Patents

Literature

950results about How to "Avoid strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Herbicide resistance genes

ActiveUS8283522B2Prevent shifting or shiftingAvoid developmentBiocideSugar derivativesGlyphosateDioxygenase

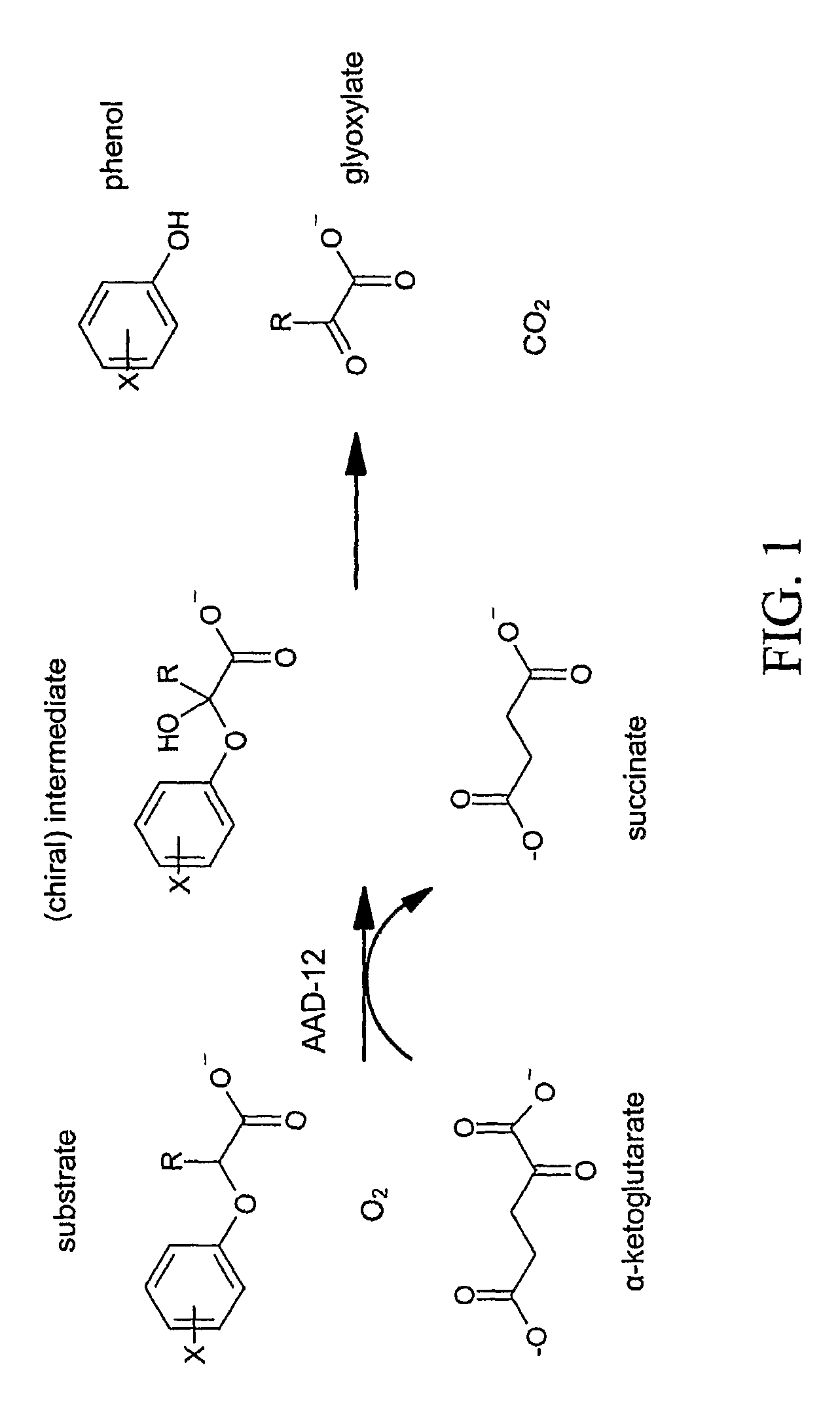

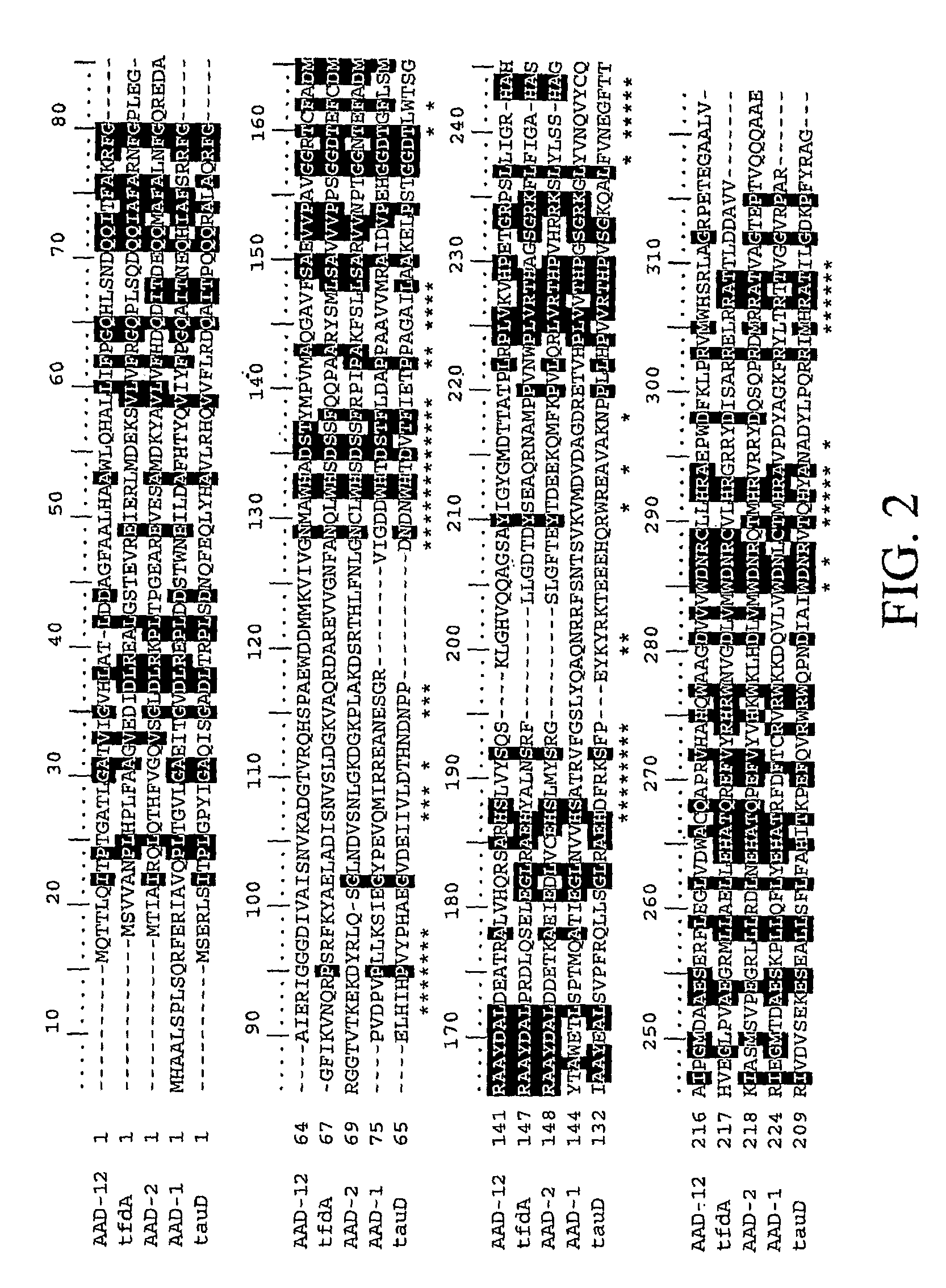

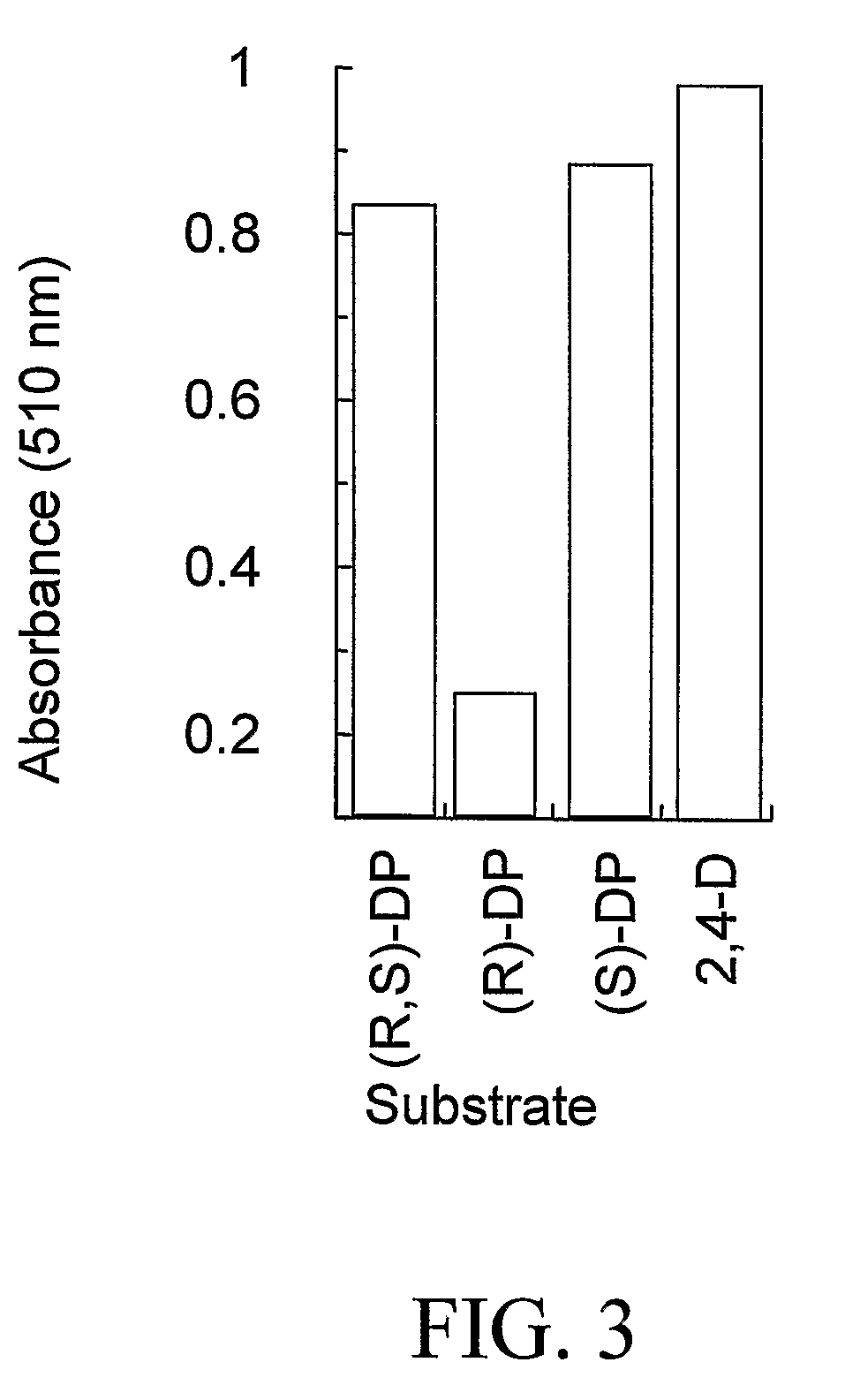

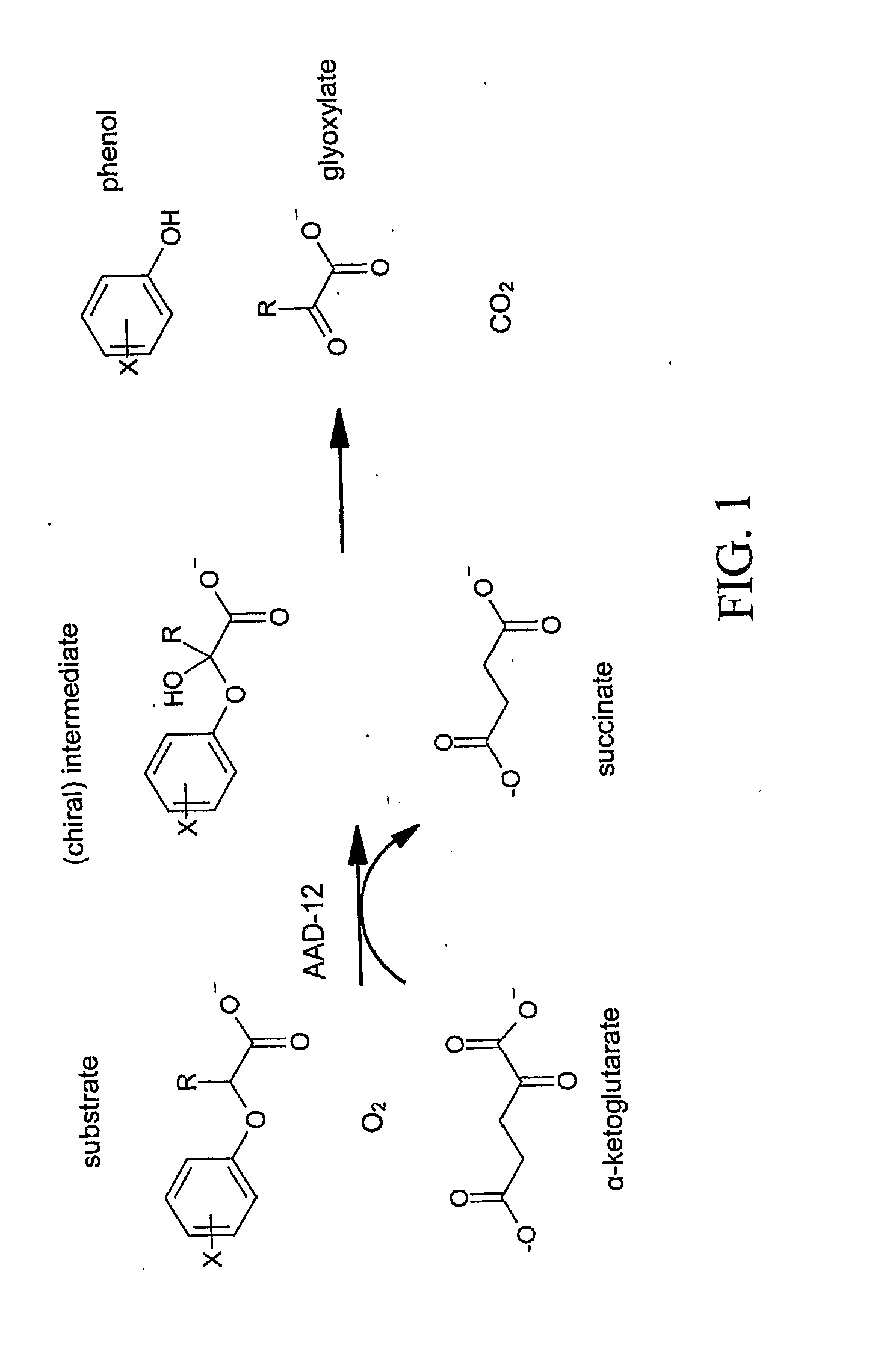

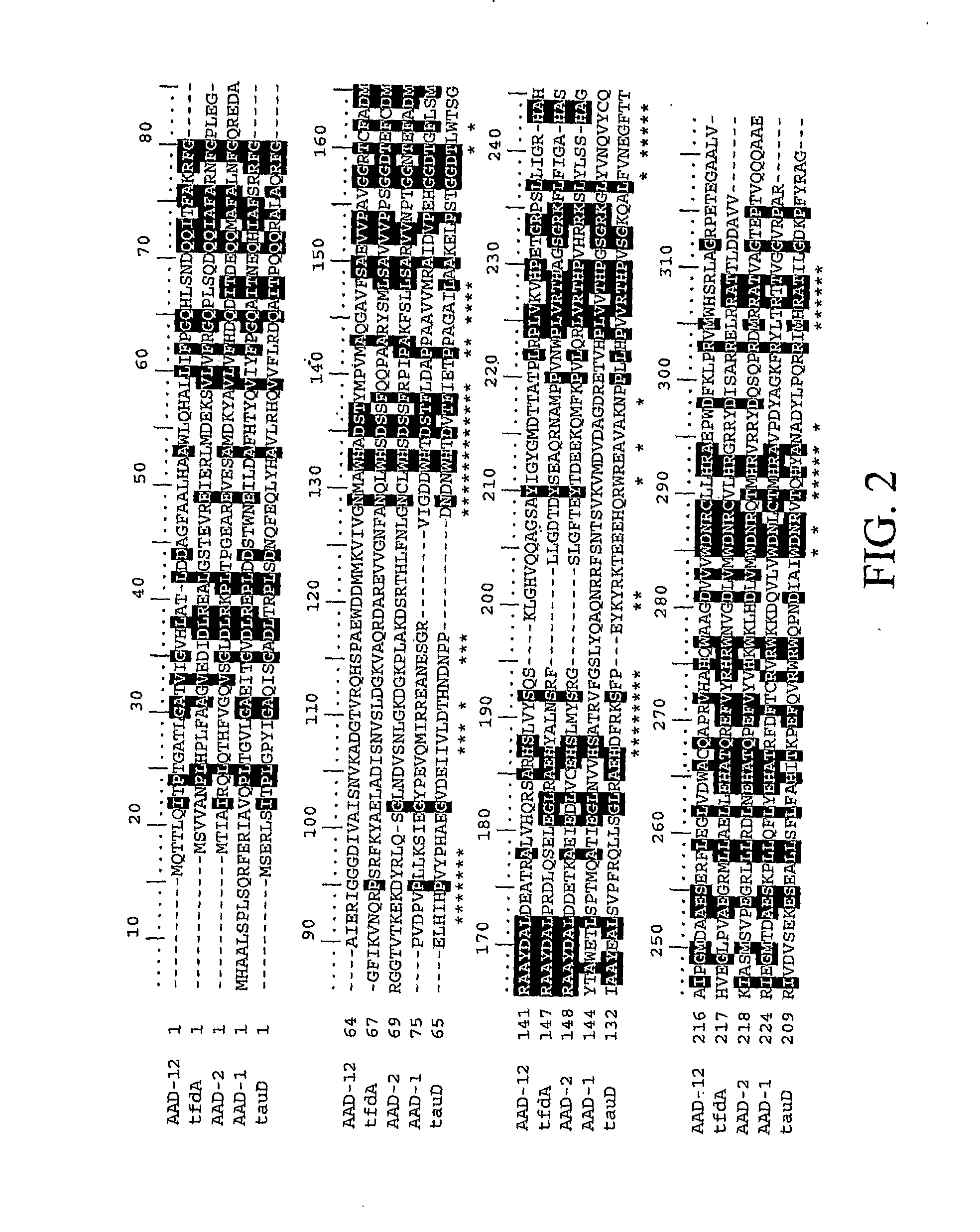

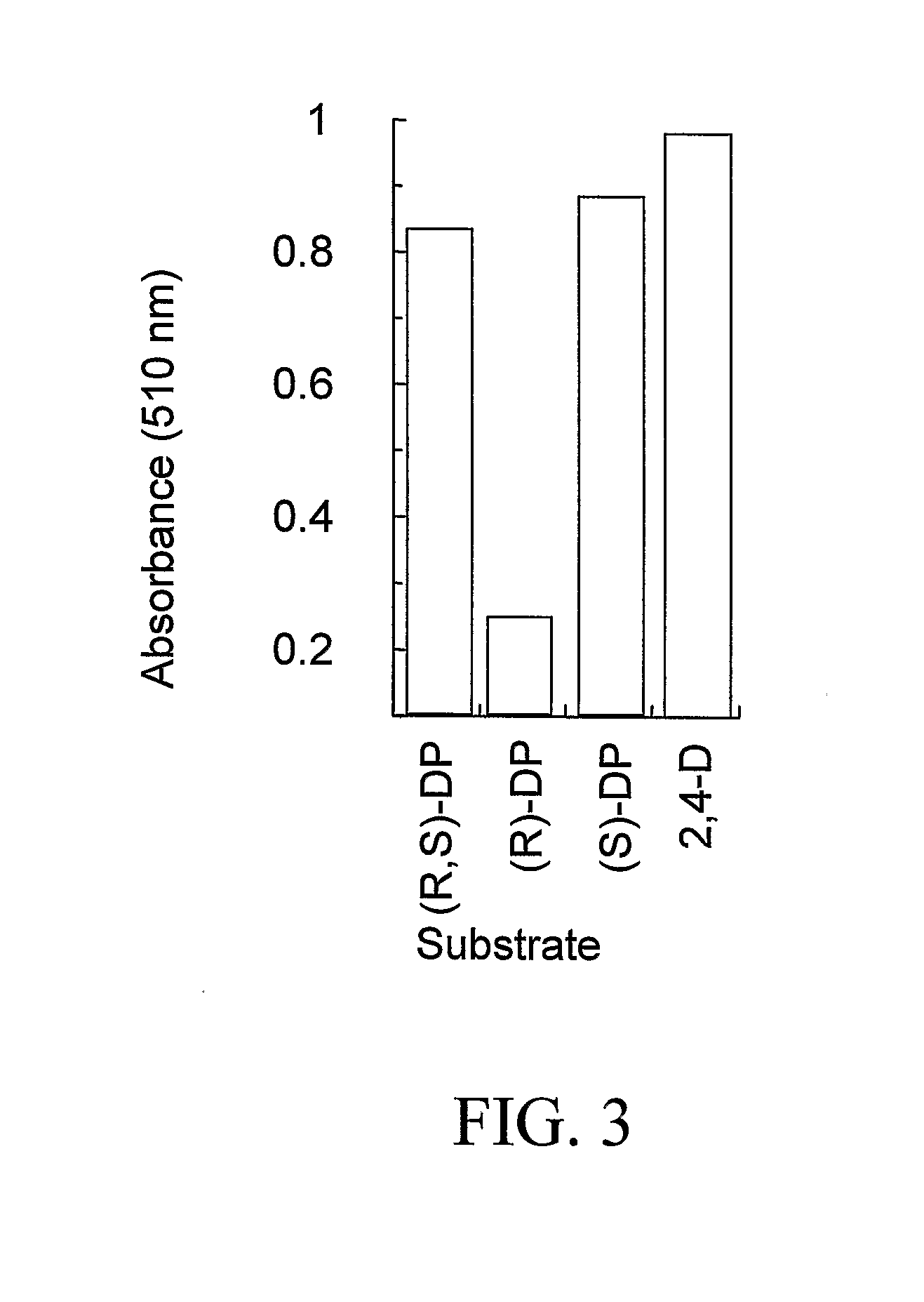

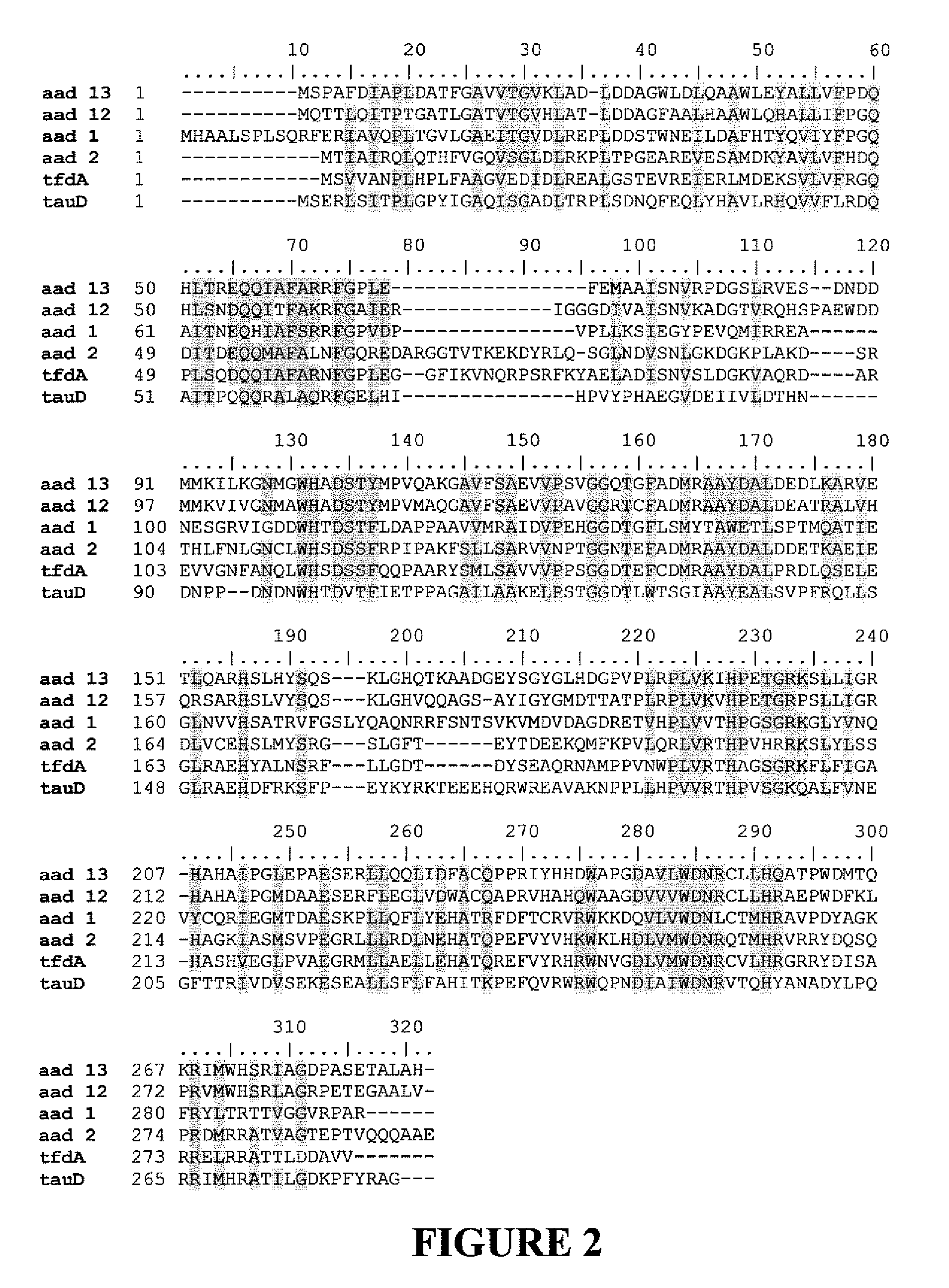

The subject invention provides novel plants that are not only resistant to 2,4-D, but also to pyridyloxyacetate herbicides. Heretofore, there was no expectation or suggestion that a plant with both of these advantageous properties could be produced by the introduction of a single gene. The subject invention also includes plants that produce one or more enzymes of the subject invention “stacked” together with one or more other herbicide resistance genes. The subject invention enables novel combinations of herbicides to be used in new ways. Furthermore, the subject invention provides novel methods of preventing the development of, and controlling, strains of weeds that are resistant to one or more herbicides such as glyphosate. The preferred enzyme and gene for use according to the subject invention are referred to herein as AAD-12 (AryloxyAlkanoate Dioxygenase). This highly novel discovery is the basis of significant herbicide tolerant crop trait and selectable marker opportunities.

