A Die for Machining Precision Switching Elements Convenient for Chip Removal

A switching element and mold technology, applied in the field of machining, can solve the problems of unreasonable design of chip removal system, complex process, poor quality of finished products, etc., and achieve the effects of simple structure, good safety and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

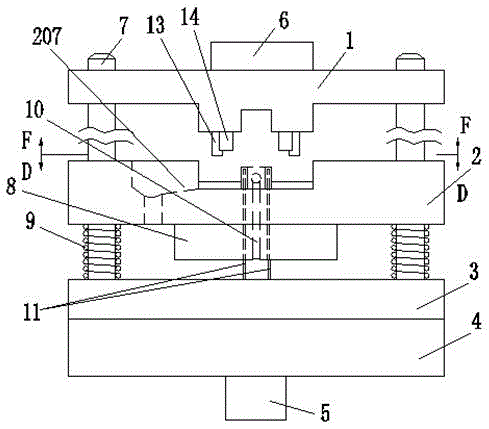

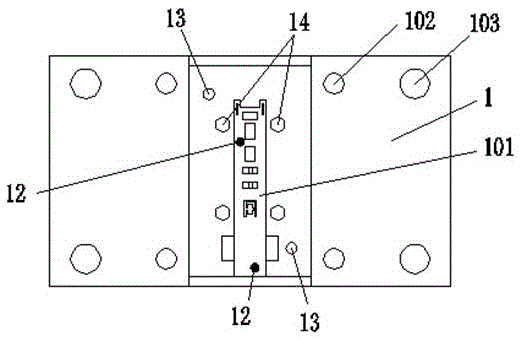

[0025] Such as Figure 1 to Figure 6 As shown, a mold for processing precision switch elements that is convenient for chip removal includes an upper template 1, a lower template 2, a support plate 4 and an electric pressure device 6 arranged on the upper template 1 for providing punching power downward, for When forming parts for this set of molds, it provides a power source with very high productivity.

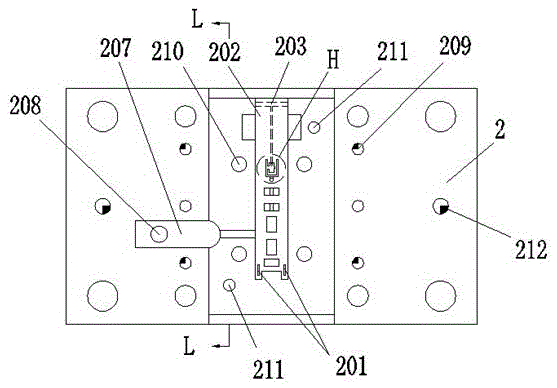

[0026] Such as figure 2 and Figure 6 As shown, the lower template 2 is a cuboid structure, with a groove in the middle, and the groove is arranged as a V-shaped inclined surface 213; bosses 214 are arranged at both ends of the groove; a punch 202 is arranged in the groove; Figure 4 As shown, the middle molding part of the punch 202 is provided with a special-shaped groove 204, and the inside of the special-shaped groove 204 is processed with a vertical connection hole 1 205, and the outside is provided with a horizontal connection hole 2 206; the punch 202 There is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com