Capacitor cleaning drying apparatus and cleaning drying method

A technology of drying equipment and capacitors, which is applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of easy breeding of environmental protection, high labor intensity, and low work efficiency, and achieve the goals of improving the working environment, low labor intensity, and improving the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

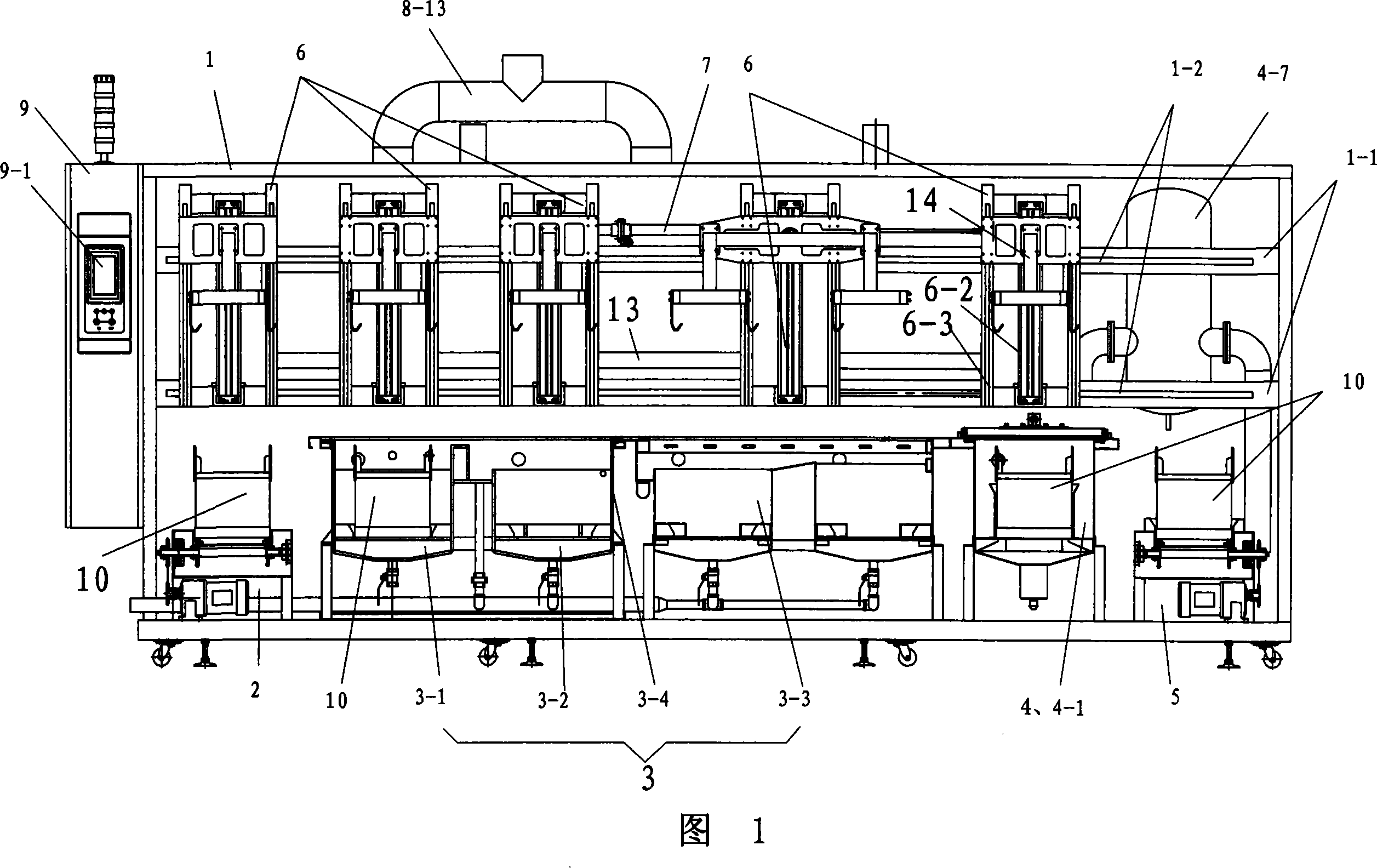

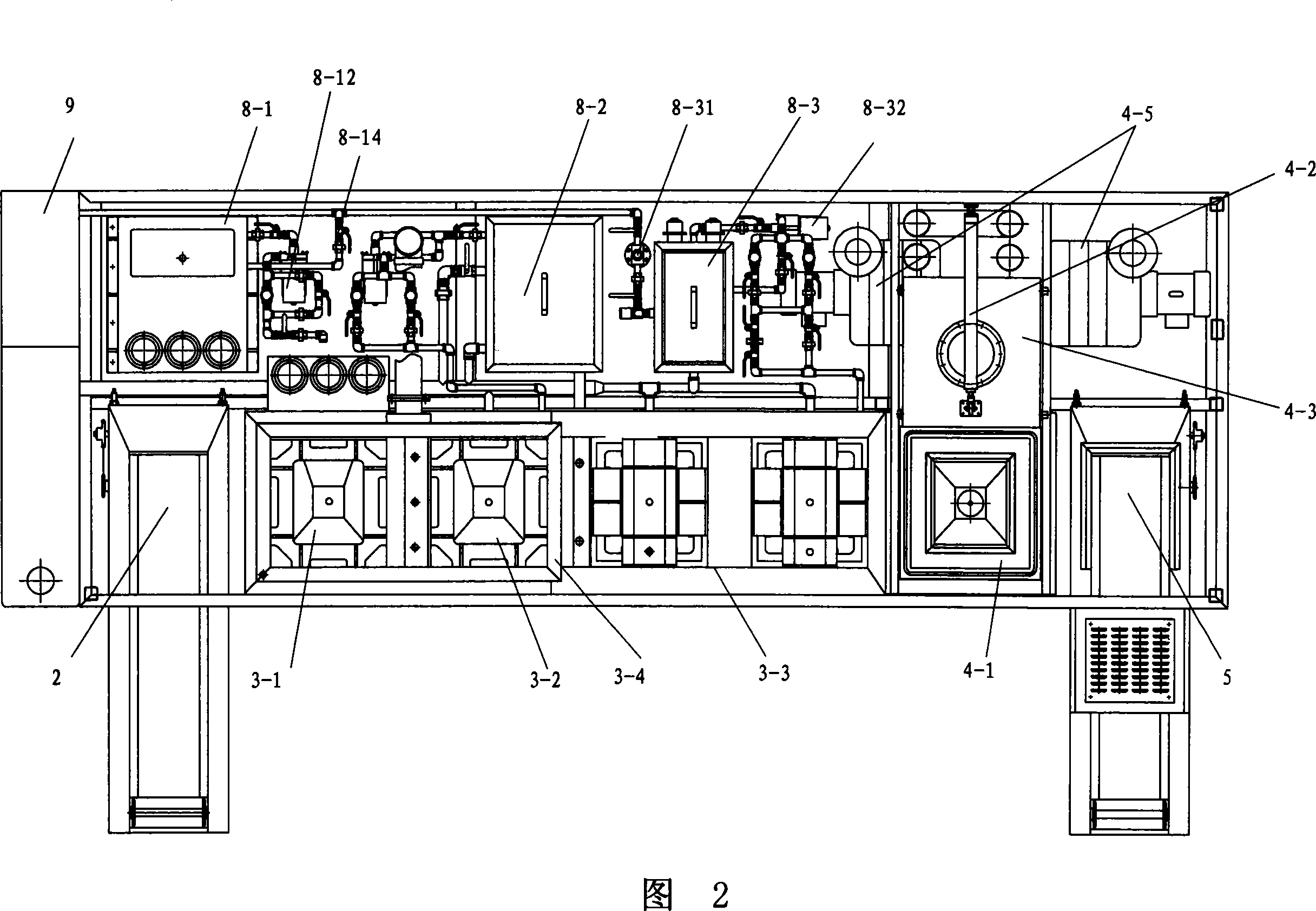

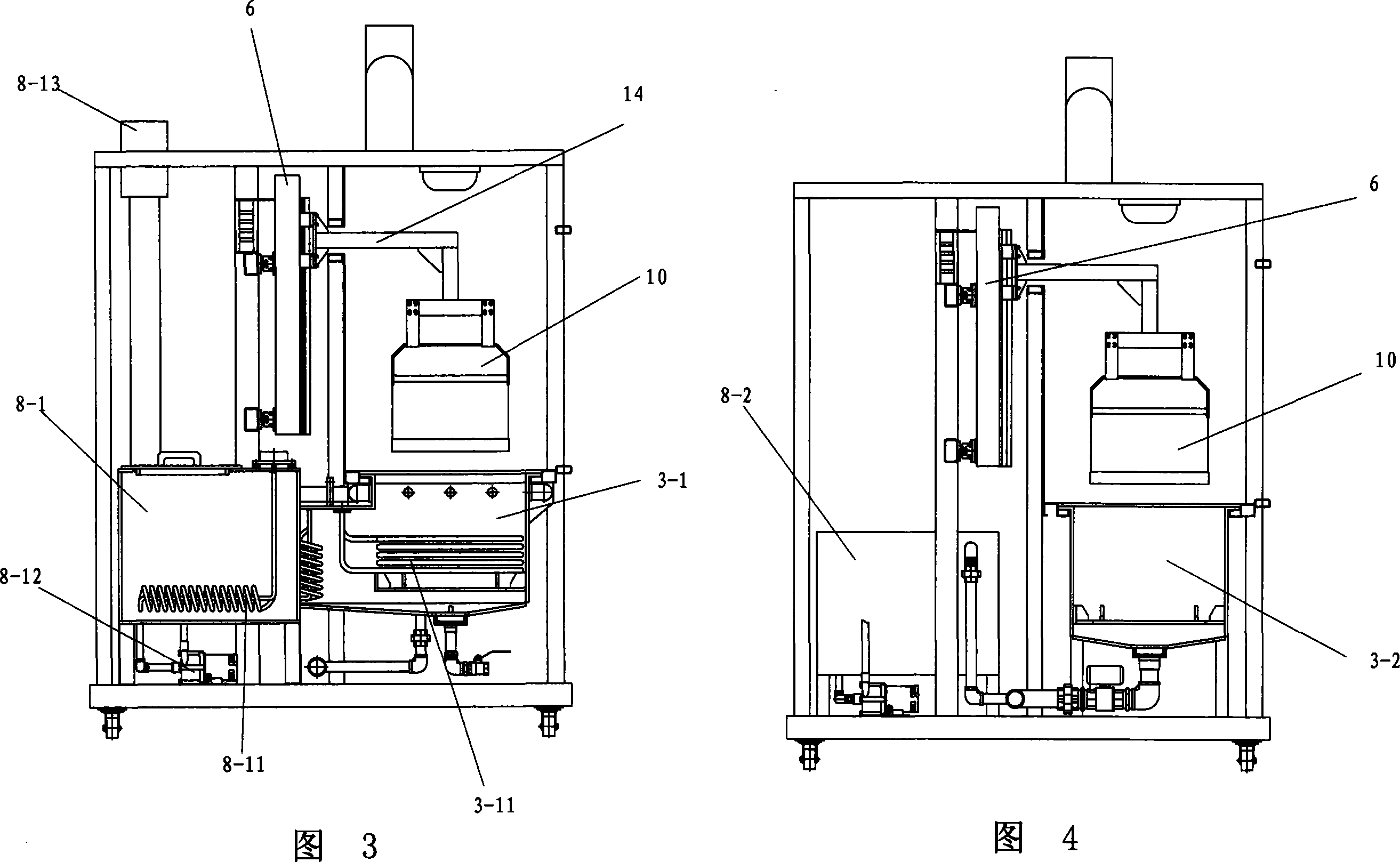

[0048] After manually setting the time, temperature and pump valve switching sequence specified by the cleaning process on the contact film panel of the automatic control cabinet, the capacitors to be cleaned are placed in the cleaning basket, and the cleaning basket is sent into the cleaning and drying equipment by the