One-piece sub-tank structure and oil pressure buffer using it

A technology of oil pressure buffer and auxiliary oil tank, applied in the field of oil pressure buffer, can solve problems such as time-consuming and money-consuming, high maintenance cost, weakening, etc., and achieve the effect of convenient oil filling, prolonging service life, and reducing use and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

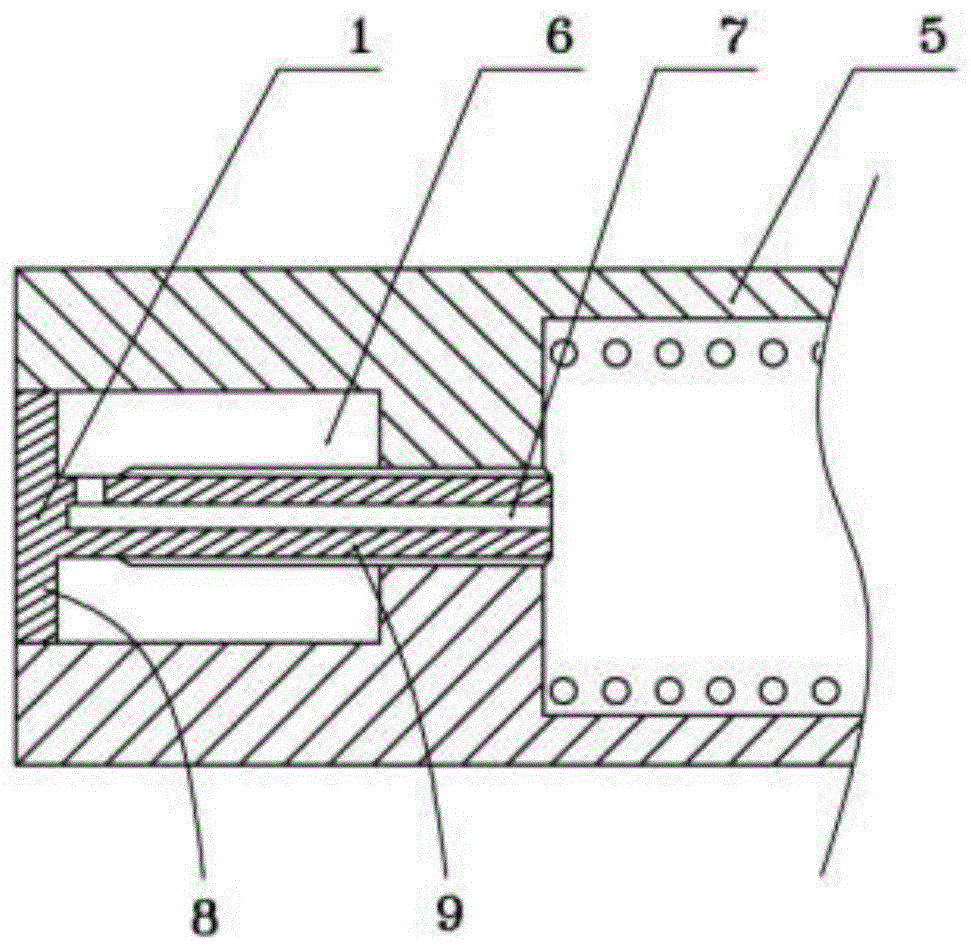

[0028] Embodiment 1, with reference to figure 1 A conjoined sub-tank structure is shown, and the oil pressure buffer using the conjoined sub-tank structure is as follows: Figure 5 As shown, the cylinder body 5 comprising the oil pressure buffer is provided with an accommodating chamber at the end of the cylinder body 5 away from the piston rod, and an oil tank rear cover 1 threadedly connected with the cylinder body 5 is arranged in the accommodating chamber; When the cover 1 is screwed to the cylinder body 5, the rear cover 1 of the fuel tank cooperates with the cylinder body 5 so that the accommodating cavity forms a closed oil storage chamber 6, and the rear cover 1 of the fuel tank also has a Connected oil delivery channel 7.

[0029] The cylinder body 5 is provided with a threaded through hole 10 for communicating the accommodating cavity with the interior of the cylinder body 5. The fuel tank back cover 1 includes a base 8 and a threaded connection portion 9 extending ...