Owner:CORTEVA AGRISCIENCE LLC

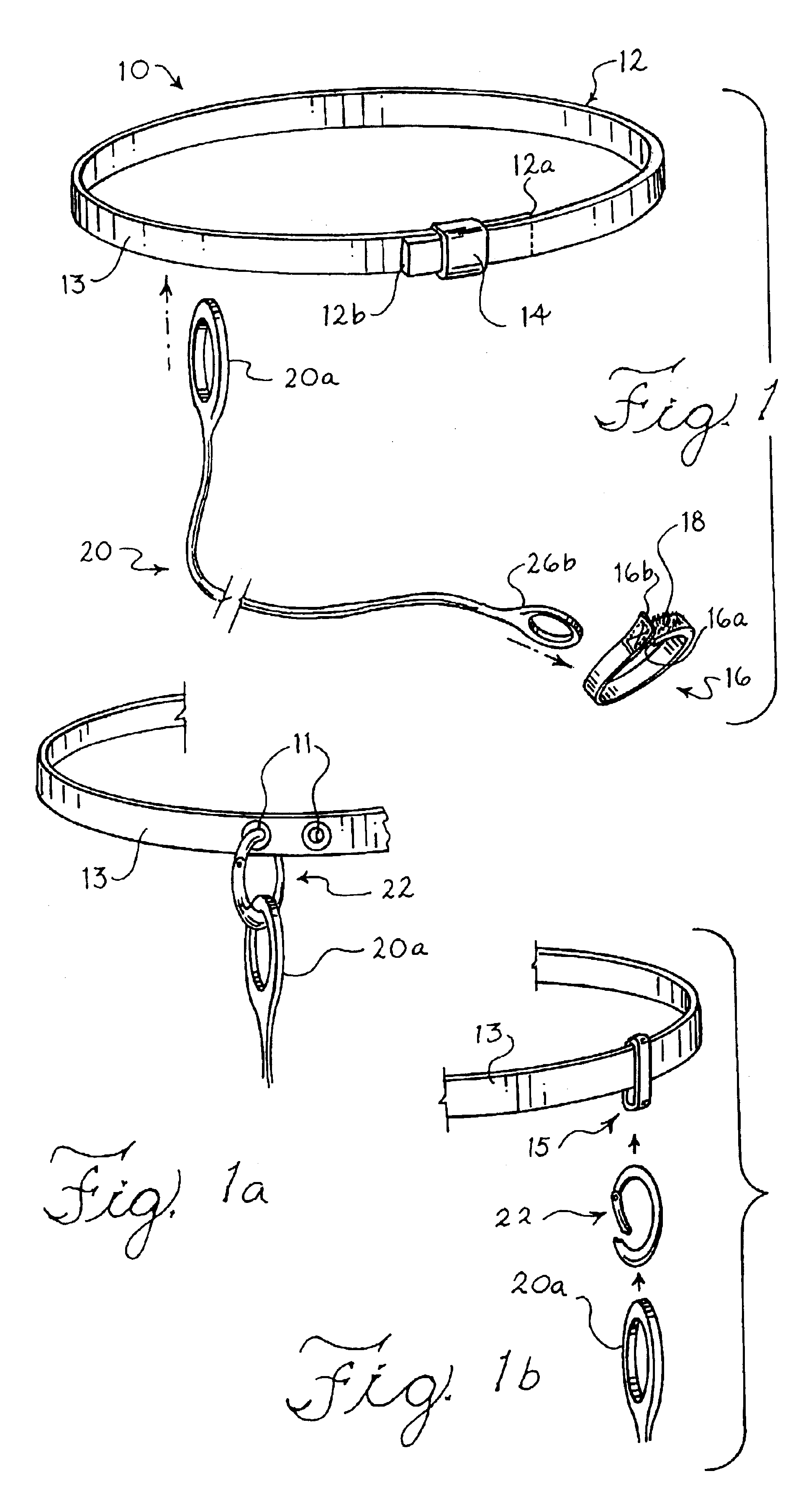

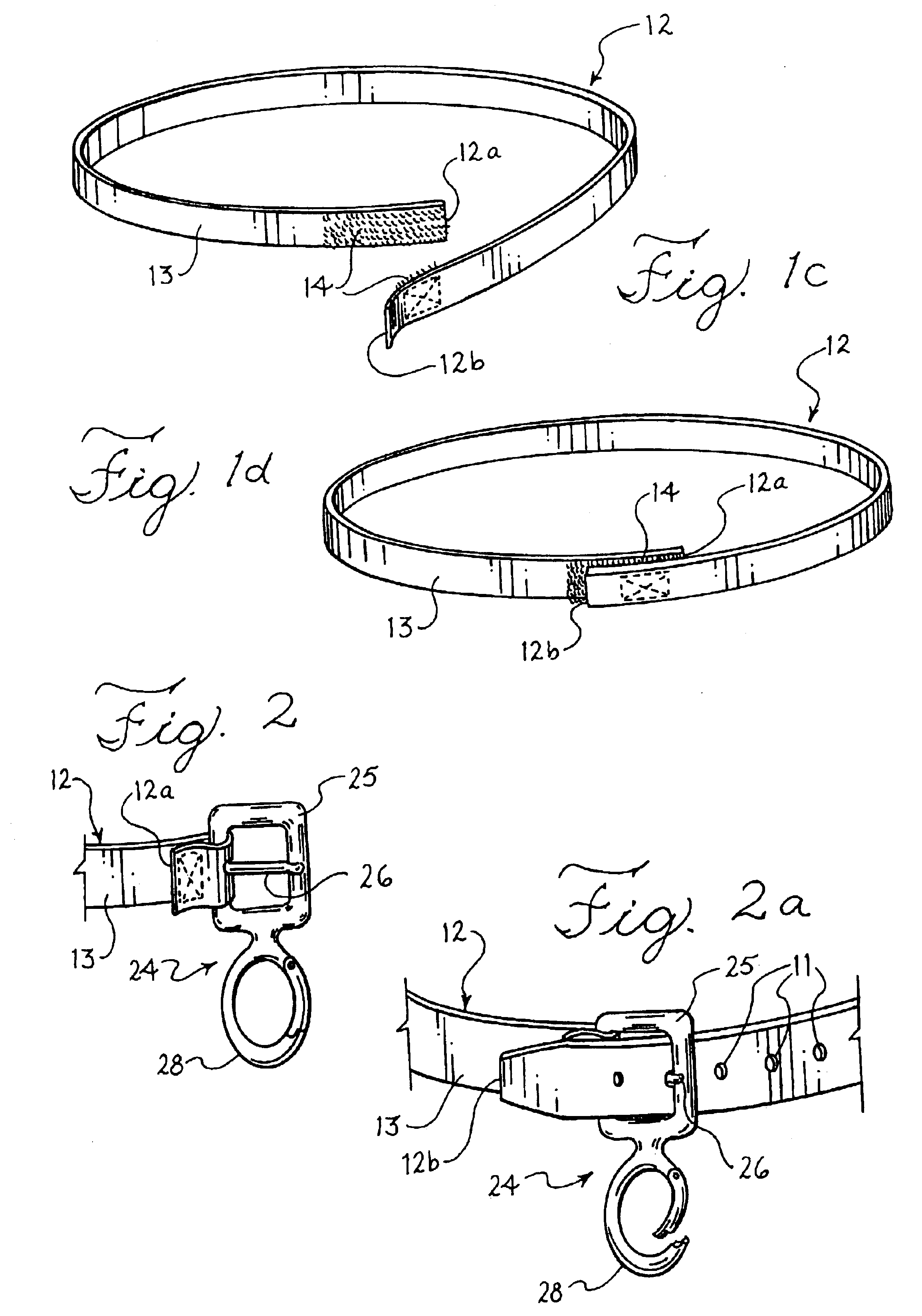

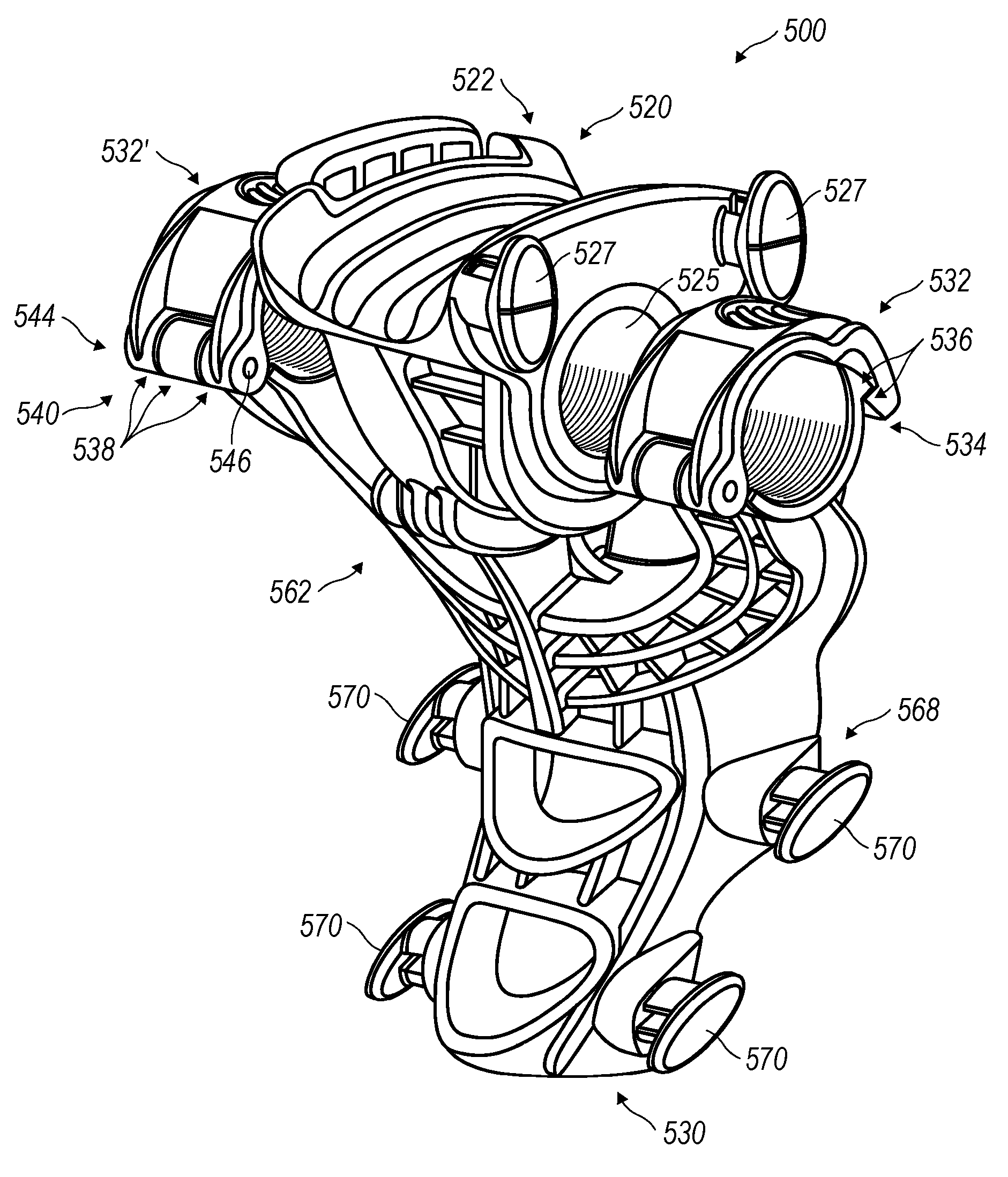

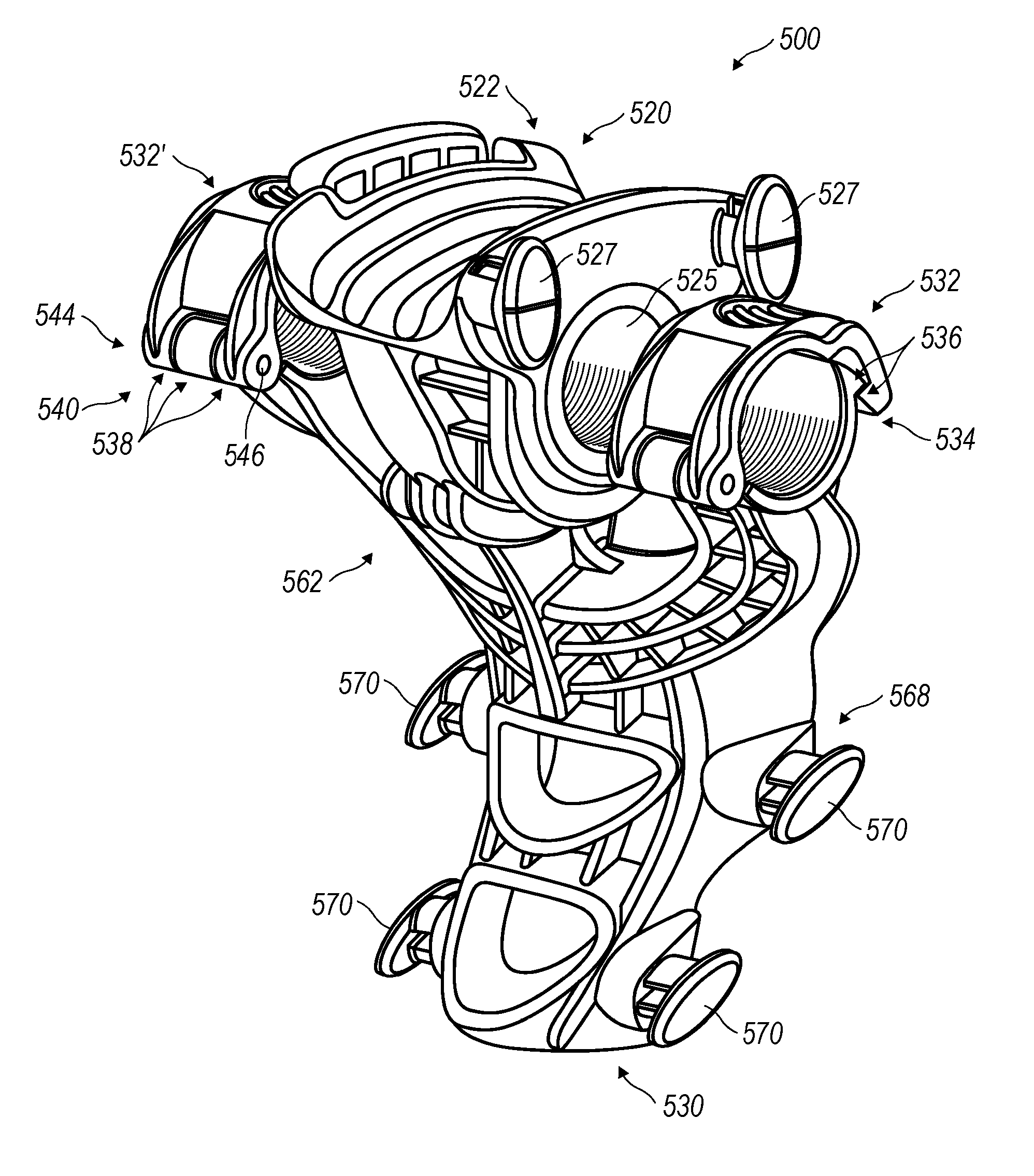

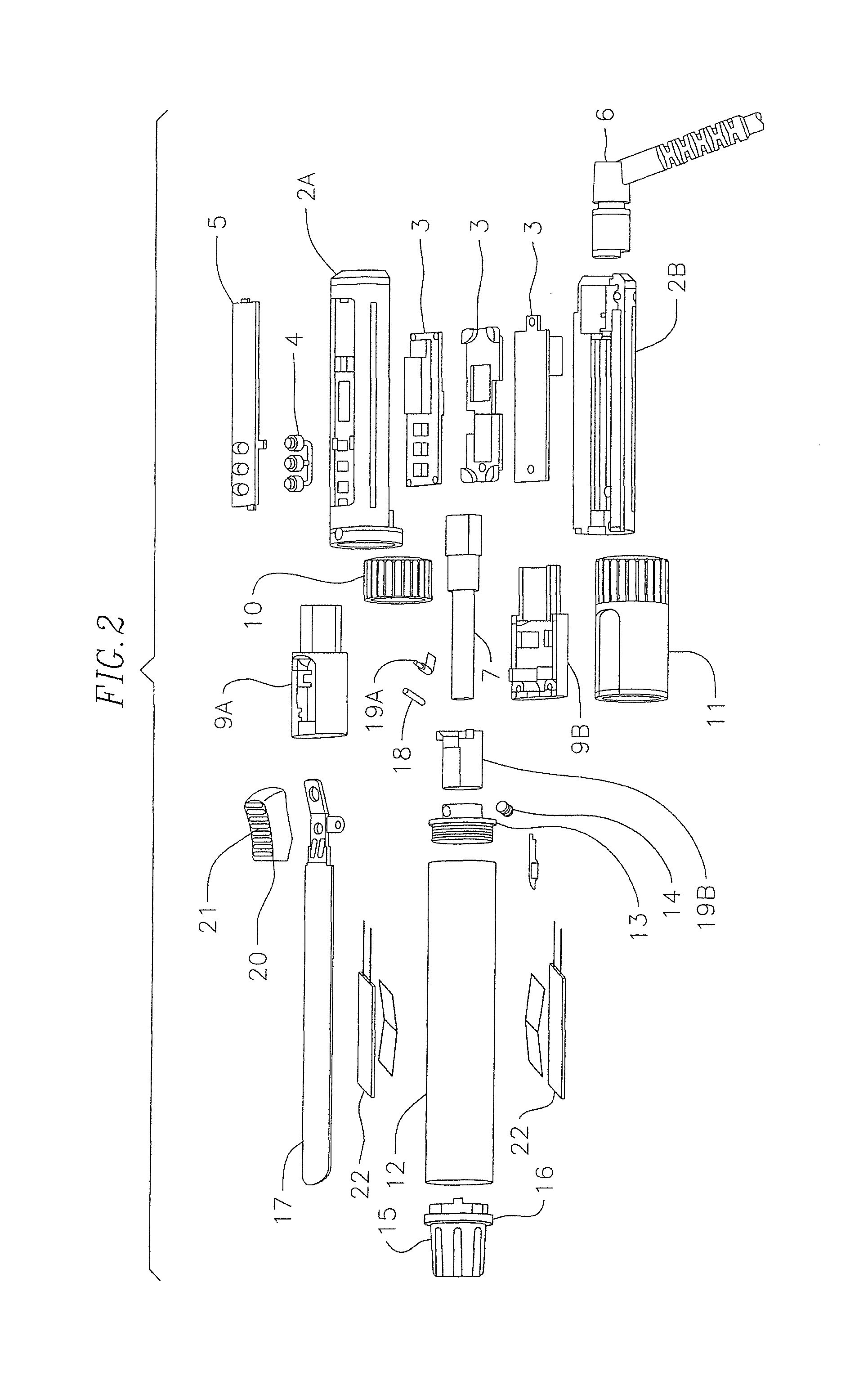

Modular resistive exercise system

InactiveUS6840894B2Easy to assembleLevel of resistive tensionResilient force resistorsElectrical resistance and conductanceResistive exercise

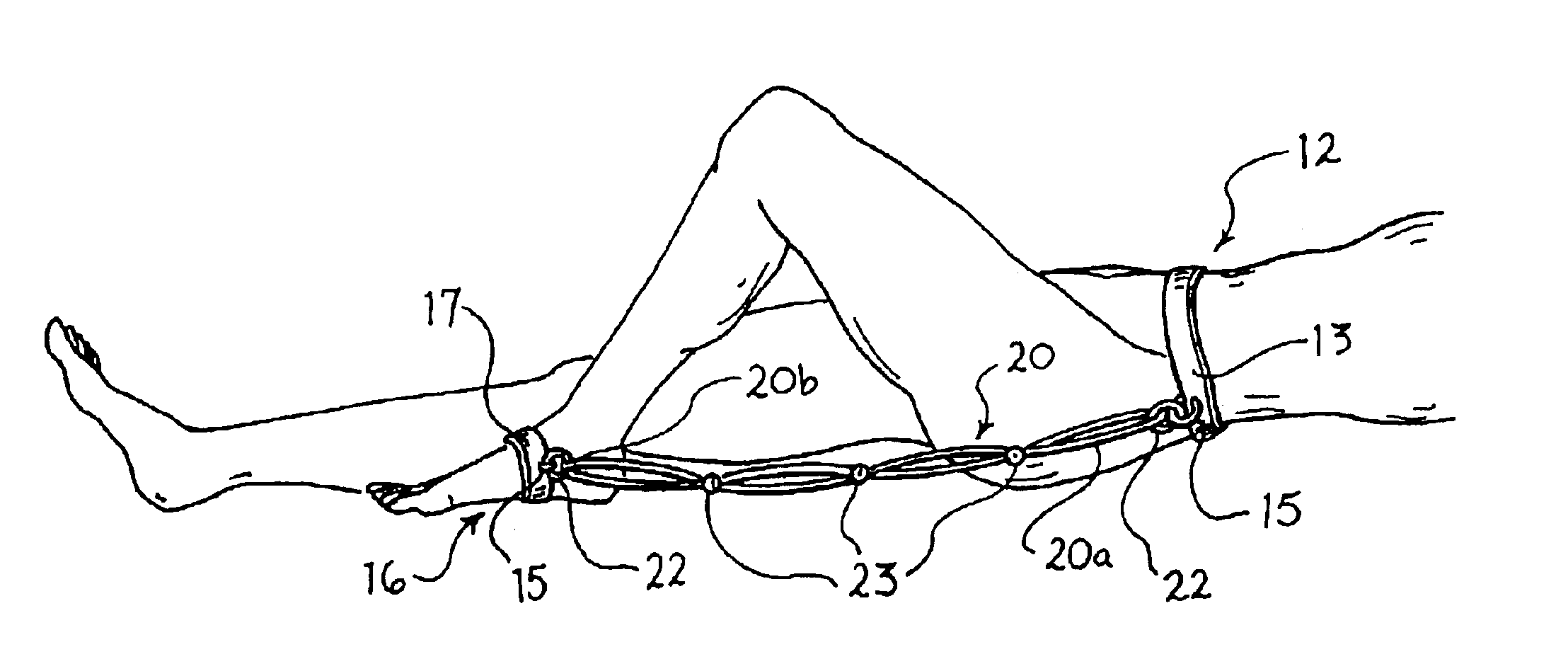

A modular, resistive, limb-muscle exercise system is disclosed comprising: (a) a torso anchoring module configured for encircling and being adjustably secured around a selected portion of a person's torso; (b) at least one limb extremity-receiving module; and (c) at least one elongate resilient module having a proximal portion being adapted for placement in operative association with module (a) and a distal portion adapted for placement in operative association with module (b), the resilient module being linearly positioned relative to the limb of the received limb extremity to provide a variable, resistive tension to the muscles of the limb associated between module (a) and module (b) during exercise of the associated limb. A kit embodiment and exercise method is also disclosed. The modular resistive limb-muscle exercise system is particularly suitable for use by physically challenged persons.

Owner:LERNER LOUIS L

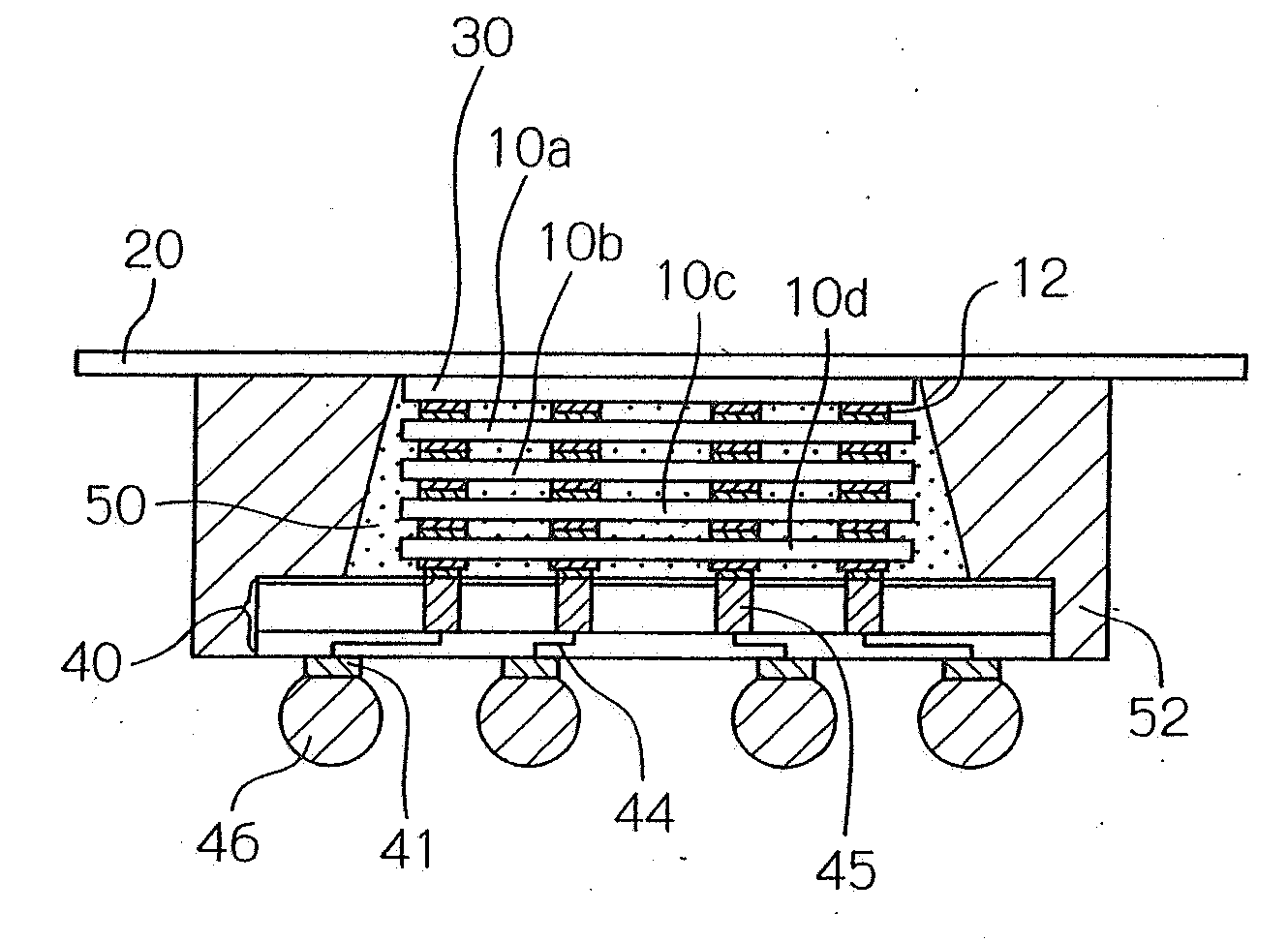

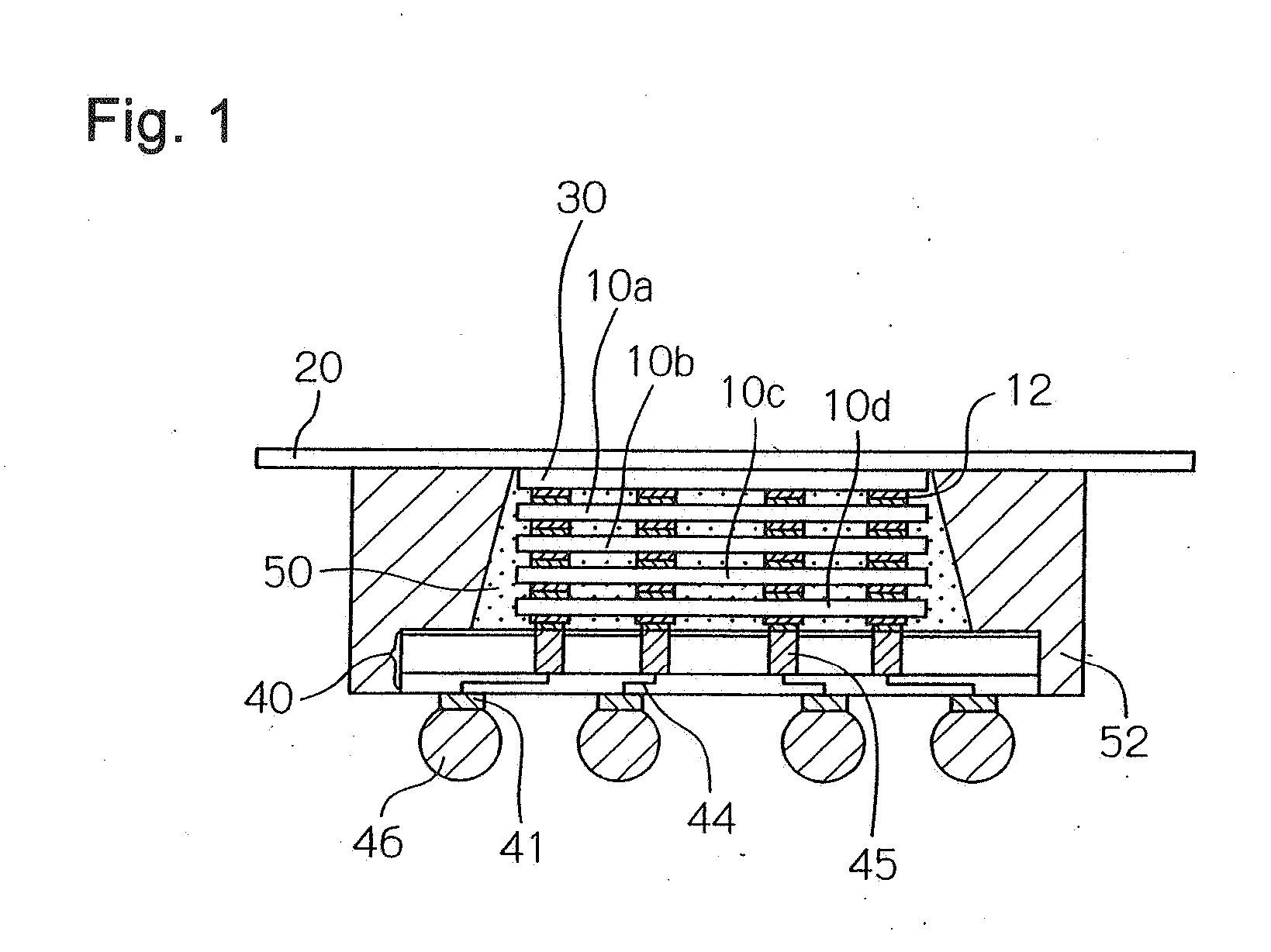

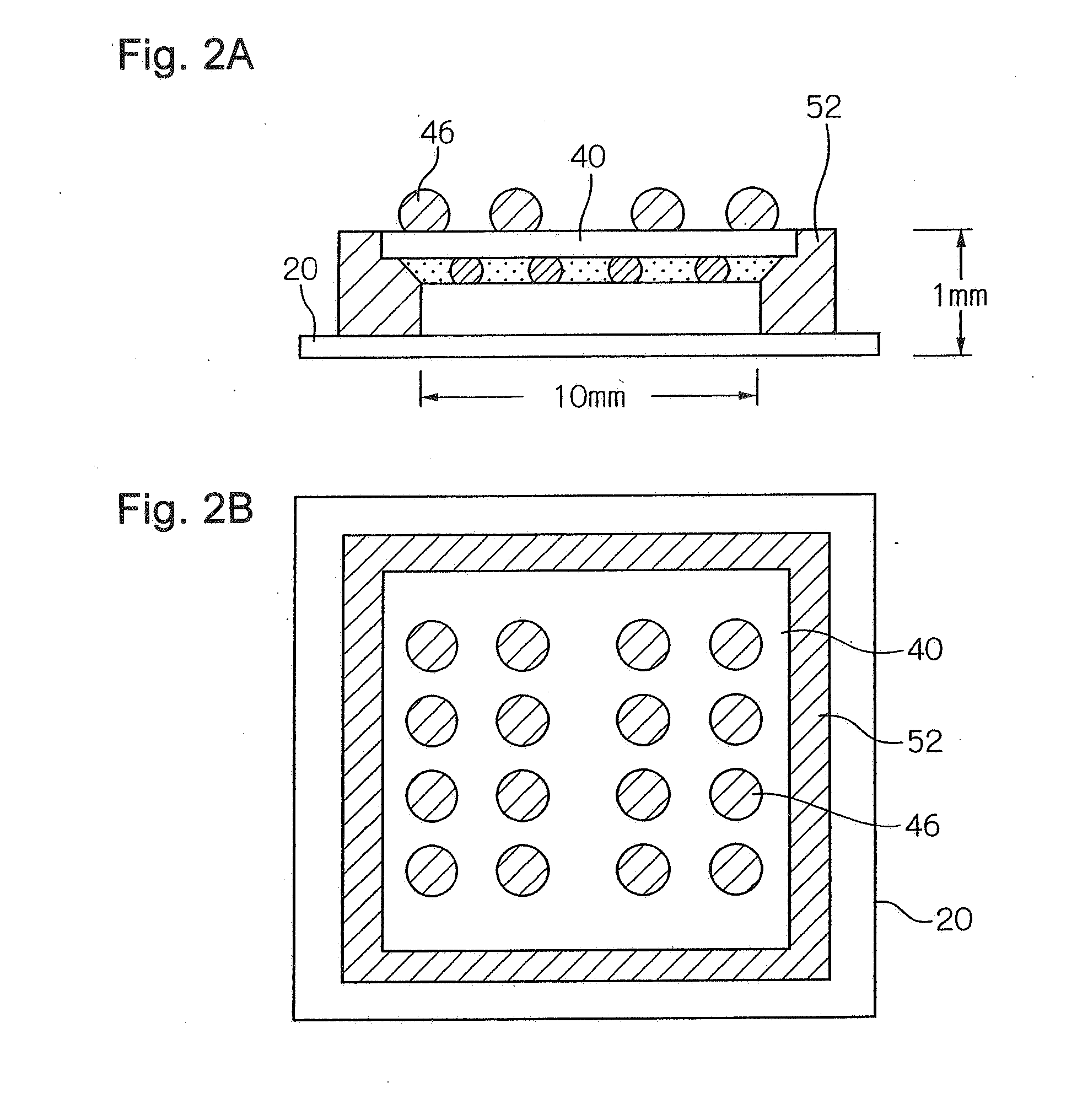

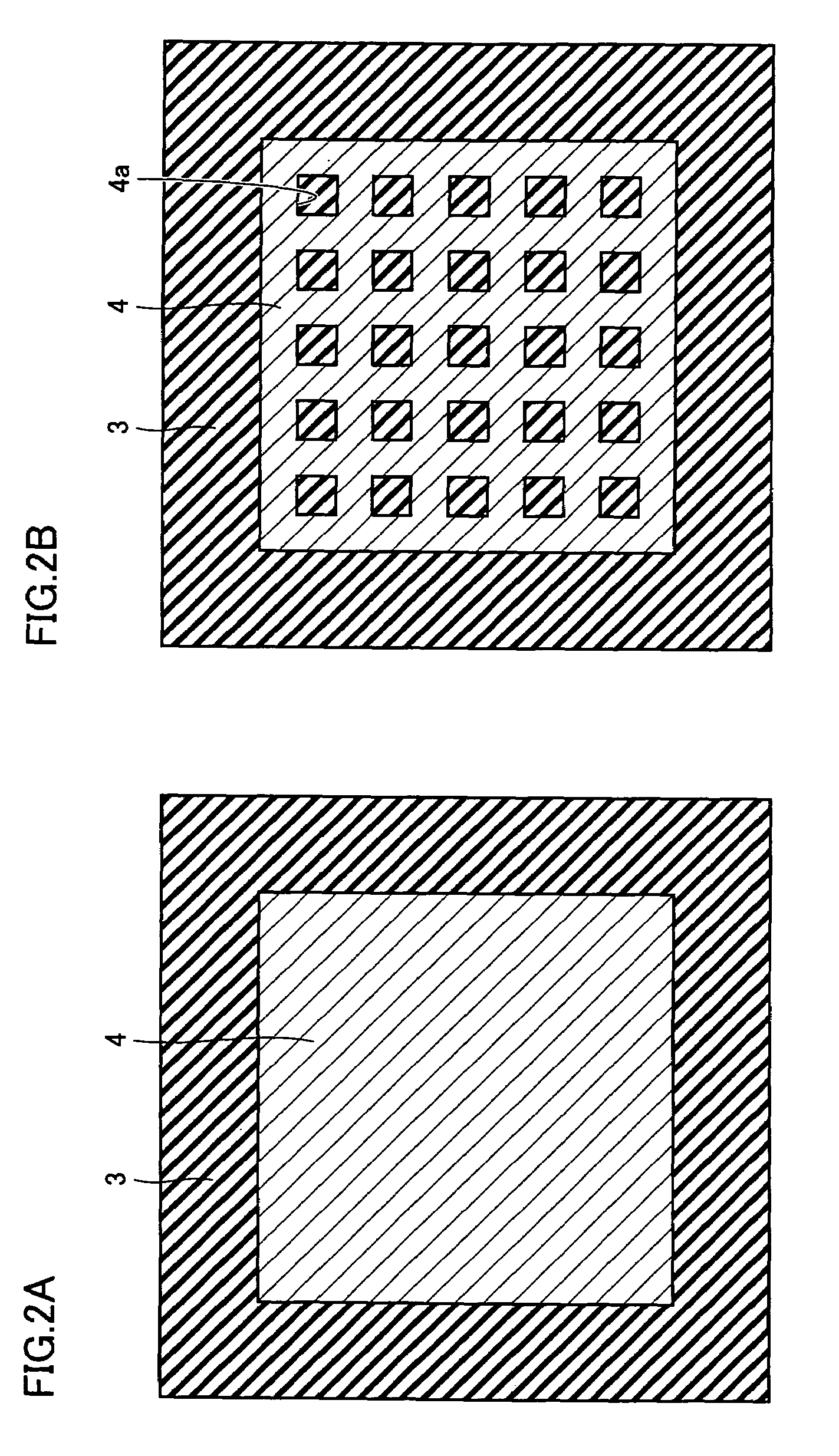

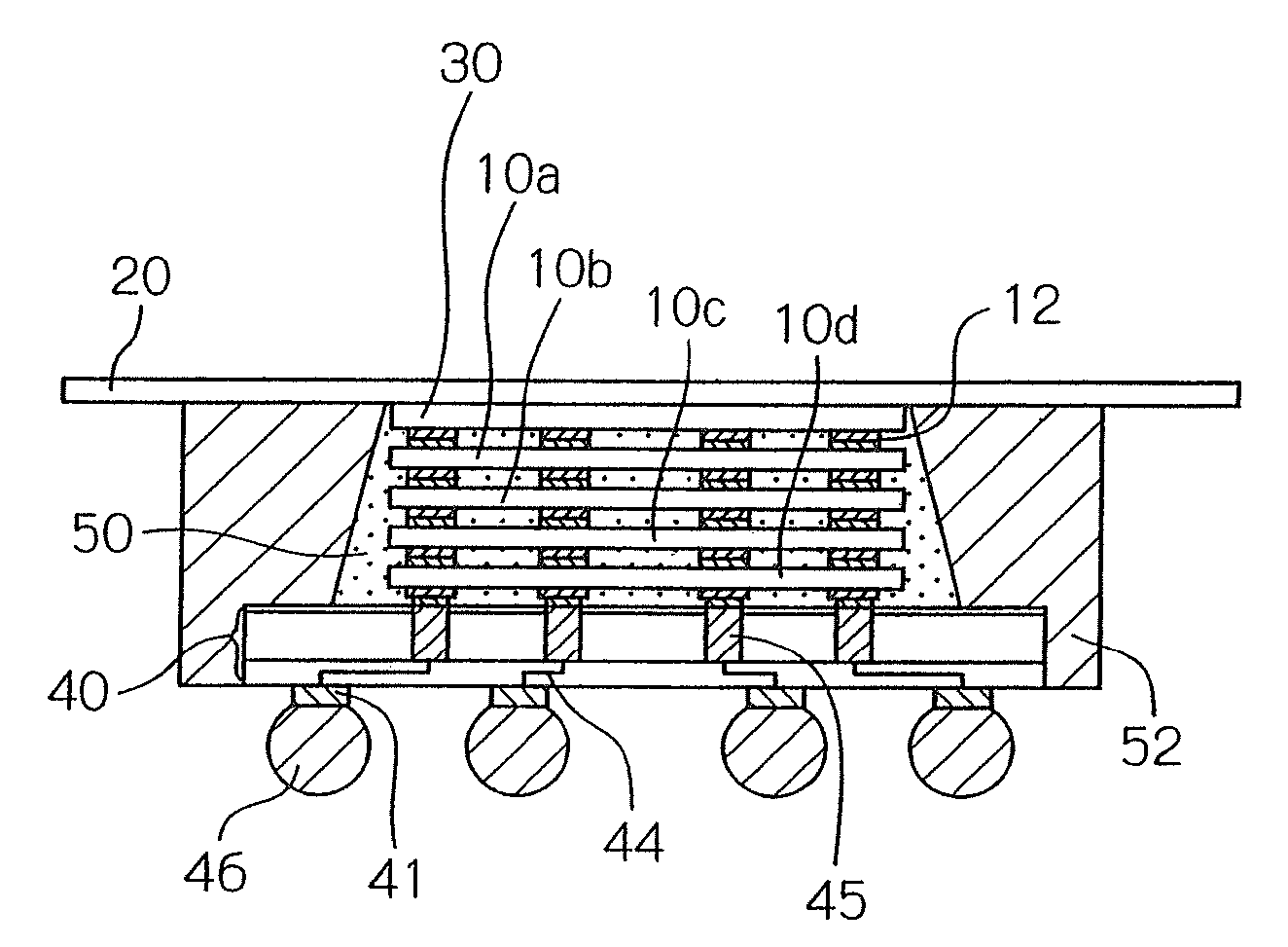

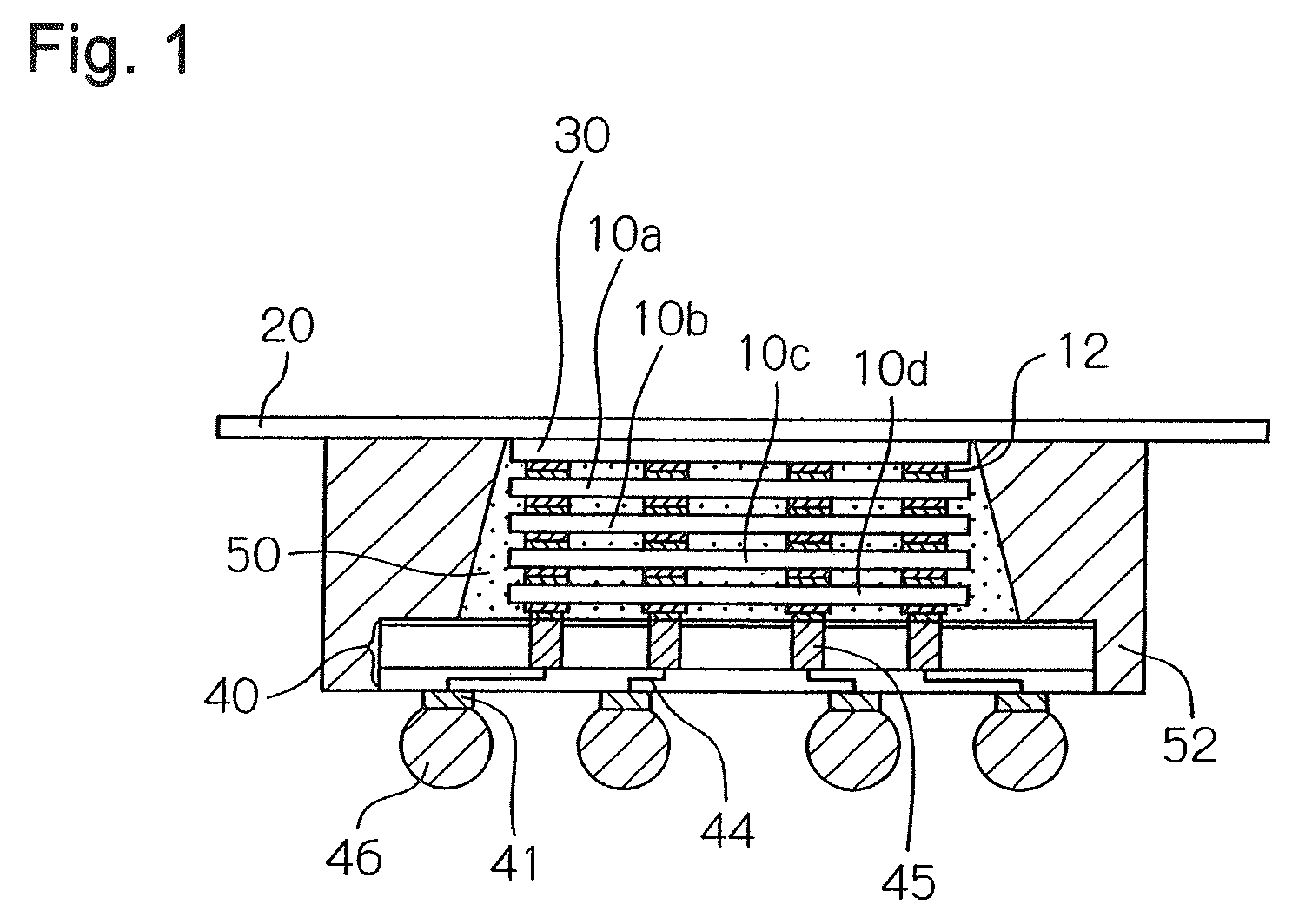

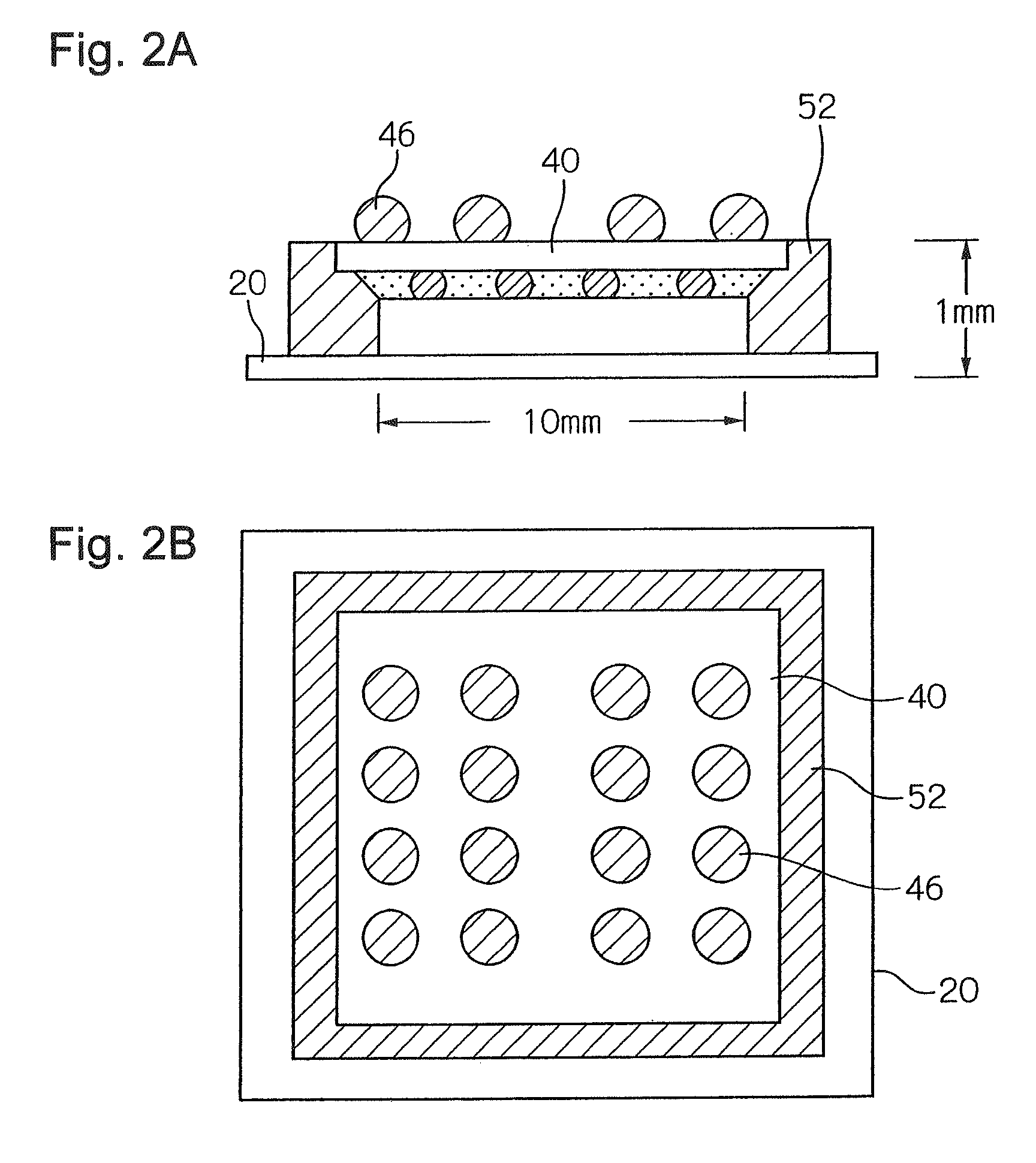

Memory module with improved mechanical strength of chips

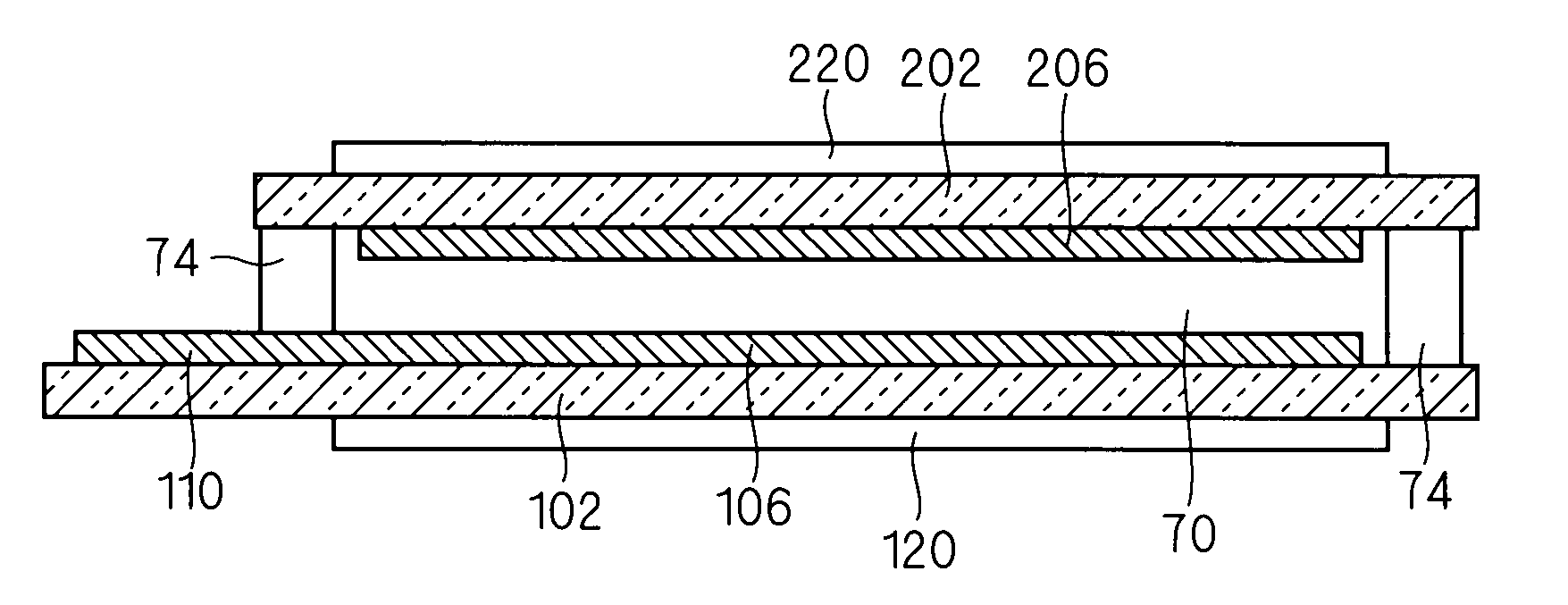

ActiveUS20060267188A1High mechanical strengthEfficiently dissipatedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsControl data

A memory module of the present invention has a memory core chip for storing information, an interface chip for controlling data input / output, an interposer chip for transmitting / receiving data to / from the outside, and an external connection terminal provided in closest proximity to the interposer chip. A heat dissipating plate is provided in closest proximity to the interface chip. The interposer chip has a substrate made of a semiconductor material that is similar to the memory core chip, a land for holding the external connection terminal, a wire connected to the external connection terminal, and an insulating film for insulating the wire. The land, wire, and insulating film are integrally formed on one surface of the interposer chip.

