Patents

Literature

399results about "Drying/impregnating machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

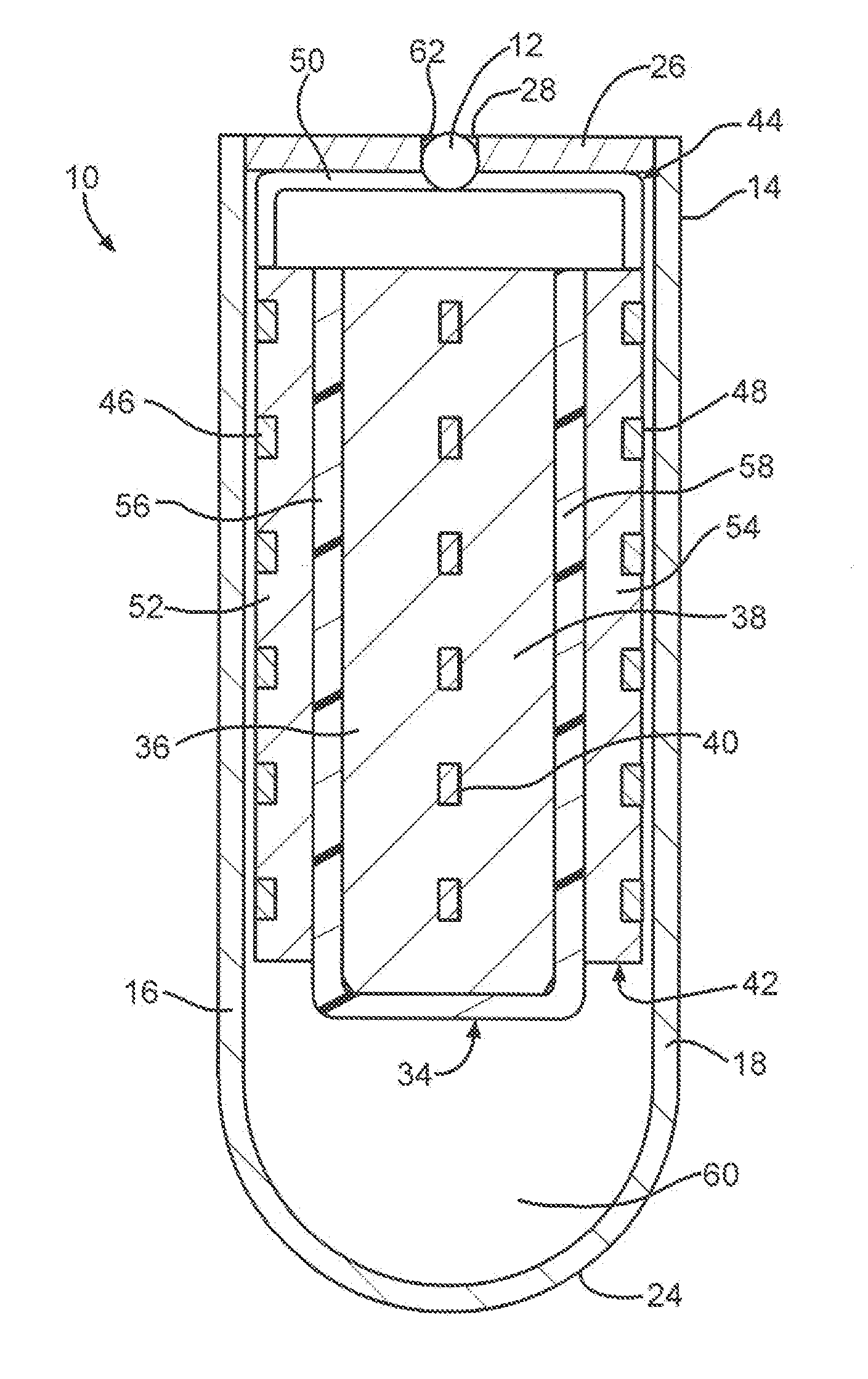

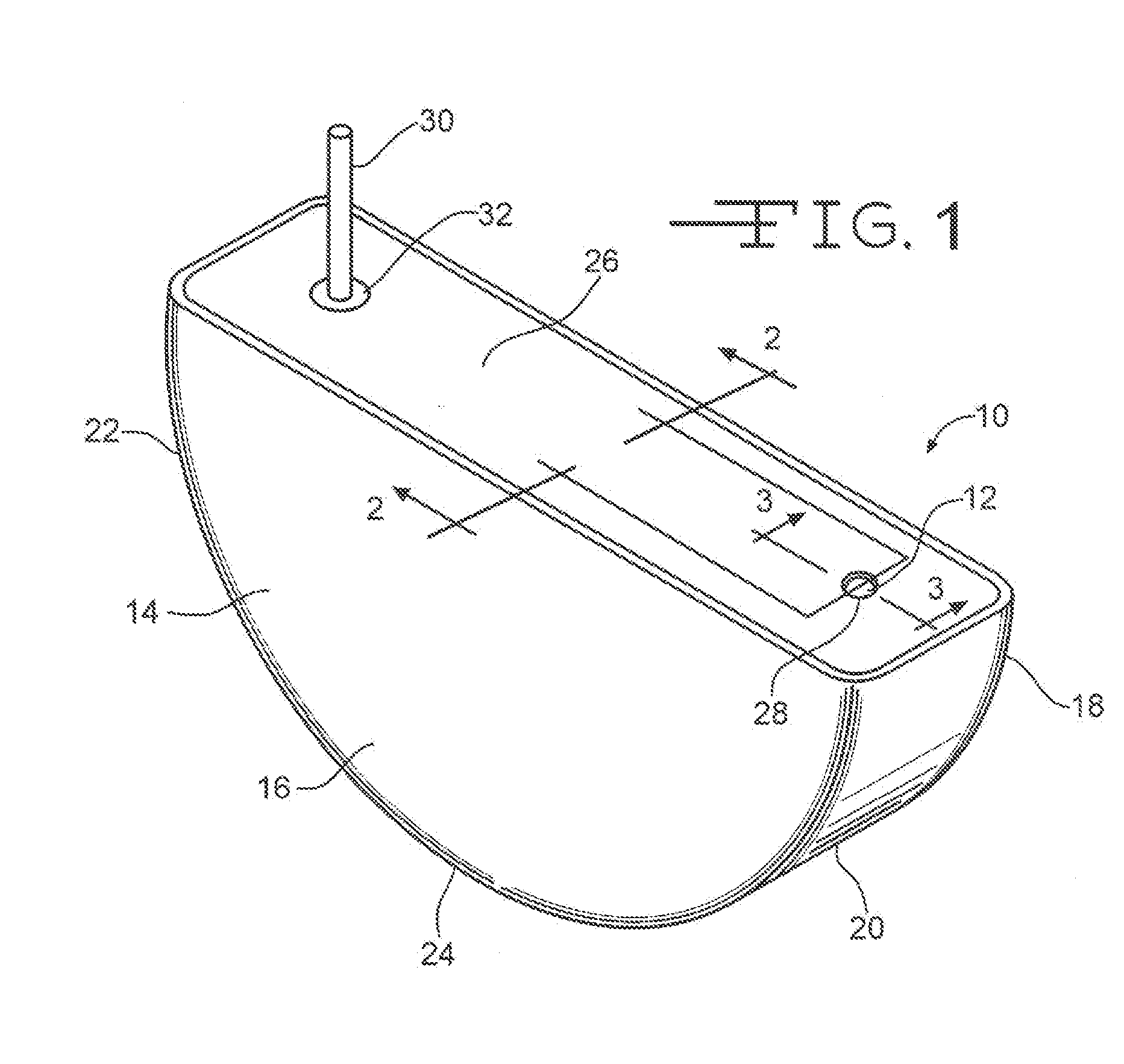

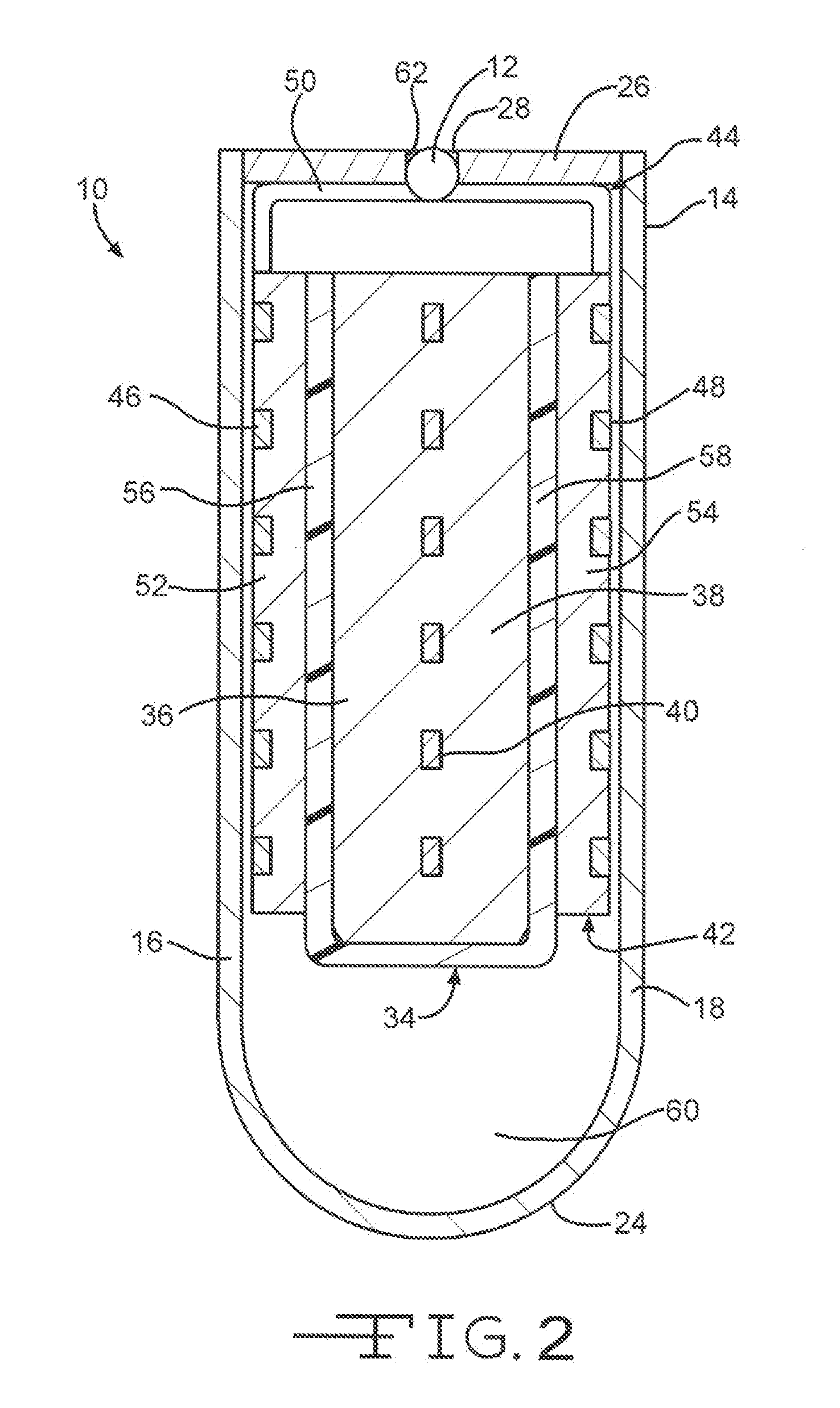

Method and apparatus for providing a sealed container containing a detectable gas

InactiveUS20060260713A1Minimal capitalMinimal labor costCell/batteries leak testingSecondary cells testingEngineeringElectrochemical cell

An apparatus for making a hermetic device containing a detectable gas and comprising a surface having a fill port comprising a vacuum pump in communication with the hermetic device through a vacuum conduit; a liquid reservoir for containing liquid to be delivered to the hermetic-device; a gas reservoir for containing a detectable gas to be delivered to the hermetic device; a transfer vessel for transferring a selected quantity of liquid and gas to the hermetic device; and a block for passing the selected quantity of liquid and gas through a fill port of the hermetic device, and disposing a seal into the fill port. A method for making a hermetic device containing a detectable gas, and an exemplary hermetic device comprising an electrochemical cell or a capacitor are also disclosed.

