Patents

Literature

472results about "Fixed capacitors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

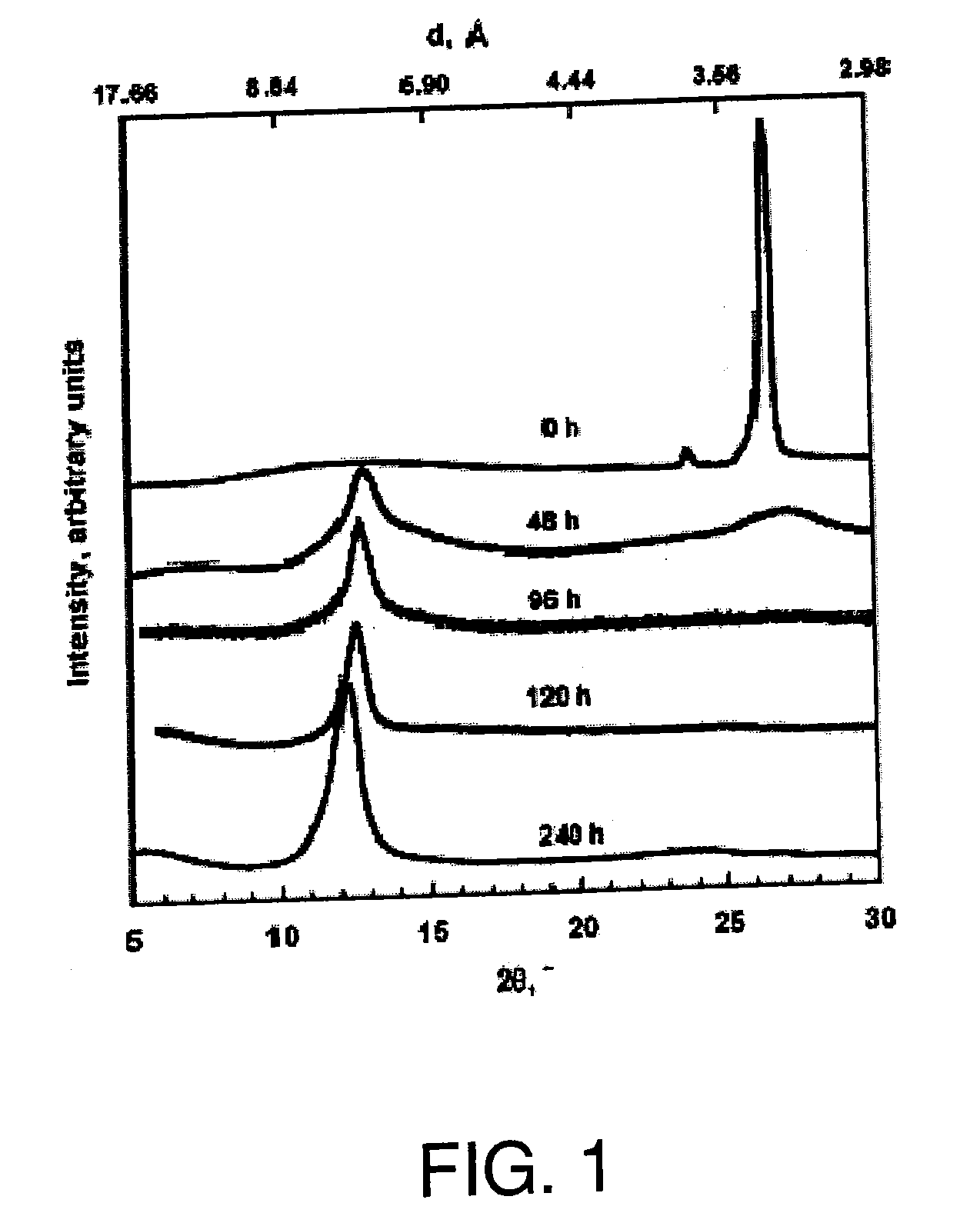

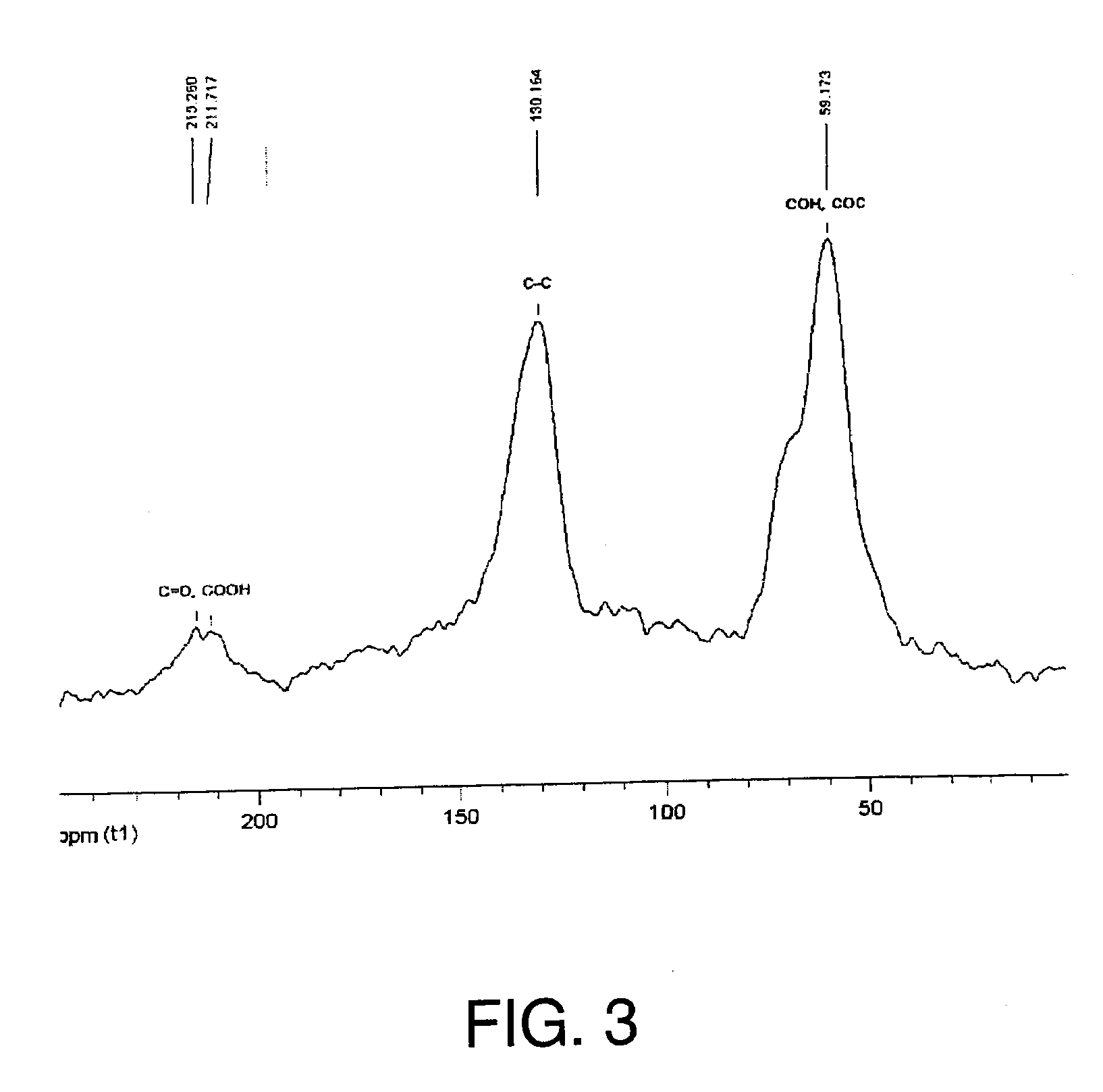

Thermally exfoliated graphite oxide

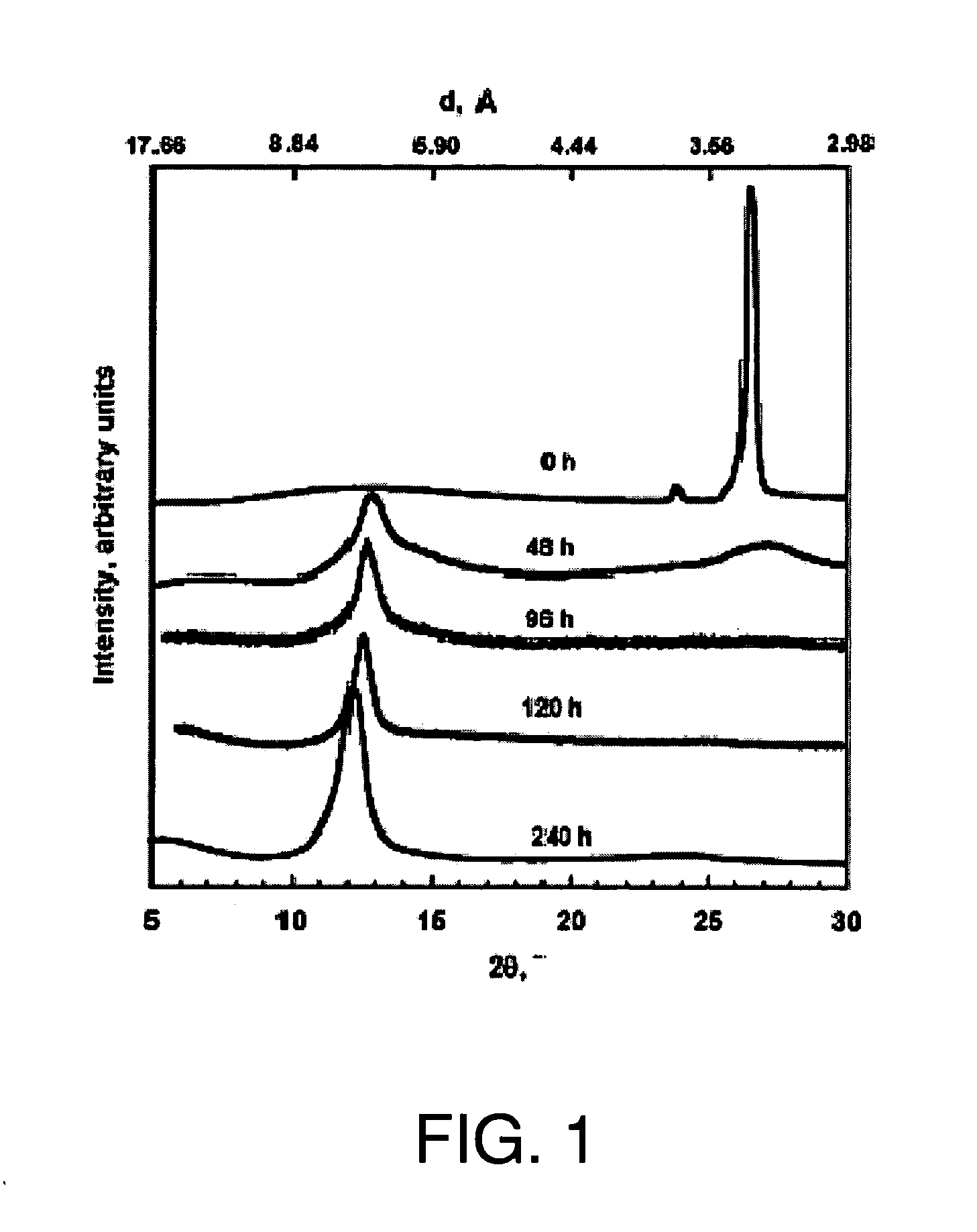

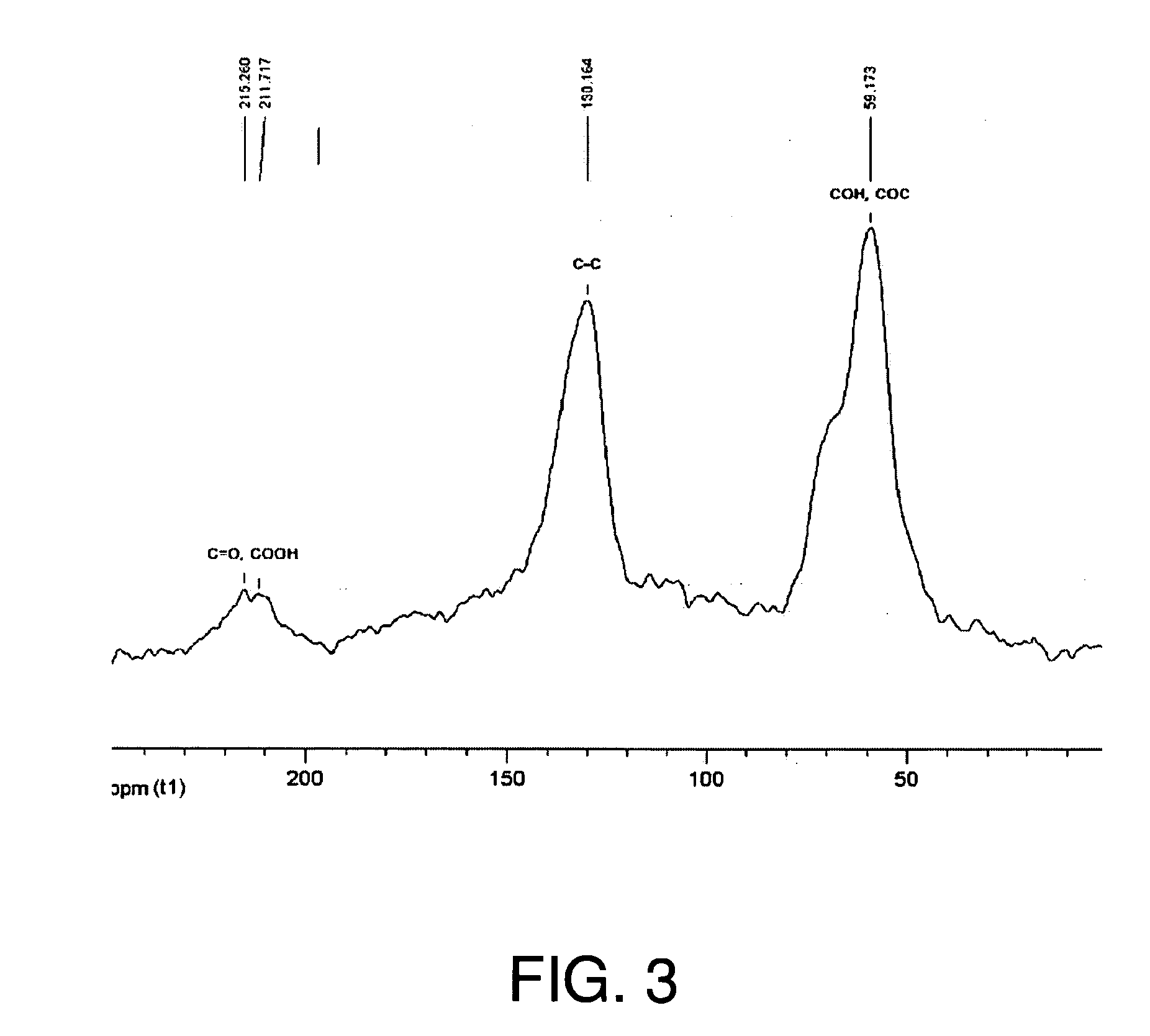

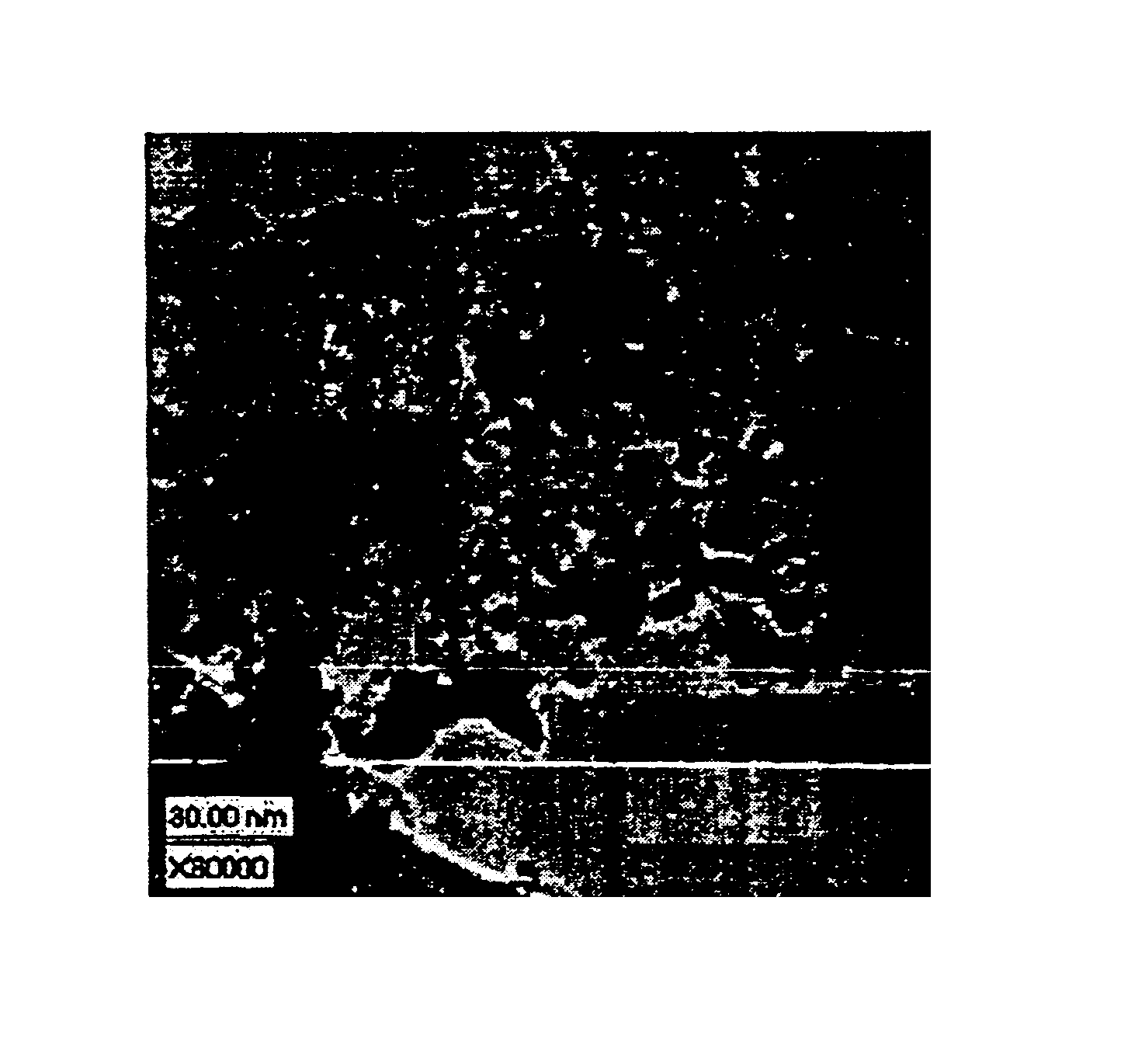

ActiveUS20070092432A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphiteX-rayMaterials science

A modified graphite oxide material contains a thermally exfoliated graphite oxide with a surface area of from about 300 m2 / g to 2600 m2 / g, wherein the thermally exfoliated graphite oxide displays no signature of the original graphite and / or graphite oxide, as determined by X-ray diffraction.

