Automatic impregnating machine

An automatic, mobile motor technology, applied in the direction of drying/dipping machines, etc., can solve the problems of secondary pollution of impregnating liquid, poor quality assurance, and reduced product quality, etc., to achieve good impregnation quality, stable and reliable product quality, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

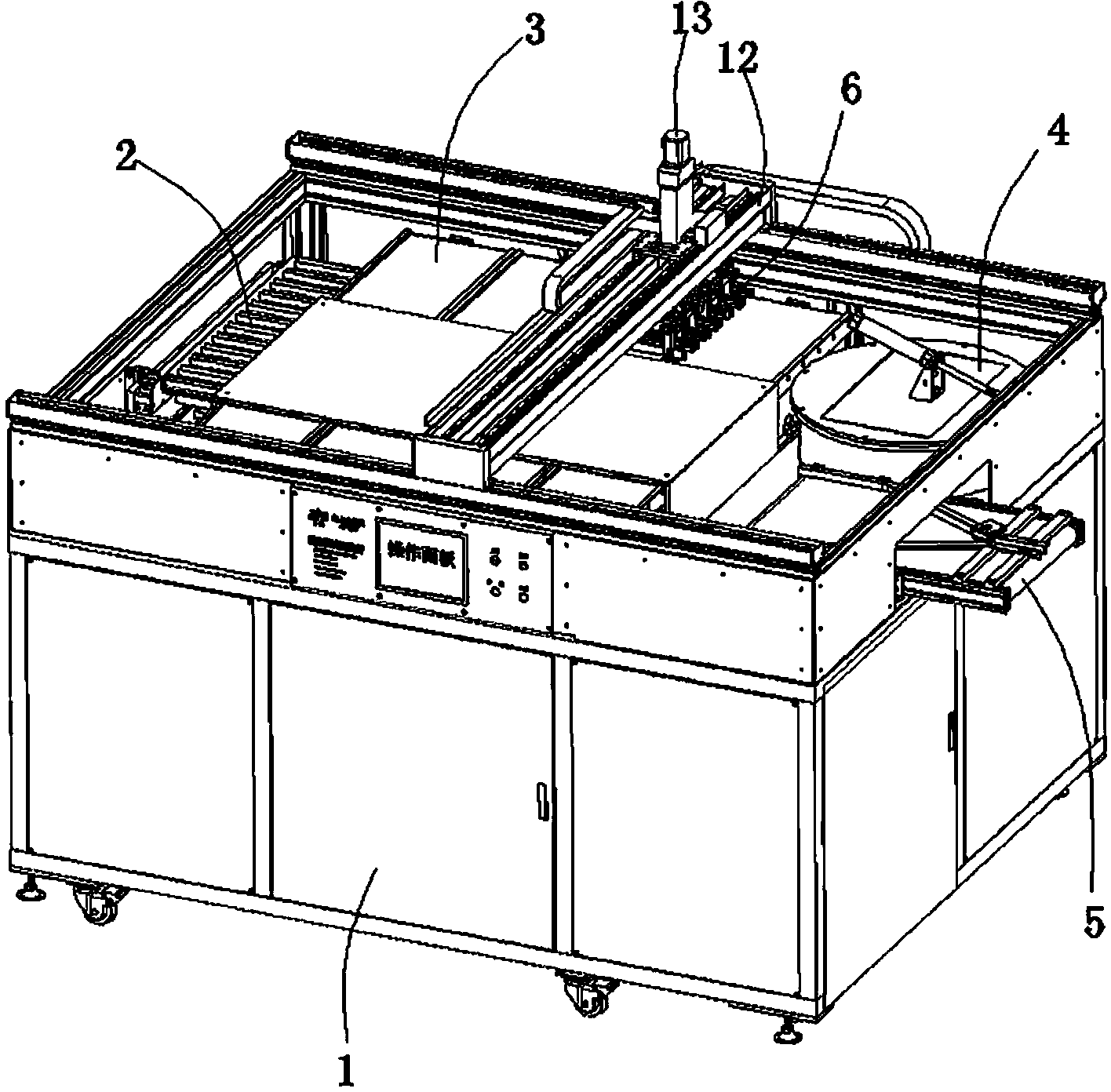

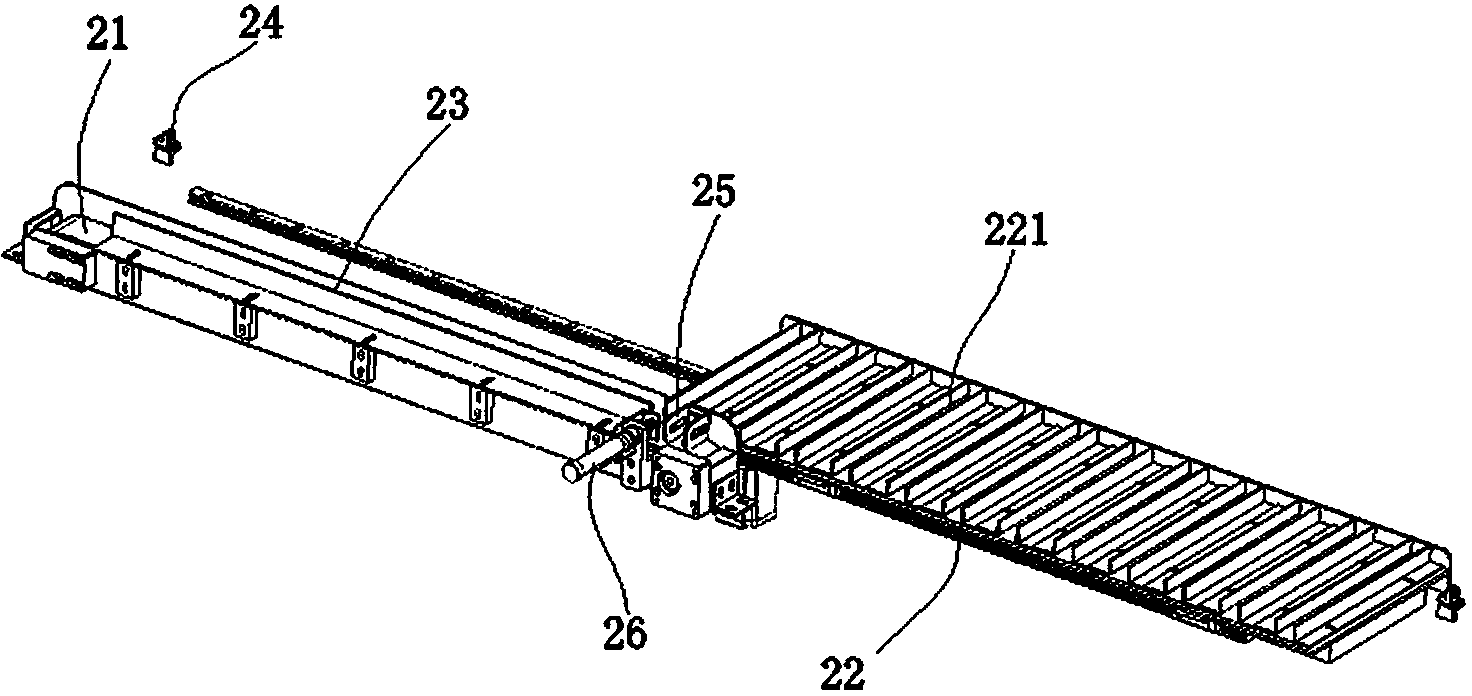

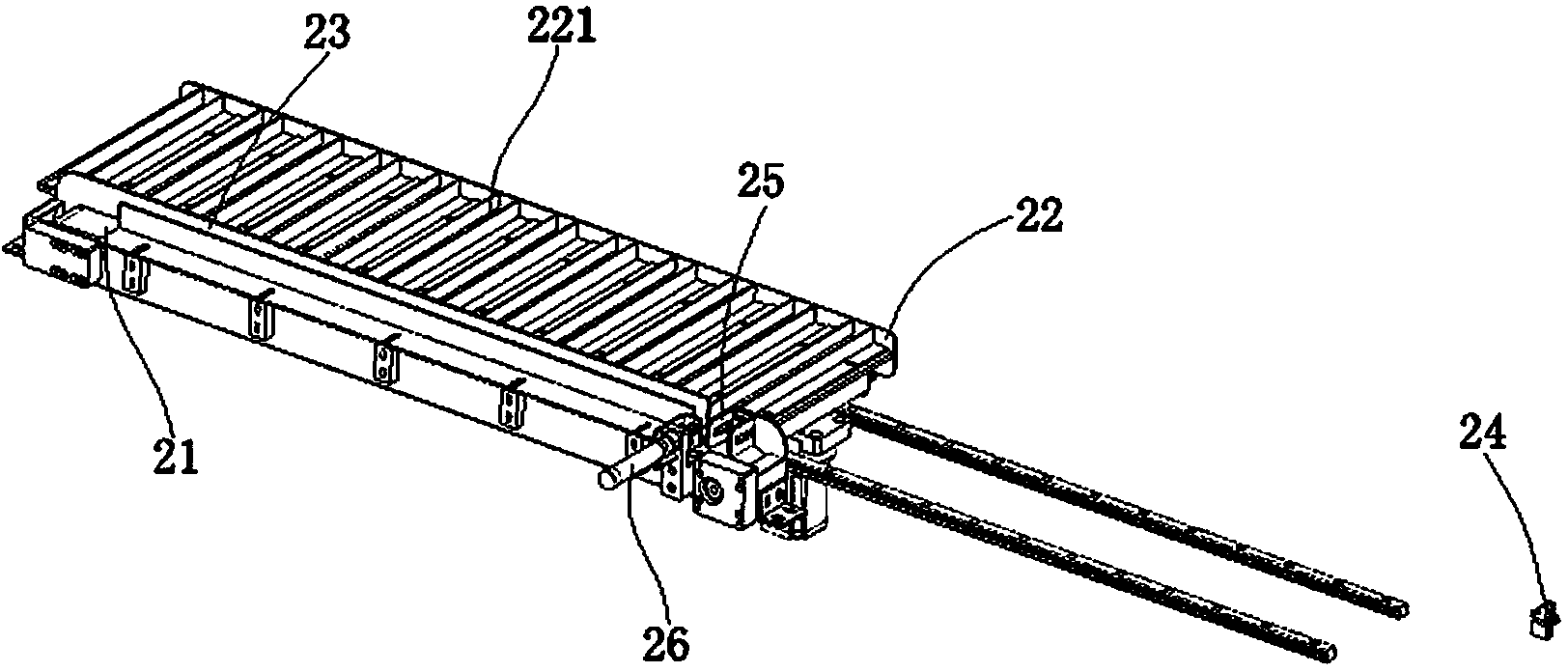

[0035] Example: see Figure 1 to Figure 10 , an automatic impregnation machine of the present invention, which includes a frame 1, on which a feeding mechanism 2, an impregnation mechanism 3, a spin-drying mechanism 4 and a feeding mechanism 5 are arranged in sequence according to the feeding direction of the material. The frame 1 is also provided with at least one manipulator 6 corresponding to the feeding mechanism 2, impregnating mechanism 3, drying mechanism 4 and unloading mechanism 5, and the impregnating mechanism 3 is connected with at least one liquid storage tank. The invention solves the loss and pollution of many links in the process of nailing and assembling the batteries of relatively large aluminum electrolytic capacitors, improves product quality, saves labor costs, and increases output. In this embodiment, the number of impregnation mechanisms is 8, and in other embodiments, different numbers of impregnation mechanisms can be set according to actual needs.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com