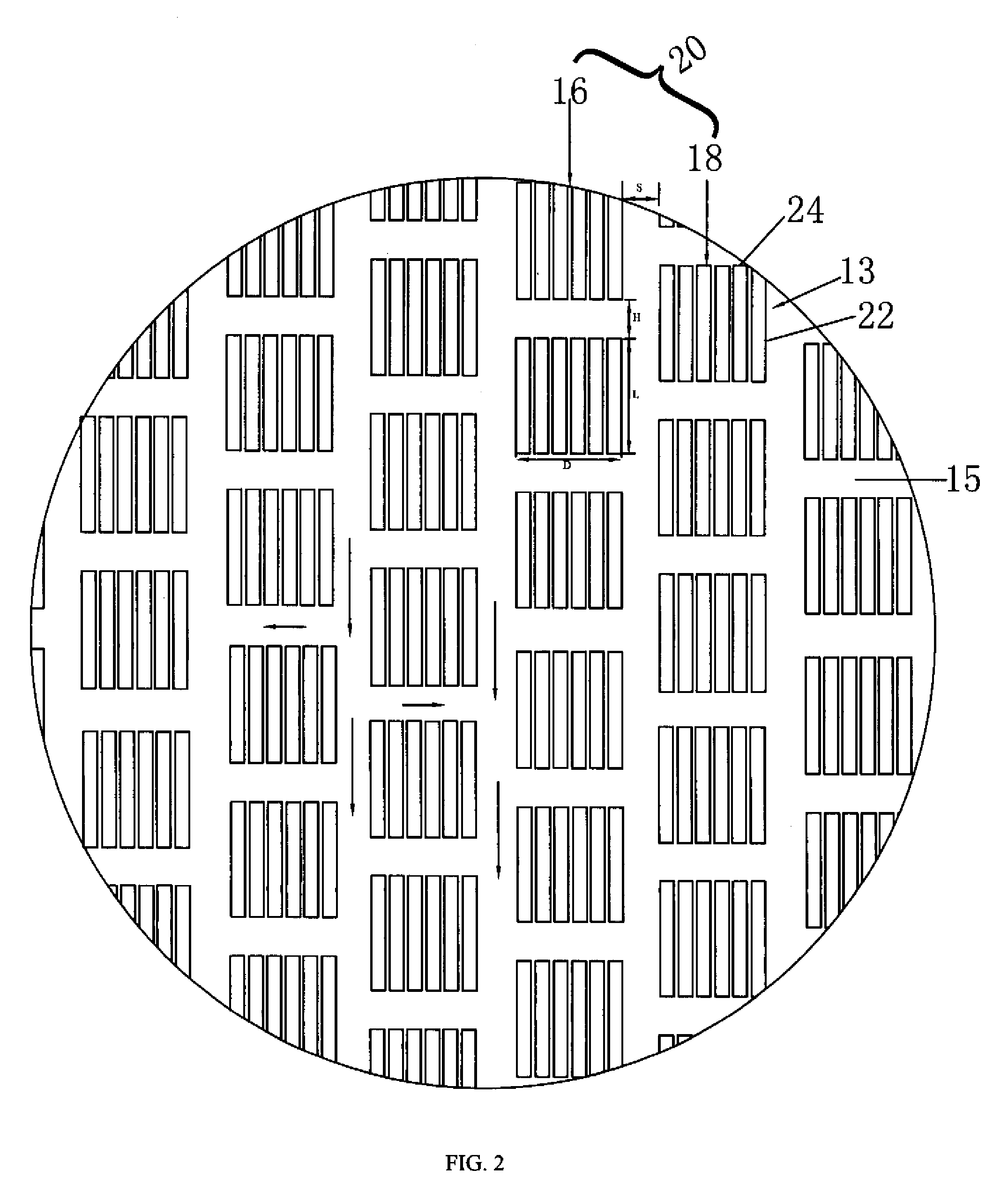

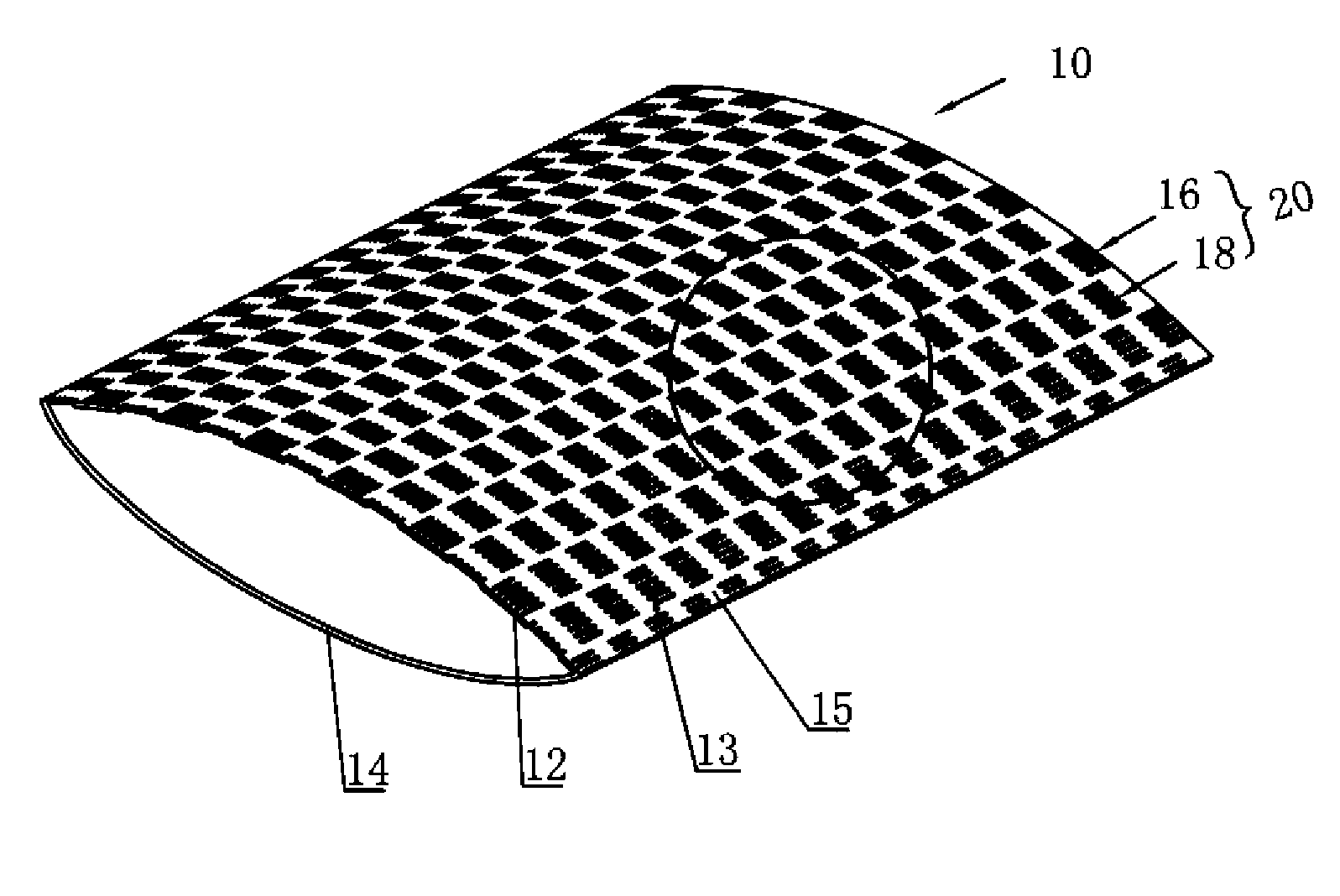

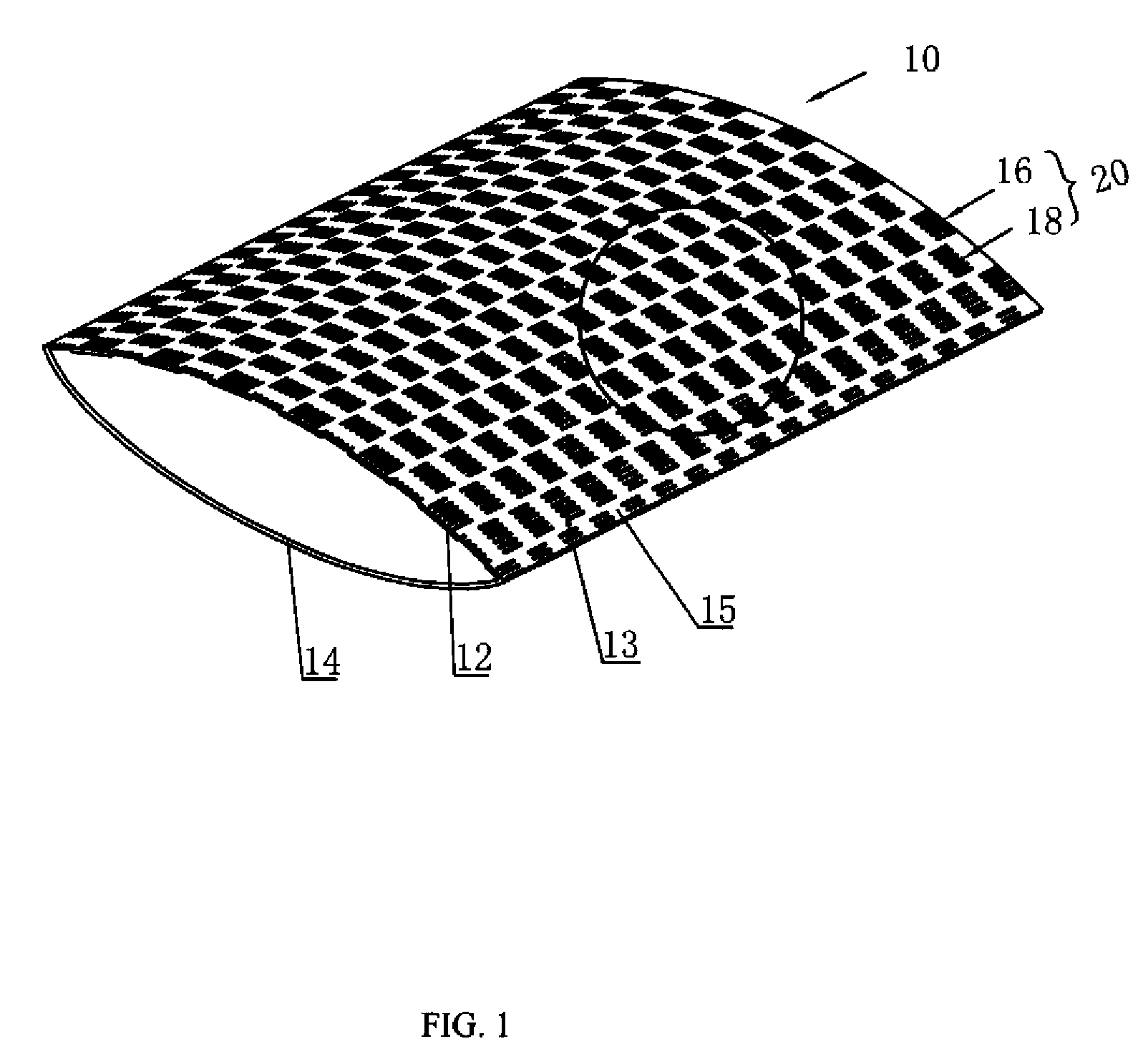

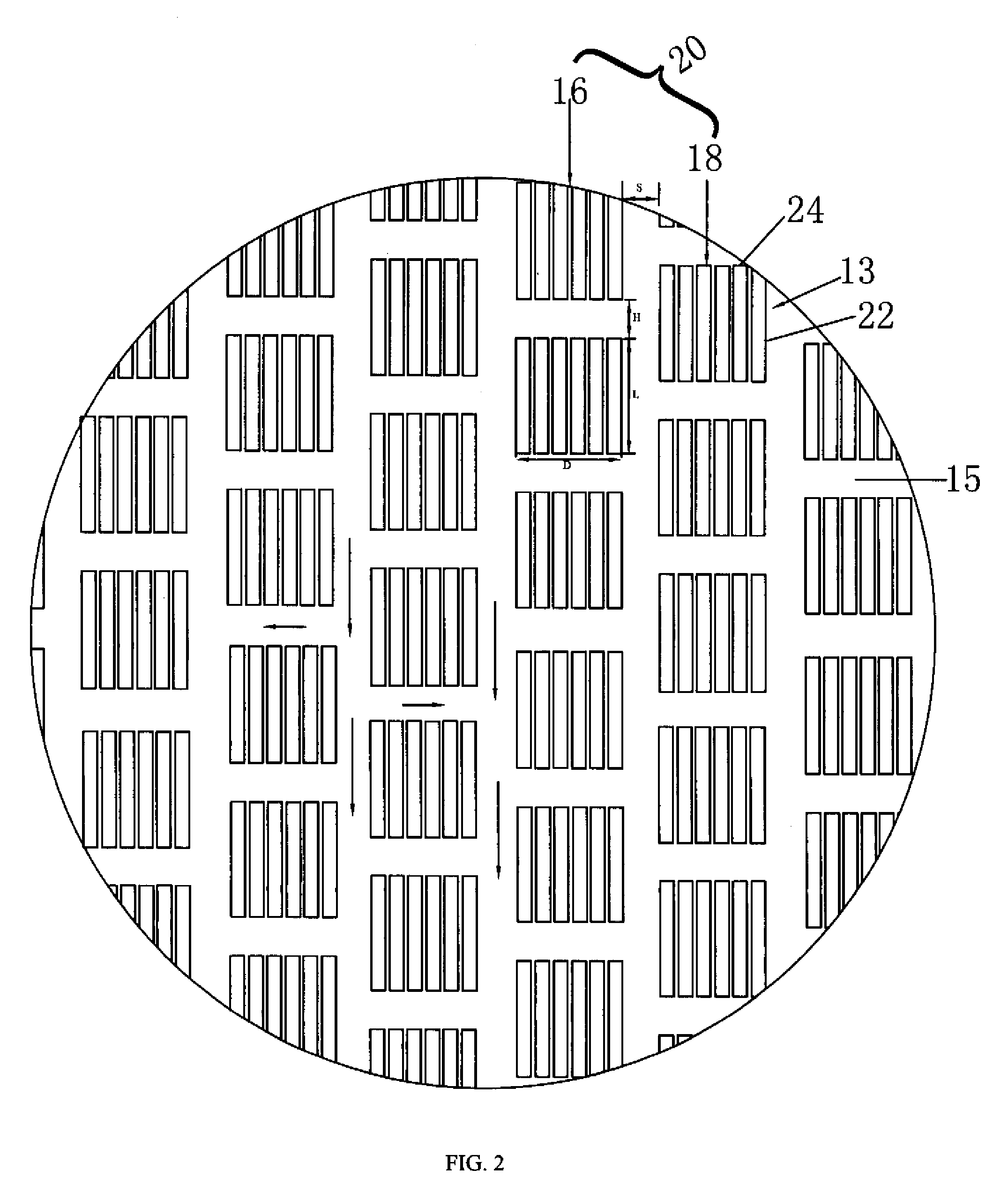

Plastic bags for vacuum packing

The plastic bag for vacuum packing provided by the present invention has embossments which space in longitudinal direction and stagger in transverse direction formed on the inner surface, and thus lots of intercommunicate channels are formed so as to eliminate the possibility to form any air pocket or internal cavity. Meanwhile, air linearly exits from the bottom to the open end, so it takes less time to evacuate the bag. Further, the bag only has one film be embossed, and thus the manufacturing process thereof is simplified and at low cost, and the bag is easy to wash. Moreover, the strength of the bag provided by the present invention is enhanced; especially the anti-avulsion capability is well improved.