Owner:THE TRUSTEES FOR PRINCETON UNIV

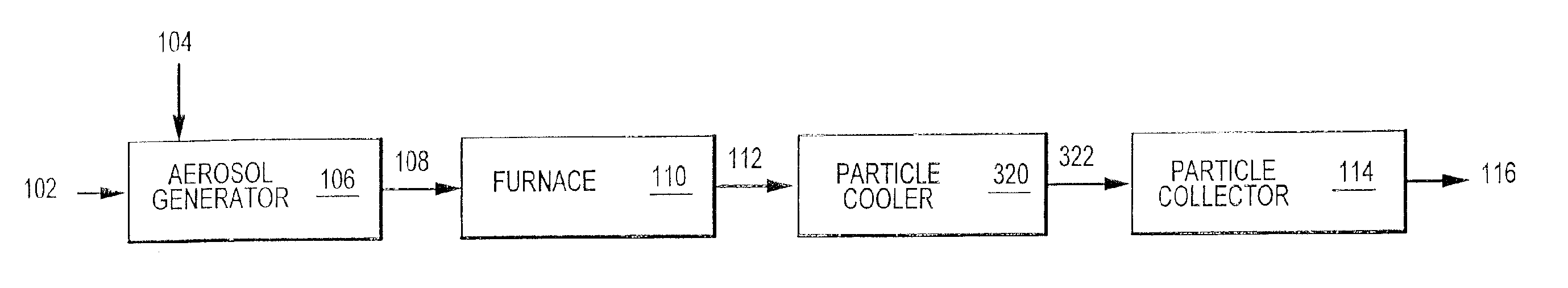

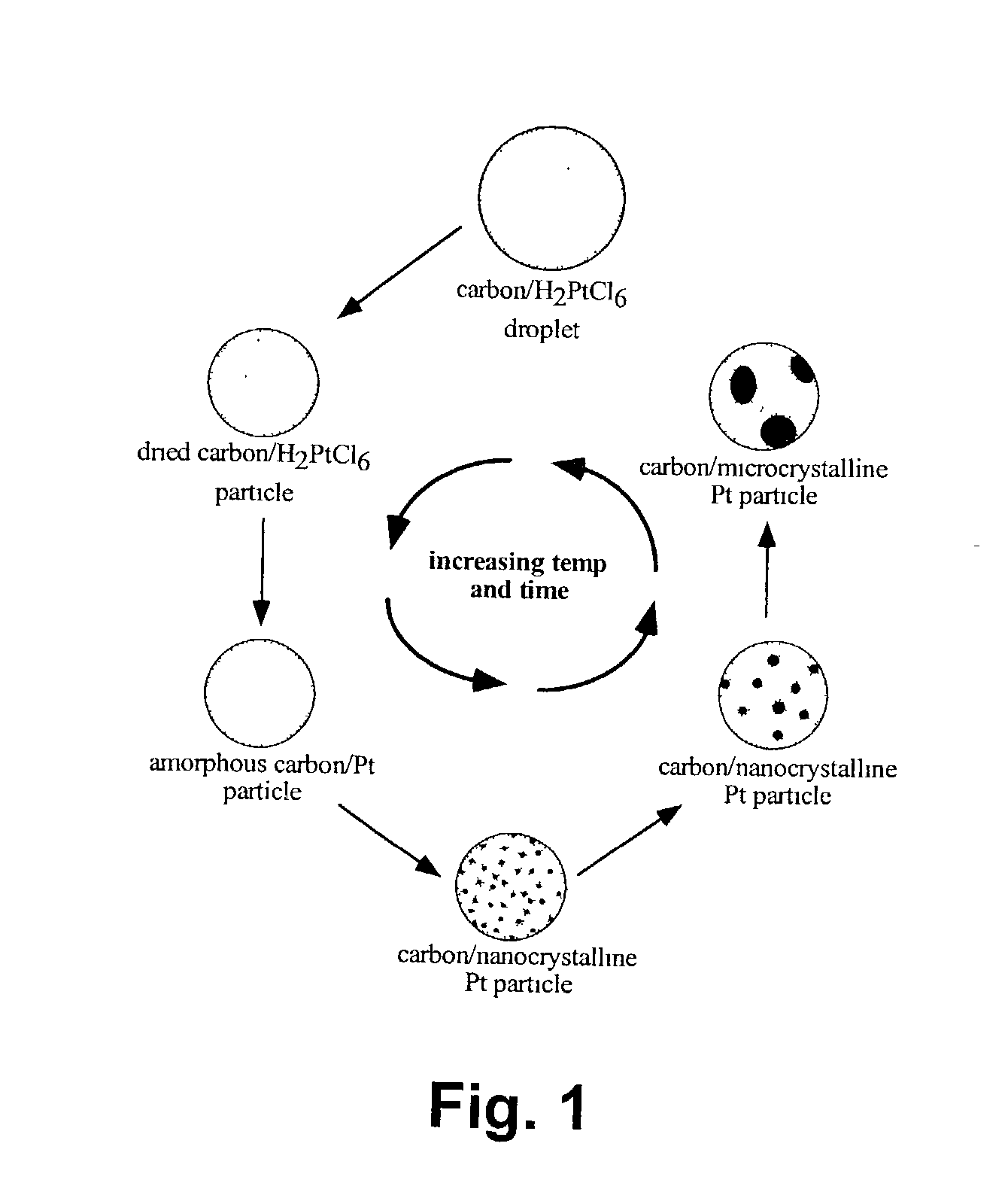

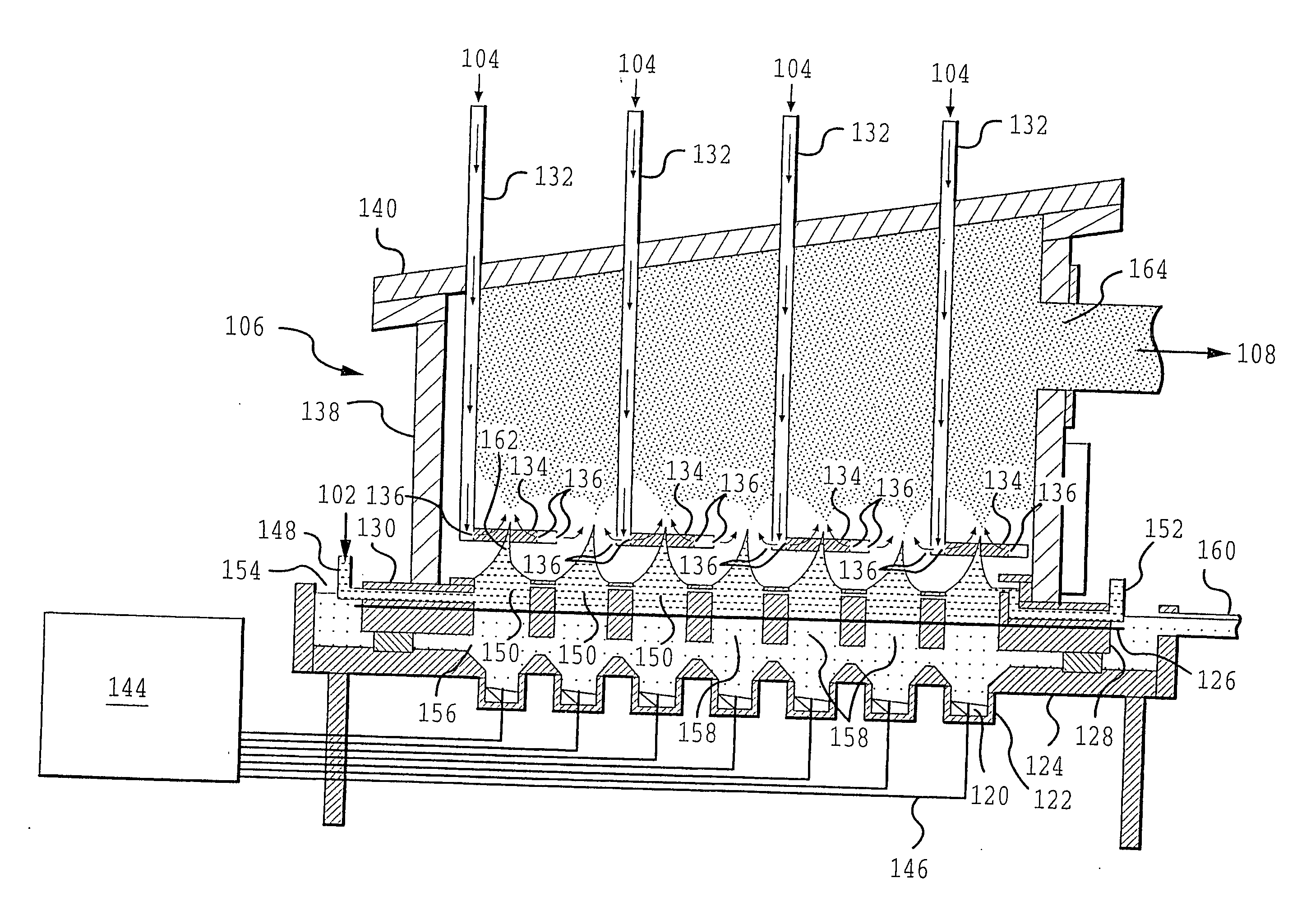

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

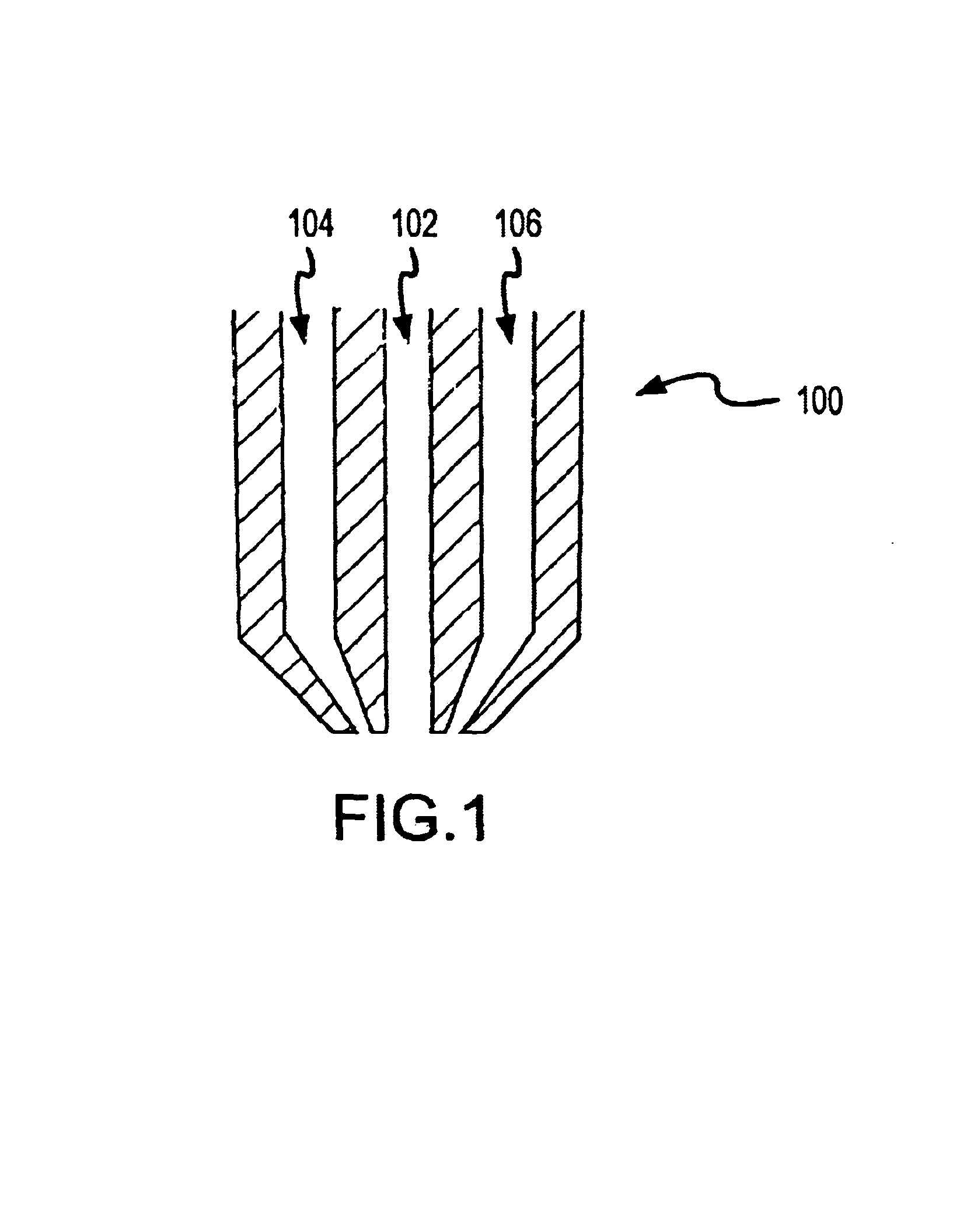

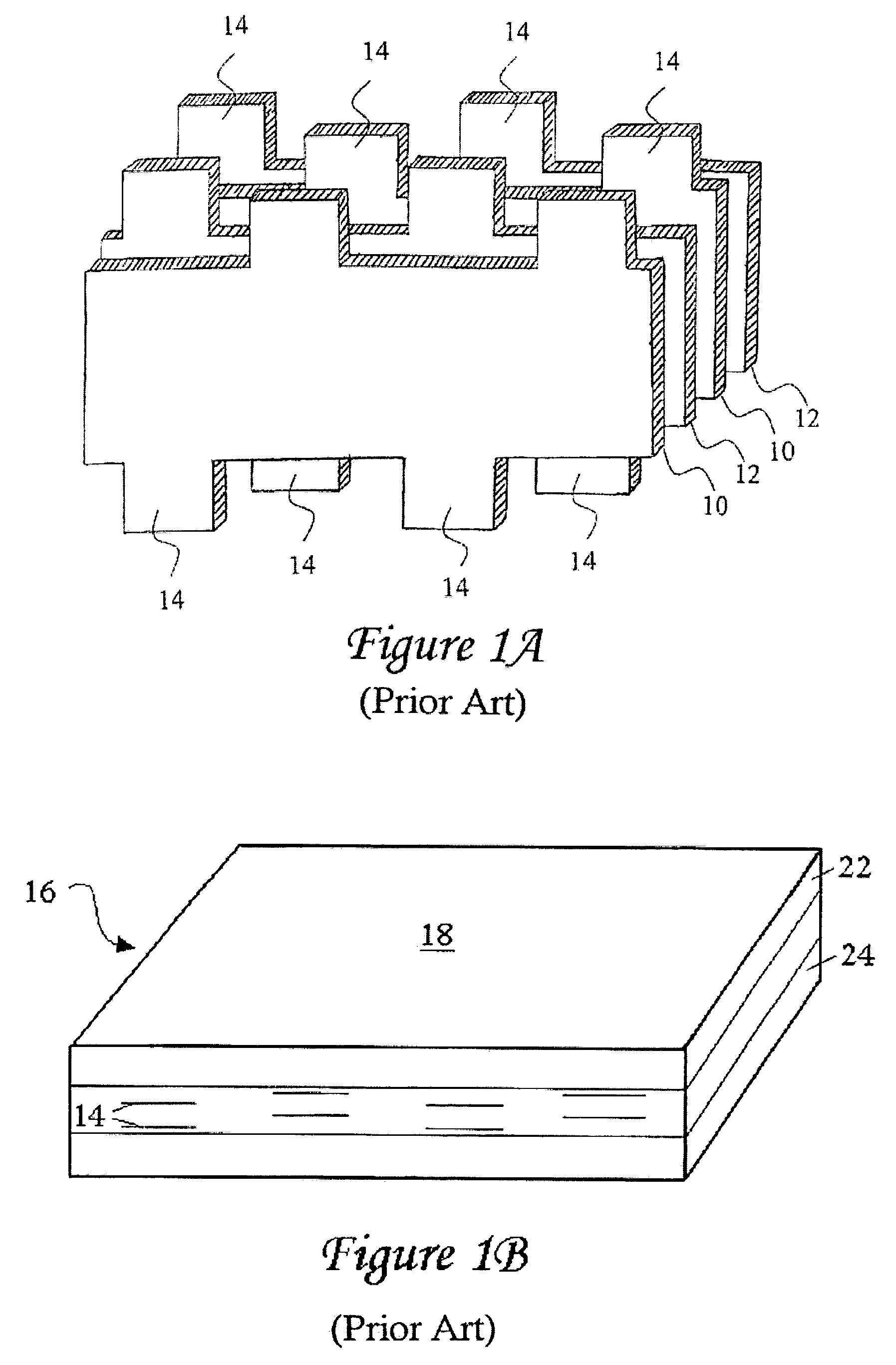

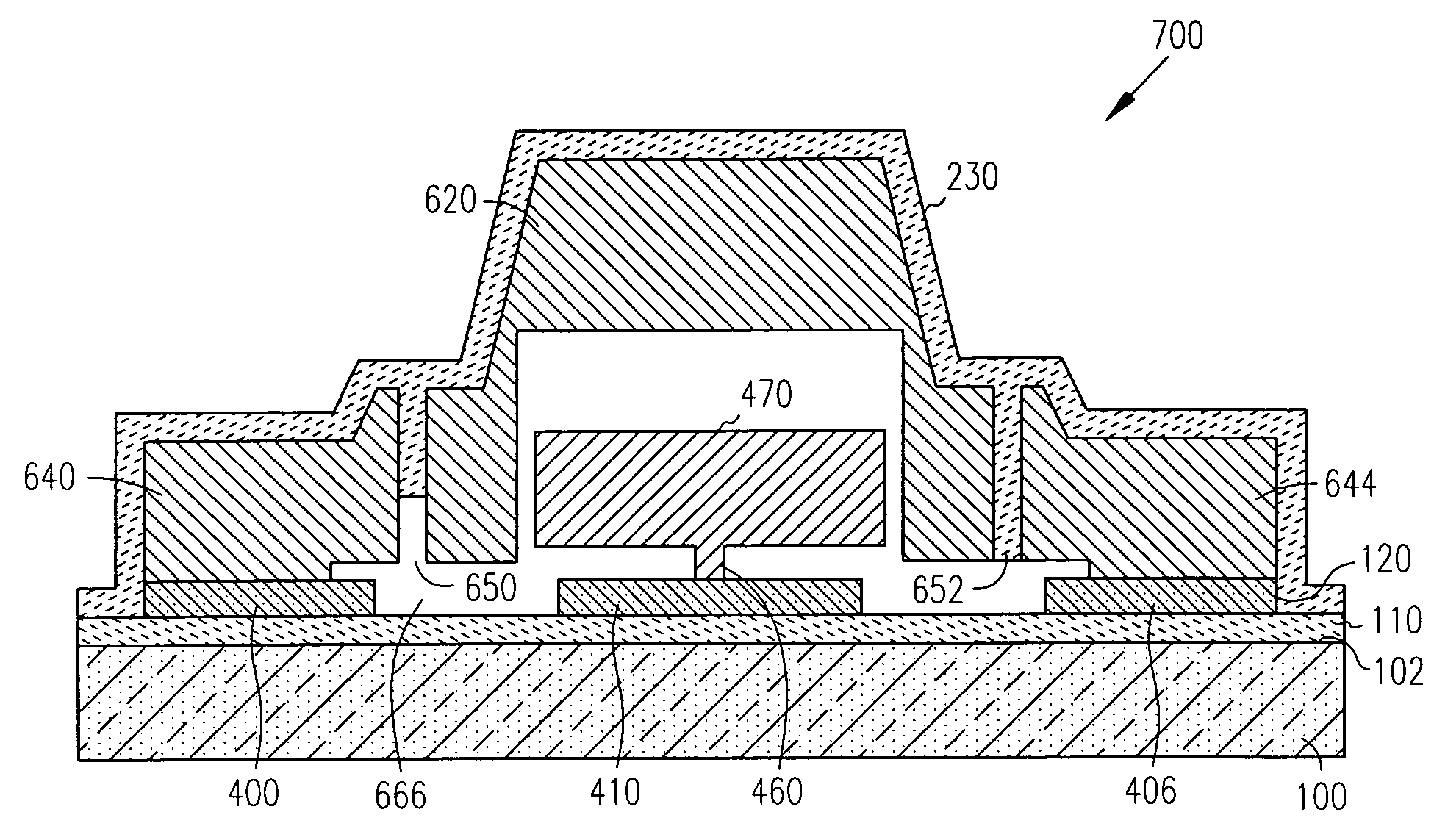

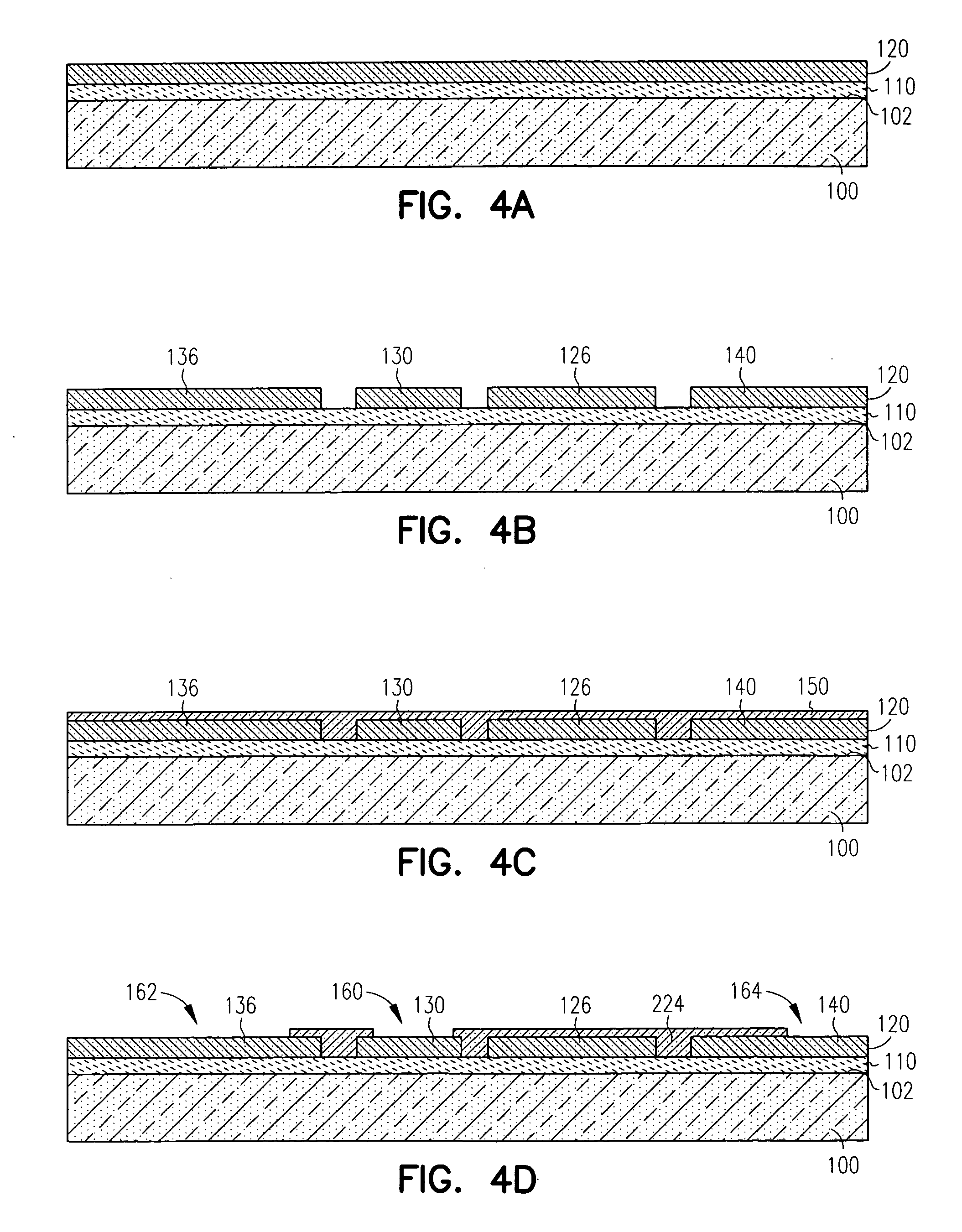

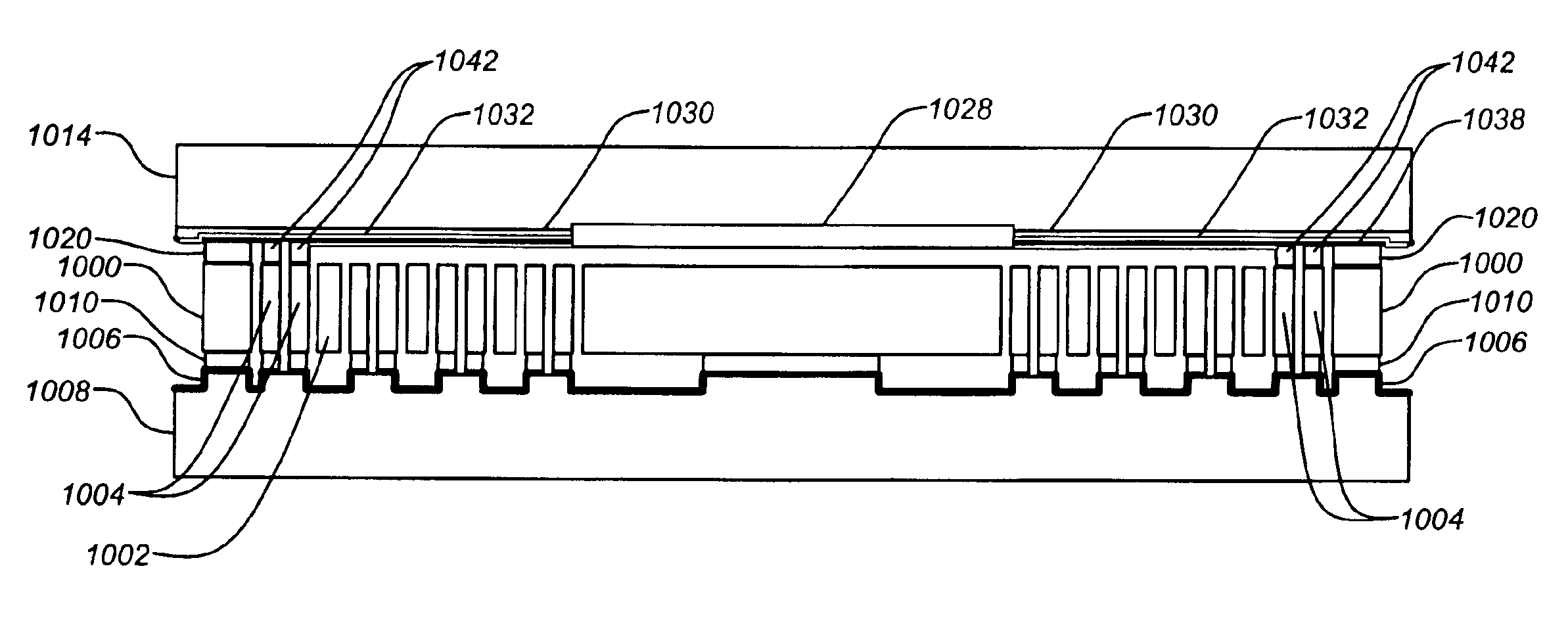

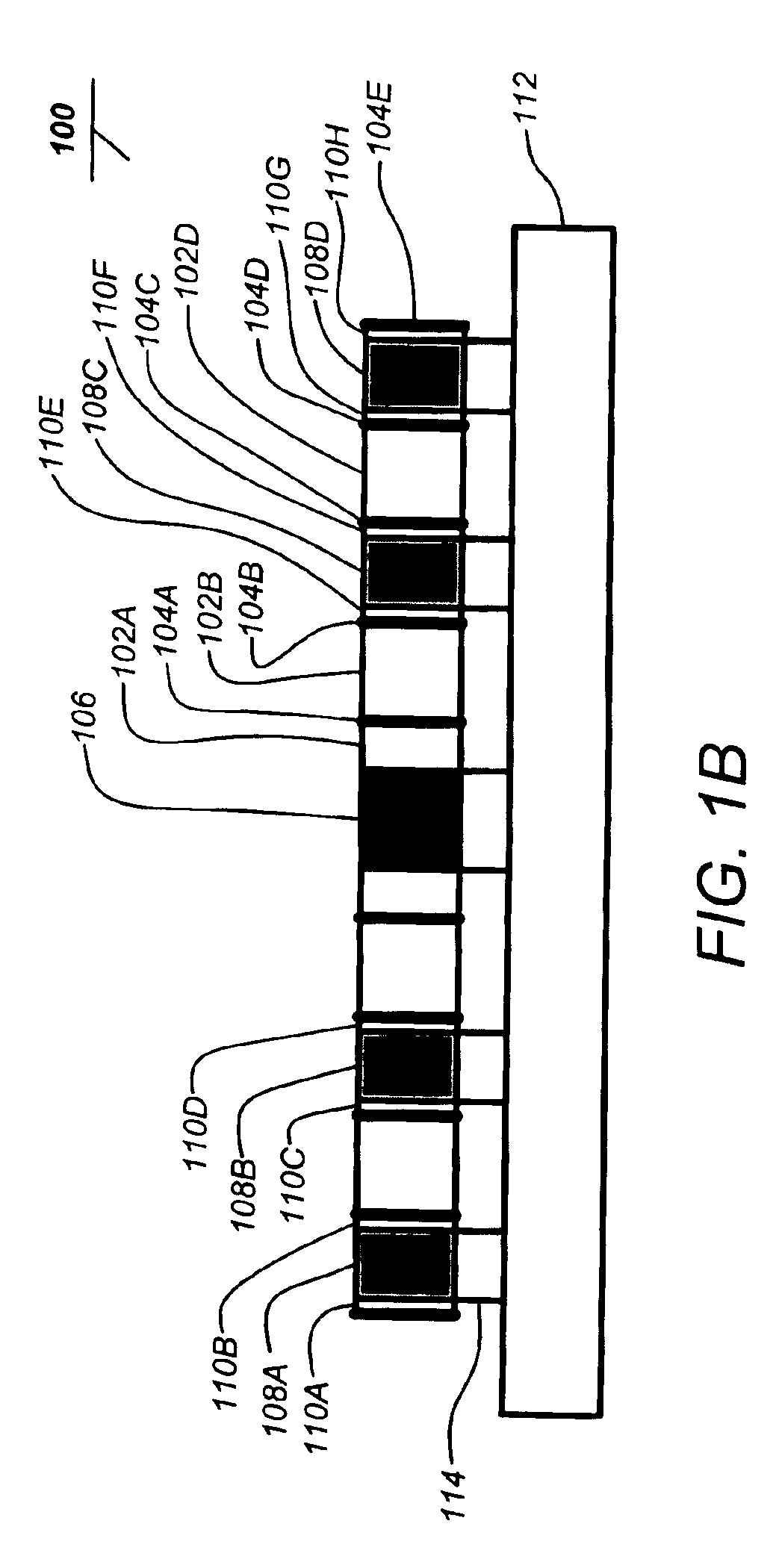

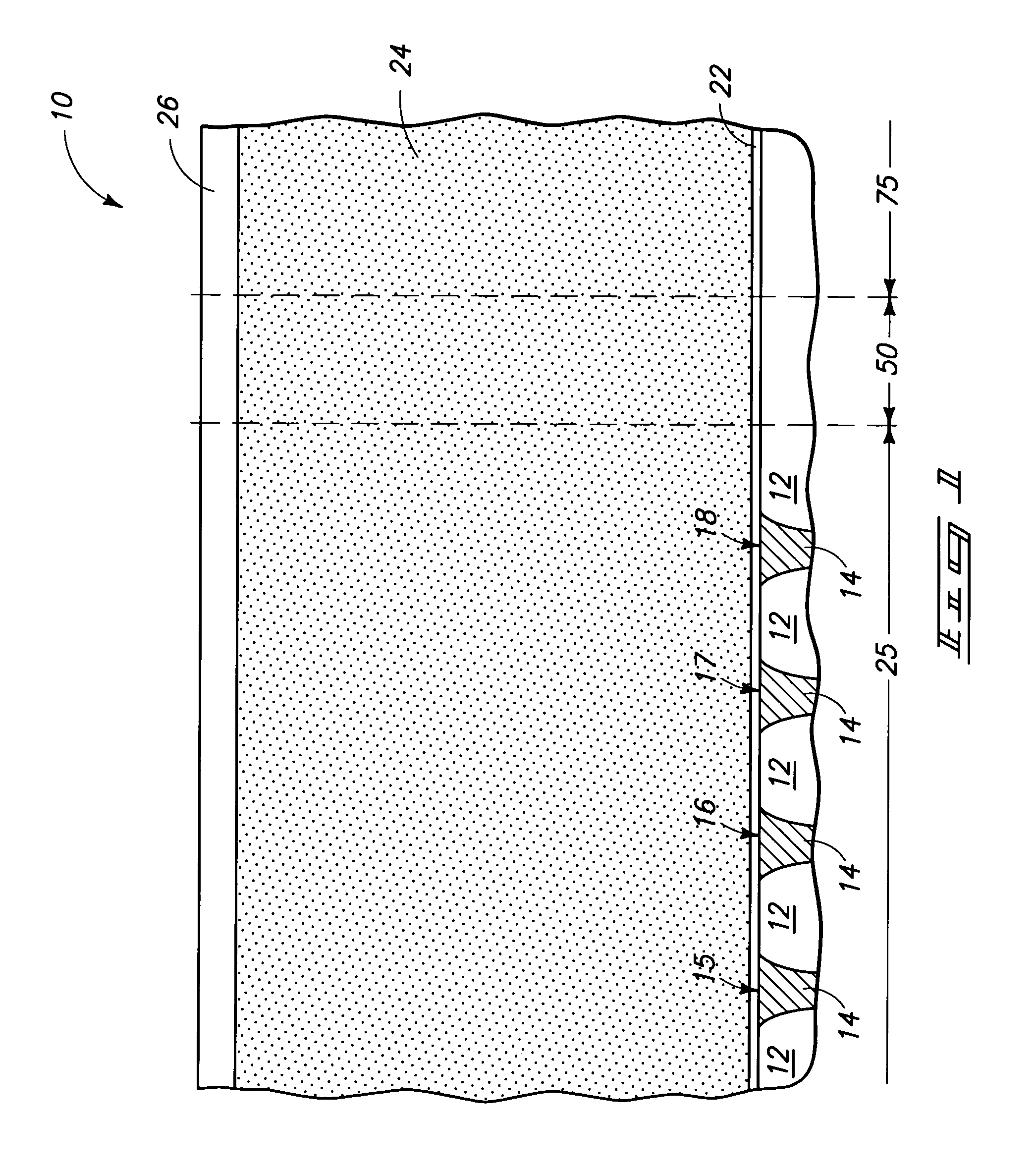

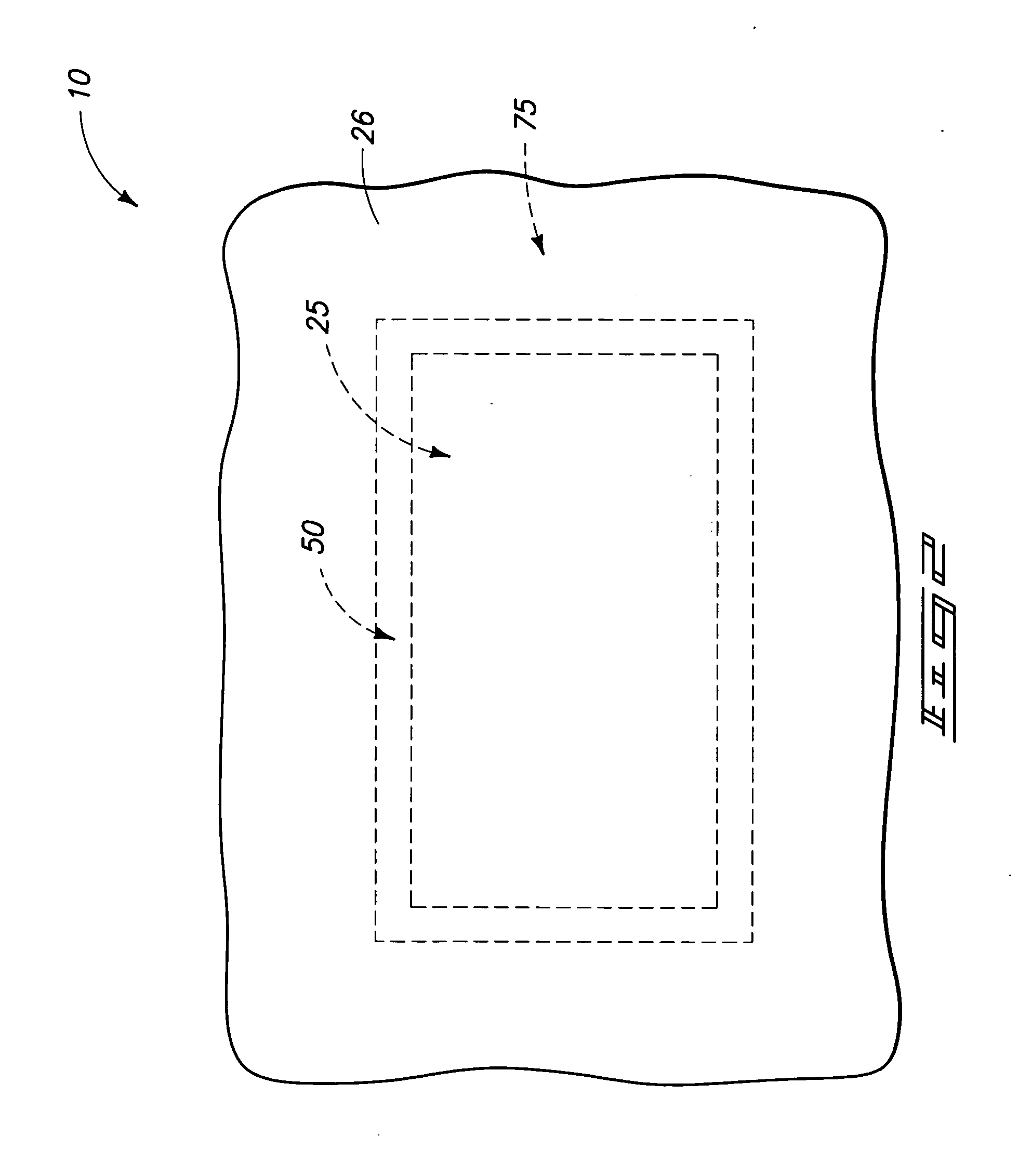

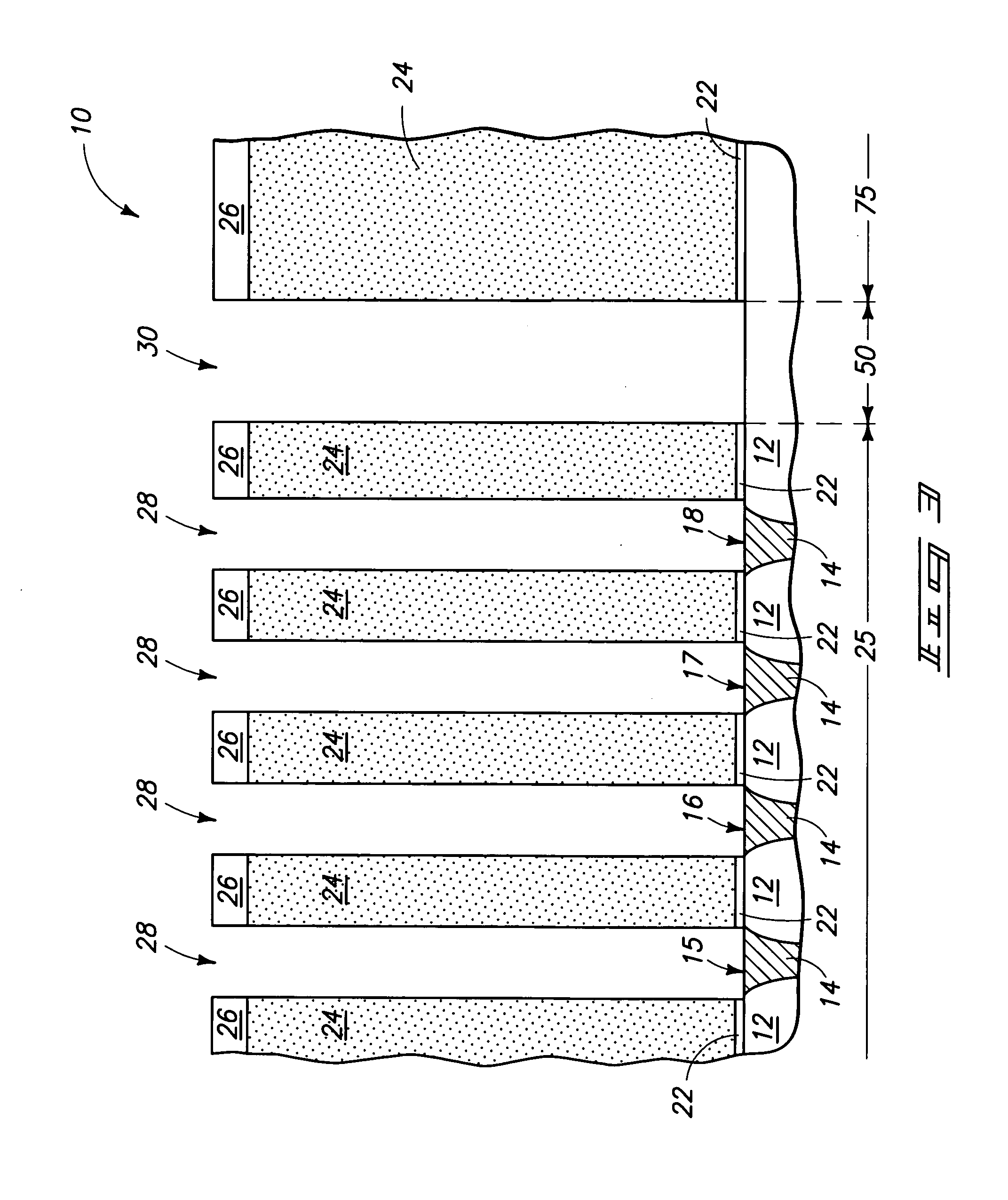

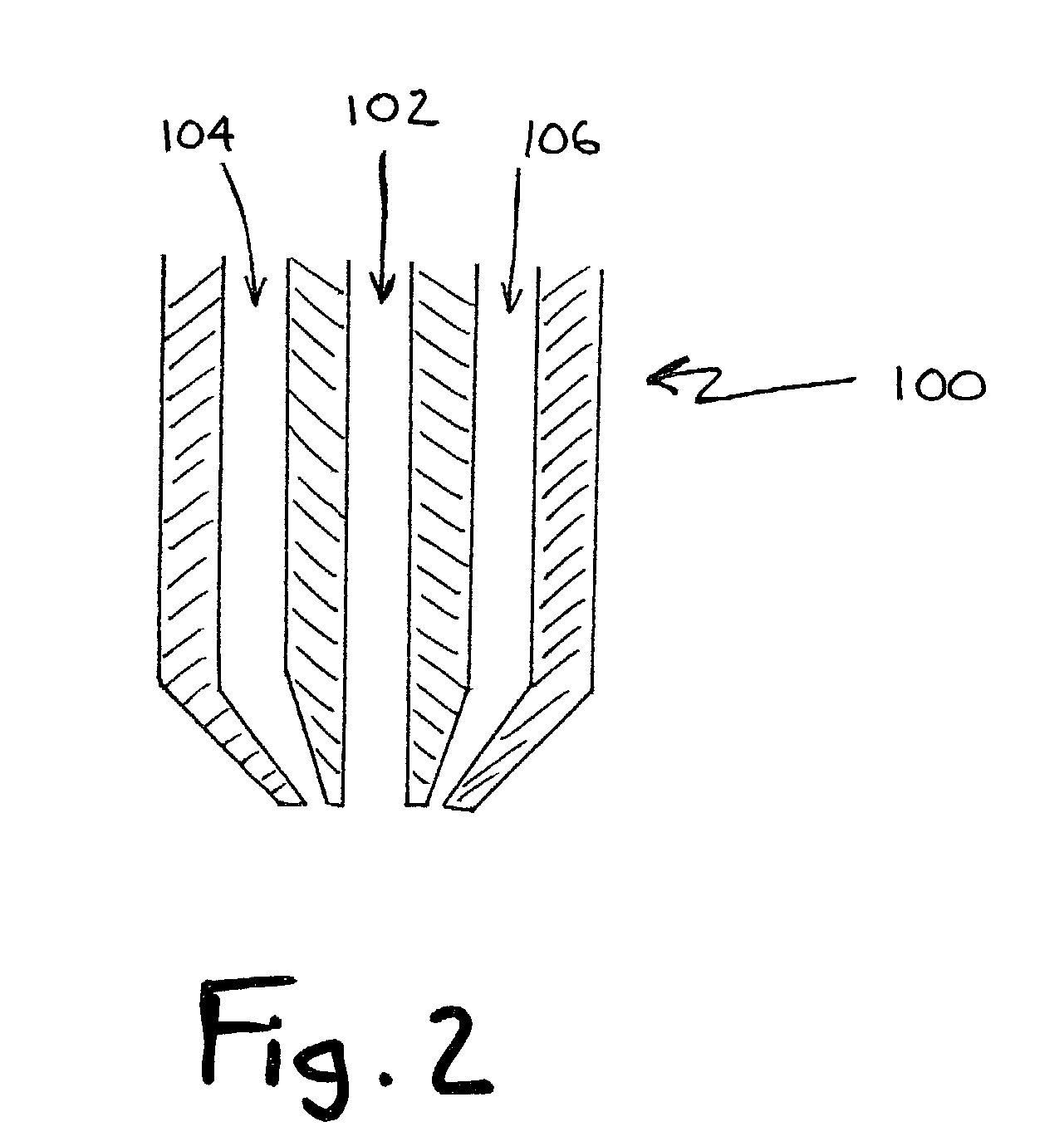

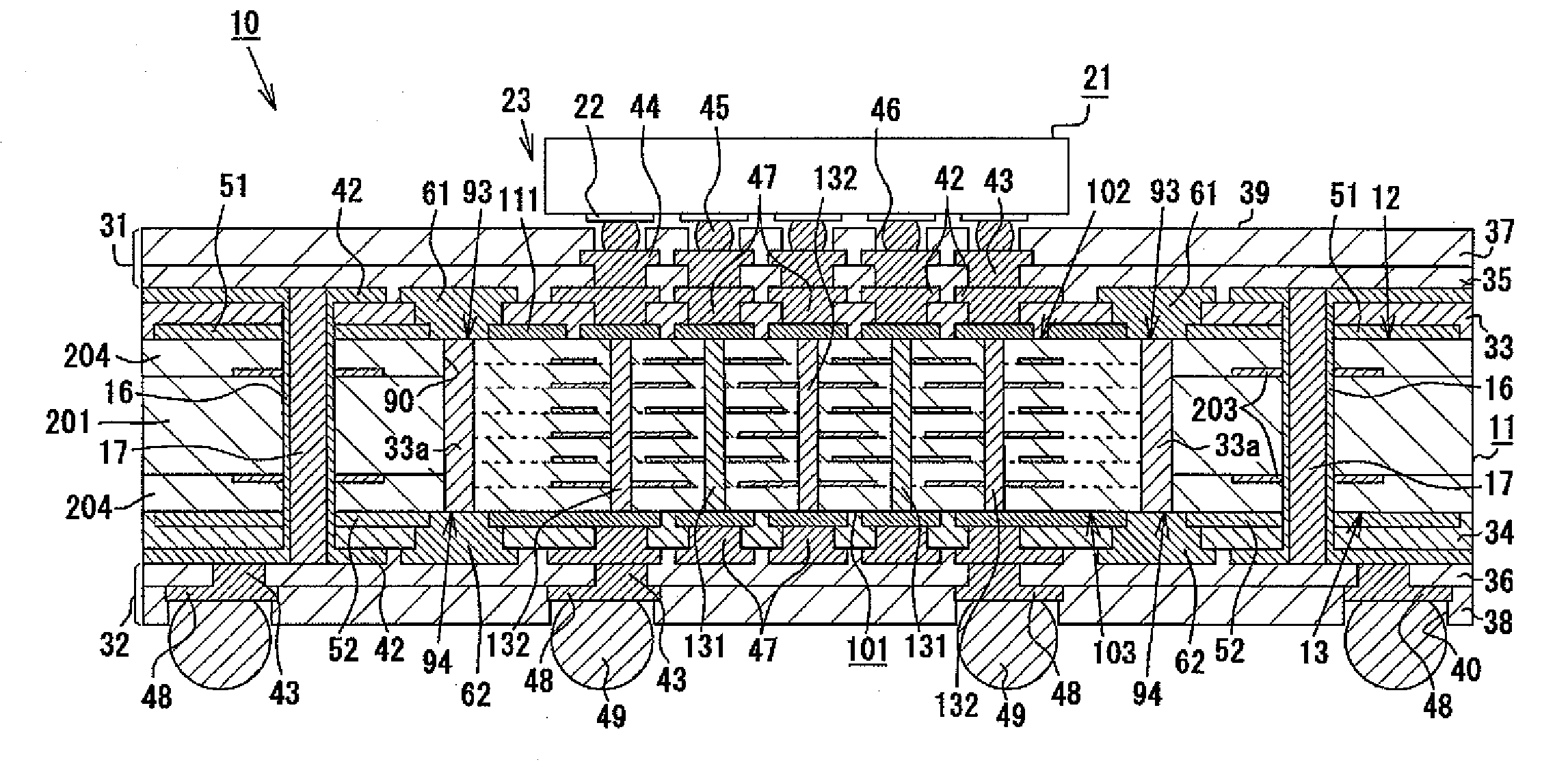

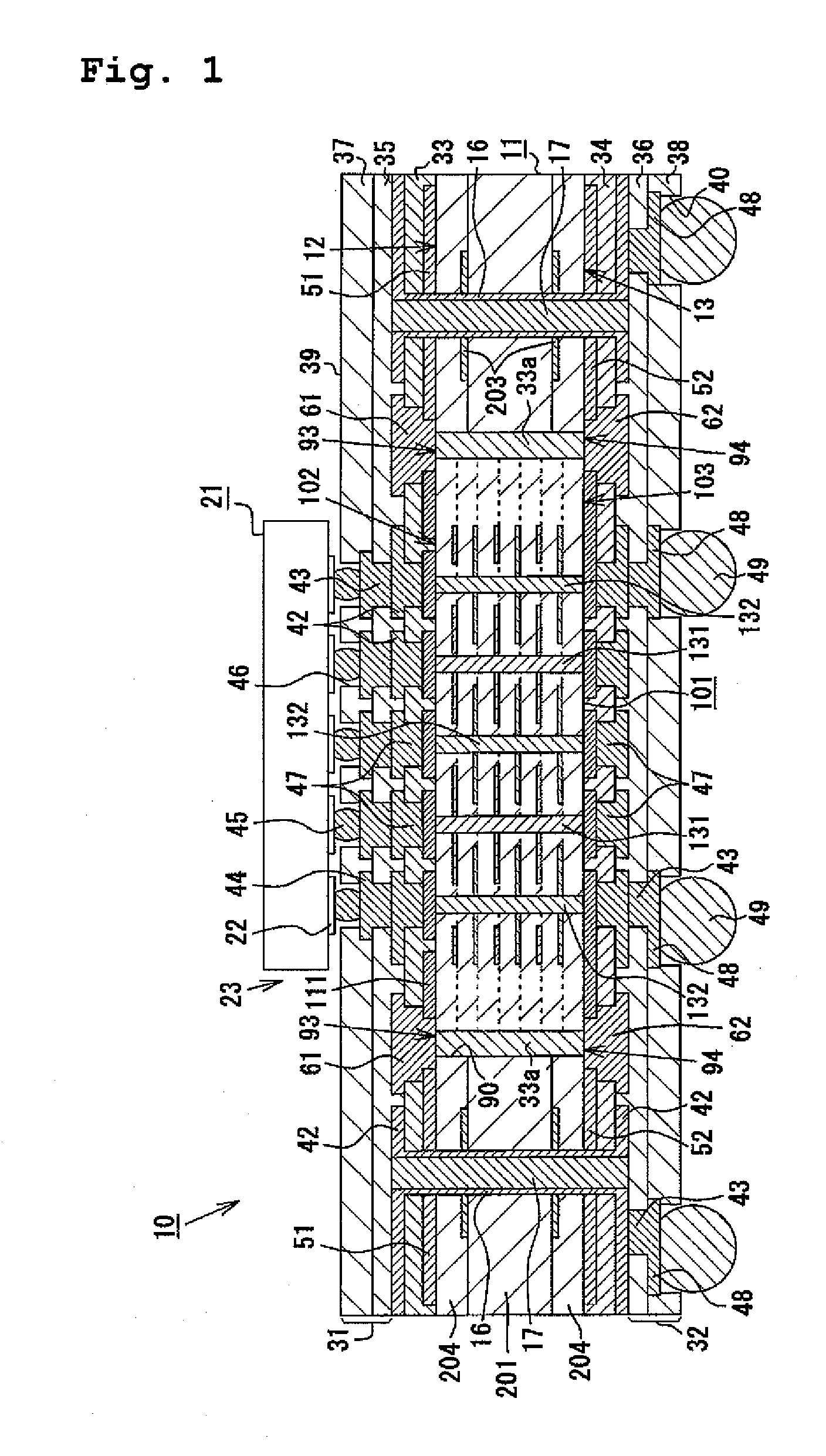

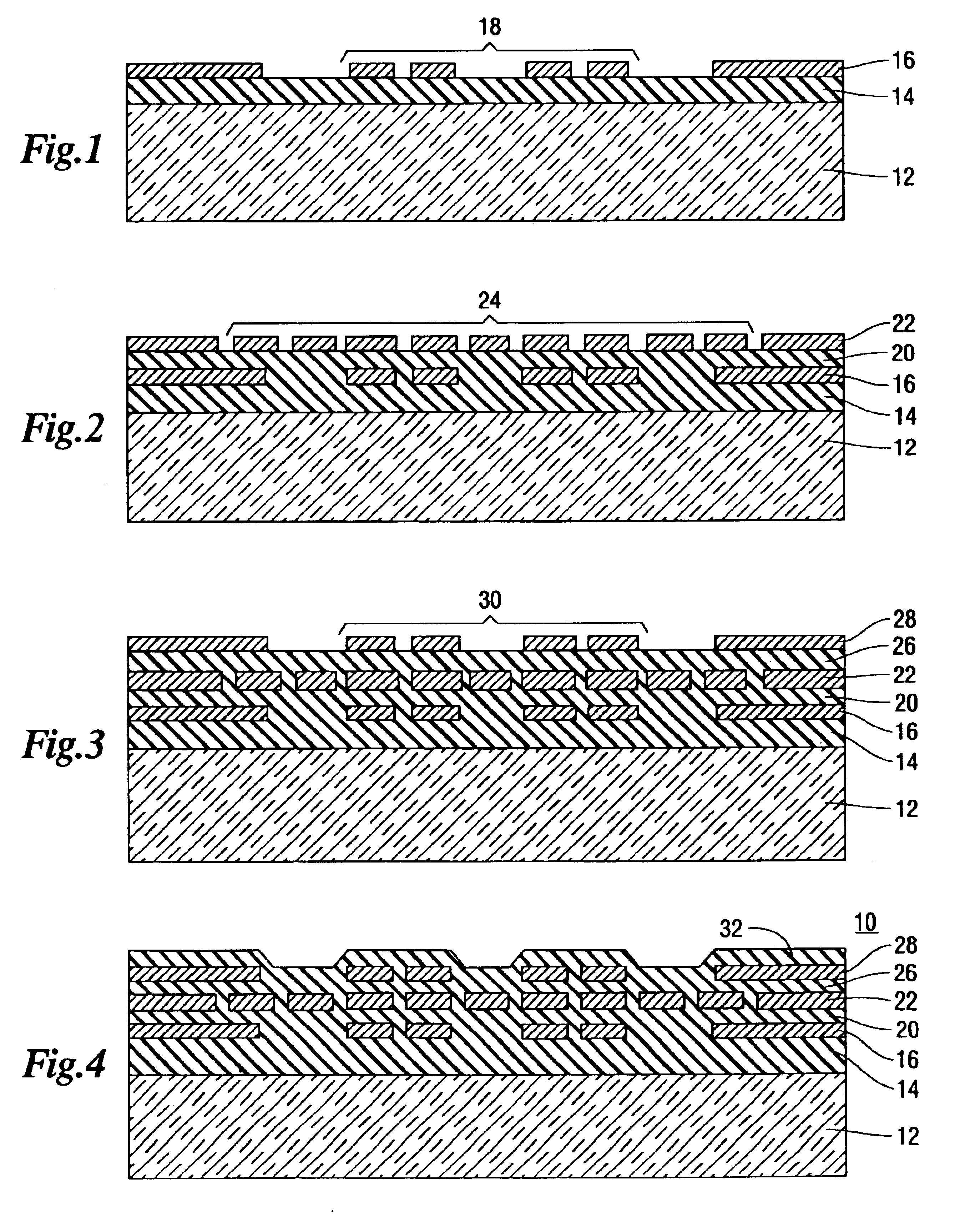

Method for forming plated terminations

InactiveUS7152291B2Improved termination featureEliminate or greatly simplify thick-film stripesElectrolytic capacitorsSemiconductor/solid-state device detailsTermination problemEngineering

Improved method steps for terminating multilayer electronic components are disclosed. Monolithic components are formed with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. Electrode and dielectric layers are provided in an interleaved arrangement and selected portions of the electrode layers are exposed. Electrically isolated anchor tabs may optionally be provided and exposed in some embodiments. Termination material is then plated to the exposed portions of the electrode layers until exposed portions of selected such portions thereof are connected. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

