Patents

Literature

125results about How to "Easy to fill oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

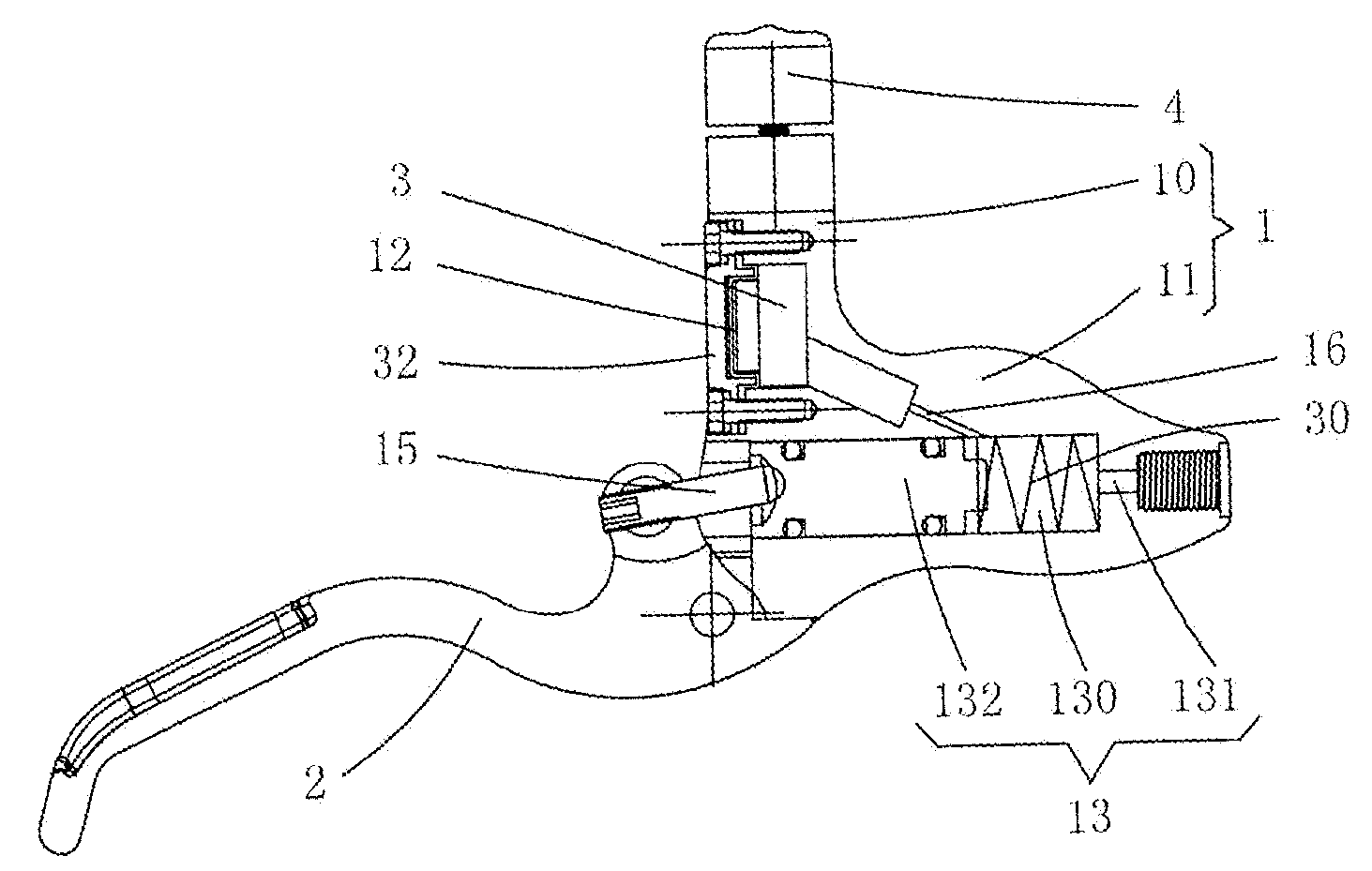

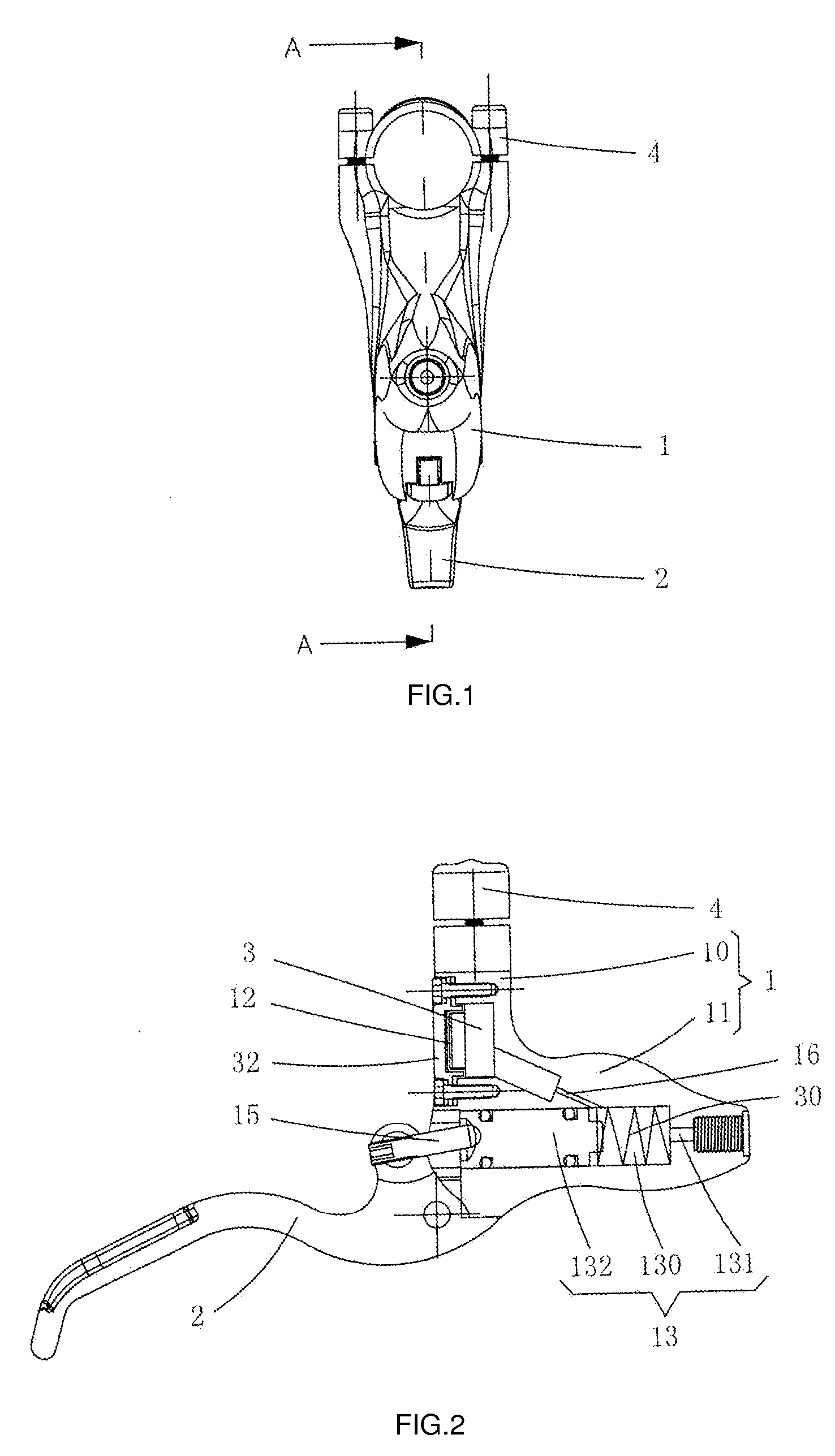

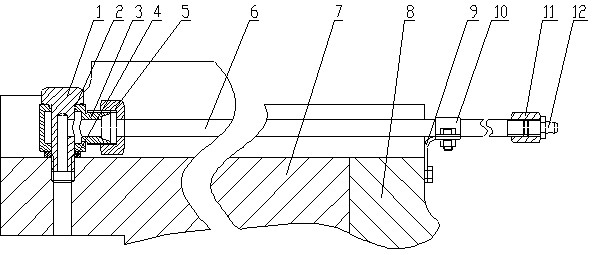

Hydraulic brake lever

InactiveUS20090120750A1Increase supplyReduce manufacturing costHand actuated initiationsFluid braking transmissionEngineeringMechanical engineering

A hydraulic brake lever generally includes a brake lever base, a handle hinged to the brake lever base, an oil reservoir and a half cover. The brake lever base may include a connecting portion and a main portion. A top of the connecting portion may be cooperable with the half cover to mount the hydraulic brake lever to a handlebar. The main portion may include a brake lever cylinder. The brake lever cylinder may include a return spring biasing a piston in the brake lever cylinder. The piston may have an outer end hinged with a push rod and another end hinged with the handle. The oil reservoir may be disposed in one side of the connecting portion adjacent the handle, and fluidly coupled to the brake lever cylinder. The position of the oil reservoir may be higher than the position of the brake lever cylinder.

Owner:HSIN TECH SHENZHEN

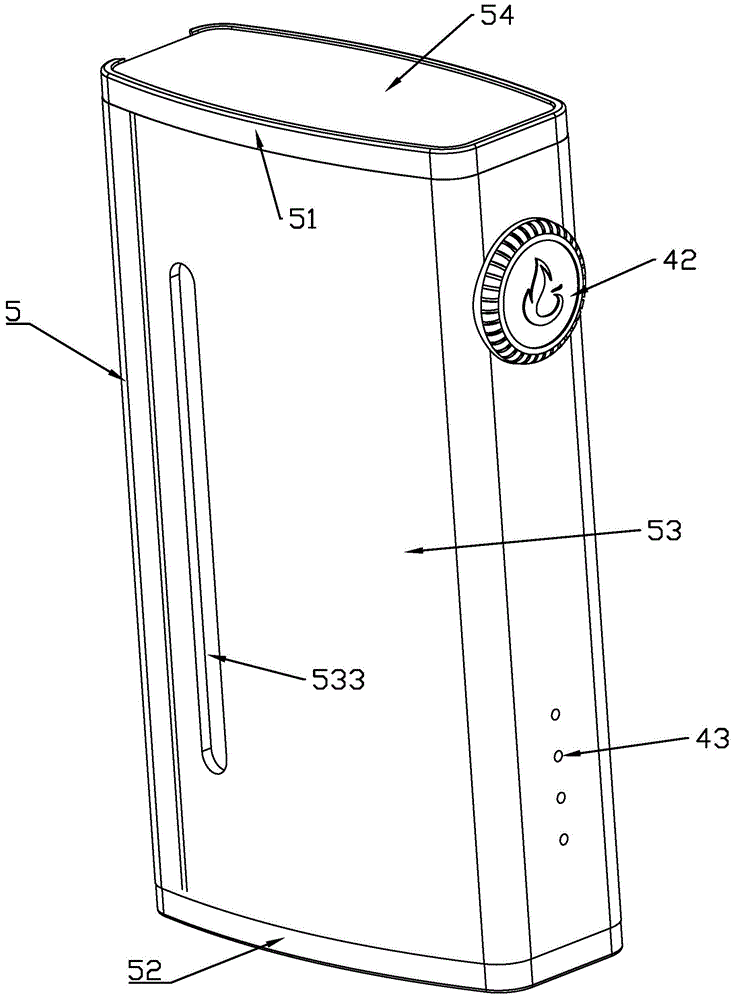

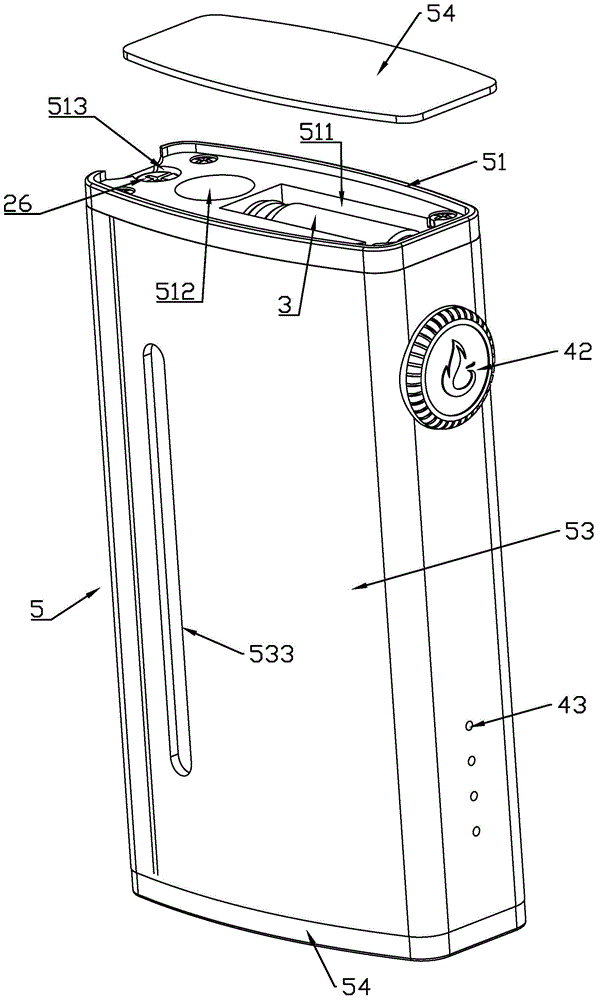

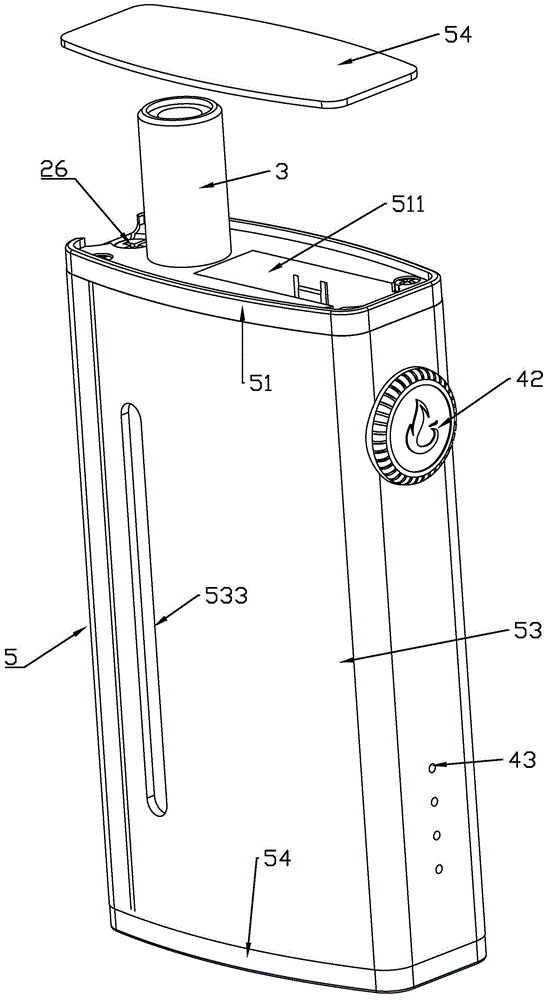

Electronic cigarette

Provided is an electronic cigarette. The electronic cigarette comprises an atomizer assembly, a tip and a battery. The atomizer assembly and the battery are arranged in the body of the electronic cigarette, a containing groove and a tip connecting hole connected with the tip are formed in the body, the tip connecting hole is communicated with the atomizer assembly, the tip is folded in the containing groove when not in use, and when in use, the tip is connected to the inside of the tip connecting hole so as to be communicated with the atomizer assembly. According to the electronic cigarette, because an electronic cigarette liquid pipe with an independent electronic cigarette liquid adding nozzle is arranged, and a detachable sealing cover is installed on the electronic cigarette liquid adding nozzle, electronic cigarette liquid can be conveniently added. Moreover, the parts of the atomizer assembly are connected without wires, and are in contact connection in a threaded manner or a plug-in manner or other manners so that a circuit can be closed, wiring inside the electronic cigarette is greatly simplified, and an atomization core can be conveniently machined, assembled and replaced. In addition, the electronic cigarette is further provided with a tool so that a costumer can conveniently unscrew the screw of the electronic cigarette liquid adding nozzle, and adjust screws, the atomizer assembly and the like, and therefore, the electronic cigarette liquid can be conveniently added, the smoking amount can be conveniently adjusted, and maintenance and replacement can be conveniently carried out.

Owner:张银虎

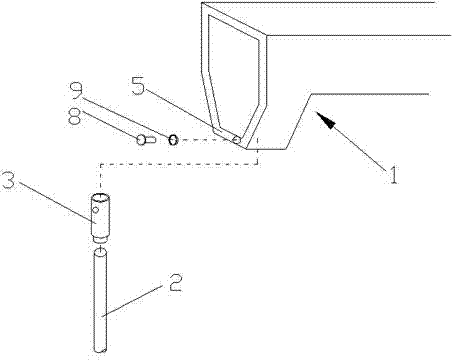

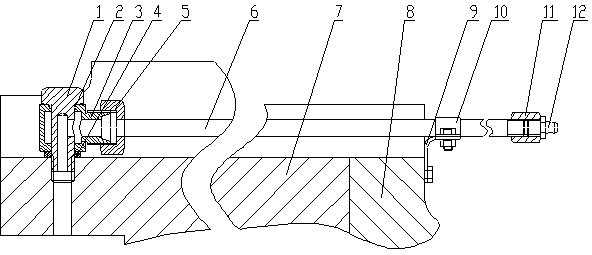

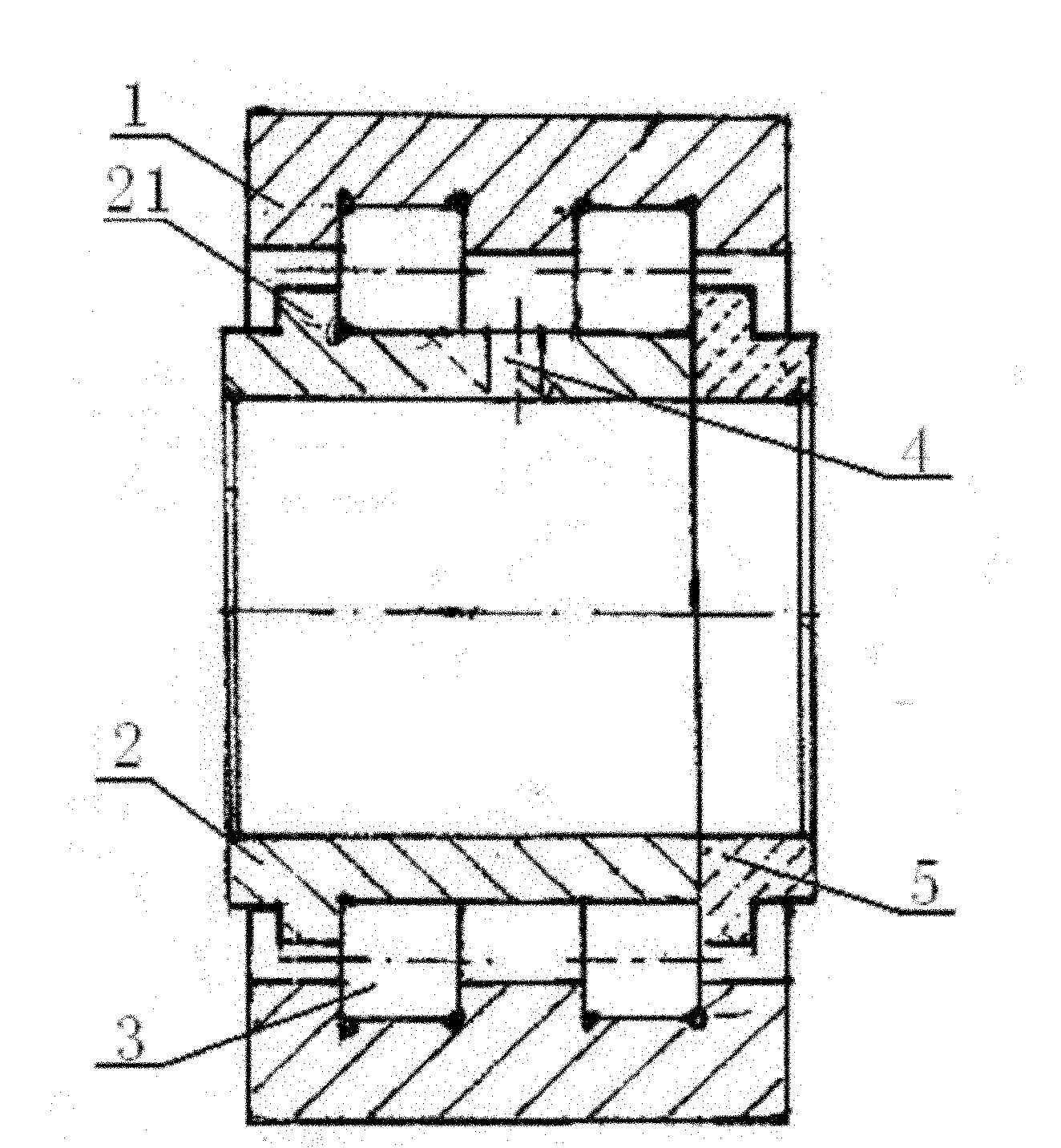

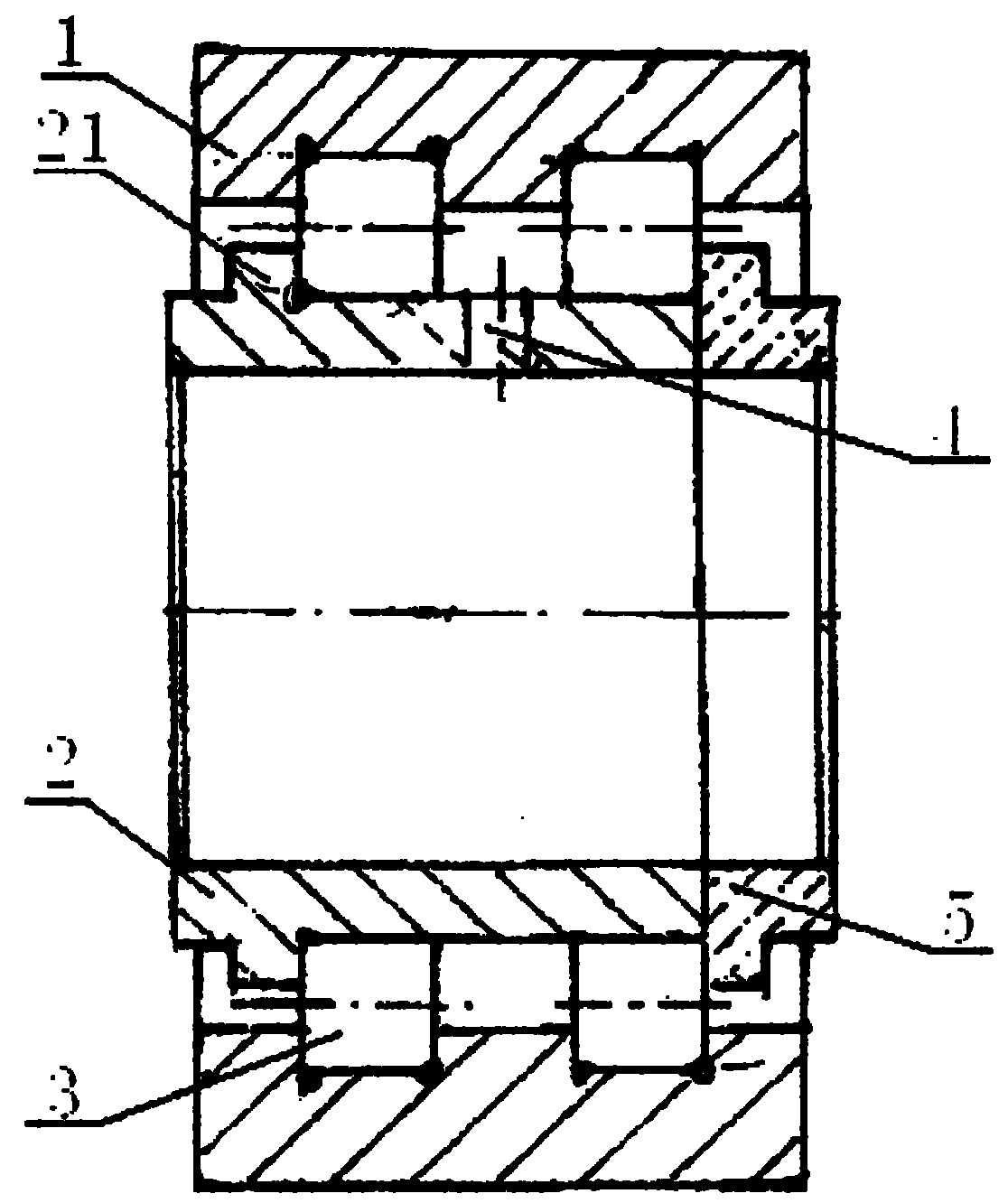

Shaft sleeve of insulation switch transmission shaft

InactiveCN102562806AEnhanced Penetration EffectIncrease penetration rateBearing componentsDrive shaftEngineering

The invention discloses a shaft sleeve of an insulation switch transmission shaft, wherein the insulation switch transmission shaft can keep containing coil continuously, can further guarantee the transmission shaft to perform flexible movements any time in the long-term use. The inner surface of a shaft sleeve body is provided with a straight oil groove from top to bottom; the upper part of the body is provided with an oil pouring hole which is communicated with the outer part and the straight oil groove. According to the invention, the inner wall of the original shaft sleeve is improved into an inner wall of a shaft sleeve of a strip straight groove (a straight oil groove) and a spiral-shaped groove (an oil groove), the permeation effect of lubricating oil to the lower part and each part of a shaft sleeve can be strengthened, and the permeation speed rate is accelerated; additionally, in order to improve the shaft seal effect further, the upper part of the shaft sleeve is provided with a ring upper oil groove which has an effect of upper part shaft seal, and water is prevented from entering; and the lower part of the shaft sleeve is provided with a ring lower oil groove which has an effect of lower part shaft seal, and the lubrication oil is prevented from flowing out by utilizing the viscosity of the lubrication oil after aggregation.

