Mold formed by buckle core pulling mechanism

A technology of core-pulling mechanism and buckle, which is applied in the field of molding molds for plastic products, can solve problems such as easy-to-break mold structure requirements, difficulty in ensuring product size, and mold instability, so as to reduce defective rate, improve production efficiency, and have a simple structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

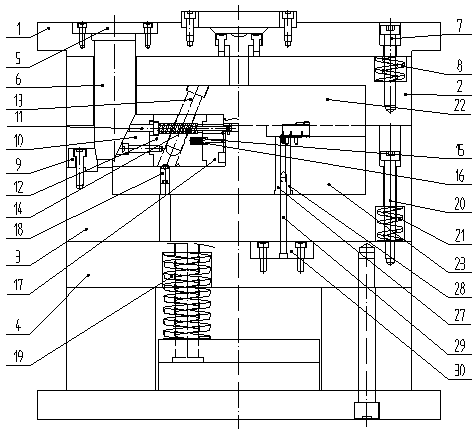

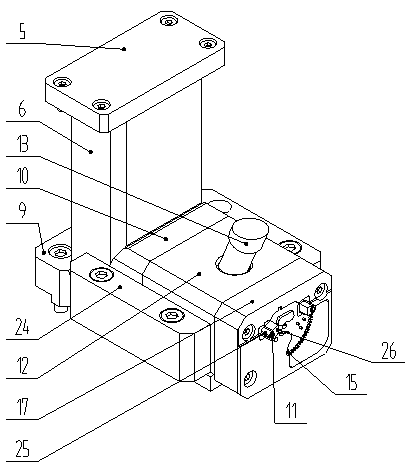

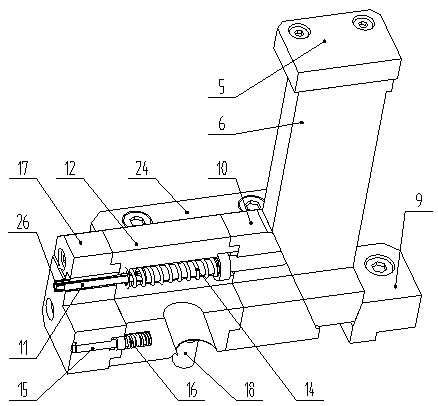

[0019] Specific embodiments of the invention will be described in detail below in conjunction with technical text and accompanying drawings.

[0020] When assembling the mould, the wedge 6 is fitted in the square hole processed by the base plate of the fixed mold 1 and is limited by the hanging table. The wedge pressure plate 5 is installed in the cavity processed by the base plate 1 of the fixed mold. It is locked and fixed, and the inclined guide column 13 is fitted in the inclined hole processed by the fixed mold insert 22 and is limited by the hanging table. In the cavity, the bolt passes through the fixed template 2 to lock and fix the fixed mold insert 22 with it, the spring A8 is installed in the counterbore of the fixed template 2, the fixed mold bottom plate 1 is in contact with the fixed template 2, and the shoulder bolt A7 passes through Tighten the fixed mold base plate 1 and spring A8 with the fixed mold plate 2 for positioning (see figure 1 ); the spring B14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com