Drying method and drying device for supercapacitor

A technology of super capacitor and drying method, applied in the direction of drying/dipping machine, etc., can solve the problems of poor drying effect and low drying efficiency, and achieve the effect of good drying effect, high drying efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

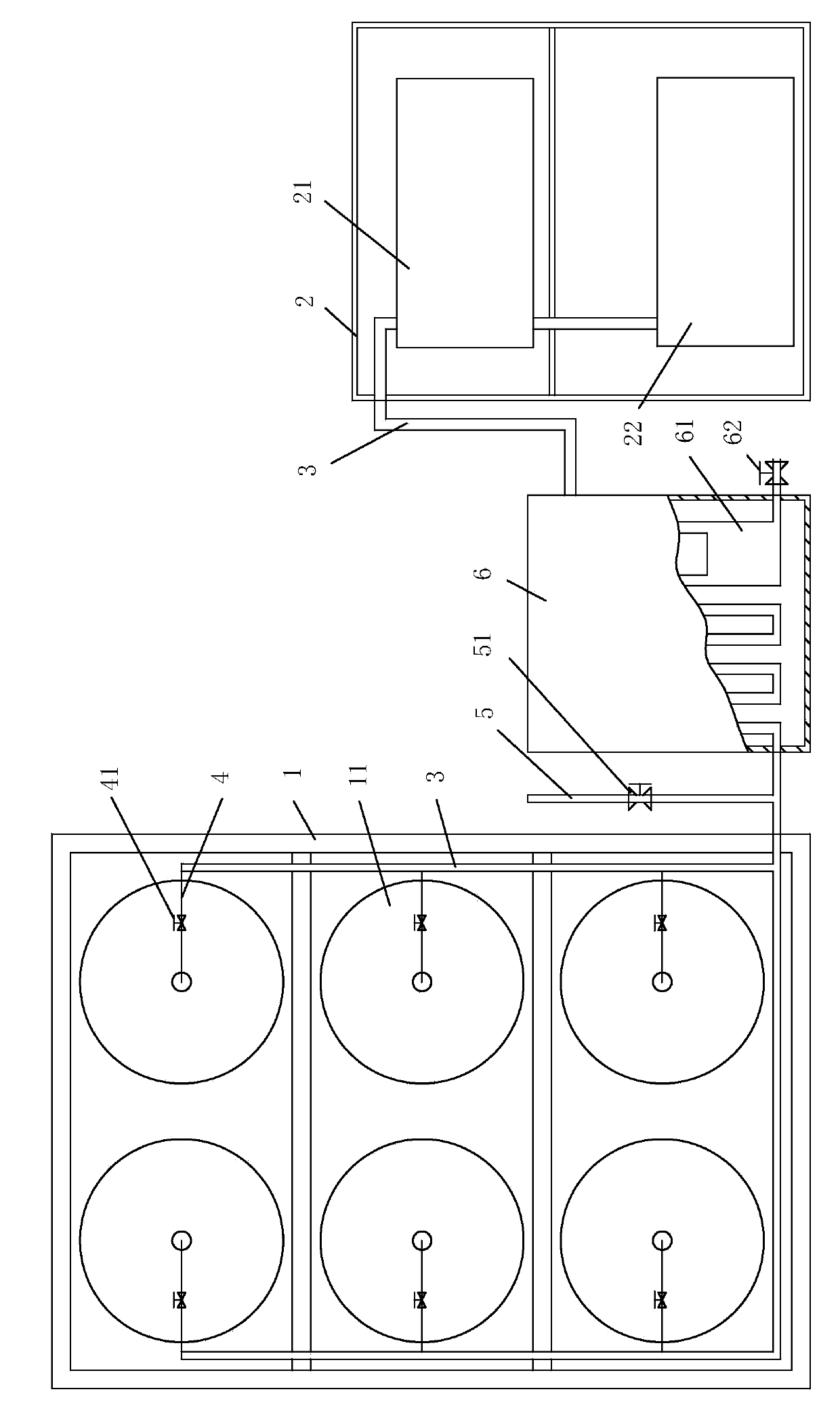

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] as attached figure 1 Shown: a supercapacitor drying method, including the following steps: (1) put the supercapacitor to be dried into the drying tank 11 of the drying furnace 1; (2) use the vacuum pump unit 2 to extract the air in the drying tank 11 to reach The vacuum degree is 0.7pa; (3) Fill the drying tank 11 with nitrogen with a pressure of 0.1Mpa; (4) The drying furnace 1 takes 3.5 hours to heat up to 160°C; (5) Use the vacuum pump group 2 to extract the nitrogen in the drying tank 11 to reach The vacuum degree is 0.7pa; (6) The vacuum pump group 2 is always on and maintains a vacuum degree of 0.7pa in the drying tank 11, while the drying furnace 1 is heated to 160°C and kept at a constant temperature for 7.5 hours for drying; (7) Turn off the vacuum pump group 2, Filling pressure in the drying jar 11 is nitrogen gas of 0.1Mpa, and opening the drying fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com