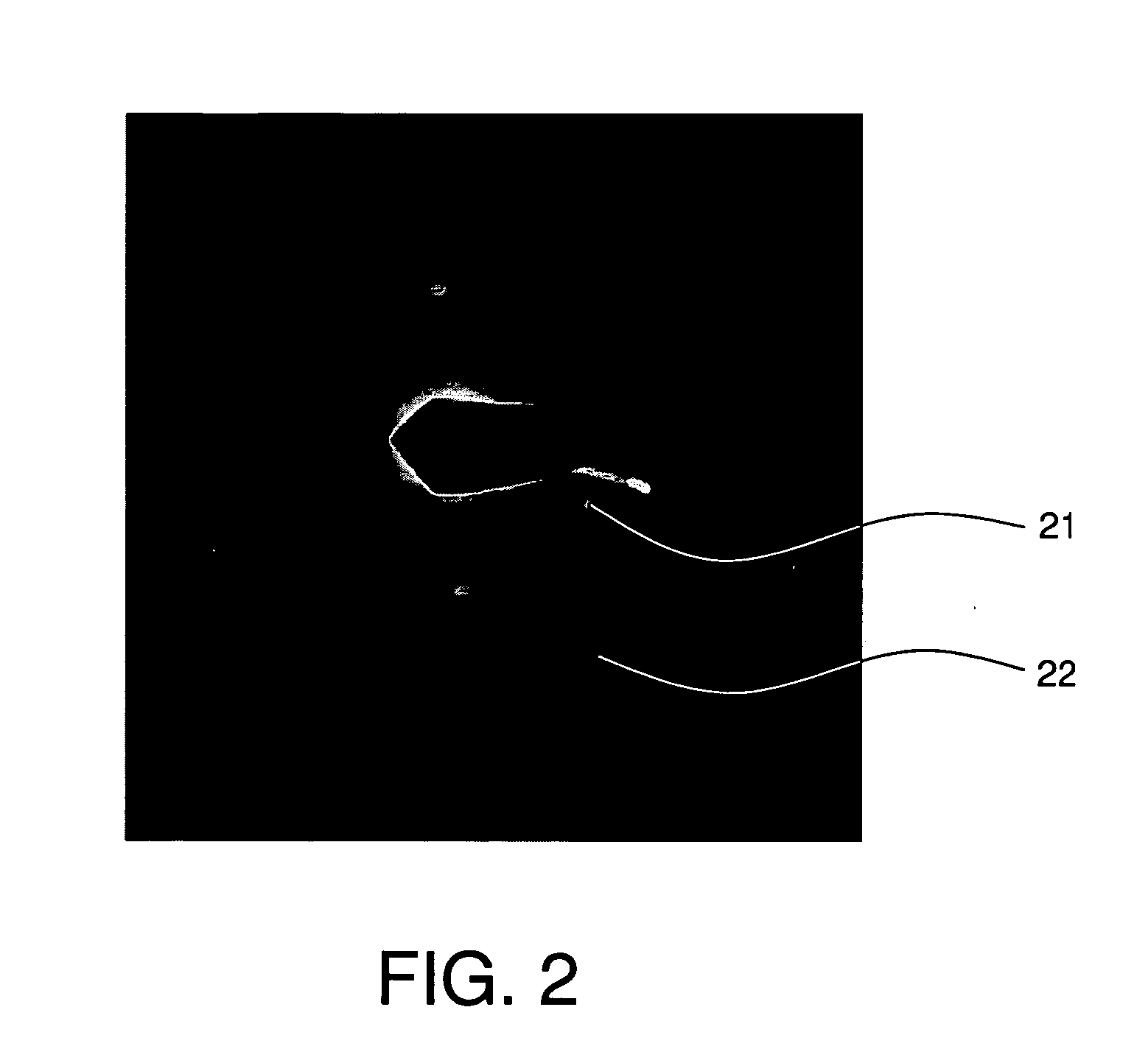

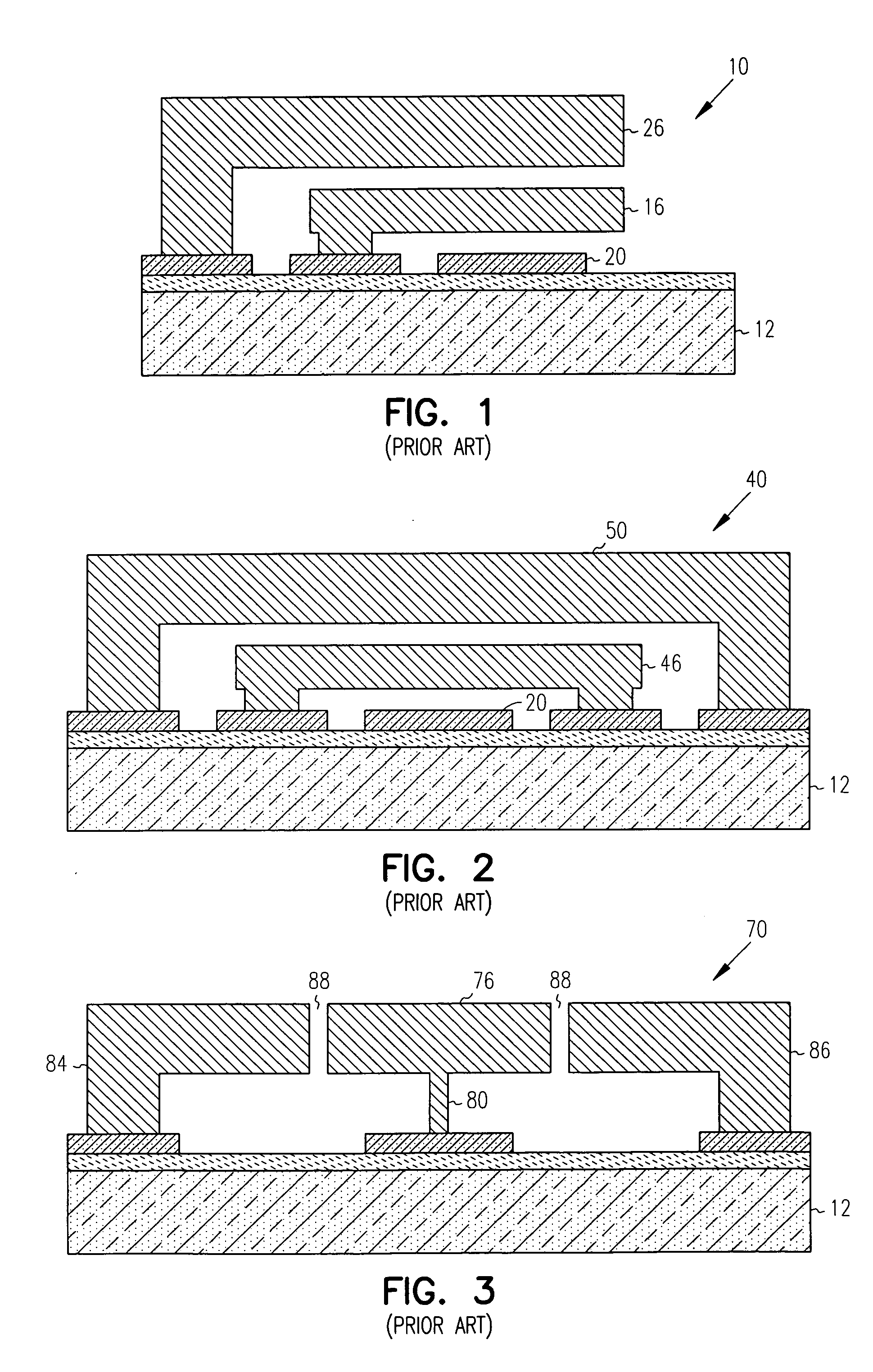

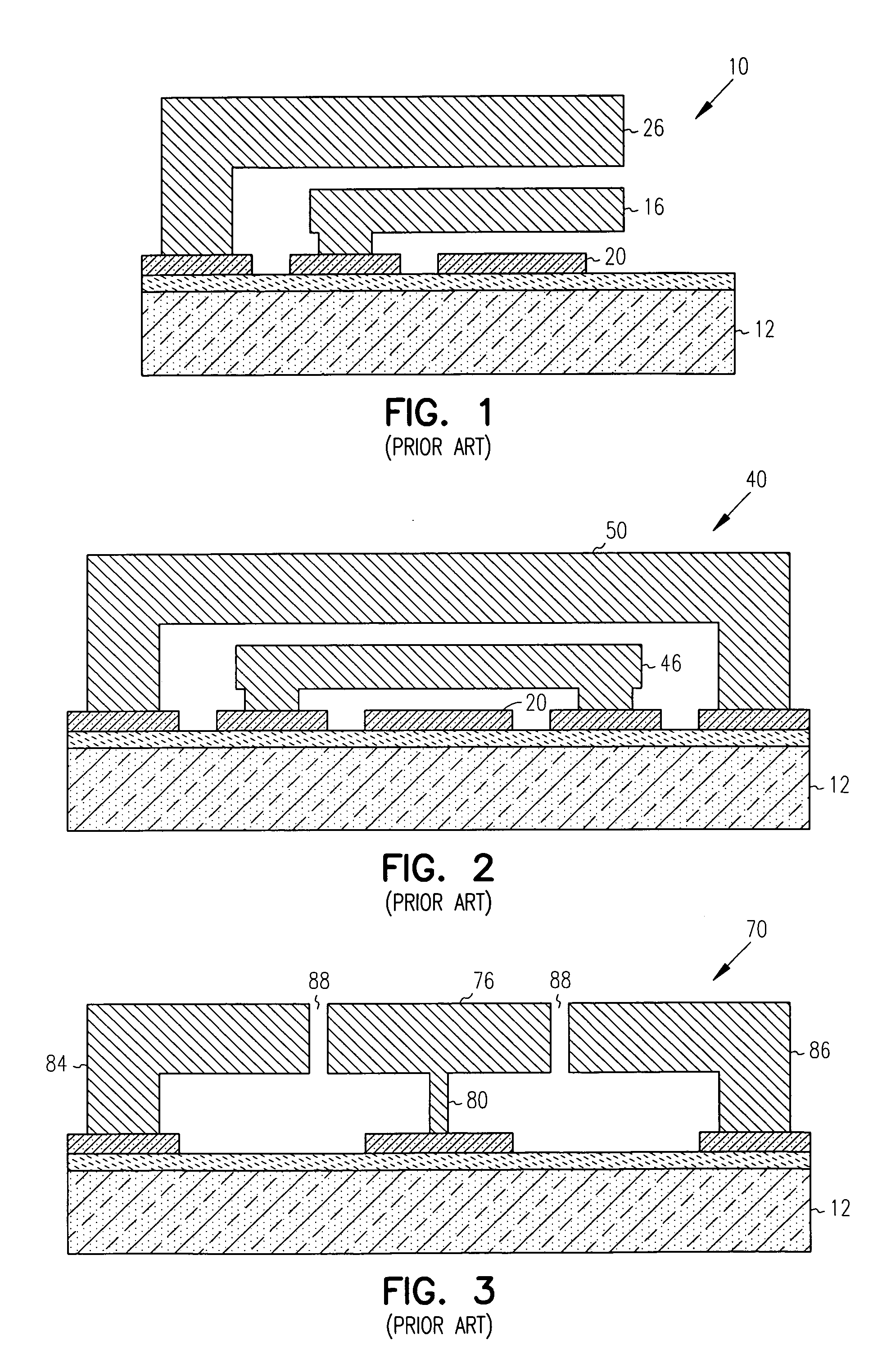

Vacuum-cavity MEMS resonator

A microelectromechanical (MEMS) resonator with a vacuum-cavity is fabricated using polysilicon-enabled release methods. A vacuum-cavity surrounding the MEMS beam is formed by removing release material that surrounds the beam and sealing the resulting cavity under vacuum by depositing a layer of nitride over the structure. The vacuum-cavity MEMS resonators have cantilever beams, bridge beams or breathing-bar beams.

Owner:INTEL CORP

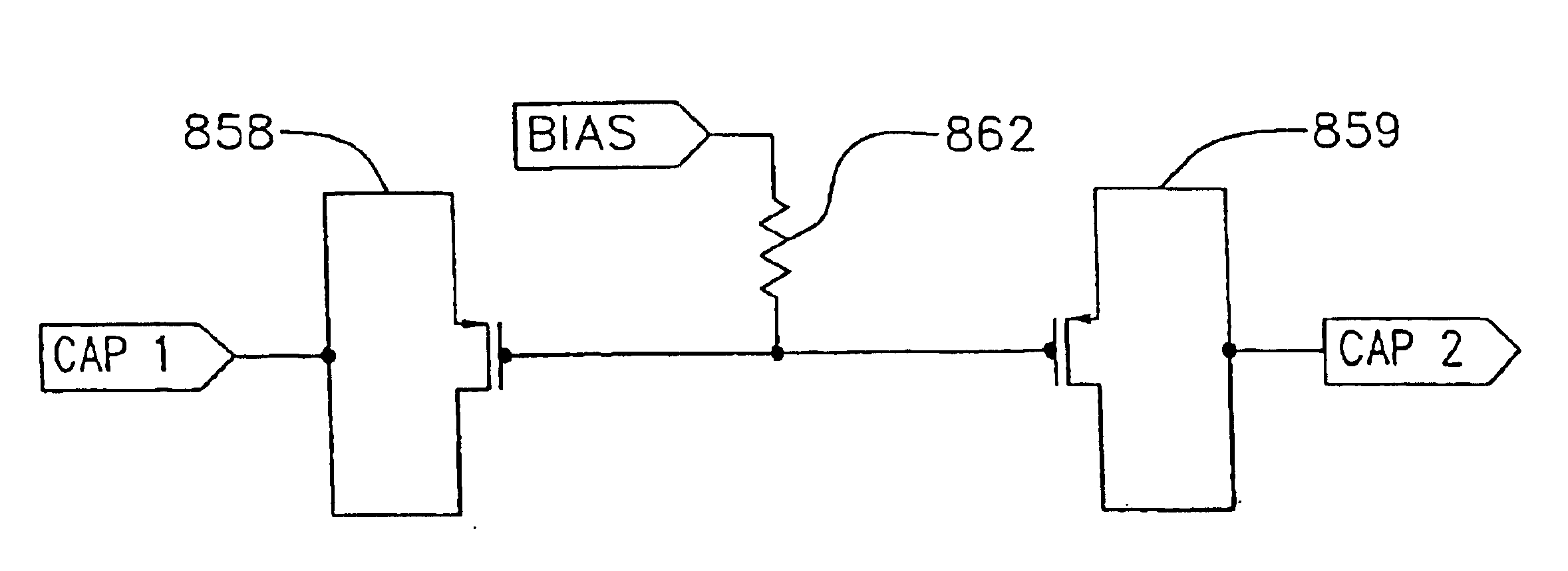

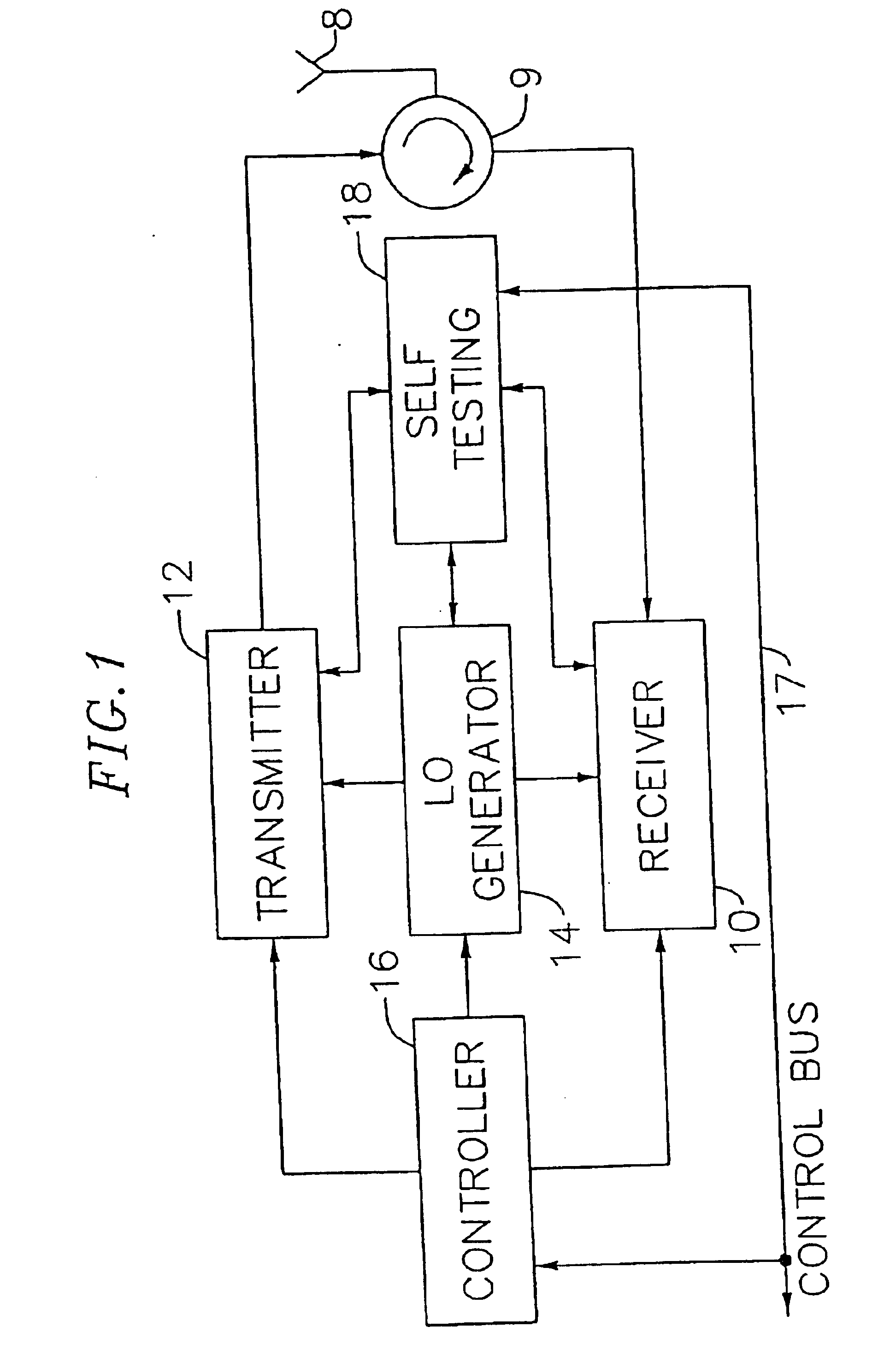

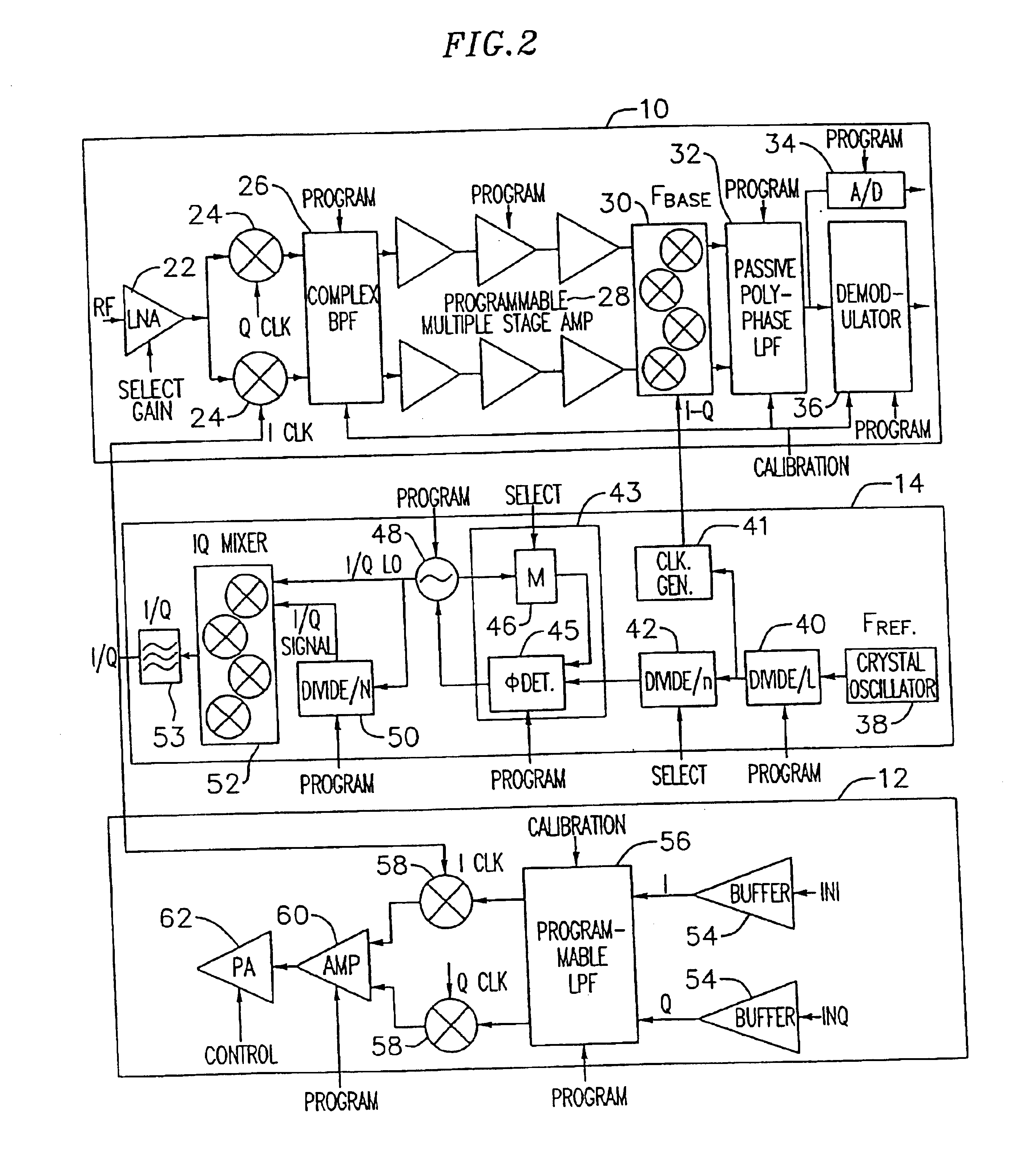

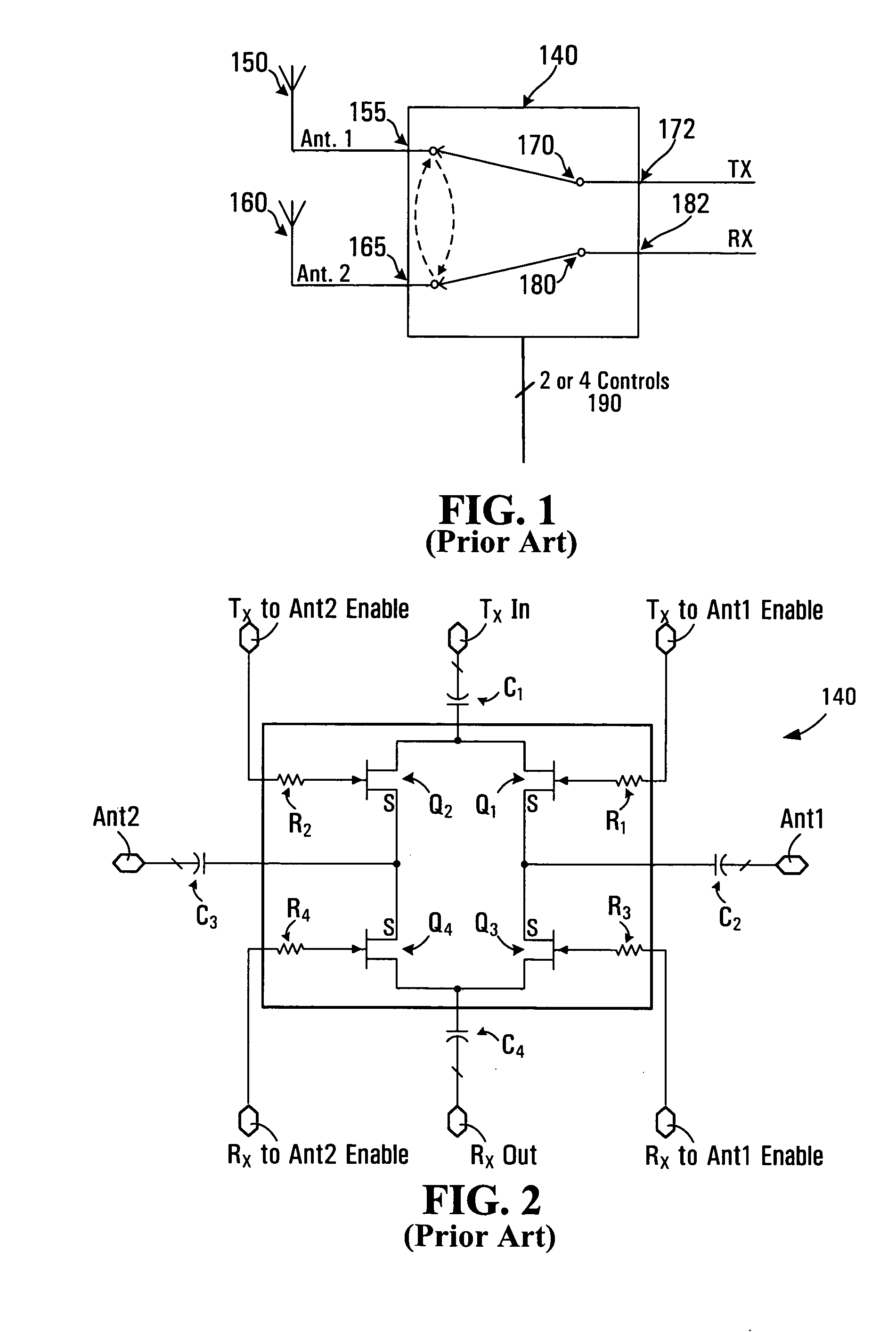

Adaptive radio transceiver with floating MOSFET capacitors

An exemplary embodiment of the present invention described and shown in the specification and drawings is a transceiver with a receiver, a transmitter, a local oscillator (LO) generator, a controller, and a self-testing unit. All of these components can be packaged for integration into a single IC including components such as filters and inductors. The controller for adaptive programming and calibration of the receiver, transmitter and LO generator. The self-testing unit generates is used to determine the gain, frequency characteristics, selectivity, noise floor, and distortion behavior of the receiver, transmitter and LO generator. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or the meaning of the claims.

Owner:AVAGO TECH INT SALES PTE LTD

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

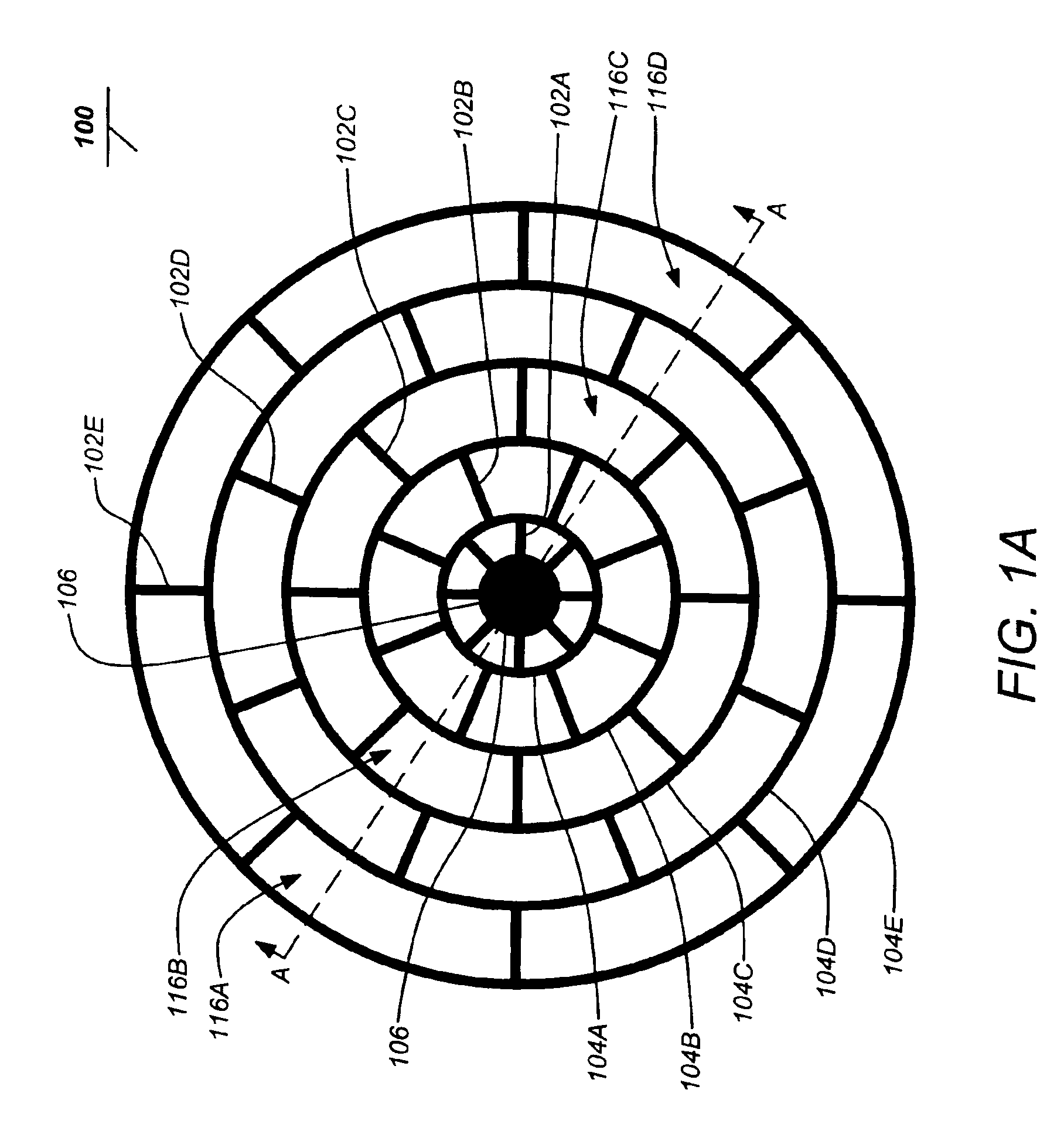

Method of producing an integral resonator sensor and case

InactiveUS6944931B2Improve Sensing PerformanceIncrease the areaGrinding machine componentsWave amplification devicesAcousticsResonator

The present invention discloses an inertial sensor having an integral resonator. A typical sensor comprises a planar mechanical resonator for sensing motion of the inertial sensor and a case for housing the resonator. The resonator and a wall of the case are defined through an etching process. A typical method of producing the resonator includes etching a baseplate, bonding a wafer to the etched baseplate, through etching the wafer to form a planar mechanical resonator and the wall of the case and bonding an end cap wafer to the wall to complete the case.