Owner:WILSON GREATBATCH LTD

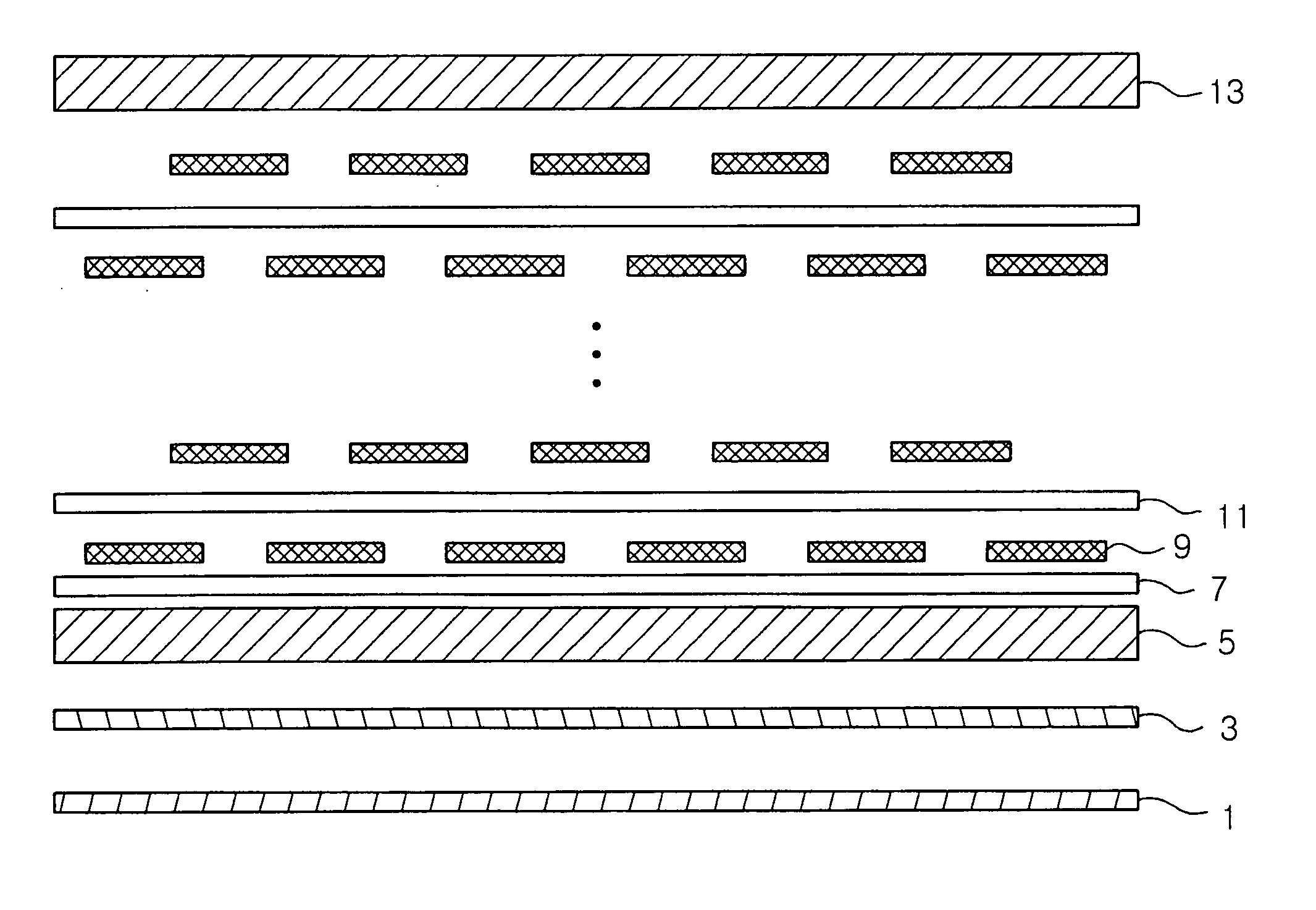

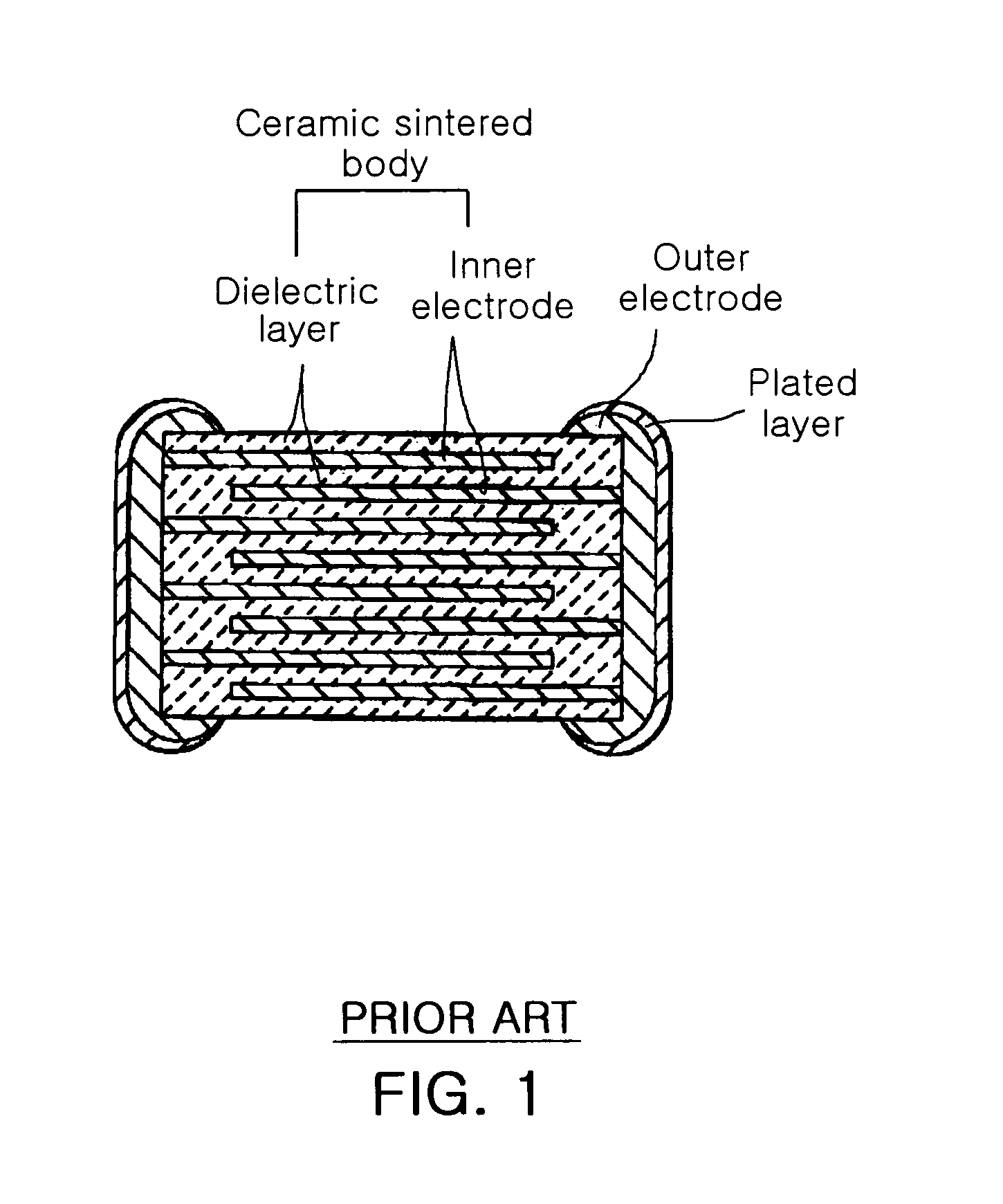

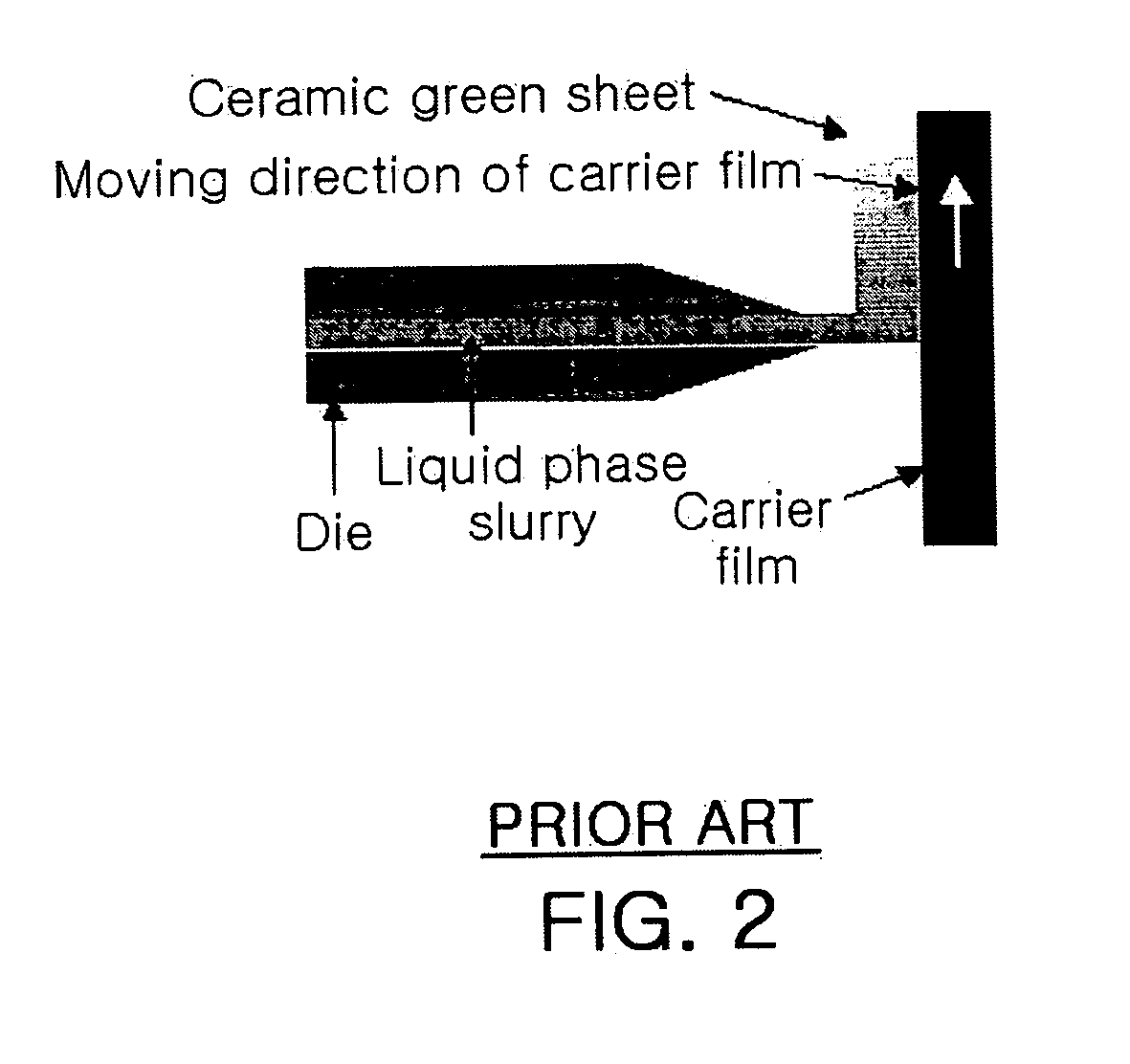

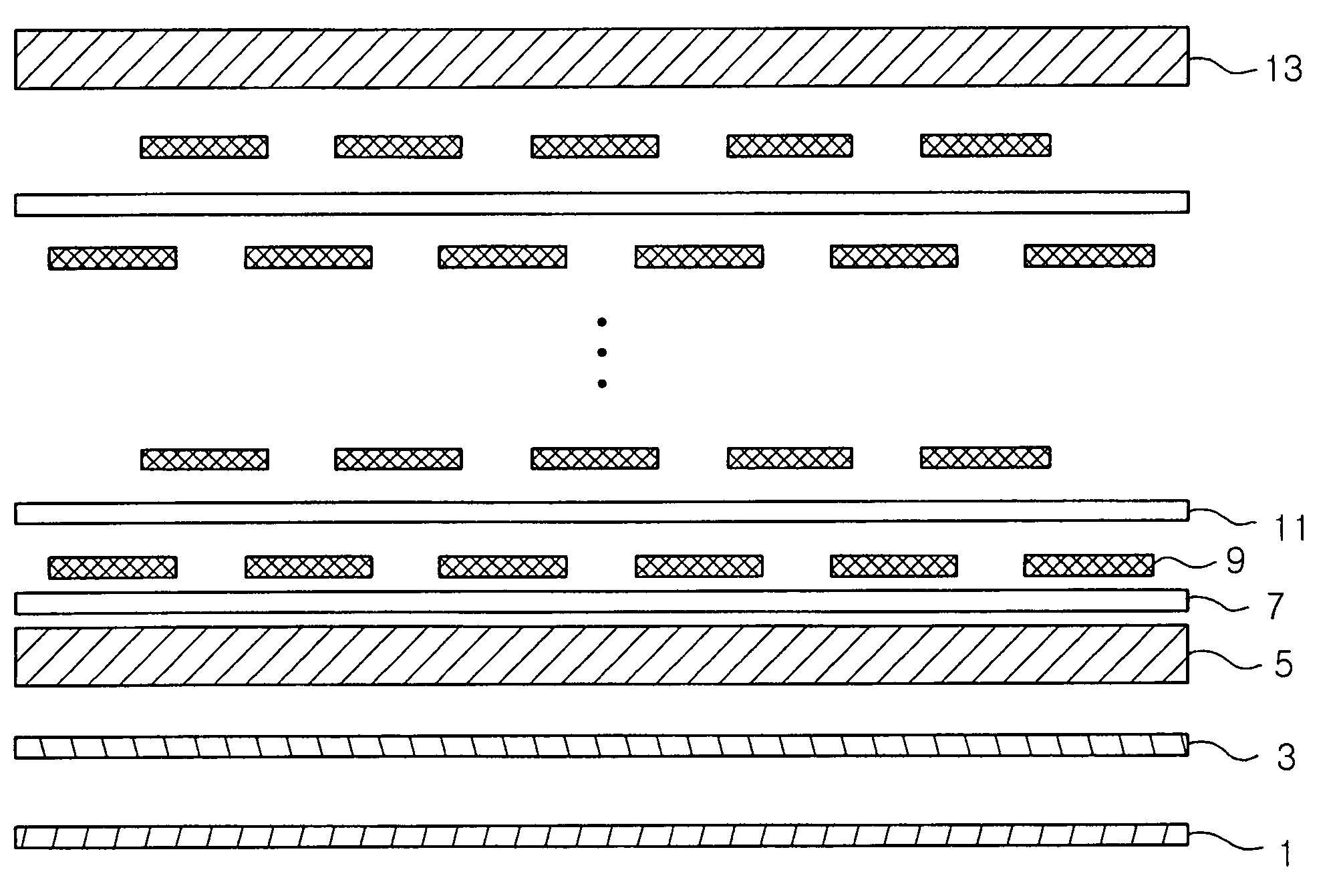

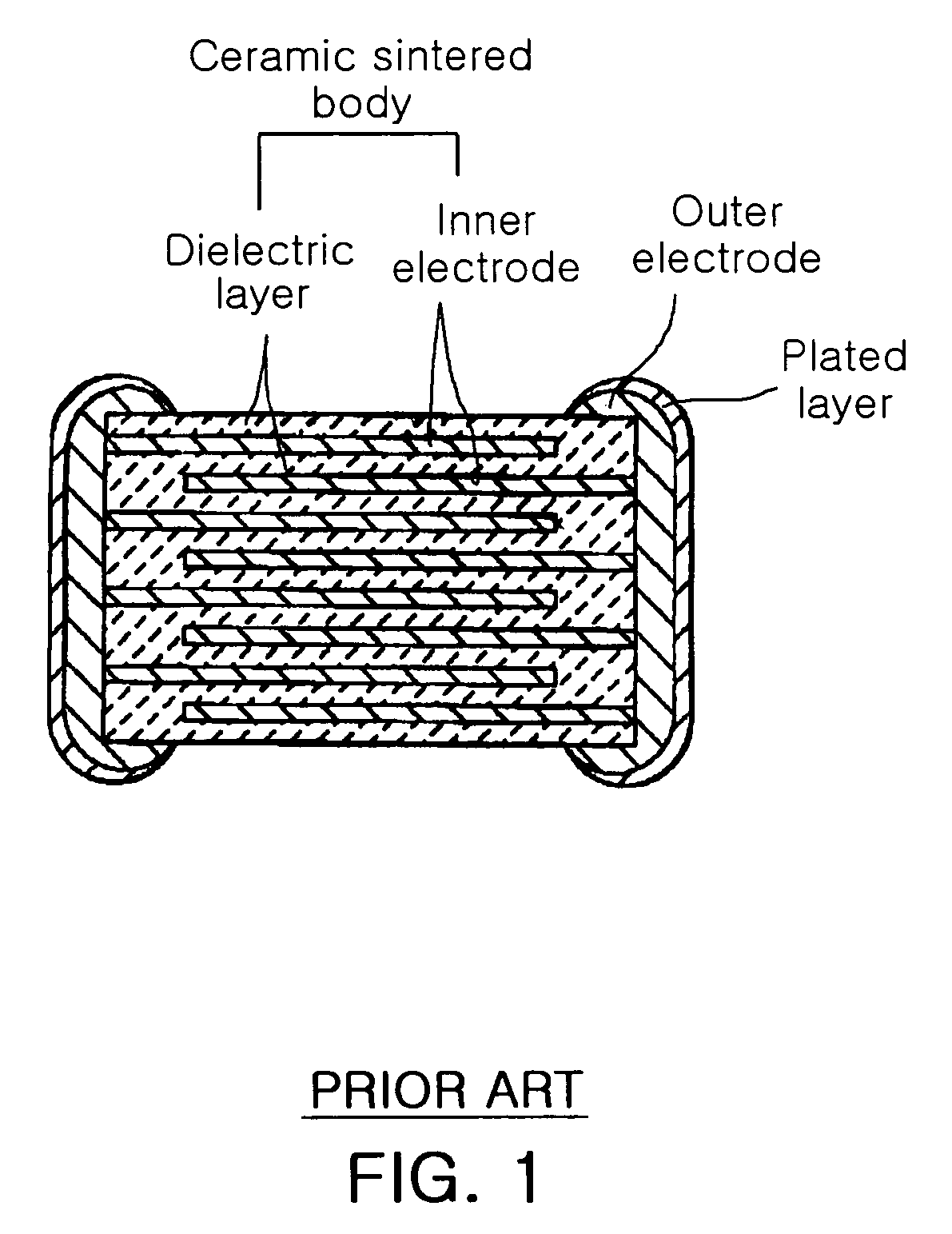

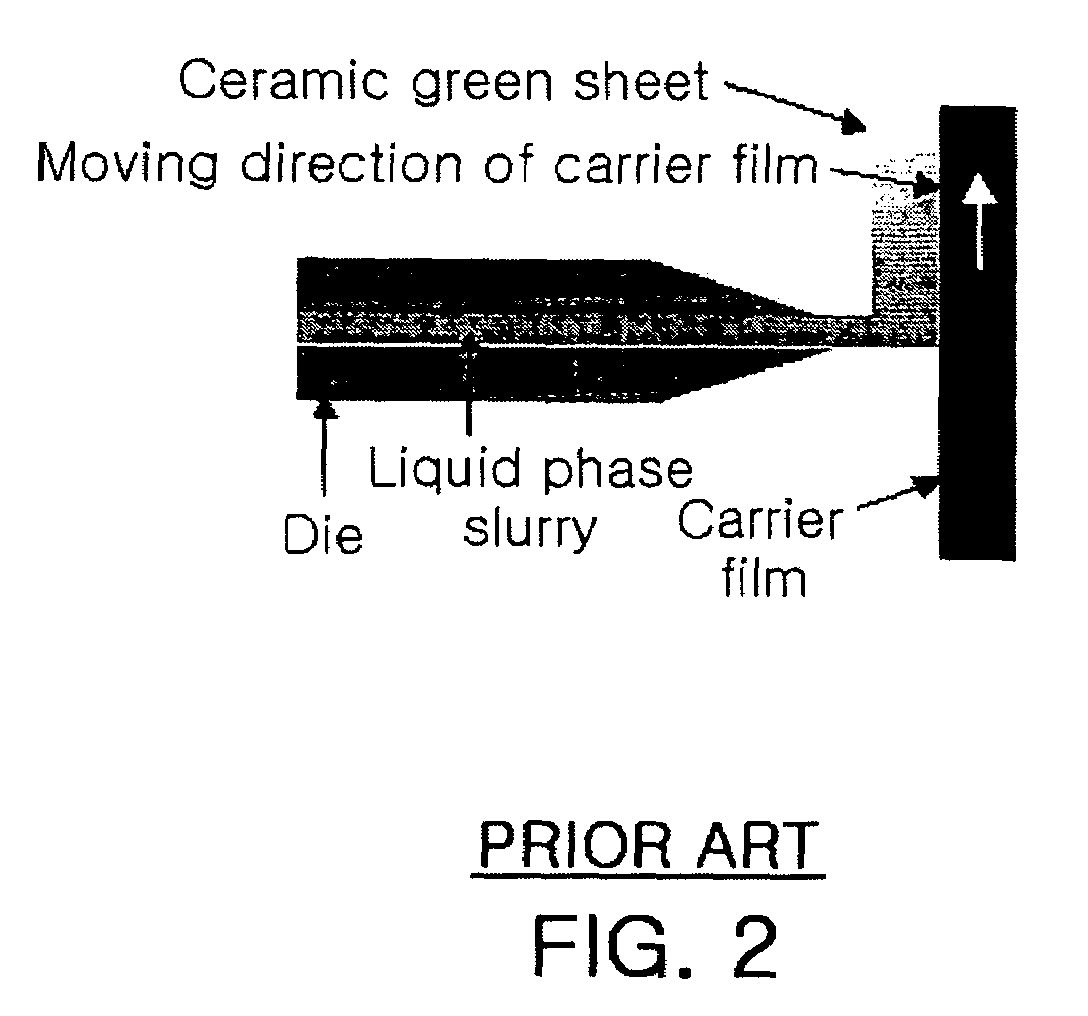

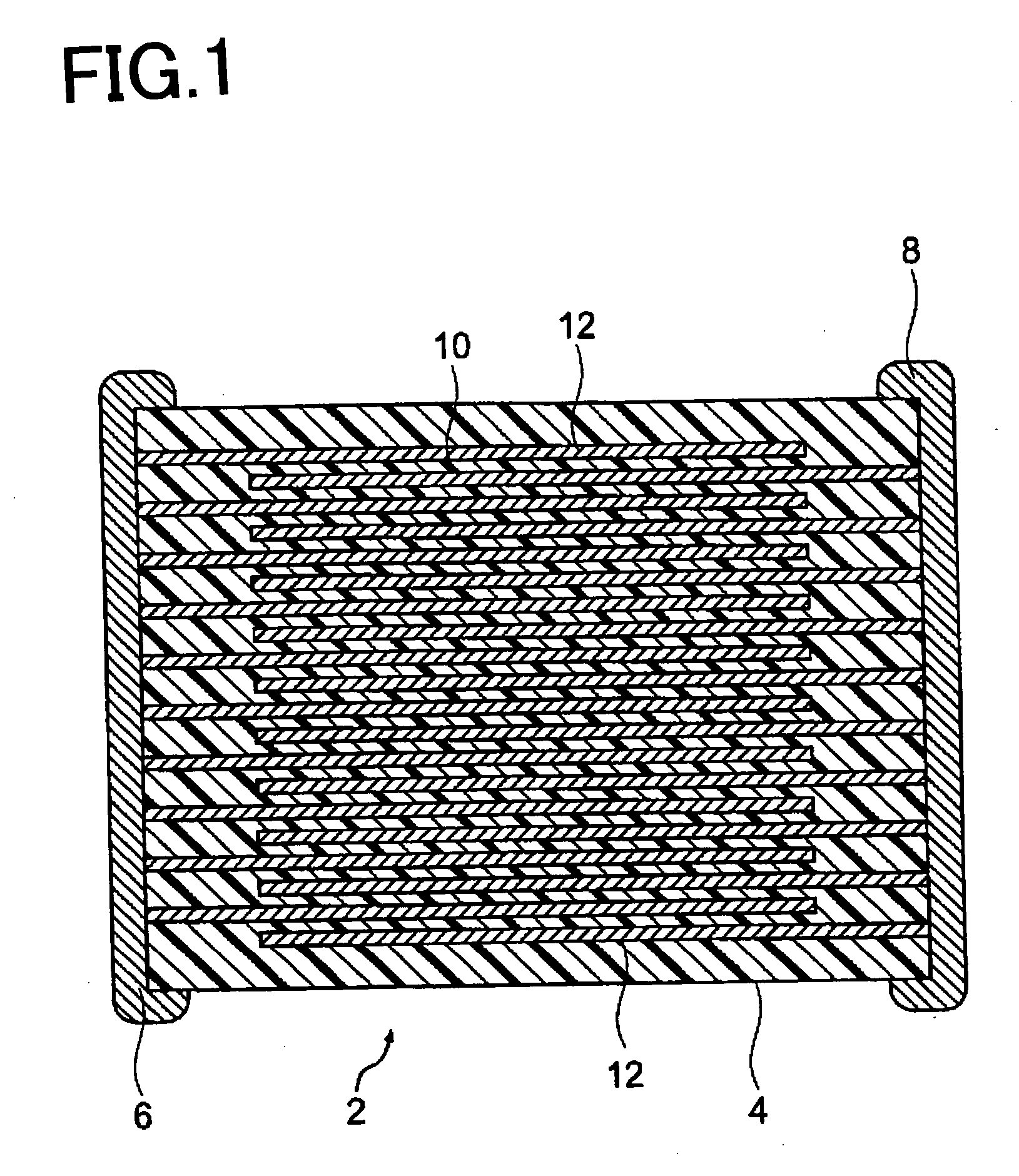

Method of manufacturing multilayered ceramic capacitor by spin coating and multilayered ceramic capacitor

Disclosed herein is a method of manufacturing a multilayered ceramic capacitor by a spin coating process, and a multilayered ceramic capacitor obtained by the above method. The method of the current invention provides a plurality of dielectric layers formed by spin coating, in which the process of coating the dielectric layer and the process of printing the inner electrode can be provided as a single process. Therefore, the thickness of the dielectric layer is easily controlled while the dielectric layer is formed to be thin. Further, since the dielectric layers and the inner electrodes are formed successively, the processes of separating and layering the dielectric layers, and the process of compressing the ceramic multilayered body can be omitted. Thereby, the ceramic multilayered body need not be compressed, and thus, a pillowing phenomenon does not occur in the multilayered ceramic capacitor.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

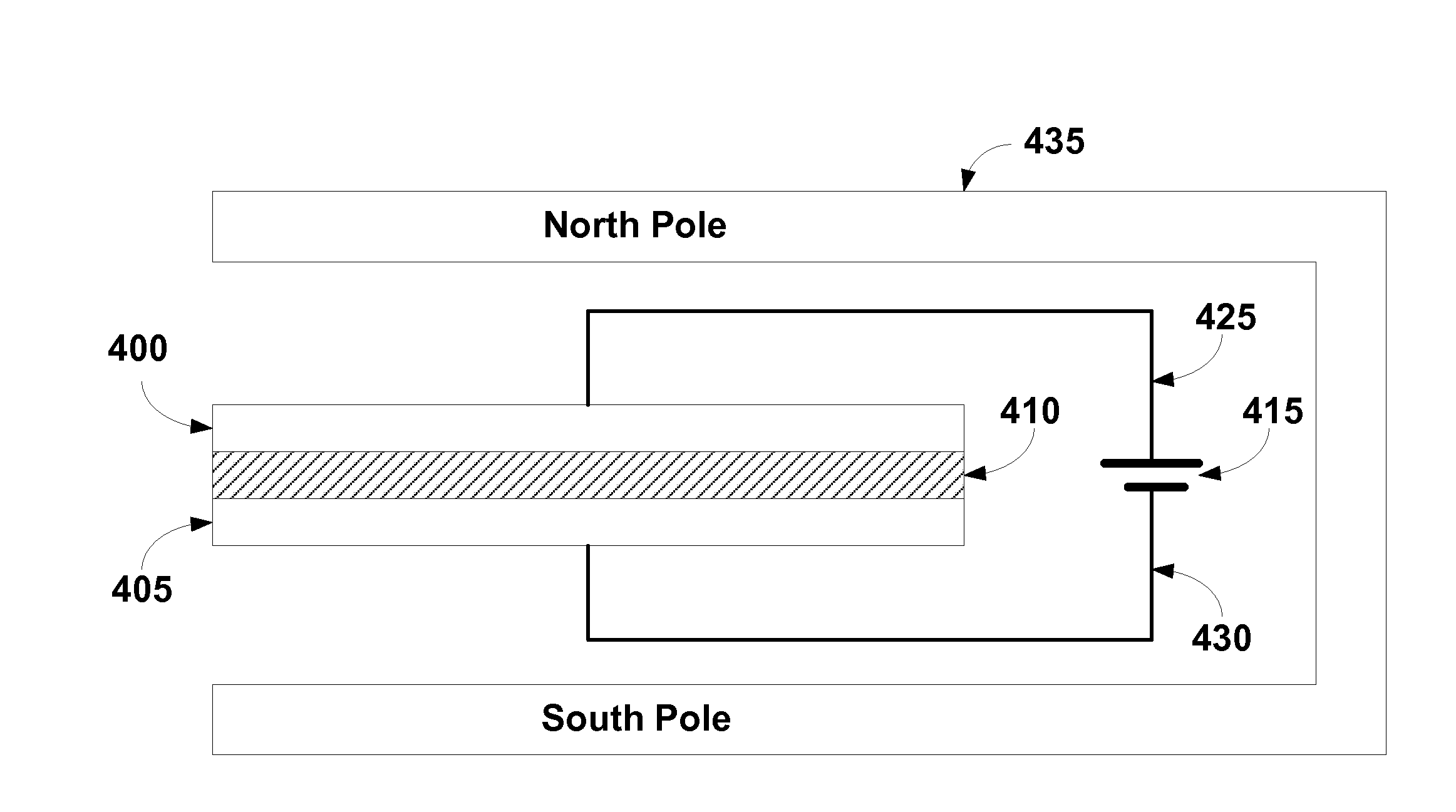

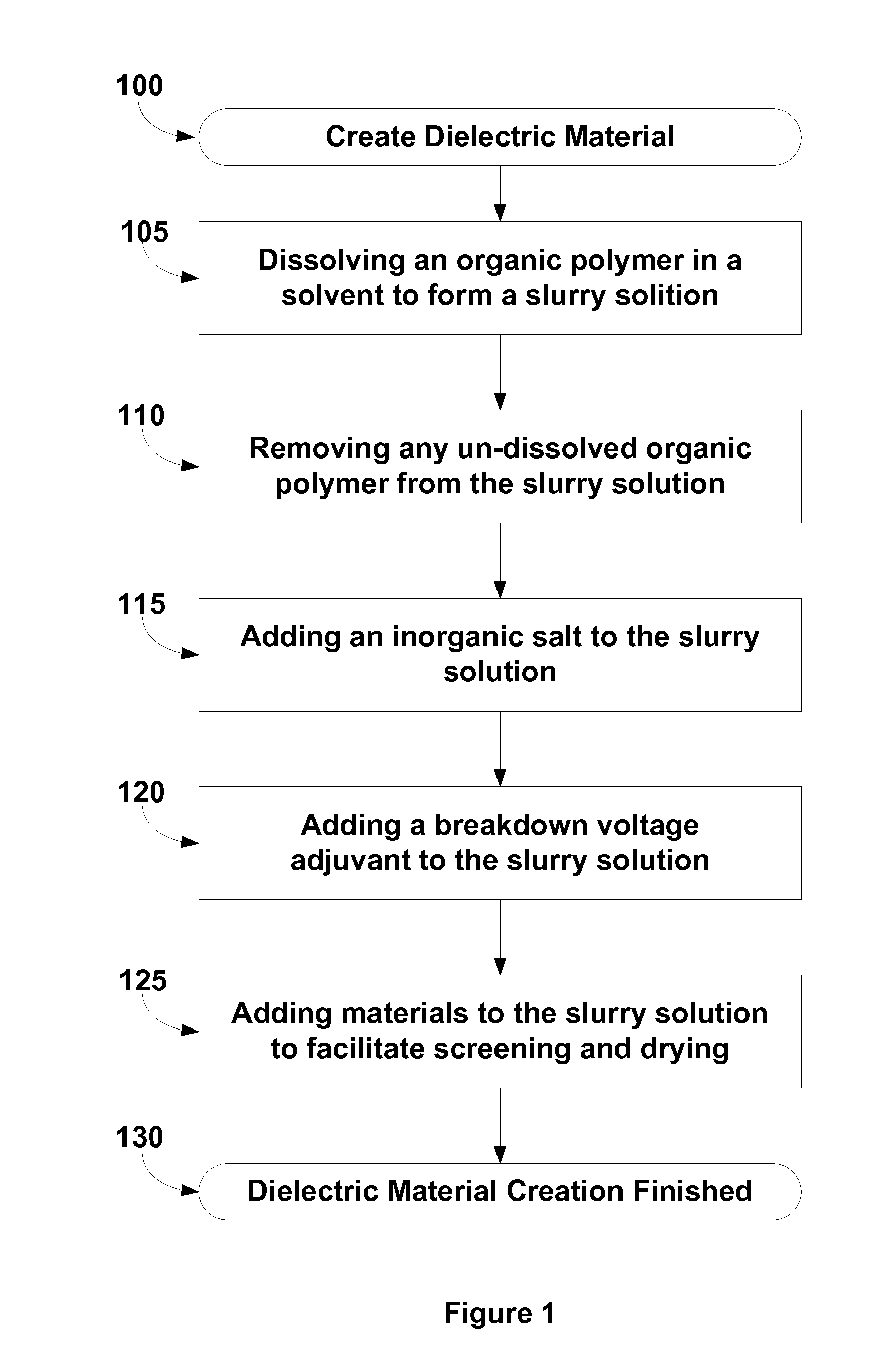

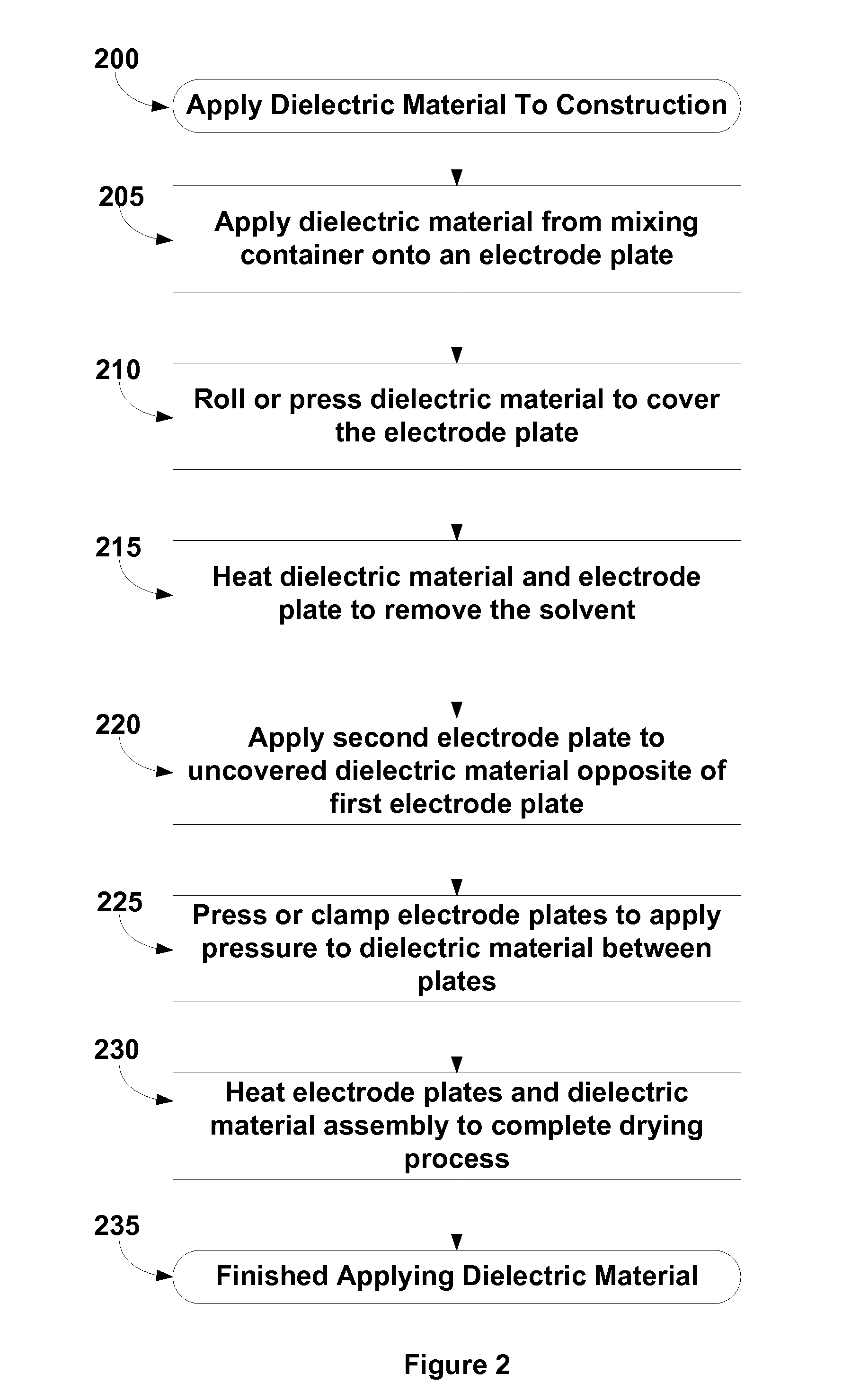

Very thin dielectrics for high permittivity and very low leakage capacitors and energy storing devices

ActiveUS20150000090A1High dielectric constantAvoiding electrical breakdownLamination ancillary operationsFixed capacitor dielectricShellacPermittivity

Methods are disclosed for creating extremely high permittivity dielectric materials for use in capacitors and energy storage devices. High permittivity materials suspended in an organic non-conductive media matrix with enhanced properties and methods for making the same are disclosed. Organic polymers, shellac, silicone oil, and / or zein formulations are utilized to produce thin film low conductivity dielectric coatings. Transition metal salts as salt or oxide matrices are formed at low temperatures utilizing mild reducing agents.