feeding mechanism Enter the acid treatment box, soak in the acid treatment box with the pH value of the acid solution ≤ 2 and the temperature in the box at 40-70°C for 3-8 minutes, and then be thrown up and down at a frequency of 5-10 times / minute for 0.5-3 Minutes, after completion, deliquify and drain at a high position for 0.5-1.5 minutes; then enter the front and rear cylinders of the first rinse box and the second rinse box for rinsing, and the cleaning baskets are in the first rinse box and the second rinse box The front and rear cylinders are first soaked for about 1 minute, then thrown up and down for 4-6 minutes at a frequency of 5-10 times per minute, ...

Embodiment 2

[0050] After manually setting the time, temperature and pump valve switching sequence specified by the cleaning process on the contact film panel of the automatic control cabinet, place the capacitors to be cleaned in the cleaning basket, and the cleaning basket is sent from the feeding mechanism to the cleaning and drying equipment In the pre-washing box in the ultrasonic hot water pre-washing box, the ultrasonic wave is first turned on for 1.5-4 minutes, then stopped and then thrown up and down at a frequency of 5-10 times / minute for 2-6 minutes, and the temperature in the box is 40-70 ℃, the ultrasonic frequency is 20-50KHz; after the completion, drain water at a high position for 0.5-1.5 minutes; then send the cleaning basket into the ultrasonic alkali treatment box, first turn on the ultrasonic for 1-4 minutes, then stop and then 5-10 times / minute The frequency is thrown up and down for 2-6 minutes, the alkaline solution is a degreasing solution, the temperature is 45-65°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com