Patents

Literature

608results about How to "Smooth demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

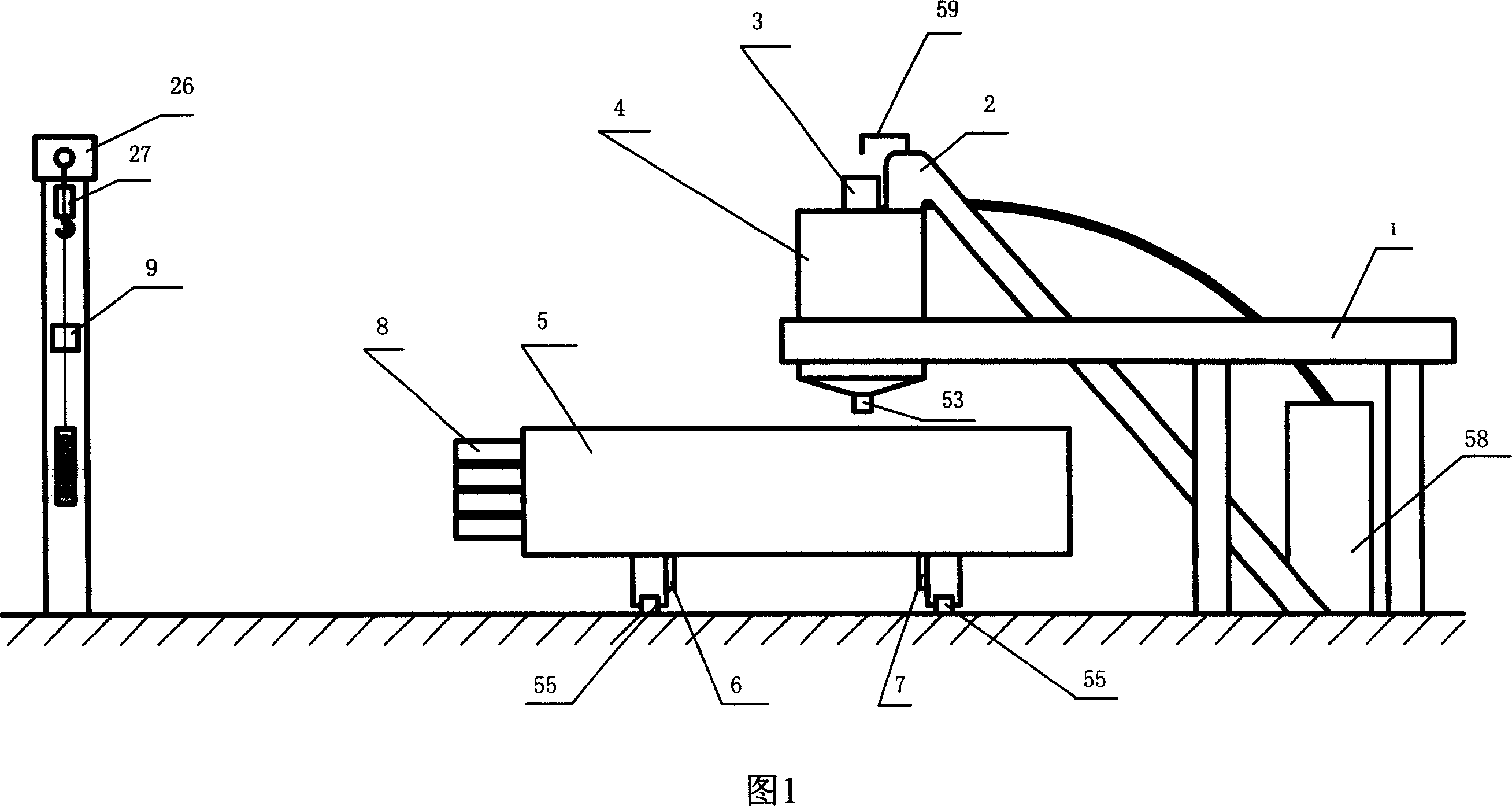

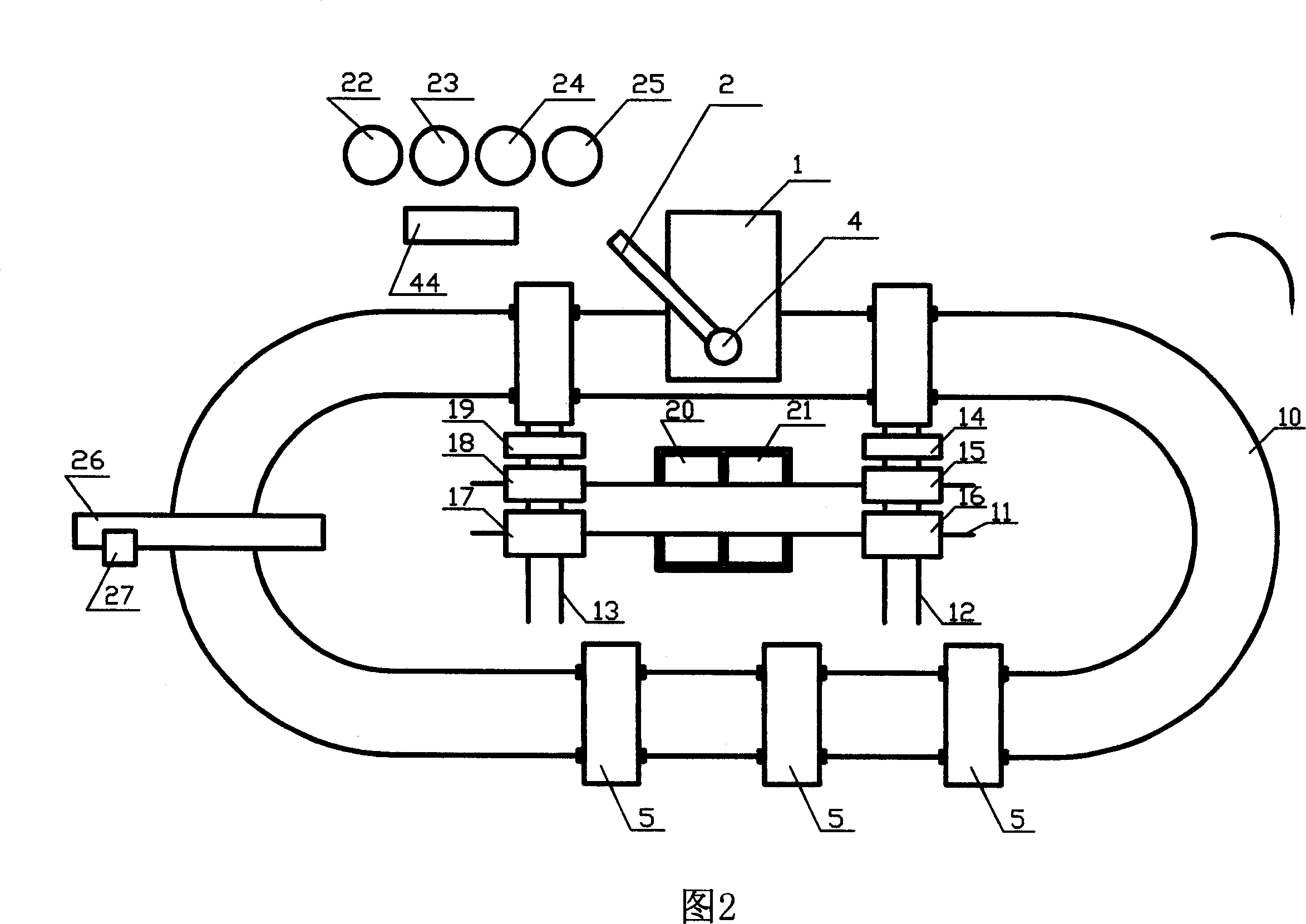

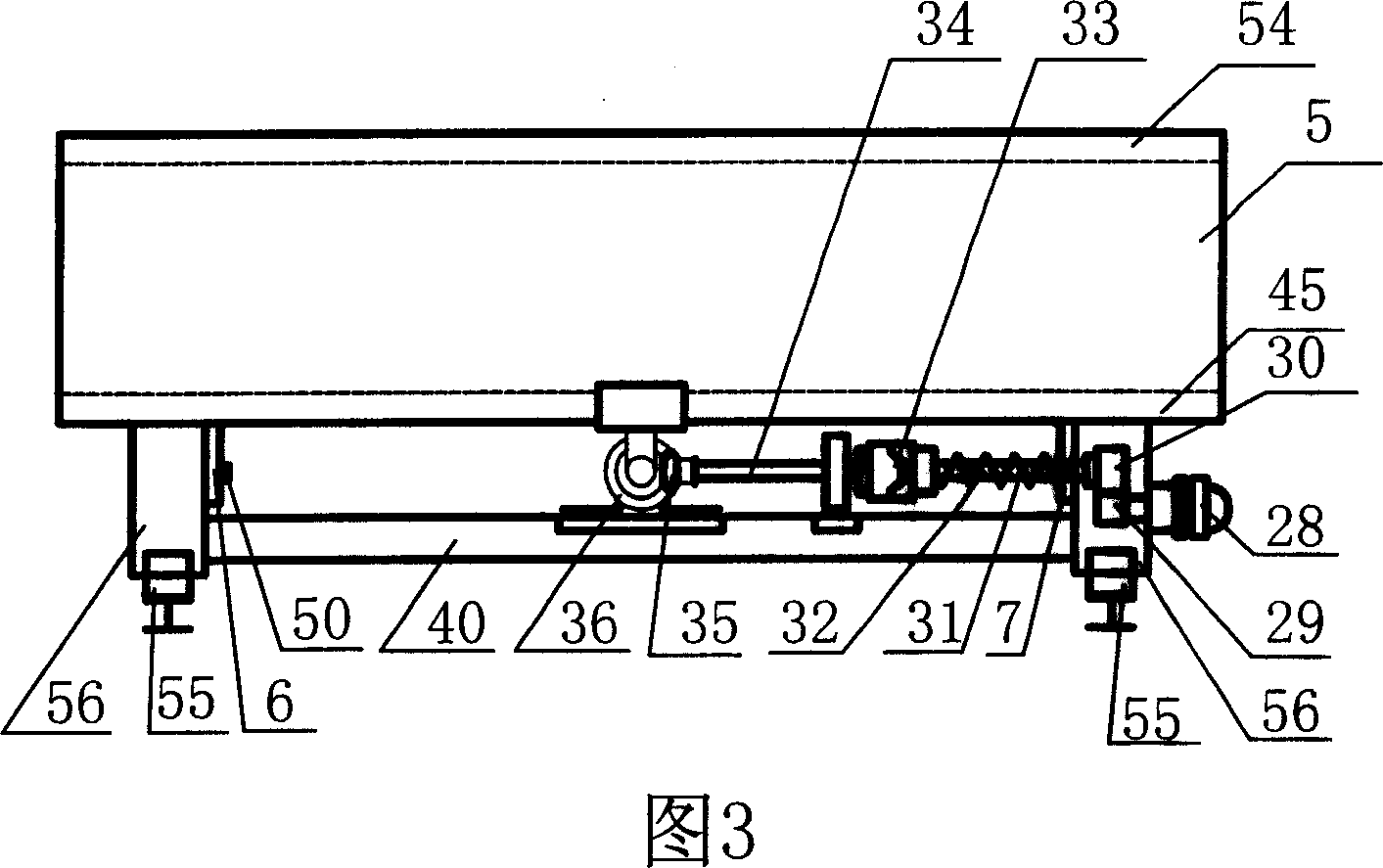

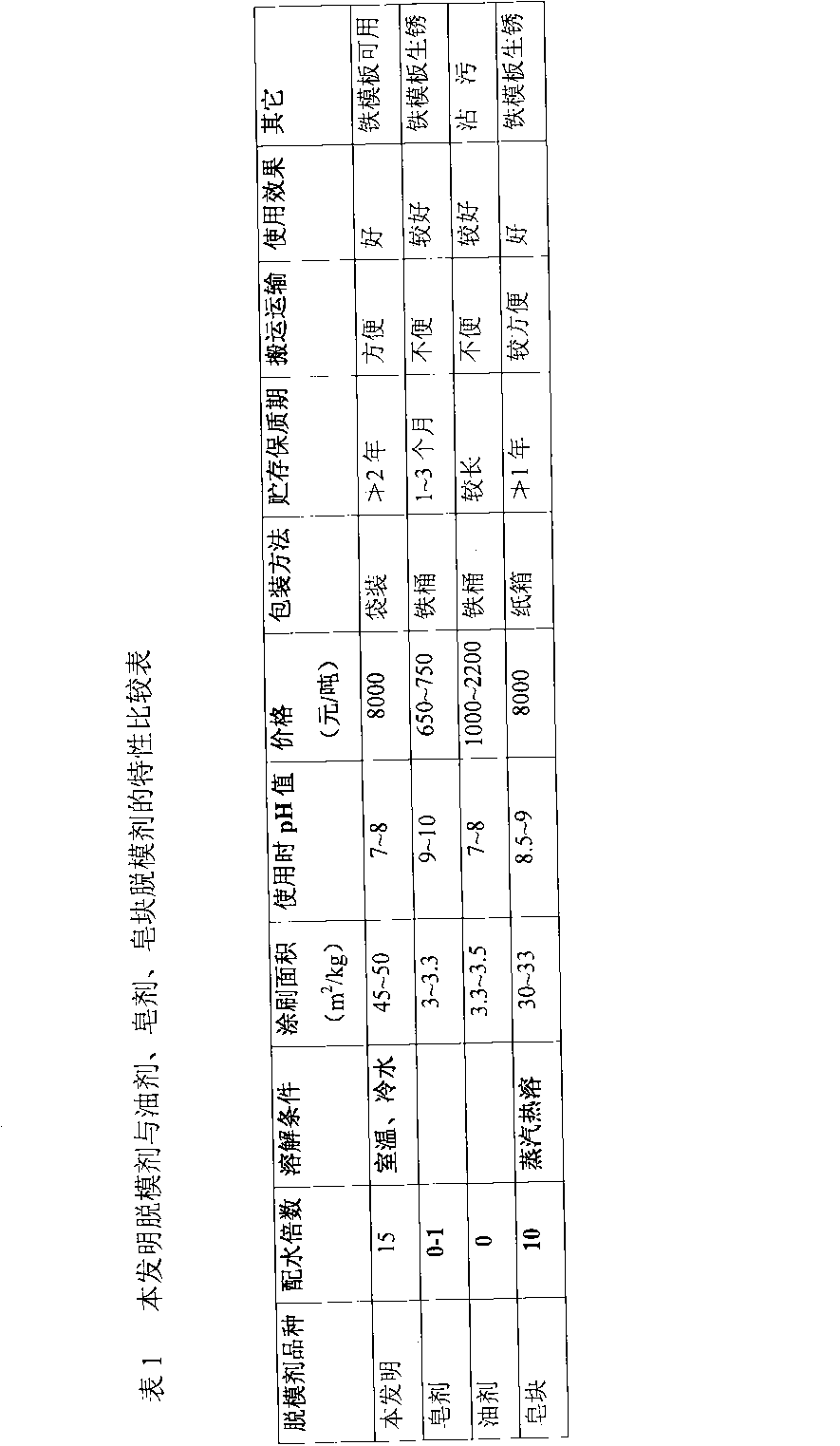

Technology and device for manufacturing gypsum lightweight cavity wallboard and building block

InactiveCN1927560AIncrease productivityRealize continuous pouring moldingCeramic shaping plantsCeramic shaping liningsProduction lineBrick

The invention relates to a method for producing gupse hollow wall plate and brick, which can demould without rotating core tube. Wherein, said method comprises combining mould, mounting core tube, irrigating, taking out core tube and opening mould; before combining mould, plating demoulding agent on the template and plating set retarder on the core tube to retard the slurry contacted with the core tube; and it can demould without rotating core tube. The inventive product line comprises feeding device, mixing irrigator, mould machine, installer, core taking device and lifter; the mixing pot of mixing irrigator is fixed on the platform of mixer; the material of storage pot via feeding device is fed to the mixing pot; the bottom of irrigate valve of mixing pot is opposite to the mould chamber of mould machine; the mould machine moves on annular track. The invention has high efficiency and low cost.

Owner:长沙归一新材料科技股份有限公司

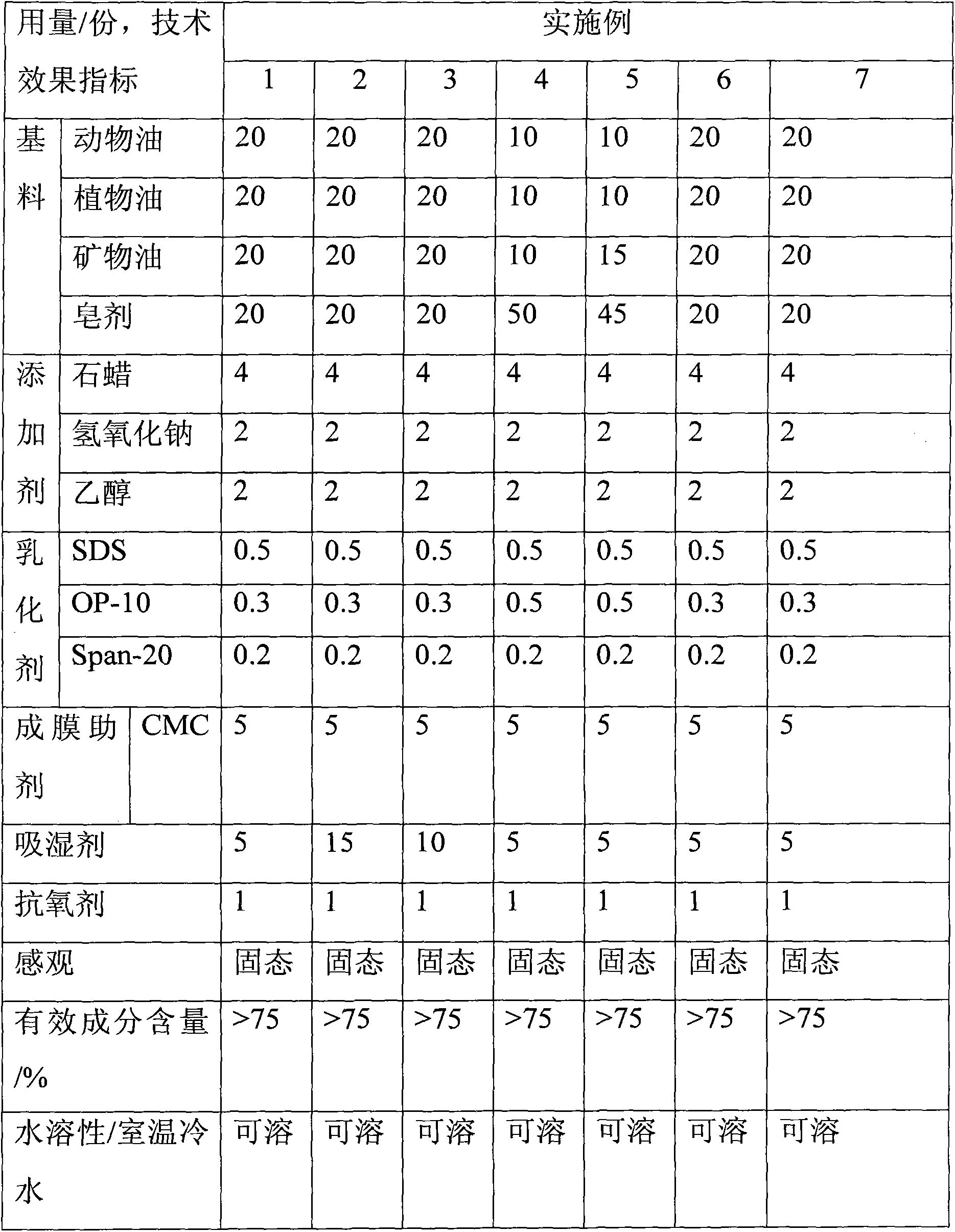

Oily solid releasing agent and preparation method thereof

ActiveCN103450995AChange physical propertiesIncrease distanceLubricant compositionParaffin waxAlcohol

The invention provides an oily solid releasing agent which is prepared from the following components in parts by weight: 80-85 parts of base material, 0.8-1.2 parts of emulsifier, 5-10 parts of film-forming assistant, 5-15 parts of additive, 5-15 parts of moisture absorber and 1-5 parts of antioxidant. The base material contains animal oil, vegetable oil, mineral oil and a soaping agent. The additive is a compounded additive containing high-carbon hydrocarbon, alcohol and alkali, wherein the high-carbon hydrocarbon is paraffin; the additive accounts for 5% of the base material. The invention also relates to a preparation method of the releasing agent.

Owner:北京慕湖外加剂有限公司

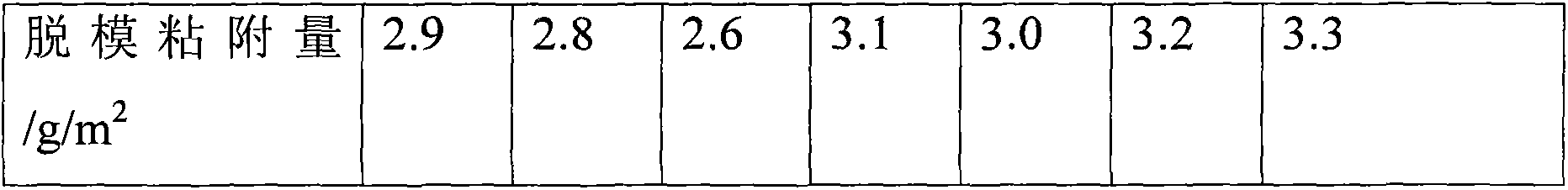

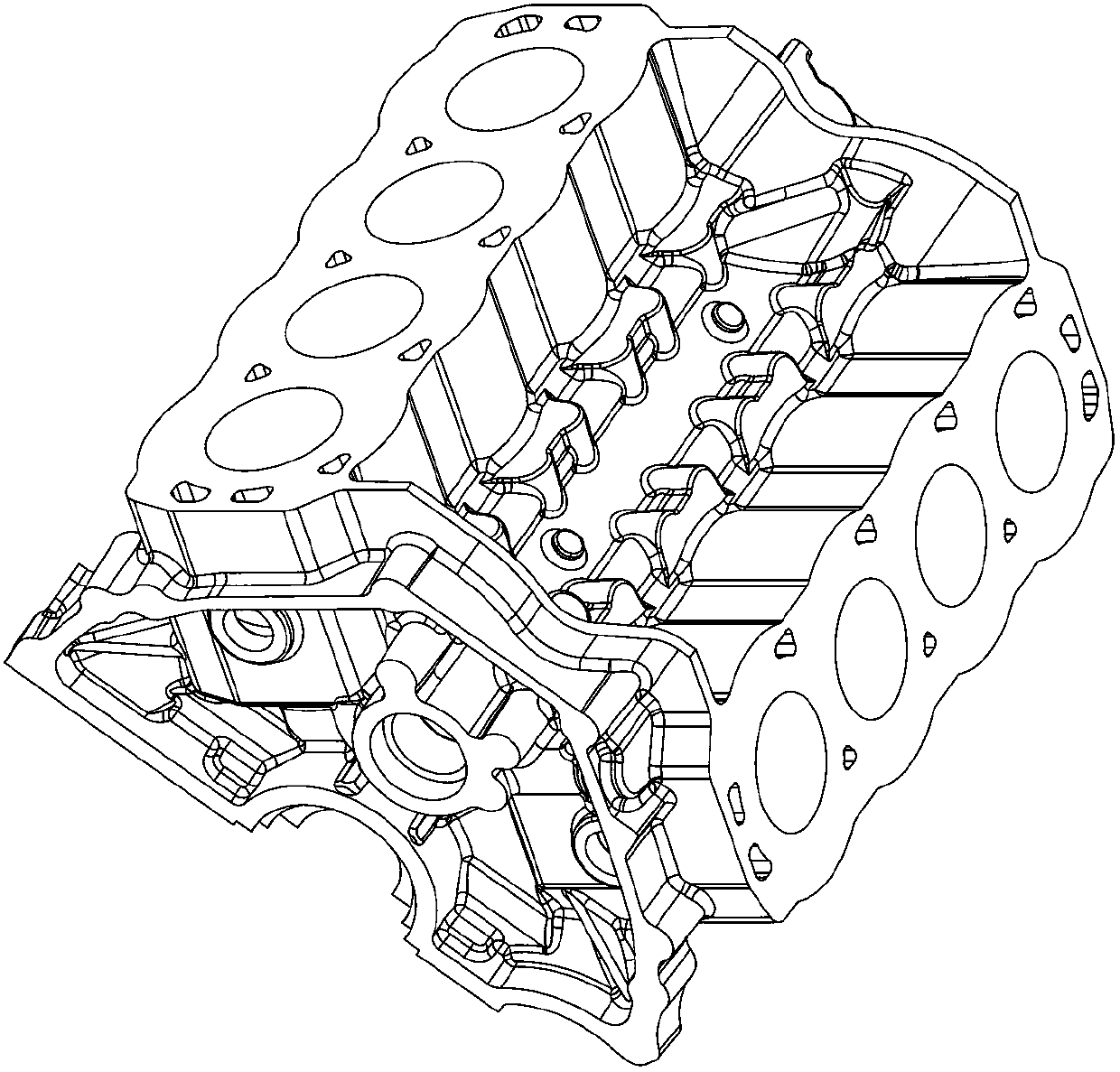

V8 type gray cast iron cylinder body casting pouring method

ActiveCN103121082AStable flow rateSmall structureFoundry mouldsFoundry coresAssembly structureMaterials science

The invention discloses a V8 type gray cast iron cylinder body casting pouring method which is carried out by adopting a core assembly pouring mode. The V8 type gray cast iron cylinder body casting pouring method comprises the following steps of: 1, setting a pouring position of a casting; 2, arranging a pouring system; 3, assembling a core assembly; and 4 pouring. Compared with the prior art, the V8 type gray cast iron cylinder body casting pouring method has the characteristics of relatively simple core assembly structure, high yield and low production cost.

Owner:宁波亿泰来模具有限公司

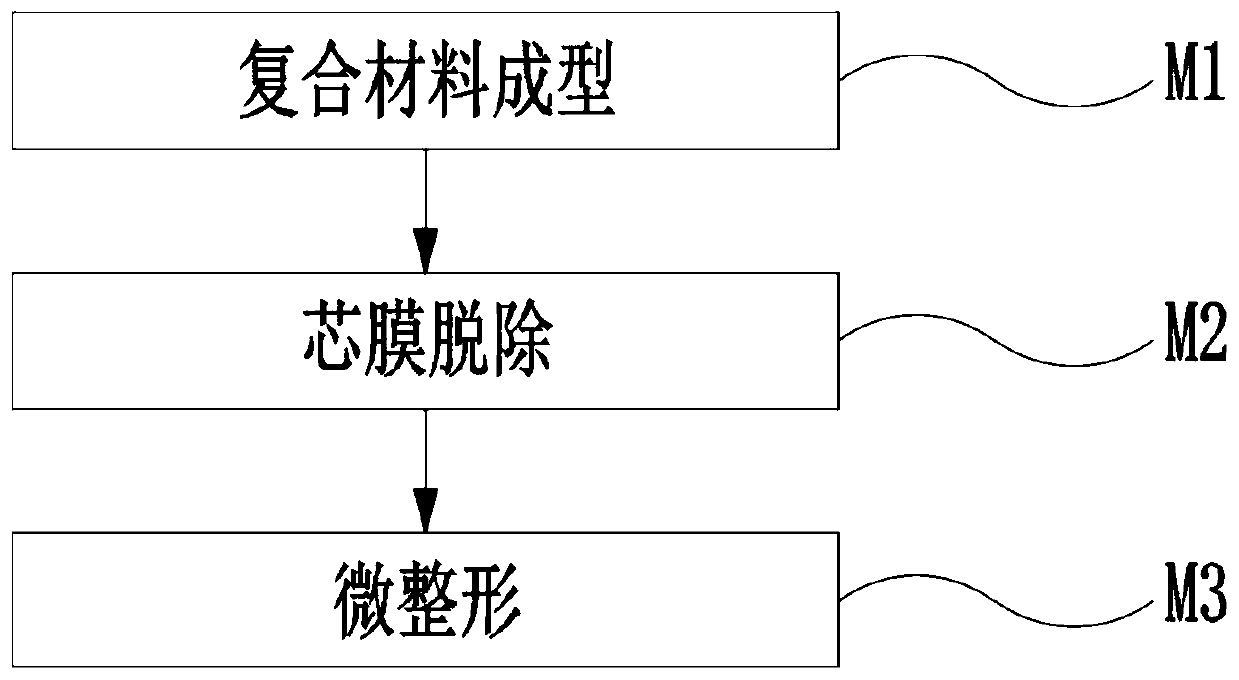

Fiber reinforced plastic and method for producing sculpture from fiber reinforced plastic

The present invention relates to a fiber reinforced plastic and a method for producing sculpture from the fiber reinforced plastic, wherein the fiber reinforced plastic is prepared from a WSP6101 type epoxy resin, acetone or propylene oxide butyl ether, a curing agent, a curing accelerator, a demolding agent, a mineral filler and reinforcing fibers, and the method for producing the sculpture from the fiber reinforced plastic comprises mold preparing, molding process and finishing so as to obtain the finished product. According to the present invention, the fiber reinforced plastic has characteristics of good heat resistance, high strength and easy molding; the soft membrane method is used to prepare the mold, such that the high-quality work shape can be copied, and the smooth demolding can be ensured; and the resin glue liquid prepared by adding the curing agent and the curing accelerator is used to connect the reinforcing fibers to prepare the fiber reinforced plastic sculpture, and the reinforcing fibers are added at different positions according to different requirements, such that the obtained finished product does not generate deformation, and the precision and the integrity are significantly improved.