Owner:GUANGZHOU ARGION ELECTRIC APPLIANCE CO LTD

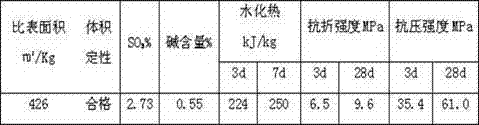

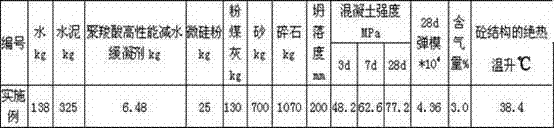

Concrete for nuclear power station

The invention relates to concrete, in particular to concrete for a nuclear power station and belongs to the technical field of building construction. The concrete for the nuclear power station comprises the following components by mass percent: 8-30 percent of Portland cement, 1-20 percent of coal ash, 0.5-10 percent of silica powder, 35-55 percent of macadam, 20-40 percent of sand, 0.1-1 percent of polycarboxylic acid high-performance water-reducing and set-retarding admixture and 2-15 percent of water. The invention has the benefit that the prepared concrete consumes a small amount of cement, has high strength and high elastic modulus, achieves the characteristics of very strong durability and favorable workability through addition of silica powder and control of harmful ingredients, can reduce the phenomenon of delayed ettringite formation, has favorable pumping property and is suitable for mass concrete pumping construction.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

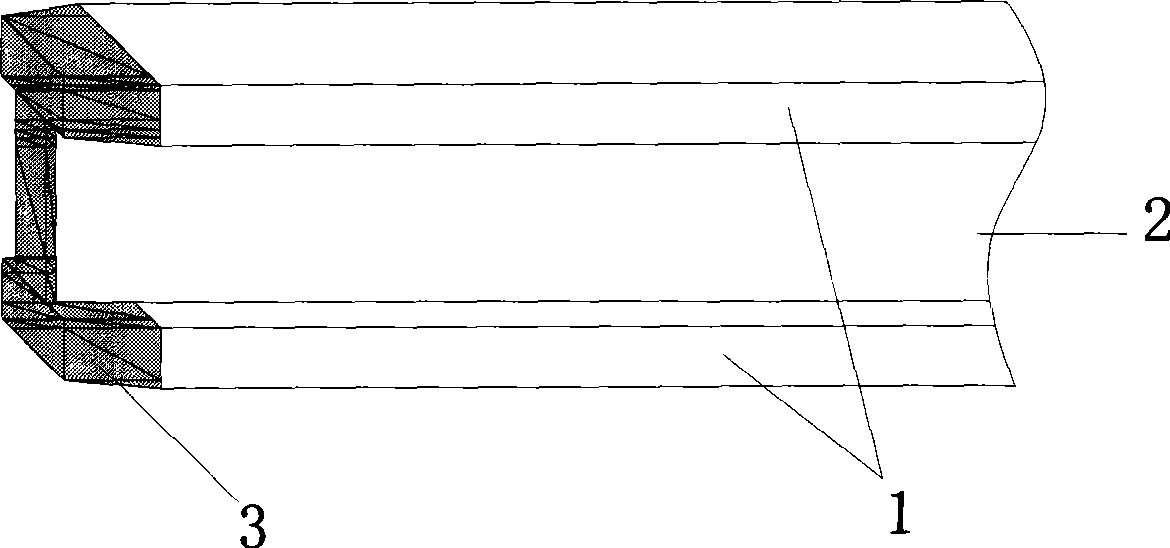

High-strength durable wooden I-shaped beam

InactiveCN101487331AIncrease stiffnessGood value for moneyForms/shuttering/falseworksGirdersShaped beamSingle plate

The invention provides a high-strength durable wood I-typed beam which has the advantages of high rigidity, lightweight, high-strength, convenient assembly and disassembly, easy cutting, high cost performance, high durability, turnover use for an average year, and industrialized production. The high-strength durable wood I-typed beam comprises a flange girth, a web plate and an end protective sleeve. The upper surface, lower surface and the interior of a flange girth substrate in the flange girth are provided with flange girth modified processing single plates. The surface and the interior of a web plate substrate in the web plate are provided with web plate modified processing single plates. The flange girth modified processing single plates and the web plate modified processing single plates are glue soaking processing single plates. The used adhesive selects water soluble phenol resin with low molecular weight or melamine-formaldehyde resin. The high-strength durable wood I-typed beam is mainly used as the supporter in a building moulding board system, and can also be used in the fields such as supporting members of building structure roofs, and the like.

Owner:NANJING UNIV OF TECH

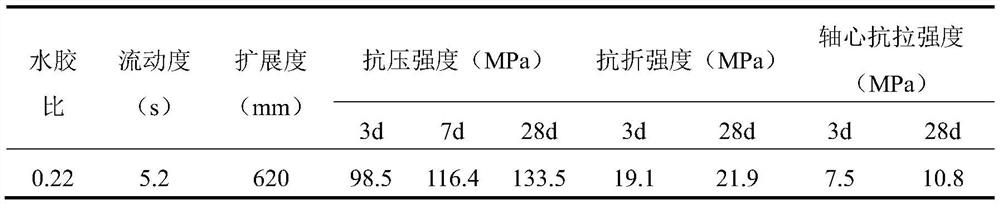

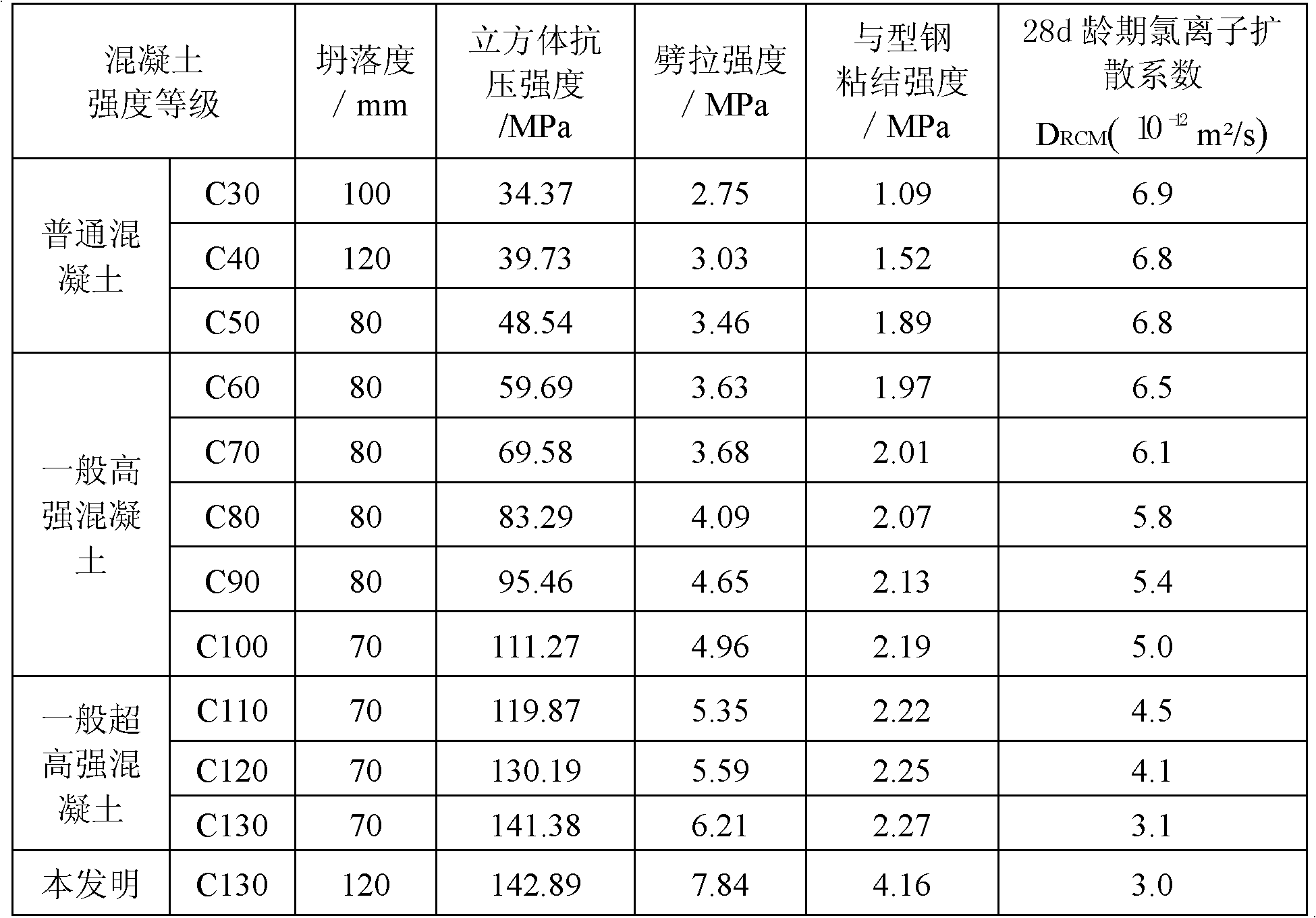

Self-compacting C120 premixed dry concrete and preparation method thereof

ActiveCN112209683AAddressing Reunion's FlawsEvenly distributedBridge erection/assemblyBuilding material handlingBreaking strengthPortland cement

The invention provides self-compacting C120 premixed dry concrete and a preparation method thereof, and belongs to the technical field of concrete materials. The self-compacting C120 premixed dry concrete is prepared from the following components in parts by weight: 480-550 parts of Portland cement, 40-55 parts of coarse aggregate, 70-80 parts of steel fiber, 470-550 parts of fine aggregate, 11-15parts of admixture and 145-190 parts of mineral admixture. According to the premixed dry material concrete prepared by the invention, the compressive strength is not lower than 120MPa, the breaking strength is not lower than 20MPa and the axial tensile strength is not lower than 8MPa after 28d, and after the premixed dry material concrete is transported to a construction site and is directly mixed with water, the self-compaction and vibration-free functions can be realized immediately after discharging, and the premixed dry material concrete has high strength and durability.