Owner:CARVER SCI INC

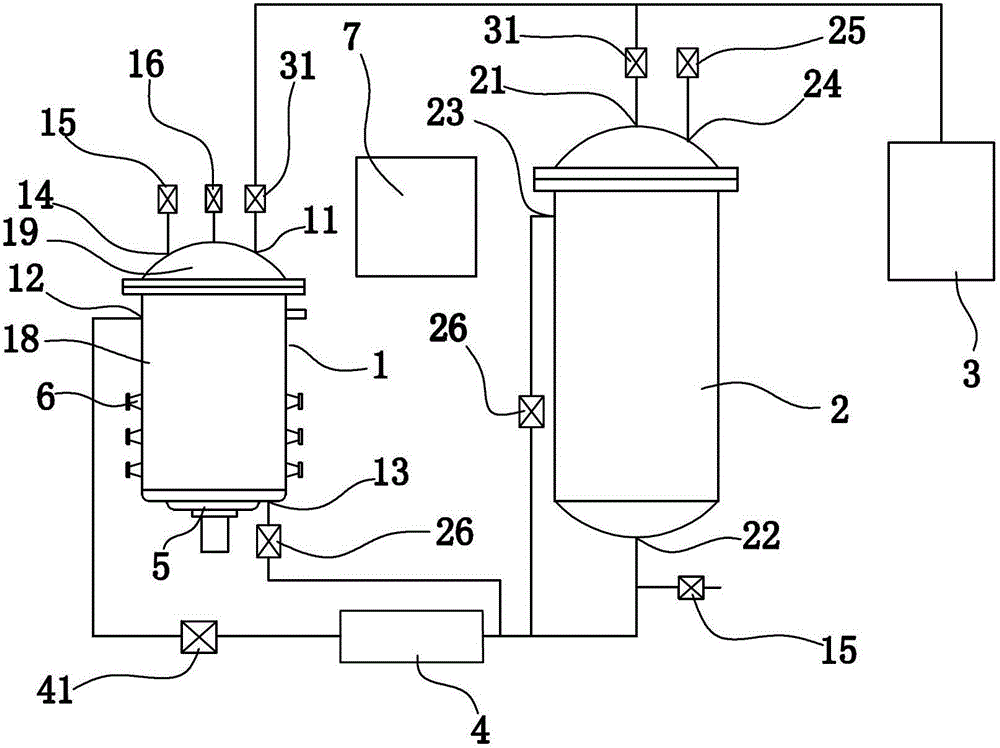

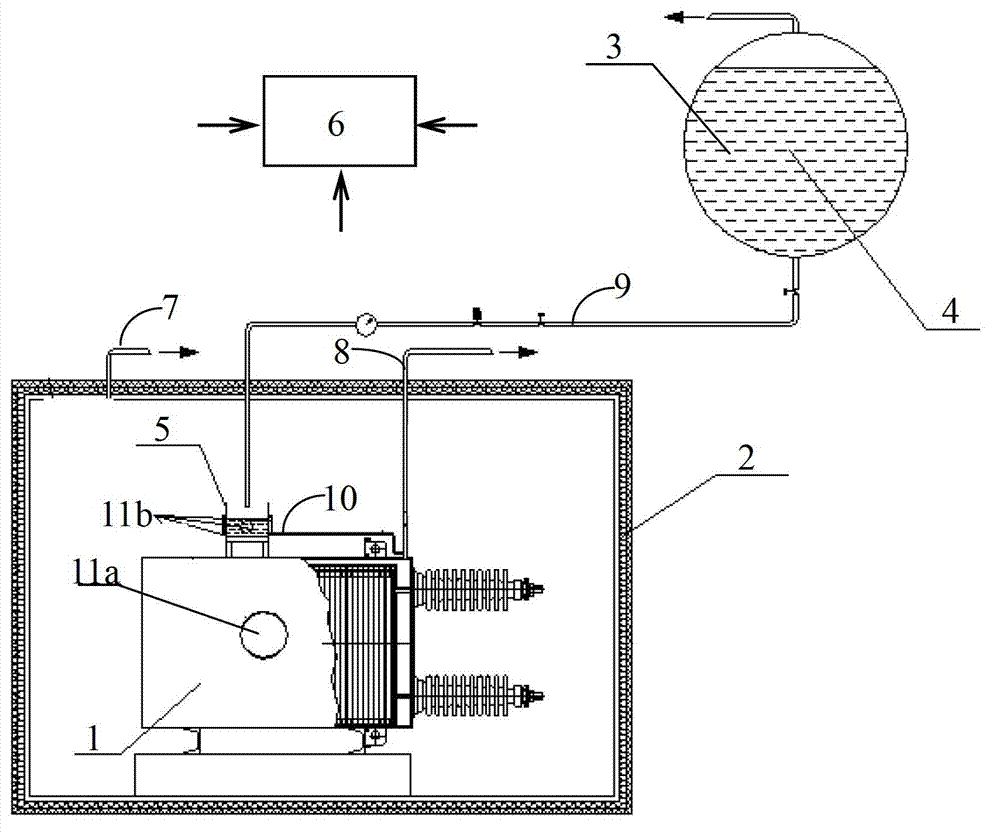

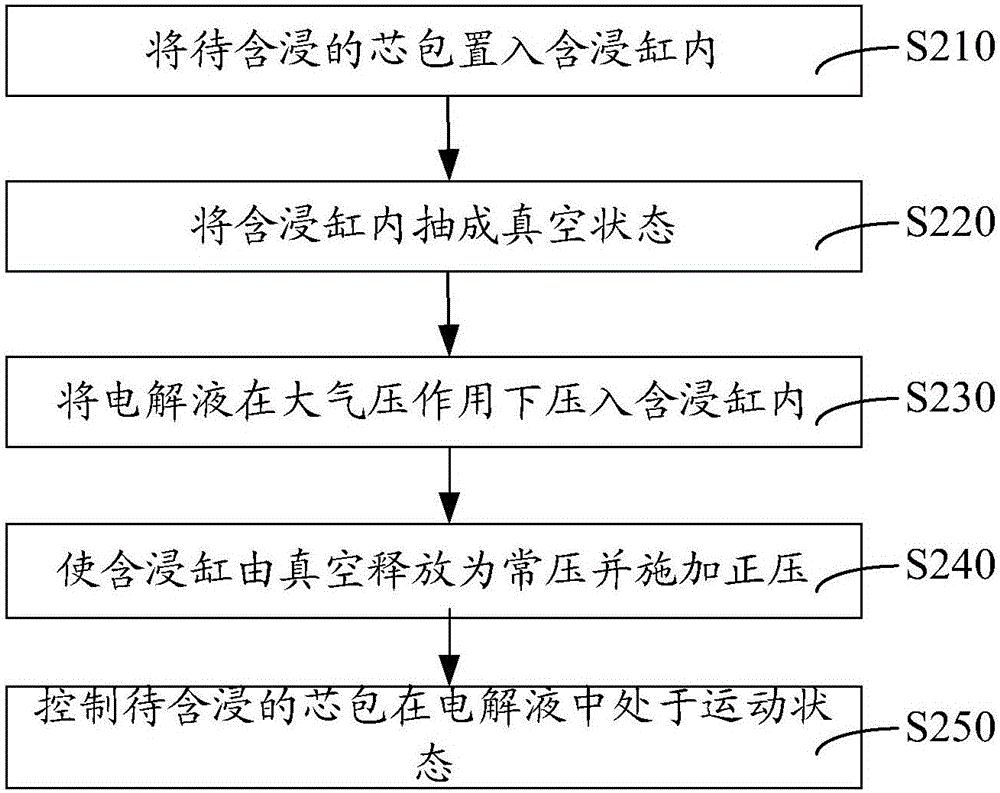

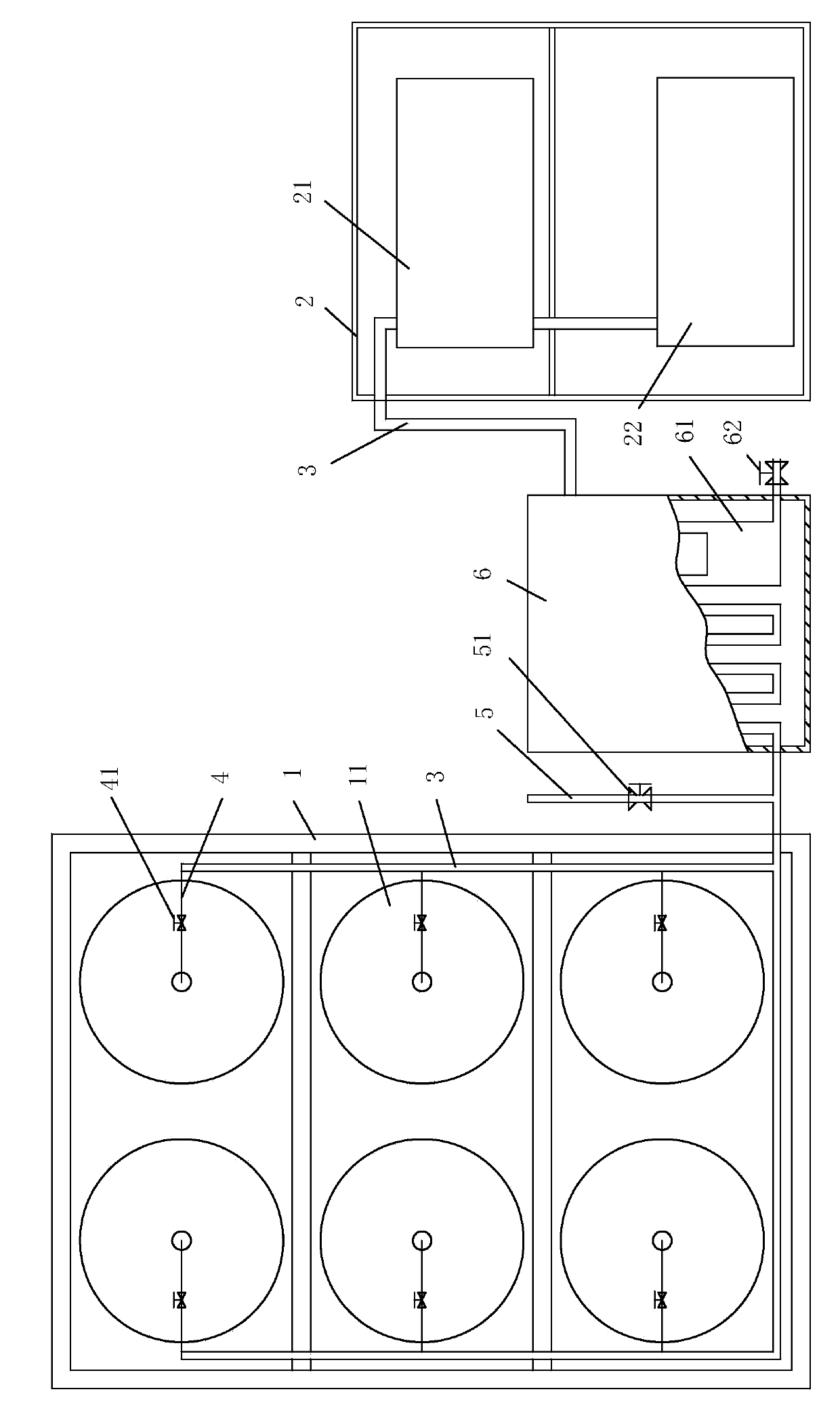

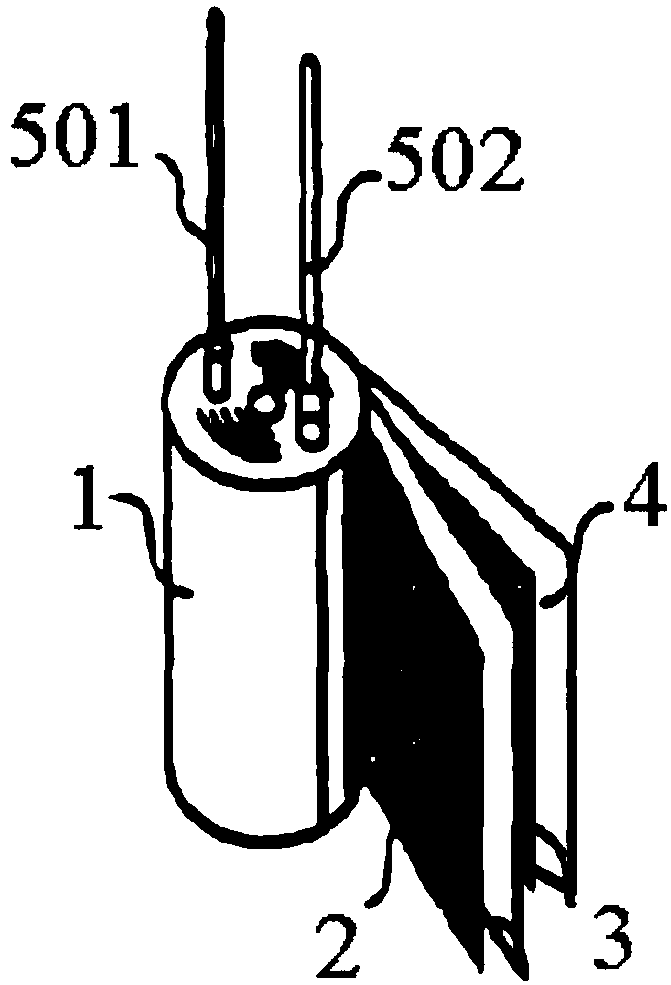

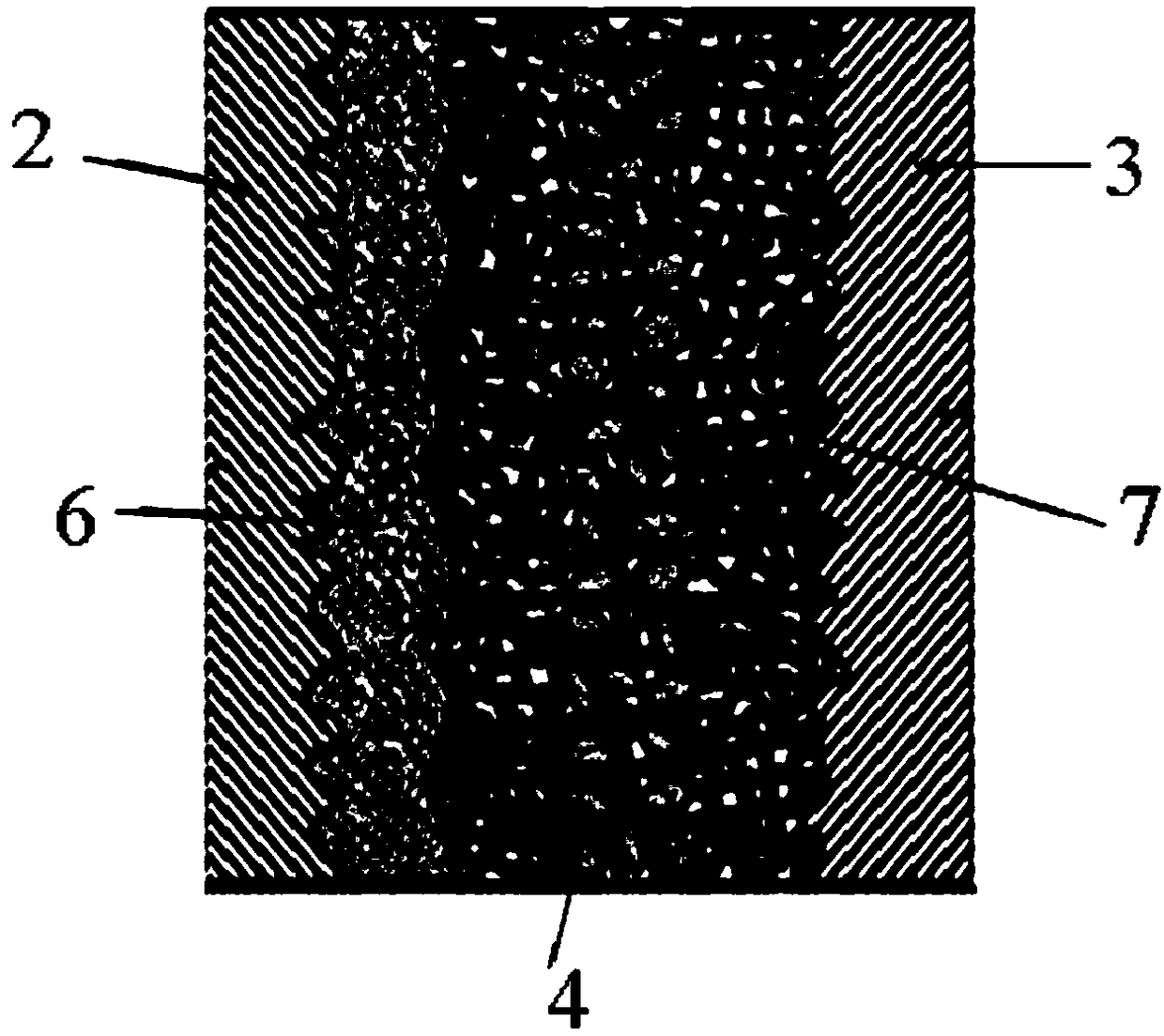

Fast impregnation method for capacitor core package and device thereof

InactiveCN102723199ANo pollutionEasy accessElectrolytic capacitorsDrying/impregnating machinesAtmospheric pressureMoisture

The invention discloses a fast impregnation method for a capacitor core package. The method comprises the following steps of putting the core package required to be impregnated into an impregnation tank, and sealing the impregnation tank; opening a liquid storing barrel, pouring the impregnation liquid into the liquid storing barrel; vacuumizing the impregnation tank through a vacuum constant pressure device; during vacuumizing, extracting moisture and air in the core package of the capacitor at the same time; injecting the impregnation liquid from the liquid storing barrel in the impregnation tank in a vacuum state; immersing the core package of the capacitor in the impregnation liquid, fast penetrating the impregnation liquid in the core package of the capacitor to be impregnated by the vacuum state in the impregnation tank, keeping the vacuum state in the impregnation tank; releasing the vacuum state in the impregnation tank instantaneously to be normal atmosphere, and penetrating the impregnation liquid in the core package of the capacitor to be impregnated by the atmospheric pressure. The invention further discloses a device for implementing the method. The method and device provided by the invention has the advantages of short impregnation time, high efficiency, good impregnation quality and low energy consumption.

Owner:李玉祥

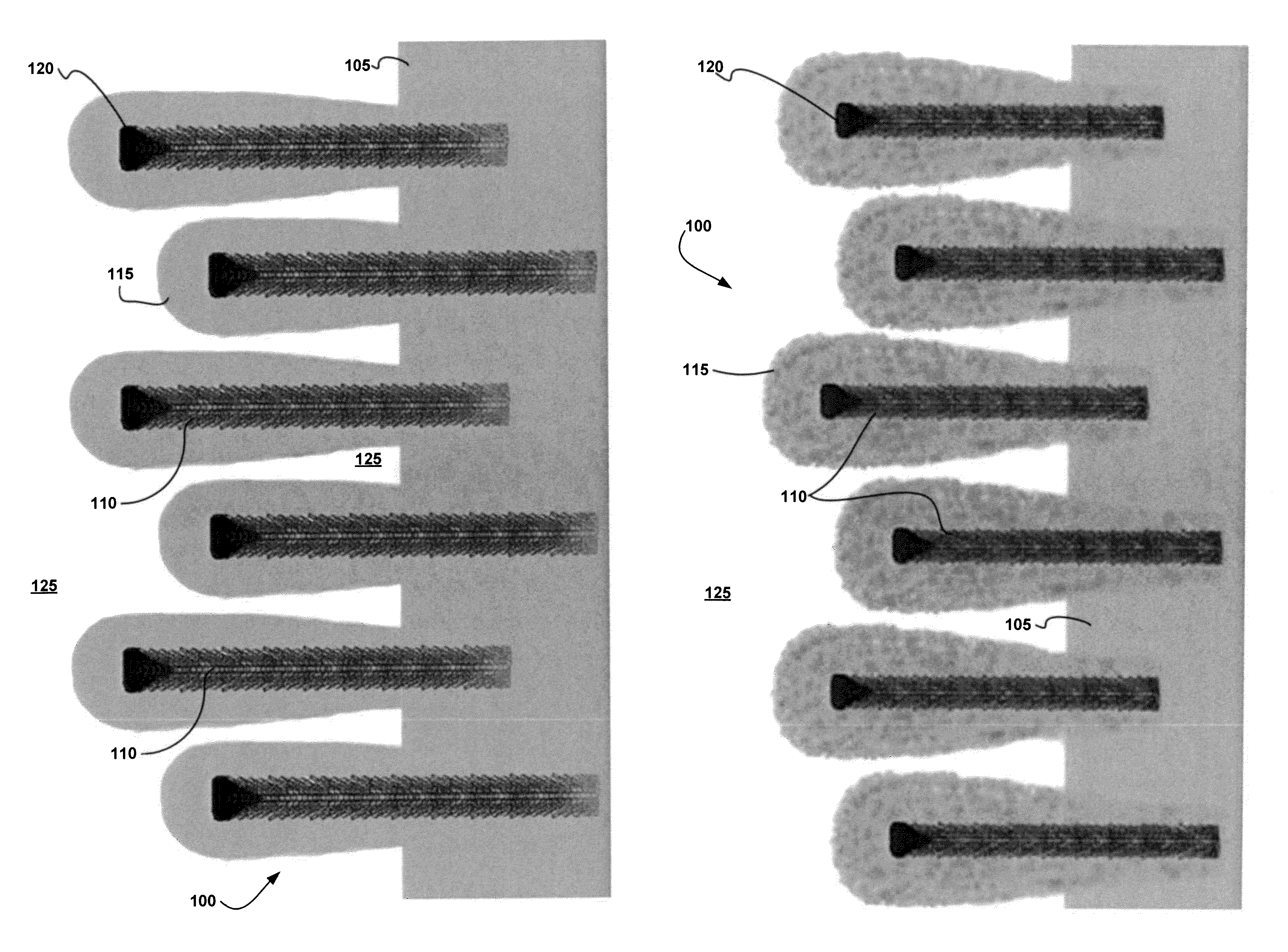

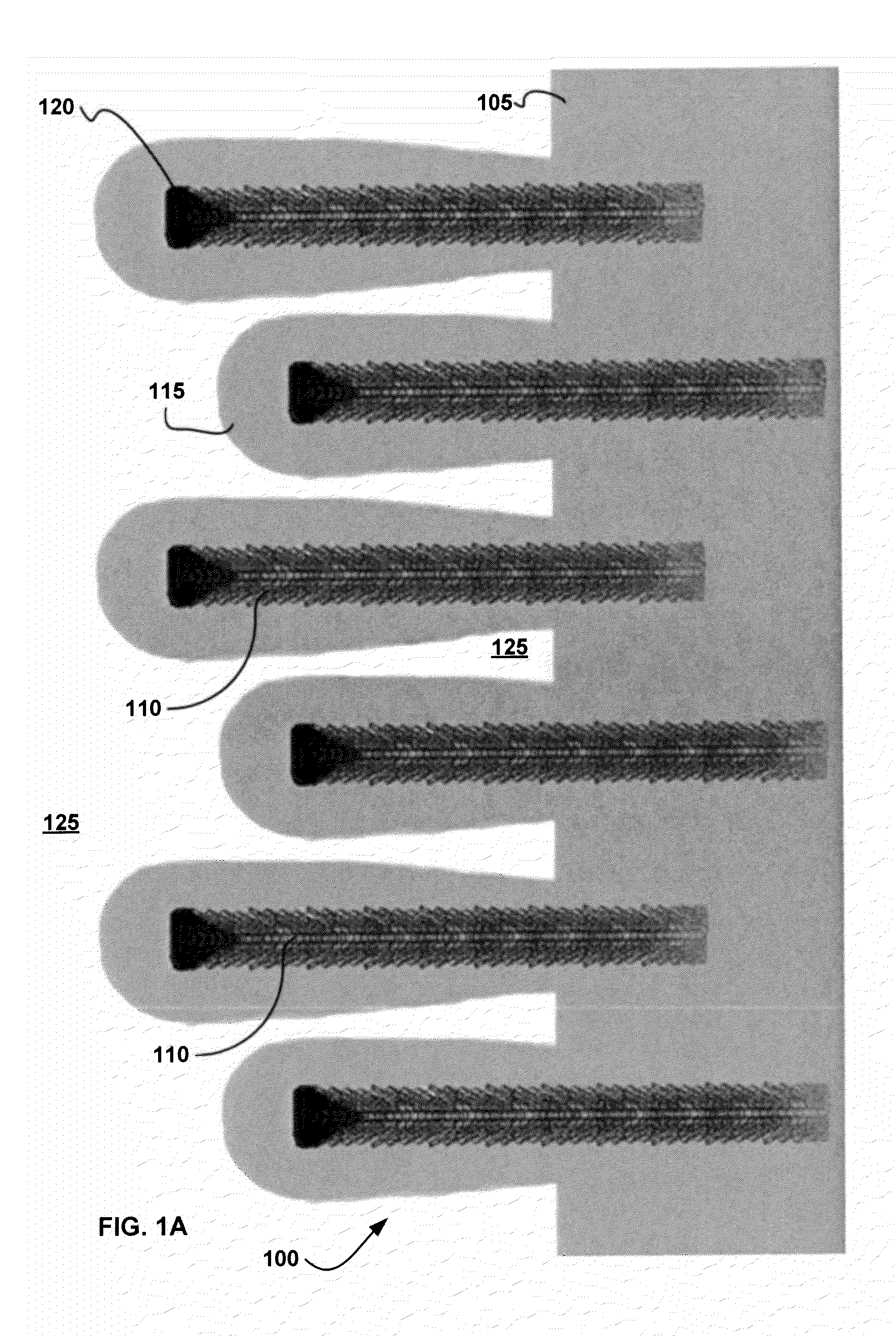

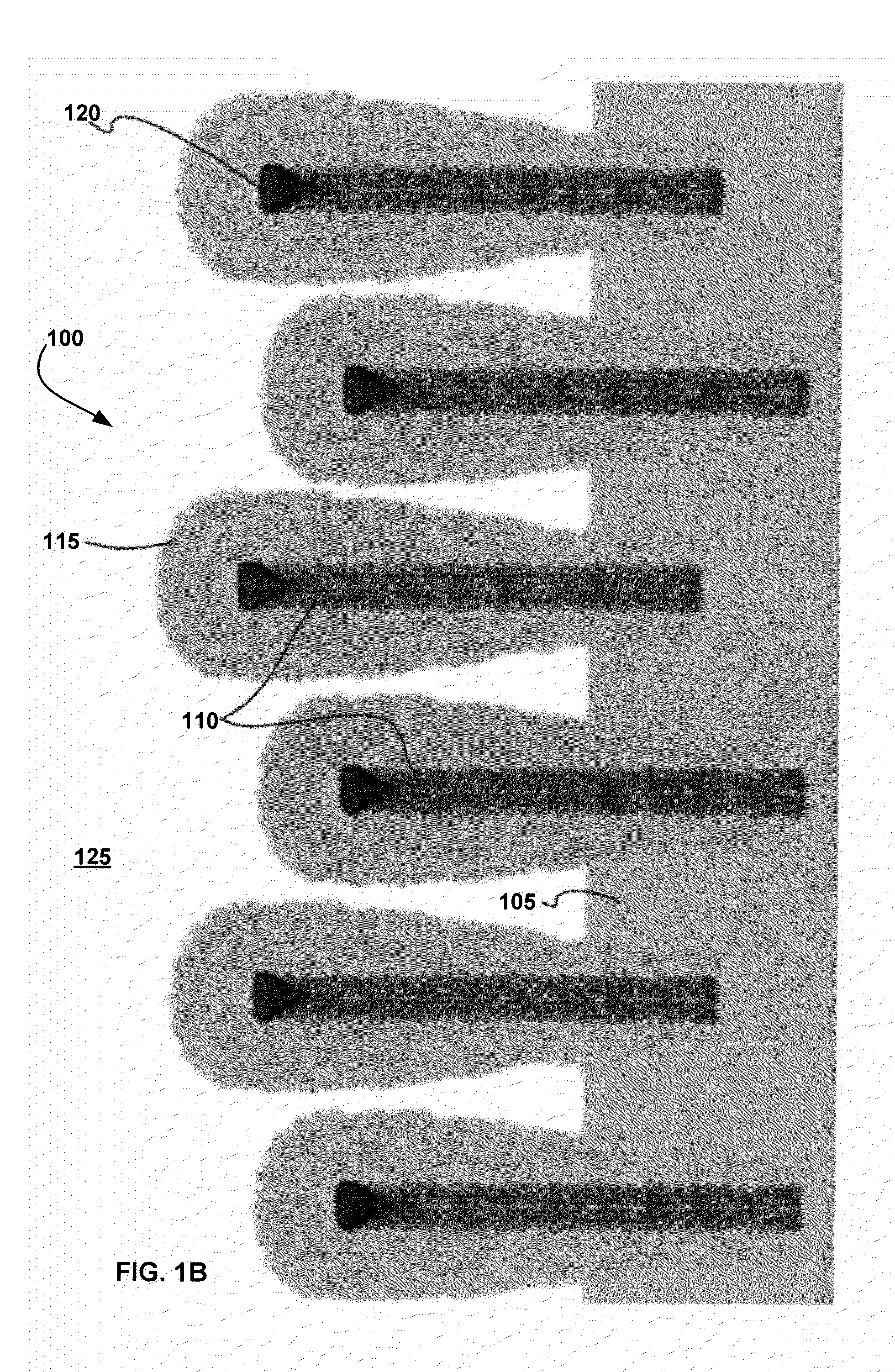

Hybrid Energy Storage Device Production

ActiveUS20130171340A1Electrode manufacturing processesHybrid capacitor electrodesLithiumCarbon nanofiber

A novel hybrid lithium-ion anode material based on coaxially coated Si shells on vertically aligned carbon nanofiber (CNF) arrays. The unique cup-stacking graphitic microstructure makes the bare vertically aligned CNF array an effective Li+ intercalation medium. Highly reversible Li+ intercalation and extraction were observed at high power rates. More importantly, the highly conductive and mechanically stable CNF core optionally supports a coaxially coated amorphous Si shell which has much higher theoretical specific capacity by forming fully lithiated alloy. Addition of surface effect dominant sites in close proximity to the intercalation medium results in a hybrid device that includes advantages of both batteries and capacitors.