Owner:CALIFORNIA INST OF TECH +1

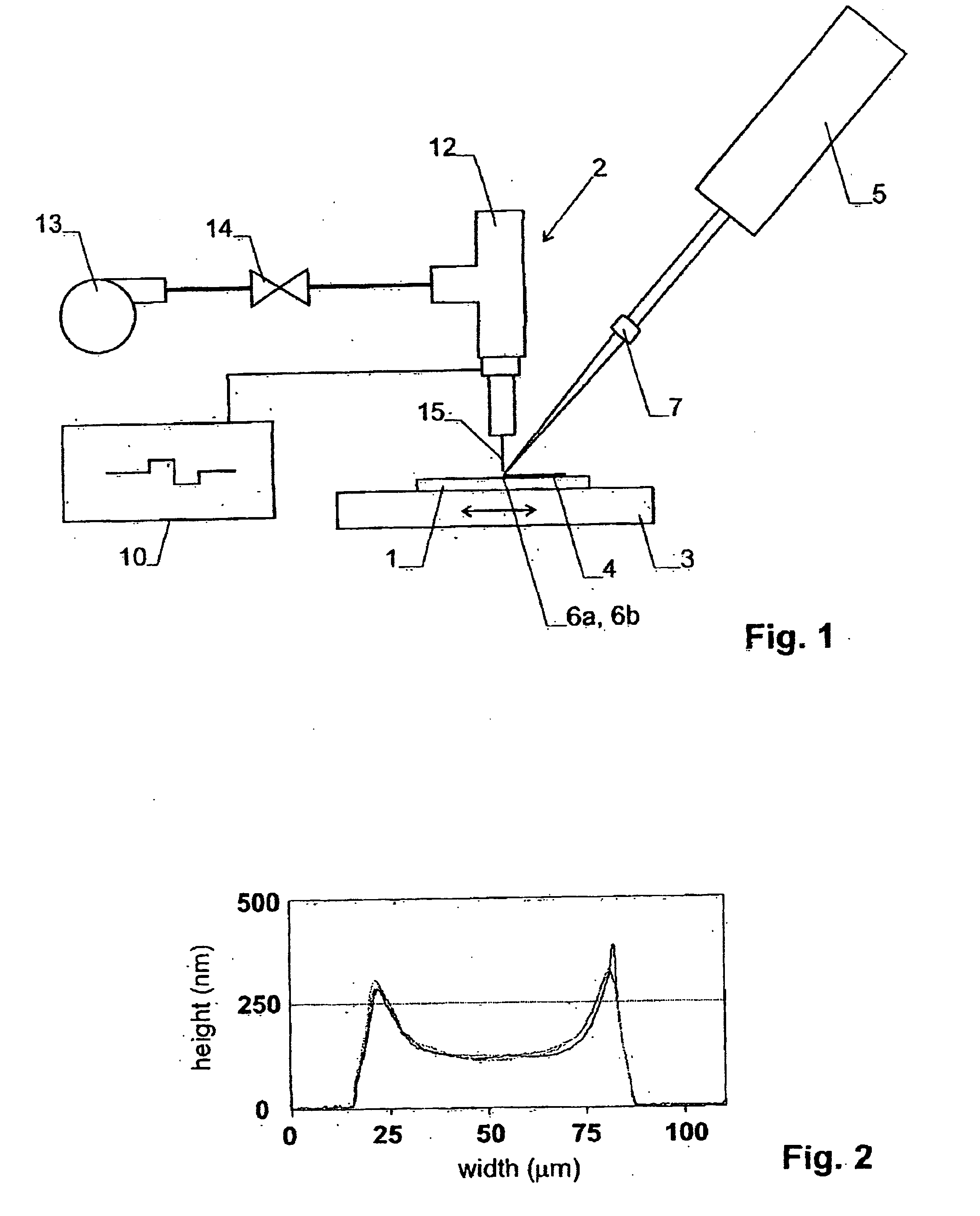

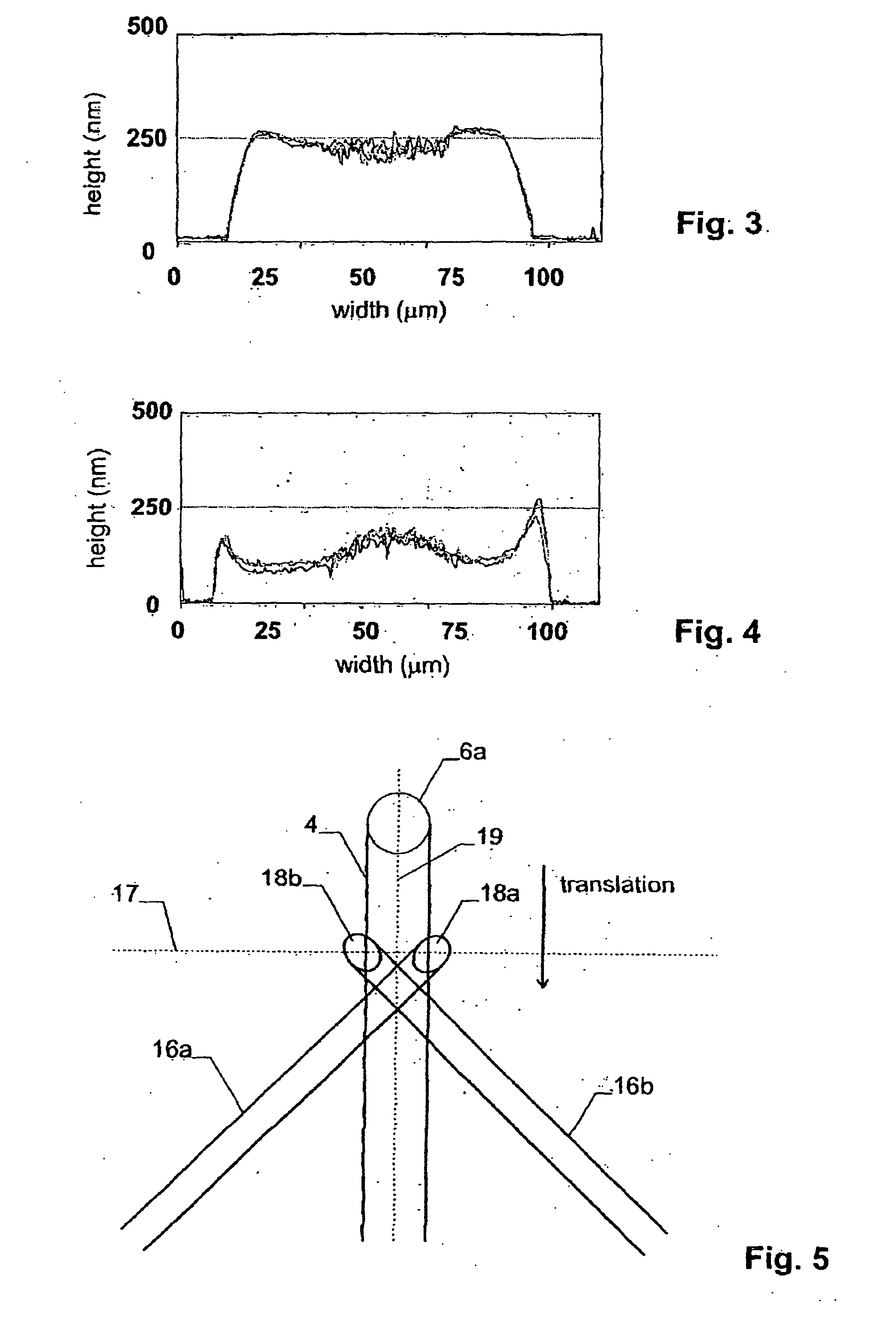

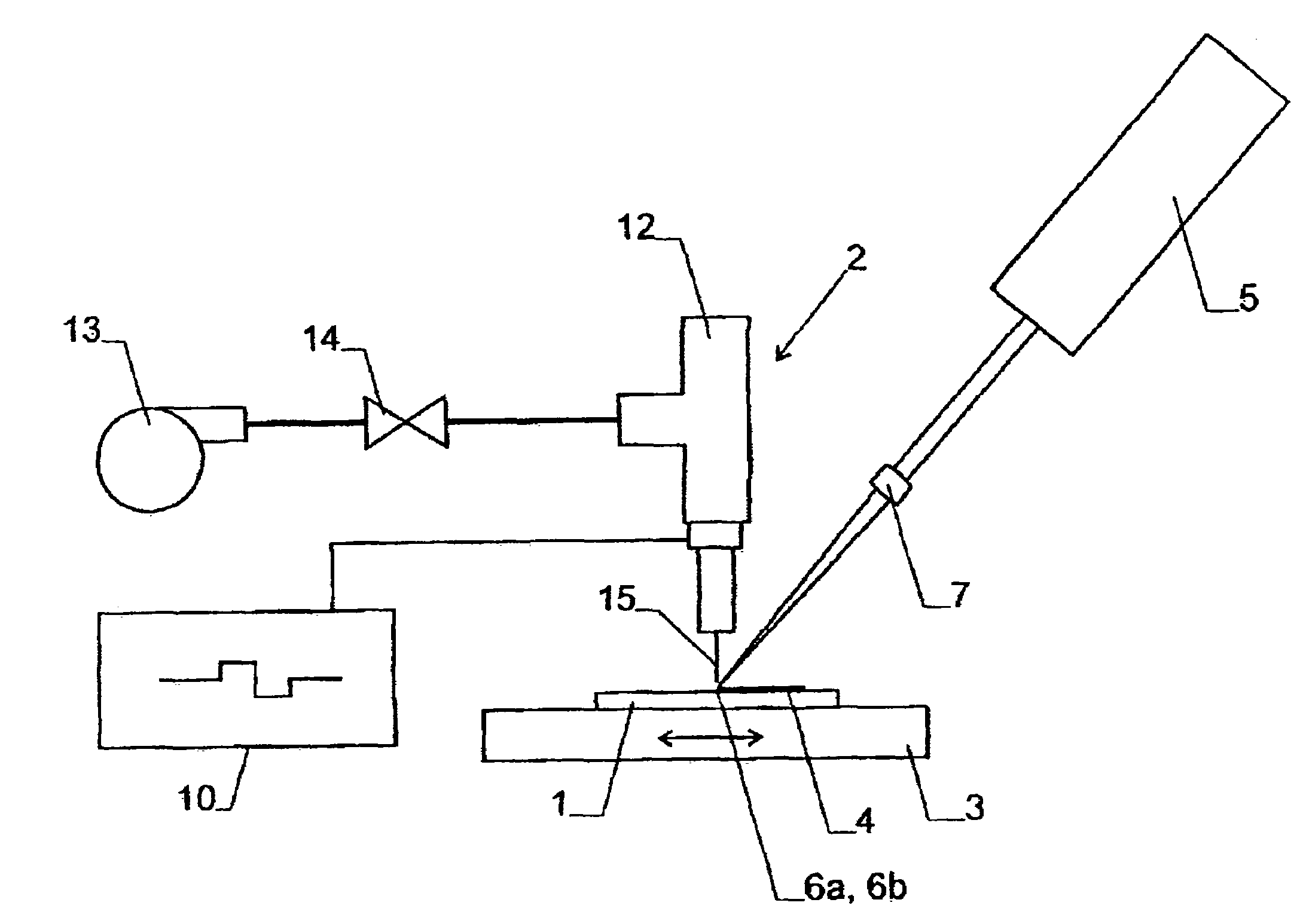

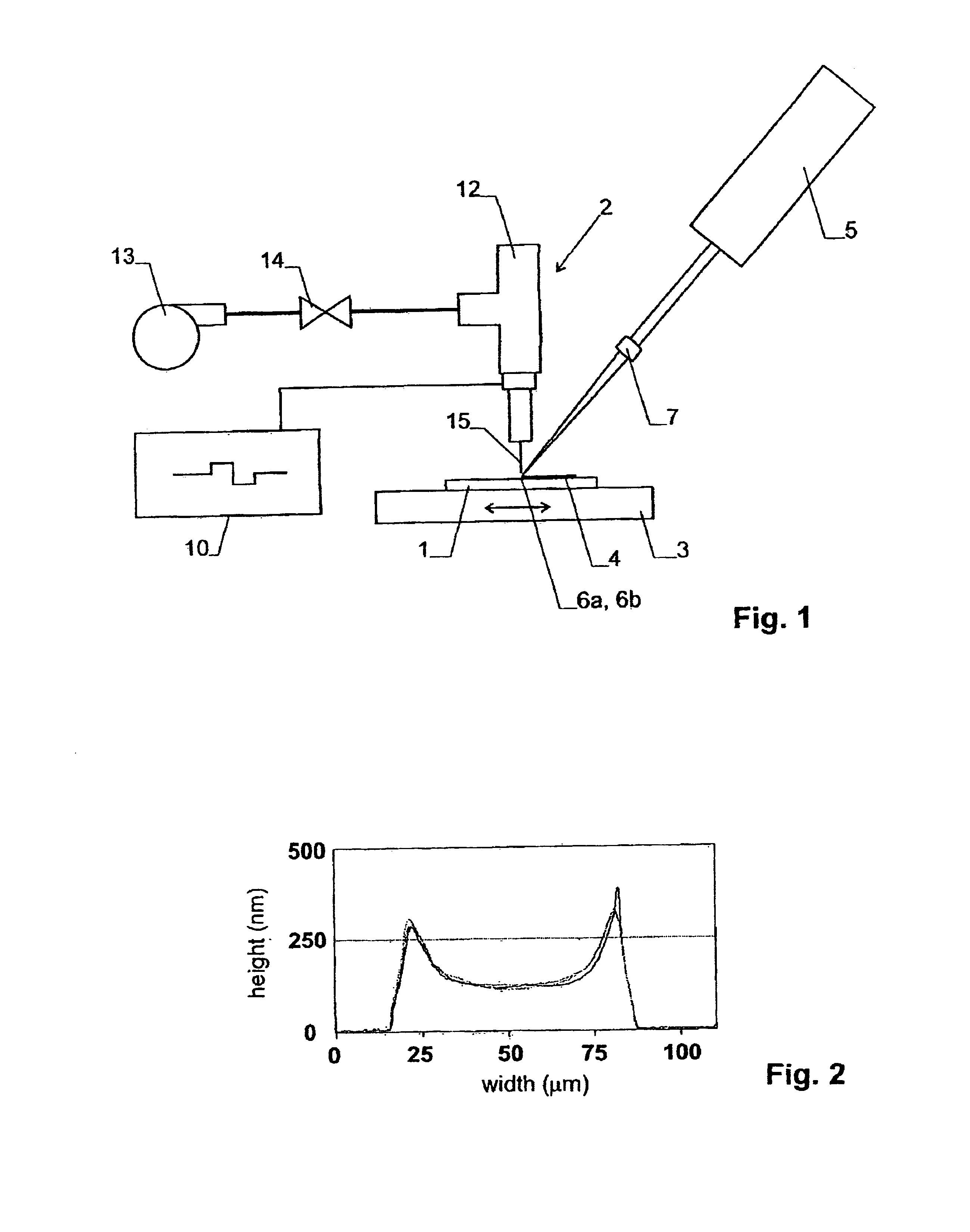

Maskless nanofabrication of electronic components

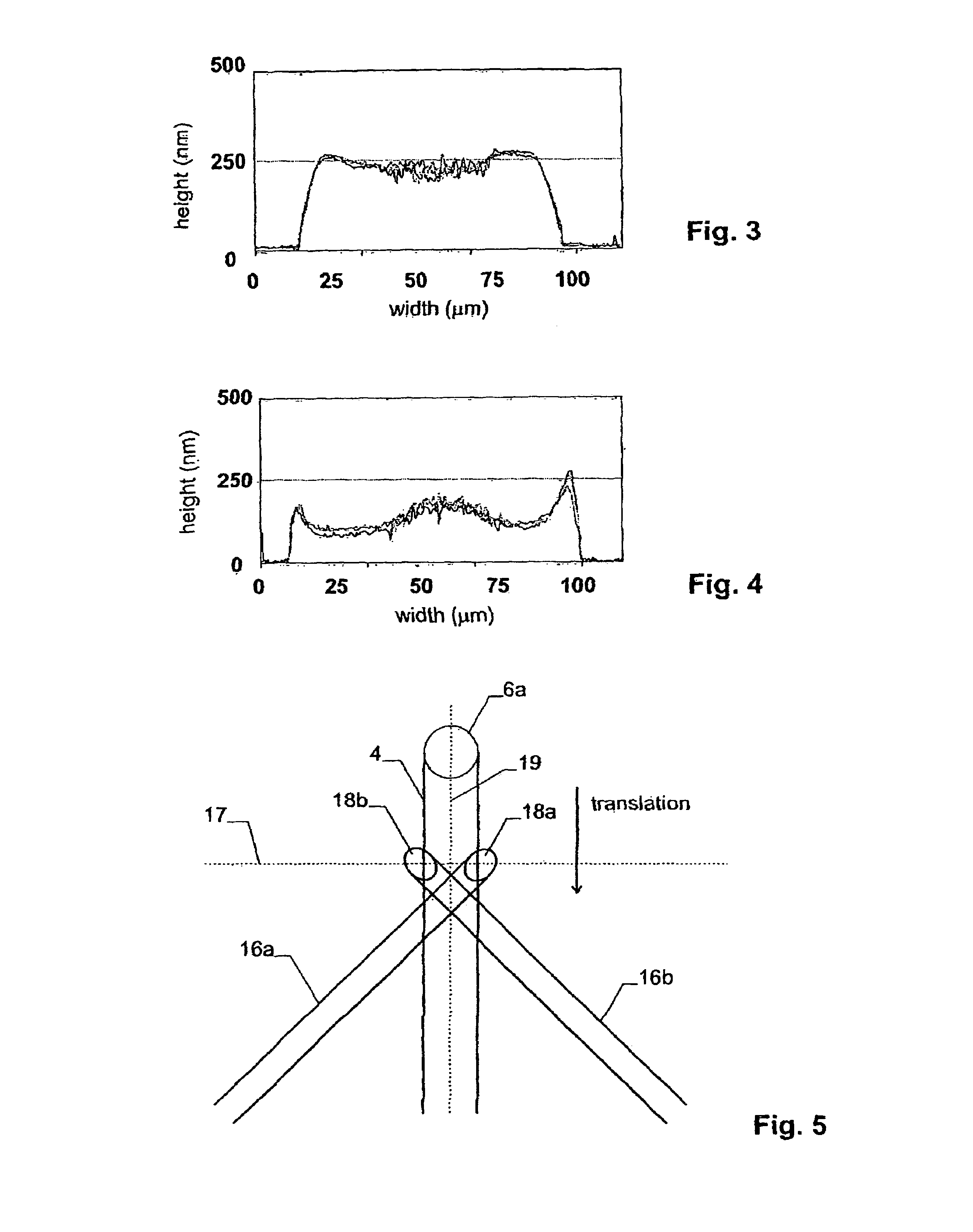

InactiveUS20100035375A1Reduce the amount requiredEfficient methodRadiation applicationsSolid-state devicesElectronic structureNanoparticle

The present invention relates to systems, materials and methods for the formation of conducting, semiconducting, and dielectric layers, structures and devices from suspensions of nanoparticles. Drop-on-demand systems are used in some embodiments to fabricate various electronic structures including conductors, capacitors, FETs. Selective laser ablation is used in some embodiments to pattern more precisely the circuit elements and to form small channel devices.

Owner:RGT UNIV OF CALIFORNIA +1

Methods of etching polysilicon and methods of forming pluralities of capacitors

A method of etching polysilicon includes exposing a substrate comprising polysilicon to a solution comprising water, HF, and at least one of a conductive metal nitride, Pt, and Au under conditions effective to etch polysilicon from the substrate. In one embodiment, a substrate first region comprising polysilicon and a substrate second region comprising at least one of a conductive metal nitride, Pt, and Au is exposed to a solution comprising water and HF. The solution is devoid of any detectable conductive metal nitride, Pt, and Au prior to the exposing. At least some of the at least one are etched into the solution upon the exposing. Then, polysilicon is etched from the first region at a faster rate than any etch rate of the first region polysilicon prior to the etching of the at least some of the conductive metal nitride, Pt, and Au.

Owner:MICRON TECH INC

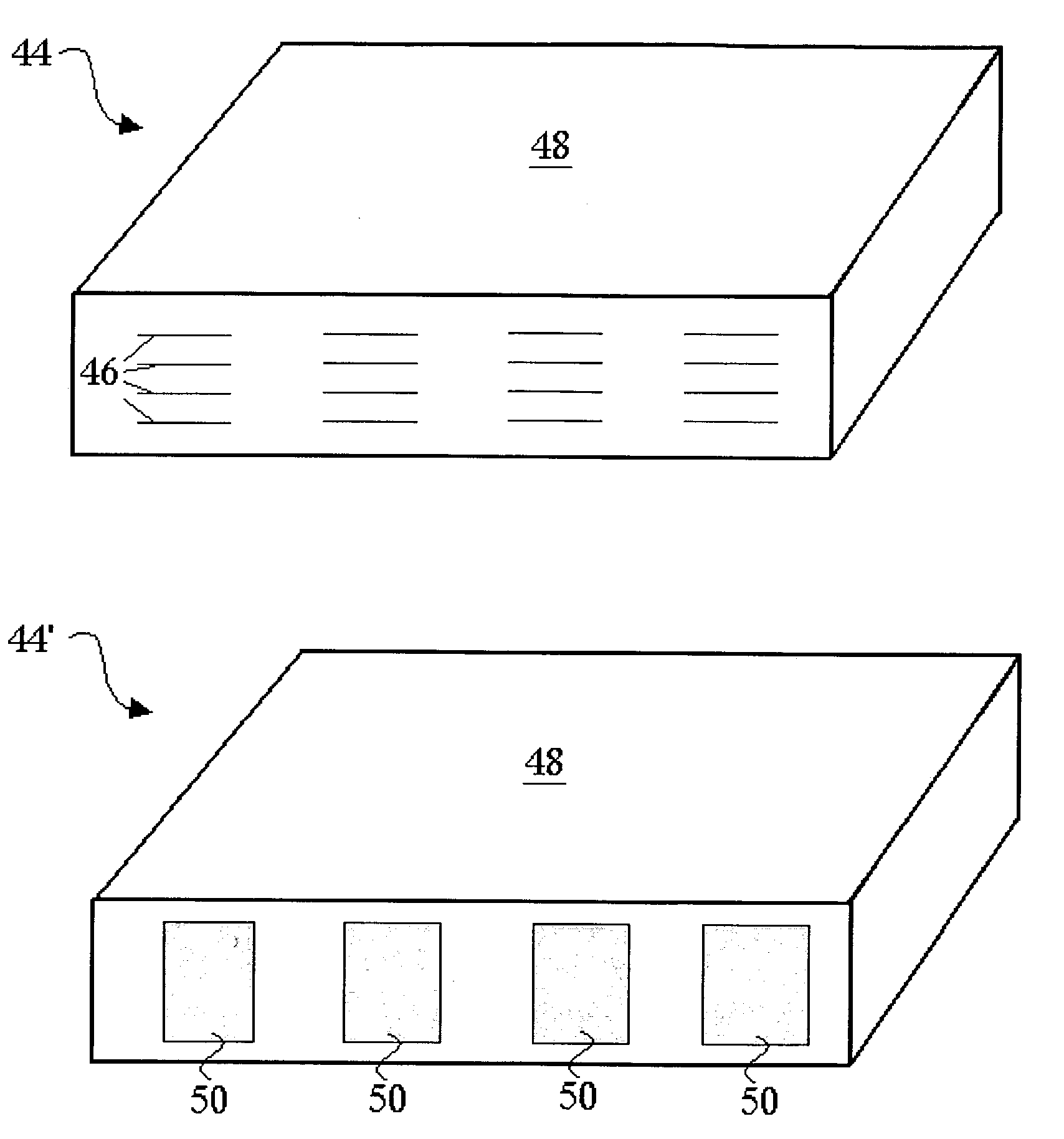

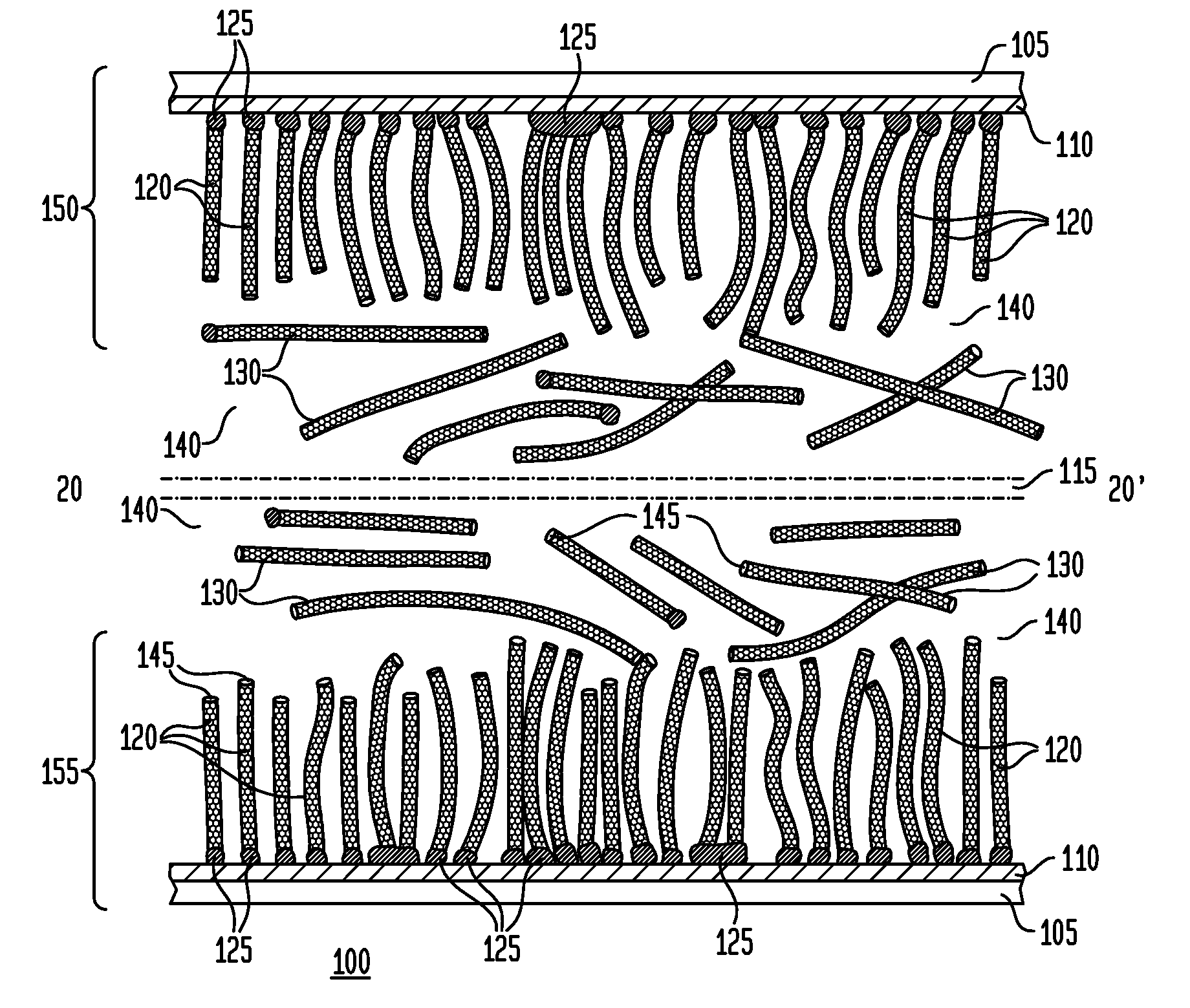

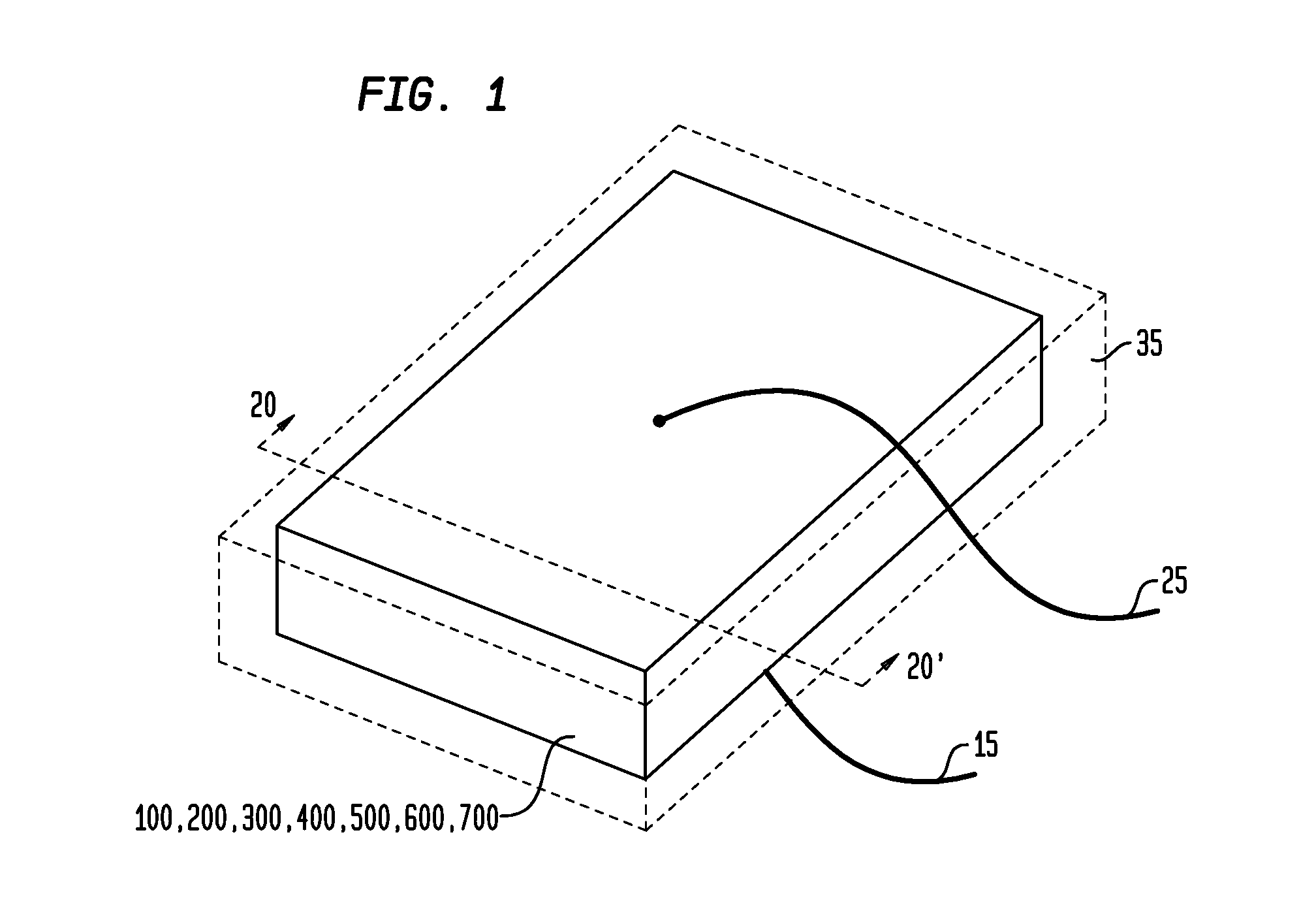

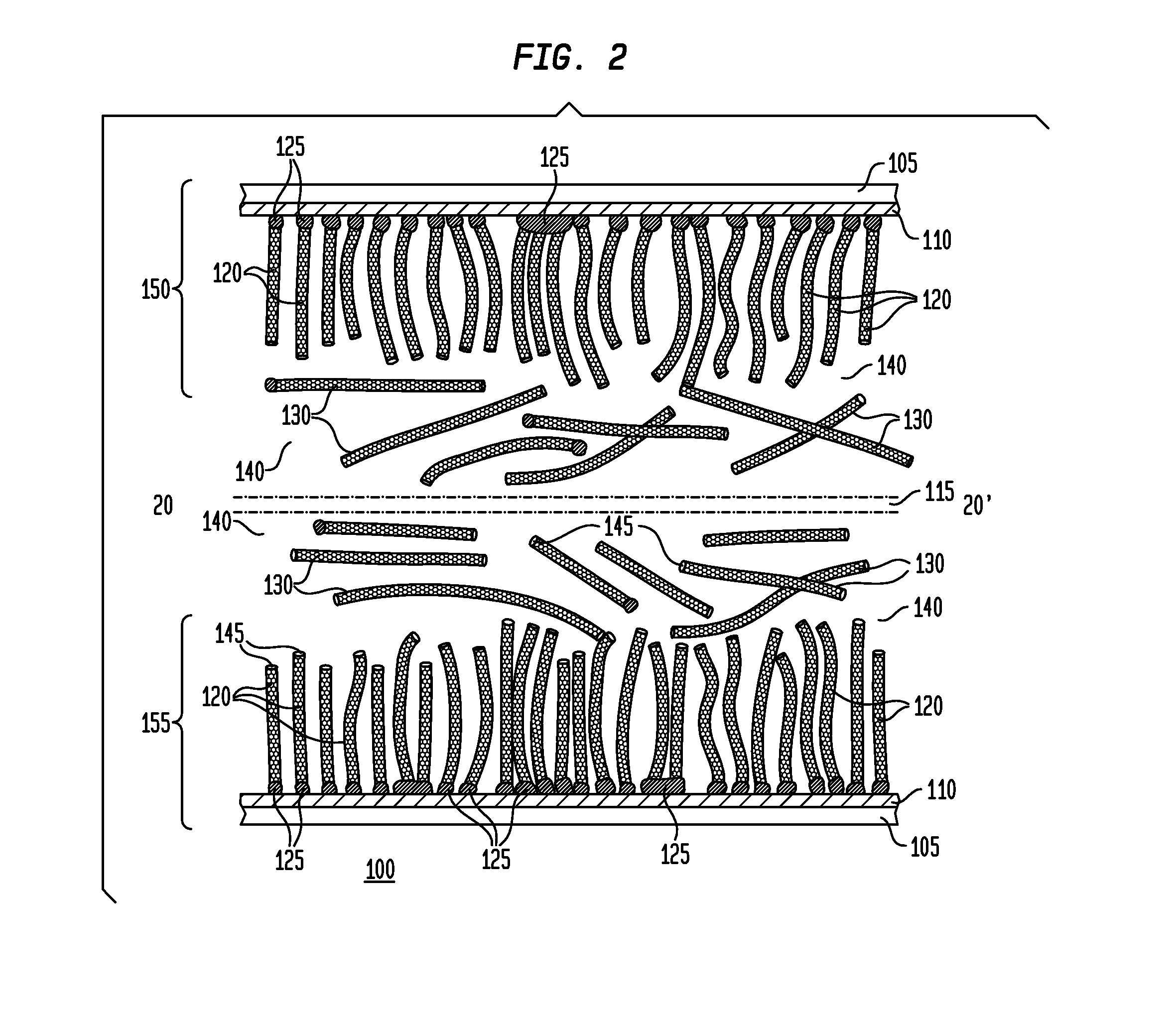

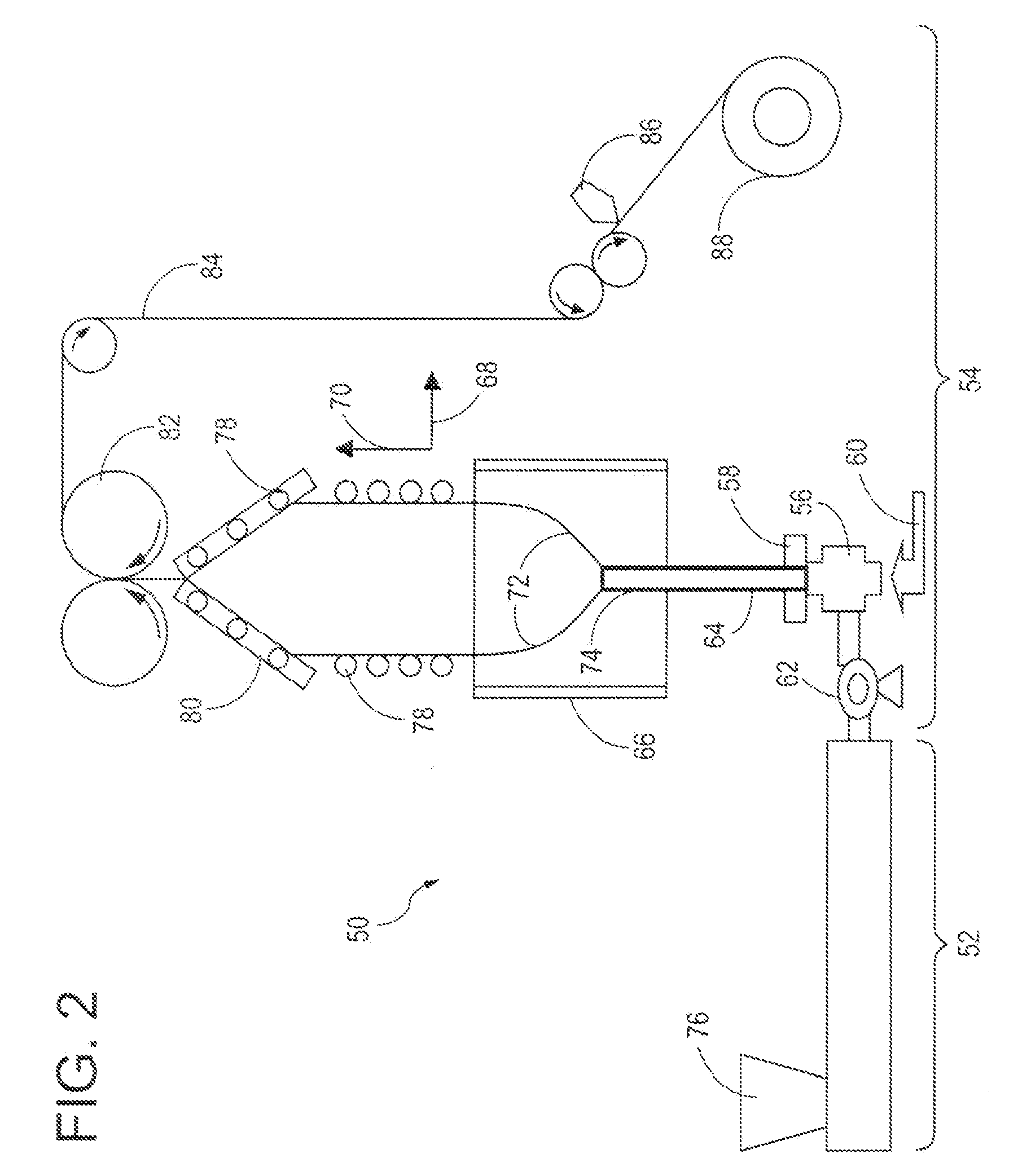

Method of and Printable Compositions for Manufacturing a Multilayer Carbon Nanotube Capacitor

InactiveUS20110204020A1Increase powerImprove cycle lifeMaterial nanotechnologyNanomagnetismElectrical conductorCatalyst nanoparticles

Multilayer carbon nanotube capacitors, and methods and printable compositions for manufacturing multilayer carbon nanotubes (CNTs) are disclosed. A first capacitor embodiment comprises: a first conductor; a plurality of fixed CNTs in an ionic liquid, each fixed CNT comprising a magnetic catalyst nanoparticle coupled to a carbon nanotube and further coupled to the first conductor; and a first plurality of free CNTs dispersed and moveable in the ionic liquid. Another capacitor embodiment comprises: a first conductor; a conductive nanomesh coupled to the first conductor; a first plurality of fixed CNTs in an ionic liquid and further coupled to the conductive nanomesh; and a plurality of free CNTs dispersed and moveable in the ionic liquid. Various methods of printing the CNTs and other structures, and methods of aligning and moving the CNTs using applied electric and magnetic fields, are also disclosed.