Owner:YICHUN UNIVERSITY

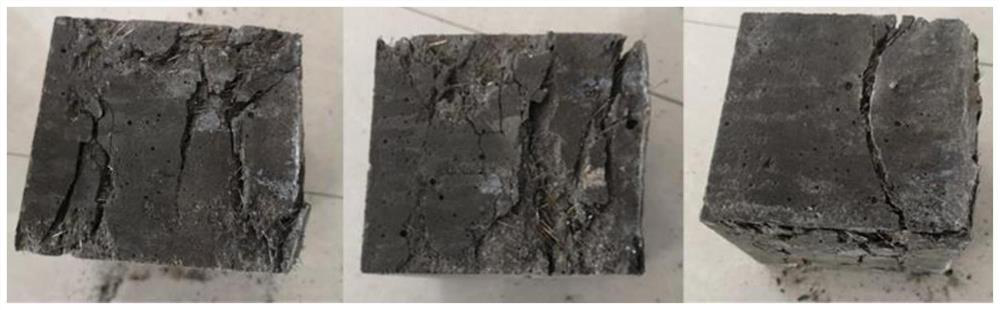

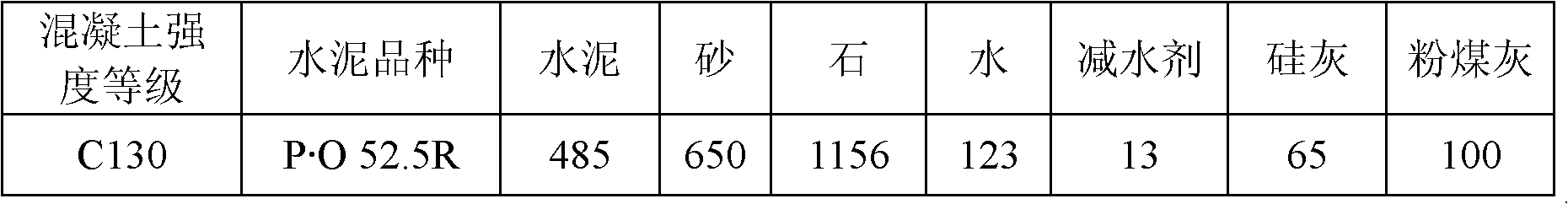

C130 (strength grade) concrete for section steel-concrete combined structure

InactiveCN101913816AIncreased durabilityHigh Strength and DurabilityNatural stateUltimate tensile strength

The invention discloses C130 (strength grade) concrete for a section steel-concrete combined structure, which is characterized by being prepared by mixing cement, fine aggregate, coarse aggregate, water, water reducer, siliceous dust and flash ash in a mass / volume ratio of 485:650:1,156:123:13:65:100. The preparation method of the concrete comprises: adding the fine aggregate and half of the total amount of water into a forceful stirrer in turn according to a weight mixing ratio, uniformly stirring for 1 to 2 minutes, and adding the coarse aggregate; uniformly stirring for 2 to 4 minutes, and adding the cement, the siliceous dust and the flash ash; uniformly stirring for 2 to 3 minutes and adding the water reducer and the rest of water; and uniformly stirring for 2 to 3 minutes, and discharging to obtain a concrete mixture. The concrete has obviously improved section steel binding performance in a natural state and capability and coordinate operation performance of the concrete and the section steel can be fully played, so that the bearing capacity and performance of a member considerably are greatly improved and the durability, high-volume stability and economy of the member are improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

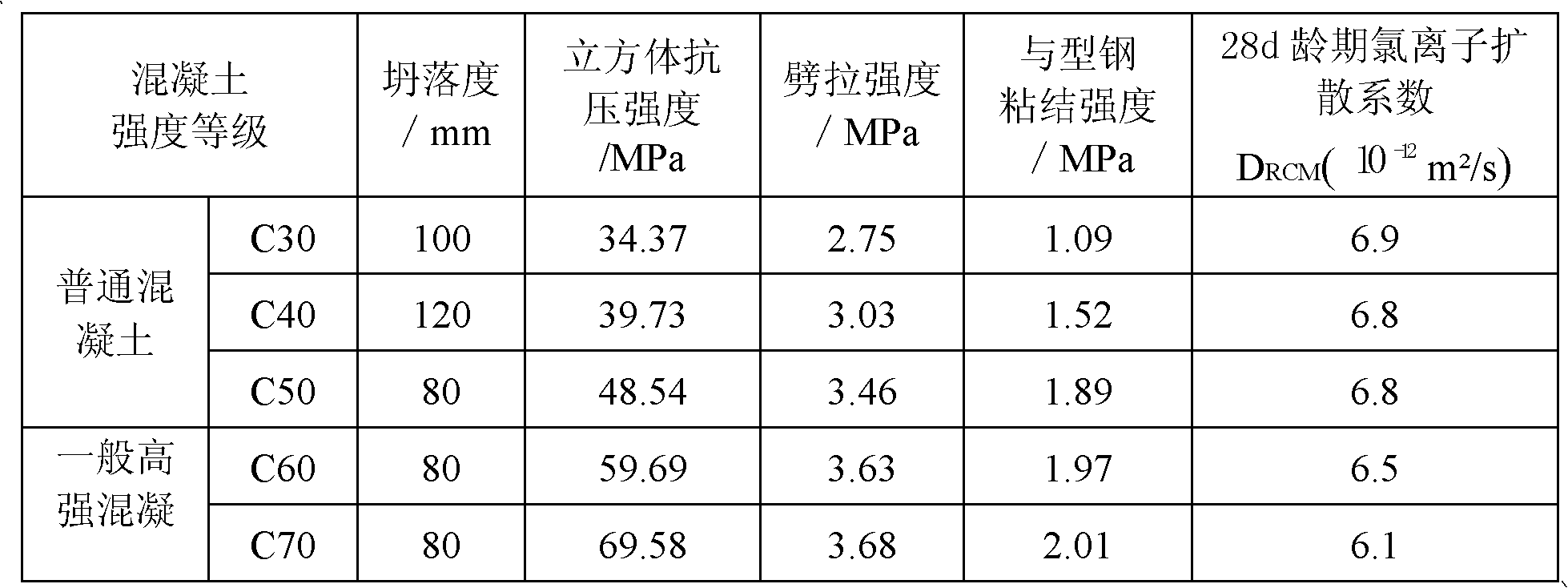

Concrete with strength grade of C70 for section steel concrete composite structure

InactiveCN101195530AImprove workabilityImprove volume stabilitySolid waste managementSilica fumeReinforced concrete

The invention discloses a concrete with strength grade of C70 for composite structure of steel reinforced concrete. Mixed proportion of the concrete is that cement: coarse: aggregate: fine aggregate: water: effective water reducer: silica fume: fly ash is 400:576:1224:148:8:30:120. Component unit is Kg / m3. The concrete is in good mechanical properties (comprising strength, plastic and bond behavior between section steel and concrete), excellent in working performance, good in durability and relatively lower in cost, and is suitable for the composite structure of steel reinforced concrete. The use of the concrete reduces construction procedures, saves steel, improves construction efficiency and has remarkable economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