Owner:CF TRAVERSE LLC

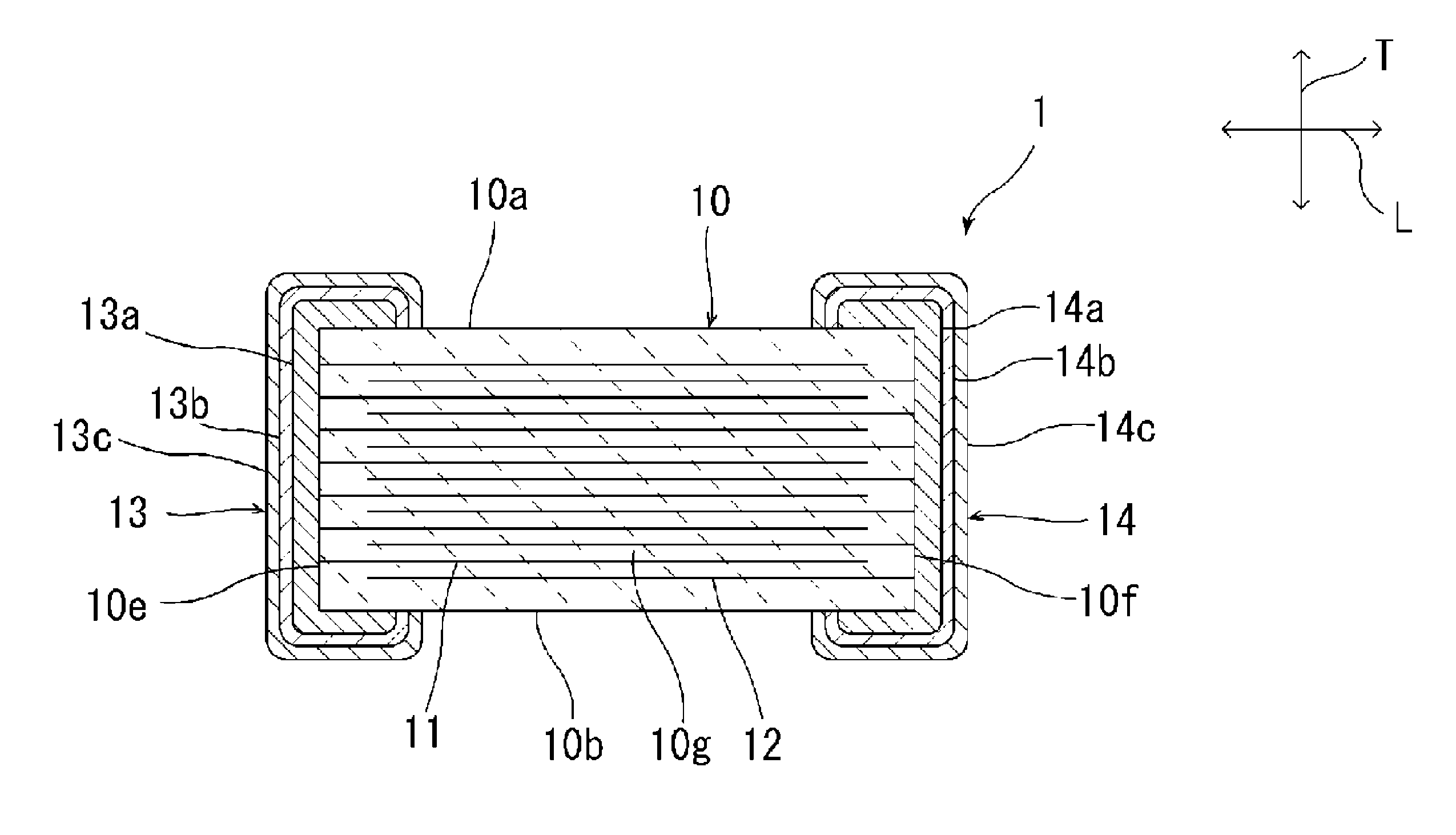

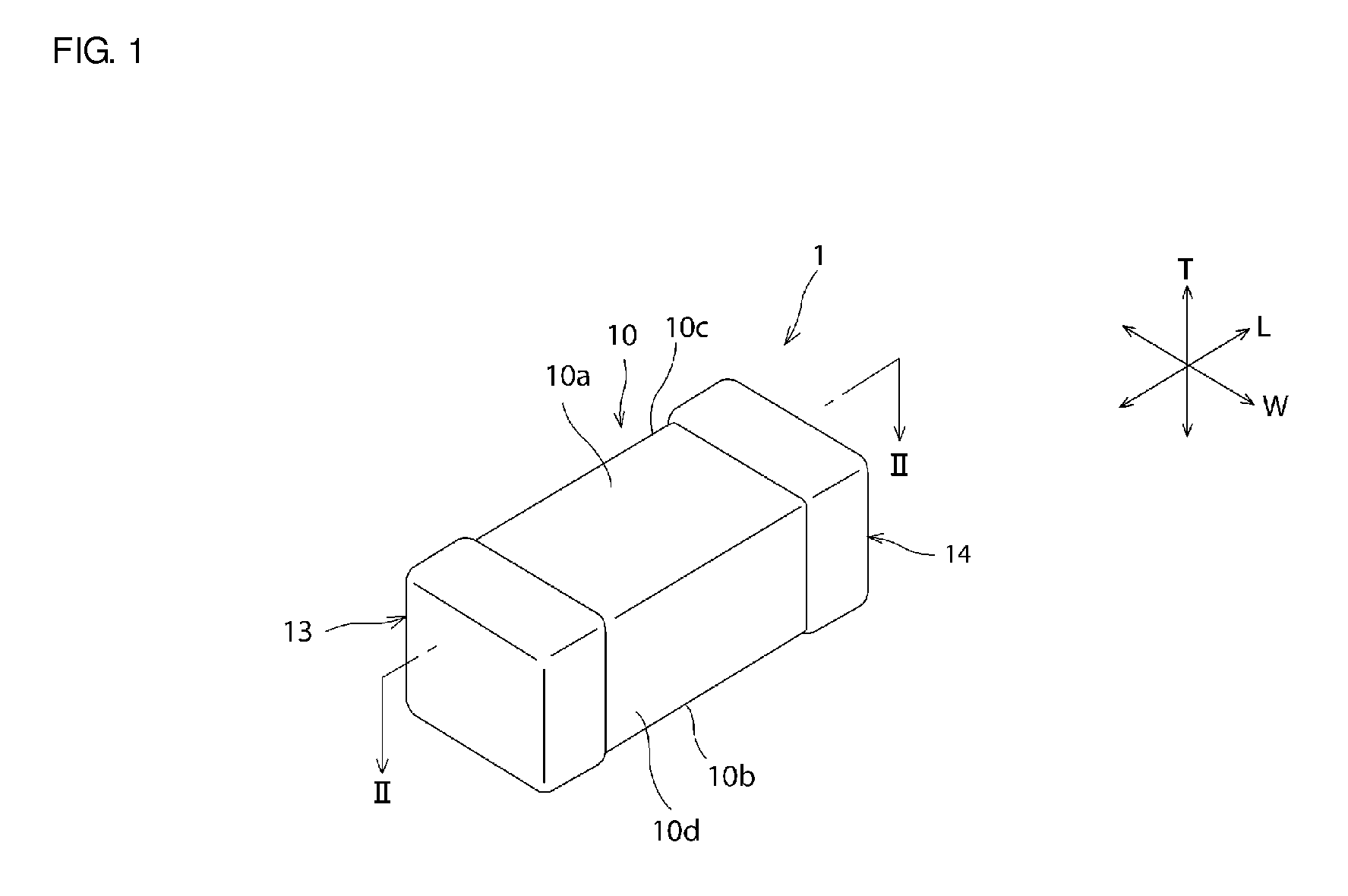

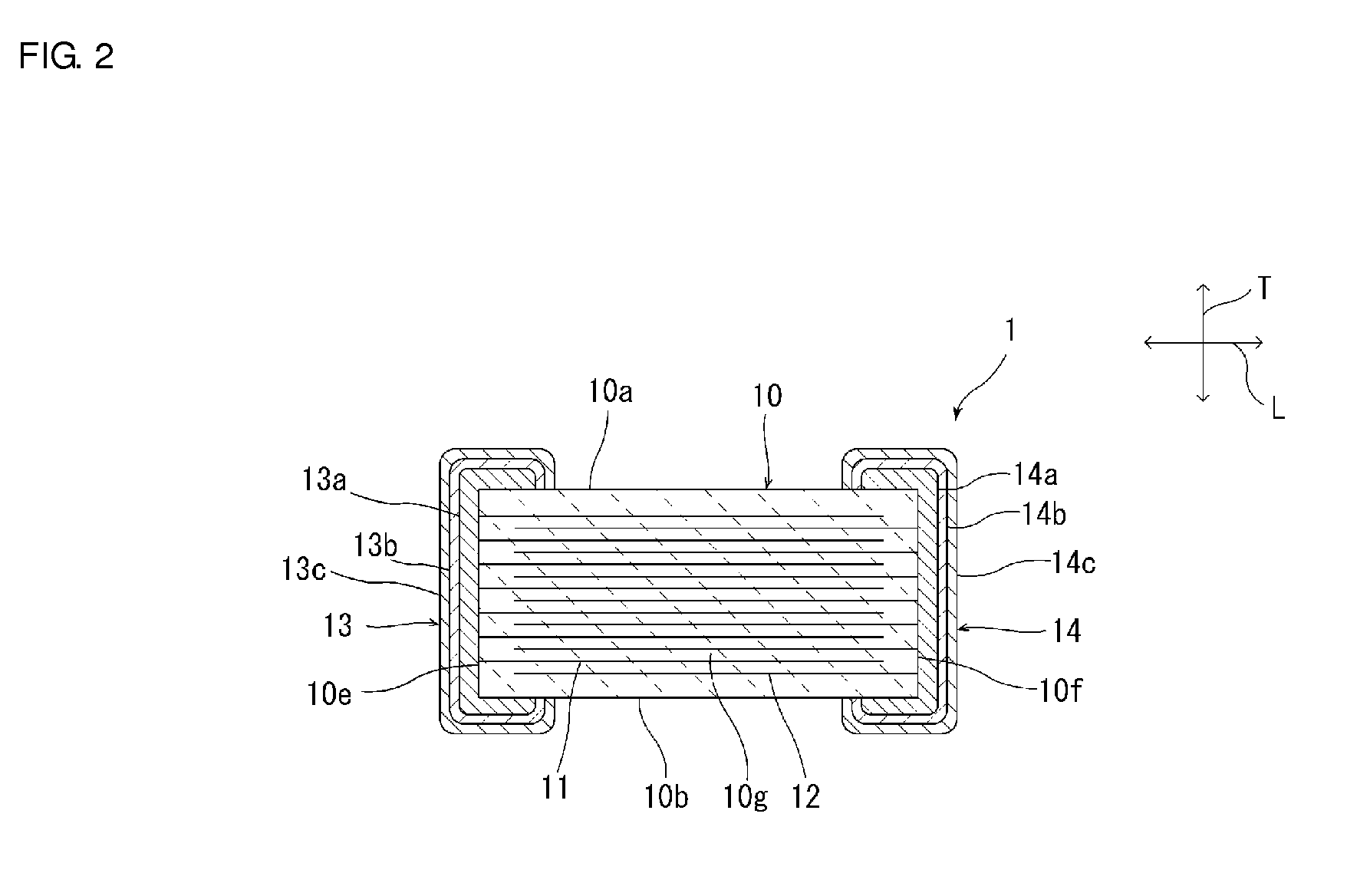

Ceramic electronic component

ActiveUS8988850B1Not easy to damageFixed capacitor electrodesFixed capacitor dielectricConductive materialsElectronic component

A ceramic electronic component includes a ceramic body and first and second outer electrodes. The first and second outer electrodes are located on the ceramic body. The first outer electrode includes a first resin electrode layer, and the second outer electrode includes a second resin electrode layer. Each of the resin electrode layers includes a conductive material and a resin. The moisture content of the resin electrode layers is about 0.005 mass % or less.

Owner:MURATA MFG CO LTD

Method of manufacturing multilayered ceramic capacitor by spin coating and multilayered ceramic capacitor

Disclosed herein is a method of manufacturing a multilayered ceramic capacitor by a spin coating process, and a multilayered ceramic capacitor obtained by the above method. The method of the current invention provides a plurality of dielectric layers formed by spin coating, in which the process of coating the dielectric layer and the process of printing the inner electrode can be provided as a single process. Therefore, the thickness of the dielectric layer is easily controlled while the dielectric layer is formed to be thin. Further, since the dielectric layers and the inner electrodes are formed successively, the processes of separating and layering the dielectric layers, and the process of compressing the ceramic multilayered body can be omitted. Thereby, the ceramic multilayered body need not be compressed, and thus, a pillowing phenomenon does not occur in the multilayered ceramic capacitor.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

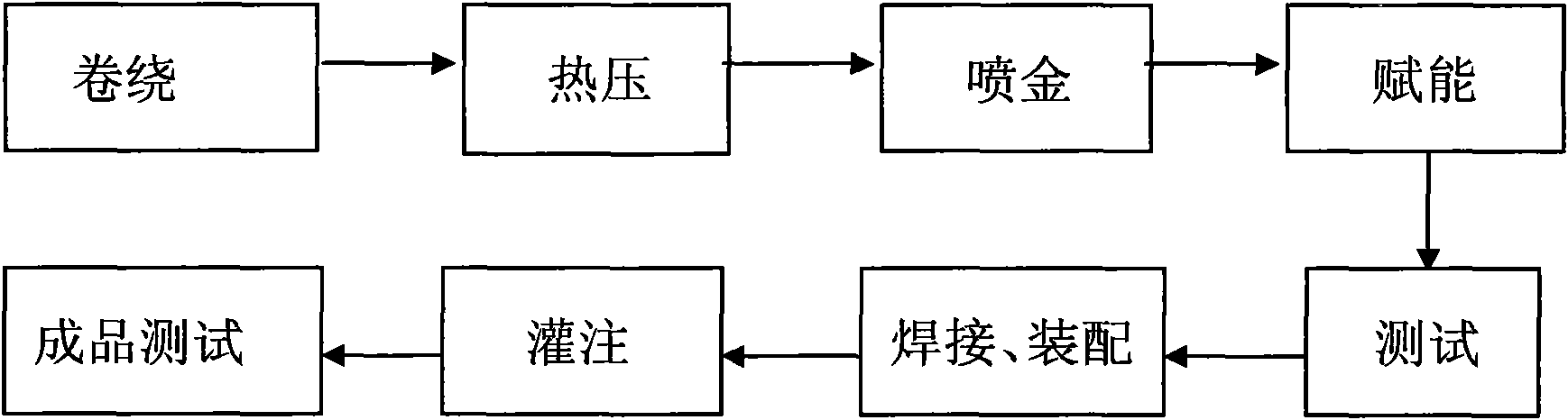

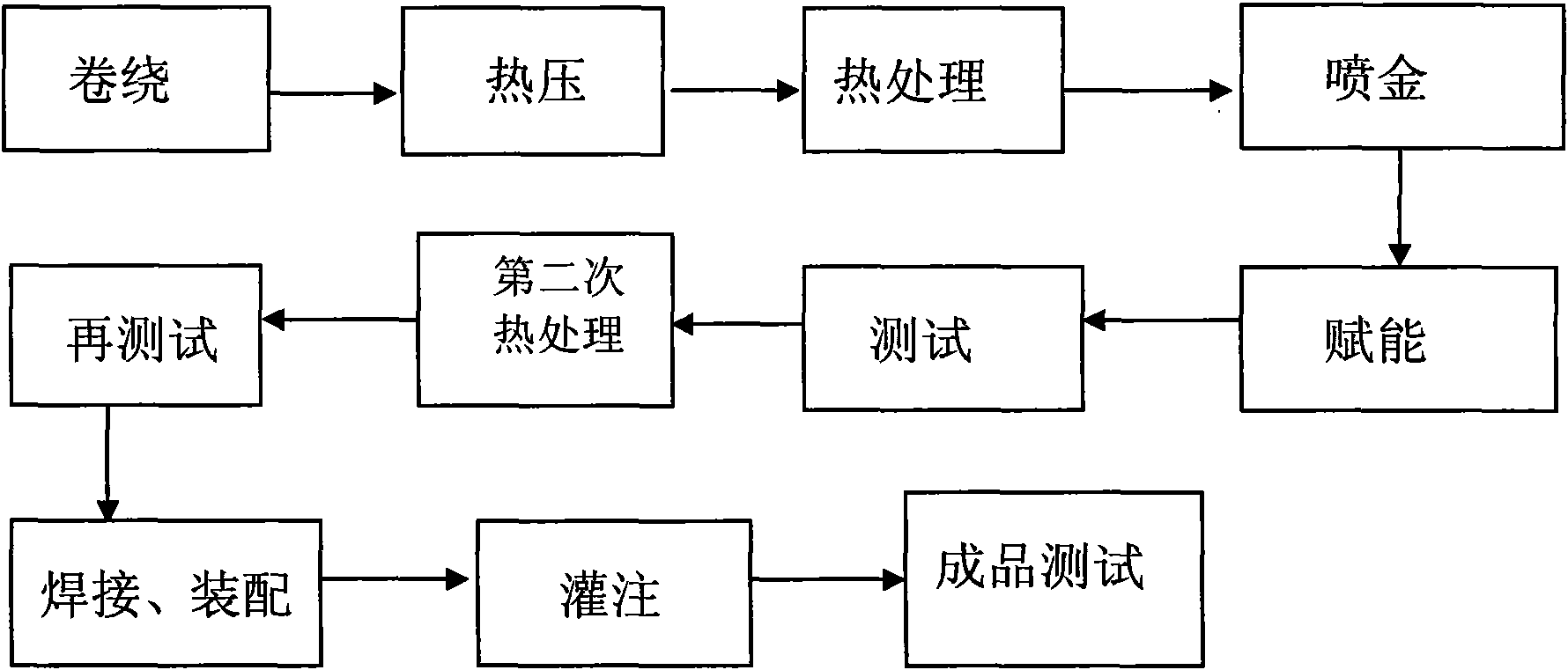

Manufacturing method capable of effectively improving product life of capacitor

ActiveCN101567265AIncrease capacityExtend your lifeWound capacitorsDrying/impregnating machinesProduct testingEngineering

The invention discloses a manufacturing method capable of effectively improving product life of a capacitor, which comprises the following manufacturing steps of: first step: winding; second step: hotpressing; third step: metal spraying; fourth step: energizing; fifth step: testing; sixth step: welding and assembling; seventh step: filling; and eighth step: final product testing. The method is characterized in that a heat treatment step is further included between the second step: hot pressing and the third step: metal spraying, and a second heat treatment step and second testing are furtherincluded between the fifth step: testing and the sixth step: welding and assembling. The method mainly aims at a motor capacitor which is subjected to heat treatment process after finishing the primary winding and hot pressing so as to remove moisture inside a core and stabilize product capacity; and after the test step, the product is subjected to heat treatment, thereby improving the product life.

Owner:SHANGHAI CHUNLI ELECTRONICS IND

Processing method for vacuum drying impregnation of capacitor

InactiveCN102856084AEasy to integrateRemove completelyDrying/impregnating machinesLow vacuumAluminum foil

The invention discloses a processing method for vacuum drying impregnation of a capacitor. The method comprises the following steps of heating a power capacitor to 80-90 DEG C; cooling the internal temperature of the power capacitor to 70-80 DEG C, and improving the vacuum degree of the gas partial pressure in a vacuum tank to 0.5-1 Pa step by step; opening an ultrasonic generating component which is arranged on the external wall of the power capacitor, and cooling the internal temperature of the power capacitor to 40-60 DEG C, and reducing the gas partial pressure of the vacuum tank at 0.2-0.5 Pa, and meanwhile slowly pouring insulating medium oil in the power capacitor shell for 8-22 h; after the internal part of the power capacitor is filled with the insulating medium oil, maintaining the opening state of the ultrasonic, reducing the internal temperature of the power capacitor, maintaining the internal temperature at 30-40 DEG C, and controlling the vacuum degree of the gas partial pressure in the vacuum tank about 0.2-0.5 Pa. According to the processing method provided by the invention, the gas integrated into the insulation medium oil and the local few low vacuum gas which is sealed between solid medium layers and between medium and aluminum foil layers by the insulation medium oil can be exhausted more easily.

Owner:ENERTECH SUZHOU ENERGY TECH CO LTD

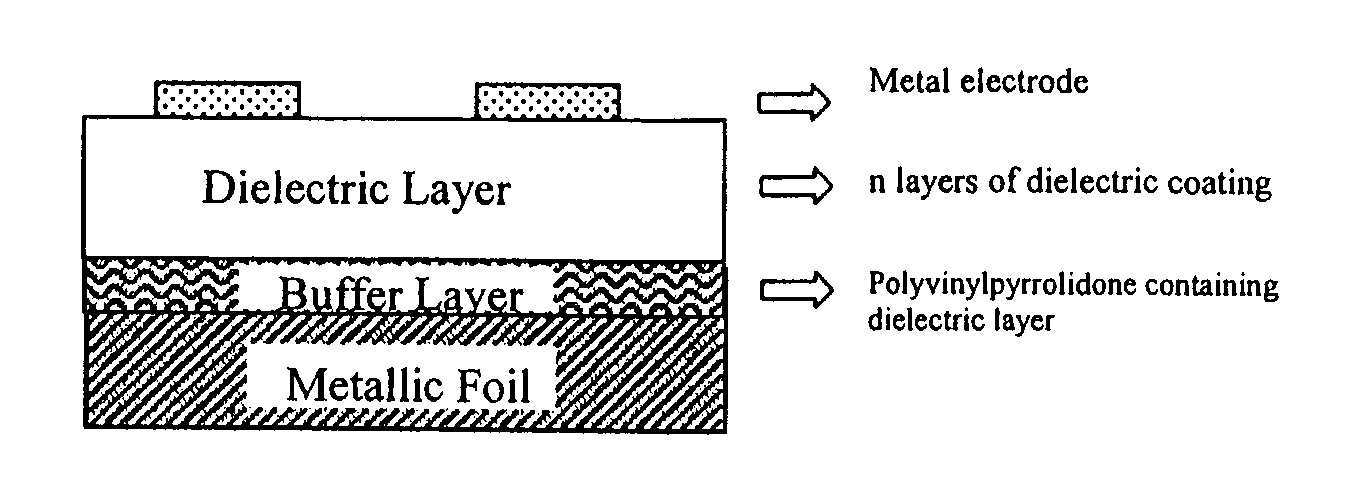

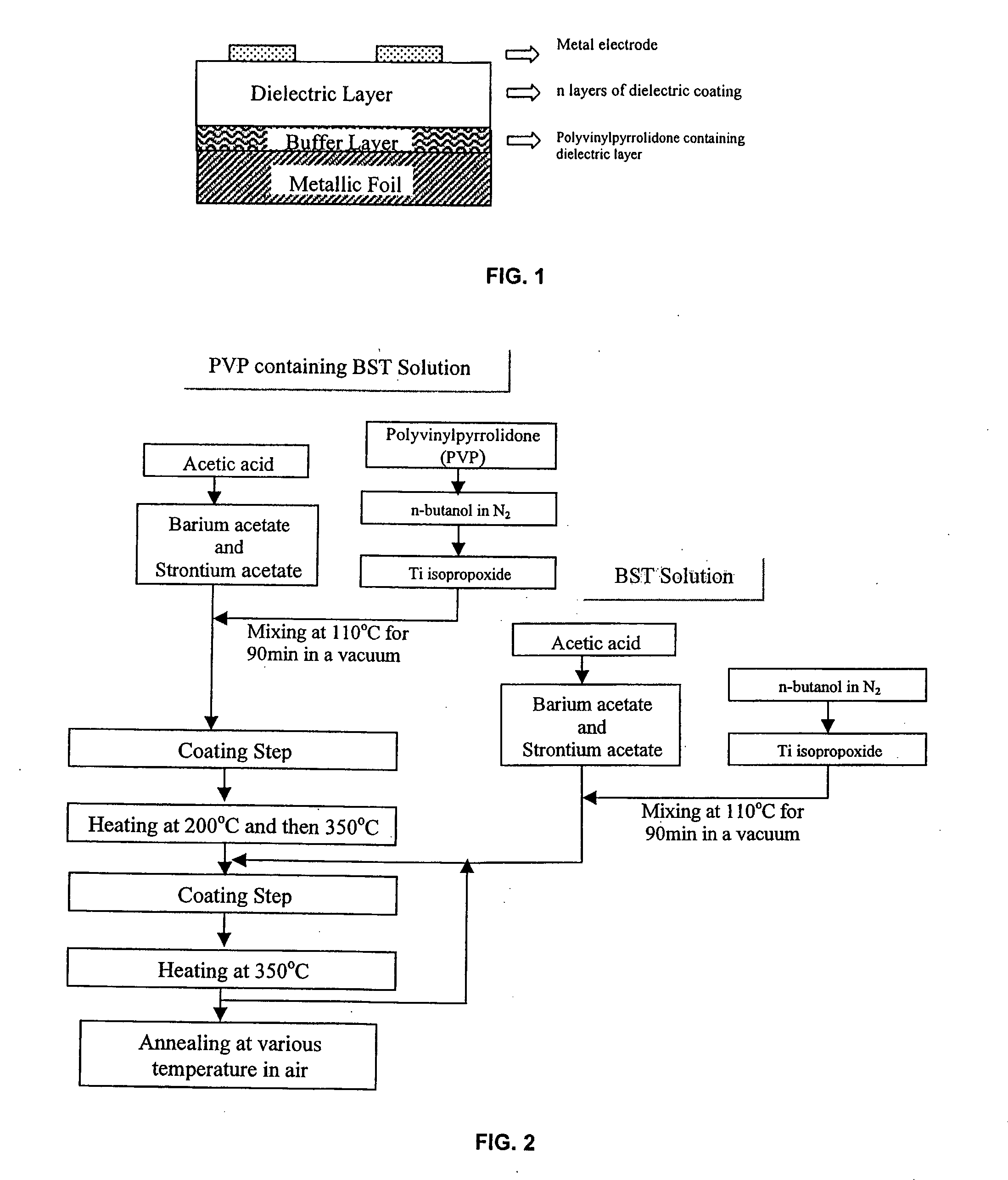

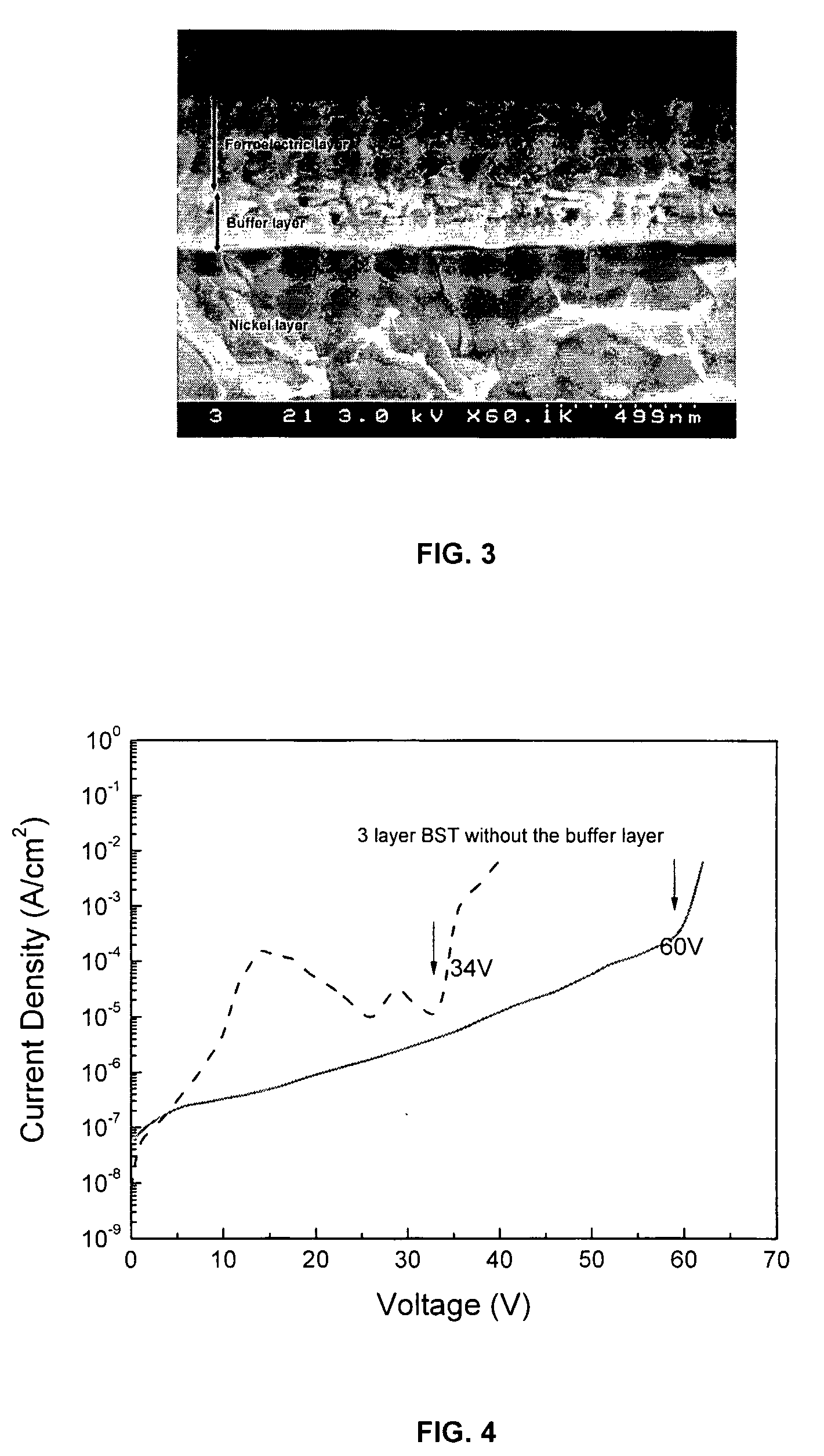

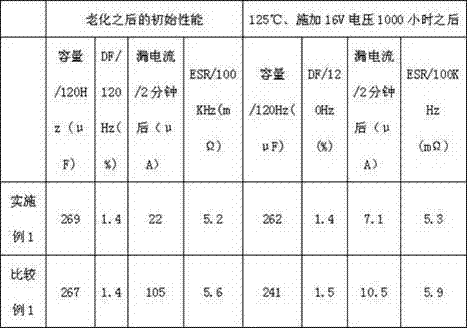

Thin Film Ferroelectric Composites, Method of Making and Capacitor Comprising the Same

InactiveUS20080171230A1Promotes structural relaxationReduces stress evolutionThin/thick film capacitorLayered productsBreakdown strengthOptoelectronics

Thin film ferroelectric capacitor composites exhibiting reduced leakage current and enhanced breakdown strength are prepared using sol-gel processing. The composite contains a buffer layer and at least one dielectric layer and is formed by depositing by sol-gel processing onto a substrate a composition containing a heterocyclic amide, such as polyvinylpyrrolidone.

