Method for manufacturing brake drum for automobile

A production method and brake drum technology, applied in the direction of brake drums, etc., can solve the problems of reducing the safety factor of the whole vehicle and reducing the service life of brake drums, so as to improve the driving safety factor, prolong the service life, and solve the problems of easy cracking and easy The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

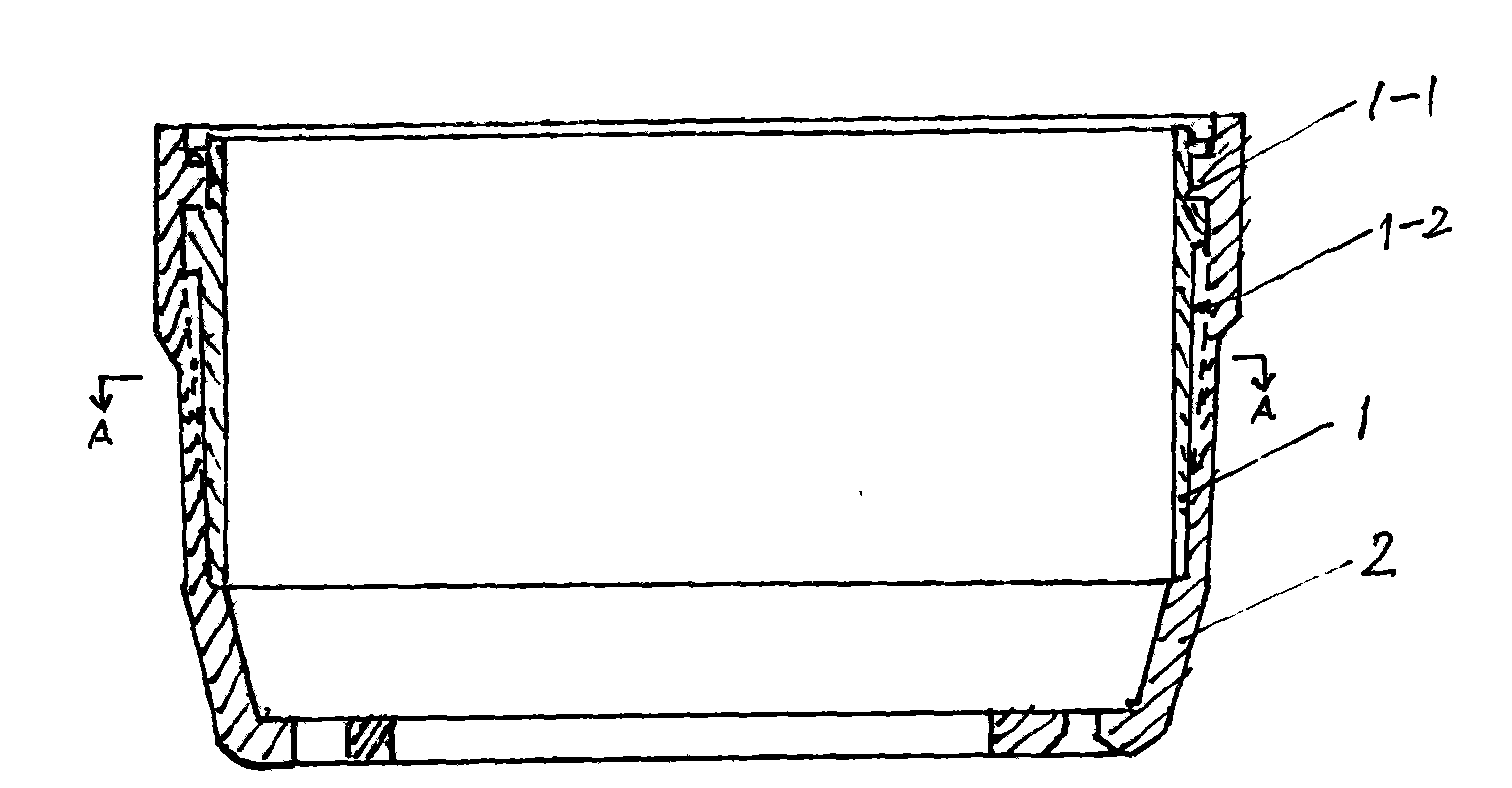

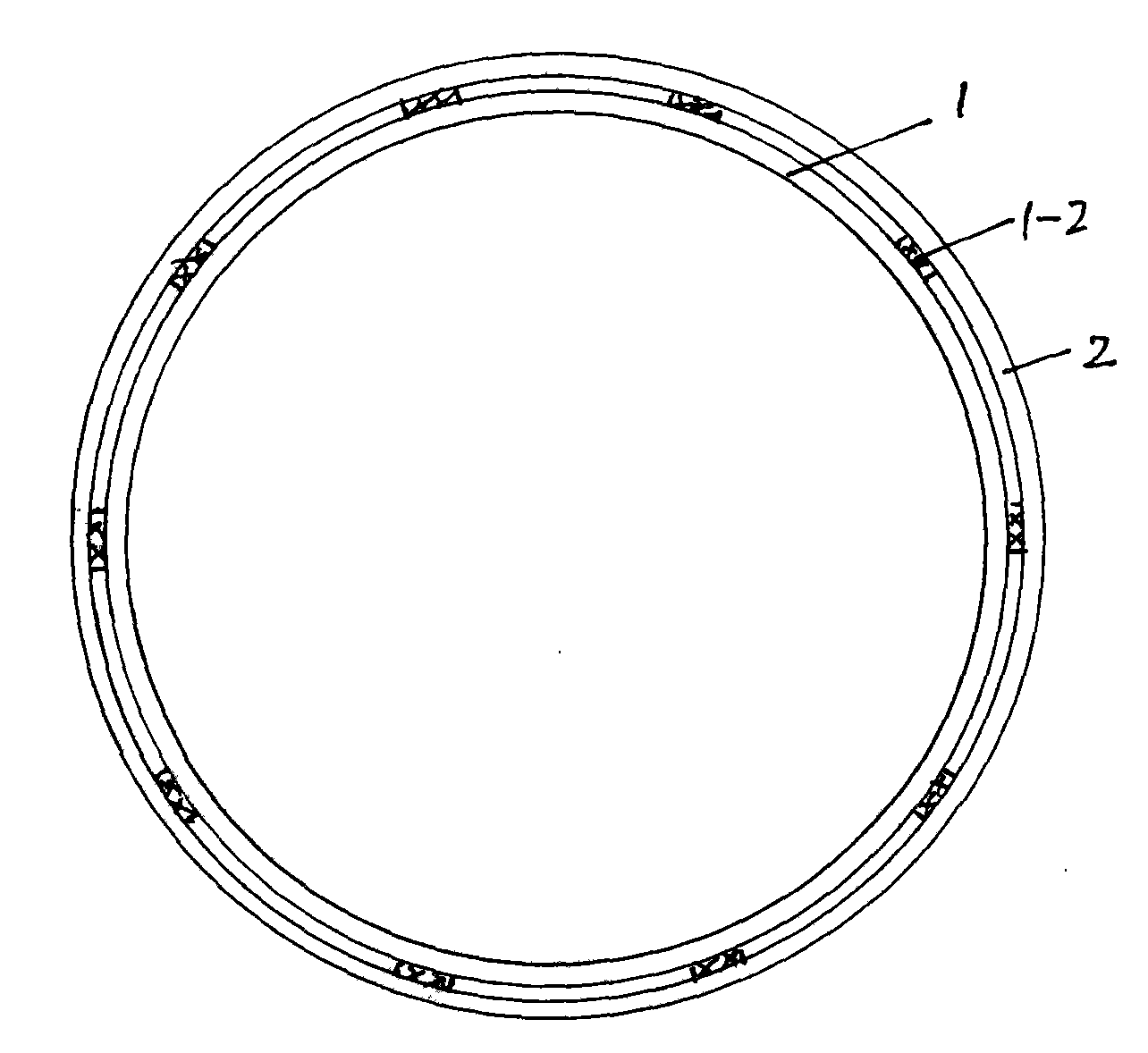

[0009] First make the brake sleeve 1, make it into a hollow circular drum shape with gray cast iron HT250, the wall thickness of the upper part is not less than 20mm, the lower part is not less than 10mm, and an annular groove 1 is processed on the outer surface 20mm below the top edge of the brake sleeve 1 -1, it is 20mm wide and 10mm deep. Ten protruding longitudinal reinforcing ribs 1-2 integrated with the brake sleeve 1 are evenly distributed on the lower part of the outer annular surface of the brake sleeve 1 . Put the brake sleeve 1 into the casting molding cavity of the outer sleeve 2 casting mold, and then pour the ring graphite cast iron QT450-15 to form the outer sleeve 2 by using the inlay casting technology. The lower part makes the combination between the brake sleeve 1 and the overcoat 2 firm and difficult to disengage. Brake sleeve 1 is used as the lining of overcoat 2 top, and its bottom is apart from overcoat 2 bottom about 1 / 5th place. A high-performance br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com