Vacuum baking oven for pole pieces of battery

A vacuum oven, battery pole piece technology, applied in electrode manufacturing, drying, dryer and other directions, can solve the problems of large moisture fluctuation, small size of vacuum oven, easy to affect production efficiency, etc., to achieve uniform temperature and gas atmosphere , The drying effect is basically the same, and the effect of avoiding oxidation or even burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

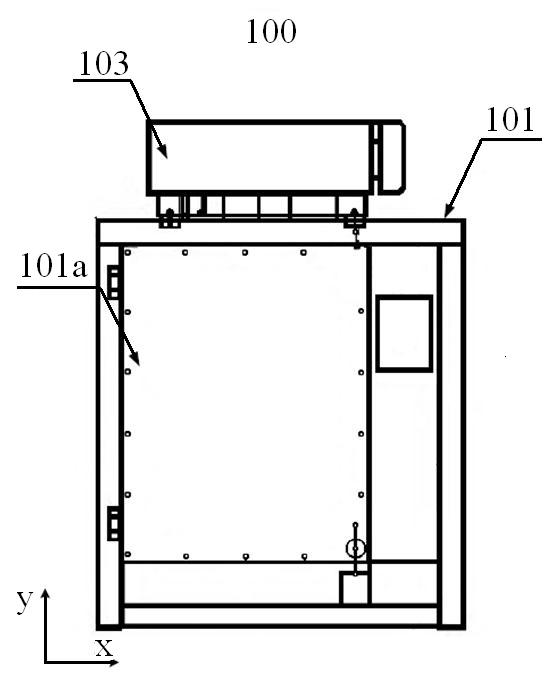

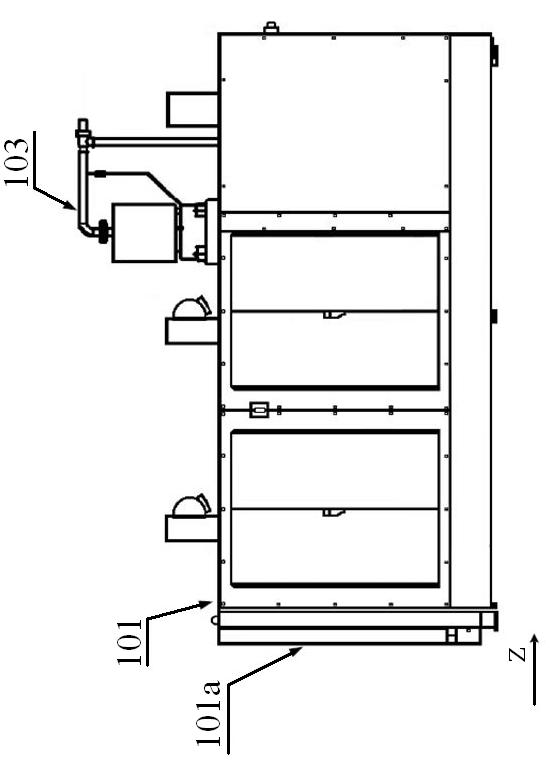

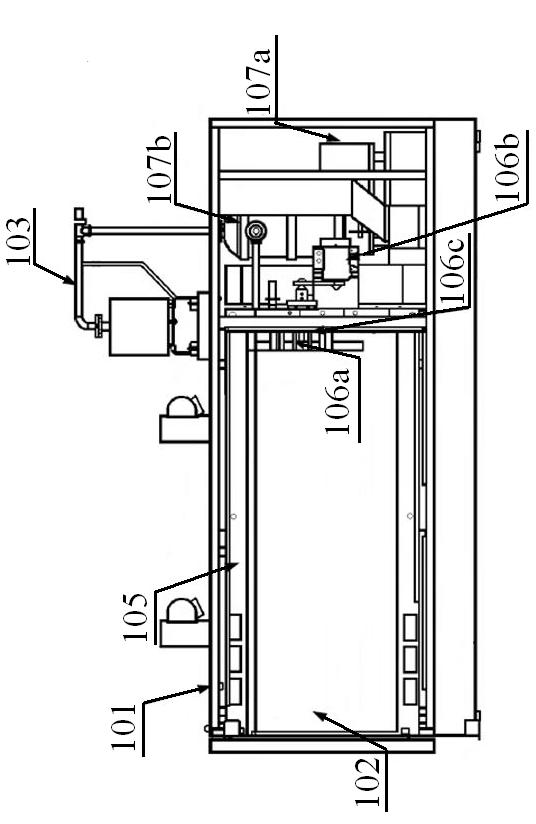

[0065] Hereinafter, the oven of the present invention will be described by taking the drying of pole pieces weighing 100 kg at a time as an example.

[0066]Set the drying temperature to 160°C, and place the pole piece on a trolley and push it into the drying room. First, evacuate to 1 Torr; then, inject industrial nitrogen with a purity of 99.99%, and raise the temperature; when the temperature reaches 265°C, evacuate again to 12Torr; then, at 160°C, 12Torr constant temperature and pressure, carry out 5 Hours of baking; after the baking is over, inject nitrogen gas again to restore the vacuum value in the drying chamber to 760Torr; then, inject nitrogen gas into the cooling part to cool down, and when the temperature cools below 100°C, inject cooling water instead To accelerate the cooling to 50 degrees Celsius; finally, take out the pole piece.

[0067] After measurement, the parameters of the pole piece dried by the oven of the present invention are as follows: the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com