Owner:ZOU QIN +2

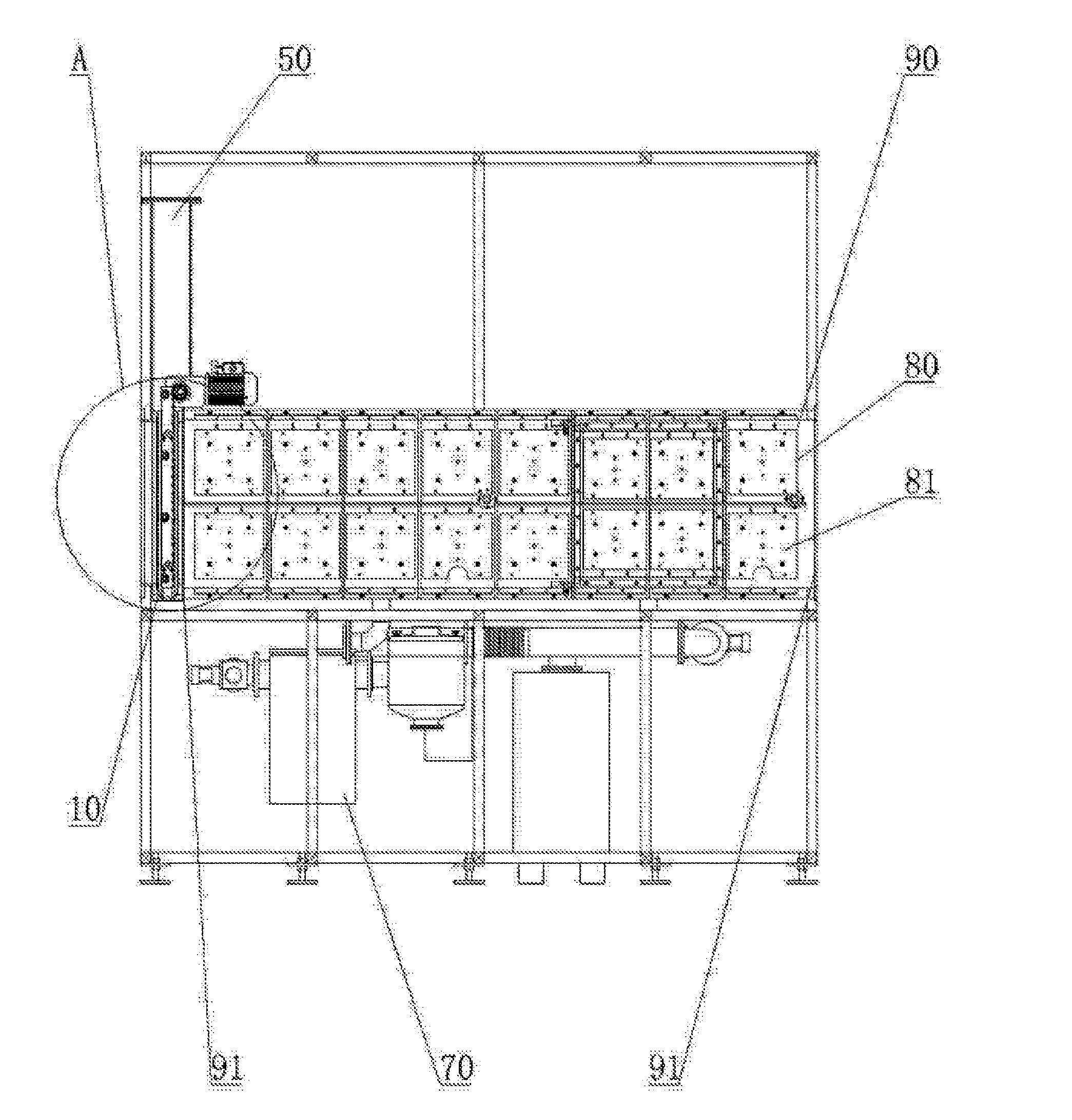

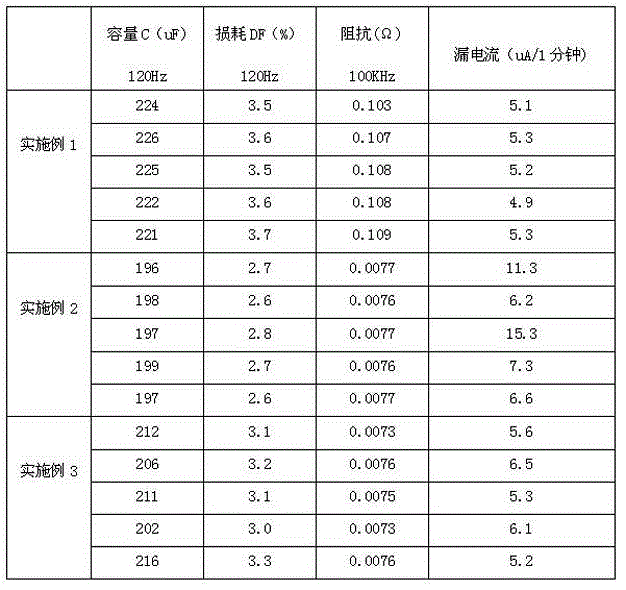

High-reliability solid electrolytic capacitor manufacturing method

InactiveCN102867651ALow conductivityReduce the effect of capacitor performanceSolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolysisCarbonization

The invention relates to a high-reliability solid electrolytic capacitor and a manufacturing method thereof. The manufacturing method comprises the following steps: performing carbonization, formation and repair on a core formed through winding; then respectively impregnating in a monomer and a oxidizer, and performing polymerization reaction; when the polymerization reaction reaches a certain degree, impregnating the core in the monomer again, and performing polymerization while heating; and then, packaging, aging and sorting. According to the invention, the manufactured solid electrolytic capacitor has the advantages of low equivalent series resistance, low drain current and high reliability.

Owner:SHENZHEN POLYCAP ELECTRONICS TECH

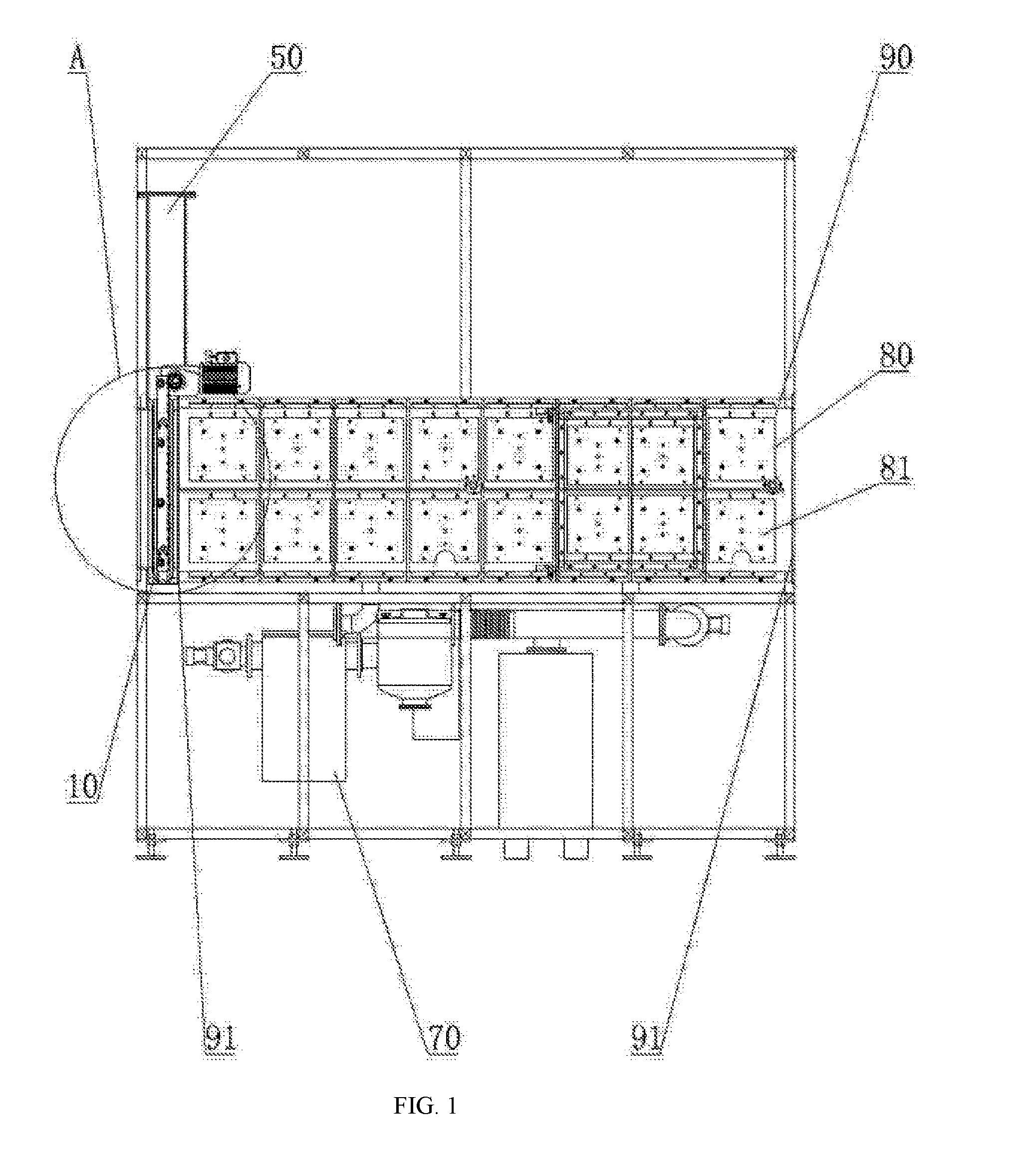

Automatic vacuum drying device

ActiveUS20160258681A1Easy to install and repairEfficient dryingDrying using combination processesFinal product manufactureProduction lineVacuum extraction

An automatic vacuum drying device comprises a drying oven, a heating device used to heat the drying oven, a vacuum extraction device used to evacuate the drying oven, a nitrogen input device used to input nitrogen into the drying oven, and a transporting device located inside the drying oven and used to transport materials, two first openings are located at two opposite sides of the drying oven, an automatic sealing door is mounted on at least one of the first openings, the automatic sealing door includes a first door plank and a second door plank parallel to the first door plank, an elevator structure is located between the first door plank and the second door plank, the elevator structure is used to lift the first door plank and the second door plank. The automatic vacuum drying devices can form an automatic vacuum drying production line conveniently, and the automatic vacuum drying production line has high degree of automation, and high processing efficiency, such that it is possible to drastically improve the vacuum drying efficiency.

Owner:SHENZHEN TIME HIGH TECH EQUIP

Manufacturing method for solid-liquid mixed type aluminum electrolytic capacitor

ActiveCN103560006AAvoid excessive leakageAvoid short circuit problemsElectrolytic capacitorsDrying/impregnating machinesElectrolysisSteel bar

The invention discloses and provides a manufacturing method for a solid-liquid mixed type aluminum electrolytic capacitor. The manufacturing method is quite low in ESR and good in high frequency filtering performance, can be used for achieving certain oxide film repair ability, improves voltage of the electrolytic capacitor and reduces leak current. The manufacturing method includes the following steps that an isolating paper roll is interfered between anodizing aluminum foil and cathode foil to be wound into a core package, wherein the anodizing aluminum foil is well riveted with an outgoing line; the core package is welded on a stainless steel bar in a spot welding mode, and an oxide film is charged and repaired in formation liquid; the charged core package is rinsed thoroughly and dried; the dried core package is impregnated in turbid liquid; the impregnated core package is dried and then is impregnated in electrolyte solution; the impregnated product is provided with a rubber plug and sealed with an outer shell to form a semi-finished capacitor; aging and charging are carried out on the sealed semi-finished capacitor to form the finished capacitor.

Owner:ZHUHAI LEAGUER CAPACITOR

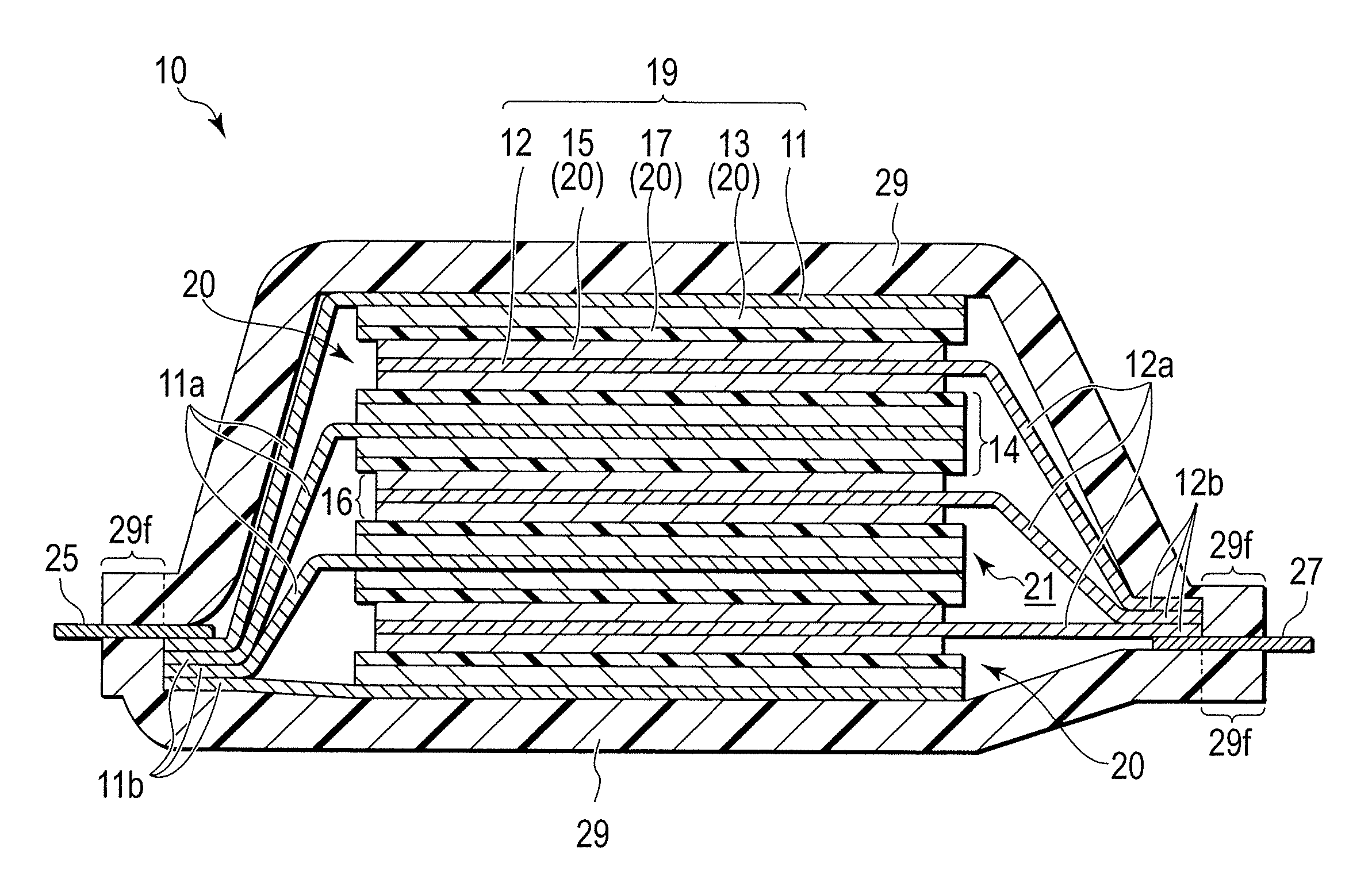

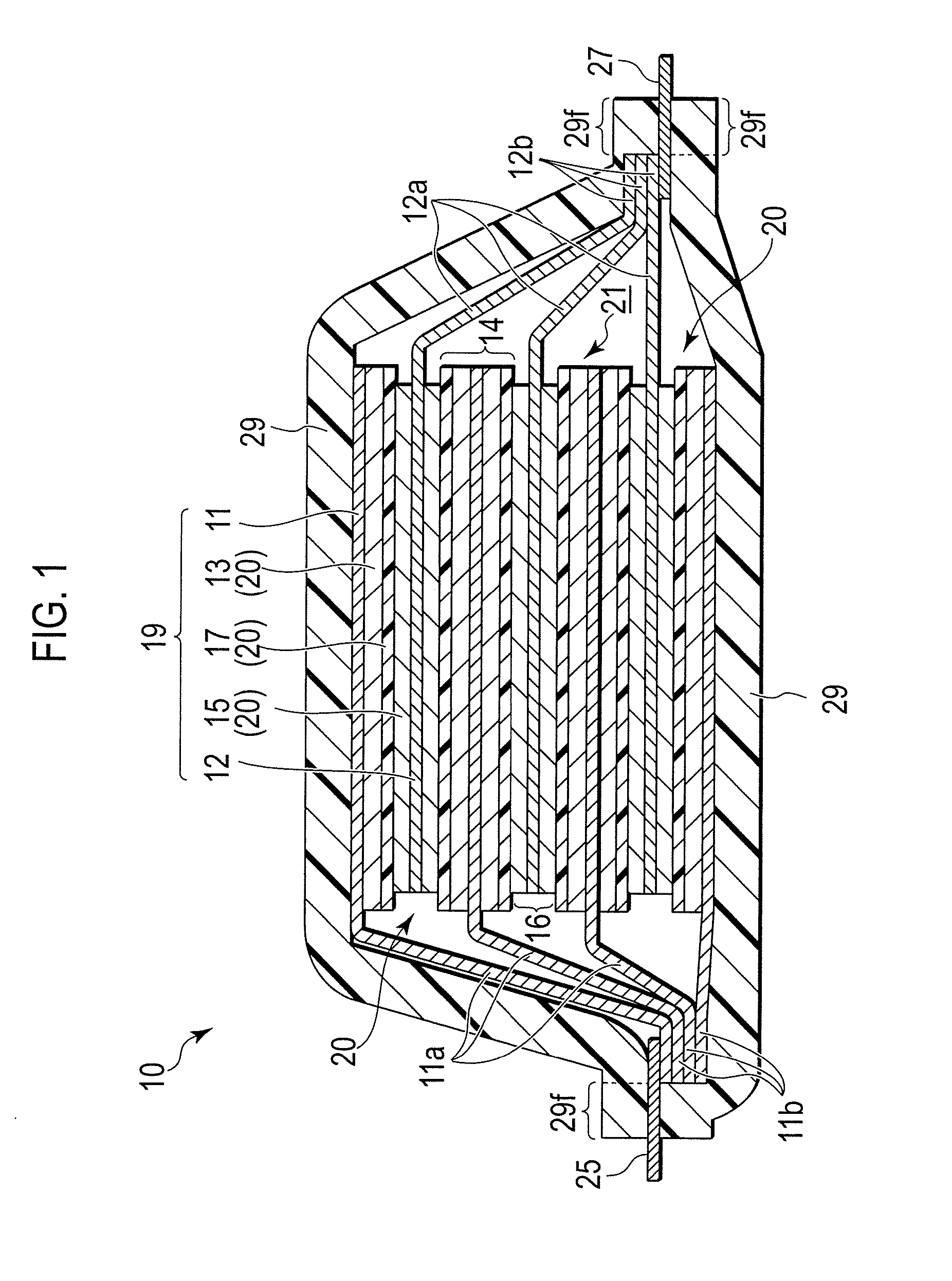

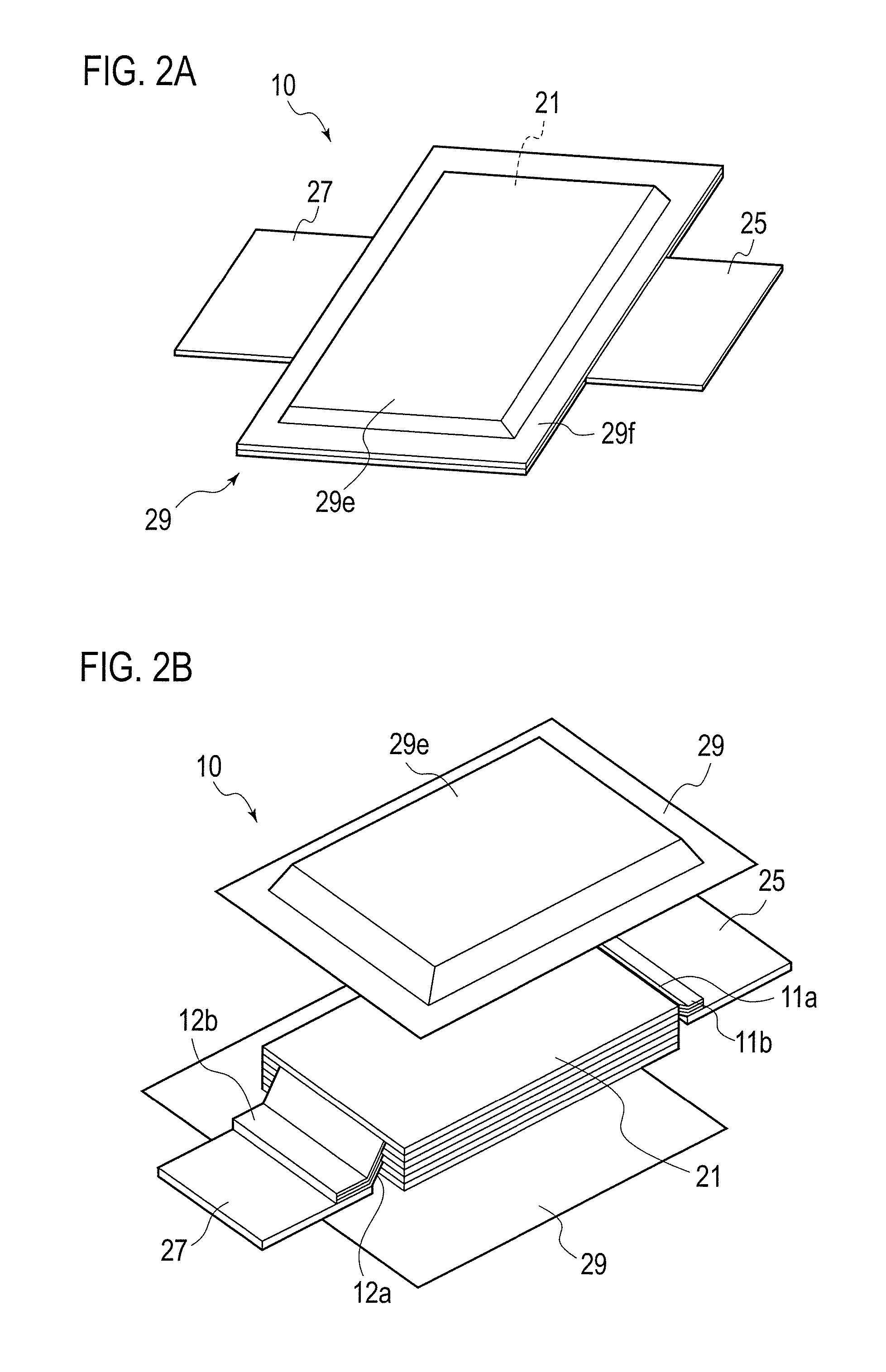

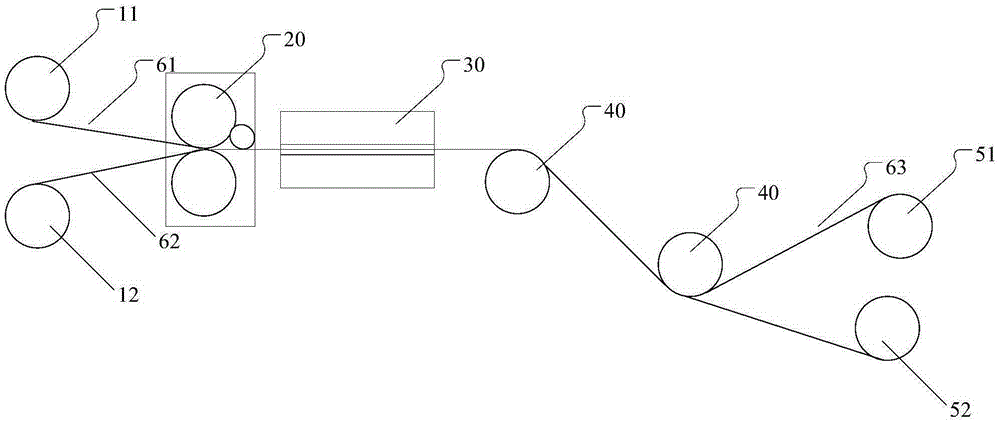

Method and device for manufacturing film-wrapped electrical device

ActiveUS20140373344A1Easy to transformElectrode carriers/collectorsCapacitor housing/encapsulationEngineeringAtmospheric pressure

Provided is a method for manufacturing a film-wrapped electrical device, including: a first injection step of depressurizing, to a given pressure lower than atmospheric pressure, the inside of an injection chamber (2) in which a bag-shaped laminate film wrapping member (29) is placed, the laminate film wrapping member (29) having an opening portion (29a) and housing an electrode assembly (21′) including a positive electrode and a negative electrode stacked with a separator therebetween, and injecting part of a predetermined injection amount of an electrolyte solution (20) into the wrapping member (29) through the opening portion (29a); and a second injection step of, after the first injection step, pressurizing the inside of the injection chamber (2) to a pressure higher than the given pressure and injecting the rest of the predetermined injection amount of the electrolyte solution (20).

Owner:AUTOMOTIVE ENERGY SUPPLY +1

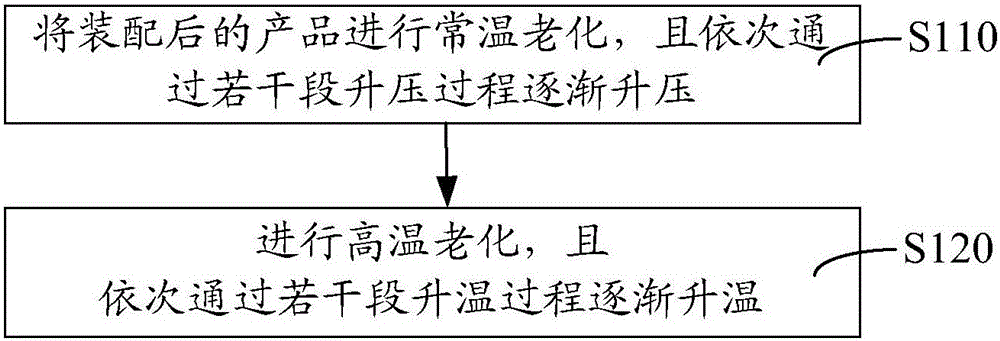

Manufacturing method for aluminum electrolytic capacitor

InactiveCN105931862AImprove stabilityAvoid explosive situationsDrying/impregnating machinesElectrolytic capacitor manufactureRoom temperatureVoltage boosting

The invention relates to a manufacturing method for an aluminum electrolytic capacitor. The manufacturing method comprises the processes of cutting, riveting and coiling, impregnating, assembling and aging, wherein the aging process comprises the steps of carrying out normal-temperature aging on the assembled product, and gradually increasing voltage through multiple sections of voltage-boosting processes which are implemented at intervals in time sequence; carrying out high-temperature aging, and gradually increasing temperature through multiple sections of temperature-increasing processes which are implemented at intervals in time sequence, wherein damaged oxide films generated in the processes of cutting, riveting and coiling and the like can be repaired by the normal-temperature aging process; the oxide films can be subjected to crystal form conversion and can be stabilized by the high-temperature aging process; the stability of the product in the voltage-boosting process can be improved by the normal-temperature aging process; the condition of protrusion or explosion of the product caused by one-time direct temperature increasing can be avoided due to the high-temperature aging process; and the performance of the product can be detected in time after each section of the temperature-increasing process is completed so as to detect unqualified products in each stage in advance in order to improve the process.