Owner:国网江苏省电力有限公司宝应县供电分公司 +3

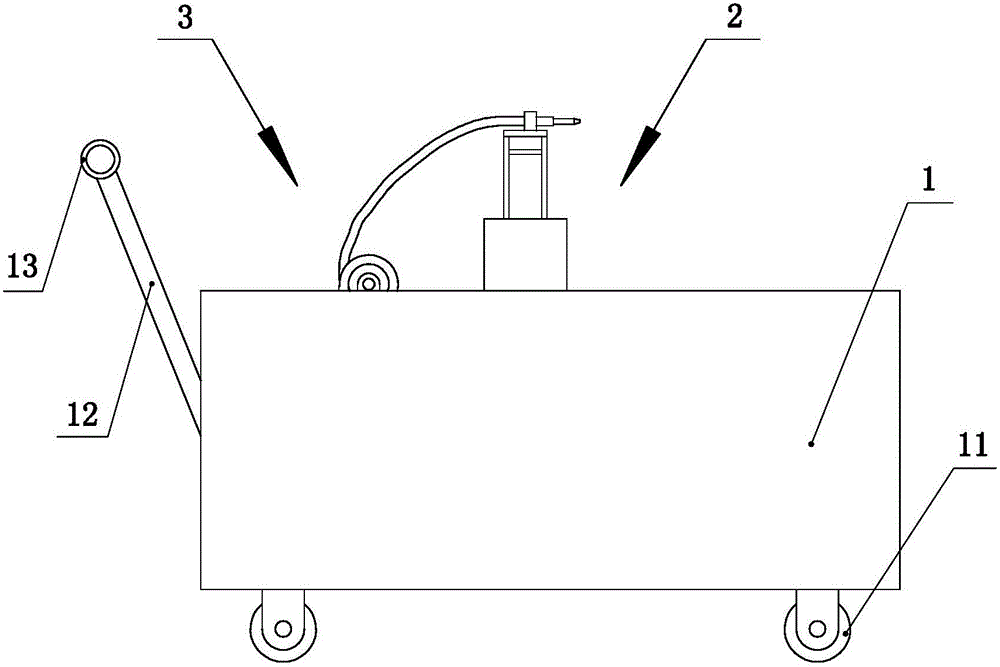

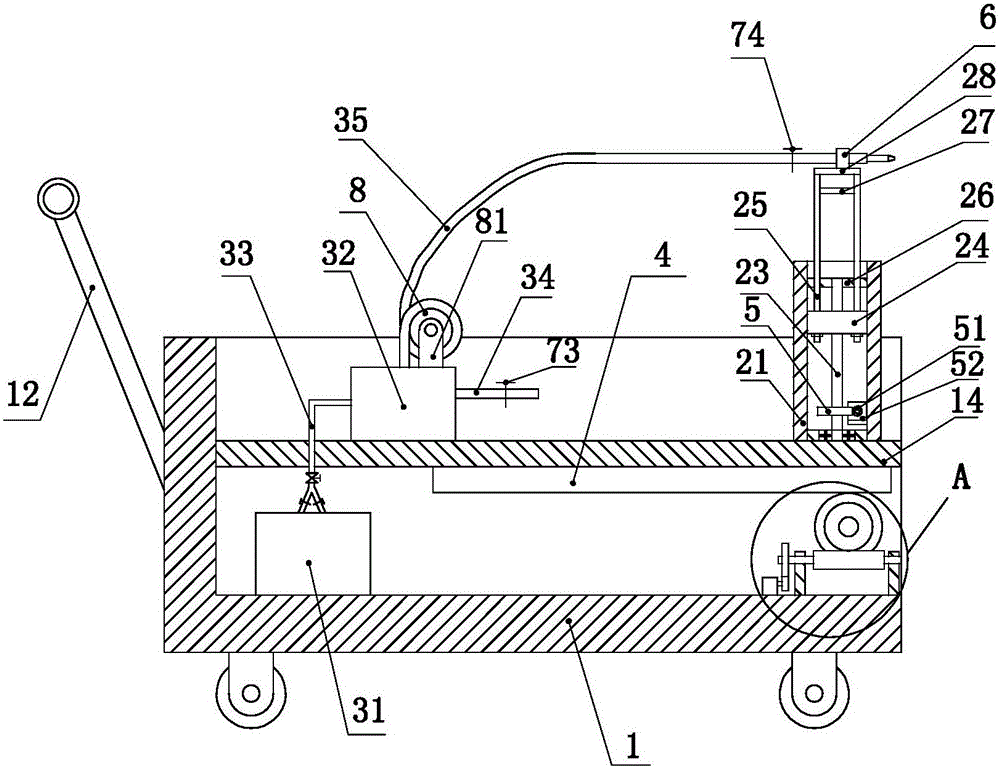

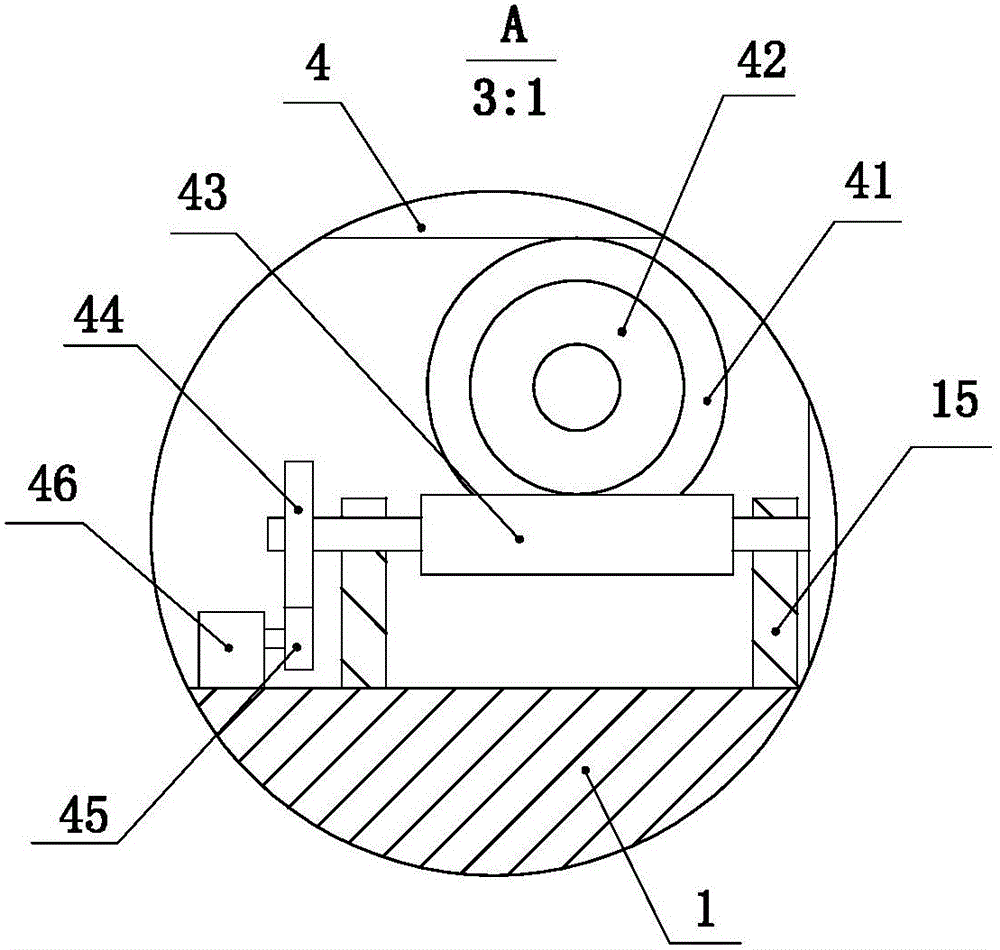

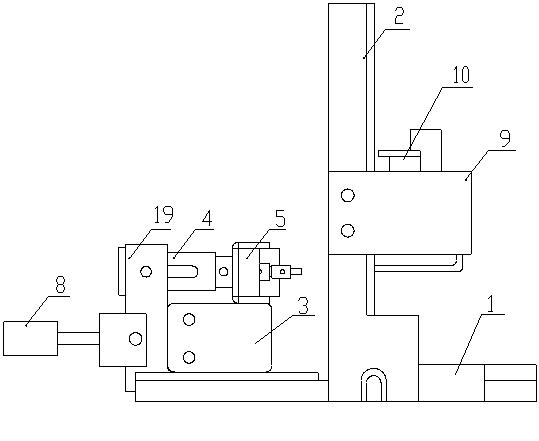

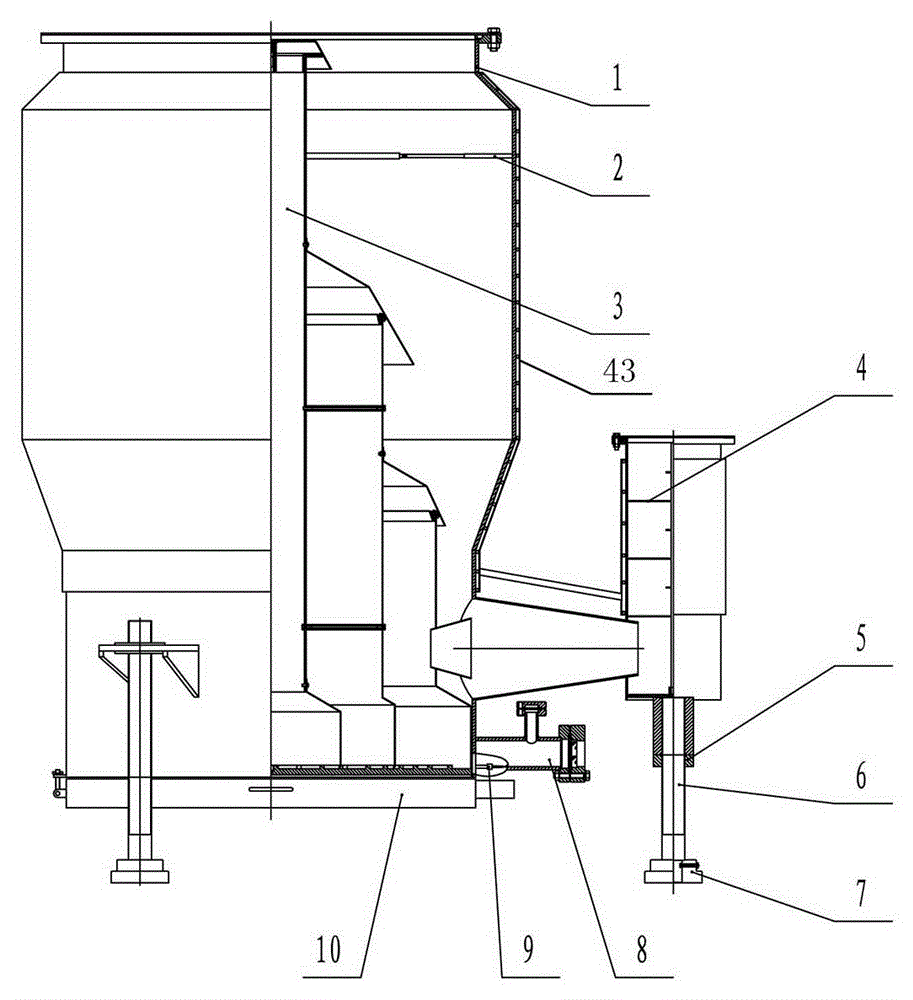

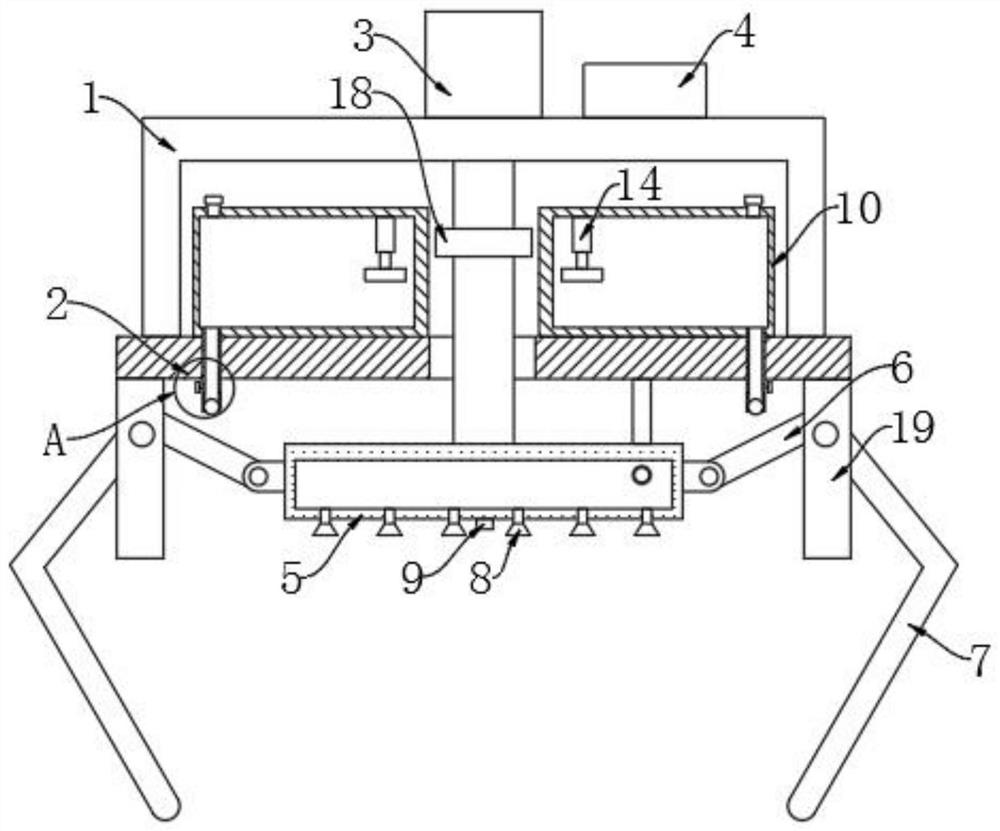

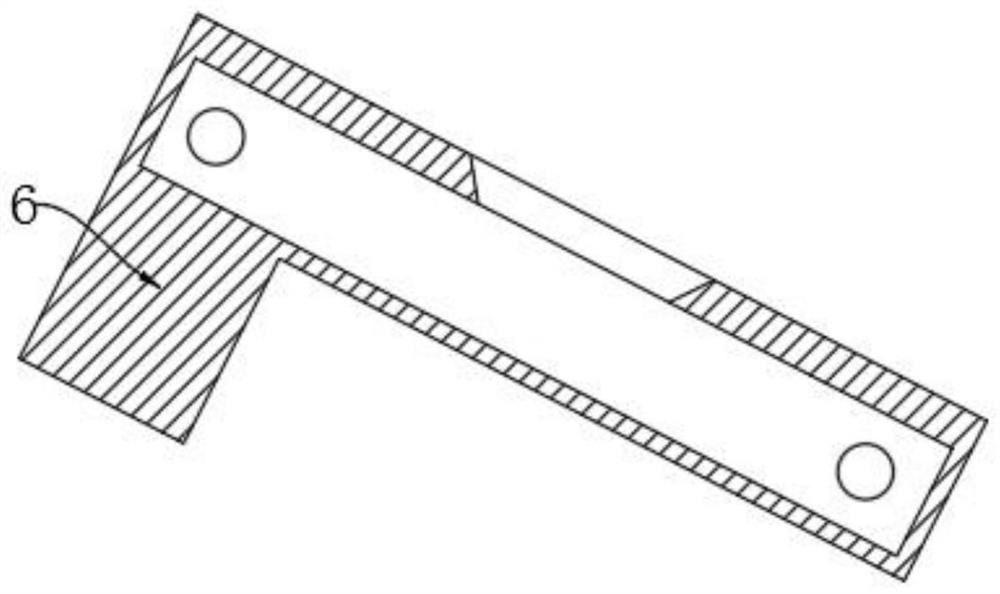

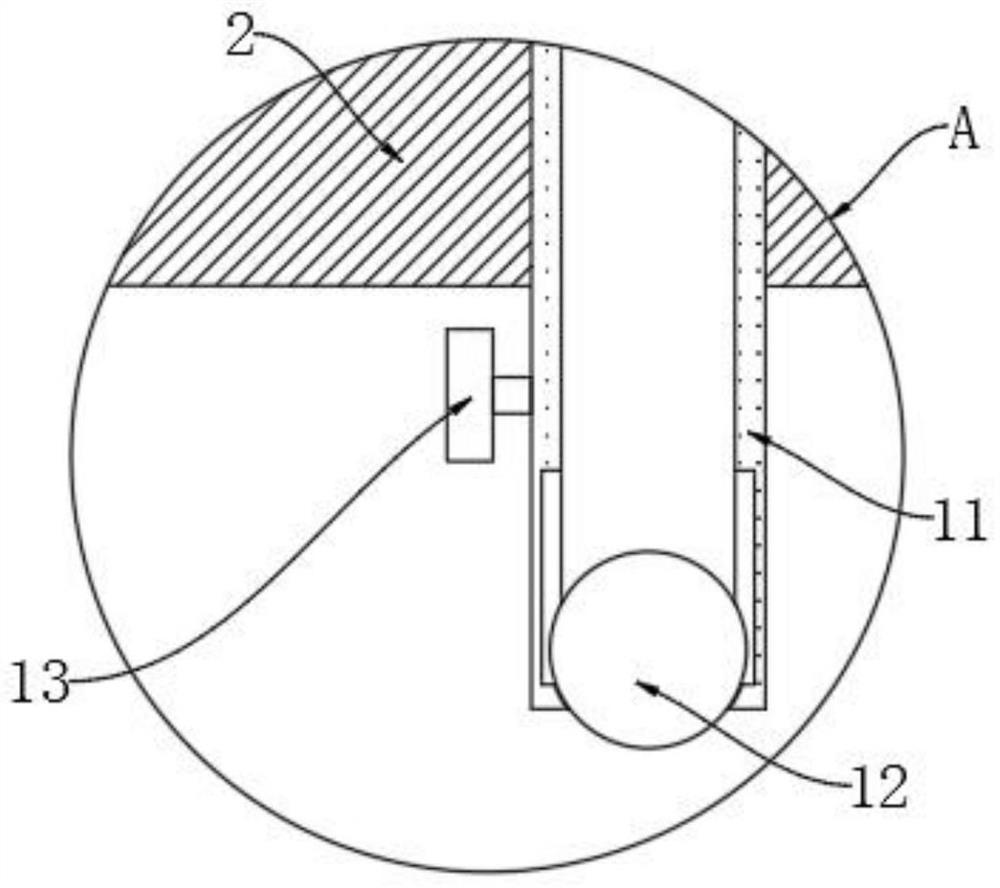

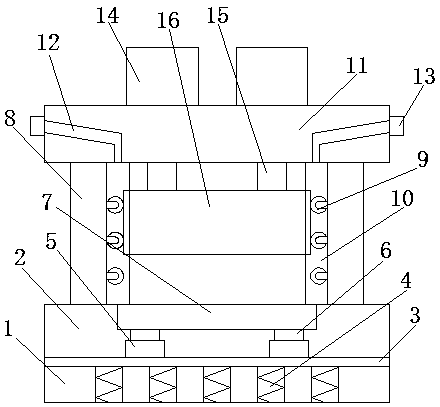

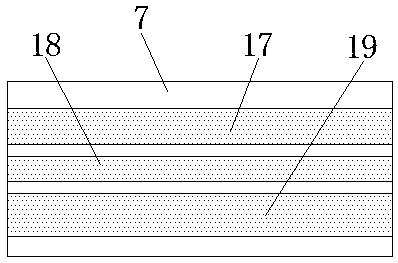

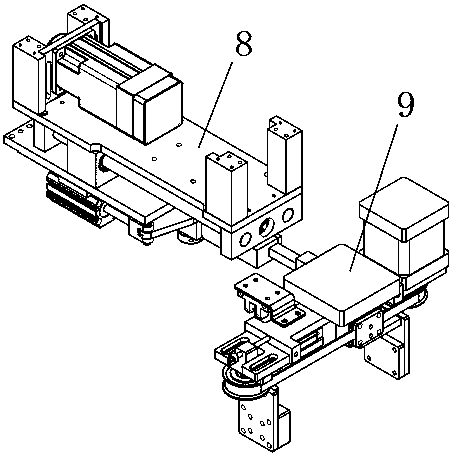

Simple oil injecting device of hydraulic mechanism

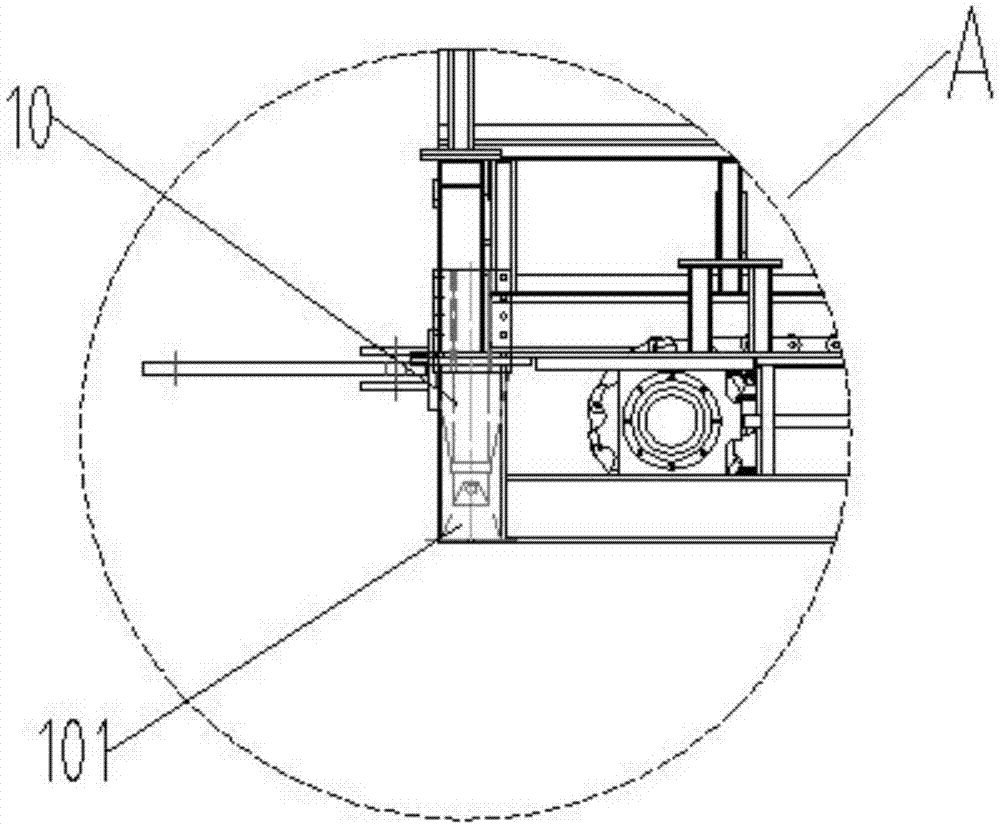

ActiveCN104961090AEasy to fill oilAvoiding the problem of getting into pump pumpsLiquid transferring devicesFuel tankDual purpose

A simple oil injecting device of a hydraulic mechanism is used for solving the problem that when oil is supplemented to the hydraulic mechanism, work efficiency is low. Traveling wheels and a handrail pushing a trolley body to travel are arranged on the trolley body, a partition plate is arranged in the inner cavity of the trolley body and provided with a lifting assembly in a sliding mode, and a horizontal movement assembly used for driving the lifting assembly to slide left and right in the horizontal plane is arranged on the trolley body. The lifting assembly comprises guiding components, a lead screw, a lead screw nut, supporting rods and a platform, wherein the lead screw is arranged among the guiding components, the lead screw nut is arranged in the middle of the lead screw, the supporting rods are fixed to the lead screw nut, and the platform is fixed to the tops of the supporting rods. A rotating assembly driving the lead screw to rotate is arranged on the partition plate. An oil supplying assembly is arranged on the trolley body and comprises a pumping and beating dual-purpose vacuum pump, an oil storing bag, an oil outflow pipe, an oil suction pipe and a gas pipe, and the oil suction pipe is arranged in an oil tank. By means of the simple oil injecting device, hydraulic oil in the oil tank can be fast pumped to the oil storing bag, oil injecting work is achieved, and work efficiency is high.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