Owner:北京一和堂文化发展有限公司

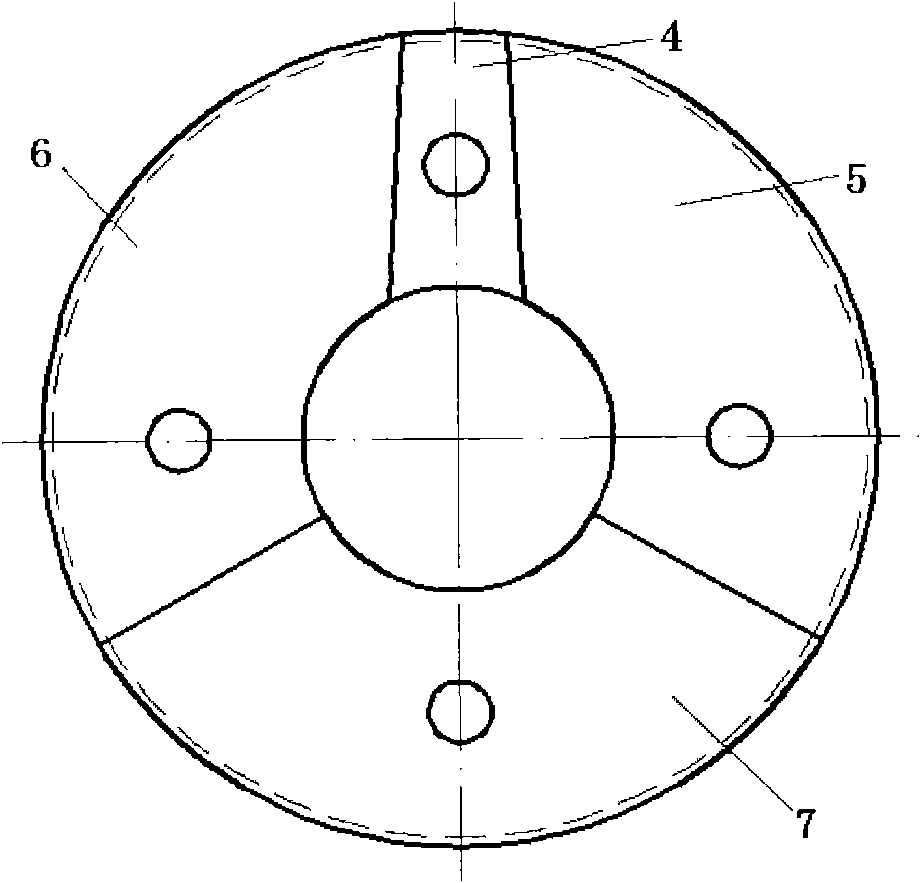

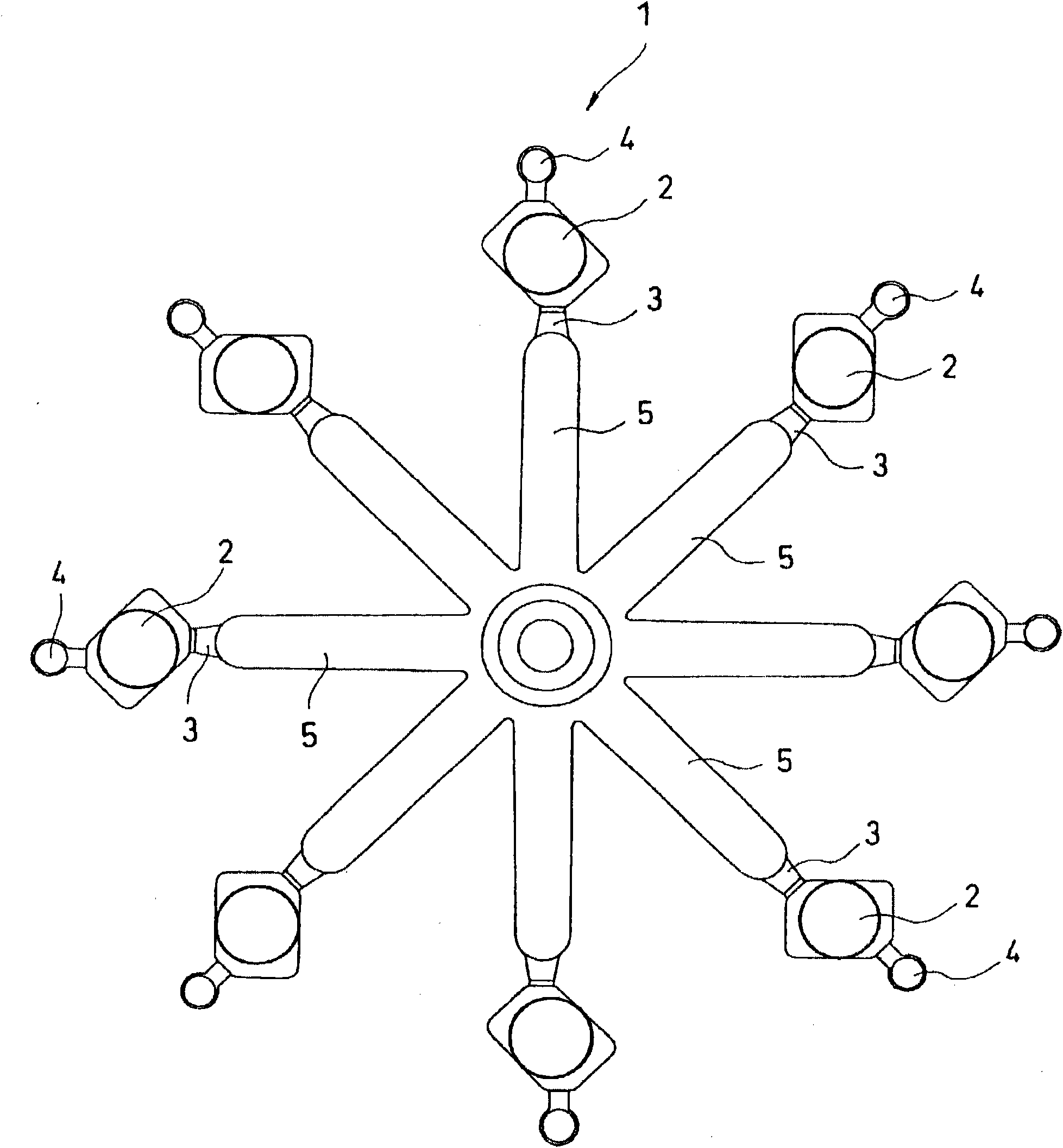

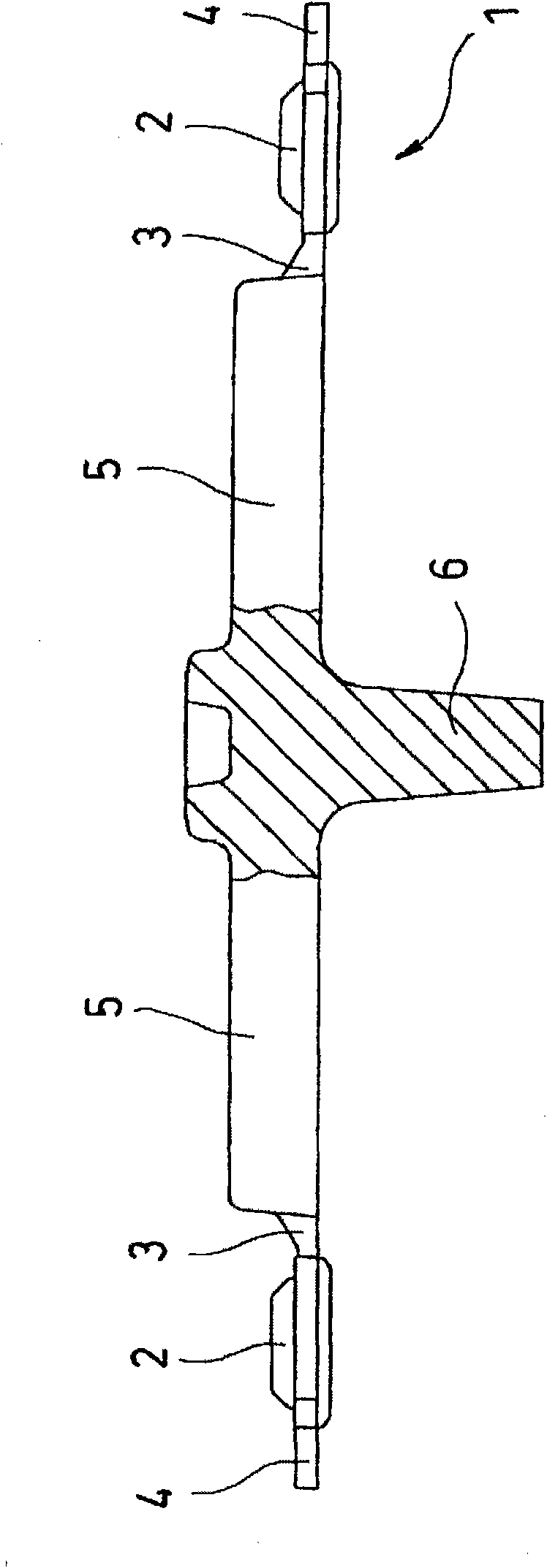

Core mold for spinning and forming large-size complex curved generatrix thin-wall member with transverse inner ribs

The invention relates to a core mold for spinning and forming a large-size complex curved generatrix thin-wall member with transverse inner ribs, wherein a clamping plate is positioned between the head part and tail part of the core mold and sheathed on a positioning shaft at the tail part of the core mold; the clamping plate and the head part of the core mold are hollow shells, and the clamping plate and the head part of the core mold take the shape of a curved generatrix; an aperture of an inner hole at one end of the head part of the core mold is an assembling hole of the positioning shaftat the tail part of the core mold; on the end surface of the core mold, a circle of groove is arranged around the assembling hole at the tail part of the core mold, and used for positioning the clamping plate; a screw hole for hanging the core mold is arranged at the other end of the core mold; and the assembling hole, at the head part of the core mold, of the positioning shaft at the tail part of the core mold, and a hanging hole at the other end of the head part of the core mold are in tapered transition. All the parts of the core mold are rotary parts, and the combined horizontal and longitudinal split technology is adopted for the core mold, therefore, the large-size complex curved generatrix thin-wall members with the transverse inner ribs can be demolded smoothly after spinning and forming. The core mold has the characteristics of easiness of processing and assembly, and low manufacturing cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

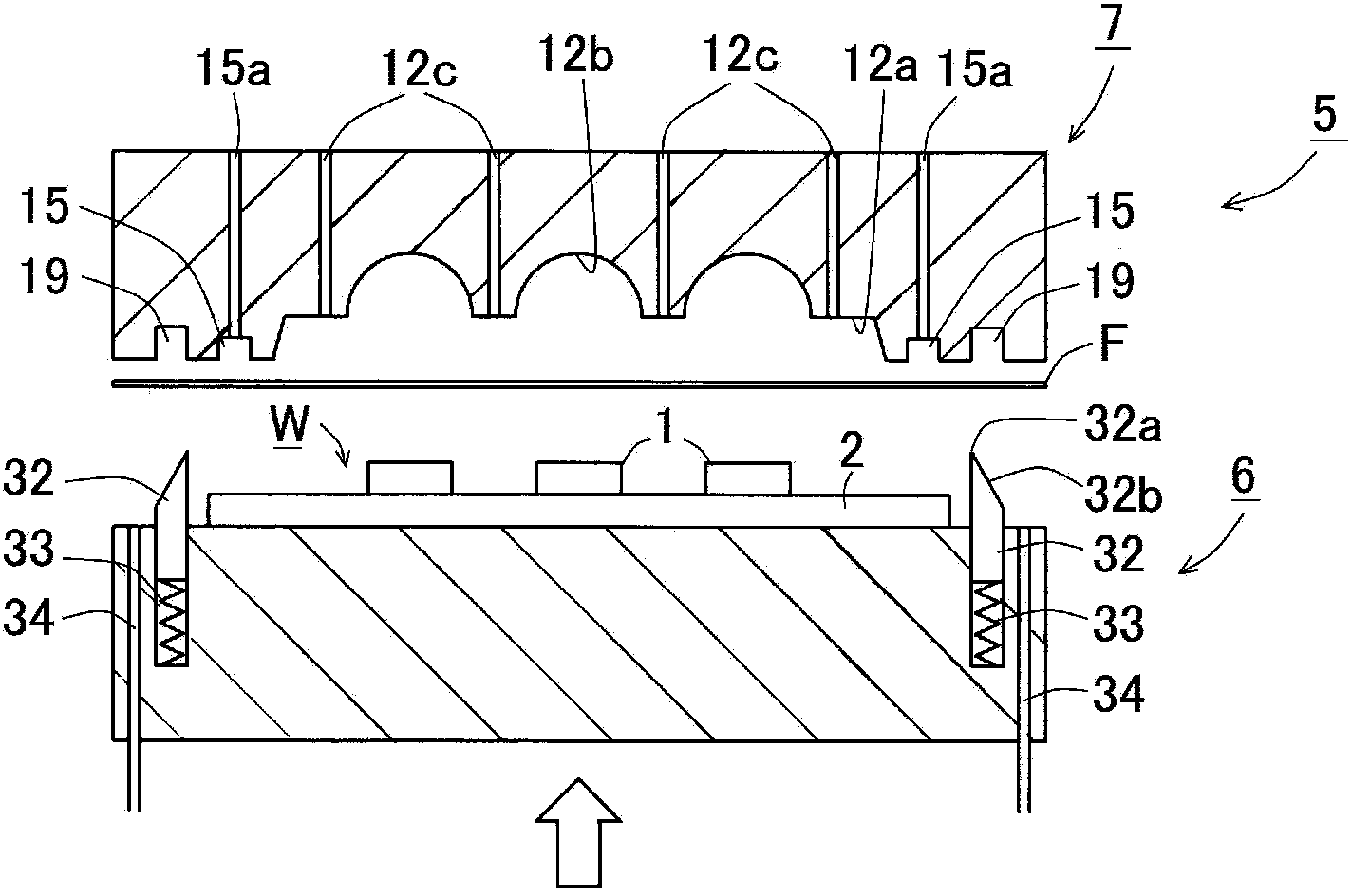

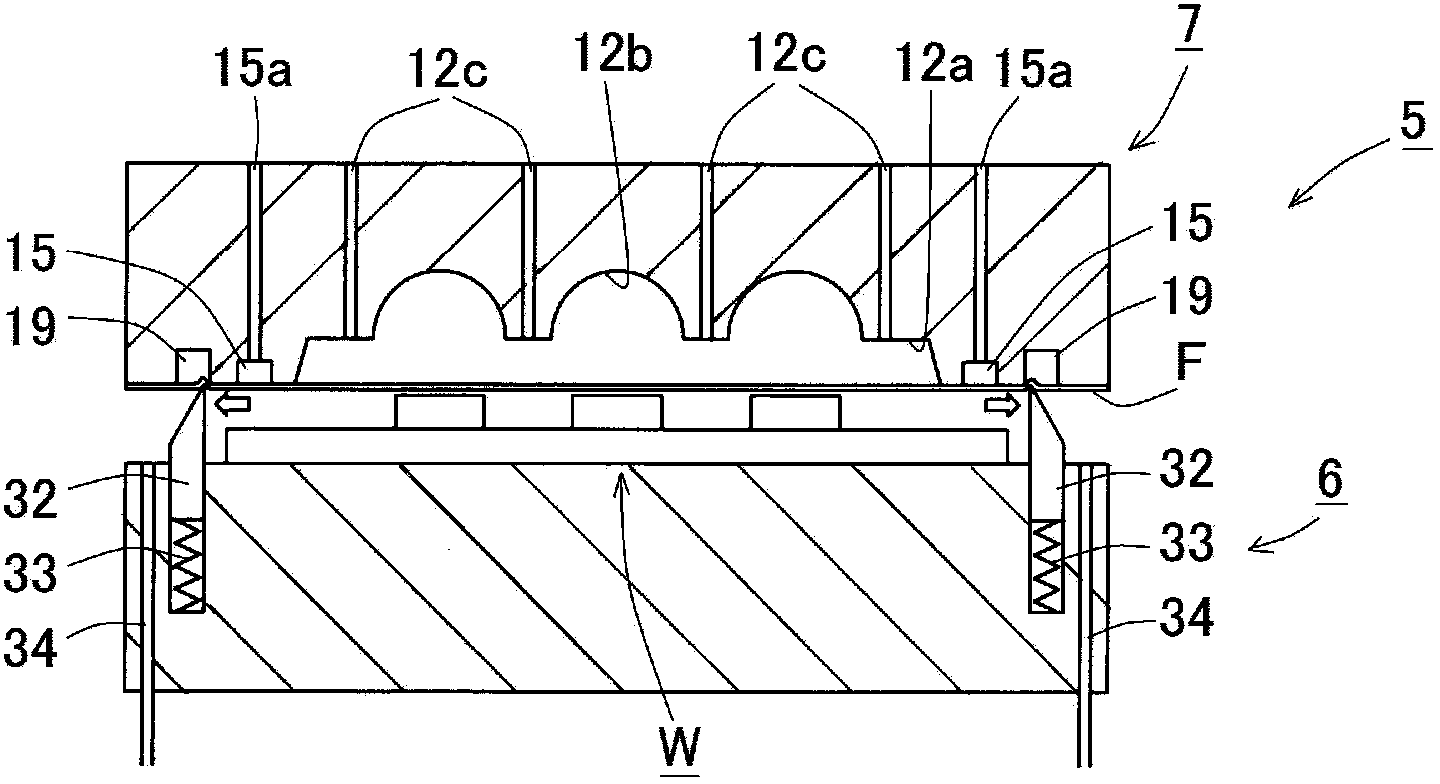

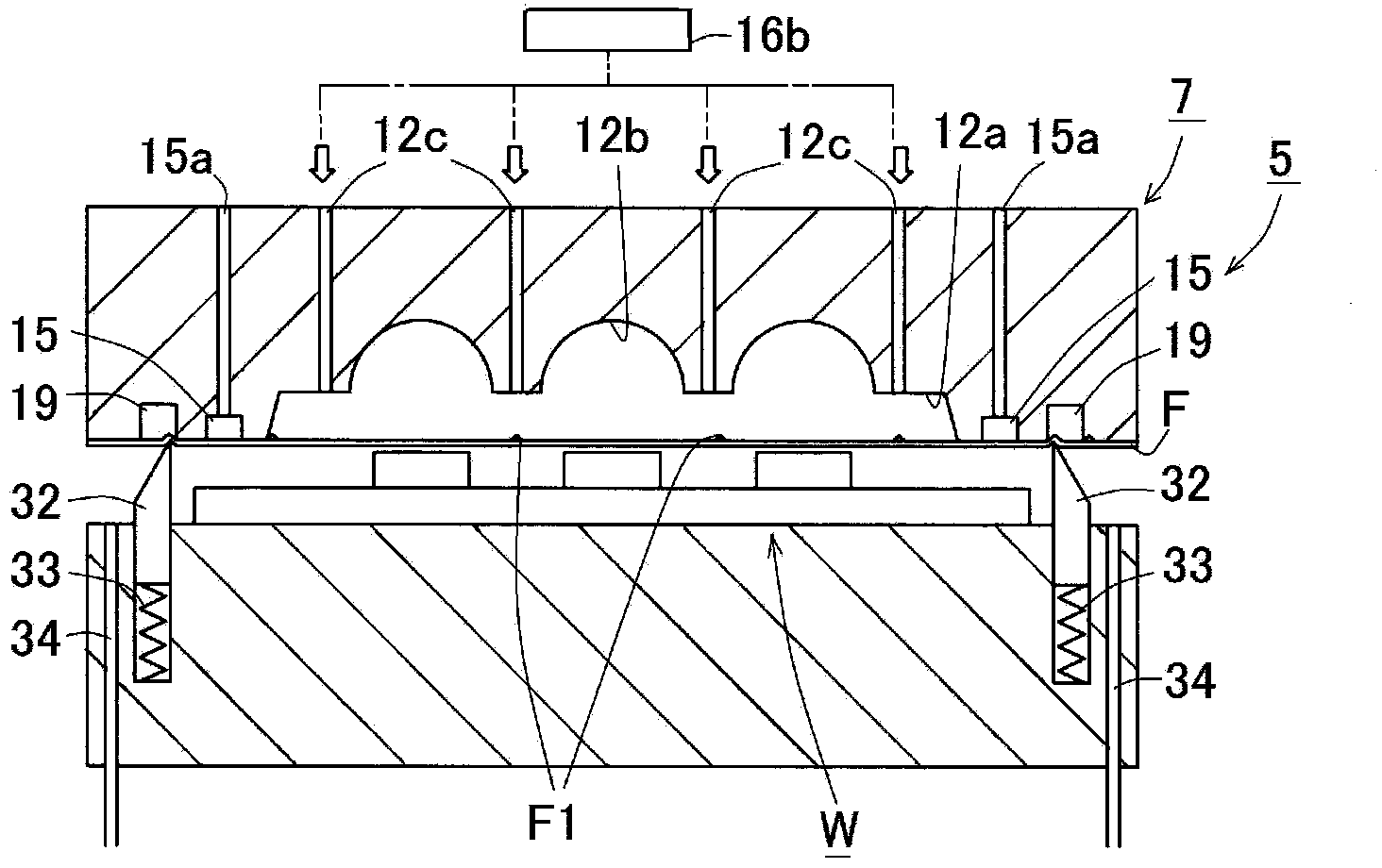

Resin molding machine and method of resin molding

ActiveCN103545224AImprove forming qualityReliable demouldingSolid-state devicesSemiconductor/solid-state device manufacturingWrinkleEngineering

The resin-molding apparatus improving further more, the filling ability and molding quality of the epoxy molded compound the work is resin-molded using the release film and resin-molding method of the long person shape are provided. The possible to squirt air and alienate the release film (F) from the molding clamp plane multiple vent holes (12c, 12e, 18a, 18b) inhaling air and absorbs the release film (F) in the avoirdupois clamp side or are installed in the avoirdupois (7). And in the type (6), as long as the width direction both sides of the release film (F) of the long person shape which is faced with the work mounting side and is returned suffers in the width direction both sides of the release film (F) of the long person shape and it is pressed down with the release film (F) and the tension is applied to not only the longitudinal direction but also the width direction and the film wrinkle is removed the film wrinkle correcting member (32) of pair is installed.

Owner:APIC YAMADA CORP

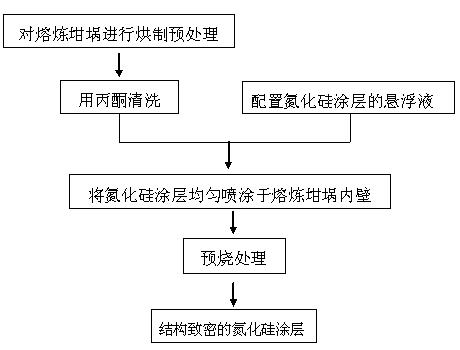

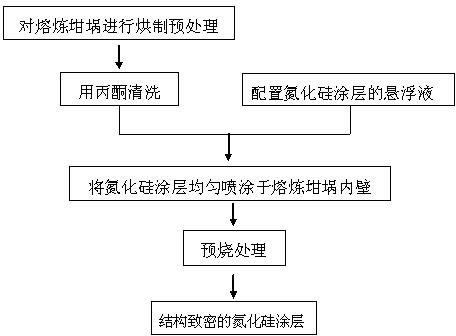

Preparation method of coating for melting crucible

InactiveCN102221293AExcellent adhesionMeet the use requirementsPretreated surfacesCrucible furnacesCrucibleIngot

The invention belongs to the technical field of coating preparation. A preparation method of a coating for a melting crucible comprises the following steps of: pre-drying the melting crucible; preparing a suspension by adopting a PVP (Polyvinyl Pyrrolidone) absolute ethanol solution and silicon nitride; uniformly spraying the suspension on the inner wall of the melting crucible; and pre-burning the melting crucible with sprayed coating to form a silicon nitride coating with uniform thickness and compact structure on the inner wall of the melting crucible. The method has the advantages that: the melting crucible is pre-dried and cleaned before being sprayed to contribute to adhesion of the coating; the PVP absolute ethanol solution is added to the suspension of the coating, the absolute ethanol is evaporated after the crucible is dried, the adhesive PVP leads the coating to be adhered on the inner wall of the crucible, and the coating has higher adhesive force, so that the crucible is prevented from reacting with and adhering melt, smooth demolding of ingots is realized, impurities are prevented from entering melt, the purification effect of the melt is realized, and the using requirement for the coating in a casting process is fulfilled.

Owner:DALIAN UNIV OF TECH

Demolding device and demolding method

The invention provides a demolding device and a demolding method, which belong to the technical field of injection molding and are used for demolding an injection workpiece in a mold. The demolding device comprises a base, a stop block, a driving assembly and an ejector pin, wherein the base is arranged on one side of the mold and can move up and down relative to the mold; the stop block is arranged between the mold and the base, is fixedly connected with the base and is provided with a through hole, and the size of the through hole is smaller than that of the end, which is in contact with the stop block, of the injection workpiece; the driving assembly is fixedly connected with one end, outside a cavity of the mold, of an insert pin of the mold, the insert pin can penetrate through the through hole in the stop block to stretch into the cavity of the mold and can horizontally move relative to the base; the ejector pin is fixedly connected with the bottom of the base. With the demolding device and the demolding method, the molded injection workpiece can be successfully separated from the mold, and the surface damage or deformation of the injection workpiece can be avoided.

Owner:上海飞乐汽车控制系统有限公司

Magnesium oxychloride and magnesium oxysulfate compound cement foam fire door core board and preparation method thereof

The invention provides a magnesium oxychloride and magnesium oxysulfate compound cement foam fire door core board and a preparation method thereof. The core board comprises the following raw materials: magnesium oxide, an anhydrous magnesium chloride solution, a magnesium sulfate solution, desulfurization gypsum, superfine carbon fiber, superfine micro-silica, a cationic polyacrylamide solution, ferrous sulfate and an efficient foaming agent, between which the ratio is 100:60:66.6:2:0.8:0.5:0.5:0.5:0.5. The method comprises the following steps: uniformly mixing the anhydrous magnesium chloride solution and the magnesium sulfate solution, adding the anhydrous magnesium chloride solution and the magnesium sulfate solution into a stirring machine, adding the cationic polyacrylamide solution and a ferrous sulfate solution into the stirring machine, and adding superfine carbon fiber, lightly calcined magnesium oxide, desulfurization gypsum, superfine microsilica and a foaming solution in sequence while performing stirring; pushing a stack of moulds, in which foaming slurry is poured, into a curing stove, curing the moulds for 8-10h, and then performing demoulding; and after demoulding, performing moisture preservation and temperature control curing and water control curing respectively until the moisture content is less than or equal to 10%. The core board provided by the invention is environmentally friendly and light, has high-strength and favorable high temperature resistance and meets the national requirements for fire prevention and safety.