Owner:深圳市万腾电子有限公司

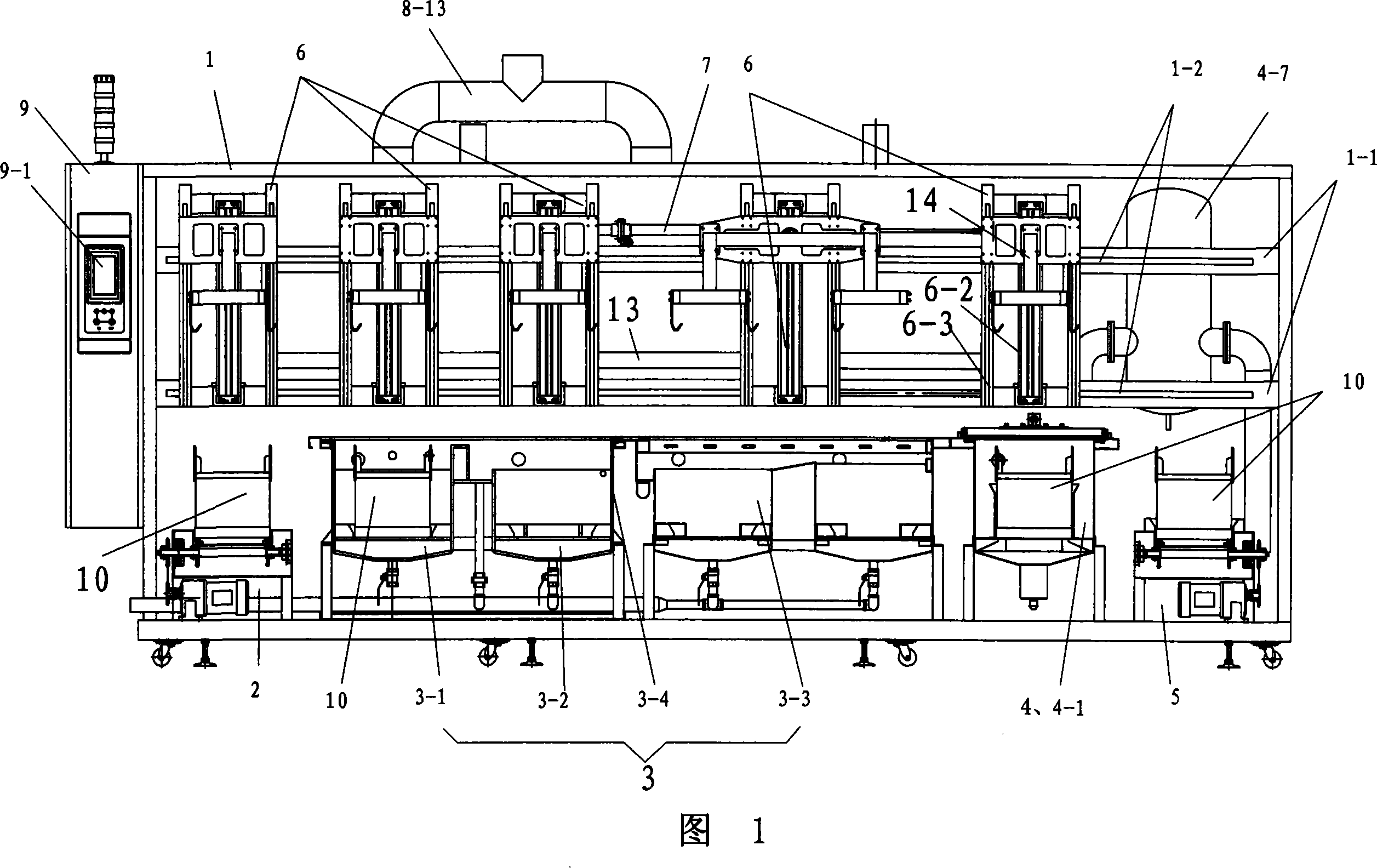

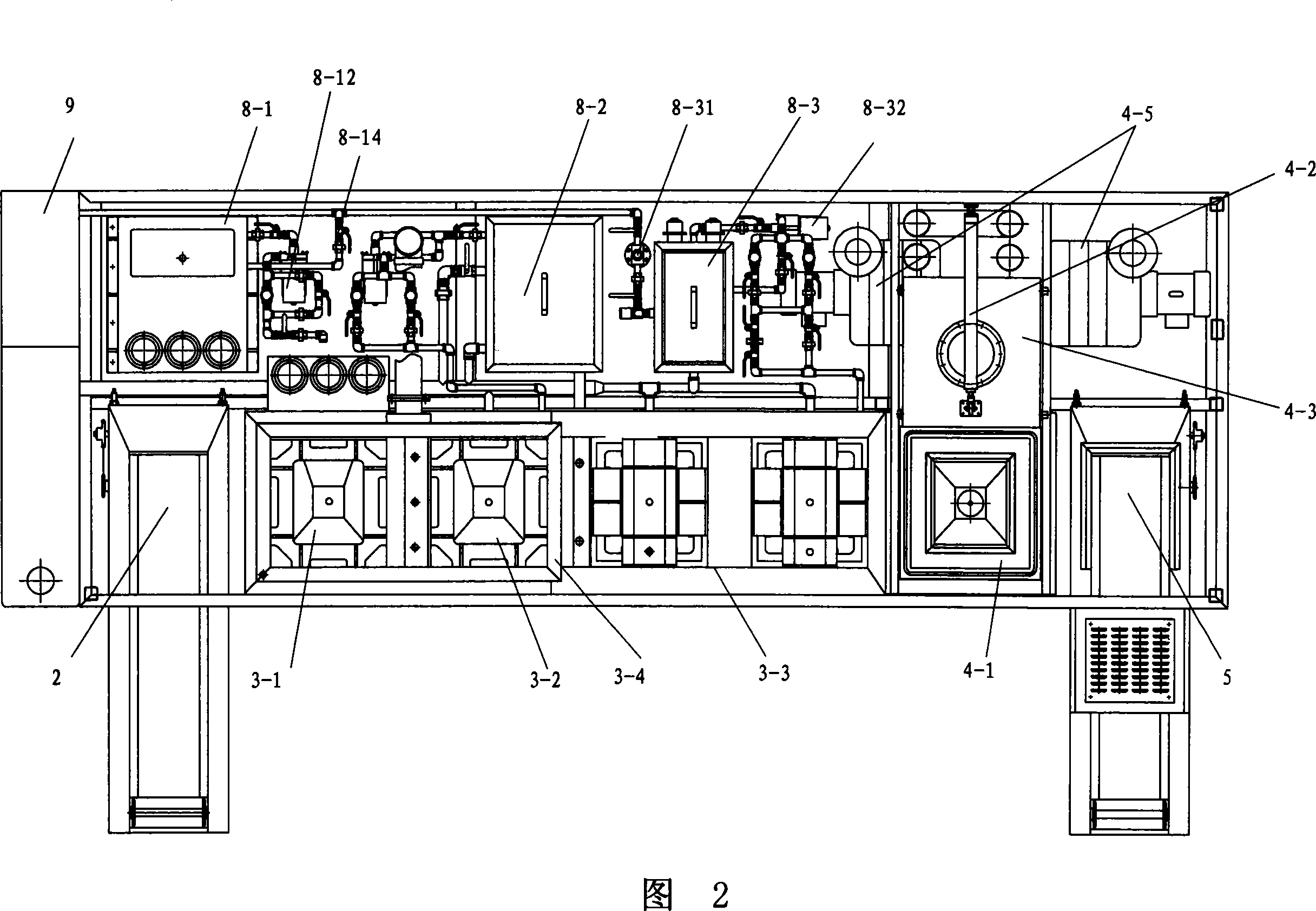

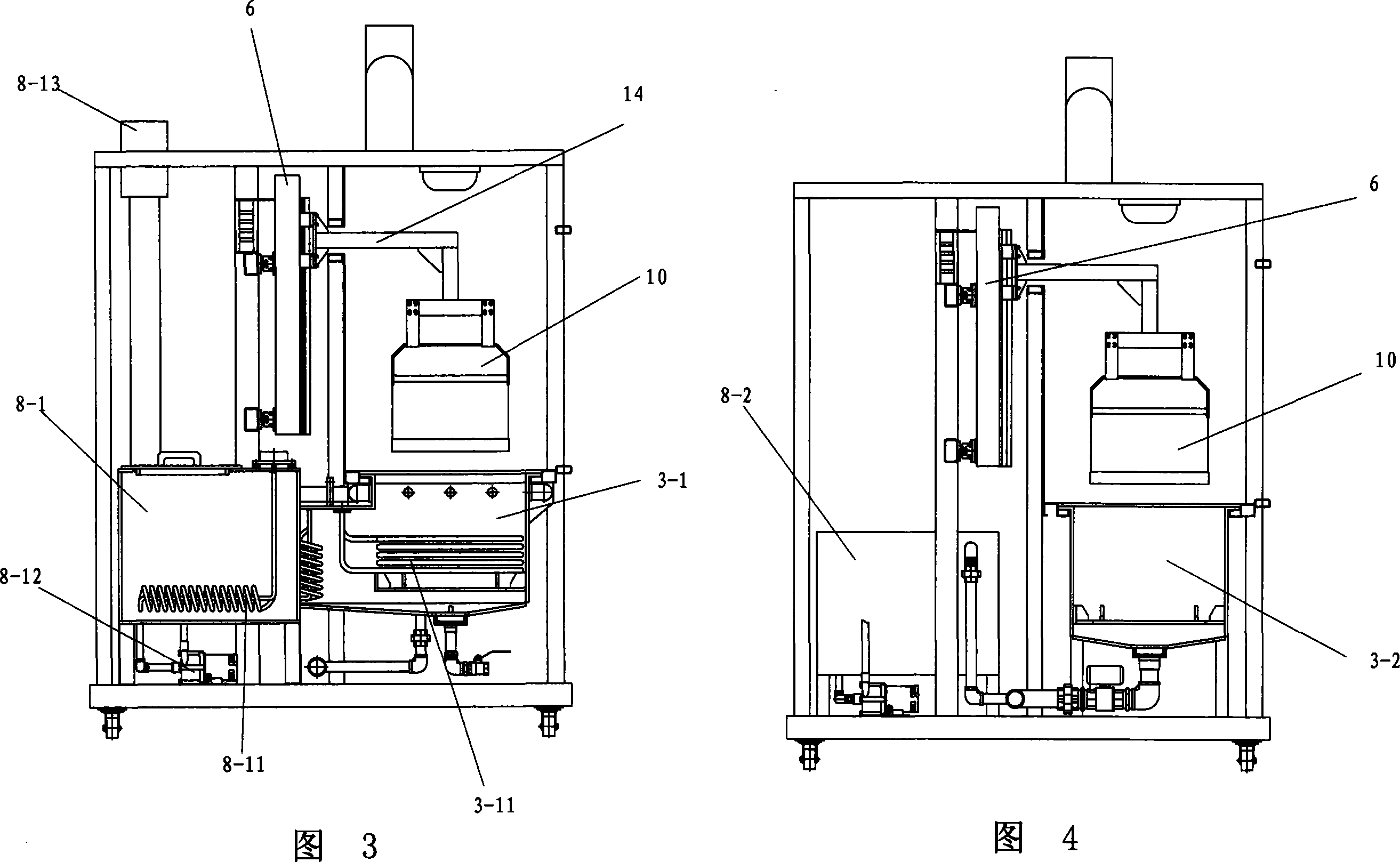

Capacitor cleaning drying apparatus and cleaning drying method

InactiveCN101178980AReduce labor intensityConvenient for centralized processingDrying/impregnating machinesWater savingMan machine

The invention relates to a cleaning and drying device for a capacitor, which consists of a host machine and an electric control cabinet, wherein, the host machine comprises a feeding mechanism, a cleaning and rinsing device, a drying device, a discharging mechanism and an auxiliary liquid system which are sealed inside a box; the cleaning and rinsing device is provided with an acid or alkali processing box and one to four rinsing boxes in sequence; the drying device has a drying box; the electric control cabinet consists of a touch film panel of man-machine exchange and a PCL programmable controller. The invention has a low labor strength for operation personnel; as the cleaning and rinsing course is finished inside a sealed box, volatile chemical medicament generated by solution or solvent is discharged reasonably from a vent-pipe, thus improving the labor environment and facilitating the discharging and centralized treatment for waste gas. As water for rinsing can be reused, water is saved. Heat air inside a blast heater is discharged through an induced draft fan, resulting in a negative pressure inside the box, thus decreasing the drying temperature inside the capacitor, saving energy sources and avoiding effect on the capacitor quality under a drying state of a relative high temperature.

Owner:李继忠

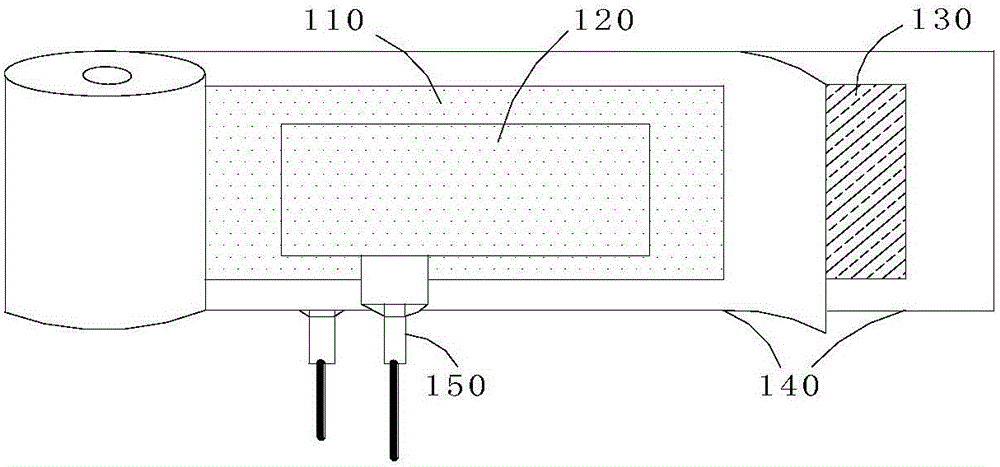

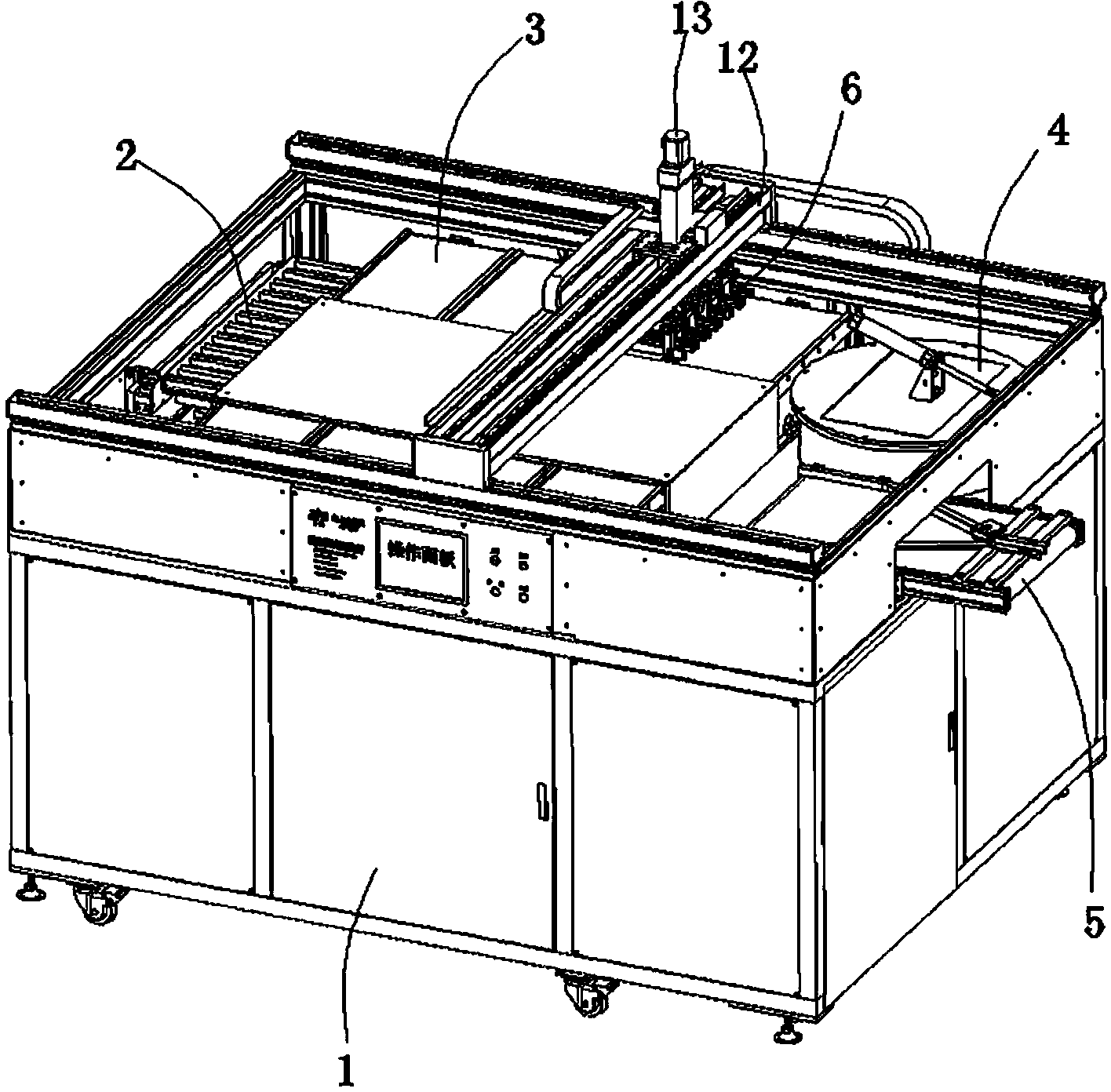

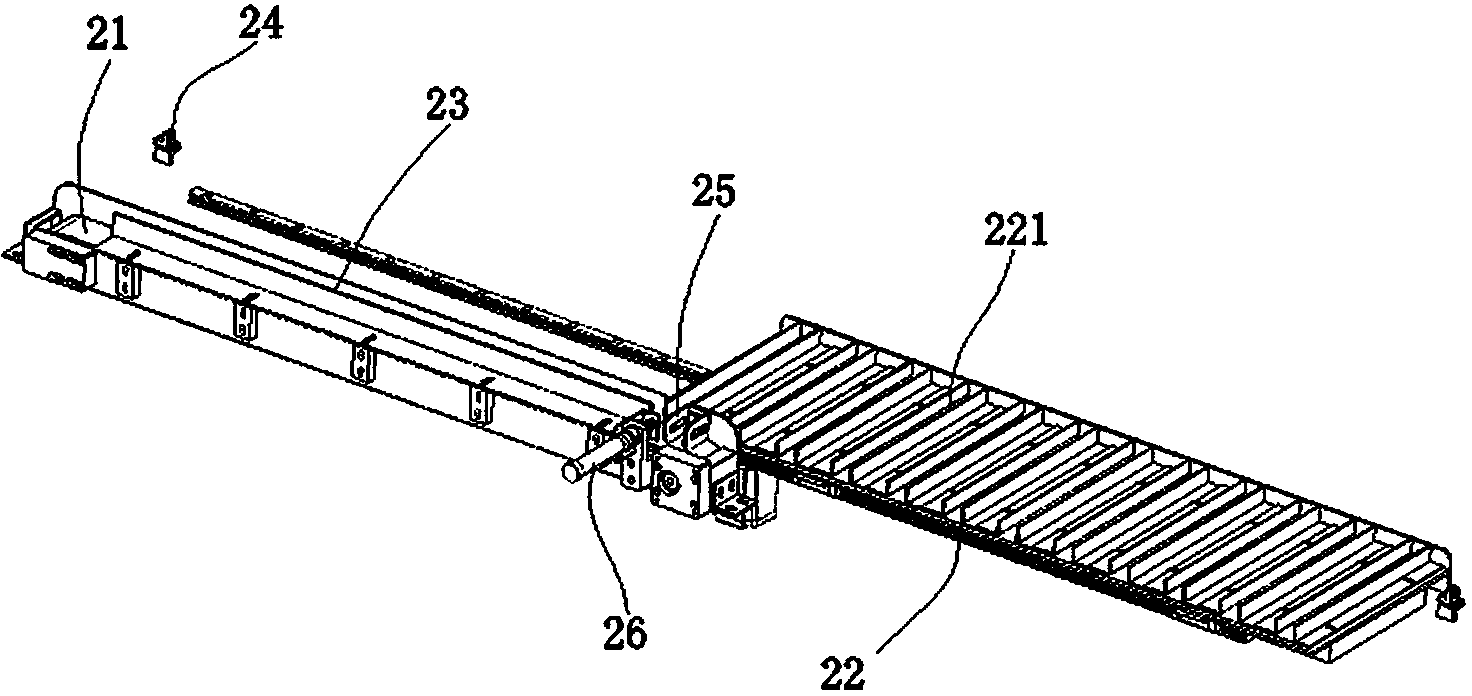

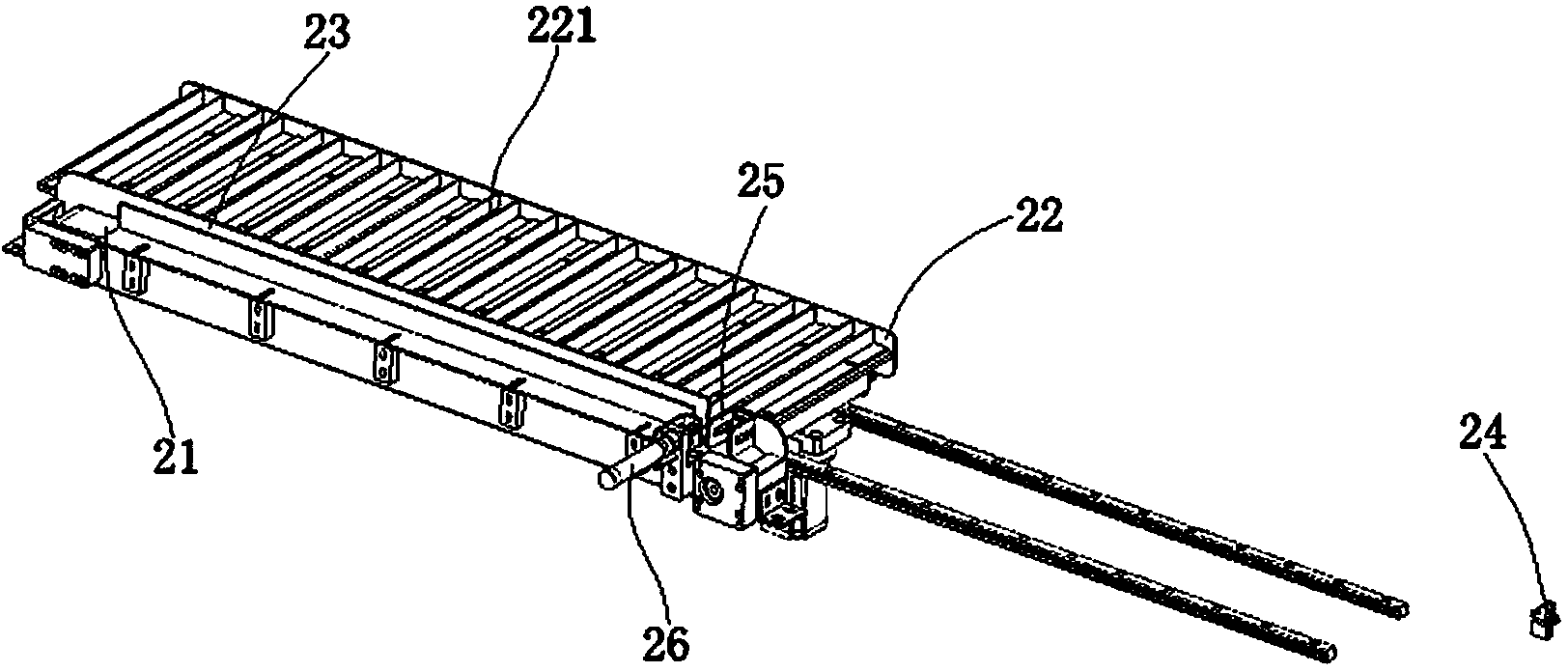

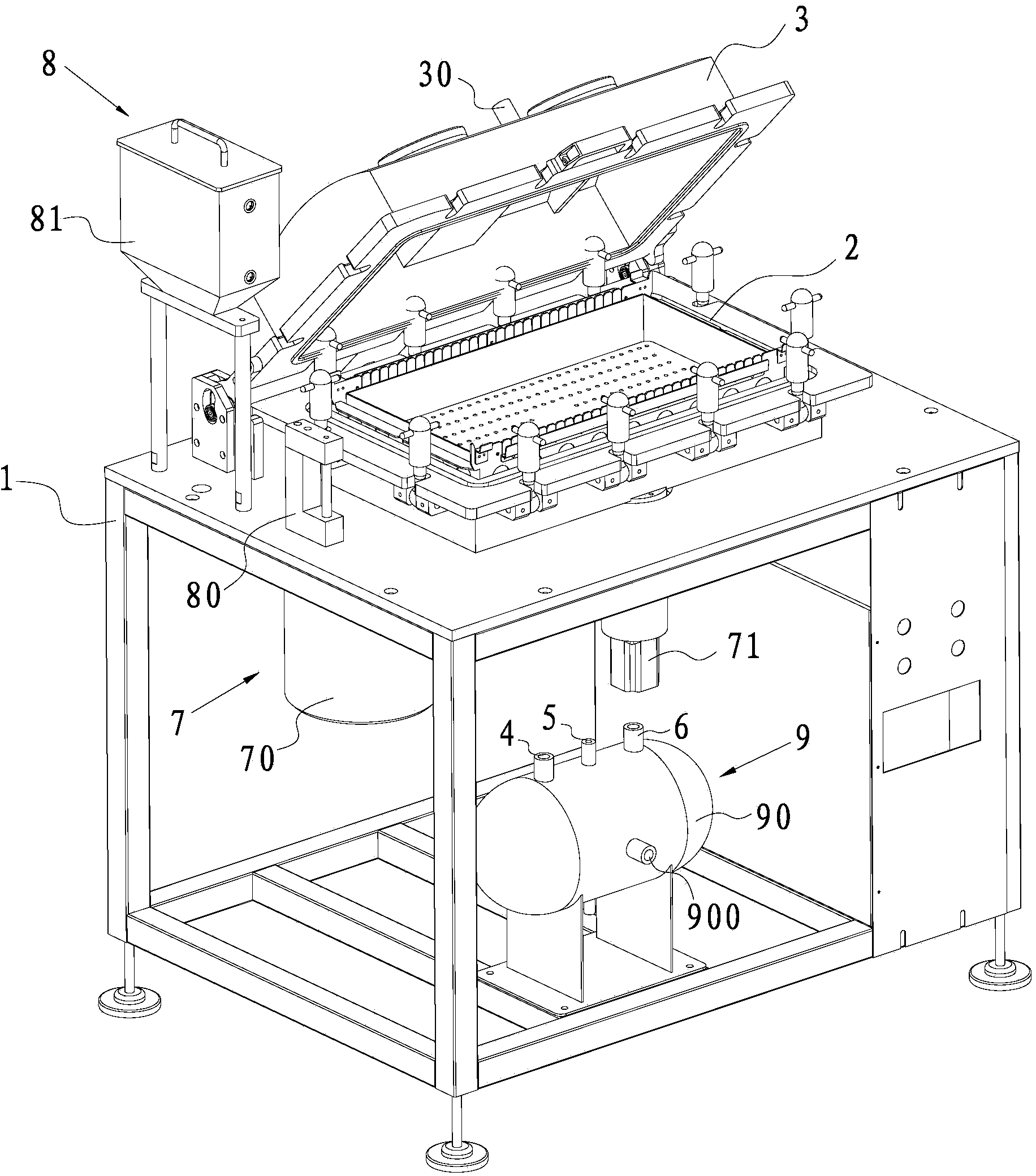

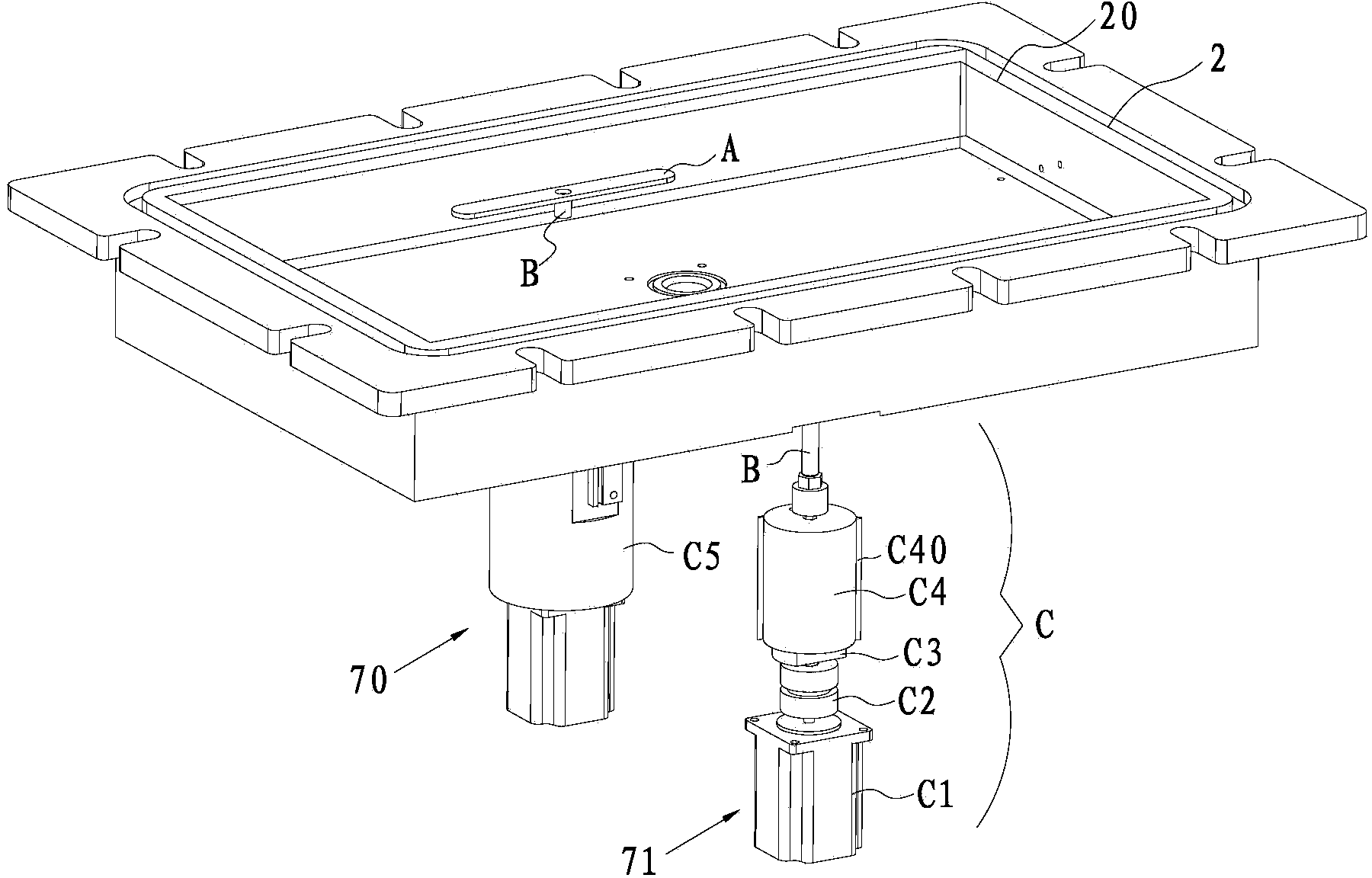

Automatic impregnating machine

ActiveCN104036976ASolve lossSolve pollutionDrying/impregnating machinesBiochemical engineeringManipulator

The invention discloses an automatic impregnating machine. The automatic impregnating machine comprises a rack; a feeding mechanism, an impregnating mechanism, a spin-drying mechanism and a blanking mechanism are sequentially arranged on the rack according to the material feeding direction; at least one manipulator is arranged on the rack, corresponding to the feeding mechanism, the impregnating mechanism, the spin-drying mechanism and the blanking mechanism; the impregnating mechanism is connected with at least one liquid storing barrel. With the adoption of the automatic impregnating machine, the processes of feeding, impregnating and spin-drying of a cell can be quickly, efficiently and fully automatically performed, thus the degree of automation is high, the production efficiency can be effectively improved, and the production cost is decreased; in addition, the impregnating efficiency is high, the impregnating quality is high, the energy consumption is small, no pollution is brought to the environment, the spin-drying quality is high, and the product quality is stable and reliable.