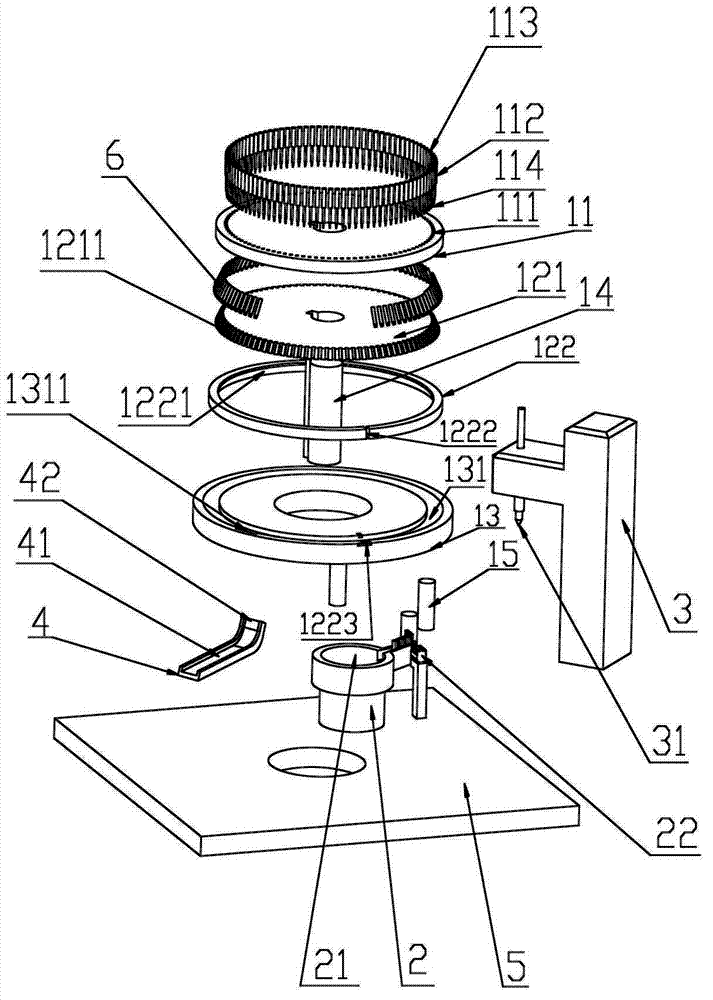

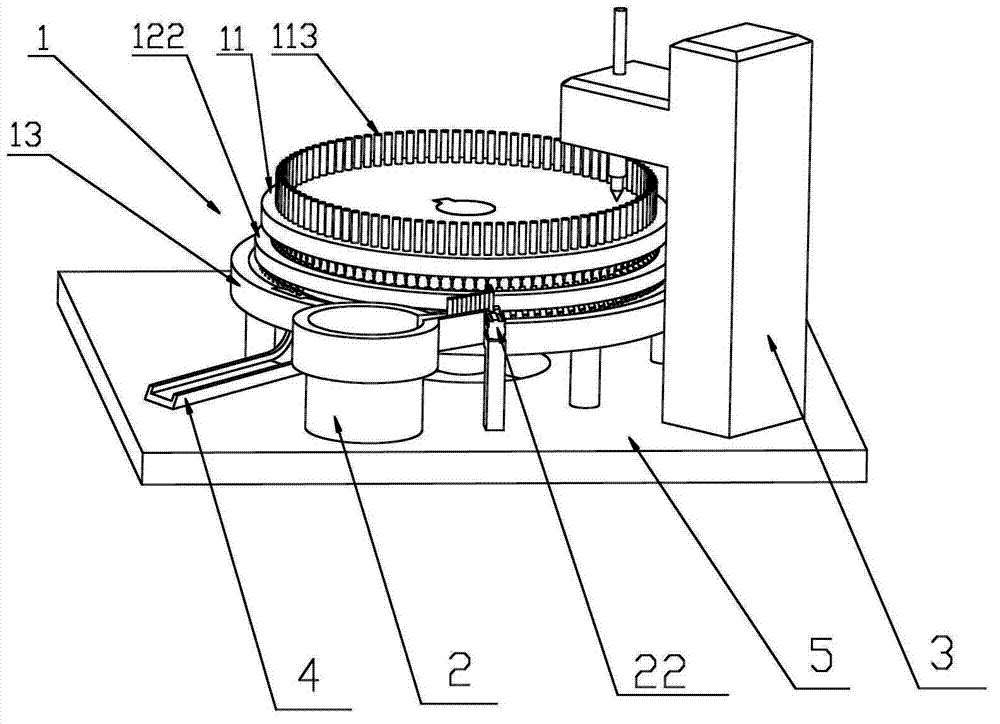

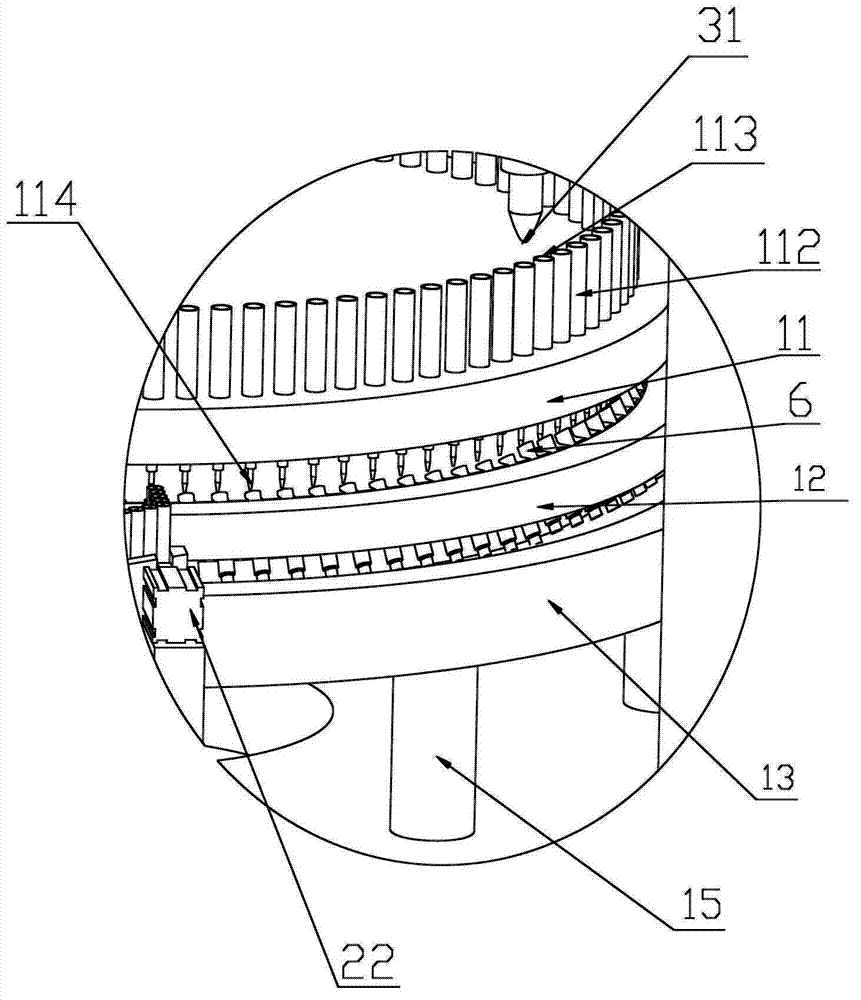

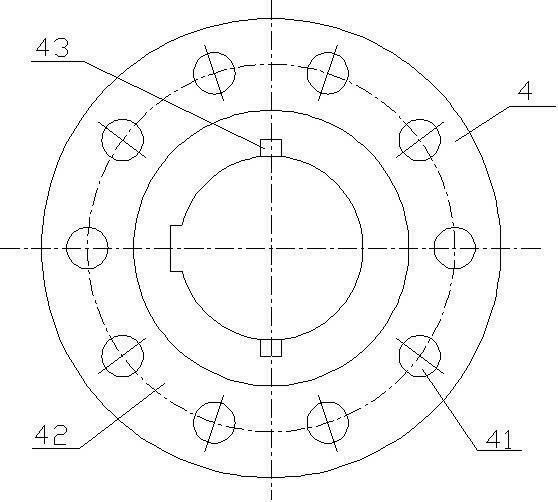

Oiling device of electronic cigarette

The invention relates to an oiling device and discloses an oiling device of an electronic cigarette. The oiling device comprises a driving unit, a feeding unit, an oiling machine, a discharging unit and a working table, wherein the driving unit is arranged on the working table; the oiling machine is arranged on the working table and is placed above the driving unit; and the feeding unit and the discharging unit are respectively arranged on the working table and are distributed at one side of the driving unit. The driving unit further comprises an oil cup plate, a middle round-plate, a guide-rail plate and a driving shaft, wherein the middle round-plate further comprises an inner plate and an outer plate. The oiling device has the beneficial effects that the device is simple in structure and convenient in use and is suitable for batch production; and a full-automatic oiling manner can be realized, the production cost is reduced, and the working efficiency is improved.

Owner:中山市合沃电子科技有限公司

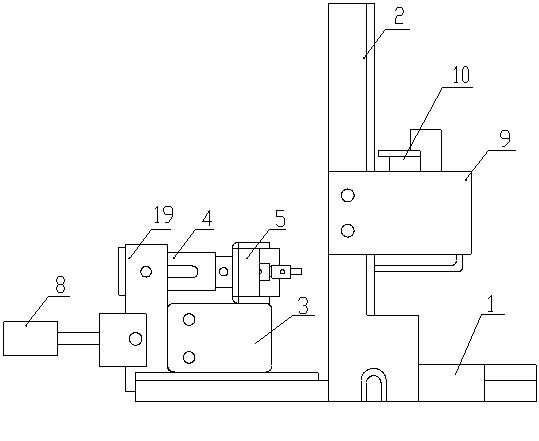

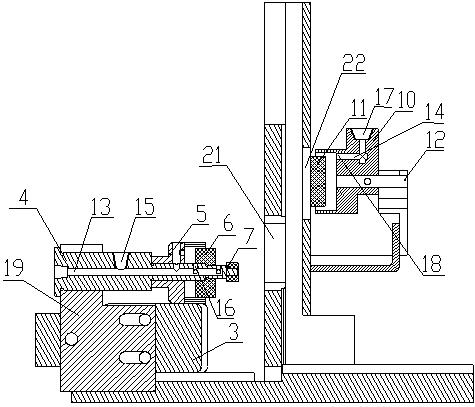

Full automatic bearing oiling device

InactiveCN102029238AReduce oiling timeImprove oiling efficiencyLiquid surface applicatorsCoatingsEngineering

The invention discloses a full automatic bearing oiling device, and relates to an oiling device. The full automatic bearing oiling device comprises a base, wherein the middle part of the base is fixedly connected with a vertically arranged bearing channel; a support is arranged on the left side of the bearing channel; a sliding block is connected with the support in a sliding mode in the transverse direction; the upper top end of the sliding block is fixedly connected with a material pushing shaft; the left end of the sliding block is connected with a first cylinder; the right part of the material pushing shaft is sleeved with an erasing head clip; the right end of the erasing head clip is fixedly connected with a big sponge block on the left side; the right end of the material pushing shaft is fixedly connected with a small sponge block on the left side; the middle part on the right side of the bearing channel is fixedly connected with a fixed plate; the fixed plate is fixedly connected with a fixed block; a pull rod is arranged in the middle part of the fixed block; one end, facing the bearing channel, of the fixed block is fixedly connected with a big sponge block on the right side; one end of the push rod is fixedly arranged in the fixed block; and the other end of the push rod is connected with a second cylinder. The invention ensures that the oiling of a bearing is performed automatically, the oiling time is shortened, and the oiling efficiency and the production efficiency are greatly improved.

Owner:JIANGSU YILITONG TECH

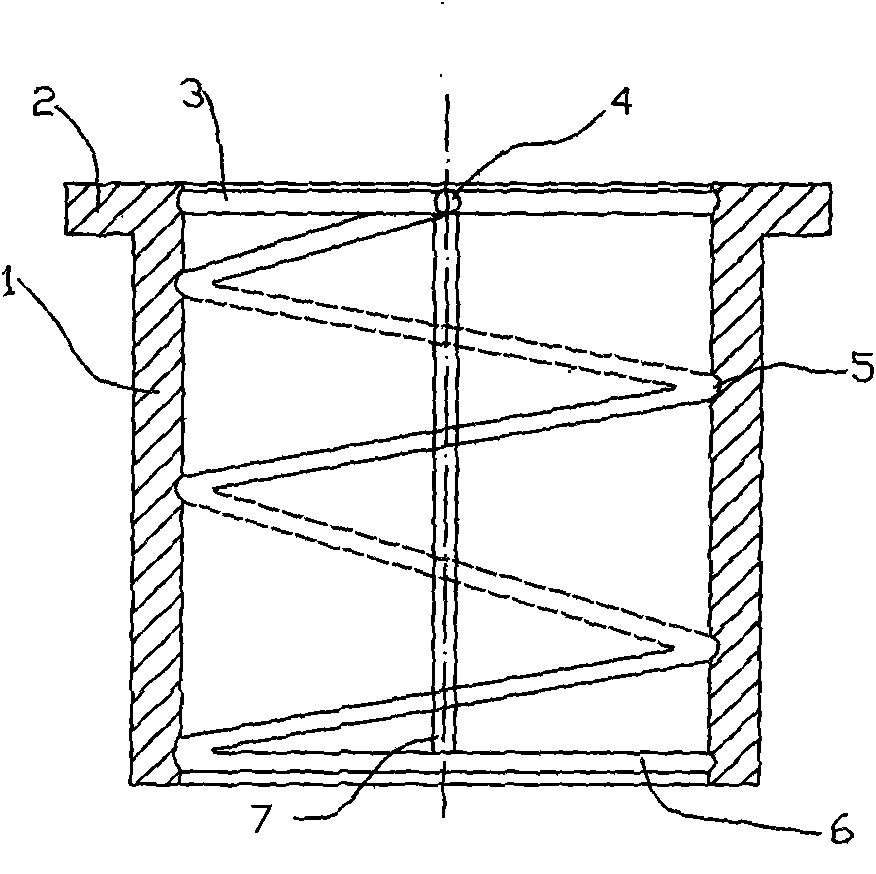

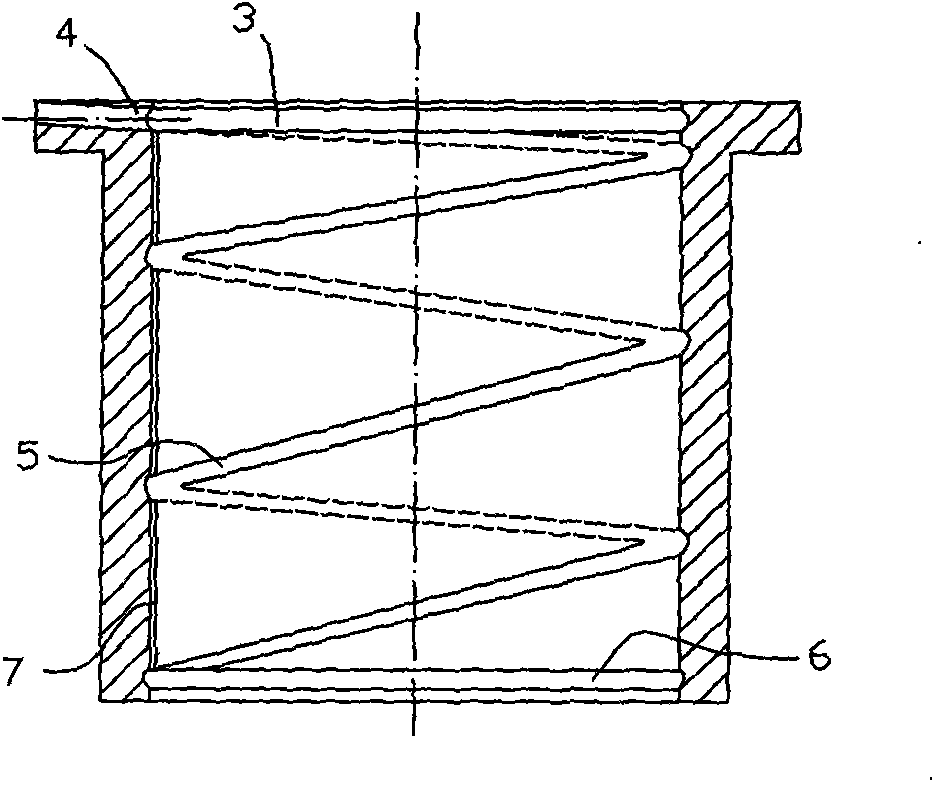

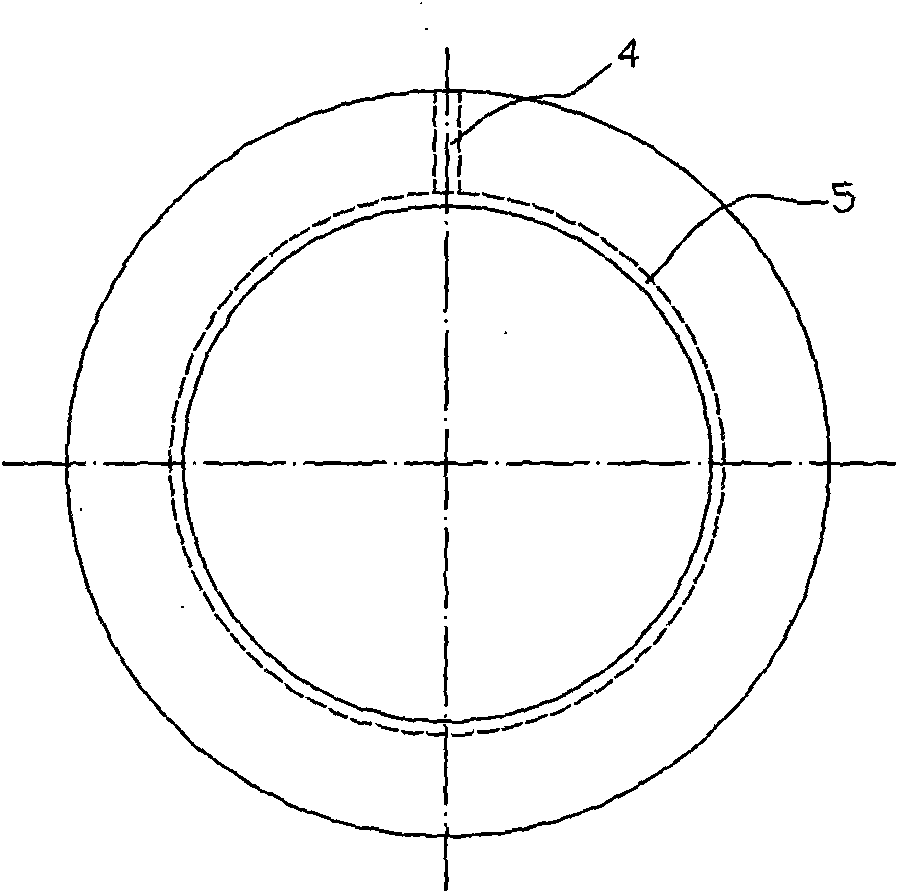

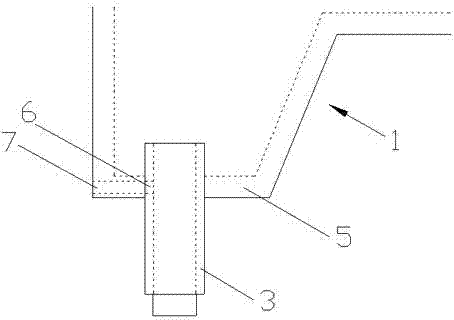

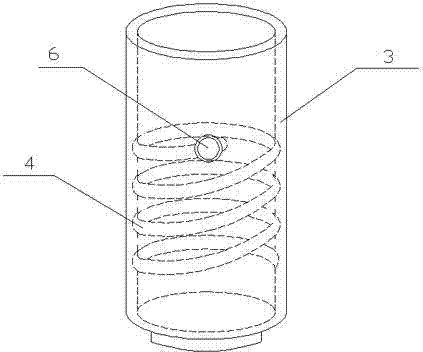

Lubricating device for needle bar of sewing machine

InactiveCN102337647ASimple structureReduce friction areaLubrication/cooling devicesBiomedical engineeringSewing machine

The invention relates to a lubricating device for a needle bar of a sewing machine, which comprises a vertical cylindrical needle bar arranged on the lower end of a handpiece shell and a cylindrical needle bar sleeve; the needle bar sleeve is connected to the handpiece shell and is sleeved at the outer side of the needle bar; an oil storage groove is arranged on the inner wall of the needle bar sleeve, and an oil injection hole is arranged in the upper part of the side face of a cylinder of the needle bar sleeve. The lubricating device is characterized in that the oil storage groove on the inner wall of the needle bar sleeve is helical with the axial line of the cylinder as a middle axle. The helical oil storage groove is used for reducing the friction area of the needle bar and the needle bar sleeve so as to reduce heat. Meanwhile, the helical groove is used as a flow channel for liquid lubricating grease to ensure that the grease is uniformly distributed within 360 degrees in the vertical and sectional directions of the axial line of the needle bar sleeve. The helical oil storage groove has a simple structure, and the upper end of the helical oil storage groove is arranged at the oil injection hole of the needle bar sleeve to conveniently inject oil.