Owner:MICRON TECH INC

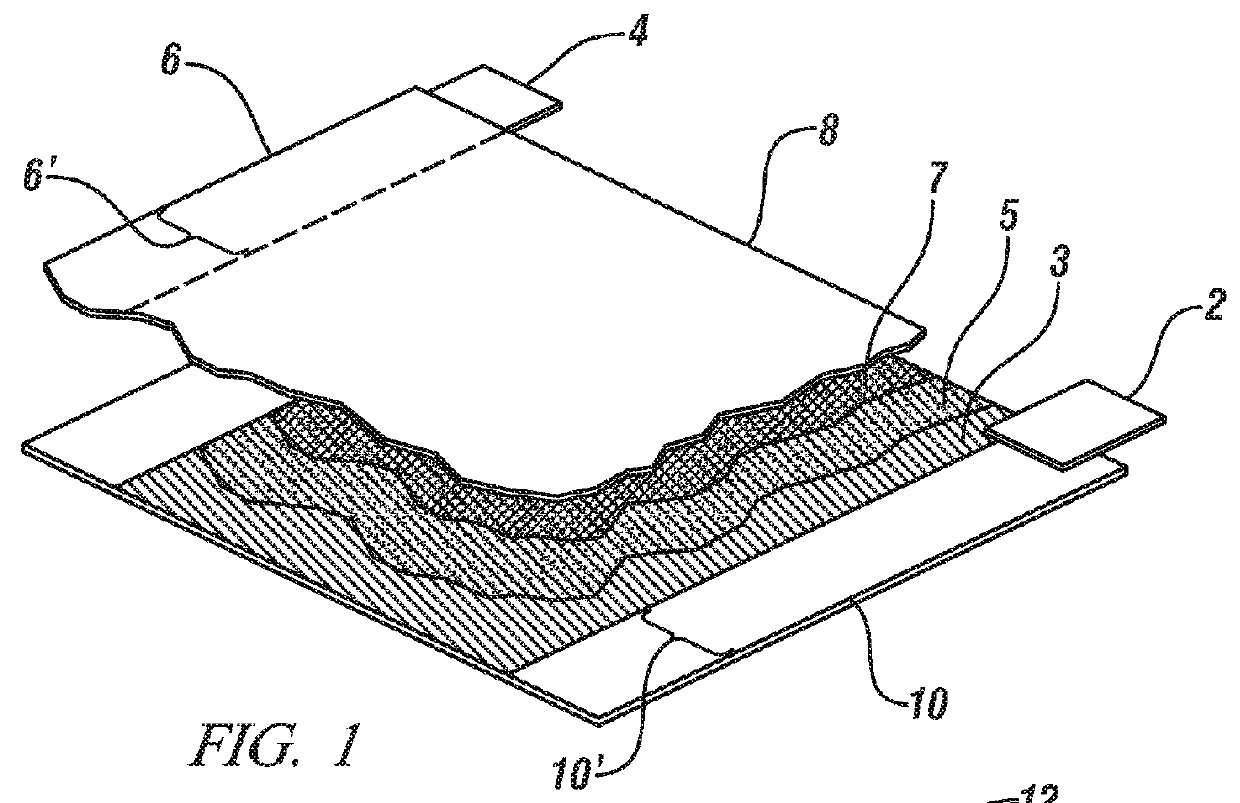

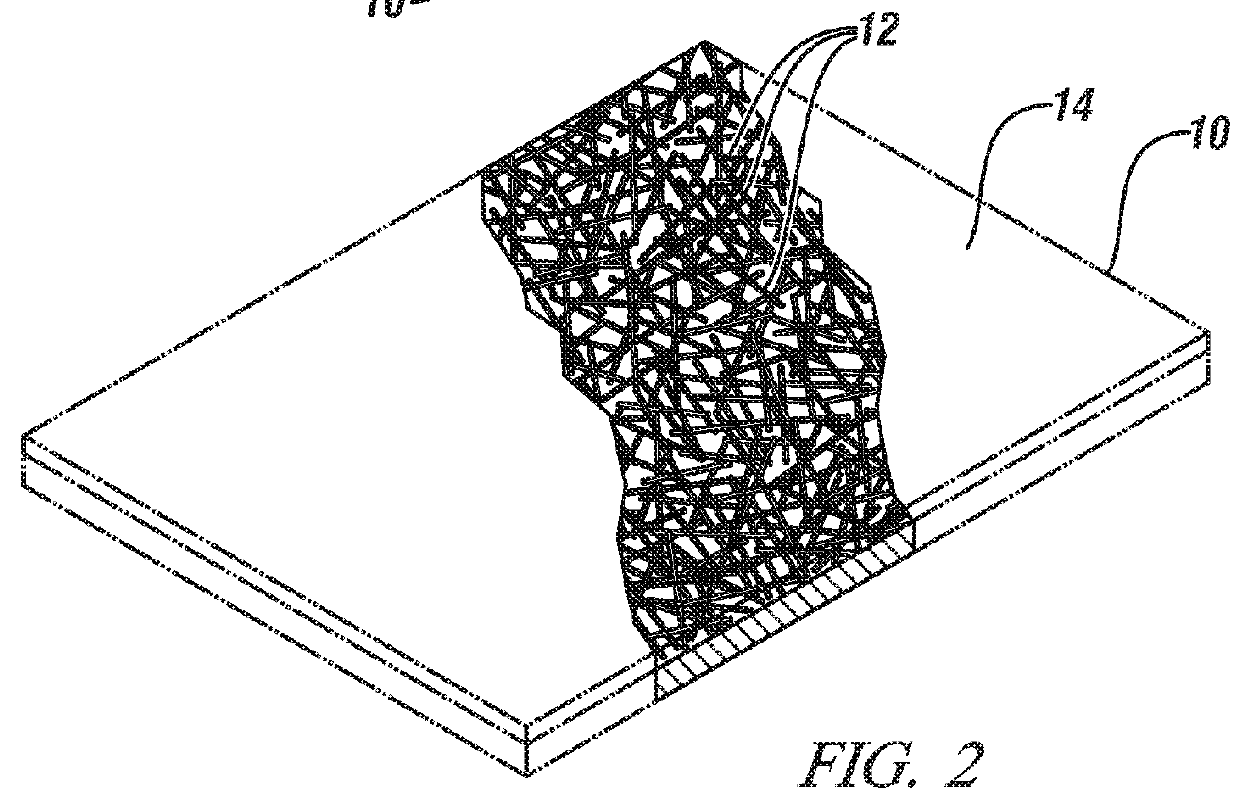

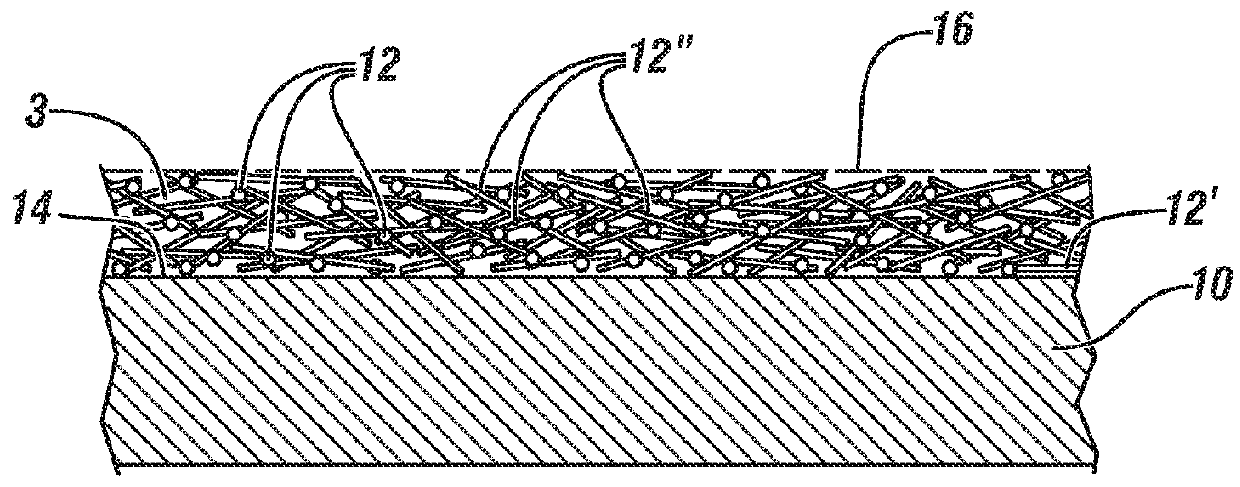

Reinforced battery electrodes

ActiveUS9362551B2Avoid strainMaintain electrical continuityElectrode carriers/collectorsActive material electrodesElectrical batteryShape-memory alloy

The gravimetric and volumetric efficiency of lithium ion batteries may be increased if high capacity materials like tin and silicon may be employed as the lithium-accepting host in the negative electrode of the battery. But both tin and silicon, when fully charged with lithium, undergo expansions of up to 300% and generate appreciable internal stresses which have potential to spall off material from the electrode on each discharge-charge cycle, resulting in a progressive reduction in battery capacity, also known as battery fade. A method of reinforcing such electrode materials by incorporating within them fiber reinforcements or shaped, elongated reinforcements fabricated of shape memory alloy is described. Electrode materials incorporating such reinforcements are less prone to damage under applied stress and so less prone to battery fade.

Owner:GM GLOBAL TECH OPERATIONS LLC

Novel Herbicide Resistance Genes

ActiveUS20110203017A1Prevent shifting or shiftingAvoid developmentBiocideSugar derivativesGlyphosatePyridine

The subject invention provides novel plants that are not only resistant to 2,4-D, but also to pyridyloxyacetate herbicides. Heretofore, there was no expectation or suggestion that a plant with both of these advantageous properties could be produced by the introduction of a single gene. The subject invention also includes plants that produce one or more enzymes of the subject invention “stacked” together with one or more other herbicide resistance genes. The subject invention enables novel combinations of herbicides to be used in new ways. Furthermore, the subject invention provides novel methods of preventing the development of, and controlling, strains of weeds that are resistant to one or more herbicides such as glyphosate. The preferred enzyme and gene for use according to the subject invention are referred to herein as AAD-12 (AryloxyAlkanoate Dioxygenase). This highly novel discovery is the basis of significant herbicide tolerant crop trait and selectable marker opportunities.

Owner:CORTEVA AGRISCIENCE LLC

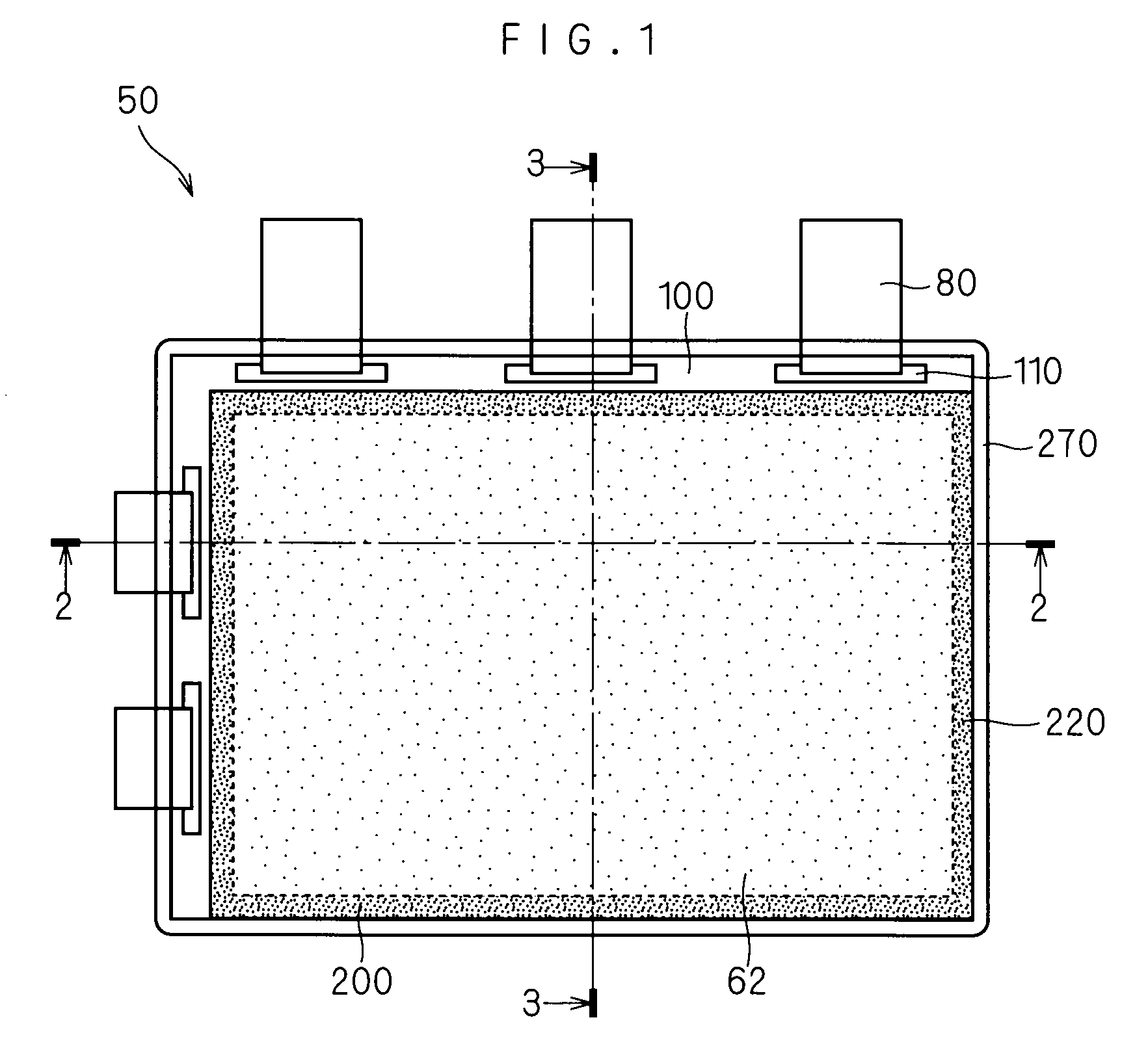

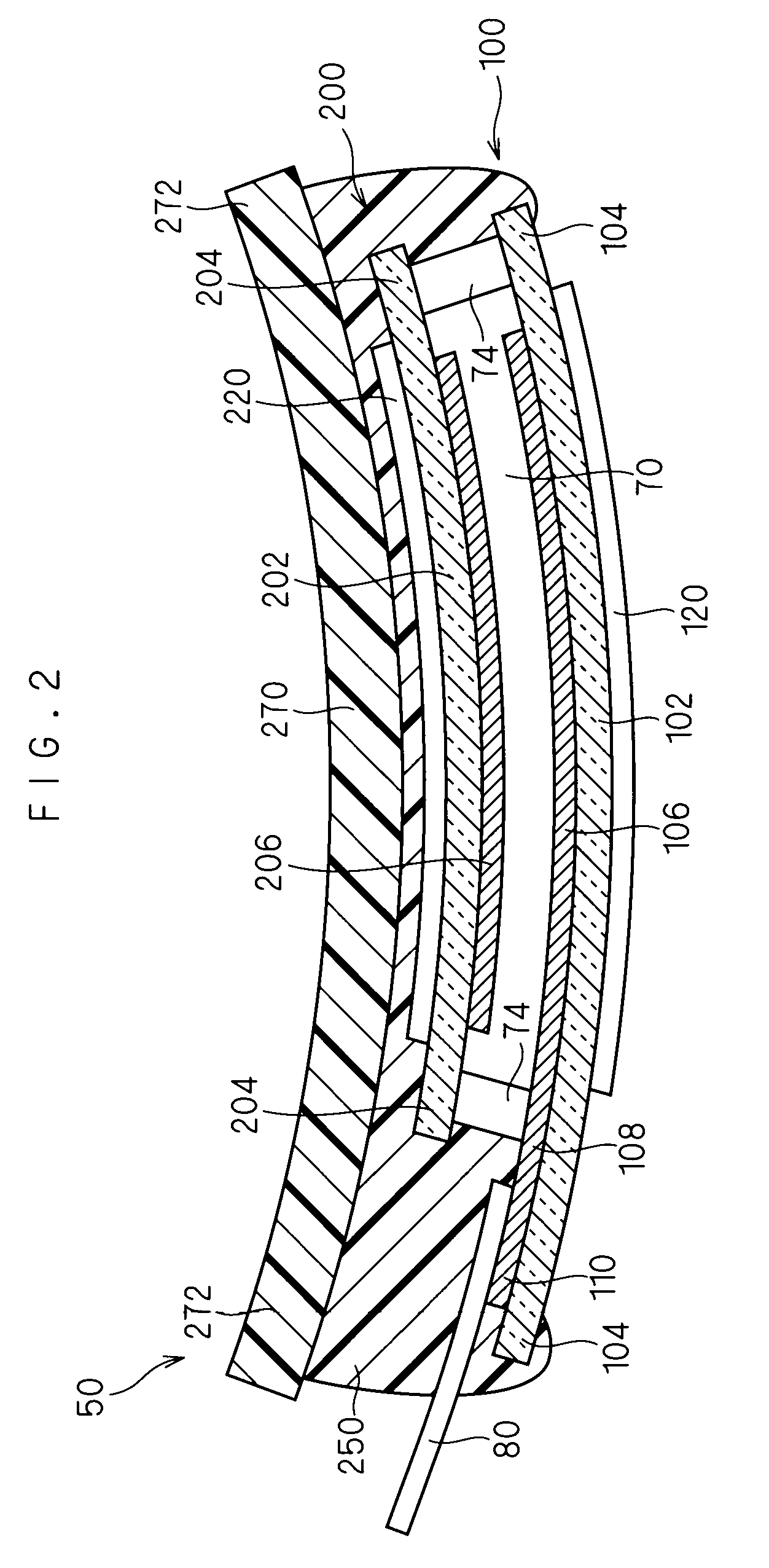

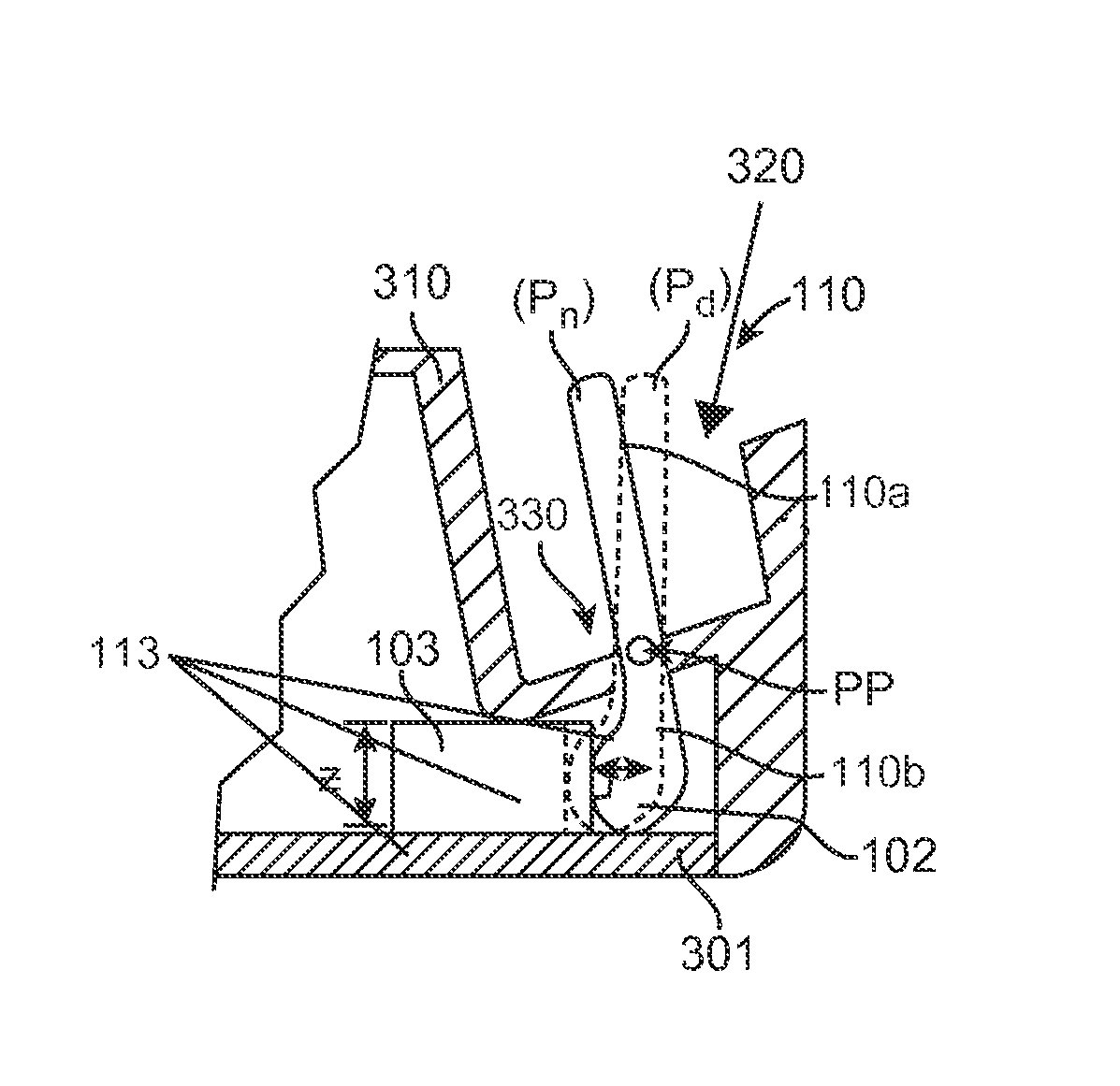

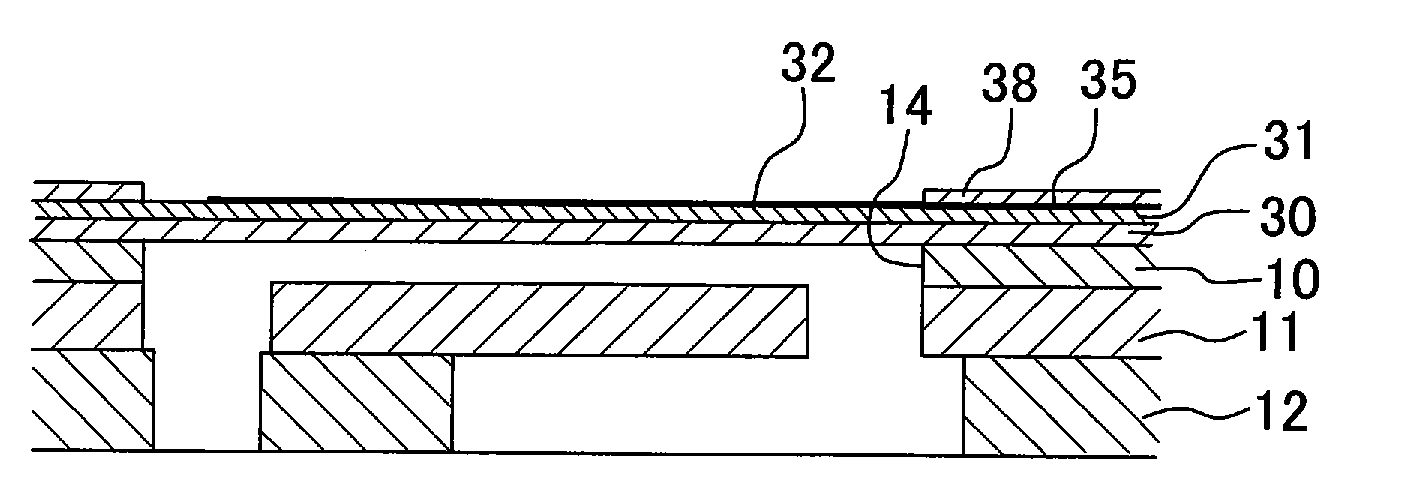

Display device and method of producing the same

ActiveUS20090290113A1Image qualityIncreased durabilityLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

The display device includes a pair of insulating substrates arranged so as to be opposed, a bonding layer, and a strain suppressing plate. The bonding layer is provided on the outer surface side of one insulating substrate. The strain suppressing plate has rigidity higher than that of the insulating substrate to suppress the strain caused by curving the insulating substrate. The strain suppressing plate is fixed to the insulating substrate by the bonding layer.

Owner:MITSUBISHI ELECTRIC CORP

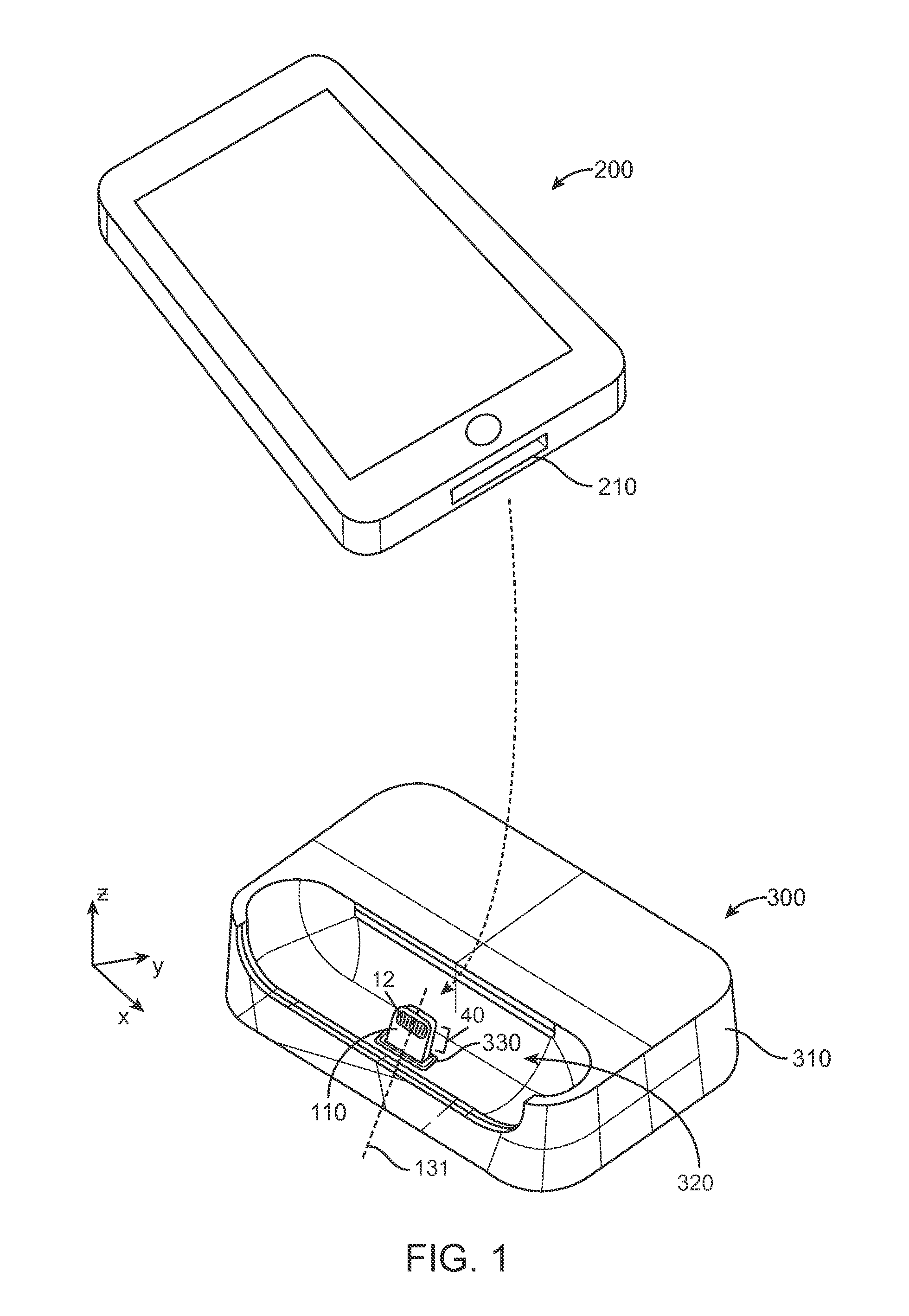

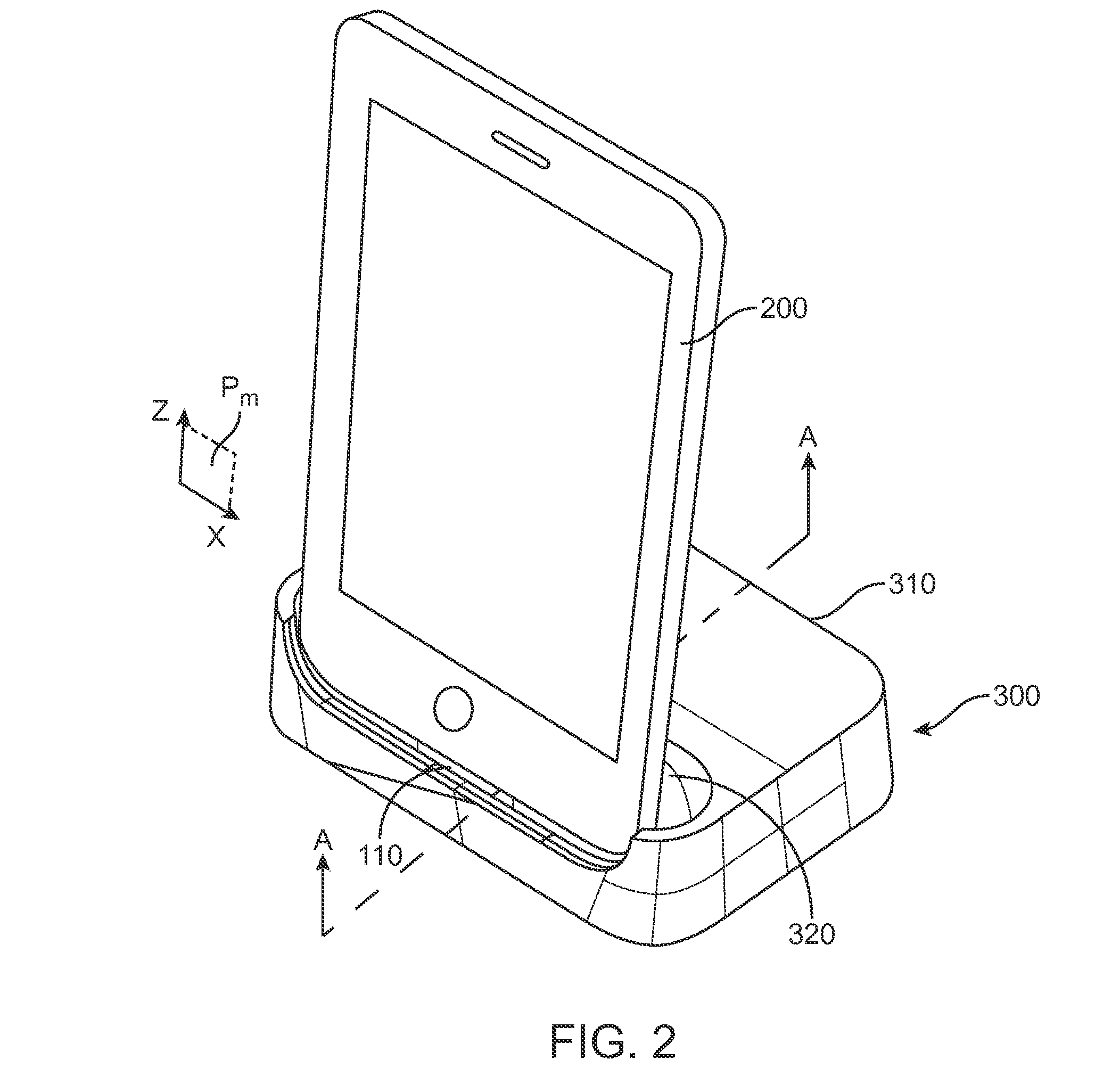

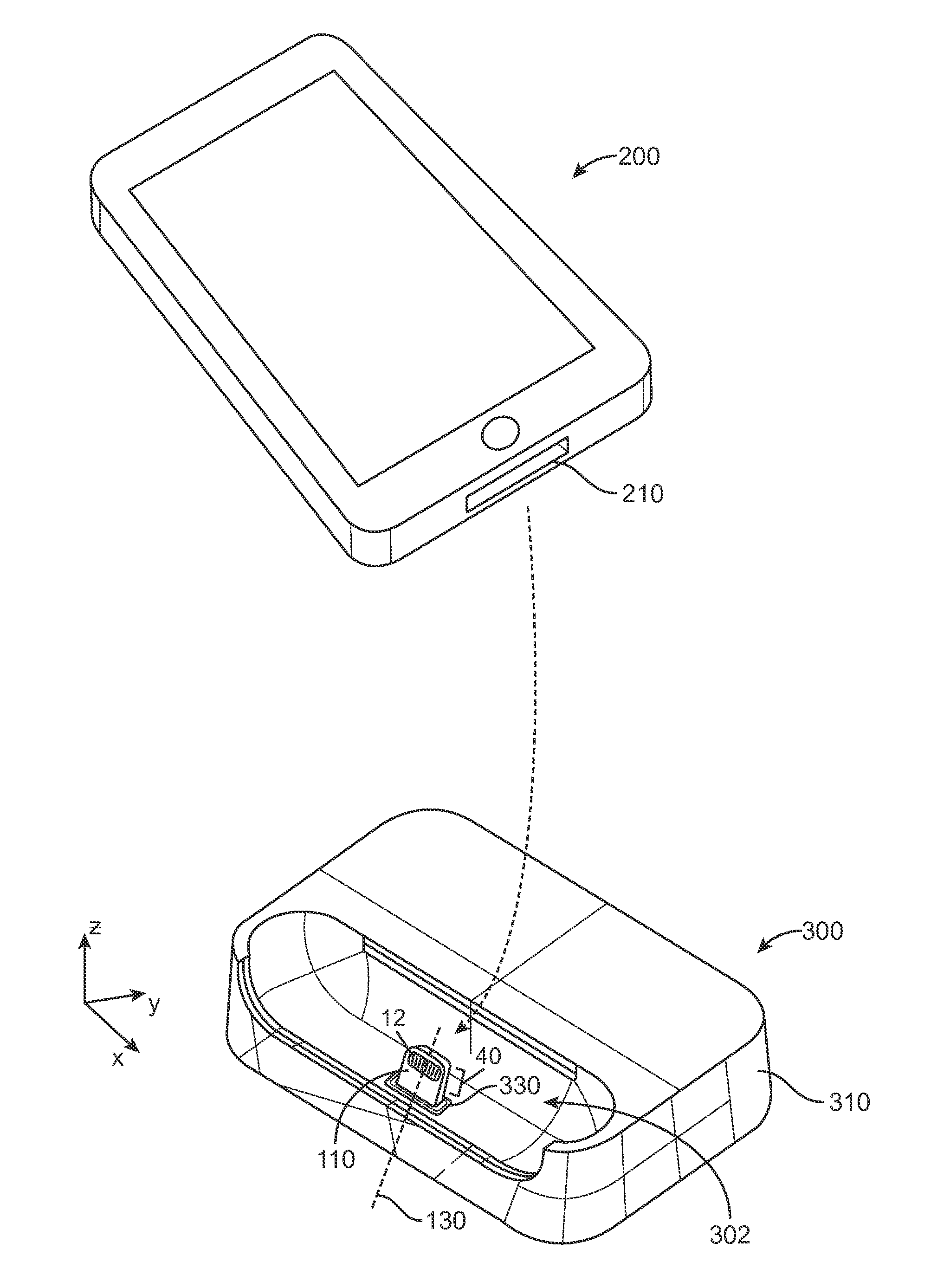

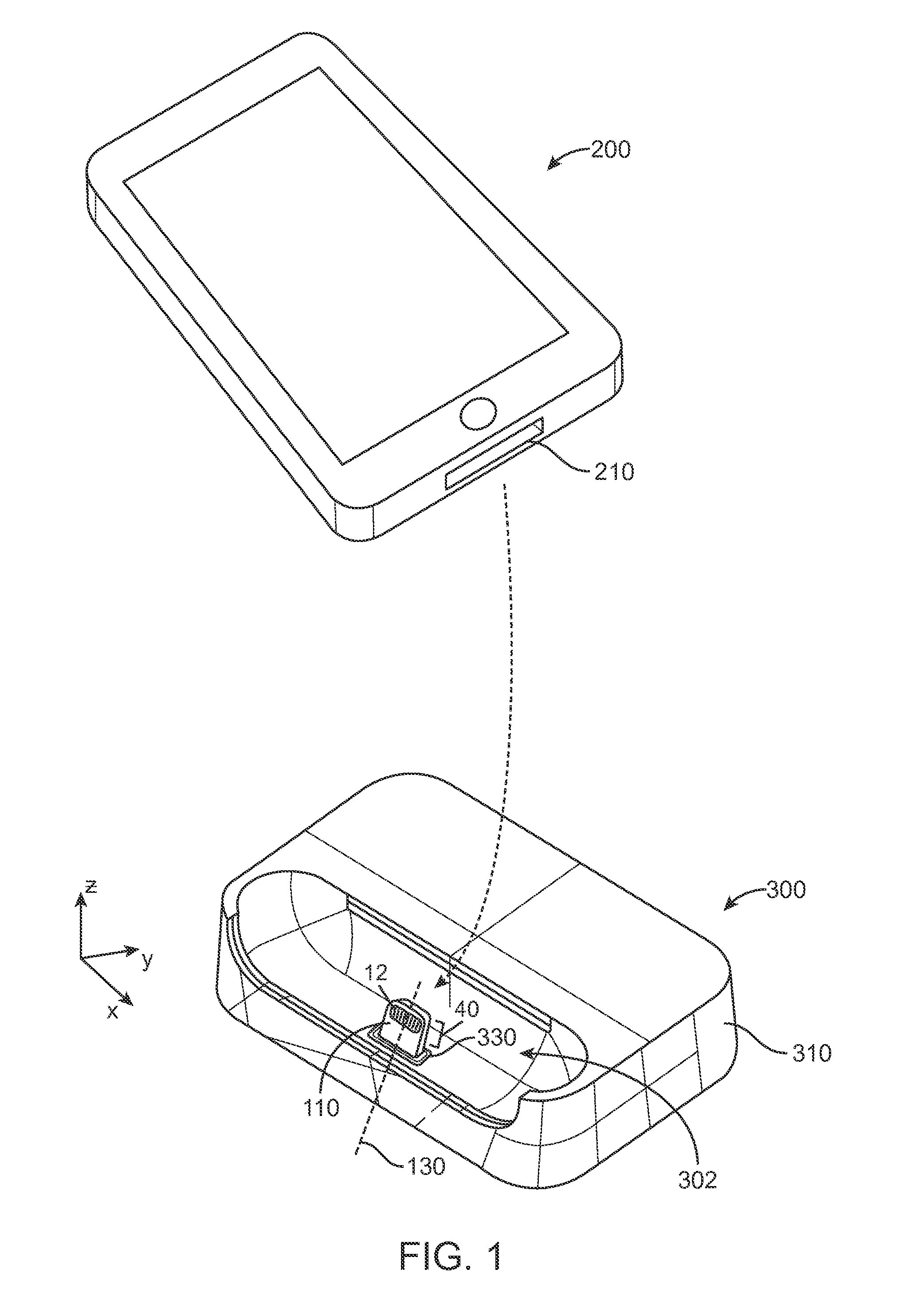

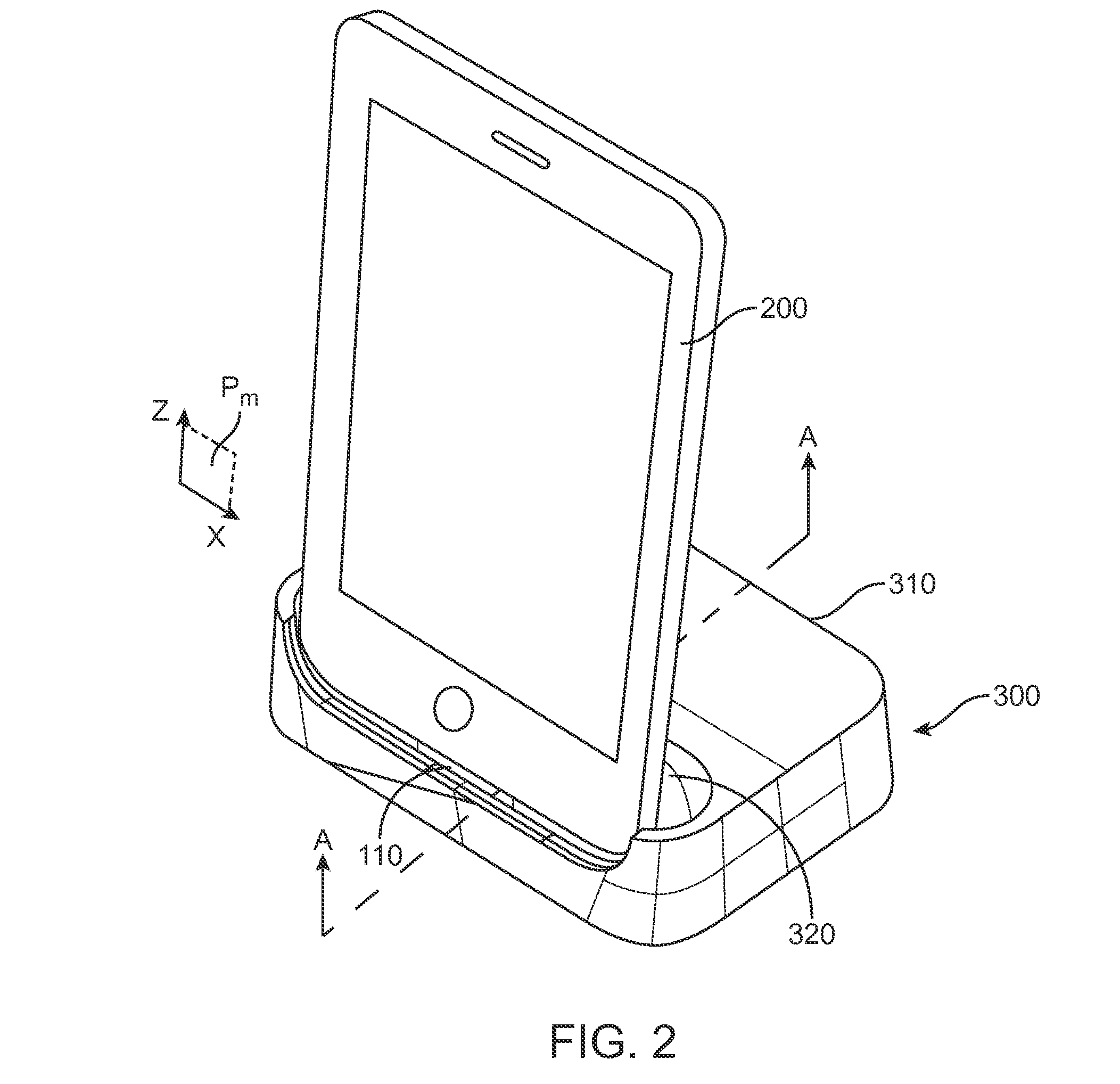

Dock connector with compliance mechanism

ActiveUS8986029B2Reduce the possibilityFlexible and durableBatteries circuit arrangementsIncorrect coupling preventionDocking stationEngineering