Owner:海城市大德广消防门业材料有限公司

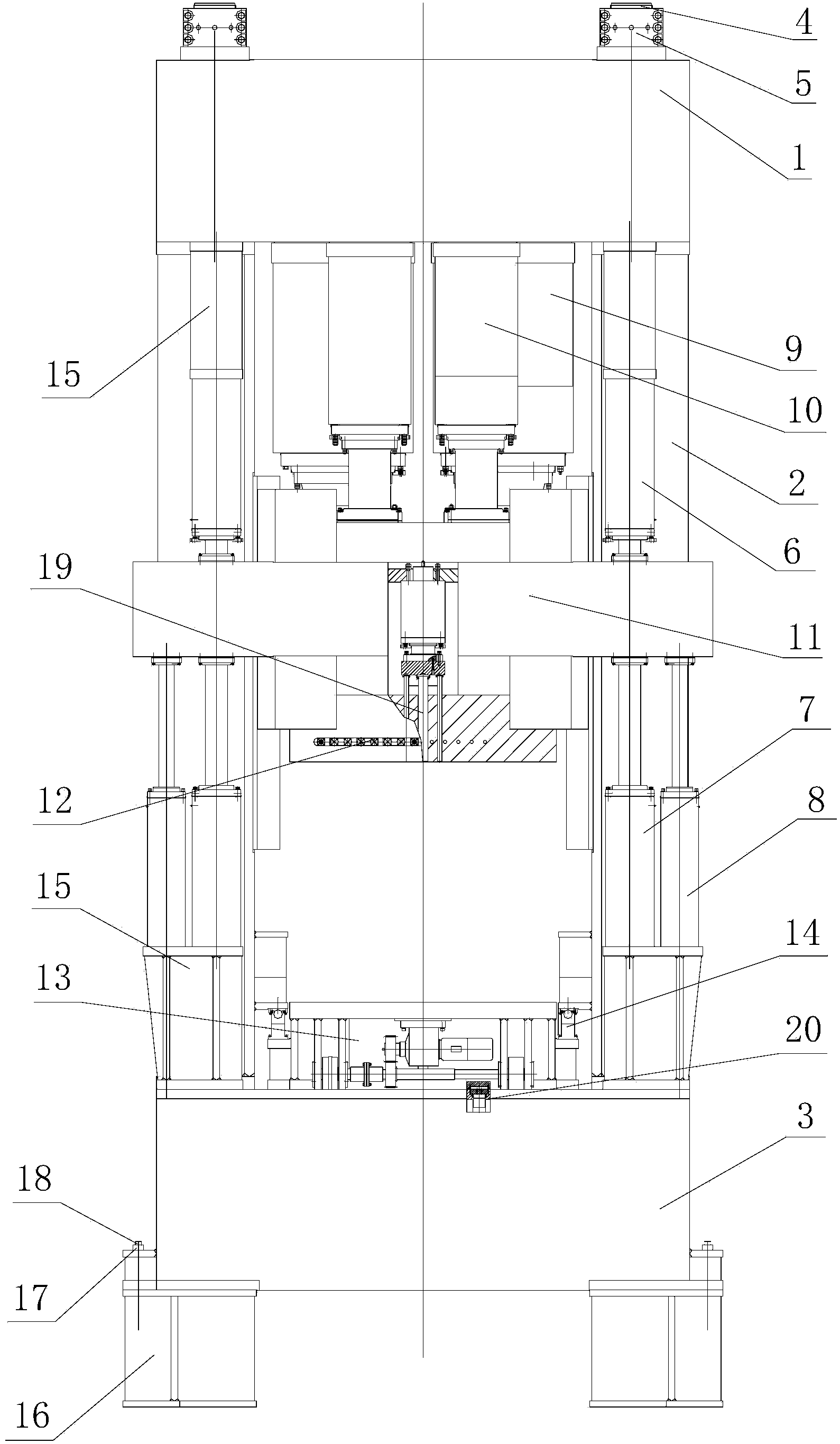

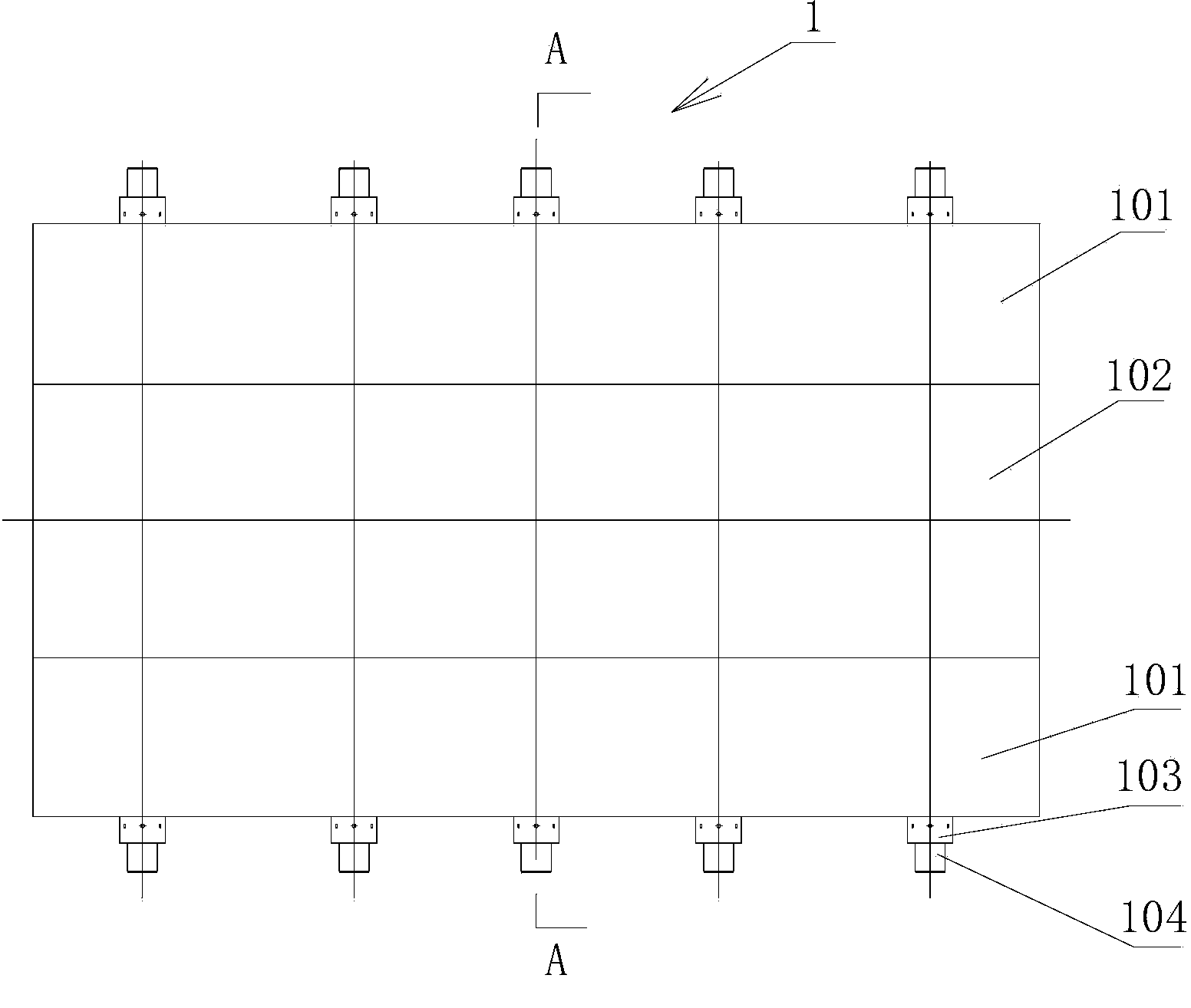

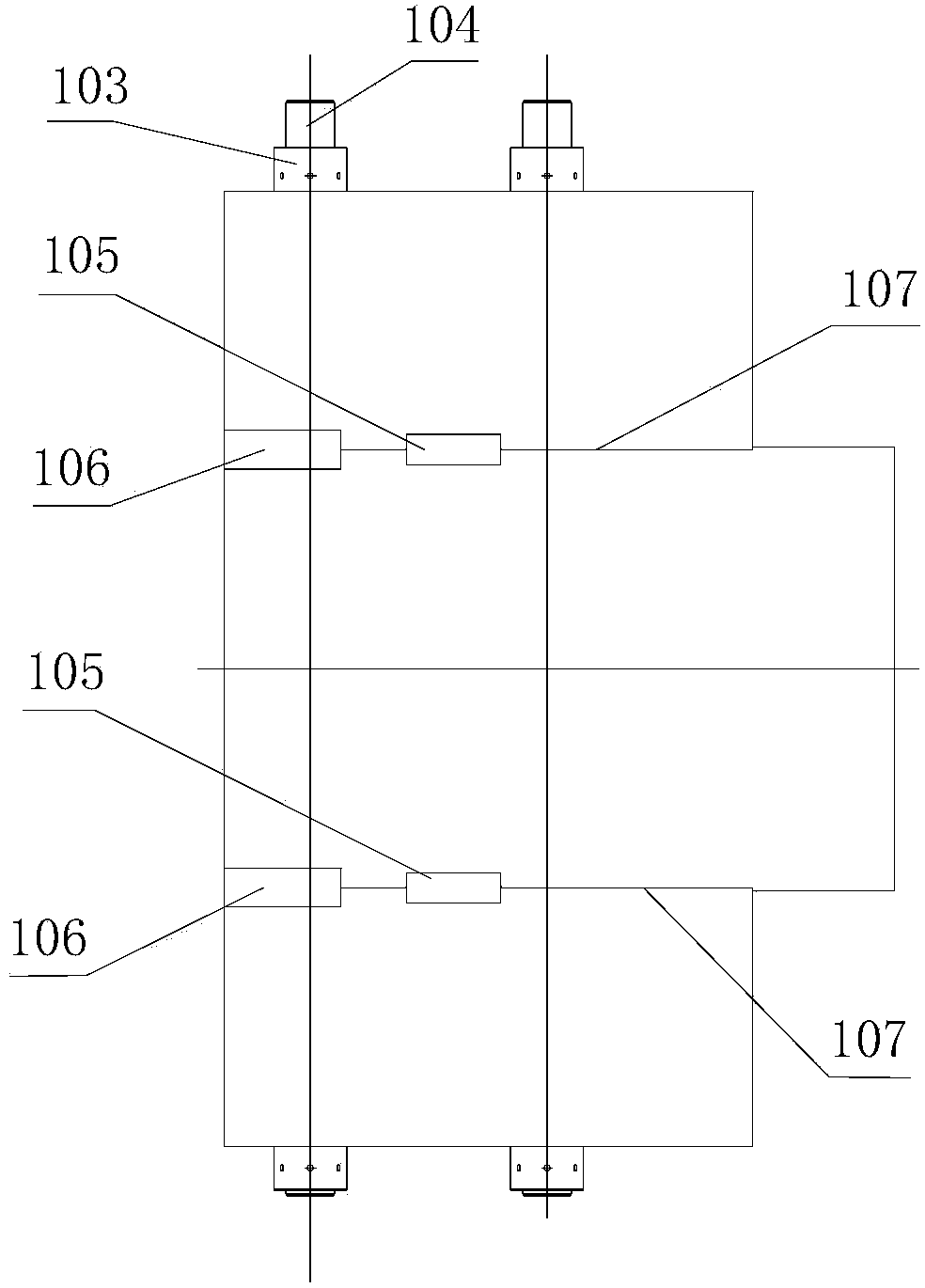

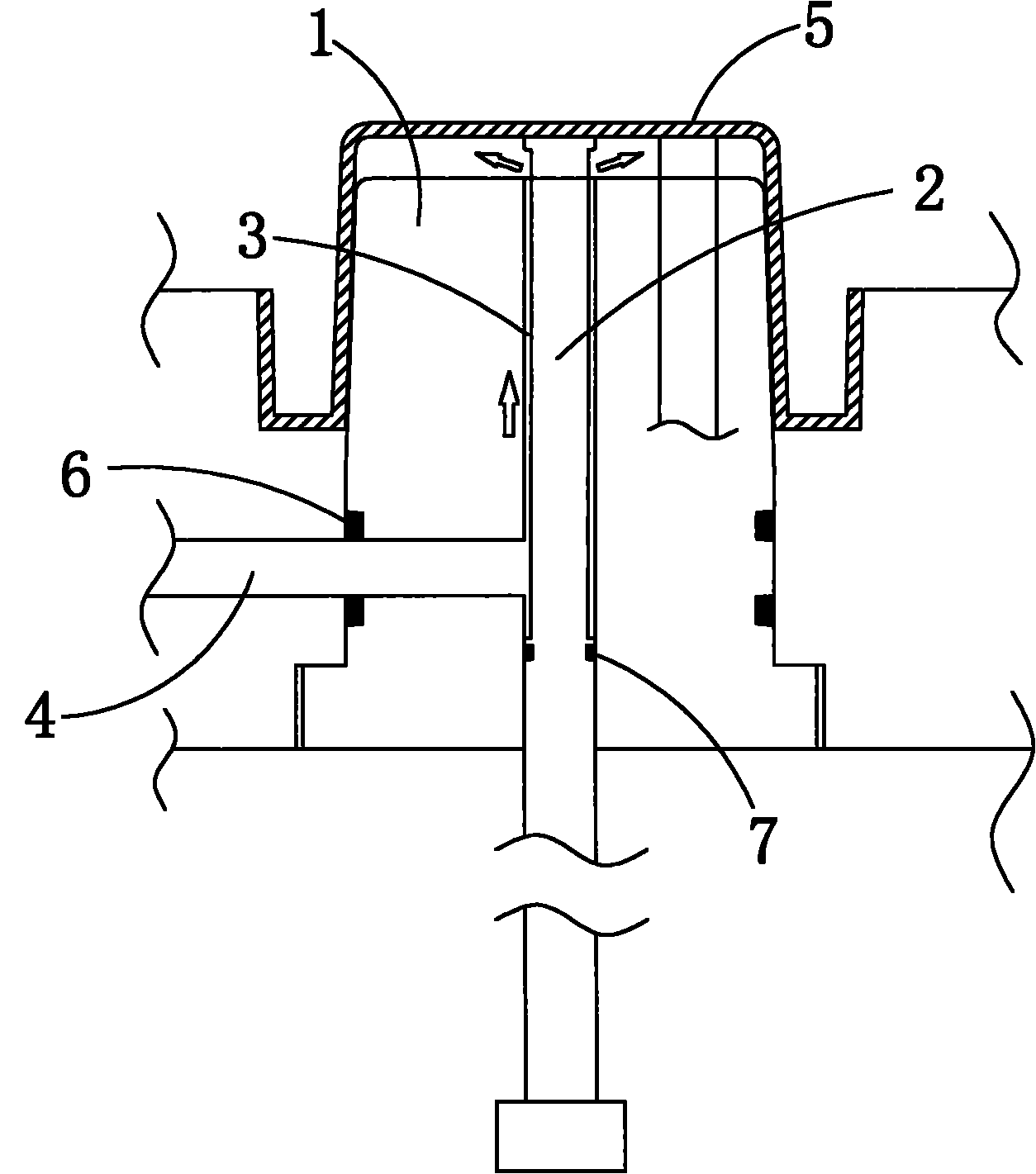

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Functional additive for starch-base biological degradation packaging material and producing method thereof

The invention relates to a functional additive for strach- based biological degradation packing material and the preparation method. It belongs to a multi- functional premixer for adjuvant, and solves bad product performance caused from improper utilization of adjuvant agent. The components comprised by said fuctional additive and their weight proportion are as follows: demoulding agent 1- 10%, viscosity adjustment agent 10- 40%, plasticizing agent 5- 30%, fillings 20- 50%, crosslinking agent 1-5%, starch modifier 1- 5%. The process comprises following steps: feeding raw material into high- speed agitator, mixing for 10 minutes at 40 -80 Deg. C, discharging and getting functional additive. The additive is characterized in that it can greatly reduce fiber distribution speed, can improve slurry processing flowing property, is favouable for starch products shaping, can increase product flexibility and strength, meets non- degradation packing material property standard and state environmental requirment.

Owner:贾军毅

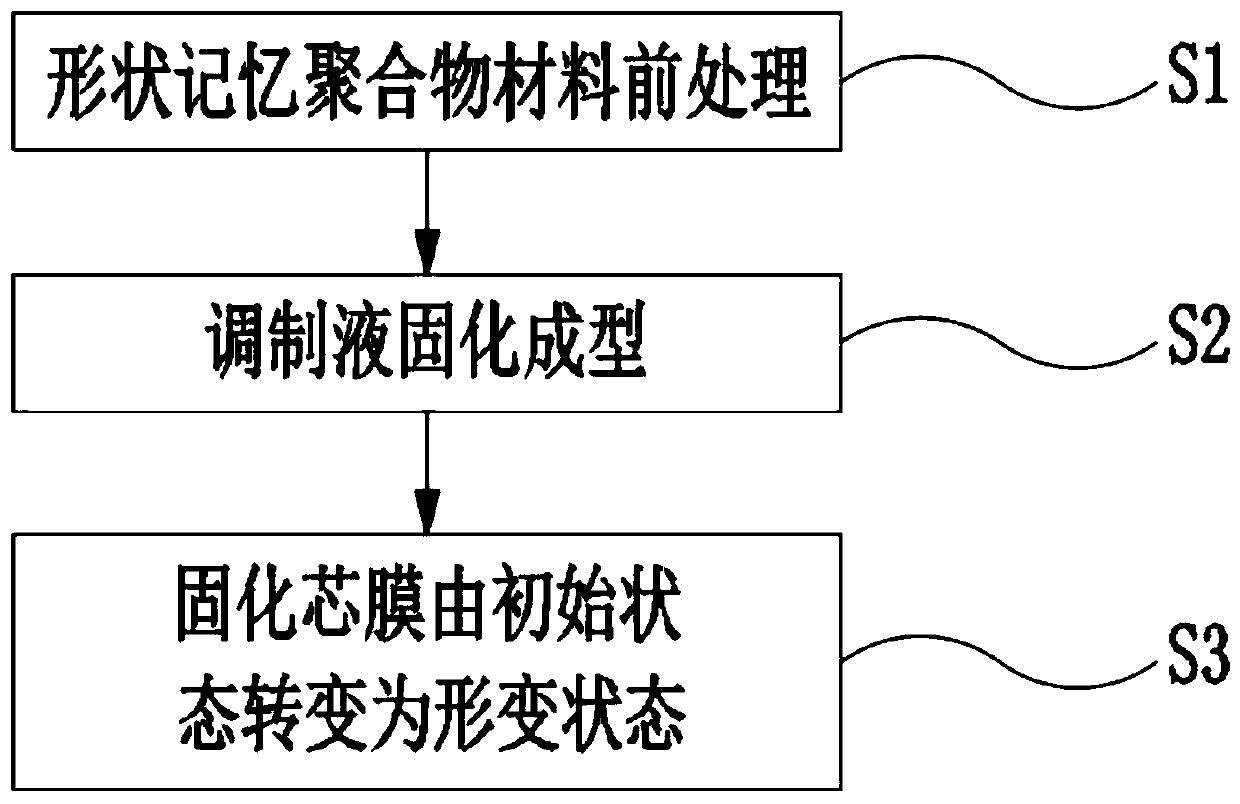

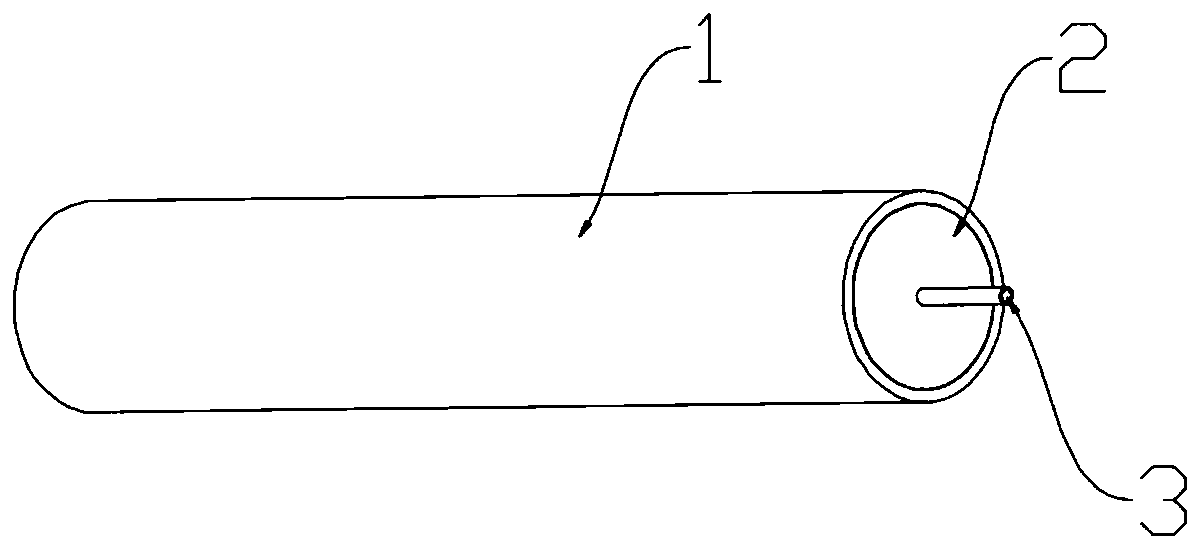

Core mold, manufacturing method of core mold and irregular composite pipe forming method

The invention provides a core mold, a manufacturing method of the core mold and an irregular composite pipe forming method, and relates to the technical field of irregular pipe manufacturing. The coremold is made of shape memory materials. The irregular composite pipe forming method comprises the steps that a resin matrix composite prepreg material adheres to the core mold, a composite prepreg lamination layer is formed, then put into an auxiliary rigid mold, pressurized, heated, solidified and cooled, and then a solidified product C is obtained; the temperature of the solidified product C isrisen to be larger than the temperature corresponding to the glass transition point of the core mold, the core mold is converted to be in a rubber state and separated from a solid composite in a peeled mode, and the core mold is drawn out, so that an irregular composite pipe preformed product is obtained; and the surface of the manufactured irregular composite pipe preformed product is subjectedto polishing treatment, so that an irregular composite pipe is obtained. According to the core mold, the manufacturing method of the core mold and the irregular composite pipe forming method, mold removal is easy, the surface accuracy of the product is high, and the core mold, the manufacturing method of the core mold and the irregular composite pipe forming method are suitable for irregular structures which are difficult to achieve mold removal of metal core molds. In addition, the shape memory core mold can be used repeatedly, the production cost is low, and the core mold is suitable for various composite products with the complex shapes.

Owner:HARBIN INST OF TECH

Secondary demoulding mechanism with gear and racks for injection mould

The invention discloses a secondary demoulding mechanism with a gear and racks for an injection mould, comprising an upper compound plate and a lower compound plate, wherein a cavity is installed below the upper compound plate; an ejection support plate is installed on the lower compound plate; a through hole is formed in the lower compound plate; the ejection rod of an injection moulding machine penetrates through the through hole and then contacts with the ejection support plate; an ejection needle pushing plate and an ejection needle fixing plate are installed on the ejection support plate; a stripping plate push rod and a return rod are fixed in the ejection needle fixing plate; a return spring is installed outside the return rod; a mould leg is installed on the lower compound plate; a support plate is installed on the mould leg; a core fixing plate, a core and a stripping plate are installed on the support plate; and a moulded plastic part is arranged among the core, the stripping plate and the cavity. The secondary demoulding mechanism with a gear and racks is characterized in that an acceleration rack is fixed between the lower compound plate and the support plate; installation holes are formed in the ejection needle pushing plate and the ejection needle fixing plate; an ejection needle rack and the gear are installed in the installation holes; the gear is fixed in the ejection needle pushing plate via a rotary shaft; the gear is matched with the acceleration rack and the ejection needle rack respectively; an ejection needle is installed on the ejection needle rack; and the ejection needle penetrates through the core and then contacts with the plastic part.

Owner:TAIZHOU KAIHUA AUTOMOBILE MOULD CO LTD

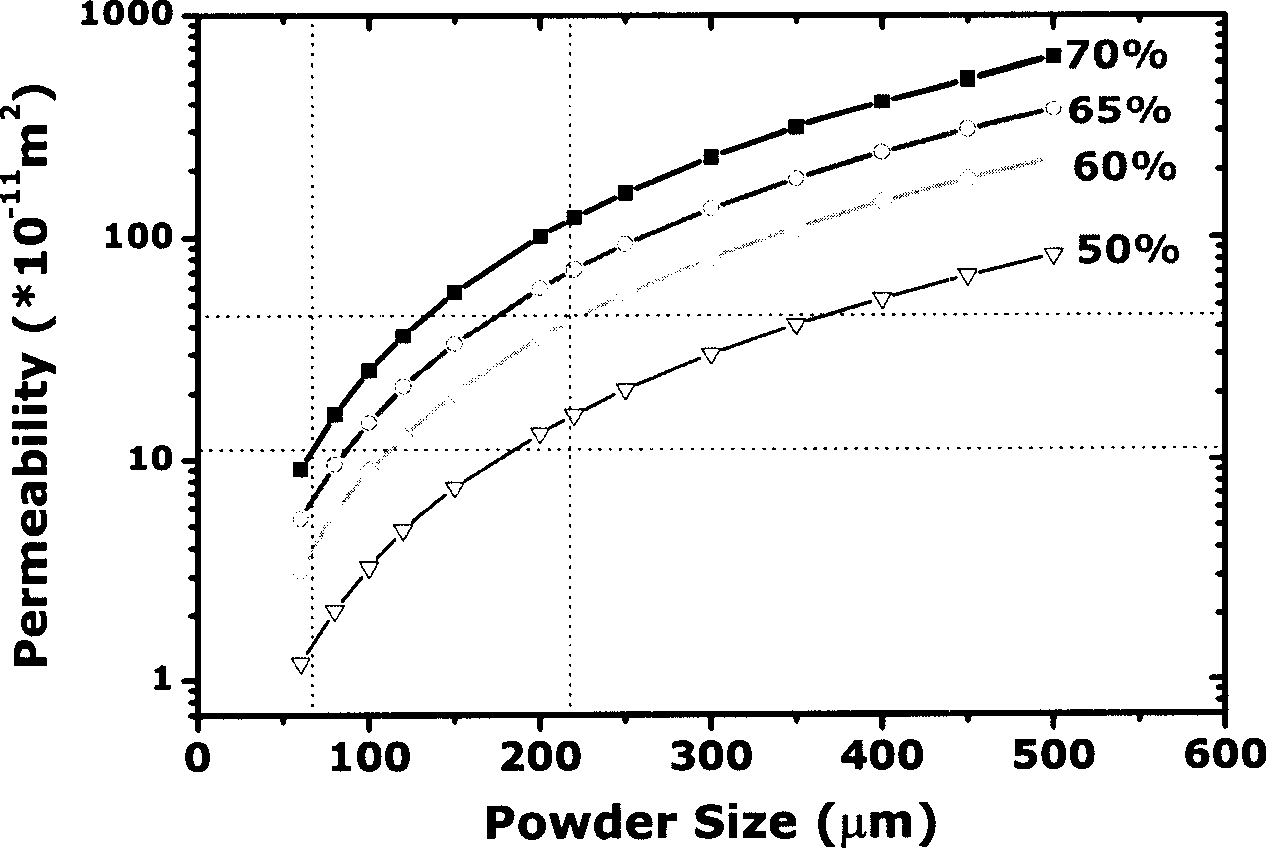

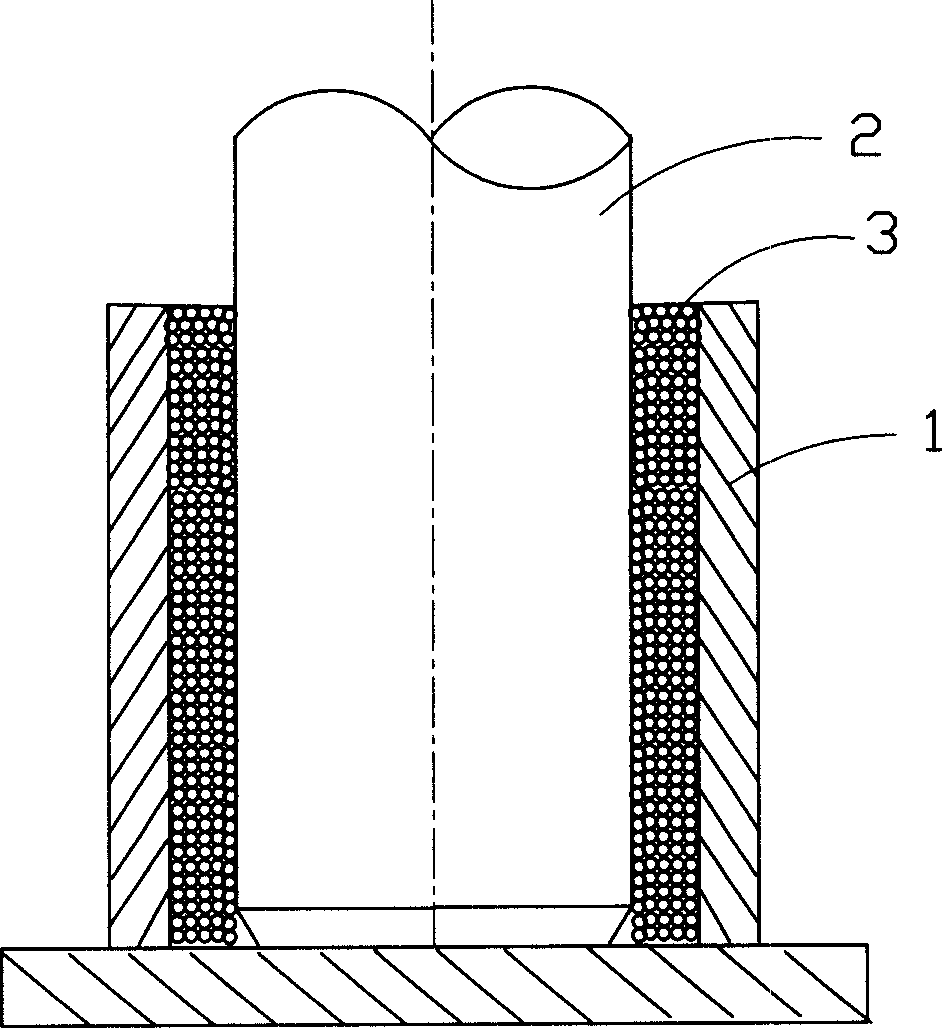

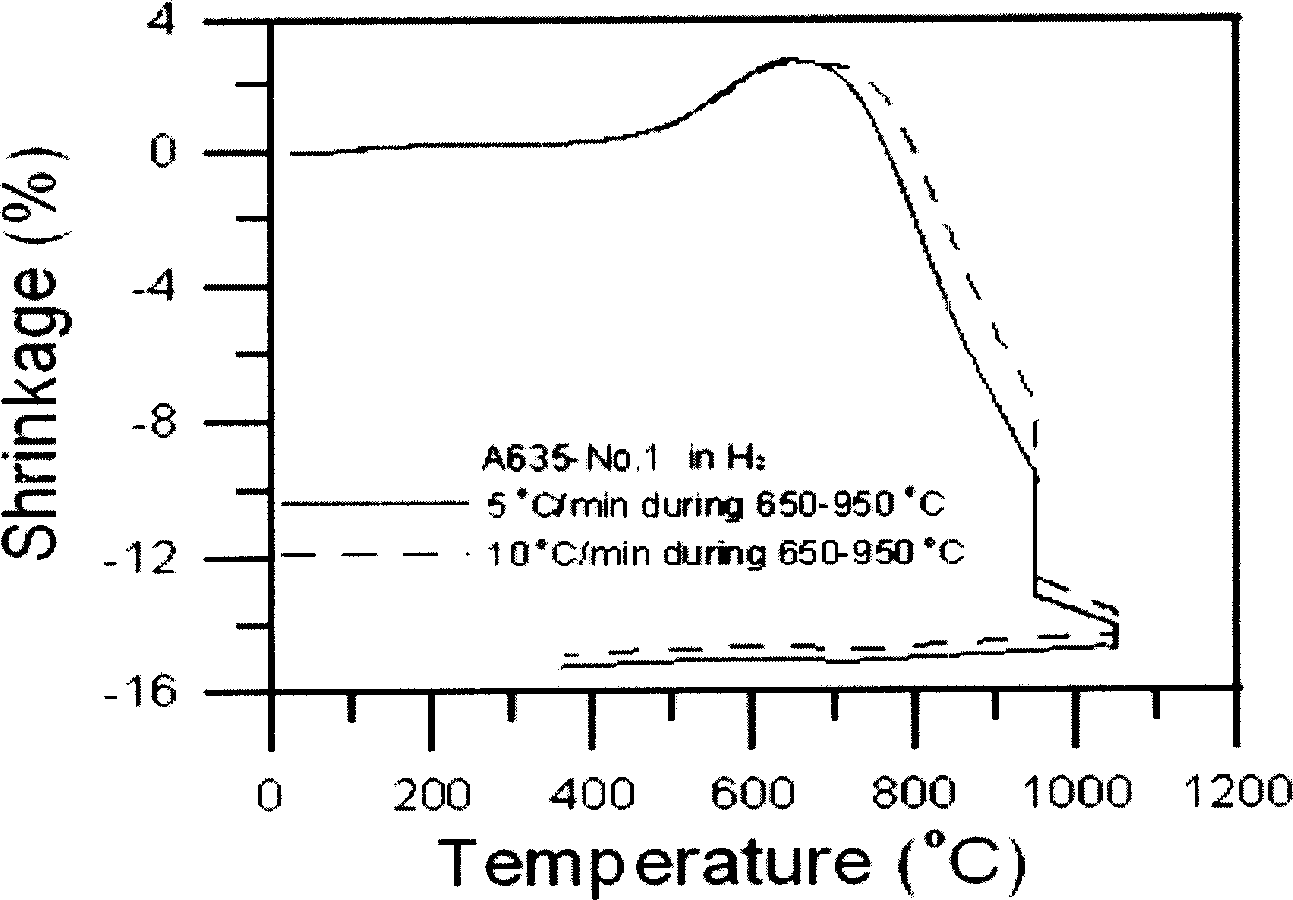

Heat pipe and manufacturing method thereof

InactiveCN1912521AReduce contact areaImprove adsorption capacityIndirect heat exchangersSurface bindingHeat pipe