Owner:吴江丰榖布艺整理厂

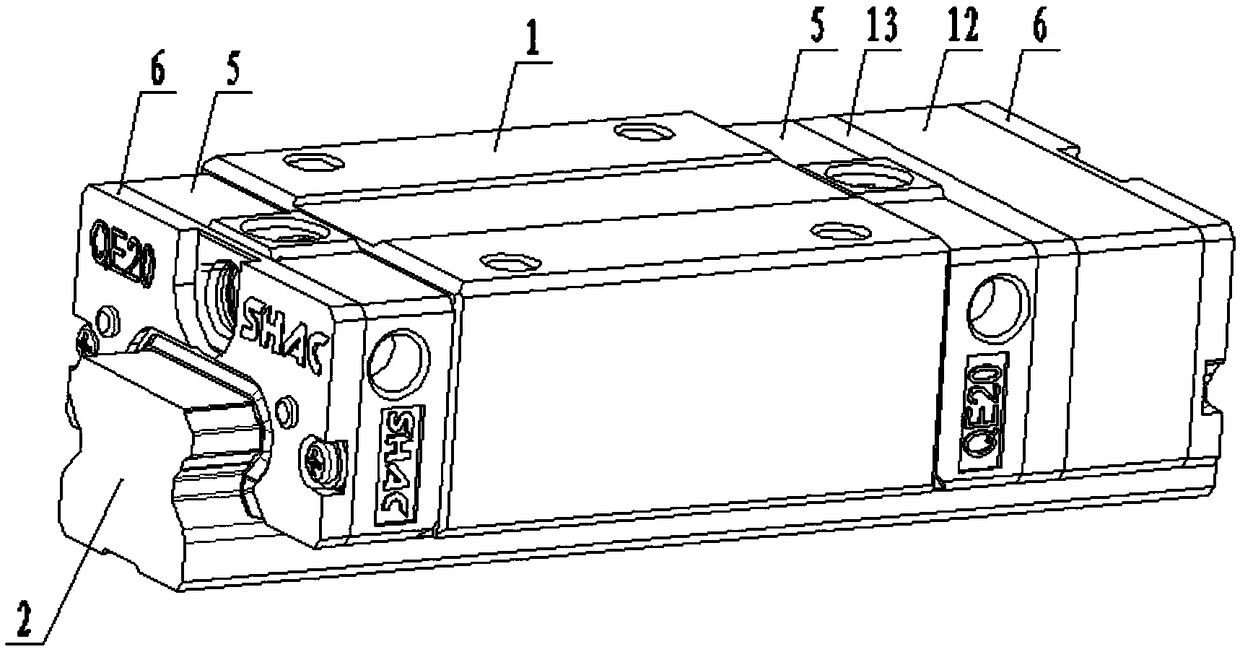

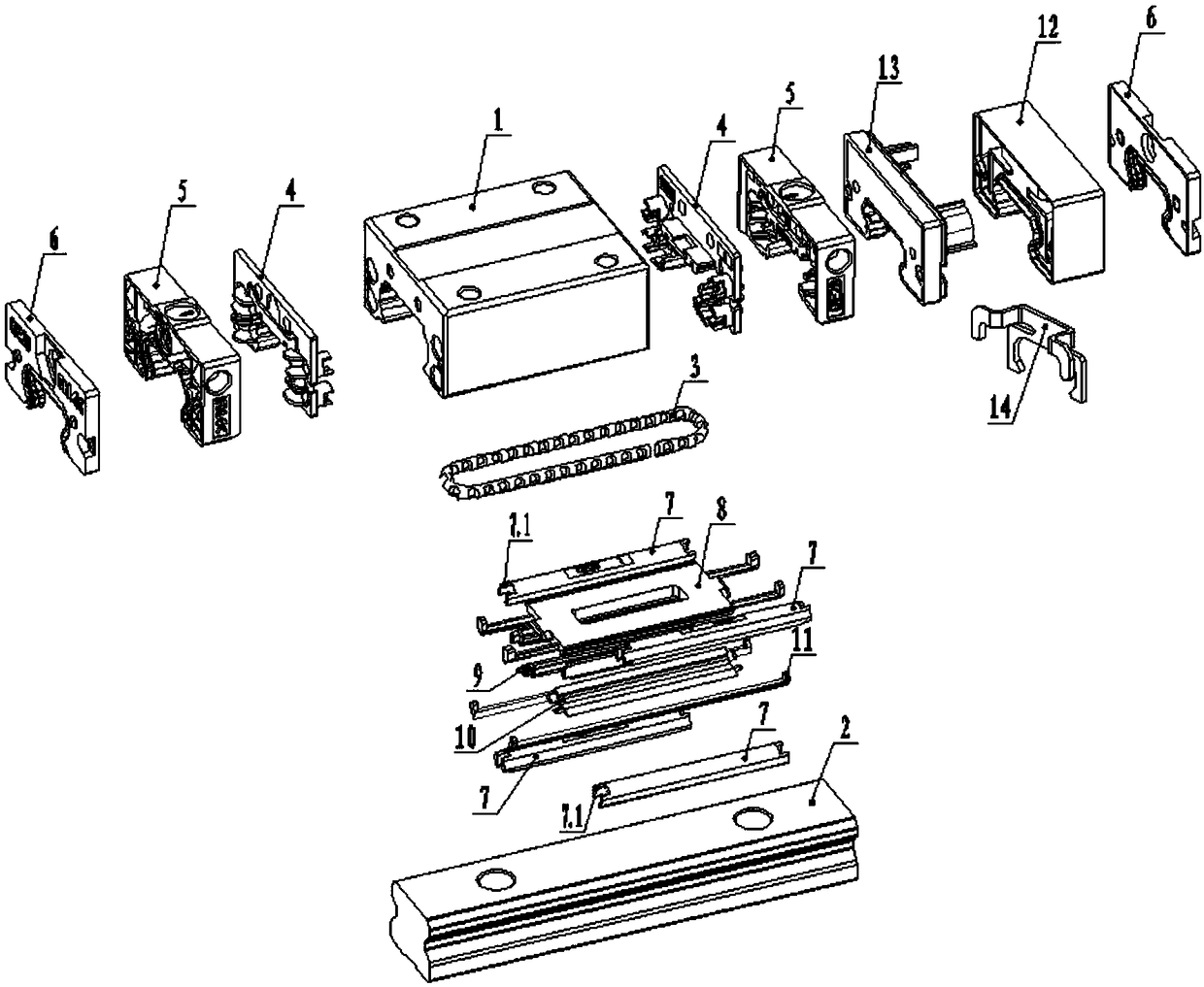

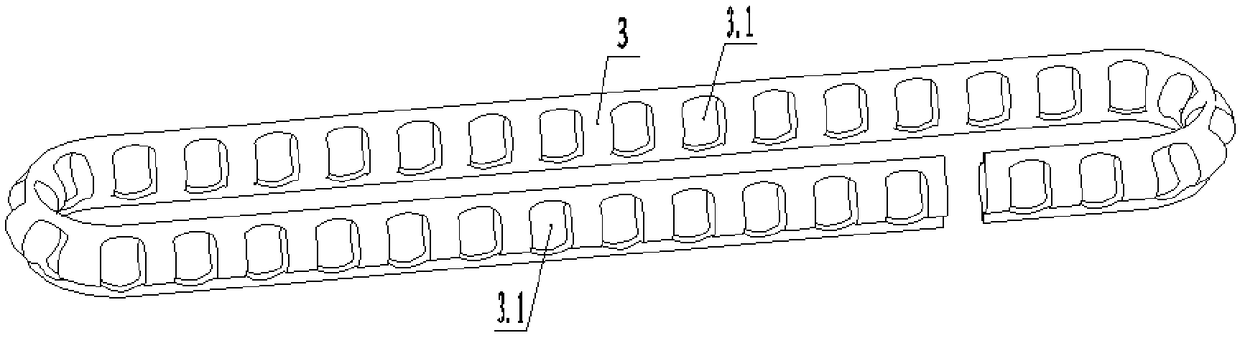

Linear guide rail

PendingCN108662017AGuaranteed uptimeAvoid damageLinear bearingsEngine lubricationEngineeringMechanical engineering

The invention provides a linear guide rail. The linear guide rail comprises a sliding block, a guide rail, a rolling body, a rolling body chain, two inner cycles, two outer cycles, a lubricating pieceand two dust covers. The sliding block is arranged on the guide rail in a rolling mode through the rolling body chain and the rolling body arranged in the rolling body chain. The inner cycles are fixedly arranged at the left end and the right end of the sliding block correspondingly. The rolling body chain is inserted in the space between the sliding block and the guide rail through the inner cycles to form an inner circulating roller way. The outer cycles are fixedly arranged at the outer ends of the inner cycles. One dust cover is fixedly arranged at the outer end of the outer cycle at theleft end. The lubricating piece is fixedly arranged at the outer end of the outer cycle at the right end. The other dust cover is fixedly arranged at the outer end of the lubricating piece. The linearguide rail is compact and stable in structure, the rolling body operates stably, the operating speed is increased, the lubricating time is kept long, and thus, maintenance is not needed for a long time, and the maintenance cost is reduced. The lubricating effect between the sliding block and the guide rail is good, the structure of an oil guide element enables lubrication to be achieved no matterin which way the linear guide rail is placed, and a dust-proof strip is provided with a big end and a small end and thus can be mounted correctly and conveniently.

Owner:LISHUI JIEXIANG TECH CO LTD

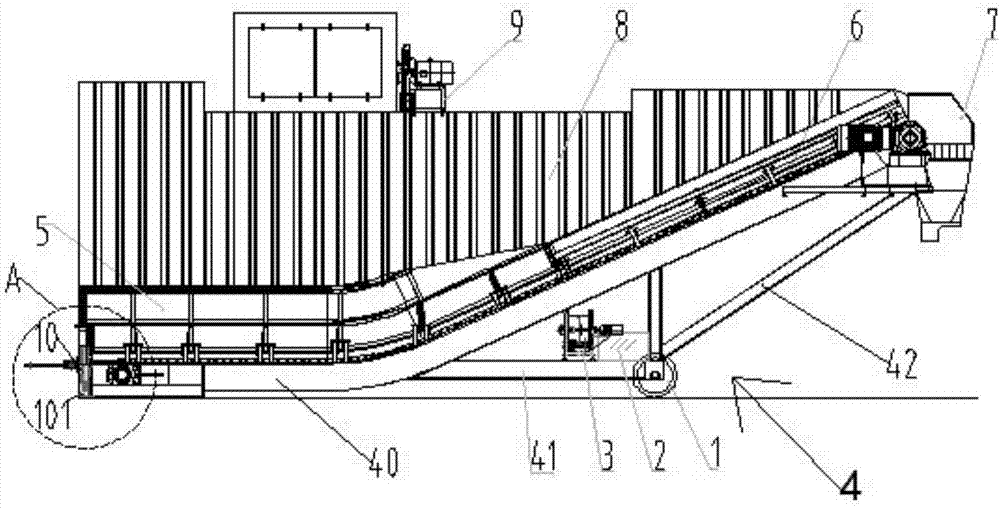

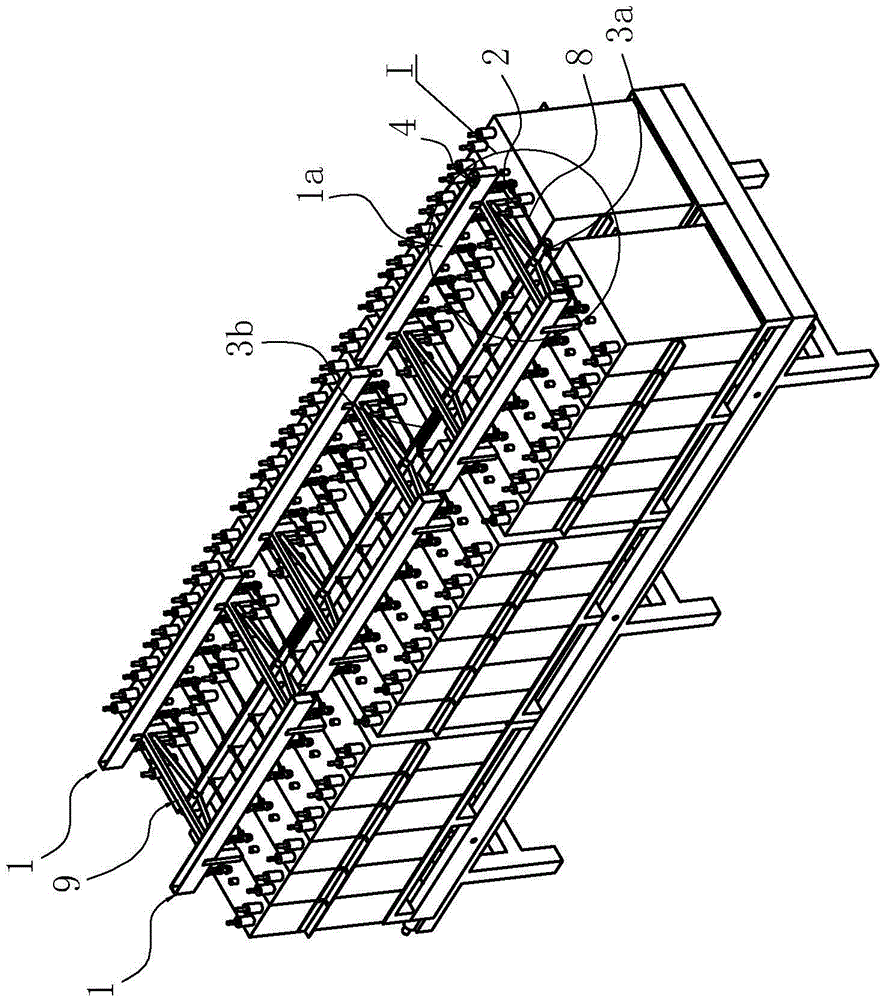

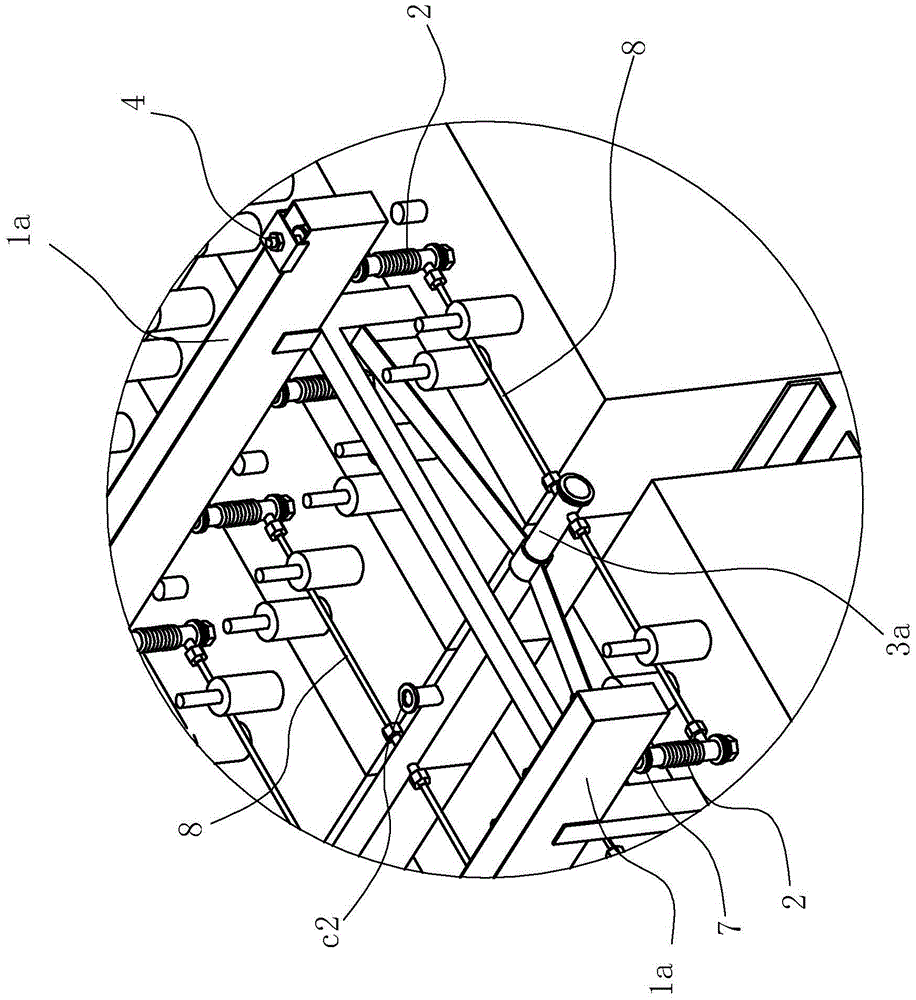

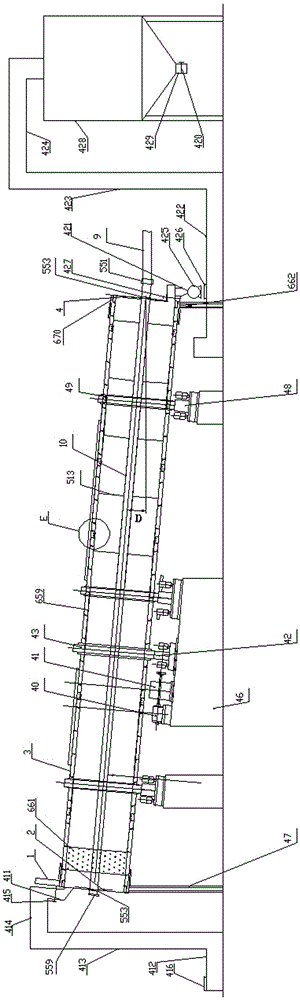

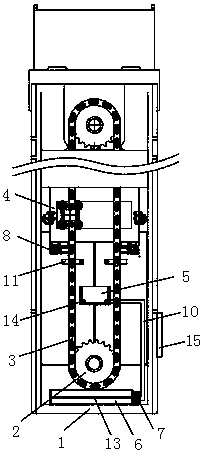

Movable continuous feeding chain plate conveying device

InactiveCN107512526AIncrease profitSimple structureConveyorsPackagingIndependent walkingSpecial position

The invention provides a movable continuous feeding chain plate conveying device. The movable continuous feeding chain plate conveying device comprises a walking mechanism, a chain plate conveying system, a control system, a cantilever crane mechanism, a feed port, a discharge port, a cable power distribution coiling block, a dust cover and a dust remover. The chain plate conveying system is arranged on the cantilever crane mechanism, and the cantilever crane mechanism is arranged on the walking mechanism. The action of the cantilever crane mechanism is controlled by the control system, and the control system is connected with the cable power distribution coiling block. The feed port is arranged on the tail of the chain plate conveying system, and the discharge port is arranged on the head of the chain plate conveying system. The dust cover is arranged above the chain plate conveying system. The dust cover is provided with the dust remover. The movable continuous feeding chain plate conveying device can convey various blocky materials or loosened materials to conveying terminals at any position in the horizontal direction or the inclined direction (not exceeding 25 degrees) and meanwhile achieve a function of stacking the materials and has the advantage of being movable. The movable continuous feeding chain plate conveying device is provided with the independent walking mechanism, movement in place is achieved, a special position or a fixed matched facility is not needed, and it is not need to enlarge an infrastructure.

Owner:JIANGSU WANBAO MACHINERY

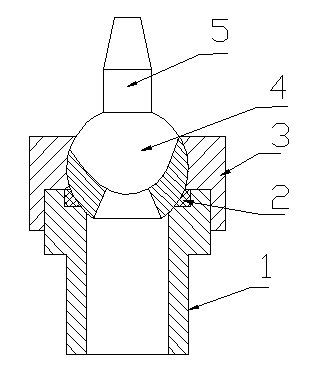

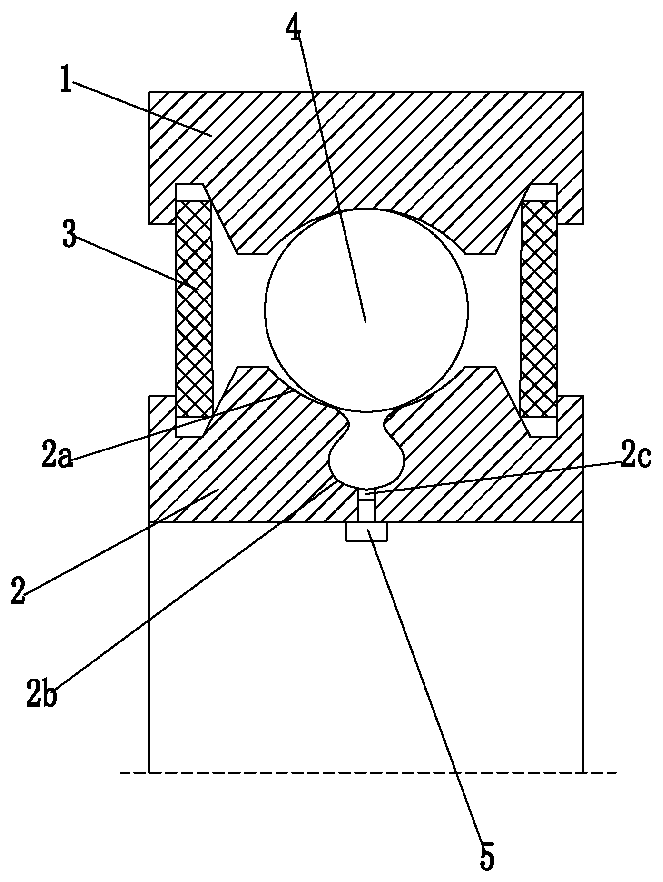

Oil filling nozzle

An oil filling nozzle is characterized in that a spherical ball joint is arranged at the upper end opening of a fixing pipe, a sealing ring is arranged between the ball joint and the fixing pipe, the ball joint is fixed to the upper end opening of the fixing pipe through a bowl-shaped cover, the ball joint, the bowl-shaped cover and the fixing pipe have movable degree of freedom, and the oil filling nozzle is fixedly arranged on the ball joint and is communicated with a middle hole of the fixing pipe through a middle hole of the ball joint. The oil filling nozzle has the advantages of fine adaptability and convenience in oil filling.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

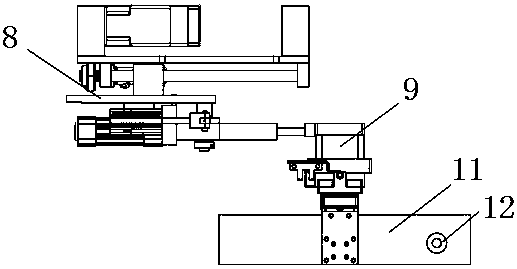

Hydraulic gear grinding clamp

PendingCN109848488AAchieve positioningEffective positioningGear-cutting machinesGear teethGear grindingEngineering

The invention discloses a hydraulic gear grinding clamp. The clamp comprises a clamp body, wherein the clamp body is divided into an upper clamp body and a lower clamp body that are fixedly connected;an elastic sleeve for sleeving and positioning the inner hole of a gear to be machined seals and sleeves around the upper outer wall of the upper clamp body; an upper oil storage cavity for storing hydraulic oil is arranged inside the upper clamp body; an elastic-sleeve tension oil passage that communicates with the upper oil storage cavity and is partially arranged between the outer wall of theupper clamp body and the inner wall of the elastic sleeve is also arranged inside the upper clamp body; and a hydraulic drive structure for pressing the hydraulic oil in the upper oil storage cavity into the elastic-sleeve tension oil passage and further pressing the hydraulic oil into between the outer wall of the upper clamp body and the inner wall of the elastic sleeve is arranged on the lowerclamp body. According to the hydraulic gear grinding clamp, the gear to be machined can be sleeved with the elastic sleeve, and the hydraulic drive structure drives the hydraulic oil in the upper oilstorage cavity to flow into the elastic-sleeve tension oil passage and then press the elastic sleeve, so that the elastic sleeve positions the inner hole of the gear.