Owner:APPLE INC

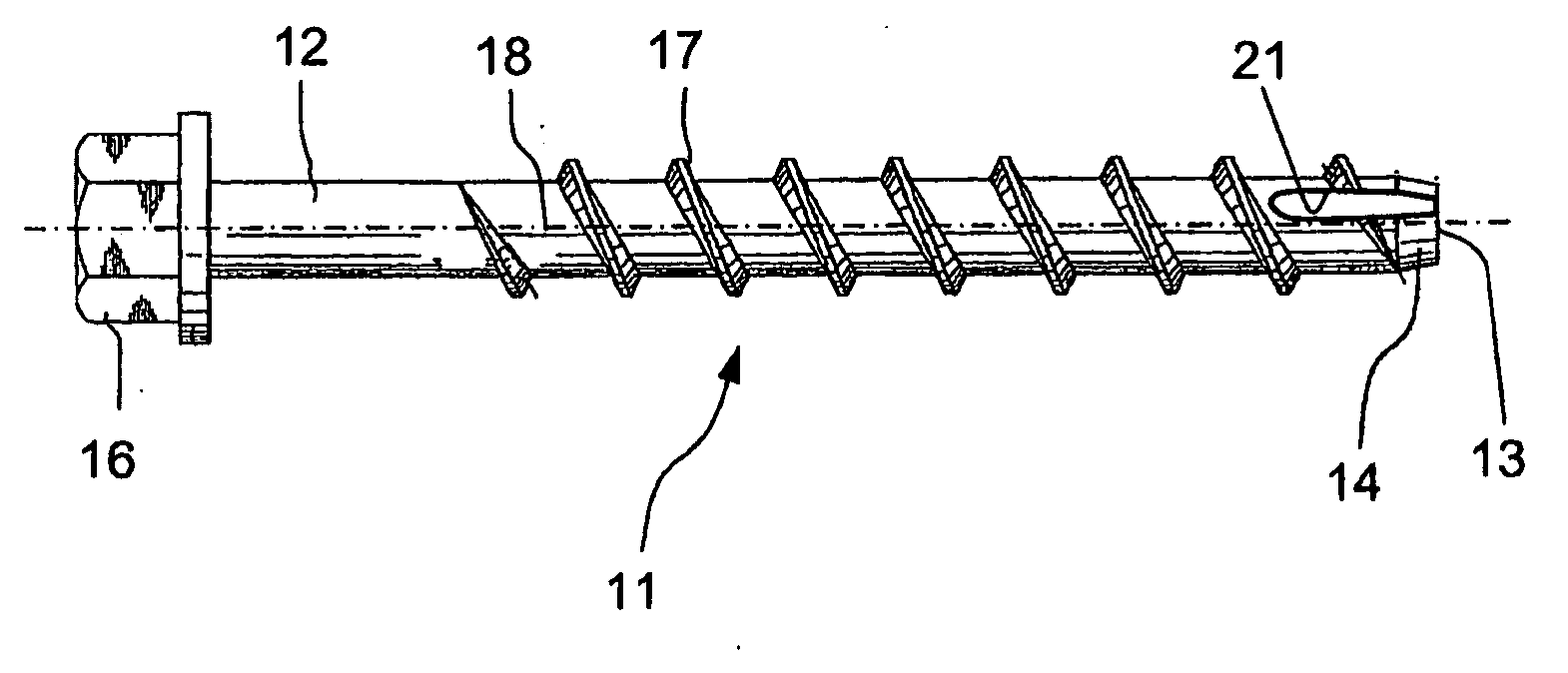

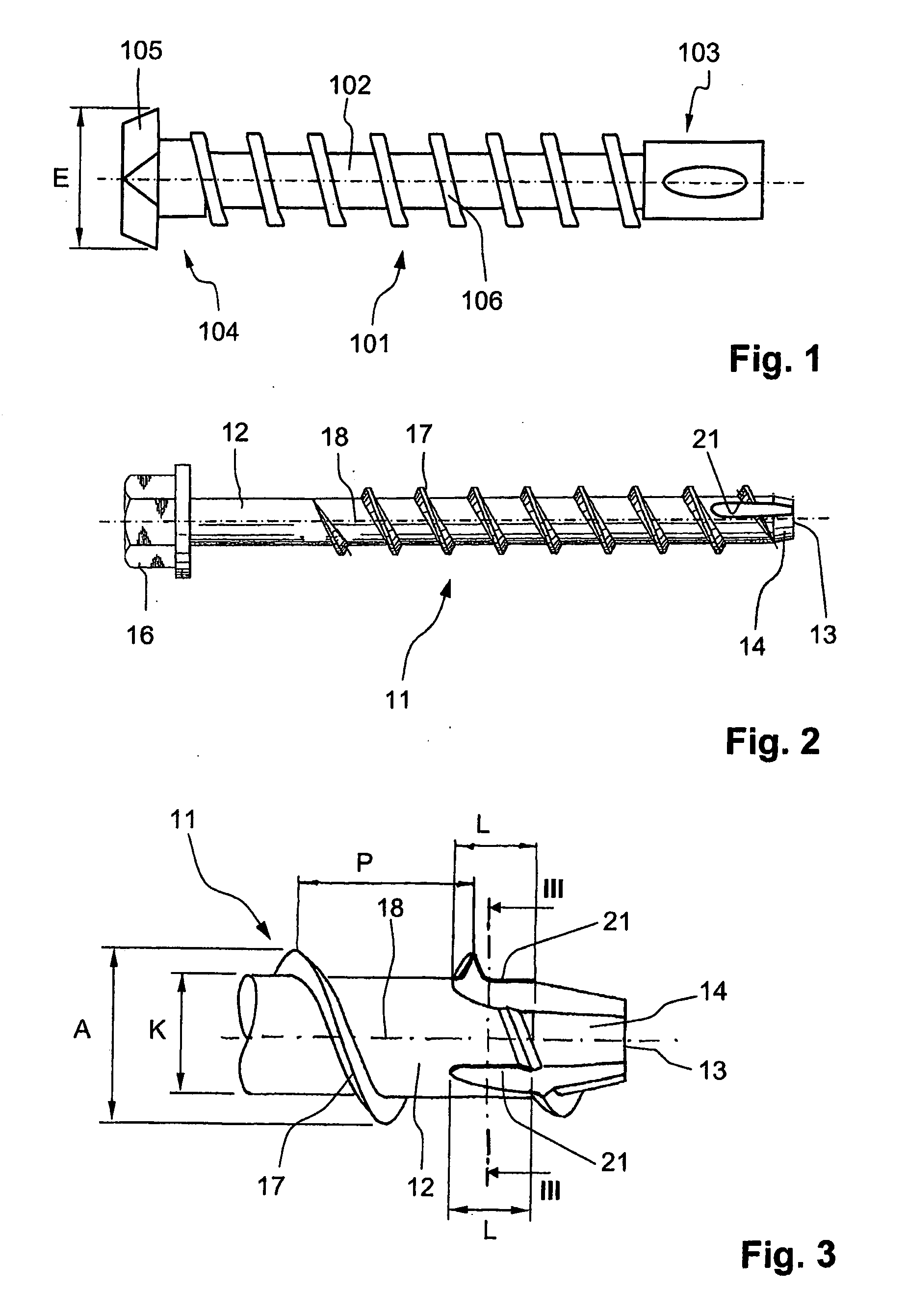

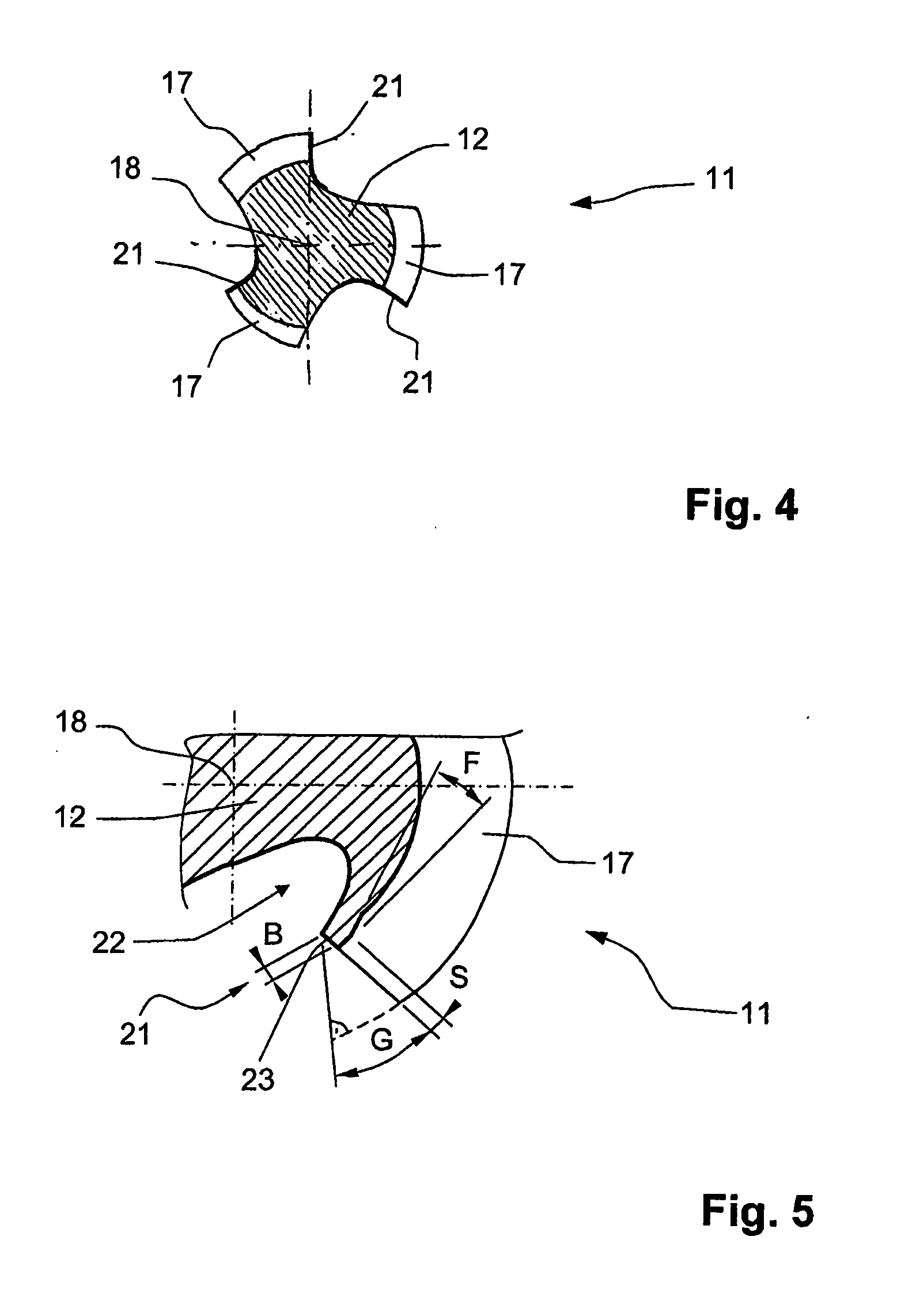

Method for anchoring a fastening element in a mineral component, and fastening element for mineral components

A method is described for anchoring a fastening element (11) in a mineral component (1), in which a bore hole (2) is provided in the component (1) using a drill bit having a nominal drill bit diameter, and a fastening element (11) is then screwed into the provided bore hole (2). The fastening element (11) has a shank (12) which is provided with rotary engagement device (16) for a setting tool, and has a core diameter (K) and cutting edges (21) on a first end region. The fastening element has a self-tapping thread (17) in which the difference between the outer diameter of the thread (17) and the core diameter (K) of the shank (12) corresponds to 0.05 to 0.7 times the pitch of the thread (17). A drill bit is used which has a nominal drill bit diameter corresponding to 0.95 to 1.10 times the core diameter (K) of the shank (12). Also described is a fastening element (11) for anchoring in a mineral component (1).

Owner:HILTI AG

Herbicide resistance genes for resistance to aryloxyalkanoate herbicides

ActiveUS8278505B2Prevent shifting or shiftingAvoid developmentBiocideSugar derivativesGlyphosatePyridine

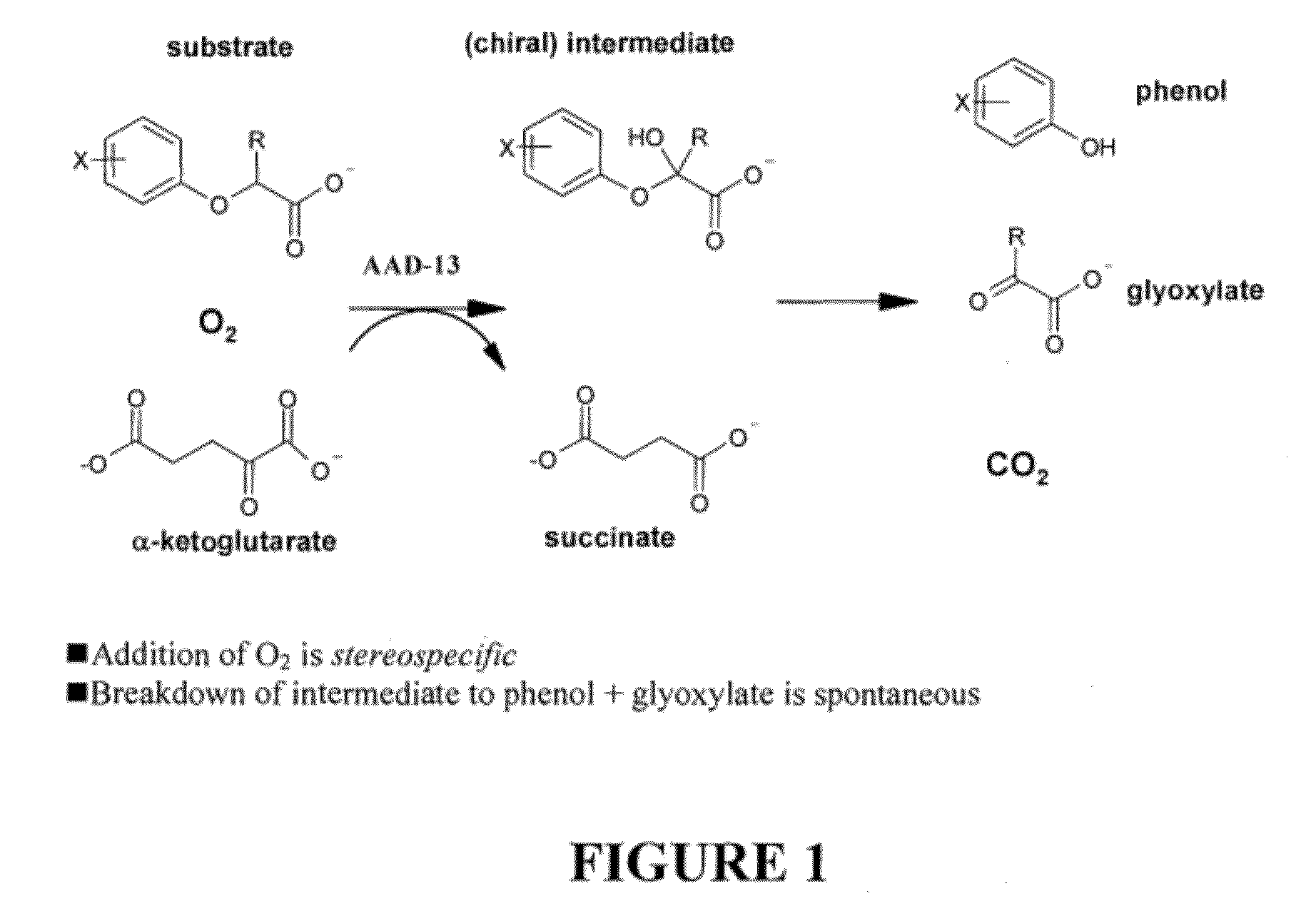

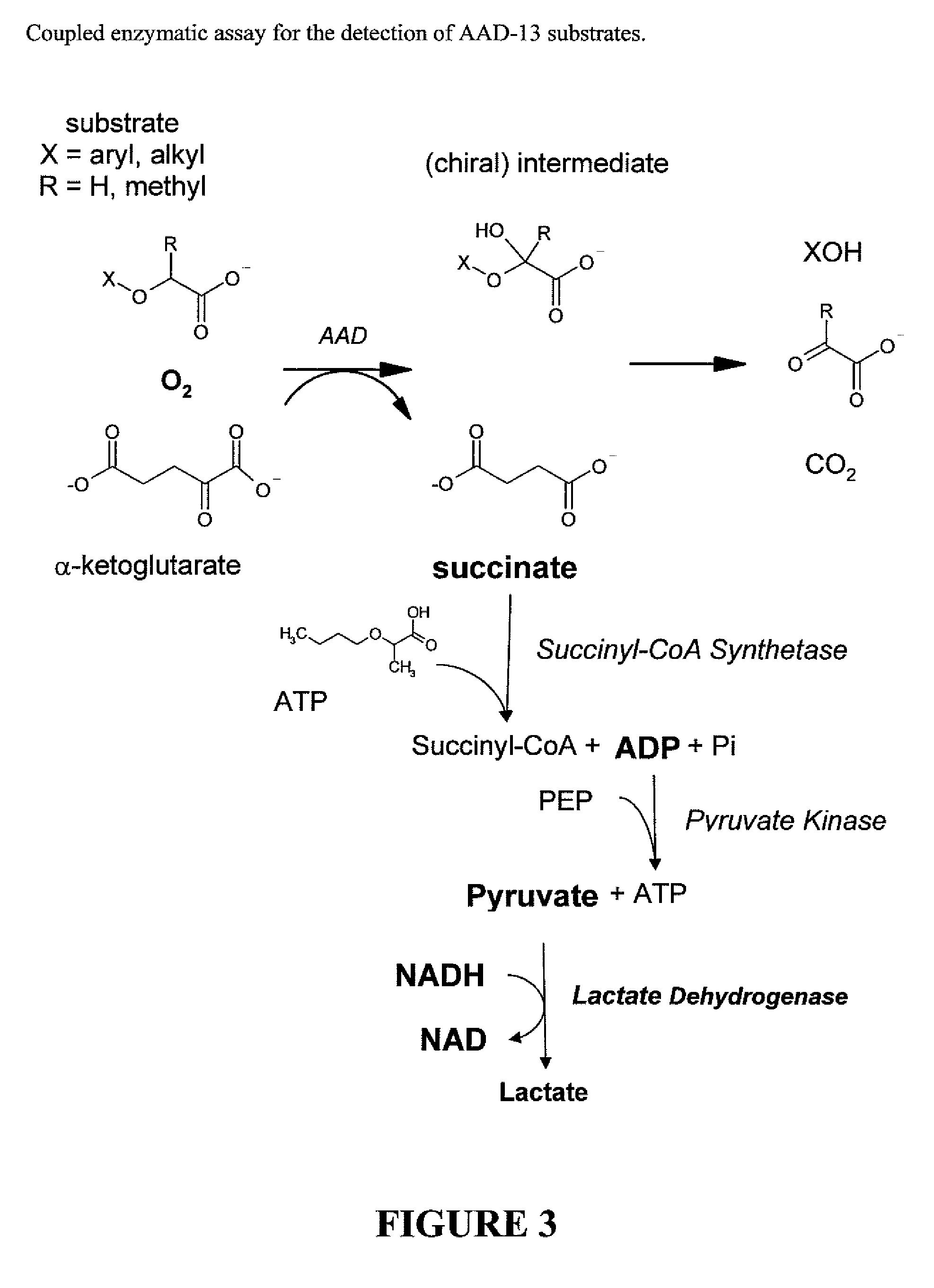

The subject invention provides novel plants that are not only resistant to 2,4-D, but also to a pyridyloxyacetate herbicide. The subject invention also includes plants that produce one or more enzymes of the subject invention “stacked” together with one or more other herbicide resistance genes. The subject invention enables novel combinations of herbicides to be used in new ways. Furthermore, the subject invention provides novel methods of preventing the development of, and controlling, strains of weeds that are resistant to one or more herbicides such as glyphosate. The preferred enzyme and gene for use according to the subject invention are referred to herein as AAD-13 (AryloxyAlkanoate Dioxygenase). This highly novel discovery is the basis of significant herbicide tolerant crop trait and selectable marker opportunities.

Owner:CORTEVA AGRISCIENCE LLC

Anti-microbial composition and method for producing the same

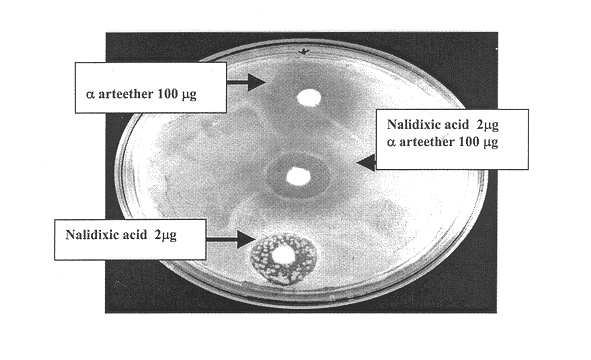

This invention is related to the development of strategic and novel composition comprising alpha arteether and nalidixic acid or quinolone drugs, said composition useful as an advanced generation drug to counter the resistance development itself and having a potential to be used in treating infectious diseases and in inhibiting the resistance developed due to mutation in the gyr A gene of bacteria, particularly in those cases where drug resistant strains are known to appear very frequently.

Owner:COUNCIL OF SCI & IND RES

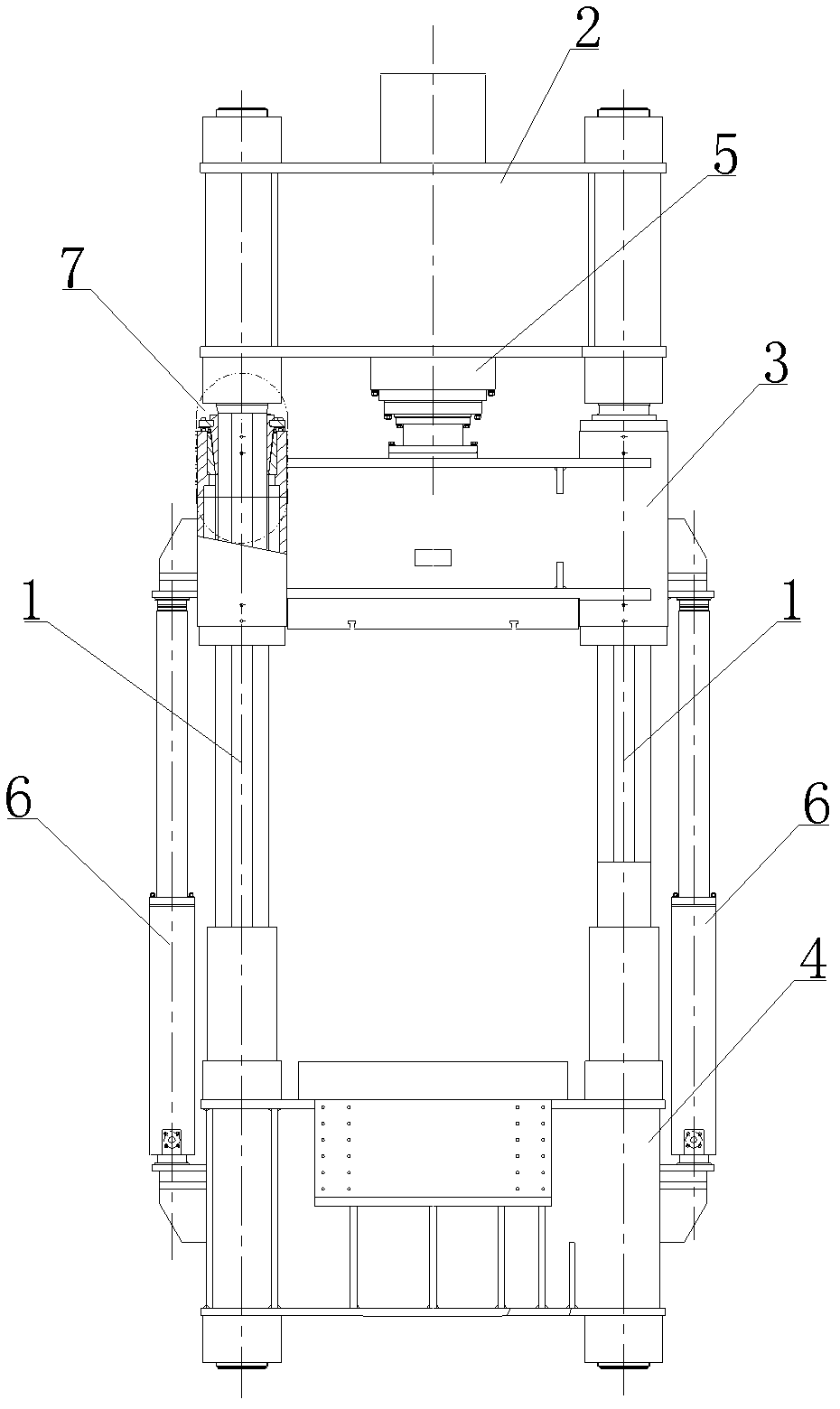

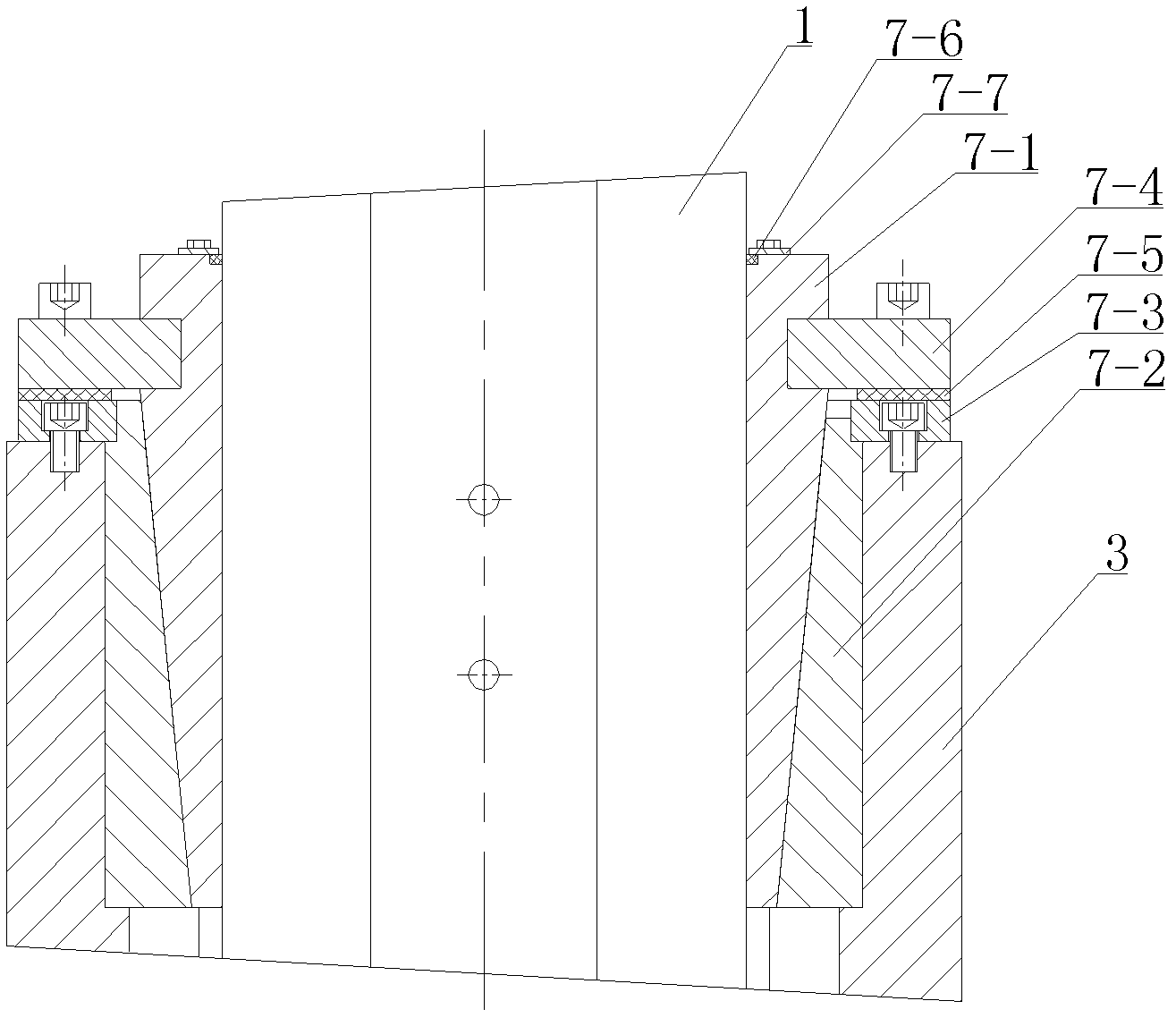

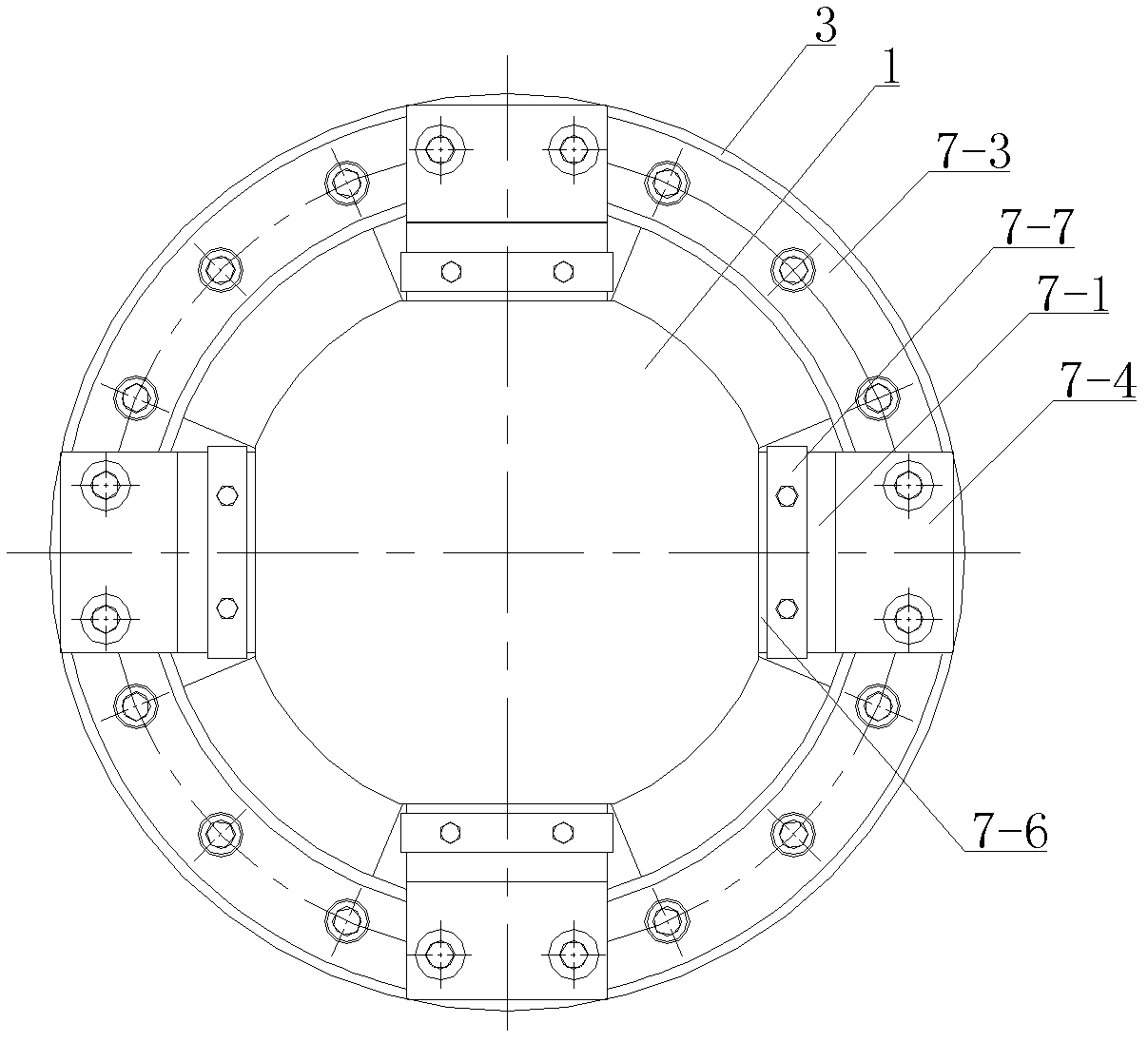

Four-column forging hydraulic machine

The invention relates to a four-column forging hydraulic machine which is composed of columns, an upper beam, a middle beam, a lower beam, a working oil cylinder and a return cylinder. A column guiding structure is arranged between the middle beam and the columns. The four-column forging hydraulic machine is characterized in that the column guiding structure comprises four groups of guiding assemblies composed of guiding plates and wedge plates, the wedge plates are pressed and fixed in the middle beam through pressing plates, supporting plates are arranged close to the upper ends of the guiding plates, adjusting pads are arranged between the supporting plates and the pressing plates, the lower end of a piston rod of the working oil cylinder is provided with a cylindrical cavity, the cylindrical cavity is internally provided with a first spherical pad and a spherical column, a supporting sleeve is sleeved outside the spherical column, a support structure is arranged at the upper part of a raised part at the lower end of the supporting sleeve, an elastic pad is arranged between the supporting structure and the raised part, and the lower end of the supporting sleeve is internally provided with a second spherical pad. According to the structure, the columns and the guiding structure are in surface contact, so that the local stress is reduced, and the traction injury of the columns is avoided. In addition, the second spherical pad, the spherical column and the first spherical pad are rotated in a matching way, therefore, the deflection of the piston rod along the axis is avoided, and the traction injury and the damage of the working oil cylinder and the piston rod are reduced.

