Simple oil injecting device of hydraulic mechanism

A technology of oil injection device and hydraulic mechanism, which is applied in the direction of distribution device, liquid distribution, transportation or transfer device, special distribution device, etc., which can solve the problem of low working efficiency of hydraulic mechanism and achieve the effect of convenient oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

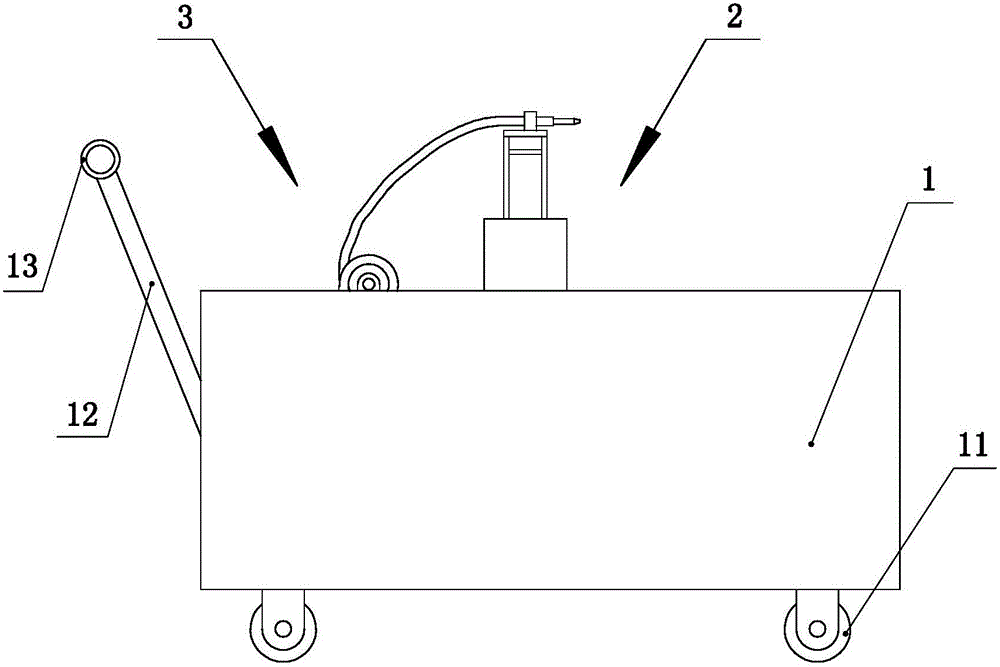

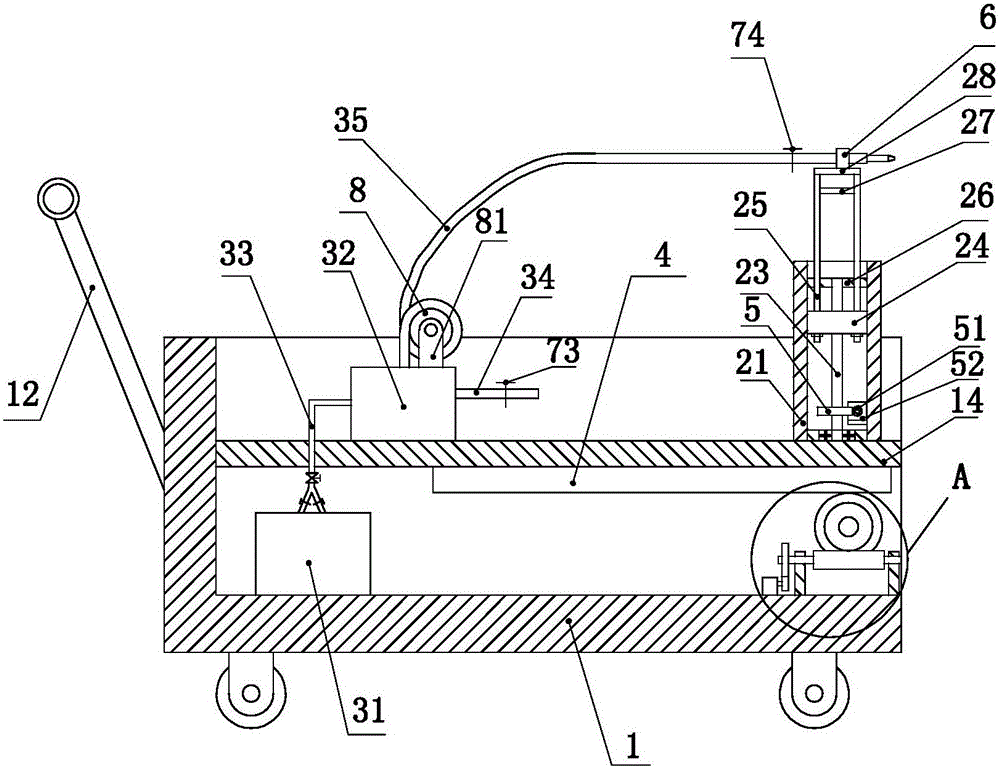

[0028] Such as Figure 1 to Figure 11 As shown, the present invention mainly includes a car body 1, a lift assembly 2, an oil supply assembly 3, a translation assembly and a rotation assembly, and the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 