Embodiment 2

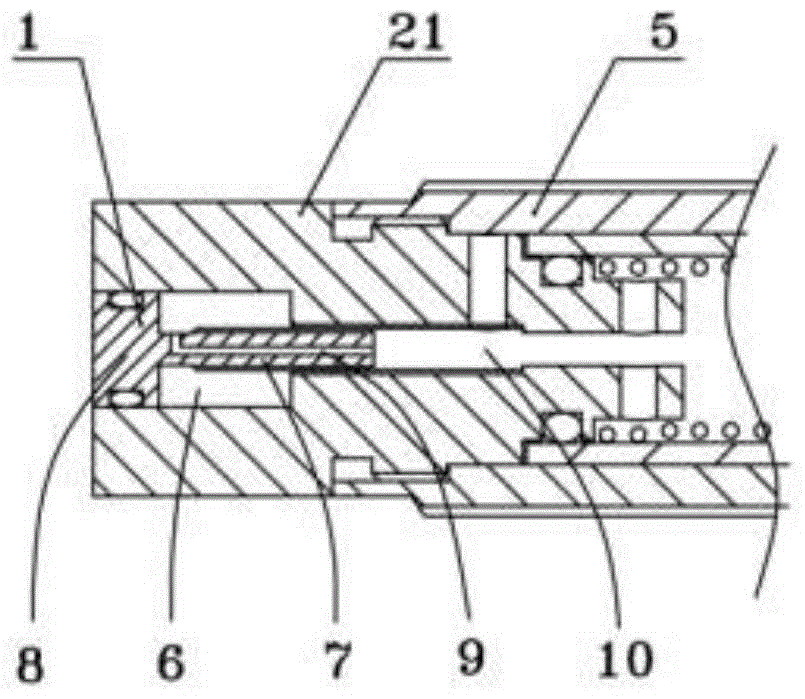

[0030] Embodiment 2, with reference to figure 2 A conjoined sub-tank structure is shown, and the oil pressure buffer using the conjoined sub-tank structure is as follows: Figure 6 As shown, the cylinder body 5 comprising the oil pressure buffer is provided with an end cap 21 at the end far away from the piston rod, and the end cap 21 is threadedly connected with the cylinder body 5, and the end cap 21 is provided with an accommodation chamber, and A fuel tank rear cover 1 threadedly connected with the end cap 21 is arranged in the storage chamber; when the fuel tank rear cover 1 and the end cap 21 are screwed together, the fuel tank rear cover 1 and the end cap 21 cooperate so that the accommodating cavity forms an airtight oil storage chamber 6. The oil tank rear cover 1 is also provided with an oil delivery channel 7 connecting the oil storage chamber 6 with the inside of the cylinder body 5 .

[0031]The end cover 21 is provided with a threaded through hole 10 for commun...

Embodiment 3

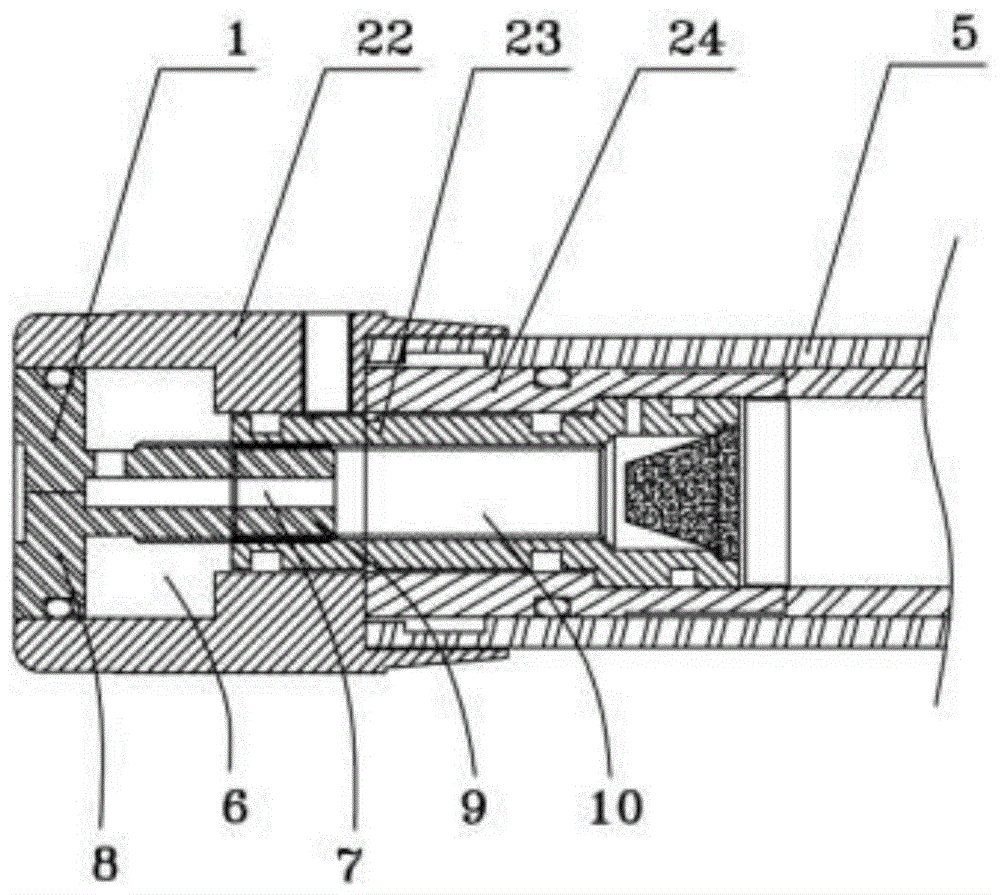

[0032] Embodiment 3, with reference to image 3 A conjoined sub-tank structure is shown, and the oil pressure stabilizer using the conjoined sub-tank structure is as follows Figure 7 and Figure 8 shown, where Figure 8 In order to use the air return type oil pressure stabilizer with the conjoined auxiliary oil tank structure, the cylinder body 5 of the oil pressure buffer is included, and the end of the cylinder body 5 away from the piston rod is also provided with a regulating valve. The regulating valve includes an regulating nut 22, a valve The valve core 23 and the valve housing 24, the valve housing 24 is connected with the cylinder body 5, the adjusting nut 22 is connected with the valve core 23, the valve core 23 can rotate relative to the valve housing 24, and the valve core 23 and the valve housing 24 are provided with relatively matching oil holes , by rotating the spool 23 to adjust the diameter of the oil hole, so as to realize the adjustment of the speed and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com