Owner:TIANJIN TIANDUAN PRESS CO LTD

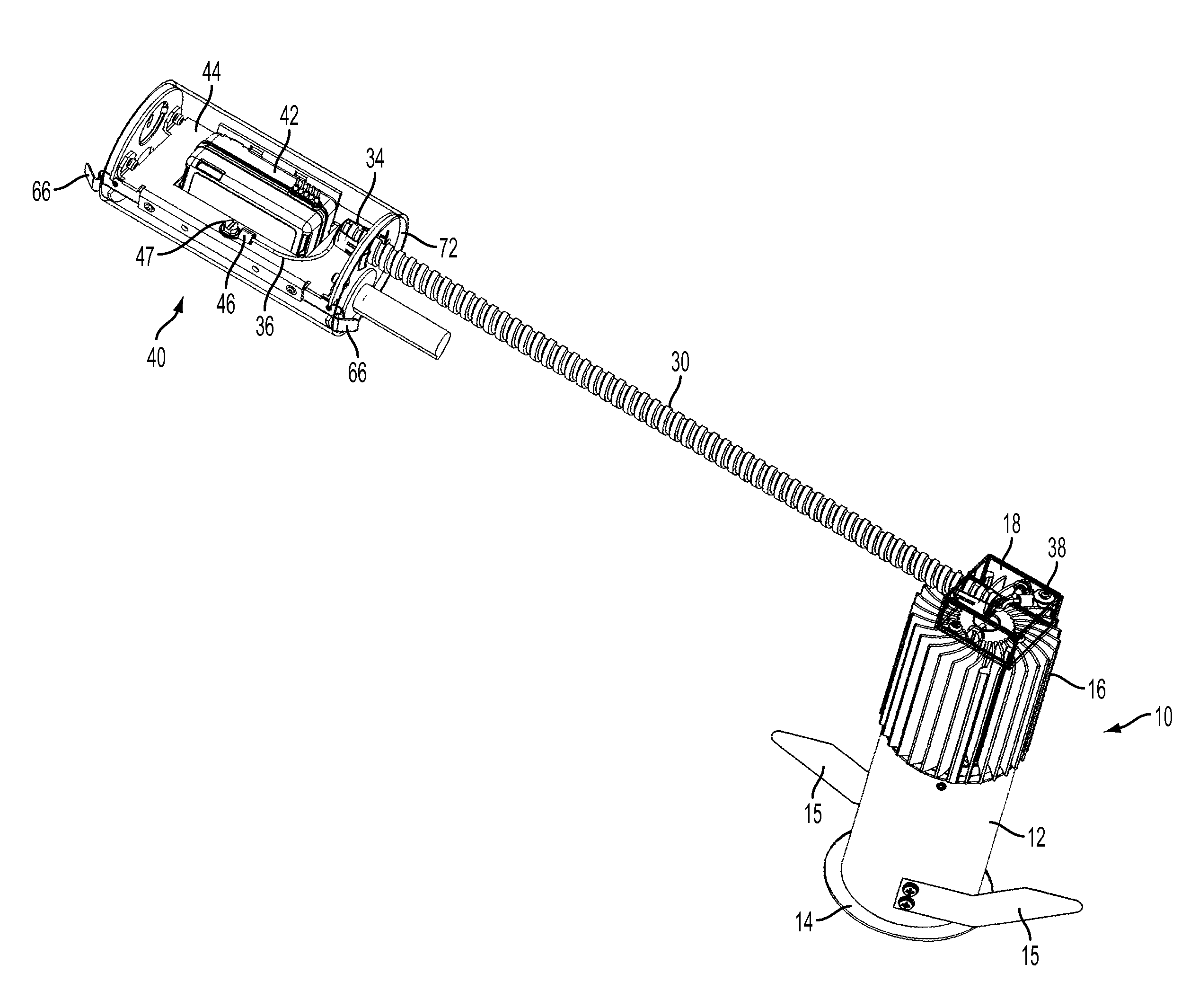

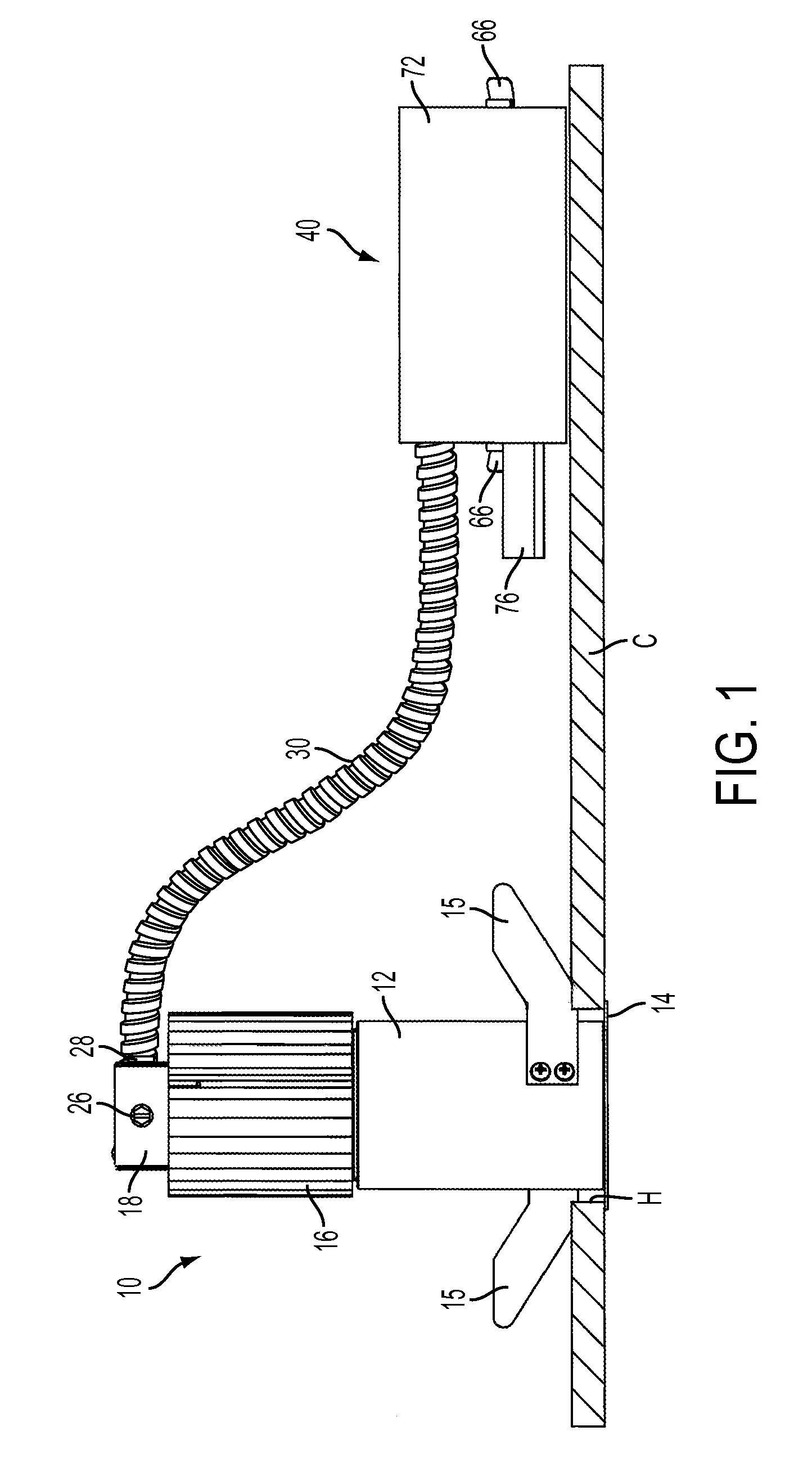

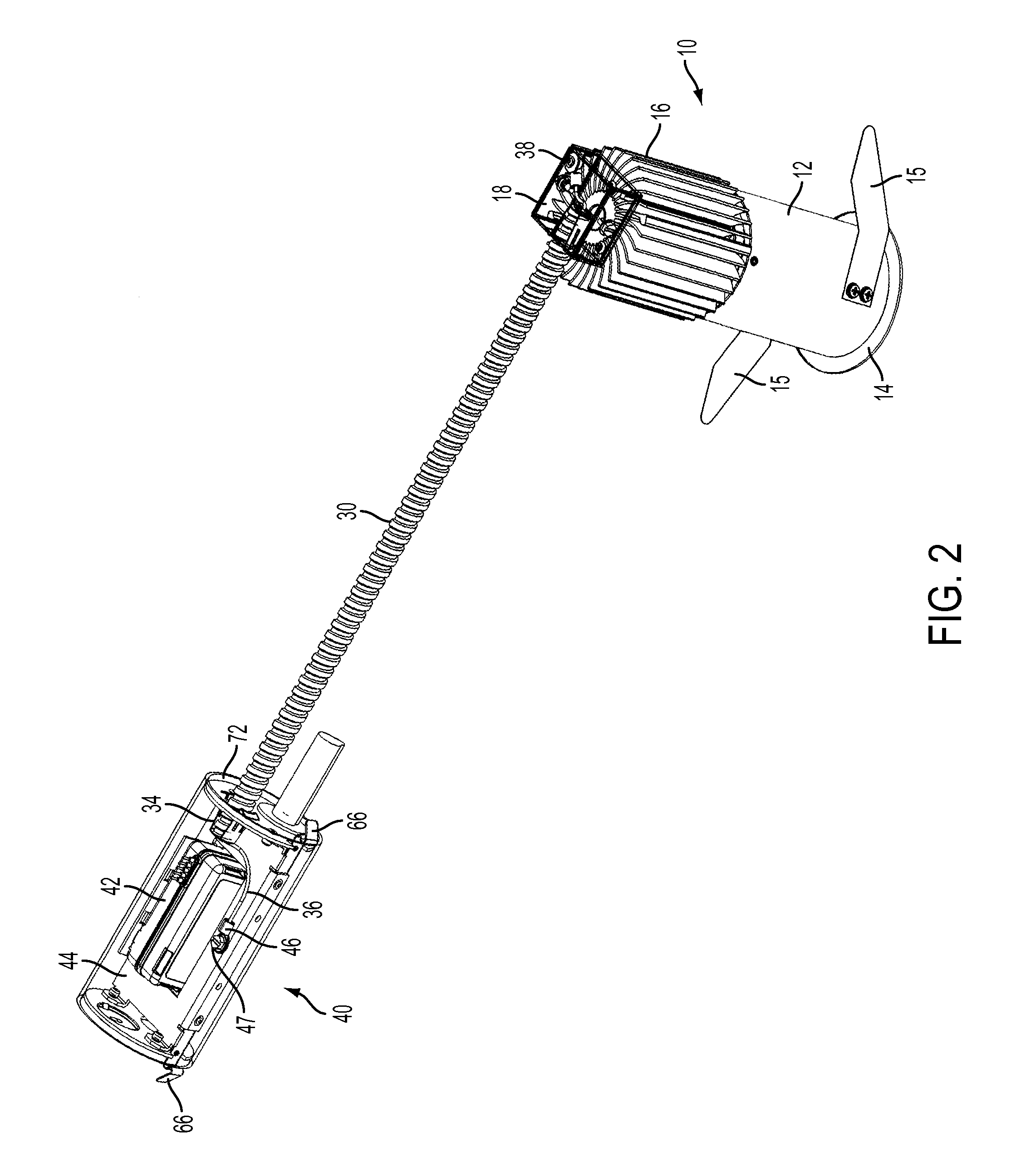

Recessed Lighting Fixture and Flexibly Attached Compact Junction Box

ActiveUS20120287616A1Avoid connectionPrevents undue strainSubstation/switching arrangement detailsPoint-like light sourceElectrical connectionJunction box

A recessed lighting fixture includes a lamp housing and a separate compact junction box, which contains a power supply that drives the lamp and serves in part to divide the interior cavity of the junction box into two separate wiring compartments. The junction box has two end walls spaced along an axis and a releasably secured, sleeve-like cover (side wall) surrounding and closing the cavity. The cover can be moved axially in either direction relative to the end walls to open the wiring compartments. The junction box and the lamp housing are mechanically connected only by a flexible conduit and a flexible tether, which prevents undue strain on the electrical connections between the joined components. The lighting fixture is particularly suitable for retrofit installations, especially where small-aperture downlights are desired.

Owner:HUBBELL LIGHTING INC

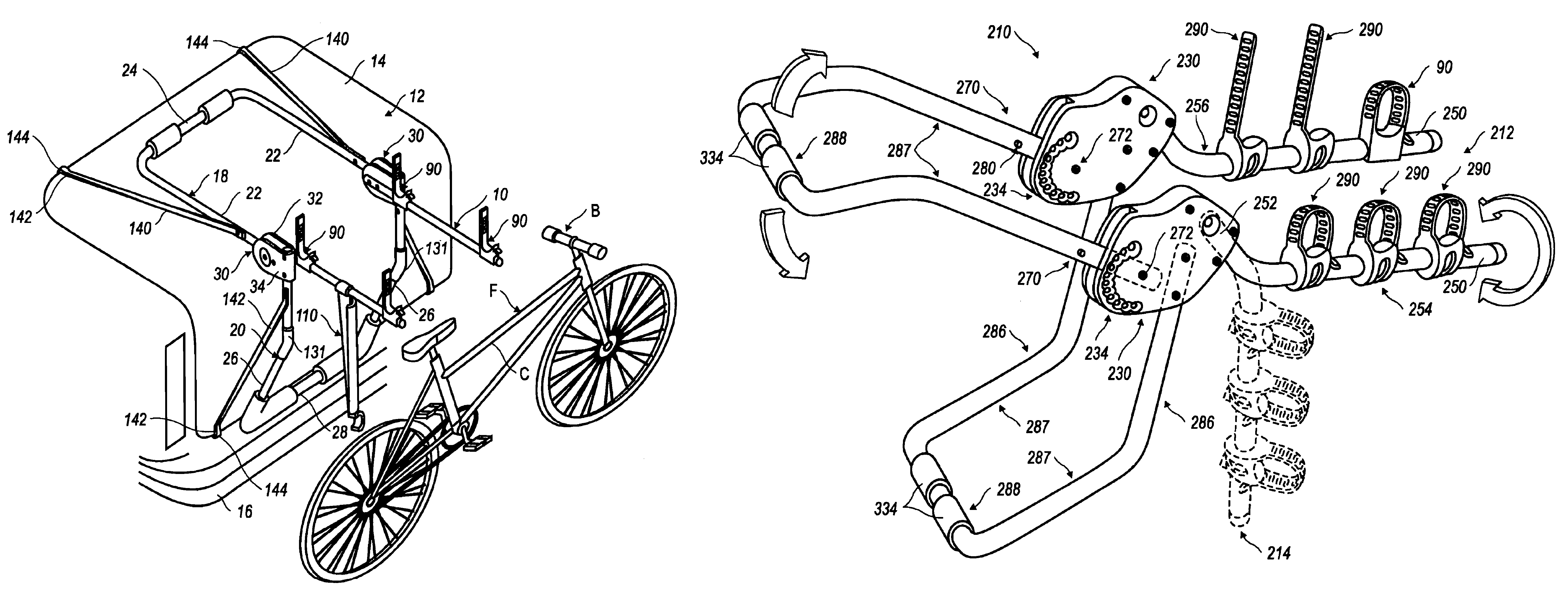

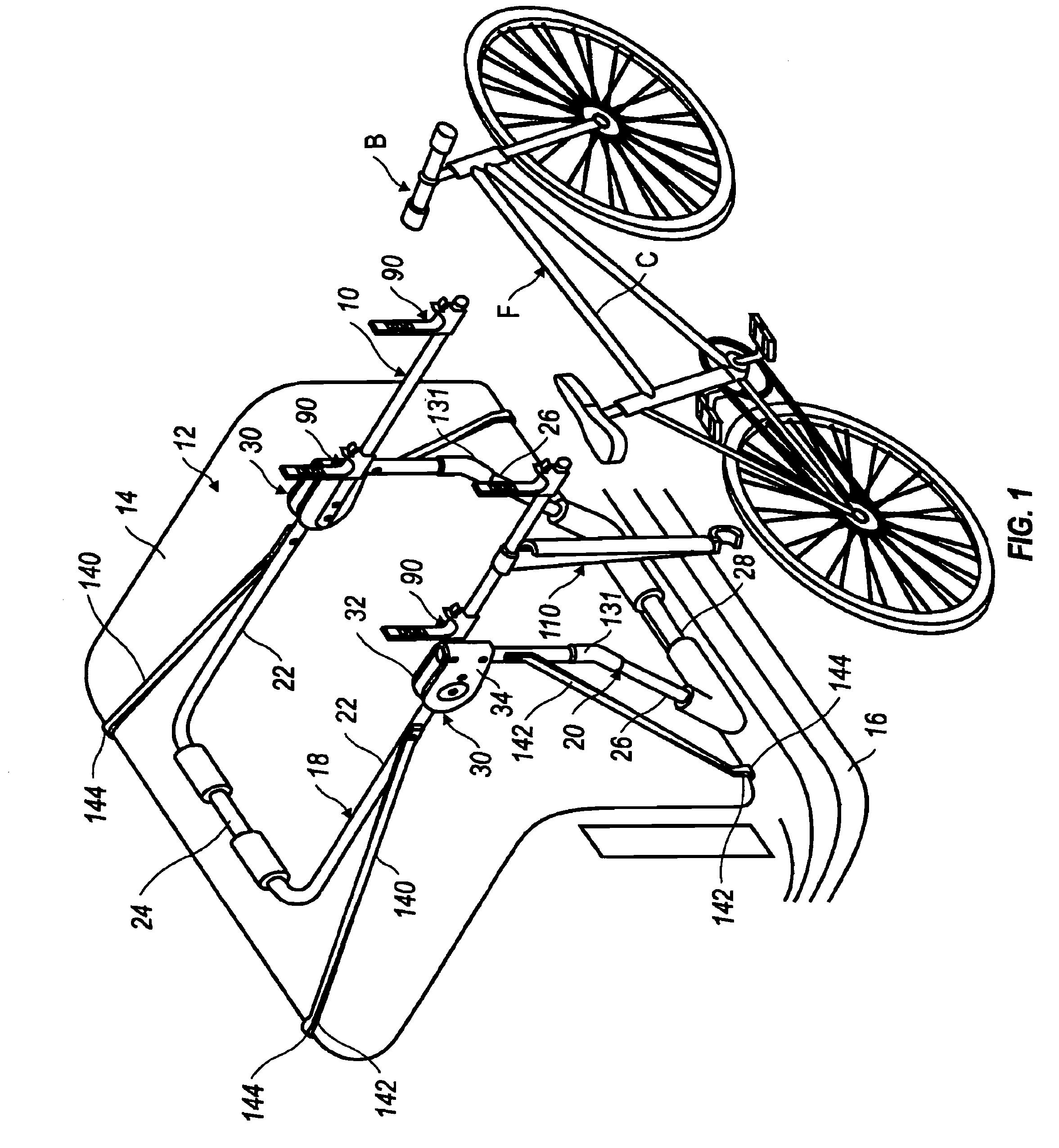

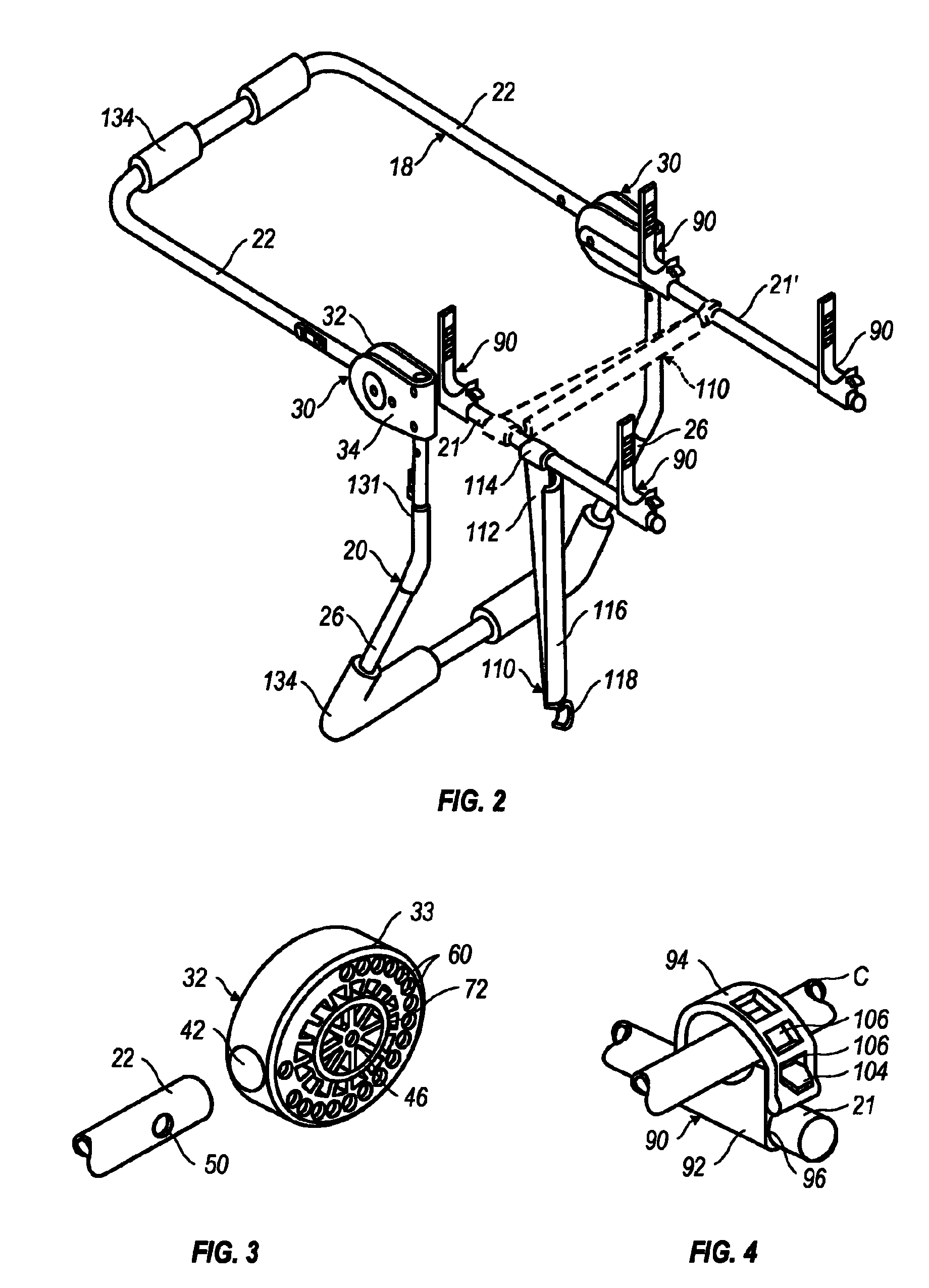

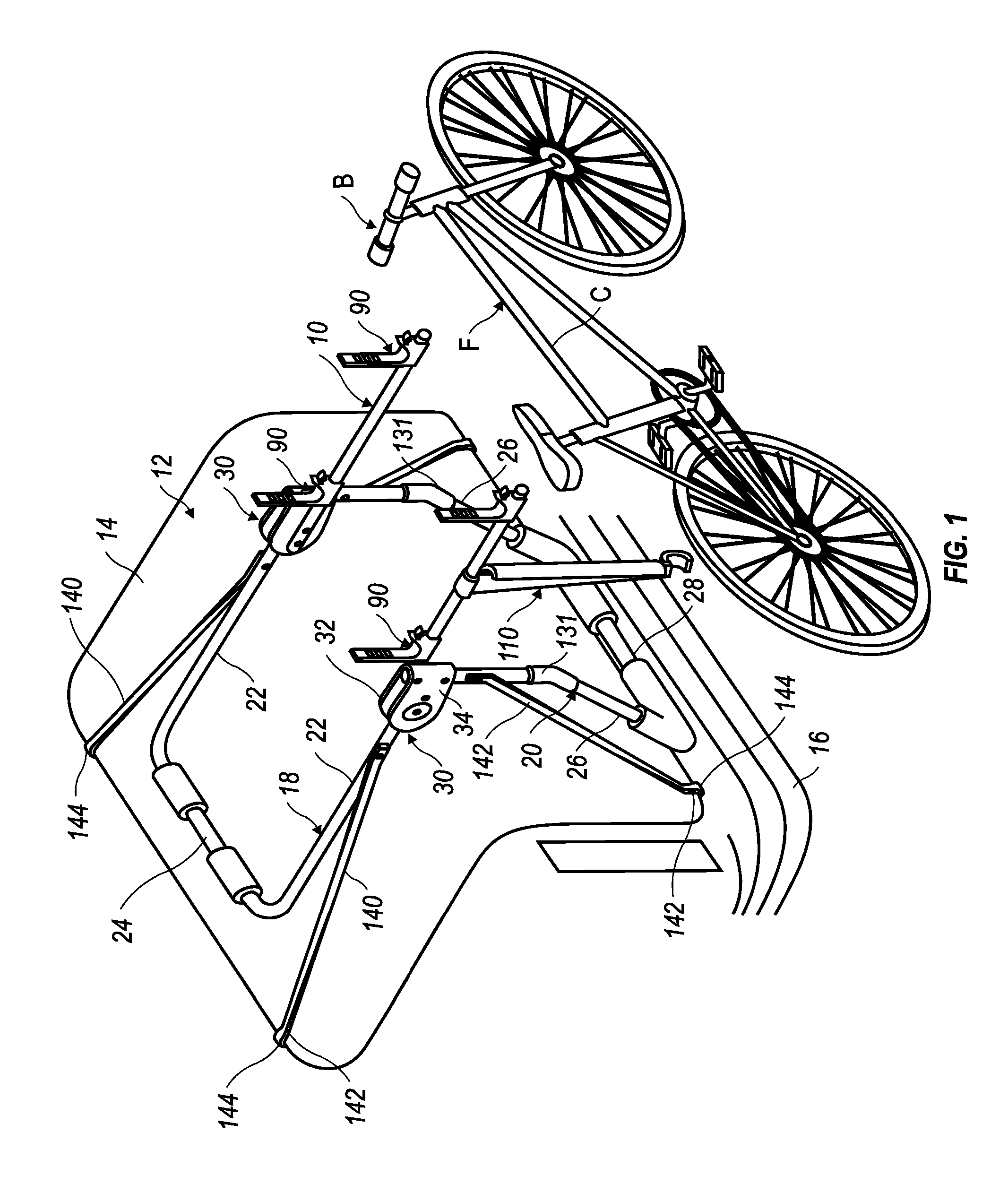

Anti-sway arrangement for cargo on a load carrier

ActiveUS20070235487A1Good compatibilityImprove the usefulnessTravelling carriersSupplementary fittingsVehicle frameEngineering

Method and apparatus for providing and anti-sway arrangement for stabilizing a bicycle supported upon a cradle borne upon an elongate arm of a vehicular mountable load carrier. The arrangement includes a cradle borne upon an elongate arm of a vehicular mountable load carrier. The elongate arm is insert-received in a through-hole located in the cradle and the cradle is configured to abuttingly receive a portion of a bicycle frame thereupon. An anti-sway device is included that has a substantially Y-shape with two upper arms straddling the cradle, and the two upper arms are joined together at a lower common leg thereof. Each of the two upper arms have an arm engaging portion having a releasable clasp that is operator transitionable between a clasping configuration in which the anti-sway device is secured to the elongate arm and an open configuration in which the device is installable upon and removable away from the arm in a direction transverse to a longitudinal axis of the elongate arm and whereby the anti-sway device accommodates installation onto, and removal off of, the elongate arm of the load carrier without disengagement of the cradle from the elongate arm.