Owner:定州市新华机械制造有限公司

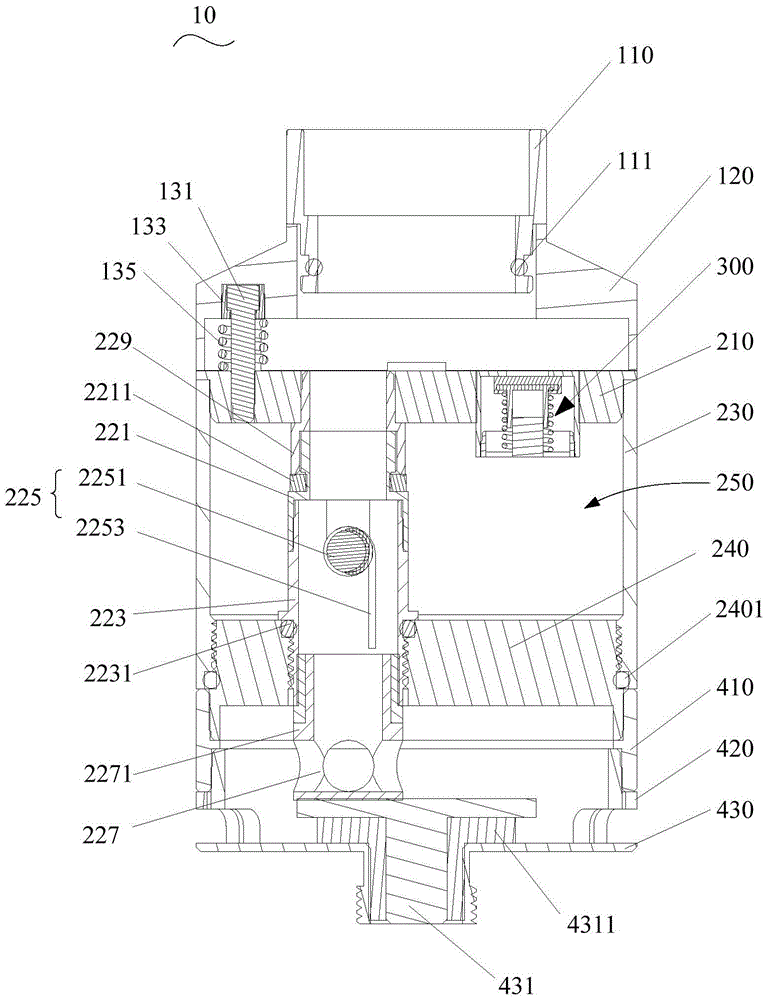

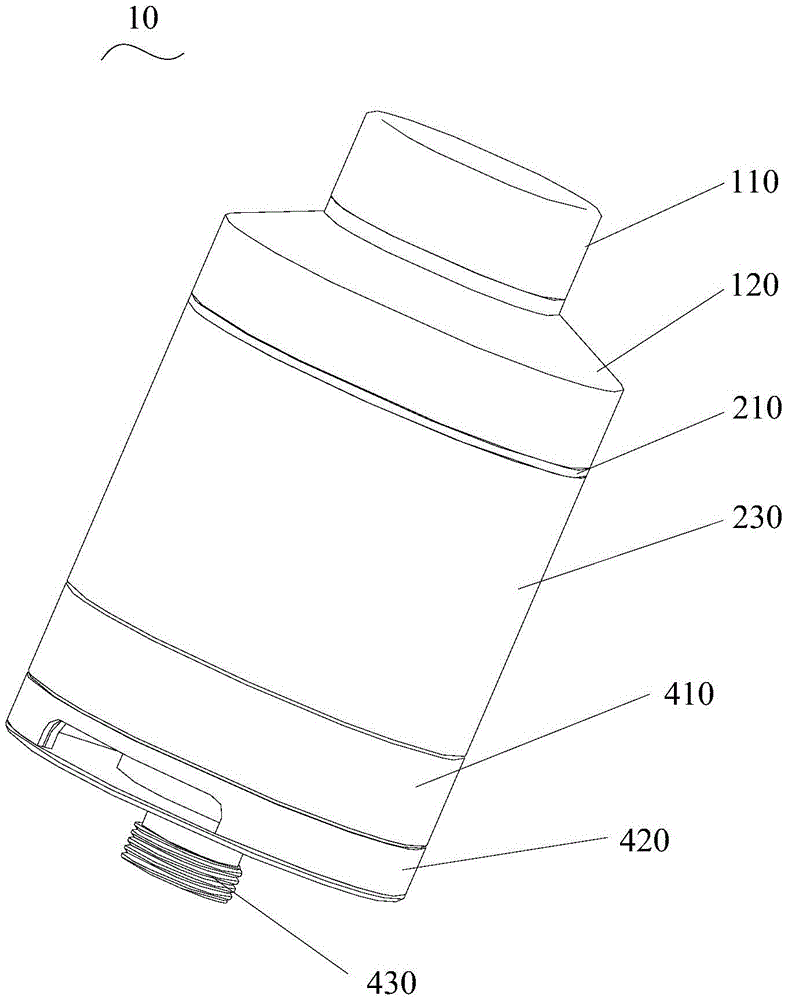

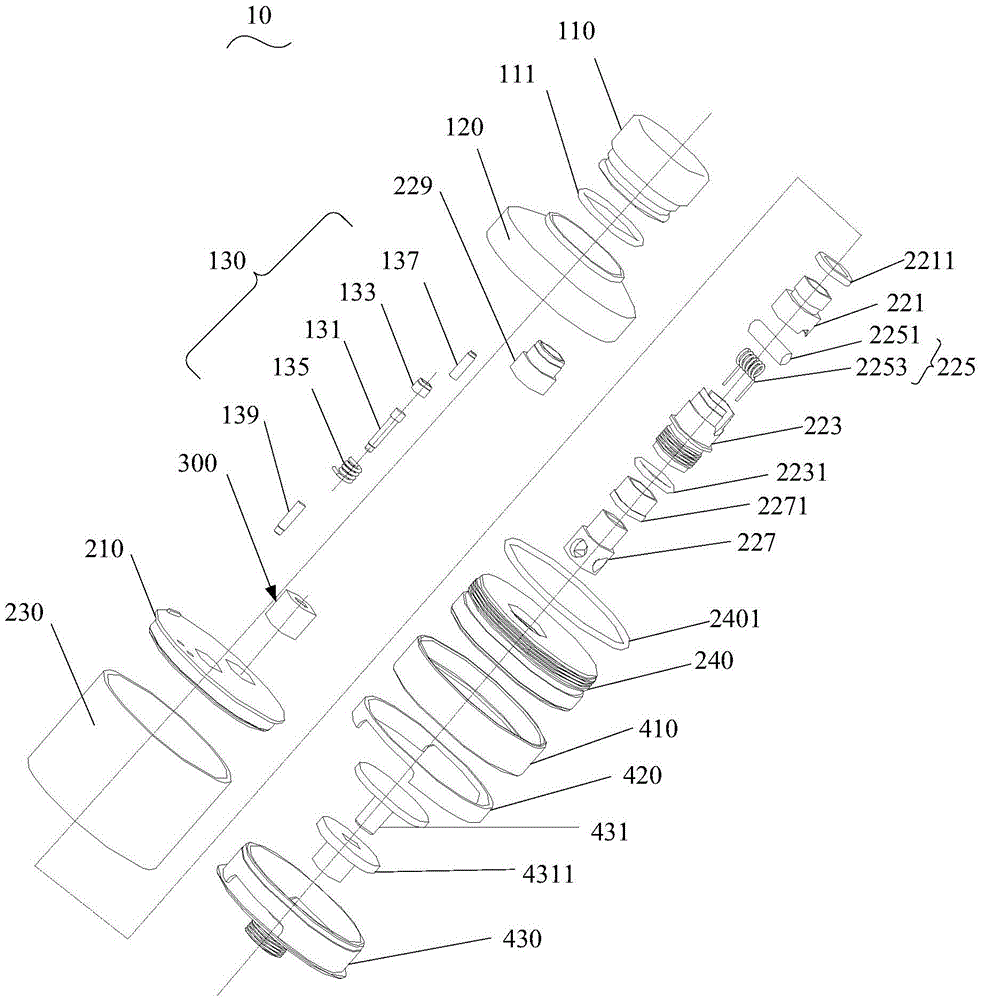

Electronic cigarette atomizer and electronic cigarette

ActiveCN105533810AAvoid the problem of dripping into the fog holeAvoid the problem of mistakenly dripping e-liquid into the fog holeTobacco devicesEngineeringElectronic cigarette

The invention relates to an electronic cigarette atomizer and an electronic cigarette. The electronic cigarette atomizer comprises a suction nozzle assembly, an atomizing assembly and a rotating assembly for connecting the suction nozzle assembly with the atomizing assembly. The rotating assembly comprises a rotating shaft and a rotating sleeve which are rotationally connected, the rotating sleeve is fixed to a suction nozzle base, one end of the rotating shaft is fixedly connected with an upper cover, and the other end of the rotating shaft is sleeved with the rotating sleeve. When tobacco tar is injected, it is unnecessary to pull up the suction nozzle assembly, and the rotating assembly enables the suction nozzle assembly to rotate around the rotating shaft, so that the suction nozzle base rotates relative to the upper cover; the suction nozzle base can shield a mist hole in the upper cover while exposing a tar injecting hole, the problem that the tobacco tar is dripped into the mist hole by mistake is avoided, and the tar is convenient to inject. The electronic cigarette comprising the electronic cigarette atomizer is good in airtightness, and tar injection is convenient.

Owner:SHENZHEN HANGSEN STAR TECH +1

Lubricating oil refueling device for mining dump wheel side reducer

ActiveCN102287607AOptimize layoutLess susceptible to contaminationHubsGear lubrication/coolingReducerPetroleum engineering

The invention discloses a lubricating oil filling device for a mining self-unloading wheel reducer, which belongs to the field of mining self-unloading vehicles. The device comprises a wheel hub, wherein an oil filling hole is formed on the wheel hub; an oil pipe and an oil cup are arranged on the wheel hub; one end of the oil pipe is connected with the oil filling hole on the wheel hub; the other end of the oil pipe is connected with the oil cup; and the oil pipe is arranged in the groove of the wheel hub. The lubricating oil filling device has the advantages that: the lubricating oil filling hole of the wheel reducer is easy to form and difficult to pollute, and oil can be conveniently filled.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

Oiling system of capacitor

ActiveCN105551835ANo pollution in the processSimple structureDrying/impregnating machinesEngineeringExhaust pipe

The invention relates to an oiling system of a capacitor. The oiling system comprises an oiling groove, a three-way exhaust pipe, a liquidometer and a general oiling pipe, wherein the oiling groove is positioned over the capacitor; the liquidometer is inserted into the oiling groove; the upper port of the three-way exhaust pipe is connected with a through hole at the bottom of the oiling groove; the lower port of the three-way exhaust pipe is used for being connected with a dipping hole of the capacitor; the side port of the three-way exhaust pipe is connected with one end of an oil inlet pipe; the oiling system is characterized by further comprising a distribution pipe; the distribution pipe and the oiling groove are distributed in the same direction; the distribution pipe is not higher than the side port; and the other end of the oil inlet pipe and the general oiling pipe are respectively connected with the distribution pipe. After the structure is adopted, oil in the oiling groove, the three-way exhaust pipe, the oil inlet pipe and the distribution pipe can be recycled through an oil pump for the distribution pipe or a vacuum oil absorption manner after oiling and before taking out the capacitor from a tank; therefore, the oiling system disclosed by the invention is very simple in structure, convenient to recycle oil, low in waste and free from environmental pollution; and thus, the oiling system disclosed by the invention is worthy of being popularized and applied in the existing capacity industry.

Owner:宁波海融电器有限公司

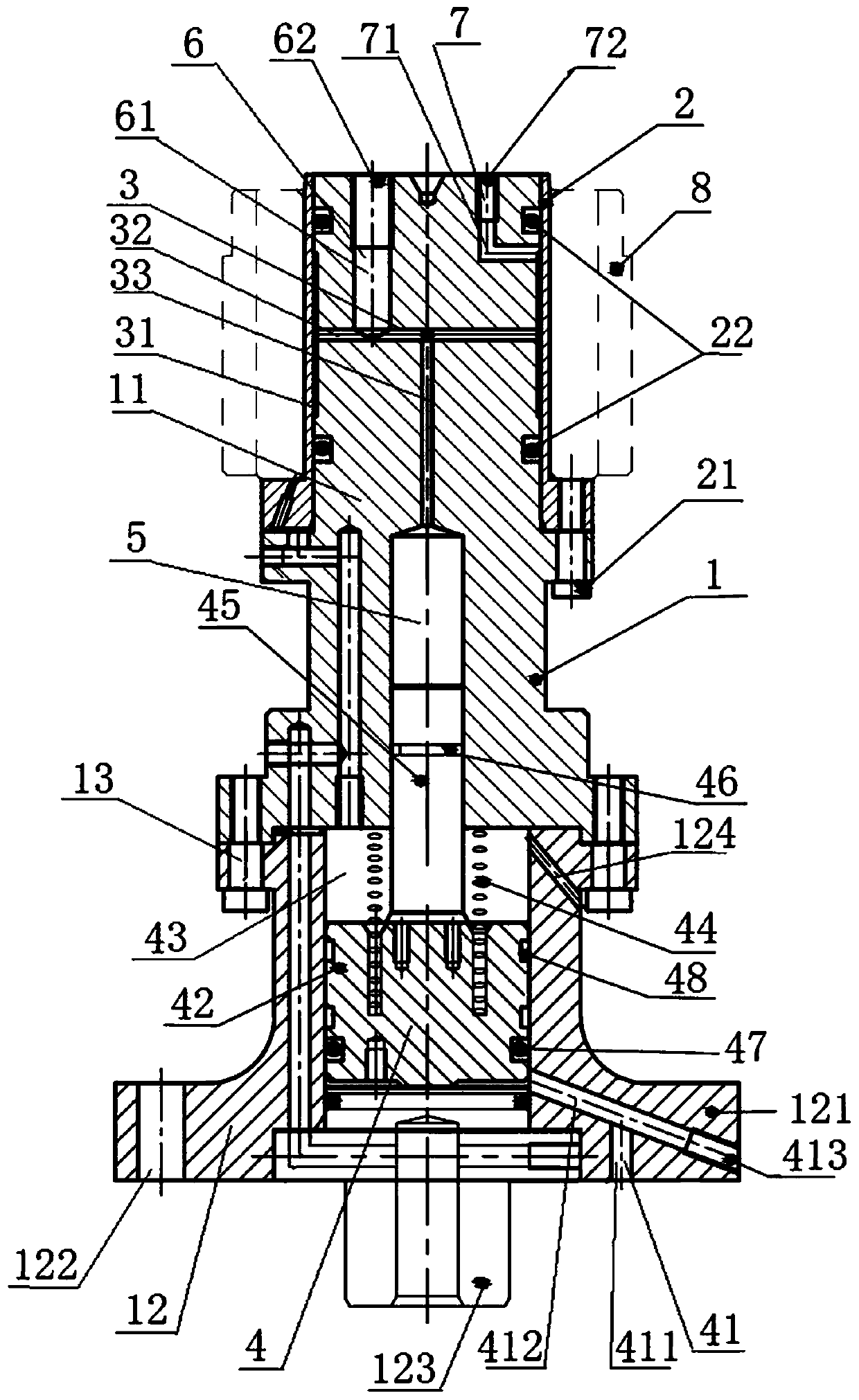

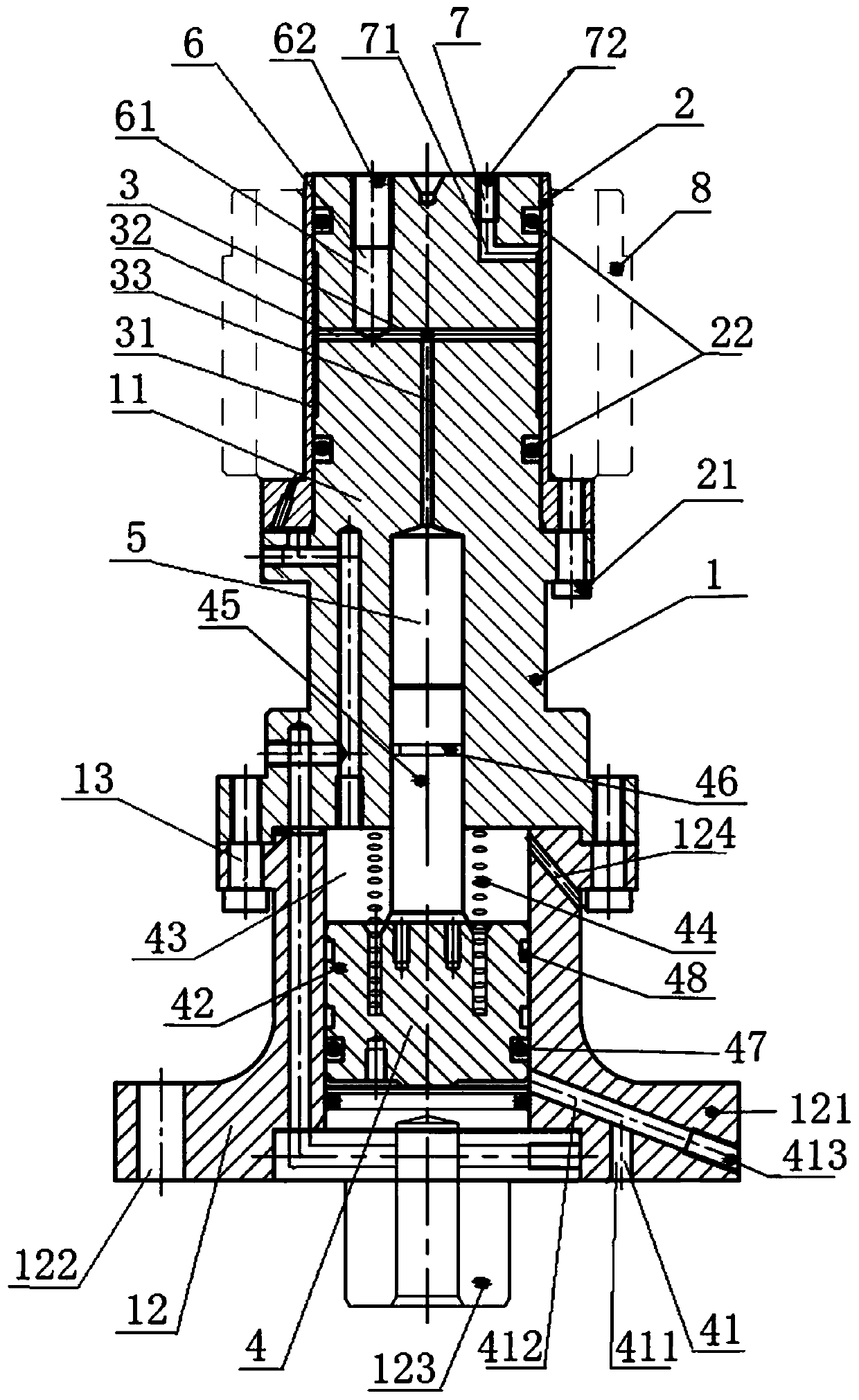

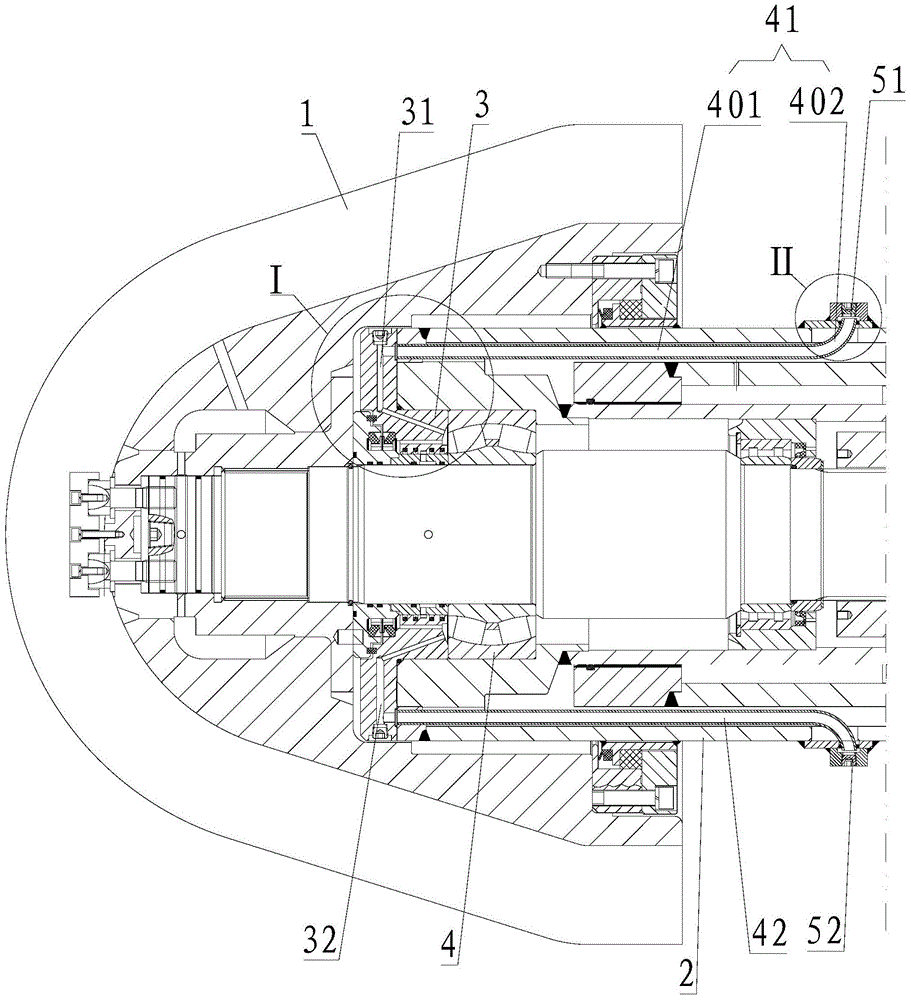

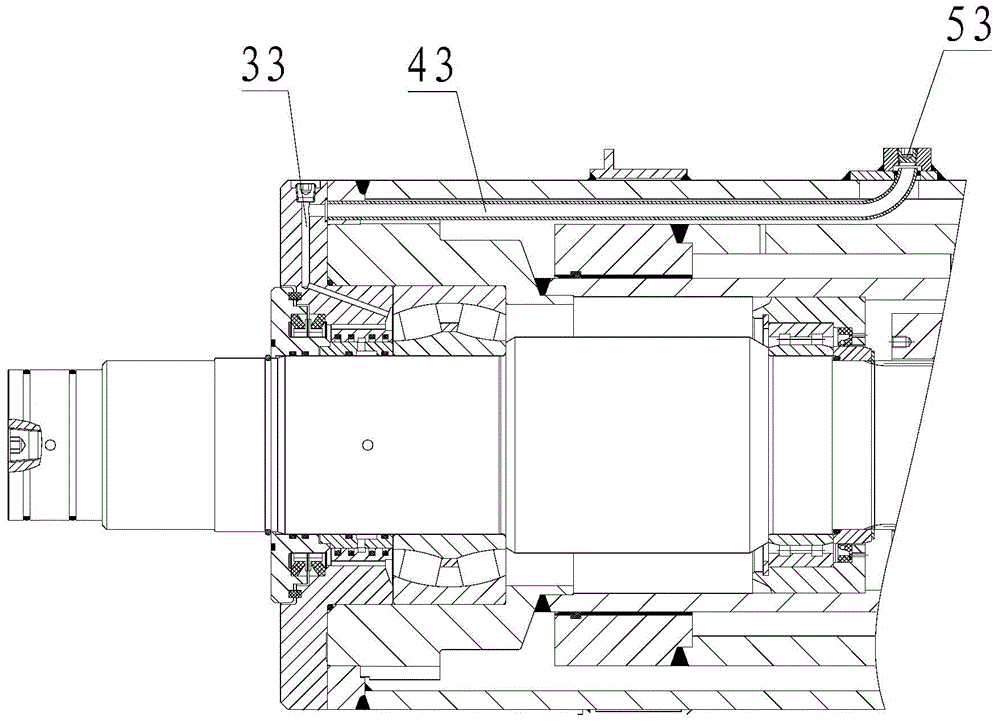

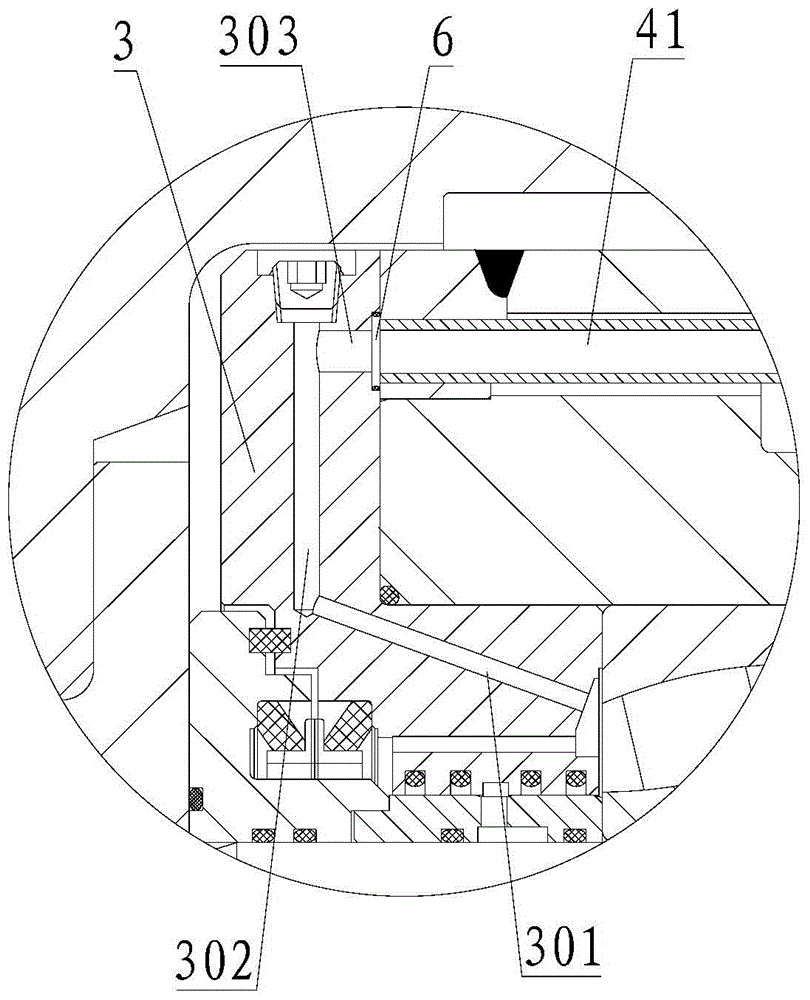

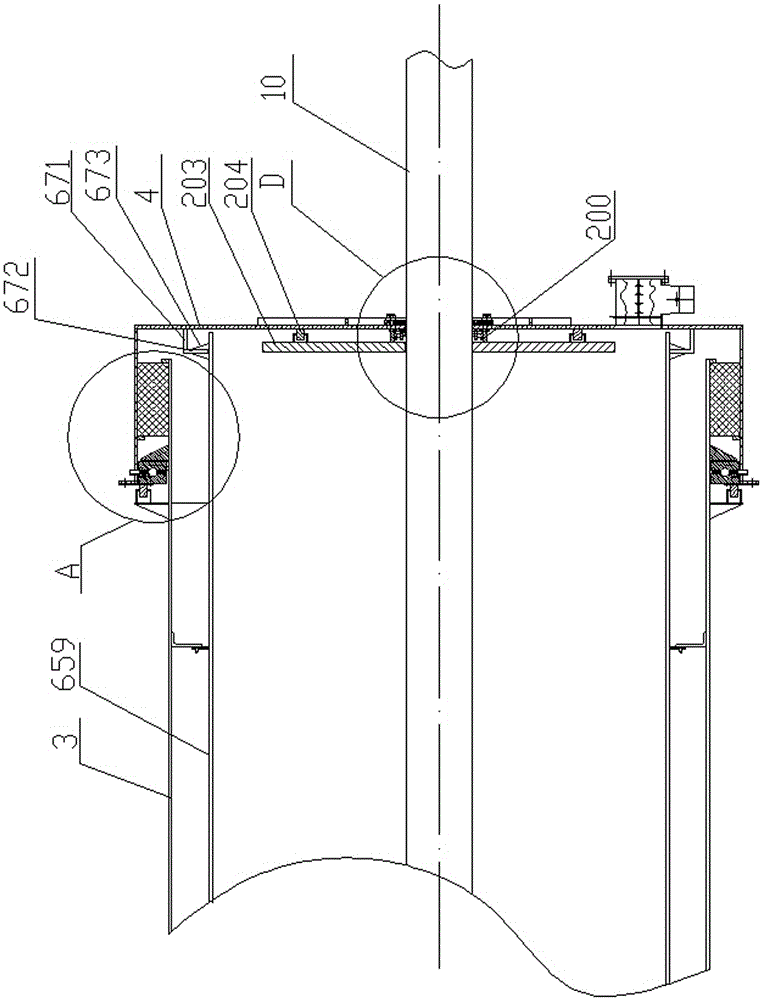

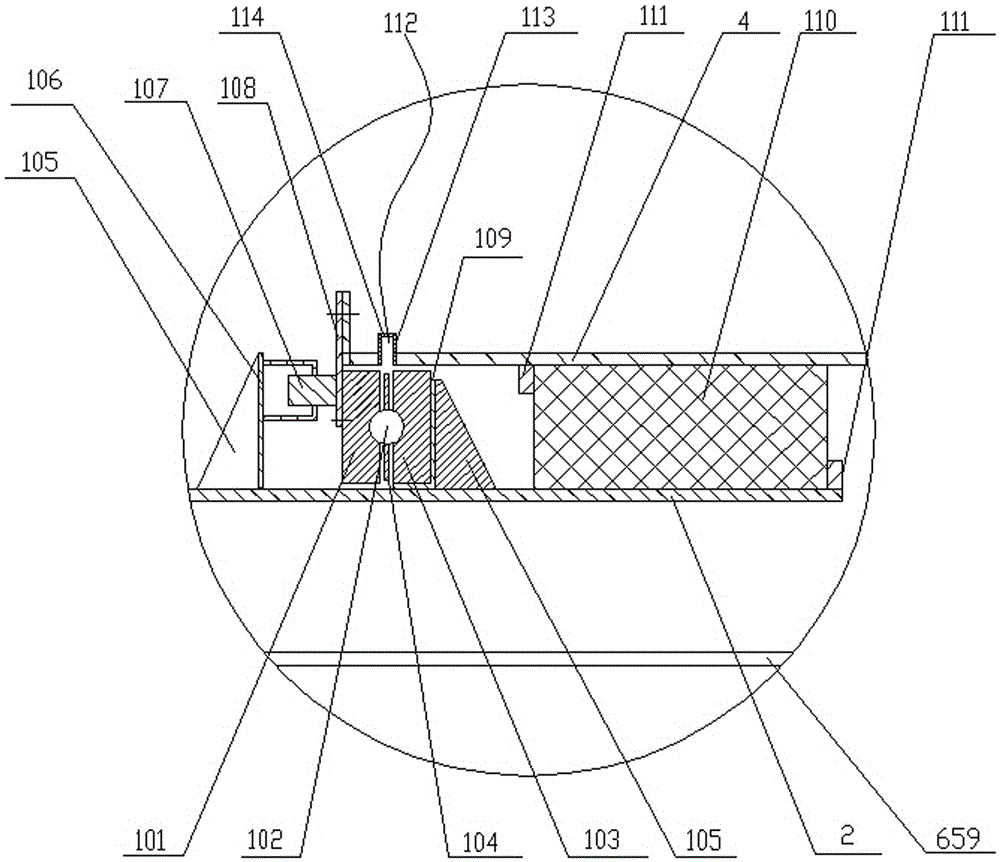

Cutting mechanism and heading machine

ActiveCN104453888AEasy to fill oilEasy to operateTunnelsCutting machinesEngineeringPetroleum engineering