Owner:NTHDEGREE TECH WORLDWIDE

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

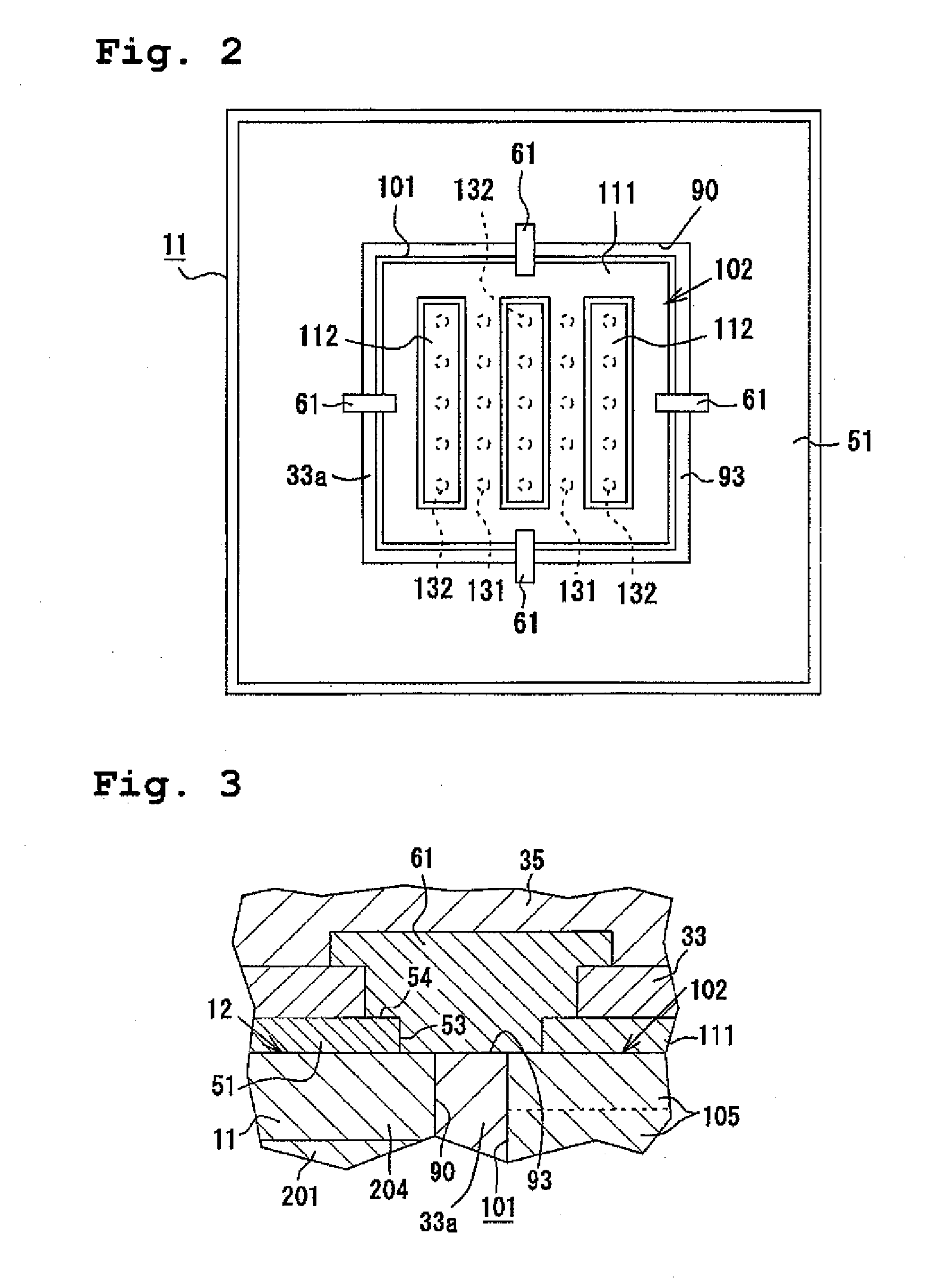

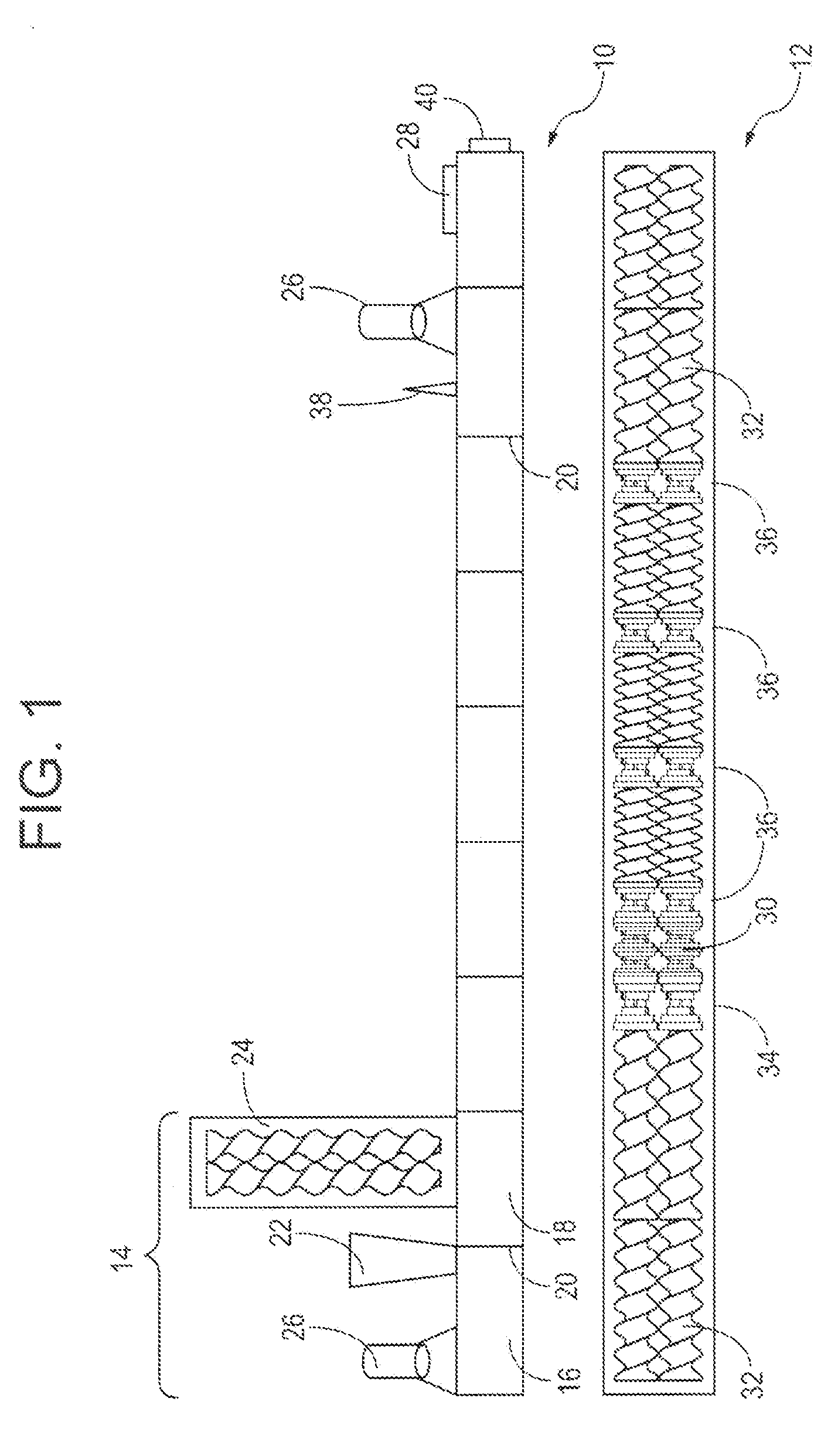

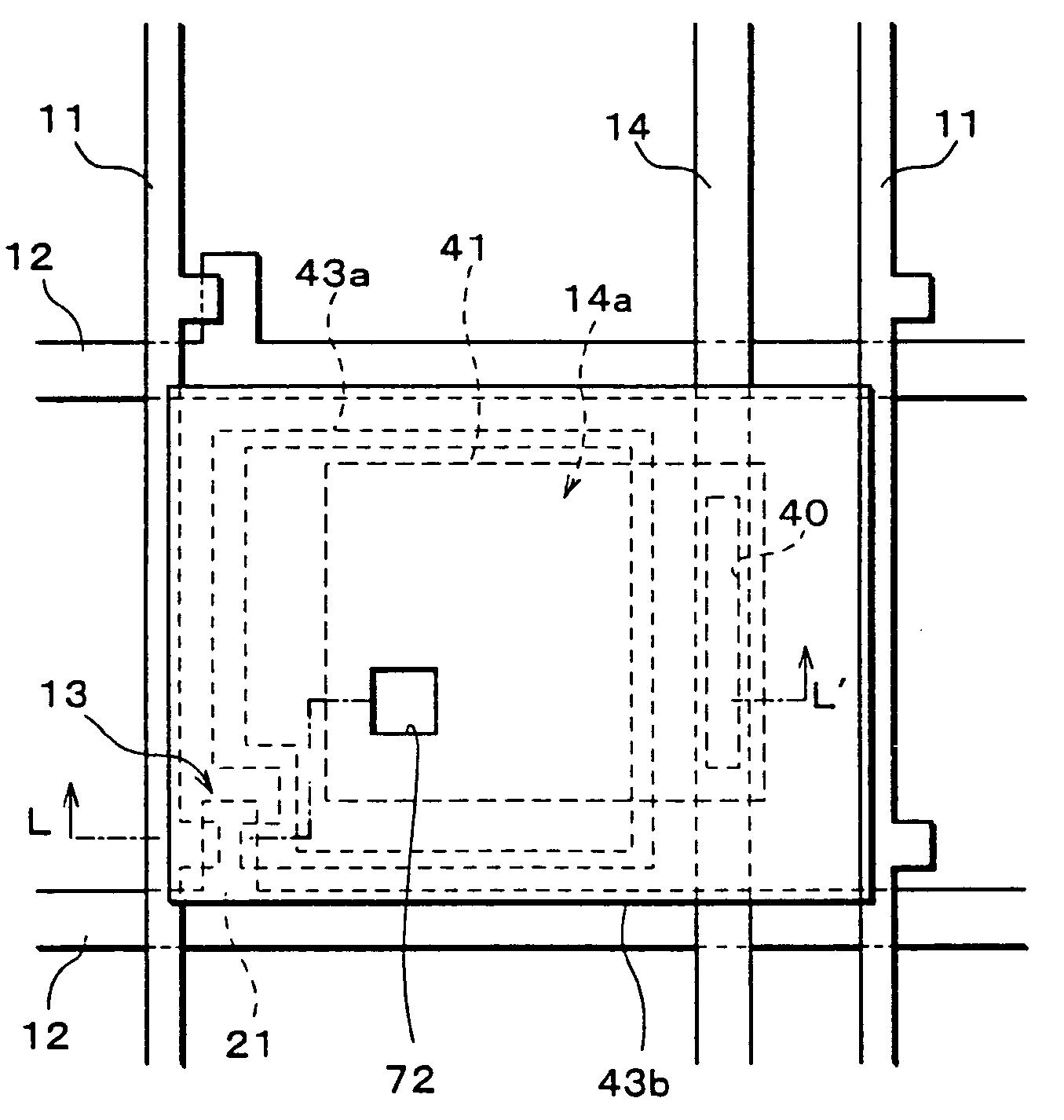

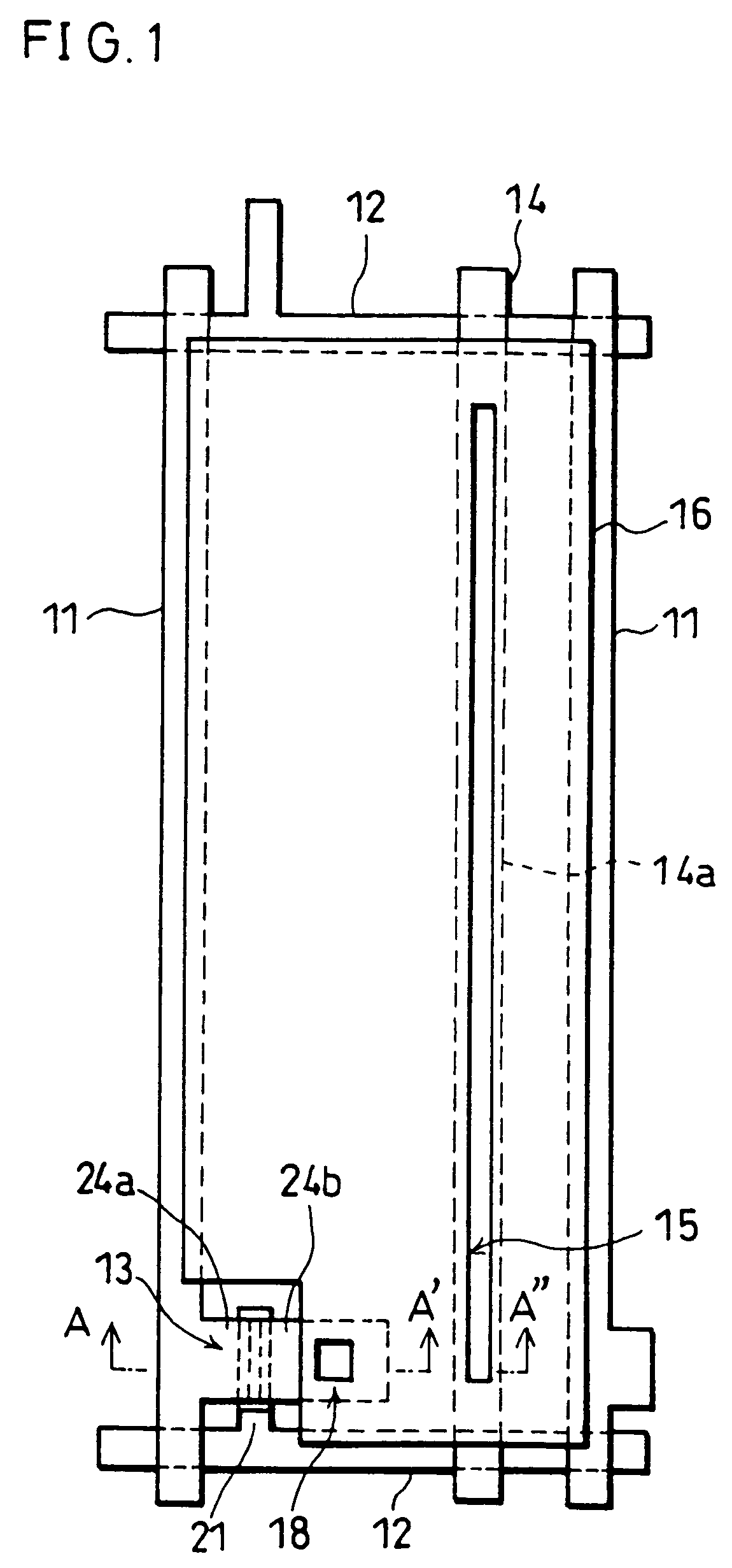

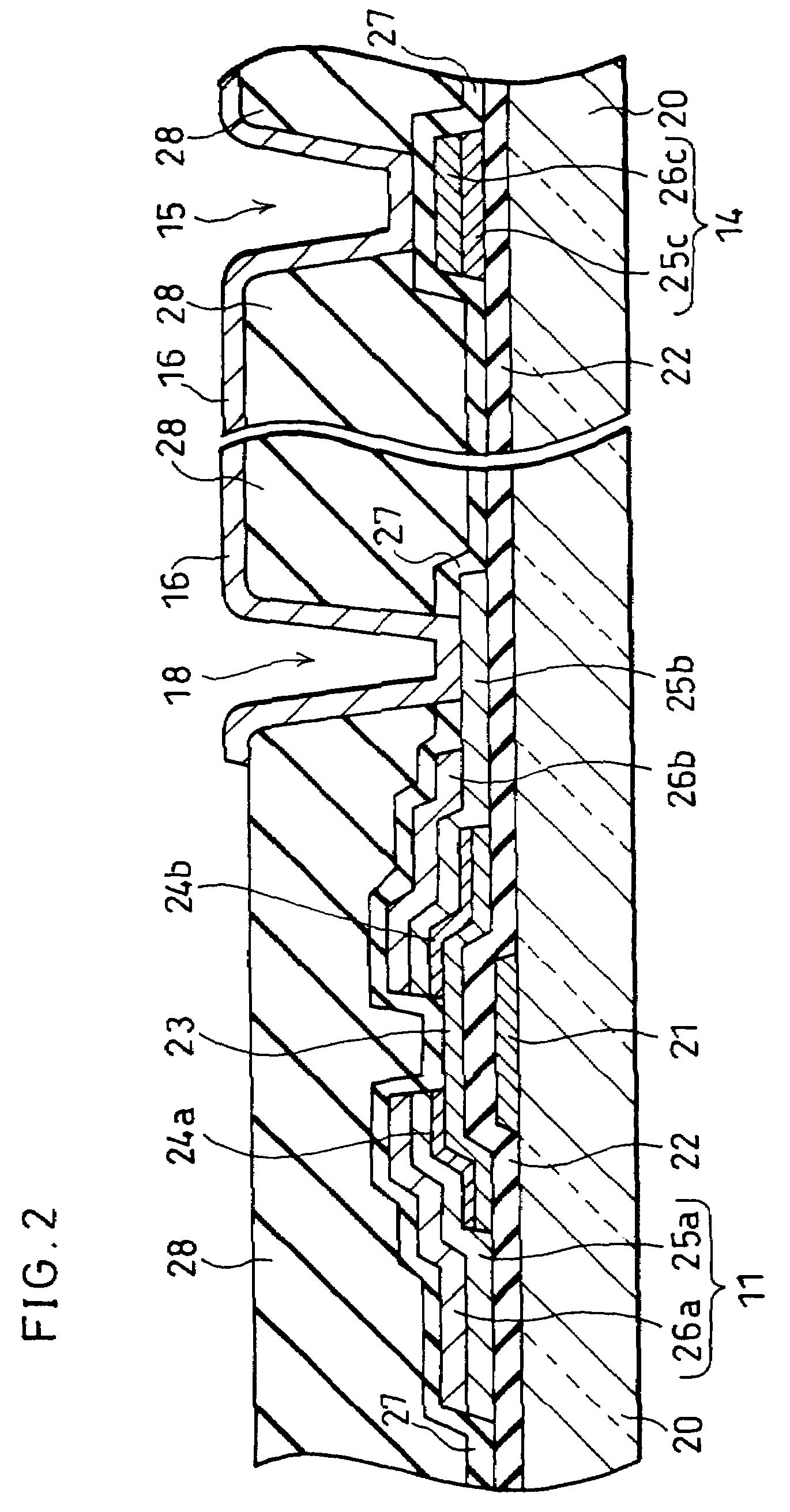

Method for manufacturing wiring board

ActiveUS20070281394A1Electrolytic capacitorsSemiconductor/solid-state device detailsElectrical conductorElectronic component

A method for manufacturing a wiring board which can simplify a manufacturing step. In a preparation step, a core board and an electronic component are prepared. In an insulating layer formation and fixing step, after accommodating the electronic component in an accommodation hole, a lowermost resin insulating layer is formed, and a gap between the electronic component and the core board is filled with a part of the lowermost resin insulating layer so as to fix the electronic component to the core board. In an opening portion formation step, a portion of the lowermost resin insulating layer located directly above the gap between the electronic component and the core board is removed so as to form an opening portion exposing a part of a core board main surface side conductor and a component main surface side electrode. In a main surface side connecting conductor formation step, a main surface side connecting conductor is formed in the opening portion so as to connect the core board main surface side conductor to the component main surface side electrode.

Owner:NGK SPARK PLUG CO LTD

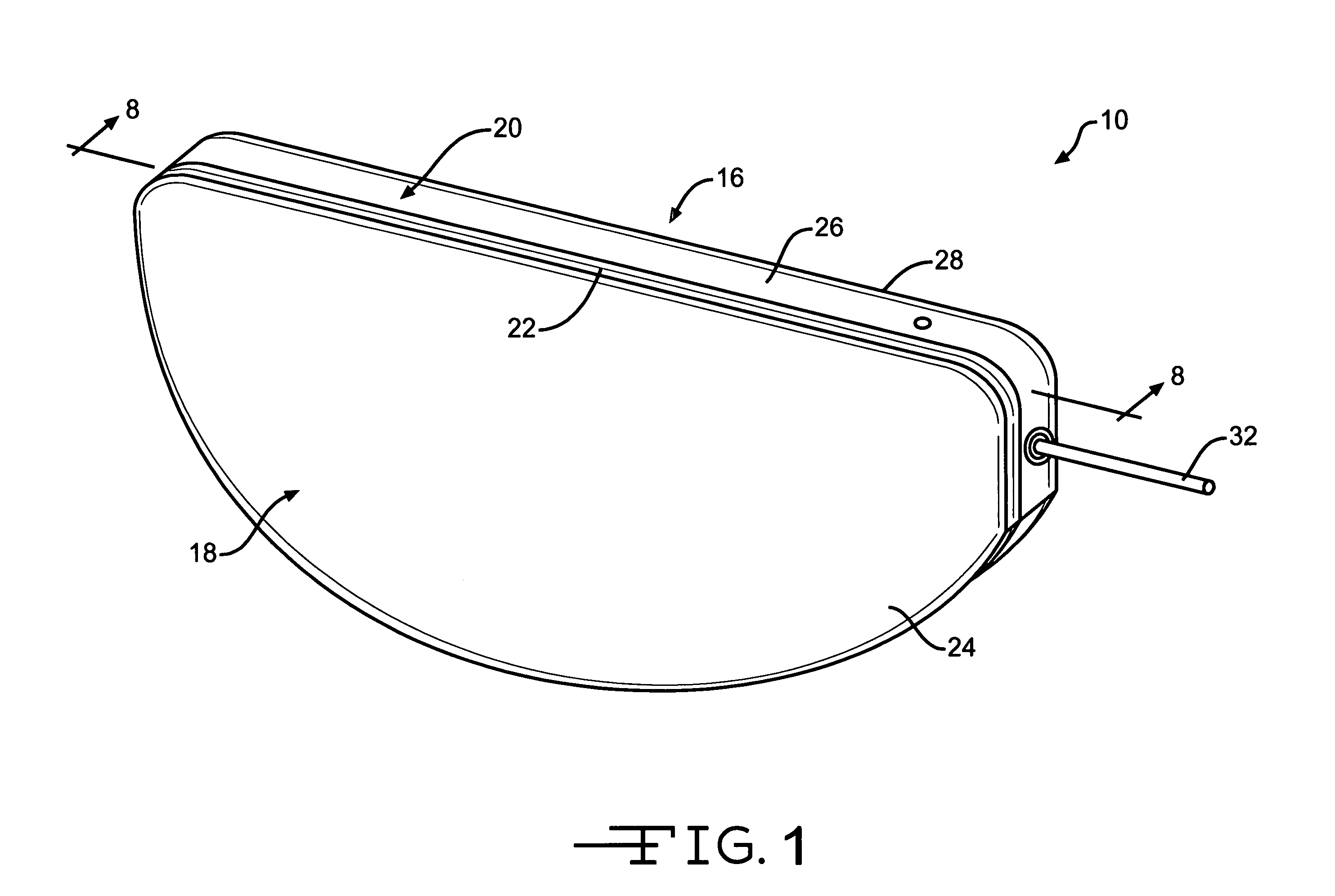

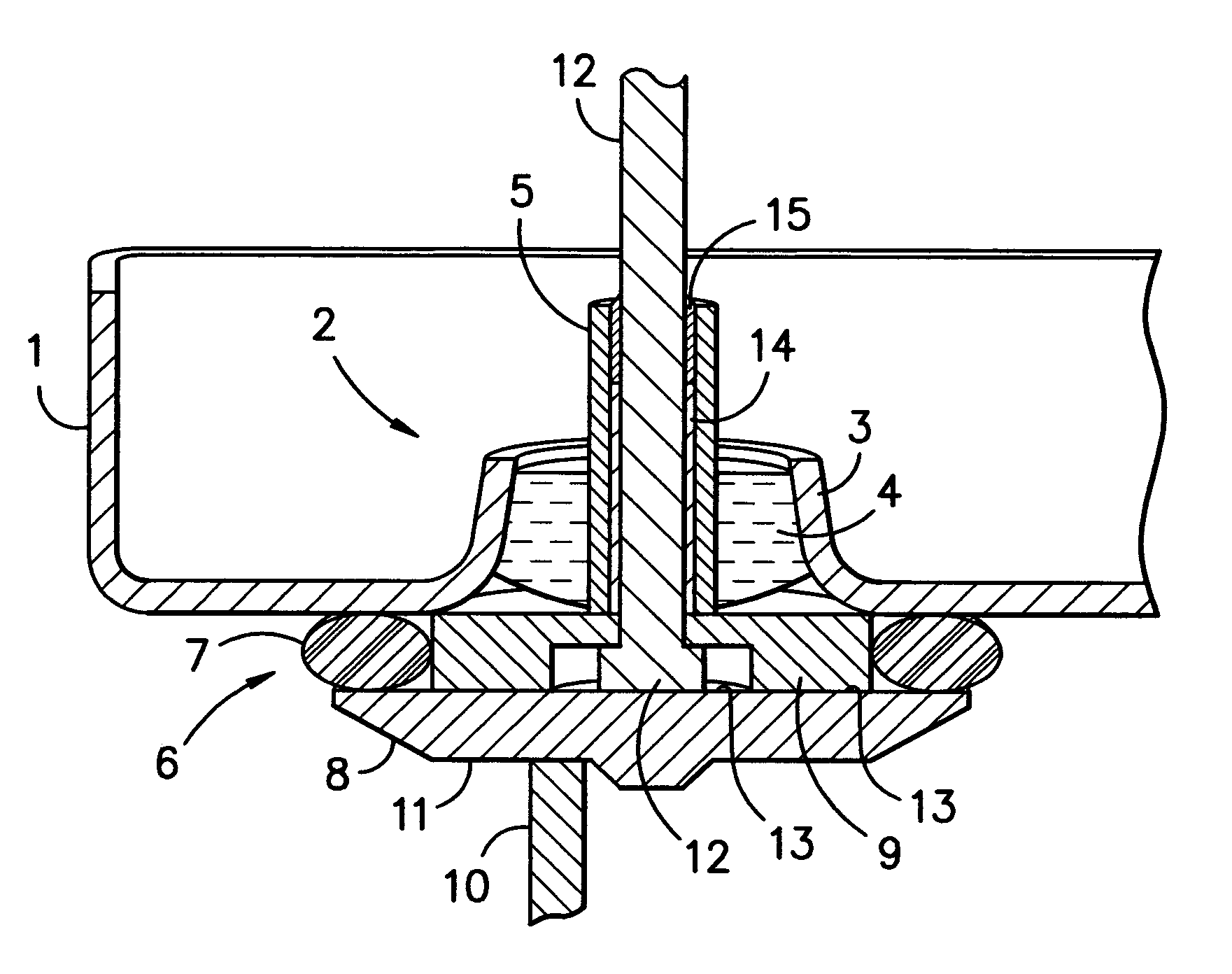

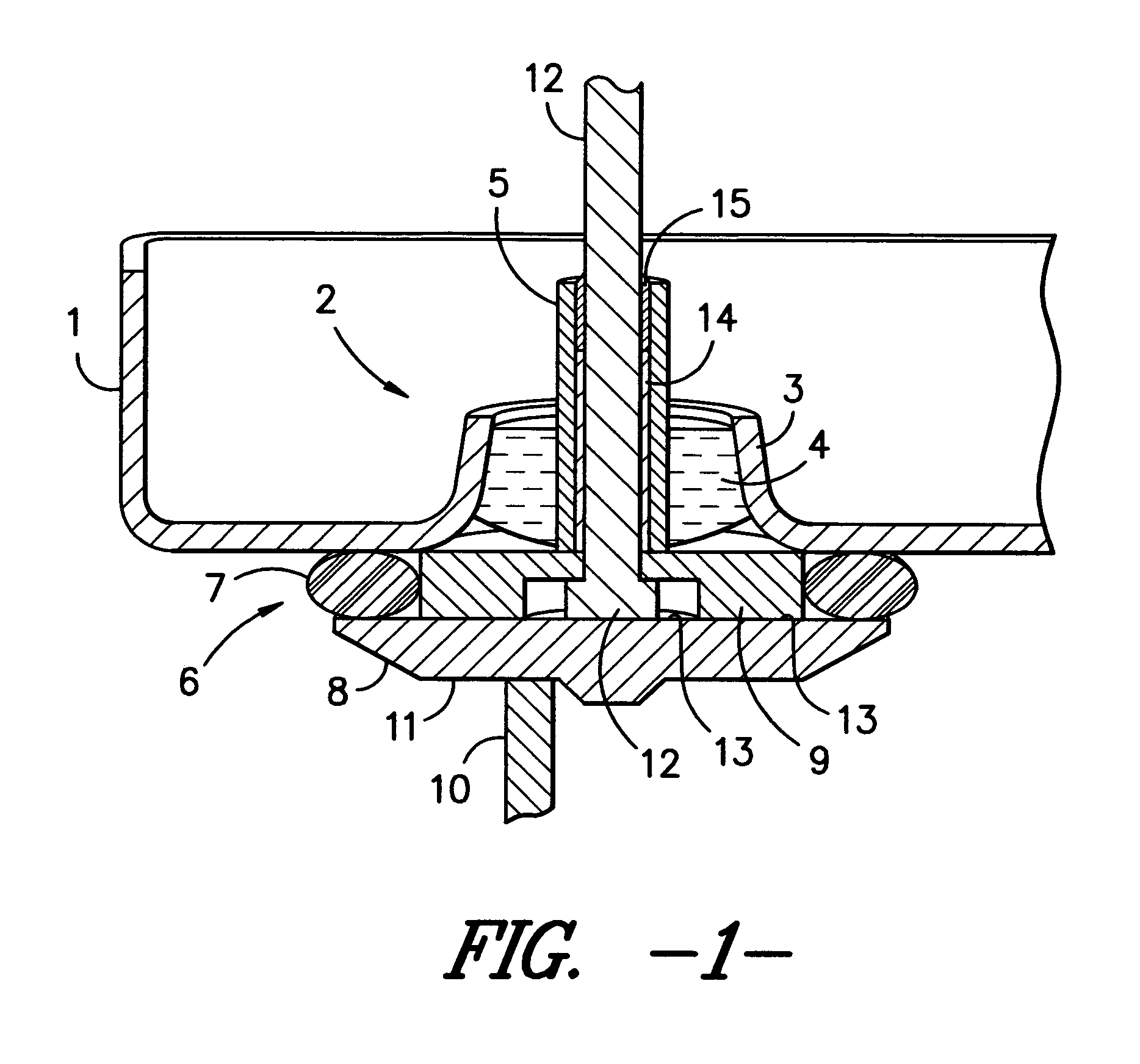

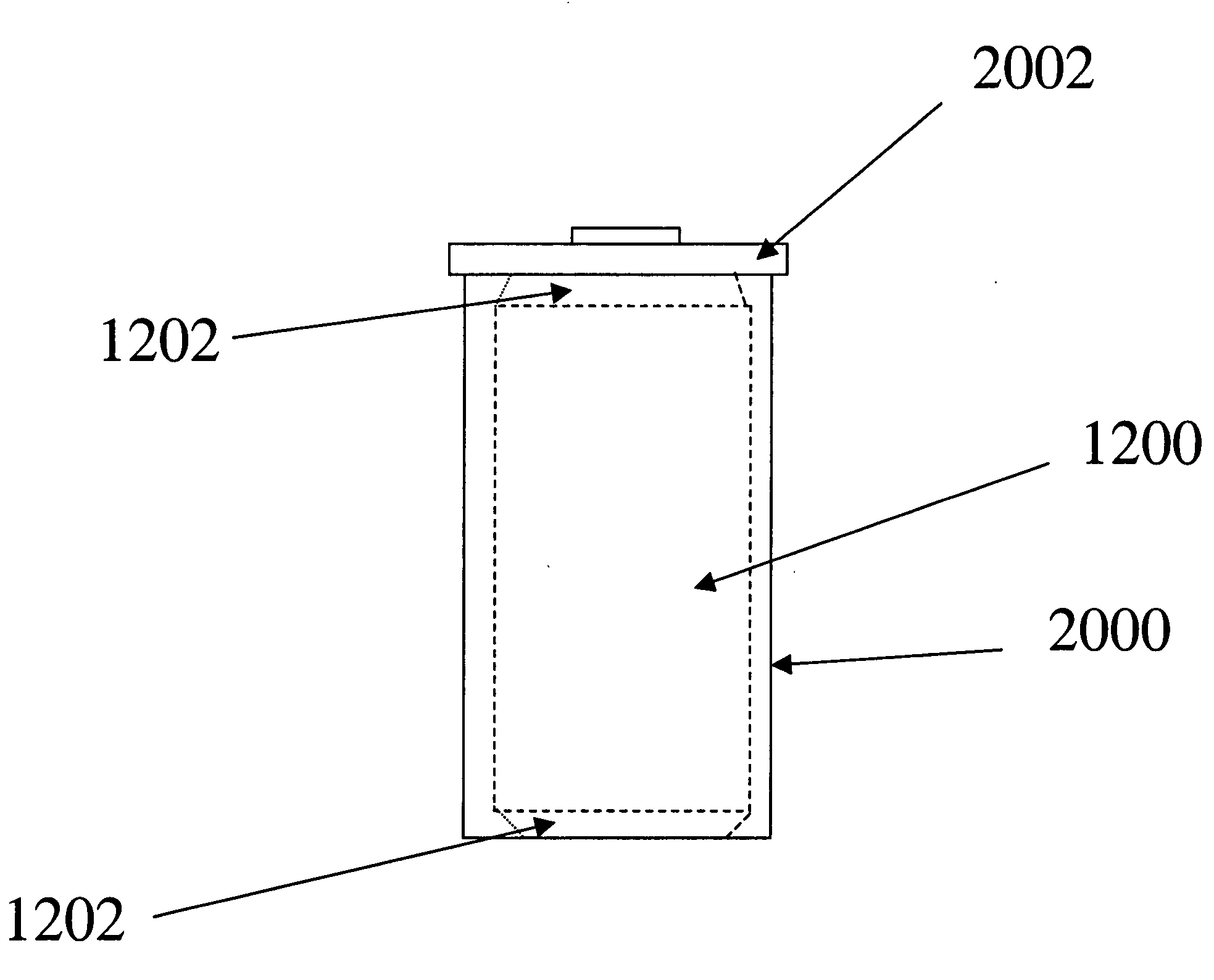

Flat back case for an electrolytic capacitor

ActiveUS7012799B2Benefit in costPrecise positioningElectrotherapyCapacitor electrodesElectrolysisElectrical battery

An enclosure for an electrical energy storage device such as a wet tantalum electrolytic capacitor or an electrochemical cell such as a lithium / silver vanadium oxide cell is described. The enclosure comprises two metallic casing components or portions. The first is a drawn member having a planar face wall supporting a surrounding sidewall and is shaped to nest the anode, cathode and intermediate separator components. The surrounding sidewall has an annular flange at its outer periphery. A mating cover is a stamped planar piece of similar material whose periphery fits inside the annular flange or rim as a complementary piece.

