Swelling soil modifier

A technology of expansive soil and improver, applied in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve the problems of lack of good solutions, prolong construction time, cost engineering costs, etc., and achieve changes in chemical properties and physical properties. , The effect of reducing roadbed damage, reducing plastic limit and liquid limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

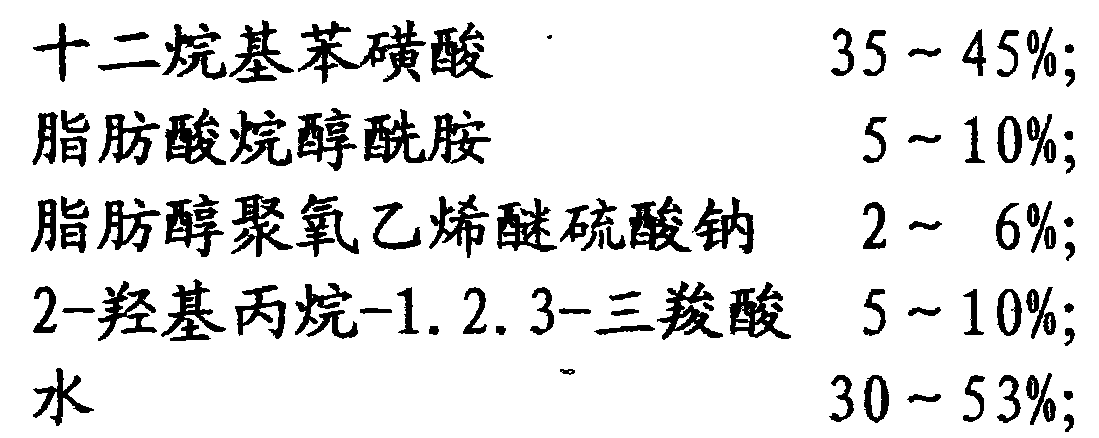

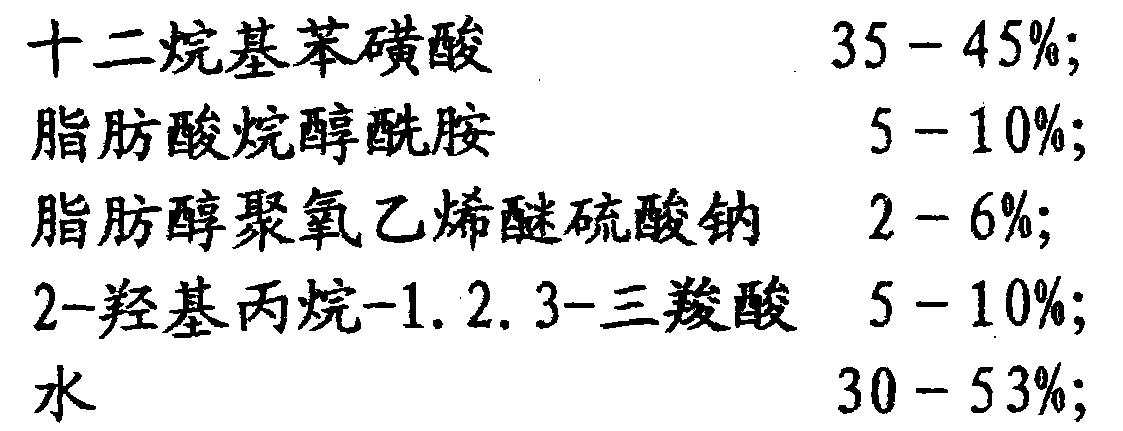

[0021] Get 45 kilograms of dodecylbenzenesulfonic acid, 6 kilograms of fatty acid alkanolamides, 3 kilograms of fatty alcohol polyoxyethylene ether sodium sulfates, 8 kilograms of 2-hydroxypropane-1.2.3-tricarboxylic acids and 38 kilograms of water make 1 Expansive soil stabilizer No. is suitable for stronger expansive soil.