Owner:THULE SWEDEN AB

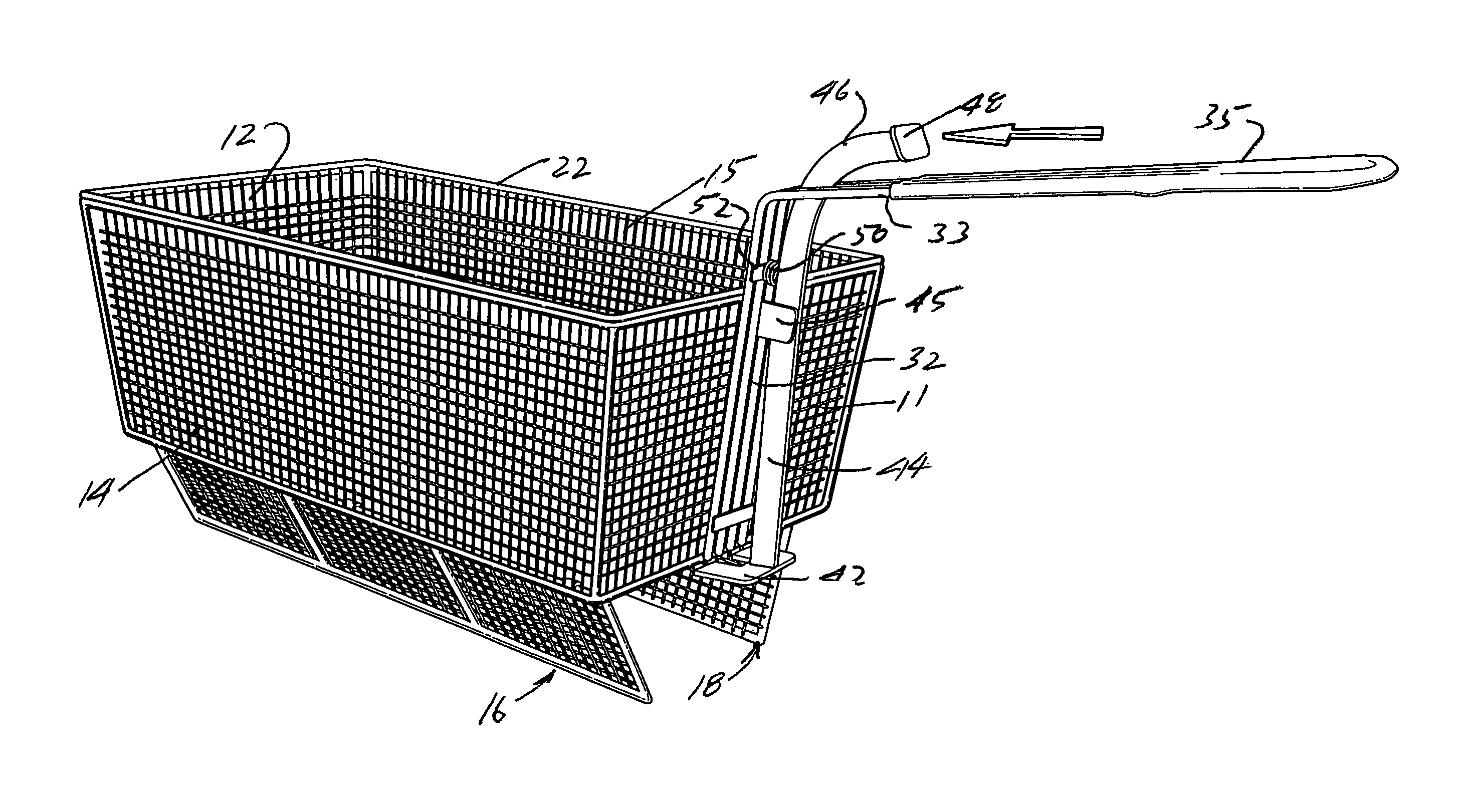

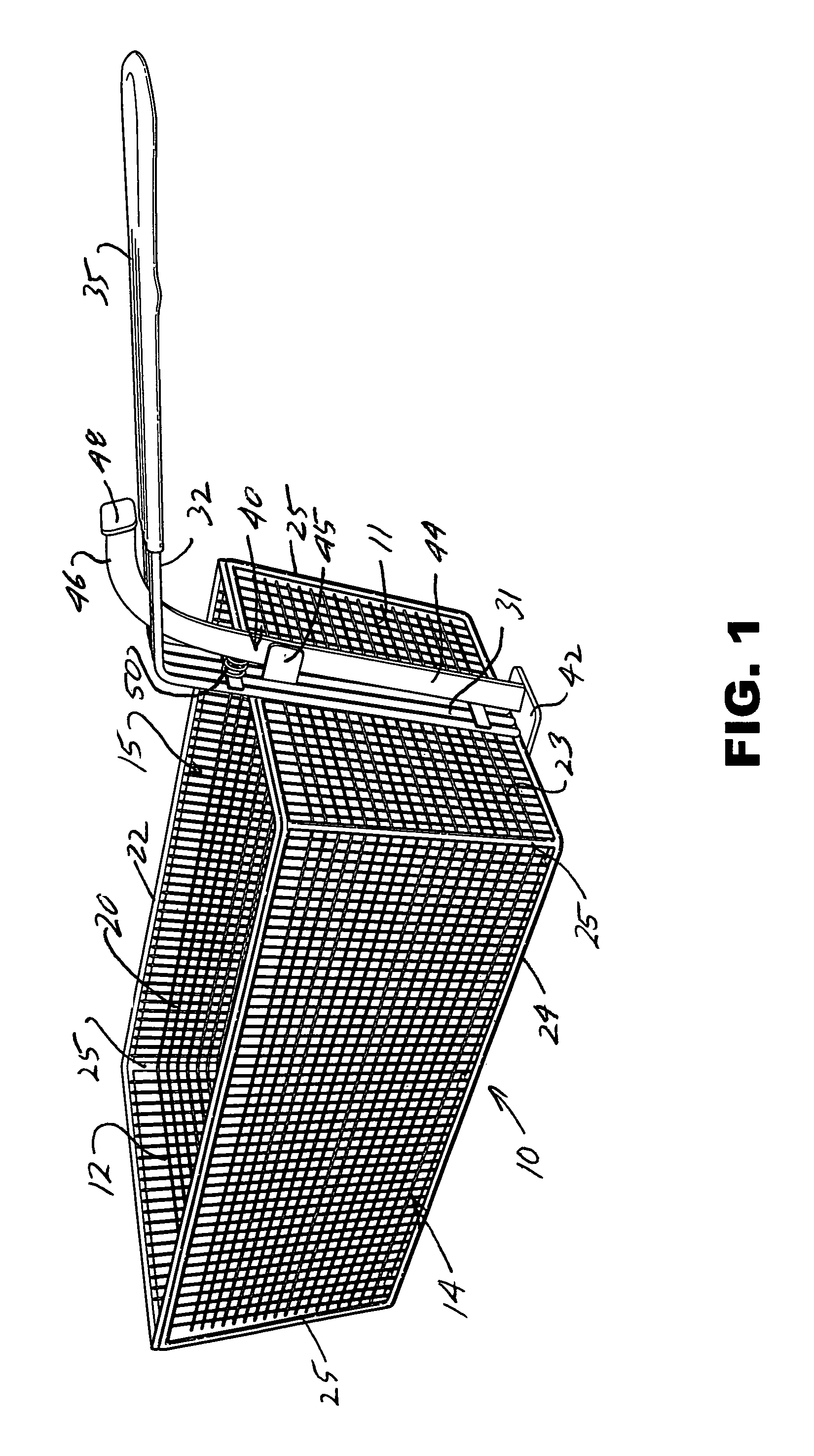

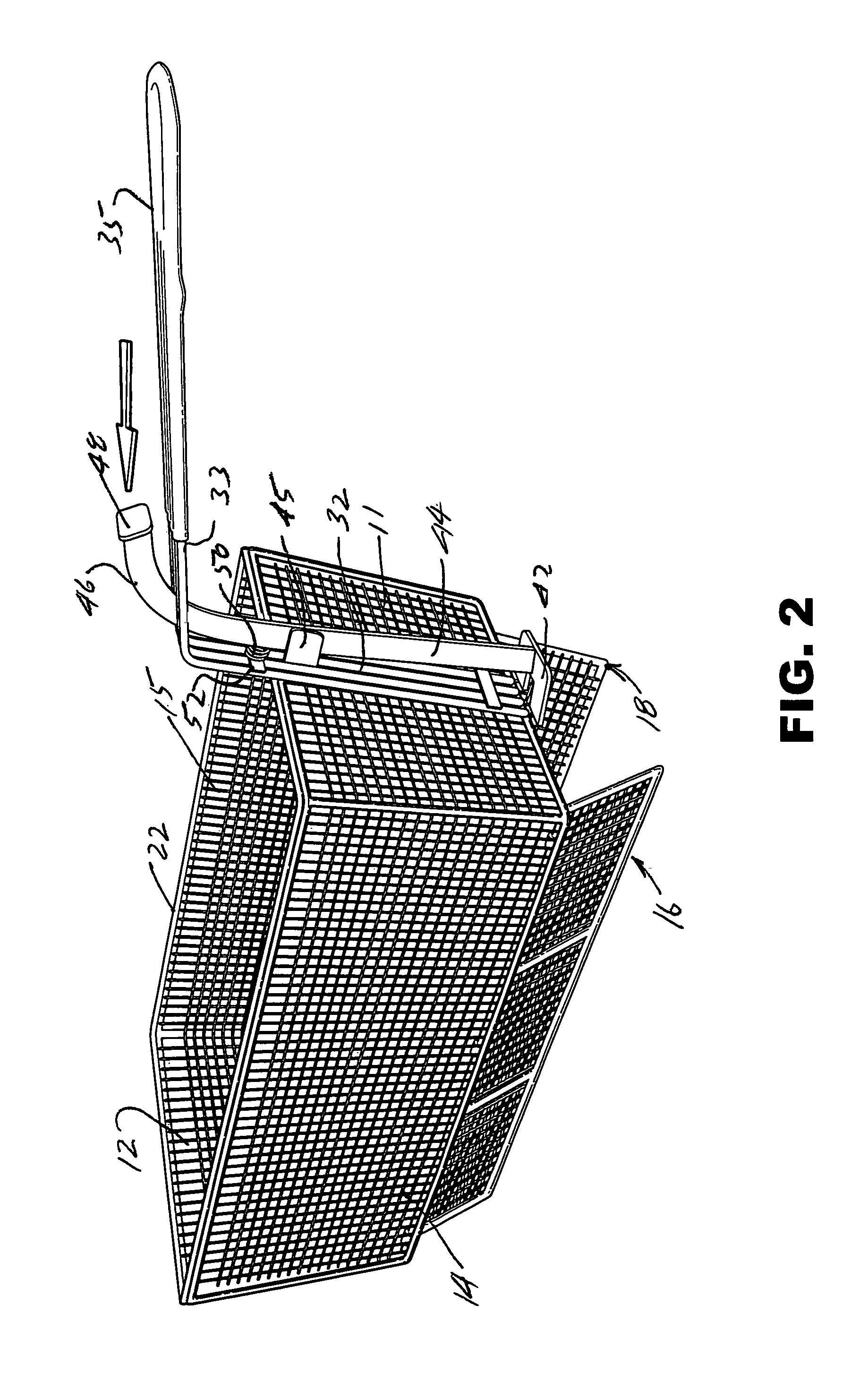

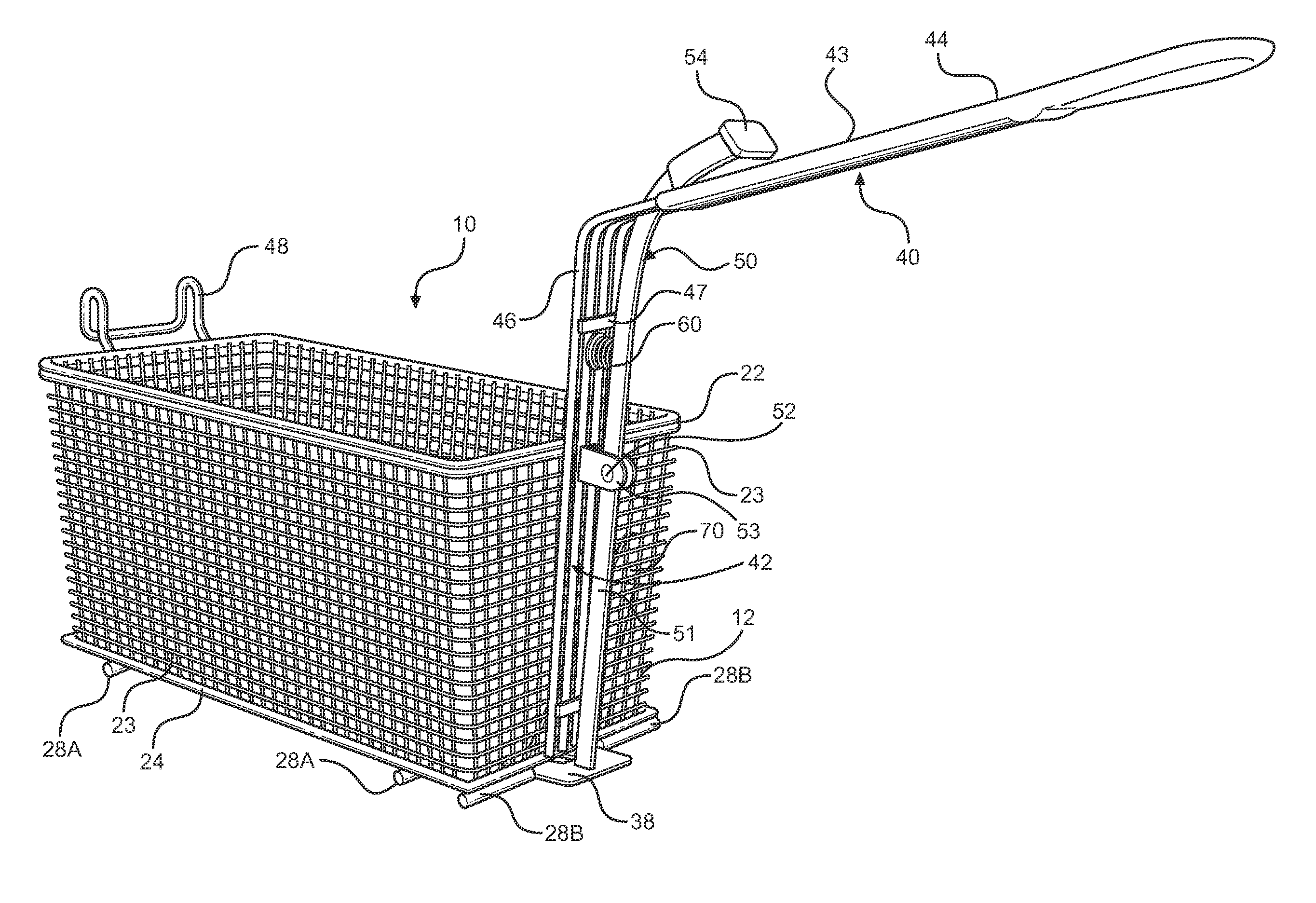

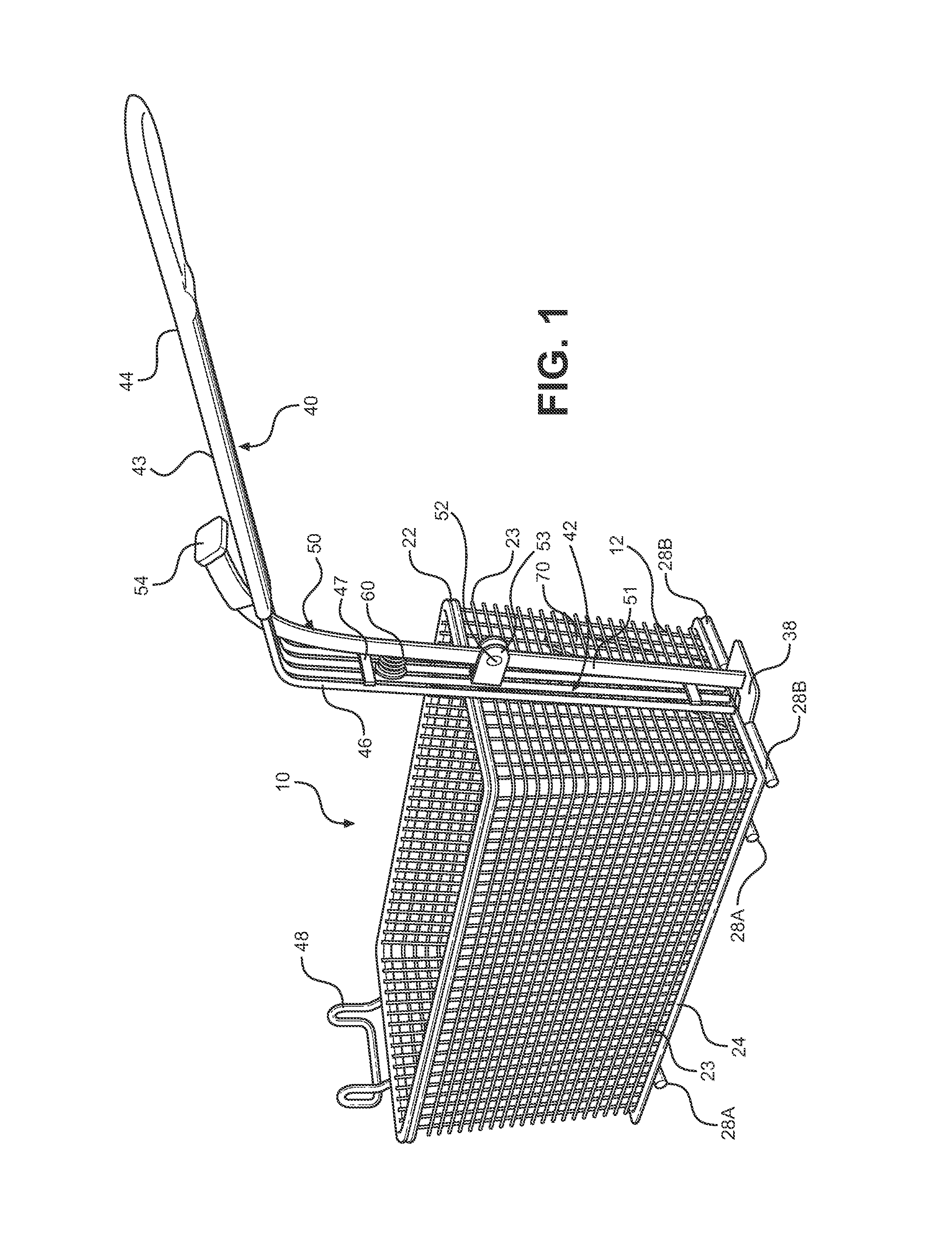

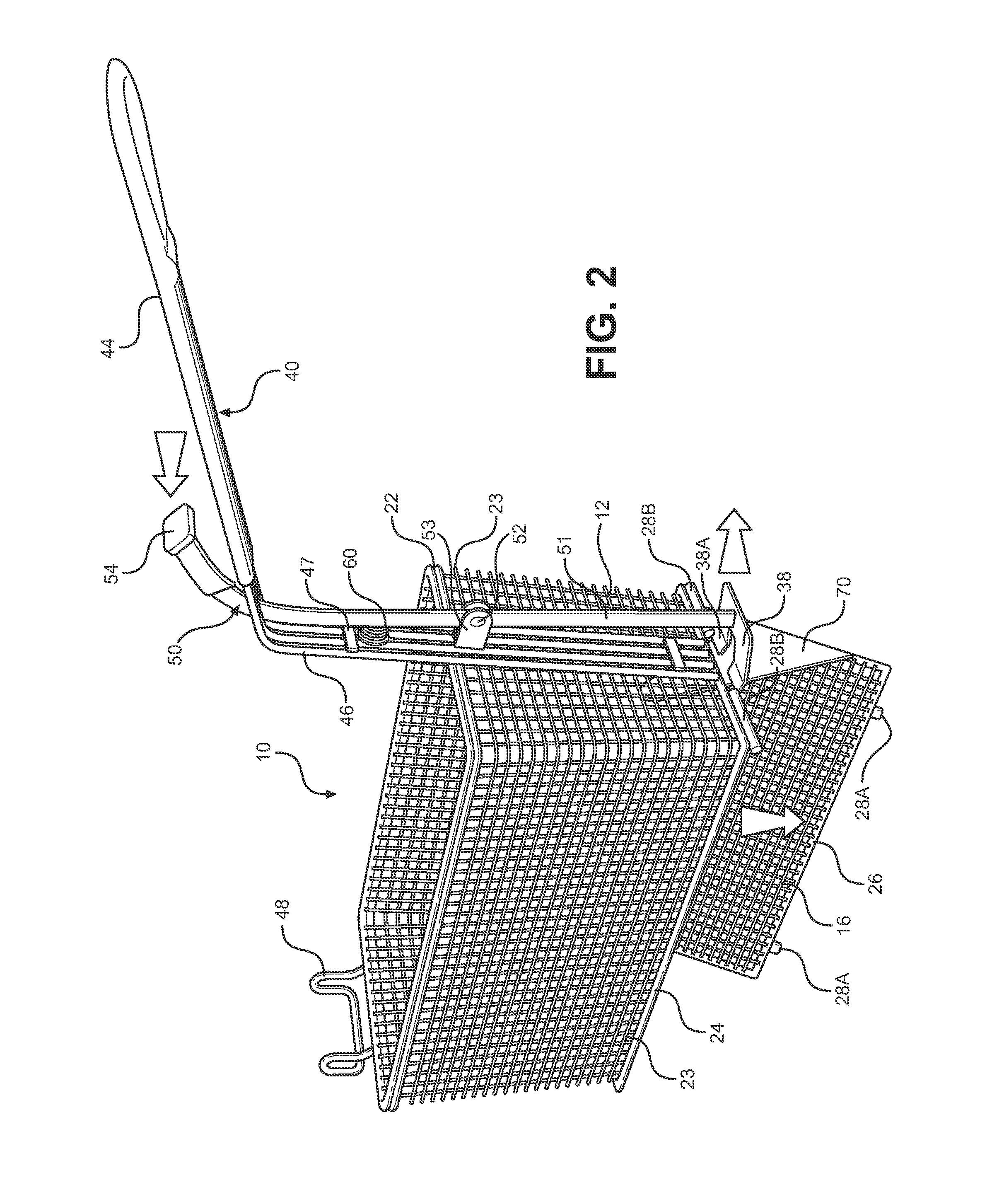

Bottom opening fryer basket

A fryer basket having at least one bottom wall or panel that is normally retained in a closed relationship relative to side walls of the basket but which is released to pivot to an open position upon operation of a latching mechanism that is operable adjacent to a handgrip of a handle connected to the basket.

Owner:PRH1

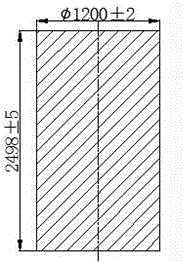

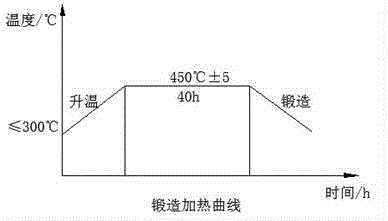

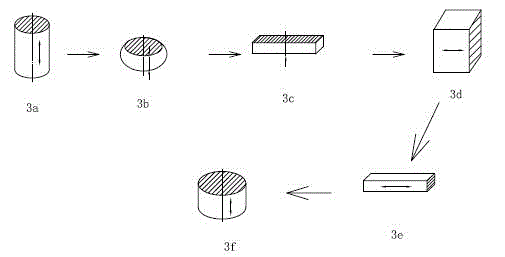

Forging forming technology of aluminum alloy straight-flanked ring with extra-large specification

The invention relates to a forging forming process of an aluminum alloy straight-flanked ring with an extra-large specification. The forging forming process comprises the fist step of blanking; the second step of a first heating before forging, wherein two heating stages are included; the third step of billet fabricating, wherein four stages are included; the fourth step of machining and damage removing; the fifth step of a second heating before forging; the sixth step of forging and ring rolling; the seventh step of heat treatment, wherein two heat treatment stages are included; the eighth step of machining to appropriate dimensions. By means of the forging forming process of the aluminum alloy straight-flanked ring with the extra-large specification, forging formability and mechanical performance of the aluminum alloy straight-flanked ring with the extra-large specification are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

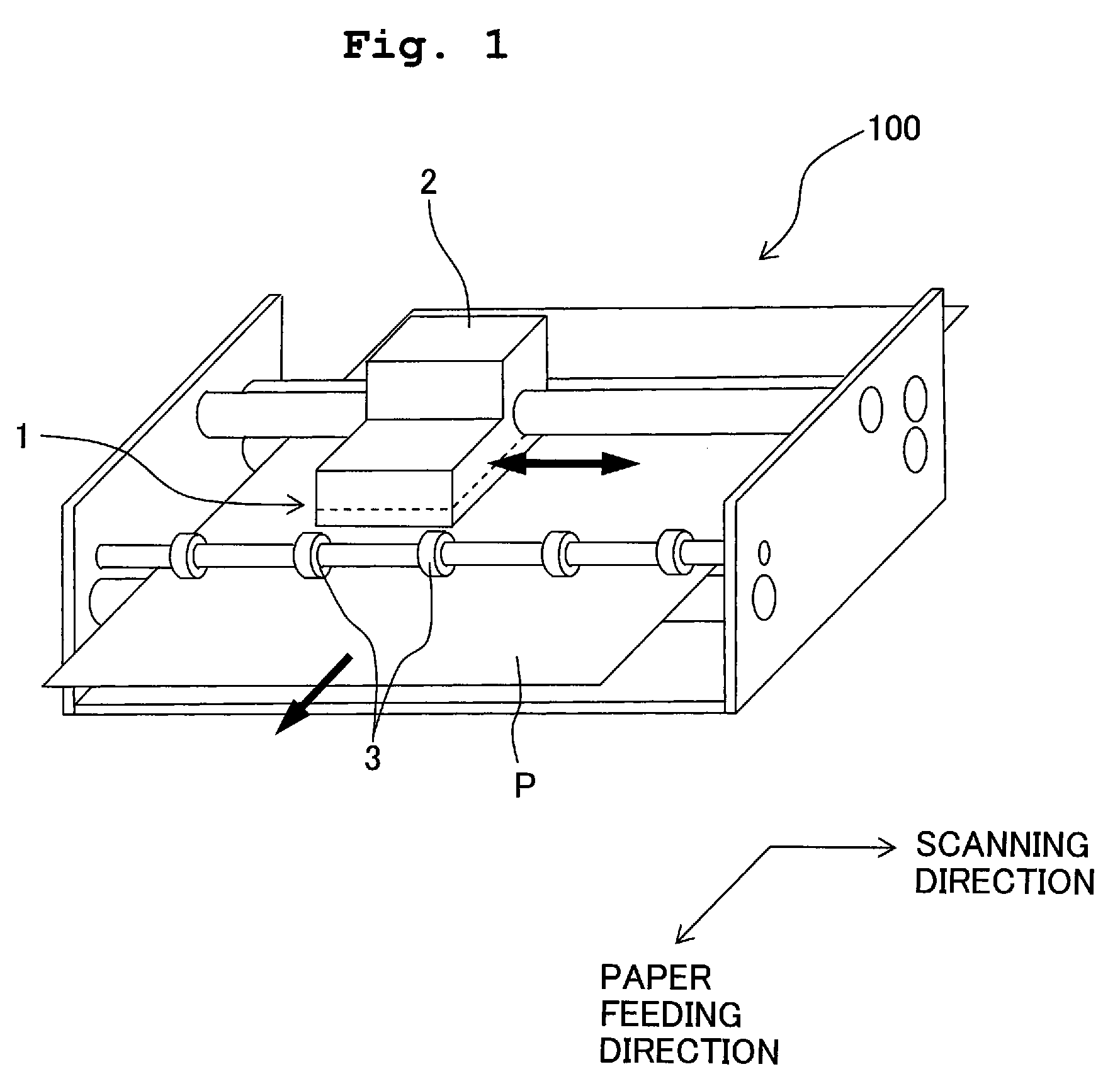

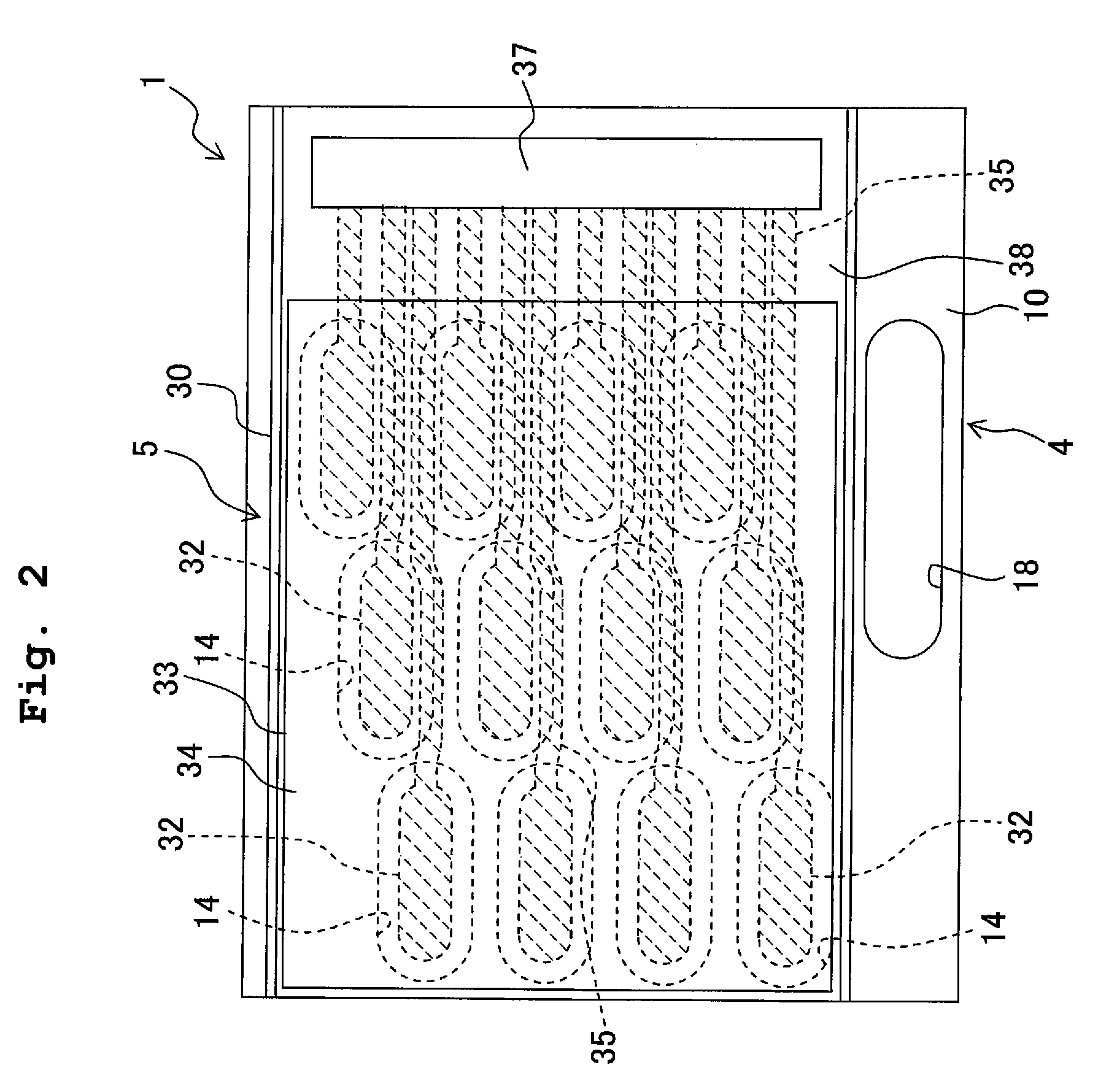

Liquid transport apparatus and method for producing liquid transport apparatus

ActiveUS20090219347A1InhibitionNot easy to damagePrintingPiezoelectric actuatorsElectrical and Electronics engineering

A piezoelectric actuator includes a vibration plate, a plurality of individual electrodes, wiring sections each extending from corresponding one of the individual electrodes and passing between the other individual electrodes other than the corresponding individual electrode, a piezoelectric layer arranged on the vibration plate to cover the individual electrodes, and a common electrode arranged on a surface of the piezoelectric layer disposed on a side opposite to the piezoelectric layer. At least portions of the plurality of wiring sections, each of which is allowed to pass between the another individual electrodes, are covered with a second insulating layer. Accordingly, it is possible to suppress the occurrence of the strain of the piezoelectric layer in the area between the individual electrodes through which the wiring section is allowed to pass, without providing any complicated shape of the common electrode in which the common electrode is partially cut out.

Owner:BROTHER KOGYO KK

Bottom opening fryer basket

ActiveUS8584579B1Easy to engageReduce painRigid containersDeep fat fryersEngineeringMechanical engineering

A fryer basket having at least one bottom panel that is normally retained in a closed relationship relative to side walls of the basket but which is released to pivot to an open position upon operation of a latching mechanism that is operable adjacent to a handgrip of a handle connected to the basket and wherein a blocking member carried by the at least one bottom panel prevents the latching mechanism from returning to its closed position until the at least one bottom panel is returned to its closed positioned after having been opened.

Owner:PRH1

Dock connector with compliance mechanism

ActiveUS20140069710A1Reduce the possibilityFlexible and durableBatteries circuit arrangementsSemiconductor/solid-state device detailsDocking stationEngineering

Docking stations having a connector with a compliance mechanism to provide improved durability and flexibility are provided herein. The compliance mechanism may be attached to a connector in a base of a docking station and may include any or all of a flexure, a torsion bar, damping members, a compressive foam member, and an engineered base plate. The compliance mechanism may be configured to provide sufficient rigidity to the connector to support a portable device when mounted on the connector within the dock in an upright position, sufficient flexibility to allow angular displacement of a mounted portable device, and sufficient elasticity to provide a resilient biasing force to return the connector and a mounted portable device from a displaced position to the upright position.

Owner:APPLE INC

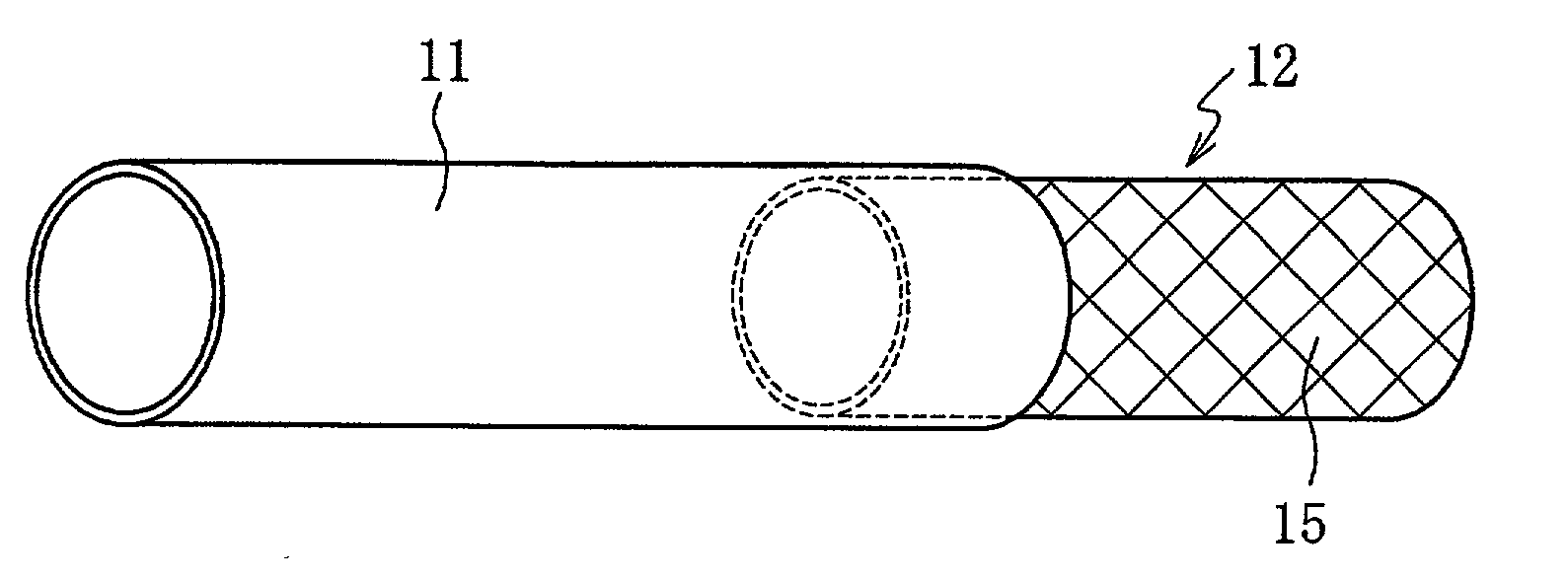

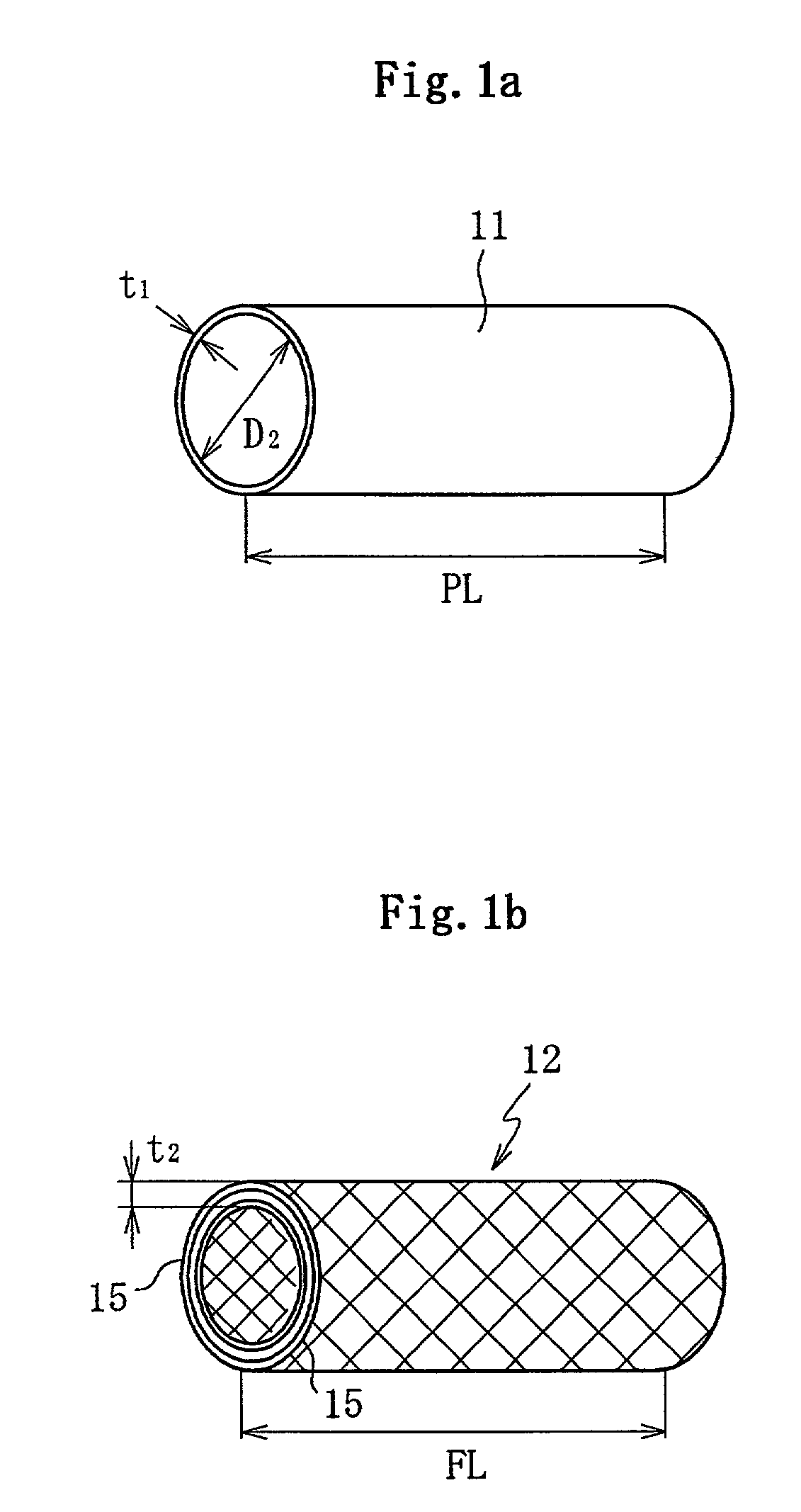

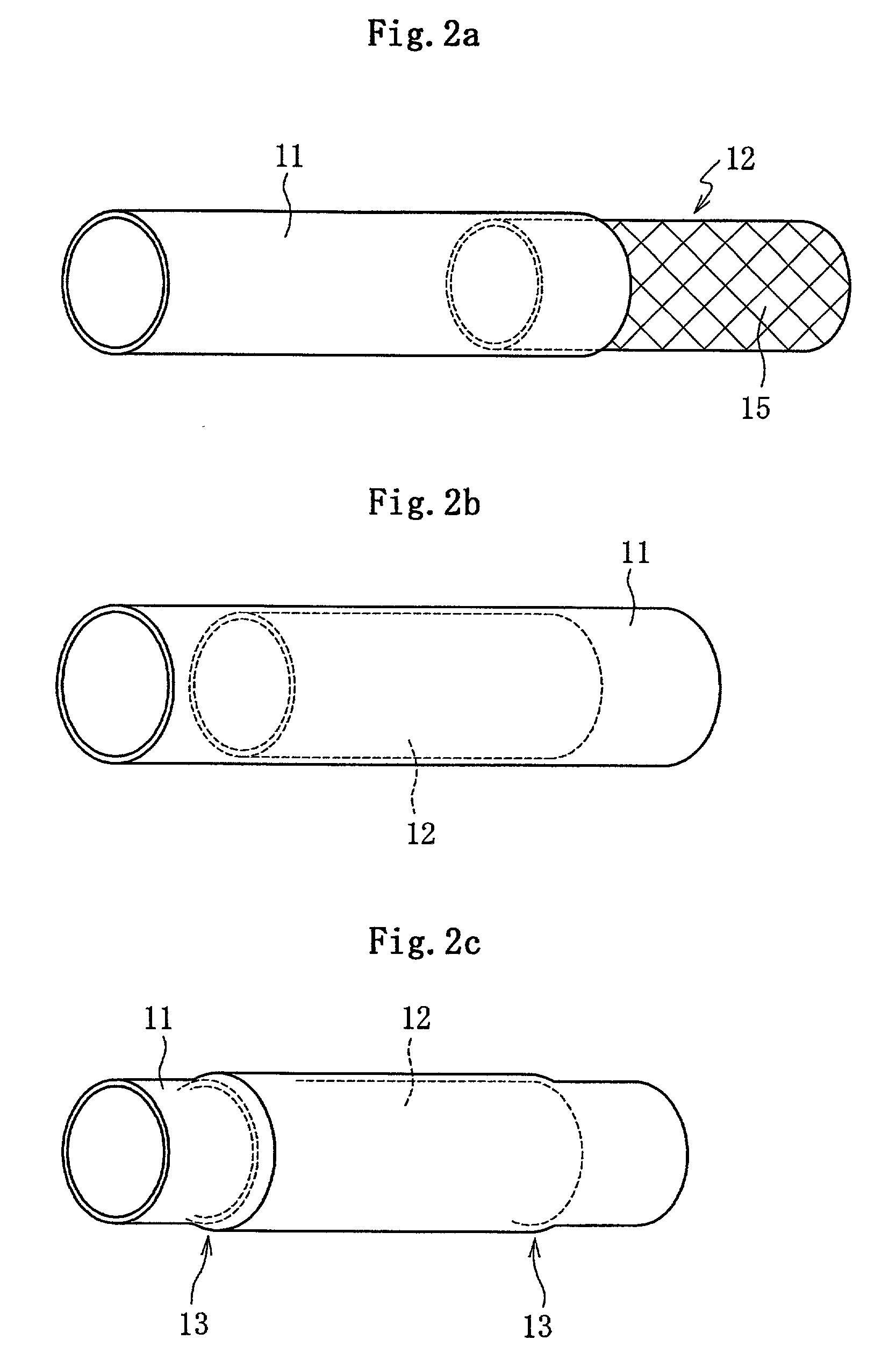

Fiber reinforced plastic pipe and power transmission shaft employing the same

ActiveUS20020117228A1Reduce thicknessIncrease the diameterShaftsFlexible pipesSurface layerFiber bundle

A fiber reinforced plastic pipe is provided to prevent it from being damaged and make full use of its practical performance when the fiber reinforced plastic pipe, reduced in thickness and increased in diameter by pultrusion process, is reduced in the circumferential direction and inserted into a metal pipe. The fiber reinforced plastic pipe, reduced in thickness and increased in diameter by pultrusion process, includes a fiber bundle spun and aligned in the longitudinal direction, and circumferential reinforced fiber sheet provided at least on one of the outer and inner surface layers. The circumferential reinforced fiber sheet is inserted into the metal pipe to form a power transmission shaft such as an intermediate shaft for use with a propeller shaft or a drive shaft.

Owner:NTN CORP +2

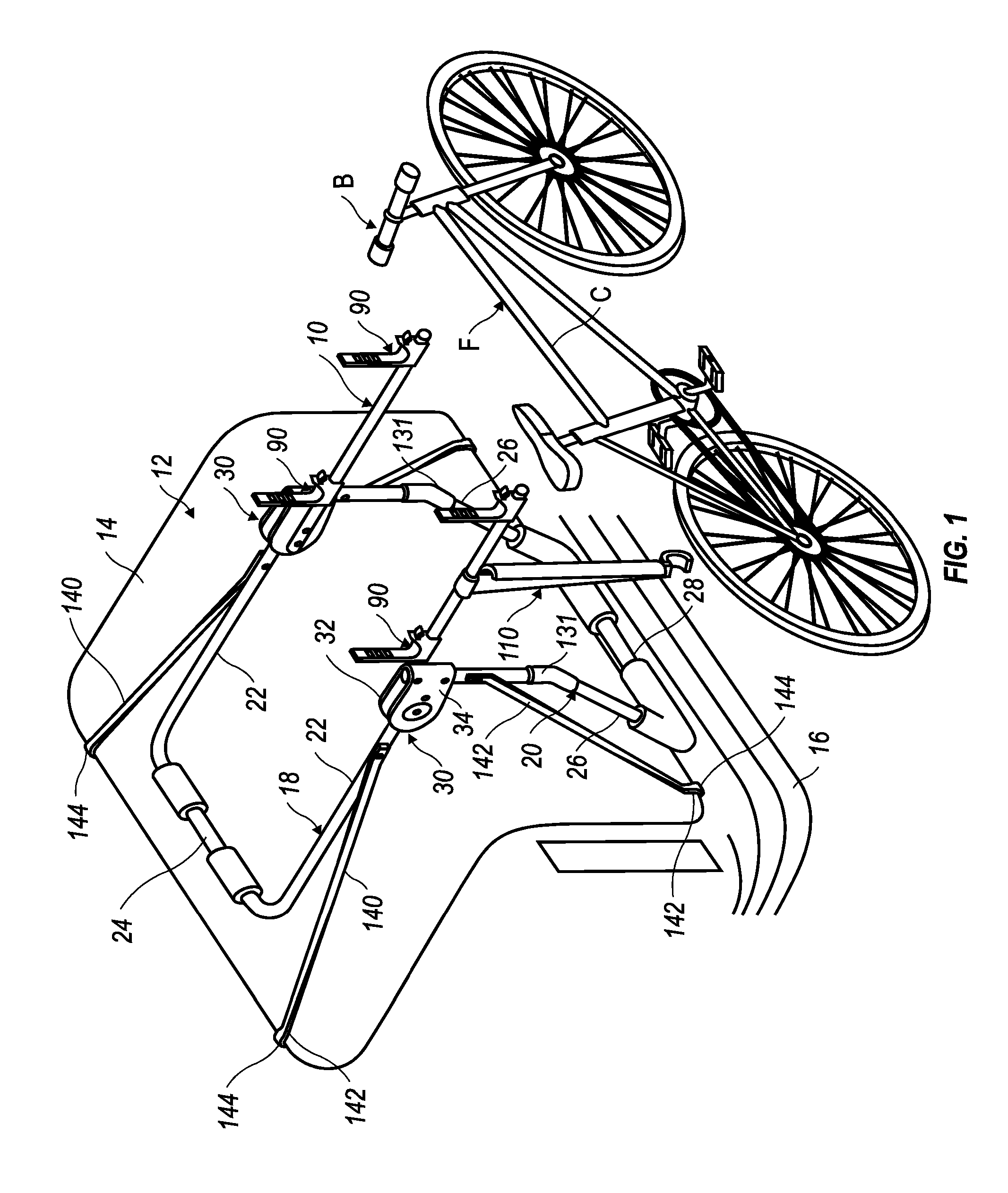

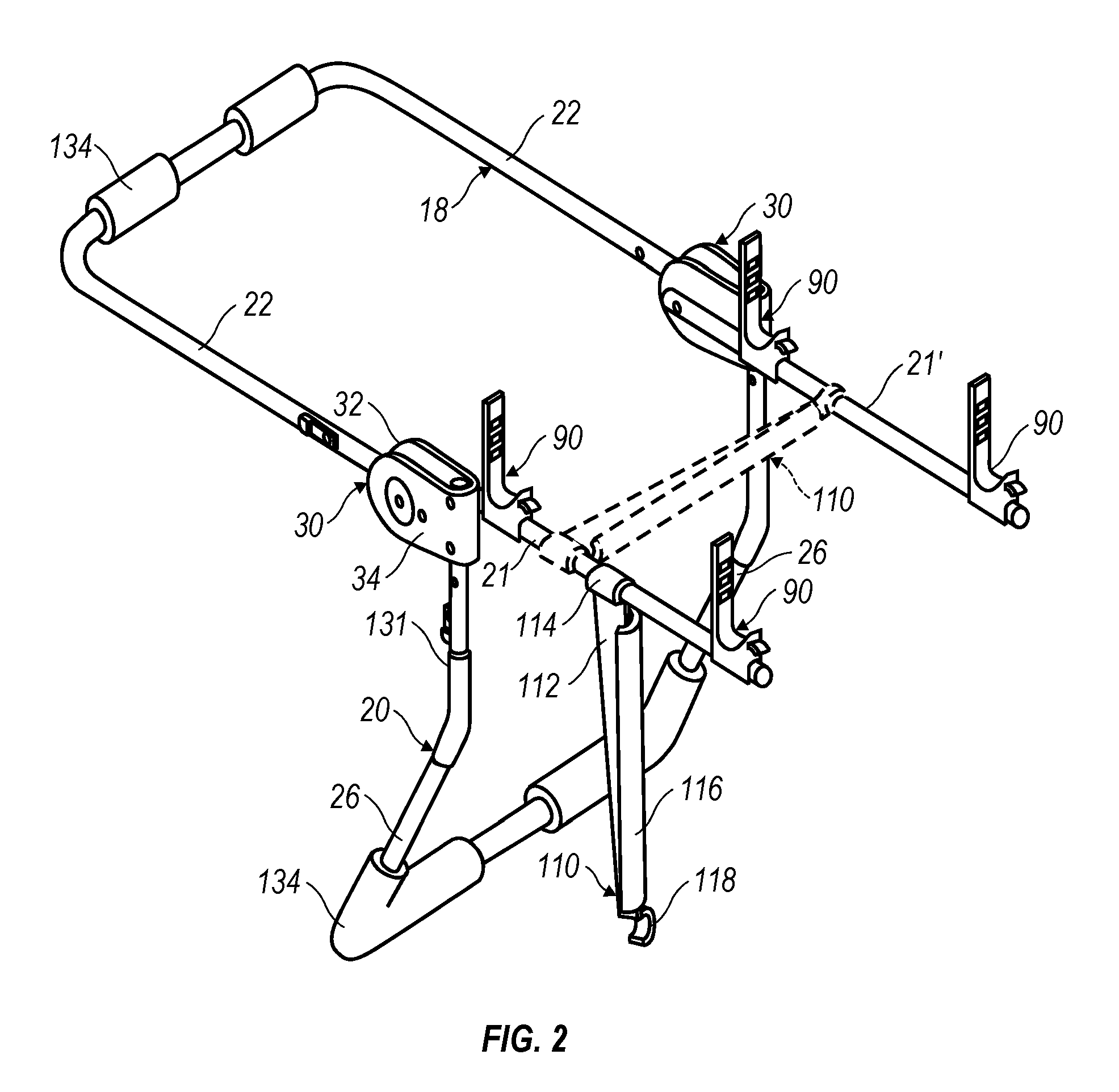

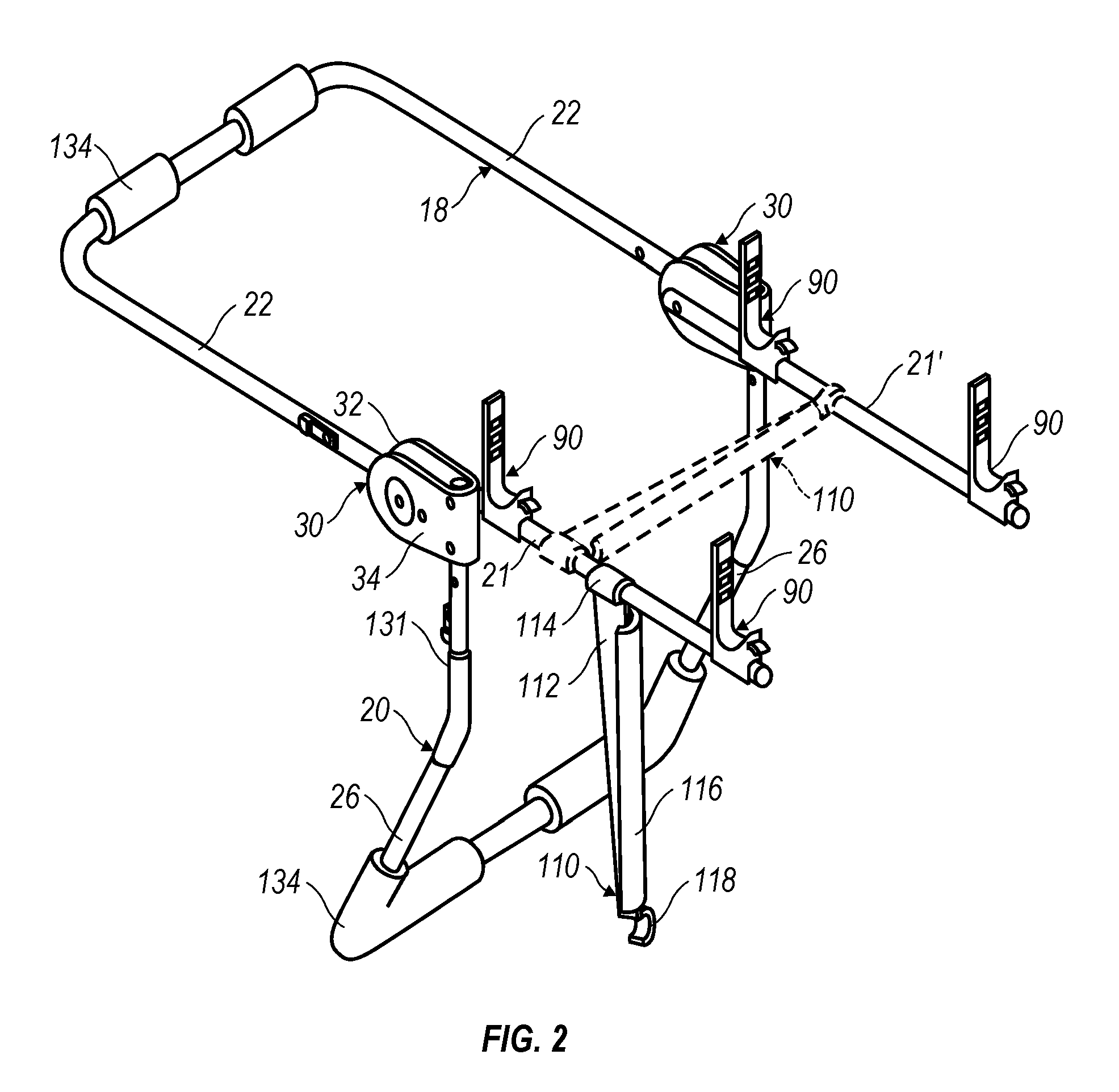

Actuable load carrier cradle

ActiveUS7810685B2Avoid strainReduce tightnessPipe supportsMining devicesReciprocating motionEngineering

Method and apparatus for providing a load carrier arrangement for transporting a bicycle when secured thereupon. The load carrier arrangement including a frame assembly adapted to be mounted to the carrying vehicle. The frame assembly has at least one elongate arm configured to receive a bicycle cradle thereupon. The bicycle cradle is mounted upon the arm and is operator configurable between a bicycle transporting configuration and a non-transporting configuration. The cradle has a through-passage within which the elongate arm is received and the cradle is operator reciprocal on the elongate arm in the non-transporting configuration thereby facilitating variable longitudinal positioning of the cradle by the operator upon the arm. The cradle has an increased resistance to longitudinal reciprocation on the elongate arm in the bicycle transporting configuration in comparison to the non-transporting configuration. In this manner, the cradle is effectively longitudinally fixed on the elongate arm in the bicycle transporting configuration to an extent that a secured portion of a carried bicycle in the cradle is longitudinally fixed relative to the elongate arm during transport on the load carrier arrangement.

