Electric spark composite machining process in magnetic field

A compound machining and EDM technology, applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of easy wear of electrodes, difficulty in chip removal, unstable processing, etc., and achieve easy realization, good processing effect, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

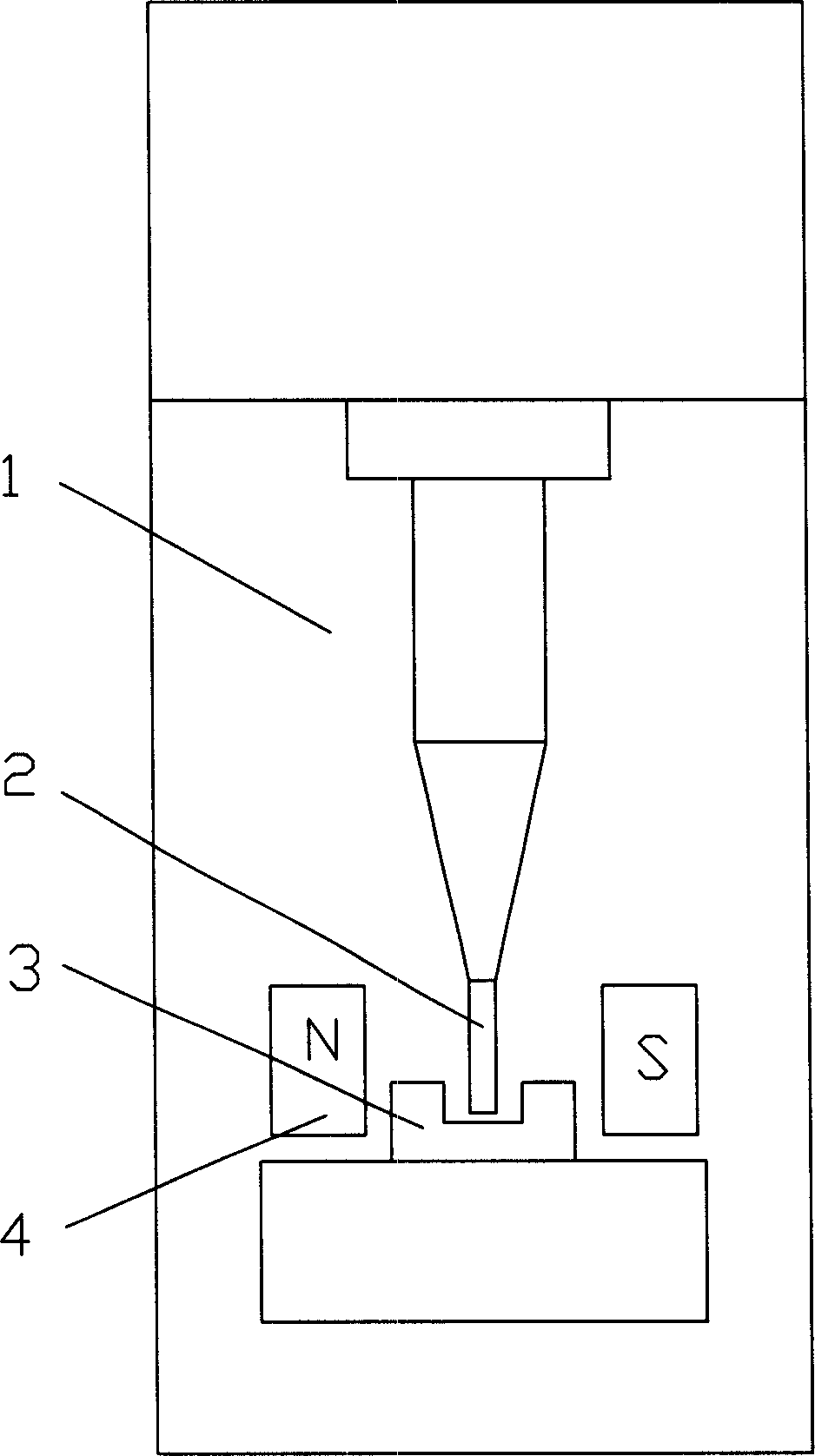

Image

Examples

Embodiment approach 1

[0010] Embodiment 1: A comparative test is carried out on a 1 mm thick stainless steel plate on a small hole machine;

[0011] Test conditions: EDM the positive pole of the workpiece, the negative pole of copper with a diameter of 2 mm, the magnetic pole gap is 20 mm, the magnetic field strength is 510 mT electromagnetic field, and the processing medium is tap water.

[0012] Test data: When EDM is performed alone, the maximum processing speed is 0.91 mm per minute, and after magnetic field EDM is combined, the maximum processing speed is 4.055 mm per minute, and the speed is increased by 4.5 times.

Embodiment approach 2

[0013] Embodiment 2: a comparative test is carried out on a stainless steel plate with a thickness of 8.6 millimeters on the small hole machine;

[0014] Test conditions: EDM the positive pole of the workpiece, the negative pole of copper with a diameter of 2 mm, the magnetic pole gap is 20 mm, the magnetic field strength is 510 mT electromagnetic field, and the processing medium is tap water.

[0015] Test data: When EDM is performed alone, the maximum processing speed is 1.6 mm per minute, and after magnetic field EDM is combined, the maximum processing speed is 7.53 mm per minute, and the speed is increased by 4.6 times.

Embodiment approach 3

[0016] Embodiment 3: A comparative test is carried out on a red copper plate with a thickness of 2 mm on the small hole machine;

[0017] Test conditions: EDM the positive pole of the workpiece, the negative pole of copper with a diameter of 2 mm, the magnetic pole gap is 20 mm, the magnetic field strength is 510 mT electromagnetic field, and the processing medium is tap water.

[0018] Test data: the maximum processing speed is 7.74 mm per minute when EDM is used alone, and the maximum processing speed after magnetic field EDM is 16.45 mm per minute, and the speed is increased by 2.1 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com