A heat pipe consists of a heat conduction shell and a capillary structure. Its preparing method includes setting capillary structure in said shell, forming capillary structure by superposing screen mesh layer with particle layer, combining core bar surface with screen mesh, inserting core bar into said shell then filling micro powder in gas between said shell and screen mesh and sintering it with high temperature for obtaining product of heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

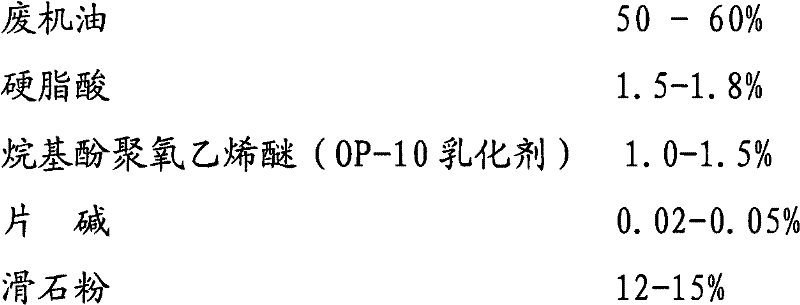

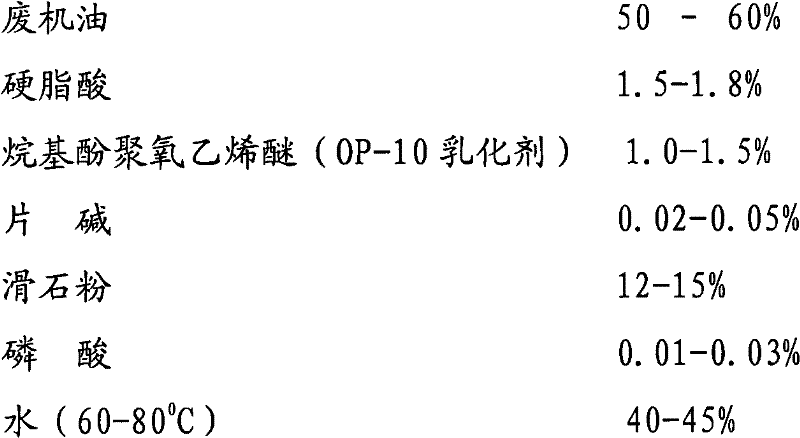

Foam concrete preform release agent and preparation method thereof

InactiveCN102191120ABroaden applicationFast film formationLubricant compositionFoam concretePhosphoric acid

The invention relates to a foam concrete preform release agent and a preparation method thereof. The foam concrete preform release agent comprises the following components by weight percent: 50-60% of waste oil, 1.5-1.8% of stearic acid, 1.0-1.5% of alkylphenol polyoxyethylene ether (OP-10 emulsifier), 0.02-0.05% of flake caustic soda, 12-15% of talc, 0.01-0.03% of phosphoric acid and 40-45% of water (60-80 DEG C). When the release agent prepared by adopting the formula is used for mould release, the foam concrete preform has no oil stain on the surface, no spallation and no edge defect and is good for second construction; and the preform has low dimensional deviation, the film-forming speed is high, the production cycle is short and the work efficiency is increased. In addition, the prepared release agent can be used to prevent the wooden mould from warping and deforming.

Owner:ZUNYI JIANTAI LIGHT ENERGY SAVING MATERIAL

Water soluble mandrel moulding method of dipulse engine shell

The invention discloses a water soluble mandrel moulding method of a dipulse engine shell. The method comprises the following steps of: A, preparing a separator, a dabber and a shaft sleeve matched coaxially; B, preparing a quartz sand mixed cementing compound which comprises the following components in parts by weight: 350-450 parts of quartz sand, 9-10 parts of polyvinyl alcohol, 0.4-0.6 part of starch and 30-50 parts of water; first, mixing polyvinyl alcohol and starch to form mixed powder, then, mixing and stirring the mixed powder with water to form grume-free liquor, and finally, stirring and mixing quartz sand with the grume-free liquor; C, moulding the quartz sand mixed cementing compound as a sand sleeve; D, curing the sand sleeve; E, processing the external surface of the sand sleeve and the inner end face of the sand sleeve; F, assembling the dabber, the separator, the shaft sleeve and the sand sleeve; and G, performing surface treatment for the sand sleeve. The method disclosed by the invention is simple in moulding process, short in production period and low in cost, satisfies the design demand, and is suitable for being widely applied to the technical field of moulding solid rocket engine shells.

Owner:湖北三江航天江北机械工程有限公司

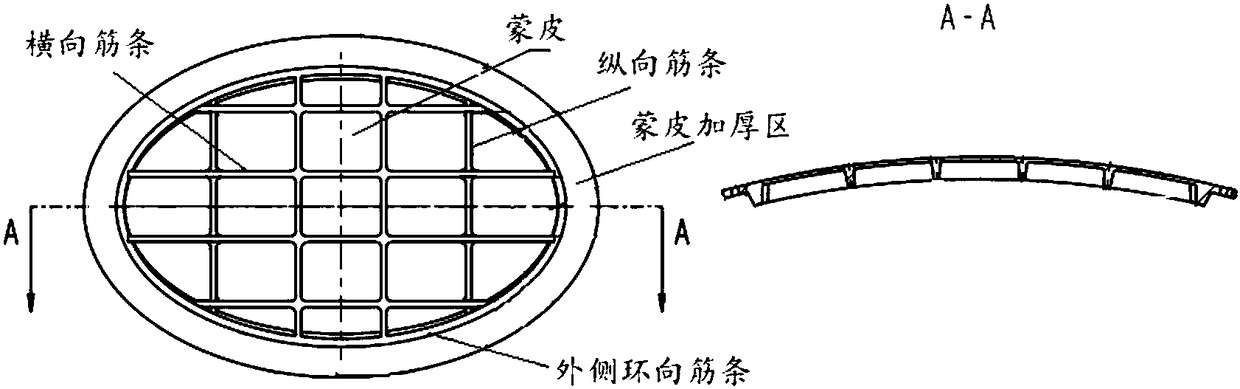

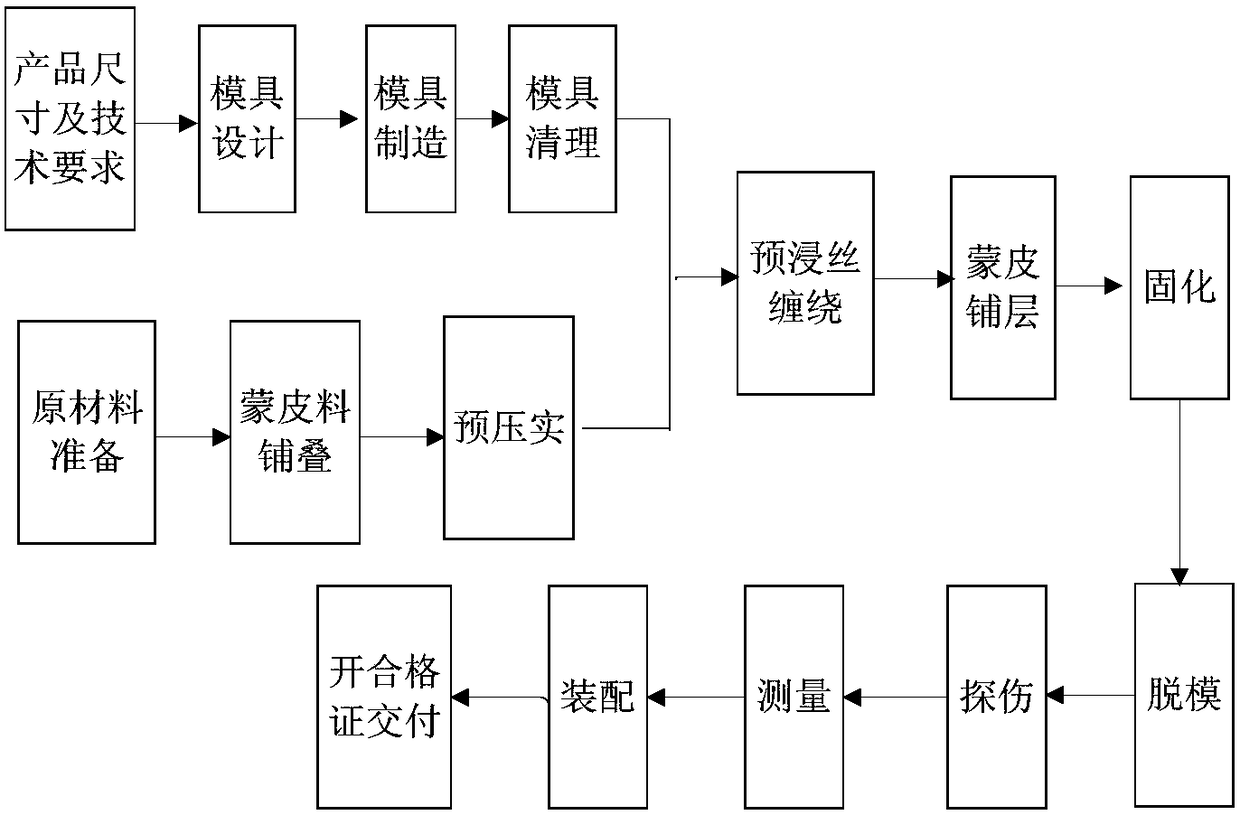

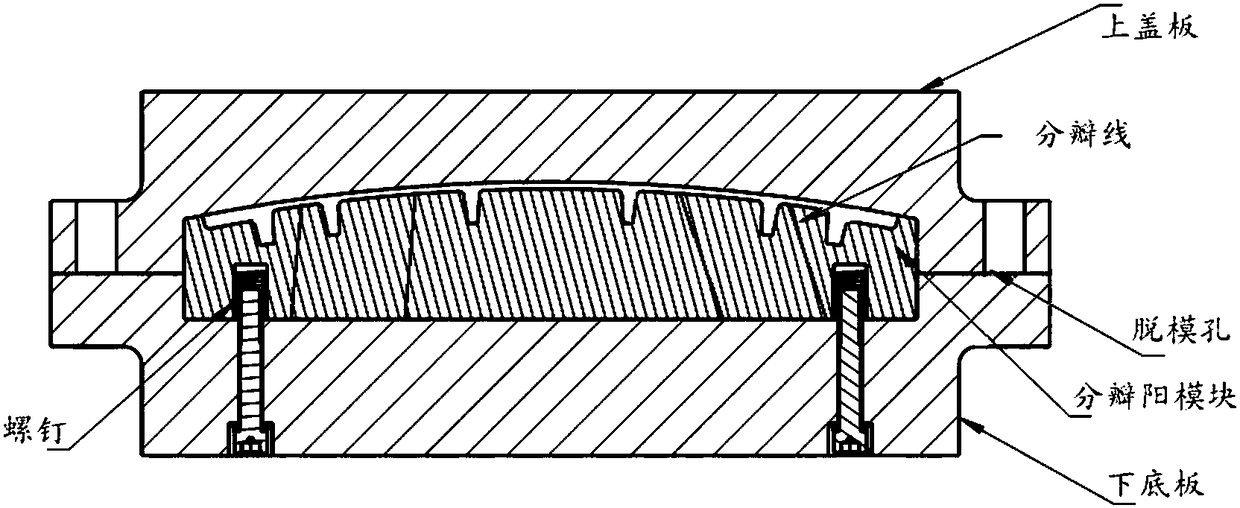

Composite material grid skin structure part die compression molding forming method

ActiveCN108407332AUniform thicknessGood internal and external qualityCompression moldingSkin structure

The invention relates to a composite material grid skin structure part die compression molding forming method, and belongs to the technical field of composite material forming. A set of control measures suitable for skin grid structure part die compression molding forming technology are found through reasonable rib winding and skin laying technological design, one-time integral forming of a composite material skin grid structure part is achieved, product deformation is small, the thickness is uniform, the operation efficiency is high, and rib winding and skin layer laying for the composite material skin grid structure part can be completed only through one day.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