Owner:THULE SWEDEN AB

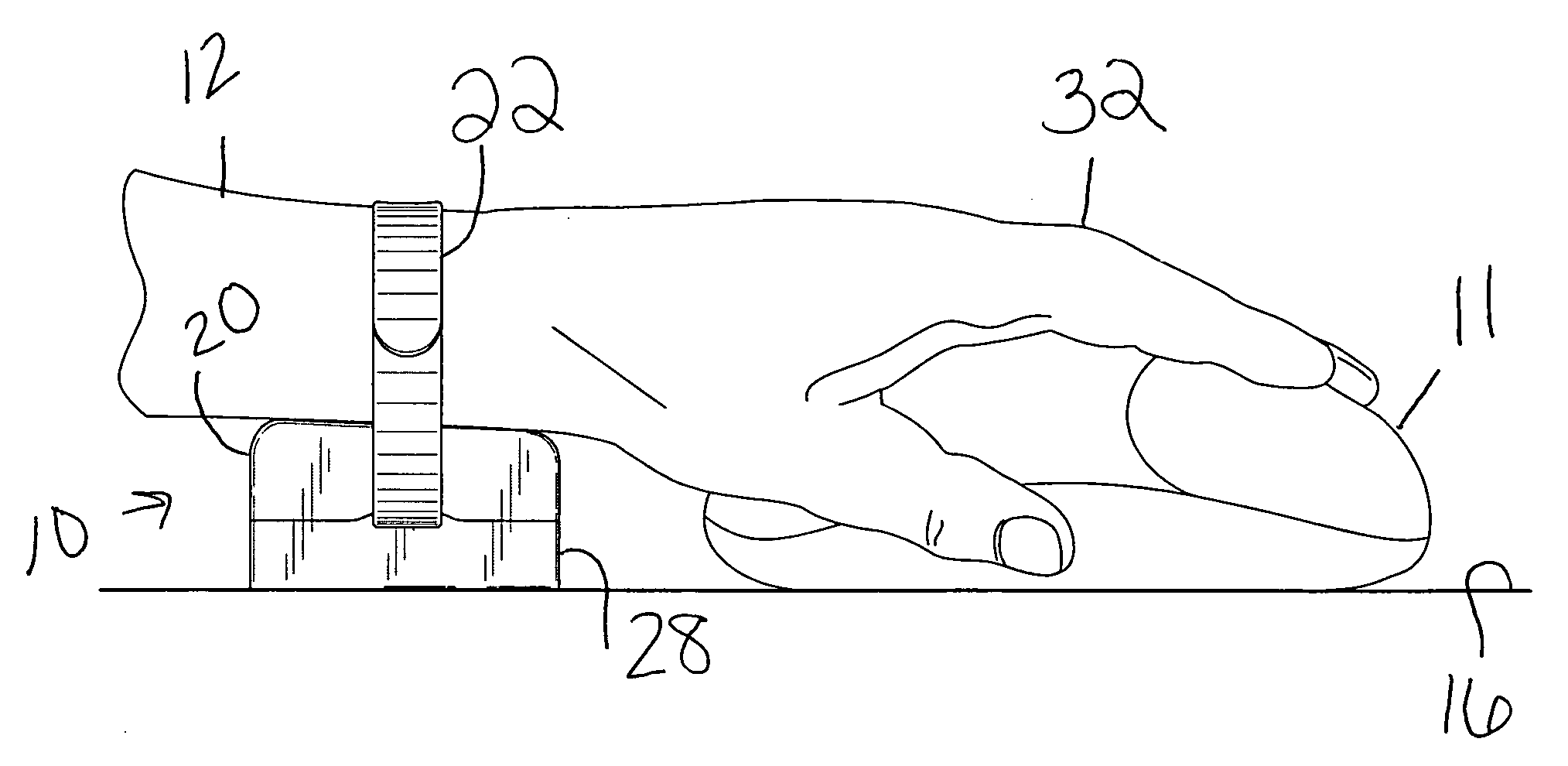

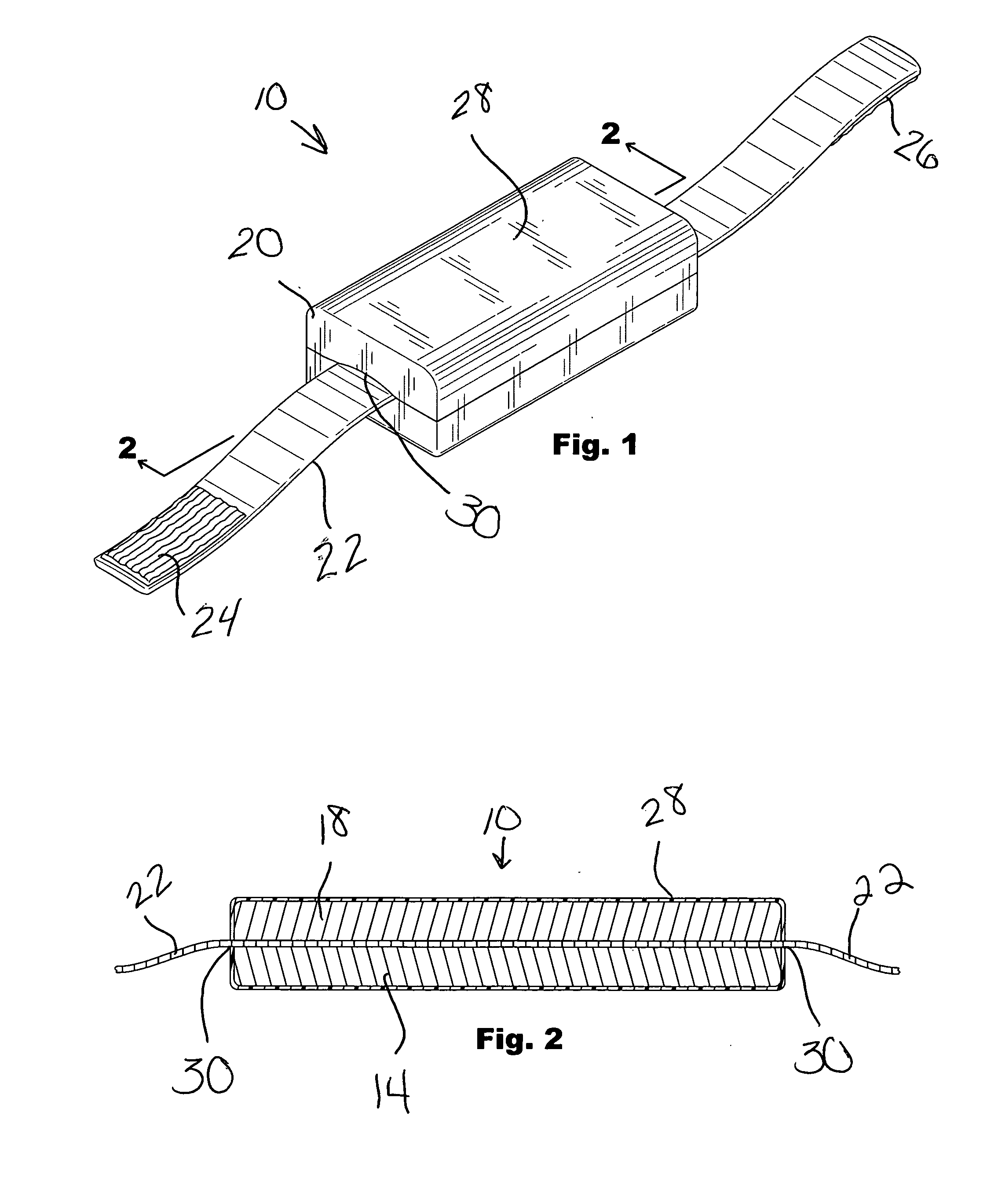

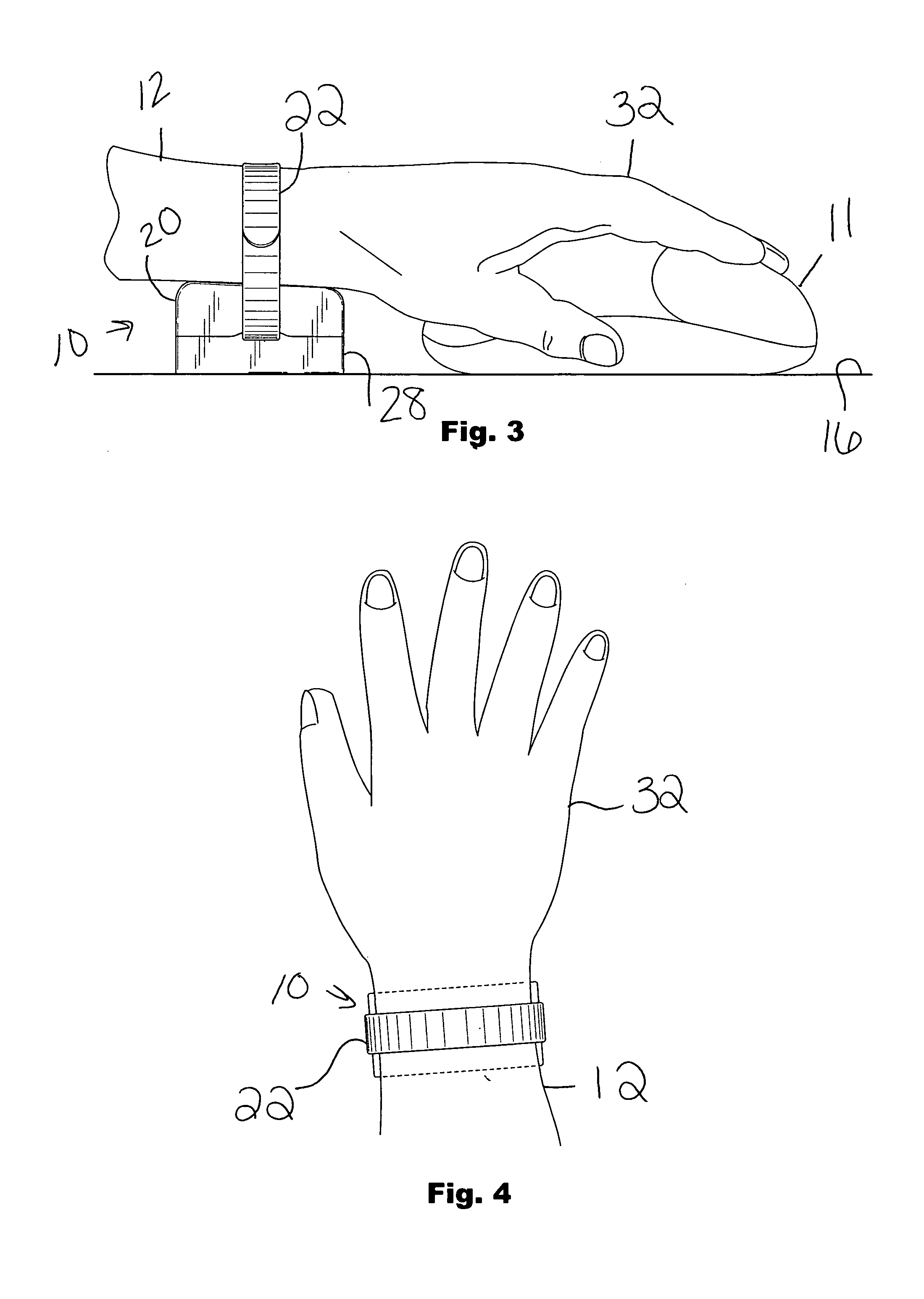

Portable wrist rest system

InactiveUS20050121562A1Avoid fatigueAvoid strainOffice tablesWriting supportsCTS - Carpal tunnel syndromeWrist support

A portable wrist resting pad for relieving and alleviating the strain and fatigue to the wrist and arm from repetitive and continual use of a computer mouse and keyboard includes a first support member for disposition on the desk surface, a second support member mounted to the first support member and having a density less than the first support member, and a wrist strap that extends outwardly from opposite ends of the support members for encompassing the wrist and attaching the support pad to the wrist. The wrist support pad elevates the wrist the appropriate distance from the work surface to relieve strain and fatigue to the wrist and arm for preventing carpal tunnel syndrome; and preferably one wrist support pad should be secured to each wrist to obtain maximum benefit from the portable wrist rest pads.

Owner:BAUMGARDNER DANNY D

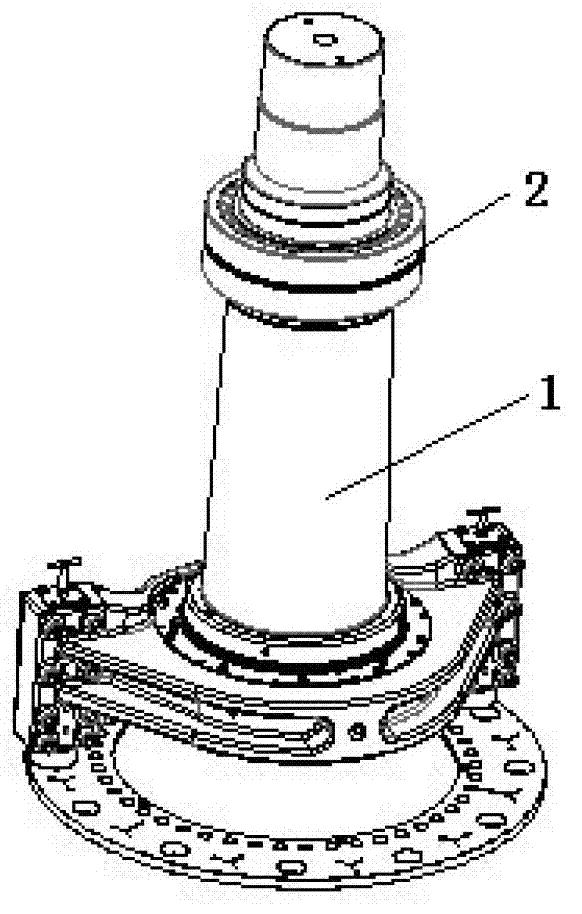

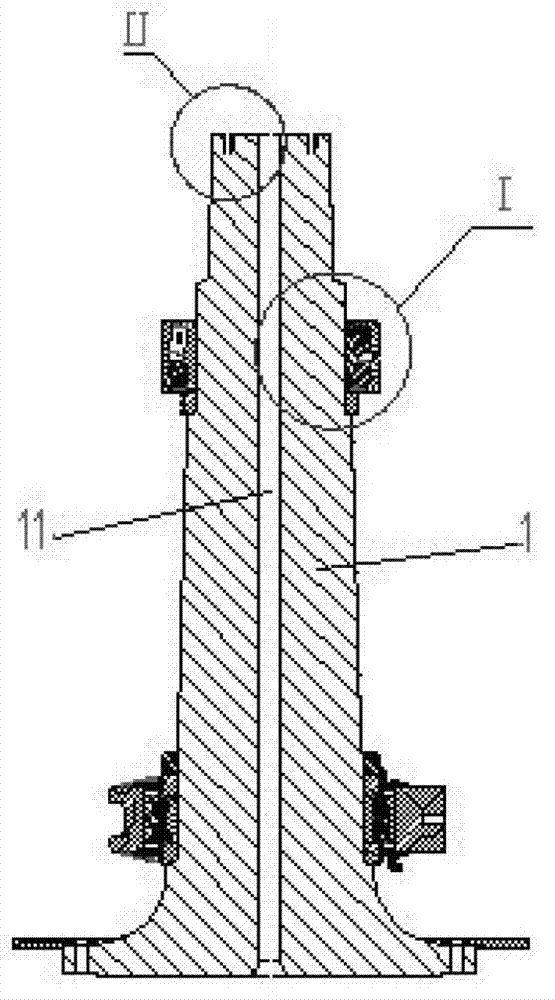

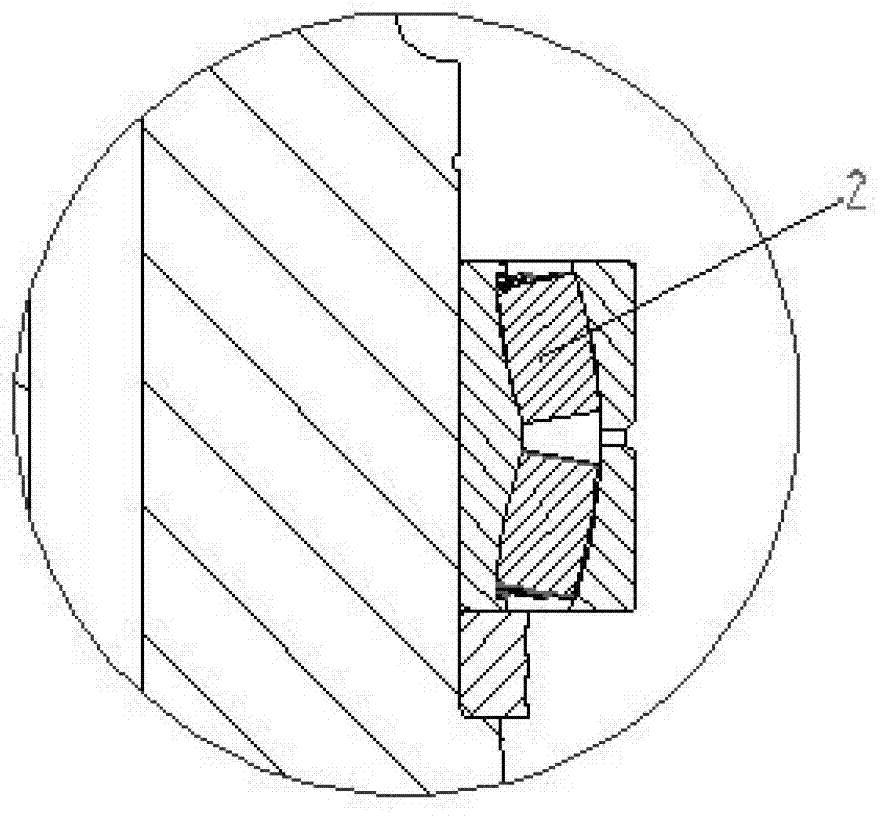

Disassembling method of wind turbine generator system main bearing with shaft sleeve

The invention discloses a disassembling method of a wind turbine generator system main bearing with a shaft sleeve. The disassembling method is mainly used for disassembling the main bearing from a main shaft. The disassembling method comprises the following steps: A. cooling the main shaft; B. heating a bearing inner race of the main bearing, and C. dissembling the main bearing from the tail end of the main shaft using match of a bearing tensioner and the main bearing under the effect of external force. A certain temperature difference is formed between the main shaft and the bearing inner race of the main bearing by cooling the main shaft and heating the bearing inner race of the main bearing, magnitude of interference of assembling of the main shaft is offset using the expansion caused by heat and contraction caused by cold theory, and the main bearing can be disassembled from the main shaft safely and quickly using the bearing tensioner. Integrality of disassembling of the main bearing is guaranteed, damages to the main shaft by using the bearing tensioner to disassemble the main bearing directly can be avoided, and recycle of the main shaft saves large cost for an enterprise. The disassembling method of the wind turbine generator system main bearing with the shaft sleeve is simple in operation procedures at the same time, and an ideal disassembling method of the wind turbine generator system main bearing with the shaft sleeve is achieved.

Owner:GUODIAN UNITED POWER TECH CHIFENG

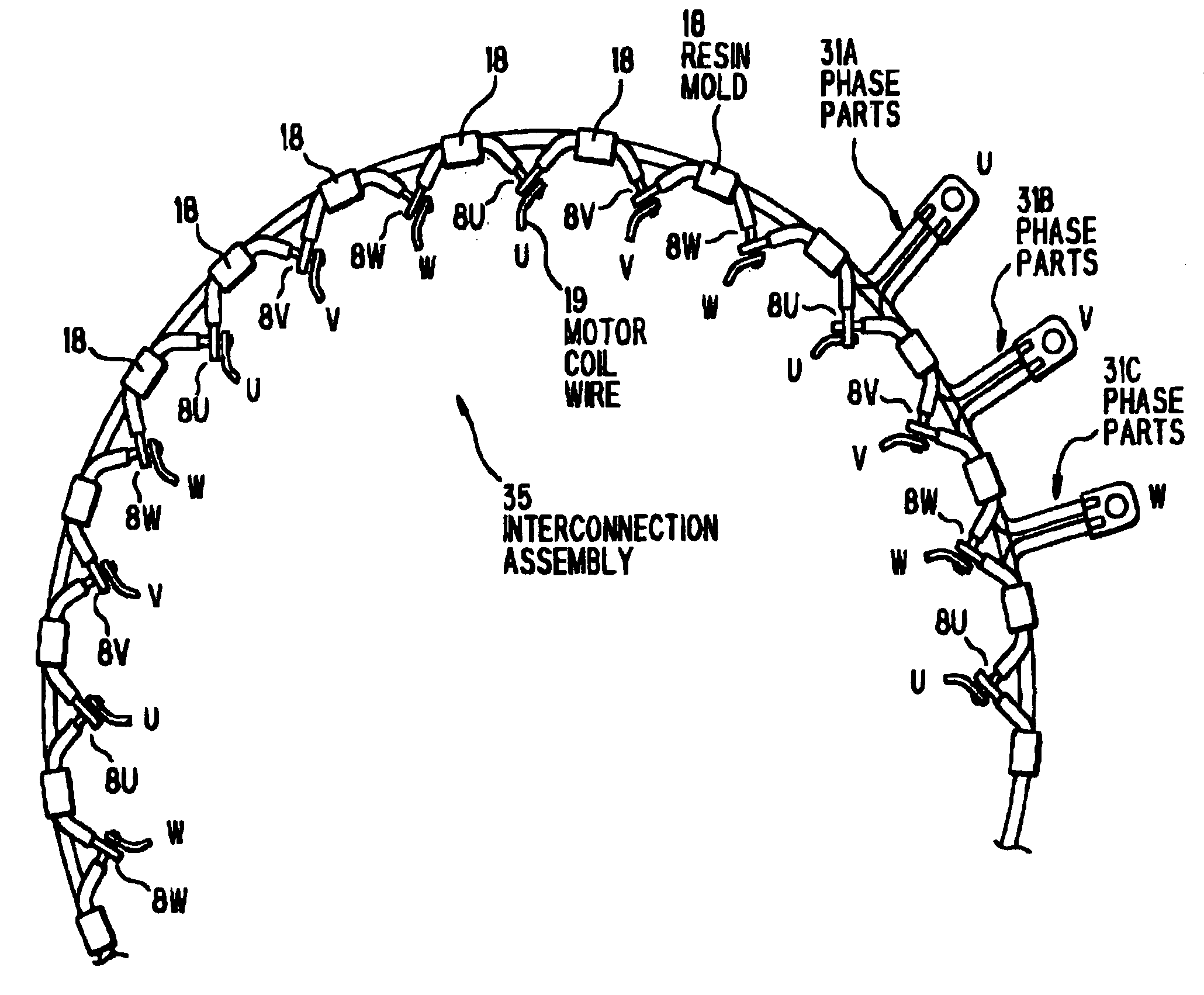

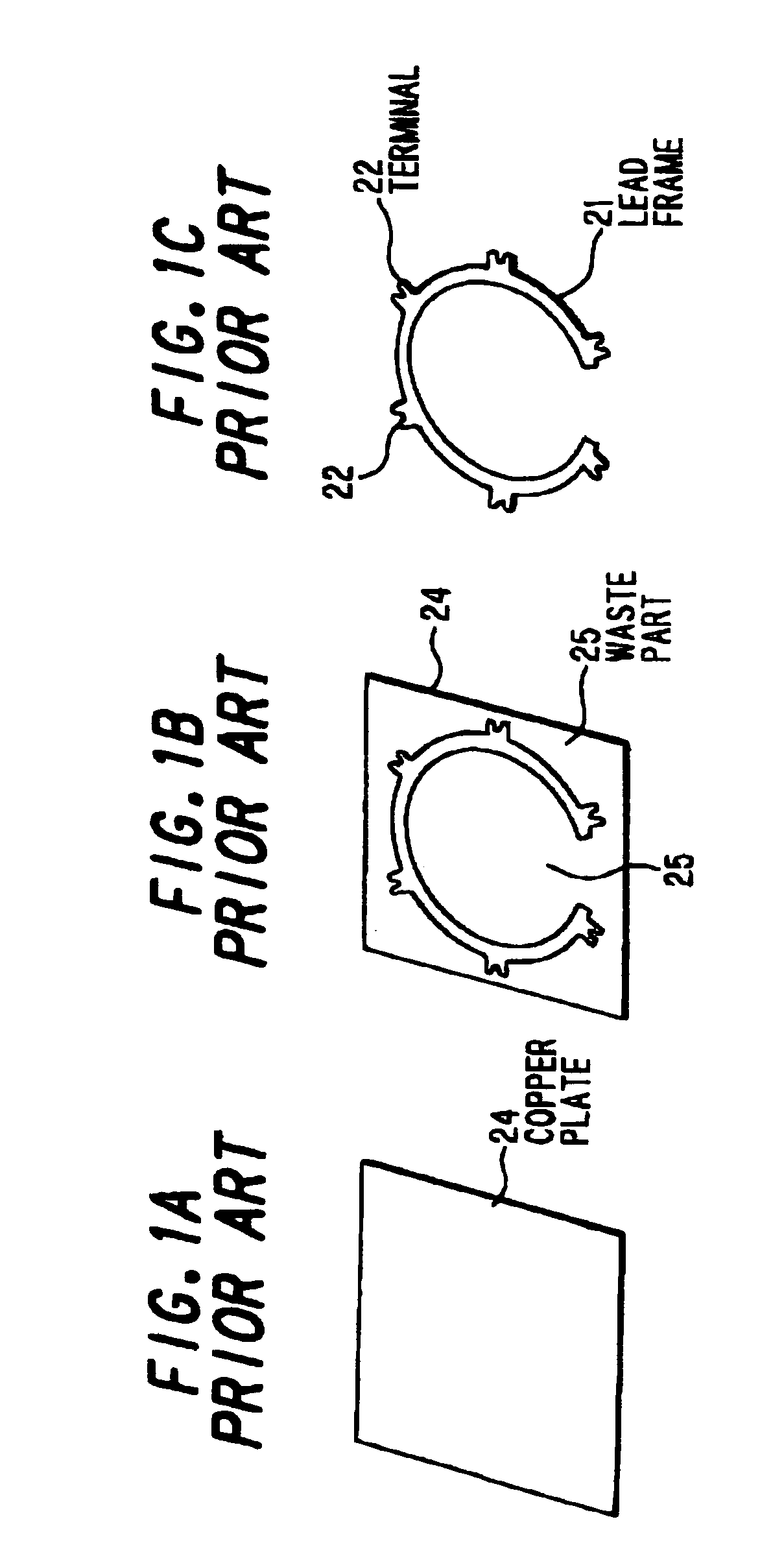

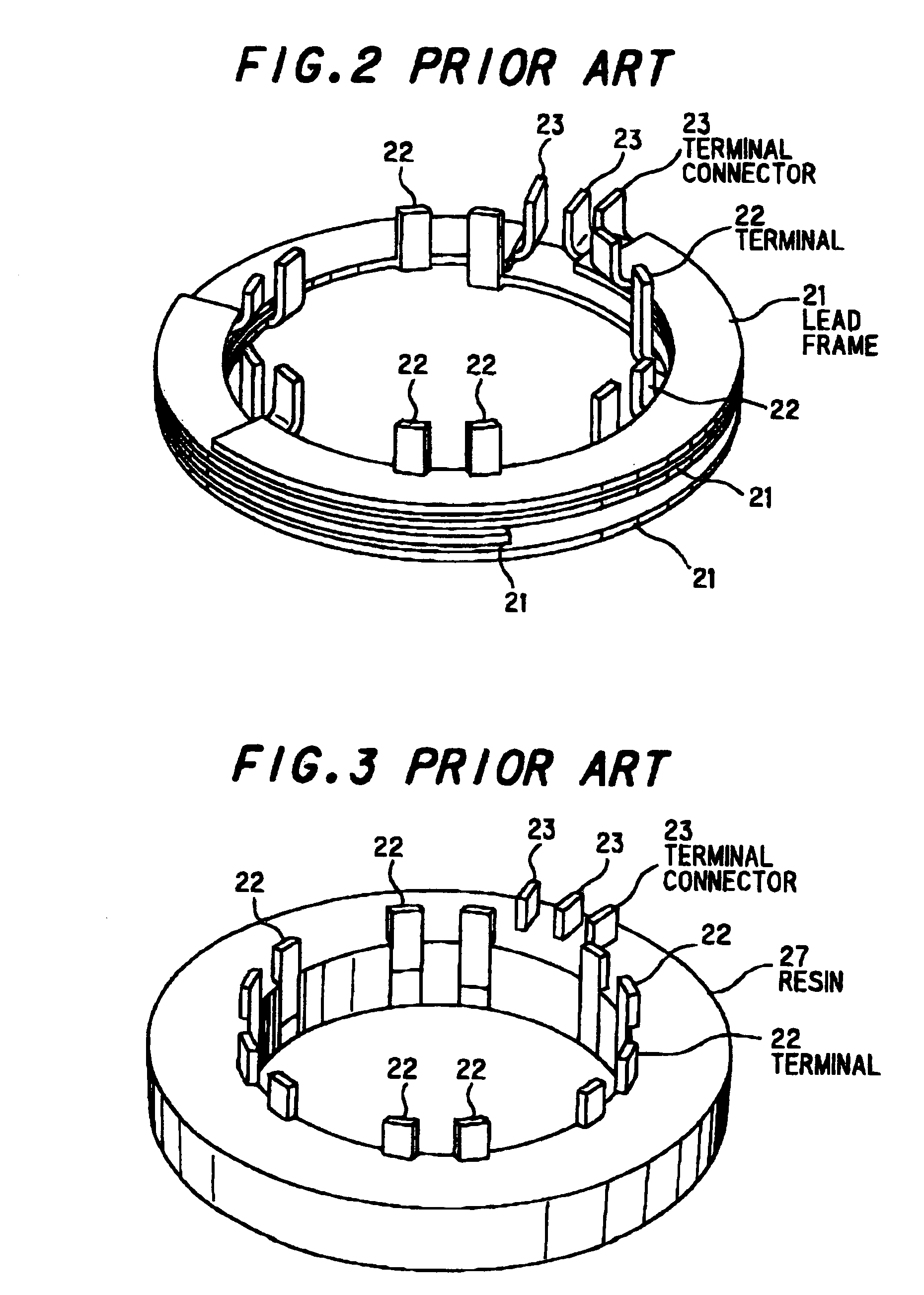

Interconnection assembly for an electric motor and method of making the same

InactiveUS7045920B2Avoid strainReduce wasteSynchronous generatorsMagnetic circuitElectrical conductorEngineering

An interconnection assembly has phase parts for U phase, V phase and W phase. The phase parts each are of a plurality of interconnection assembly parts that are connected in the form of a ring and include a conductor section to which a motor coil wire is connected, the conductor section being formed by stripping fluororesin insulation at a predetermined position, and the phase parts are partially fixedly bundled.

Owner:HITACHI CABLE +1

Anti-sway arrangement for cargo on a load carrier

ActiveUS7757917B2Avoid strainReduce tightnessTravelling carriersSupplementary fittingsEngineeringMechanical engineering

Method and apparatus for providing and anti-sway arrangement for stabilizing a bicycle supported upon a cradle borne upon an elongate arm of a vehicular mountable load carrier. The arrangement includes a cradle borne upon an elongate arm of a vehicular mountable load carrier. The elongate arm is insert-received in a through-hole located in the cradle and the cradle is configured to abuttingly receive a portion of a bicycle frame thereupon. An anti-sway device is included that has a substantially Y-shape with two upper arms straddling the cradle, and the two upper arms are joined together at a lower common leg thereof. Each of the two upper arms have an arm engaging portion having a releasable clasp that is operator transitionable between a clasping configuration in which the anti-sway device is secured to the elongate arm and an open configuration in which the device is installable upon and removable away from the arm in a direction transverse to a longitudinal axis of the elongate arm and whereby the anti-sway device accommodates installation onto, and removal off of, the elongate arm of the load carrier without disengagement of the cradle from the elongate arm.