The invention discloses a cutting mechanism and a heading machine. The cutting mechanism comprises a cutting head, a telescopic part, a bearing and a floating sealing frame, wherein an oil inlet path, an oil outlet path and an oil overflow path are formed in the floating sealing frame; the oil inlet path, the oil outlet path and the oil overflow path are communicated with a bearing cavity of the bearing; the cutting mechanism further comprises an oil inlet pipeline, an oil outlet pipeline and an oil overflow pipeline which are positioned between a telescopic protective barrel and a telescopic outer barrel of the telescopic part, or formed in the barrel wall of the telescopic protective barrel; one ends of the oil inlet pipeline, the oil outlet pipeline and the oil overflow pipeline respectively correspondingly communicated with the oil inlet path, the oil outlet path and the oil overflow path, and the other ends of the oil inlet pipeline, the oil outlet pipeline and the oil overflow pipeline are communicated with the outer part of the telescopic protective barrel; an oil inlet sealing part, an oil outlet sealing part and an oil overflow sealing part which are respectively arranged on end openings of the other ends of the oil inlet pipeline, the oil outlet pipeline and the oil overflow pipeline are used for selectively communicating or sealing the corresponding pipelines with the outside. The cutting mechanism has the advantages of convenience in oil injecting operation and oil exhausting operation, and the service life of the bearing is prolonged.

Owner:SANY HEAVY EQUIP

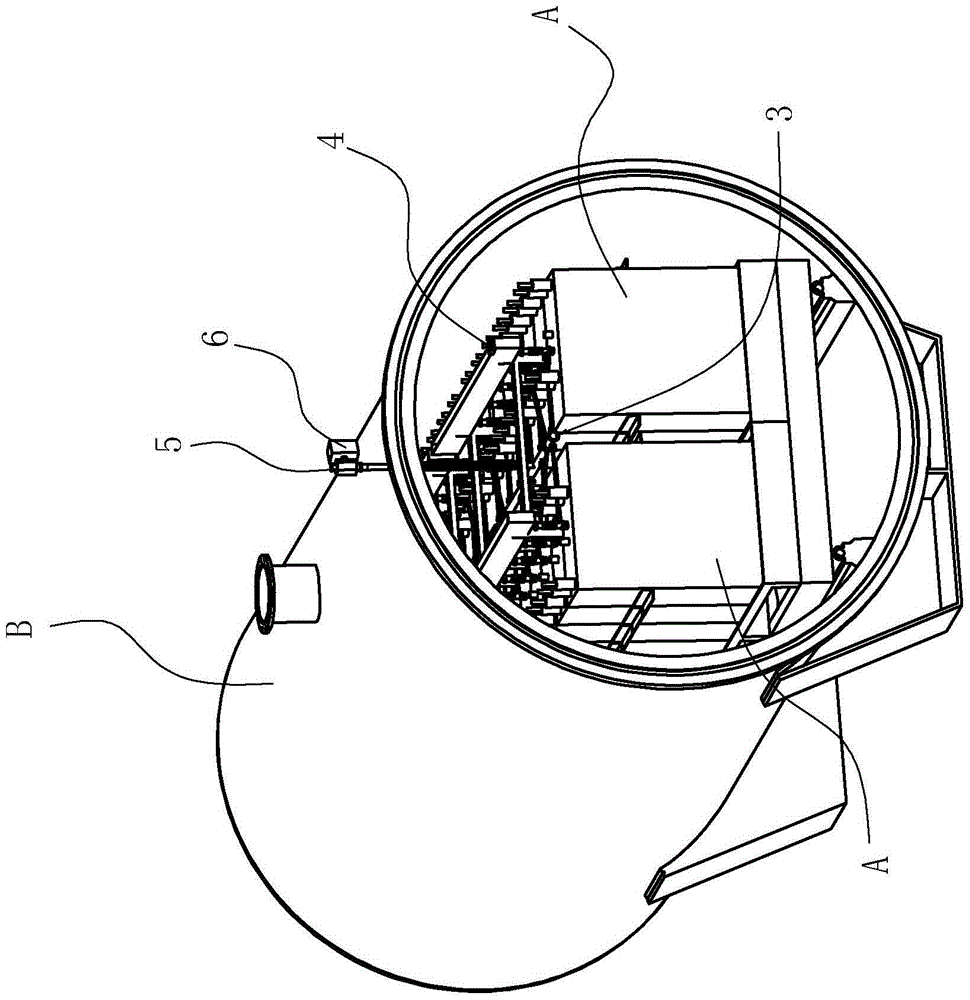

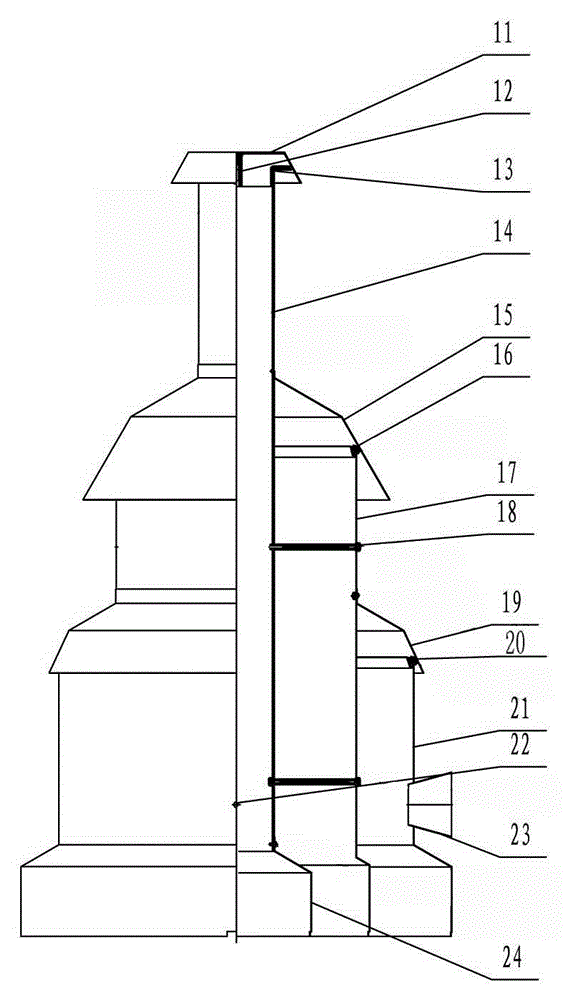

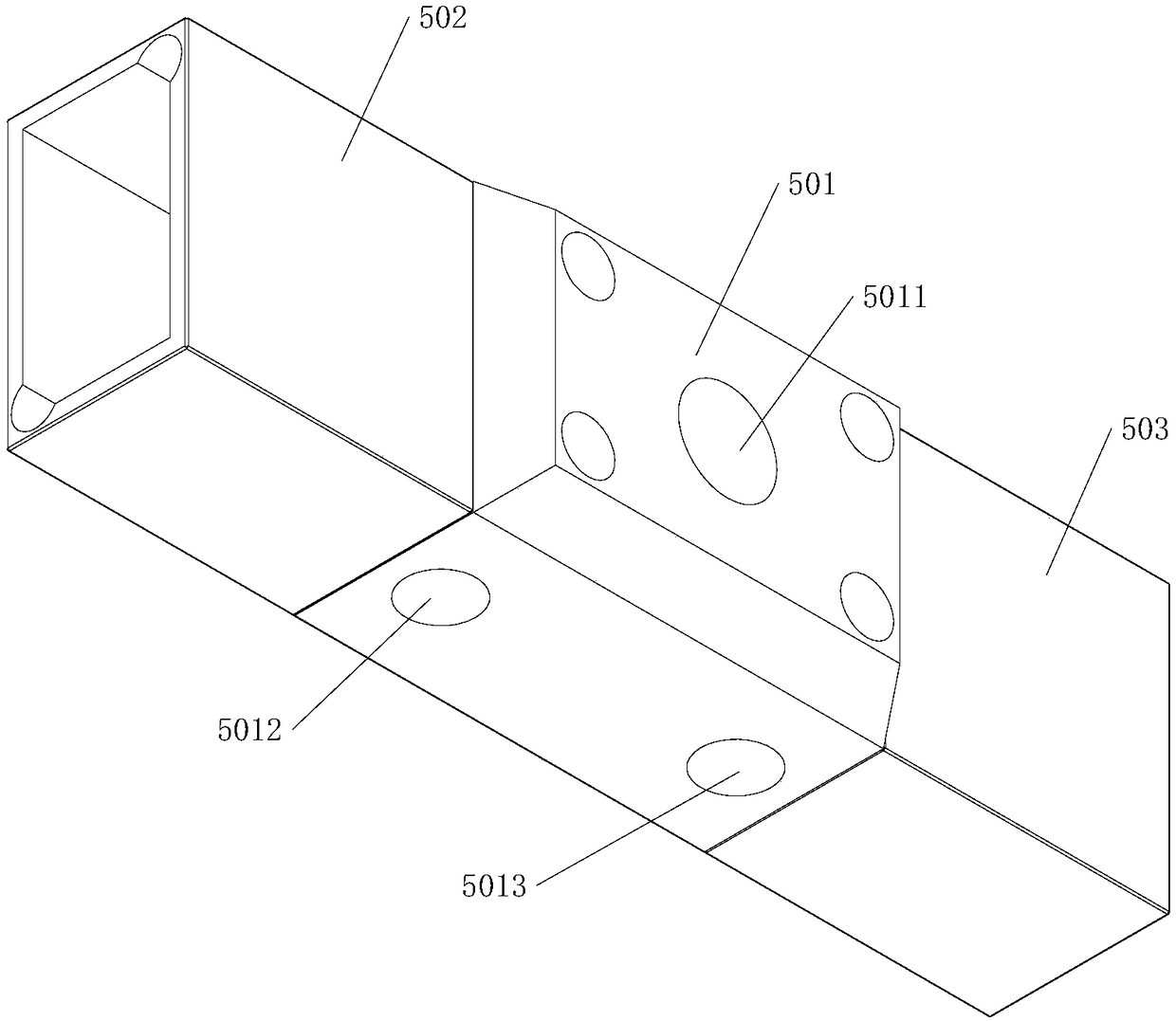

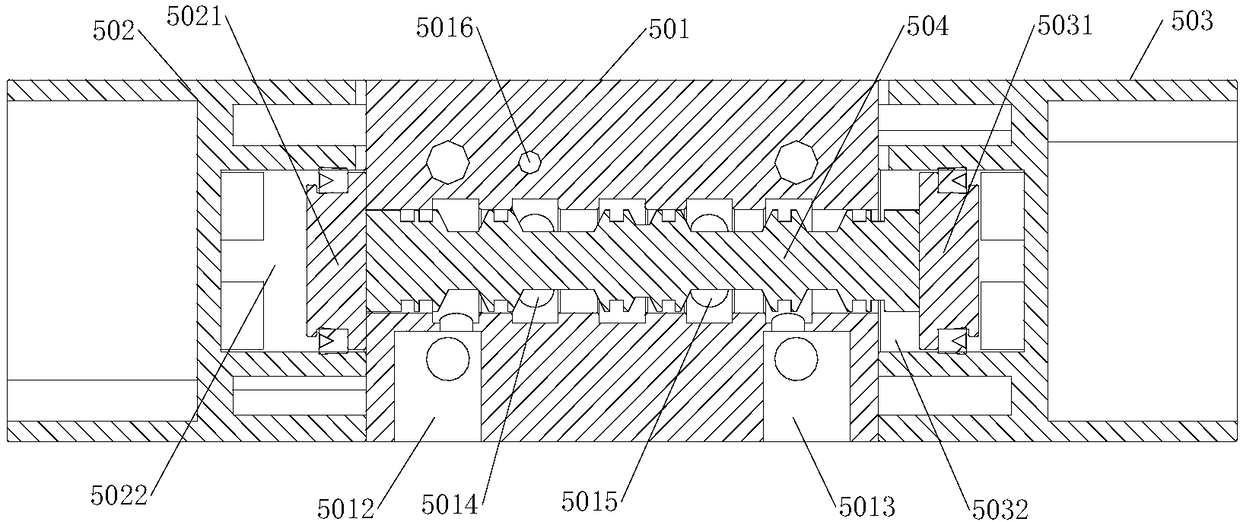

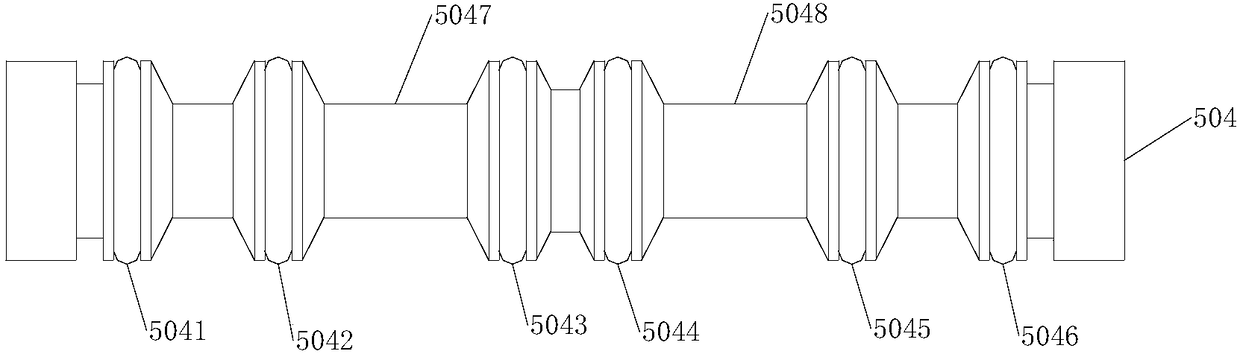

Large-caliber high vacuum oil diffusion pump

ActiveCN104989679ACompact structureShort heating timeMachines/enginesDiffusion pumpsElectricityCore component

The invention discloses a diffusion pump, and particularly relates to a large-caliber high vacuum oil diffusion pump, which is suitable for a vacuum furnace and a vacuum coating machine. The large-caliber high vacuum oil diffusion pump comprises a pump body, and a pump core component arranged in the pump body, wherein a heater is arranged at the bottom of the pump body; an oil stop device is arranged in an exhaust port of the pump body; the pump body adopts a convex cavity structure; the pump core component is vertically mounted in a center oil tank in the pump body, and is formed into an integral structure by a first-stage guide pipe, a second-stage guide pipe and a third-stage guide pipe arranged in sequence from inside to outside; umbrella cap-shaped diffusion nozzles are respectively arranged at the upper parts of all the guide pipes; a spraying nozzle is vertically welded at the bottom of the third-stage guide pipe; the first-stage guide pipe is higher than the second-stage guide pipe; and the second-stage guide pipe is higher than the third-stage guide pipe. The large-caliber high vacuum oil diffusion pump has the characteristics of large caliber, high limit vacuum degree, high pumping rate, low oil return rate and low electricity consumption.

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

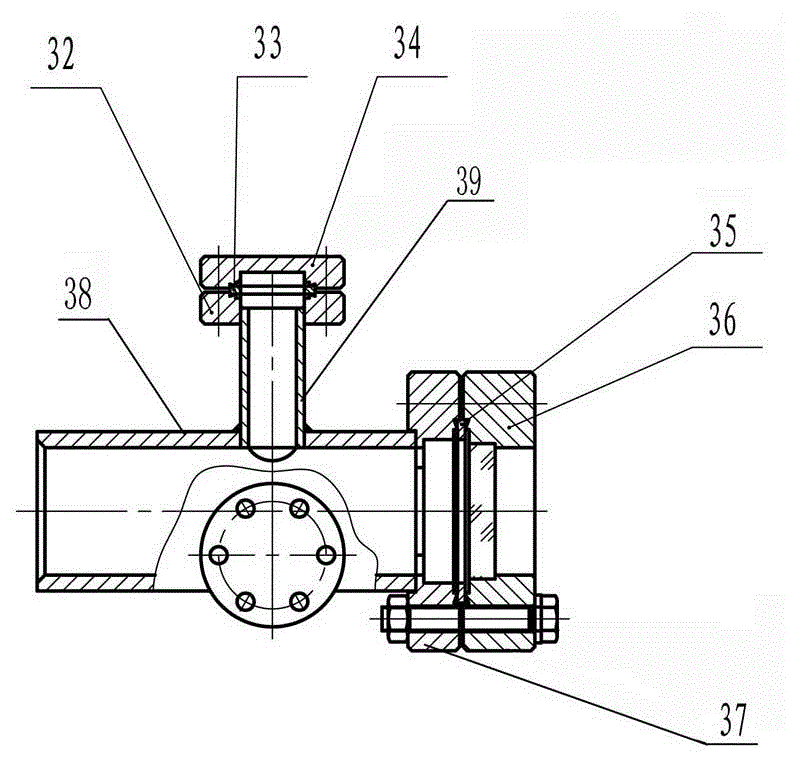

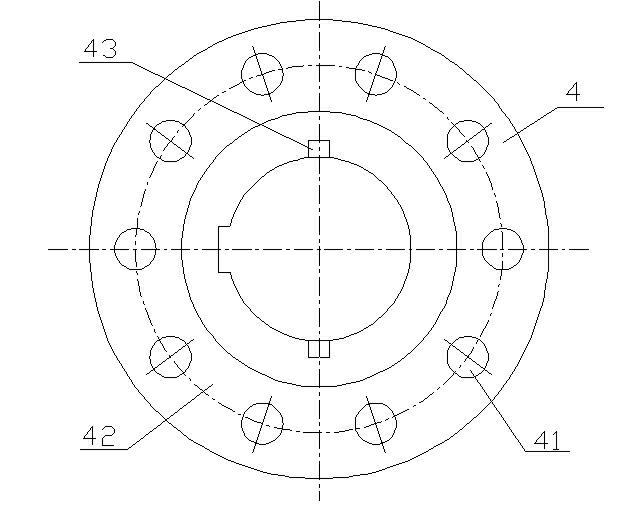

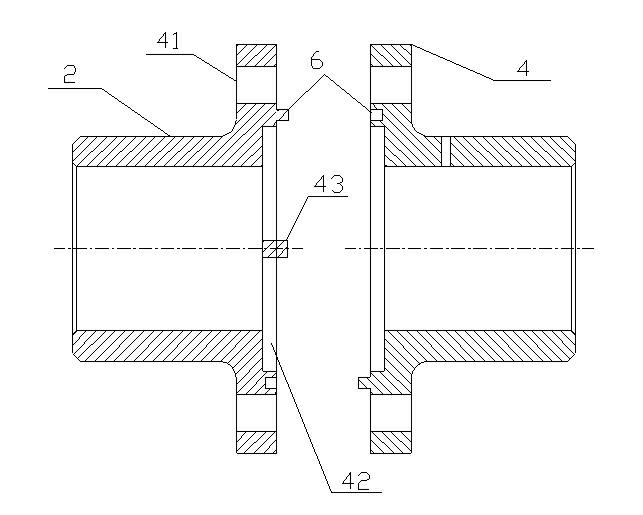

Coupling for stirring device

InactiveCN102644672APrecise positioningNot easy to pop outCouplings for rigid shaftsEngineeringDrive shaft

The invention relates to a coupling for a stirring device. A driving shaft and a driven shaft which are used for being connected with the stirring device rotate jointly so as to transmit torque. The coupling comprises two hollow half-coupling barrels, one end of each half-coupling barrel is provided with a boss extending outwards from a side wall of the barrel, and the two bosses are provided with fixing holes corresponding to each other. The coupling is characterized in that identical annular grooves are arranged on planes of the two bosses, and at least one axial limiting protrusion is arranged in the annular grooves. The grooves for placing annular elastic pieces are arranged in the bosses of the coupling, simultaneously the limiting protrusion is arranged, the positioning action on the elastic pieces is enhanced, the elastic pieces are fixed easily in installation, and the elastic pieces cannot jump out easily in dismantling so that the loss is avoided. Inserting structures matched with each other can be arranged on the two half couplings, assist a thread connecting piece in enlarging friction between the two half couplings, and reduce stress and consumption of the thread connecting piece.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