Shown, car body 1 is main body of the present invention, is provided with traveling wheel 11 at car body bottom, is provided with slanting bar 12 at car body rear side, is provided with handrail 13 at slanting bar free end, just can promote by holding handrail Bodywork.

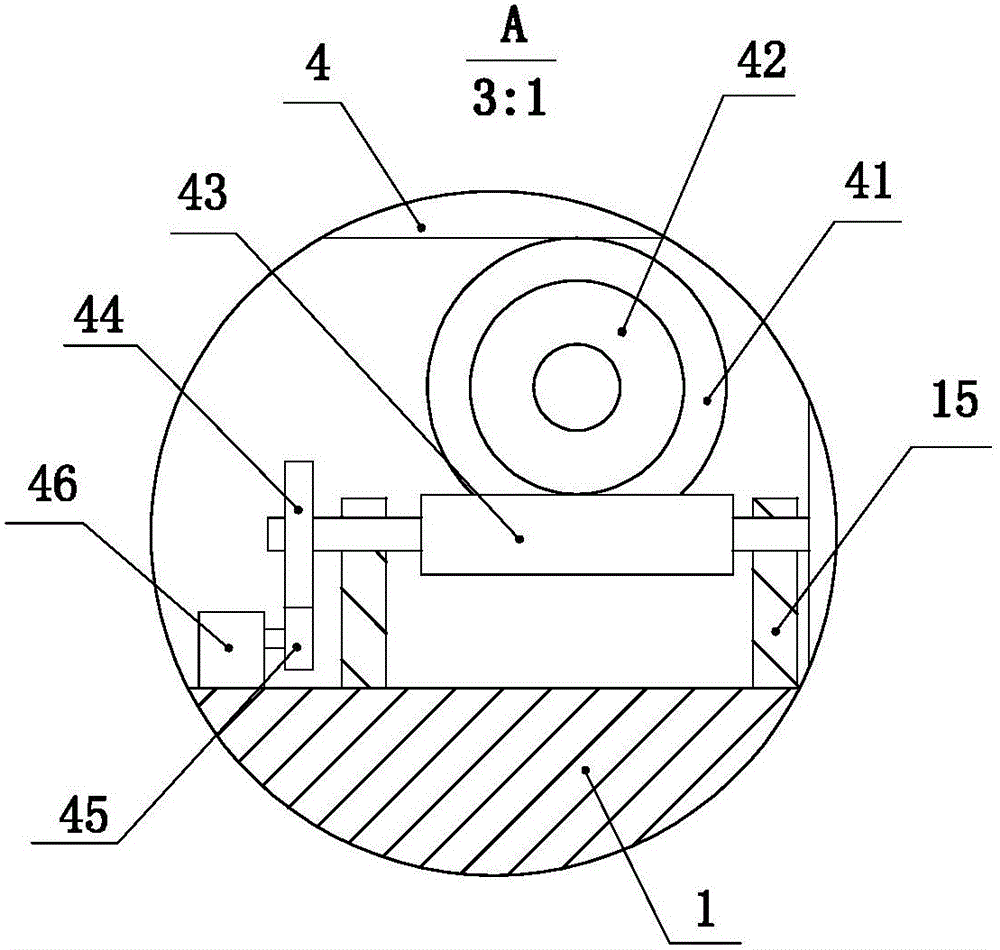

[0030] Such as figure 2 Shown, the car body is a hollow structure, and the inner cavity of the car body is provided with a dividing plate 14 placed horizontally, and a tooth bar 4 is slidably installed on the dividing plate. The lower side) extends out of the partition and is located below the partition. A bar-shaped hole is provided on the dividing plate, the upper side of the tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com