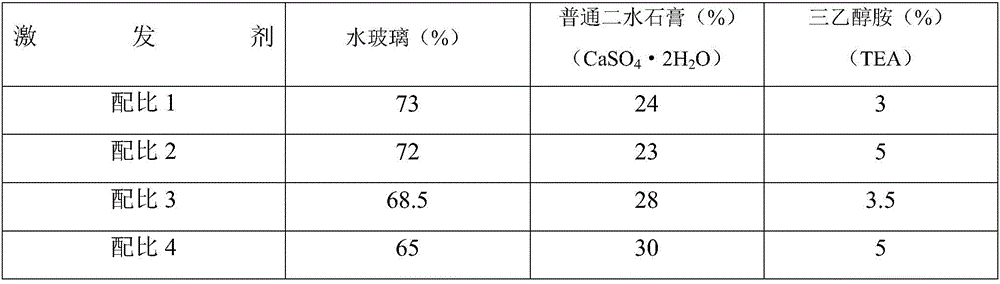

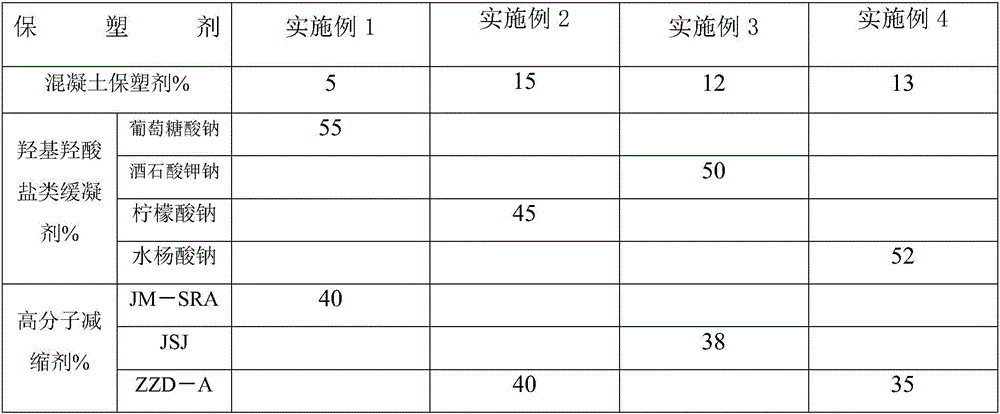

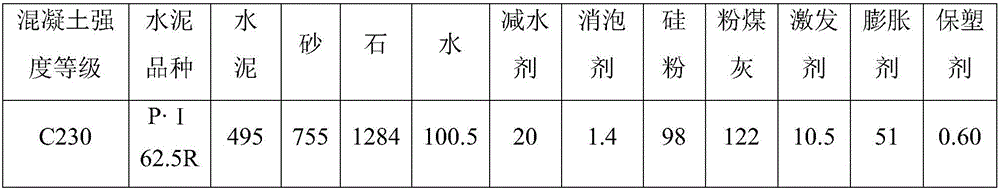

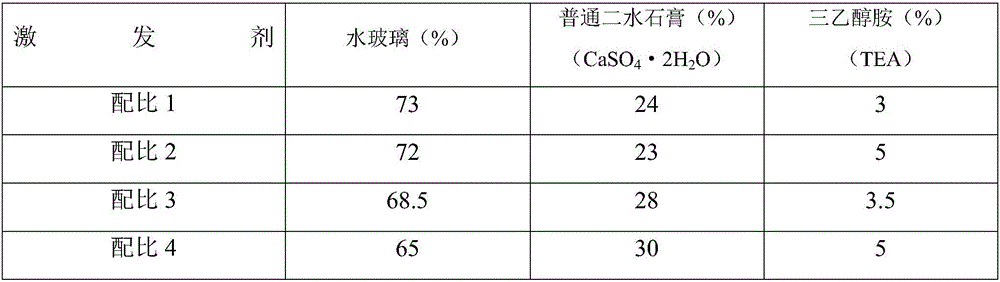

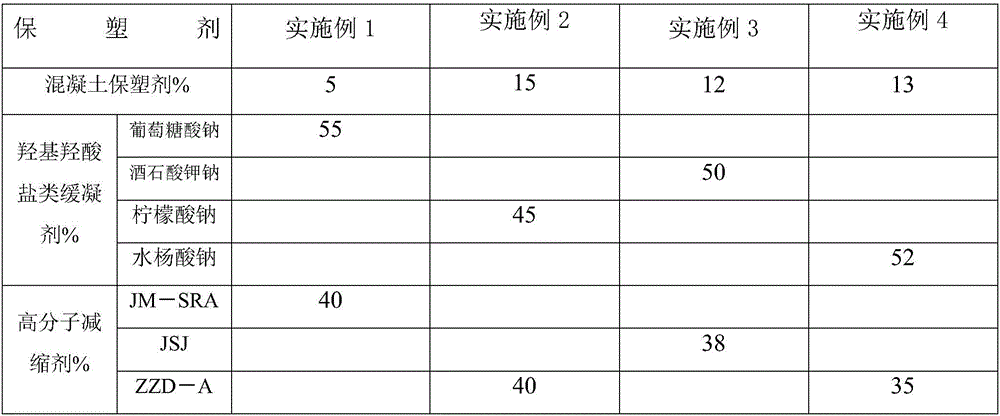

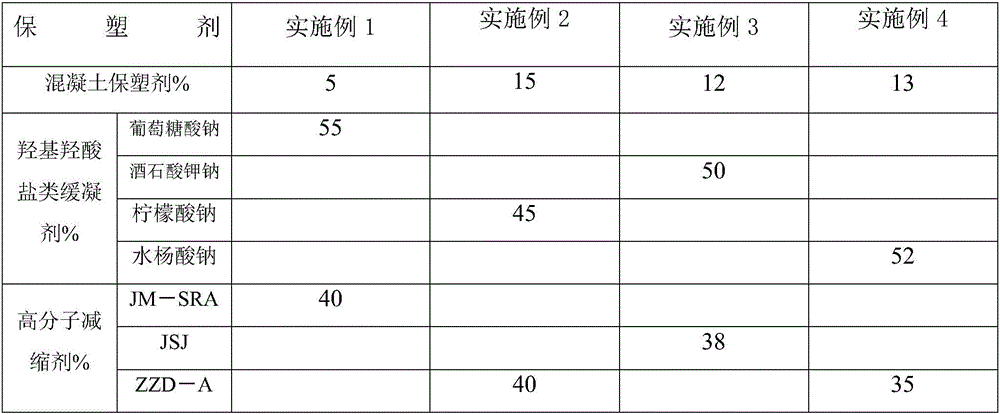

Concrete used for steel reinforced concrete composite structure and having C230 strength grade

InactiveCN105837119AIncreased durabilityHigh Strength and DurabilitySolid waste managementMixing operation control apparatusNatural stateMechanical property

Concrete used for a steel reinforced concrete composite structure and having the C230 strength grade is disclosed. A ratio of cement, fine aggregate, coarse aggregate, water, a water reducing agent, a defoaming agent, silica fume, fly ash, an activator, an expanding agent and a composite plastic retaining agent is 495:755:1284:100.5:20:1.4:98:122:10.5:51:0.60. The preparing method includes fully mixing the water reducing agent, the activator and the composite plastic retaining agent with the water to obtain a mixture, adding the fine aggregate and one third of the mixture into a stirrer in order, fully mixing, adding the coarse aggregate one third of the mixture in order, fully stirring, adding the cement, the expanding agent, the silica fume and the fly ash, fully stirring, adding the defoaming agent and the rest of the mixture, stirring and discharging. The concrete significantly improves adhesion performance between section steel and concrete under natural states, effectively exerts mechanical properties of the steel and the concrete and synergistic properties, greatly improves bearing capacity, using performance and durability of structural components, and has good high size stability and economical performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Plastic bag for vacuum packing

Owner:GUANGZHOU ARGION ELECTRIC APPLIANCE CO LTD

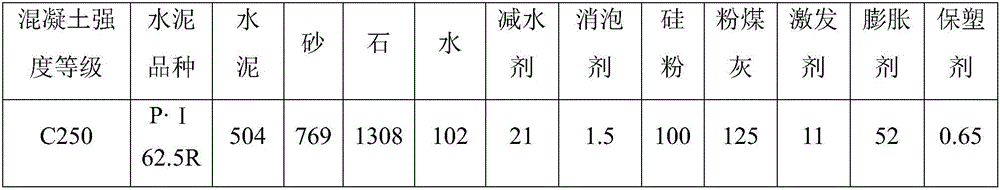

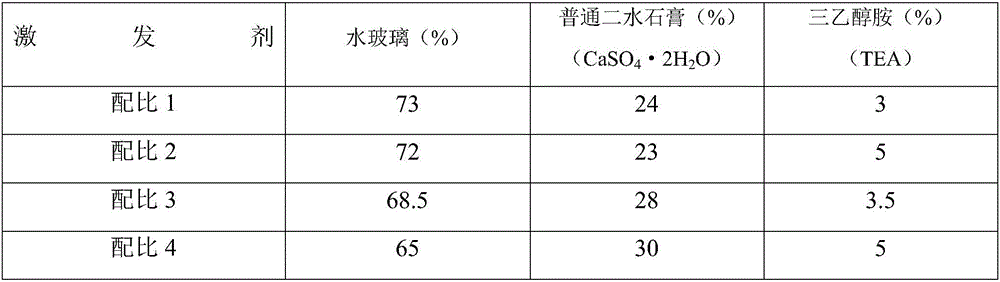

Concrete for steel reinforced concrete composite structure C250 strength grade

InactiveCN105777017AImprove workabilityImprove volume stabilityStructural elementReinforced concrete

