Inverse-7 type automatic paper collecting machine

A paper machine and automatic technology, which is applied in the printing industry to achieve the effect of reducing the upper space, opening the upper space and stably placing it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

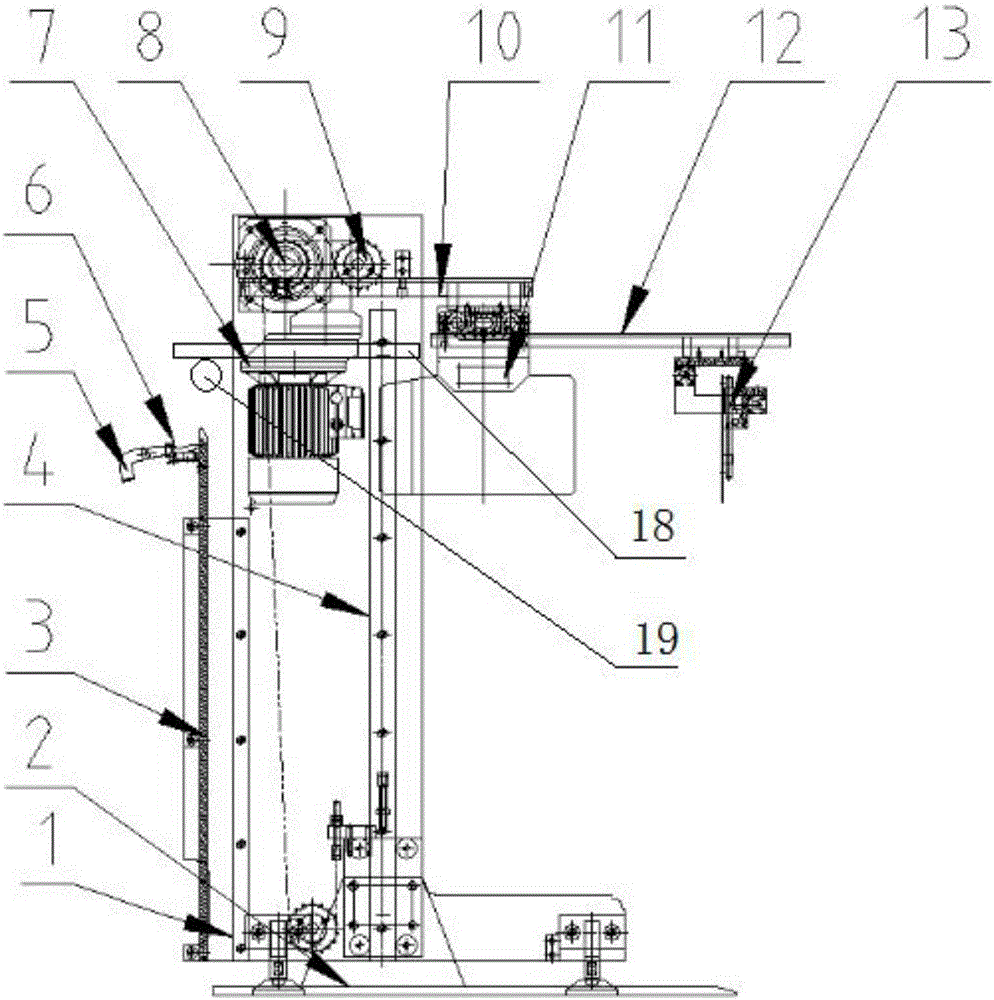

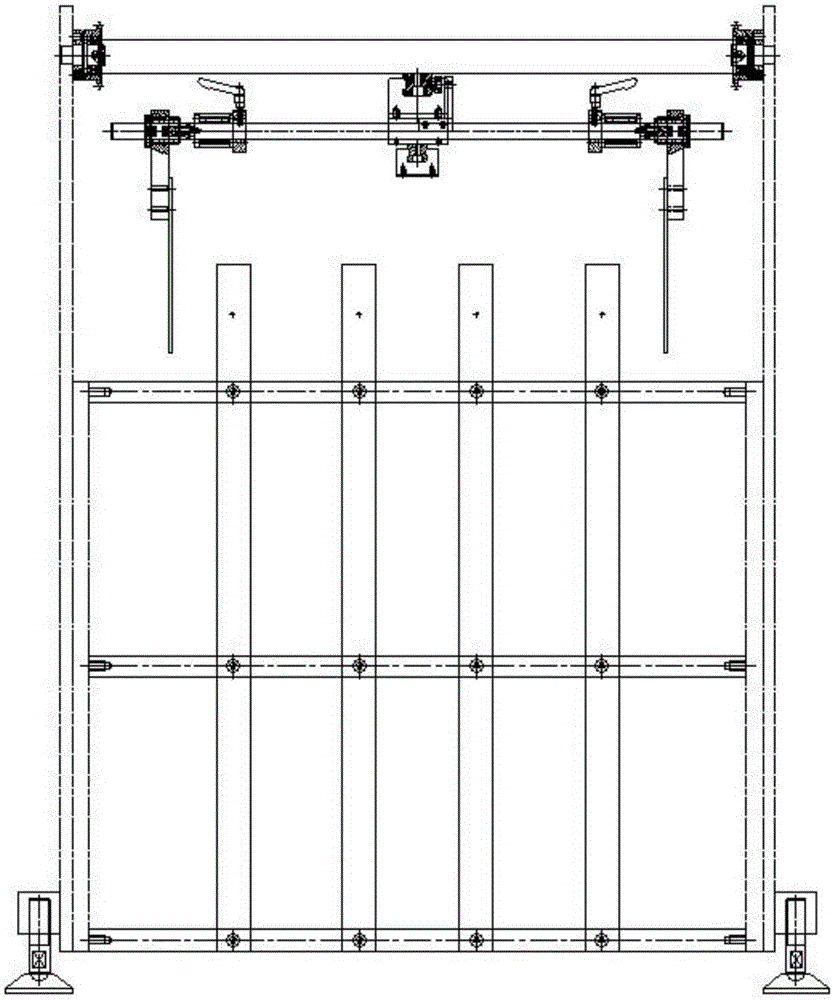

[0020] Such as Figure 1-5 As shown, the inverted 7-type automatic paper delivery machine includes a frame 1, the side plate of the described frame 1 is an inverted 7-type structure, and the described frame 1 is provided with a paper feed guide rail 19 and a delivery table device, so The paper delivery table device includes a paper limit adjustment device