Owner:WILSON GREATBATCH LTD

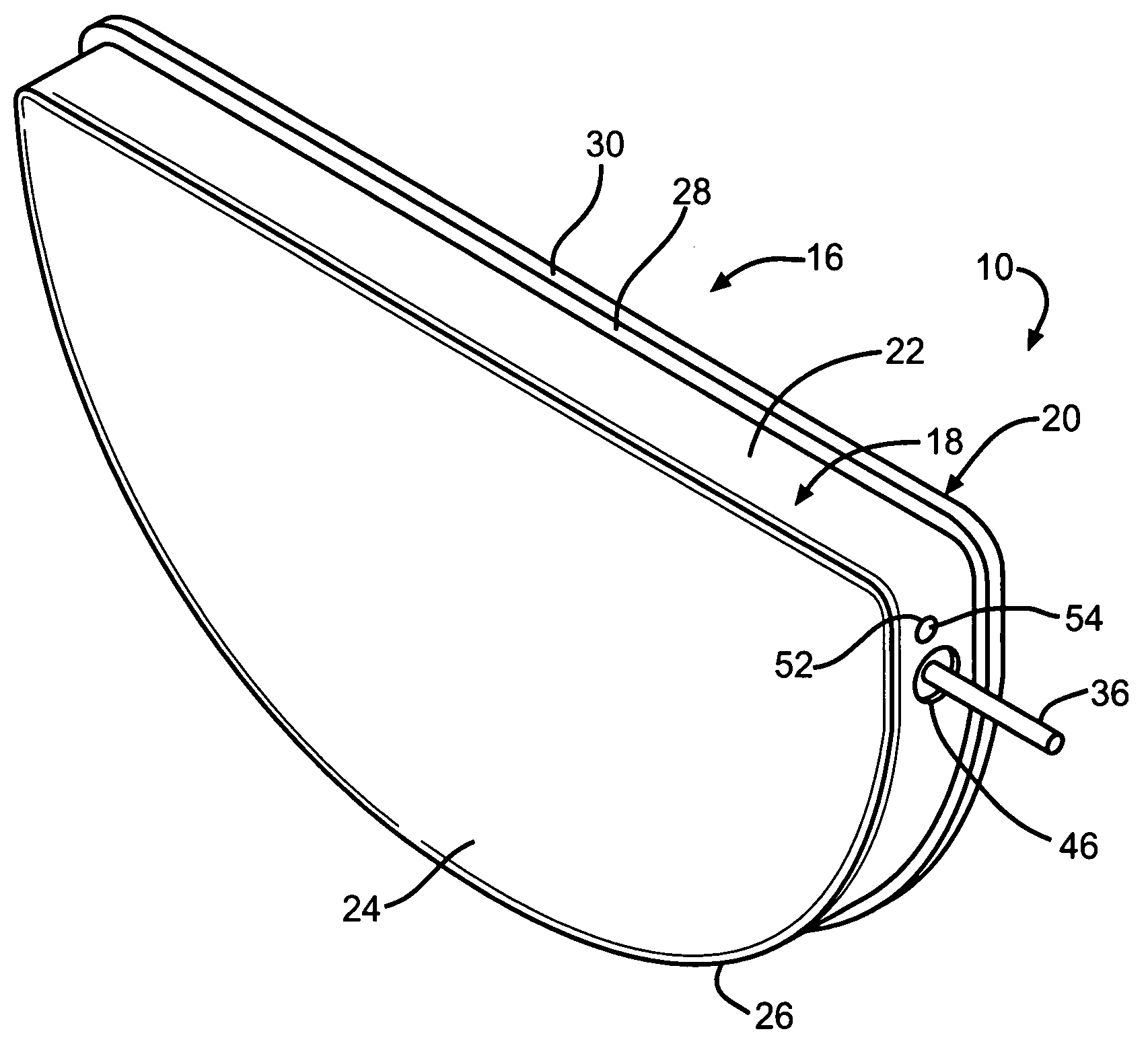

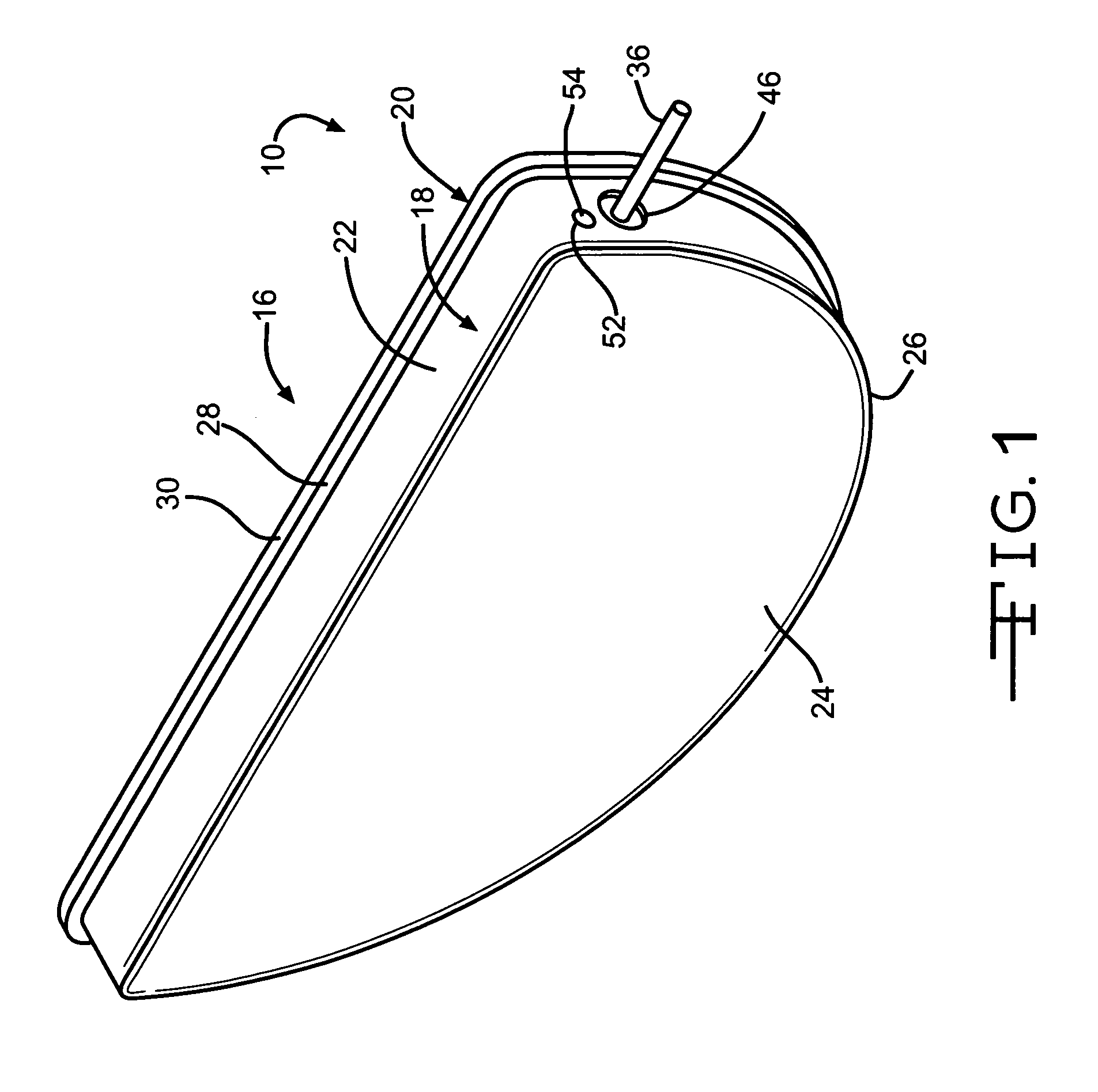

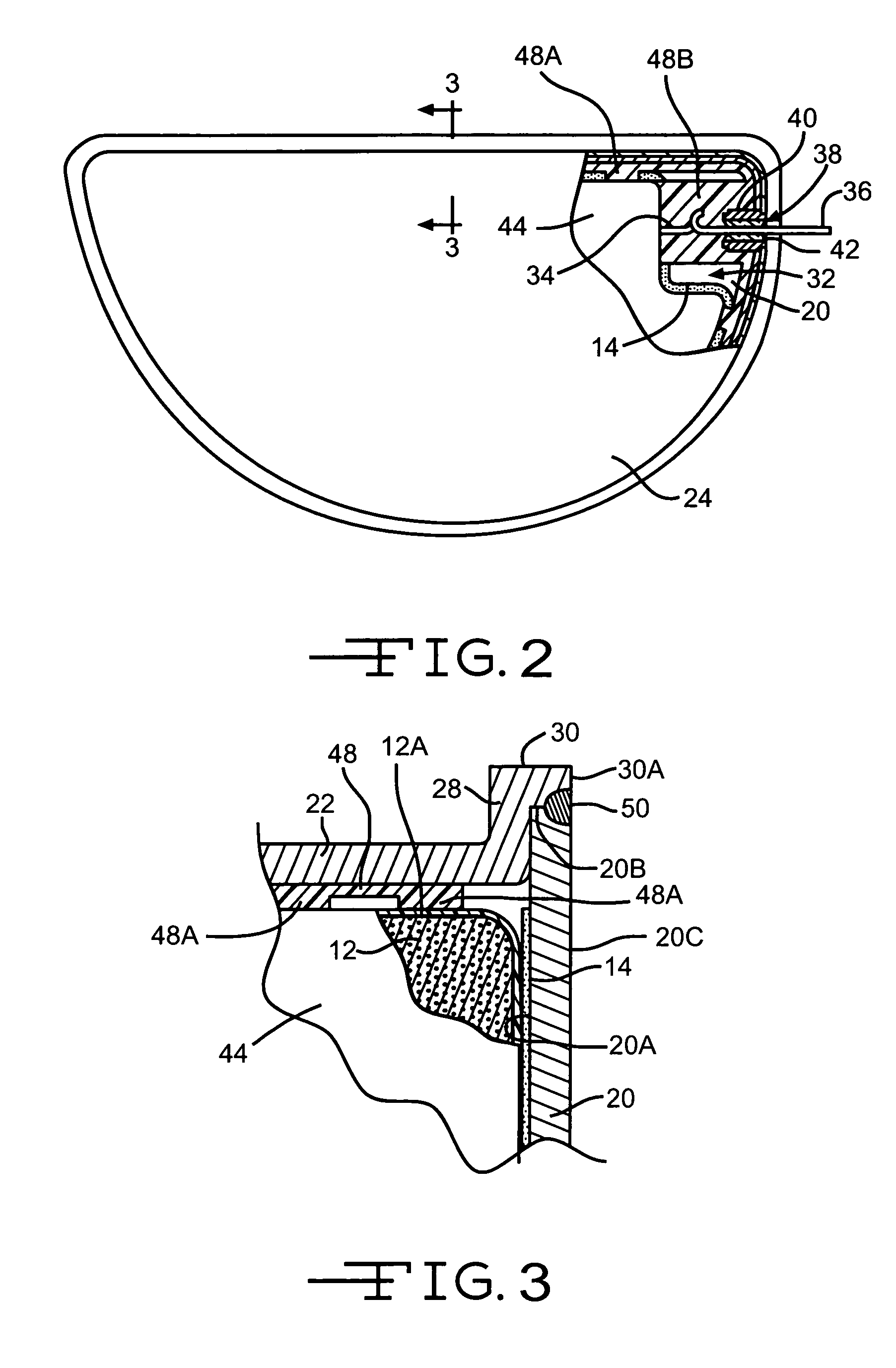

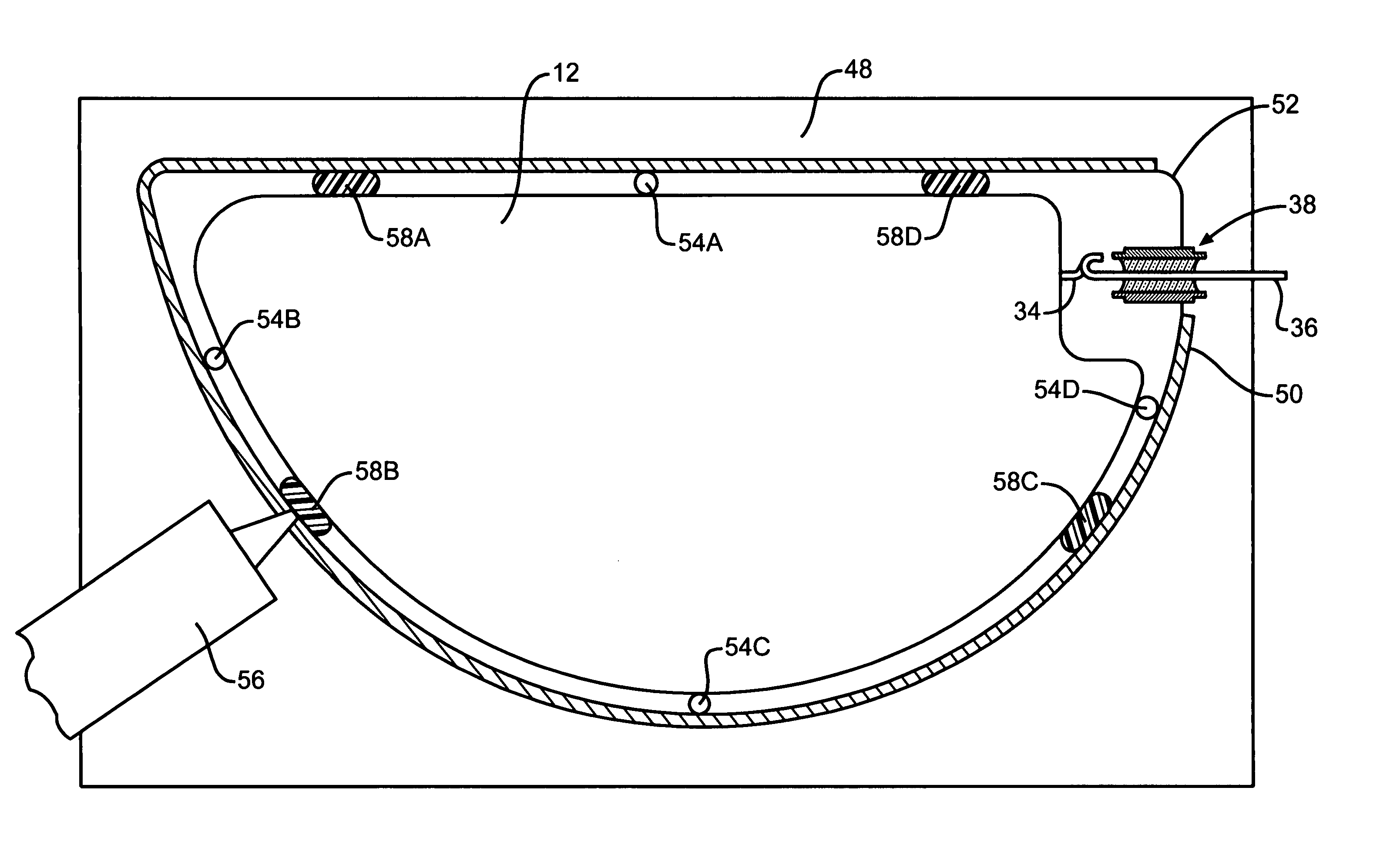

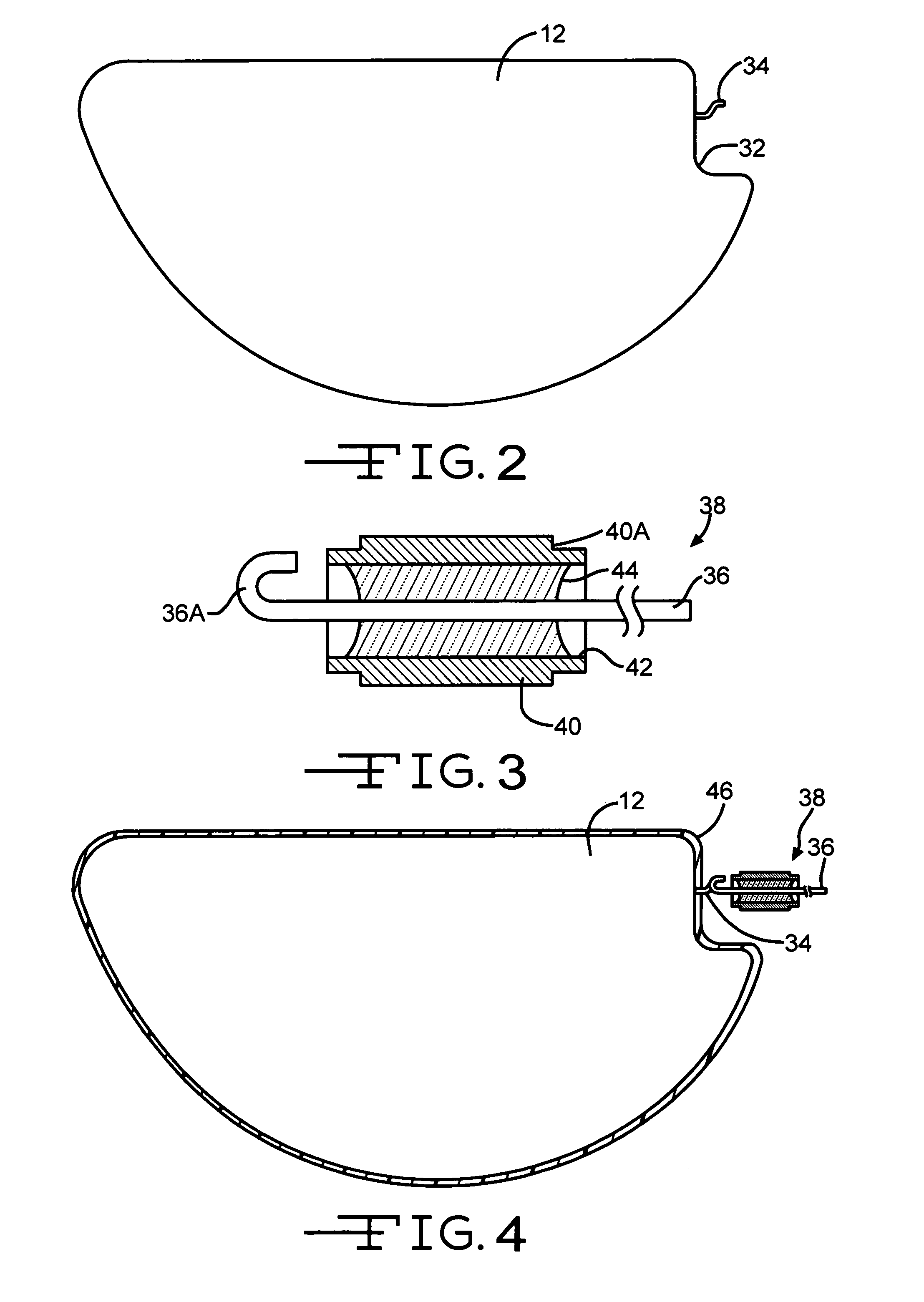

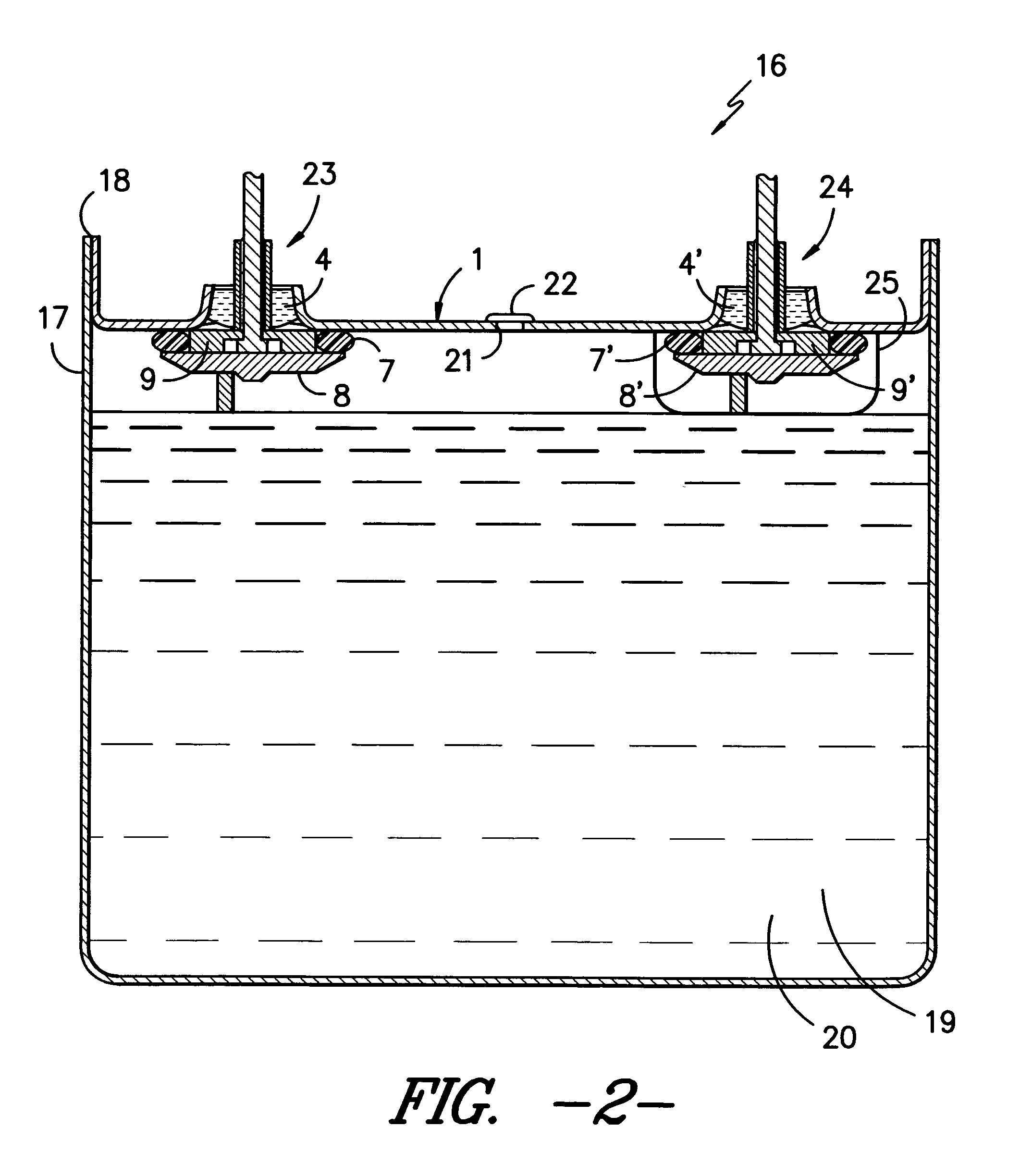

Polymeric restraints for containing an anode in an electrolytic capacitor from high shock and vibration conditions

ActiveUS7092242B1Improve reliabilityImprove securityHybrid capacitor separatorsLiquid electrolytic capacitorsVibration controlElectrolytic capacitor

An electrolytic capacitor comprising a plurality of polymeric structures molded about the periphery of the anode pellet is described. The polymeric structures contact between a weld strap surrounding the butt seam between mating “clamshell” casing portions and the anode pellet sidewall. That way, the anode pellet is restrained from moving along both an x- and y-axes inside the casing. Having the cathode active material contacting the opposed major casing sidewalls being in a closely spaced relationship with the anode pellet through an intermediate separator prevents movement along the z-axis. The resulting capacitor is particularly well suited for use in high shock and vibration conditions.

Owner:WILSON GREATBATCH LTD

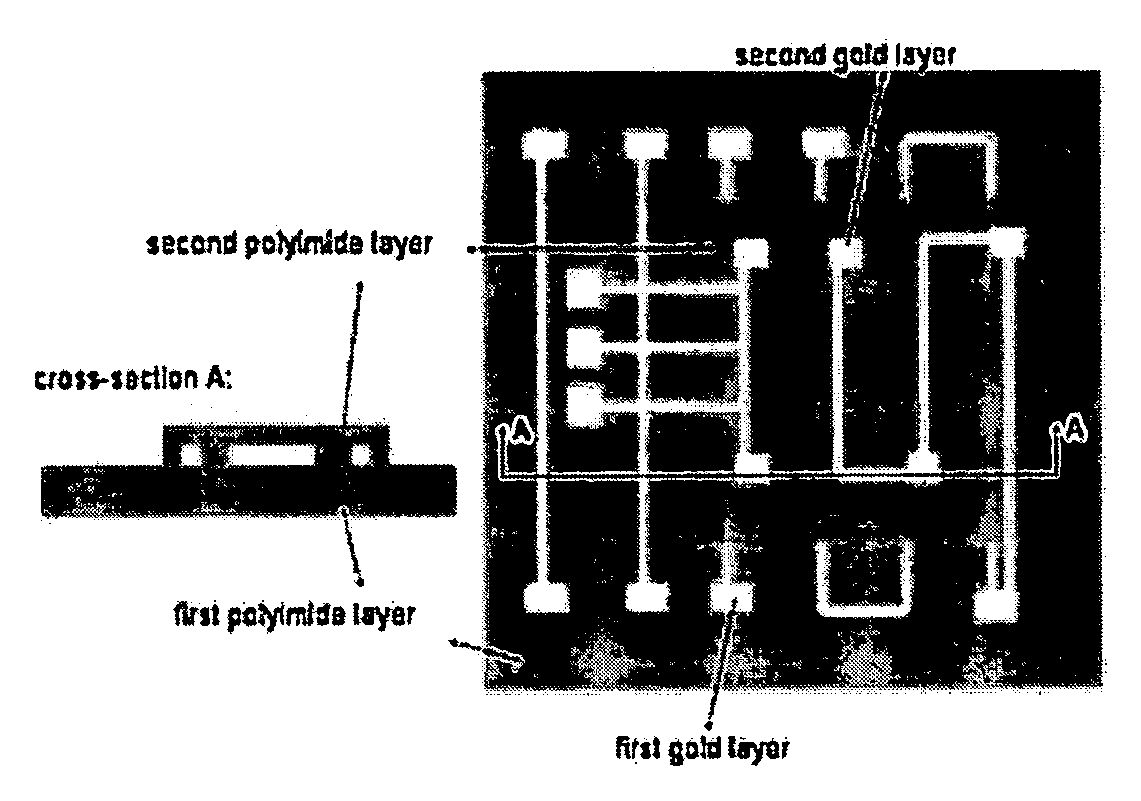

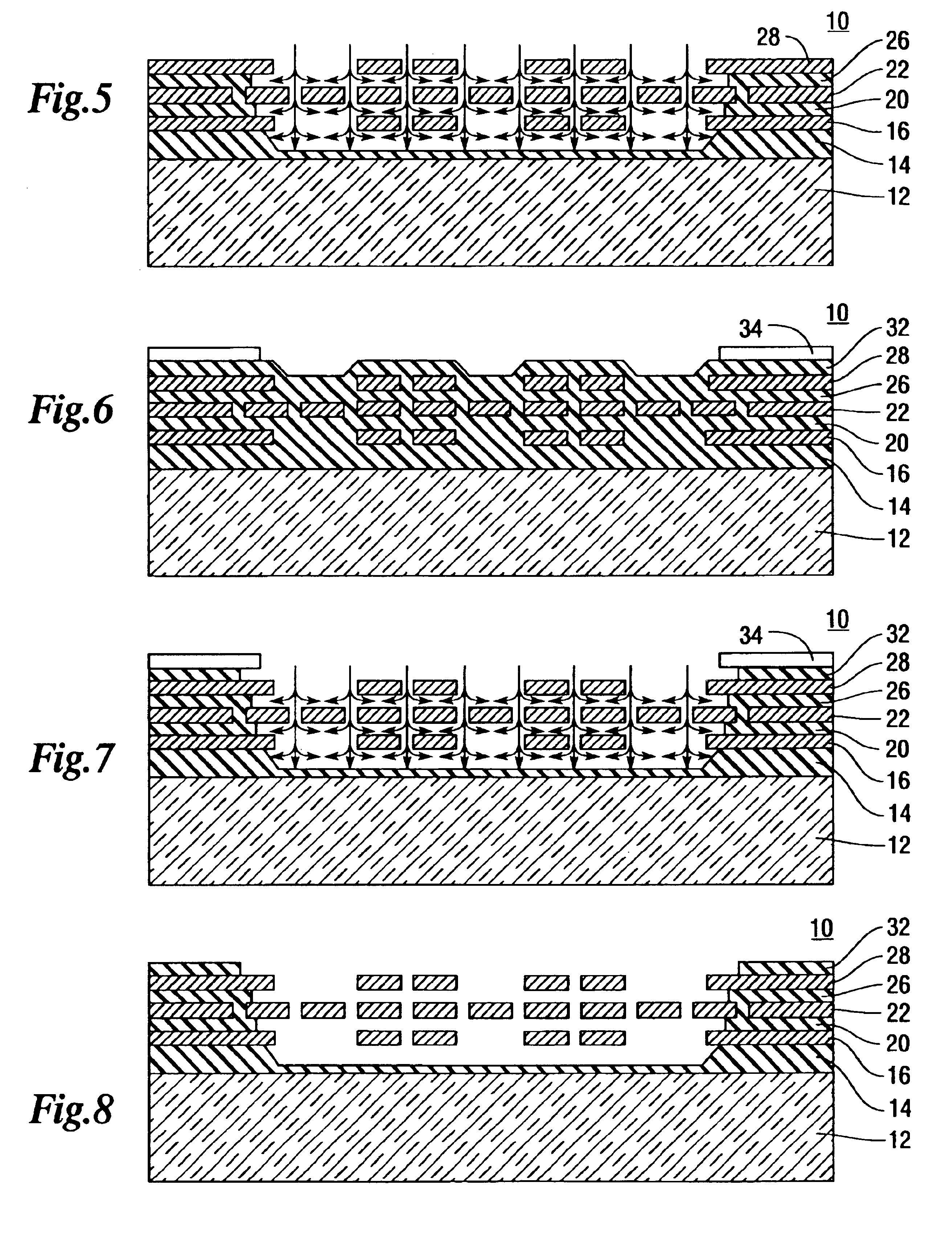

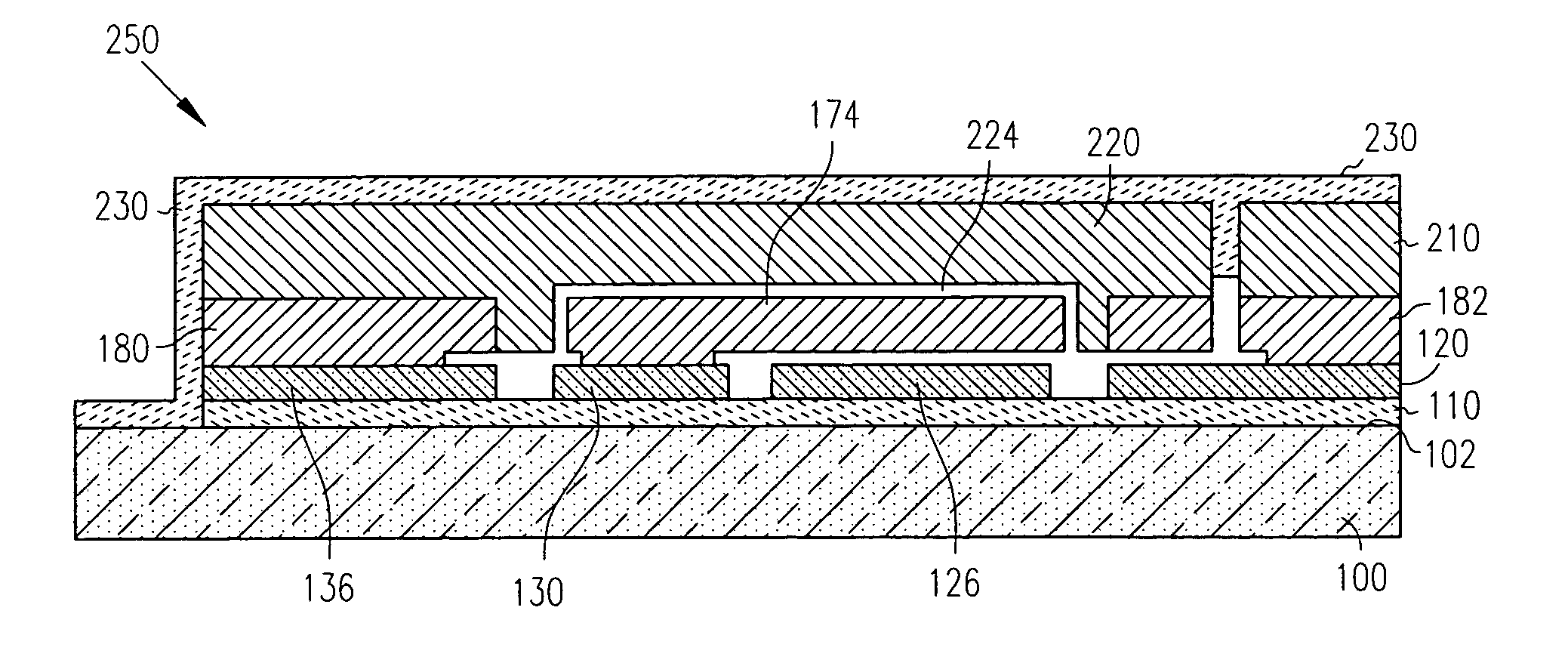

Multi-metal layer MEMS structure and process for making the same

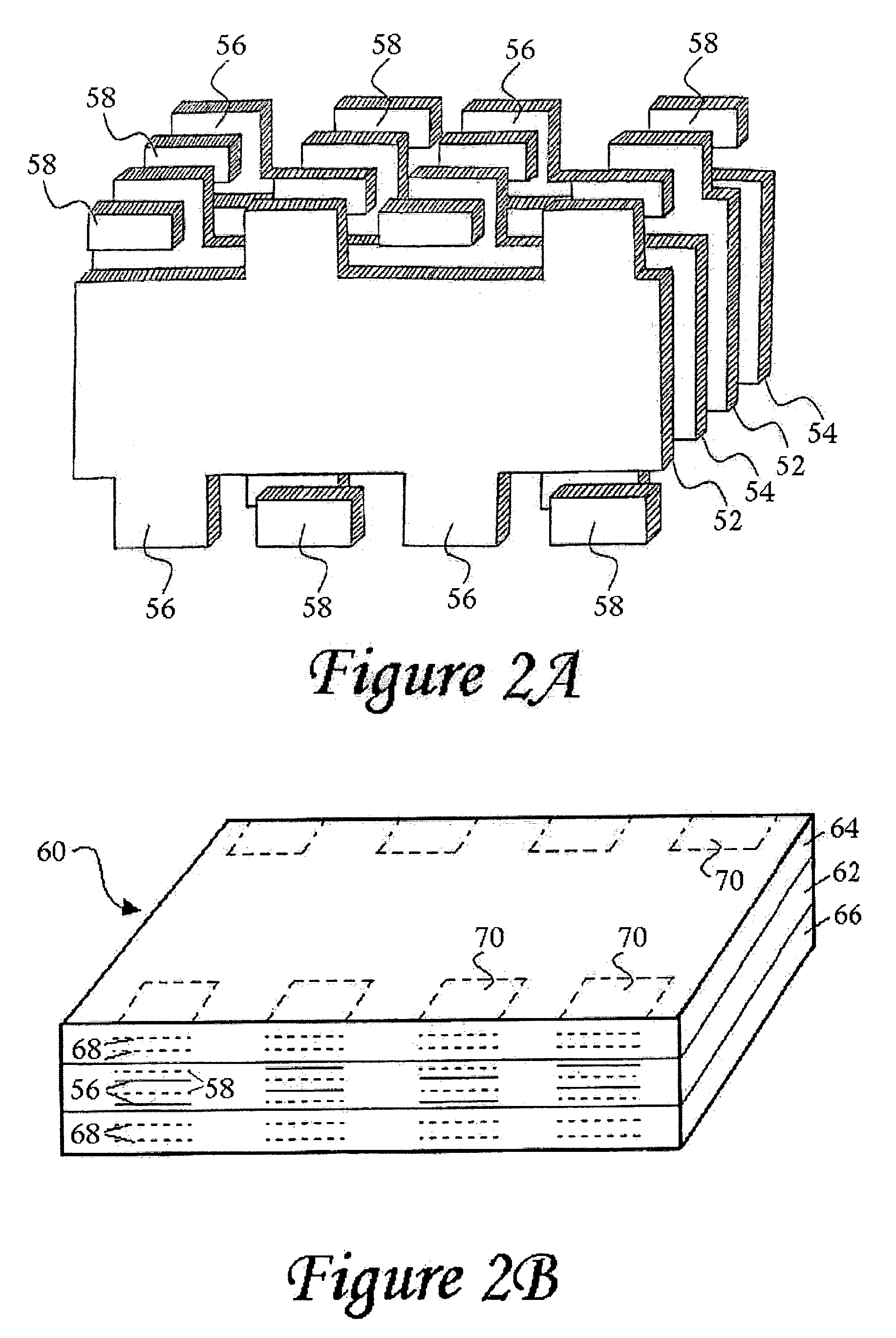

The present invention is directed to a structure comprised of alternating layers of metal and sacrificial material built up using standard CMOS processing techniques, a process for building such a structure, a process for fabricating devices from such a structure, and the devices fabricated from such a structure. In one embodiment, a first metal layer is carried by a substrate. A first sacrificial layer is carried by the first metal layer. A second metal layer is carried by the sacrificial layer. The second metal layer has a portion forming a micro-machined metal mesh. When the portion of the first sacrificial layer in the area of the micro-machined metal mesh is removed, the micro-machined metal mesh is released and suspended above the first metal layer a height determined by the thickness of the first sacrificial layer. The structure may be varied by providing a base layer of sacrificial material between the surface of the substrate and the first metal layer. In that manner, a portion of the first metal layer may form a micro-machined mesh which is released when a portion of the base sacrificial layer in the area of the micro-machined mesh is removed. Additionally, a second layer of sacrificial material and a third metal layer may be provided. A micro-machined mesh may be formed in a portion of the third metal layer. The structure of the present invention may be used to construct variable capacitors, switches and, when certain of the meshes are sealed, microspeakers and microphones.

Owner:AKUSTICA

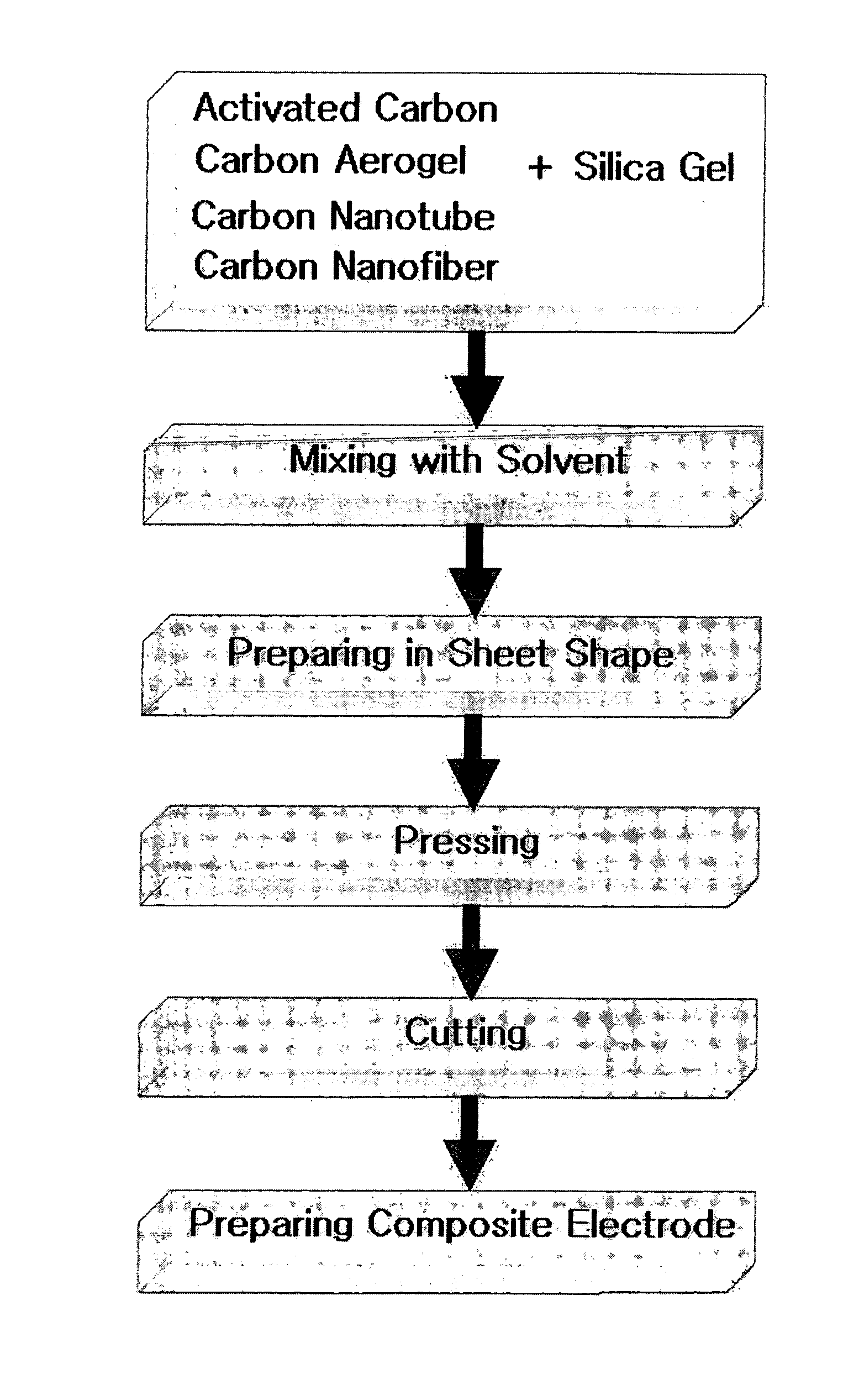

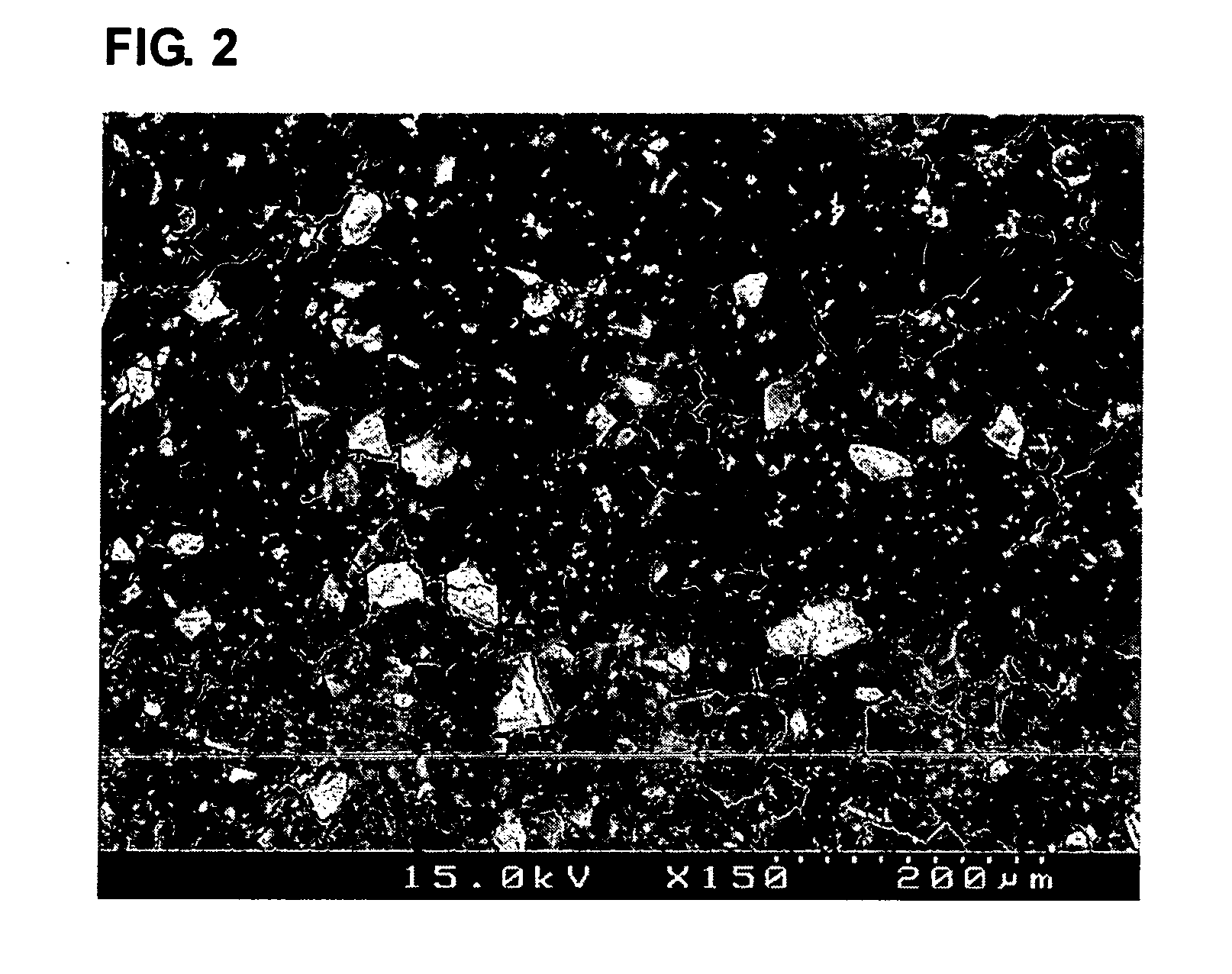

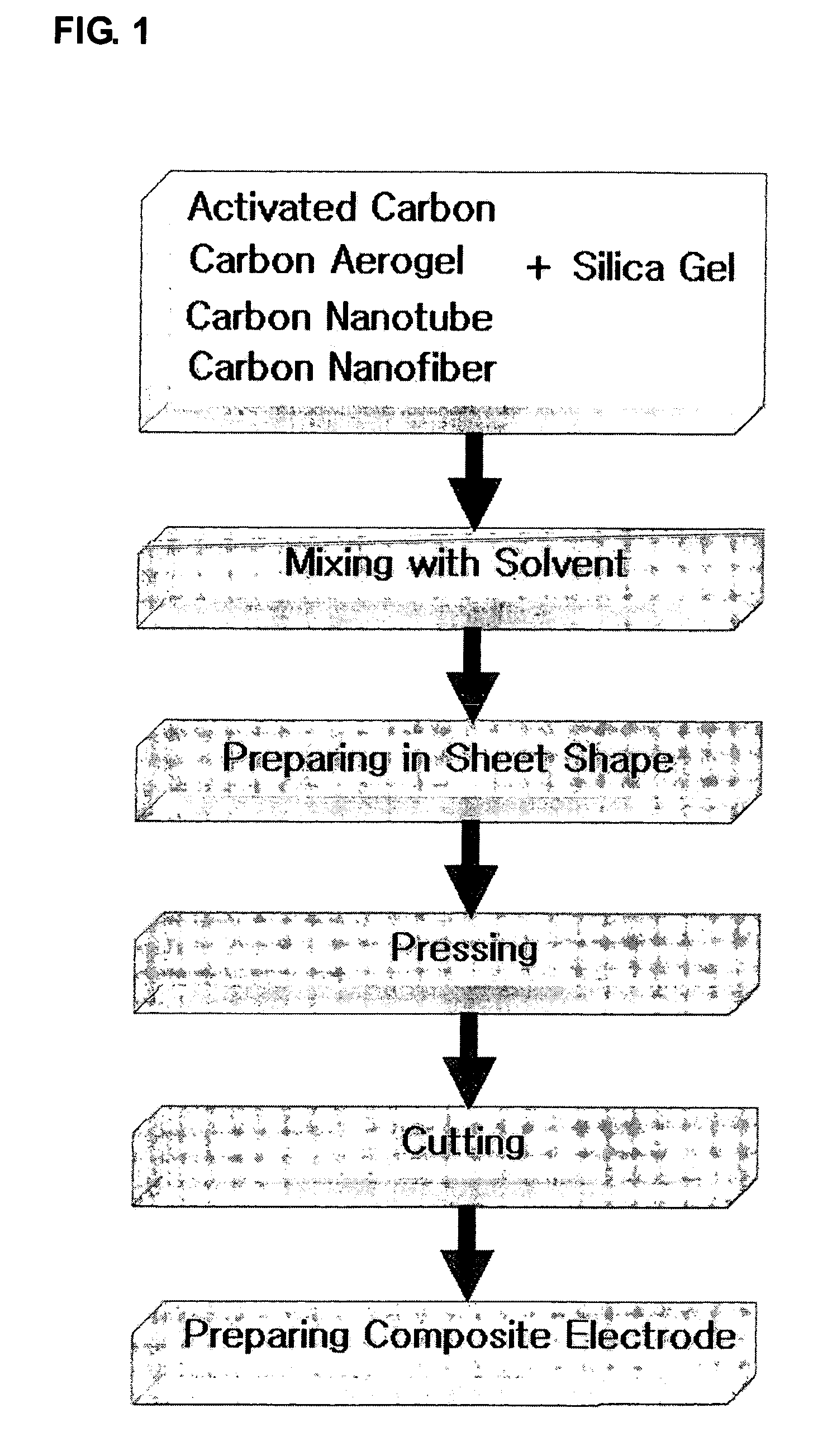

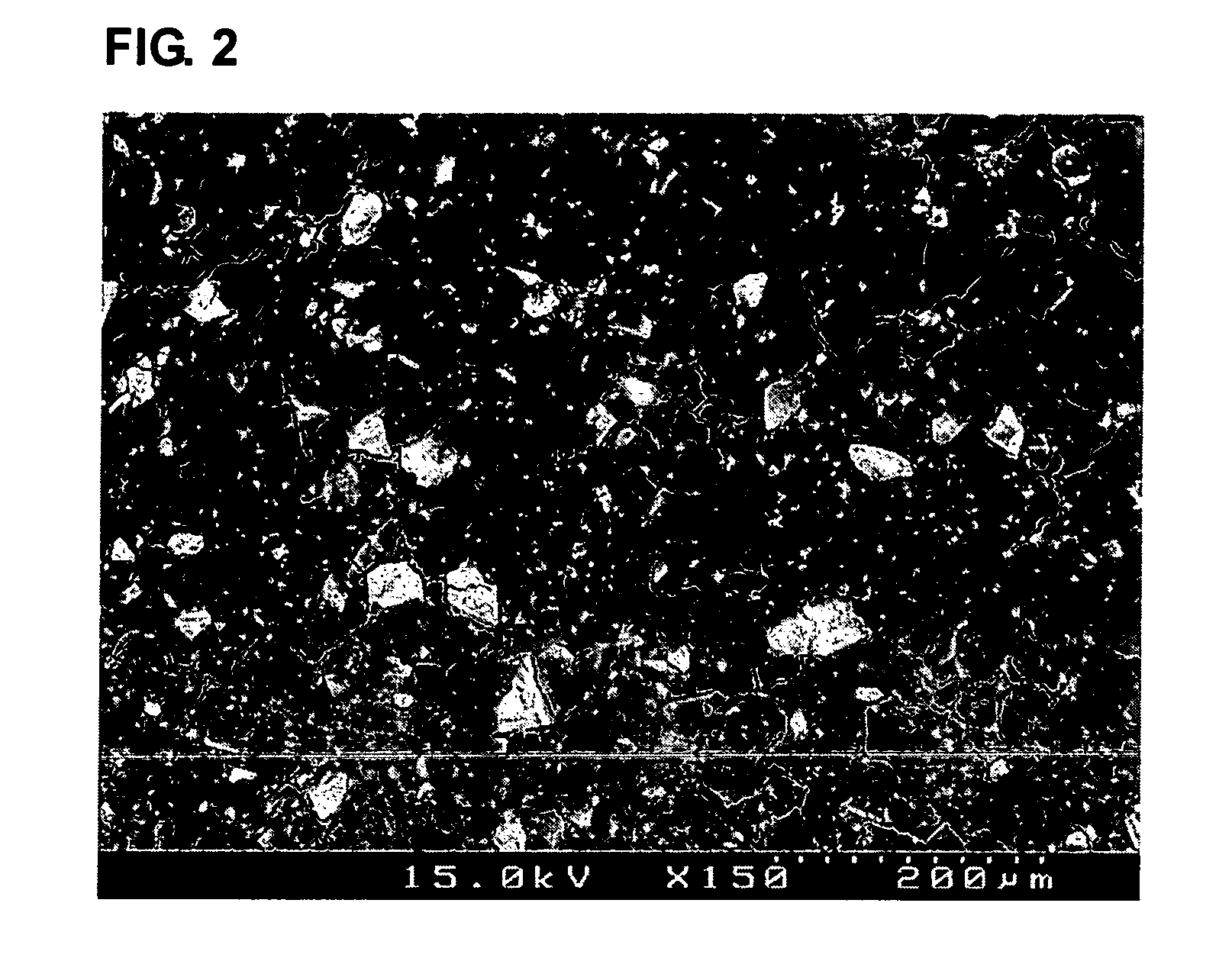

Carbon-porous media composite electrode and preparation method thereof

InactiveUS20050155216A1Improve hydrophilicitySimple processMaterial nanotechnologyElectrolytic capacitorsWater useCapacitance

The present invention discloses a carbon-porous media composite electrode material, a composite electrode using the same and a preparation method thereof. The carbon-porous media composite electrode can be applied for a device such as a secondary battery, a capacitor or the like, or for preparing ultra pure water using a capacitive deionization process, purifying salty water or the like.