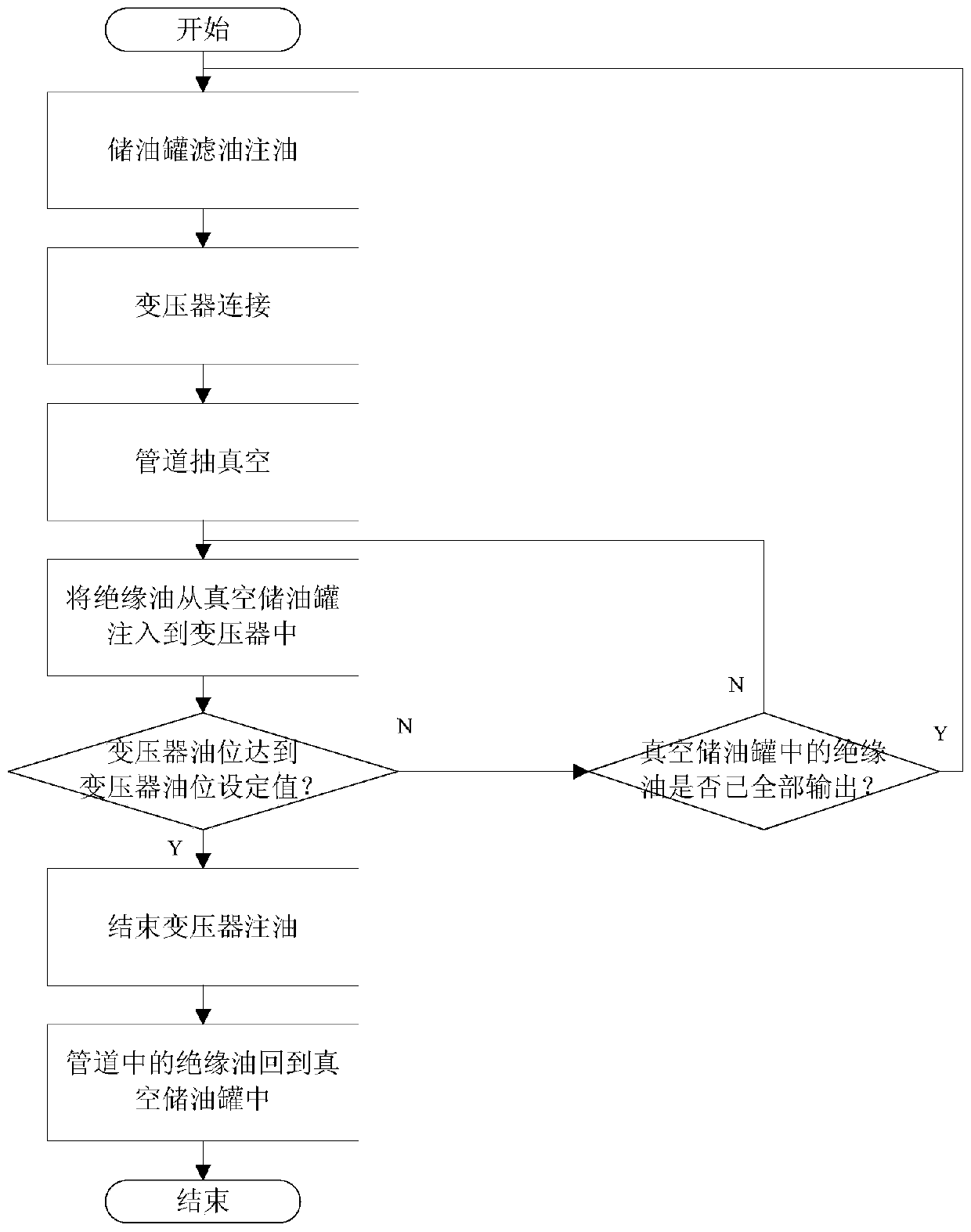

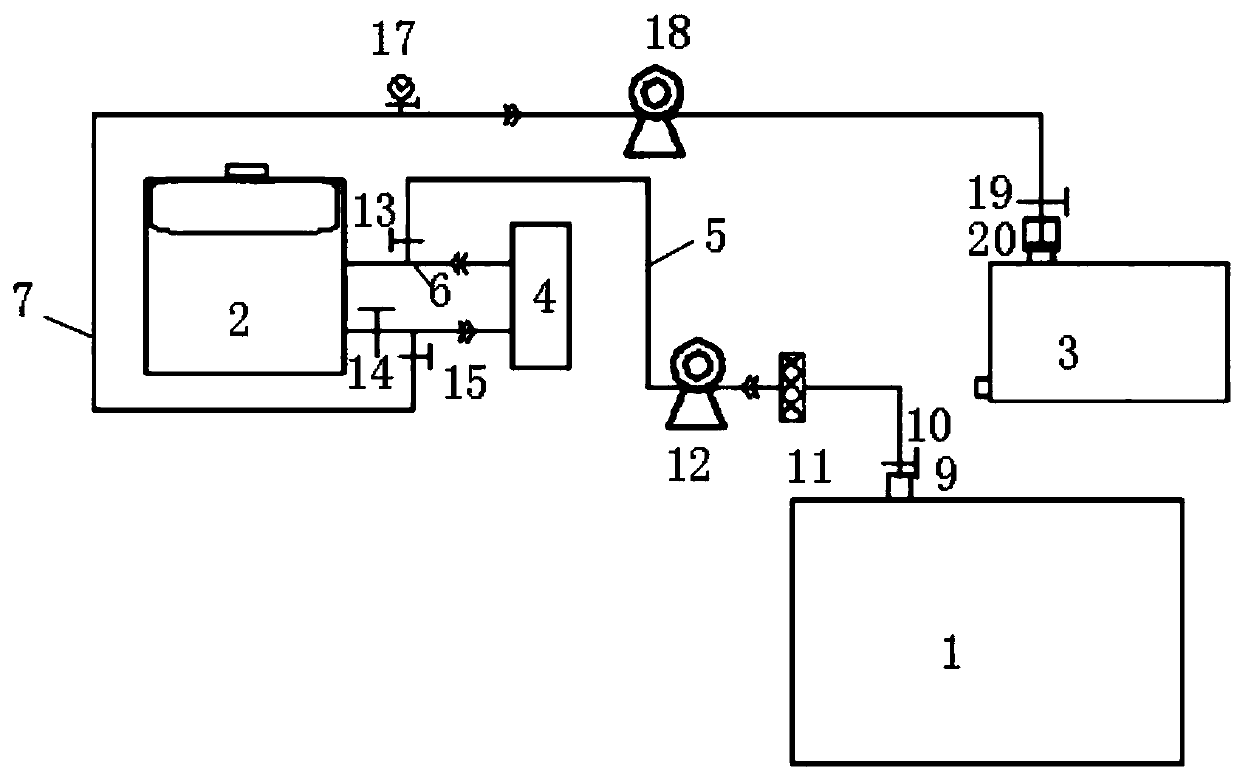

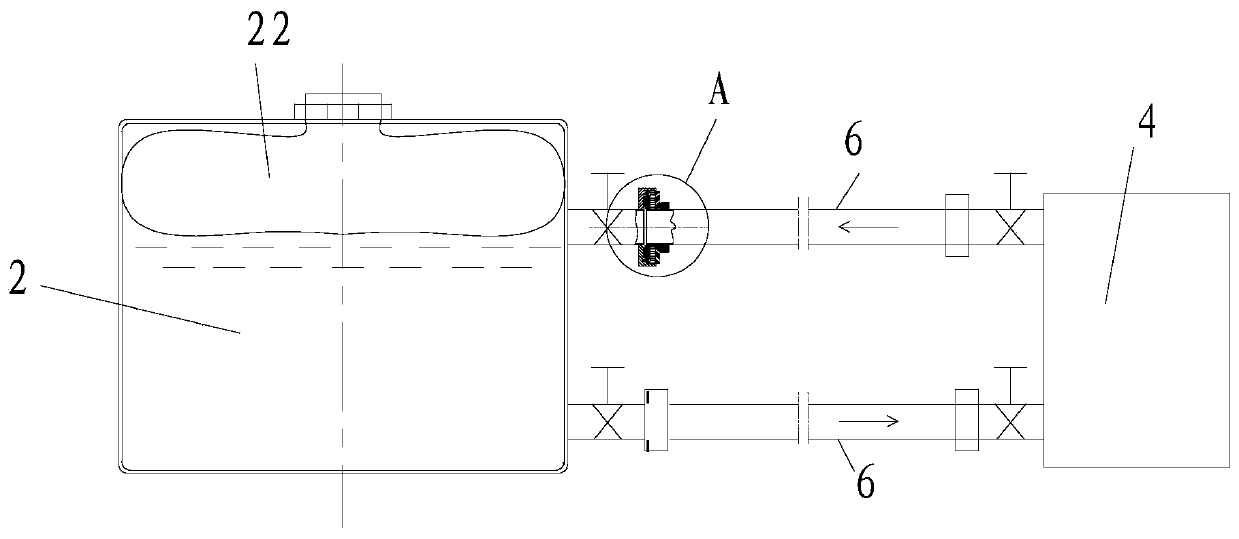

Vacuuming oiling method for transformer, and equipment for realizing the method

PendingCN109741926AGuaranteed qualityPrevent spoilageTransformers/inductances coolingInductances/transformers/magnets manufactureTransformerProcess engineering

The invention provides a vacuuming oiling method for a transformer, comprising: an oil filtering and oiling process of a storage tank, a connection process of the transformer, an oiling process of thetransformer, and an oil returning process, wherein the oil filtering and oiling process of the storage tank comprises vacuum filtering and storing the insulating oil in the vacuum storage tank; the connection process of the transformer comprises connecting the vacuum storage tank to the transformer through an adapter for vacuuming the pipeline; the oiling process of the transformer comprises injecting the insulating oil into the transformer from the vacuum storage tank; and the oil returning process comprises returning the insulating oil in the pipeline between the adapter and the vacuum storage tank to the vacuum storage tank. The method can remove impurities in the insulating oil, keep the oiling environment in an extremely high vacuum state, and insulate the air from the insulating oilto prevent the insulating oil from deteriorating. The invention also provides vacuuming oiling equipment for a transformer for realizing the vacuuming oiling method for the transformer.

Owner:GUANGDONG CHAMPON ELECTRIC CO LTD

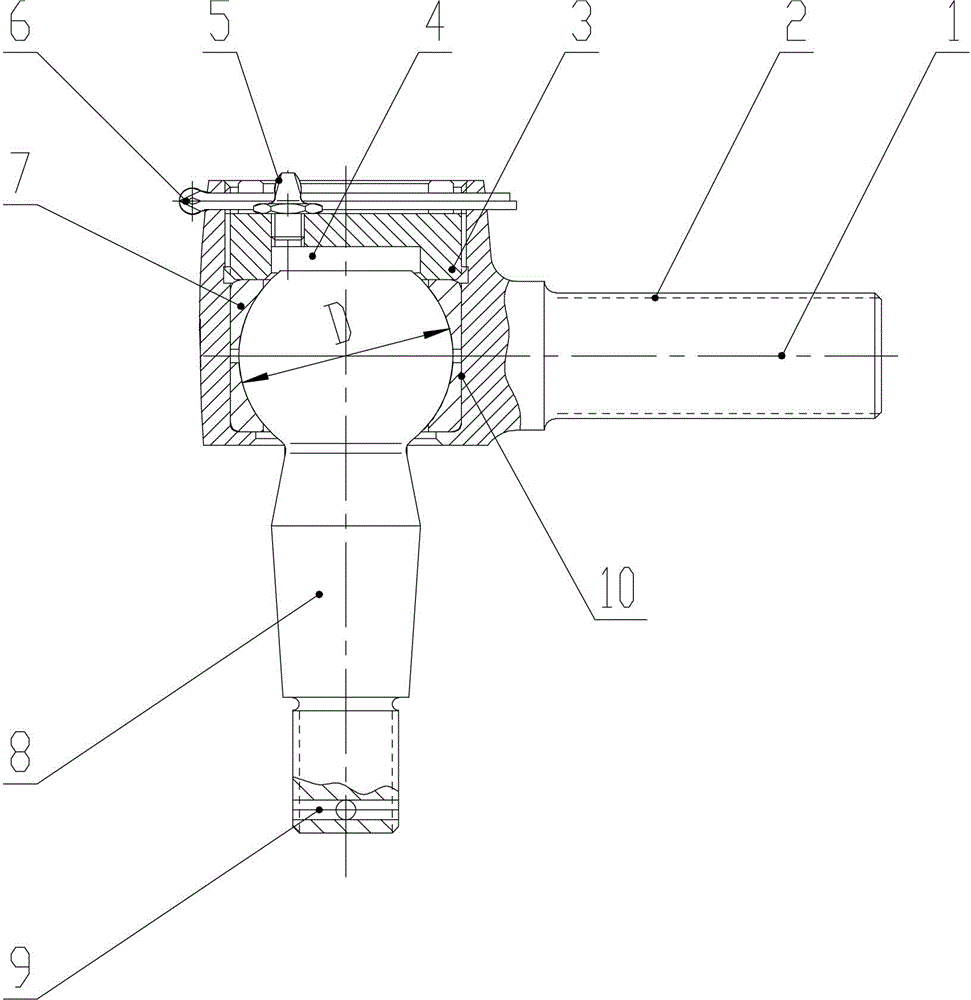

Mining truck tie rod catching handle assembly

InactiveCN104675847AImprove the lubrication effectPrevent looseningSteering linkagesPivotal connectionsEngineeringTruck

The invention discloses a mining truck tie rod catching handle assembly. The mining truck tie rod catching handle assembly is provided with a catching handle, wherein a mounting hole is formed in the catching handle, a spherical wrist is arranged in the mounting hole, a ball pin is arranged in the spherical wrist, and an adjusting cover for pressing the ball pin is arranged at the top part of the mounting hole. The mining truck tie rod catching handle assembly is characterized in that an oil inlet groove is formed in the adjusting cover, an oil nozzle is arranged at the top part of the adjusting cover, the oil nozzle is communicated with the oil inlet groove, and a cotter pin is also arranged between the adjusting cover and the catching handle. According to the mining truck tie rod catching handle assembly, oil can be filled conveniently, the ball pin and the spherical wrist can be lubricated well, the adjusting cover is prevented from being loosened, and the catching handle assembly is mainly applied to the mining truck tie rod catching handle assembly.

Owner:李德新

Reciprocating pneumatic valve, air cylinder with same and grease pump

PendingCN108386702ASimple structureThe overall structure is simple and reliableValve arrangementsLubricating pumpsOil and greaseEngineering

The invention relates to a pneumatic valve, in particular to a reciprocating pneumatic valve, an air cylinder with the reciprocating pneumatic valve and a grease pump. The reciprocating pneumatic valve comprises a main valve body, a reversing core rod, a left valve body and a right valve body. The left valve body and the right valve body are fixed to the two sides of the main valve body correspondingly. The reversing core rod is movably installed in a reversing core hole of the main valve body. The reciprocating pneumatic valve is simple in structure, reliable in operation, low in machining cost and convenient to use. The air cylinder achieves automatic reciprocating and is simple in structure and practical, a reversing valve and intake and exhaust channels are separated from a piston anddo not occupy the movement space of the piston, the air cylinder is rapid in response, small in occupied space, small in volume, low in manufacturing cost, low in energy consumption and long in service life, the seal effect of the air cylinder and the seal effect of the reciprocating pneumatic valve are good, and assembly and maintenance are convenient. The grease pump is simple and reliable in structure, achieves simultaneous oil suction and oil filling and is not prone to blockage, oil suction and oil filling are not influenced by the temperature, and the efficiency is high.

Owner:山东洁普斯自动化科技有限公司

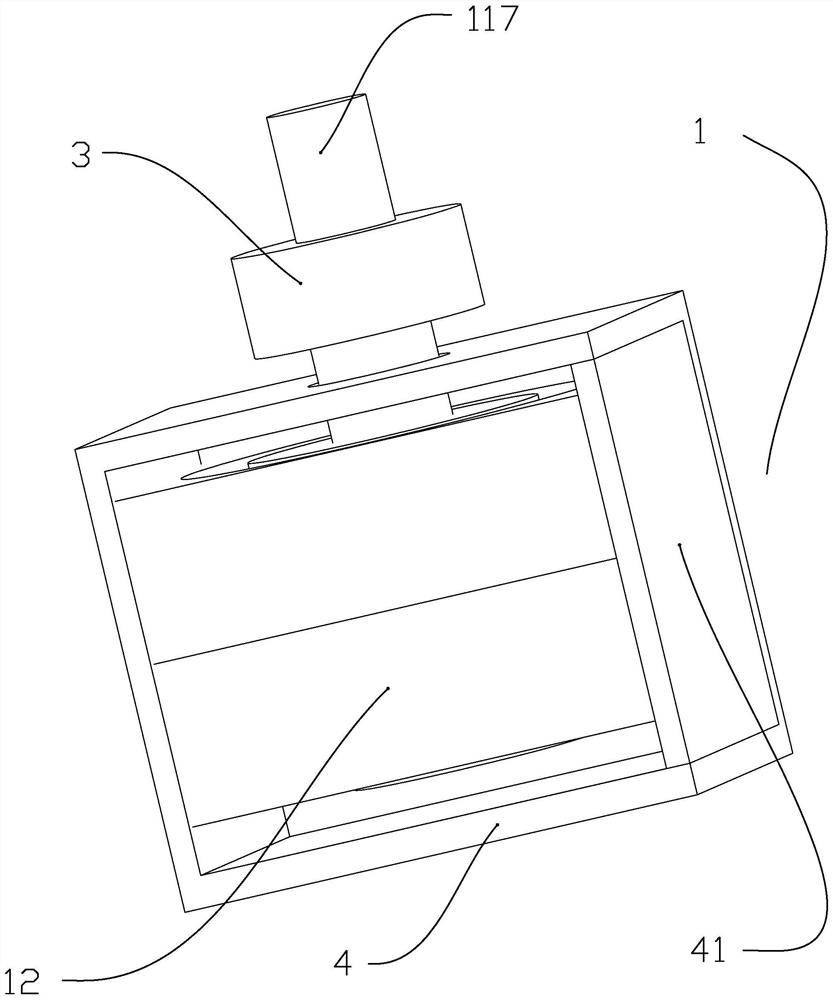

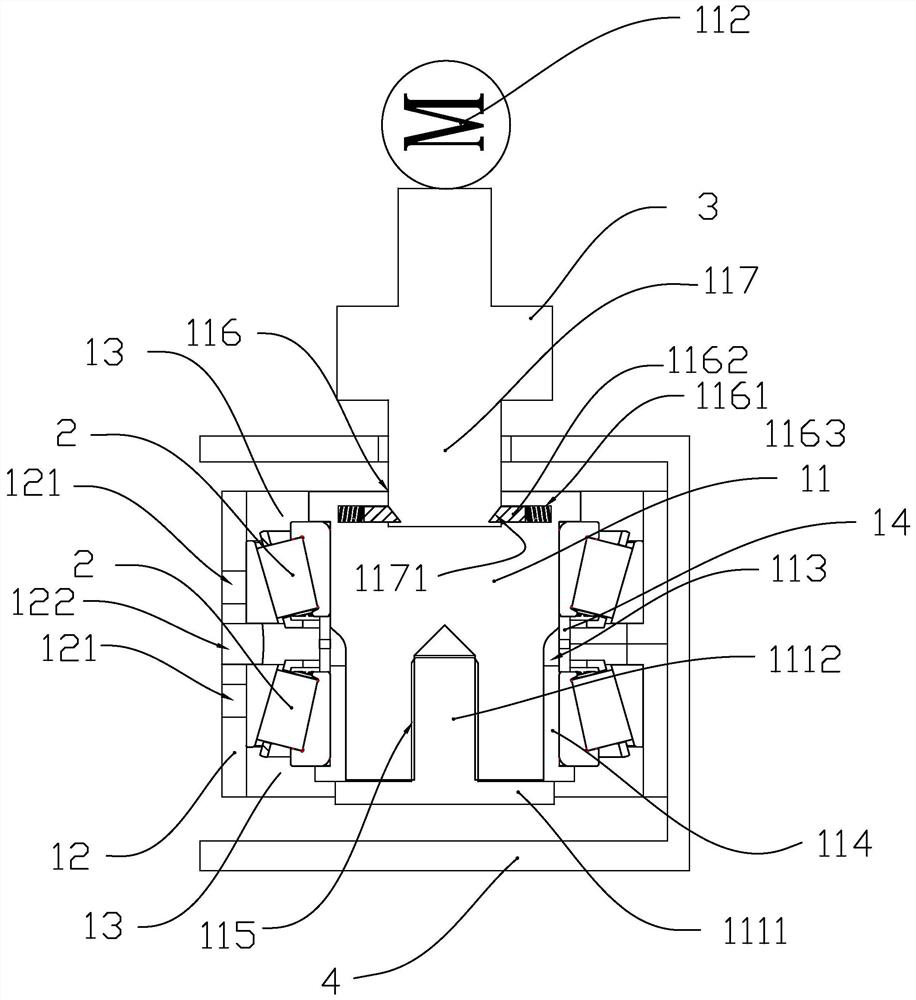

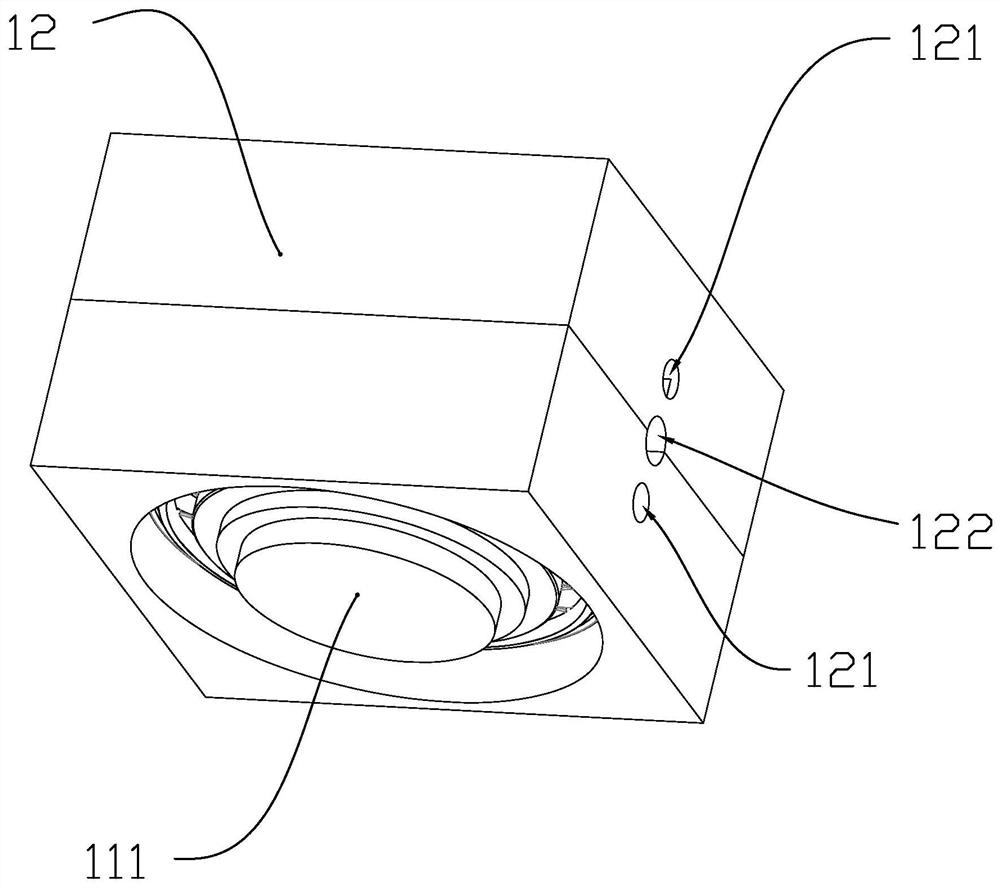

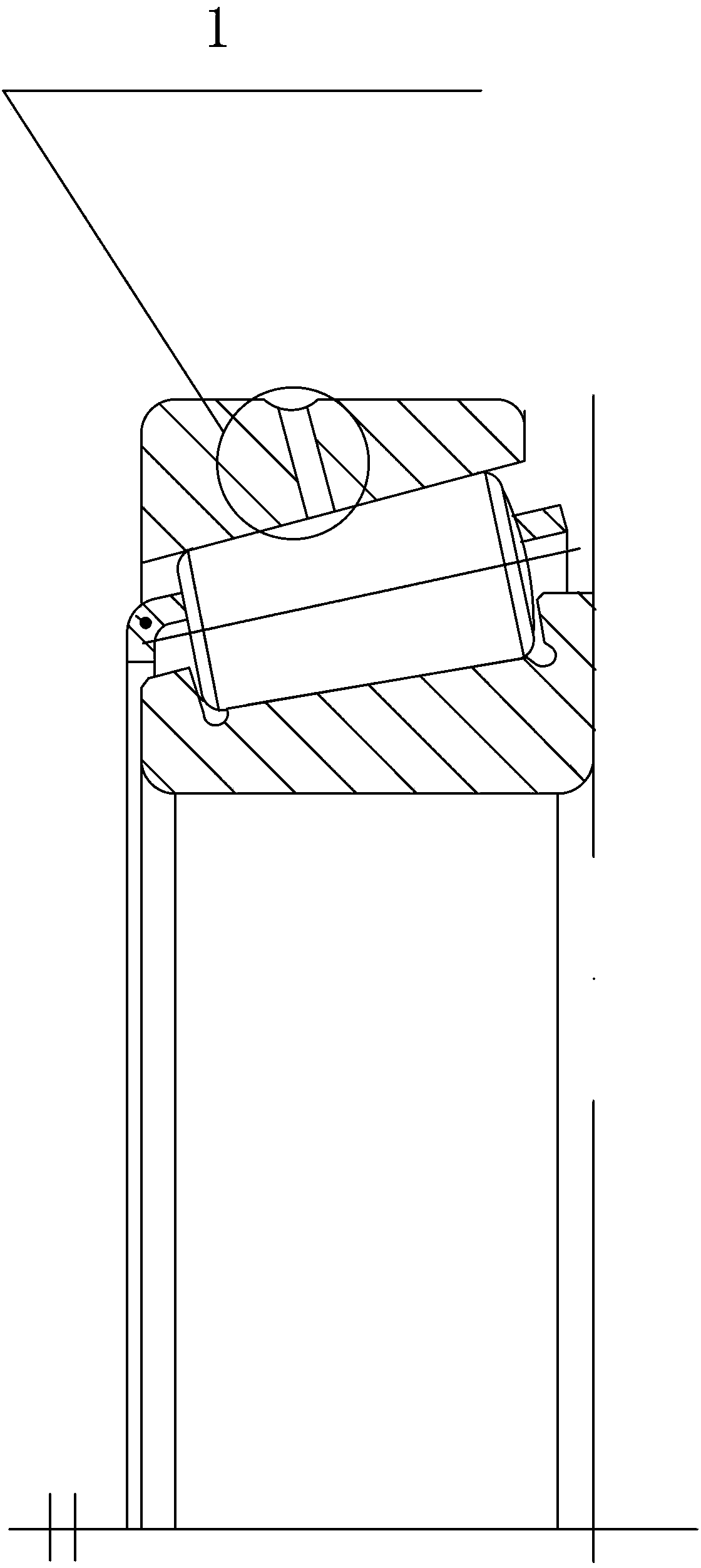

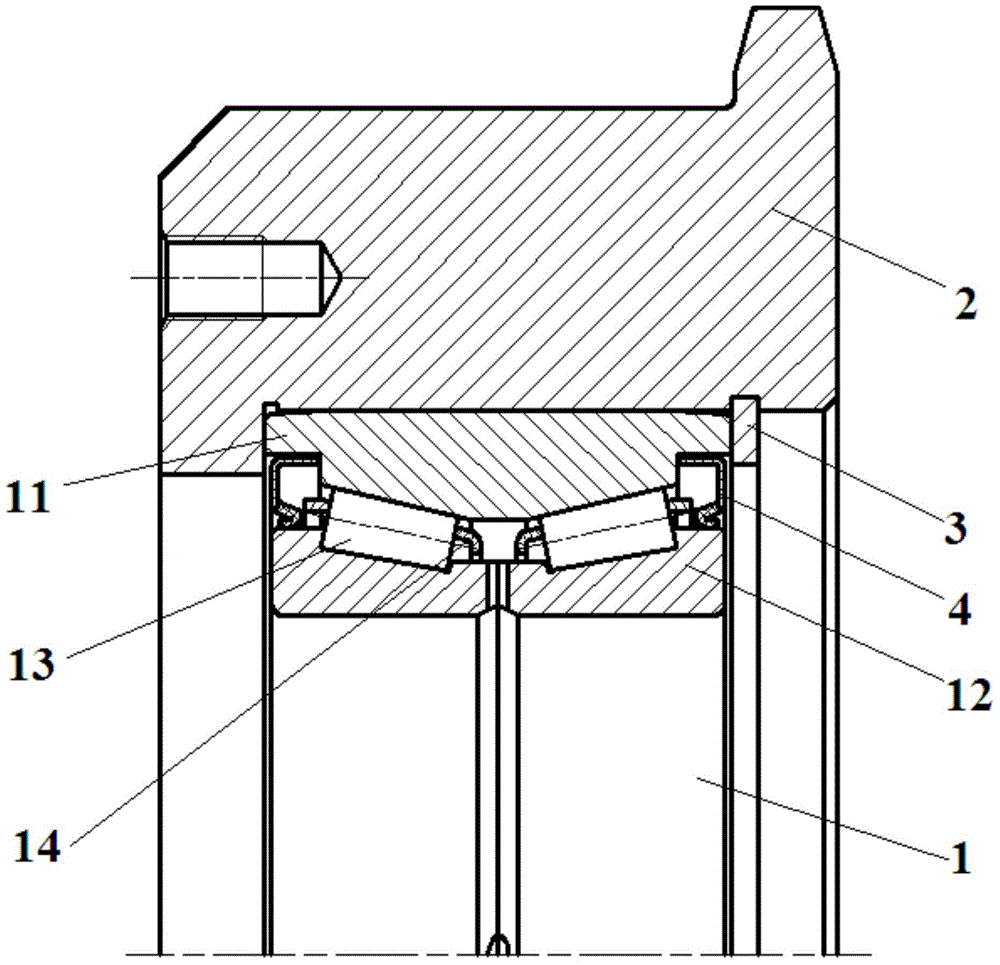

Prediction device for tapered roller bearing during configuration of pretightening force

