Surfboard having a skin of reinforced fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

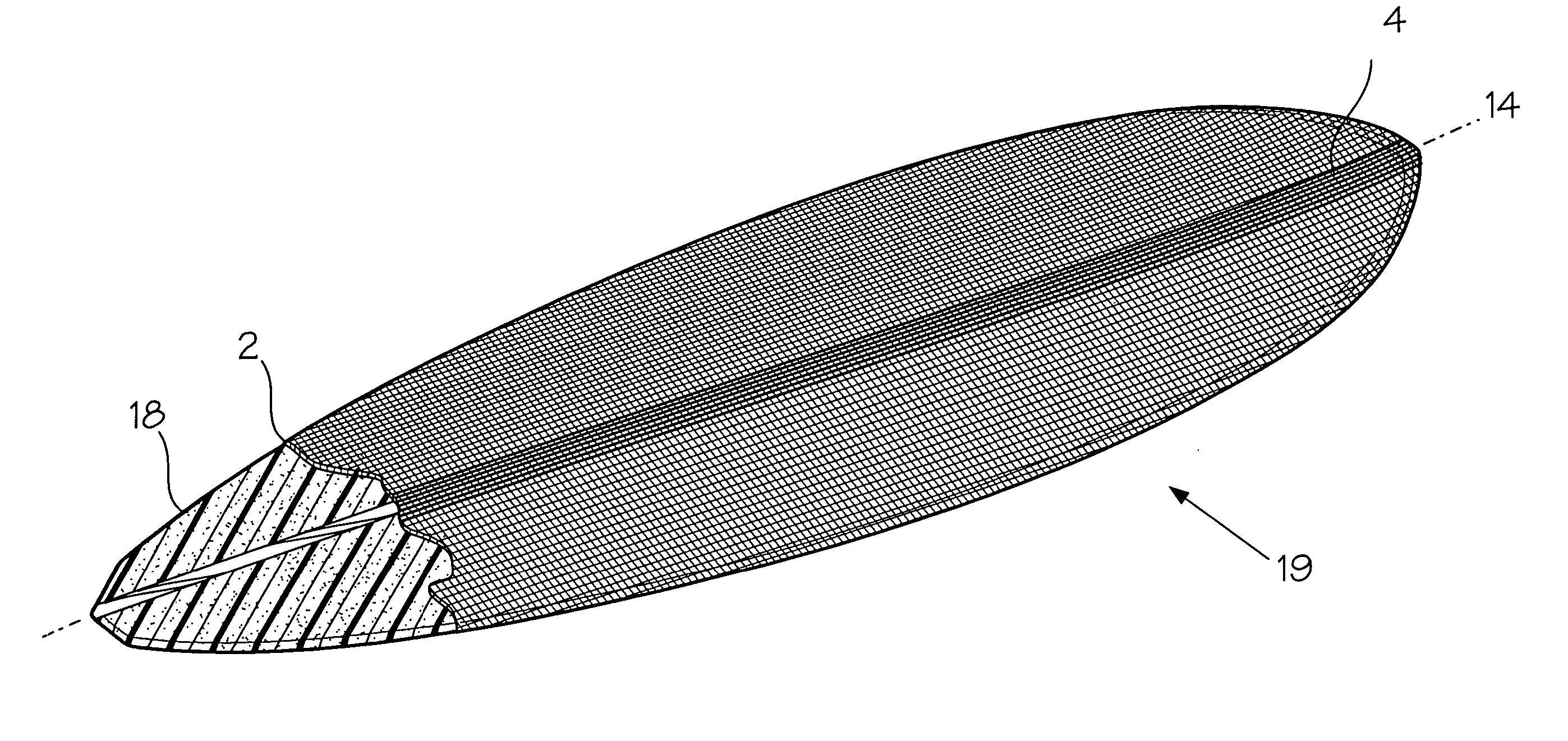

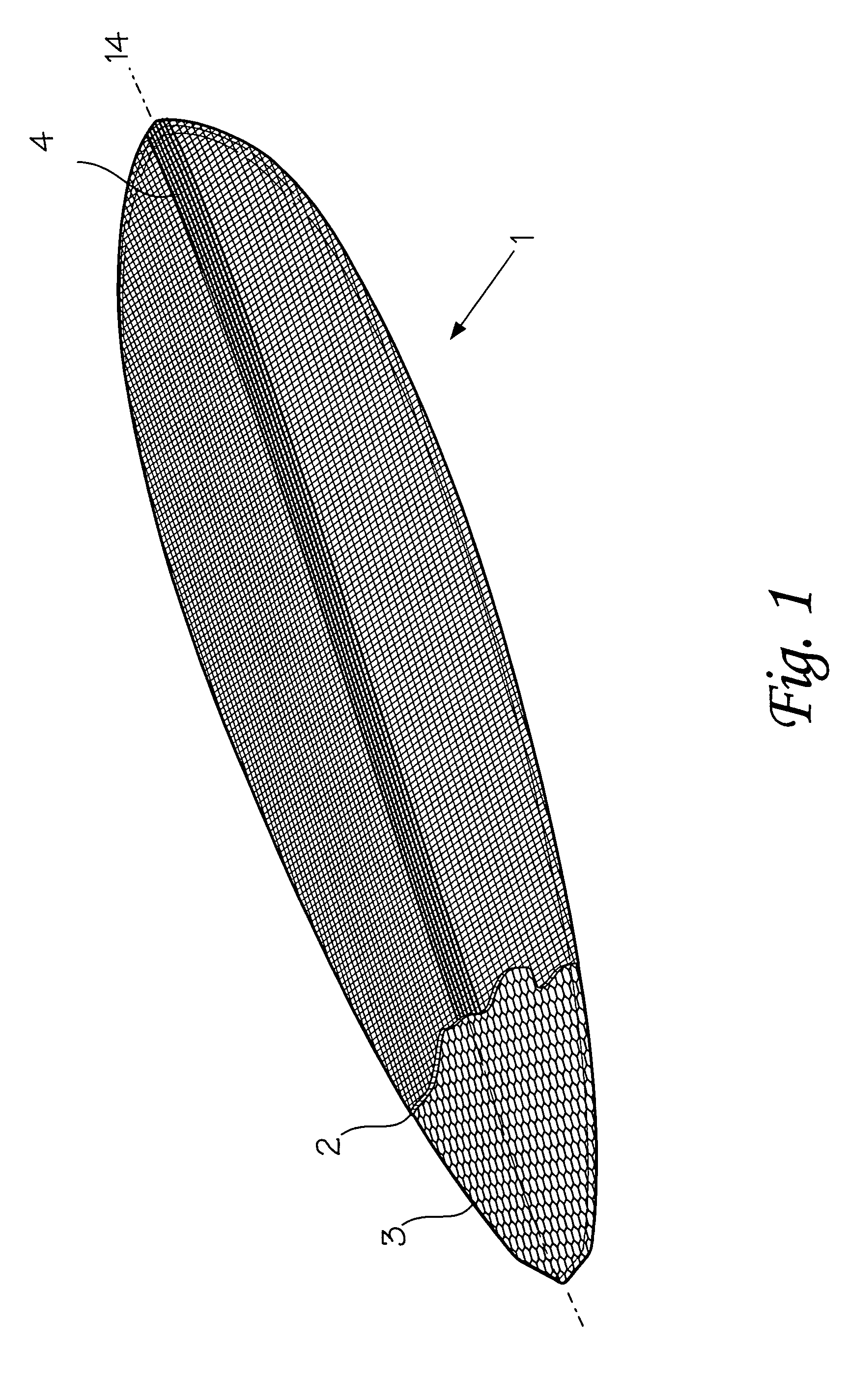

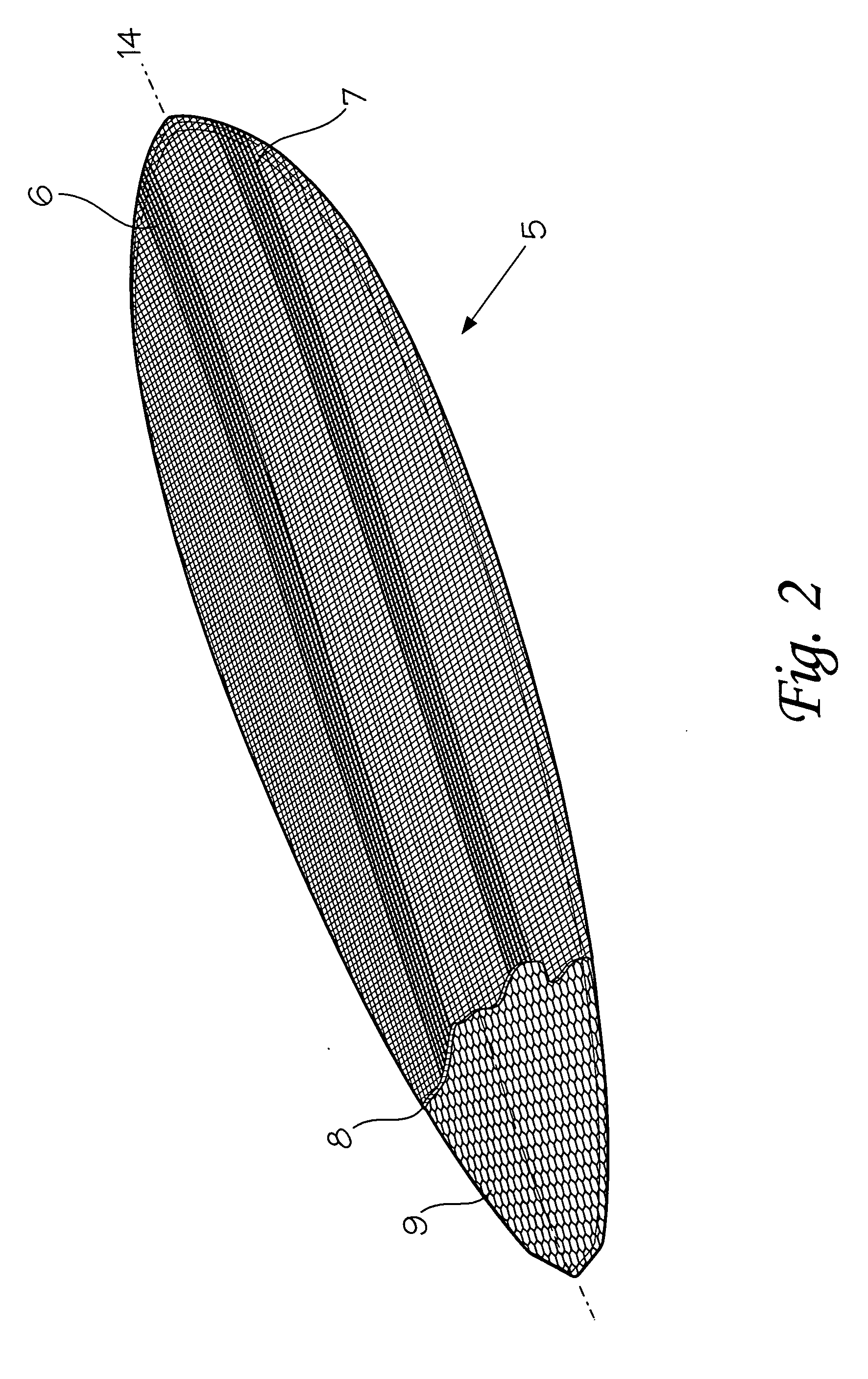

[0028] In a typical or representative process of forming a surfboard, the foam core or blank is formed in a large, cement mold roughly the desired shape of the finished surfboard. The mold is constructed in two halves, and the two halves are clamped together and heated. Liquid polyurethane containing a foaming agent is introduced into the mold, the heat initiates the foaming reaction, and a dense, white foam is produced. After the foaming is completed, the mold is opened and the foam core is taken out and allowed to harden. Once the core is hard, it is cut in half vertically from the nose to the tail. A thin wooden stringer is glued between the two halves. The core is then clamped back together to dry. The stringer provides longitudinal stiffness and strengthens the board.

[0029] Next, the outline of the finished board is traced onto the rough core and the outline is cut out with a saw. Starting with the bottom of the core, the surface is smoothed and contoured to its final shape wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com