Owner:KOREA INST OF SCI & TECH

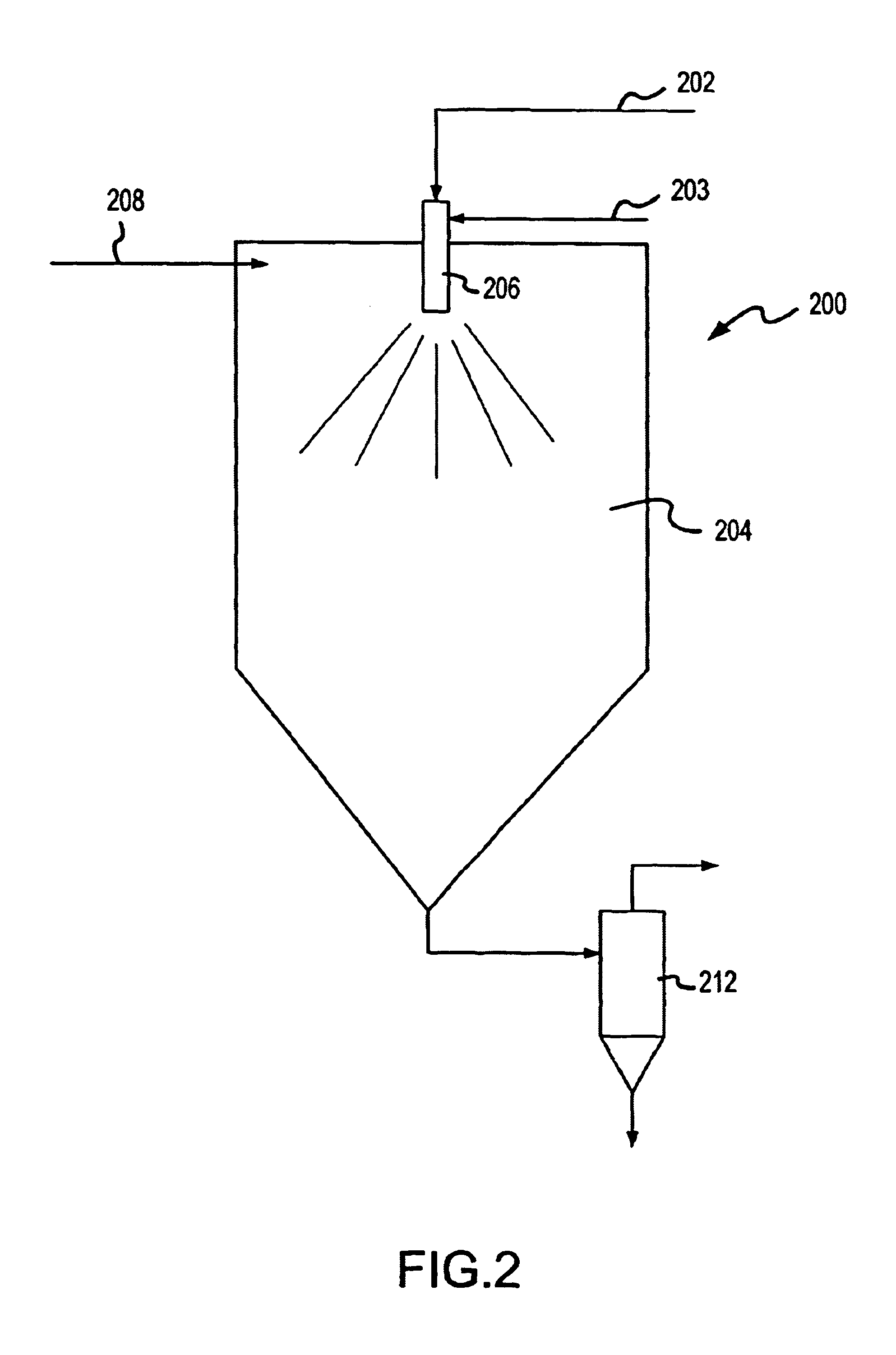

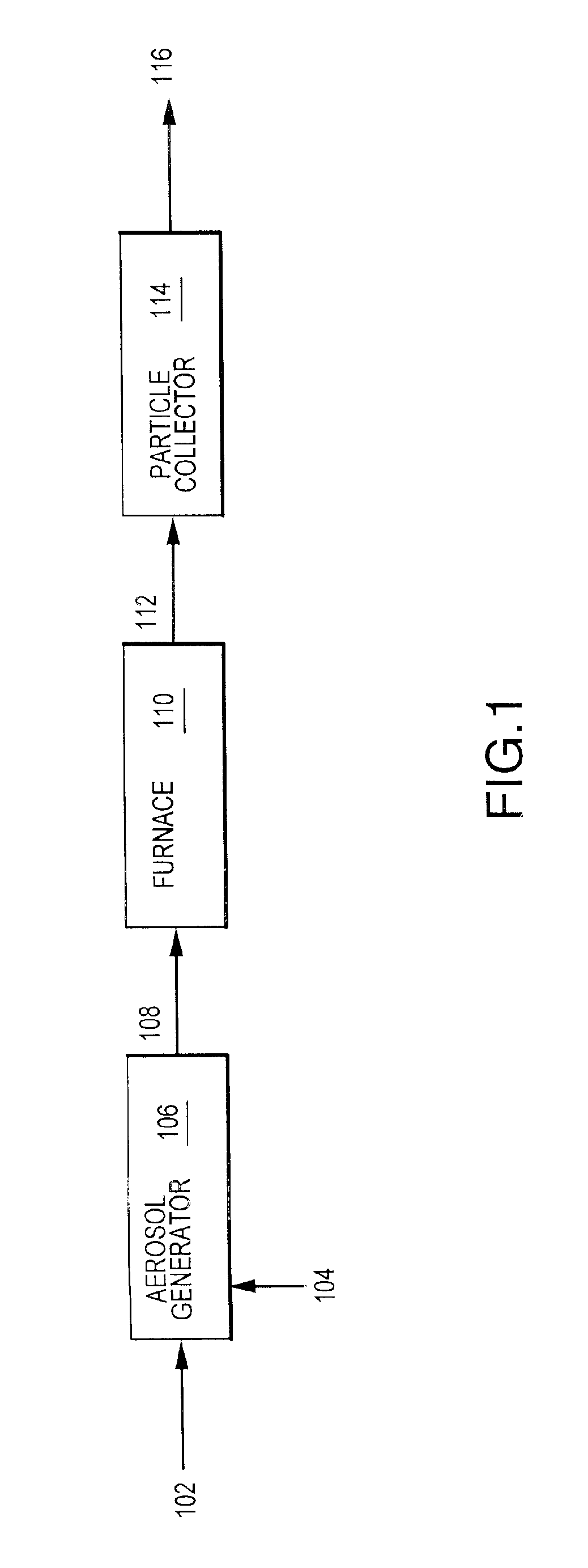

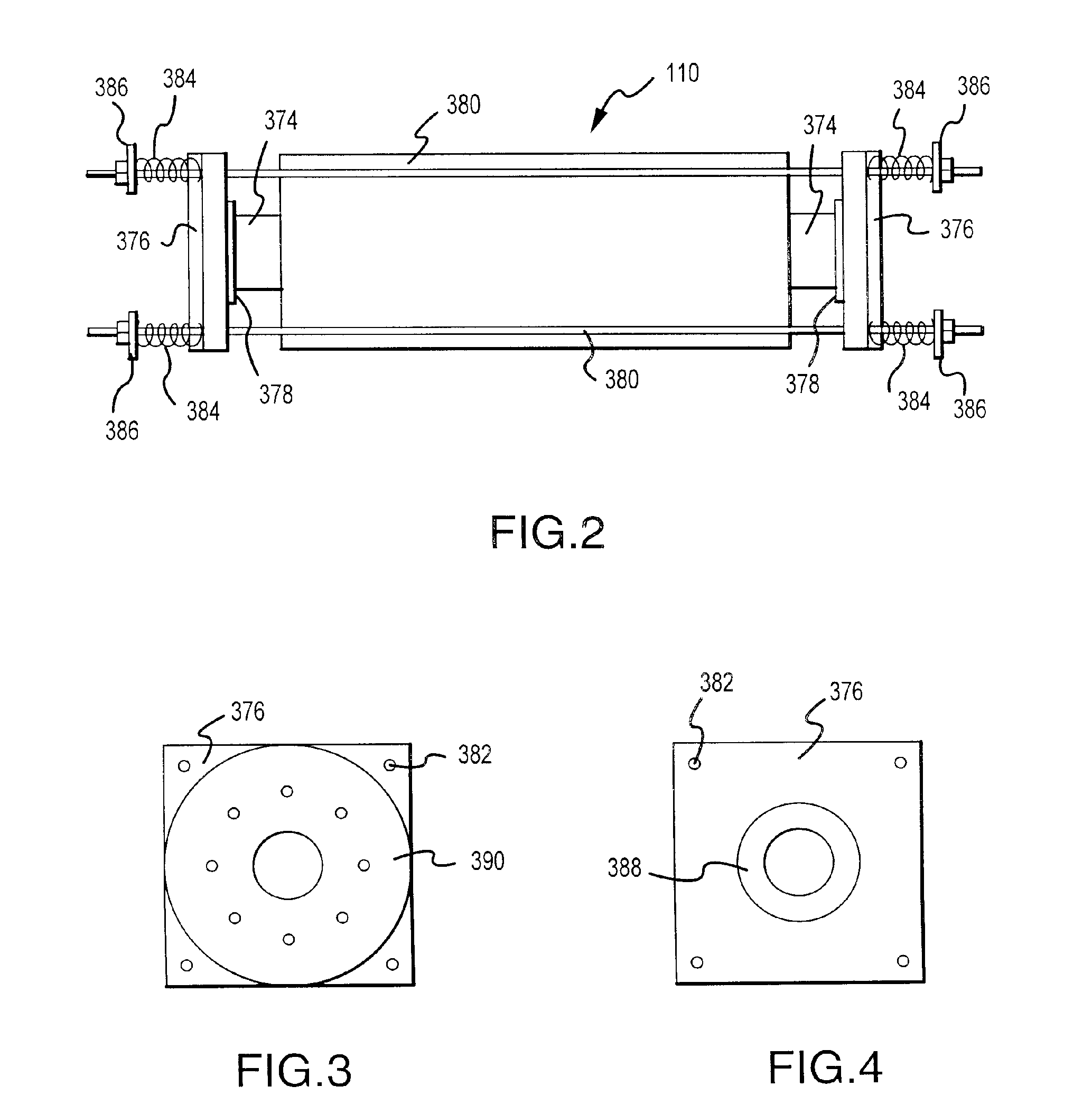

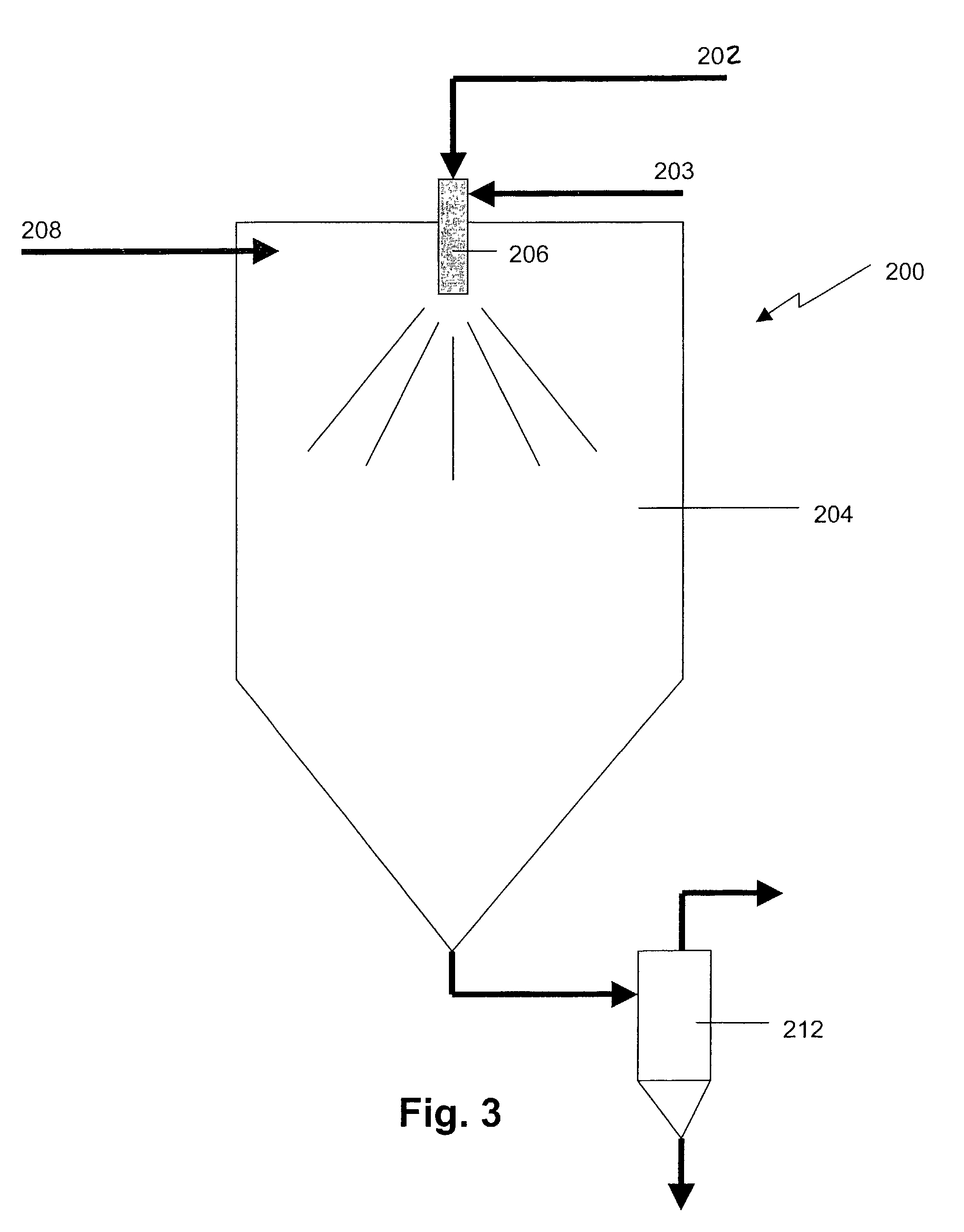

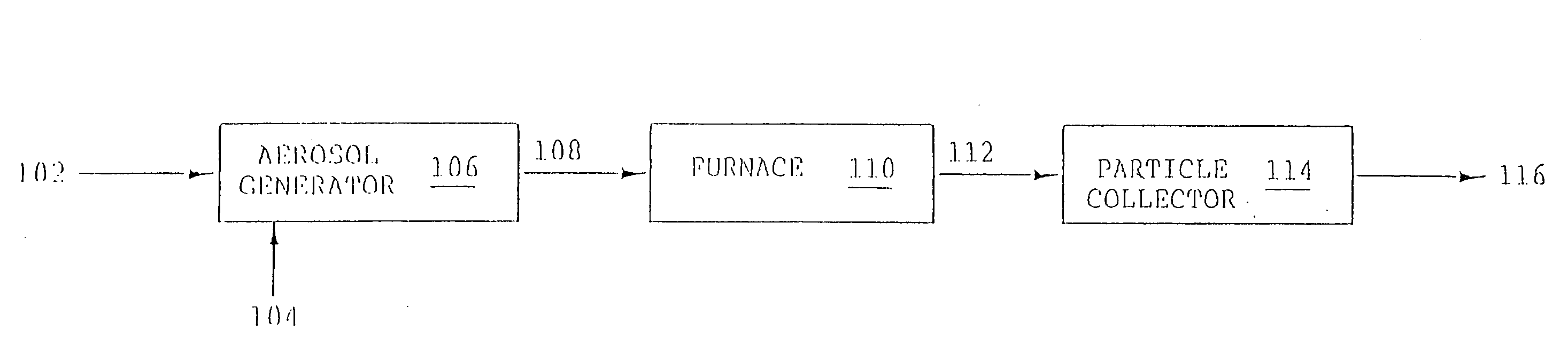

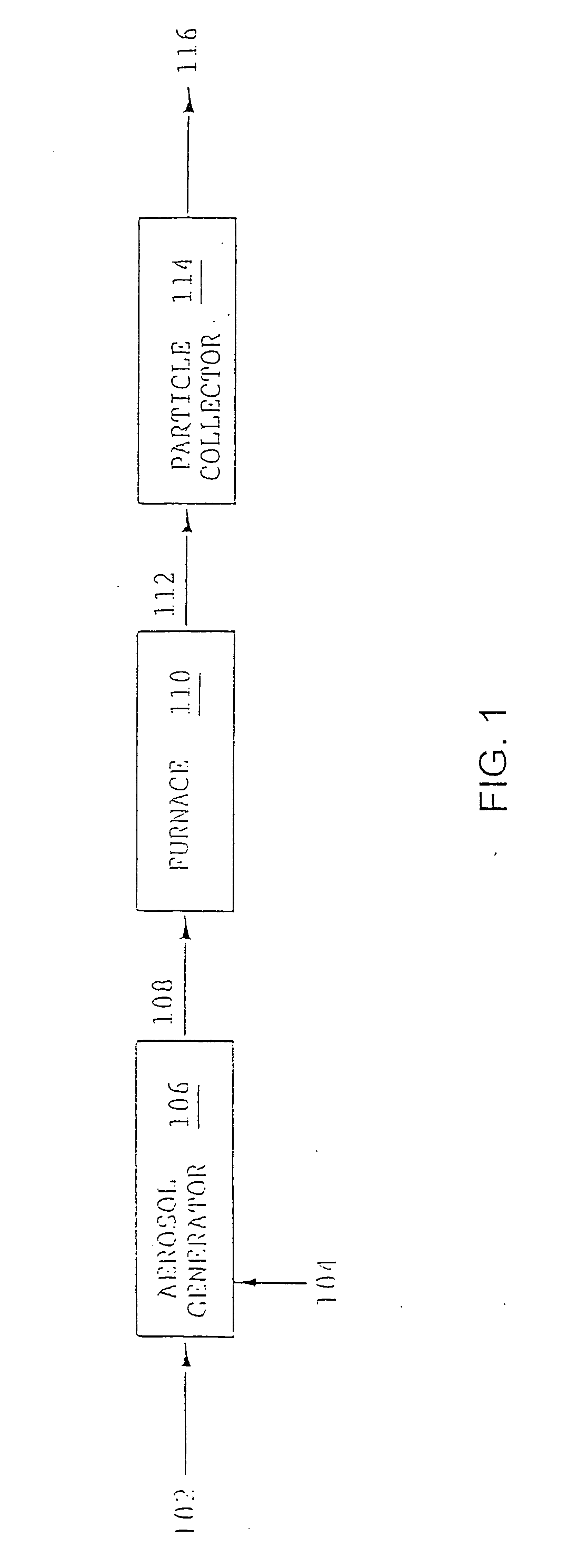

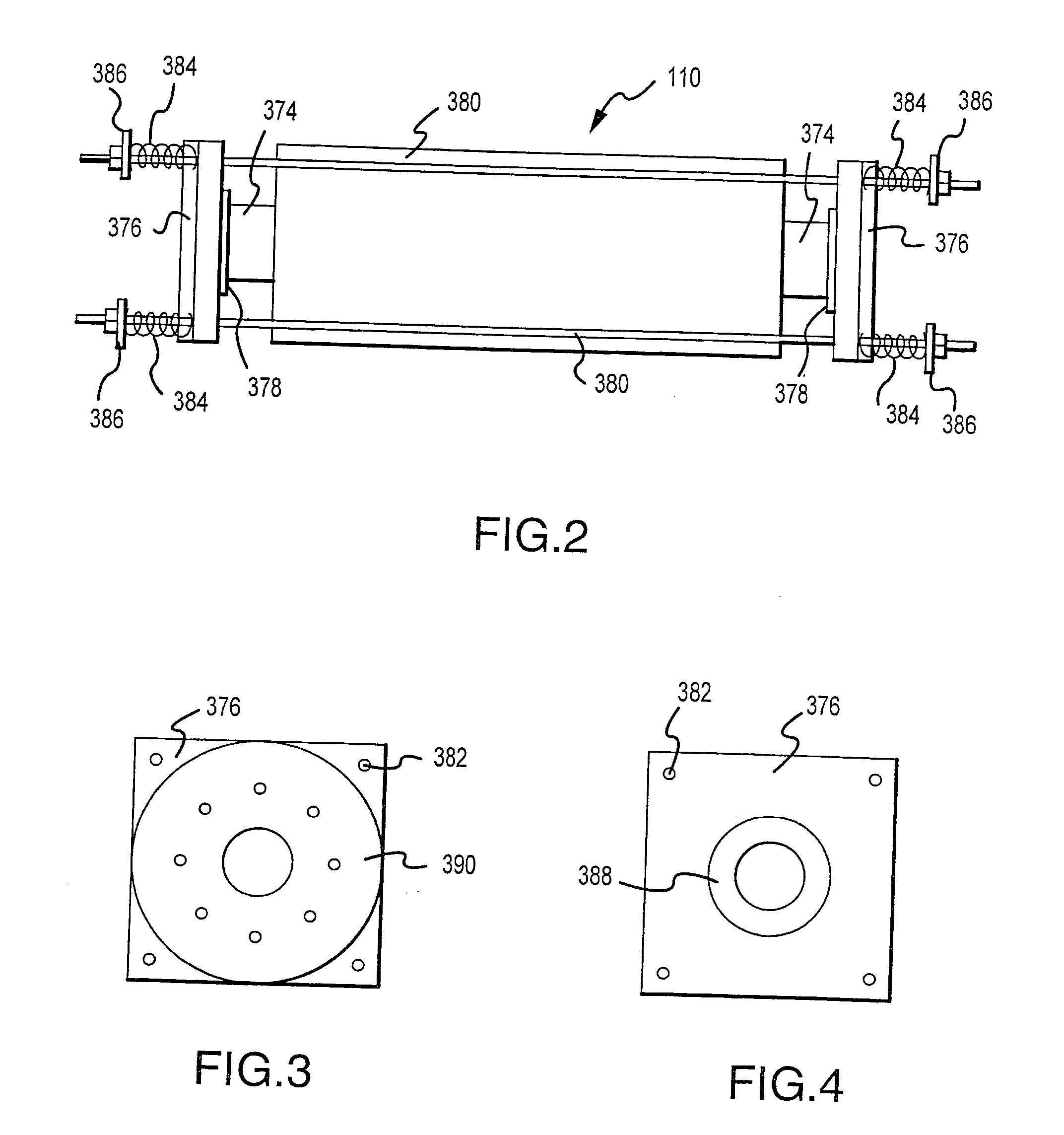

Aerosol method and apparatus, particulate products, and electronic devices made therefrom

Metal-carbon composite powders and methods for producing metal-carbon composite powders. The powders have a well-controlled microstructure and morphology and preferably have a small average particle size. The method includes forming the particles from an aerosol of powder precursors. The invention also includes novel devices and products formed from the composite powders.

Owner:CABOT CORP

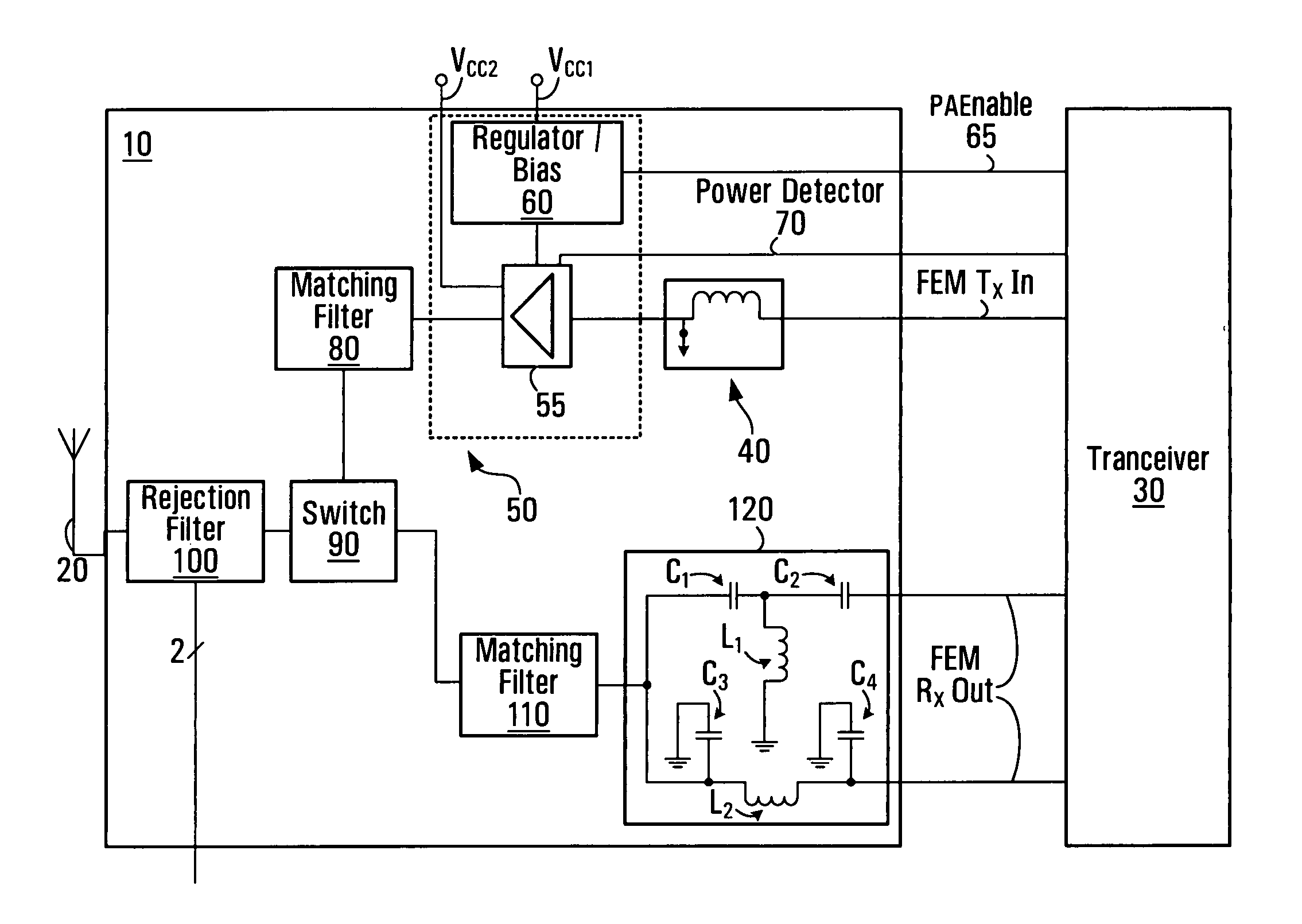

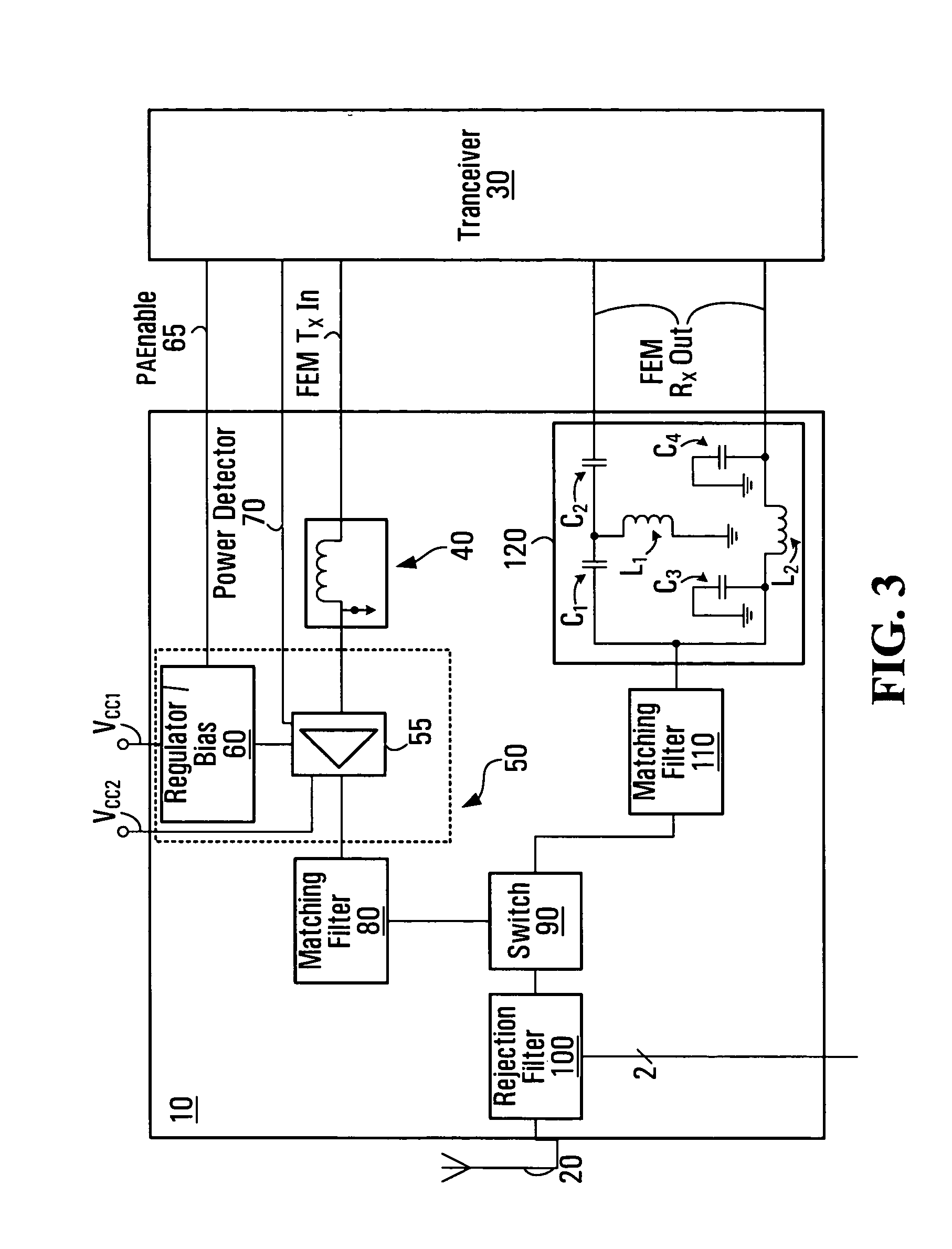

Device and methods for high isolation and interference suppression switch-filter

ActiveUS20060281418A1Shorter electrical couplingSmall footprintMagnetic/electric field screeningFixed capacitorsRadio equipmentOut of band rejection

Systems and methods are provided for a stacked die configuration of a high isolation switch and a rejection filter where transmit and receive signals are desired to have a high out-of-band rejection and a low loss band-pass region. In some aspects of the invention the high isolation switch is a double pole double throw switch modified to operate as a high isolation single pole double throw (SPDT) switch. In some aspects of the invention the high isolation switch is a conventional high isolation SPDT switch. The switch is mounted on a low profile rejection filter having metallization on a portion of an outer surface of the rejection filter. The metallization on the outer surface of the rejection filter provides an AC ground layer in close proximity to the switch that provides a short coupling path between the switch and the AC ground. The resulting switch-filter component also results in a smaller footprint than if the two devices were mounted individually and / or adjacently. The switch-filter component has applications in devices requiring high isolation between transmit and receive paths, for example use within a front-end module (FEM) of a single antenna, multi-radio device.

Owner:SIGE SEMICON

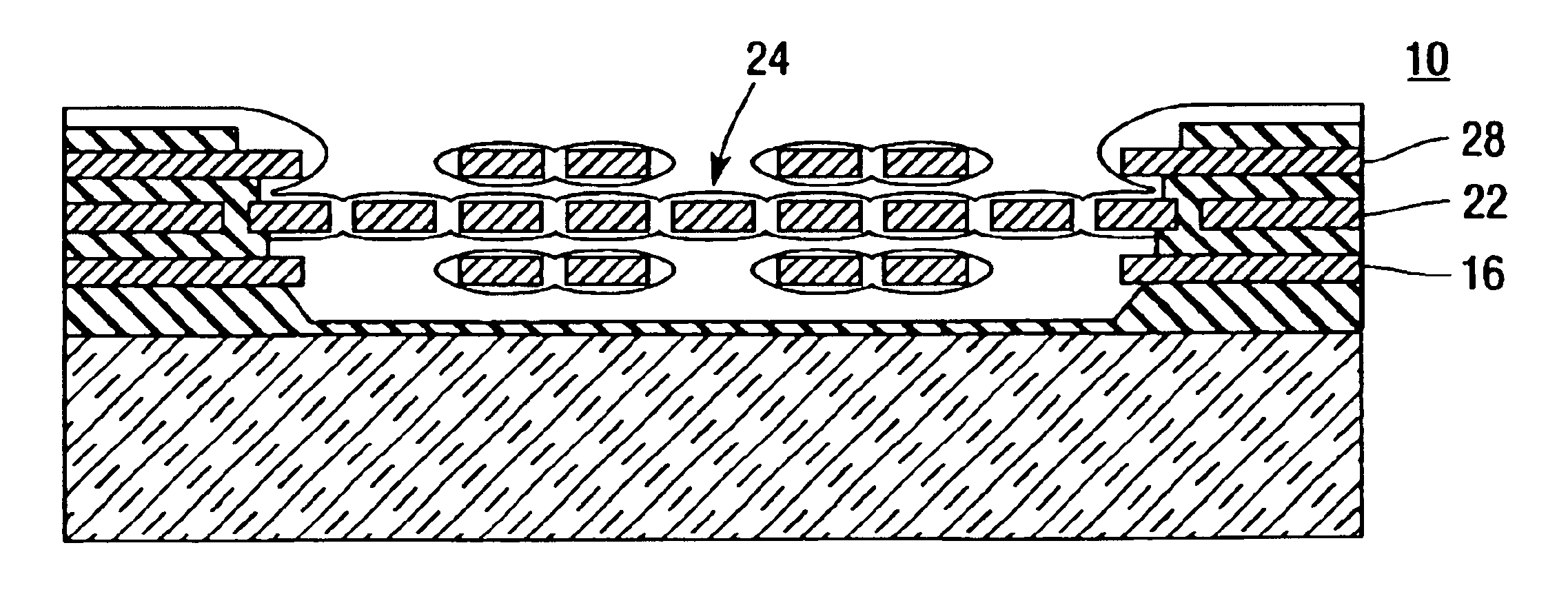

Hermetically sealed electrolytic capacitor

ActiveUS7206186B1Direct currentImprove performanceClosuresLiquid electrolytic capacitorsElectrolysisHermetic seal

An electrolytic capacitor is provided having a metal-glass-metal hermetic seal and a liquid seal, which protects the hermetic seal from the electrolyte solution in the capacitor. The liquid seal is formed by compressing an elastomeric ring between the underside of the lid of the capacitor and a terminal plate, connected to the capacitor element, whereby compression of the elastomeric seal is maintained by the lead, which connects the terminal plate and a metal post in the hermetic seal.

Owner:CORNELL DUBILIER MARKETING

Coated silver-containing particles, method and apparatus of manufacture, and silver-containing devices made therefrom

InactiveUS20050061107A1Increase loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

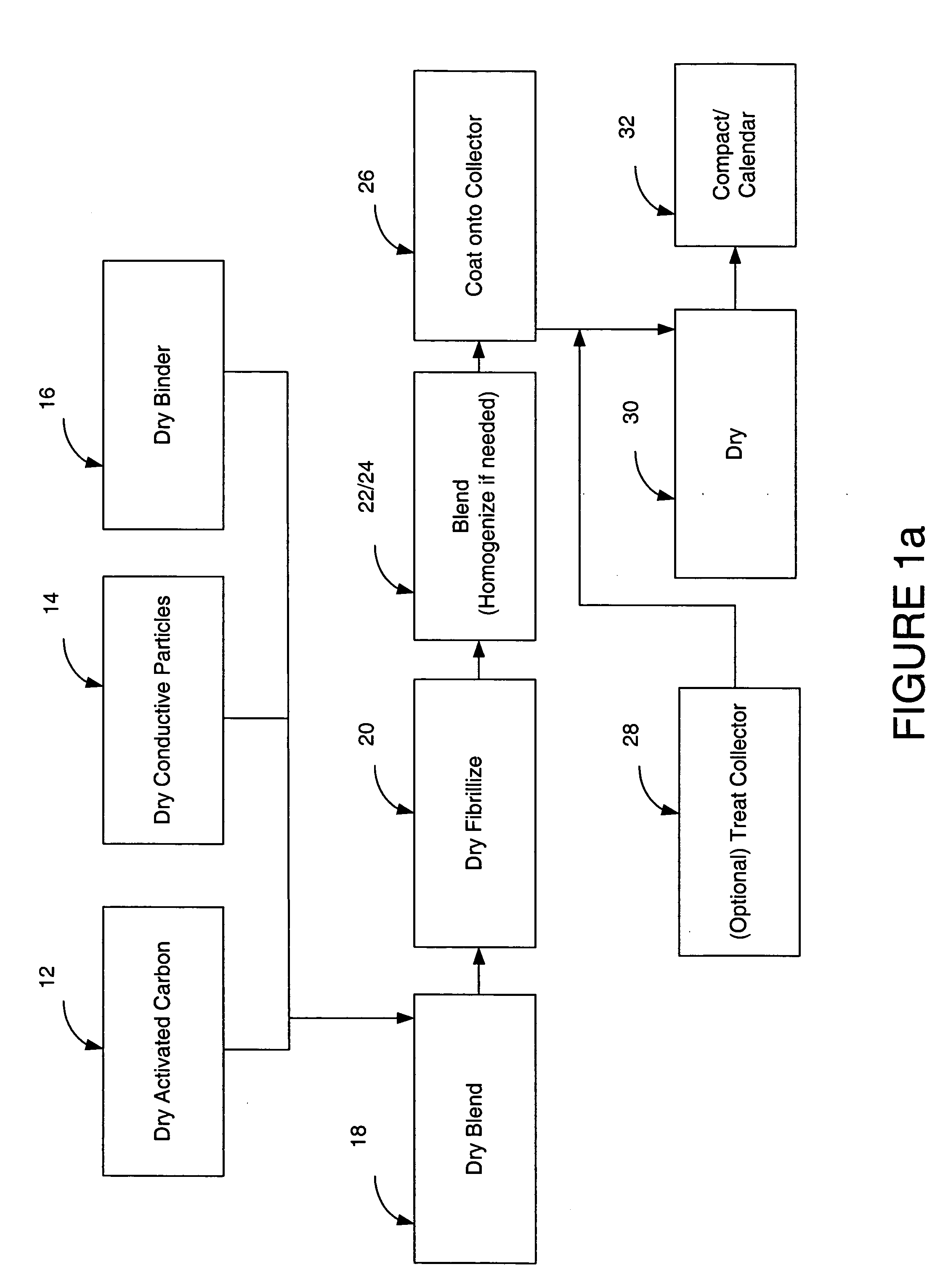

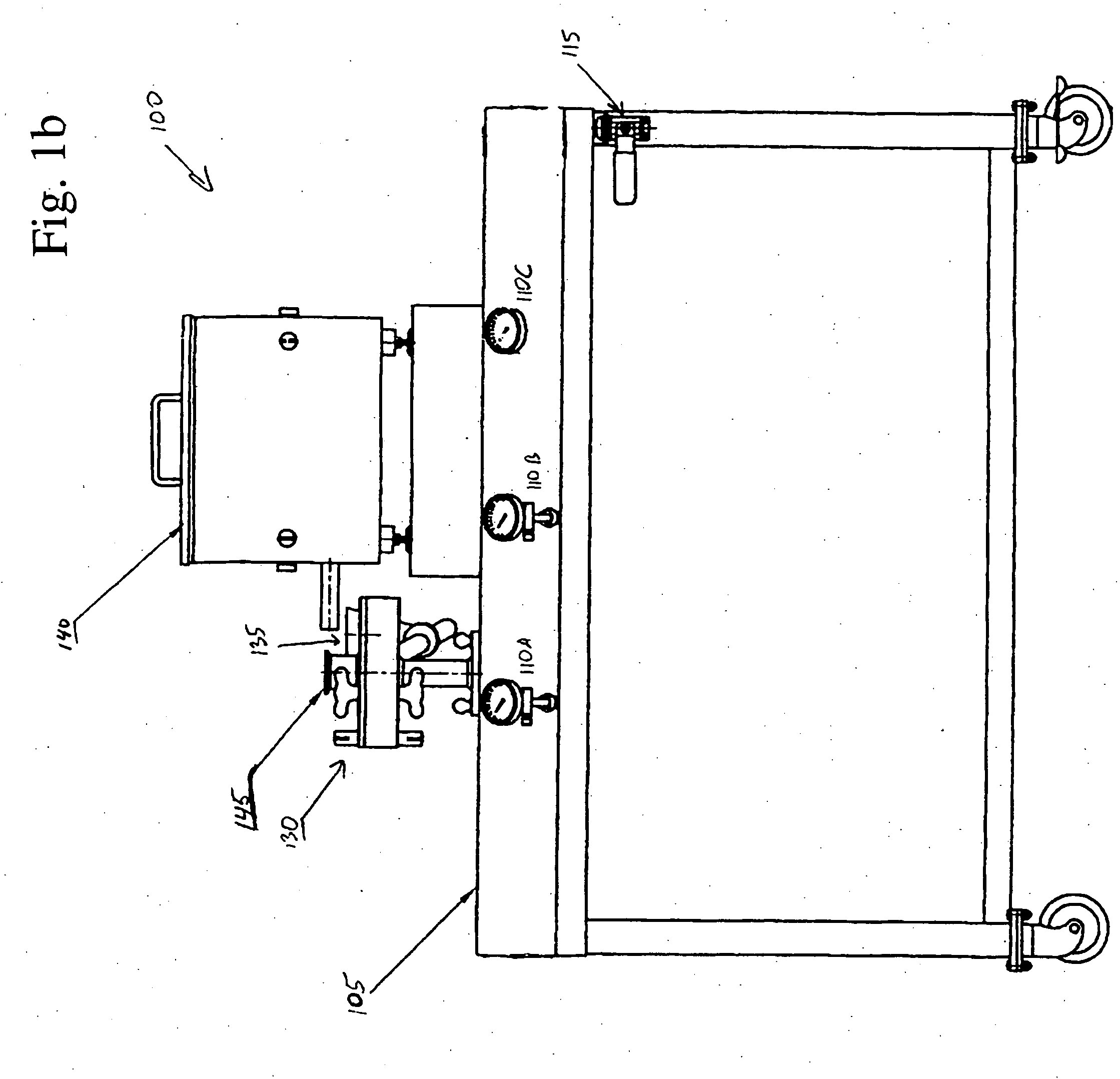

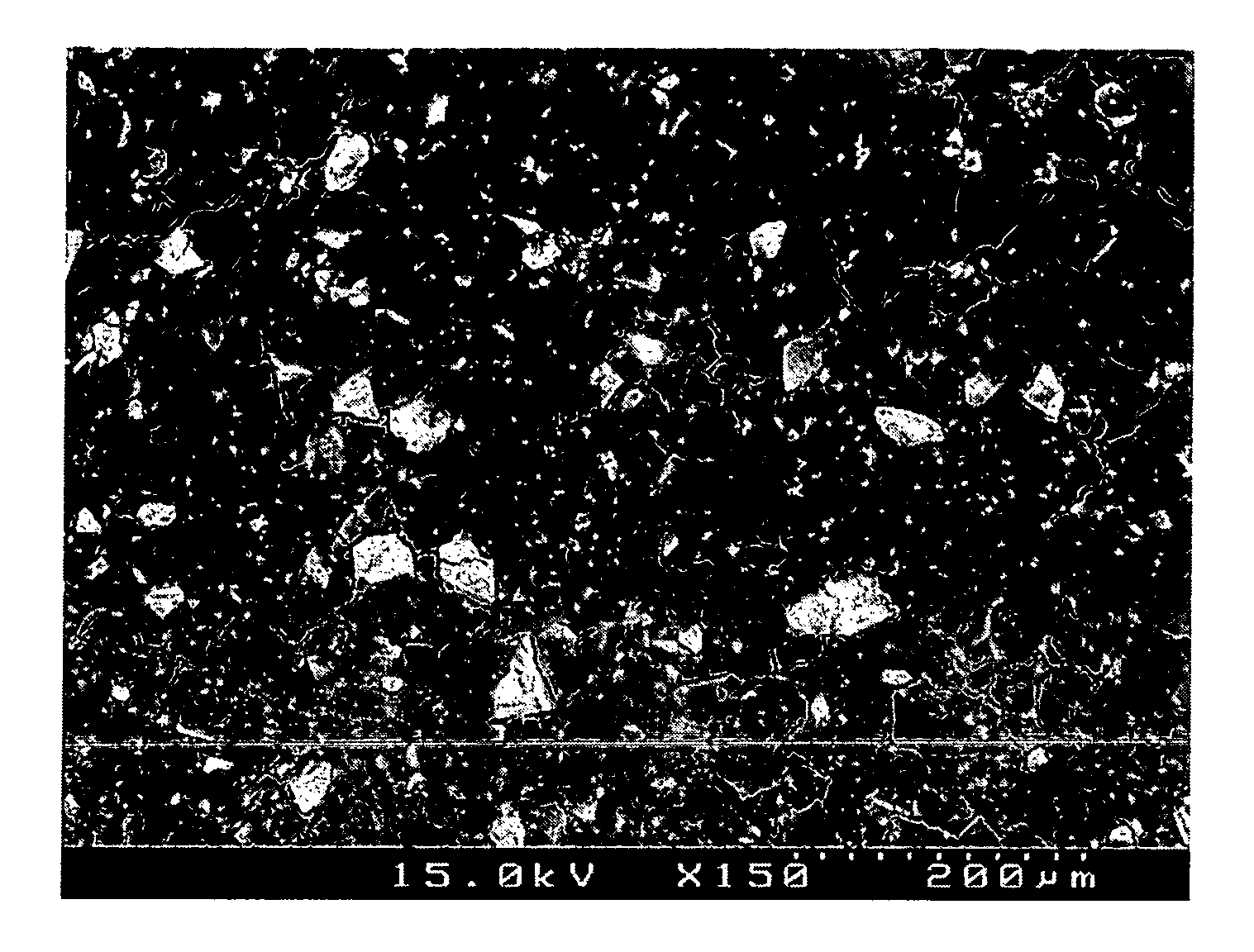

Particle based electrodes and methods of making same

ActiveUS20060146475A1Long lasting, durable, and inexpensive energy storage devicesImprove throughputHybrid capacitor electrodesDouble layer capacitorsCoated electrodesEnergy storage

A coated electrode is provided for use in energy storage devices. The coated electrode comprises a dry fibrillized polymer that is fibrillized with no processing additives.