The invention discloses concrete for the steel reinforced concrete composite structure C250 strength grade. The matching ratio of cement to fine aggregate to coarse aggregate to water to water reducing agent to antifoaming agent to silica powder to coal ash to exciting agent to expanding agent to composite plastic retaining agent is 504:769:1,308:102:21:1.5:100:125:11:52:0.65. A preparing method includes the steps that the water reducing agent, the exciting agent and the composite plastic retaining agent are evenly stirred into water to obtain a mixture, and the fine aggregate and 1 / 3 of the total mixture are sequentially added into a stirring machine according to the weight ratio and stirred to be even; the coarse aggregate and 1 / 3 of the total mixture are added and stirred to be even; the cement, the expanding agent, the silica powder and the coal ash are added and stirred to be even; the antifoaming agent and the residual mixture are added, and the mixture is stirred and discharged. By means of the concrete, the bonding performance between structural steel and the concrete can be remarkably improved under the natural state, the mechanical performance and the cooperative work performance of the steel and the concrete are effectively developed, the carrying capacity, the use performance and the durability of a structural element are greatly improved, and the concrete has the good high volume stability and the good economy.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

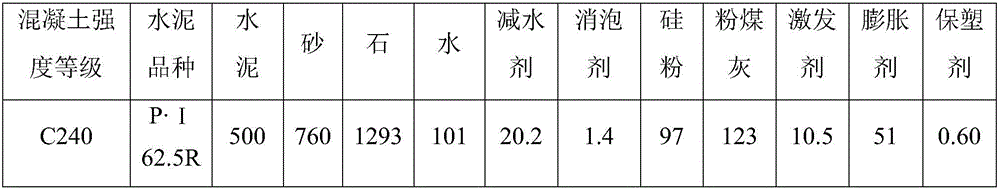

Concrete having strength grade of C240 and used for steel reinforced concrete combined structure

InactiveCN105906258AImprove workabilityImproves natural bonding propertiesCement mixing apparatusReinforced concreteStructural element

The invention discloses a concrete having a strength grade of C240 and used for a steel reinforced concrete combined structure. The concrete is prepared from cement, fine aggregate, crude aggregate, water, a water reducer, an antifoaming agent, silicon powder, fly ash, an exciting agent, an expanding agent and a composite plasticity-maintaining agent in a ratio of 500: 760: 1293: 101: 20.2: 1.4: 97: 123: 10.5: 51: 0.60. The preparation method comprises the following steps: uniformly mixing the water reducer, the exciting agent and the composite plasticity-maintaining agent with water so as to obtain a mixture, successively adding the fine aggregate and one third of the mixture into a mixer according to weight proportion and carrying out uniform mixing; adding the crude aggregate and another one third of the mixture and carrying out uniform mixing; adding the cement, expanding agent, silicon ash and fly ash and carrying out uniform mixing; and adding the antifoaming agent and the residual mixture and carrying out stirring and discharging. The concrete prepared in the invention can substantially improve bonding between section steel and concrete in a natural state, gives full play to respective mechanical properties and mutual cooperation performance of the section steel and concrete, greatly improves the bearing capability, usage performance and endurance of a structural element, and has high volume stability and economic performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete with strength grade of C90 for section steel concrete composite structure

InactiveCN101195531AIncreased durabilityHigh Strength and DurabilitySolid waste managementSuperplasticizerMechanical property

The invention discloses a concrete with strength grade of C90 for composite structure of steel reinforced concrete. Mixed proportion of the concrete is that cement: coarse: aggregate: fine aggregate: water: effective water reducer: silica fume: fly ash is 450:493:1207:150:12:60:90. Component unit is Kg / m3. The concrete is in good mechanical properties (comprising strength, plastic and bond behavior between section steel and concrete), excellent in working performance, good in durability and relatively lower in cost, and is suitable for the composite structure of steel reinforced concrete. The use of the concrete reduces construction procedures, saves steel, improves construction efficiency and has remarkable economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

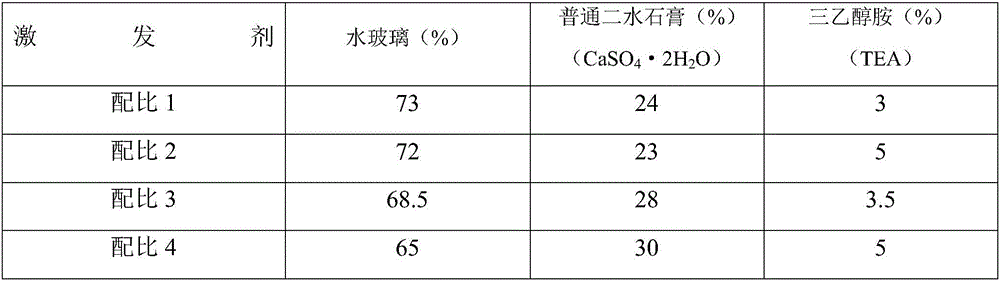

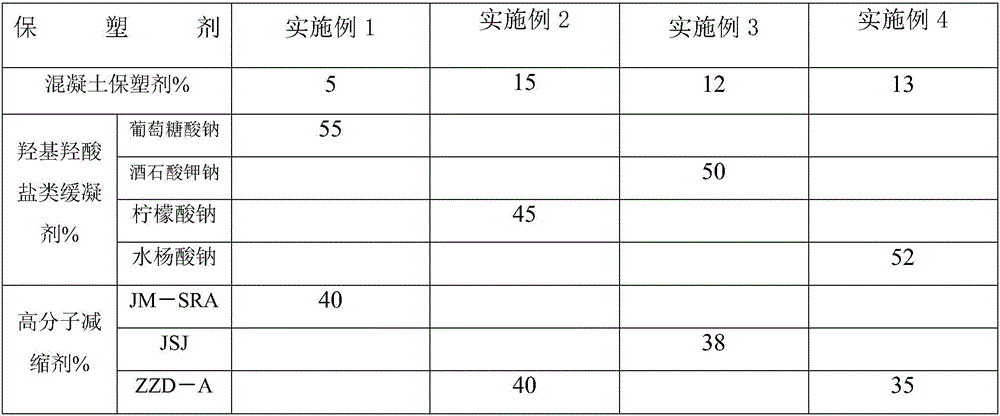

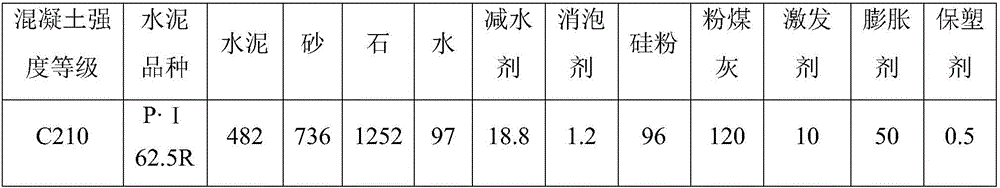

C210-strength-level concrete for steel reinforced concrete composite structures

The invention discloses a C210-strength-level concrete for steel reinforced concrete composite structures. The concrete is composed of 482 parts of cement, 736 parts of fine aggregate, 1252 parts of coarse aggregate, 97 parts of water, 18.8 parts of high-performance water reducing agent, 1.2 parts of defoaming agent, 96 parts of silicon powder, 120 parts of fly ash, 10 parts of excitant, 50 parts of excitant and 0.50 part of composite plastic retaining agent. The preparation method comprises the following steps: uniformly mixing the water reducing agent, excitant and composite plastic retaining agent in the water to obtain a mixture, and sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to the weight ratio; adding coarse aggregate and 1 / 3 of the mixture, and uniformly mixing; adding the cement, expanding agent, silica fume and fly ash, and uniformly mixing; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can obviously improve the bonding property between the steel bar and concrete in a natural state, effectively displays the respective mechanical properties and synergic working properties of the steel and concrete, greatly enhances the carrying capacity, service performance and durability of the structural member, and has high volume stability and favorable economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Heat-preserving and fire-proof composite plate with light weight and producing method thereof

InactiveCN102155070BImprove fire resistanceIncreased durabilityRoof covering using slabs/sheetsRoof toolsFiberSurface layer

The invention relates to a heat-preserving and fire-proof composite plate with light weight and a producing method thereof; specifically, the method comprises the following steps: integrally welding a steel side frame, a steel truss and two layers of steel wire nets into a steel framework, and placing the formed steel framework in a mould; blending and mixing quick-hardened sulfate aluminum cement and coal ash, adding water and a foaming agent, and adding admixture and continuously mixing uniformly if necessary; pouring the obtained mixture into the mould with the steel framework to form a core plate in an injection molding manner; after the core plate is solidified, paving a layer of fiber net cloth on the surface of the core plate, and forming a cement surface layer on the fiber net cloth to obtain the composite plate of the invention. The composite plate has the excellent performances of light weight, heat preservation, fire resistance, shock resistance, weight bearing and the like, and can be widely used as a roof plate, a net frame plate, a floor plate, and the like.

