Oily solid releasing agent and preparation method thereof

A release agent, solid-like technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of long cycle, rising cost, rising cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

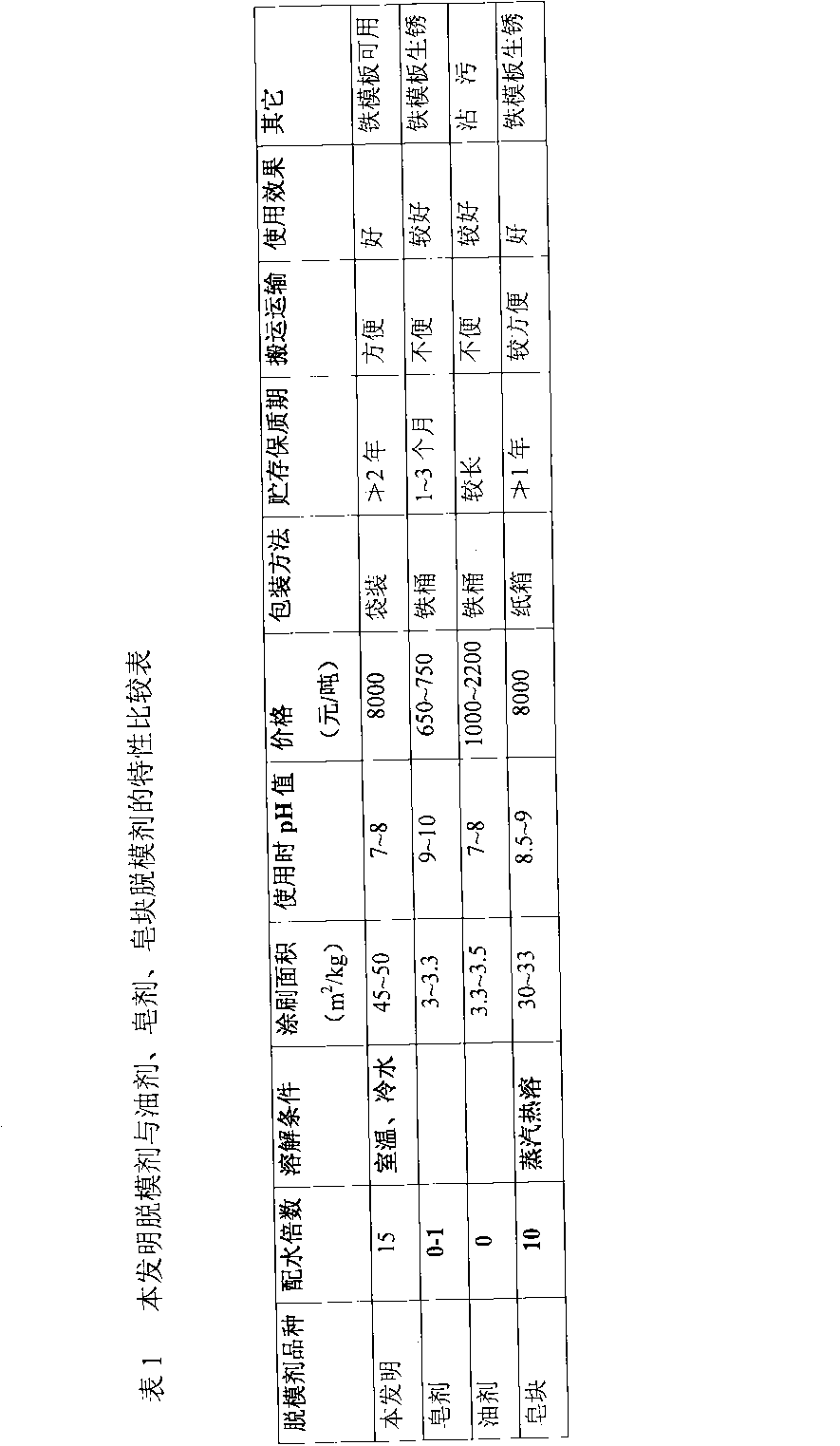

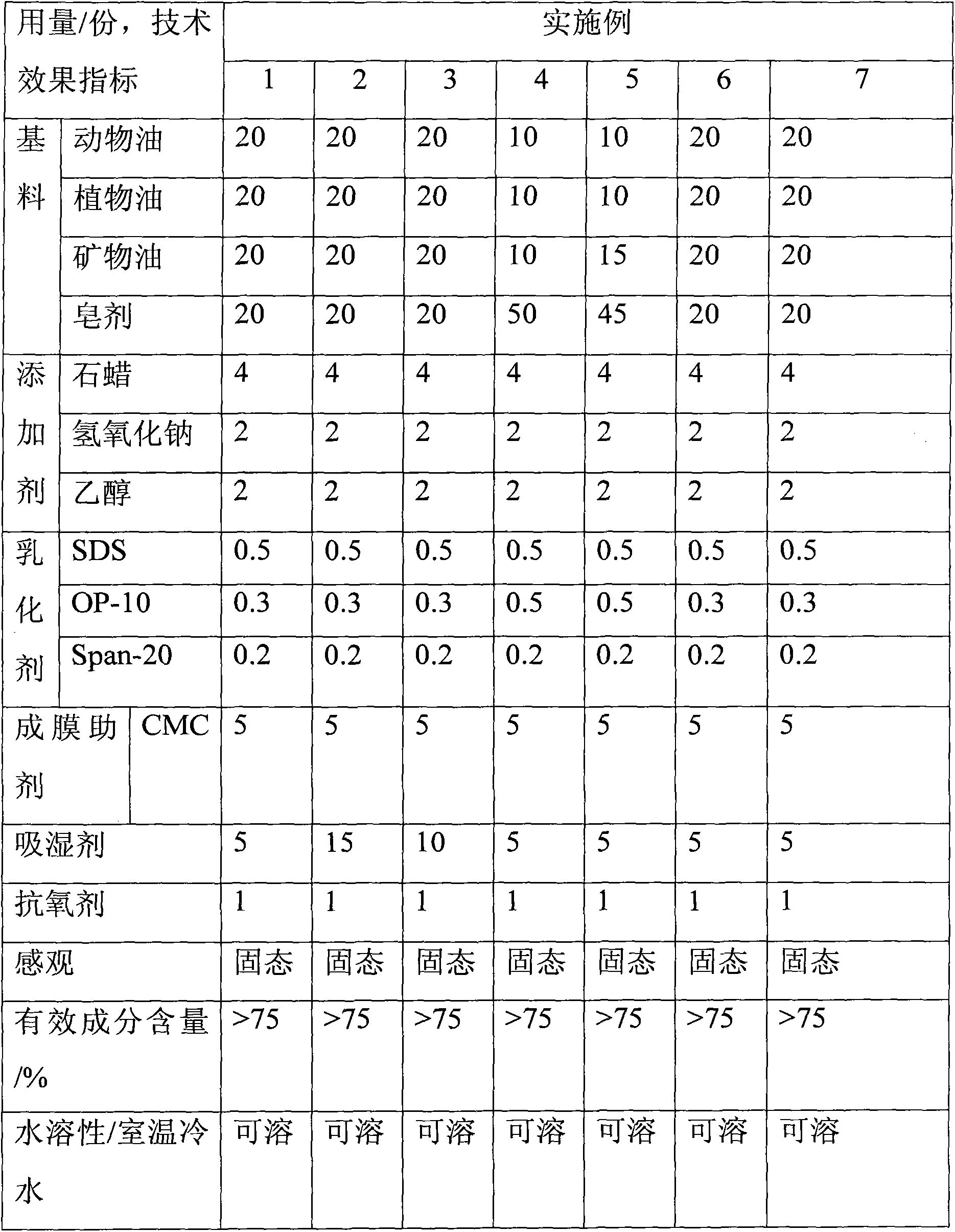

[0037] The present invention will be described in detail below in conjunction with specific embodiments. Examples are shown in Table 2.

[0038] Table 2 Technical solutions of the embodiments of the present invention

[0039]

[0040]

[0041] Table 3 Technical solutions of comparative examples of the present invention

[0042]

[0043]

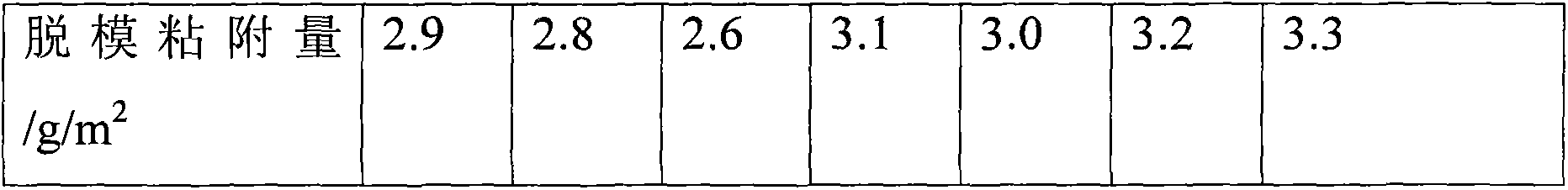

[0044] Release effect Adhesion test standard JC / T945-2005.

[0045] Regarding the amount of hygroscopic agent used. Through the comparison of Example 1-2 and Comparative Example 1-2, it can be seen that the addition of a certain amount of hygroscopic agent has an important impact on the shape of the final product and the amount of water-soluble matter, and the amount of hygroscopic agent that is too large or too small will cause demoulding Only when the amount of hygroscopic agent is in the range of 5-15 parts can a solid granular or powder release agent be obtained, and the adhesion amount is small. The comparison between Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com