Owner:TESLA INC

Carbon-porous media composite electrode and preparation method thereof

InactiveUS7505250B2Improve hydrophilicitySimple processMaterial nanotechnologyElectrolytic capacitorsCapacitanceWater use

The present invention discloses a carbon-porous media composite electrode material, a composite electrode using the same and a preparation method thereof. The carbon-porous media composite electrode can be applied for a device such as a secondary battery, a capacitor or the like, or for preparing ultra pure water using a capacitive deionization process, purifying salty water or the like.

Owner:KOREA INST OF SCI & TECH

Conductive ink containing thermally exfoliated graphite oxide and method of making a conductive circuit using the same

ActiveUS20080302561A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphiteConductive polymerPhysical chemistry

Owner:THE TRUSTEES FOR PRINCETON UNIV

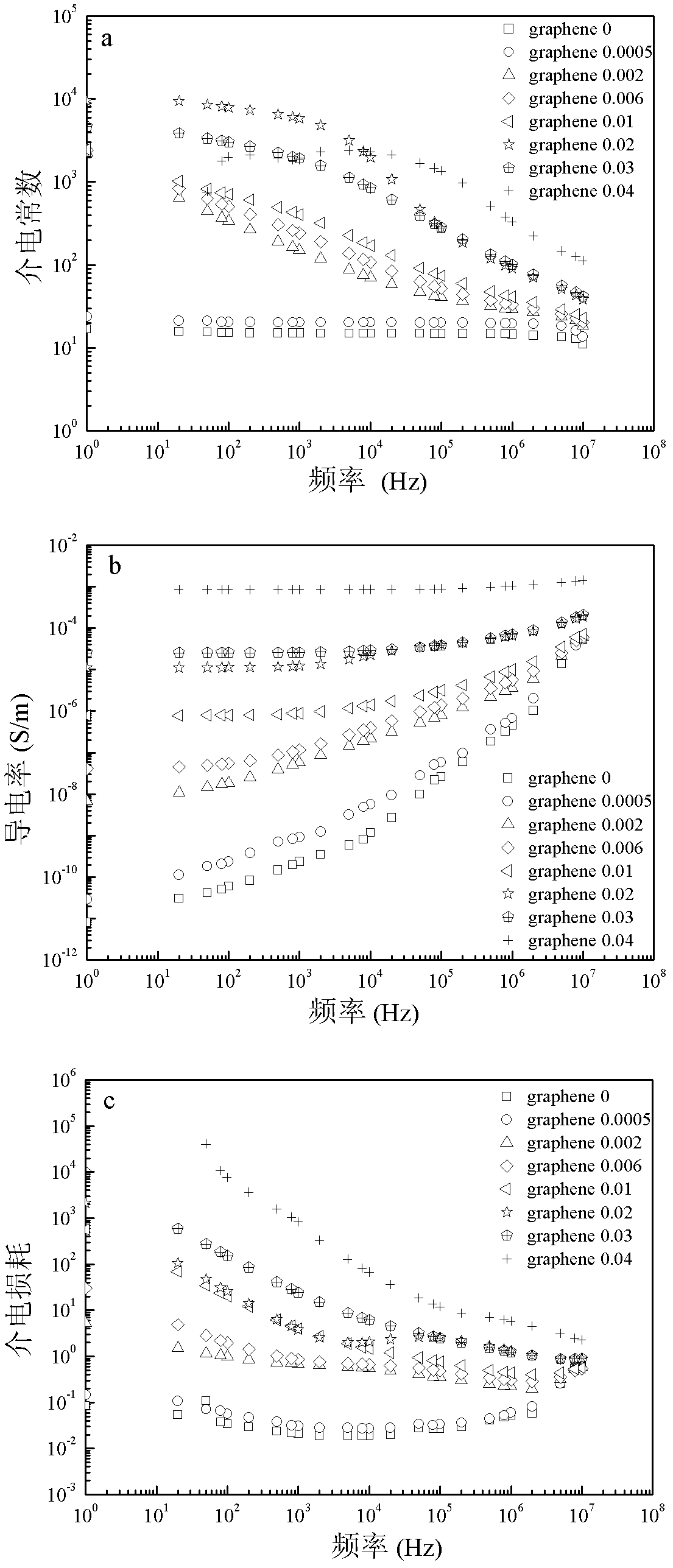

Polyvinylidene fluoride/graphene composite and preparation method thereof

ActiveCN102604275AHigh dielectric constantImprove toughnessFixed capacitorsDielectricPolyvinylidene difluoride

The invention discloses polyvinylidene fluoride / graphene composite and a preparation method thereof. The preparation method includes: reducing oxidation graphene by reductant, mixing the reduced graphene and polyvinylidene fluoride with N, N-dimethylacetamide solvent to be solution, drying and hot-pressing the solution to obtain the polyvinylidene fluoride / graphene composite. The prepared polyvinylidene fluoride / graphene composite has the following advantages that 1) dielectric constant of the polyvinylidene fluoride / graphene composite is high and can reach 7940 on the condition of 100Hz frequency and the weight percentage of the graphene is 0.02; and 2) flexibility is fine. Meanwhile, the preparation method has the advantages of simple operation and high stripping and dispersing degree of graphene and the like.

Owner:嘉善县国创新能源研究院

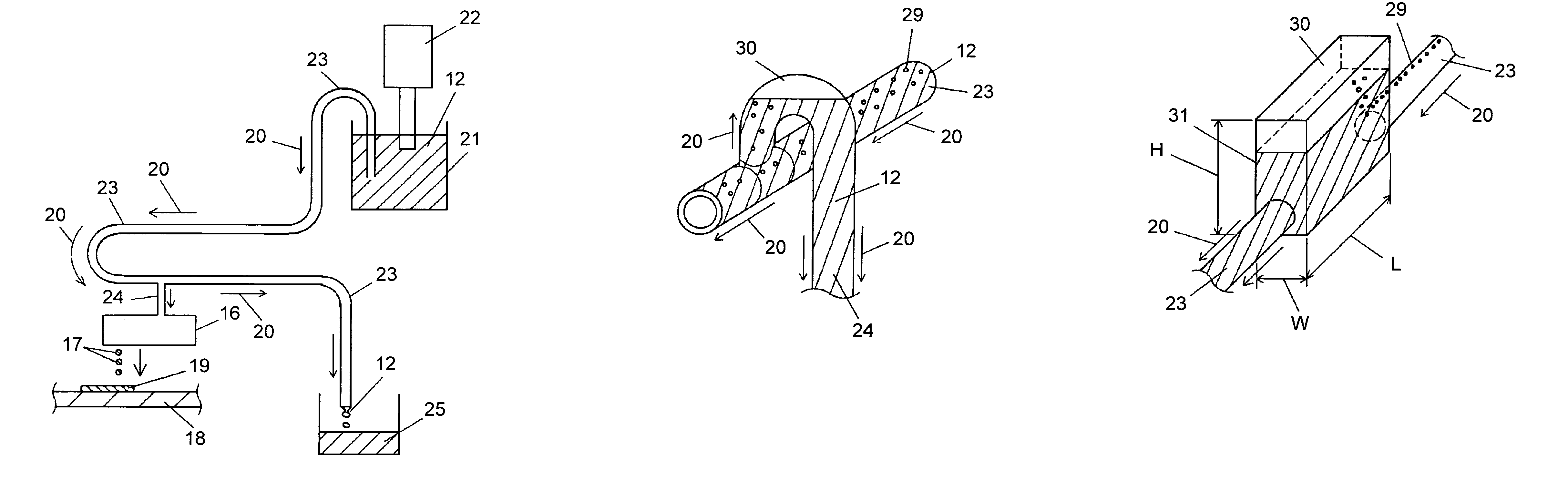

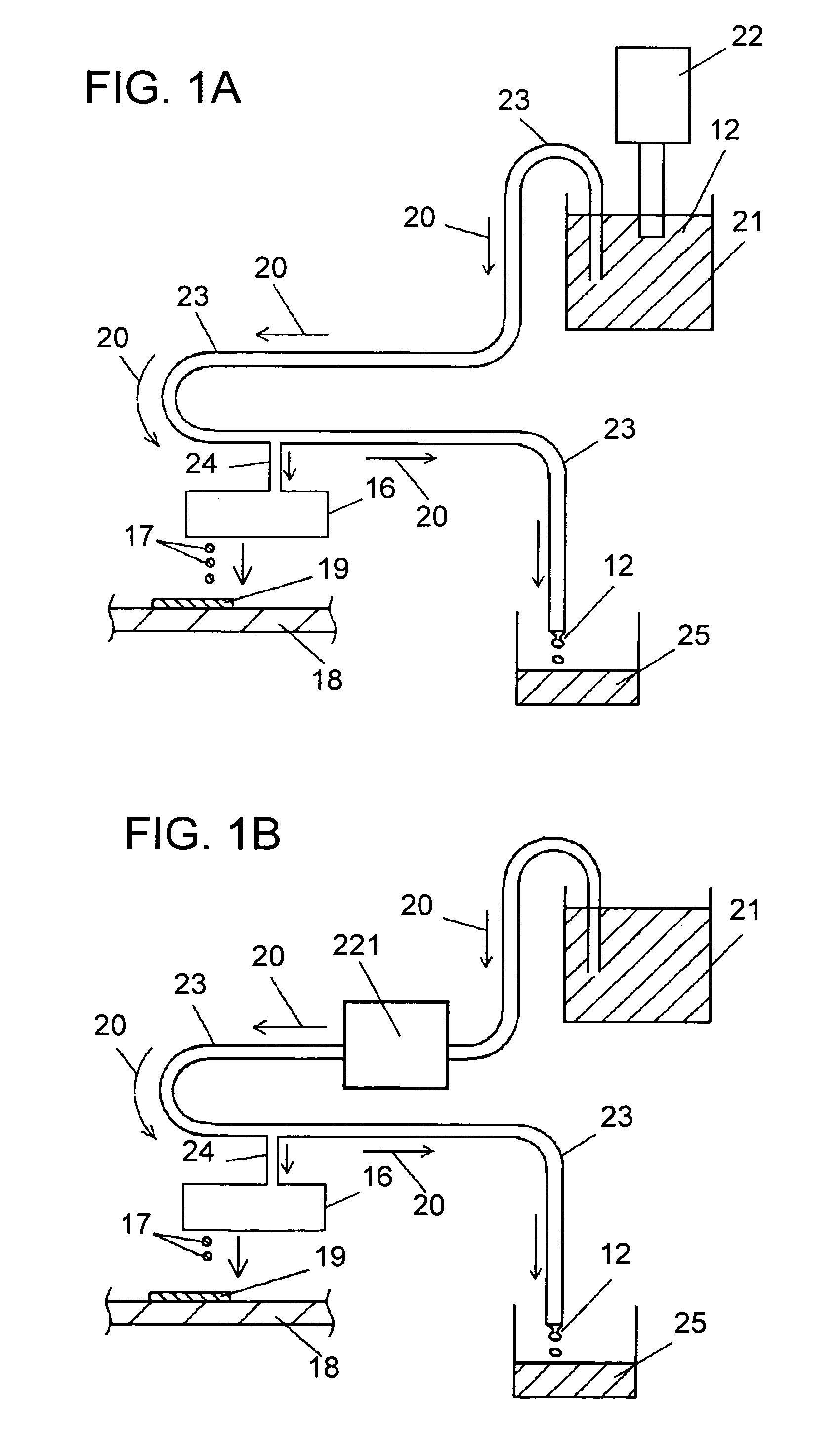

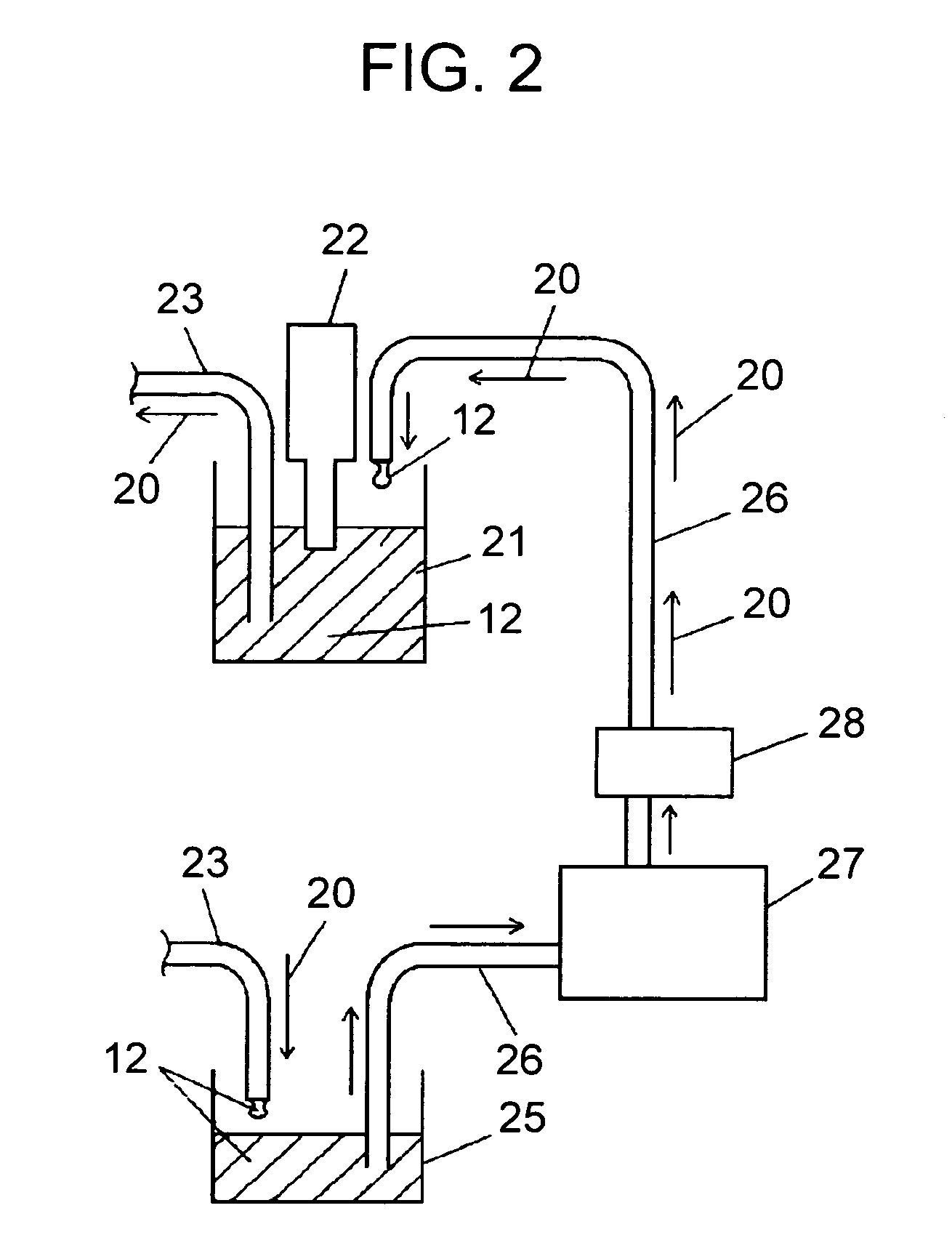

Ink jet device, ink jet ink, and method of manufacturing electronic component using the device and the ink

InactiveUS7097287B2Ink jet printing with stabilityReduced stabilityFixed capacitorsNon-conductive material with dispersed conductive materialEngineeringElectronic component

Owner:PANASONIC CORP

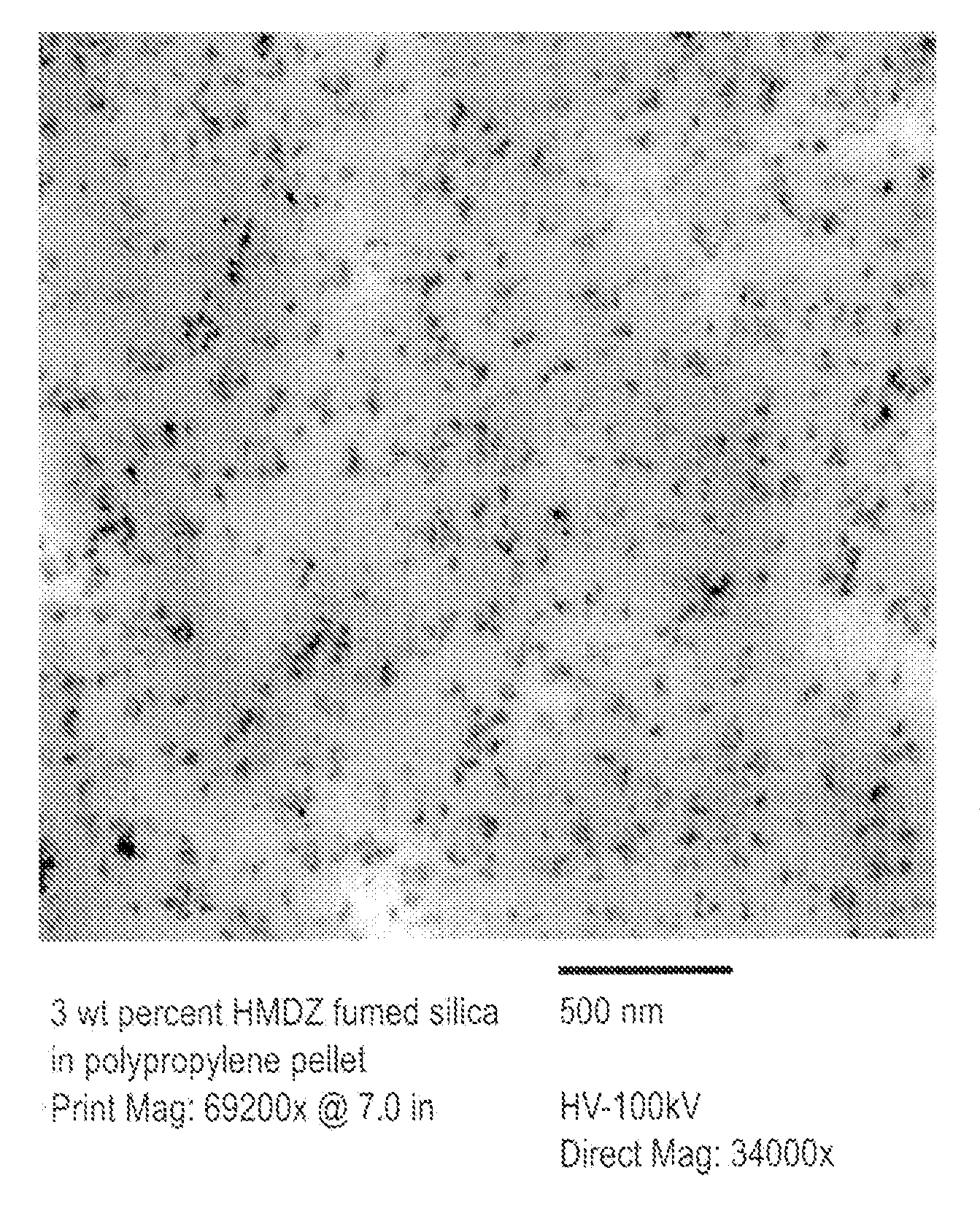

Biaxially Oriented Nanocomposite Film, Method of Manufacture, and Articles Thereof

A method comprises mixing a nano-filler and a polymer composition to form a nanocomposite; extruding the nanocomposite as a melt through a spiral mandrel die to form a molten tube; expanding the tube biaxially by means of mechanical force and air pressure to form a bubble; and collapsing the bubble to form at least one sheet of a biaxially oriented nanocomposite film, wherein the biaxially oriented nanocomposite film has a breakdown strength of at least 300 V / micrometer.

Owner:GENERAL ELECTRIC CO

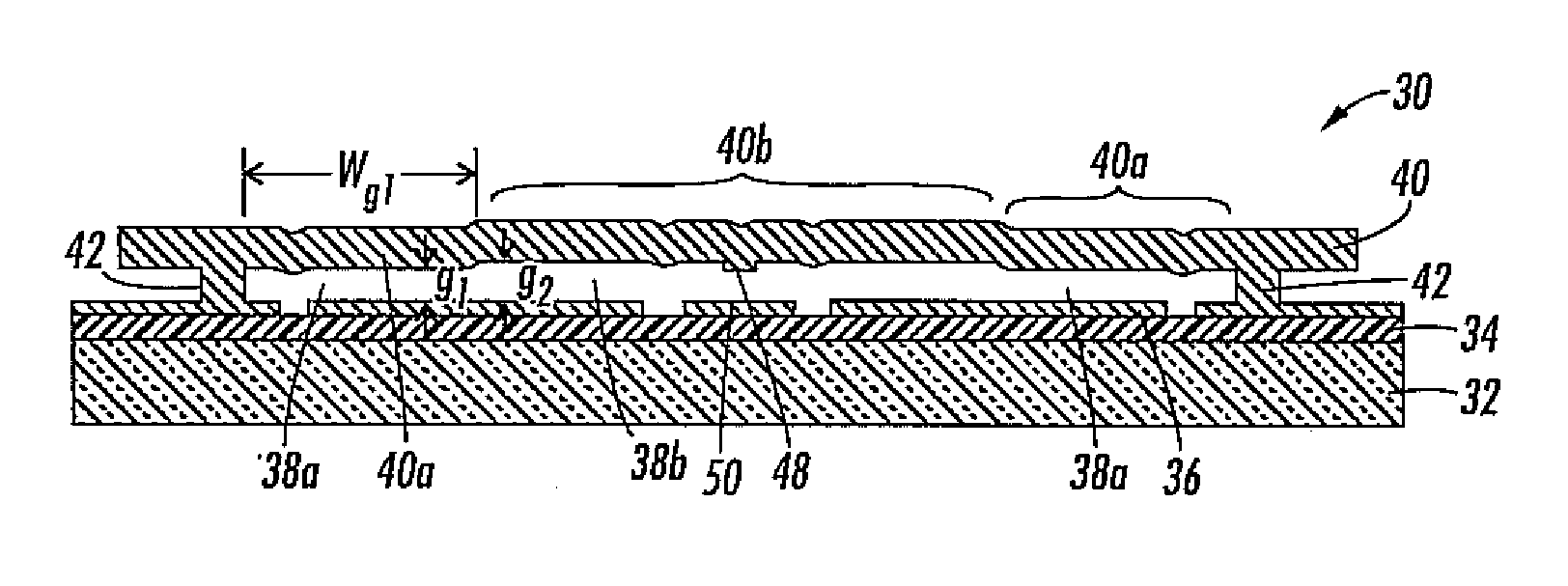

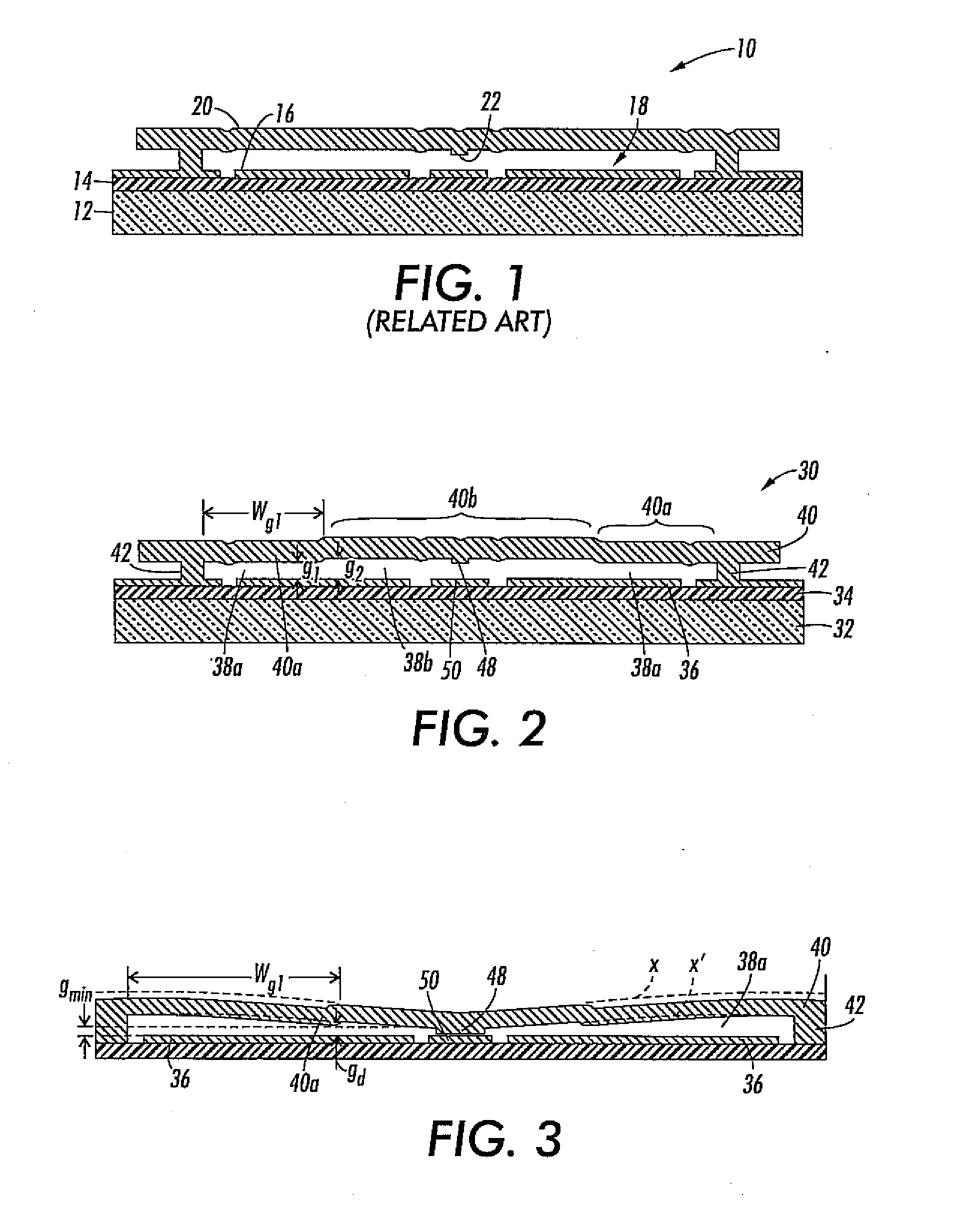

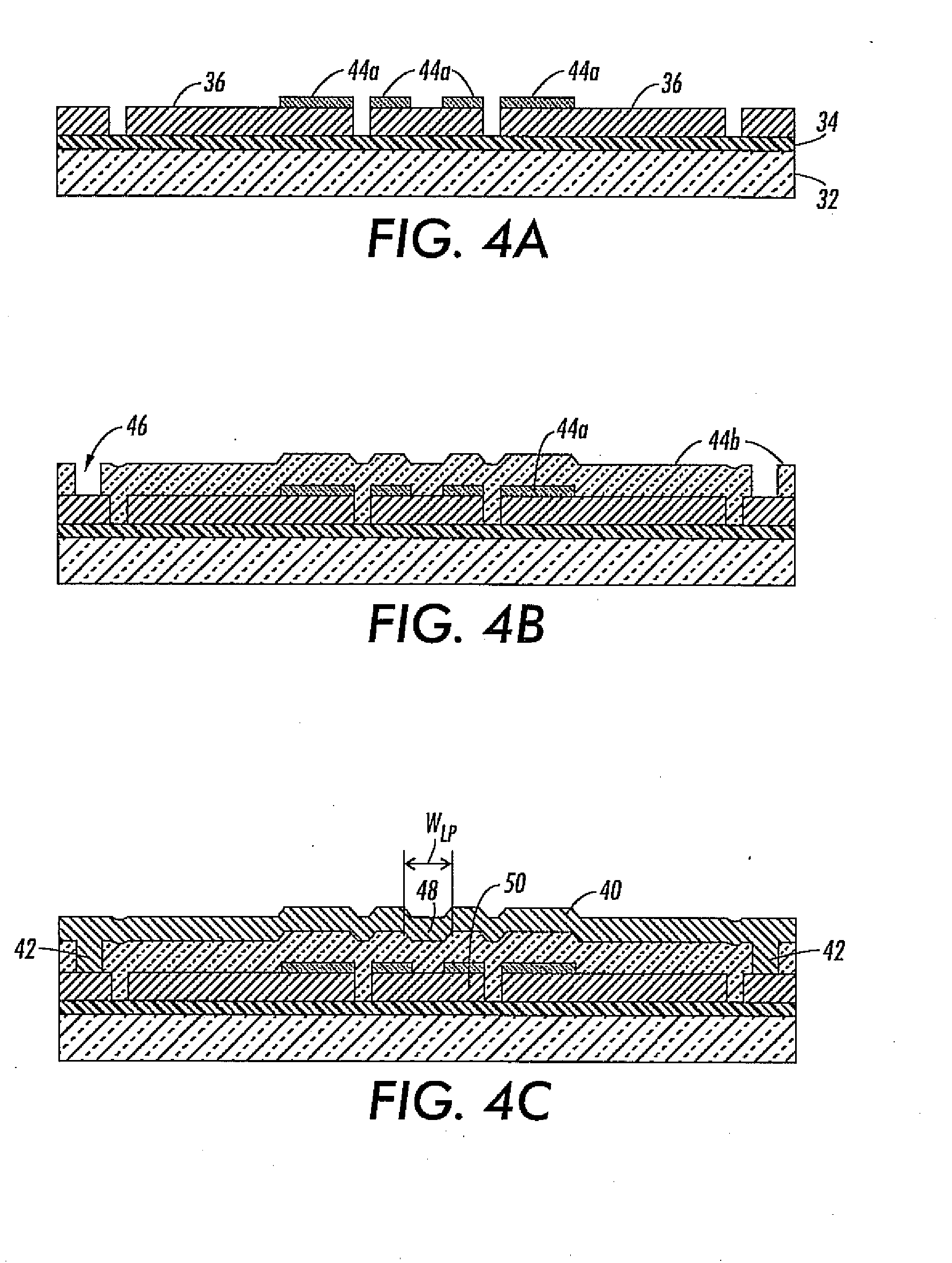

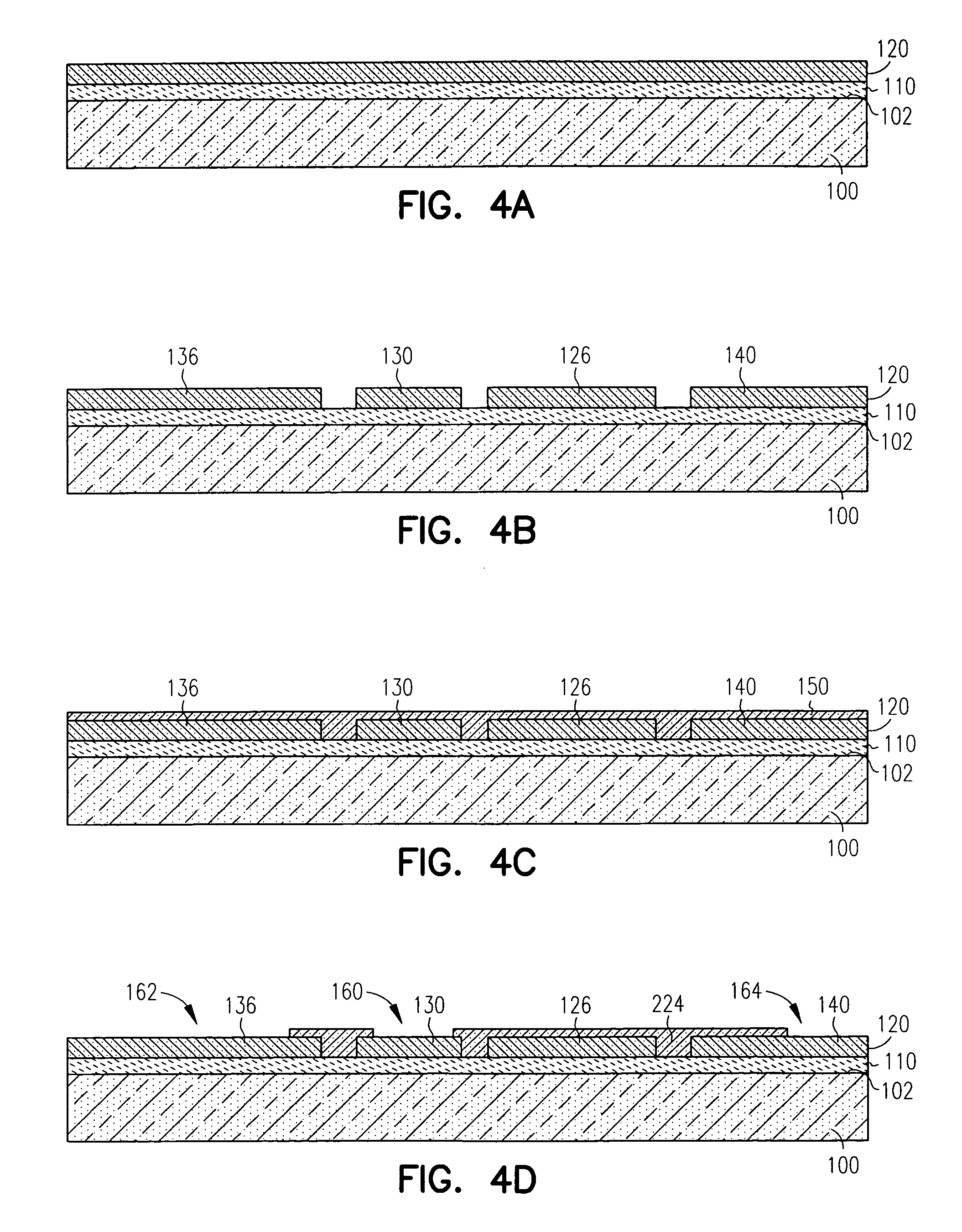

Electrostatic actuator device and method of making the device

InactiveUS20080048520A1Reduce decreaseReduce the amount requiredElectrostatic/electro-adhesion relaysElectrolytic capacitorsEngineeringElectrostatic actuator

The present application is directed to novel electrostatic actuators and methods of making the electrostatic actuators. In one embodiment, the electrostatic actuator comprises a substrate, an electrode formed on the substrate and a deflectable member positioned in proximity to the electrode so as to provide a gap between the electrode and the deflectable member. The deflectable member is anchored on the substrate via one or more anchors. The gap comprises at least one first region having a first gap height positioned near the one or more anchors and at least one second region having a second gap height positioned farther from the anchors than the first region. The first gap height is smaller than the second gap height.

Owner:XEROX CORP

Vacuum-cavity MEMS resonator

A microelectromechanical (MEMS) resonator with a vacuum-cavity is fabricated using polysilicon-enabled release methods. A vacuum-cavity surrounding the MEMS beam is formed by removing release material that surrounds the beam and sealing the resulting cavity under vacuum by depositing a layer of nitride over the structure. The vacuum-cavity MEMS resonators have cantilever beams, bridge beams or breathing-bar beams.

Owner:INTEL CORP

Maskless nanofabrication of electronic components

InactiveUS7682970B2Reduce the amount requiredEfficient methodRadiation applicationsSolid-state devicesElectronic structureNanoparticle

Owner:RGT UNIV OF CALIFORNIA +1

Active matrix substrate, method of manufacturing the same, and image sensor incorporating the same

InactiveUS7250991B2Preventing signal transmission delay in signal lineIncrease in number of manufacturing stepTransistorTelevision system detailsLiquid-crystal displayActive matrix

A signal line and a pixel capacitor wire that doubles as a pixel capacitor electrode are fabricated parallel to each other from the same electrode layer through patterning thereof. Therefore, no additional steps are required to form the pixel capacitor wire. In such an arrangement, the pixel capacitor wire and the signal line are disposed parallel to each other; therefore, delays of signal transmission in the signal line and crosstalk between pixels are prevented from occurring. The active matrix substrate incorporating this arrangement is suitably used in liquid crystal display devices, image sensors, and the like. Similar advantages are available with an arrangement in which the signal line and the pixel capacitor wire are disposed parallel to each other, and the storage capacitor electrode, which will constitute a storage capacitor with the pixel electrode therebetween, and the scanning line are fabricated from the same electrode layer through patterning thereof.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com