Manufacturing method for solid-liquid mixed type aluminum electrolytic capacitor

An aluminum electrolytic capacitor, electrolytic capacitor technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of low ESR, leakage and short circuit, low repair oxide film, etc., to achieve excellent overall performance, avoid excessive leakage or short circuit bad. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

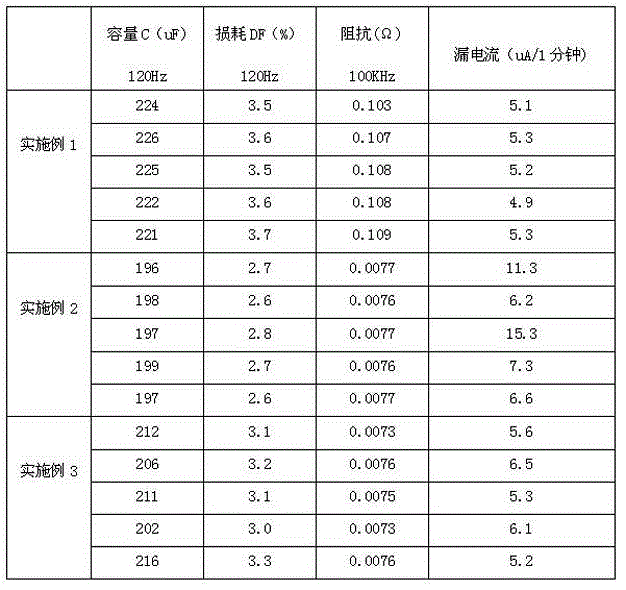

Embodiment 1

[0023] This embodiment is a liquid aluminum electrolytic capacitor, and its preparation steps are as follows:

[0024] ① Rivet the aluminum foil with the guide pin of the nailing machine and wind the anode aluminum foil, cathode aluminum foil and electrolytic paper into a core package. The electrolytic paper is between the anodized aluminum foil and the cathodic The cathode foil should be wide; the length should be longer than the overlapping part of the anodized aluminum foil and the cathode foil to prevent short circuit of the core package;

[0025] ② Vacuum impregnate the wound core with electrolyte, and the electrolyte adopts wide temperature electrolyte;

[0026] ③ Assemble the core package impregnated with the electrolyte into the shell and rubber plug;

[0027] ④ Aging and sorting the assembled bare casing according to the process;

[0028] ⑤ Print and pack the selected finished products after testing.

Embodiment 2

[0030] This embodiment is a solid aluminum electrolytic capacitor, and its preparation steps are as follows:

[0031] ① The guide pin is riveted on the aluminum foil by a nail coiler, and the anode aluminum foil, cathode foil, and release paper are wound into a core package. width;

[0032] ② Spot weld the wound core package on the iron bar, and pre-install the rubber plug before spot welding;

[0033] ③ Carry out chemical formation and carbonization treatment on the core bag;

[0034] ④ The processed core contains impregnated thiophene monomer and ferric p-toluenesulfonate oxidant;

[0035] ⑤ Polymerized and dried or directly impregnated with polythiophene suspension and dried;

[0036] ⑥ Aging sorting after assembly with shell;

[0037] ⑦ Test, package and print the selected finished products.

Embodiment 3

[0039] This embodiment is a solid-liquid hybrid aluminum electrolytic capacitor, which includes the following steps:

[0040] ① The guide pin is riveted on the aluminum foil by a nail coiler, and the anode aluminum foil, cathode foil, and release paper are wound into a core package. The release paper is placed between the anodized aluminum foil and the cathode foil. The above anodized aluminum foil is wide, and the release paper is wood pulp fiber material or synthetic fiber material;

[0041] ② Spot weld the core pack on the stainless steel iron bar and charge and repair the oxide film in the forming solution;

[0042] ③ Rinse and dry the charged core pack;

[0043] ④ The dried core contains an impregnation suspension, which is a polymer material with polythiophene or polypyrrole or polyaniline as the main component;

[0044] ⑤ impregnate the impregnated core package into electrolyte solution after drying, the electrolyte solution includes solvent, solute and additive, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com