and a paper delivery table 2, and the paper 18 passes through the paper feed guide rail 19, and enters the paper delivery table 2 after being adjusted by the paper limit adjustment device (the paper delivery table device is a paper limit adjustment device). The overall collective name of the device and the delivery table).

[0021] The delivery table 2 is located directly below the paper adjustment device, and the delivery table 2 can move up and down through the transmission mechanism.

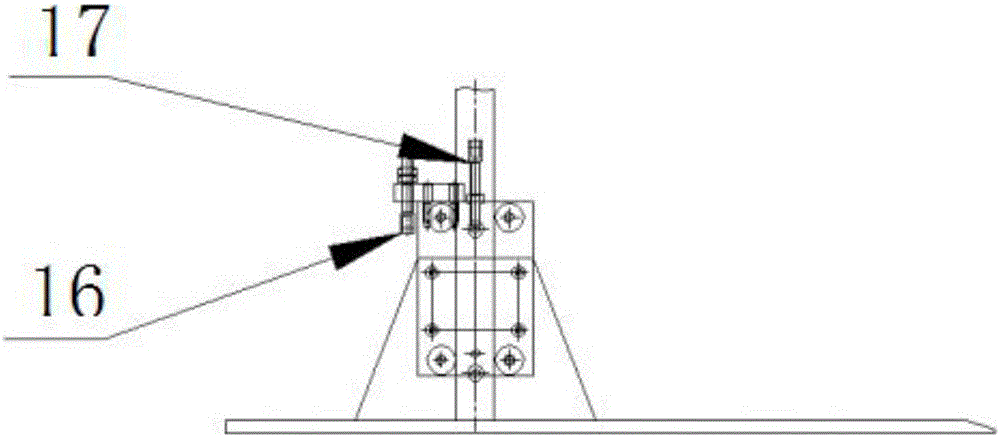

[0022] The paper limit adjustment device includes a front paper stopper 3, a rear paper stopper 13, and both sides of the paper stopper 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com