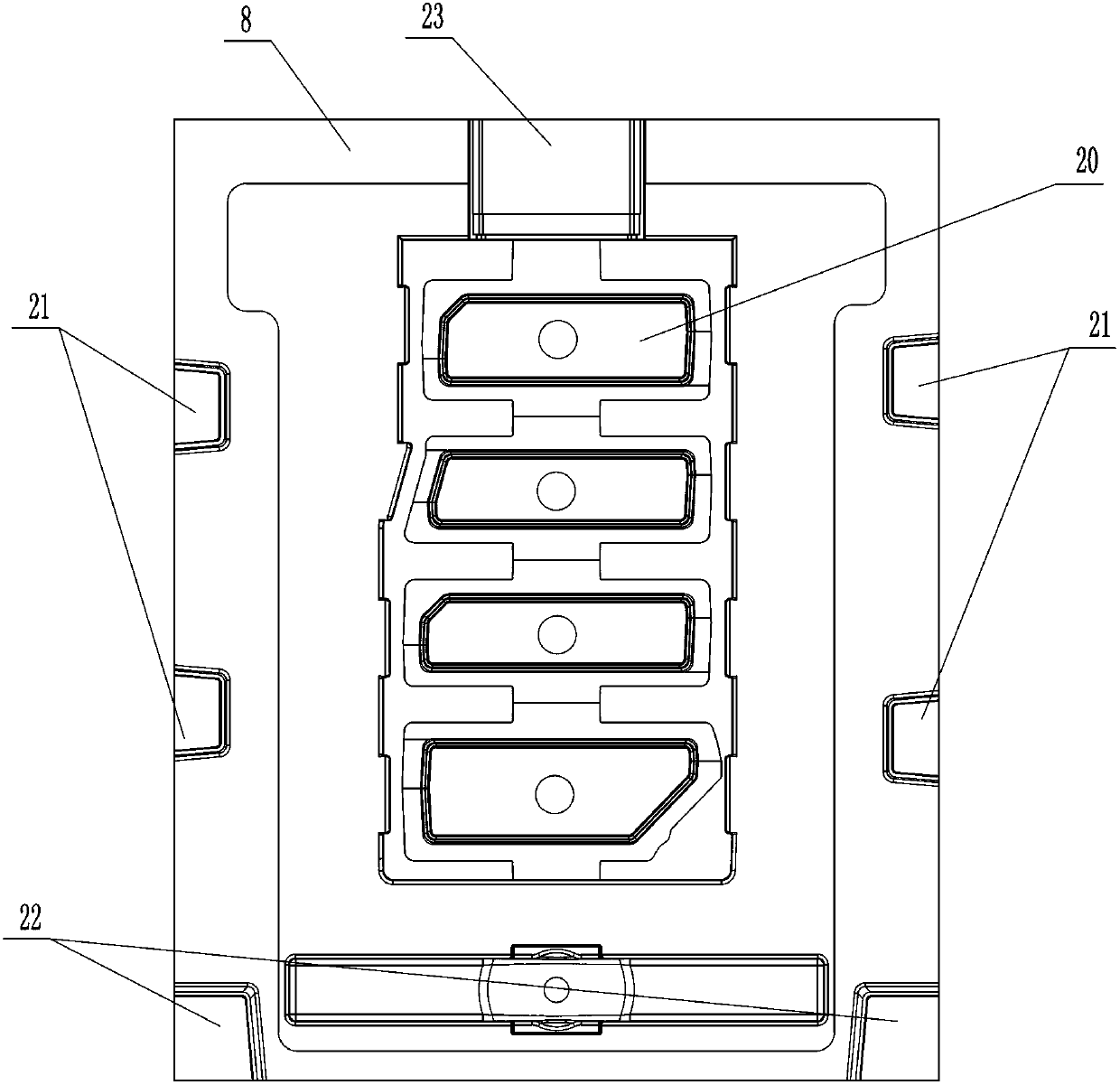

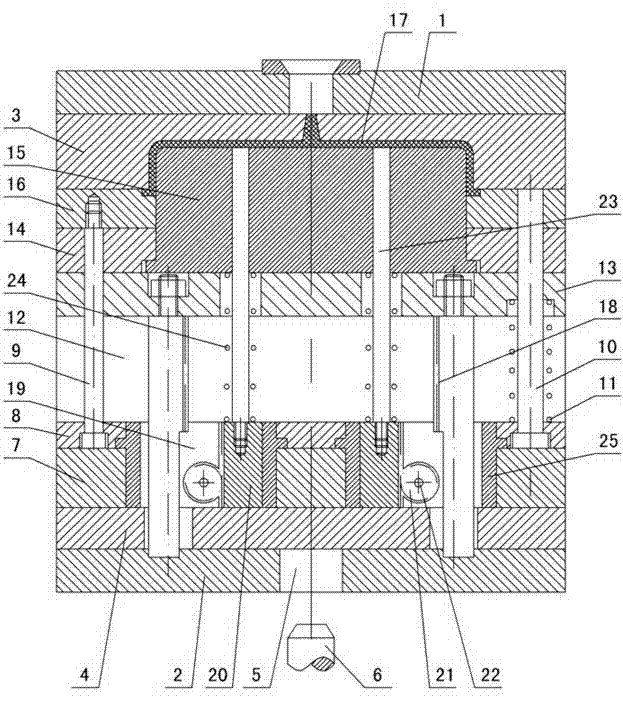

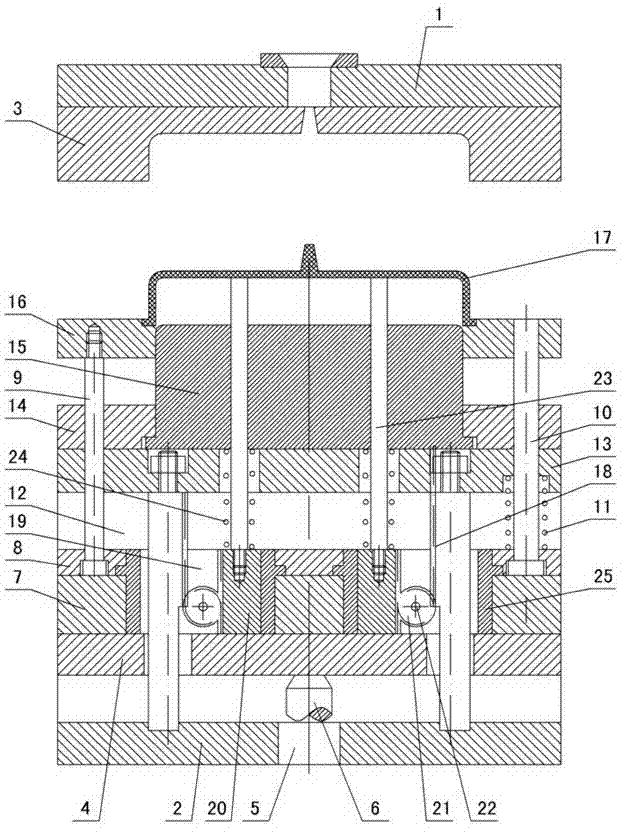

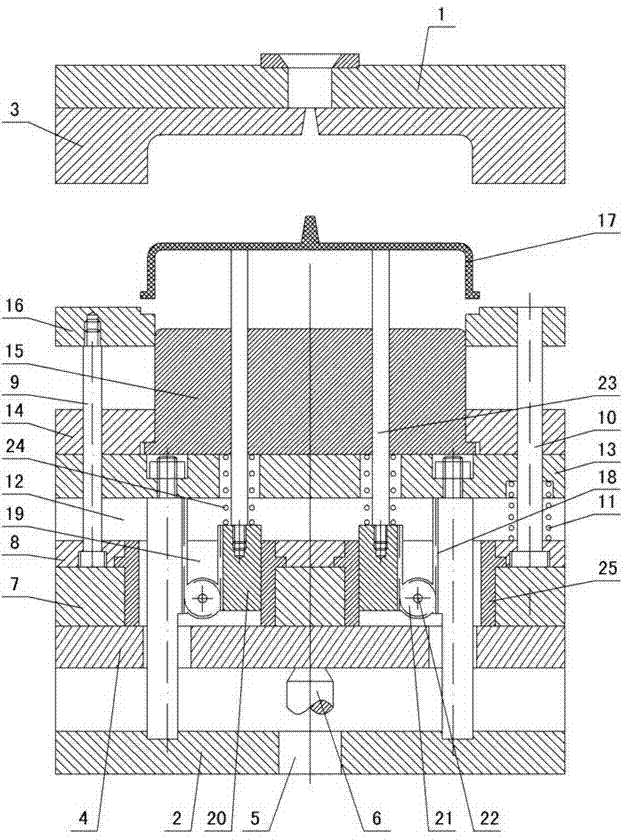

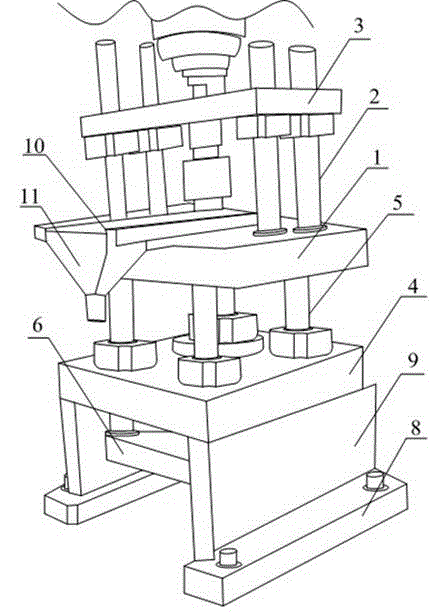

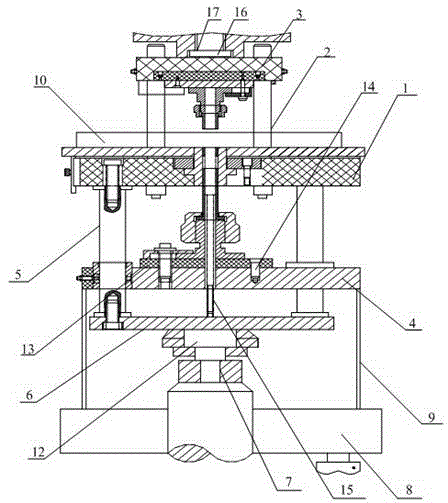

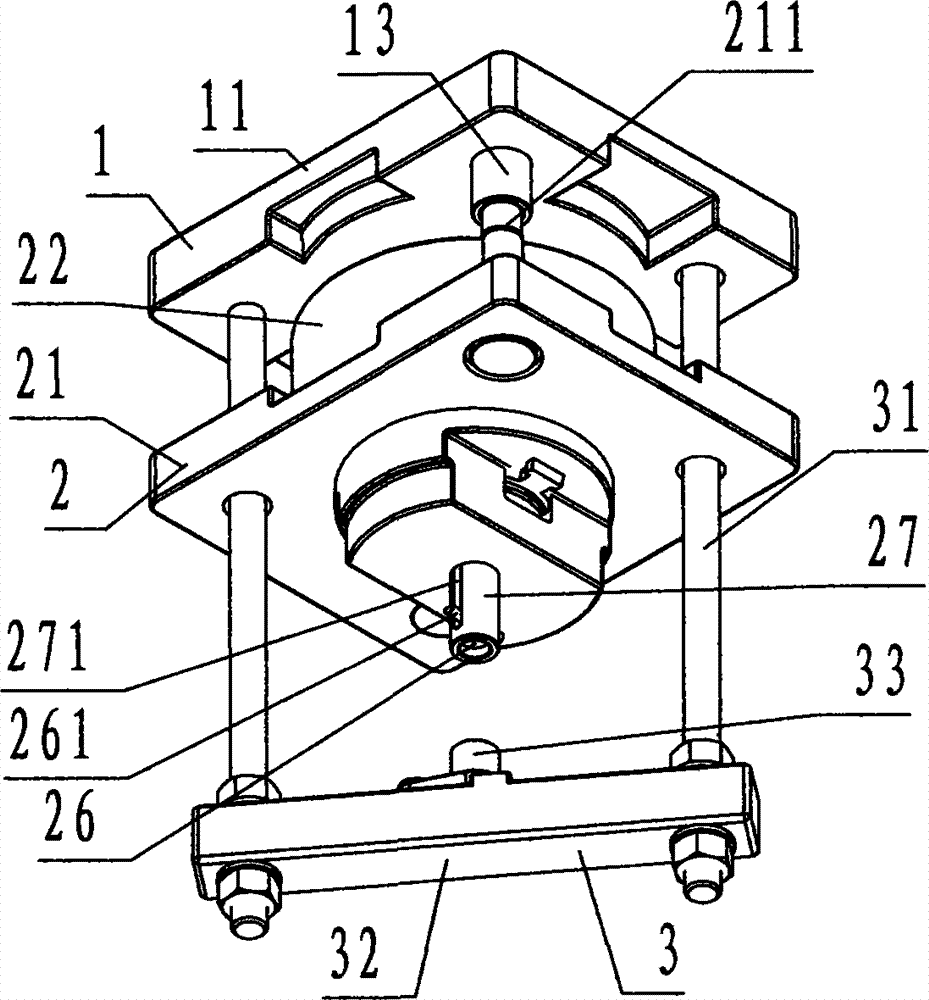

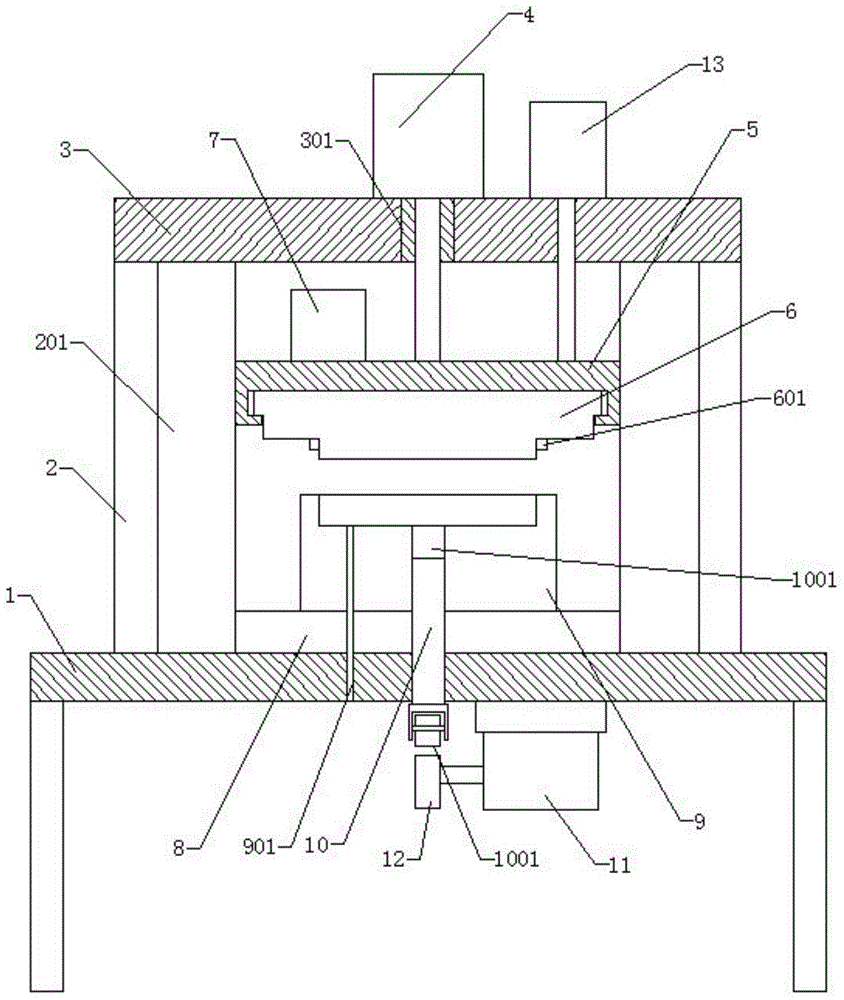

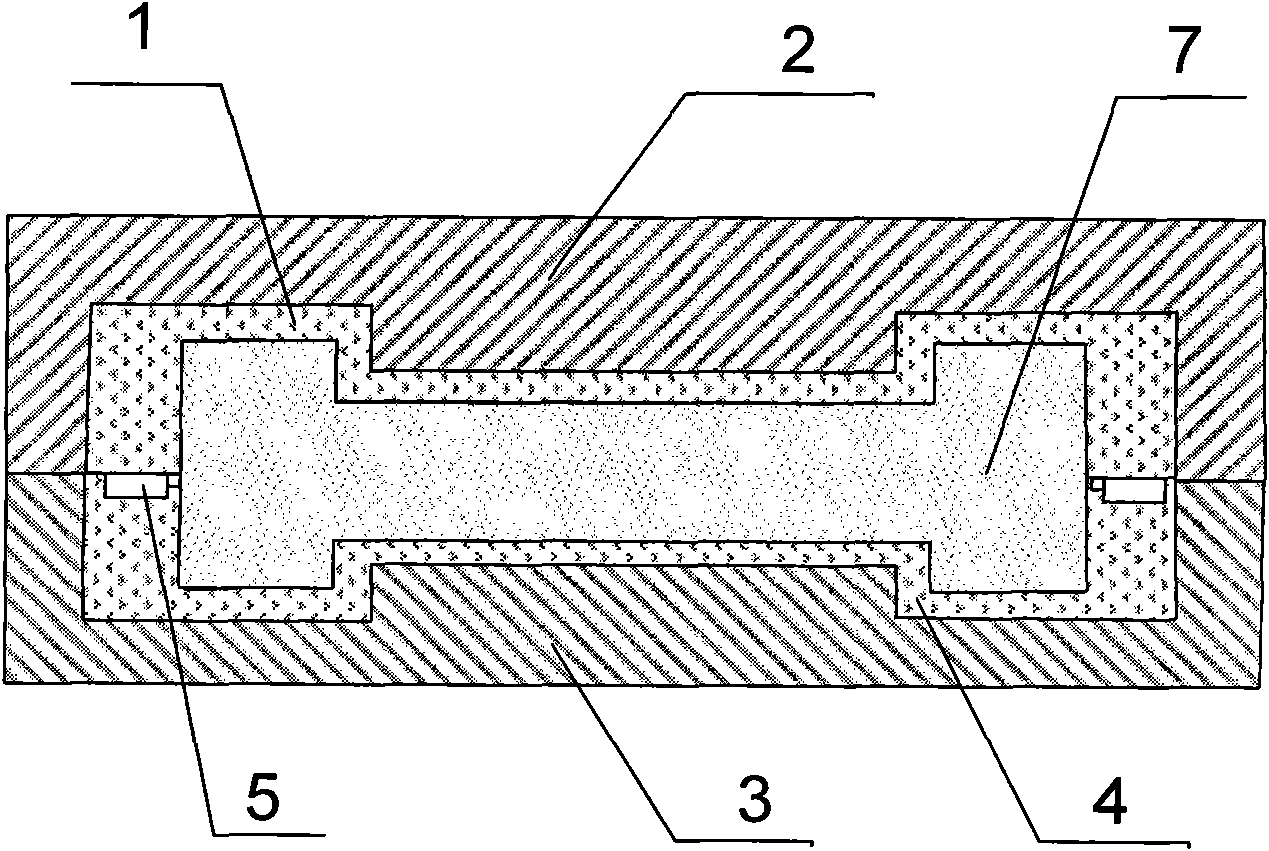

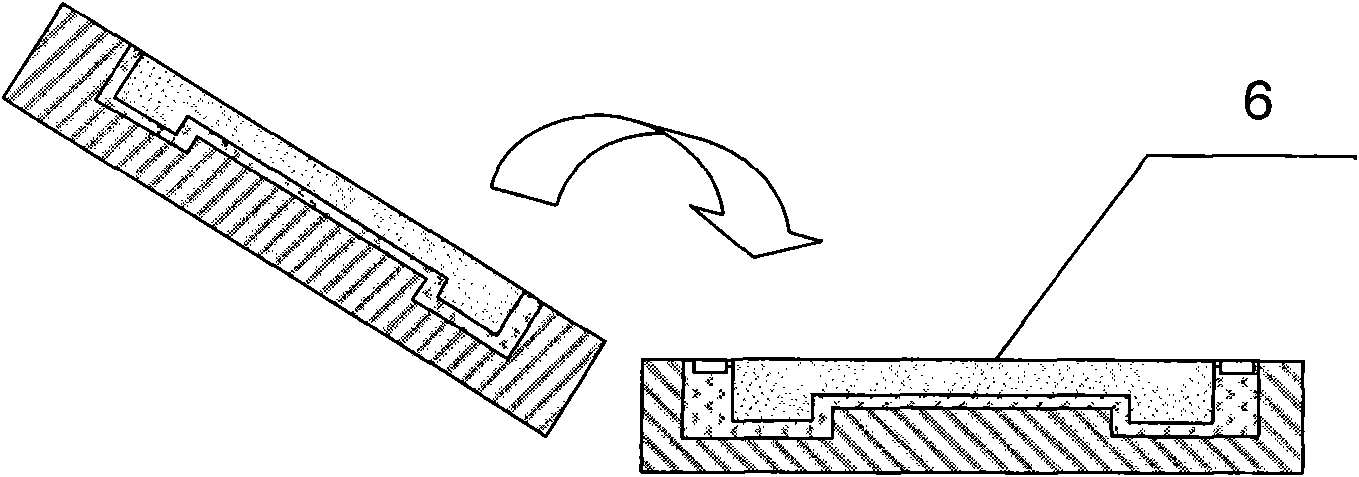

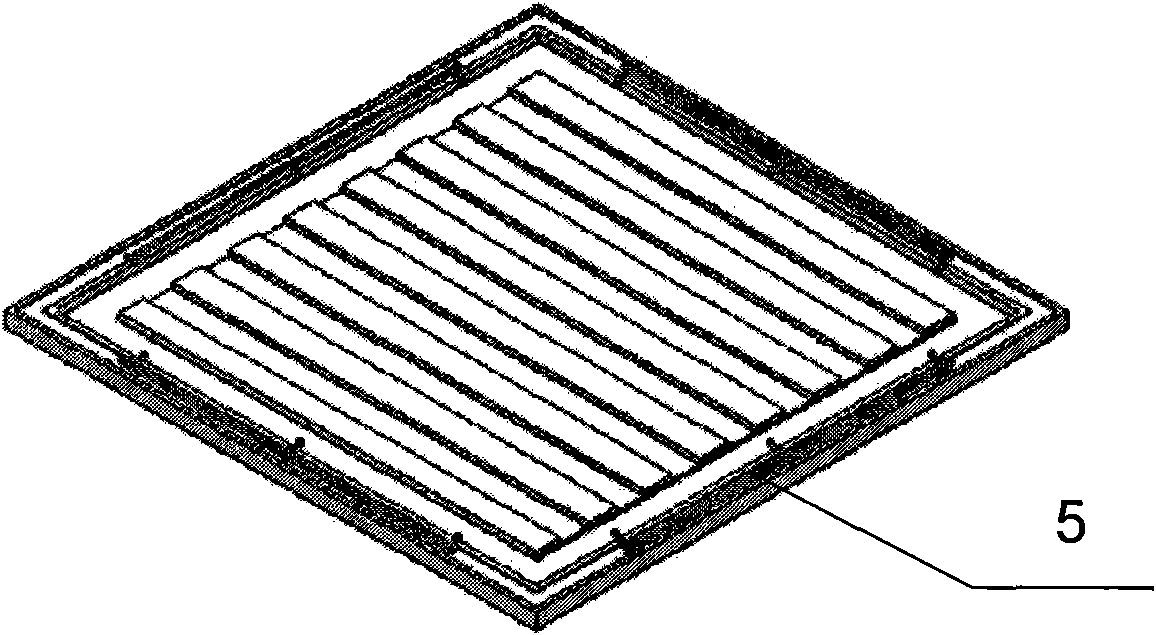

Automatic powder forming die carrier based on powder metallurgy press and implementation method thereof

The invention discloses an automatic powder forming die carrier based on a powder metallurgy press, which solves the problems in the prior art that the structure of the die carrier is complex, the manufacture cost is high, and the die replacement operation is fussy. The automatic powder forming die carrier comprises a parent plate, an upper die plate, a lower die plate, a linkage mechanism and a fixing mechanism, wherein the upper die plate is arranged above the parent plate and is movably connected with the parent plate through an upper guide post; the lower die plate is fixedly arranged under the parent plate; the linkage mechanism is used for driving the parent plate to do a reciprocatory motion; and the fixing mechanism is used for supporting and fixing the lower die plate. In order to realize the automatic powder forming die carrier, a feeding plate is arranged at the upper end surface of the parent plate, and a material collecting funnel communicated with the feeding plate is also arranged at the end part of the feeding plate. The invention also discloses an implementation method based on the die carrier. Under the premise that a main structure is not chanced, the structure of the die carrier is simplified, the implementation is very convenient, and the die carrier can be suitable for continuous and automatic production, so that the production cost is reduced, and the production efficiency is increased. Thus, the die carrier is suitable for promotion and application.

Owner:黄彬

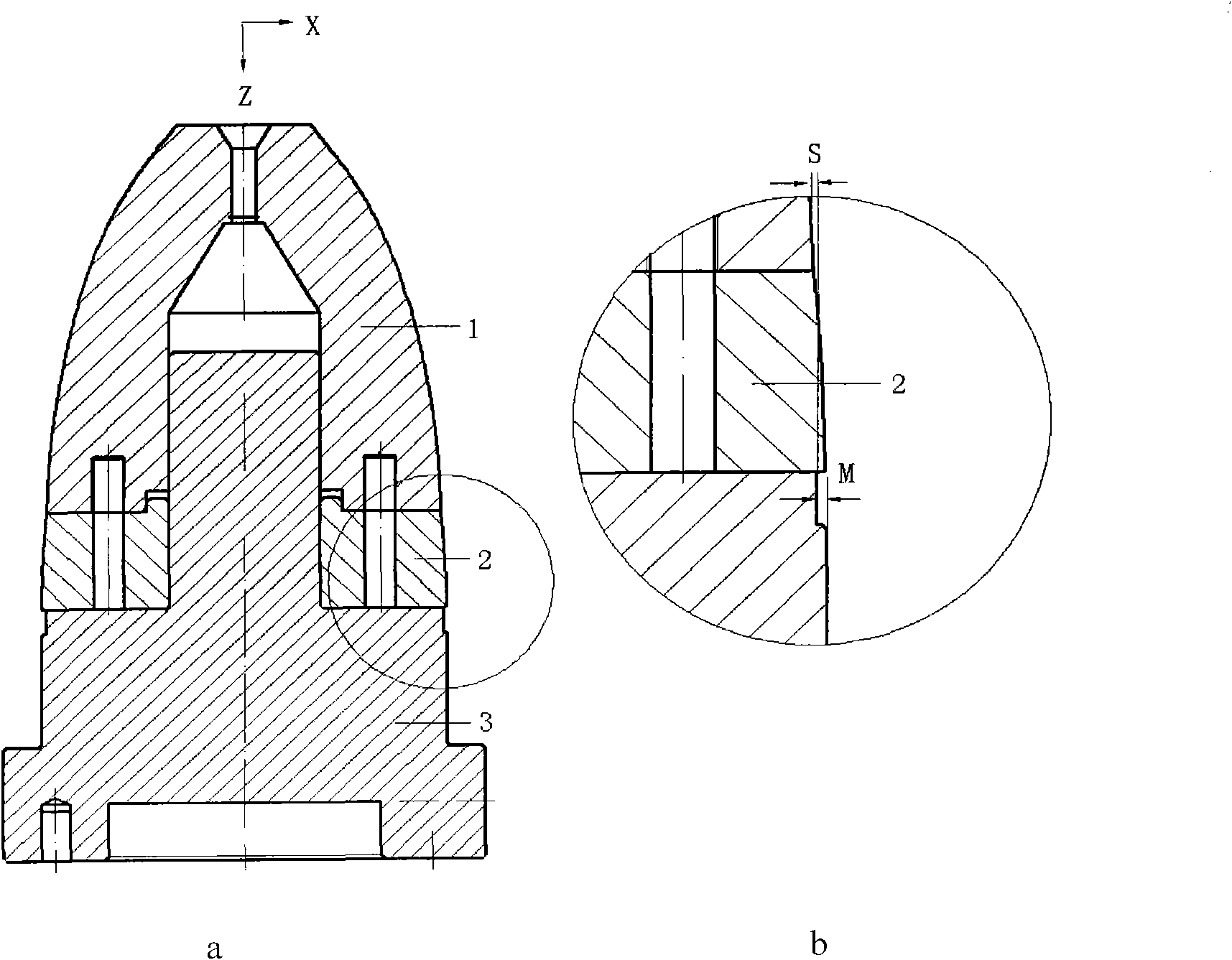

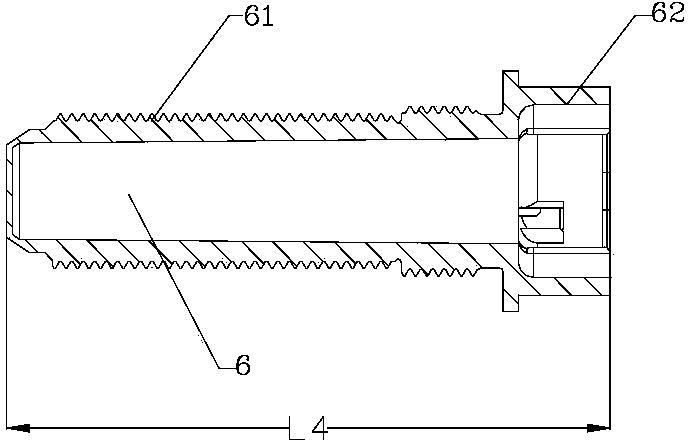

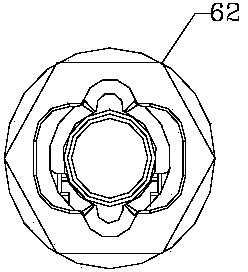

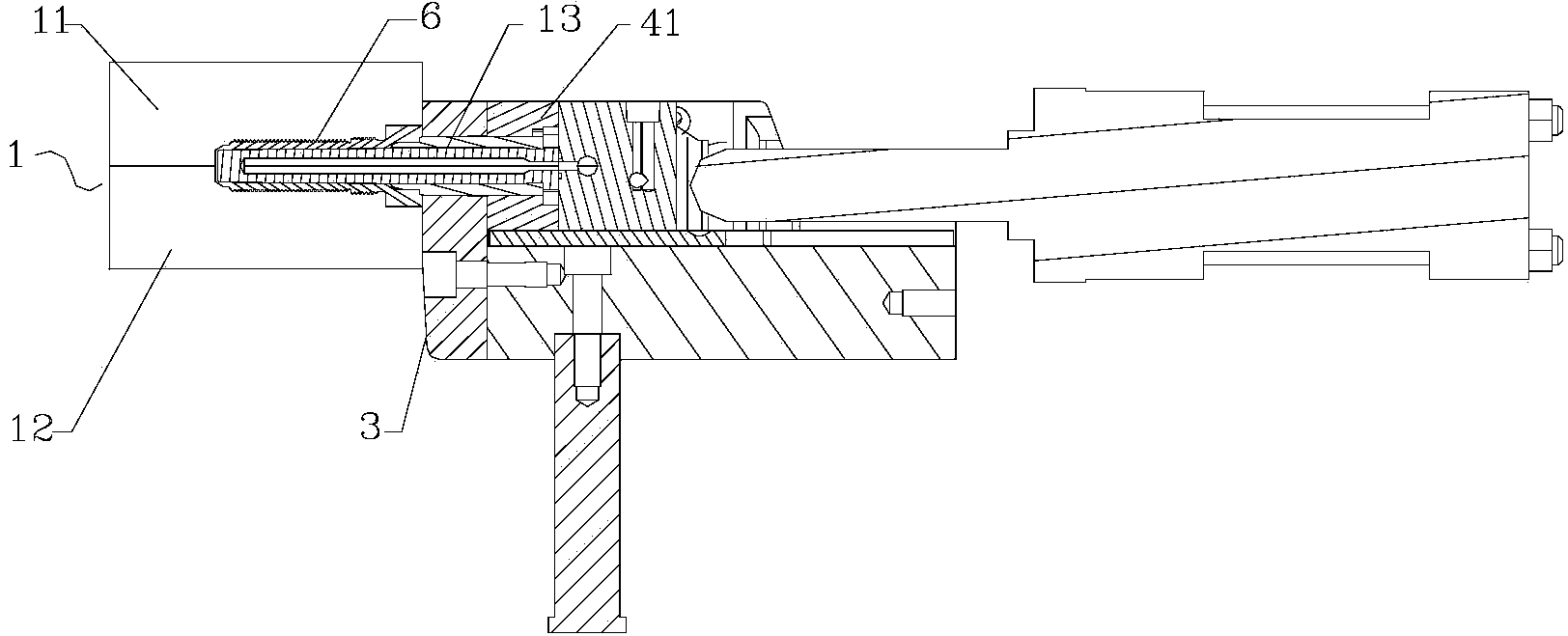

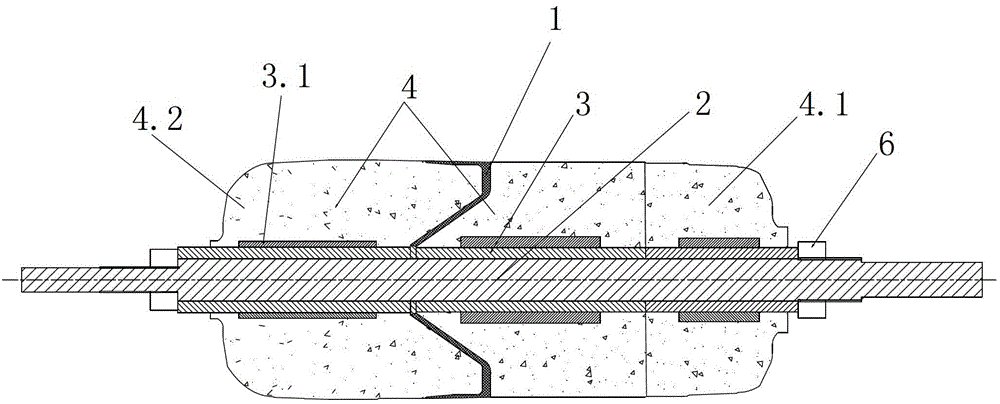

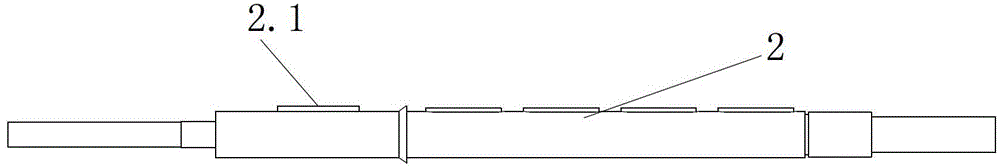

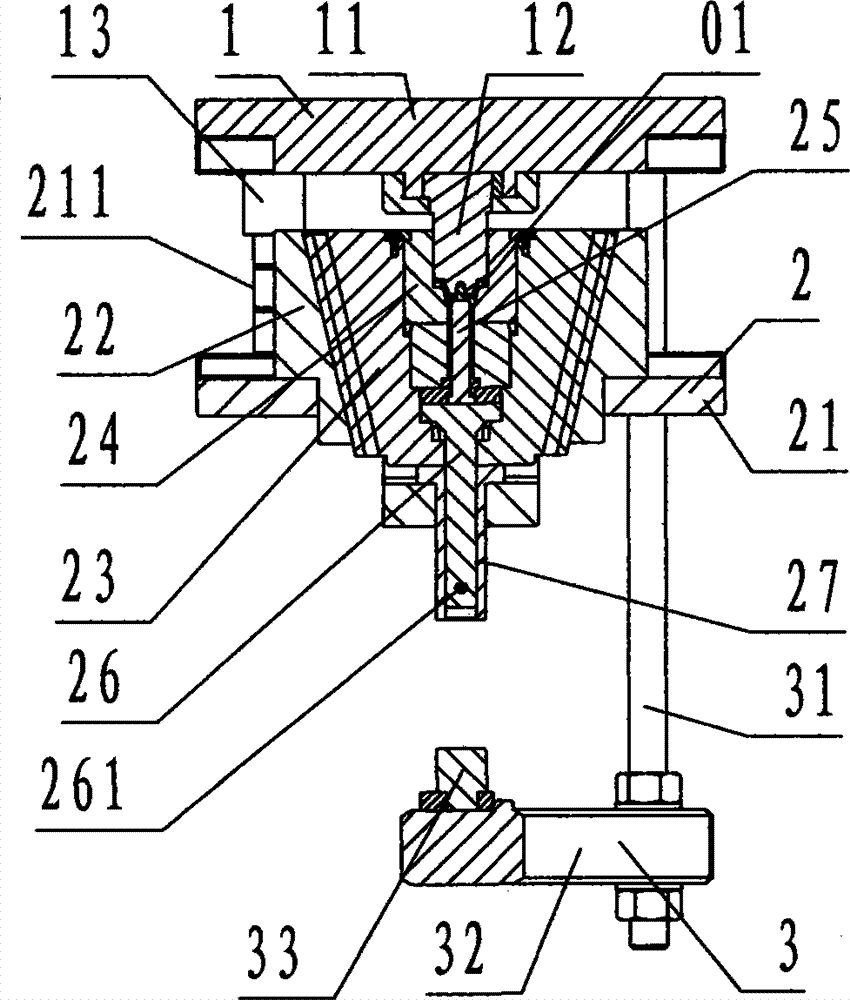

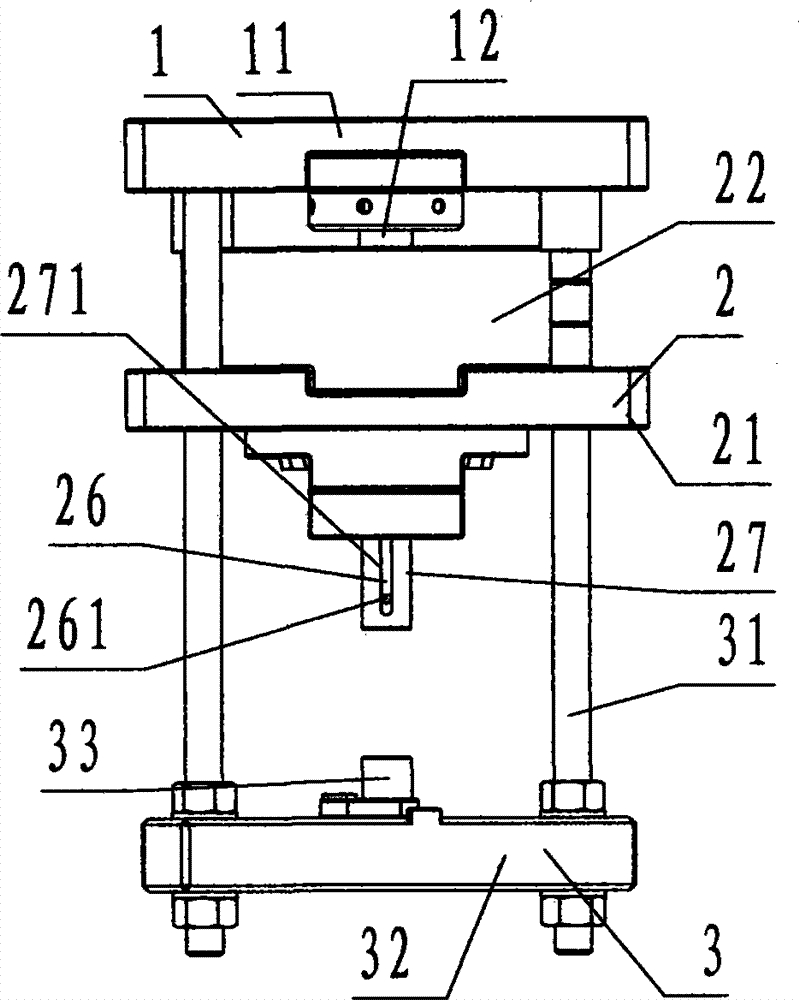

Half stamp forging forming die

ActiveCN103658487ASmooth demouldingAvoid the disadvantages of re-cuttingForging/hammering/pressing machinesPunchingDevice form

The invention discloses a half stamp forging forming die. The half stamp forging forming die comprises an upper die (1), a lower die (2) and a die ejector (3). A device formed by the parts is adopted, a core punch is arranged on the upper die, and the lower die is composed of a base, a guide column, a conical cavity sleeve, a half sliding block, a half cavity, a core rod, an ejector rod and an ejector sleeve, wherein the ejector rod is provided with a linkage pin, the ejector sleeve is provided with a delay slotted hole, and an ejector column is arranged on the die ejector. In the working process, the core punch conducts punching upwards through forging materials to make the half sliding block move downwards and concentrically contracts along a conical inner cavity of the conical cavity sleeve at the same time, and a die cavity defined by the core punch, the half cavity and the core rod is utilized to make the forging materials into a back off product through stamp forging and forming; in the die ejection process, the upper die is utilized to conduct upward reset, and the ejector column of the die ejector is driven to upwards push the ejector sleeve in an ejection mode to drive the half sliding block to move upwards. By the utilization of the technical scheme that transverse die sinking and core pulling are conducted on the half cavity through the conical cavity sleeve and the half sliding block, the back off product does not need to be secondarily cut due to the fact that the product is manufactured through stamping forging and forming, and therefore the purposes of improving efficiency and reducing cost are achieved.