Owner:河北中体建筑工程有限公司

Concrete with strength grade of C70 for section steel concrete composite structure

InactiveCN101195530BImprove adhesionWork well togetherSolid waste managementSuperplasticizerWater reducer

The invention discloses a concrete with strength grade of C70 for composite structure of steel reinforced concrete. Mixed proportion of the concrete is that cement: coarse: aggregate: fine aggregate: water: effective water reducer: silica fume: fly ash is 400:576:1224:148:8:30:120. Component unit is Kg / m3. The concrete is in good mechanical properties (comprising strength, plastic and bond behavior between section steel and concrete), excellent in working performance, good in durability and relatively lower in cost, and is suitable for the composite structure of steel reinforced concrete. Theuse of the concrete reduces construction procedures, saves steel, improves construction efficiency and has remarkable economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

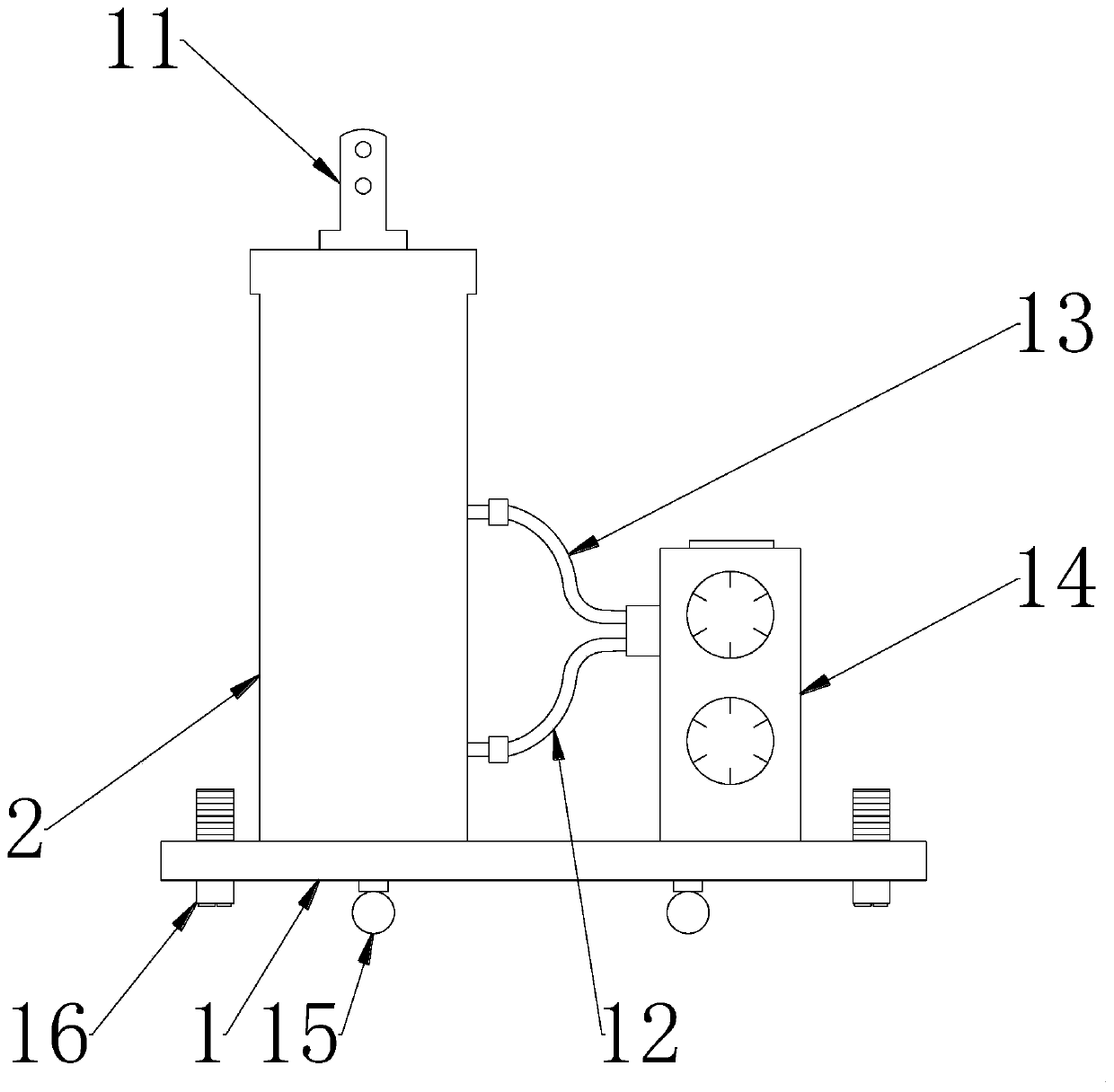

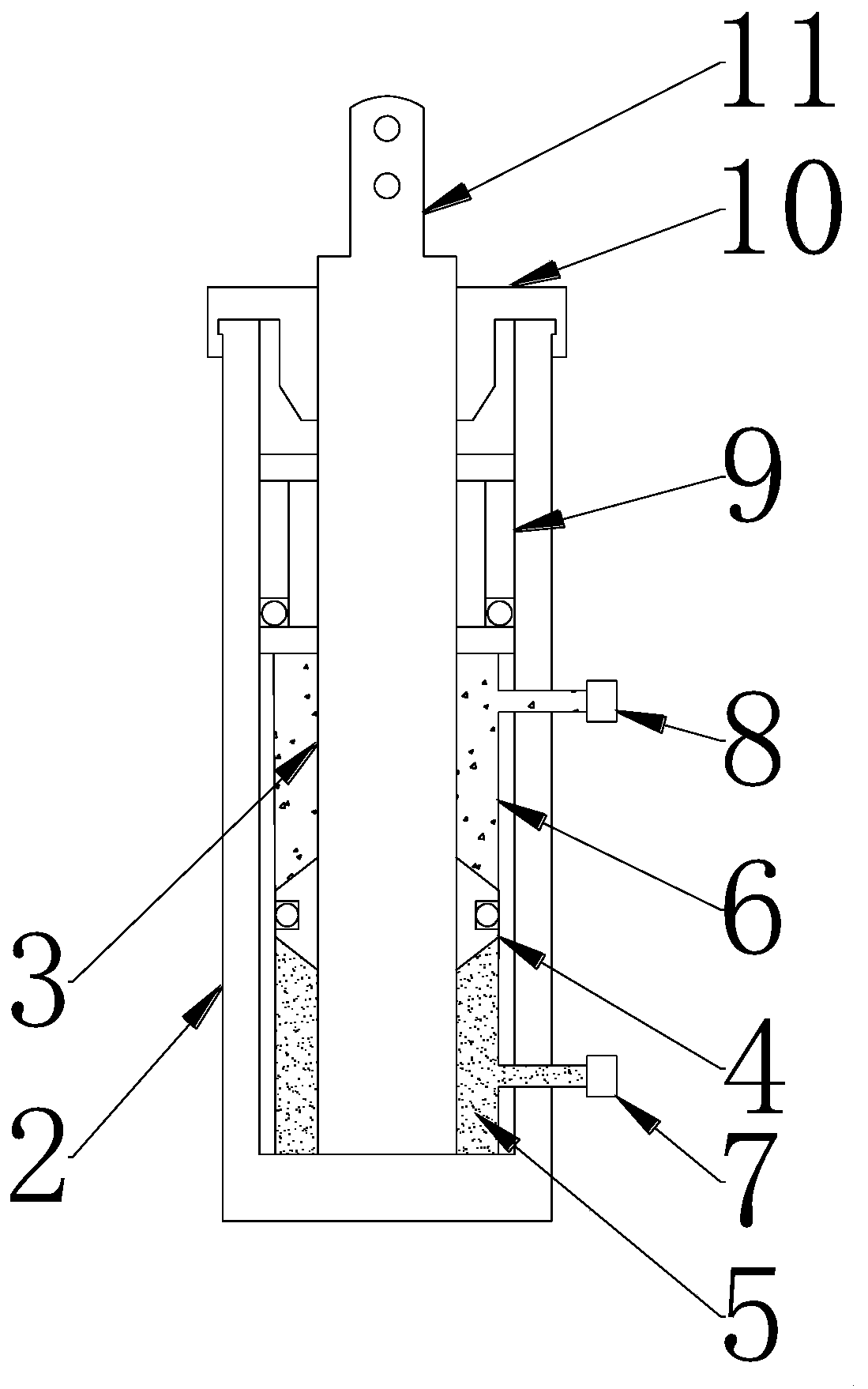

Hydraulic vibration device

InactiveCN110714955AIncreased durabilityHigh strength and durabilityPortable framesFluid-pressure actuator componentsEngineeringCylinder block