Owner:DONGGUAN DONG JIN MACHINERY

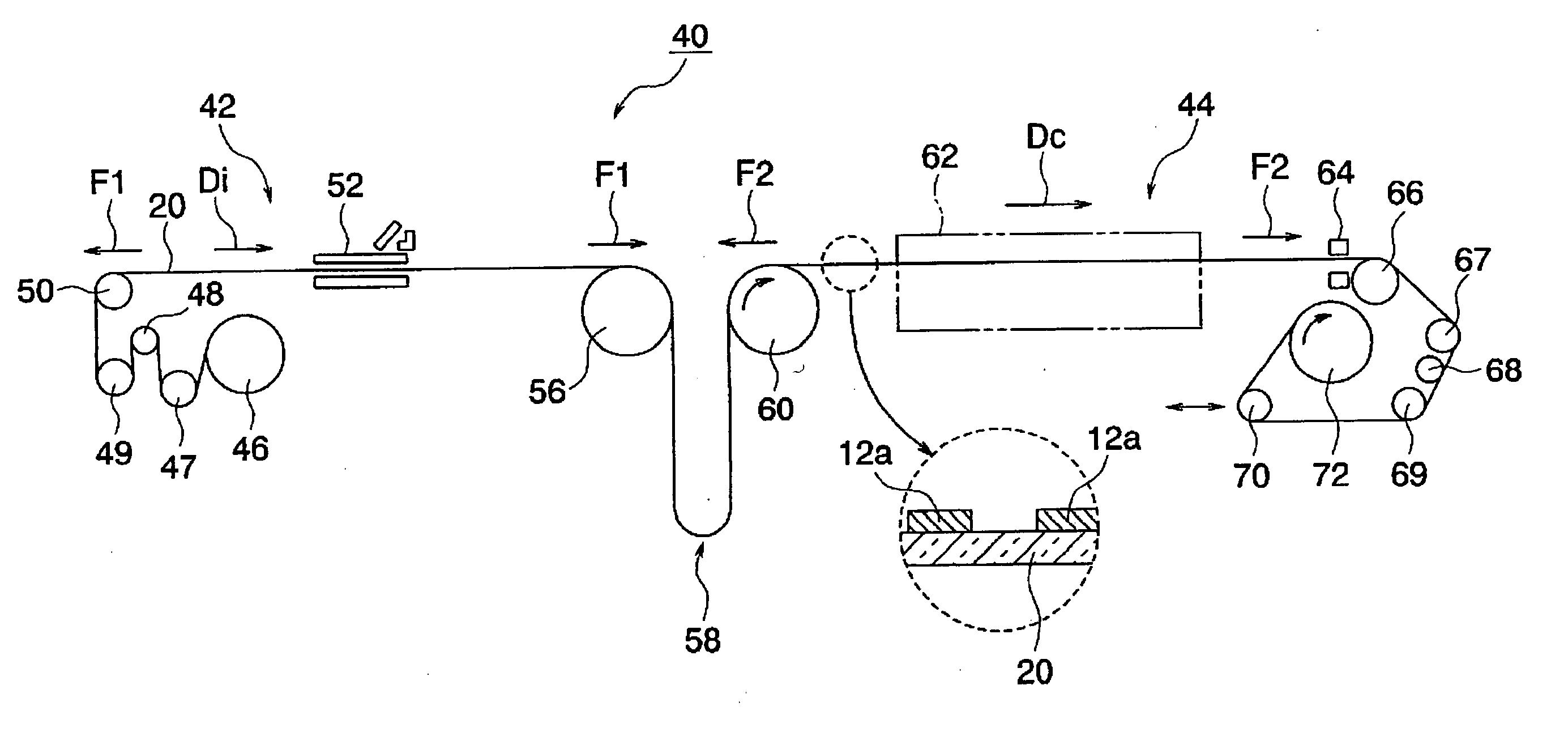

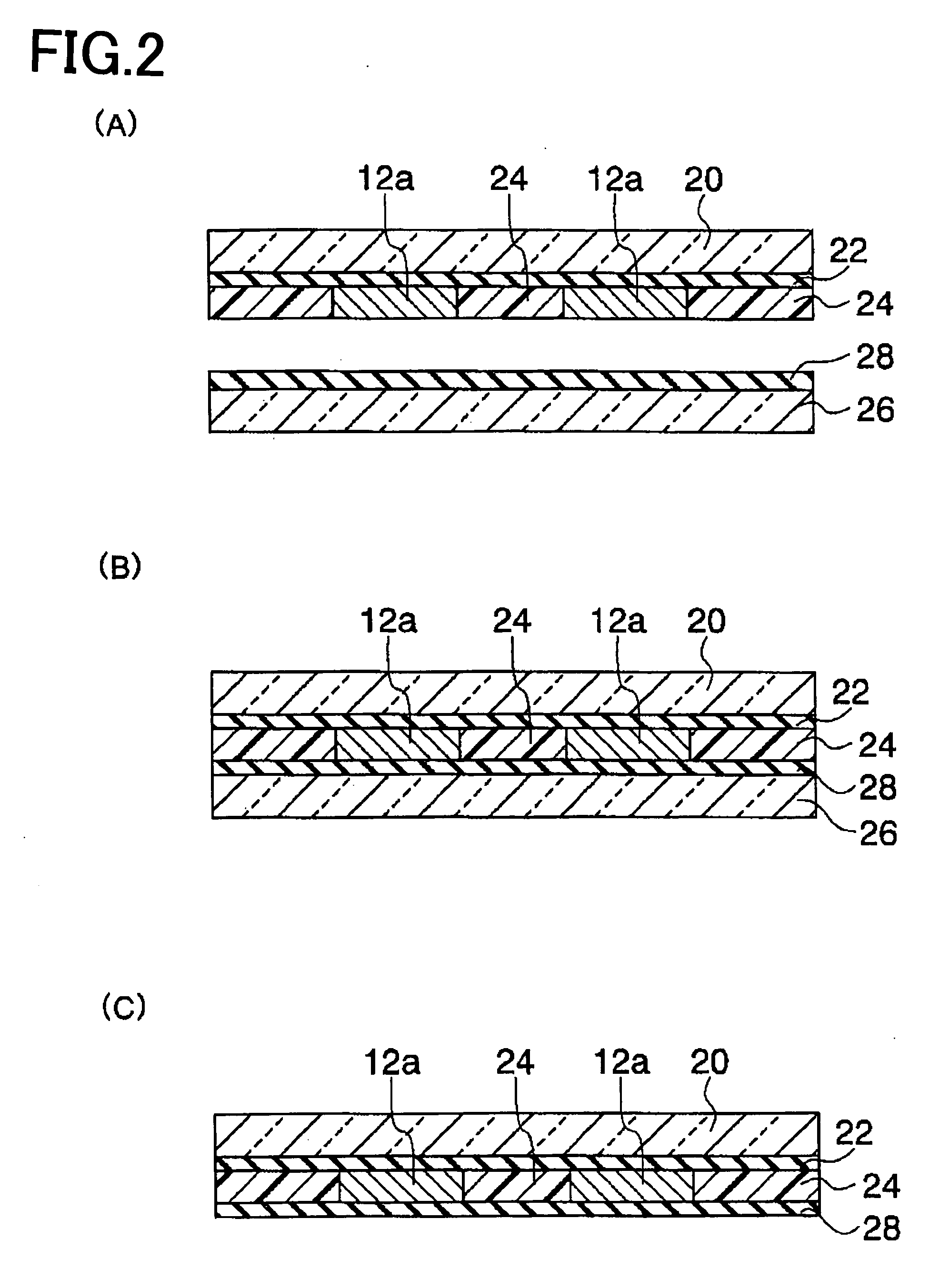

Printing and drying method, method of production of electronic device, and printing and drying system

ActiveUS20060213382A1Prevent dust depositionAvoid defectsDrying/impregnating machinesPrinted circuit dryingEngineeringMethods of production

A printing and drying method comprising laying a support sheet 20 elongated in the long direction so as to bridge both a printing zone 42 and a drying zone 44, in the printing zone 42, giving the support sheet 20 a first tension F1, in that state, printing the support sheet 20 with predetermined patterns, then feeding the support sheet 20 toward the drying zone 44, in the drying zone 44, giving the support sheet 20 on which the predetermined patterns were printed a second tension F2, and in that state, drying it in a drying chamber 62. The first tension F1 and the second tension F2 are given by separate tension giving means, and the second tension F2 is tension given along the support sheet 20 in the long direction and able to prevent shrinkage of the support sheet 20 in the long direction while passing through the drying zone 44.

Owner:TDK CORPARATION

Impregnation improvement method of high-voltage winding type solid-state electrolytic capacitor

InactiveCN108172423ALow viscosityShorten impregnation timeSolid electrolytic capacitorsDrying/impregnating machinesElectrolysisEngineering

The invention provides an impregnation improvement method of a high-voltage winding type solid-state electrolytic capacitor. The impregnation improvement method of the high-voltage winding type solid-state electrolytic capacitor comprises processes of dispersion liquid processing, cutting, core pack fabrication, formation, water drying, impregnation, dispersion liquid drying, assembling, aging, thumb-printing, processing and packaging. With the impregnation improvement method of the high-voltage winding type solid-state electrolytic capacitor, provided by the invention, the technical problemsof long impregnation time consumption, large energy consumption and high cost in production of the winding solid-state electrolytic capacitor in the prior art are solved.

Owner:HUNAN AIHUA GRP

Drying method and drying device for supercapacitor

InactiveCN103745840AImprove drying efficiencyService life is not affectedDrying/impregnating machinesSupercapacitorNitrogen

The invention relates to the capacitor manufacture field, and is to provide a drying method and drying device for a supercapacitor. The drying method for the supercapacitor comprises the following steps: (1) putting the supercapacitor to a drying chamber arranged in a drying furnace; (2) extracting the air in the drying chamber until the vacuum degree is lower than 1 pa; (3) filling nitrogen to the drying chamber; (4) heating the drying furnace for 2-5 hours until the temperature reaches 120-200 DEG; (5) extracting the nitrogen in the drying chamber until the vacuum degree is lower than 1 pa; (6) keeping the vacuum degree in the drying chamber to be lower than 1 pa, and meanwhile, holding the temperature of the drying furnace to be 120-200 DEG for 5-10 hours and performing drying; and (7) filling the nitrogen into the drying chamber, opening the drying furnace and the drying chamber, and taking out the supercapacitor which has been dried. The drying efficiency of the drying method for the supercapacitor is high; the drying effect is good without influencing the service life; and the drying device of the drying method for the supercapacitor is simple in structure and is capable of satisfying the drying requirements.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

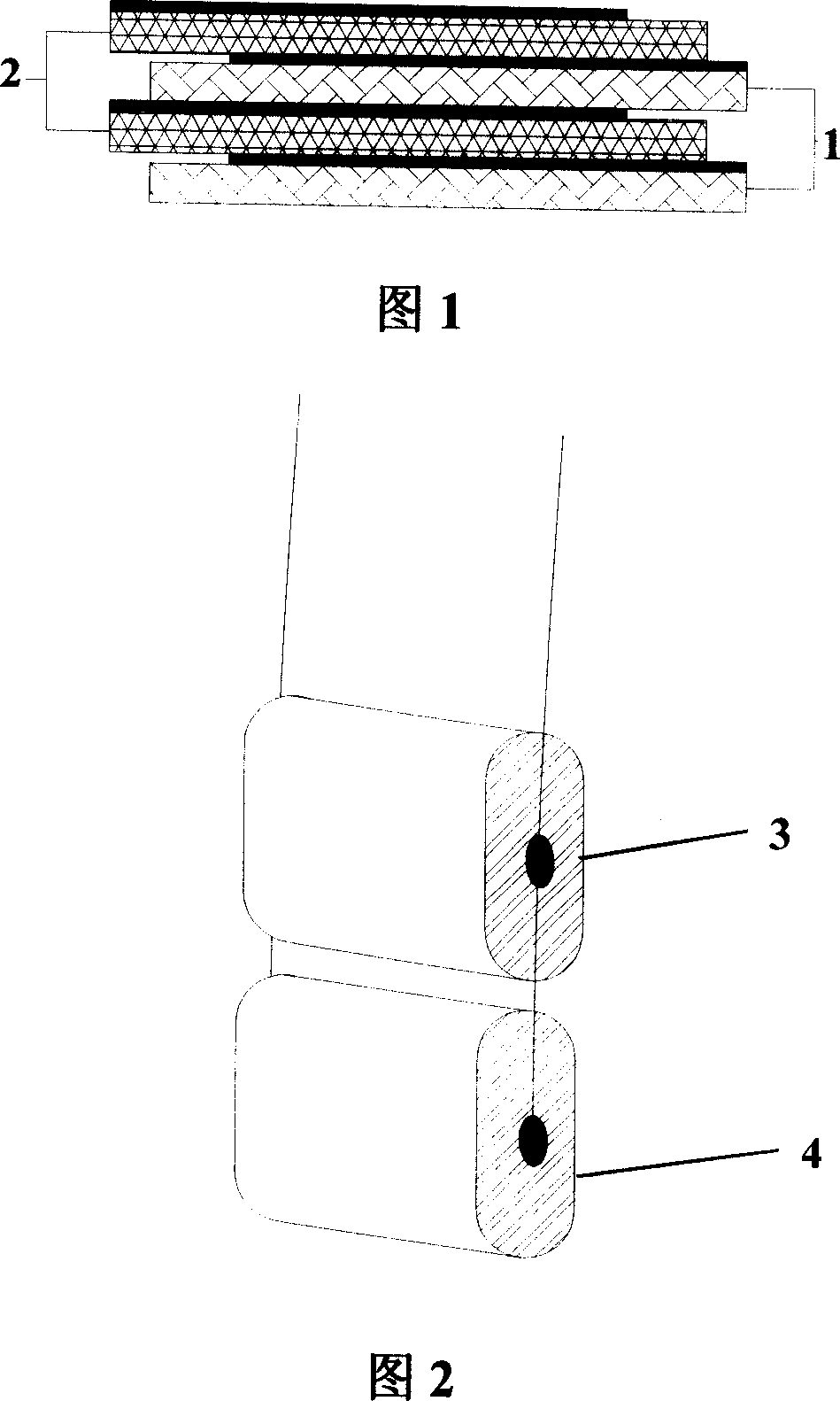

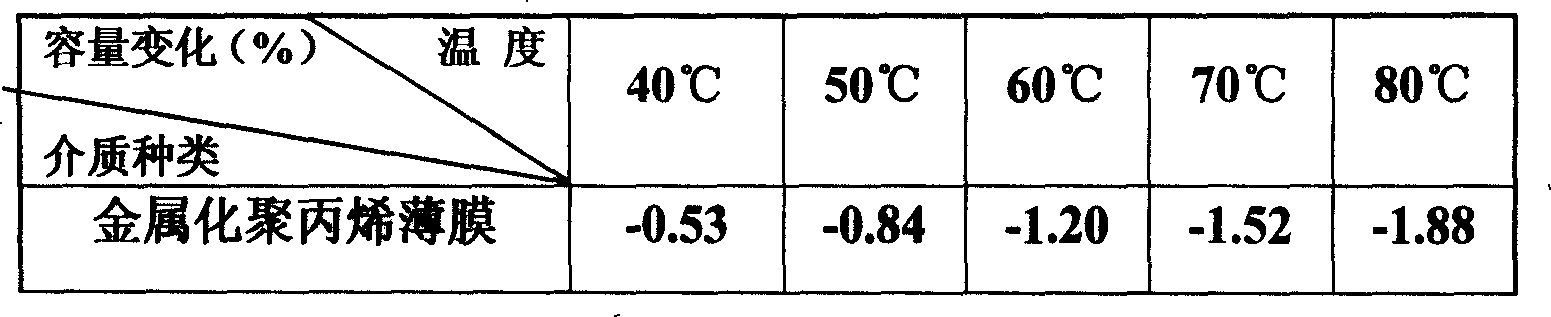

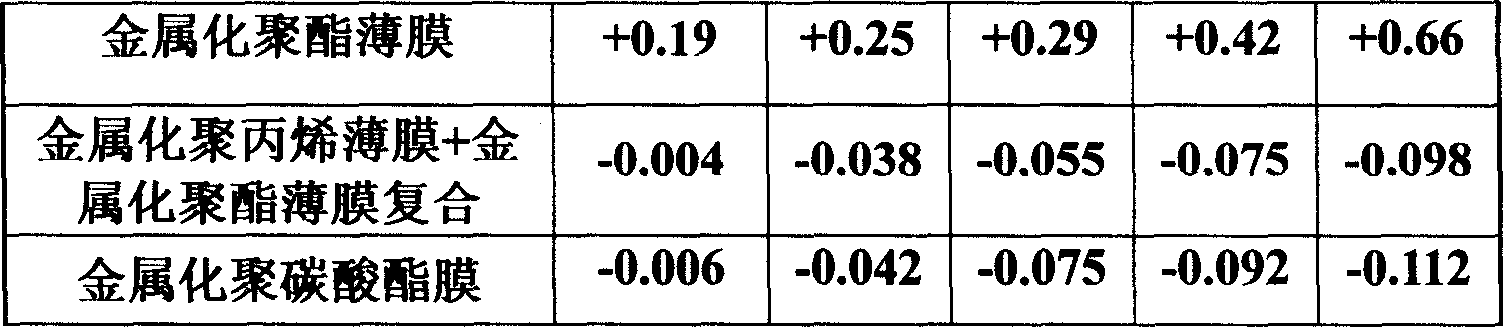

Capacitor with good capacity-temperature stabilization and its preparing method

InactiveCN101026036ALow costIncrease capacityThin/thick film capacitorFixed capacitor dielectricPolyesterHost material

This invention relates to a compound dielectric capacitor, in which, its main body is a core formed by a metalized polymer film and a metalized polypropylene film and the capacitor is made by internal parallel winding and winding outer parallel method,which can solve the problem that the production process of PC, the main material of current metalized PC capacitors will pollute environment and stabilize the volume of capacitors under different temperatures.

Owner:SHANGHAI HAOYE CAPACITORS

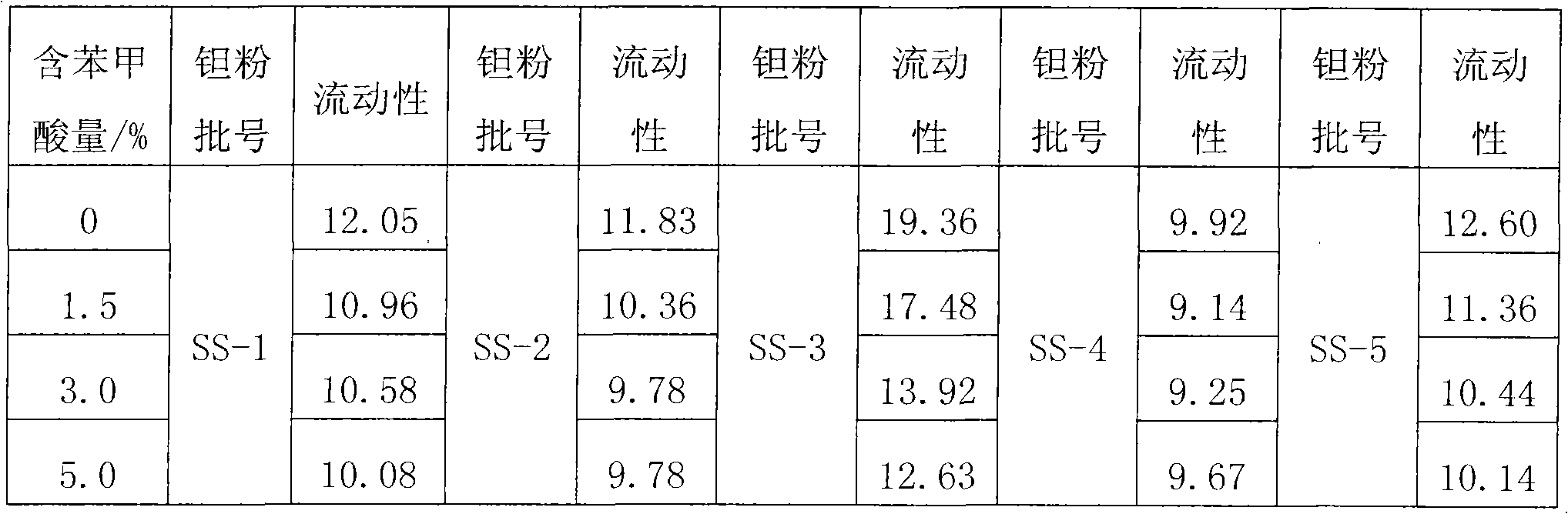

Composite impregnant capable of substantially prolonging service life of metallic film capacitor and preparation method thereof

ActiveCN103943359AReduce moisture contentReduce negative impactFixed capacitorsDrying/impregnating machinesThermal dilatationMolecular sieve

The invention relates to a composite impregnant capable of substantially prolonging the service life of a metallic film capacitor and a preparation method of the composite impregnant. The composite impregnant comprises, by weight, 7.0 parts to 8.5 parts of modified soybean oil, 2.5 parts to 4.5 parts of polyisobutene, and 1.0 part to 3.0 parts of modified molecular sieves. The preparation method of the composite impregnant comprises the modified soybean oil preparation step, the modified molecular sieve preparation step and the composite impregnant preparation step. According to the composite impregnant, the amount of water generated in the raw material production process and the using process can be effectively reduced, namely, the negative factors influencing the service life of the metallic film capacitor are further reduced, and therefore the service life of the metallic film capacitor is prolonged, the failure rate of the metallic film capacitor is reduced, and the metallic film capacitor is used more safely and reliably. In addition, the composite impregnant has lower dielectric loss and a lower thermal expansion coefficient, and is better in thermal stability, and favorable for substantially prolonging the service life of the metallic film capacitor.

