Method for manufacturing plastic mould of automobile door plate loudspeaker mask

A technology of plastic molds and manufacturing methods, which is applied in the field of manufacturing plastic molds for automotive door panel speaker masks, which can solve the problems of short mold life, unstable product quality, and easy flashing and burrs of products, and achieve increased strength and tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings to facilitate understanding of the present invention, but not to limit the content of the present invention.

[0056] A kind of manufacture method of automobile door panel loudspeaker mask plastic mold, its steps are as follows:

[0057] 1. Plastic part structure selection (analysis):

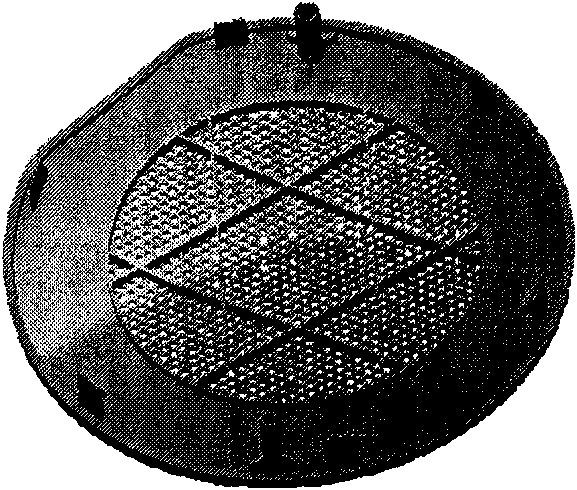

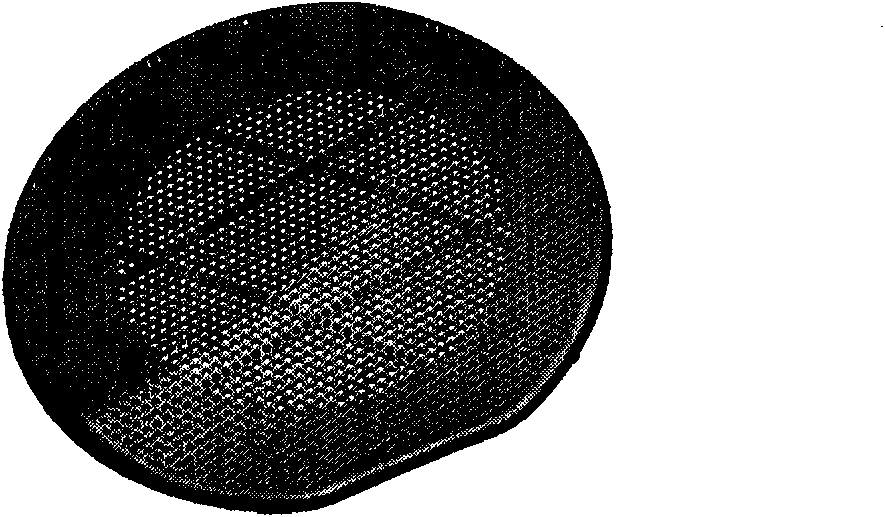

[0058] The left and right decorative parts of the car door panel speaker mask are two symmetrical plastic parts in a mirror image relationship. For the sake of beauty, the upper surface of the decorative part is a streamlined curved surface, and the other surfaces are mostly composed of curved surfaces. The lower part also has two hollow cylindrical holes for installation and positioning, six installation clips and a hexagonal reinforcing rib. The total height of the part is 30mm, the specific size For the exact data of 180*t3.0, see the digital model of the part.

[0059] The biggest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com