Gradual change type single board structure of wedge-type flashboard

A gradual change and gate technology, which is applied in the direction of sliding valves, engine components, mechanical equipment, etc., can solve leakage and other problems, achieve the effect of avoiding excessive leakage and improving strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

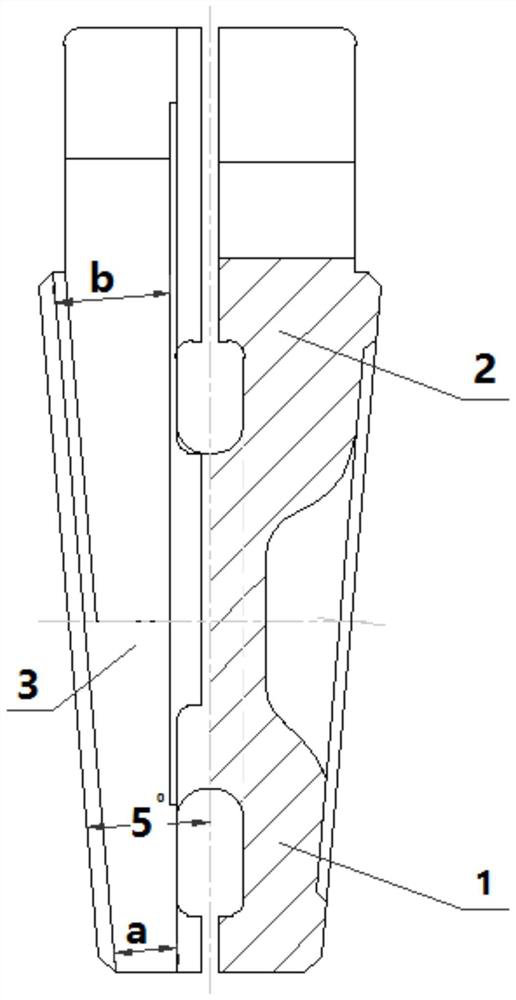

[0014] as attached figure 1 As shown, a gradual veneer structure of a wedge-type ram includes a veneer whose thickness gradually increases from the lower end of the ram to the upper end of the ram.

[0015] The change of the gradual thickening is uniform.

[0016] The gradient thickening described above is based on the angle θ as the standard for gradual thickening

[0017] The angle θ ranges from 3° to 10°.

[0018] The preferred value of the angle θ is 5°.

[0019] The gradual single-plate structure of the wedge-type ram is aimed at uniform-thickness rams.

[0020] The strength and rigidity of the sealing surface at the upper end (2) of the gate plate are enhanced.

[0021] A gradual single-plate structure of a wedge-type ram. The main design points of the structure are the upper end of the ram, the lower end of the ram, and the single plate. The specific instructions are as follows:

[0022] In view of the fact that the sealing surface of the uniform-thickness ram and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com