InactiveCN112985677AEasy to fill oilEasy to installBearing assemblyMeasurement of torque/twisting force while tighteningElectric machineryEngineering

The invention relates to the technical field of bearings, and particularly discloses a prediction device for a tapered roller bearing during configuration of pretightening force. The prediction device comprises a bearing tool, the bearing tool comprises a core shaft for mounting a bearing to be measured and a shell matching an outer ring of the bearing to be measured, the core shaft is provided with two bearing mounting stations, one end of the core shaft is connected with a locking nut, the other end of the core shaft is connected with a motor, a torque sensor is arranged between the core shaft and the motor, a temperature measuring hole is formed in the shell, and a temperature sensor is arranged on the temperature measuring hole. With the adoption of the structure, the detection device for the tapered roller bearing during configuration of pretightening force is provided, and is used for detecting the influence of factors such as mounting fit, rigidity of a shaft and the shell, temperature and the like on a pretightening load in practical application; the influence caused by the lubricating oil, the flow of the lubricating oil and the shaft system temperature rise in the bearing operation process and the coupling effect of the temperature rise and the pretightening load are further detected.

Owner:C&U CO LTD +2

Closed double-layer barrel aerobic fermentation cylinder

InactiveCN105646013AReduce frictional resistancePrevent material leakageClimate change adaptationOrganic fertilisersTreatment effectEngineering

The invention discloses a closed double-layer barrel aerobic fermentation cylinder, comprising a support device, a barrel, a powder driving device, a ventilation device and a feeding and discharging system, wherein the barrel and the power driving device are respectively arranged on the support device; the barrel comprises a feeding fixed end cover, a middle rotating barrel and a discharging fixed end cover; the middle rotating barrel comprises an inner barrel and an outer barrel which are arranged along the same axial direction and are fixedly connected with each other by a connecting support plate; a material retaining seal structure is arranged between one end of the inner barrel of the middle rotating barrel and the feeding fixed end cover, and another material retaining seal structure is positioned between the other end of the inner barrel of the middle rotating barrel and the discharging fixed end cover; the feeding fixed end cover and the discharging fixed end cover are respectively connected with the middle rotating barrel by an end cover fixing device; each end cover fixing device comprises a rotation fixing structure and a rotation support structure. The closed double-layer barrel aerobic fermentation cylinder is simple in structure, high in working efficiency and degree of automation, reliable in operation and good in treatment effect, is free from odor spillover in the treatment process, and is capable of realizing harmless and resource utilization of kitchen wastes.

Owner:张共敏 +2

Grabbing mechanism for manipulator

InactiveCN113211474AFacilitate automatic oil fillingGuaranteed smooth grippingGripping headsFuel tankStructural engineering

The invention discloses a grabbing mechanism for a manipulator. The grabbing mechanism comprises a mounting frame, a supporting plate is fixedly connected to the lower surface of the mounting frame, an electric telescopic rod and a vacuum generator are arranged on the upper surface of the mounting frame, and the telescopic end of the electric telescopic rod penetrates through the supporting plate and is fixedly connected with an adsorption box; and a driving rod is rotatably connected to the surface of the adsorption box, a clamping rod is fixedly connected to the end face of the driving rod, a through opening is formed in the lower surface of the adsorption box, a vacuum suction cup is fixedly connected to the inner wall of the through opening, a proximity switch is arranged on the lower surface of the adsorption box, and an oil storage box is fixedly connected to the upper surface of the supporting plate. According to the grabbing mechanism for the manipulator, by arranging the adsorption box, the vacuum generator and the suction cup, objects can be adsorbed conveniently, by arranging the electric telescopic rod, the driving rod, the clamping rod and a concave block, the objects can be clamped conveniently, and therefore the grabbing mechanism can clamp the objects on the basis of adsorption of the suction cup, and stability of the objects during movement is guaranteed.

Owner:田和英

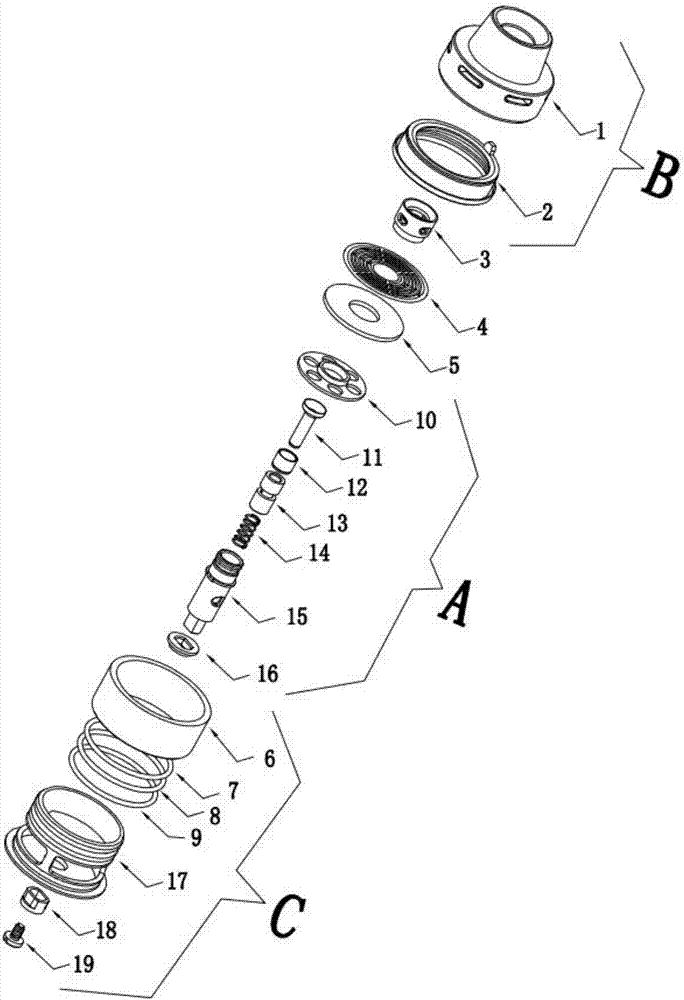

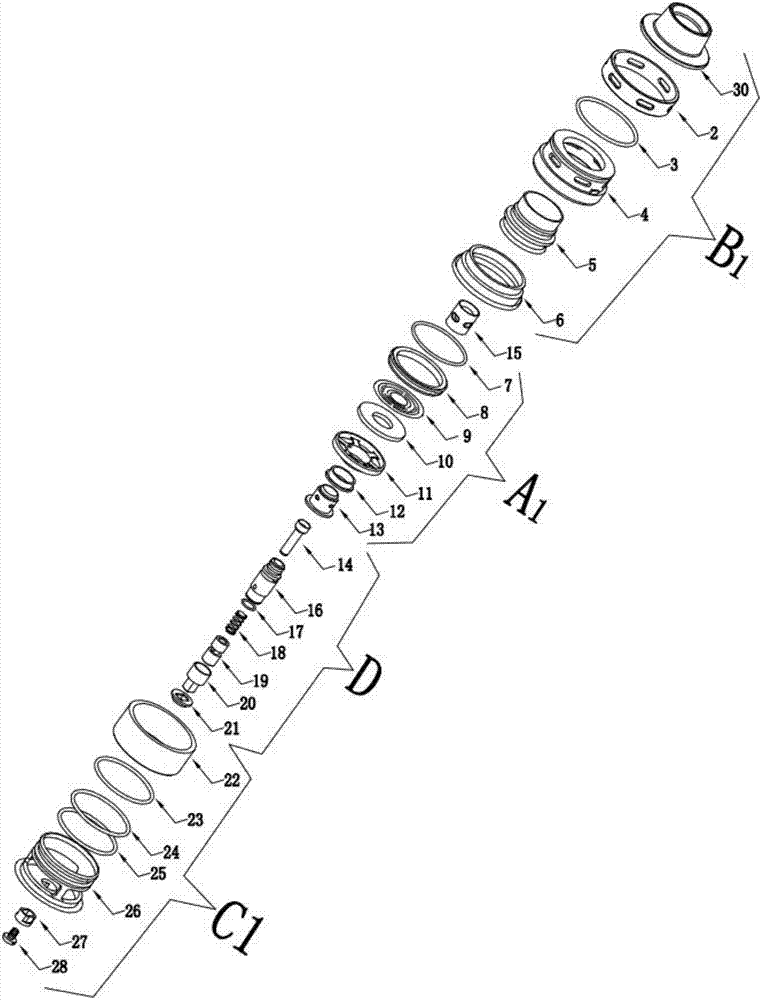

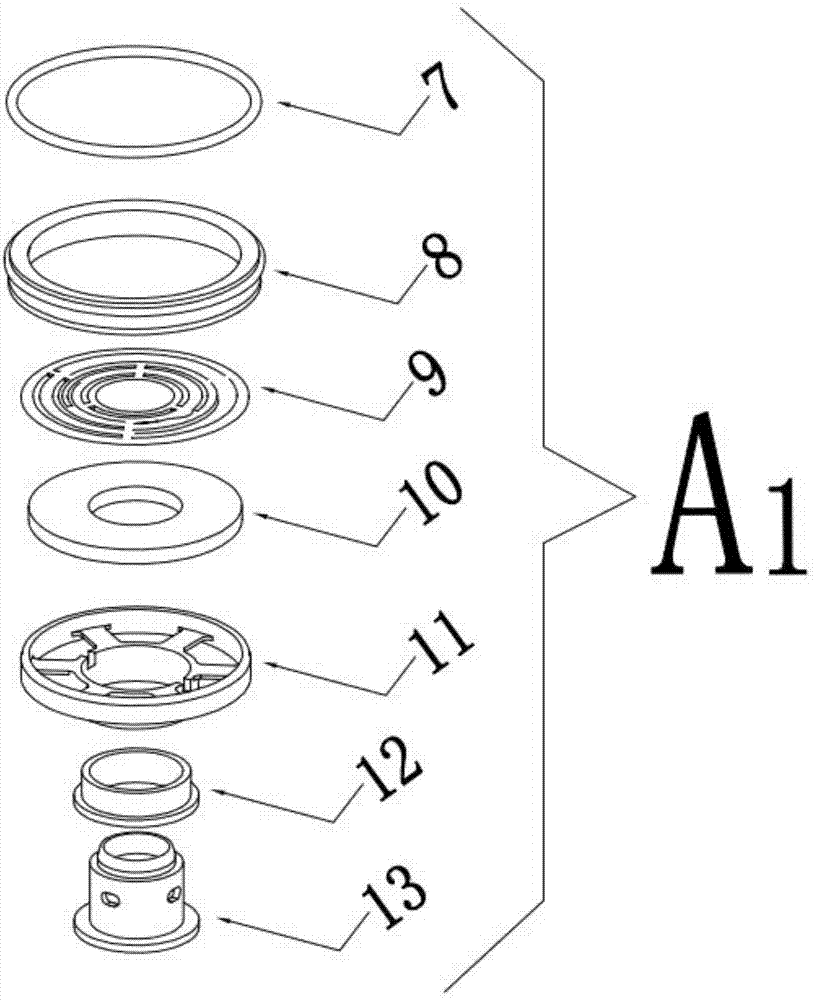

Atomizer of heating piece

The invention relates to an atomizer of a heating piece. The atomizer of the heating piece specifically comprises an atomizing core assembly A1, a cigarette holder assembly B, a cigarette holder assembly B1, a base assembly C, a base assembly C1, an oil injection assembly A and an oil injection assembly D. After adopting the above technical scheme, oil injection is convenient, a heating net is a composite series-parallel circuit made of a ring-shaped heating coil metal material, and can make a current conduct directional movement, and after the heating net is powered on, the current spreads from the inner ring of the heating net to the outer ring of the heating net, intersects with a negative pole at the outer ring and produces heat; the power is high, and the amount of produced smoke is big; the appearance of the atomizer and the heating piece is novel, and the purpose of a large amount of smoke and good taste can be achieved.

Owner:SHENZHEN EIGATE TECH CO LTD

Supporting idler wheel bearing

InactiveCN102182757AUnique structureIncrease distanceRoller bearingsBearing componentsLubricationWater jet

The invention relates to a supporting idler wheel bearing which comprises an outer ring, an inner ring and two rows of rollers, wherein the two rows of rollers are arranged between the inner ring and the outer ring and are separated from each other with certain distance; the inner ring is provided with an oil injection hole and corresponds to the interval space between the two rows of rollers; and the length of the roller is 4mm and the outer diameter of the roller is 4mm. The supporting idler wheel bearing has an unique structure; as the two rows of rollers are arranged at intervals, the frictional resistance is avoided; as the size of the roller is reduced, the distance among the rollers can be enlarged, and as the inner ring is provided with the oil injection hole, oil can be injected and stored conveniently, the lubrication effect is good, the service life of the bearing is prolonged by one time compared with a traditional bearing; and the supporting idler wheel bearing is mainly applied on a water pump of a water-jet loom cam.

Owner:上海川野精密轴承有限公司

Stainless steel plate bending machine

InactiveCN108176738ARegulatory useImprove adaptabilityShaping toolsShaping safety devicesArchitectural engineeringAtmospheric pressure

The invention discloses a stainless steel plate bending machine. The stainless steel plate bending machine comprises a base, a bending die, support pillars, a top beam, pressure cylinders, telescopicrods and a bending cutter, wherein the support pillars are arranged on two sides of the upper part of the base; the top beam is arranged at the upper ends of the support pillars; the pressure cylinders are arranged on the top beam; the telescopic rods are arranged at the lower parts of the pressure cylinders; the lower ends of the telescopic rods are connected with the bending cutter; the bendingdie is arranged under the bending cutter; sliding blocks are arranged under the bending die; sliding rails are arranged under the sliding blocks; a balancing plate is arranged under the sliding rails;a vibration reduction seat is arranged under the balancing plate; vibration reduction springs are arranged in the vibration reduction seat. The stainless steel plate bending machine is simple in structure and novel in design; a bending groove I, a bending groove II and a bending groove III are formed in the stainless steel plate bending machine; the bending angles can be adjusted according to thedifference of machining processes; the adaptability of the stainless steel plate bending machine can be effectively improved; the stainless steel plate bending machine has a high value of popularization.

Owner:JIANGSU TAI TONG NEW MATERIAL CO LTD

Deep groove ball bearing allowing grease to be added therein

InactiveCN107605954AEasy to operateOiling in timeBearing componentsBall bearingPetroleum engineering

The invention relates to the technical field of bearings, and discloses a deep groove ball bearing allowing grease to be added therein. The deep groove ball bearing comprises an outer ring, an inner ring, a sealing ring and a plurality of balls; an oil groove extending in the peripheral direction of an inner ring rollaway nest is formed in the bottom of the inner ring rollaway nest, an oil injecting hole is formed in the inner ring, the oil inlet end of the oil injecting hole is located in an inner circle of the inner ring, the oil inlet end of the oil injecting hole is packaged through a sealing screw, and the oil outlet end of the oil injecting hole is communicated with the bottom of the oil groove. Oil injection can be carried out in time, and the deep groove ball bearing is suitable for use in a heavy load occasion.

Owner:镇江金利源轴承有限公司

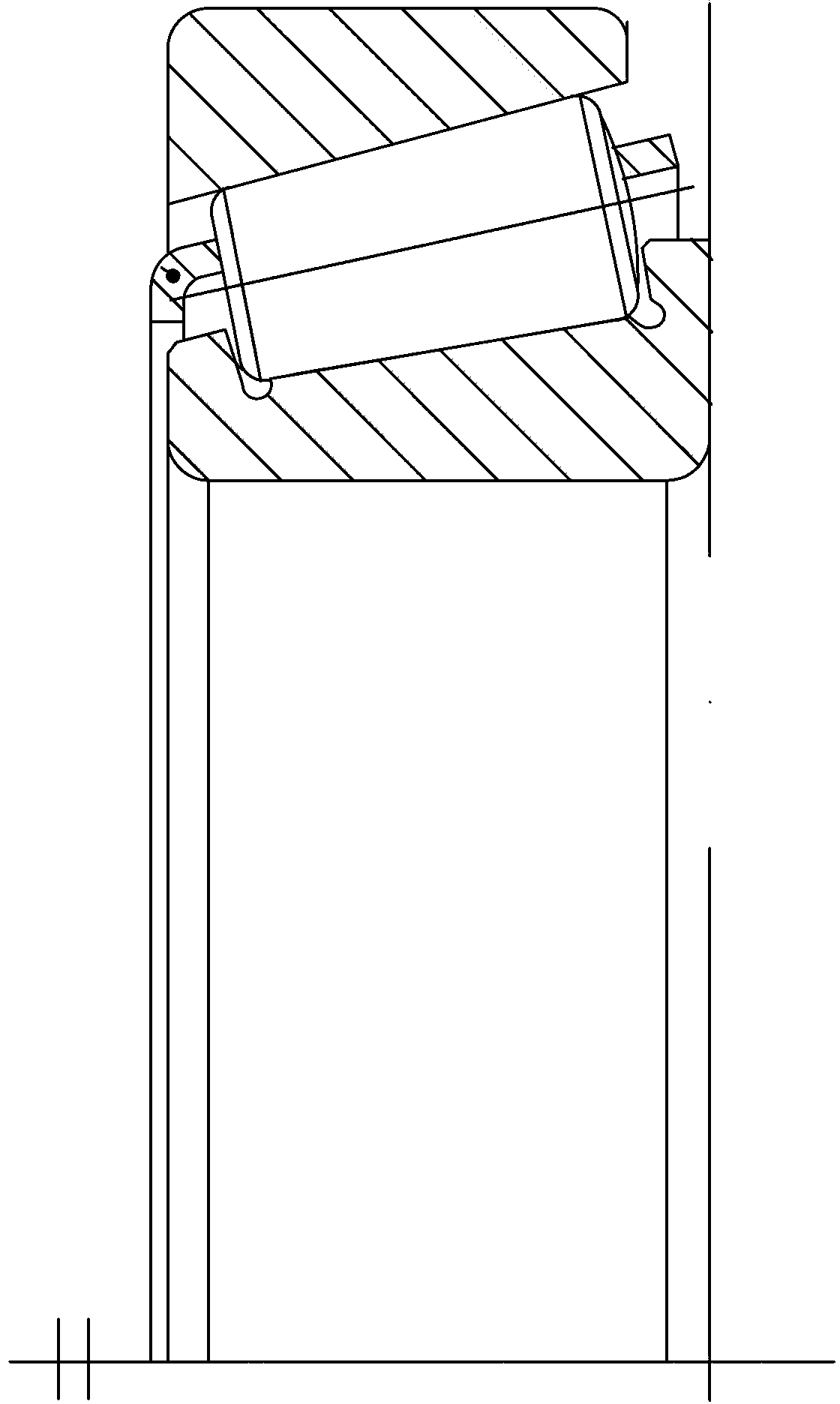

Single row tapered roller bearing

InactiveCN103790971ANot easy to burn outImprove the lubrication effectBearing componentsCircular conePulp and paper industry

The invention discloses a single row tapered roller bearing, which comprises an inner ring, an outer ring and a single row limited between the inner ring and the outer ring by a retainer, and the single row tapered roller bearing is characterized in that an oil filler point 1 which is perpendicular to an outer cone of the cone roller is arranged at the outer ring, so that the oil filler point 1 and the bearing form a certain inclination angle in a radial direction. According to the invention, an oil groove and an oil orifice are added on the external diameter of the outer ring of the cone bearing, and the single row tapered roller bearing has the beneficial effects that 1) during a usage process of the bearing, the single row tapered roller bearing has the advantages of good lubrication performance, difficult burning of the bearing, and convenient usage; and 2) during the usage process of the bearing, the oiling is convenient.

Owner:瓦房店福斯特轴承科技开发有限公司

Belt type pumping unit centralized lubrication system

PendingCN111022894AEasy to adjustEasy to fill oilConduits/junctionsLubrication containersOil canSprocket

The invention discloses a belt type pumping unit centralized lubrication system which comprises a tower footing. Two chain wheels are installed on the inner side of the tower footing and are in transmission connection through a chain, one side of the chain is connected with a rail base, two movable adjusting mechanisms are fixed to the bottom of the rail base, and fixing mechanisms are fixed to the bottoms of the movable adjusting mechanisms. An oil coating groove is fixed to each fixing mechanism, an oil coating pipe is arranged on one side of each oil coating groove, an oil distributing groove is fixed to the inner wall of one side of the tower footing, a collecting groove is fixed to the inner wall of the lower side of the tower footing, a liquid pump is fixed to the outer wall of one side of the collecting groove, an oil guide pipe is fixed to an output port of the liquid pump, and the upper end of the oil guide pipe is connected with the oil distributing groove. According to the belt type pumping unit centralized lubrication system, the oil coating grooves and the oil distributing groove can be concentrated at one point during oil injection, oil injection is automatically carried out, pumping and drainage are prevented from being carried out through the guide pipe, quickness and convenience are achieved, the oil coating groove is maintained rapidly, conveniently and conveniently, lubricating oil can be recycled, resources are saved, and cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Combined bearing for rolling mill

InactiveCN105317833ALarge effective spanEasy to locate and installRoller bearingsBearing unit rigid supportEngineeringRolling mill

The invention relates to a combined bearing for a rolling mill. The combined bearing for the rolling mill comprises a double-row conical bearing, a sealing ring, a check ring and a bearing seat. The outer-diameter portion of the double-row conical bearing is directly inserted into the bearing seat. The check ring is arranged between the double-row conical bearing and the bearing seat and used for positioning and adjusting a bearing clearance. The sealing ring is arranged between an inner ring and an outer ring of the double-row conical bearing. Compared with the prior art, the combined bearing for the rolling mill has the advantages that installation maintenance is convenient, and the clearance can be adjusted conveniently.

Owner:UBC SHANGHAI PRECISION BEARING MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com