The invention discloses a hydraulic vibration device. The hydraulic vibration device comprises a base, wherein a cylinder body is arranged on the left side of the top end of the base; a piston rod isarranged in the middle of the interior of the cylinder body; a piston is arranged in the middle of the piston rod; a lower cavity is formed in the lower end of the piston in the cylinder body; an upper cavity is formed in the upper end of the piston in the cylinder body; a lower cavity communication port and an upper cavity communication port which communicate with the outside are formed in the right sides of the lower cavity and the upper cavity respectively; a guide shaft sleeve is arranged at the upper end of the upper cavity; and an end cover is arranged at the top end of the cylinder bodyaround the piston rod. The hydraulic vibration device is simple in structure, the overall structural performance of the interior of the device is guaranteed by arranging the cylinder body made of high-strength aluminum materials, the aluminum materials have good hardness and structural strength, so that the durability of the cylinder body is higher, and the service life of the device is prolonged. A sealing ring in the piston is arranged, so that the sealing performance of the device is guaranteed, the movement stroke of the piston is more accurate, and the transmission efficiency of the device is higher.

Owner:江苏昇顺机电有限公司

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407BIncreased durabilityHigh strength and durabilityReinforced concreteCarrying capacity

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete with strength grade of C90 for section steel concrete composite structure

InactiveCN100577598CIncreased durabilityHigh strength and durabilitySolid waste managementSuperplasticizerMechanical property

The invention discloses a concrete with strength grade of C90 for composite structure of steel reinforced concrete. Mixed proportion of the concrete is that cement: coarse: aggregate: fine aggregate: water: effective water reducer: silica fume: fly ash is 450:493:1207:150:12:60:90. Component unit is Kg / m3. The concrete is in good mechanical properties (comprising strength, plastic and bond behavior between section steel and concrete), excellent in working performance, good in durability and relatively lower in cost, and is suitable for the composite structure of steel reinforced concrete. The use of the concrete reduces construction procedures, saves steel, improves construction efficiency and has remarkable economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

C190 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553459BIncreased durabilityHigh strength and durabilitySolid waste managementAggregate (composite)Plasticizer

The invention discloses a C190 strength-grade concrete for a formed steel concrete composite structure, which is composed of 466 parts of cement, 842 parts of fine aggregate, 1065 parts of coarse aggregate, 97 parts of water, 19 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 75 parts of silicon powder, 119 parts of expanding agent, 7 parts of activator and 38 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

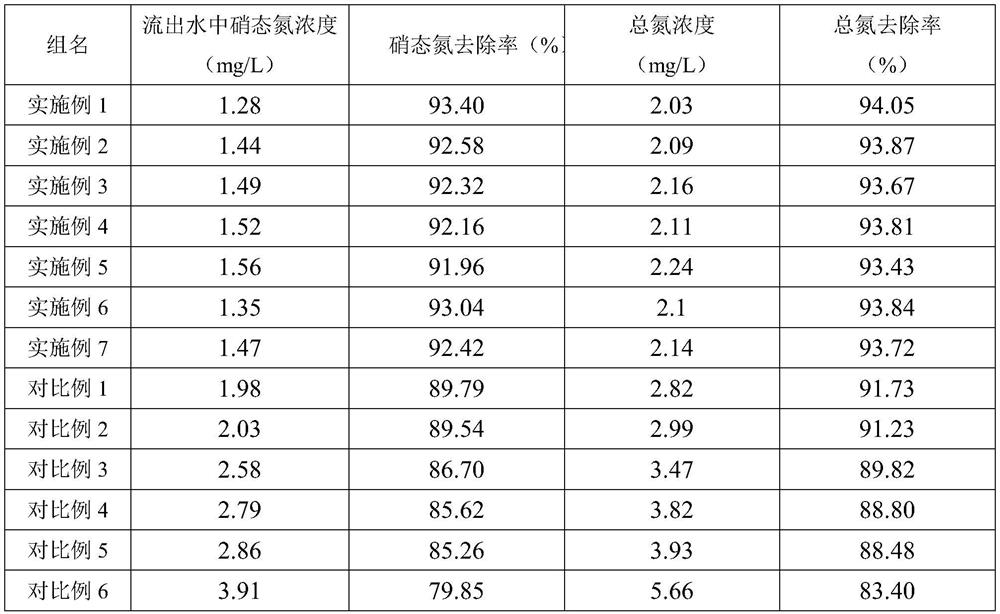

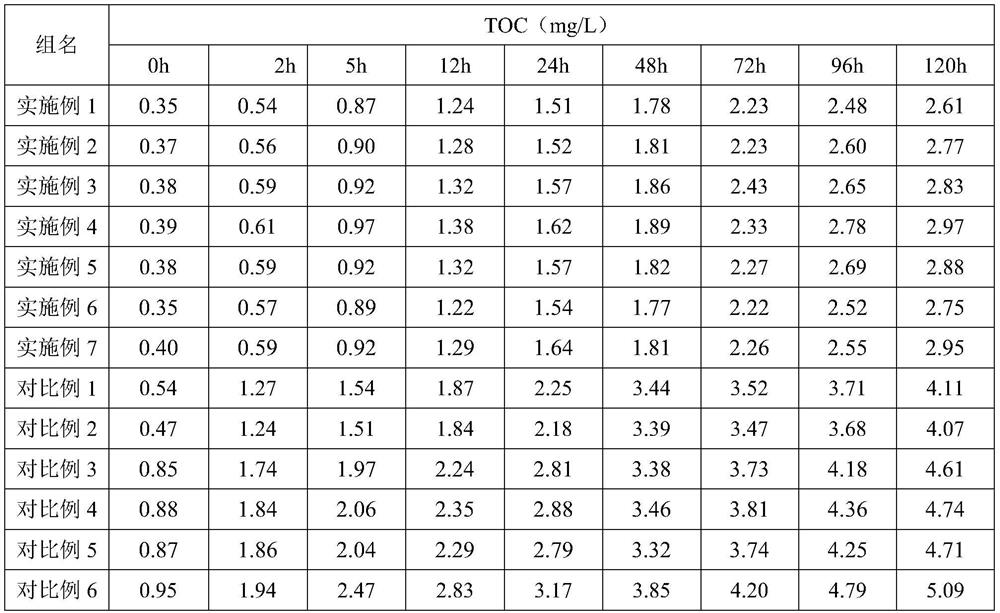

Preparation method of microbial carrier taking sludge as raw material

ActiveCN112897950AHigh mechanical strengthImprove compactnessSolid waste managementWater contaminantsSludgeMontmorillonite

The invention discloses a microbial carrier taking sludge as a raw material and a preparation method thereof. The microbial carrier comprises the following raw materials: dehydrated cement powder, cement, fly ash, zeolite powder, diatomite and bentonite in a weight ratio of (0.5-3): (6-10): (2-6): (3-8): (1-3): (2-4). The preparation method of the dewatered cement powder comprises the following steps: removing impurities from sludge or sludge, and performing standing and precipitating; reserving and dehydrating lower-layer settled sludge; performing drying at 95-105 DEG C until the weight is constant, and performing cooling, grinding and sieving to obtain a dewatered cement powder crude product; and finally, adding a biological enzyme solution into the dewatered cement powder crude product, performing uniform mixing and stirring, putting the mixture into a closed container, performing sealing for 15-24 hours, and obtaining the dewatered cement powder. According to the invention, the sludge or sludge in the river is treated by the biological enzyme and then is combined with the cement, the fly ash, the zeolite powder, the diatomite, the bentonite (montmorillonite) and other materials for use, so that the microbial proliferation rate of the prepared carrier is remarkably improved, and the treatment effect on total nitrogen and nitrate nitrogen in sewage is improved.

Owner:葛洲坝集团生态环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com