Owner:WUXI HONGGUANG CAPACITOR

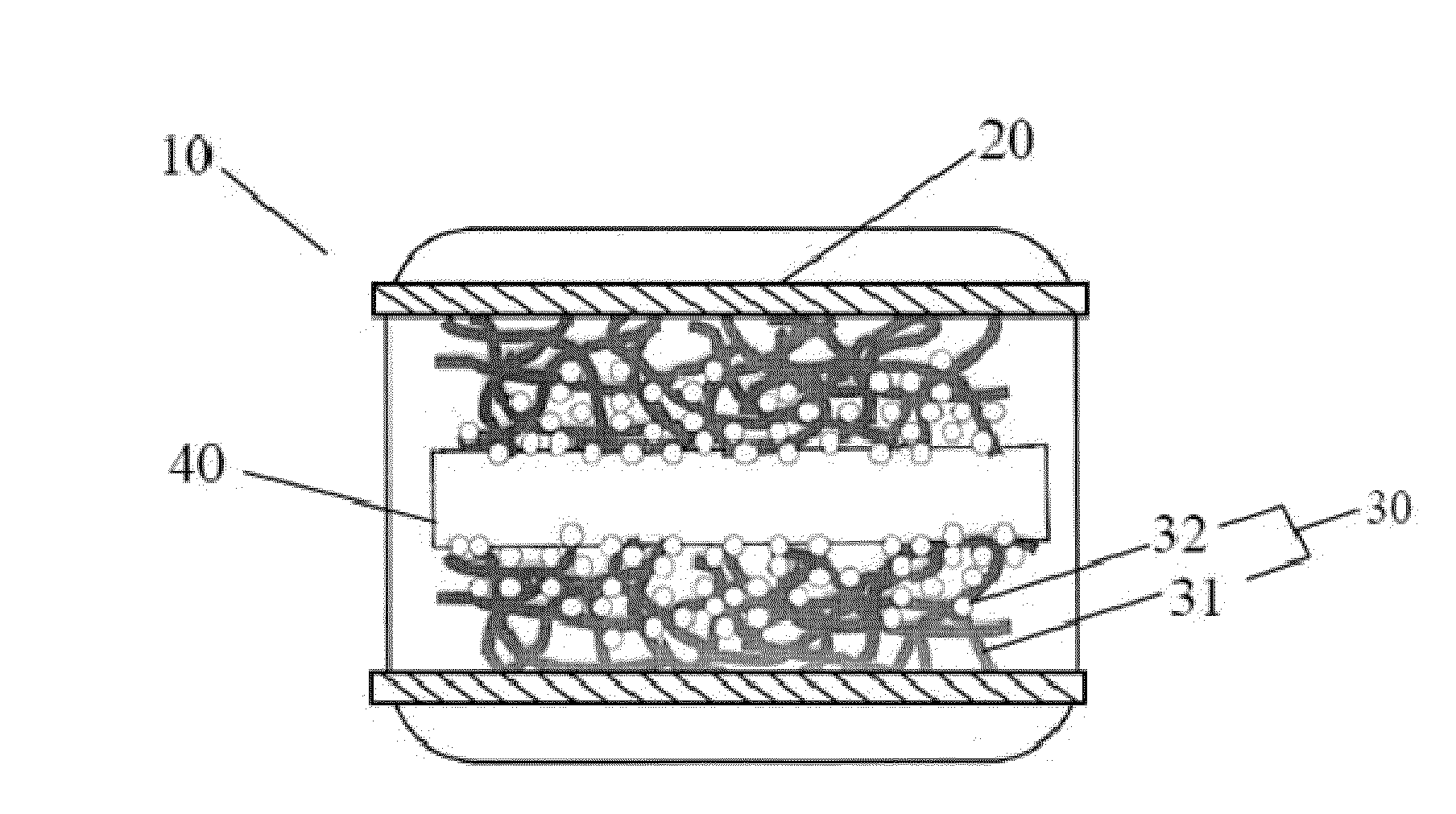

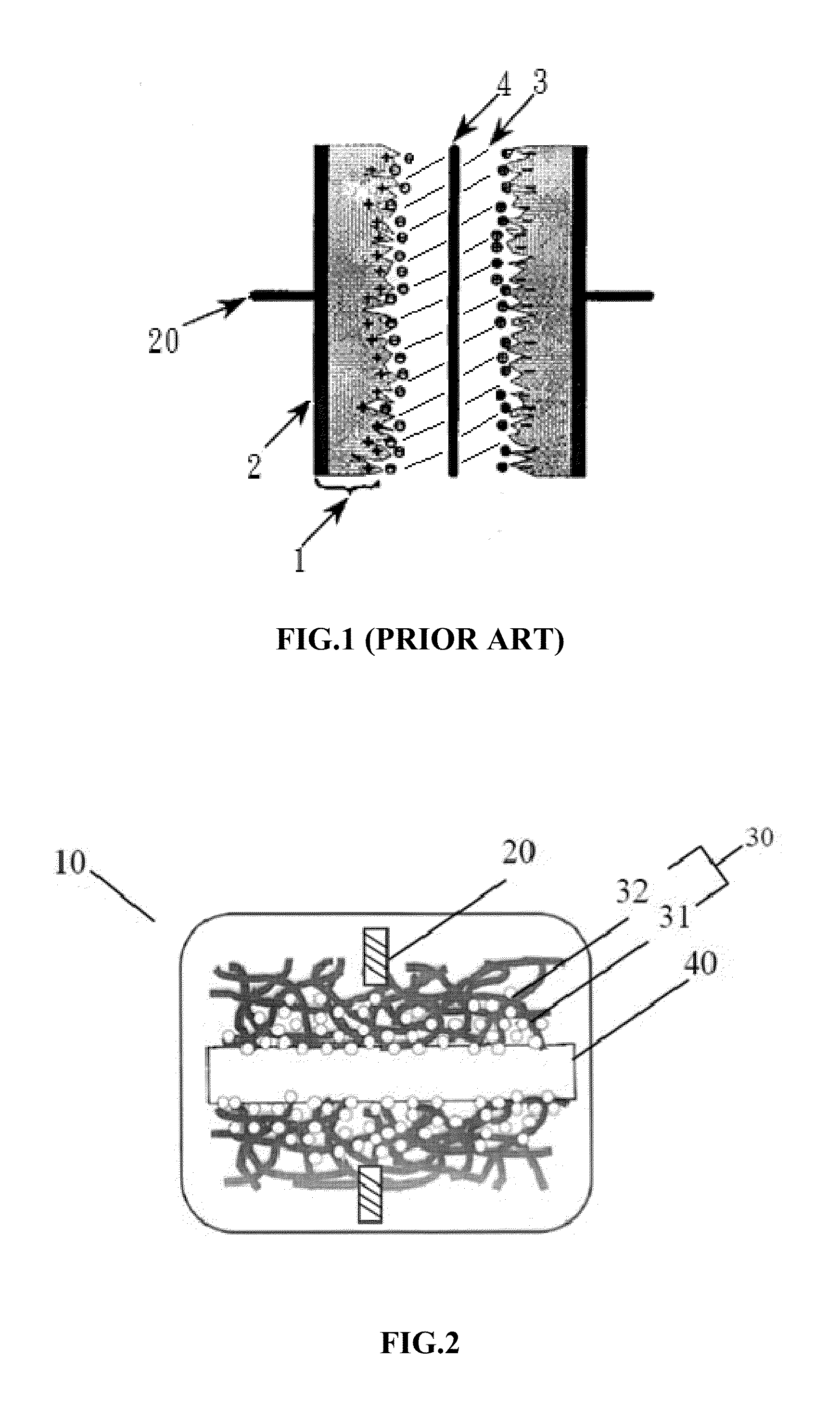

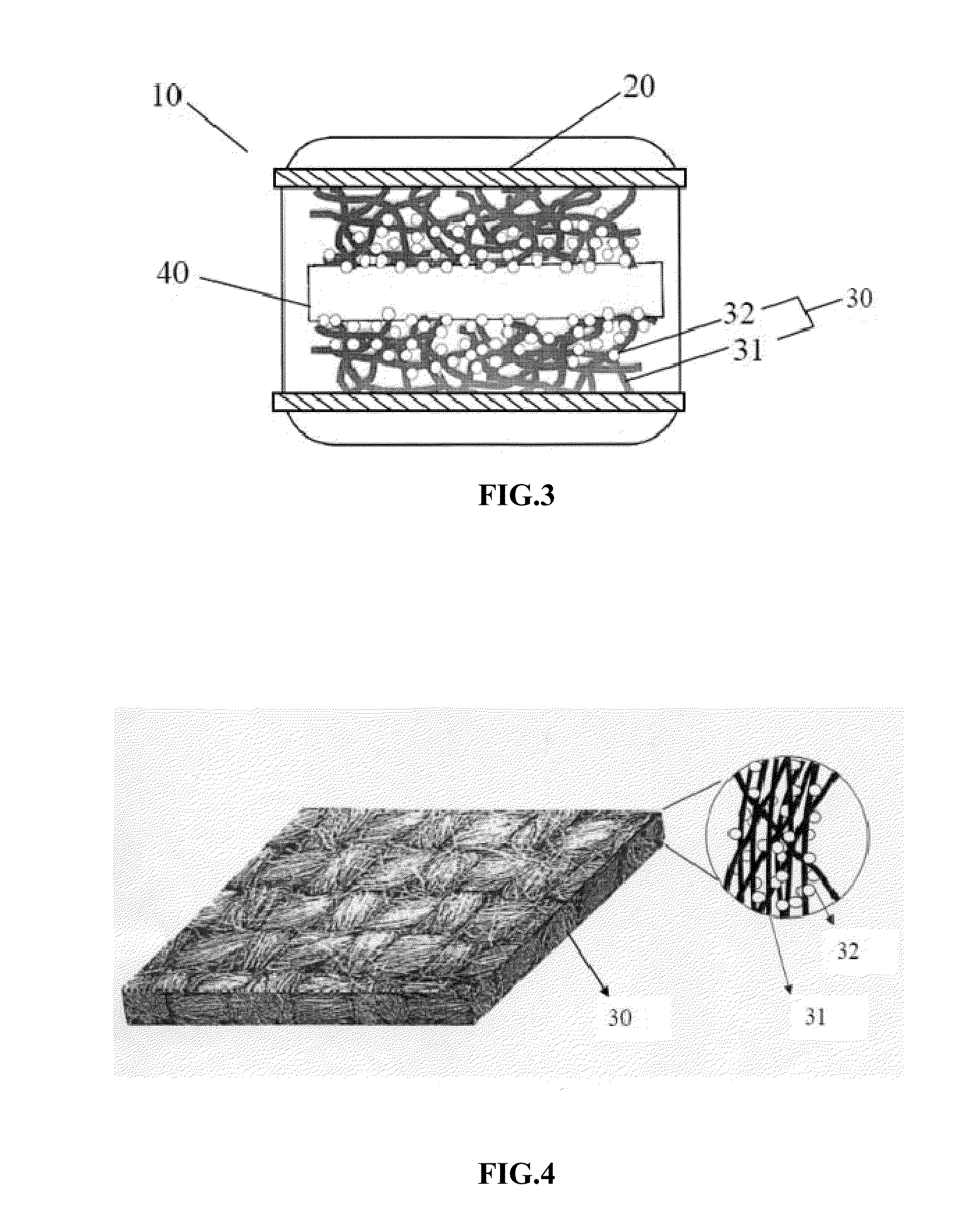

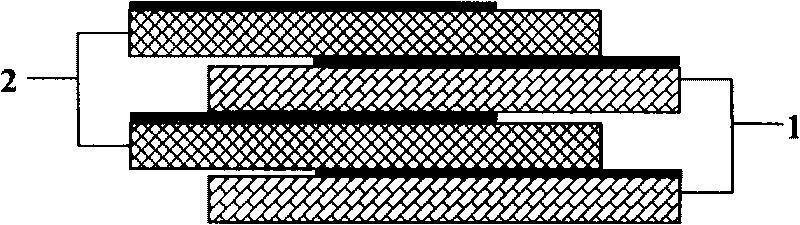

Super capacitor structure and the manufacture thereof

InactiveUS20130083452A1Improve conductivityImprove performanceHybrid capacitor electrodesElectrolytic capacitorsSandwich likeBULK ACTIVE INGREDIENT

Disclosed is a super capacitor and method of manufacture thereof. This invention relates to a solid state super capacitor comprising a solid state polymer electrolyte and a modified carbonaceous electrode. Said modified carbonaceous electrode comprises a conductive carbonaceous material covered with active ingredients. Said modified carbonaceous electrode and said solid state polymer electrolyte are layered on top of each other to form a sandwich-like structure. Said super capacitor performs much better than known super capacitor comprising liquid or gel-form electrolytes. Said super capacitor has higher conductivity, therefore can be manufactured without a current collector. Since said super capacitor contains solid state polymer electrolyte, the method of manufacturing said super capacitor is more environmentally friendly and has a higher safety level.

Owner:FENG CHIA UNIVERSITY

Manufacturing method for semi-solid aluminum electrolytic capacitor

InactiveCN108538650AImprove wettabilityGood restorativeCapacitor electrolytes/absorbentsWinding capacitor machinesCapacitanceConductive polymer

The invention proposes a manufacturing method for a semi-solid aluminum electrolytic capacitor, and relates to the technical field of aluminum electrolytic capacitors. The method comprises the following steps: S100, the making of an element; S200, a first impregnation stage, wherein the element is impregnated into a liquid at the stage; S300, a second impregnation stage, wherein the element is impregnated with a conductive polymer monomer, an oxidant and dispersion liquid at the stage; S400, a third impregnation stage, at which the element is impregnated with a treatment liquid; S500, a fourthimpregnation stage, at which the element is impregnated with an electrolyte; S600, the packaging of the element which is subjected to the fourth impregnation stage into an aluminum shell. In the invention, a mixed aluminum electrolytic capacitor (the semi-solid aluminum electrolytic capacitor) which contains the three materials (a conductive solid layer, treating fluid and the electrolyte) and isformed by the conductive polymers is disposed in the capacitor element. The semi-solid aluminum electrolytic capacitor has the characteristics of high reliability, high capacity, high ripple currentresistance and the like, has the function of promoting the repair of the defect portion of an oxide film of anode foil, and can suppress the occurrence of a short circuit fault.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

Method for sintering anode block of tantalum capacitor

ActiveCN102513538AHigh purityGuaranteed purityFixed capacitor electrodesElectrolytic capacitorsCapacitancePorosity

A method for sintering an anode block of a tantalum capacitor is characterized by including: placing tantalum anode block pressed by tantalum powder mixed with adhesive in a drying furnace filled with degreased solvent, performing airtight low-temperature solvent catalysis wet dewaxing, drying in vacuum and then performing vacuum sintering. The tantalum anode block obtained through the method maintains high specific surface area and high porosity, so that the tantalum anode block is high in specific capacity and low in leakage current, carbon content and oxygen content of the anode block can respectively drop to 0.005%-0.010% and 0.18% to 0.65%.

Owner:TAIKE TECH SUZHOU

Impregnant used by capacitor and preparation method thereof

ActiveCN104810167AEasy to useImprove cooling effectDrying/impregnating machinesAcetic acidAdditive ingredient

The invention discloses an impregnant used by a capacitor, and relates to the technical field of capacitor manufacturing. The impregnant used by a capacitor is prepared by the following ingredients: 53 to 57 parts of soybean oil, 43 to 47 parts of olive oil, 8 to 10 parts of vitamin E, 50 to 52 parts of accessory powder, 35 to 37 parts of bentonite, 20 to 22 parts of clay, 15 to 17 parts of plant ash, 5 to 7 parts of polyisobutylene, 12 to 14 parts of hydrogen peroxide, 15 to 17 parts of acetic acid, and 25 to 27 parts of concentrated sulfuric acid. The impregnant used by the capacitor and the preparation method thereof have the beneficial effects that the preparation is convenient and simple, the ingredients are easy to obtain, the equipment has little investment, operation is easy, and the prepared impregnant used by the capacitor is environmental friendly, free of pollution, good in use effects, strong in high temperature-resistance, good in heat radiation, safe, reliable, and durable in use.

Owner:安徽航睿电子科技有限公司

Preparation method of electrode, and apparatus

InactiveCN105355449AWon't leakHybrid capacitor electrodesWinding capacitor machinesPolyethylene glycolAlclad

The invention provides a preparation method of an electrode. An electrode is obtained by coating a current collector having penetrating holes with slurry, and a flexible substrate is adhered to the back side of the current collector when the first side of the electrode is coated. The flexible substrate is a copper foil, or an aluminium foil, or a polyethylene or polypropylene or polyethylene glycol terephthalate film. The thickness of the flexible substrate is 5-20[Mu]m. The opening ratio of the penetrating holes of the current collector is 2%-30%.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for manufacturing capacitor in parallel connection outside core

InactiveCN101710536ALow costIncrease capacityMultiple fixed capacitorsThin/thick film capacitorPolyesterHost material

The invention relates to a capacitor of an electric element, in particular to a method for manufacturing a capacitor in parallel connection outside a core. The capacitor is a composite dielectric capacitor, and the main component of the capacitor is a capacitor core formed by a metallized polyester film and a metallized polypropylene film. The capacitor can be manufactured by a method of winding an external part in parallel connection. The method mainly solves the technical problems that the production process of a main body material polycarbonate of the conventional metallized polycarbonate capacitor can cause certain pollution to the environment; besides, the method ensures that the capability of the capacitor is more stable at different temperatures, and greatly reduces the cost.

Owner:SHANGHAI HAOYE CAPACITORS

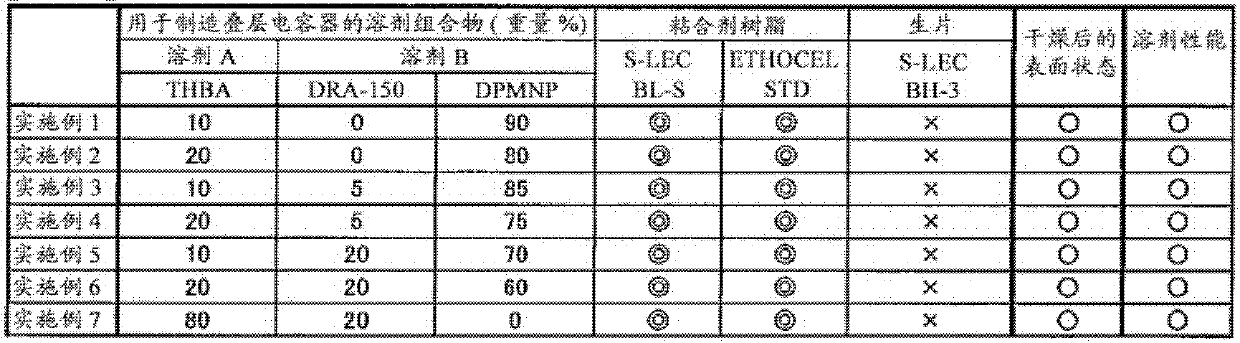

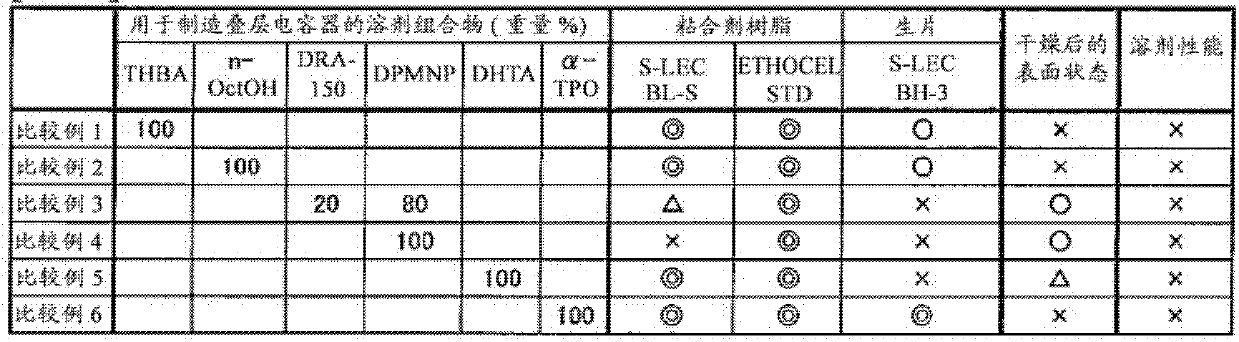

Solvent composition for manufacturing laminated ceramic part

InactiveCN102709050AInhibit and prevent erosion phenomenaPrevent peelingFixed capacitor dielectricStacked capacitorsSolubilityAdhesive

The present invention provides a solvent composition for manufacturing laminated ceramic parts. The solvent composition can be used for bringing performances of ethyecellulose and other adhesive of adhesive resin into full play, erosion phenomenon of the laminated ceramic parts is not easy to occur during the manufacturing process, evaporation and drying can be realized easily, and the coherent fitting with a coated cloth sheet is excellent. The solvent composition for manufacturing the laminated ceramic parts comprises solvent A with a boiling point below 206 DEG C and a solvent B with a boiling point above that of the solvent A. In the solvent A, the solubility of a low polarity polyvinyl butyral resin is above 5g / 100g in 25 DEG C, the solubility of ethyecellulose comprising 45.0 to 53.0 mo 1% ethyoxyl is above 5g / 100g in 25 DEG C, and in the solvent B, the solubility of a high polarity polyvinyl butyral resin is below 5g / 100g in 25 DEG C.

Owner:DAICEL CHEM IND LTD

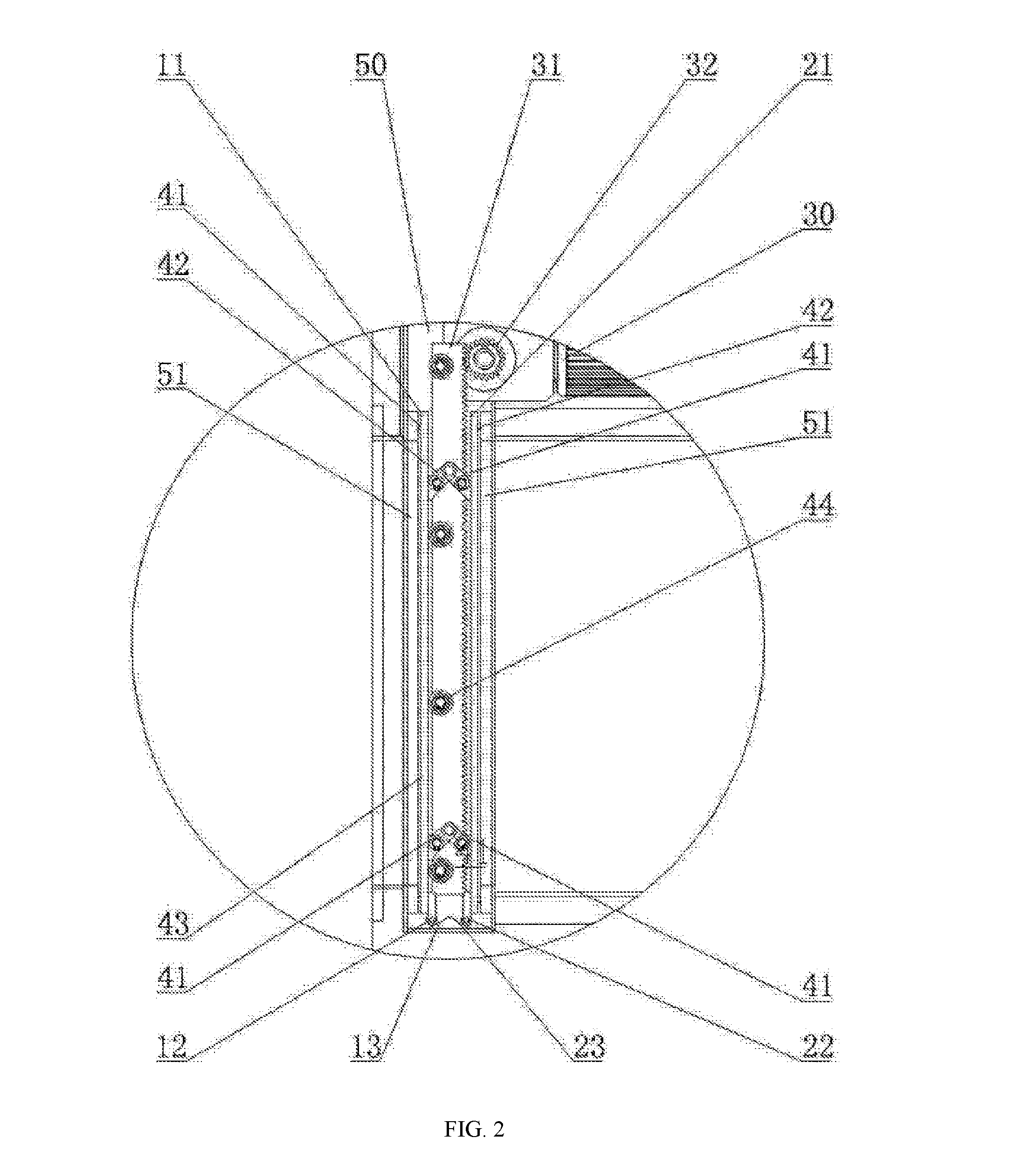

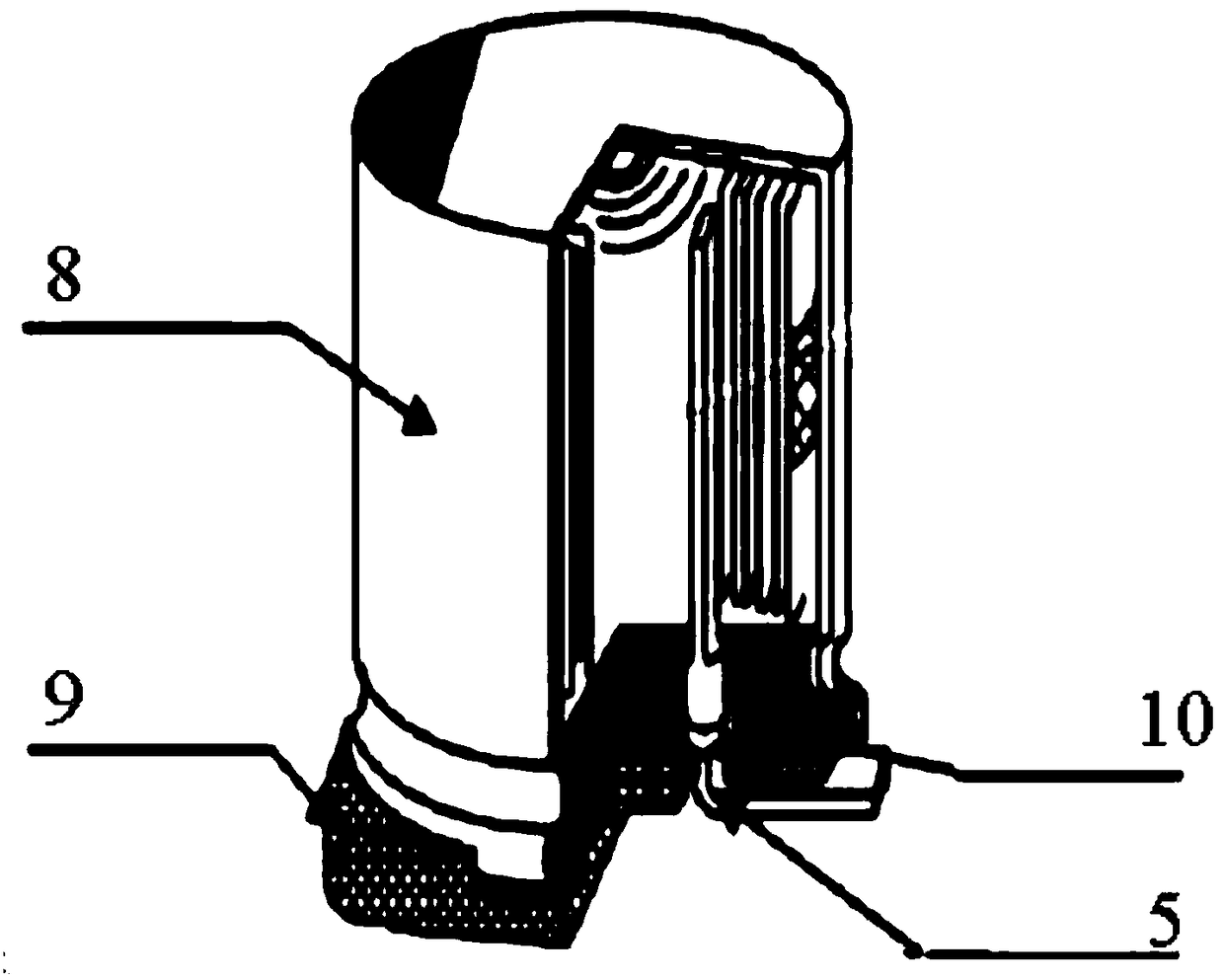

Pressurized impregnation machine for preparing aluminum electrolytic capacitor

ActiveCN103824709ADrain effectivelyReduce lossesDrying/impregnating machinesAluminium electrolysisPumping vacuum

The invention discloses a pressurized impregnation machine for preparing an aluminum electrolytic capacitor. The pressurized impregnation machine comprises a rack, an impregnation tank, a sealed cover, a carrier, a vacuumizing pipe, a bleeder pipe, and a compressed air pipe, wherein the impregnation tank is arranged on the rack, the sealed cover is hermetically connected with a mouth of the impregnation tank to form an impregnation zone, the carrier is arranged on the impregnation tank and used for containing impregnation materials, the vacuumizing pipe, the bleeder pipe and the compressed air pipe are communicated with the impregnation zone, especially, an inner container is arranged in the impregnation tank, a clearance is formed between the periphery of the inner container and the inner wall of the impregnation tank, and the pressurized impregnation machine further comprises a lifting mechanism which is positioned at the clearance and is used for adjusting the height of the carrier. According to the pressurized impregnation machine, the ascending or descending of the carrier containing the impregnation materials in the impregnation tank can be realized on the premise of not opening the sealed cover, and impregnation liquid on the surface of the impregnation materials can be effectively leached when the carrier containing the impregnation materials is taken out, so that the loss of impregnation liquid can be furthest decreased, and the cost can be further saved. In addition, the pressurized impregnation machine is simple in structure, and convenient to implement.

Owner:SHENZHEN XINGCHUANG JIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com