Solvent composition for manufacturing laminated ceramic part

A solvent composition and solvent technology, used in ceramics, multilayer capacitors, parts of fixed capacitors, etc., can solve the problems of deformation, softening of the coated sheet, insufficient corrosion resistance of the sheet, etc., and improve the adhesion. , Prevent peeling, easy to evaporate and dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

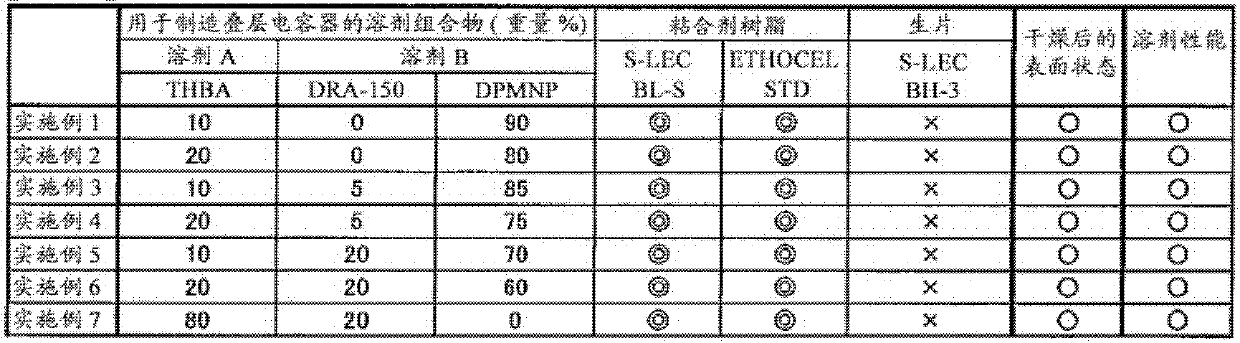

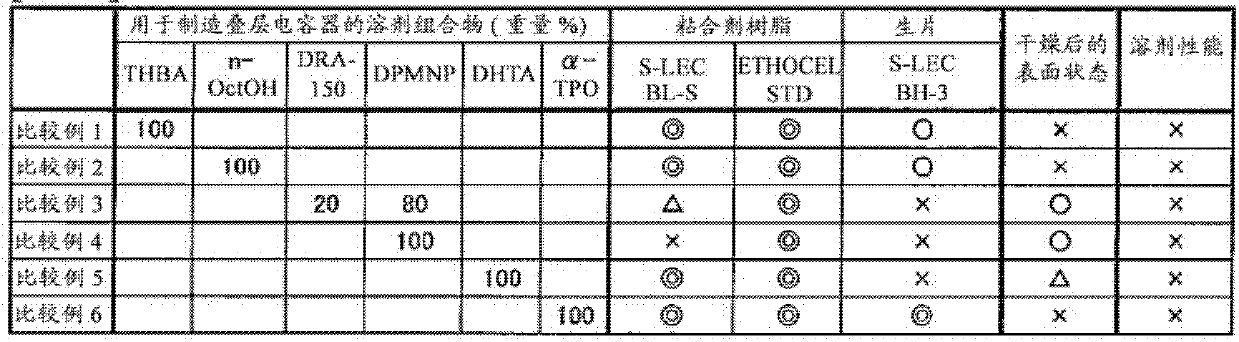

Embodiment 1~7、 comparative example 1~6

[0078] 1,2,5,6-Tetrahydrobenzyl alcohol [trade name "THBA" manufactured by Daicel Chemical Industry Co., Ltd.], triacetin [trade name " DRA-150" manufactured by Daicel Chemical Industry Co., Ltd.] and dipropylene glycol propyl methyl ether [manufactured by Daicel Chemical Industry Co., Ltd.] were mixed to prepare solvent combinations for manufacturing laminated ceramic parts in Examples 1 to 7. things. Moreover, the solvent was mixed in the ratio described in following Table 2, and the solvent composition of Comparative Examples 1-6 was prepared.

[0079] This solvent composition was divided into 3 groups, and polyvinyl butyral resin [trade name "S-LEC BL-S", manufactured by Sekisui Chemical Co., Ltd.; The content is 74mol% and the amount of hydroxyl groups is 22mol%], polyvinyl butyral resin [trade name "S-LEC BH-3, manufactured by Sekisui Chemical Co., Ltd.] is added to the second solvent composition; butyral The degree of oxidation is 65mol%, and the amount of hydroxyl gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com