Owner:宁波华平智控科技股份有限公司

Die casting mold for manufacturing fan blades

The invention discloses a die casting mold for manufacturing fan blades. The die casting mold comprises a sprue gate, a fixed mold plate, a fixed mold core, a movable mold core and a movable mold plate. The fixed mold core and the movable mold core are combined with each other to form a cavity, a runner which is communicated with the cavity is arranged at the end, which corresponds to the cavity, of the sprue gate, a sprue spreader is arranged in the runner, an extrusion device is arranged between the fixed mold core and the movable mold core and comprises an extrusion pin and a cylinder, the cylinder provides extrusion power for the extrusion pin, and one end of the extrusion pin is positioned in the runner; a slider core pulling mechanism which can drive the extrusion pin to be pulled out of the runner is arranged between the fixed mold plate and the movable mold plate. The die casting mold has the advantages that after the die casting mold is closed, the fan blades can be primarily extruded by a pressure cylinder of a die casting machine, then secondary pressurization feeding and pressing compensation can be carried out by the extrusion pin on the basis of primary extrusion, accordingly, the density of the fan blades can be guaranteed, defects such as air holes, loosening and sinking can be prevented, and the forming quality of the fan blades can be effectively improved.

Owner:SUZHOU GUANGXING MOLD

T-shaped beam casting special mold and using method thereof

PendingCN109968499AQuality improvementHigh quality, high market application prospectsDischarging arrangementMouldsShaped beamT-beam

The invention discloses a T-shaped beam casting special mold and a using method thereof, and relates to the technical field of T-shaped beam manufacturing. The T-shaped beam casting special die comprises a guide rail, wherein a walking trolley is arranged on the sliding rail in a sliding mode, a left mold and a right mold are symmetrically arranged on the walking trolley, the left mold comprises frames and panels connected to the inner side of the frames, the walking trolley is provided with mold guide devices which are positioned at the outer side ends of the two frames and provided with high-stroke spaces, the outer side ends of the two frames are provided with overturning type demolding mechanisms, an automatic slope adjusting mechanism and a locking mechanism are arranged on each frame, the tops of the automatic slope adjusting mechanisms and the tops of the locking mechanisms are hinged to the bottom of rotatable parts of the panels, combined adjusting mechanisms for adjusting theheight of the left mold and the bottom of the right mold are arranged at the bottom of the left mold and the bottom of the right mold, and supporting columns which are convenient to assemble and disassemble are arranged on the outer sides of the tops of the two frames, and during use, the supporting columns are subjected to mold closing and grouting, demoulding. The T-shaped beam casting specialmold has the advantages of being complete in function and good in T-shaped beam forming quality.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

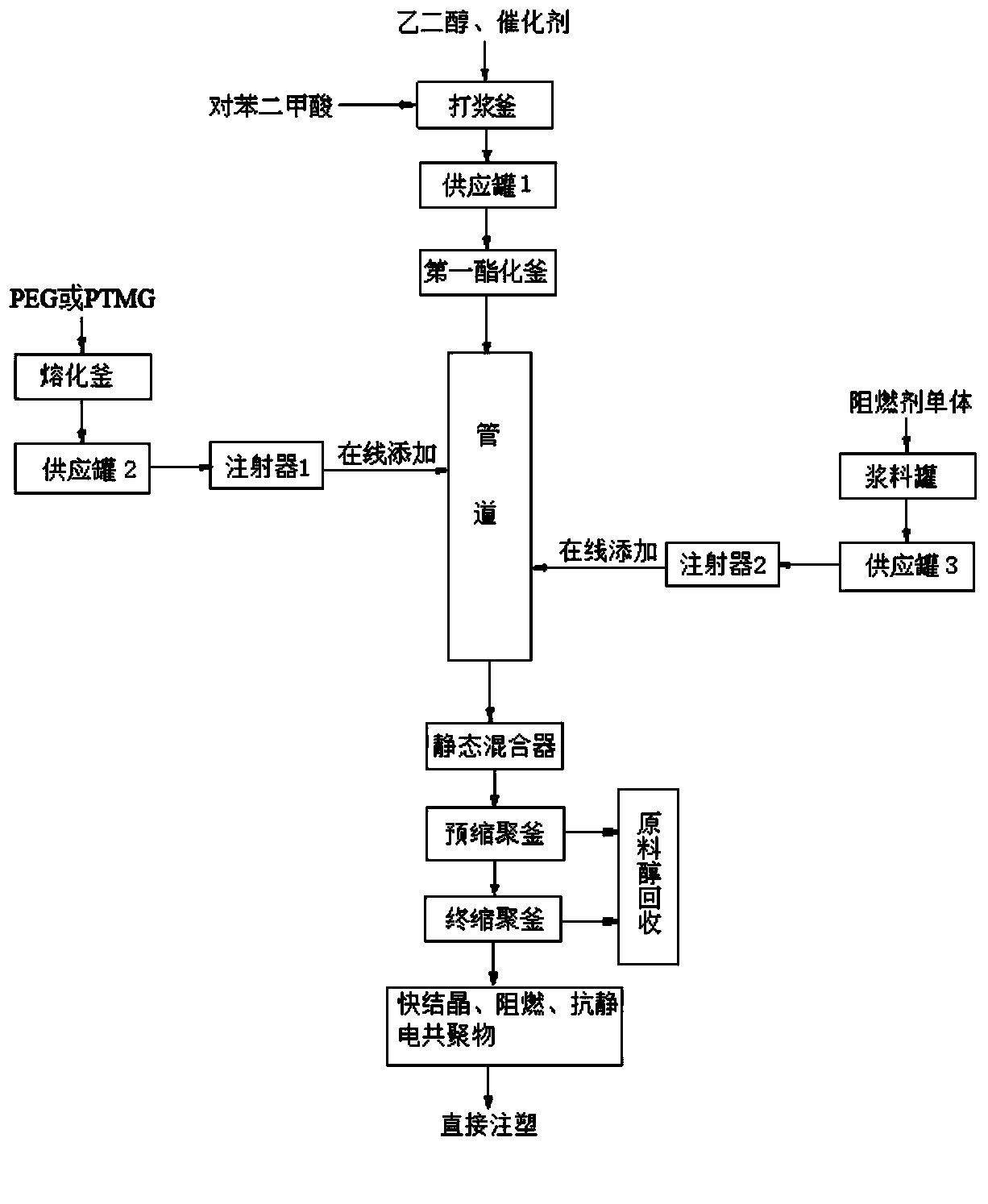

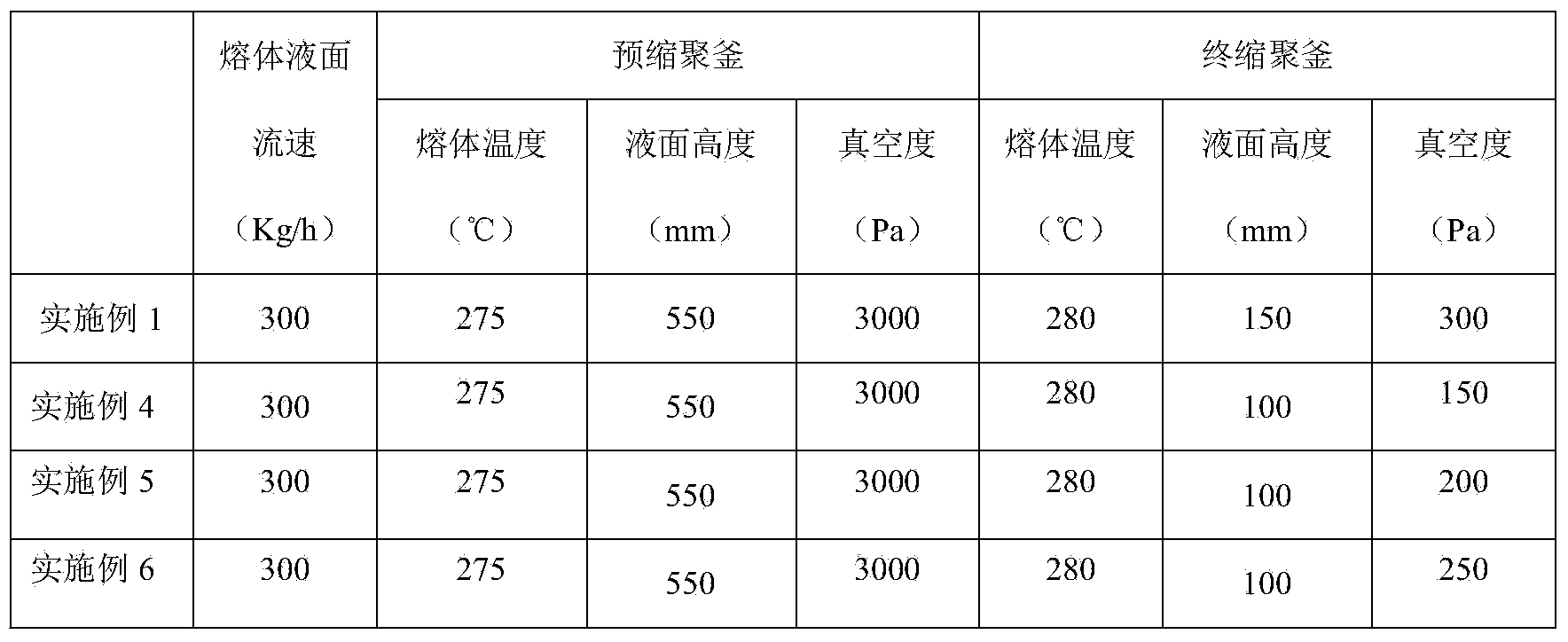

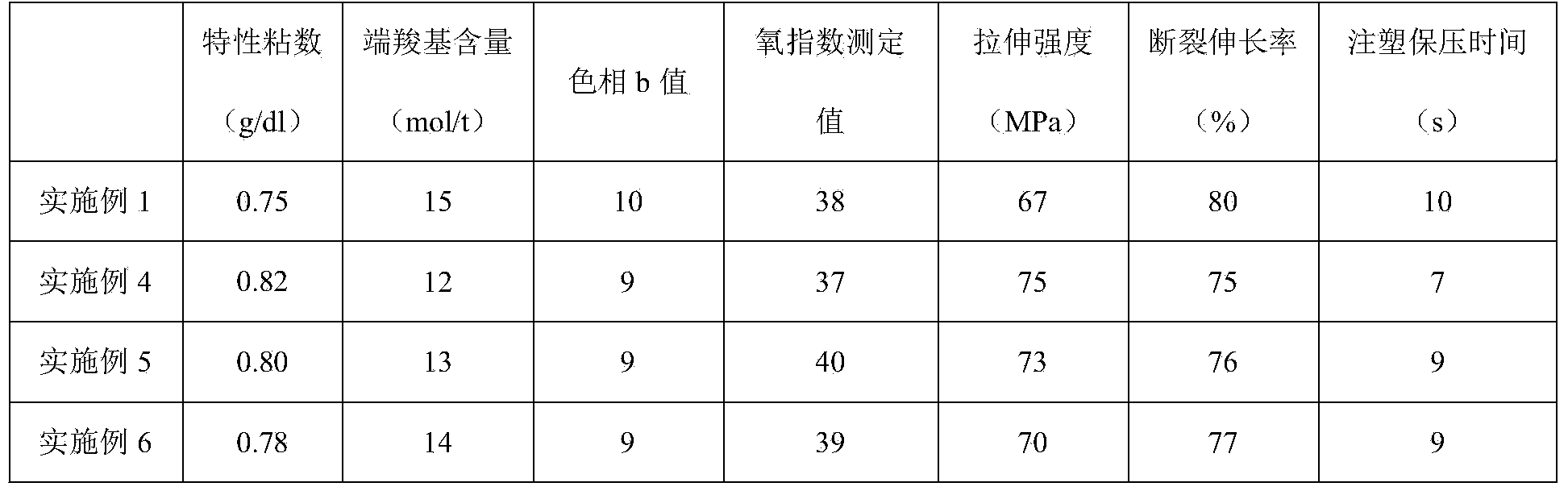

Continuous polymerization preparation method of fast crystallized and flame-retardant PET (Polyethylene Terephthalate) copolymer

The invention relates to the field of PET (Polyethylene Terephthalate) copolymer and particularly relates to a continuous polymerization preparation method of a fast crystallized and flame-retardant PET copolymer. On a continuous polymerization production line of flexible modified polyester, the fast crystallized and flame-retardant PET copolymer is continuously prepared by a novel short-flow continuous polymerization device comprising an esterification kettle, a pre-shrinking kettle and a final polycondensation kettle. The method has the advantages of low energy consumption in the preparation process, high yield and good stability of the quality, the large-scale industrial production is achieved and the products have strong market competitiveness.

Owner:CHINESE TEXTILE ACAD

Die gap gas-aid ejection pin mechanism

InactiveCN102335985ASmooth demouldingReduce distortionElectrical and Electronics engineeringEngineering

The invention discloses a die gap gas-aid ejection pin mechanism. The middle part of a die core is provided with a vertically penetrating ejection pin groove. A gap gas-aid ejection pin is inserted through the ejection pin groove. A gap exists between the middle part of the gap gas-aid ejection pin and the ejection pin groove of the die core. A gas channel is arranged in the die core. One end of the gas channel communicates with the exterior side, and the other end of the gas channel communicates with the gap. Therefore, exterior compressed gas can enter the gap through the gas channel. At the moment when the gap gas-aid ejection pin is ejected, the compressed gas is quickly led from the gap to the place between a product ejection surface and the die core, such that the vacuum state of the product ejection surface is released, and the product can be successfully ejected from the die. With the mechanism, product deformations caused by excessive ejection forces are greatly reduced.