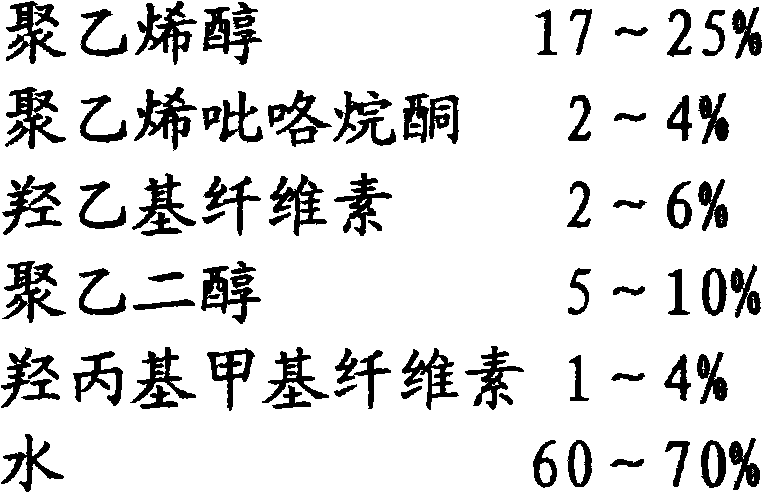

[0022] Get 25 kilograms of polyvinyl alcohol, 4 kilograms of polyvinylpyrrolidone, 2 kilograms of hydroxyethyl cellulose, 5 kilograms of polyethylene glycols, 4 kilograms of hydroxypropyl methylcellulose and 60 kilograms of water make No. 1 expansive soil curing agent.

[0023] Take 1 kg of No. 1 expansive soil stabilizer and add 100 to 200 kg of water to dilute it, then spray it on the excavated 20 cm thick road surface, stir evenly, wait for 3 to 4 hours, and then spray No. 1 expansive soil curing agent 10 The ratio of expansive soil curing agent to water is about 5 to 7 times that of expansive soil curing agent, and the amount of water used depends on...

Embodiment 2

[0025] Get 35 kilograms of dodecylbenzenesulfonic acid, 5 kilograms of fatty acid alkanolamide sodium sulfate of fatty alcohol polyoxyethylene ether, 5 kilograms of 2-hydroxypropane-1.2.3-tricarboxylic acid and 53 kilograms of water make No. 2 Expansive soil stabilizer.

[0026] Get 18 kg of polyvinyl alcohol, 2 kg of polyvinylpyrrolidone, 3 kg of hydroxyethyl cellulose, 6 kg of polyethylene glycol, 1 kg of hydroxypropyl methyl cellulose and 70 kg of water to make No. 2 expansive soil curing agent. Suitable for weak expansive soils.

[0027] Take 1 kg of No. 2 expansive soil stabilizer and add 100 to 200 kg of water to dilute it, then spray it on the excavated 20 cm thick road surface, stir evenly, wait for 3 to 4 hours, and then spray No. 2 expansive soil curing agent 10 The ratio of expansive soil curing agent to water is about 5 to 7 times that of expansive soil curing agent, and the amount of water used depends on the water content of the subgrade soil at that time. Howe...

Embodiment 3

[0029] Get 44 kilograms of dodecylbenzenesulfonic acid, 10 kilograms of fatty acid alkanolamides, 6 kilograms of fatty alcohol polyoxyethylene ether sodium sulfates, 10 kilograms of 2-hydroxypropane-1.2.3-tricarboxylic acids and 30 kilograms of water make 3 No. expansive soil stabilizer.

[0030] Take 17 kg of polyvinyl alcohol, 3.5 kg of polyvinylpyrrolidone, 6 kg of hydroxyethyl cellulose, 10 kg of polyethylene glycol, 3.5 kg of hydroxypropyl methyl cellulose and 60 kg of water to make No. 3 expansive soil curing agent in weak expansive soils.

[0031] Take 1 kg of No. 3 expansive soil stabilizer and add 100 to 200 kg of water to dilute it, then spray it on the excavated 20 cm thick road surface, stir evenly, wait for 3 to 4 hours, and then spray No. 3 expansive soil curing agent 10 The ratio of expansive soil curing agent to water is about 5 to 7 times that of expansive soil curing agent, and the amount of water used depends on the water content of the subgrade soil at tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com