A kind of braiding method of temperature sensor high temperature resistant wire

A technology of temperature sensor and high temperature resistance, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve the problems of not being easy to bear the tightness of the wrapping force, and achieve the effect of improving the yield rate and reducing the wrapping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

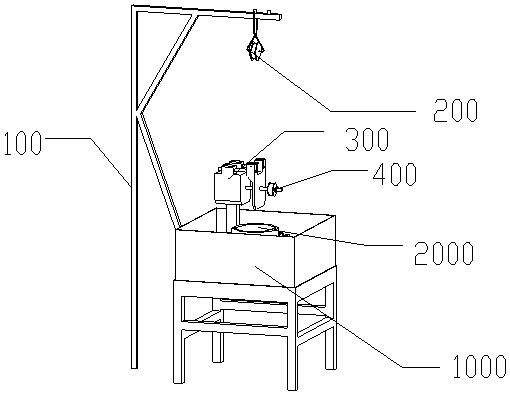

[0024] A method for braiding high temperature resistant wires for temperature sensors, which is realized by using a braiding machine 1000 in conjunction with a pulley frame 100, a gear reduction synchronous assembly 300, a synchronous wheel 400, and a braiding jig. Specifically, as image 3 As shown, the braiding machine 1000 adopts the CobraBraiding Machinery 32-450X1 braiding machine, and the braiding is relatively stable. The pulley frame 100 is erected behind the braiding machine, and the pulley 200 on the pulley frame 100 is set on the upper side of the braiding area 2000 of the braiding machine 1000, and the gear is decelerated. The synchronous assembly 300 is connected with the knitting machine 1000 on the side, and the synchronous wheel 400 is connected with the gear reduction synchronous assembly 300. Specifically, the gear reduction synchronous assembly 300 is used to match the pay-off speed and the weaving speed of the line roller of the knitting machine 1000, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com