Owner:NISSIN EDUCATION PROD KUNSHAN CO LTD

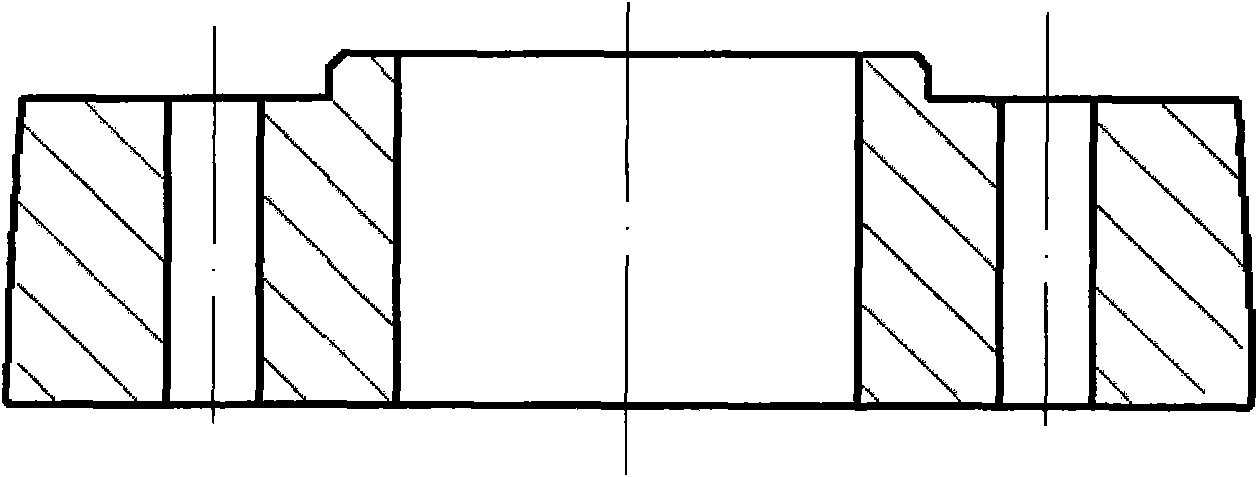

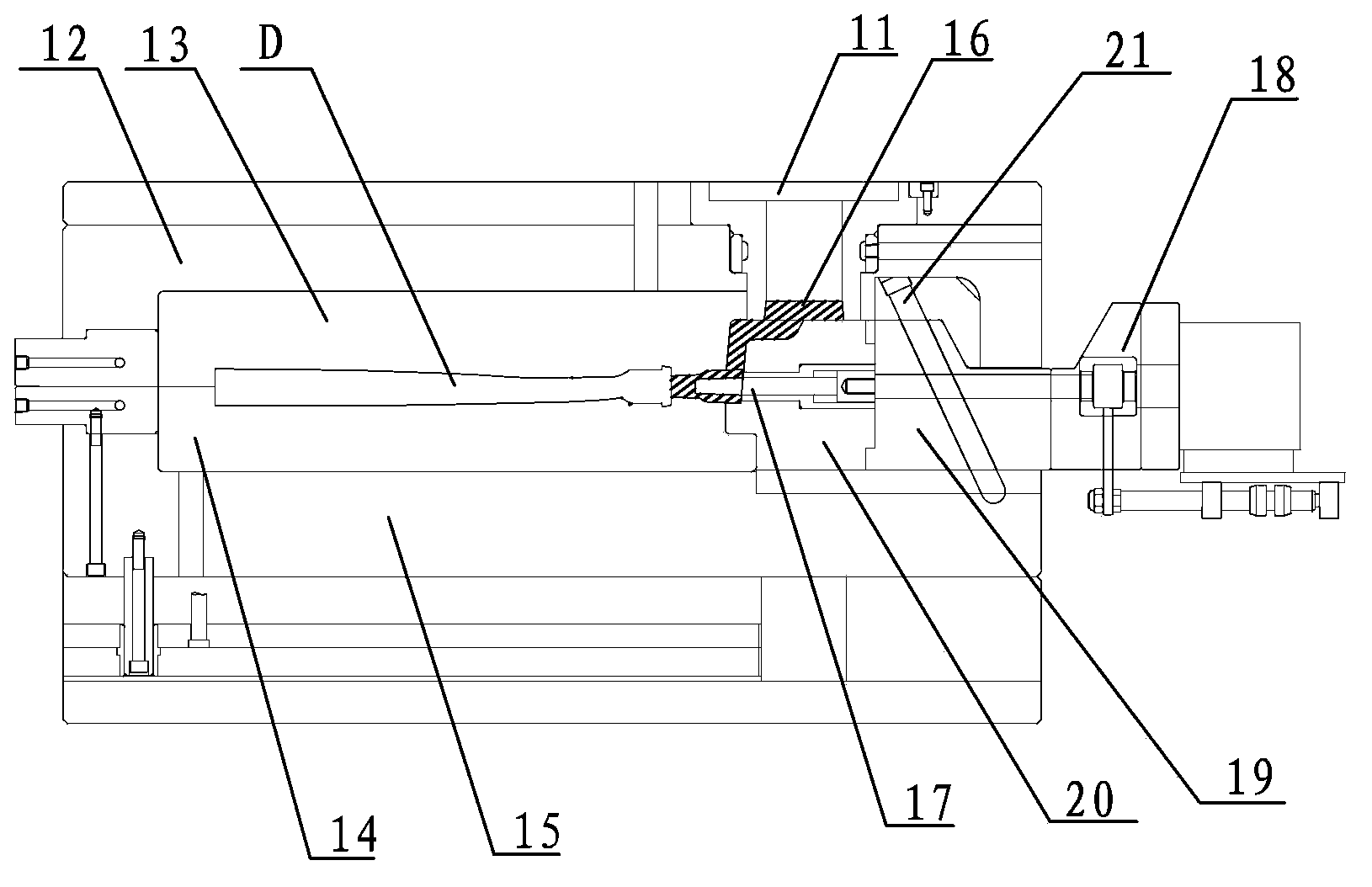

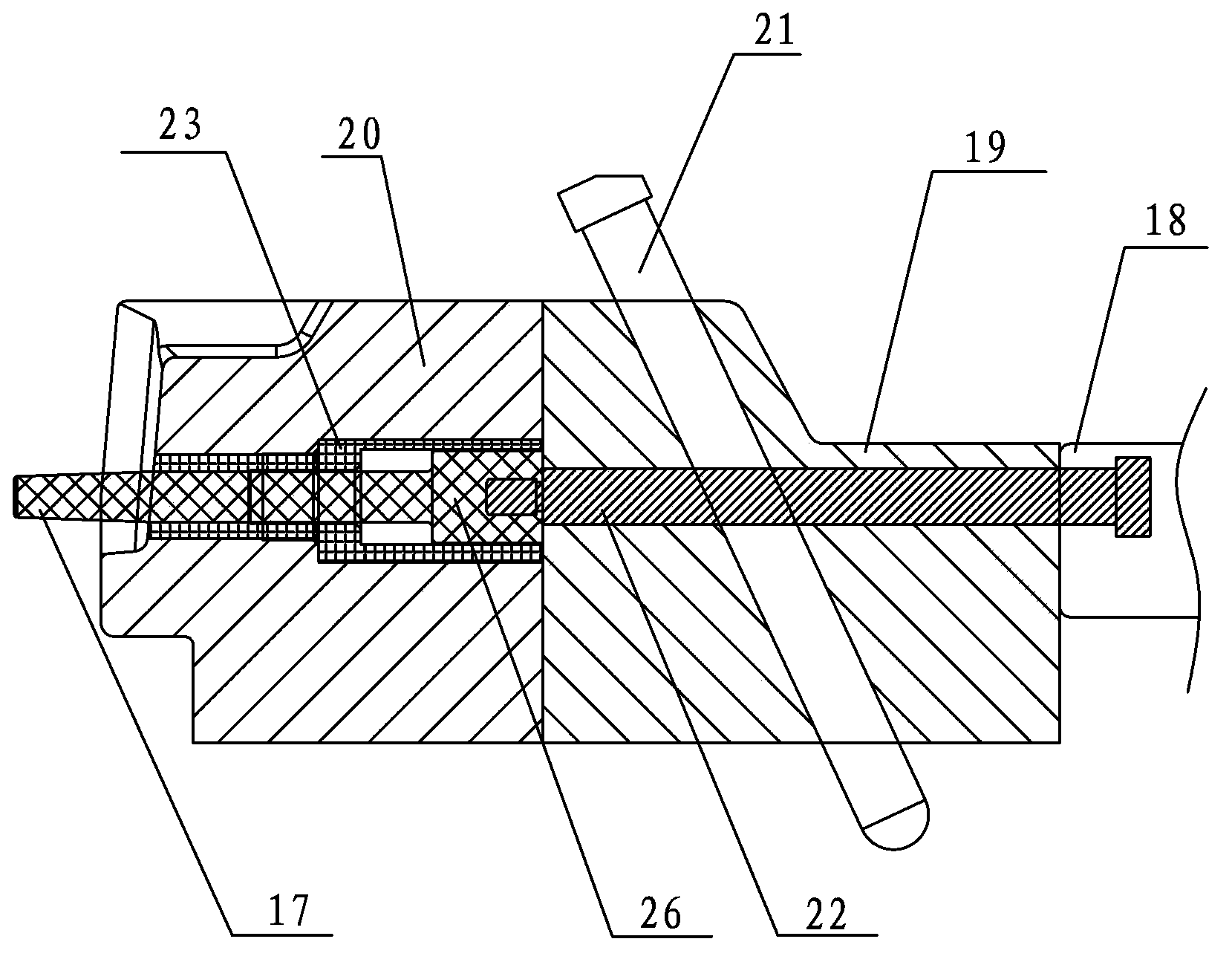

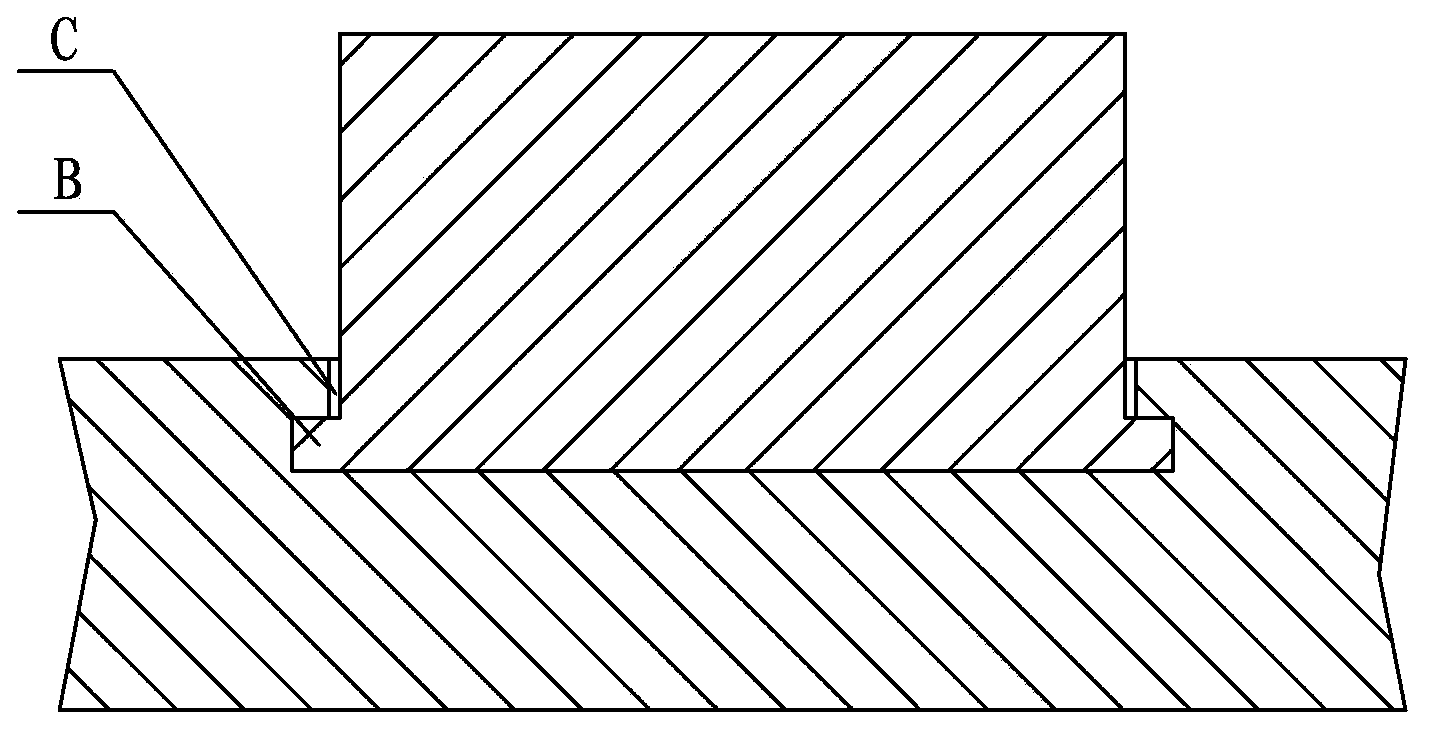

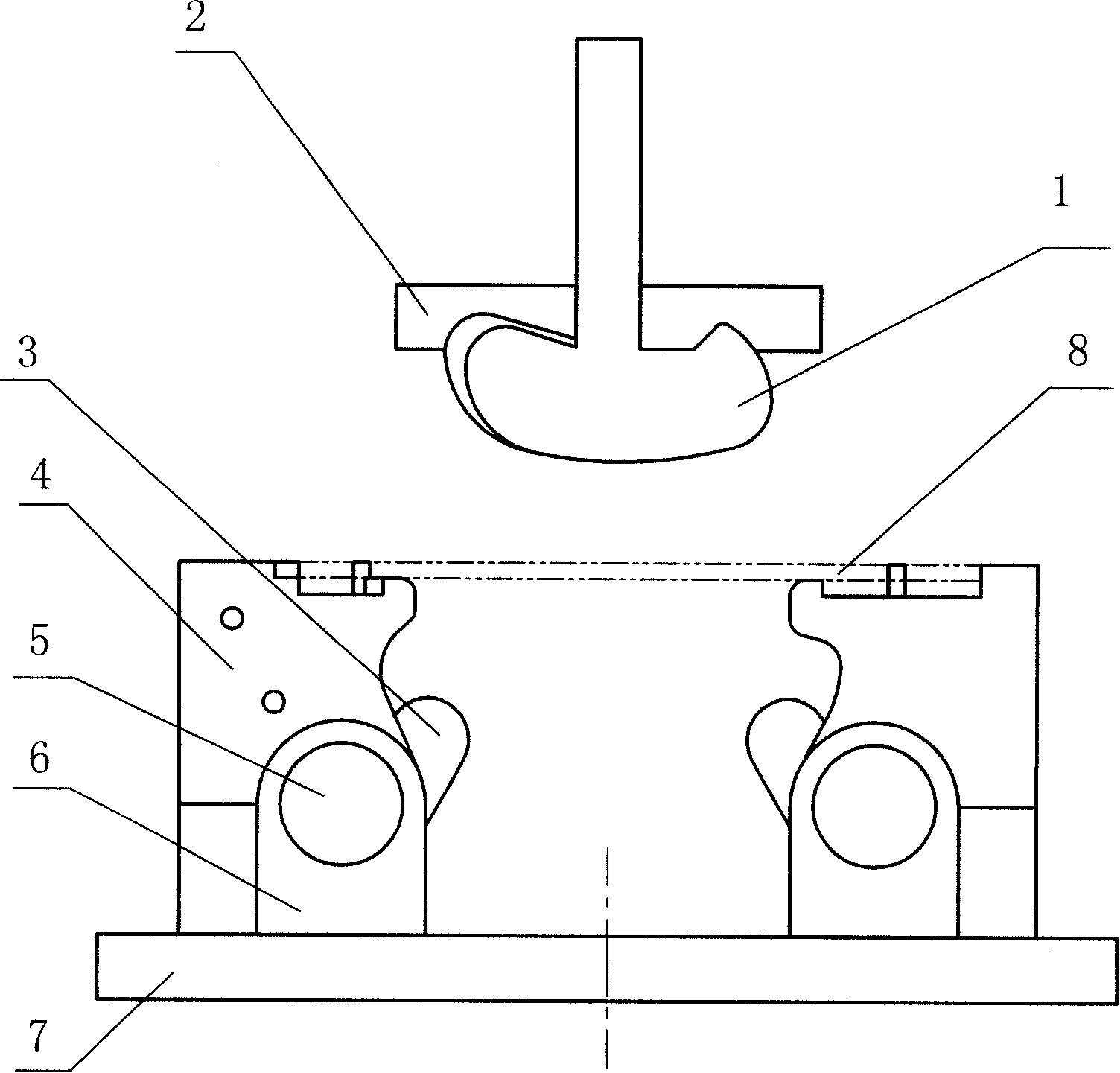

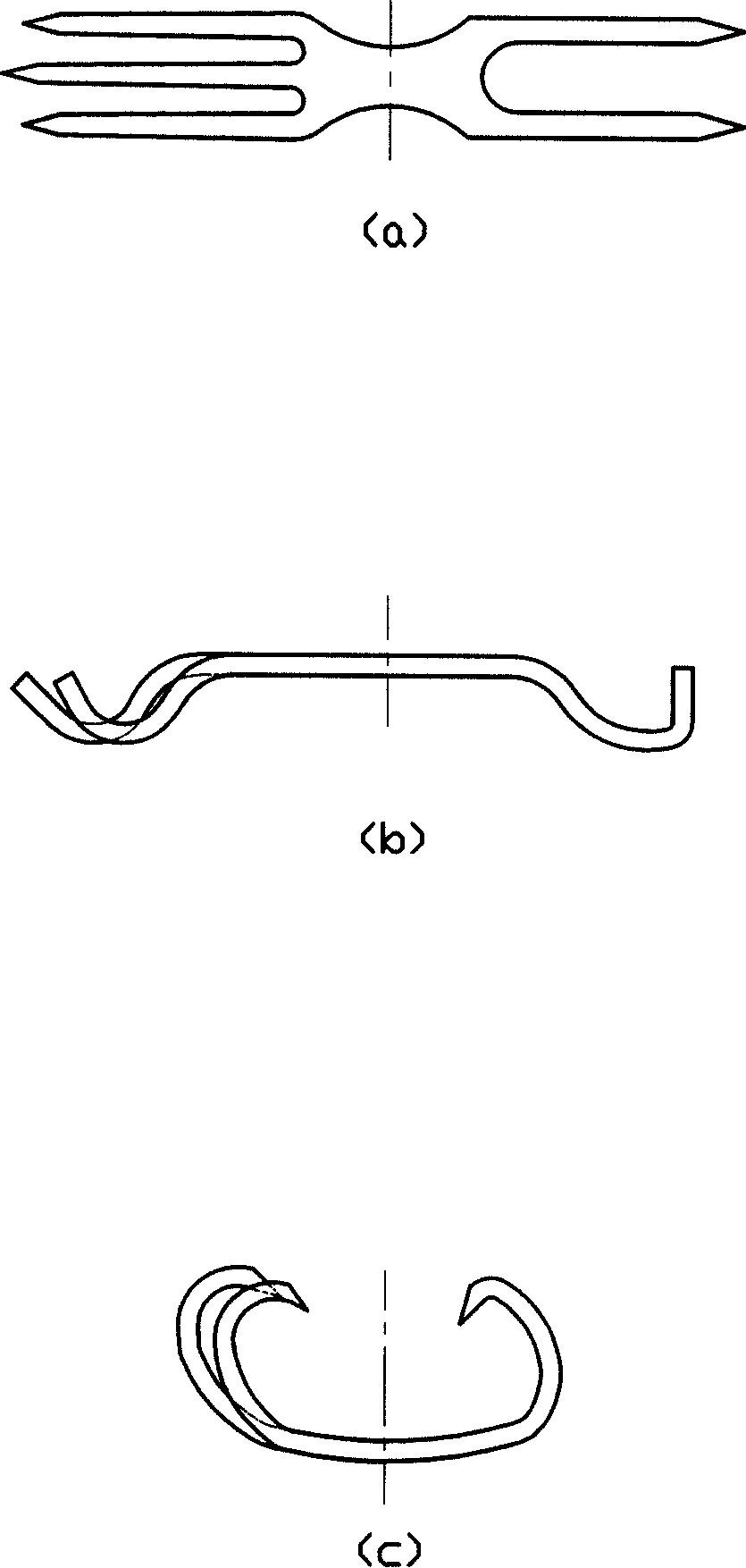

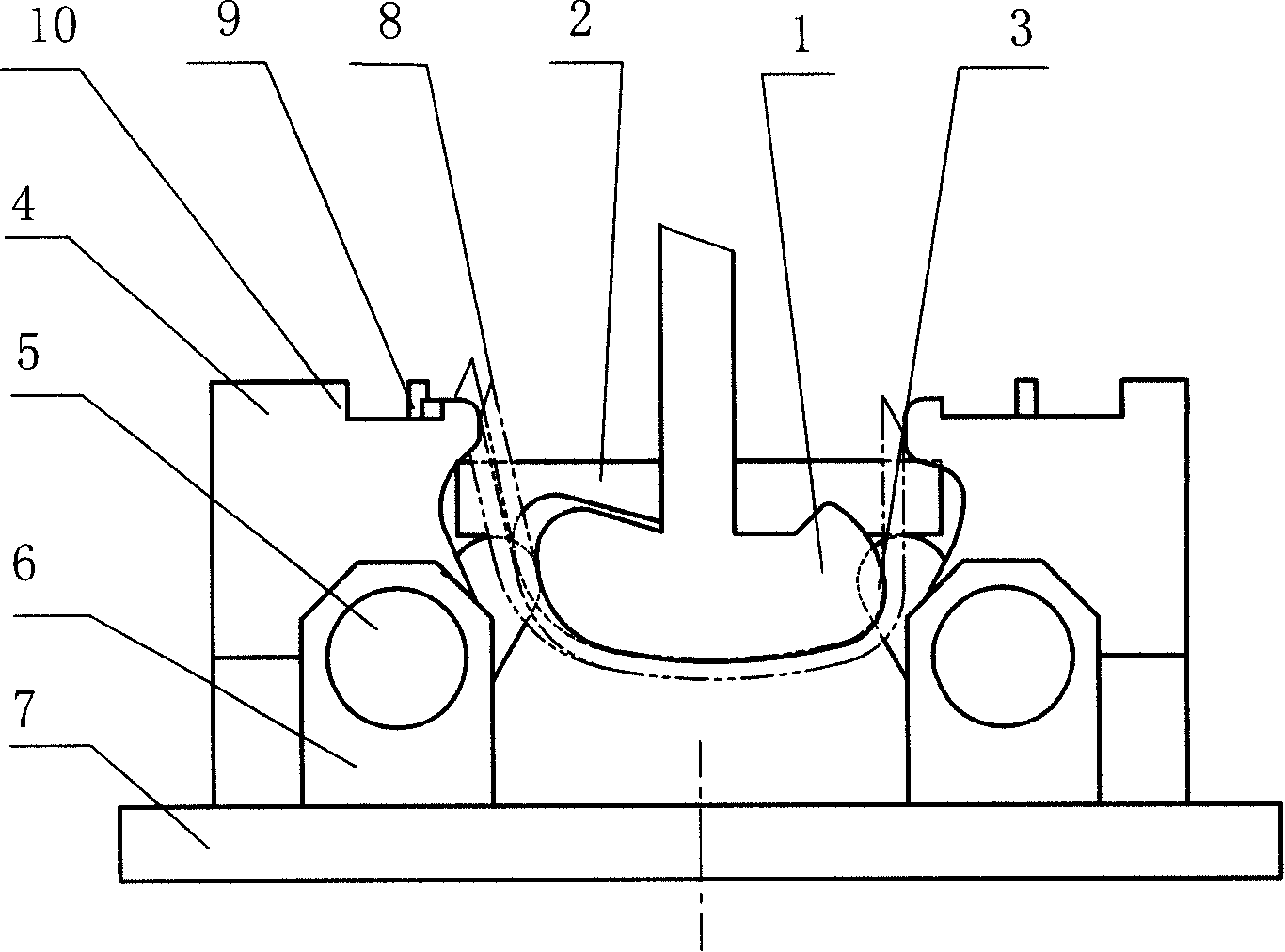

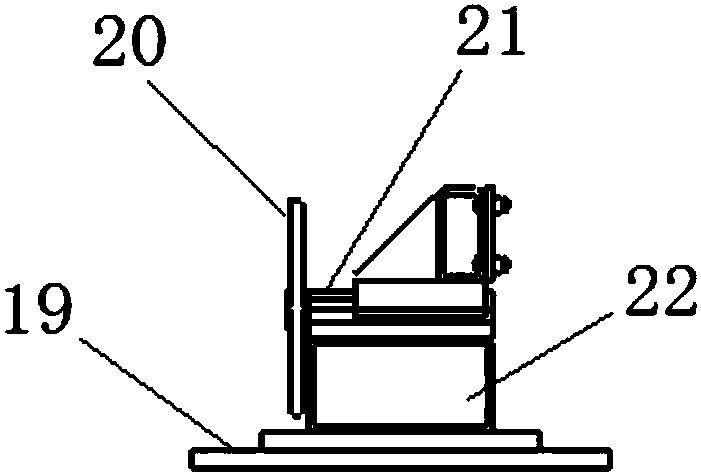

One-time thermoform composite mold for nickel-titanium shape memory alloy patellar concentrator and operation method thereof

InactiveCN101172294AReduce the number of forming operationsReduce moldShaping toolsBone implantComputer moduleAlloy

The invention relates to a compound die assembly of a fixing device for processing the human body skeleton and an operating method thereof. The compound die assembly comprises an upper male die and a lower concave die, the upper male mould comprises a concave module (1) and a press plate (2), wherein, the concave module (1) is matched with the shape of a patella collection device (8), and a vacant groove is arranged between an m claw and an n claw. The lower concave die comprises a concave module (4), a cam (3) and a lever shaft (5), the concave module (4) presents a cuboid, the upper surface is a plane for placing the flat-plate material, the side face of the concave module (4) presents a C character shape, the lever shaft (5) is arranged at the lower part of the concave module (4), the upper male die moves downwards and presses in the lower concave die in the way of two sections, the press plate (2) lies hard upon the cam (3) and drives the rotation of the concave module (4), the flat-plate material is bent and formed on the concave module (1), and a finished product is laterally taken out from the groove of the concave module (1). The invention reduces the numbers of forming and processing, reduces the cost and improves the working efficiency. A blank only is under a linear stress state during the forming process of the patella collection device, the stress state is improved, and the strength, the rigidity and the products quality are improved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Process for producing molded item of thermosetting resin and injection molding machine therefor

InactiveCN101557916AImprove cooling effectEasy to demouldOptical articlesInjection molding machineLiquid resin

A process for producing a molded item of thermosetting resin, and injection molding machine therefor, capable of preventing burring and bubble inclusion at molding operation. There is provided a process for producing a molded item of thermosetting resin with the use of a mold having a cavity for forming a product part, a gate forming a gate part, a runner forming a runner part and an overflow catcher communicating with the cavity and forming an overflow part, which process comprises the injection step of injecting a liquid resin until filling the region from the runner through the gate to the cavity and further the region from the cavity to the overflow catcher; the hardening step of heating the liquid resin within the mold so as to effect hardening; the demolding step of detaching a resin molded item having the runner part, gate part, product part and overflow part from the mold; and the cutting step of cutting the gate part and overflow part off the product part of the demolded resin molded item.

Owner:TOSHIN SEIKO CO LTD +1

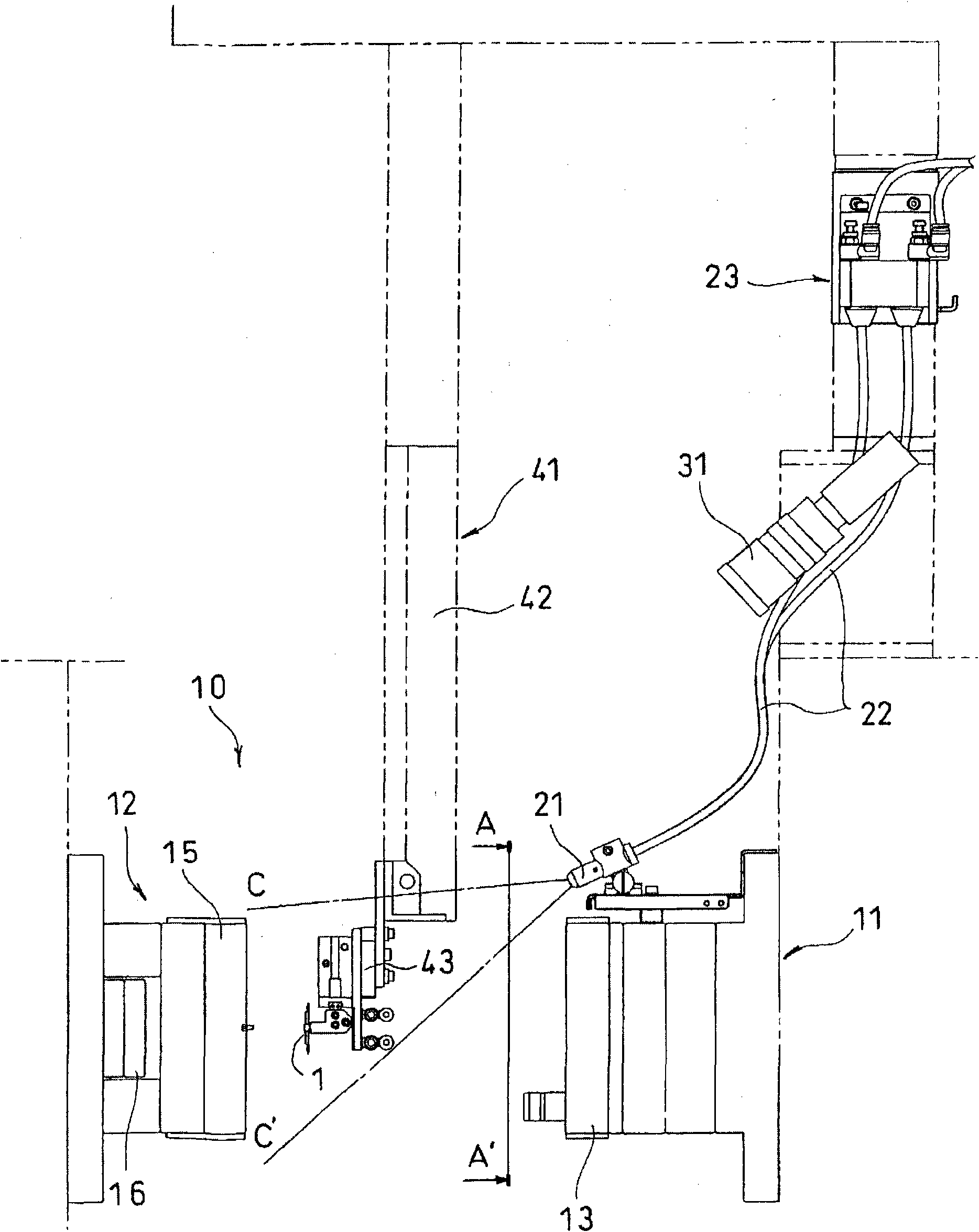

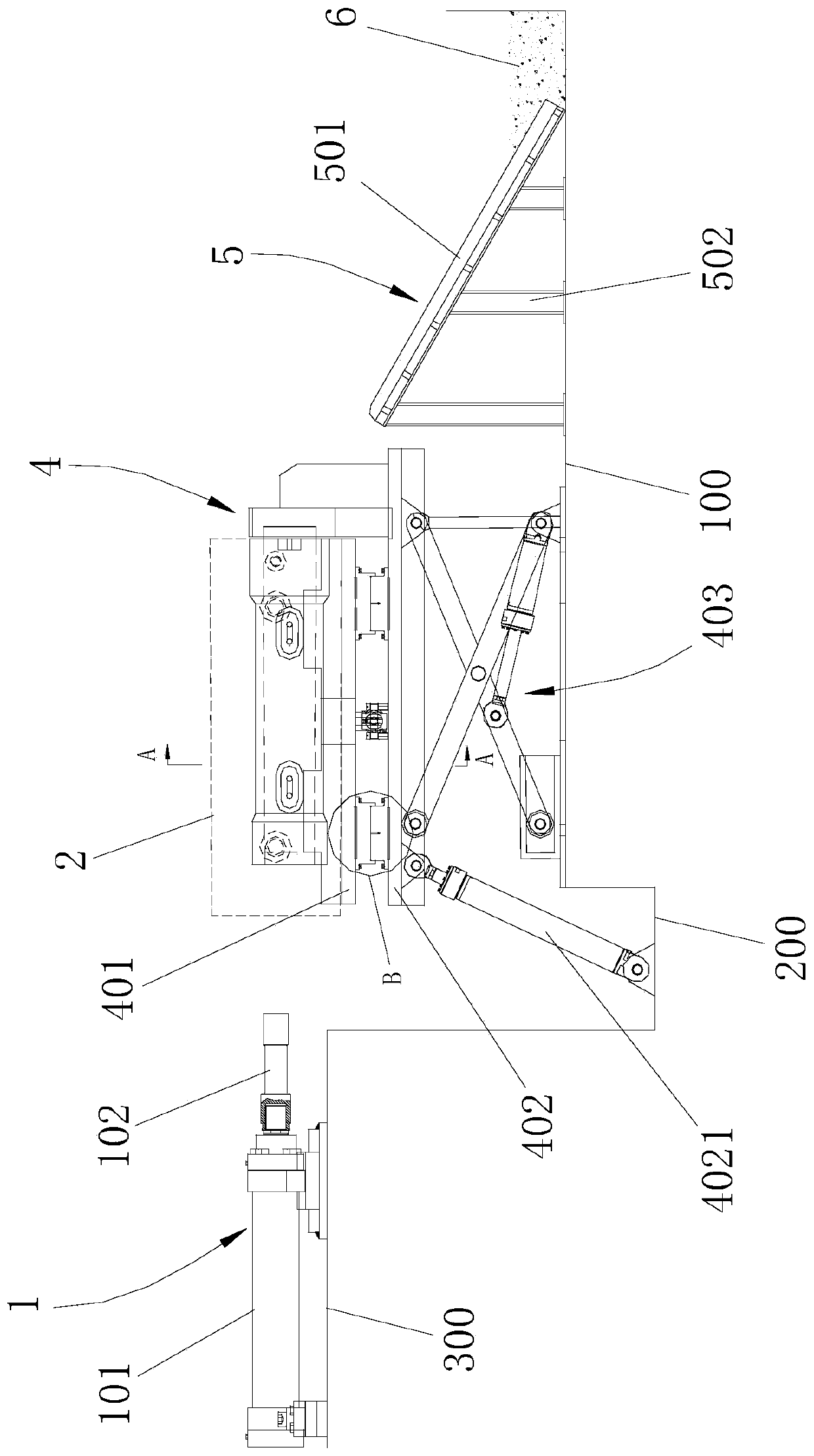

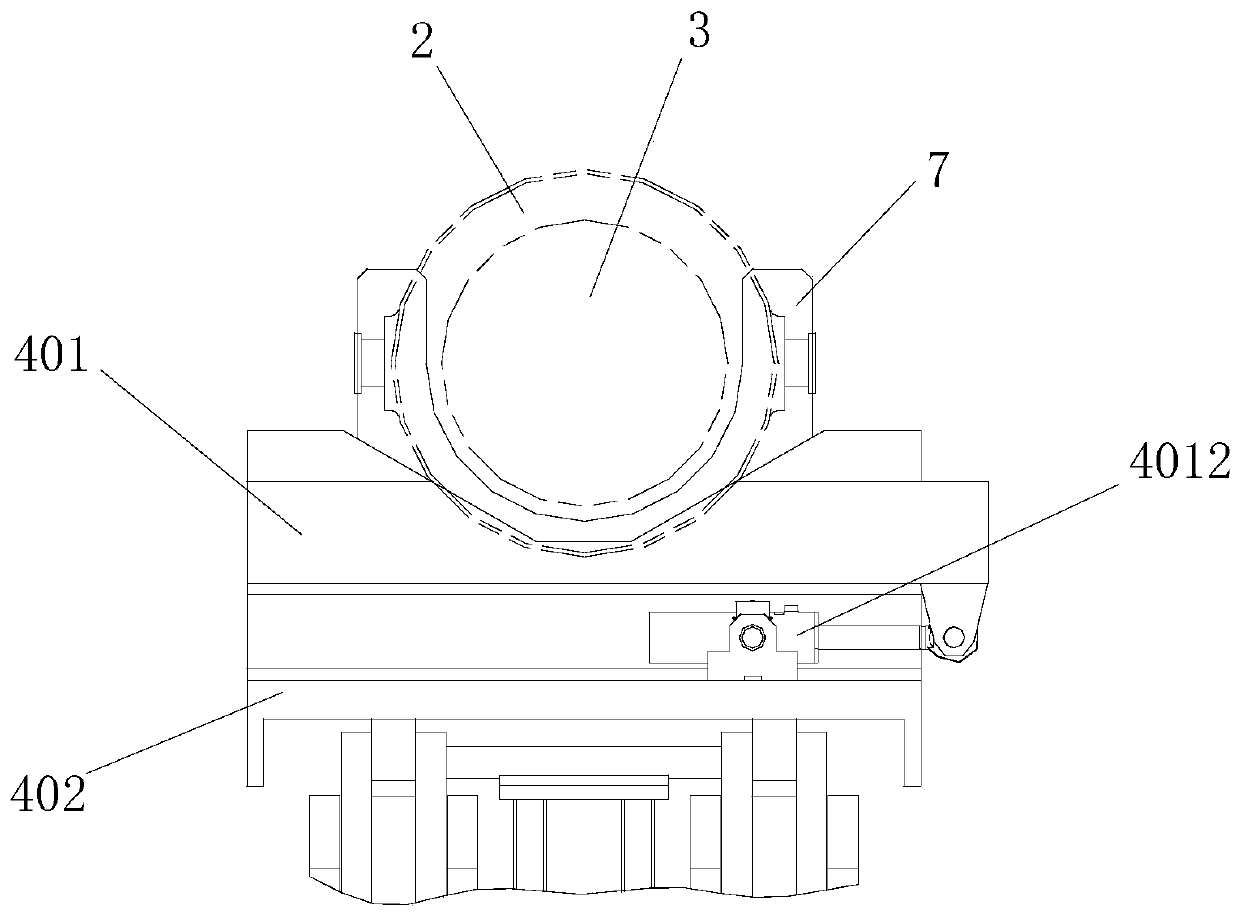

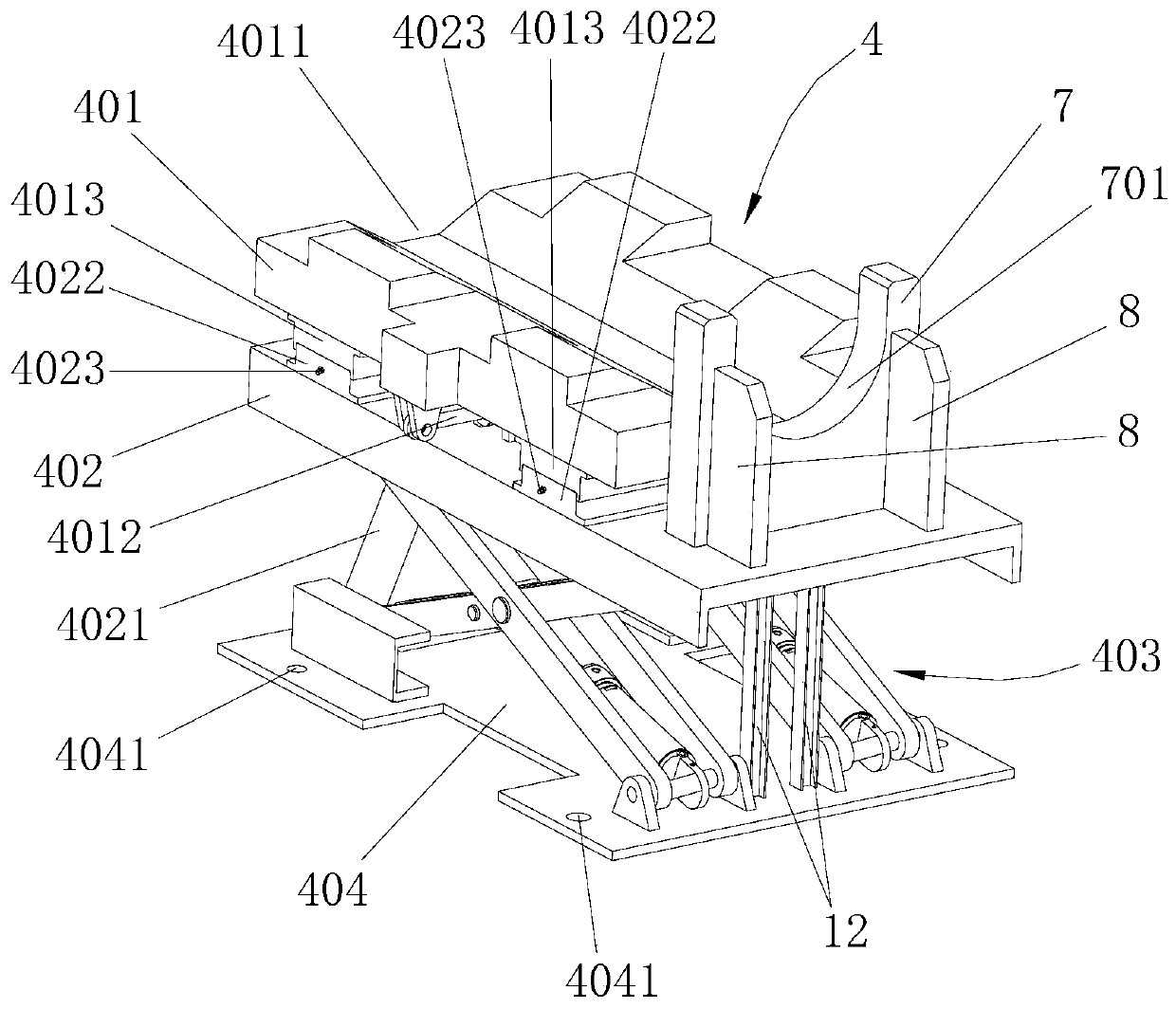

Demolding unit and demolding method

PendingCN110842178ASimple structureEasy to operateMould handling equipmentsClassical mechanicsEngineering

The invention provides a demolding unit and a demolding method. The demolding unit comprises a multi-freedom-degree lifting and overturning device, an ejecting device and a guide device; the multi-freedom-degree lifting and overturning device comprises a moving platform, an overturning platform and a lifting mechanism; the top of the lifting mechanism is connected with the overturning platform ina pivoting manner; the bottom of the overturning platform is provided with a first driving device used for pushing the overturning platform to realize overturning; the moving platform can be movably arranged at the top of the overturning platform; the top of the moving platform is fixedly provided with a steel ingot mold so that the moving direction of the moving platform is perpendicular to the axial direction of a sensing rod; the ejecting device and the guide device are correspondingly arranged at the two sides of the multi-freedom-degree lifting and overturning device; the ejecting deviceleans against the end part of the sensing rod; thrust is applied from a thrust applying end of the steel ingot mold to the sensing rod; and the guide device is connected between the steel ingot mold and a receiving buffer region. The demolding unit provided by the invention solves the technical problems that the sensing rod is relatively low in demolding efficiency and causes potential safety hazards and the steel ingot mold may be damaged in a demolding process.