Owner:THULE SWEDEN AB

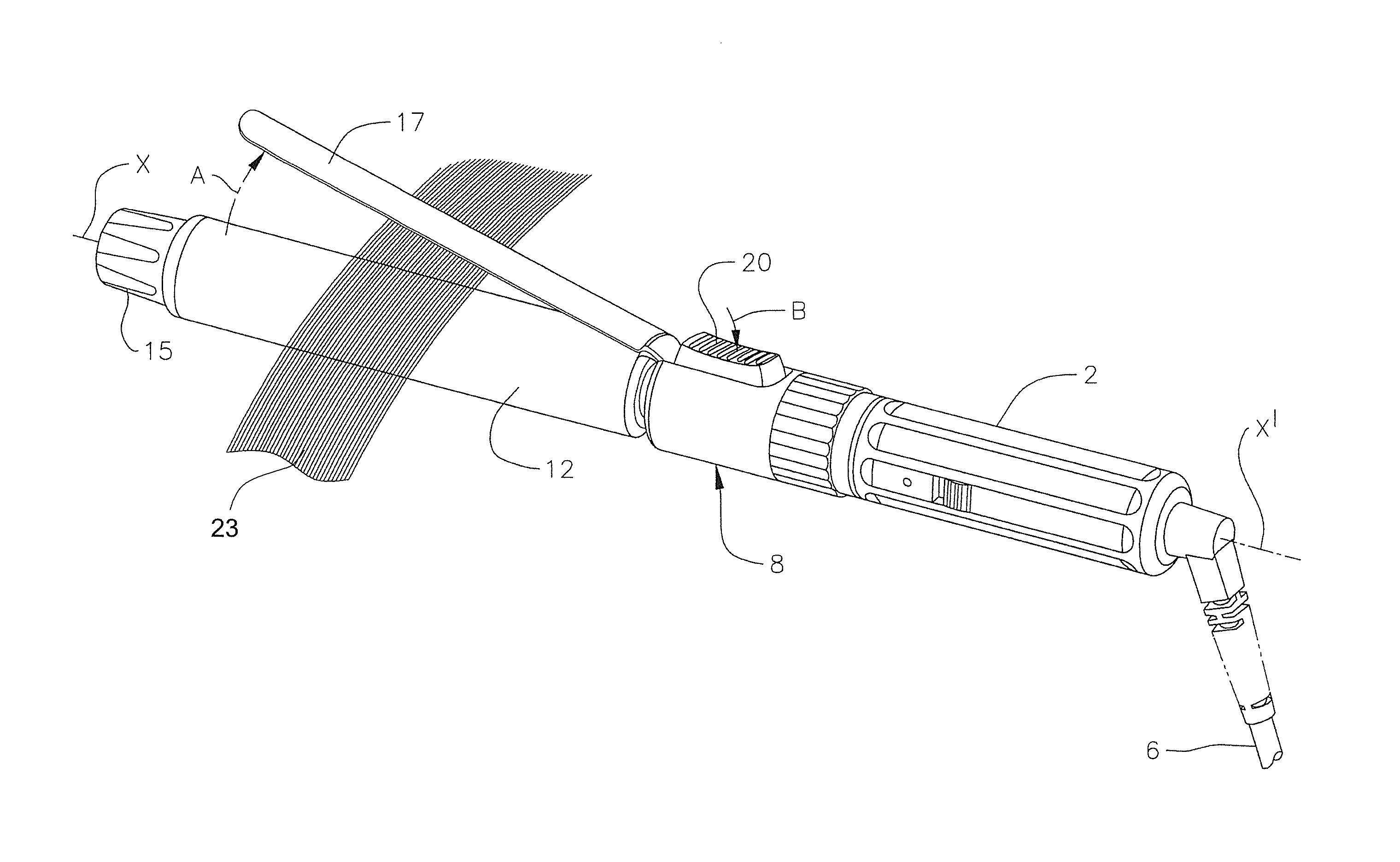

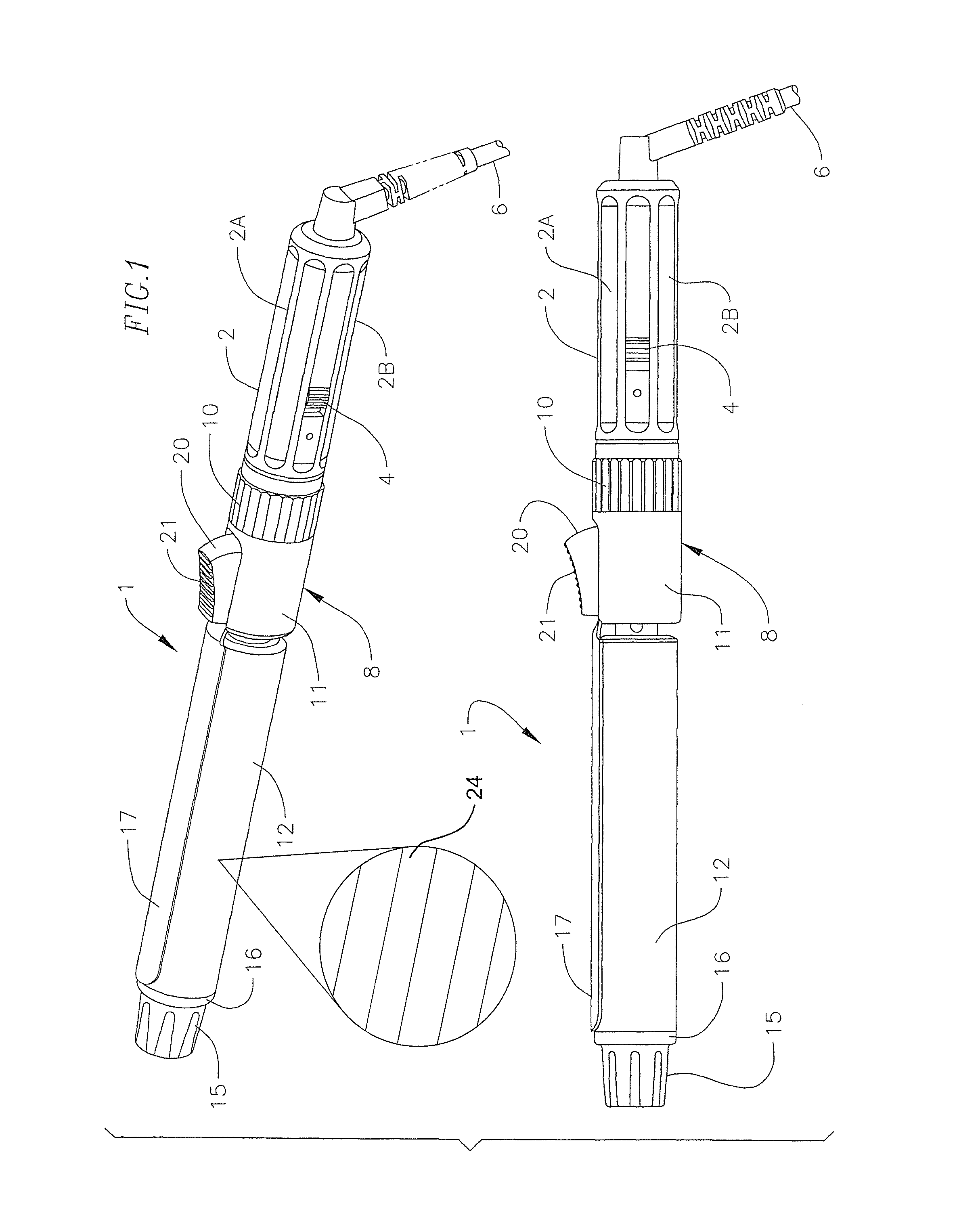

Hair curling tong

Hair curling tong (1) with a fixed handle (2) and a heated tube body (12) fixed thereto provided with clamp (17) that is fixed in a tilting way to the curling tong (1) and can be tilted between a closed position wherein the clamp (17) is held in contact with the tube body (12) by means of a spring (18) activated by a button (20) and an open position wherein the clamp is tilted away from the tube body (12), characterized in that the clamp (17) is fixed in a rotatable way to the curling tong (1) by means of a ring (10) which is rotatable over 360° around the longitudinal axis (X-X′) of the tube body (12).

Owner:EURASIA CONCEPTS

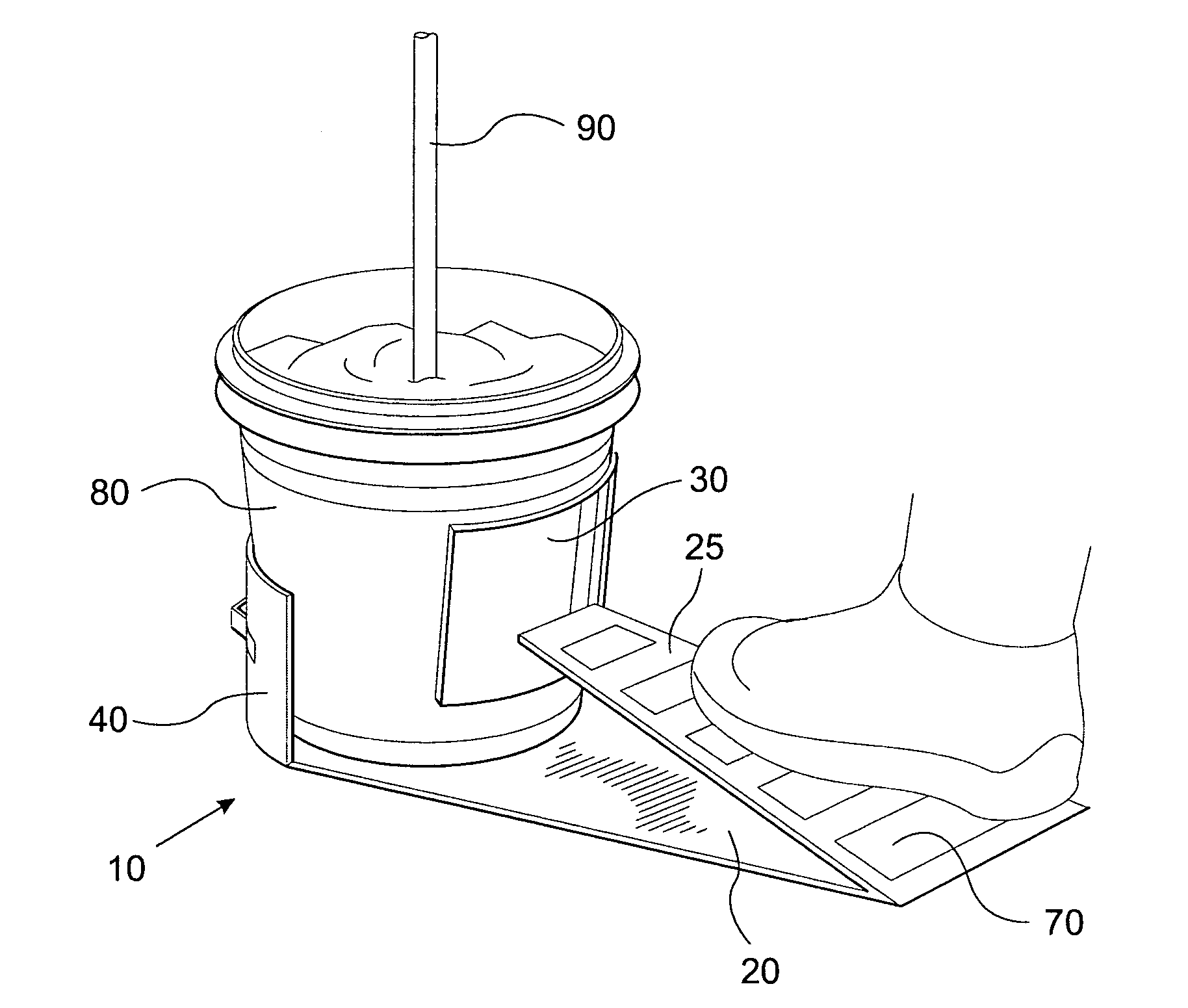

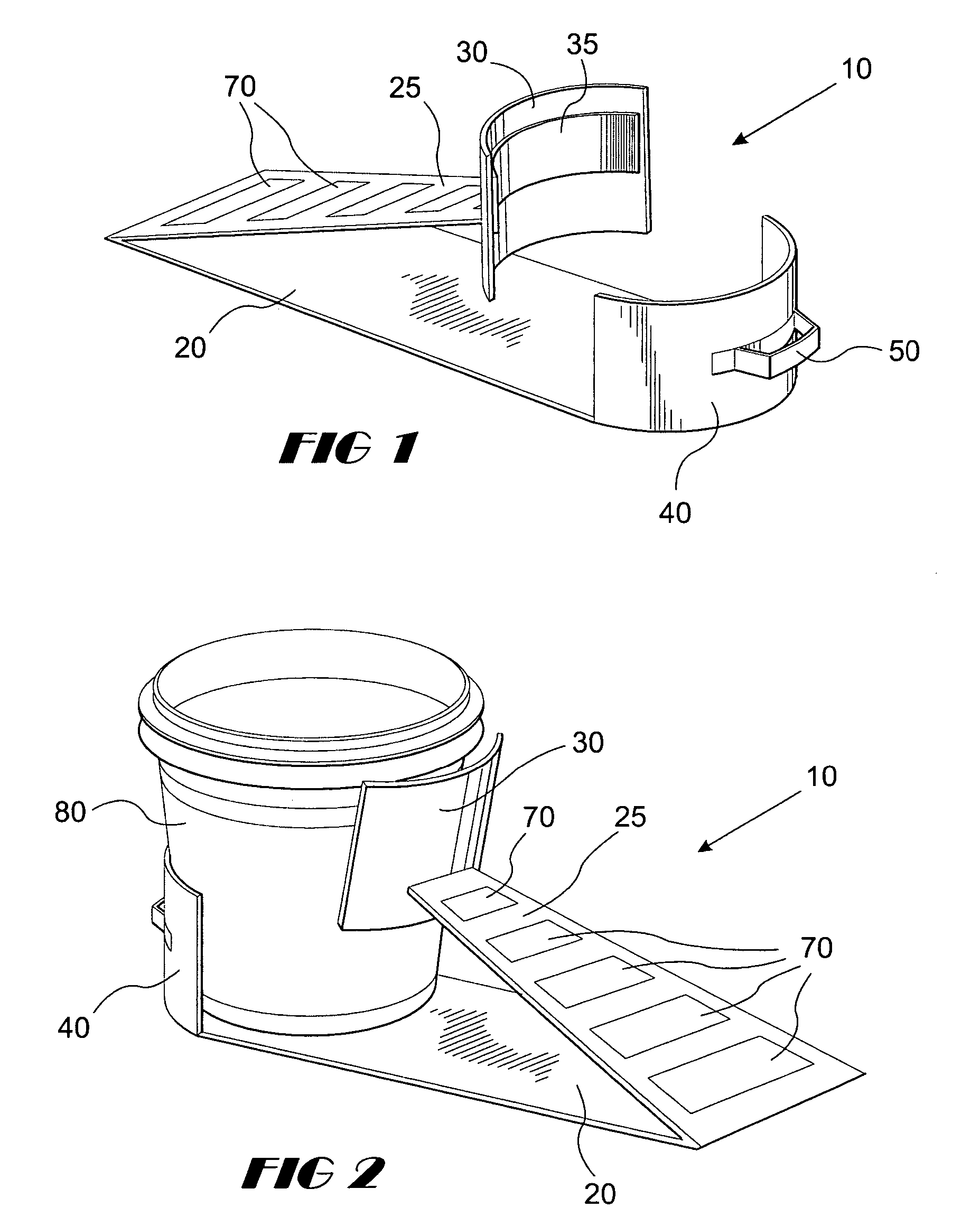

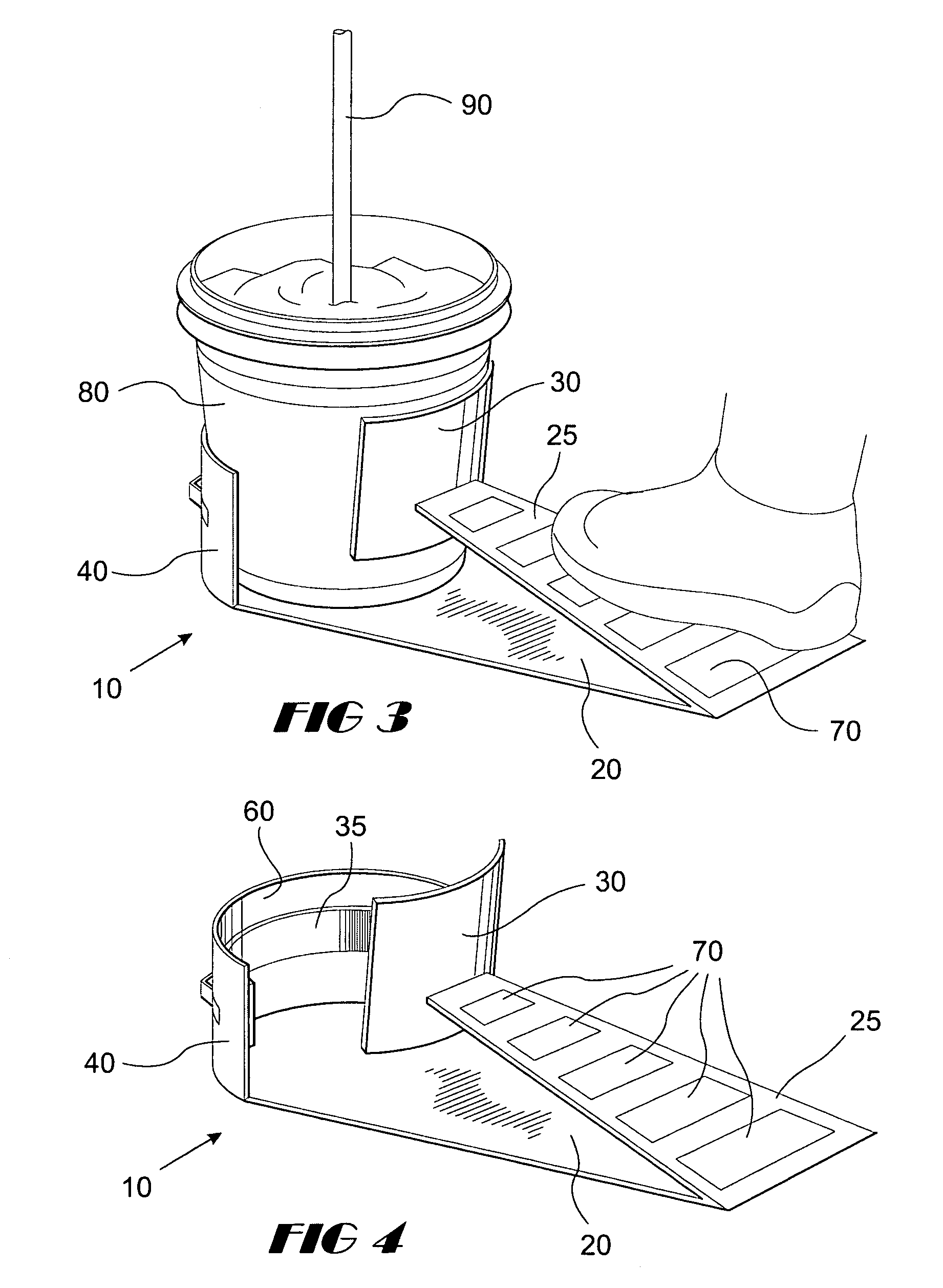

Bucket brace and method for use

InactiveUS7261262B2Prevent rotationAvoid strainCandle holdersDecorative coversEngineeringFoot pressure

A bucket brace holds a bucket in place while the bucket's contents are mixed or stirred. The bucket brace prevents the bucket from spinning due to the mixing. The bucket brace is an assembly made up of four parts: a base, a foot pressure portion, a front support, and a rear support. A handle is provided for carrying the base. The front and rear supports are of semi-circular shape, and are made of rigid or semi-rigid material, as are the base and the foot pressure portion. The foot pressure portion and the base are integral, preferably both parts being formed from the same piece of material. The foot pressure portion and the rear support preferably have surface grip portions. The handle may be made of any suitable material, preferably the same rigid or semi-rigid material as the other parts of the bucket brace. A method of use for employing the brace to hold a bucket in place while stirring or mixing the contents of the bucket is also described whereby the user places a bucket in the brace and applies foot pressure to the foot pressure portion to prevent the bucket from spinning while the user stirs or mixes the bucket contents.

Owner:DPS

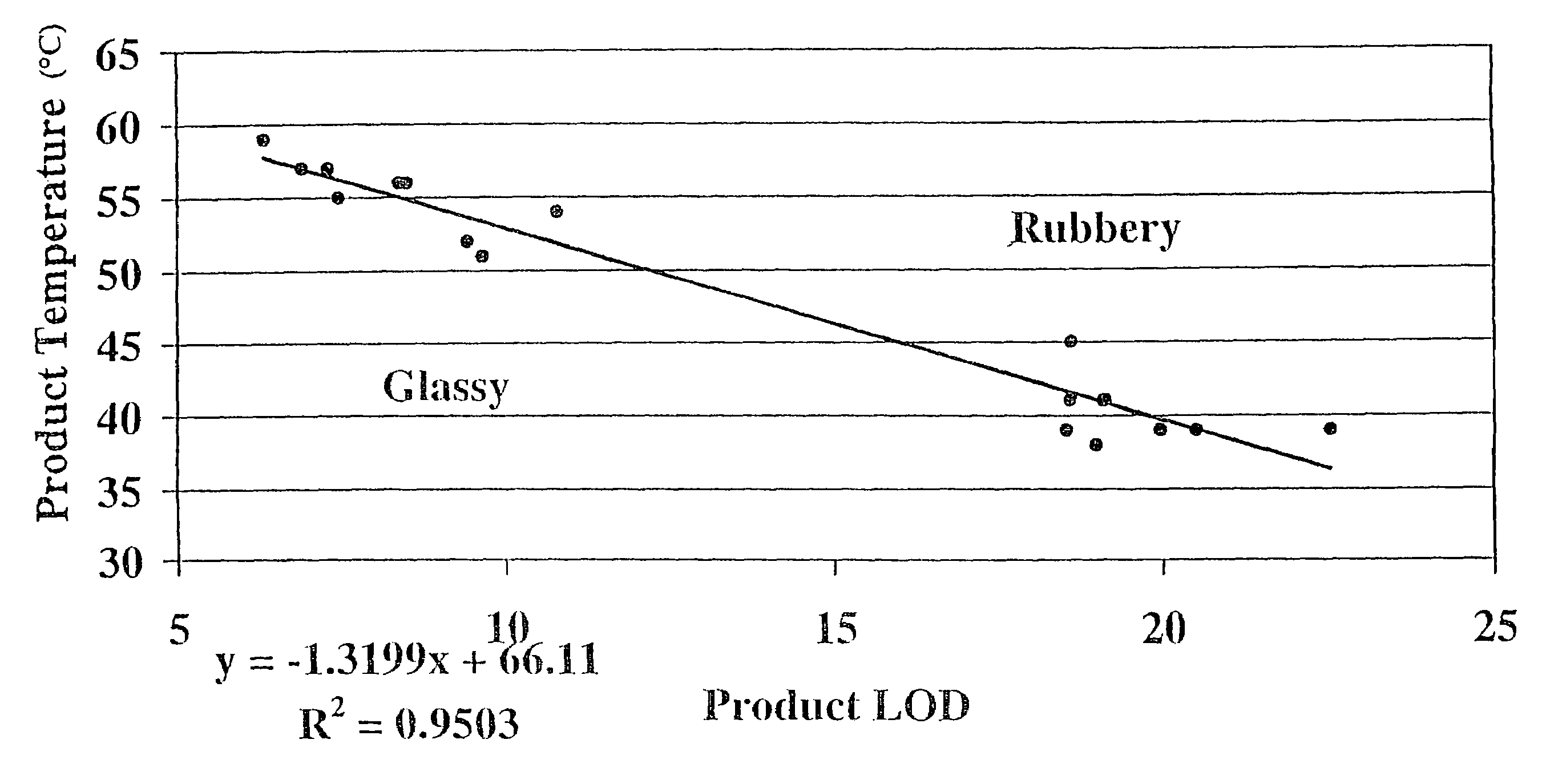

Method of drying a material having a cohesive phase

InactiveUS7067614B2High purity standardAvoid damageDrying machines with non-progressive movementsBaby linensProcess equipmentSolid content

A method for drying a material such as a polymer hydrogel which passes through a cohesive phase as it dries is disclosed. The method comprises agitating a composition while removing liquid until the solids content of the composition reaches a level at which the composition enters a cohesive phase, halting agitation, removing liquid from the composition in the absence of agitation, and resuming agitation. Practice of the present invention can eliminate the problems associated with adhesion of a material to itself and to process equipment during the cohesive phase.

Owner:GENZYME CORP

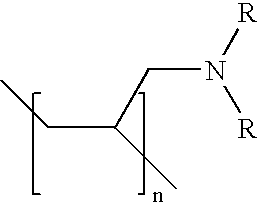

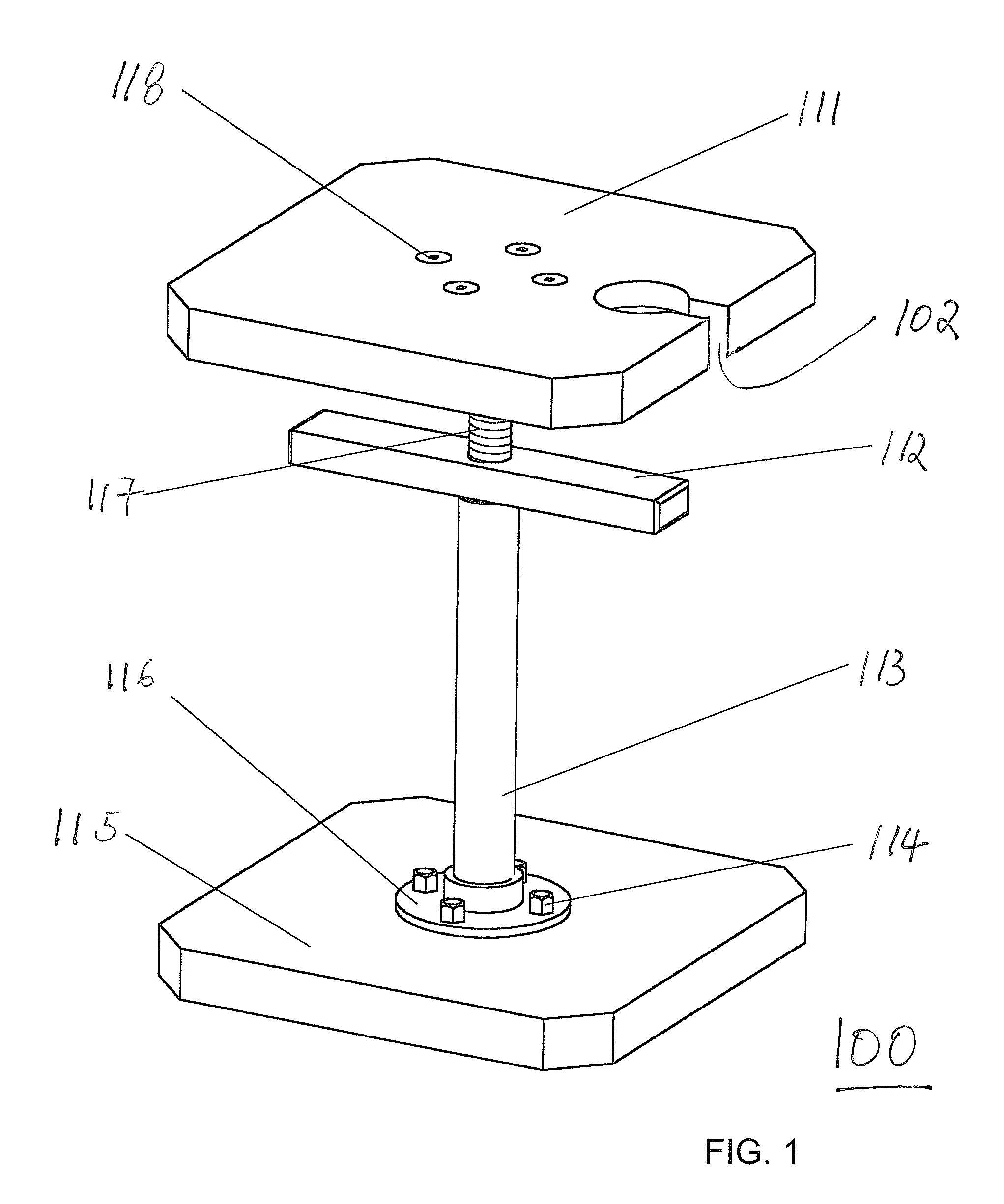

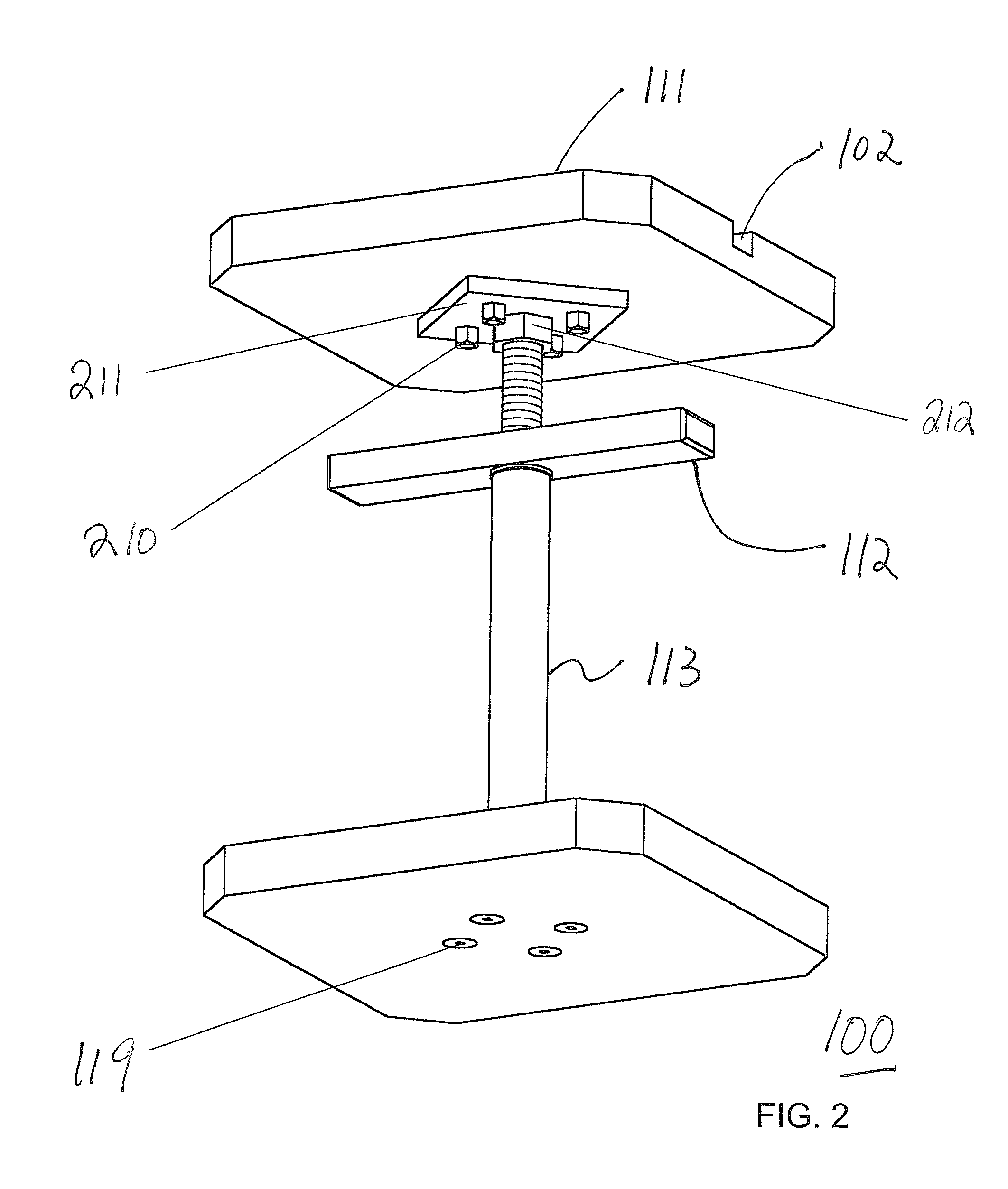

Garbage disposal installation tool

InactiveUS7685689B1Improve efficiencyImprove securityDomestic plumbingLifting devicesEngineeringScrew thread

A garbage disposal installation tool for installing garbage disposal units under sinks providing two degrees of height adjustment that consists of a flat base portion, a hollow cylindrical housing portion that has an operable locking system attached to the base portion, a hollow cylindrical shaft portion sliding longitudinally inside the housing portion, wherein sliding position temporarily secured and locked by the locking system, a flat top platform portion having an externally threaded rod portion extending perpendicular to the top platform, and a rotatable lever bar nut having an internally threaded center through hole with screw threads matchingly corresponding with the threaded rod portion, wherein rotation of the lever bar nut causes axial motion of the externally threaded rod portion resulting in raising and lowering of the top platform portion.

Owner:DEL CASTELLO FRANK M

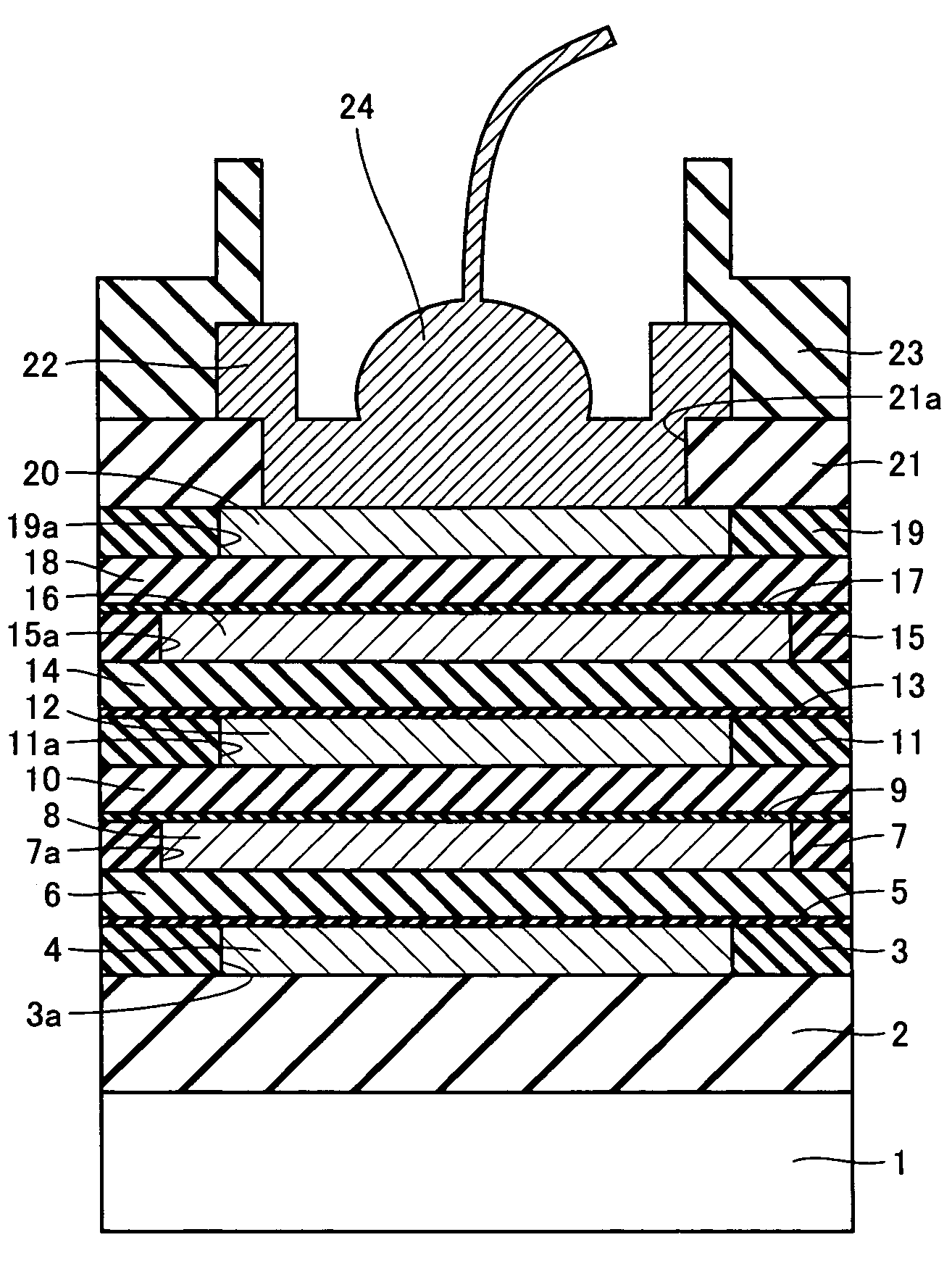

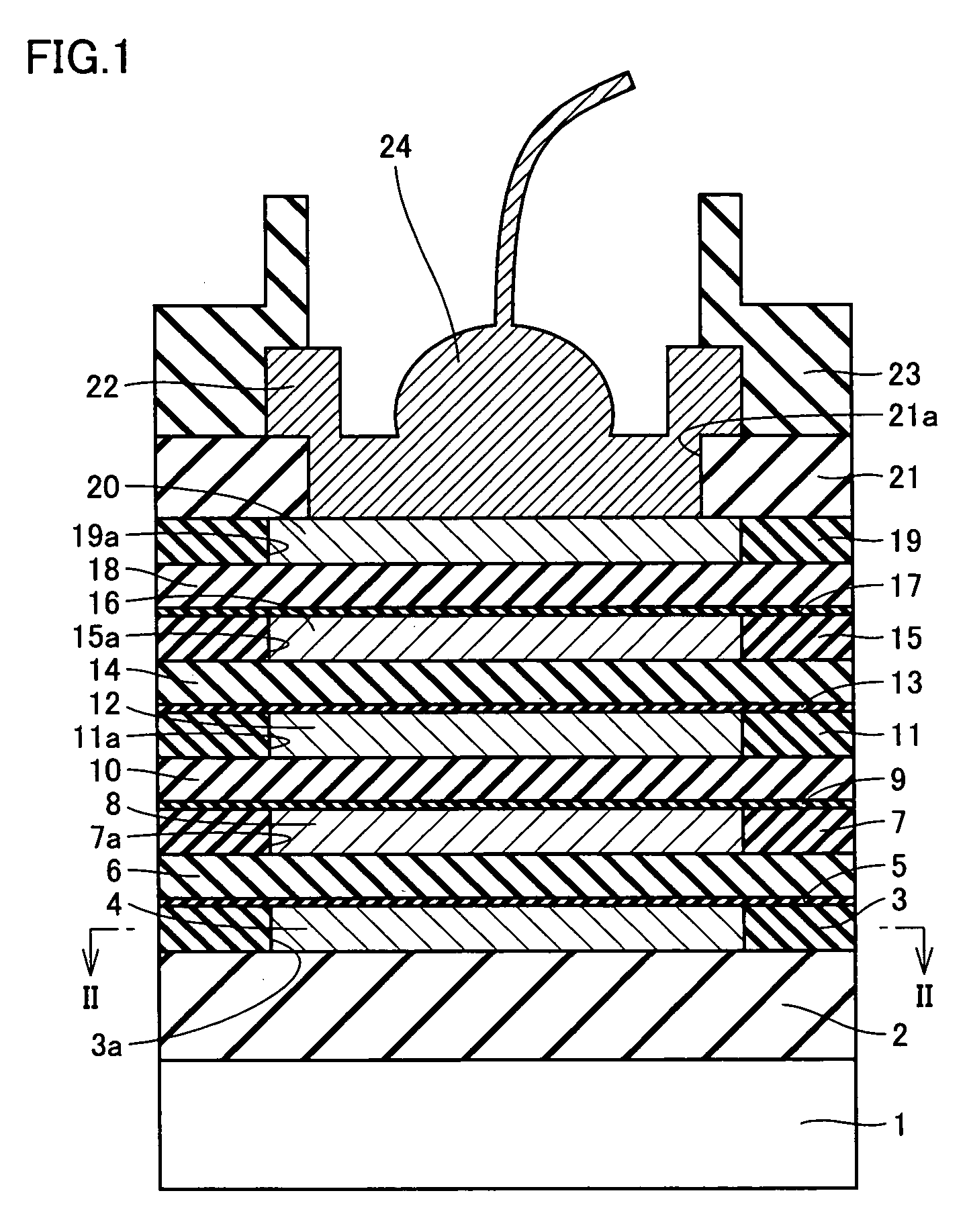

Semiconductor device which employs an interlayer insulating film of a low mechanical strength and a highly reliable metal pad, and a method of manufacturing the same

InactiveUS7202565B2Avoid crackingPrevent peelingSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectEngineering

A semiconductor device includes: multiple kinds of interlayer insulating films formed on a semiconductor substrate and having different elastic moduli, respectively; a metal pad arranged on said multiple kinds of interlayer insulating films; the interlayer insulating film of a low elastic modulus having the lowest elastic modulus and having an opening located under the metal pad, the interlayer insulating film of a not-low elastic modulus having the elastic modulus larger than the elastic modulus of the interlayer insulating film of the low elastic modulus, being layered in contact with the interlayer insulating film of the low elastic modulus, and continuously extending over the opening and a region surrounding the opening and a metal interconnection layer arranged under the metal pad, filling the opening in the interlayer insulating film of the low elastic modulus, and being in contact with the interlayer insulating film of the not-low elastic modulus.

Owner:RENESAS ELECTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com