Owner:CERI TECH +1

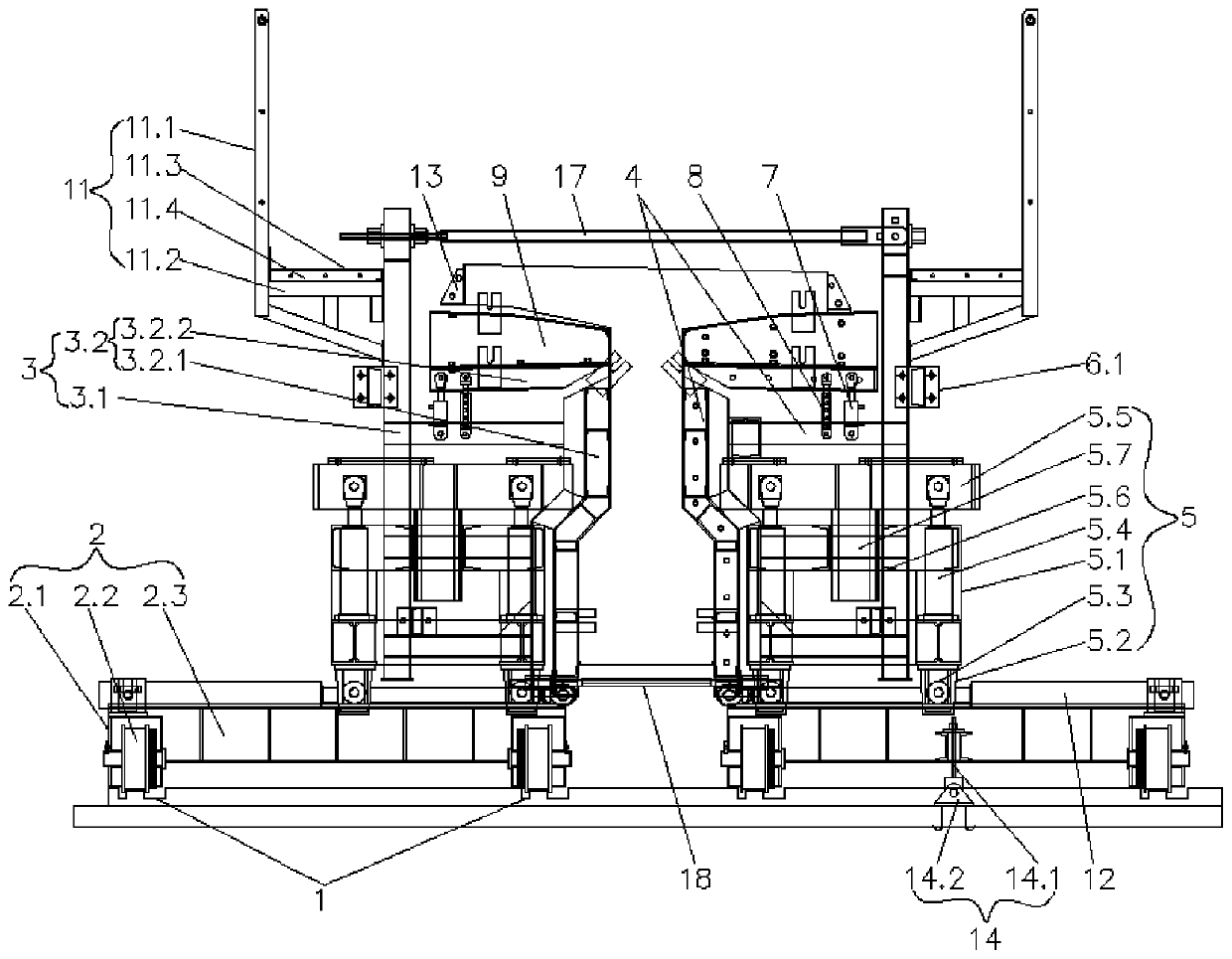

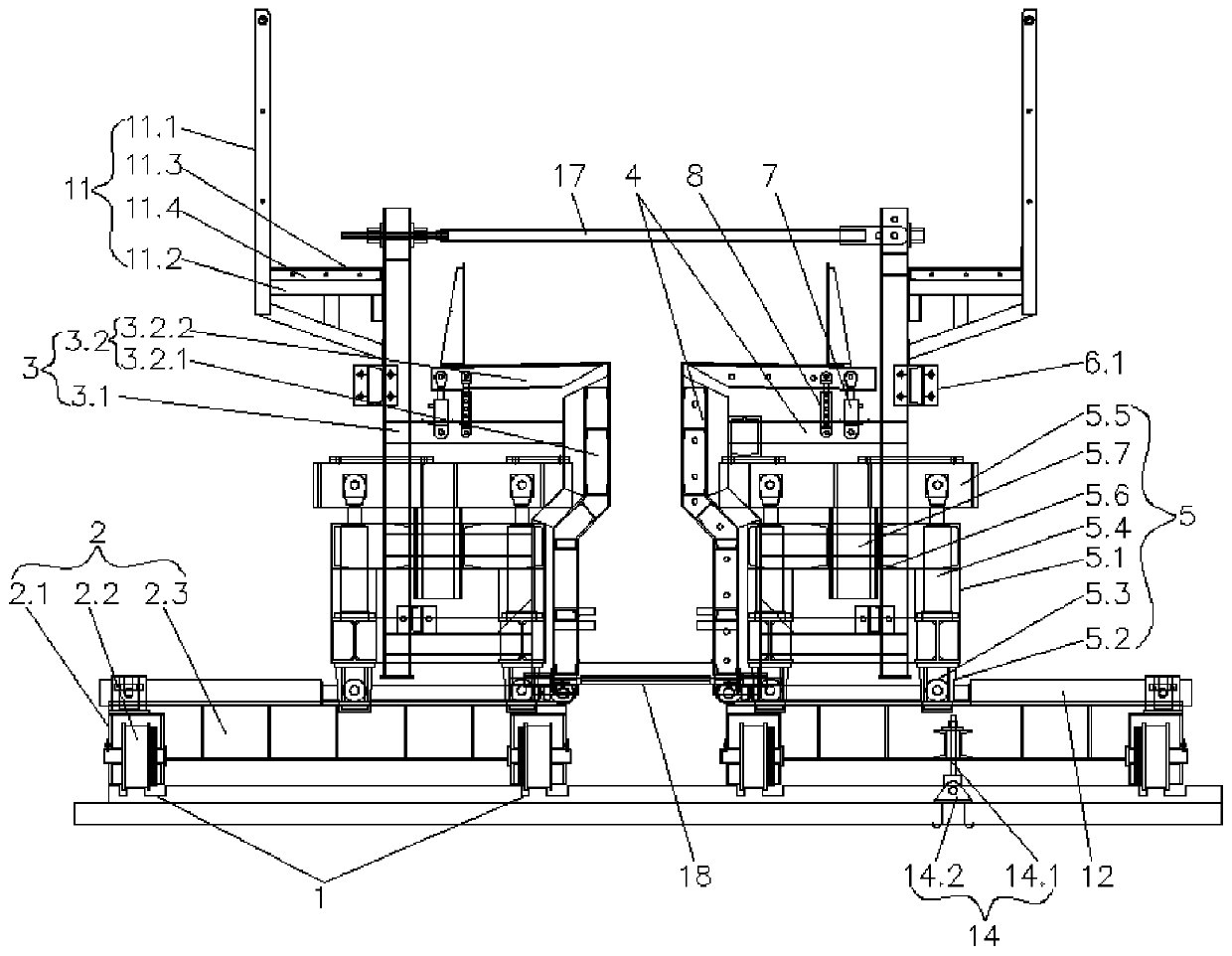

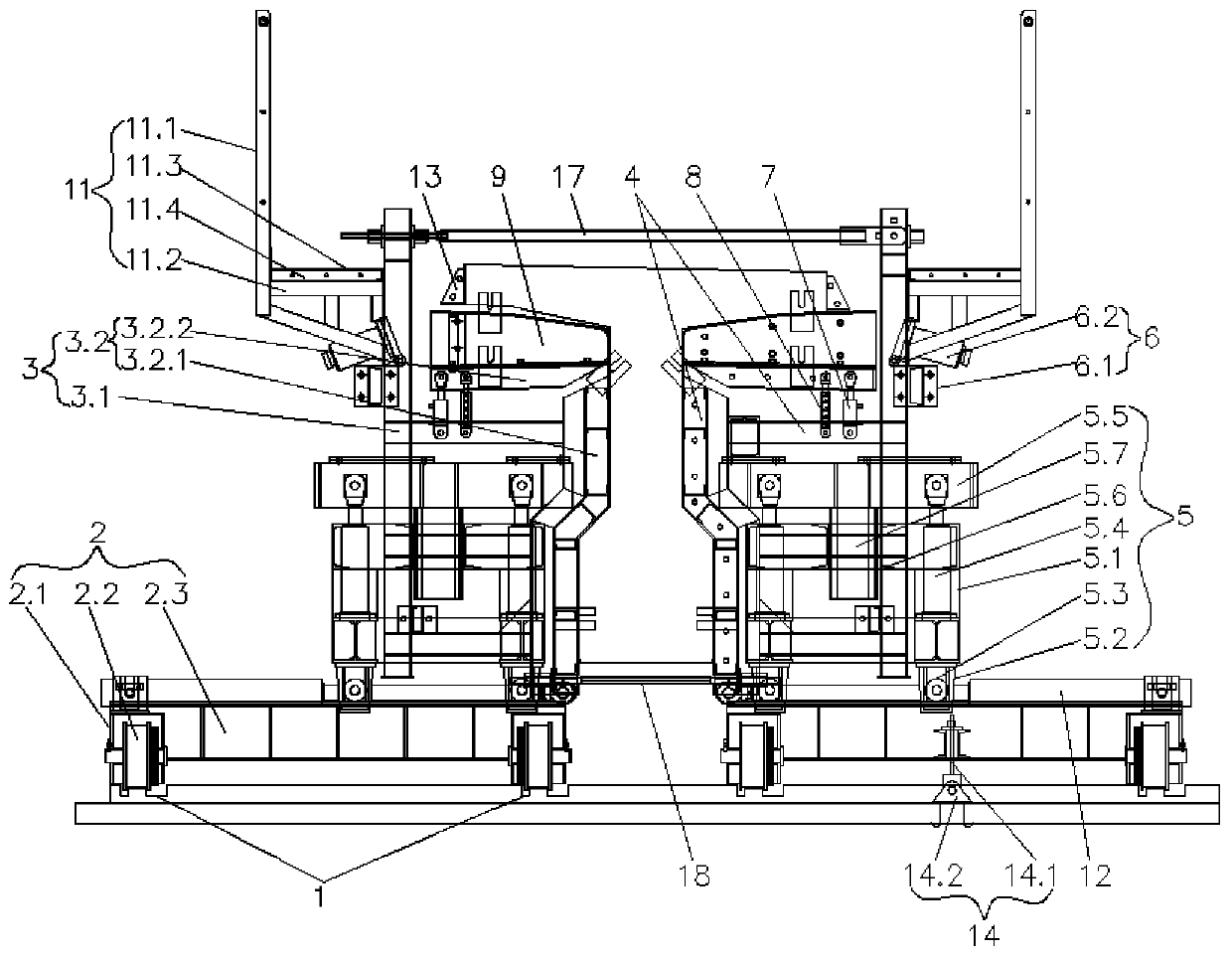

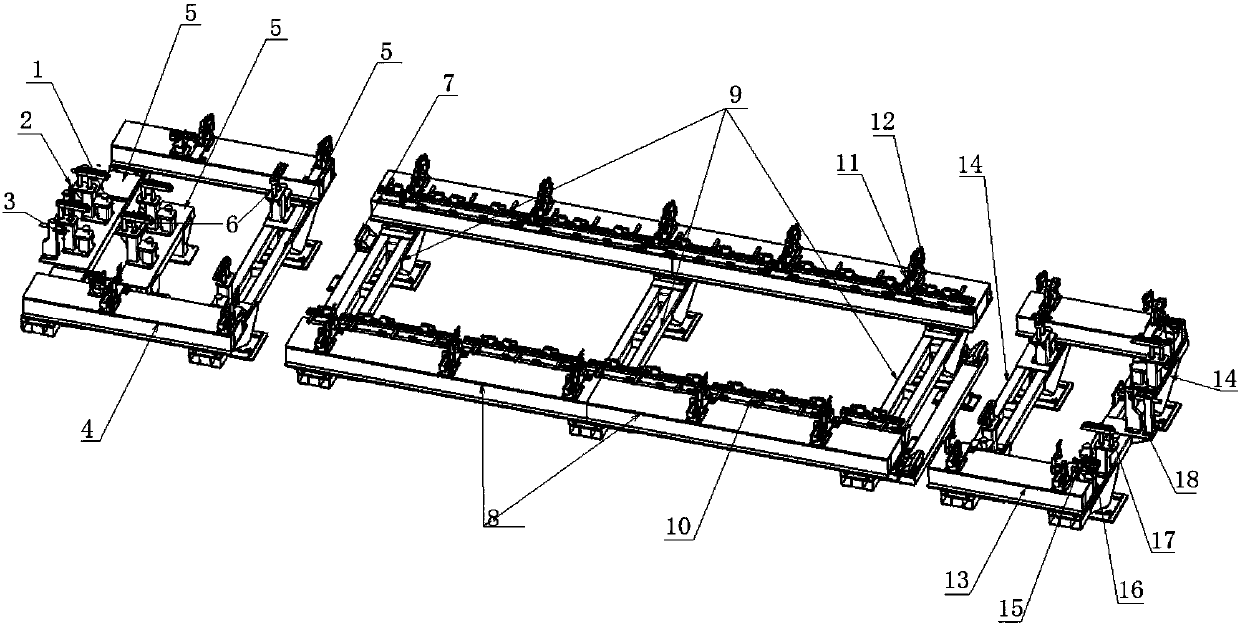

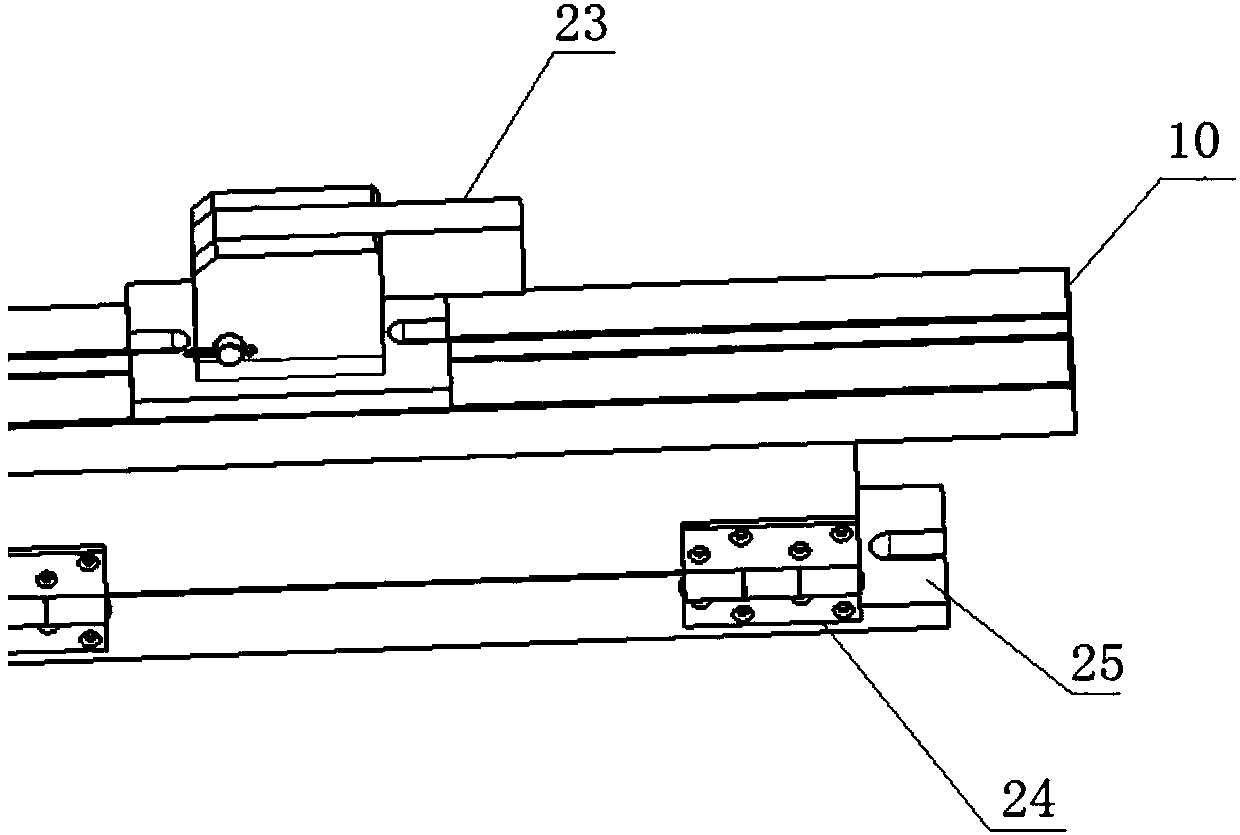

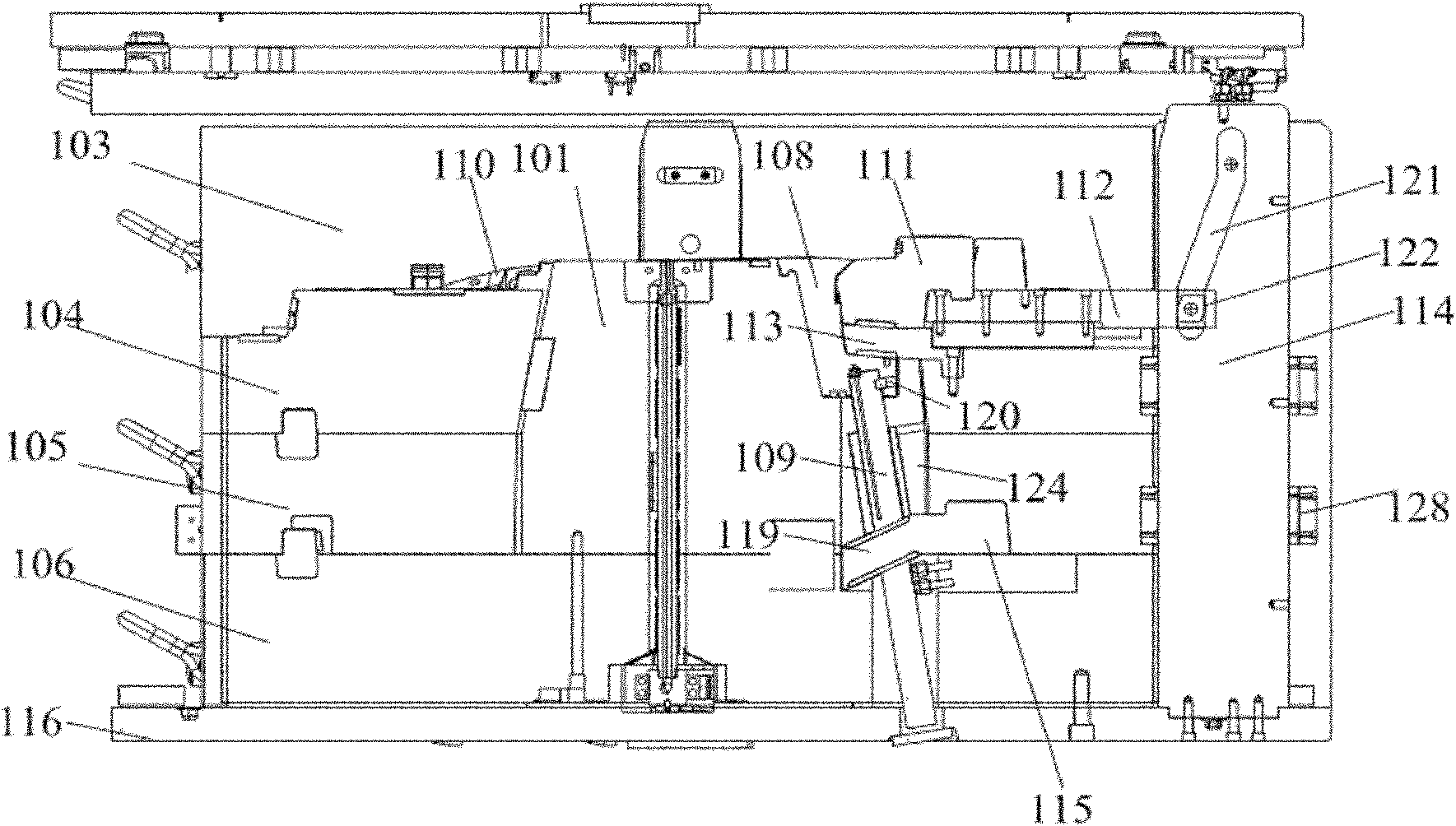

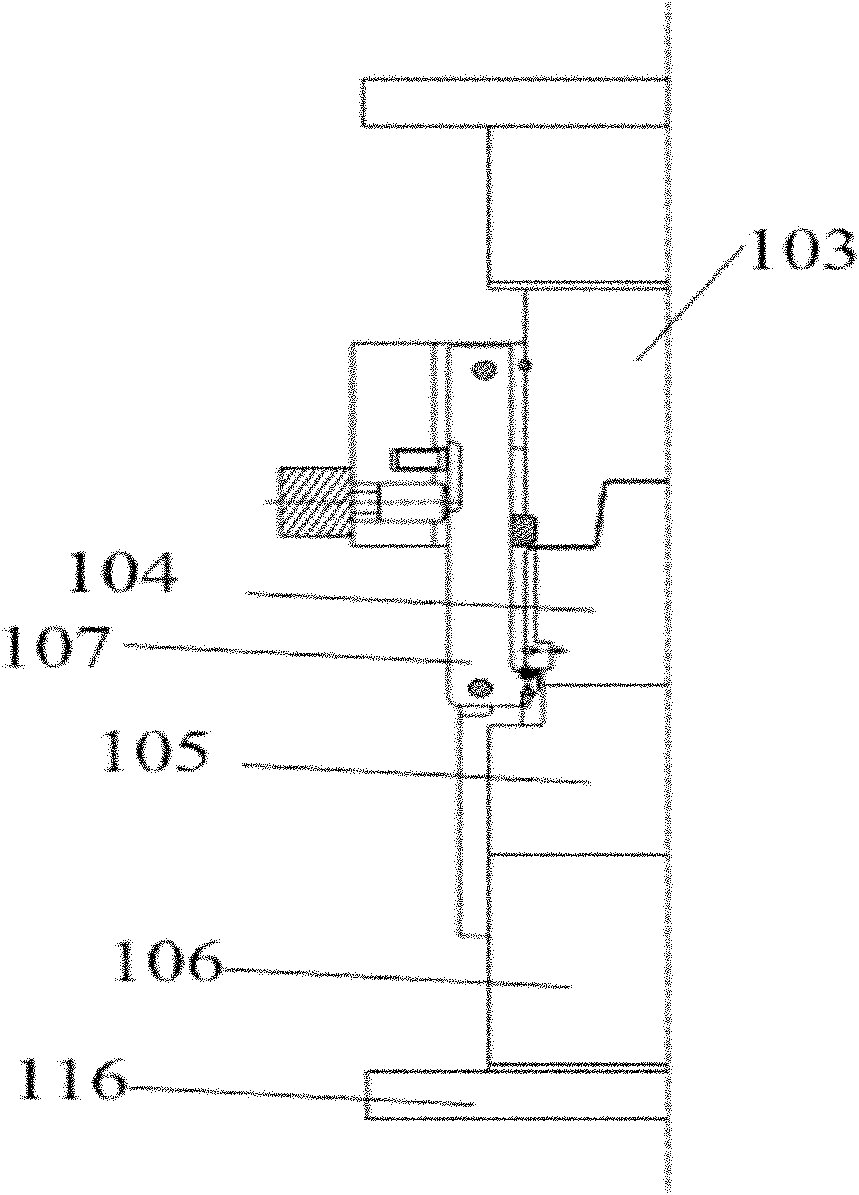

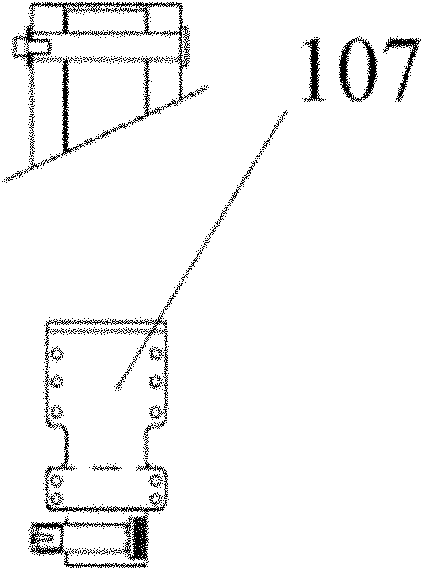

Welding tool for monorail vehicle chassis assembly

ActiveCN107790948AImprove general performanceStrong specificityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChassis

The invention provides a welding tool for a monorail vehicle chassis assembly. The tool comprises a one-dimensional end welding frame, a middle portion welding frame and a two-dimensional end weldingframe. The one-dimensional end welding frame comprises a bottom surface supporting frame, a longitudinal beam, cross beams, a one-dimensional end limiting block and a center stay wire device, and theone-dimensional end limiting block and the center stay wire device are arranged on the cross beam at the forefront end. The middle portion welding frame comprises a bottom surface supporting frame, longitudinal beams, cross beams and a vehicle body side supporting limiting block, and the vehicle body side supporting limiting block is fixed to the bottom surface supporting frame and located on theside, close to the one-dimensional end welding frame, of the vehicle body side supporting limiting block; the longitudinal beams are provided with T-shaped groove guide rails, side beam limiting blocks and side beam pressing devices, and cross beam limiting blocks are arranged on the T-shaped groove guide rails. The two-dimensional end welding frame comprises a bottom surface supporting frame, a longitudinal beam, cross beams, a side beam side limiting block and a two-dimensional end limiting block, and the two-dimensional end limiting block is arranged on the cross beam at the tail end. The tool can be smoothly and easily demolded, and the requirements for forward installing positioning and reverse installing positioning can be simultaneously met.

Owner:南京雷尔伟新技术股份有限公司

Internal-division-type fender injection mold and injection molding method of fender

ActiveCN102139525ASolve the difficulty of mold releaseSmooth demouldingEngineeringInjection molding machine

The invention provides an internal-division-type fender injection mold and an injection molding method of a fender, and relates to the field of injection molds. An inclined ejection block and a slide block are combined to eject the fender while opening the mold; in order to ensure the balance and synchronization of the ejection, a heavy-duty draw hook installed on the movable side draws a push plate at the fixed side while opening the mold, a shift block, the inclined ejection block and the slide block are uniformly driven to move by the push plate, so that the fender is ejected and left on the female mold cavity; and the fender is taken down by a manipulator. The mold stripping mode solves the problem of difficulty in mold stripping in the internal-division-type fender injection mold, so that the round inverted in the female mold can be smoothly demolded, and the round of the product can not be scratched or deformed.

Owner:TIANJIN SILVER BASSIS TECH CO LTD

Casting device capable of being continuously used

The invention discloses a casting device capable of being continuously used. The casting device comprises a working table and further comprises a supporting frame, a top plate, a hydraulic cylinder, an upper mold hanging plate, an upper mold, a high-pressure casting box, a lower mold installation plate, a lower mold, an ejector rod, a motor, a cam disk and a high-pressure spraying device. Compared with the prior art, the upper mold and the lower mold are pushed by the hydraulic cylinder to be assembled, melted metal liquid is injected into cavities of the upper mold and the lower mold through the high-pressure casting box, after the metal liquid is solidified, and the upper mold is pulled by the hydraulic cylinder to move upwards; meanwhile, the high-pressure spraying device sprays high-pressure gas, releasing agents are mixed into the gas, the cam disk is driven by the motor to rotate, when the highest point of the cam disk reaches the top end, the ejector rod is pushed to upwards move, a casting is released from the lower mold, the casting can be smoothly related accordingly, a traditional sand mold is replaced, one mold can be repeatedly used, and the casting cost is reduced.

Owner:东至县文元瓷砖加工厂

Double-faced uniform forming method of gypsum plaster ceiling board

The invention relates to a double-faced uniform forming method of a gypsum plaster ceiling board. A manufacturing mould of the gypsum plaster ceiling board is divided into a pair of upper and lower mould group; an upper mould comprises an upper soft mould and an upper hard mould, and a lower mould comprises a lower soft mould and a lower hard mould; and the soft moulds are fixedly connected with the hard moulds. The double-faced uniform forming method comprises the following steps of: firstly pouring a right amount of gypsum slurry into the upper mould during work, wherein the gypsum slurry is spread and uniformly distributed in the upper mould and uniformly vibrated to be formed; after the gypsum slurry is dried to a certain degree, starting to pour the gypsum slurry into the lower mould; after the gypsum slurry is spread and uniformly distributed in the lower mould, covering the upper mould on the lower mould, combining and extruding the upper and the lower moulds, and integrally and uniformly vibrating for forming, wherein after the upper and the lower moulds are sufficiently solidified, gypsums inside the upper and the lower moulds are formed into a whole. The upper and the lower moulds both comprise an inner mould and an outer mould, wherein the inner mould is the soft mould (made from silica gel and other materials) so as to be convenient for the gypsums to be smoothly separated from the soft mould after formed, and a flash cave is arranged in the periphery of the lower soft mould so as to be convenient for storing the superfluous gypsum slurry of the lower mould when the upper and the lower moulds are combined; and the outer mould is made of hard materials (aluminum alloy and the like) so as to be convenient to fix and move. By adopting the method, the problems of rough surface, multiple pores and lower strength of a common gypsum plaster board are solved; and the produced gypsum plaster ceiling board has few pores, fine and smooth surface and high rigidity.

Owner:石柏军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com